|

Surviving LCVPs Main Page

Surviving World War Two LCVPs

Surviving Post-World War

Two Fiberglass LCVPs Surviving

French Post-World War Two LCVPs

Replica LCVPs

Surviving

American Post-World War Two Wooden LCVPs

This page updated 7-5-2021.

An American Auto

Industry in World War Two Special Edition

In the 1950s, the U.S. contracted for another

1,465 LCVPs to be built. By that time, most of the original LCVPs

were wearing out and needed to be replaced. While the basic

original Higgins design was maintained, there were several engineering changes

made to the design. Several of these changes distinguish an

original World War Two LCVP from the 1950s version.

Unfortunately, for several

organizations, the LCVPs they own are not the original World War Two

LCVPs that they believe they have. Many organizations are under the

impression that they own Higgins-built LCVPs that were built during

World War Two. Instead, they have a 1950s era LCVP built by the Shelburne Shipyard in Shelburne, VT.

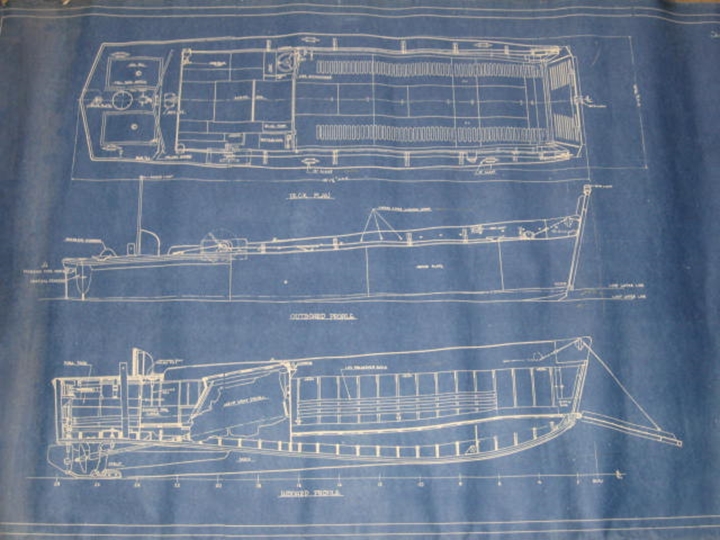

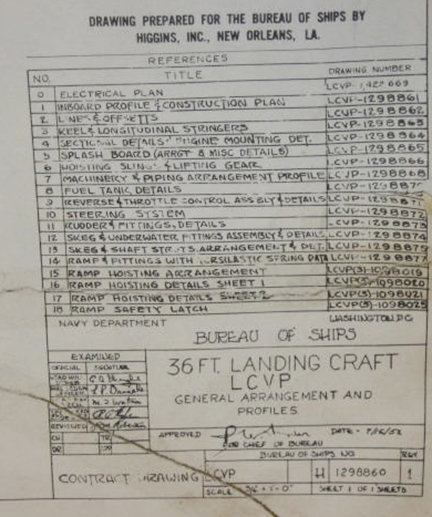

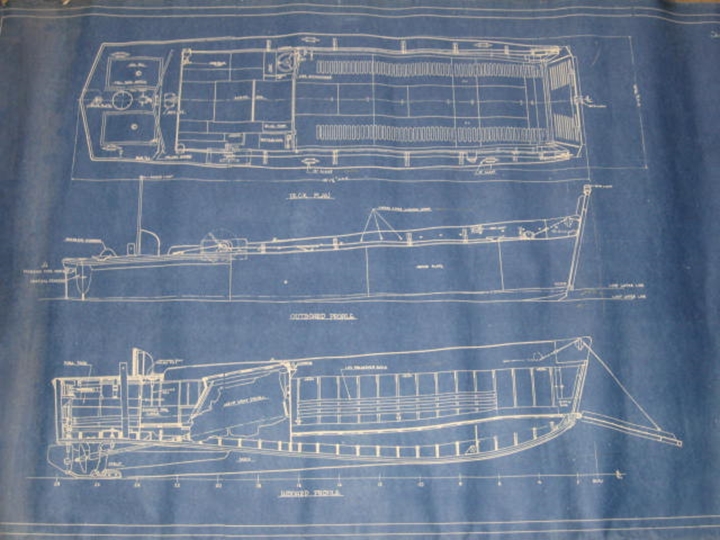

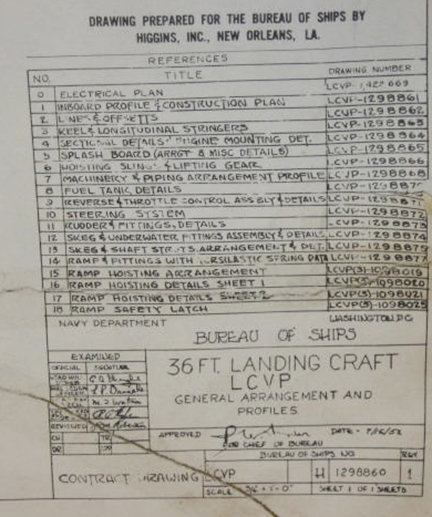

Here is an actual blue print used

by the Shelburne Shipyard to build 1,465 1950's era LCVPs.

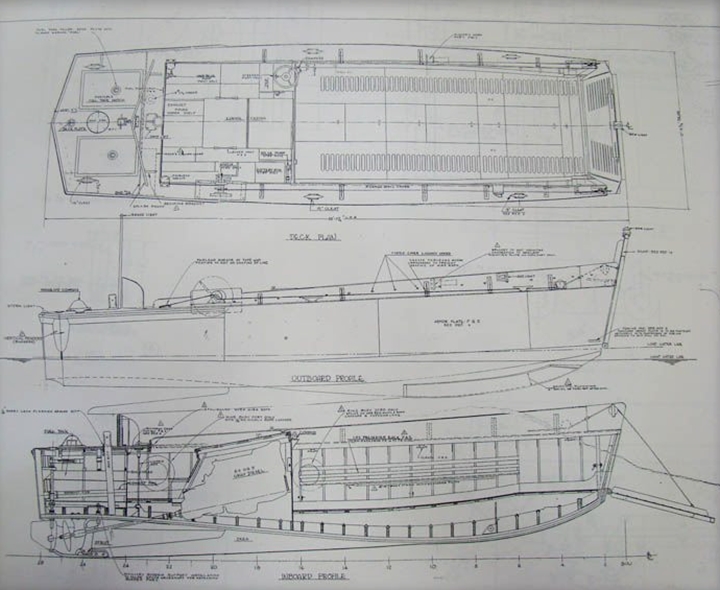

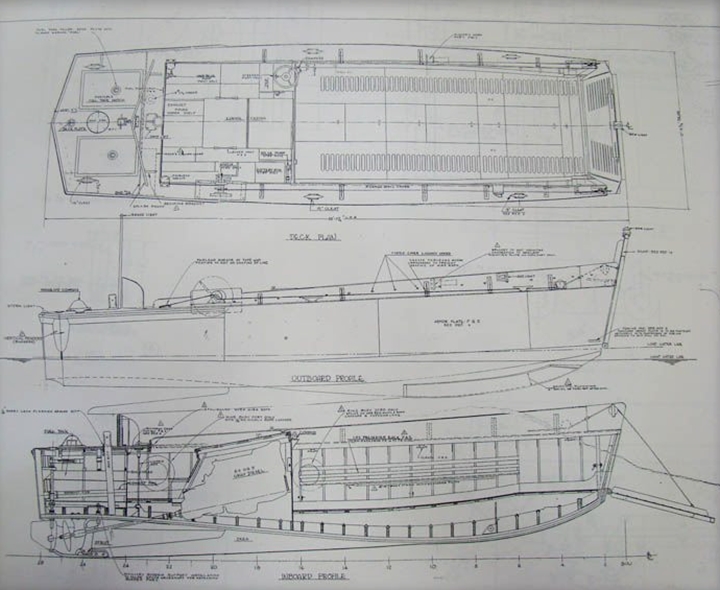

Here is a black and white print of the

modified boat. The ramp winch and ramp cable that runs outside the

boat are visible. This is one of the visible differences between the

1950s LCVPs and the World War Two era LCVPs.

This is the of 18 engineering changes

that were made to the LCVP drawings on 7-16-1952, as the Navy was

preparing to go back into production of the LCVP. Included are

changes to the fuel tanks, ramp hoisting arrangements, and three changes

involving the skeg, propeller fittings, and rudder fittings. The

fuel tanks were originally 110 gallon fabricated our of 14 gauge steel, which

were expensive to build. Replacing the two 110 gallon tanks with

four 55 gallon drums was so much simpler along with being a cost

savings. The new ramp hoisting arrangement was simpler and less

costly than the original system. The new arrangement moved the

hoist to the top of the gunwale with the cables running directly to

the ramp. The new attachment system for

the prop shaft, rudder, and skeg was likewise a cost savings due to

simpler parts.

Higgins, Inc. was the new corporation

formed when Higgins Industries liquidated its assets in November 1945.

Higgins, Inc. made the engineering changes and gave them to the Navy,

which in turn forwarded them to Shelburne Shipyard in Shelburne, VT, which then used

them to build 1,465 LCVPs. Surviving Shelburne Shipyard-built

LCVPs are listed below.

Owner: Private Owner

Location: Virginia

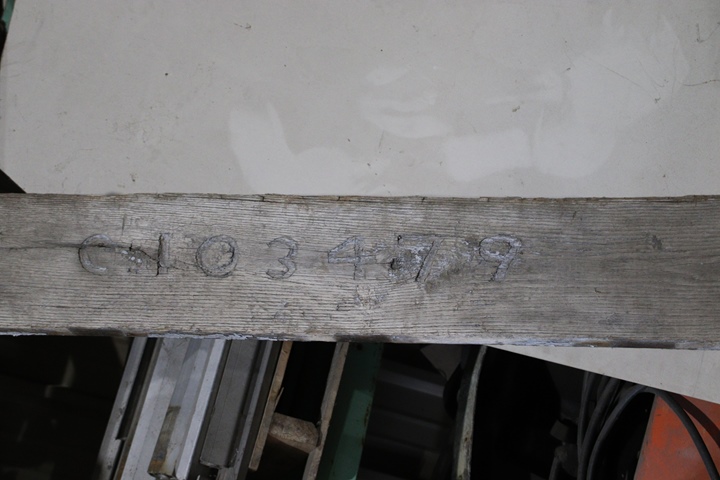

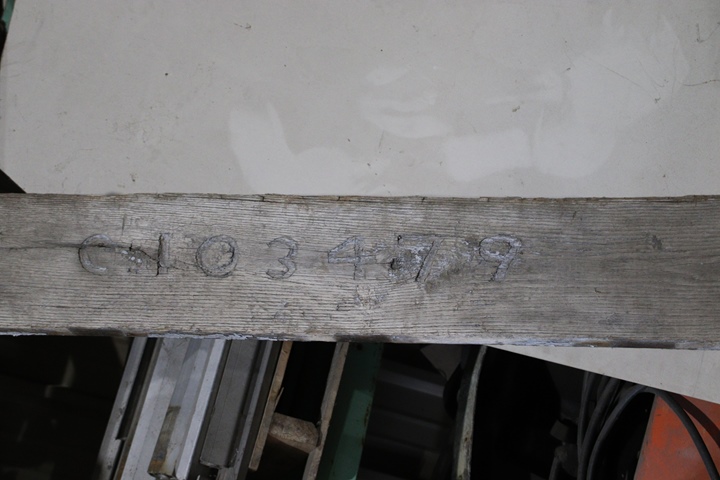

Hull Number: C-103479

Date Built: 1956

Date of Photos: June 2006 and January 2020

Comments: This LCVP is a benchmark that can be used to

evaluate other LCVPs that are most likely of post-World War Two manufacture. This

is because the hull number and date of manufacture are known for this

boat.

This boat was previously owned by Bob Gillmor

in Old Fort, OH. It was sold and is now in Virginia.

Before looking at the photos, we will explore

how C-103479 ended up in civilian ownership. When the USS Sandoval

(APA-194) was decommissioned for the third time in March 1970 in

Norfolk, VA, C-103479 was one of several LCVPs that was unloaded and stored.

The Ohio Army National Guard was able to obtain C-103479 and five other LCVPs for amphibious training at Camp Perry, OH. After a two year

repair and re-building effort at the Ohio National Guard Depot in

Newark, OH, it was determined that one of the boats could not be

repaired and was scrapped after useful items were removed. The

remaining five boats were then shipped to Camp Perry. One was

damaged in shipment. It too was stripped of usable equipment and the

hull was buried at Camp Perry. Two of the four remaining boats had

leaks that could not be fixed without a considerable amount of effort.

Usable parts were removed, and they were sold at auction. The last

two served around the shores of Camp Perry doing various tasks until

they were replaced by two LARCS three years later. C-103479 and the

other remaining LCVP were

later auctioned off to a private individual in the area who kept them in

a fruit orchard. C-103479 eventually became the property of Bob

Gillmor.

The four photos below show C-103479 at a previous owner,

before Bob Gillmor purchased it. This is how it looked while serving with

the U.S. Navy. These photos provide the best insight into what a post-World War Two

wooden LCVP looked like.

This is C-103479 in June 2006.

The 1/4 inch armor plate and ramp are still protected by the paint, with

small amounts of rust. The plywood has lost its coating of paint.

Photo from the Bob Gillmor collection.

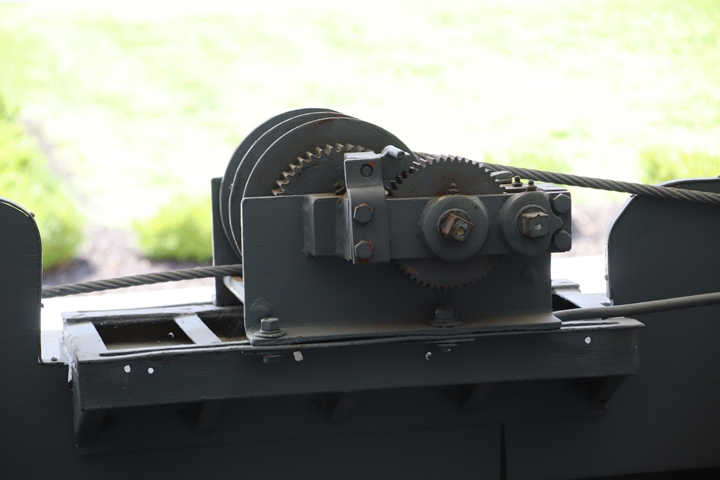

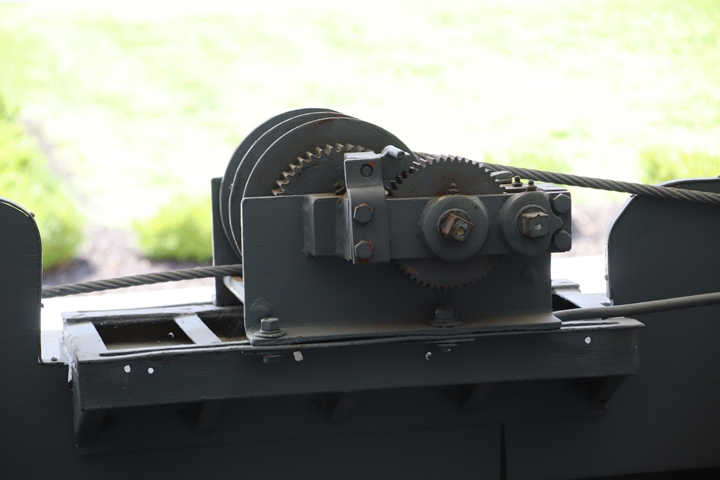

There are several key differences in this

photo that distinguish this post-World War Two LCVP from the original

versions. First, the ramp winch has been moved back up onto the

deck level. Second, from the winch, the ramp cables run outside

the boat and not internally, as did the World War Two versions.

The winch is positioned so the cable on the starboard side of the boat

goes straight towards the ramp along the deck and outside the coaming.

The cable for the port side runs towards the aft end of the boat and

then turns 90 degrees through a sheave. It then runs through a

protective sleeve along the rear of the cockpit until it goes through

another sheave where it then runs long the outside of the port coaming.

Third, there are no machine gun tubs in this boat. They were

eliminated from the post-war models. Four, the fuel tanks are 55

gallon barrels. The World War Two LCVP had fabricated two 18 gauge

150 gallon fuel tanks. These were expensive to manufacture.

The 55 gallon barrels were a significant cost savings. Photo from the Bob Gillmor

collection.

The curvature of the port fuel barrel can be

seen to the right of the exhaust pipe and behind the metal bracing rod. Photo from the Bob Gillmor

collection.

This post-World War Two boat is

different from others I have seen because the ramp cable is run through

a plastic or metal pipe. On others I have seen, the cable runs

through sheet metal brackets. Photo from the Bob Gillmor

collection.

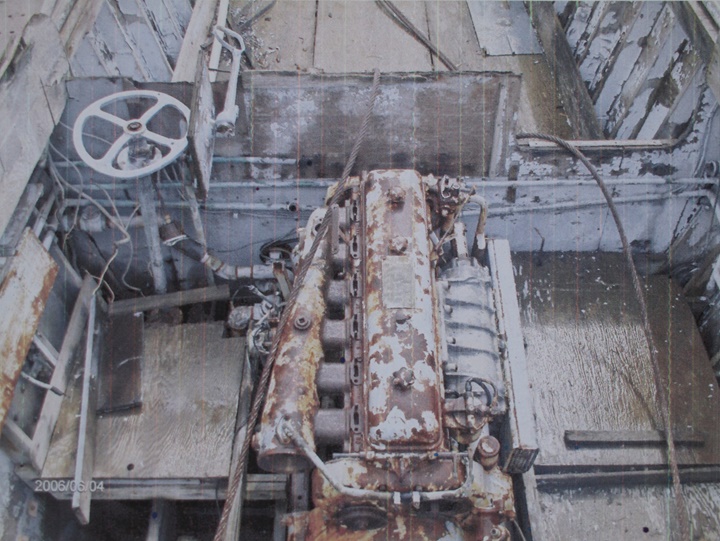

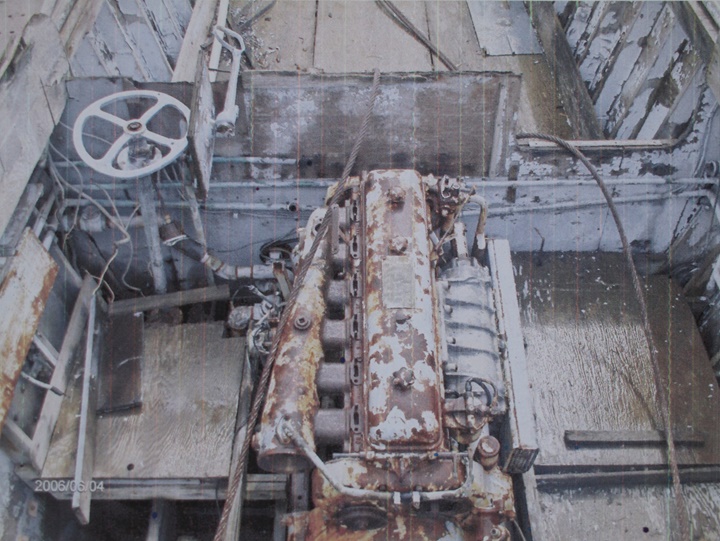

This photo shows the Gray Marine

64HN9/Detroit Diesel 6-71 engine which was the preferred engine for all

LCVPs. Photo from the Bob Gillmor collection.

I took the following photos of C-103479 in January 2020 at Bob Gillmor's foundry in Old Fort, OH. Bob

purchased the LCVP with the intent of doing a full restoration.

However, as is the case with all of us, life, business, and other more

important projects put C-103479 on the back burner. Some work was

started on the restoration.

This is the exterior identification that was

originally mounted on the front of the cockpit. Author's

photo.

Author's photo.

This photo of the interior of a

Higgins-built LCVP replica at the National World War Two Museum in New Orleans,

LA shows where this C-number board mounts on the landing craft.

Author's photo.

Currently, the 1956 LCVP was in storage at

Gillmor Ordnance in Old Fort, OH which makes replica and operating

vintage cannons. Robert Gillmor has done some restoration of the LCVP but has other current projects of higher priority. Author's photo.

It has been a while since Bob has had

time to work on C-103479. Author's

photo.

There were problems with the LCVPs given to

the Ohio National Guard. Two of them took on

a lot of water. A properly built LCVP constructed like those in

World War Two would not do this. Andrew Higgins designed the boats

with a layer of impregnated duck cloth that made the boats water tight.

Unlike a normal wooden boat that has been out of the water for a long

time, the Higgins LCVPs did not need to soak to swell the wood to make

it waterproof. This was especially important when landing craft

would be out of the water on a troop transport ship, and then be put in

the water for an amphibious landing. The LCVPs had to be sea

worthy on demand and could not wait for any swelling or caulking of

joints to be made waterproof. It is unknown whether the

impregnated duck cloth was used in the construction of this boat, or

whether it had deteriorated over time. Author's photo.

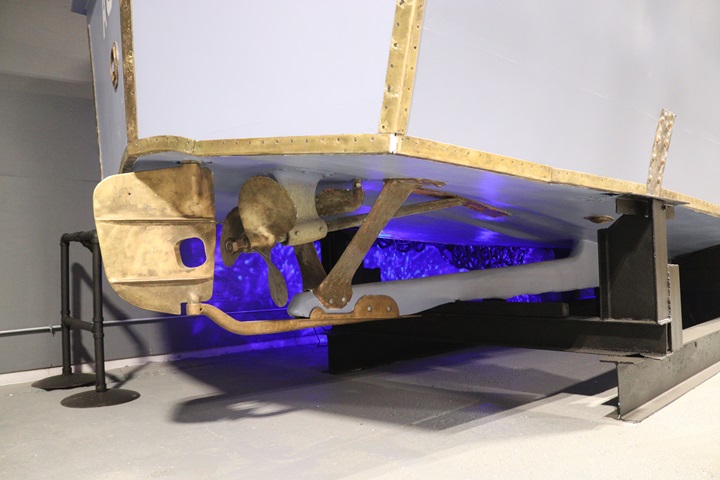

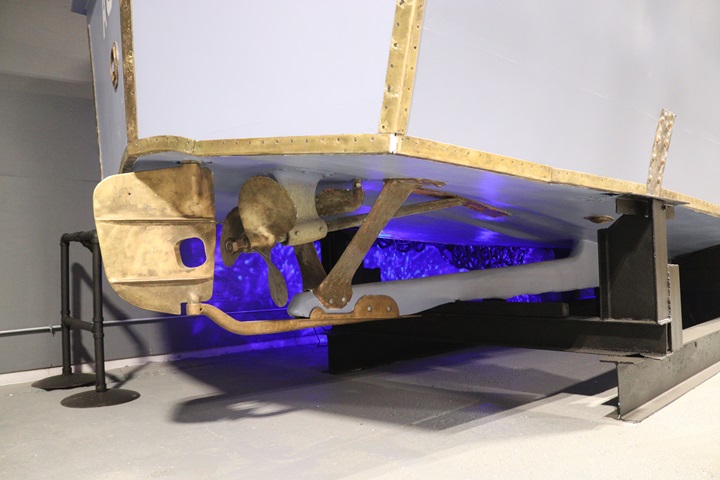

This is another trademark of a post-World

War Two LCVP. The bracing for the rudder and propeller shaft are

separate castings, rather than the one-piece casting used on the

originals. The V formed by the casting or castings attaching to

the skeg is an obvious identifier of the post-World War Two LCVPs. Author's photo.

Author's photo.

This photo was taken inside C-103479 which

is upside down. This shows that the port ramp cable comes back

inside the boat and through the sheave to the ramp. On World War

Two LCVPs, the cable and sheave are outside the boat at the ramp

interface. Author's photo.

The armor plate has been removed and is in

outside storage. Author's photo.

Owner: United States Army

Location: U.S. Army Transportation Museum, Fort Eustis, VA

Hull Number: Unknown

Date Built: Mid-1950's

Date of Photos: June 30, 2021

Comments: This is a classic example of "not knowing what I

don't know" as it pertains to comprehending the quantities and the current

locations of existing LCVPs. I was unaware of this LCVP until I

visited this museum. Internet searches had not revealed the

presence at this location. There may be more like this one I am

unaware of.

I previously visited the Army Transportation

Museum July 2008, and I don't remember it being at the museum. One

of the museum officials told me this LCVP came from Fort Benning within the

last few years. This is a cool find!!

This has the common post-World War Two type

ramp found on this genre of LCVPs. Author's photo added 7-5-2021.

The LCVP is under a roof in an open building

and also has a canvas covering over it to protect it. It can be

moved, as it is mounted on the three-axle trailer. Author's photo

added 7-5-2021.

The LCVP has the ramp cable running outside the coaming and then going

inside the boat at the ramp. This is an indicator of a post-World

War Two-era LCVP. Author's photo added 7-5-2021.

Author's photo added 7-5-2021.

The V-brace for the skeg and rudder is

typical of the post-World War Two LCVPs. Author's photo added

7-5-2021.

This photo shows the ramp cable running outside of the boat and the

absence of the gun tubs. Both are typical of the LCVPs built in

the 1950s. Author's photo added 7-5-2021.

The LCVP on display at the Army

Transportation Museum is in excellent condition. Author's photo

added 7-5-2021.

Owner: Private Owner

Location: Virginia

Hull Number: C-26903

Date Built: 1954

Date of Photos: Unknown

Comments: This LCVP was previously in Tacoma, Washington and

was purchased by the new owner in July 2020.

Photos of C-26903 can be seen here:

https://forums.g503.com/viewtopic.php?f=77&t=317662

Note that it has the externally run ramp

cables that enter the boat near where they mount to the ramp. It

also has the three piece propeller and rudder mounting brackets.

Most of the superstructure is missing, but the hull looks to be in

excellent condition.

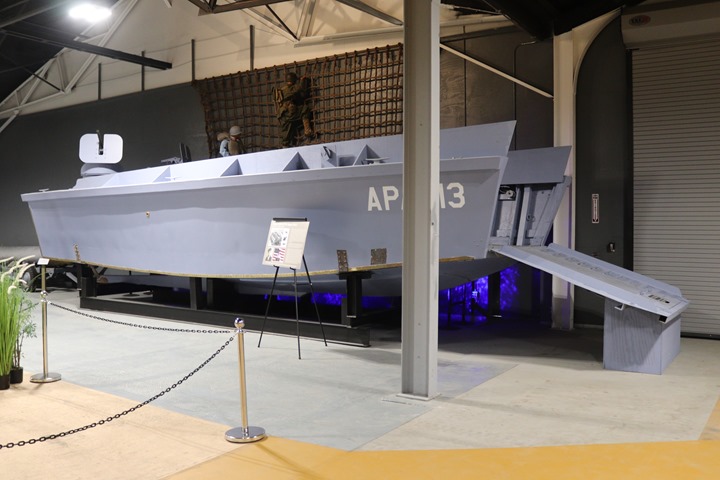

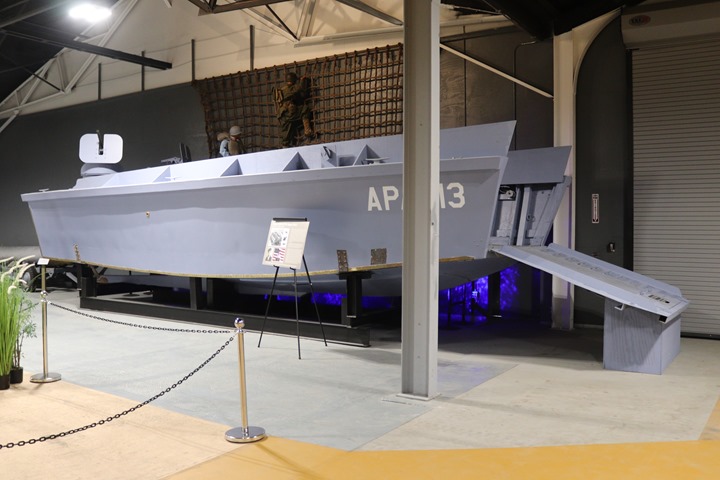

Owner: Indiana Military Museum

Location: Vincennes, IN

Hull Number: Unknown

Date Built: 1950s

Date of Photos: September 2014, January 2019, February 2020

Comments: This 1950s era LCVP was purchased in 2012 by the museum, which was located in Port St. Lucie, Fl.

It had been used by

oil companies in the Gulf of Mexico. Most of the original top of

the boat was missing and had to be replaced by the museum, along with

fabricating a new ramp. The restoration makes the LCVP look like a

World War Two boat. The ramp hoist system is similar, but not the

same as a World War Two boat. For the common visitor, it is close

enough. On one trip to the museum, the docent told me the boat

came in without gun tubs, which they added. However, the one

attribute that identifies this as a 1950's built LCVP is the skeg and

propeller shaft hull mountings. They are the type used in on the

1950s LCVPs. This boat was built by the Shelburne Shipyard in

Shelburne, VT in the 1950s.

In the newly opened annex, which opened

January 15, 2019, the LCVP is on

display in the same location it was during its restoration. It is

part of a diorama with a net against the wall simulating the side of a

ship and a soldier climbing down to take his place in the LCVP.

Author's photo.

When the LCVP first went on display, the

ramp hoist cables and winch had not been installed. Author's

photo.

When I returned in early 2020, a World War

Two type ramp hoist cable system had been added. The cable can be

seen up from the inside of the boat, then attaching to the ramp with

the sheaves outside. This is as it was done during World War Two

on the LCVPs. Author's photo.

In this photo, the cable can be seen running

from the winch along the inside of the boat. It then goes up the

starboard side and out of the boat through two sheaves and to the ramp.

The cable for the port side goes down, underneath the deck, then back

up the port side, and out through two sheaves to the ramp. Author's

photo.

This is a closer view of the winch and cable. The winch should

actually be located back in the crew area. But this gives the

impression of a World War Two ramp hoist system. Author's photo.

Museum volunteers built this ramp in

their shop. Author's photo.

The mannequin dressed at the boat's coxswain

is another nice piece of the diorama showing his location while

operating the boat. A jeep and a small anti-tank gun were the

maximum vehicle load for the LCVP. Author's photo.

The LCVP came in without any gun tubs.

Post-World War Two LCVPs did not have the gun tubs installed. Museum volunteers have done an excellent job of re-creating the World War

Two gun tubs with machine guns and armor plate installed. A very

nice historical touch. Author's photo.

The photo below shows how corroded the

propeller, rudder, and associated hardware were in 2014. A

considerable amount of time and effort was needed by volunteers at the

Indiana Military Museum to get them back to the original condition shown

here. Author's photo.

This type of hardware that mounts the skeg and

propeller shaft to the hull is the type that is used on the 1950s-built

LCVP. It is this hardware that identifies this as a 1950s LCVP.

Author's photo.

Owner: Mott Military Museum

Location: Groveport, OH

Hull Number: Unknown

Date Built: 1950s

Date of Photos:

June 2012, December 2015. August 2016,

November 2018, July 2020

Comments: This LCVP, which was built in the 1950's by the Shelburne Shipyard in Shelburne, VT, has been on display for

many years at the museum. It was outside for many years, then

moved inside a three-walled building in 2016, and then restored.

It has been restored to its original 1950s configuration.

It is the best of the post-war era LCVP restorations I have seen to

date.

June 2012:

For several years, the LCVP at the Mott Military Museum sat outside in

the elements. The 1950s cable hoist system is visible. The

winch is mounted on the gunwale and the cable for starboard side runs

outside the boat. It then crosses under the outside sheave and

enters the boat. Author's photo.

By December 2015 it had to be covered up.

Author's photo.

August 2016:

Now it was inside a three walled building

and undergoing restoration. There are three sections of armor on

the side. Author's photo.

Author's photo.

The armor plate had been reinstalled and waiting on paint.

Author's photo.

New floor boards were installed.

Author's photo.

The exhaust for the engine is visible. Also visible is one of the

four 55-gallon barrels used for fuel tanks on the post-World War Two

LCVPs.

Author's photo.

It has a Gray Marine/Detroit Diesel engine. The engine is missing the

blower and air silencer. Author's photo.

Note the canvas duck that acts as a gasket

between the boat and the ramp. On the port side, the ramp hoisting

cable can be seen entering the inside of the boat and running over

the sheave to the ramp. This is an attribute of a 1950s LCVP. Author's photo.

November 2018

The restored LCVP is in its new protective

building. The reason for the three walls is local building codes

required a restroom if the fourth wall had been included. Author's

photo.

The canvas duck gasket can be seen between

the boat and the ramp. The ramp is not entirely pulled closed so

there is a gap. Author's photo.

Author's photo.

July 2020:

The Mott Military Museum LCVP in its building in July 2020. The

ramp is now down. Author's photo.

The museum has built a viewing stand on the

port side of the LCVP. This allows for photos of the interior by

visitors. Author's photo.

This is the ramp winch mounted to the top of

the gunwale. Cables go both to the front and rear of the boat,

typical of a 1950s ramp hoist system. The previous photo from

June 2012 shows the cable running outside the boat to the front.

Author's photo.

The cable runs to the rear, enters a

sheave, and goes across the rear of the crew compartment. It then

turns around another sheave and runs along the outside on the portside

of the boat. Note the 55 gallon barrels used as fuel tanks and the

lack of gun tubs. These along with the ramp cable system are all

attributes of a 1950s-built LCVP. Author's photo.

The cable is running down the outside of the LCVP. Author's photo.

Author's photo.

The Mott Military Museum's LCVP has the

V-bracket that mounts to the skeg from the hull. It has another

bracket that mounts the propeller shaft to the hull. Both of these

are of the 1950s design for the LCVP. Author's photo.

Owner: Museum of American Armor

Location: Long Island, NY

Hull Number: Unknown

Date Built: 1952 to 1958

Date of Photos: June 2019

Comments: I was able to visit this LCVP at its former home,

the

International Museum of World War Two in Natick, MA in June 2019. Two months

later, the museum abruptly closed and the LCVP was sold to the Museum of

American Armor. Some sources indicate this LCVP came from Alaska.

This is how the LCVP looked from the parking

lot of the now closed International Museum of World War II before it

closed. It is good to see that the former owners put it under a

roof. Author's photo.

It still has its armor plating installed.

Author's photo.

Author's photo.

One of the observable signs of a post-World War Two LCVP is the ramp

cable running down the side of the boat and then running to the inside

just before attaching to the ramp. Author's photo.

Author's photo.

Author's photo.

The interior looks to be in better condition

than the outside of the LCVP. This example has the three sets of

long boards running along the inside of the hulls. Not all

post-World War Two LCVPs have these still installed. Author's

photo.

The combination throttle and transmission

lever is still in the boat with several gauges which have been painted

over. It looks like museum volunteers were able to paint the

LCVP's interior. Author's photo.

There are also no gun tubs as is the norm

with the post-war LCVPs. Author's photo.

This has the three-piece propeller, skeg, and rudder support typical of

the 1950's built LCVPs. Author's photo.

Author's photo.

Owner: National Museum of Pacific War - LCVP-1

Location: Fredericksburg, TX

Date of Photos: Unknown

Comments: In

November 2014, the museum received two LCVPs from an unknown

source. One was restored and is currently on display the

museum's Pacific Combat Zone. A YouTube video of the LCVP

indicates it is a post-World War Two boat.

YouTube video of LCVP-1

Note that the ramp cables enter the boat just before going to the sheave

at the ramp. This indicates this is a post-World War Two LCVP.

Owner: National Museum of Pacific War - LCVP-2

Location: Fredericksburg, TX

Date of Photos: Unknown

Comments: The second boat arrived with most of the port side

missing and was used as a parts boat for the display unit. A photo

of the boat indicates it is post-World War Two.

Museum Press Release on both LCVPs - Photo of LCVP-2

Owner: World War II Veterans History Project

Location: Florida

Date of Photos: 2020

Comments: This was formerly at the Museum of the

American G.I., College Station, TX. I had been told some years

back that there was a LCVP at the Museum of the American G.I.,

but I could never obtain any confirmation. An Orlando

Sentinel newspaper

article on April 23, 2020, told of a LCVP

that came from College Station, TX and was now in the possession of

the World War II Veterans History Project for restoration.

It appears the Museum of the American G.I. has donated or sold the LCVP

to the Veterans History Project.

While much of the LCVP is missing, there are

a couple of photos on the World War II Veterans History Project's

website that indicate this was built in the 1950s by the Shelburne

Shipyard in Shelburne, VT. There is one photo that shows the 1950s

type V-bracket for the skeg and a separate casting for the propeller

shaft mountings. Another photo shows 55

gallon barrels being used for fuel tanks.

World War

II Veterans History Project Website Photos are at the bottom

of the page.

Owner: American Military Museum (Tankland)

Boat Number: Unknown

Year Built: Unknown

Location: El Monte, CA

Comments: This LCVP is marked PA 21-17 on the side. Added

11-30-2020.

Photos at:

https://www.flickriver.com/photos/sarge_schultz/36150654604/

https://flickriver.com/photos/sarge_schultz/36150652934/

In this photo two more LCVPs can be seen behind the PA 21-17. Both

are fiberglass. The first one is 36VP65100. It has LST 1191-4

on the side of it. The second one has no markings. |