|

Hughes Aircraft Company Patents

Hughes Aircraft Company During World War Two

A Unit of Hughes Tool

Company

Culver City, CA

1932-1986

This page added 2-22-2023.

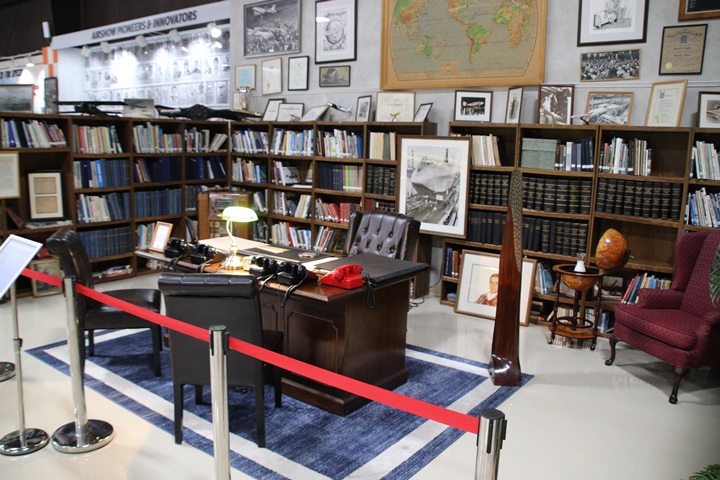

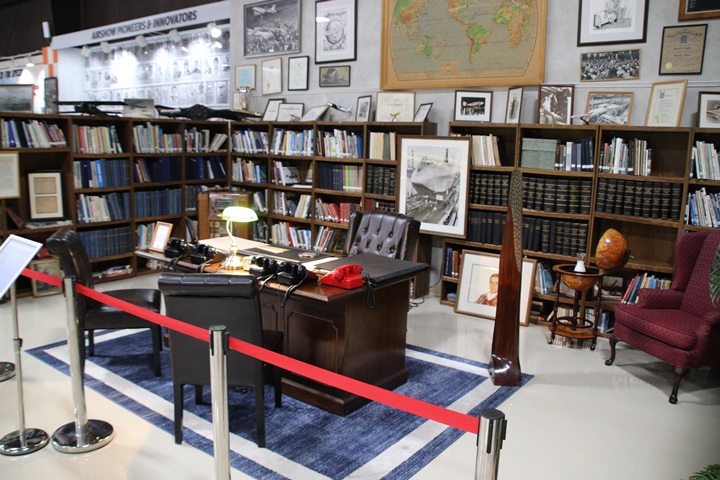

This page on the Hughes Aircraft Company, a

unit of the Hughes Tool Company, began for me in July 2022 when I visited the

Florida Air Museum in Lakeland, FL. This was the first time I had

the opportunity to visit the museum and was most interested in what

I could learn there. Strangely,

the most interesting display was not an aircraft nor a piece of military

hardware, but Howard Hughes' office. In 1924, Howard Hughes, Jr.

became majority owner the Hughes Tool Company when his father, Howard

Hughes, Sr. passed away from a heart attack. Previously in 1908,

Howard Hughes, Sr. patented a roller cutter bit that became standard in

the oil drilling industry. This made the Hughes Tool Company into

a very profitable enterprise. At the age of 18, Howard Hughes

gained control of Hughes Tool Company and began using the profits from

the company to fund other projects in which he was interested. In 1934,

he created the Hughes Aircraft Company as a Unit of the Hughes Tool Company.

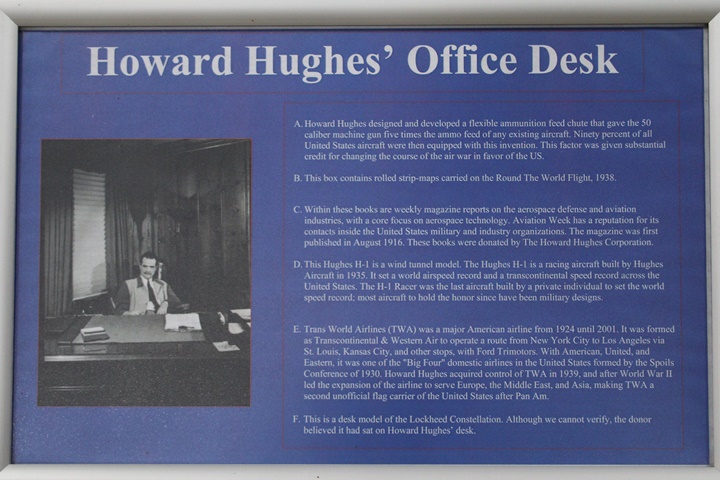

This is the re-creation of Howard Hughes'

office at the Florida Air Museum. In 2003 the Museum obtained the

Howard Hughes archives. Author's photo.

Author's photo.

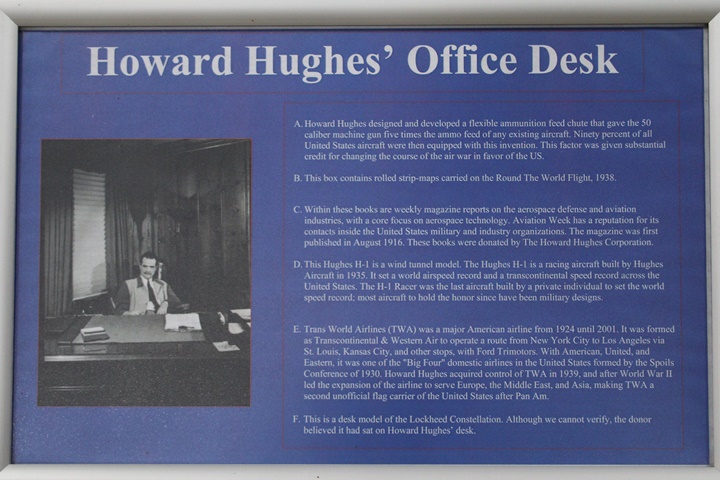

Item "A" on this information placard caught

my attention as it noted he designed the flexible ammunition feed used

on many American bomber and patrol aircraft during World War Two.

While Mr. Hughes was known as a very good engineer, I wondered at the

time if he was really the inventor of this device. While he, no

doubt, was mentally capable of this task, would Mr. Hughes have

had the time to focus on this while he was making movies, setting world

aviation records, dating Hollywood starlets, and purchasing TWA.

Anyone with five telephones on their desk is more focused on the big

picture rather than the intimate details that are needed to produce a

patent. Also, he

was the inspiration and the force behind the building of the world's

largest transport aircraft, the Hughes HK-4, more commonly known as the

Spruce Goose. Author's photo.

| |

On top of one of the bookcases was an

example of a Hughes flexible ammunition feed. At the time, I was

not ready to research this further, but knew that someday in the future

something would cause me to take on this project. Author's photo.

The trigger which caused me to look at the Hughes flexible

ammunition chute in depth occurred just six months later in January 2023,

when I made my annual visit to the Champaign Aviation Museum in Urbana,

OH. The museum is restoring a B-17G named the "Champaign Lady,"

and I visit at least once a year to see how the progress is coming on

the project. Author's photo.

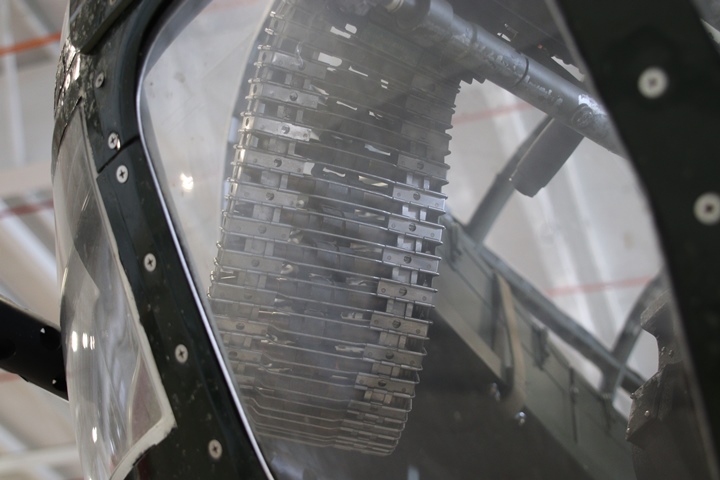

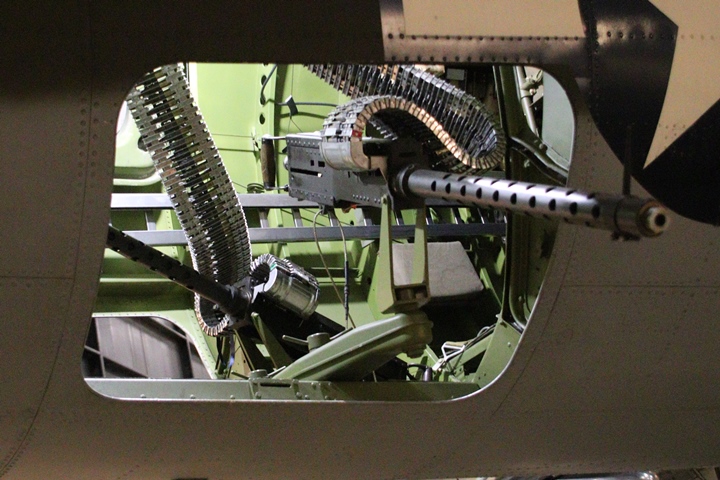

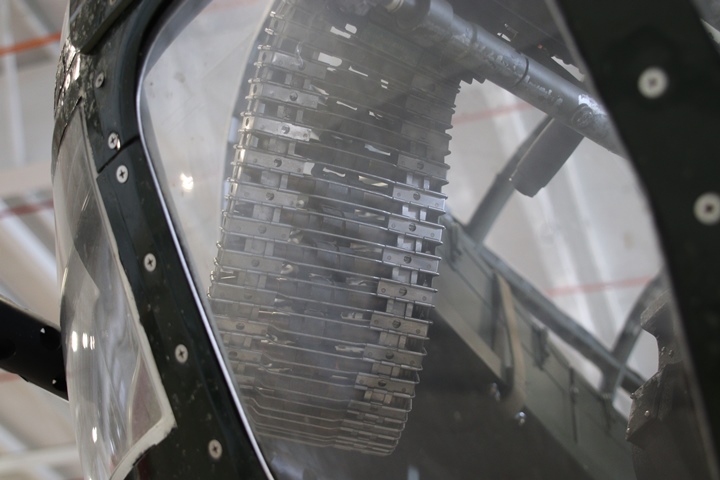

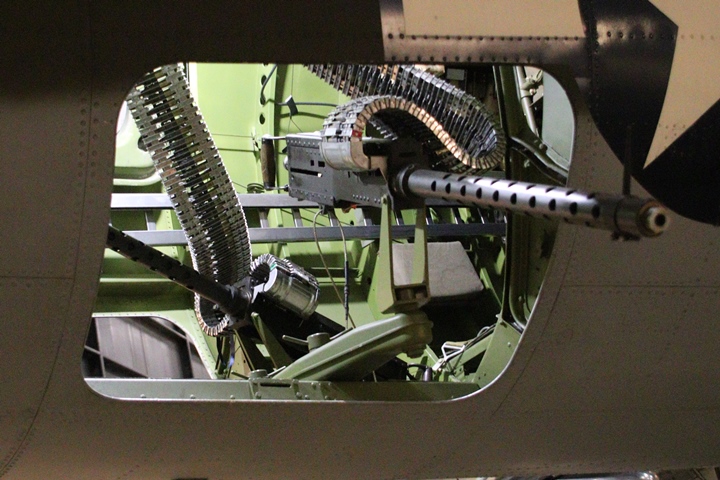

What caught my attention is that all of the

flexible .50 caliber machine guns in the aircraft now had Hughes

flexible ammunition feeds. The B-17 is a work in progress and each time

I return I find more has been added to the aircraft. Author's

photo.

Hughes Aircraft Company World War Two

Products: The story of the Hughes Aircraft Company during

World War Two, to be blunt, is not a pretty story. In several

cases, Hughes Aircraft Company was more of a hindrance to the winning of

World War Two than what it contributed. Two exceptions were the

flexible ammunition feeds and small motors that helped feed cartridges

into .50 caliber weapons used on American bomber, patrol, and fighter

aircraft. These items were produced by the Armament Division of

Hughes Aircraft which was focused helping to win World War Two.

Table 1 tells part of the dark story of Hughes

Aircraft during World War Two. The company had $21,909,000

in major contracts during the war.

$20,275,000 or 92.5% was the Hughes XF-11 twin engine

reconnaissance aircraft. One hundred aircraft were ordered on

USAAF contract 33038-A1079. By the end of the war, none had been

completed and the production contract was cancelled. Two were

finally completed in 1946, and one crashed during a test flight.

The second flew once and then was scrapped in 1949. This was a

totally wasted effort and the money and the manpower could have well

been used by other companies in the Los Angeles, CA area to produce

products that acually helped win World War Two.

But it gets worse. For those familiar

with World War Two history, they will know this as the infamous H-4

Hercules or better known as the Spruce Goose.

One will note that in Table 1 there is no

contract for a H-4 aircraft. It turns out that Howard Hughes was

able to borrow $20 million from the Defense Plant Corporation to build

the aircraft. He also put $8 million of his own money into the

project. It only flew once for 26 seconds at 70 feet of altitude

on November 2, 1947. Author's photo.

During World War Two workers all across the

country were putting money each payday into Saving Bonds to help finance

the winning of World War Two. The Hughes Aircraft Company under

Howard Hughes took advantage of these patriotic Americans and used $40

million that could have well been put to a better purpose.

According to one source, during World War Two Hughes Aircraft employed

80,000 workers, most of them no doubt working on the H-4 and XF-11

aircraft programs. This was again a waste of labor which could

have been well used to make equipment that was needed to win World War

Two.

Table 1 - Hughes

Aircraft Company's Major World War Two Contracts - Culver City,

CA

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. |

|

Product - Customer |

Contract Number |

Contract Amount |

Contract Awarded

Date |

Completion

Date |

| Chutes Feed -

USAAF |

535-AC-31627 |

$130,000 |

7-1942 |

10-1942 |

| Adaptor

Assemblies - USAAF |

535-AC-38127 |

$88,000 |

3-1943 |

2-1945 |

|

Airplanes FX11 - USAAF |

33038-AC-1079 |

$20,275,000 |

11-1943 |

8-1945 |

| Booster Assys Cal

50 - USAAF |

4235-AC-247 |

$162,000 |

1-1944 |

3-1944 |

| Gunnery Parts -

USAAF |

4235-AC-295 |

$100,000 |

5-1944 |

2-1945 |

| Antennas - Navy |

XSR-83426 |

$93,000 |

11-1944 |

6-1945 |

| Feed Mech Models

T20 - Army Ordnance |

4200-ORD-594 |

$110,000 |

12-1944 |

2-1945 |

| Aircraft JB3

- USAAF |

33038-AC-7822 |

$420,000 |

2-1945 |

7-1945 |

| Classified - Navy |

5-SR-7247 |

$133,000 |

6-1945 |

6-1946 |

| Classified - Navy |

5-SR-7248 |

$398,000 |

6-1945 |

6-1946 |

| Total

|

|

$21,909,000 |

|

|

However, there are two unrecognized persons

within the Hughes Aircraft Company that are true World War Two

industrial heroes. There names were Mr. Harry E. Elliot and Mr.

Claude C. Slate.

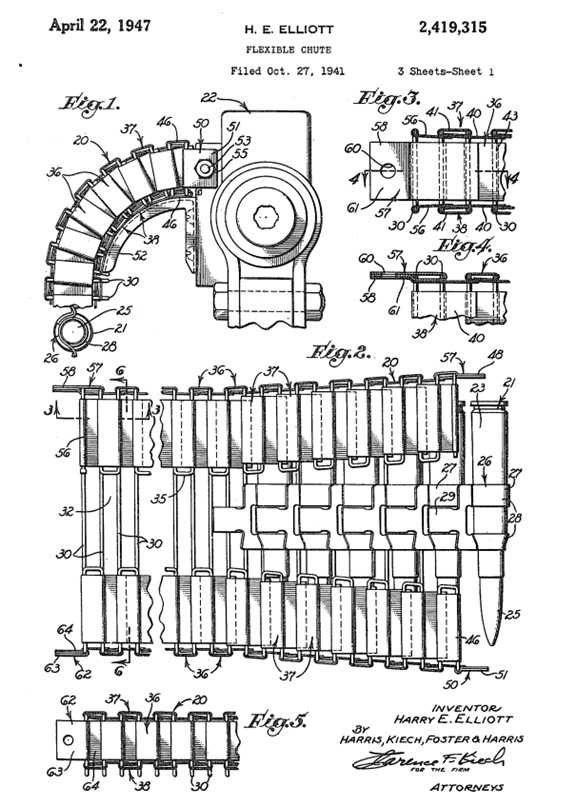

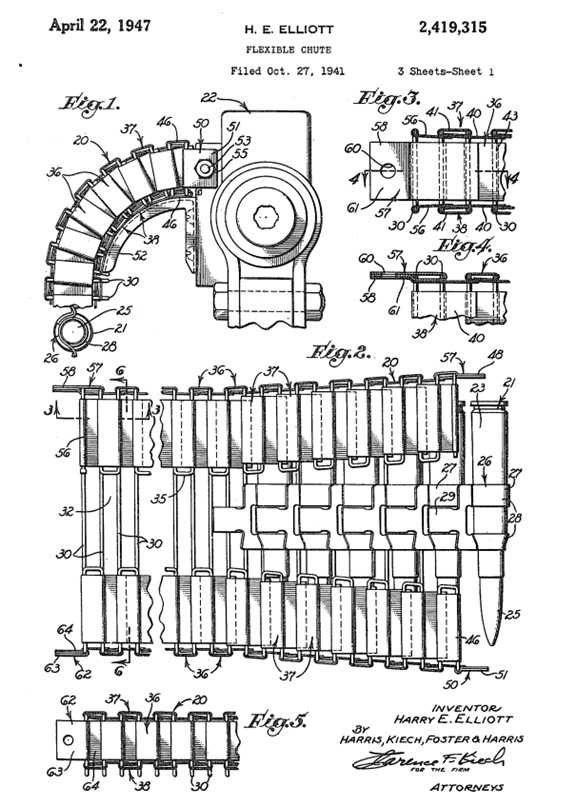

Once I returned home from the Champaign

Aviation Museum in January 2023, I did a patent search

and found that Patent Number 2,419,315 dated April 22, 1947, for a "Flexible Chute" does not have Mr. Howard

Hughes' name on it. This is as I expected. The Florida Air Museum

is incorrect in naming Howard Hughes as the inventor of the device.

The name on

the patent is Mr. Harry E. Elliot. Mr. Elliot filed for the patent

on October 27, 1941. His invention was just in time to be used on

every American bomber and patrol aircraft that had defensive .50 caliber

machine guns. The use of the flexible ammunition feeds, or chutes

allowed the gunners to have a jam-free passage of the shells from remote

ammunition boxes to the weapon.

This is the first page of the patent.

Note that the continuous, small diameter wire that holds the flexible

chute together has squared ends on both of the interior sides of the

assembly. This changed during the course of the war as the

interior square sections became fully radiused.

This is the fourth page of the patent and

the first of seven pages of the written description. The entire

patent is shown at: Hughes

Aircraft Patents

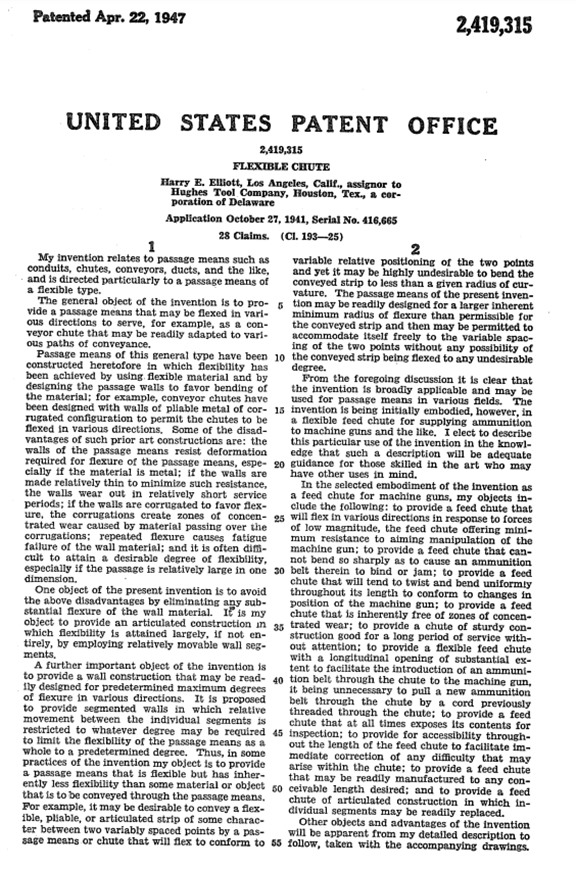

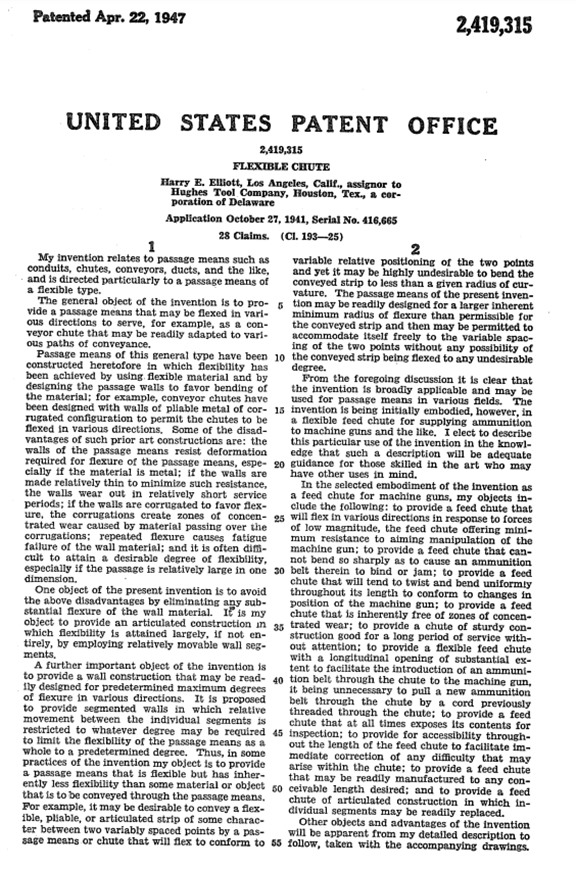

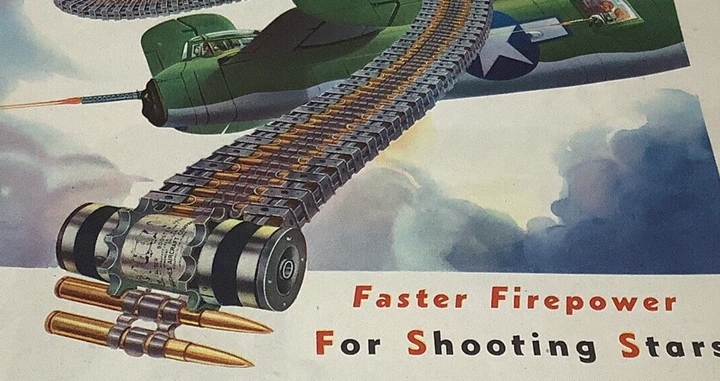

This image from a 1944 Hughes Aircraft

Company advertisement shows that the interior wires are now semi-circles

within the assembly. The feed chutes are called Hughes flexible

feed chutes in this advertisement. Also shown in the

advertisement is a Hughes ammunition booster, which was an electric

motor that helped pull the cartridges into the weapon.

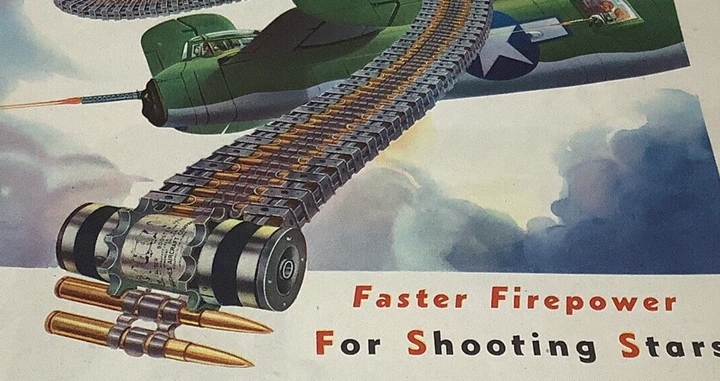

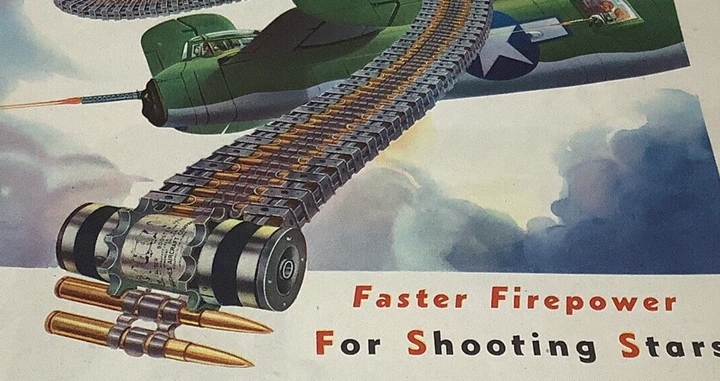

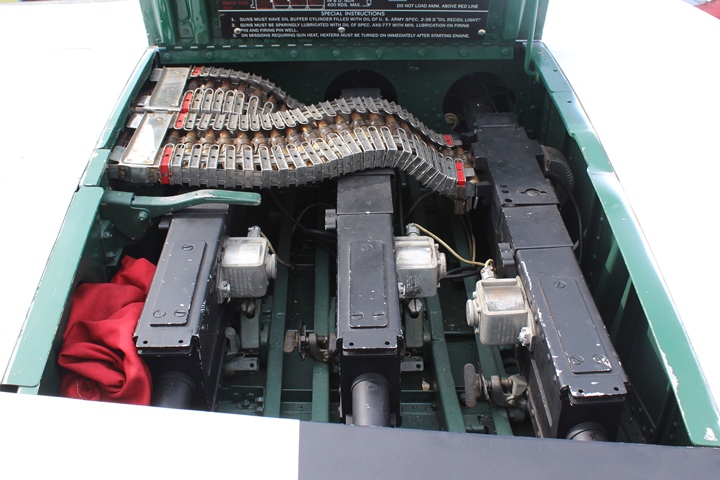

More patent research into the Hughes

ammunition booster shown above found another patent by another Hughes

Aircraft Company employee, Mr. Claude C. Slate.

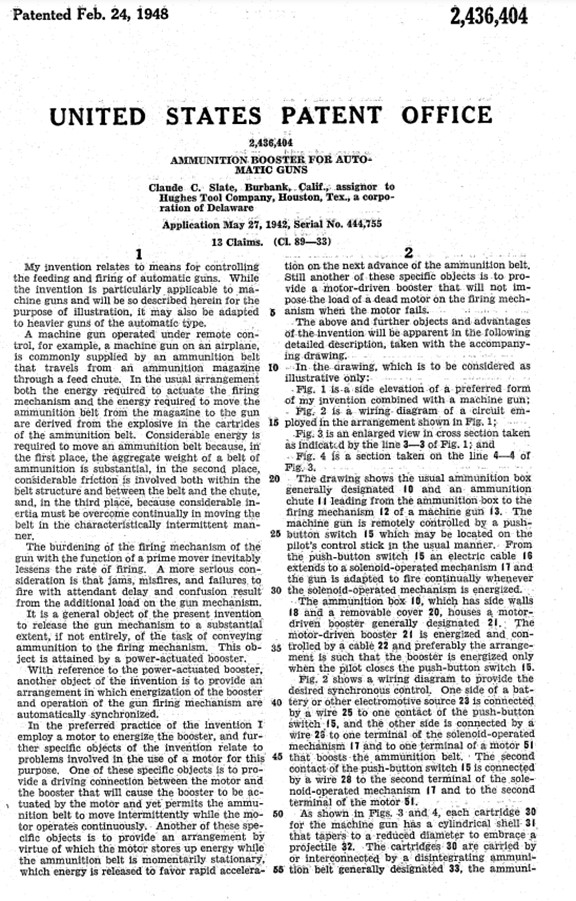

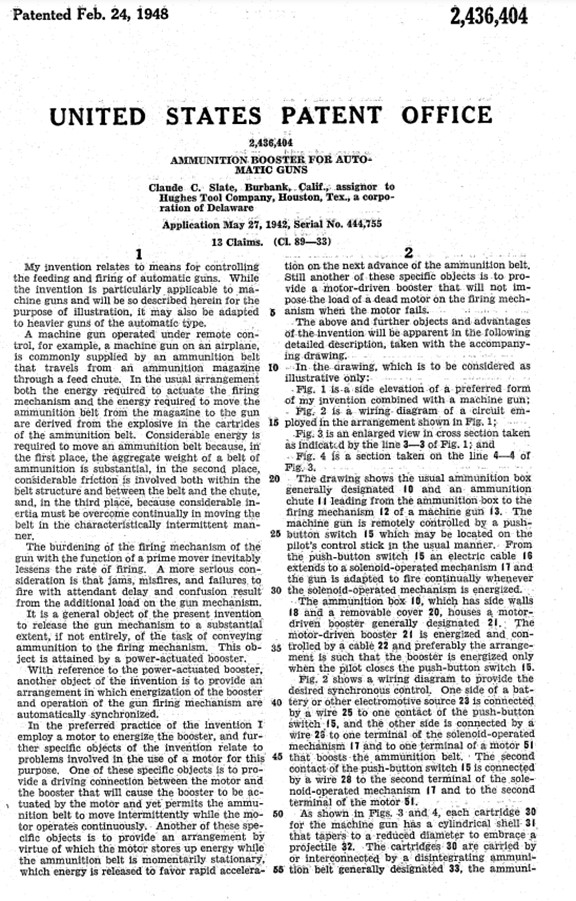

Mr. Slate filed for patent number

2,436,404, titled "Ammunition Booster for Automatic Guns," on May 27,

1942, and it was granted on February 24, 1948. His invention was

complimentary to Mr. Elliott's patent, as it provided a method of

overcoming the weight of the cartridges and the friction in the feed

chutes as the ammunition was pulled into the weapon. Figure 1 on

the first page of the patent below shows that the booster pulled the

cartridges out of the ammunition box and pushed them through the

flexible feed chute. Figure 2 shows the electrical wiring circuit

to power the device.

As this patent application was submitted after

the one for the flexible feed chute, it may very well have been that it

was discovered that the machine guns were not able to effectively pull

the cartridges through the flexible feed chute due to the added

friction. Mr. Slate developed an elegant solution for the problem.

These are the first two pages of Mr. Slate's

patent. The entire patent can be seen at:

This image shows Mr. Slates invention

wrapped in its protective wrapping. Photo Courtesy of the National

Air and Space Museum.

No doubt, Mr. Elliott or Mr. Slate never received the

recognition for their inventions that helped the United States win World

War Two and no doubt helped save many aircraft and airmen from being

shot down. The inventions were assigned to the Hughes Tool Company

of Houston, TX. This is standard industry procedure. The two

patents with my name on them are the property of the company I worked for at the time.

Mr. Harry E. Elliot and Mr. Claude C. Slate helped win World War Two.

No doubt their inventions saved the lives of many American airmen with

their inventions by allowing American bomber and patrol aircraft gunners

to reliably feed ammunition into their weapons. The same can be

said for American fighter aircraft that utilized these inventions.

Production of the flexible feed tubes and

ammunition boosters: Table 1 shows the company's first major

contract was for the flexible feed chutes. That is puzzling, given

the fact that there was only one contract for $130,000. For as

many applications in which the product was used, it would seem there

should be more contracts. It could be that there were several

contracts for less than $50,000 or that they were being ordered directly

from the aircraft manufacturers.

Many times the major contract listing does not

tell the entire story of what transpired 80 years ago. The "War

Industrial Facilities with Public and Private Funds as of September 30,

1943" shows that Hughes Aircraft was tooled to produce 60,000 feet per

quarter by February 1943. This was financed by internal company

funds. The same document also shows that Hughes Aircraft tooled

itself to produce 3,000 ammunition boosters per quarter. This run

rate was also achieved in February 1943.

As with the flexible feed tubes, there is only

one contract 4235-AC-247 for $162,000 awarded January 1944 for

ammunition boosters. Most likely there were other contracts for

less than $50,000 to purchase this device.

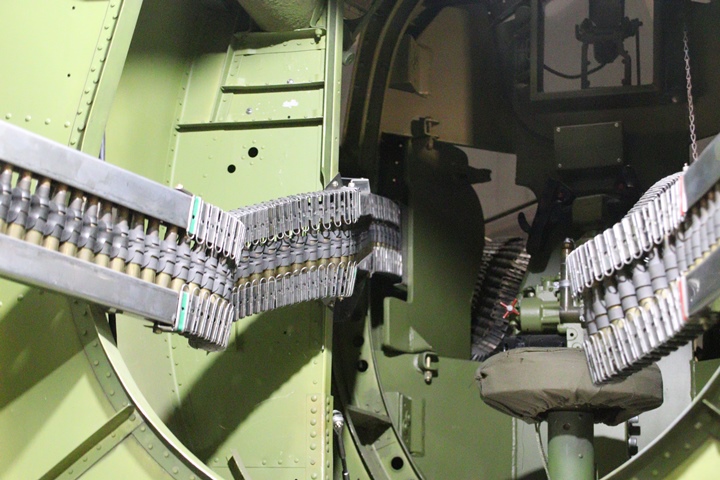

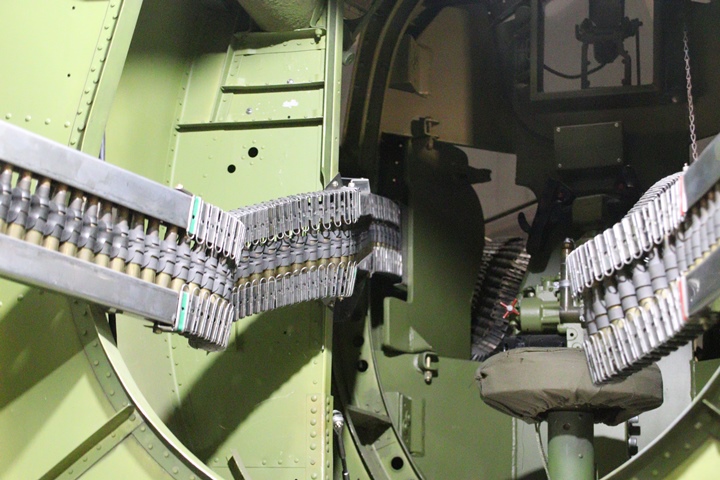

Hughes Flexible Feed Chutes: Below are

more photos of the flexible feed chutes in the "Champaign Lady," along

with other warplane applications for Mr. Elliot's invention.

Author's photo.

Author's photo.

Author's photo.

This image of the port side flexible shows the change from the original

patent drawing. The wires are radiused rather than square as shown

in the patent. This was no doubt found to be easier to manufacture

after the patent had been submitted. Author's photo.

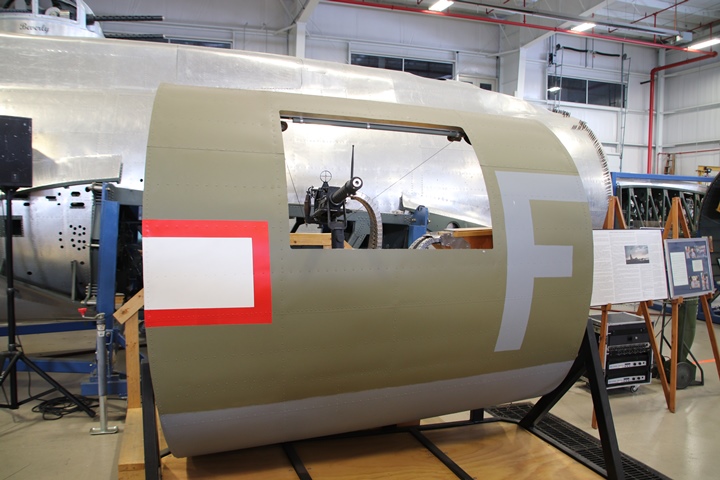

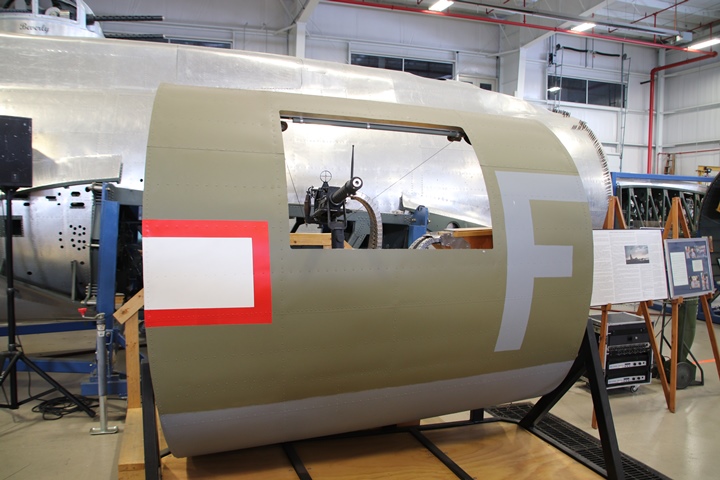

How cool is this? The museum volunteers have fabricated a section

of sheet metal to represent the port side machine gun station.

This was also new in January 2023. Note that the "Champaign

Lady's" fuselage is split into to sections behind the display.

Author's photo.

A visitor to the museum can stand behind the

weapon and see how it feels to move it around. The wire rope is

spring loaded within a tube over the window and brings the .50 caliber

machine gun back to this home position when not being operated by the

gunner. I was unaware of this mechanism until I tested it out for

myself. Author's photo.

Life is a continual learning process.

It was not until I was editing my photos that I realized this is not a

Hughes-built feed chute. This is a totally different design.

There are several other types of patented feed chutes. It is

unknown which company manufactured this type of feed chute. While

this is not a Hughes Aircraft Division-built feed chute, this display at

the museum does show how the waist gunner positions utilized feed

chutes. It may well be a post-World War Two-era feed chute.

Author's photo.

Because the B-17's fuselage is split, a

visitor can look into the rear section and see the waist gunners'

positions. Author's photo.

The waist gunner's weapons were fed with

Hughes flexible feed chutes from wooden ammunition boxes. Author's

photo.

Author's photo.

The tail of the "Champaign Lady" is missing

the tail gunner's position. Author's photo.

The tail gunner's section is in the lobby of

the museum and is the first thing a visitor sees when he or she comes

through the entrance. Author's photo.

Author's photo.

B-17 tail gunners had their .50 caliber

rounds fed via Hughes flexible feed chutes from wooden ammunition boxes.

Author's photo.

B-17 Bonus Information: If one

has ever watched World War Two footage of B-17 or B-24 bombing missions

over Europe, there will normally be video taken from the underside of an

aircraft showing the bombs falling towards the target and then striking

the ground below. I have never given it much thought as to where the cameras were located in the B-17 until my trip to

the Champaign Aviation Museum in January 2023. Because the

fuselage is in two sections, one can look into the radio room from the

rear of the forward fuselage section. In doing so on this trip, I

noticed an open door in the aircraft floor. I could not see from

my location what was in the space below the floor, so I had to hold my

camera over the area with my arms extended to photograph what was

located in the bottom of the aircraft.

This is the camera bay of the B-17 that recorded

the accuracy of the aircraft's bombing mission. In all of the

times I have been around or in a B-17, this was the first time I have

seen this. Author's photo.

Author's photo.

More Applications for Mr. Harry E. Elliot's

Patented Flexible Feed Chutes:

B-25 "Champaign Gal" at the Champaign

Aviation Museum is just a few feet away from the B-17 "Champaign Girl." Author's photo.

A flexible feed chute can be seen in the

nose of the B-25. Author's photo.

Author's photo.

This Martin B-26 Marauder on display at the

National Museum of the United States Air Force in Riverside, OH also has

Mr. Elliot's invention in it. Author's photo.

Author's photo.

This photo is looking into the starboard

side waist gun position. Author's photo.

This image is looking in through the port

side waist gunner's position. Author's photo.

This image is looking back to the tail

gunner's position. The .50 caliber rounds are stored in solid

metallic chutes and then fed into the Hughes flexible feed chutes at the

bulkhead opening. Author's photo.

This shows the interface between the solid

metal chutes and the Hughes type, which then thread their way to the

machine guns. Author's photo.

The B-24D also located at the National

Museum of the United States Air Force has flexible feed chutes for the

waist guns. Author's photo.

Author's photo.

Author's photo.

Wing mounted guns in American fighter

aircraft like this P-51D also used the Hughes flexible feed chutes

during World War Two. Author's photo.

Author's photo.

The waist gun positions on the Martin PBM

Mariner PBM-3D/S models were the first in the series to utilize the

Hughes flexible feed chutes which routed the .50 caliber

cartridges from wooded ammunition boxes mounted on interior fuselage. Author's photo.

This B-29 General Electric-built foreword

lower turret utilized Hughes flexible feed chutes. Author's photo.

This was on display at the Kansas Aviation

Museum in Wichita, KS. Author's photo.

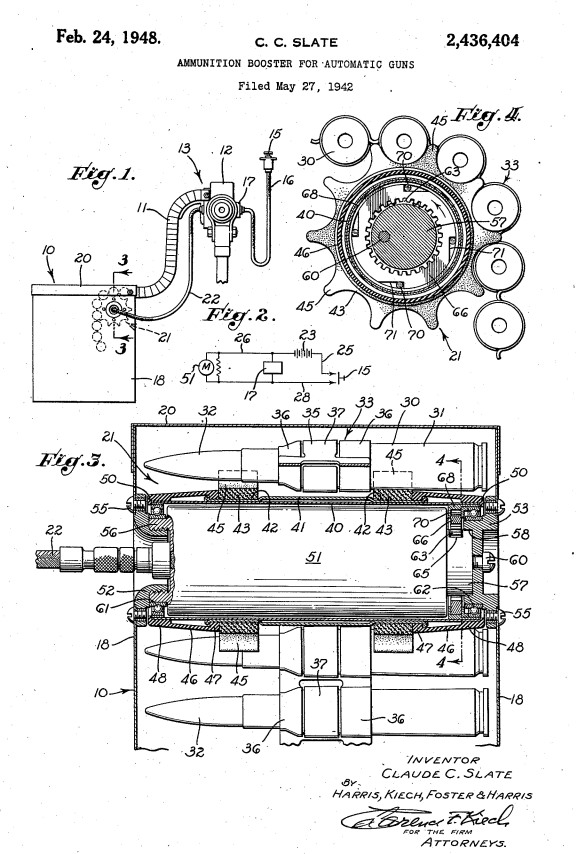

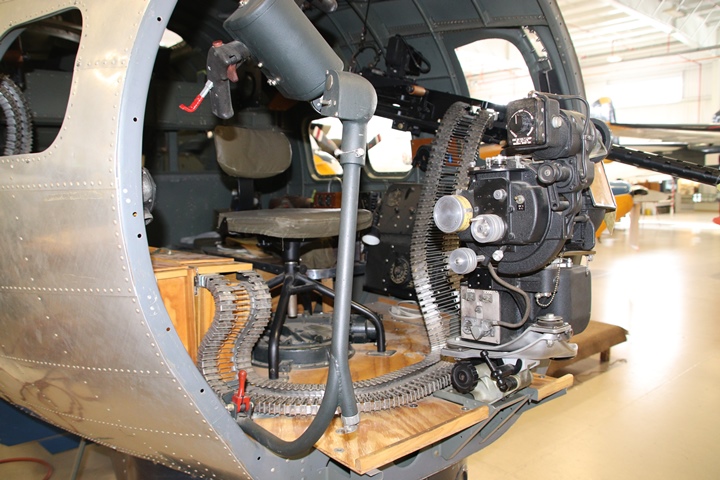

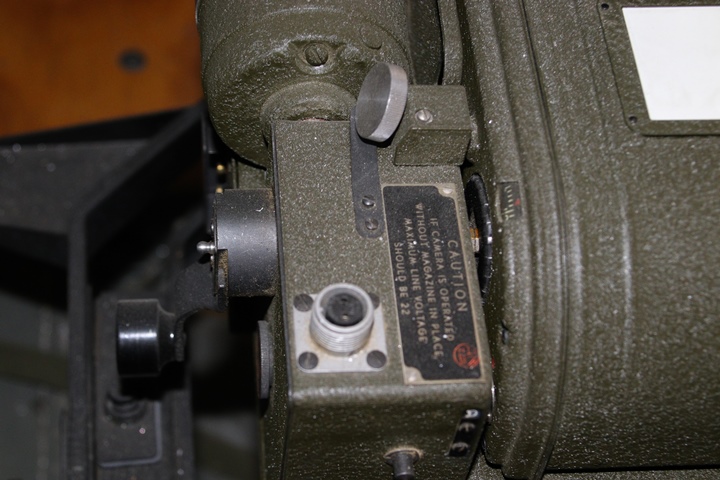

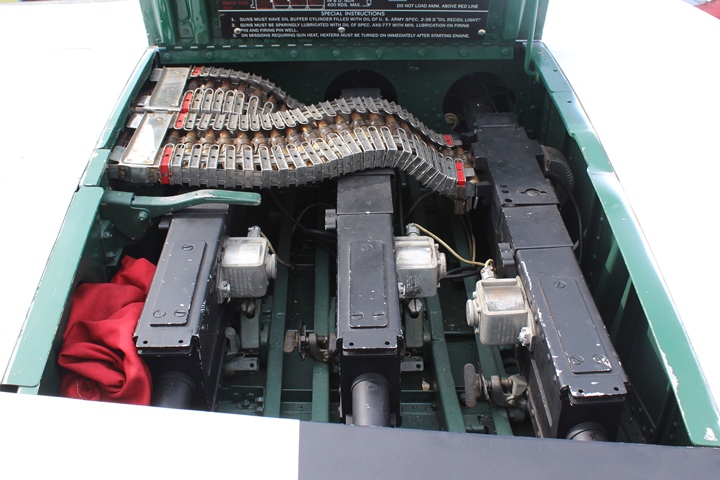

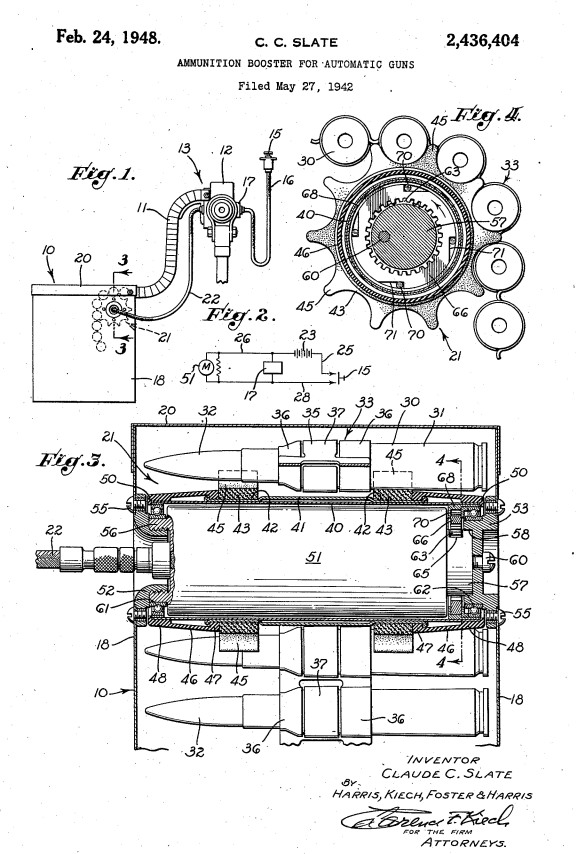

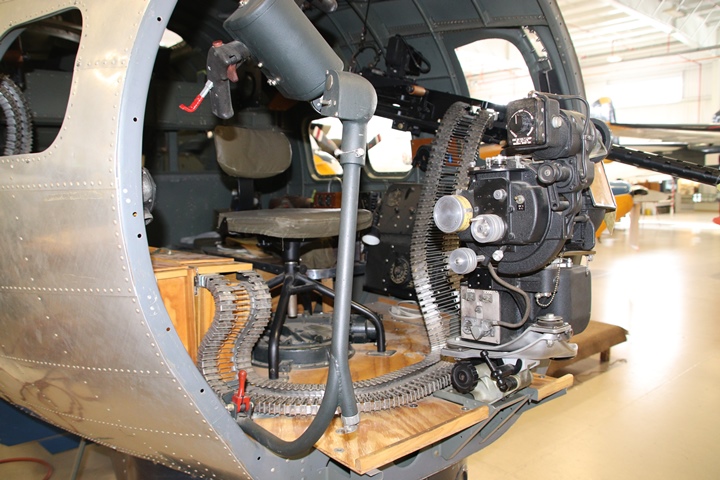

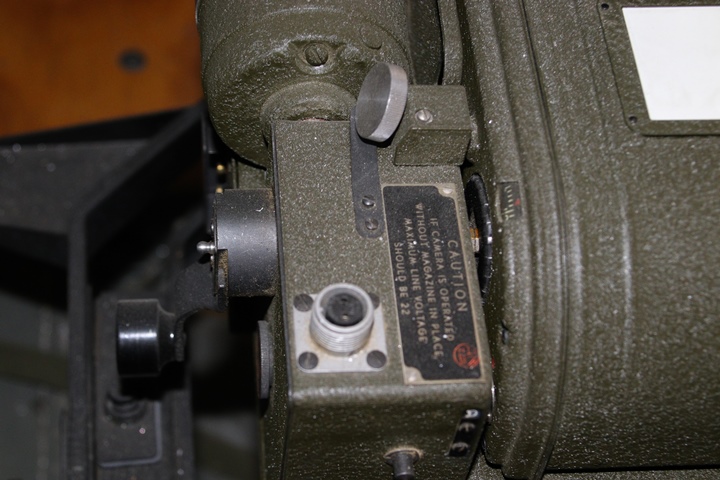

More of the "Booster Assys Cal 50" ordered

under contract 4235-AC-247 are the small electric motors shown here.

The motor is shown in this image at the end

of a Hughes flexible feed chute.

Other Hughes Aircraft World War Two

Products: Shown below are several other products Hughes

Aircraft worked on during World War Two.

The Consolidated-Vultee Aircraft Corporation

built 11,537 basic trainers like this one on display at the Air Zoo

Aerospace & Science Museum in Kalamazoo, MI. Hughes Aircraft did

contribute to the winning of World War Two as it provided 5576 wings and

6370 rear fuselage sections under subcontract. Author's photo.

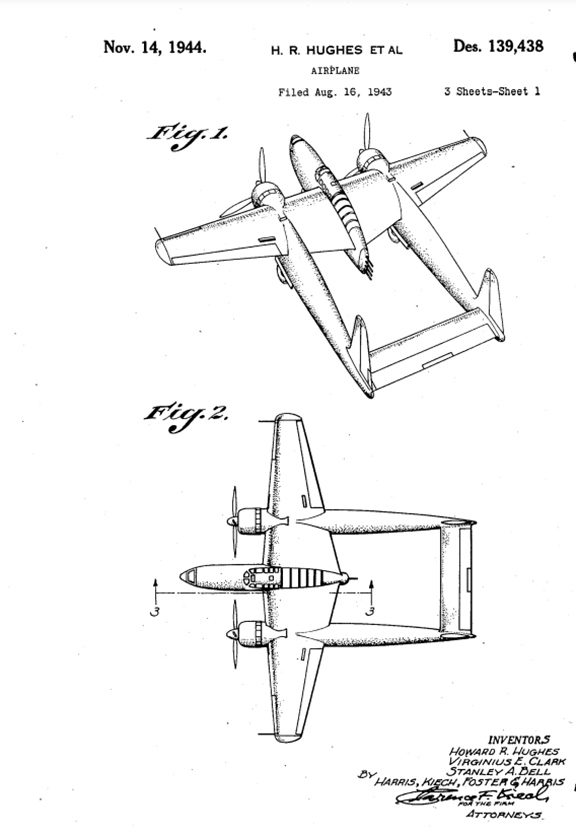

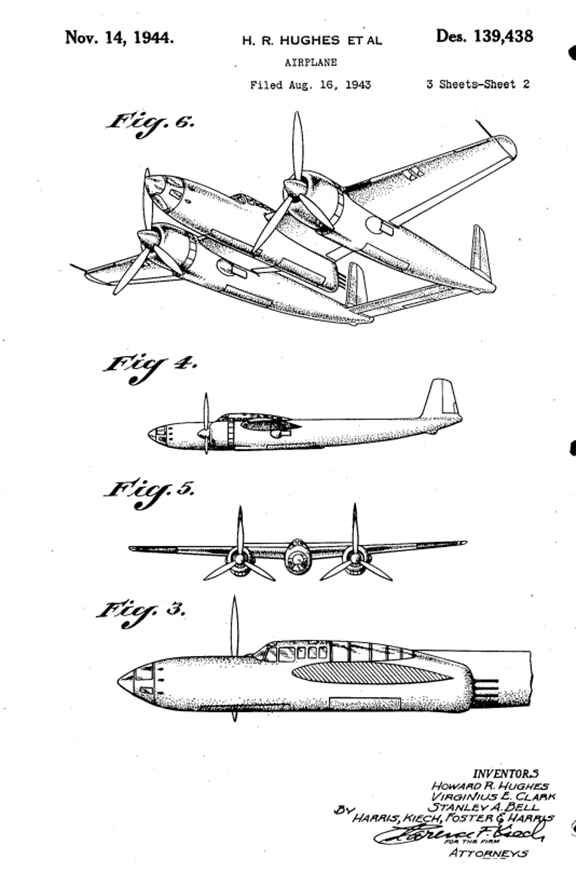

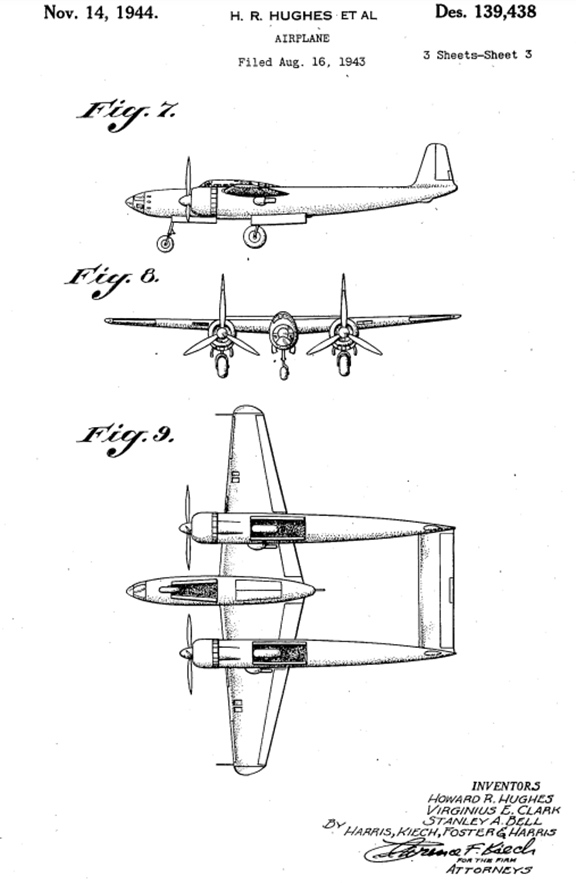

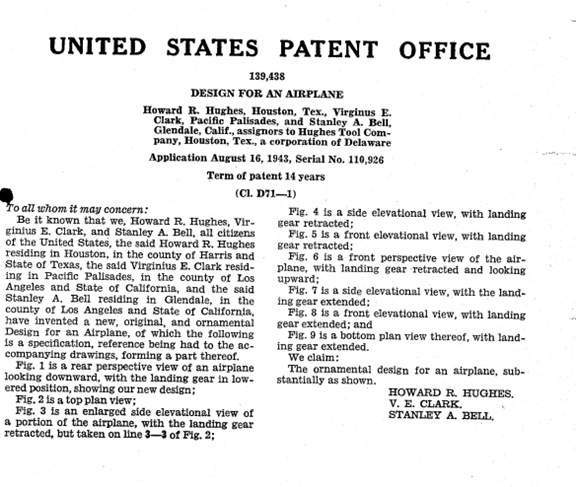

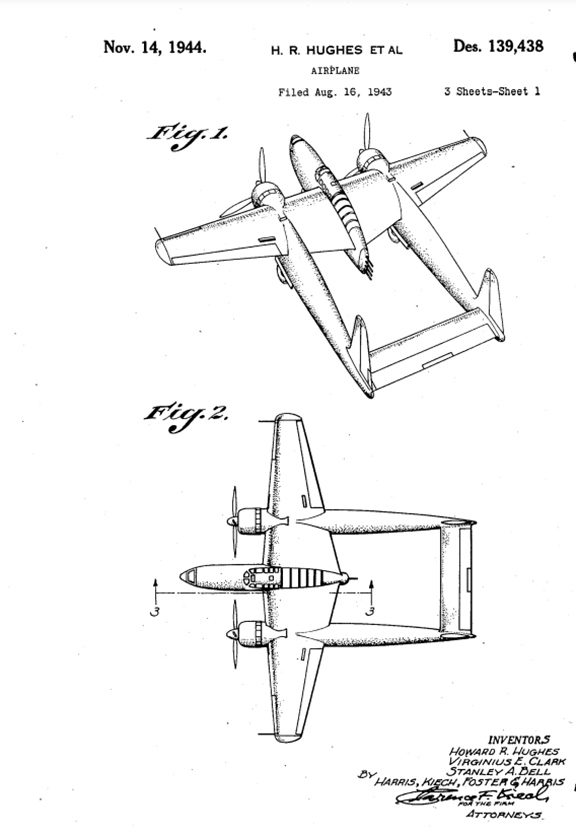

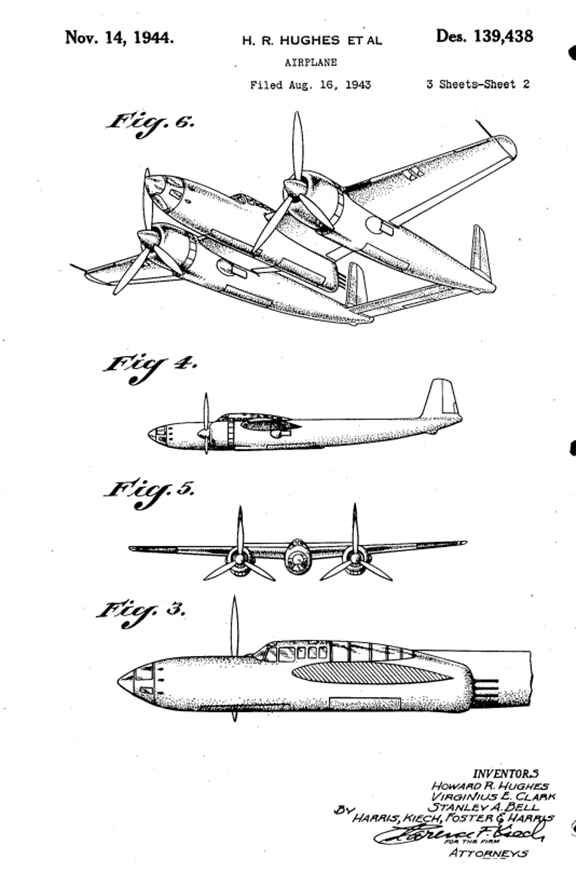

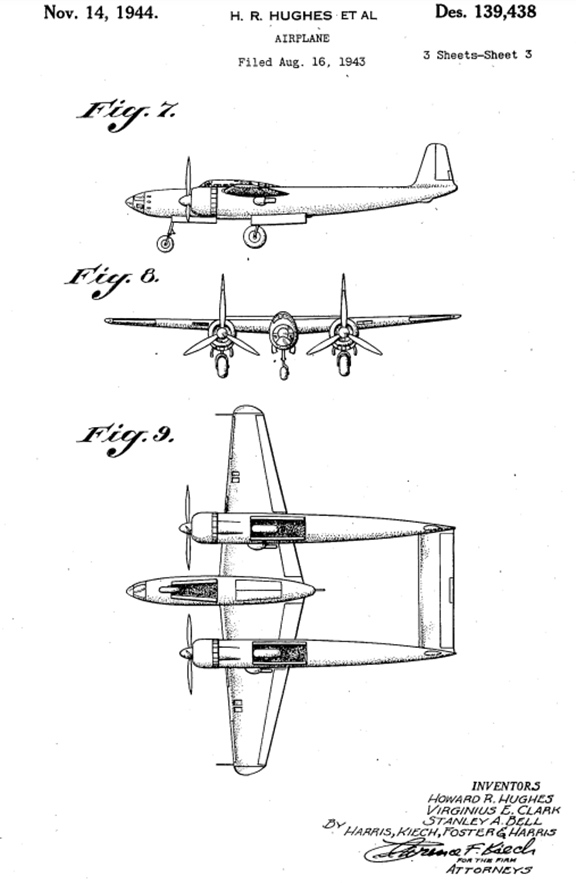

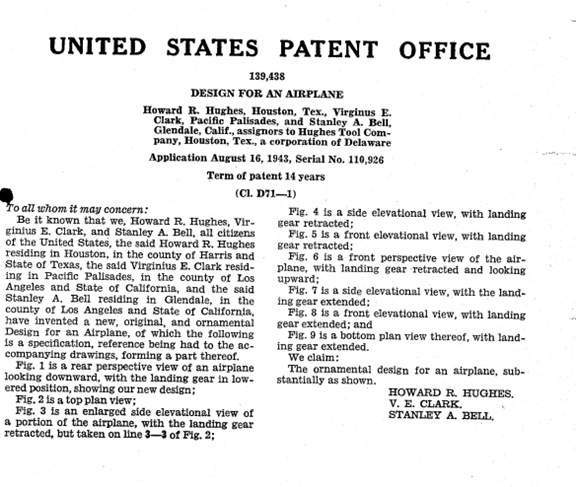

Howard R. Hughes Et Al Patent 139,438 for

an Airplane: This patent for the Hughes Aircraft Company's

XF-11is typical of aircraft patents awarded during this era. No

explanation was required as to why this was different or better than

previous patented aircraft All that appeared to be required were

drawings of the aircraft and the names of the inventors. This

particular patent was granted fifteen months after it was filed.

JB-3 Tiamat: The Aircraft JB3

associated with contract 33038-AC-7822 for $420,000 was an air-to-air

missile. Thirty five were built. While the program was

cancelled due to funding in 1948, Hughes later produced AIM-4 air-to-air

that was used by the United States Air Force in the 1950s and 1960s.

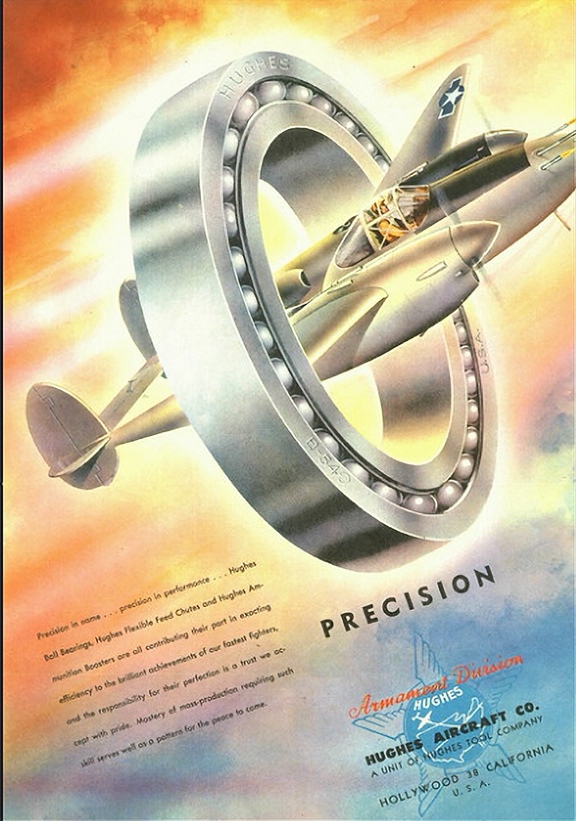

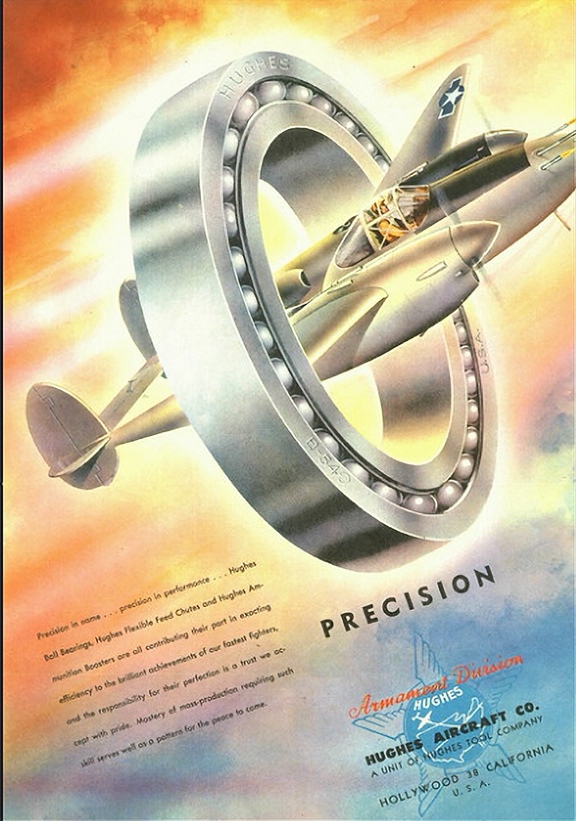

Ball Bearings:

This advertisement for the Hughes Armament

Division shows that beside the flexible feed chutes and ammunition

boosters, it also produced ball bearings. This is a surprise as

this is a totally different type of product that requires specialized

machine tools and assembly equipment. From the advertisement, it

would appear that the bearings were being used in the Lockheed P-38.

The Armament Division of Hughes Aircraft

appears to have been the portion of the company that really contributed

with several products to help win World War Two.

Hughes Aircraft Company H-4 Hercules:

Below are two more photos of the H-4 which is on display at the

Evergreen Aviation and Space Museum in McMinnville, OR.

The Hughes H-4 is currently on display at

the Evergreen Aviation and Space Museum. Author's photo.

While the H-4 was nicknamed the "Spruce

Goose," it was constructed entirely of birch. This image shows the

huge interior of the aircraft. Note the size of the mannequin as

compared to the interior of the aircraft. Author's photo.

The Hughes Aircraft Company Plants:

The aircraft facility was in Culver City, CA as shown in the photo

below. The Armament Division was located in Hollywood, CA.

It is unknown where and how large this facility was.

It was at this location that the Hughes H-4

shown above was built. This was 28 miles from Long Beach, CA where

the H-4 had to be put in the water for its one short test flight.

Howard Hughes went back to the Defense Plant Corporation and asked for

another $2 million dollars to move from Culver City to Long Beach.

There didn't seem to be any long-term thought when the project was

started as to how it was going to be moved so it could fly.

The facility and airport shown in the photo no

longer exist.

The Hughes Aircraft Duramold plant was located

at 6775 Centinela Avenue in Los Angeles, CA.

Post-World War Two Products:

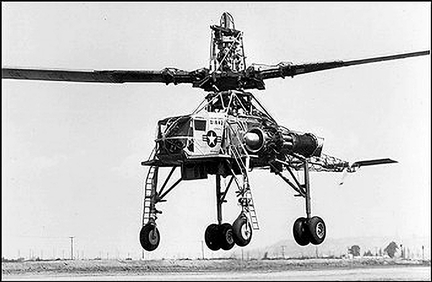

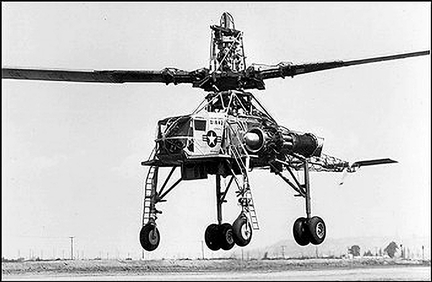

This is the last aircraft built by the

Kellett Aircraft Company. After World War Two, Kellett was awarded

a contract for a heavy lift helicopter. However, because the

company filed for reorganization under the bankruptcy laws, Hughes

Aircraft Company purchased the rights for the XH-17 for $250,000.

There were no production contracts that came from this purchase.

This Hughes TH-55 is on display at the Army

Transportation Museum at Fort Eustis, VA. Hughes delivered 860 TH-55s to the U.S. Army which

trained 30,000 student pilots between 1969 and 1988. Author's

photo.

Author's photo.

|

|

|