|

Graham-Paige Motors Corporation in World War Two

Detroit, MI

1927-1947- As Graham-Paige

Motors Corporation

1947-1952 - As Kaiser-Frazer Corporation

1952-1953 - As Kaiser Motors

1953-1963 - As Kaiser-Willys Corporation

1963-1970 - As Kaiser Jeep Corporation (Purchased by American Motors)

Rest in Peace

This

page updated on 1-17-2023.

This is an interesting and

convoluted story of a small vehicle manufacturer that stopped production

of automobiles in 1940 with the limited production of the Graham

Hollywood after only 1,378 were built. While this great looking

automobile (See Below) had plenty of initial orders, plant production

problems prevented the filling of the customer orders, and most were

cancelled. Production was stopped on the Hollywood and the plant

closed. However, it quickly opened back up and started on war

contracts, with a good percentage of its plant being leased to Chrysler

and the remaining for its own war output.

DeSoto Division of

Chrysler leased Graham-Paige's West Warren Avenue Plant in Detroit

for the first war contracts taken on by the Chrysler Corporation.

Starting before the United States became involved in World War Two, DeSoto

began building Martin B-26 rear fuselages in the plant. Later it would build

Curtiss SB2C Helldiver wing center sections in the plant along with

forward end fuselages for the Boeing B-29 Superfortress. In 1946

Chrysler bought the plant and it became the DeSoto Warren Plant.

After World War Two, in 1947, the

automobile portion of Graham-Paige was sold to what became Kaiser-Frazer

Corporation. Kaiser-Frazer started car production in the Ford Willow Run, MI,

World War Two B-24 Bomber Plant. Willow Run, like many of the factories

built or expanded for World War Two production, was financed by the US Government and

its taxpayers. No longer needed by Ford, the government took the

plant back and then sold it to the new Kaiser-Frazer Corporation.

Production of Kaisers and Frazers ran at Willow Run until 1953, when it

shifted to Toledo at what had been Willys-Overland. Mr. Kaiser and

Mr. Frazer had a dispute in 1948, and Mr. Frazer quit as president of the

company with the Frazer nameplate running until 1951. In 1952 the

company became the Kaiser Motors Corporation. Then, when it purchased Willys-Overland later in 1952, it renamed itself again.

This time, as Willys Corporation, assembly of the Kaiser moved to

Toledo, OH for its last two years of production. The last model

year for the Kaiser nameplate was1955.

After 1947 the remaining

non-automotive portion of Graham-Paige invested in real estate; and in

1962 changed its name to Madison Square Garden Corporation.

Graham-Paige also produced

and coined the name Rototiller, which is now synonymous with many

manufacturers' garden implements for tilling the soil in home gardens.

A 1941 Graham Hollywood Supercharged as seen

at the Auburn Cord Duesenberg Automobile Museum in Auburn, IN.

This was a very nice looking car, but production issues in the plant

lead to its demise. Author's photo.

There were 1,378 built at a cost of $1,250

each in 1940-1941. It was the last vehicle produced by the company

before World War Two and also the

last Graham vehicle ever produced.

Author's photo.

Author's photo.

Graham-Paige was created by the Graham

brothers, Joseph, Robert, and Ray when they purchased the Paige-Detroit

Motor Company in 1927. However, this was not the brothers' first

business endeavor in the fledging American automobile industry.

Their first business was an automobile glass manufacturer that they sold

that later became Libby-Owens-Ford. Then the brothers began

converting Model Ts into trucks and also modifying the Model TT trucks

built by Ford. Then in 1919, the brothers introduced their own

trucks known as Graham Trucks.

This 1923 Graham Brothers truck is on

display at the National Automobile and Truck Museum in Auburn, IN.

Author's photo added 1-17-2023.

Author's photo added 1-17-2023.

Author's photo added 1-17-2023.

Author's photo added 1-17-2023.

The truck is highly identifiable from the rear

as to which company made this vehicle. Author's photo added 1-17-2023.

In 1926, the Dodge Brothers purchased

all of the stock of the Graham Brothers and in 1930 all Graham Brother

trucks became Dodge trucks. With the money from the sales of their

stock to Dodge, the Graham Brothers then were able to purchase the

Paige-Detroit Motor Company and enter the highly competitive American

automobile industry.

Graham-Paige won the Army-Navy "E" Award

once during World War Two.

The announcement of the award was made on June 22, 1943.

Graham-Paige

World War Two Products: Table 1 shows that the company had

$65,755,000 in major contracts largely from the U.S. Navy during World

War Two. The largest group of contracts was for several types of

amphibious tractors for the Navy. The four contracts for these

types of vehicles totaled $43,934,000 or 66.8% of the total value.

Contracts for amphibious tractor parts and equipment totaled another

$16,469,000 or 25%. The two sums added together totaled

$60,403,000 or 91.8% of all contracts. U.S. Navy contracts for

amphibious tractors and their parts dominated Graham-Paige's World War

Two output.

The next largest group of

contracts, also from the Navy, were six contracts totaling 2,021,000 for

torpedo parts which was 3% of the total major military contracts.

99.3% of the contracts were for the Navy. The three contracts for

the Army totaled $476,000.

Graham-Paige also was a

subcontractor to both the Wright Aeronautical Corporation and the

Packard Motor Car Company. In February 1941 Wright announced that

it had contracted with Graham-Paige for the manufacture of connecting

rods for its R-2600 aircraft engine. The contracted amount was $10,000,000 and the parts were for the new Wright engine plant

in Lockland, OH, north of Cincinnati, OH. Production of the R-2600

began at Lockland in June 1941 and continued through October 1945. Graham-Paige supplied

connecting rods for the 60,456

R-2600 engines made at Lockland. Beginning in

1945, Graham-Paige began furnishing components for the 1,866 Wright

R-3300 engines that were mounted on the B-29 Superfortresses.

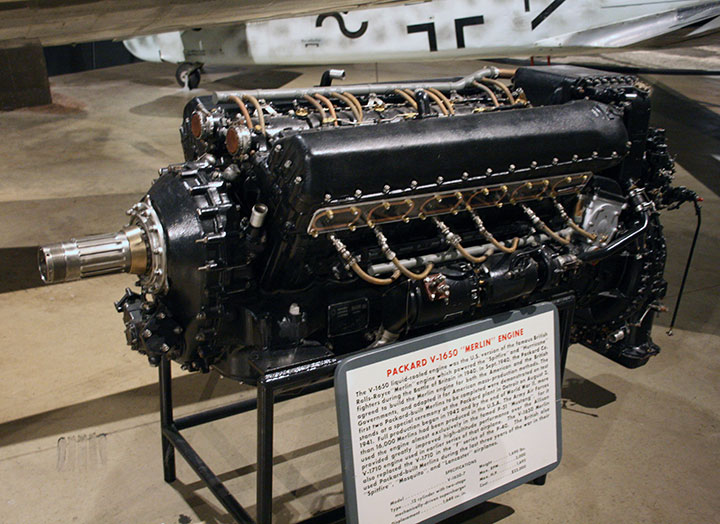

The company also furnished

engine components to Packard for use in the Rolls-Royce V-1650 Merlin aircraft

engine and for the 4M2500 marine engines that powered the PT boats.

Landing Craft, Tracked

(LVT): Donald Roebling invented the LVT concept that he first

called an “Alligator.” When large orders and equipment changes

came in during the following years, Daniel Roebling subcontracted with

the Food Machinery Corporation (FMC) to fulfill the orders. Unfortunately, I have not yet been able to find a source

that gives the quantities of the different types of LVTs built by

Graham-Paige or the other manufacturers during World War Two. Table 2 shows

that the company was assigned 757 hull numbers for the LVT-4.

As noted above, the company

had four Navy contracts for amphibious tractors totaling $43,934,000.

From the contract and other information below, one can estimate

that number of LVT-1s and LVT-3s the company built. However, even

then, there is some conflicting information.

LVT-1 - 1,225 were built by

FMC, Graham-Paige, and St. Louis Car

from 1941-1943. The first application of this type was used at Guadalcanal

in August 1942.

It did not have a ramp.

The first LVT-1 built by

Graham-Paige was accepted by the U.S. Navy inspector on or about Jun

23, 1942. This and other LVT-1s built by Graham-Paige were

done so under U.S. Navy contract NOS-97579 for $1,643,000. While it is

unknown how much each LVT-1 cost, Table 2 shows that the Graham-Paige

LVT-4 cost $23,500. If one uses this value as a rough estimate of

the cost of an LVT-1, this calculates out to be 70 LVT-1s built by

Graham-Paige.

LVT-2 - 2,963 were

constructed by FMC, Graham-Paige,

Ingersoll Steel and Disc Division of Borg-Warner, and St. Louis Car from 1942-1944. This one did not have

a ramp either.

Table 2 shows that

Graham-Paige was contracted to build 757 LVT-4s under contract OBS-863

beginning in December 1942. However, Table 4 shows that production

of the LVT-4 did not begin until a year later, in late 1943.

Therefore, most likely, the LVT-4s were built under the supplemental

contract OBS-863S beginning in November 1943. Using this contract

for the LVT-4s, $14,448,000 divided by $23,500 equals 615 LVT-4s, and

not the 757 shown in Table 2. While the two are not equal, it

could very well have been that Graham-Paige had the difference of 142

cancelled in August 1945. The Navy cancelled 1,300 units between

all of its LVT-4 suppliers in August 1945 with the end of the war with

Japan.

Most likely contract OBS-863

awarded 12-1942 for $8,596,000 was for the LVT-2. Using $23,500

again as our estimated unit cost, one arrives at 366 LVT-2s built by

Graham-Paige during World War Two.

LVT-3 - 2,964 were built

by Graham-Paige and the Ingersoll Steel and Disc Division of

Borg-Warner. This had a rear ramp that allowed the troops to exit

and also allowed the vehicles to carry a jeep. These were built under

contract

OBS-1790 for

$19,247,000. Once again, using the $23,500 cost from

Table 2 as a guide, Graham-Paige built an estimated 820 LVT-3s

LVT-4 - 8,348 were

produced by FMC, Graham-Paige, and St. Louis Car

from 1943-1945. This also had a rear ramp that allowed the

troops to exit and also allowed the vehicles to carry a jeep.

Table 2 shows that Graham-Paige was contracted for 757 LVT-4s.

Table 1- Graham-Paige Motor

Corporation's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. This table added 1-17-2023. |

|

Product - Customer |

Contract Number |

Contract Amount |

Contract Awarded

Date |

Completion

Date |

| Ordnance

Material - Navy |

Nos-78910 |

$825,000 |

11-1940 |

3-1942 |

| Material

Ordnance - Navy |

Nos-8-496 |

$712,000 |

1-1941 |

11-1942 |

| Piece Parts -

Navy |

120-S-12551 |

$81,000 |

2-1941 |

11-1941 |

| Piece Parts -

Navy |

120-S-12536 |

$207,000 |

2-1941 |

2-1942 |

| Rods Levers -

Navy |

NOS-83267 |

$262,000 |

3-1941 |

9-1942 |

| Tractors -

Navy |

NOS-97579 |

$1,643,000 |

1-1942 |

9-1942 |

| Torpedo Parts

- Navy |

120-S-16751 |

$227,000 |

2-1942 |

7-1943 |

| Torpedo Parts

- Navy |

120-S-15857 |

$69,000 |

3-1942 |

2-1943 |

| Levers

Operating - Navy |

171-S-59321 |

$52,000 |

5-1942 |

10-1942 |

| Torpedo Parts

- Navy |

120-S-19594 |

$441,000 |

10-1942 |

5-1944 |

| Amphibian

Tractors LVT - Navy |

OBS-863 |

$8,596,000 |

12-1942 |

12-1943 |

| Engines -

Navy |

120-S-24124 |

$586,000 |

2-1943 |

4-1944 |

| Torpedo Parts

- Navy |

120-S-24125 |

$842,000 |

2-1943 |

4-1944 |

| Tractor Parts

- Navy |

XSS-25412 |

$449,000 |

3-1943 |

7-1943 |

| Valves - Navy |

120-S-22360 |

$80,000 |

5-1943 |

9-1943 |

| Torpedo Parts

- Navy |

120-S-22555 |

$280,000 |

6-1943 |

7-1944 |

| Rental

Services - Army |

56-QM-1033 |

$60,000 |

7-1943 |

6-1944 |

| Operating

Levers - Navy |

171-S-68826 |

$50,000 |

11-1943 |

3-1944 |

| Amphibian

Tractors LVT - Navy |

OBS-863S |

$14,448,000 |

11-1943 |

11-1944 |

| Torpedo Parts

- Navy |

120-XSO-26564 |

$162,000 |

5-1944 |

12-1944 |

|

Landing Vehicles LVT3 - Navy |

OBS-1790 |

$19,247,000 |

7-1944 |

8-1945 |

| Landing

Vehicle Equipment- Navy |

OBS-2138 |

$360,000 |

8-1944 |

6-1945 |

|

Landing Vehicle Parts - Navy |

OBS-1991 |

$12,420,000 |

10-1944 |

7-1945 |

| Shot Bodies

76mm T4E20 - Army |

200180-ORD-8369 |

$84,000 |

12-1944 |

1-1945 |

| Shot 76mm

T4E20 - Army |

200180-ORD-10010 |

$332,000 |

2-1945 |

1-1946 |

| Total |

|

$65,755,000 |

|

|

Table 2 - Graham-Paige LVT-4 Contracted

Production

Information from "LVT(4) Amtrac - The Most Widely Used

Amphibious Tractor of World War II" by David Doyle |

|

Number Contracted |

U.S. Navy Hull Numbers |

U.S. Navy Contract Number

|

Cost per LVT-4 |

|

25 |

C-19395 - C-19419 |

NObs 863 |

$23,500 |

|

94 |

C-49953 - C-50046 |

NObs 863 |

$23,500 |

|

347 |

C-58462 - C-58808 |

NObs 863 |

$23,500 |

|

291 |

C-63499 - C-63789 |

NObs 863 |

$23,500 |

| 757 |

Total |

|

|

Table 3 - Total LVT-4 Contracted

Production

Information from "LVT(4) Amtrac - The Most Widely Used

Amphibious Tractor of World War II" by David Doyle published

2020 |

|

Company |

Number Contracted |

Percentage |

|

FMC Riverside, CA |

1,876 |

19.4% |

|

FMC San Jose, CA |

3,451 |

35.6% |

|

FMC Lakeland, Lakeland, CA |

1,825 |

18.9% |

|

FMC Sub-Total |

7,152 |

74% |

|

St. Louis Car Company |

1,698 |

17.6% |

|

Graham-Paige |

757 |

7.8% |

|

Unknown |

60 |

.62% |

|

Total |

9,667 |

100% |

|

Cancelled LVT-4s in August 1945 |

1,838 |

|

|

Total Production |

7,829 |

|

Graham-Paige was contracted to build

757 out of the 9,667 LVT-4s built during World War Two. With the

termination of hostilities in August 1945, 1,300 units were

cancelled between the four companies building the LVT-4. It

appears that Graham-Paige had 142 of the 1,300 LVT-4s cancelled at

the end of the war as noted above.

Table 4 - World War Two LVT Production

From "Amtrac: US Amphibious Assault Vehicles by

Steven Zaloga published 1987 |

|

Type |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

|

LVT-1 |

72 |

851 |

302 |

|

|

1,225 |

|

LVT(A)-1 |

|

3 |

288 |

219 |

|

510 |

|

LVT-2 |

|

|

1,540 |

1,422 |

|

2,962 |

|

LVT(A)-2 |

|

|

200 |

250 |

|

450 |

|

LVT-3 |

|

|

1 |

733 |

2,230 |

2,964 |

|

LVT-4 |

|

|

11 |

4,980 |

3,360 |

8,351 |

|

LVT(A)-4 |

|

|

|

1,489 |

401 |

1,890 |

|

LVT(A)-5 |

|

|

|

|

269 |

269 |

|

Totals |

72 |

854 |

2,342 |

9,093 |

6,260 |

18,621 |

While the U.S. Navy was the military

organization that contracted for the LVT-4, 74% were transferred to

the U.S. Army. The Army used most of them in Europe for river crossings, many of

them under fire.

The following table shows the increased use

of LVTs as they became more

available during the U.S. Navy's Central Pacific campaign during World War Two. LVTs were utilized at Guadalcanal for the

transport of supplies to the island, not in the initial assault waves.

As the war continued, the LVTs became very important where the islands

had coral atolls that prevented the 36-foot wooden landing craft such as

the LCP(L)s, LCVs, LCP(R)s, and LCVPs from crossing. Even with

their low draft, the landing craft would get hung up on the atolls.

The LVTs with their tracks could cross over the reef. A shuttle

system was instituted where the wooden landing craft would bring marines

and soldiers from the troop transports to the atoll. There, the

marines and soldiers would transfer to the LVTs which would then take

them to the beach. Transfer of the troops at the reef called for

previous training by all involved to safely and efficiently make the

troop transfer. Add a heavy surf and it became an even more

dangerous endeavor than normal. Neither Iwo Jima nor Okinawa had

reefs, but by the end of the war the LVT had become an important part of

the landing assault forces.

|

Table 5 - Number of LVTs

and LVT(A)s used in the Assault Waves during the Central Pacific

Campaign

The first LVT(A)s were armed with 37mm cannons and the later

ones with 75mm howitzers. These provided close-in fire

support for the LVTs as they made their run-in to the beach.

It is unknown whether Graham-Paige made this type vehicle. |

|

Island |

Date |

LVT |

LVT(A) |

|

Guadalcanal |

8-1942 |

0 |

0 |

|

Tarawa |

11-1943 |

87 |

0 |

|

Saipan |

6-1944 |

594 |

138 |

| Guam |

7-1944 |

381 |

75 |

|

Tinian |

7-1944 |

453 |

66 |

|

Peleliu |

9-1944 |

223 |

72 |

| Iwo

Jima |

2-1945 |

380 |

68 |

|

Okinawa |

4-1945 |

872 |

92 |

Graham-Paige built an estimated 70 of the 1,225

LVT-1s built from 1941 to 1943. This diorama at the

National Museum of the USMC depicts an LVT-1 going over a log barricade

at Tarawa. Tarawa was the first use of the LVT type amphibious

tractor for a combat assault. Author's photo added 9-30-2016.

This and the following photo show that the rear is a solid piece with no

ramp. The Marines had to go over the side as shown here and jump

down eight feet to the sand. Author's photo added 9-30-2016.

Author's photo added 9-30-2016.

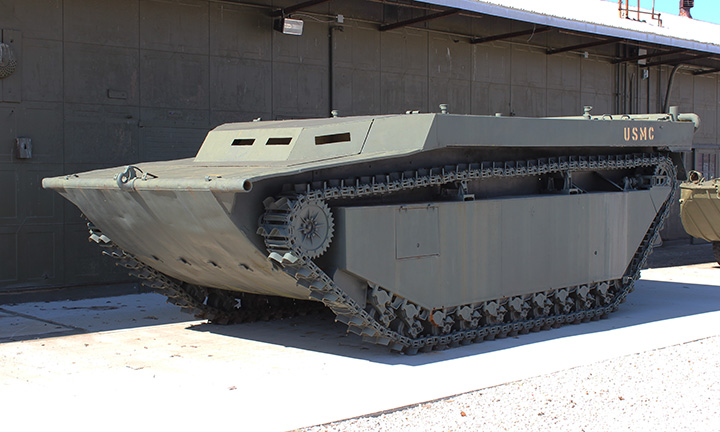

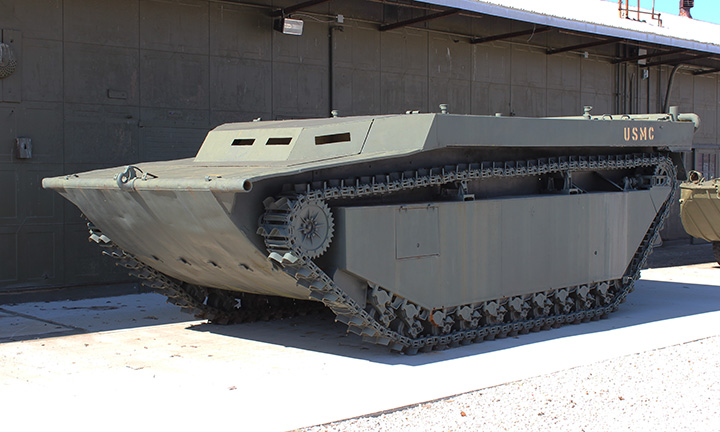

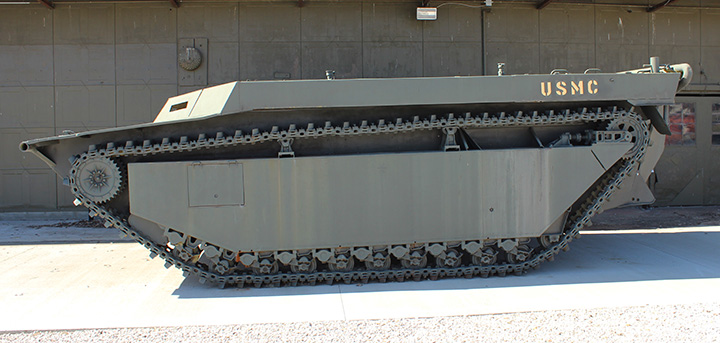

This is a 1945 LVT-4 "Water Buffalo"

that was built by St. Louis Car, one of the two other manufacturers of

this type besides Graham-Paige. This one is a movie star, having been

used in the 2005 movie "Flags of our Fathers". Author's photo from

the 2014 Portland, IN Military Vehicle Show.

According to Table 2, Graham-Paige built 757

of the LVT-4s for the war effort. Note the internal and external

armament. While this is not a Graham-Paige-built unit, it shows the huge size

and complexity of building this landing craft. Author's photo

The LVT-4 was the first in the series to

have a ramp. On the LVT-1 and LVT-2, the soldiers and marines had to

make an eight foot jump over the side to get out. The LVT-4 could

also carry small

vehicles. Author's photo.

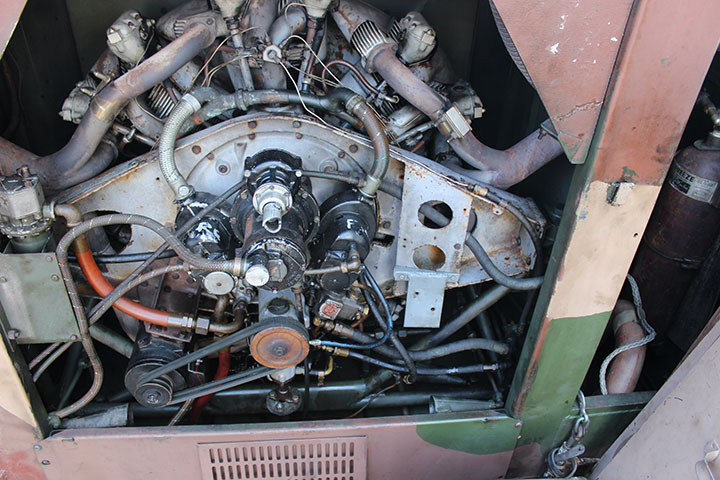

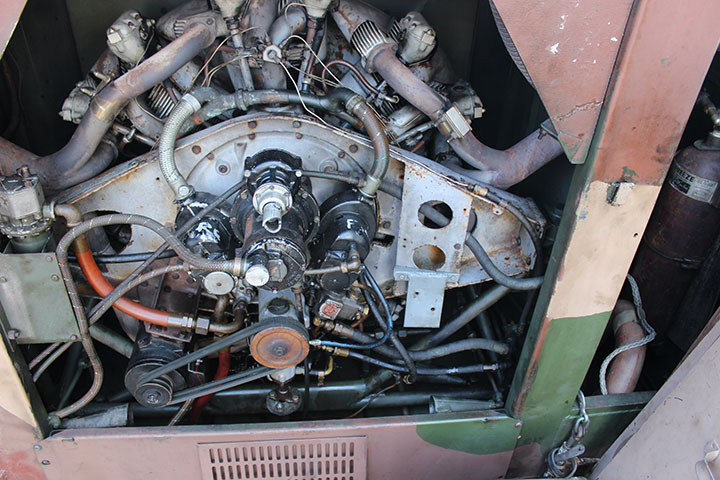

The LVT-4 was powered by a Continental

R-670-9A seven cylinder radial aircraft engine producing 250 hp.

The radial engines, originally designed to operate at relatively

constant speeds for aircraft, did not work out well when having to

constantly change RPMs while being shifted through the five speeds of the

Spicer transmission. Author's photo.

The driver's station with the Spicer transmission is just visible to the

right. The powered axle is in front of the controls and instrument

panel. Author's photo.

The instrument panel inside the LVT-4.

Author's photo.

The radio control box is on the left.

Author's photo.

The gunner's position with the .30 caliber

machine gun. In this photo, one can see the transmission better and the

covering over the driveshaft from the engine. Author's photo.

This photo shows an LVT-1 on an island in

the Pacific.

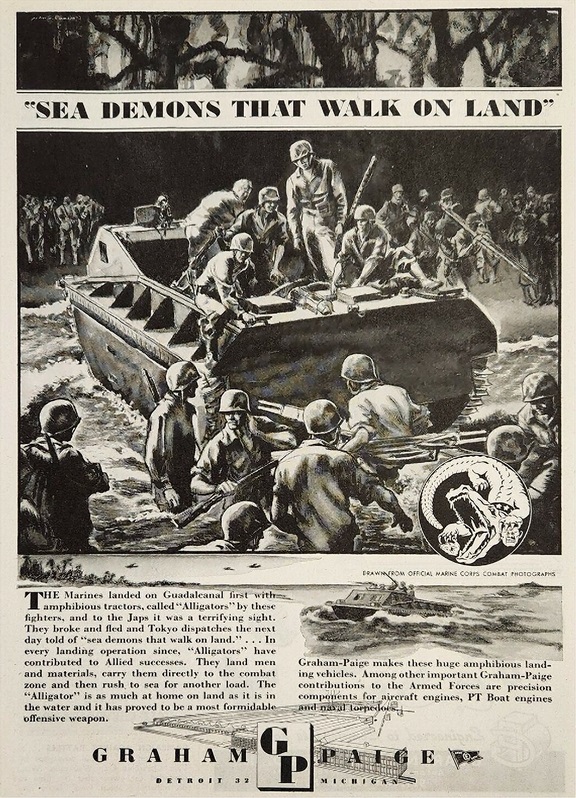

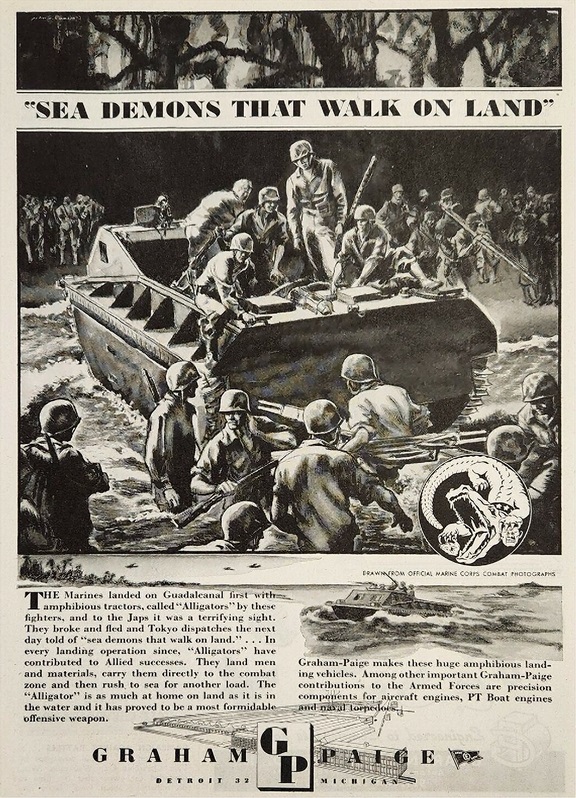

This ad notes that LVT-1s were with the First

Marine Division when it landed on Guadalcanal on August 7, 1942. The

indirect implication is that Graham-Paige-built LVT-1s were at the

initial landings at Guadalcanal. However, the first

Graham-Paige-built LVT-1 did not come off the assembly line until June

23, 1942. At that time, the First Marine Division was already in

the South Pacific. Its amphibious tractor battalion had already

formed in February 1942, and had its complement of tractors.

Advertisement added 1-17-2023.

The first use of the LVT was at the landings at

Guadalcanal on August 7, 1942, where they were used to bring supplies

ashore. Graham-Paige LVT-1's

were not part of the Guadalcanal invasion. Photo added 4-14-2015.

This is another LVT-4 that is on display at

the Indiana Military Museum in Vincennes, IN. No information is

known on which of the three companies, FMC, Graham-Page, or St. Louis

Car, actually built this particular unit. Author's photo.

Author's photo.

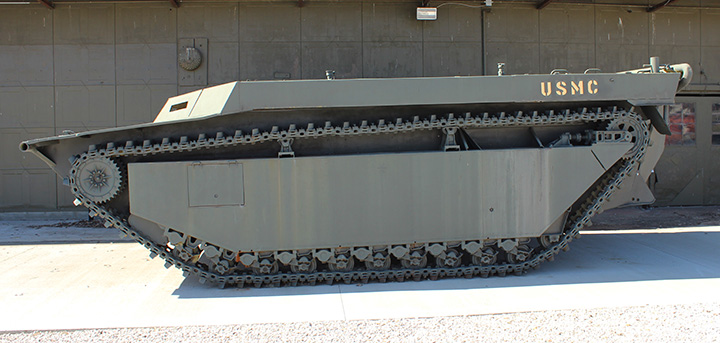

The LVT-4 is 8 feet tall. It differs from the earlier

LVT-1 and LVT-2 in that

it has a stern ramp, and the troops did not have to make the long 8 foot

jump to the beach upon landing. Author's photo.

Author's photo.

Graham-Paige built an estimated 820

Borg-Warner designed LVT-3s. A total of 2,964 were built

during

World War Two. Author's photo added 12-2-2021.

Author's photo added 12-2-2021.

This LVT-(A)4, which is armed with a 75mm

howitzer, is on

display at the American Heritage Museum in Hudson, MA. Current

historical data does not provide information on which company or

companies built this type of vehicle. Graham-Paige could have

manufactured some of these. Author's

photo added 12-2-2021.

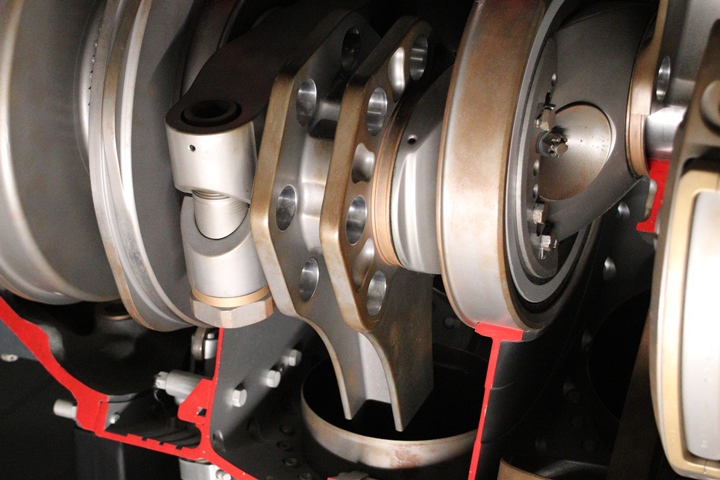

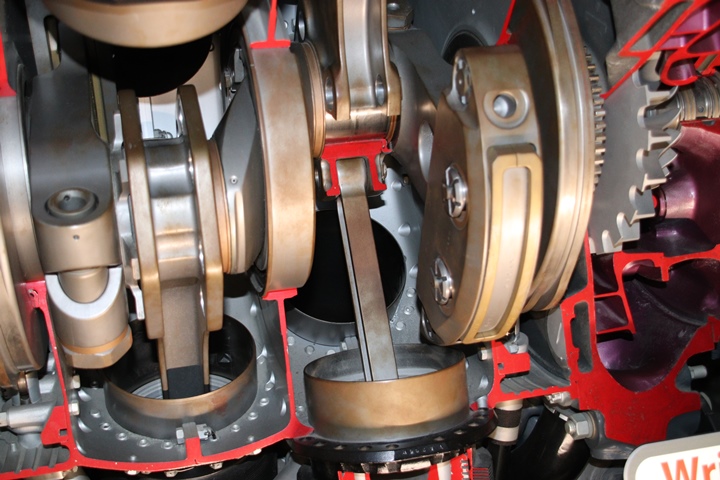

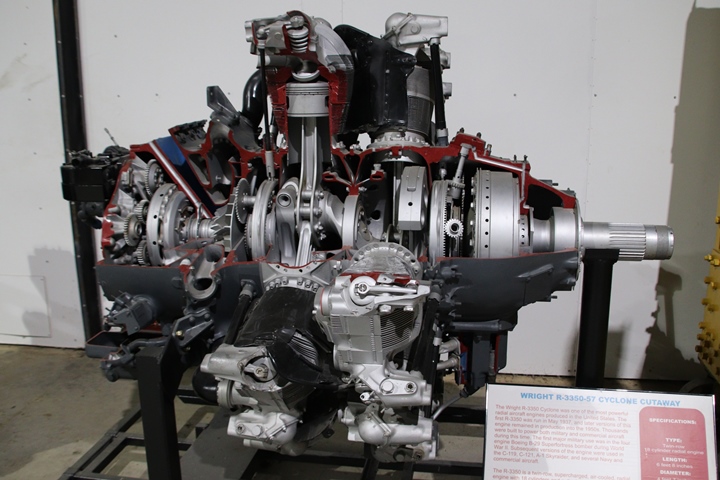

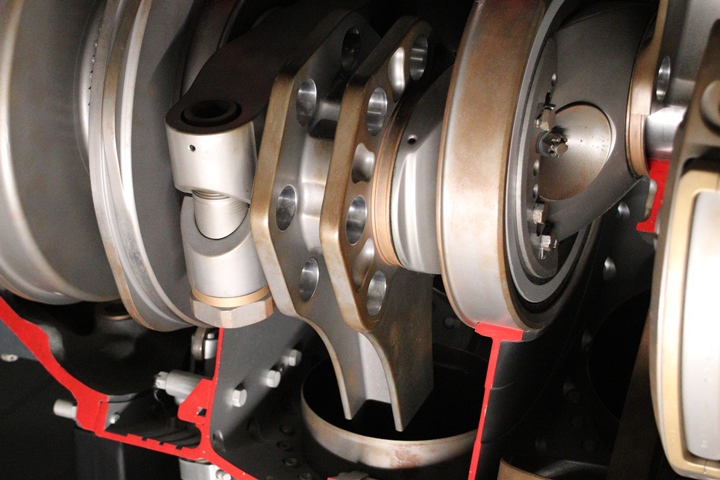

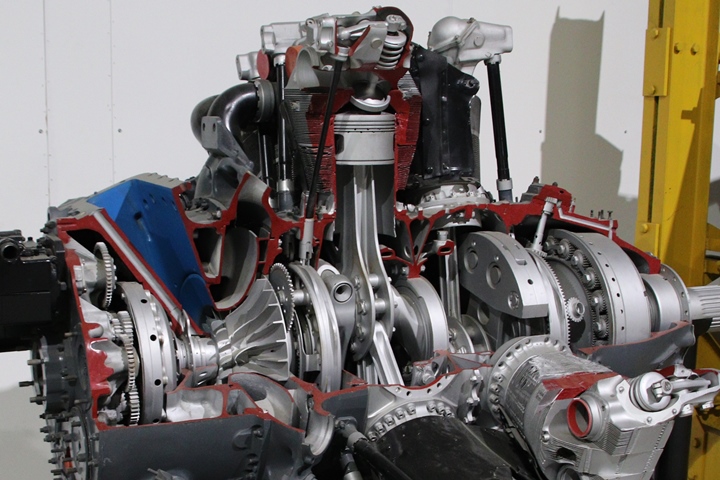

This cut-away of a Wright R-2800 is on

display at the National Museum of the United States Air Force in

Riverside, OH. Graham-Paige furnished connecting rods for these

engines that were built at the Lockland, OH Wright Engine plant.

Author's photo added 1-17-2023.

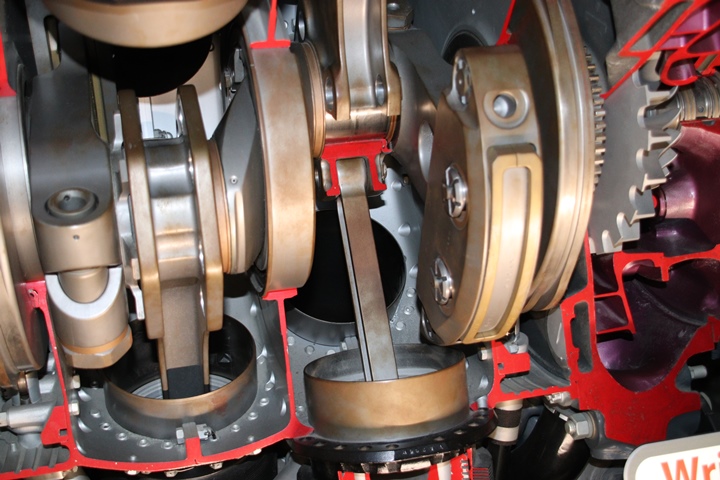

This image shows the connecting rod mounted

to the engine's crankshaft and one of the fourteen pistons. There

were a total of 60,456 R-2600 engines made at the Lockland, OH plant.

If Graham-Paige was the only supplier of the connecting rods for this

engine, it would have produced 846,384 units during the war.

Author's photo added 1-17-2023.

This image shows several connecting rods in

the R-2600 engine. Author's photo added 1-17-2023.

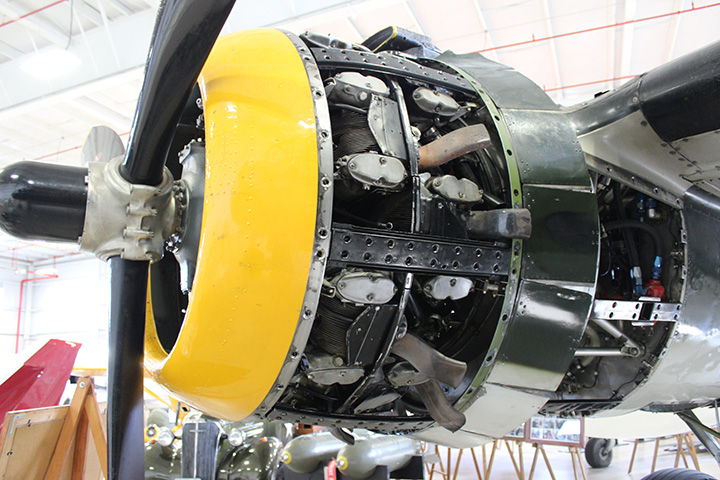

One of the big uses for the R-2600 engine

was in the B-25 "Mitchell" twin engine bomber. This is B-25

"Champaign Gal" at the Champaign Air Museum in Urbana, OH.

Author's photo added 1-17-2023.

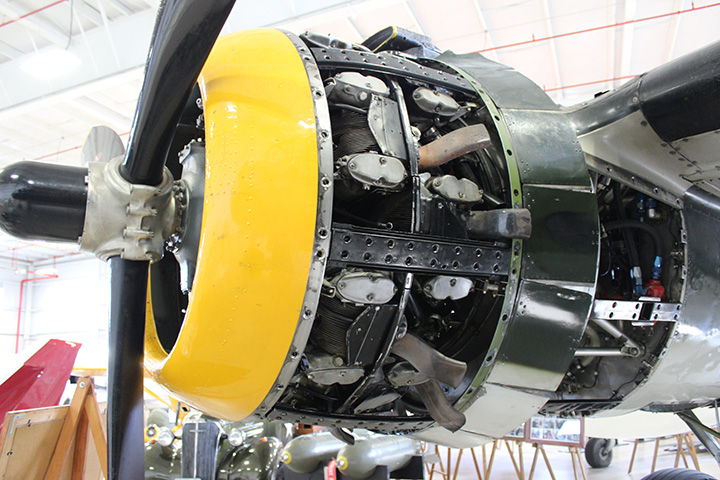

The R-2600 had two rows of seven cylinders

each. Author's photo added 1-17-2023.

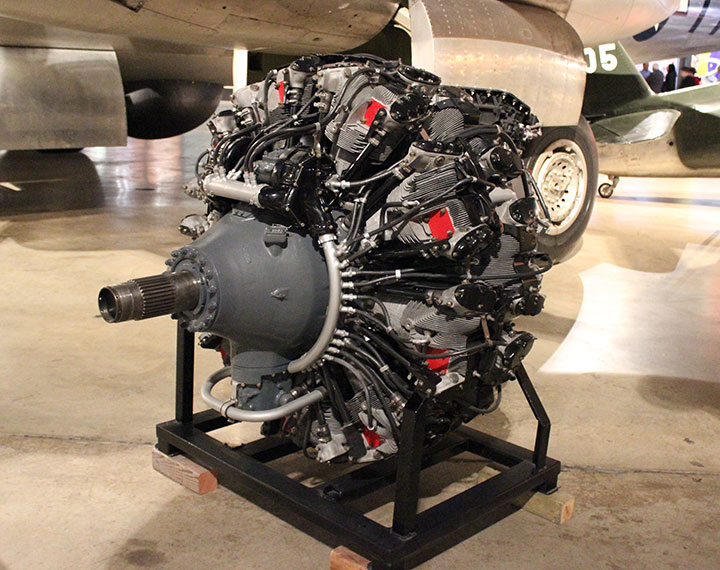

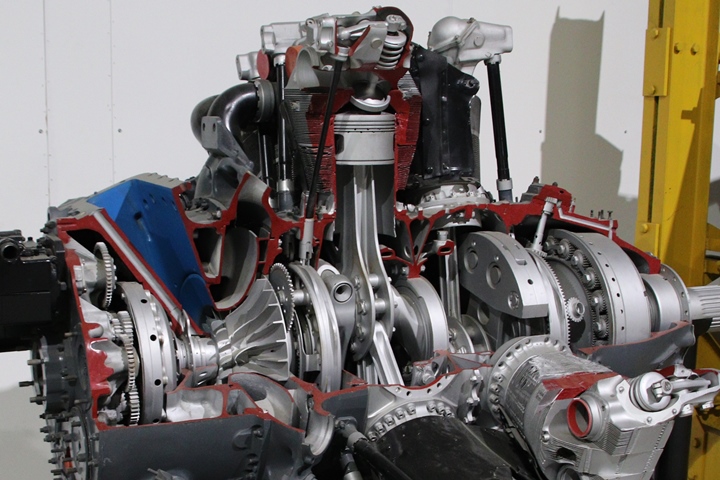

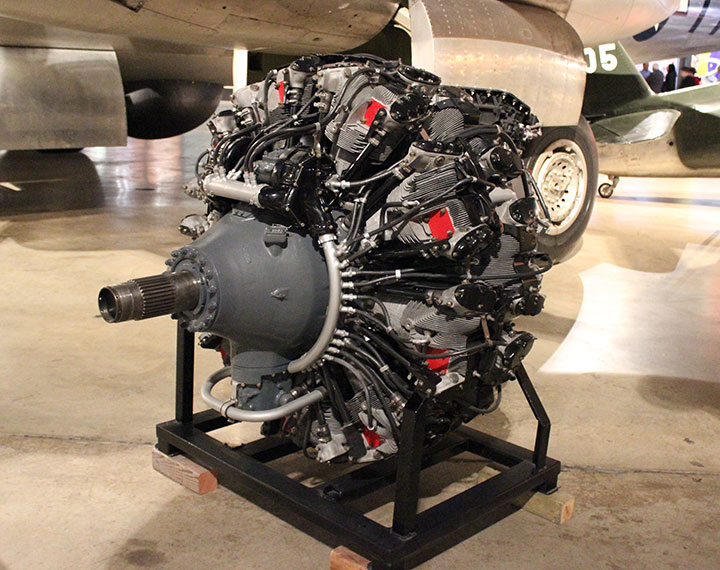

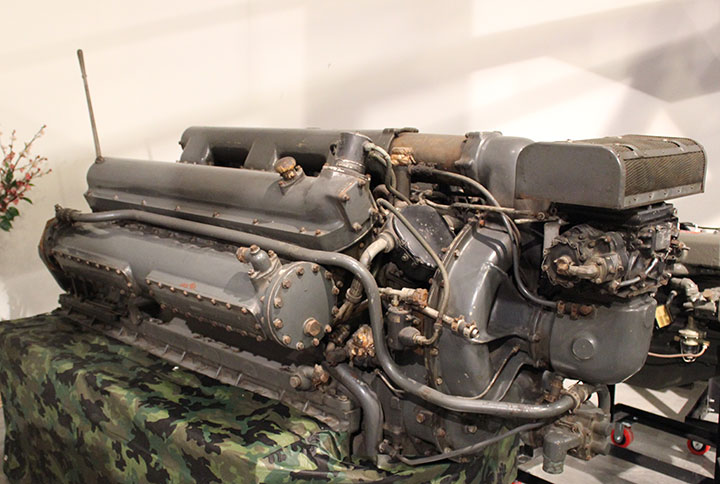

This is a Wright R-3350-23 Duplex Cyclone

engine that was used on the B-29 project during World War Two.

Graham-Paige supplied eighteen connecting rods each for the 1,866 Wright

R-3300 engines built in Lockland, OH. This would have totaled

33,588 parts for the engine. Author's photo added 1-17-2023.

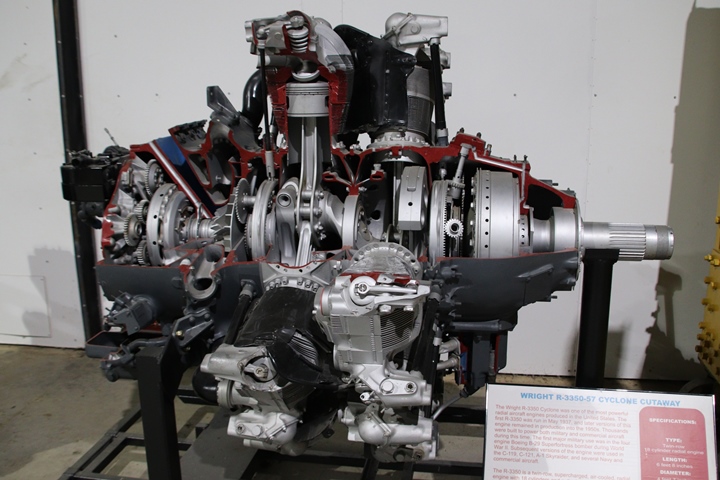

This cut-away of a R-3350 at the Museum of

Aviation Robbins AFB, GA shows the complexity of the engine.

Author's photo added 1-17-2023.

The three of the eighteen connecting rods

can be seen in this display. Author's photo added 1-17-2023.

This Martin-built B-29 44-27343, seen here at the Tinker AFB Heritage

Display, came off the assembly line at Omaha, NE in May 1945.

Author's photo added 1-17-2023.

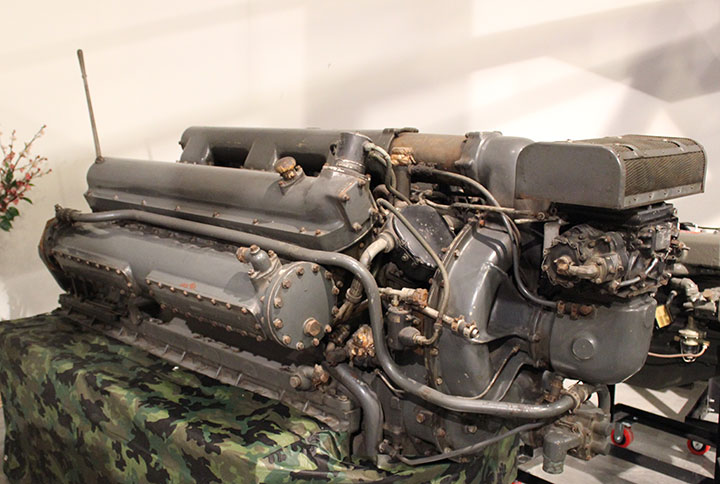

Here is a Packard 4M2500 Marine Engine for which Graham-Paige built

precision machined parts. PT boats used three of these engines;

and pilot rescue boats used two engines. Author's photo.

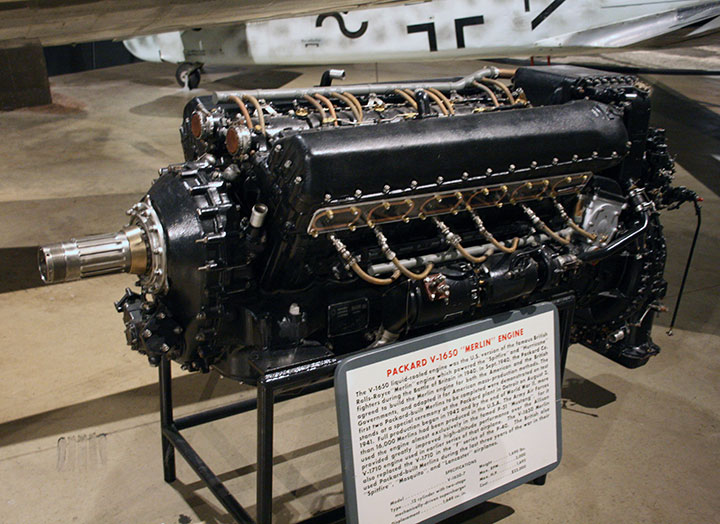

This photo shows a Packard-built V-6150, which is the US version

of the famous Rolls-Royce-built “Merlin” aircraft engine. By 1942,

Packard was in full production of both US and British versions for which

Graham-Paige also built parts. Author's photo from the National Museum

of the United States Air Force in Riverside, OH.

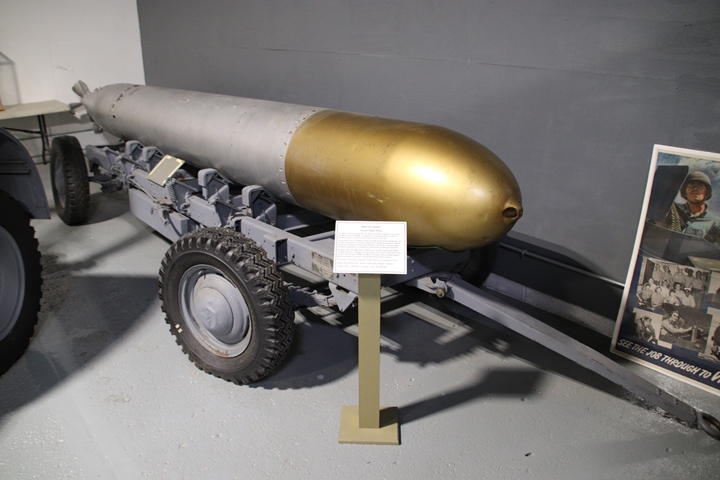

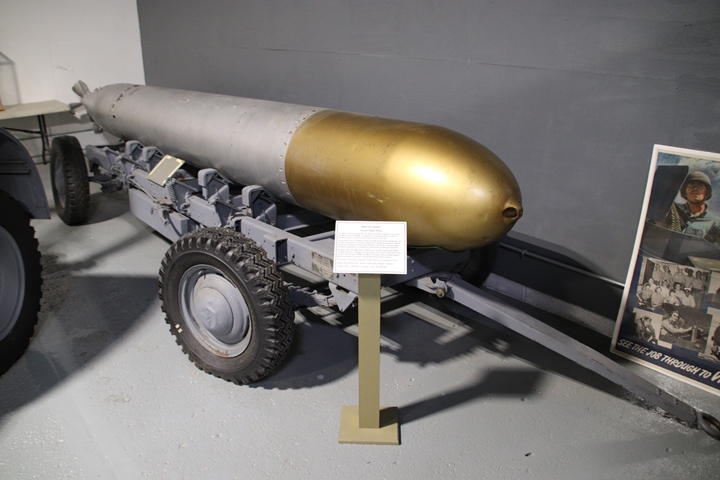

Graham-Paige had six major contracts from

the U.S. Navy for torpedo parts. These five contracts totaled

$2,021,000. The trailer has a Mark 14 torpedo on it.

Author's photo added 1-17-2023.

This 1951 Kaiser Traveler was produced by

Kaiser-Frazer after it purchased the automotive assets of Graham-Paige.

This vehicle was built in the Willow Run plant a couple of miles to the

east of the Ypsilanti Automotive Heritage Museum in Ypsilanti, MI where

it now resides.

Author's photo.

Author's photo.

This 1947 Frazer B1-6 Rototiller was built

by the Farm Division of the Graham-Paige Motors Corporation in the

Willow Run Plant under license from the Rototiller Company of Troy, NY. Author's photo from the Ypsilanti Automotive Heritage

Museum in Ypsilanti, MI.

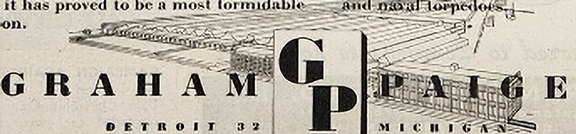

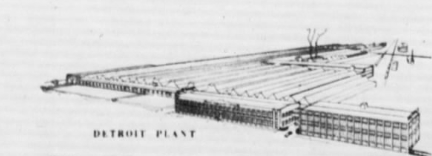

The Graham-Paige Plant:

This image and the one below were taken from

Graham-Paige World War Two advertisements. They show the general

layout of the huge complex. Image added 1-17-2023.

The Google Map Satellite views below show

that the office building in the right of the above two images still exists.

The long building in the far left of the image also still exists.

Image added 1-17-2023.

Graham-Paige was located at 8505 Warren

Avenue in Detroit, MI. Wyoming Avenue to the west of the plant is

the dividing line between Detroit and Dearborn, MI. This Google

Maps Satellite view shows the long building on the east end of the

complex is still in use. Image added 1-17-2023.

This view shows the location of the main

plant

which was razed. The east end of the office building is in the

right side of the photo. Google Maps Street View image added

1-17-2023.

This view shows more of where the main plant was located. The long

factory building can be seen in the left of the photo. It has been

re-purposed for current use. Google Maps Street View image added

1-17-2023.

The former Graham-Paige office building is in very good condition.

It is now a restaurant. Google Maps Street View image added

1-17-2023.

Google Maps Street View image added

1-17-2023.

|