|

The D-Day

Normandy Invasion

June 6, 1944

The 70th Anniversary - June 6, 2014

The U.S.

Automobile Industry was there!

This is the east end of a quiet Omaha Beach

in May 2008. In photos from June 6, 1944 the large pebbles are

shown many times. Author's photo.

Note the bunker for a 75mm German gun in the center of the photo.

Behind it are several US Memorials. Author's photo.

Early in the morning darkness of June 6,

1944 the Allied invasion force

arrived off the Normandy beaches. With a 6:30 AM scheduled start

time for the invasion and the first wave of landing craft to arrive on

the beaches, much had to be done. Out in front of the two American

beaches, Omaha and Utah, small 36 foot long wooden landing craft were

lowered over the sides of the large transport ships and placed into the

water. The US Coast Guard coxswains on each small craft reached down in

the darkness and pushed a button or turned a switch, and the Gray

Marine/Detroit Diesel 225 hp

diesel engine in them came to life. Each and everyone of them was

started by Delco-Remy Division of General Motors cranking motor!

This happened1,089 times

throughout the fleet, in the darkness of that fateful morning.

The

Delco-Remy Division of General Motors and the U.S. Automobile Industry had just started the Normandy Invasion!

A 32-man infantry platoon loads into

the 36 foot long wooden landing craft for the trip into the beach.

One of the coastguard men is trying to hold the LCVP fast to

the transport while one of the soldiers tries to get into the craft.

This is later in the day, as it is now light. and troops are loading for one

of the many waves that came in after the first. The Coast Guard

crews, if they survived the initial landing, kept going back all day with

more loads. Of the 1,089 LCVPs that started the day, 81 were

lost in the ensuing combat. LCVPs made up 16.8% of the 6,483 ships

in the invasion armada.

This iconic photo shows a group of anxious

young GI's approaching Omaha beach on D-Day in an LCVP. The LCVPs

were powered by Gray Marine modified GM Detroit Diesel 6-71 engines.

Note that several of the troops are armed with M1 carbines. The M1 carbine was produced by both the

Inland and Saginaw Steering Divisions of General Motors. Inland

also built helmet liners along with Firestone during the war.

Another photo of

young GI's making the rough ride to Omaha beach on D-Day in an another LCVP.

The beach does not look as peaceful as the day I visited it.

Brave beyond description!

Omaha Beach - Advantage to the defenders.

It doesn't take a military genius to figure out that when the 1st

Division landed on the beach below they walked directly into the Jaws of

Hell. One would have to assume that the Germans had cleared away

all of the trees and brush that would provide cover for an invading

force. Fifty-five of 81 LCVPs lost on D-Day were along this beach. Author's

photo.

There were excellent fields of fire. The ability of the

German defenders see up and down the coast made it tough going for

members of the Big Red 1 to advance up the hill. Author's

photo.

This is LCVP or Higgins boat seen here at

the the Roberts Amory Museum in Rochelle, IL, and is one of about a dozen

that still exist out of the 20,000 built. Photo courtesy of Chuck

C. Roberts of the Roberts Armory.

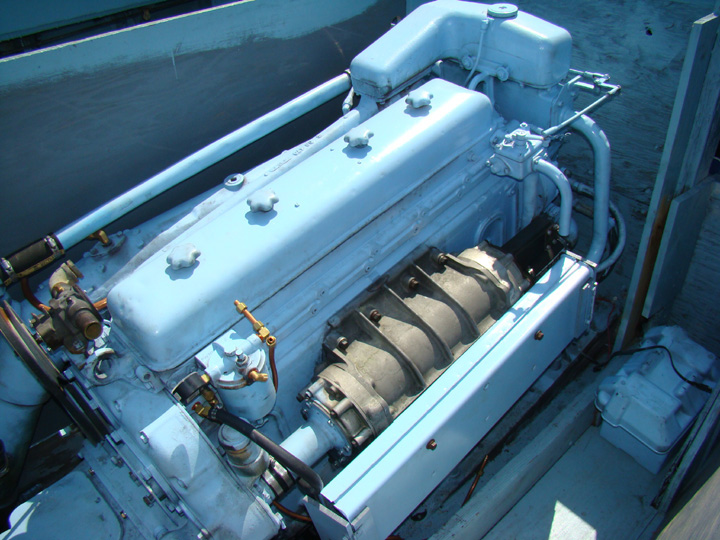

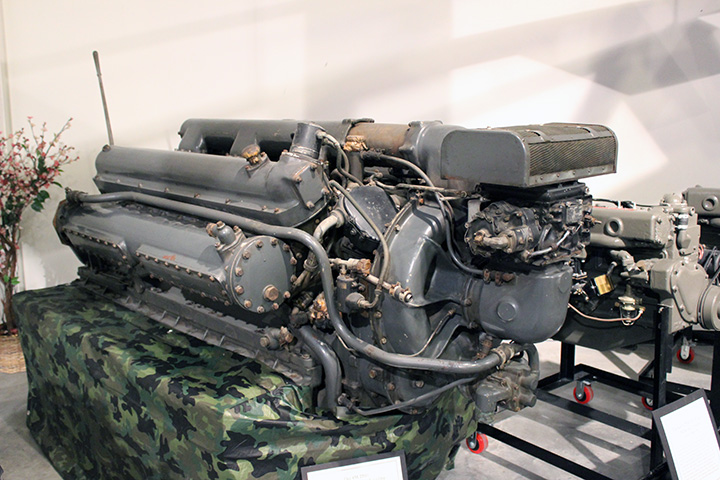

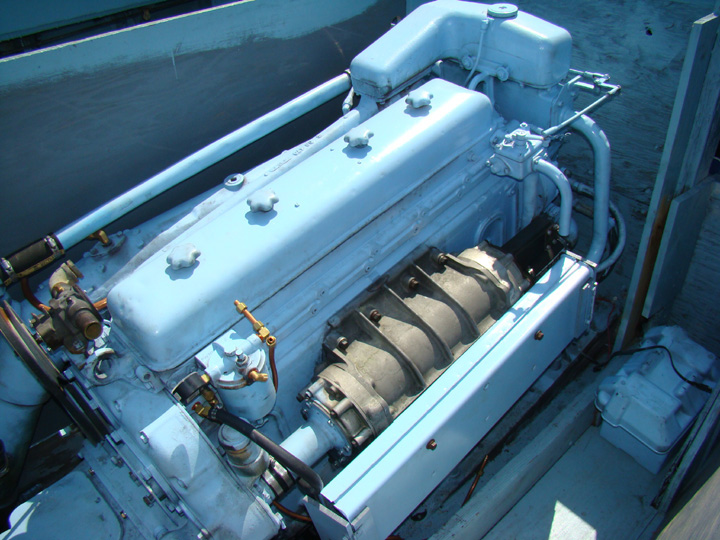

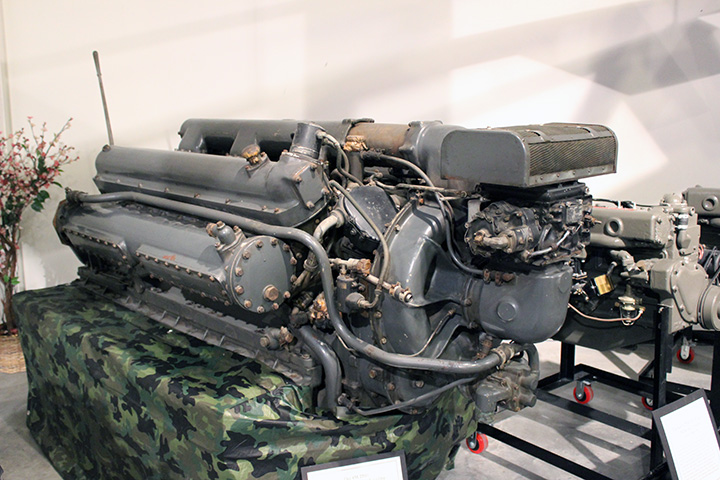

This is the Gray Marine /Detroit Diesel

engine in the LCVP pictured above. Not only did this power the

LCVP, but several other landing craft as will be seen below. Buick

provided the crankshafts for this type engine and Delco-Remy cast the

rotors for the blower. Photo courtesy of Chuck C. Roberts of the

Roberts Armory.

A Delco-Remy cranking motor and solenoid

similar to the ones that started the LCVPs and other types of landing

craft on D-Day. Photo courtesy of Chuck C. Roberts of the Roberts

Armory.

Each of these Landing Craft Infantry (Large)

or LCI(L) had a barrage balloon attached en-route to the Normandy

beaches on D-Day. These were powered by eight of the same type

Gray/Detroit diesel six cylinder engines that powered the LCVPs.

However, four of the individual engines were combined into a quad

configuration connected to a singe drive shaft. These two quad

engines then each drove a propeller. The propellers, drive shafts,

reduction gears and control units were built by the Electro-Motive

Division of GM. Seventy-two LCI(L)s took part in the invasion.

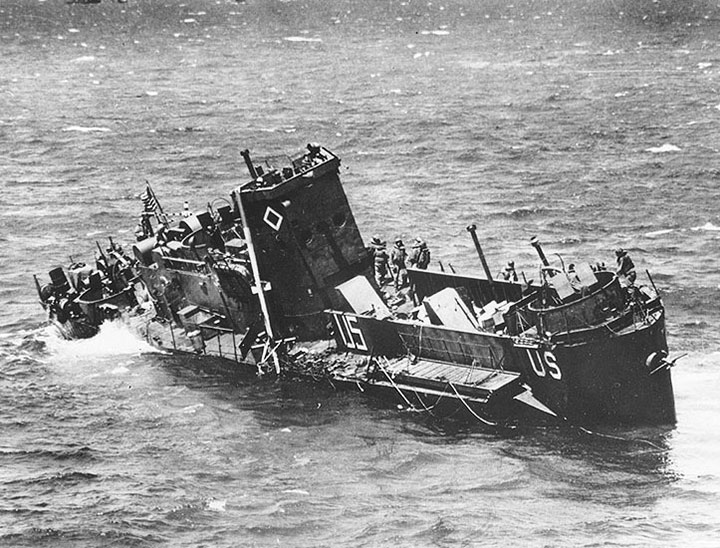

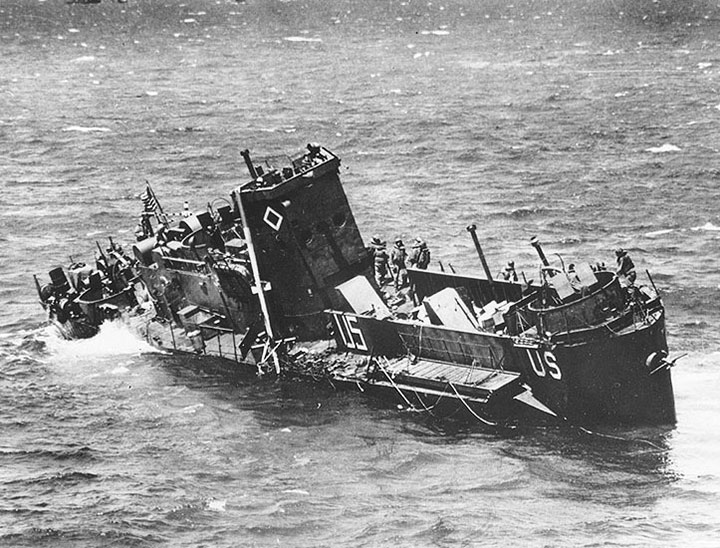

This LCI(L) is in trouble and is sinking after taking a hit from German

artillery fire on the beach. An LCI could deliverer an entire

infantry company directly to the beaches.

A Martin B-26 over some landing craft at

Normandy. Chrysler Corporation built nose and center fuselage sections for

the Marauder while the Hudson Motor Car Company built rear fuselage

sections. The Delco-Products Division of General Motors built

landing gears for it.

DUKWs (Ducks) were an amphibious version of the GMC 2.5 ton 6x6 truck which were built by both GMC and Chevrolet.

Two-thousand DUKWs were committed to the Normandy invasion.

Between June and the end of July, 1944 they transported 3.5 million tons

of supplies into France and Belgium. These are seen a supply depot

on D Day plus one. One of the advantages of the DUKW was the fact that it could be loaded at sea and

then once it had made its way to the beach could continue on and deliver

the supplies directly to the troops inland. It also then moved

with the troops as they advanced and could be used to transport troops

across rivers. Both the DUKW and LCVP were considered to be two of

the most important pieces of equipment developed for the war effort.

A total of 21,147 DUKWs were built,

14,399 by GMC in Pontiac, MI and 6,748 by Chevrolet in St.

Louis, MO.

In the quotation below from Dwight D

Eisenhower's book, Crusade in Europe, he is discussing being more

optimistic for successful amphibious landings on Sicily in July of 1943.

"This change resulted from the unforeseen

availability of a considerable number of LSTs and the quantity

production of the "duck," an amphibious vehicle that proved to be one of

the most valuable pieces of equipment produced by the United States

during the war."

Then he goes on to speak of other equipment

that the US auto industry built or made parts for.

"Incidentally, four other pieces of equipment that

most senior officers came to regarded as among the most vital to our

success in Africa and Europe were the bulldozer, the jeep, the 2-1/2 ton

truck, and the C-47. Curiously enough, none of these is designed

for combat."

More will be shown on LST's farther down the

page but half the LSTs at Normandy got there propelled by diesel engines

built by the Electro-Motive Division of GM. The jeep and the 2-1/2 truck

were also products of the US auto industry during WWII which will also

be shown below.

A Douglas C-47 or C-53 transport pulls a

Waco CG-4A glider on a supply mission on D-Day over the invasion

beaches. Previous to the landing on the beaches in the morning,

paratroopers and glider troops landed inland behind the beaches in the

dark, often with catastrophic results. The C-47s that survived

then returned to England to make supply runs like the one shown here.

Chevrolet built R-1830s engines for C-47s and C-53s

while Frigidaire of GM and Nash-Kelvinator built the propellers. Ford was the largest

producer of the CG-4A and built 4,190 of the total 13,909 constructed by

seventeen different companies.

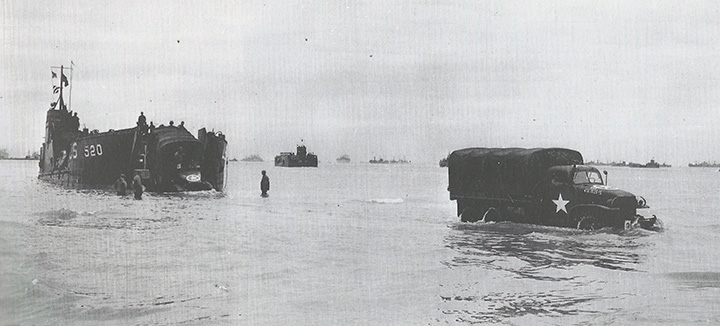

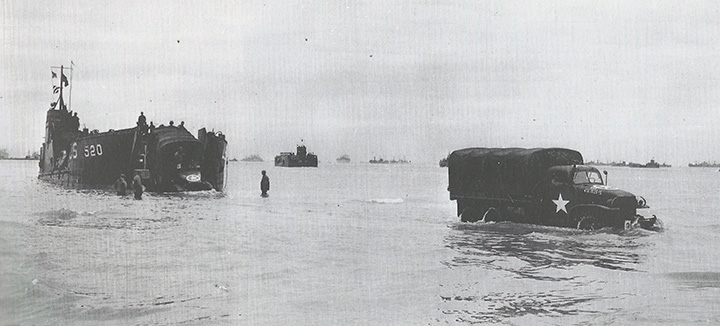

Pictured above a Landing Craft Tank (LCT) is

landing GMC 2.5 ton 6x6 trucks. Four companies built the 2-1/2 ton

6x6 truck during the Second World War; GMC and Chevrolet Divisions of General Motors,

International-Harvester, Studebaker and Reo. The International

trucks went to the USMC in the Pacific, and Studebaker and Reo trucks

went to the Russians and Australians through Lend-Lease. The US

Army in Europe was completely GMC. Two of the tens of thousands of

the type that were used in Europe starting at Normandy are unloaded.

Chevrolet assembled 151,785 of the 506,552

GMC designed and name plated 2-1/2 ton 6x6 trucks, or 29% of the total

built during the war. GMC built 354,747 of the trucks.

The LCT like the LCVP and LCIs used the

Gray/Detroit Diesel 6 cylinder engine. The LCT had three engines

driving three propellers. Eight hundred and thirty five LCTs

were used in the invasion.

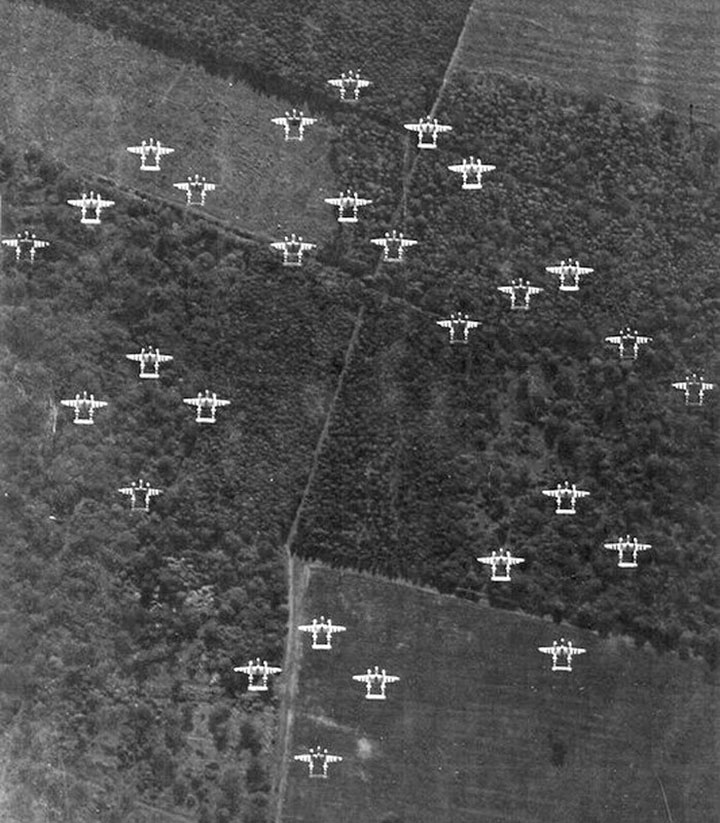

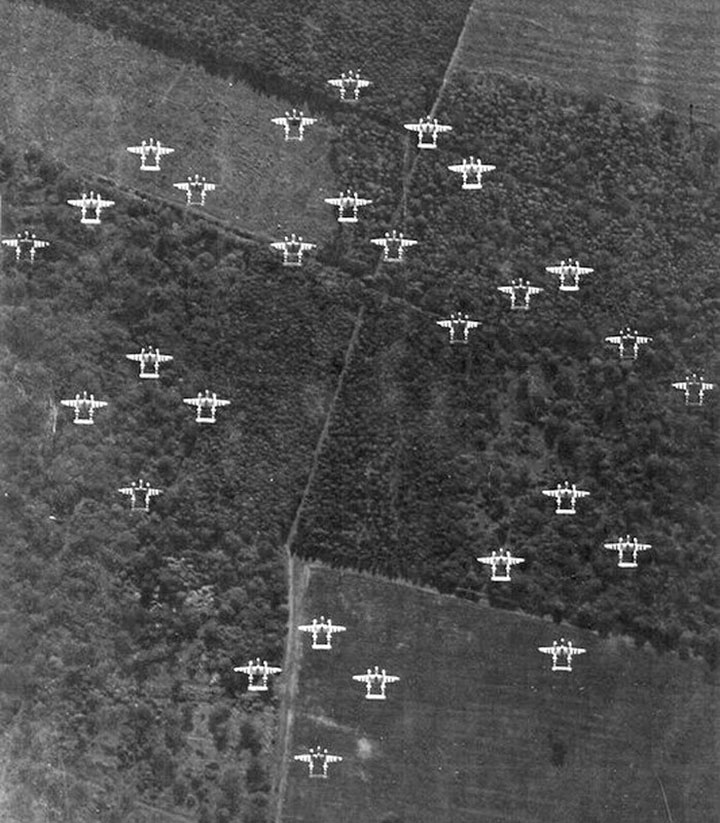

What a beautiful sight! Twenty

eight Lockheed P-38 Lightnings with invasion stripes flying over

Normandy to support the troops on the beach.

The Allison Division of

General Motors supplied the V-1710 engines for the P-38s while the Harrison Radiator

Division of GM provided the intercoolers for the turbochargers. The

Delco-Remy and Cadillac Motor Car Divisions provided most of the

castings and machined parts to build the engines. Guide Lamp

Division manufactured the cylinder sleeves while the Packard Electric

Division supplied the spark plug wires and their protective conduit.

Inland Division provided the spark plug terminal boots. Oldsmobile supplied 20mm cannons for the P-38s. Author's photo

from the Indiana War Memorial.

A LCT powered by GM diesels unloads Dodge

WC54 ambulances. Dodge built 404,817 trucks ranging from 1/2

ton to 3 ton during the Second World War. Of those 256,412 were

3/4 ton 4x4 with which Dodge has been most identified with since the

war. 26,002 were the ambulance version as seen here.

This is an interesting photo from D-Day in

that both the PT boats and the B-17s are powered by engines built by the

US auto industry. The PT boats were powered by three 1,350 hp

marine engines built by the Packard Motor Car Company. The R-1820s

that powered the B-17s were built by Studebaker. The Frigidaire

Division of GM and Nash-Kelvinator built B-17 propellers and the Chrysler plant in Los

Angeles, CA built B-17 cockpit enclosures. The .50 caliber machine

guns in the foreground could have been built by the AC Sparkplug or

Frigidaire Divisions of GM.

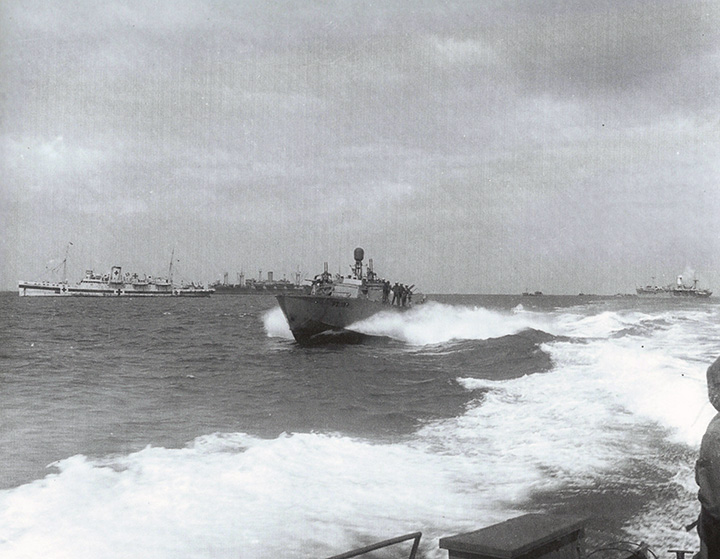

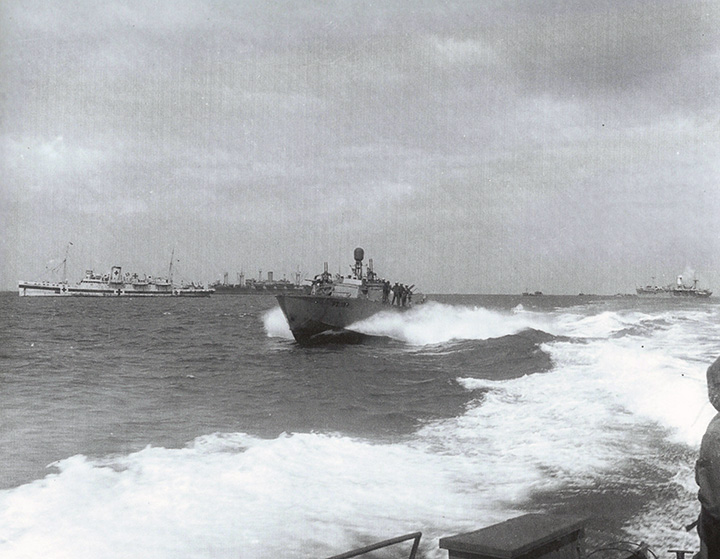

PT-199 passes by several ships in the

invasion fleet to carry an admiral to the beach. PT boats were

used to carry several admirals and generals to the beach. They

also provided security for other parts of the fleet. All PT boats

were powered by three Packard Motor Car Company 4M-2500 marine engines

that produced 1,350 hp each. Delco-Remy Division of

General Motors provided all of the starters and DC generators for the

Packard engines while the oil and water heat exchangers were built by

the Harrison Radiator Division of GM. Each engine had an automatic

ignition cut-out on it to prevent the engine from over revving when the

prop came out of the on high speed runs or in rough water. This

was built by the Delco Appliance Division of GM.

PT-109 has added aircraft 37mm canon from a P-39 on its foredeck.

Oldsmobile was a producer of the aircraft 37mm cannon.

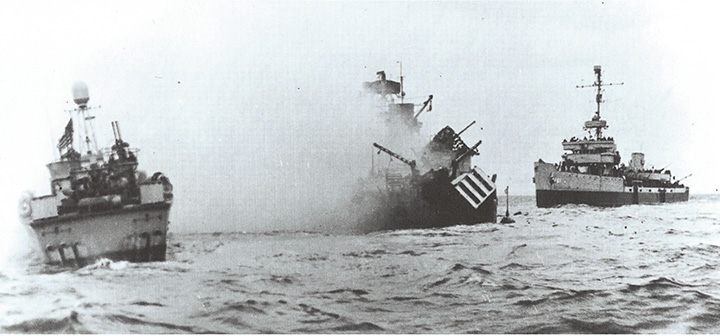

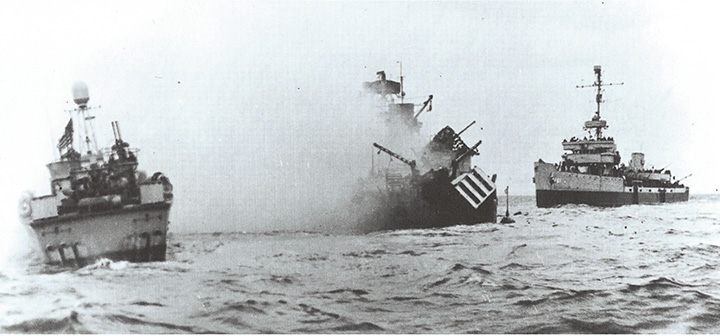

PT-509 comes to the aid of the

minesweeper USS Tide which hit a mine. Also assisting is

minesweeper USS Pheasant. PT-509 would be sunk just two months

later on August 9th by gunfire from German Minesweeper.

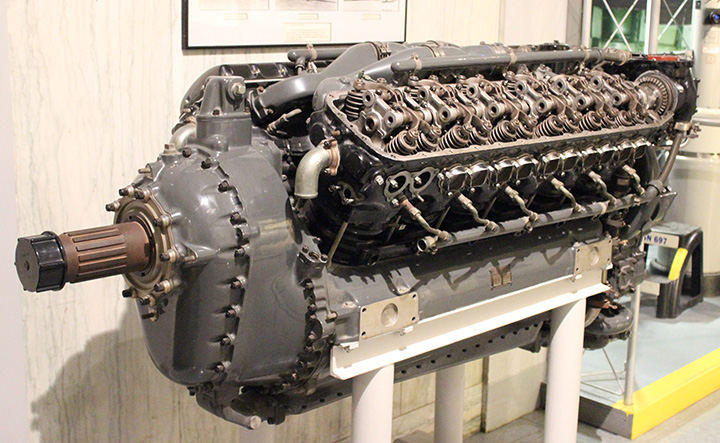

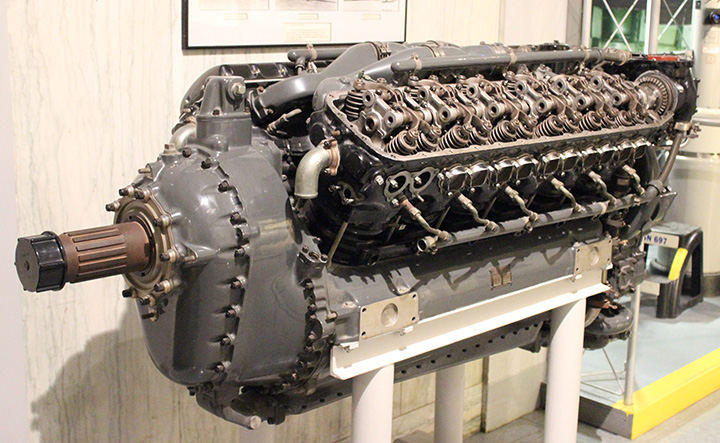

A Packard 4M2500 marine engine on

display at the National Packard Museum in Warren, OH. The 4M2500 had

twelve cylinders that displaced 2,490 cu. in. and had four valves per

cylinder. The engine weighed 2,950 lbs and operated on 100 octane

aviation fuel. By the end of the war improvements in the engine

and a larger supercharger increased the engine output to 1,800

horsepower. Author's photo.

This is an M10 tank destroyer that has just

landed and is moving off the beachhead. The Fisher Body Division

of GM produced this type tank

destroyer. Oldsmobile would have supplied the 76mm cannon, while Inland Division of GM manufactured the tank shoes and then assembled the

tracks. Delco Products of GM manufactured end links for the tracks.

Power was supplied by Detroit Diesel of GM engines.

The Eastern Aircraft Division of GM produced

300 Wildcat Vs for the Fleet Air Arm. This was the same as the

FM-1.

Brian Mulcahy took this photo of a halftrack

along the Normandy beach in 2013. It is one of many relics on

display in the area. Halftracks were produced by Autocar, Diamond

T, International Harvester and White Motor Company during the war.

Photo courtesy of Brian Mulcahy.

The halftrack has the original Guide Lamp

Division of General Motors headlight in it. Many of the vehicles

that landed at Normandy were equipped with Guide Lamp headlights,

taillights and blackout lamps. Photo courtesy of Brian Mulcahy.

Ford and Chevrolet built R-2800 radial

aircraft engines that powered Republic P-47 Thunderbolts while Hudson

produced ailerons for the fighters.

This photo was taken at the Ford Willow Run

plant to commemorate the 100,000th Nash-Kelvinator built

Hamilton-Standard propeller being assembled onto a B-24. While

this photo was being taken, my grandfather back at the Nash-Kelvinator

plant in Lansing, MI was a foreman in charge of the balancing department

and making sure that the next 58,134 propellers to come out of the plant

would be properly balanced. The Nash-Kelvinator plant in Lansing

production of propellers was the second largest in WWII, only bested by

the main Hamilton-Standard plant in Connecticut.

Ford built one third of the big four engine

bombers in the Willow Run plant outside of Detroit. It also made

an emergency production run at the request of the USAAF of over 50,000

GE turbo-superchargers that could not only have been used in the B-24s

shown here, but B-17s, P-47s and P-38s. .

Buick built a new plant to build the R-1830

aircraft engine and all of its production went on B-24s. Chevrolet

also built the R-1830 and some its output powered the Liberators along

with C-47s and C-53s.

Getting ready! Here rows of towed 40mm

Bofors anti-aircraft guns are secured and made ready for the invasion.

Chrysler, Firestone, and Pontiac made the weapons.

Chrysler, Pontiac, and Hudson produced Oerlikon 20mm anti-aircraft guns

that were on all of the larger ships in the invasion fleet.

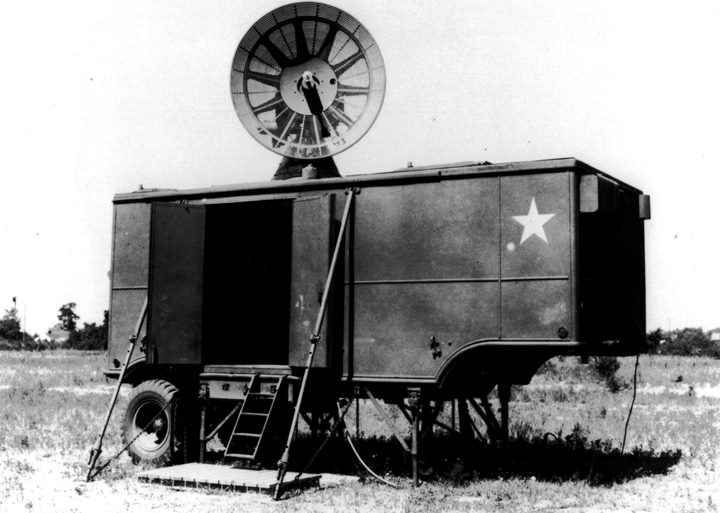

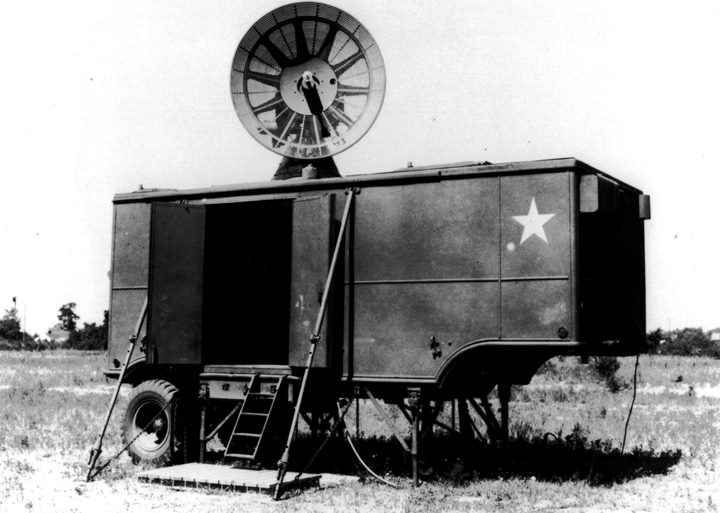

Twenty SCR-584 gun laying radar units were

brought ashore on the June 6, 1944 to provide anti-aircraft protection

for the Normandy beaches. The SCR-584 was a major advance in radar

technology, and controlled the aiming of four 90mm anti-aircraft guns.

It had the ability to lead the target aircraft, and determined in

advance the range, azimuth and altitude the 90mm guns needed to be aimed

at to hit an enemy aircraft. Combined with the new proximity fuzes

used in the 90mm guns, the SCR-584 was a major advance in providing

ground forces with protection against enemy air raids. First used

by the US Army at Anzio, the SCR-584 quickly cleared the skies of German

aircraft.

The Dodge Main plant on Jefferson Avenue

made the all of the parabolic antennas and antenna mounts for the

SCR-584. This totaled 2,098 units.

The Packard Motor Car Company was the sole

source of the American built Rolls-Royce Merlin V-1650 engines for the

North American P-51 Mustang. Buick supplied the engine blocks.

An M4 Sherman tank rolls out of LST-21 on to

one of the two British beaches. Ten companies built approximately

49,234 of the Sherman tanks during WWII. Three of the auto companies built the M4; Chrysler,

Fisher Body Division of GM and Ford. Forty percent of the M4

production came from Chrysler at its Tank Depot in Warren, MI and

Fisher-Body produced 20% of the Sherman production in its Tank Depot in

Grand Blanc, MI. Ford, Chrysler and the Detroit Diesel Division of

GM all produced engines for the tank. Oldsmobile built the 75mm

and 76mm cannons.

In this rare color photo an LST (Landing

Ship Tank) is unloading a GMC 6x6 2-1/2 ton truck modified to carry fuel,

which is one of the many configurations it was converted to. Each

of the two trucks is pulling fuel trailers. The Checker Car

Company, known for its taxicabs, built fuel trailers during the Second

World War. Also on the beach is the ubiquitous Jeep. Between

Ford Motor Company and Willys-Overland 641,000 of the versatile vehicles

were manufactured during the war. A third company, American Bantam

built 2,400 of the type.

1,051 LSTs were constructed during WWII,

half of which had two 12-567 900 hp diesel engines built by the

Electro-Motive Division (EMD) of General Motors. The US Navy in

WWII was big on dual sourcing of engines, so it would split the

procurement of engines between two companies. The EMD engines were

the same type it manufactured for powering what at the time what were

the new diesel-electric locomotives.

In this aerial photo shows what appear to be

mostly GMC trucks exiting nine LSTs to carry the proverbial beans,

bullets and bandages to the front line troops. The infantry, tanks

and halftracks have moved on. Now it is time to supply the

prodigious amount of material it takes to fight a modern war.

There are also eight or more M4 Sherman tanks in two rows between two

columns of trucks in the center of the photo. It appears that an

LCT and several other landing craft are waiting for the tide to come

back in to be refloated. The LSTs will also need a high tide to

back off the beach.

Two hundred and thirty three LSTs were used

at Normandy, including LST-325 shown here moving up the Ohio River after

taking part in a D-Day commemoration at the Evansville ShrinersFest

2014. LST-325 is powered by GM Electro-Motive diesels and made 40

trips to the Normandy beaches over a nine month period after the

invasion. She is the only LST still operating under her own power.

Author's photo.

In the final analysis, all of the equipment

shown above has only one purpose. Support the infantrymen, in this

case paratroopers, on the ground. This tech sergeant looks weary

after surviving the jump in the dark in the early morning hours.

All of the landing craft, ships, airplanes,

tanks, trucks and other equipment produced not only by the auto industry

but by the rest of the industrial might of the United States was all

directed to supporting infantrymen like those shown here advancing from

the beaches. In the end, it is the infantryman that wins the wars.

Everyone else and all their equipment are there to get him to the battle

site and support him once he is there.

No battle or war is without its costs. The American Cemetery is

over looking the Normandy Beach known as "Bloody Omaha". One out

of every 18 Americans who landed on the Normandy beaches or parachuted

into the areas behind the beaches on June 6, 1944 was

killed. Many of them were laid to rest in this cemetery. The

author's

photo was taken on Memorial Day, 2008.

This webpage does not profess to be a

comprehensive portrayal of the U.S. Auto Industry's contribution to the

winning of the invasion on D-Day or the consequent battles in Europe

that ended the war. What is shown are a few examples of what the

industry contributed on that fateful and important day in history.

David D Jackson

6-6-2014

|