|

General

Motors of Canada in World War Two

1918-Current

Vehicle production

ended 2019

This page updated

2-15-2022.

From 1918 to 2019General Motors of Canada was

a vehicle assembly operation for vehicles designed by the GM car and

truck divisions located within the United States. Its last

assembly plant in Oshawa, ONT closed in 2019. GM of Canada is now

only a marketing organization for GM vehicles built in other countries.

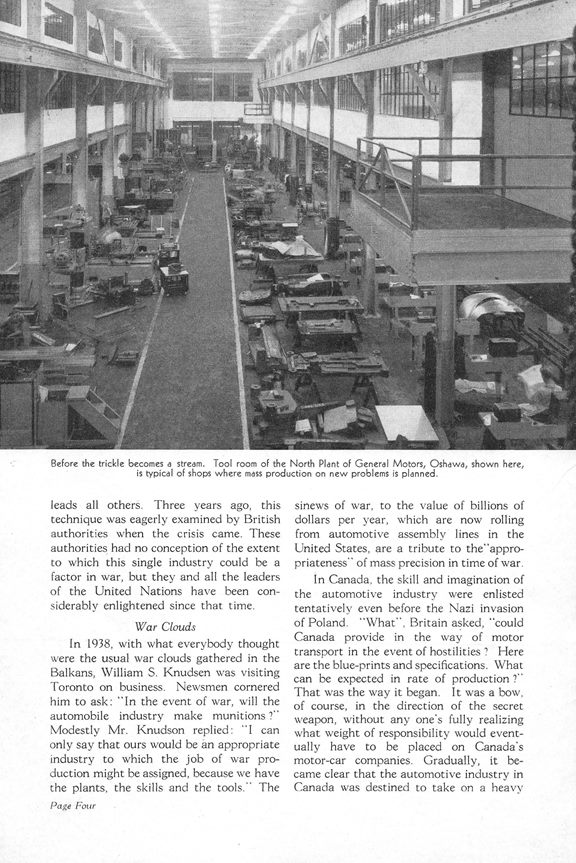

This is the GM of Canada Oshawa complex

looking north. The photo was taken while it was still in operation. Lake Ontario is the body

of water at the bottom of the photo. Just out of sight in the

lower left hand corner of the photo, or southwest of the plant, is the

location of Camp X. Camp X was a top secret location for the

training of British Commonwealth commandos during World War Two.

Ian Fleming, creator of the James Bond series of spy novels, visited

Camp X during the war. He was only an observer and not a trainee

at the camp. While in Oshawa, he stayed in a hotel on Bond

Street. The Ontario Regiment Museum is afew miles north of the plant.

Several World War Two vehicles built in this

plant are on display there.

During World War Two the

Canadian automobile industry supplied over 800,000 trucks for Great

Britain and the British Commonwealth. The Canadians not only built vehicles and armaments in GM plants, but

also in Canadian Ford and Chrysler plants. GM of Canada had plants

in Windsor

and Oshawa Ontario, and Regina Saskatchewan. The Division included Canadian Modified Conventional Pattern

Trucks, which were basically civilian trucks for military use, and

Canadian Military Pattern Trucks that were designed and manufactured

specifically for military use.

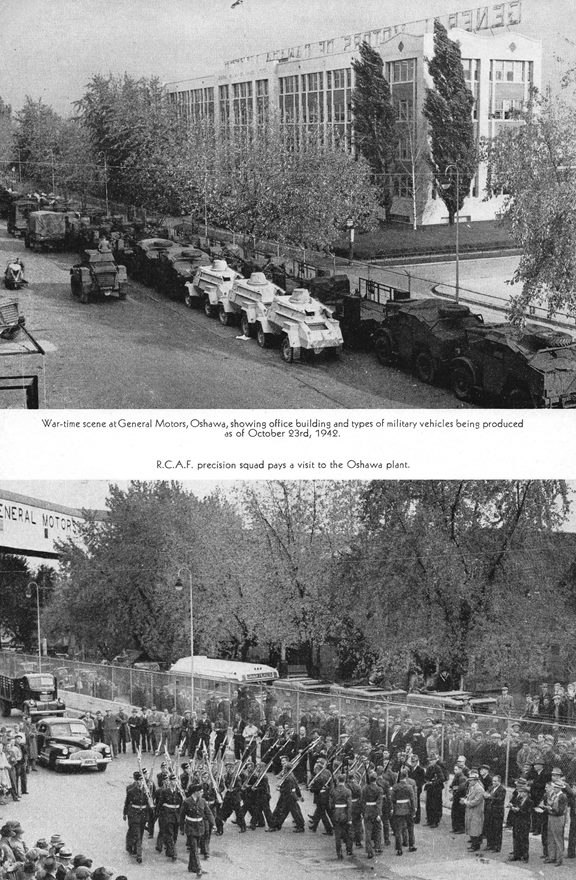

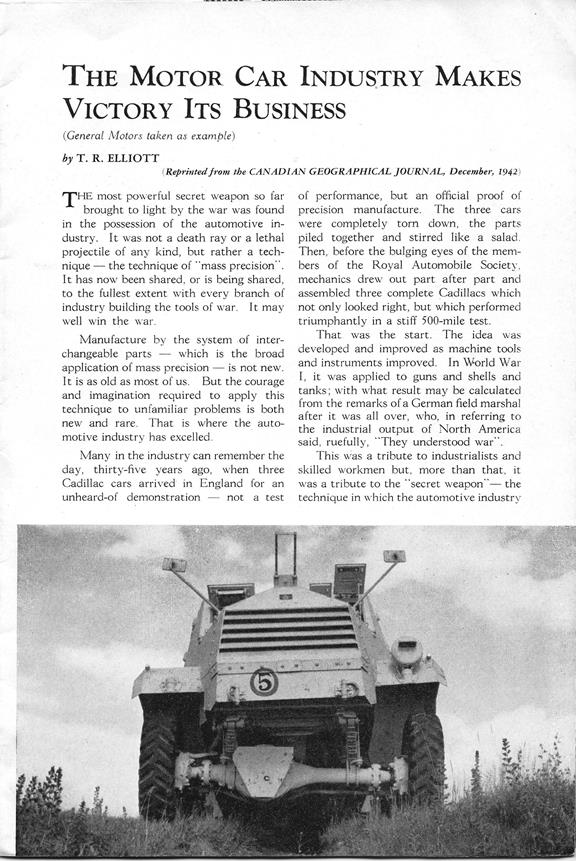

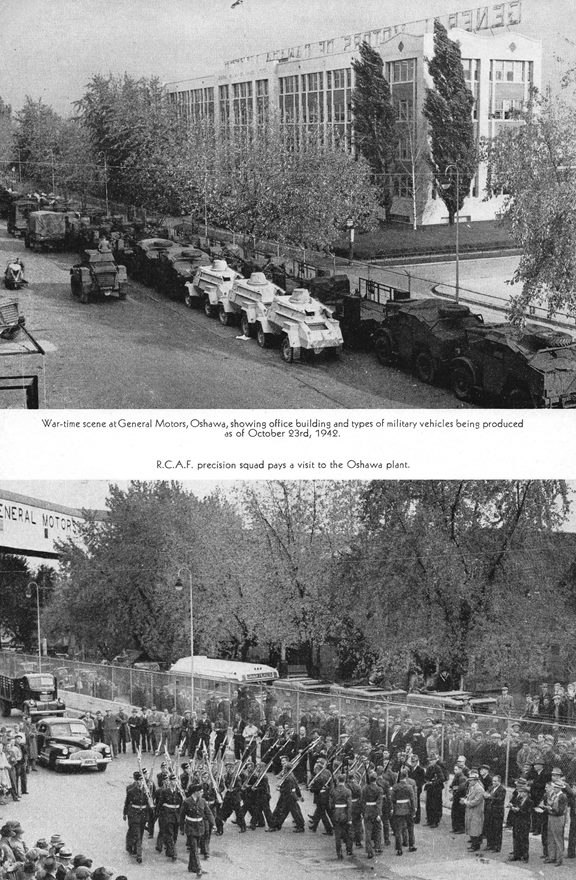

This October 1942 photo shows the street

behind the GM of Canada office building in Oshawa, ONT lined with "Otter"

light reconnaissance cars and Canadian Pattern Military Trucks.

Oshawa built 1,781 of the "Otters" used by the British in

North Africa and Europe.

General Motors of Canada

World War Two Production Statistics: (1,506) Mark 1 "Fox" Armored Cars, (1,781)

"Otter" Light Reconnaissance Cars, (3,961) GM CT15A Armored Trucks, Modified

Canadian Military Pattern Trucks, (201,000) Canadian

Military Pattern Trucks (CMPT), (1,032) De Havilland Mosquito aircraft

fuselages, machine guns, gun sights, anti-tank gun carriages, and

tooling for naval gun mounts and 3.7 cm anti-aircraft gun carriages.

Locations:

Oshawa, ONT - All of the vehicles were built

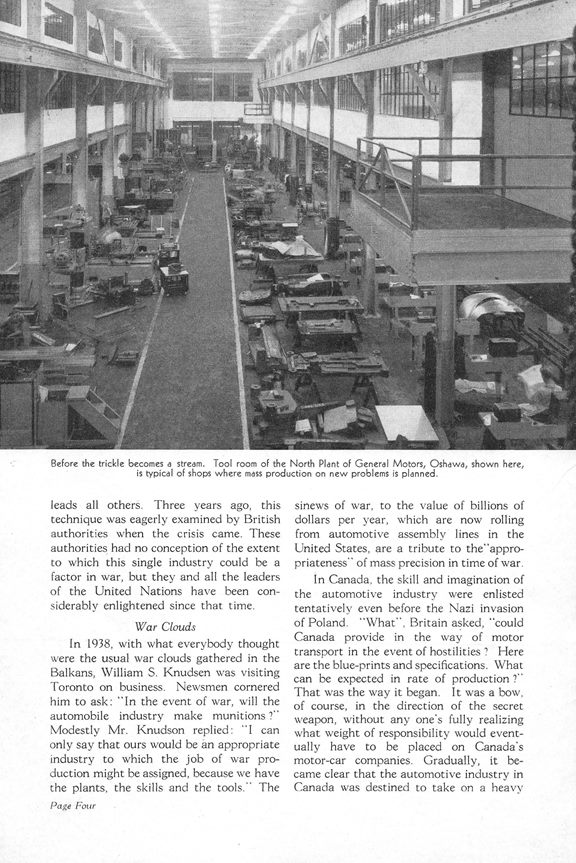

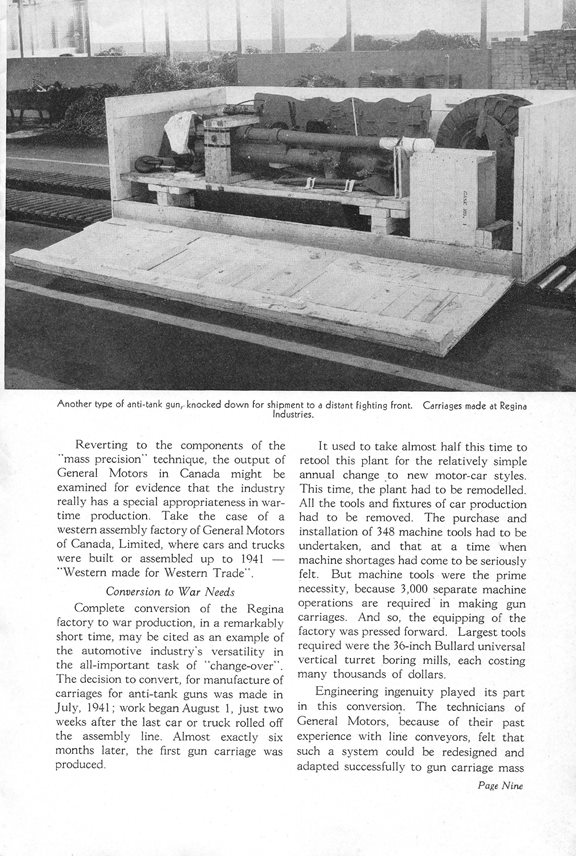

in this plant. A close read of page 16 of "The Motor Car Business

makes Victory its Business" below indicates that the Oshawa tool room

made the tooling and fixtures for 3.7 cm anti-aircraft gun carriages,

which were then supplied to another company. It also states that

Oshawa supplied tooling and fixtures to an un-named Montreal company which was first to

make mounts for naval guns.

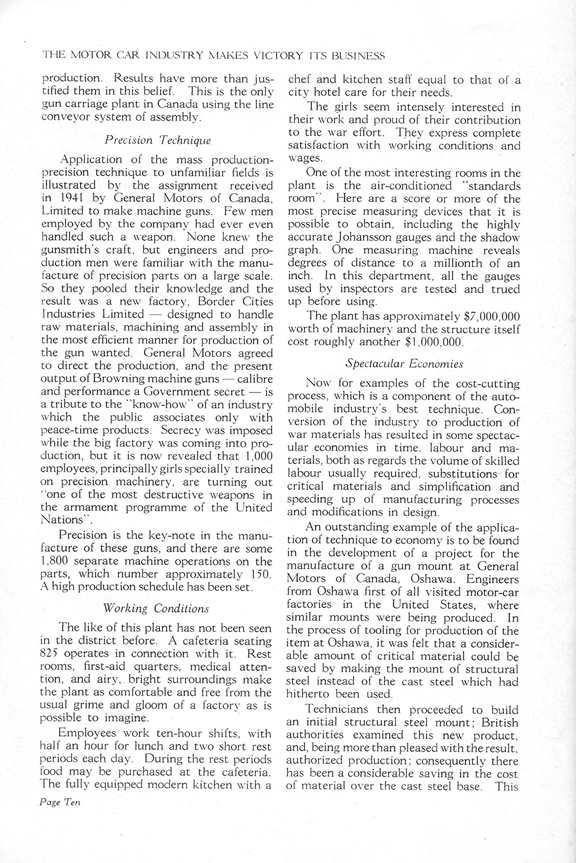

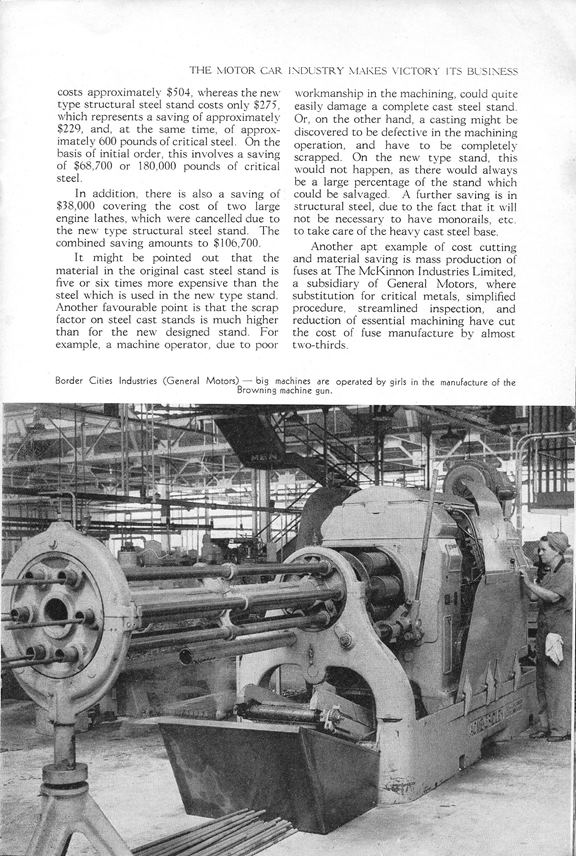

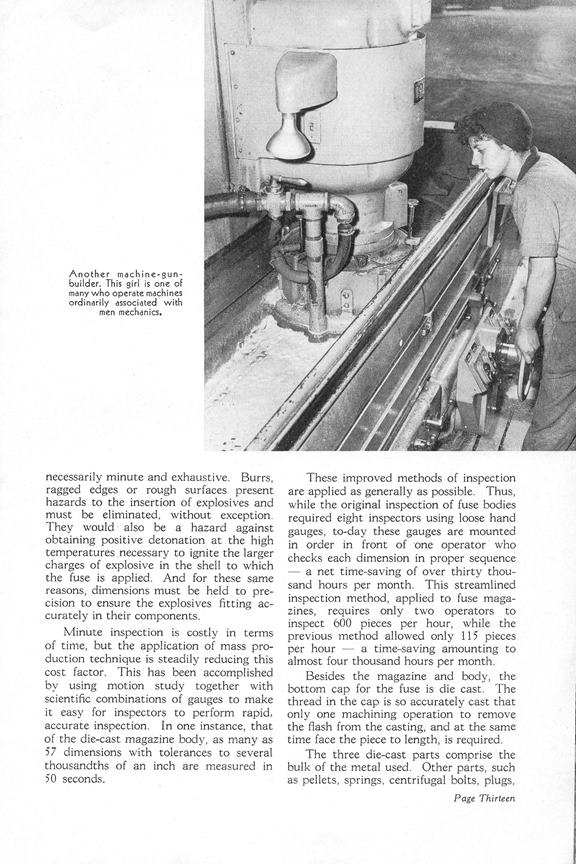

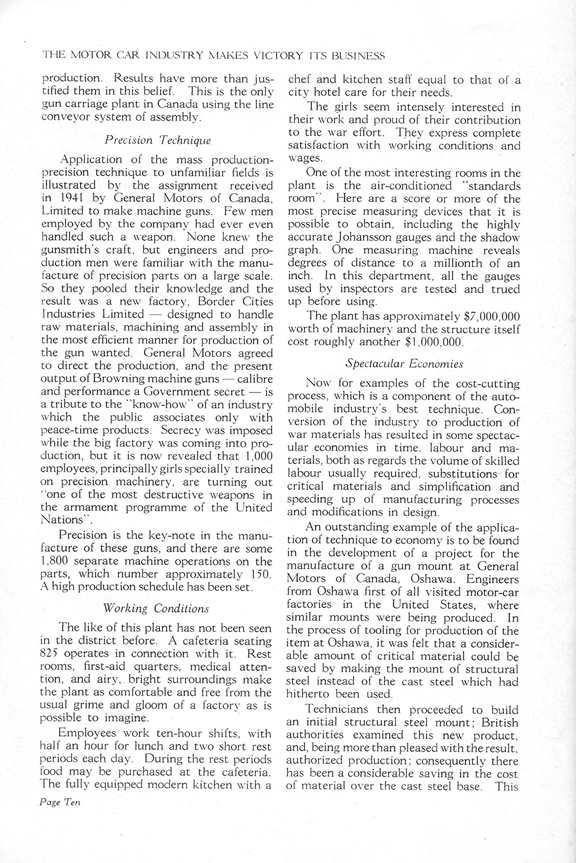

Border Cities plant in Windsor, ONT - This was a Canadian government-owned plant managed by GM of Canada. Built in 1942, the plant

produced 25,000 M1919A4 .30 caliber Browning machine guns.

Walkerville plant in Windsor, ONT - This plant was adjacent to the

Border Cities plant and was first used by GM of Canada in 1919.

During World War Two, it produced naval gun mounts.

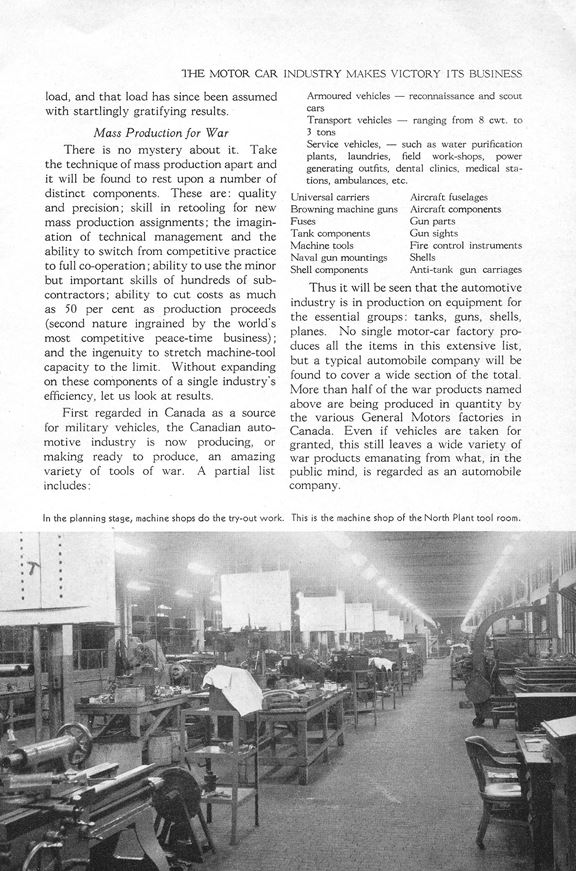

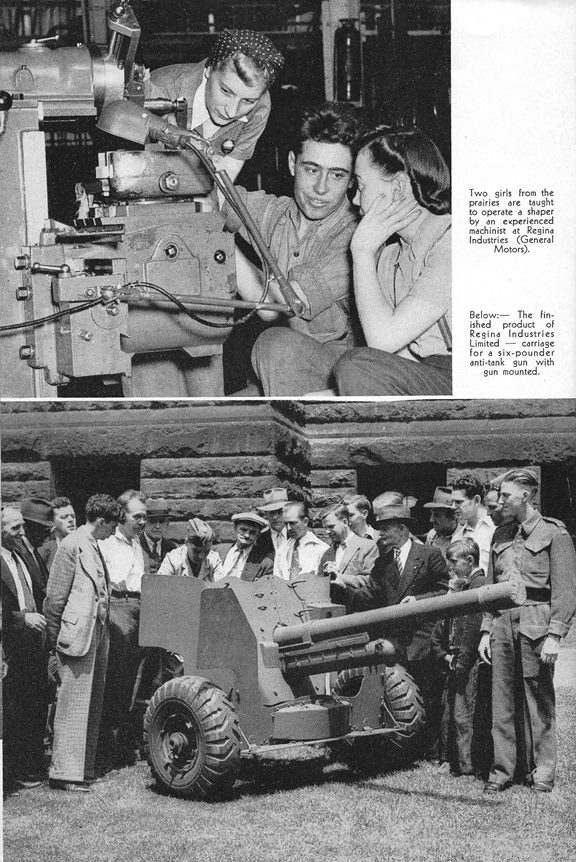

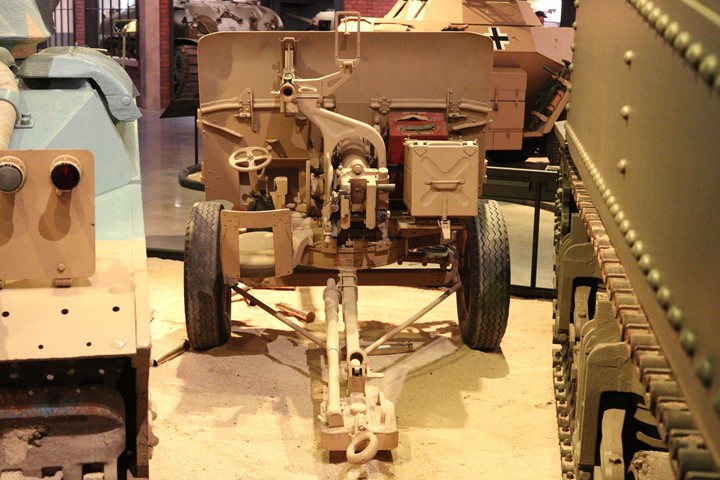

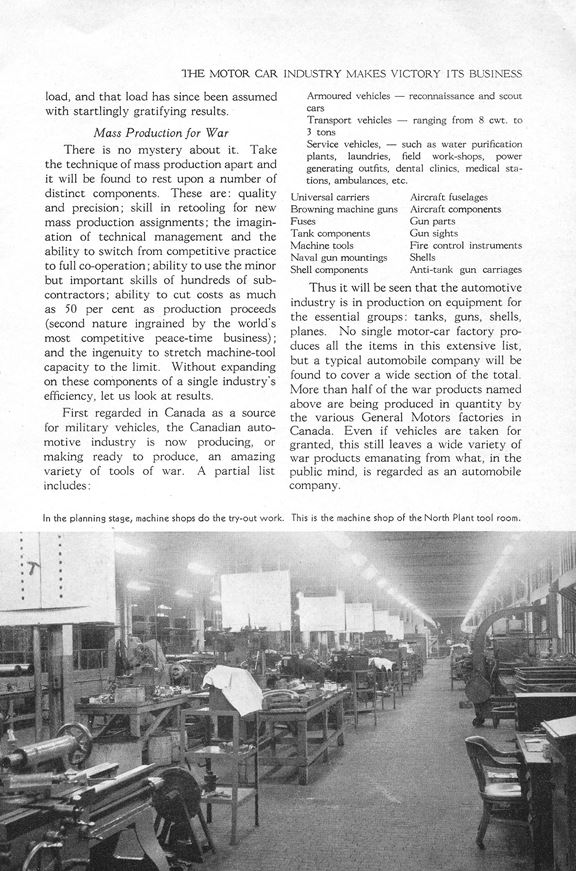

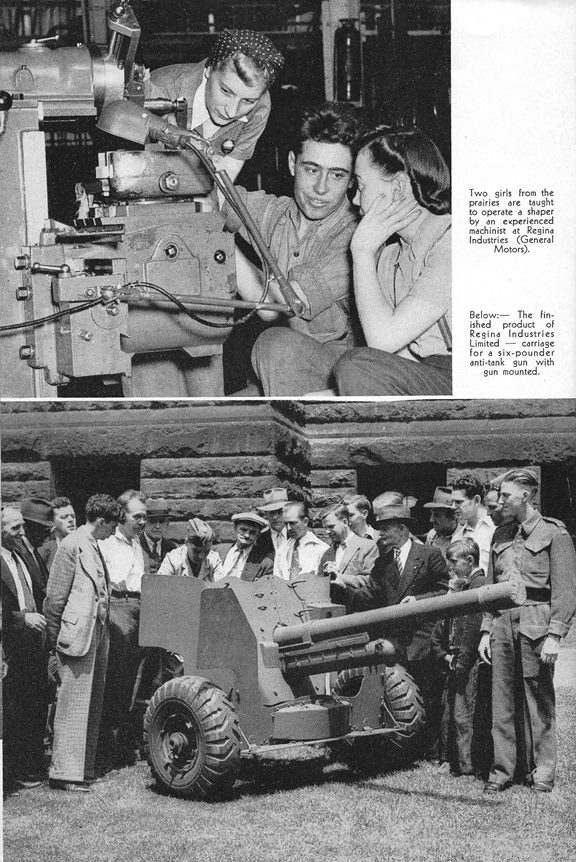

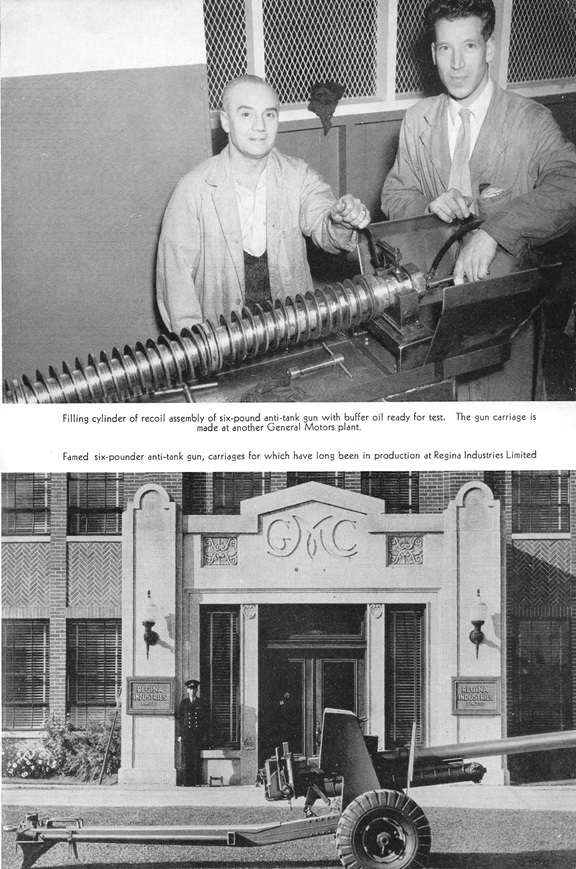

Regina, Saskatchewan - Normally a car

assembly plant, this location produced gun carriages for 2-pounder and

6-pounder anti-tank guns. More

information can be found in the "The Motor Car Industry Makes Victory

its Business" below.

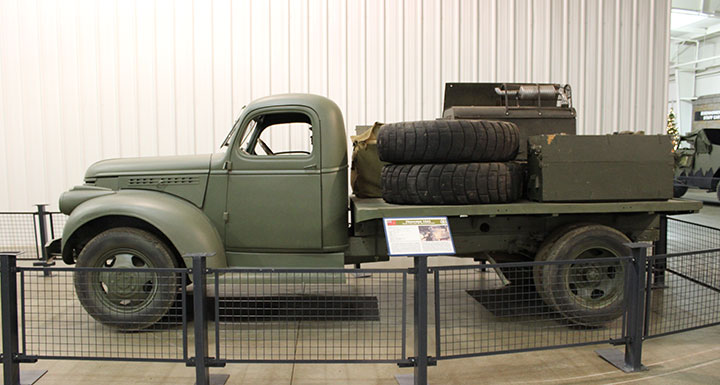

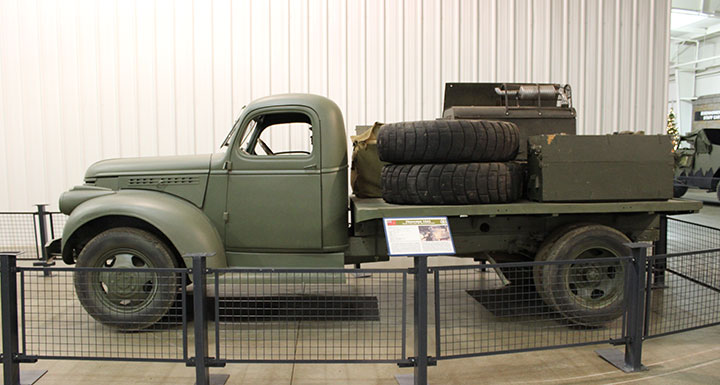

GM of Canada built the Chevrolet 3 ton 4x2

trucks used by the famous Long Range Desert Group in North Africa.

This particular model is a radio truck with a Boys 20mm anti-tank gun

for armament.

De Havilland Mosquito KA 114 is one of 1,032

of this type built by De Havilland during the Second World War at its Downsview

plant in Toronto, Ontario. The aircraft was constructed mostly of

wood, including the fuselages made by General Motors of Canada. It

is one of three flying Mosquito in the world. KA114 is seen here at the 2013 Hamilton,

Ontario Airshow.

This Mosquito's all wooden fuselage, built by the

Mosquito Bomber Group, was on display at the 2006 Selfridge Air National

Guard Base Airshow. GM of Canada made 1,032 wooden fuselages like

this during WWII. Author's photo added 12-24-2015.

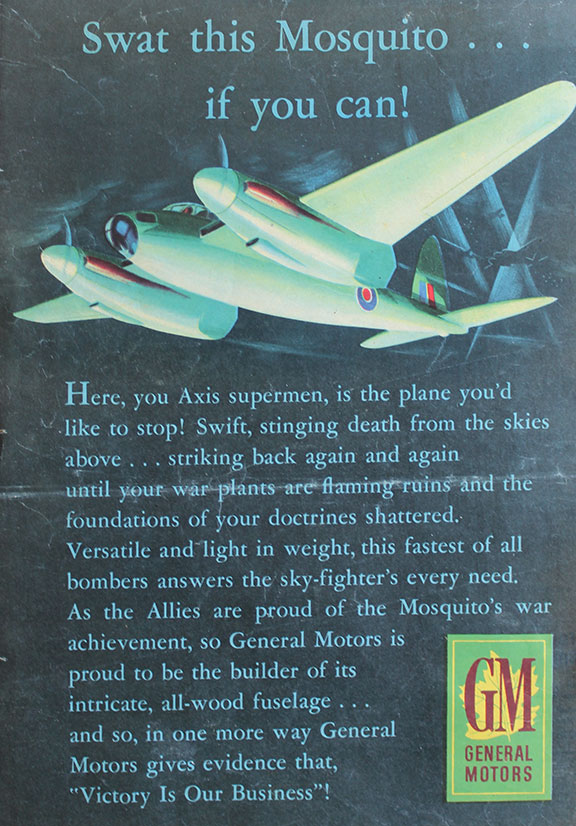

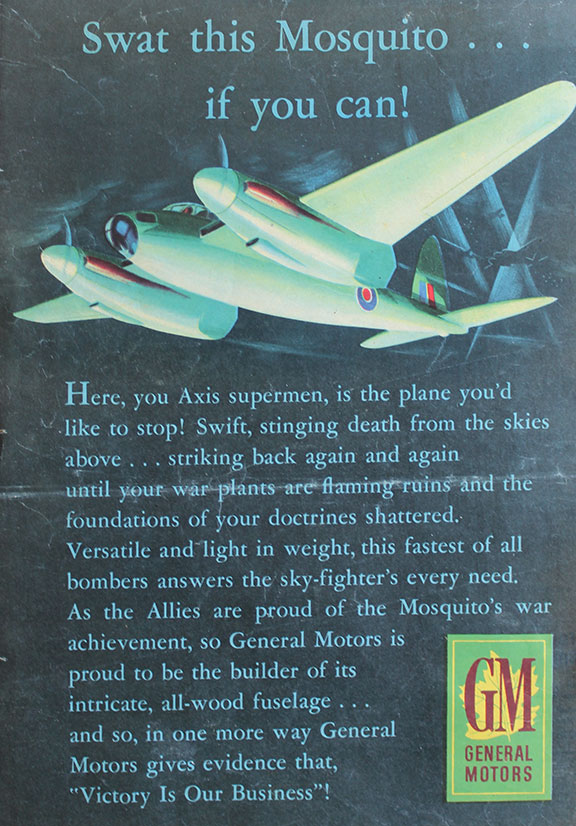

This GM of Canada advertisement states that it

is the builder of the all wooden fuselages for the Canadian-built

Mosquitoes. It is unknown which plant built the fuselages.

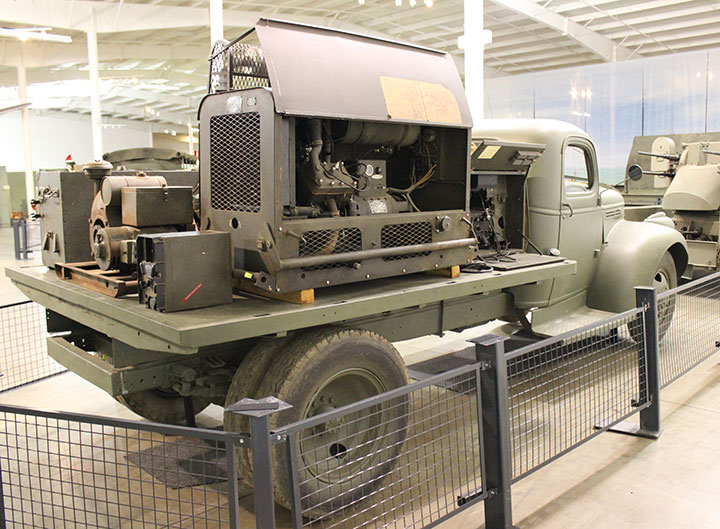

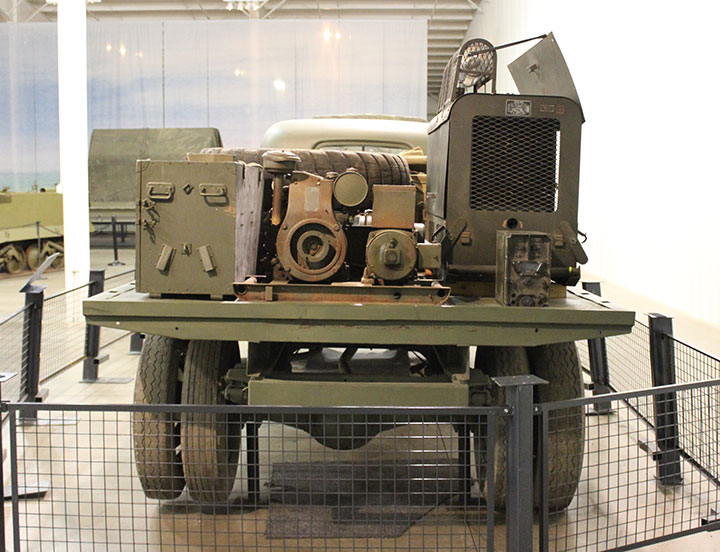

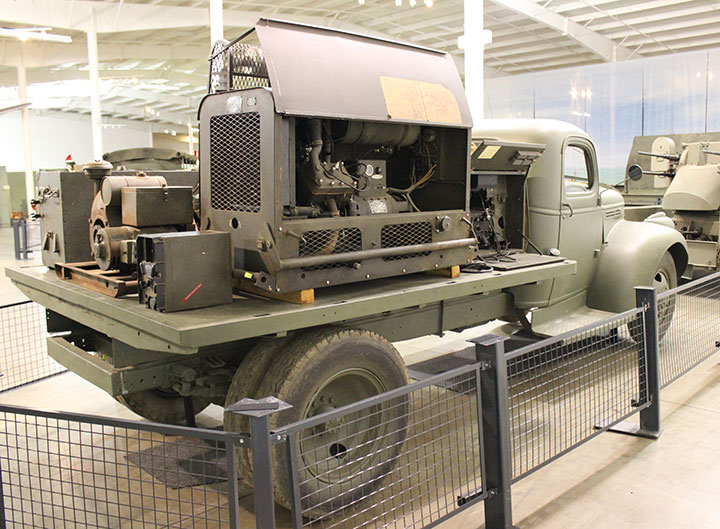

This GM of Canada radio truck is on display

at the Ontario Regiment Museum in Oshawa, ONT. This truck is 3.6

miles from where it was built in 1943. Author's photo added

1-13-2021.

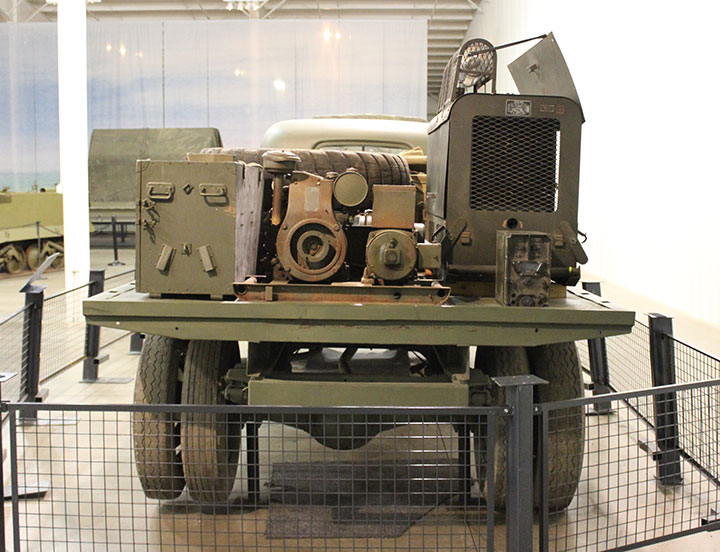

This is serial number 1 of this type of radio

truck. Author's photo added 1-13-2021.

Author's photo added 1-13-2021.

Author's photo added 1-13-2021.

The radio truck came equipped with a No.19

radio set. Author's photo added 1-13-2021.

This GM of Canada General Service truck has

a wireless set in the canvas covered body. Author's photo added

2-15-2022.

Author's photo added 2-15-2022.

Besides the wireless set are two operator

chairs. Author's photo added 2-15-2022.

This CMPT at the museum was

also built 3.6 miles away, in the former GM of Canada plant.

Author's photo added 1-13-2021.

This version is a water tanker. Canadian troops could fill their

canteens or other containers from the seven spigots across the rear of

the vehicle. There was also a steel tube overhead structure for a

tarp to keep the sun off the water tank. Author's photo added

1-13-2021.

Author's photo added 1-13-2021.

One of the engine covers is off the of engine

which protrudes into the cab. This is what is known in the

trucking industry as a cab forward design. I think an " engine in

the cab" is more appropriate. Author's photo added 1-13-2021.

Author's photo added 1-13-2021.

This is a GM of Canada-built 15-CWT 4x4

General Service truck. It was part of the reenactment of Sword

Beach at 2019 Conneaut D-Day 75. Author's photo added 8-21-2019.

Author's photo added 8-21-2019.

This photo shows how the engine is covered

as it protrudes into the cab of the vehicle. Author's photo added 8-21-2019.

This GM of Canada C8A 1C1 Heavy Utility

Personnel (HUP) is part of the many vehicles on display at the

Canadian War Museum. Author's photo added 2-15-2022.

The HUP could transport soldiers.

Author's photo added 2-15-2022.

Author's photo added 8-21-2019.

This is a GM of Canada-built 15-CWT 4x4

armored truck. It was on display at the Virginia Museum of

Military Vehicles' 2016 open house. Author's photo added

8-21-2019.

Author's photo added 8-21-2019.

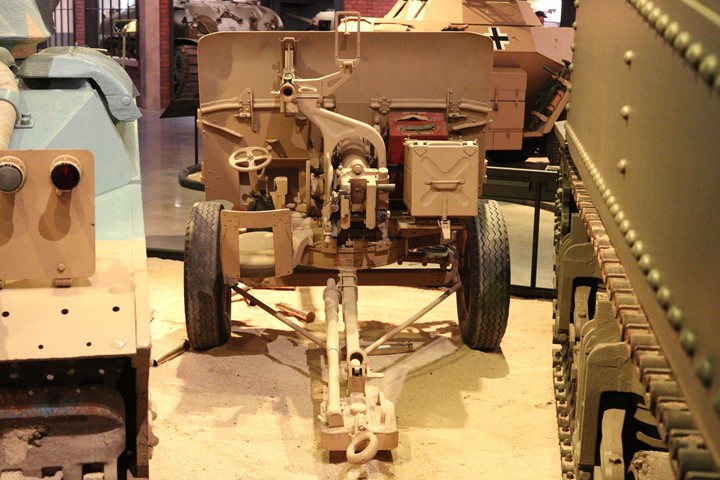

GM of Canada in Regina, Saskatchewan

produced 2-pounder anti-tank guns like this one in the American Heritage

Museum in Hudson, MA. Author's photo added 8-21-2019.

Author's photo added 8-21-2019.

This de-militarized M1919A4 was built by the Borders Industries plant of

GM of Canada during World War Two. It is on display at the Museum

of the Soldier in Portland, IN. Author's photo added 1-13-2021.

It is surprising that this is chambered for

the U.S. Cal .30 rather than for British .303 caliber cartridges.

Author's photo added 1-13-2021.

Author's photo added 1-13-2021.

This 1941 Chevrolet three ton-truck

was built in Oshawa, Ontario as a service truck for the RAF.

Due to the loss of 75,000 of its 80,000 vehicles at Dunkirk, trucks like

these became very important to the British in rebuilding its national

stock of trucks. Manufacturing continued until 1943. Because

the trucks were not four-wheel-drive, many, like this one, were used by

the RAF at its airfields.

For some reason, when the truck axles were lifted off the floor for

display, the truck did not end up level.

Note that this has right hand steering.

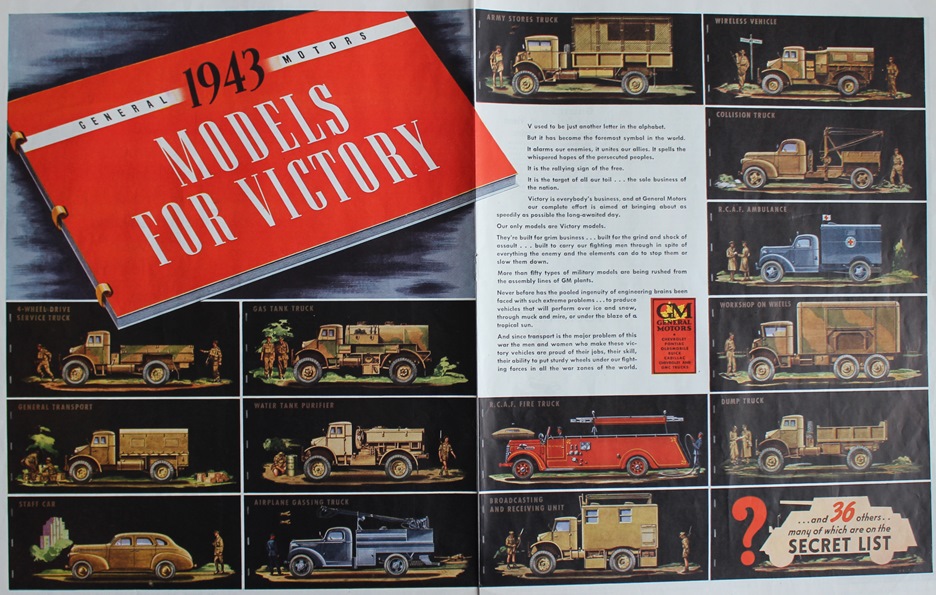

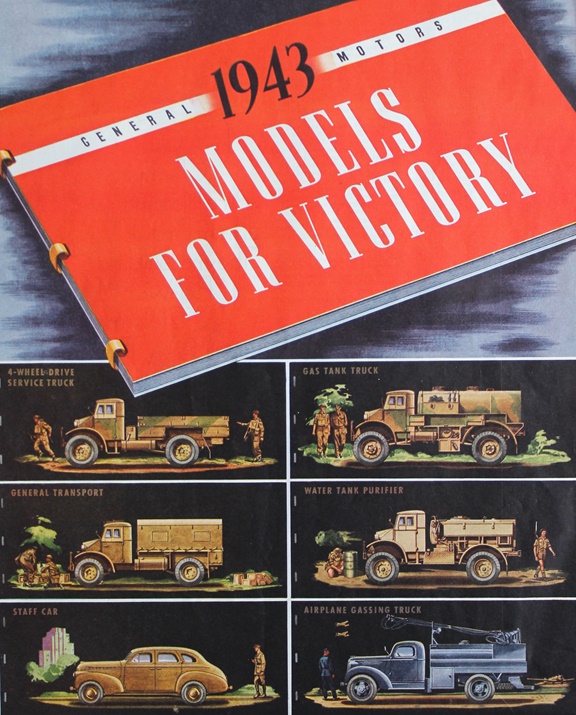

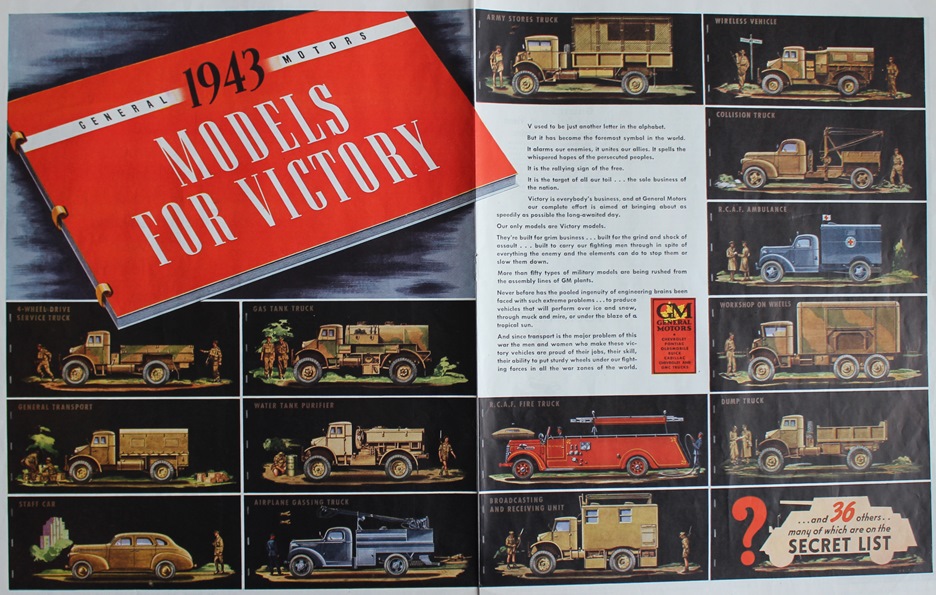

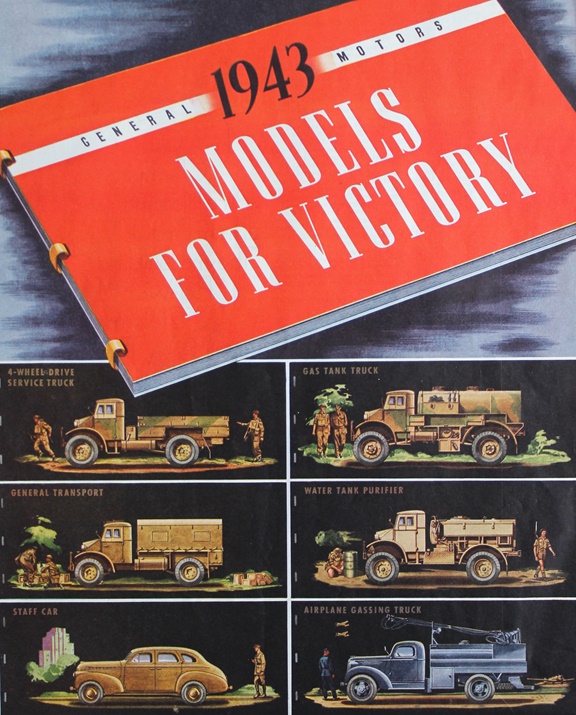

This two page magazine advertisement from

1943

shows all of the vehicles Oshawa produced at that time for the

Commonwealth military forces.

Above (L-R) are water color

renderings of a four wheel drive service truck, a gas tank truck, a

general transport truck, a water tank purifier truck, a staff car, and an

aircraft gas truck.

Starting at the top and working across and

down is an army stores truck, wireless truck, collision

truck, RCAF ambulance, workshop on wheels, RCAF fire truck, dump truck,

broadcast and receiving truck, and then 36 others on the "secret" list.

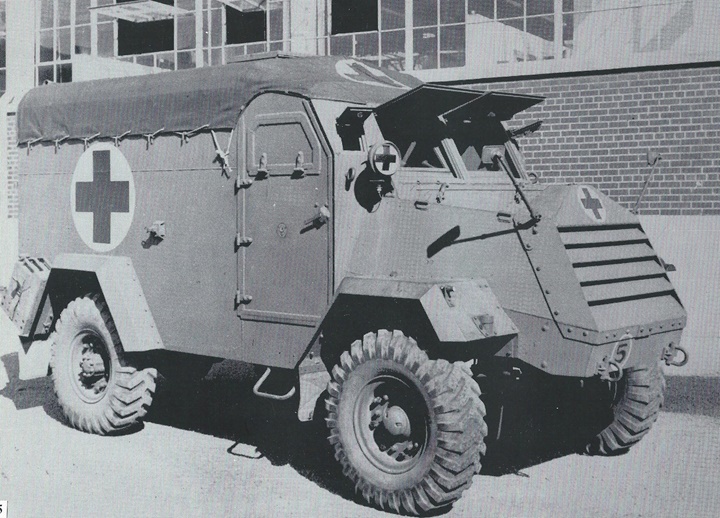

One of those is the armored ambulance pictured below.

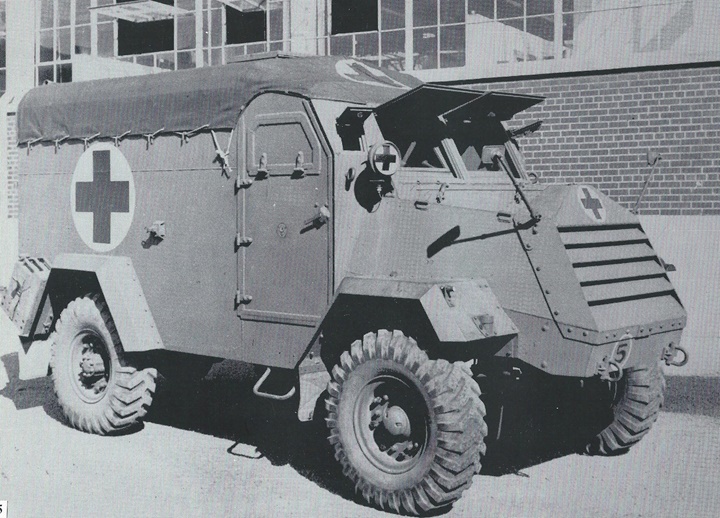

This armored ambulance that could carry four

stretchers was built late in the war.

The Canadian War Museum in downtown Ottawa

has an armored ambulance on display. Author's Photo added

1-8-2017.

Author's Photo added 1-8-2017.

Author's Photo added 1-8-2017.

This Fox armored car, seen at 2009 Windsor,

Ontario Airshow, was designated as a GM MK.1. It was another product of

GM of Canada. Chevrolet designed the chassis, GMC Division supplied the

270 cubic inch gas powered engine from the U.S. Final assembly was done by GM of

Canada.

The Fox armored car was built during 1943.

GM of Canada built 1,506 Fox armored cars

for the Canadian Forces. This vehicle and the Otter below are both

on display at the Canadian War Museum. Author's photo added

2-15-2022.

Author's photo added 2-15-2022.

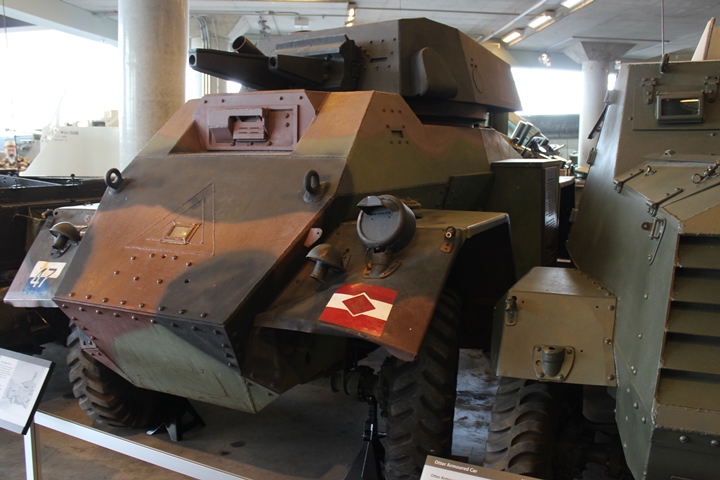

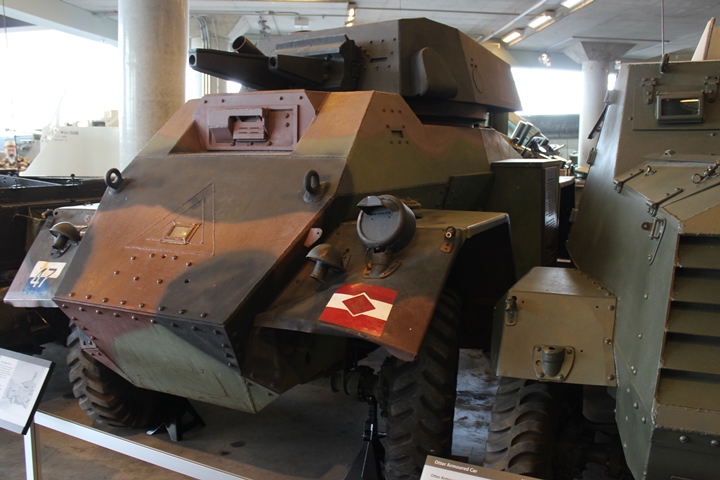

GM of Canada built 1,781 Otter armored cars

during World War Two. The Otter was based on the British Humbler

light reconnaissance vehicle. Author's photo added 2-15-2022.

Author's photo added 2-15-2022.

3,961 CT15A GM of Canada Armored Trucks like

this one were built in 1944 and 1945 for service with

British Empire armies. This would have been another of the 36

"secret" trucks referred to in the 1943 advertisement above.

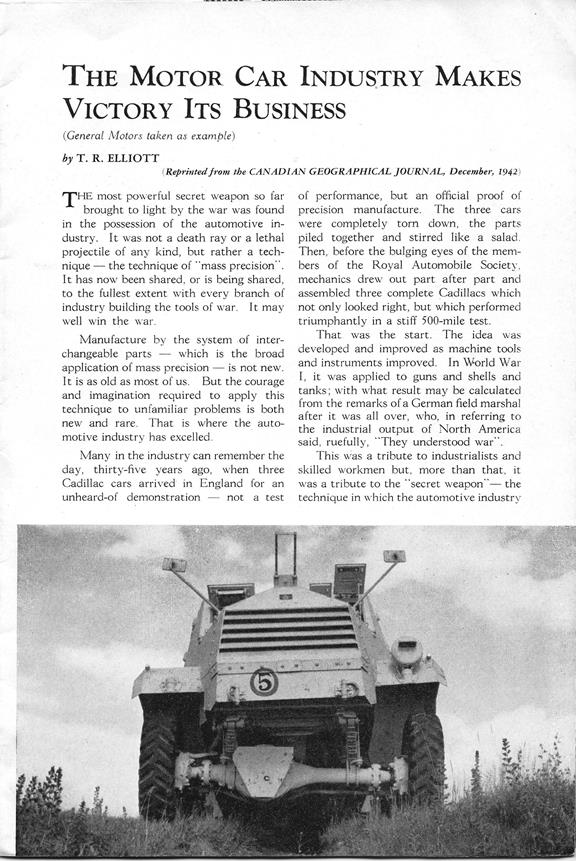

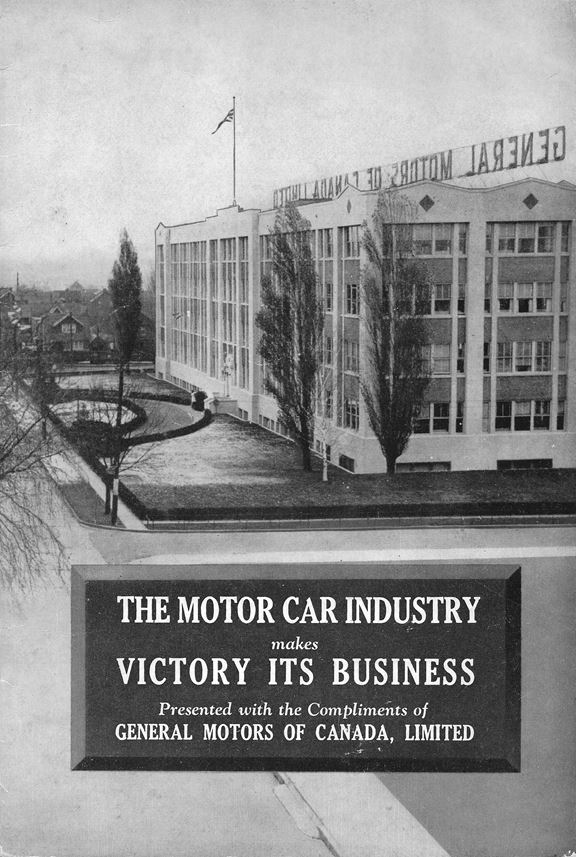

"The Motor Car Industry

makes

Victory its Business"

This short eighteen page

monograph, published by GM of Canada in December of 1942, gives an

excellent overview of what the Canadian auto industry was doing to

support the war effort. Canada had been

supporting Great Britain, which desperately needed military vehicles and

weapons. The monograph is a reprint of an

article that appeared in the December 1942 issue of Canadian Geographic.

It generally describes the actions of the entire Canadian auto industry,

using GM as the prime example.

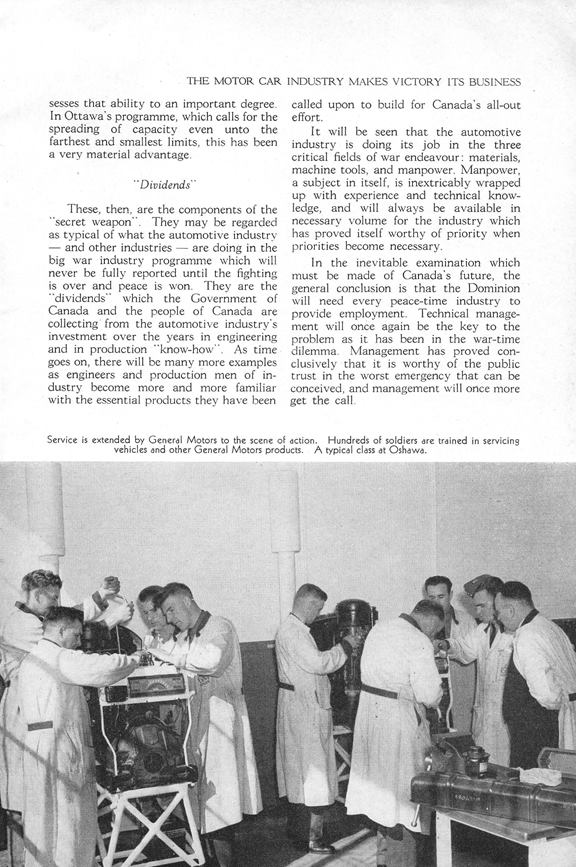

The pages below provide information and photos

of the Otter light reconnaissance car that was being built in Oshawa

during 1942. The article also notes that the GM plant in Regina,

Saskatchewan was producing gun carriages for six pounder anti-tank guns.

The Border Cities Industries plant of GM Canada was identified as the

producer of Browning machine guns. The caliber of the weapons was not revealed, as it is considered in 1942 to be a

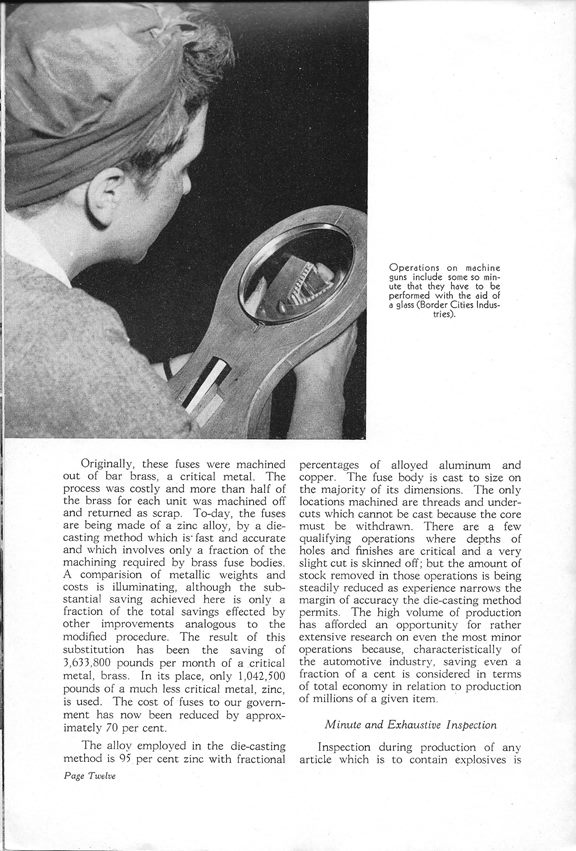

military secret. McKinnon

Industries Limited, which was separate from GM of Canada as a subsidiary

of GM, is identified as producing fuses for the war effort.

This photo shows the heavy duty front wheel

drive of the Otter.

Half of the items listed on this page were

built by GM of Canada. Those known to have been built by this

Division include armored vehicles, transport vehicles, Browning machine

guns, fuses, aircraft fuselages, and gun carriages.

Coming down the assembly line are two of the

1,781 Otter light reconnaissance vehicles that were produced by GM of

Canada at its Oshawa plant.

Eleven of the Otters have been equipped

with their standard armament of a Bren gun. Others were also armed with a Boys 20mm

anti-tank gun.

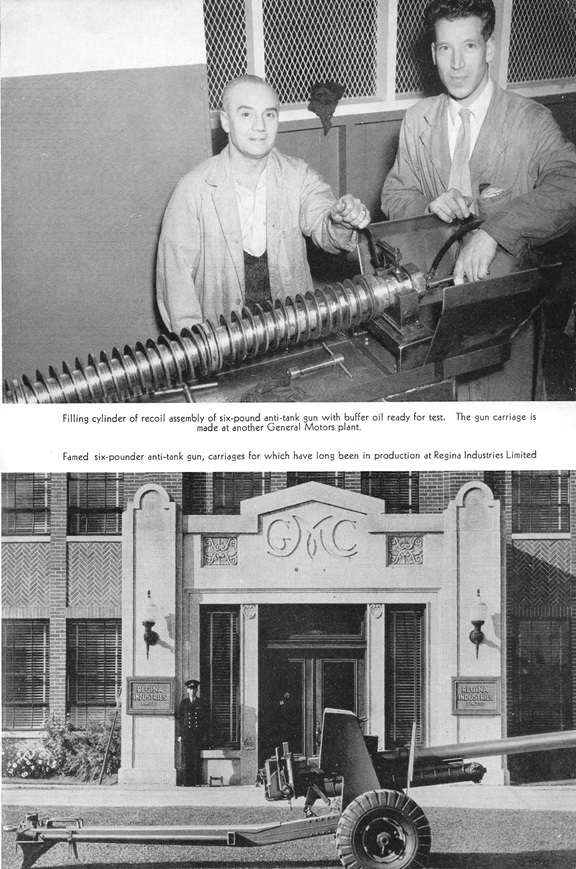

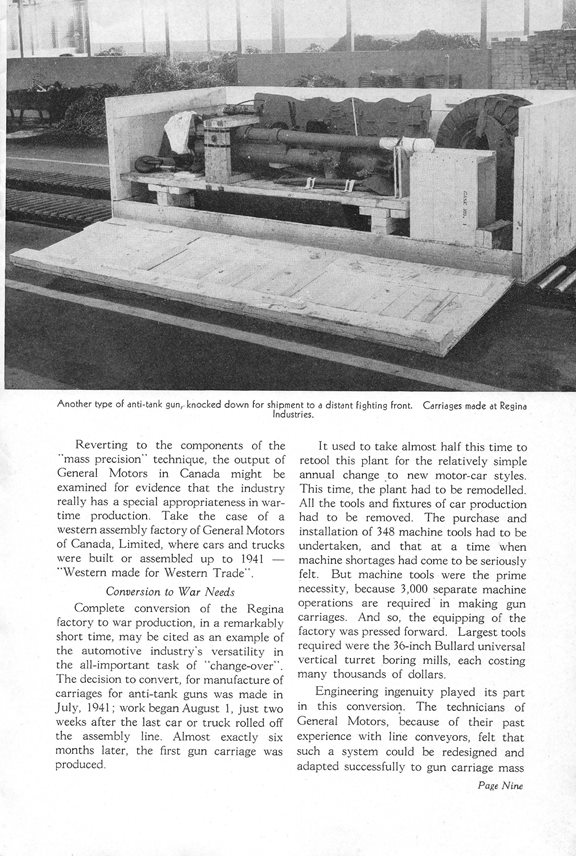

During 1942, The Regina plant of GM of Canada

produced the carriages for the six pounder anti-tank gun. The photo

below implies that the plant also built carriages for types of anti-tank

gun, which could have been for the 17 pounder, among others.

The machine is either boring

out the barrel or rifling the bore itself. Using multi-spindle

machines such as this one sped up production. The last paragraph of the text

introduces McKinnon Industries, which was separate from GM of Canada as

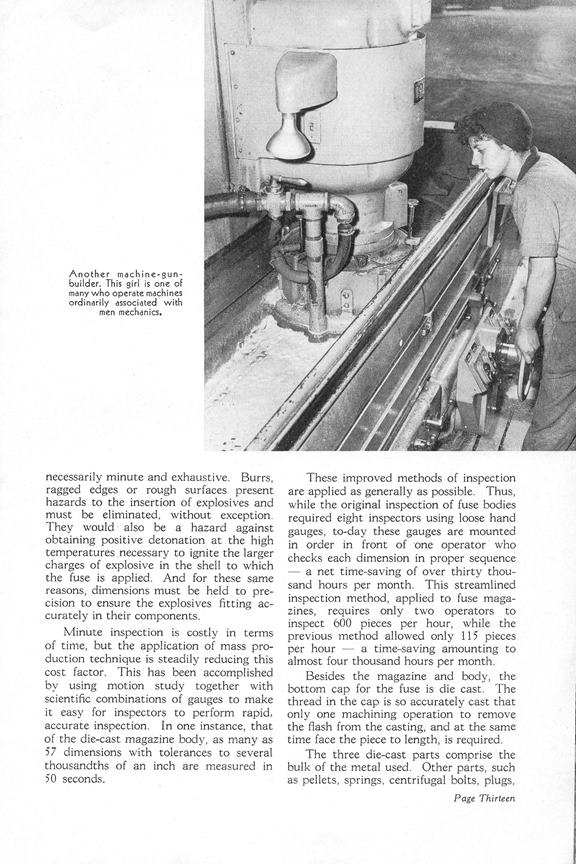

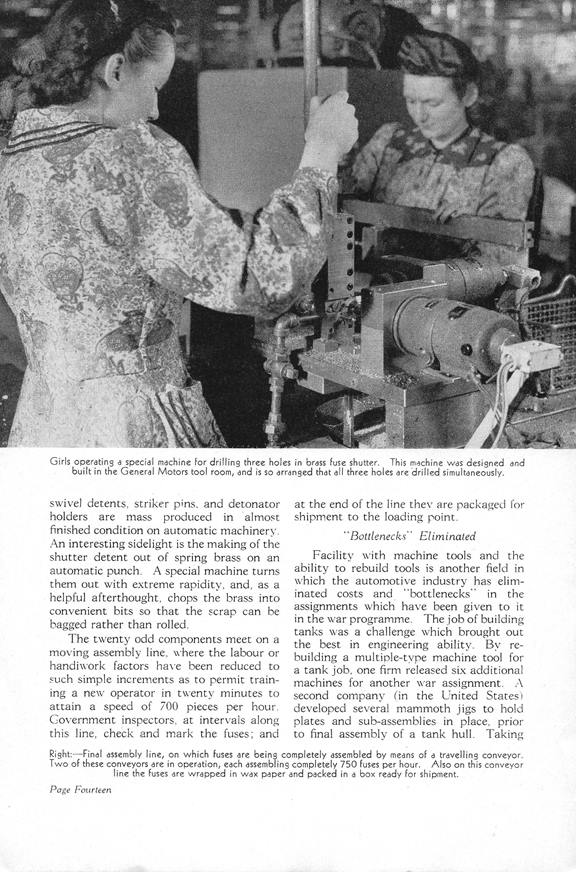

a subsidiary of GM, as the manufacturer of fuses for the military.

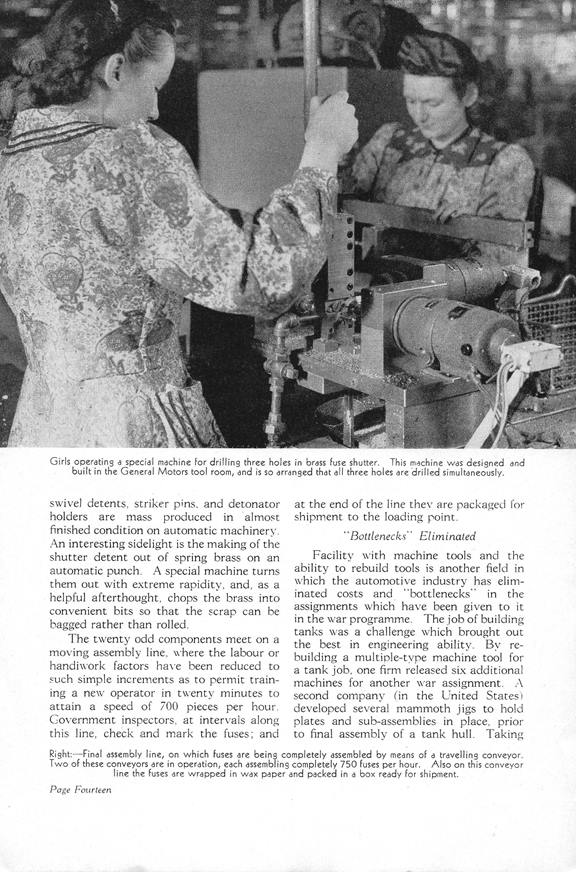

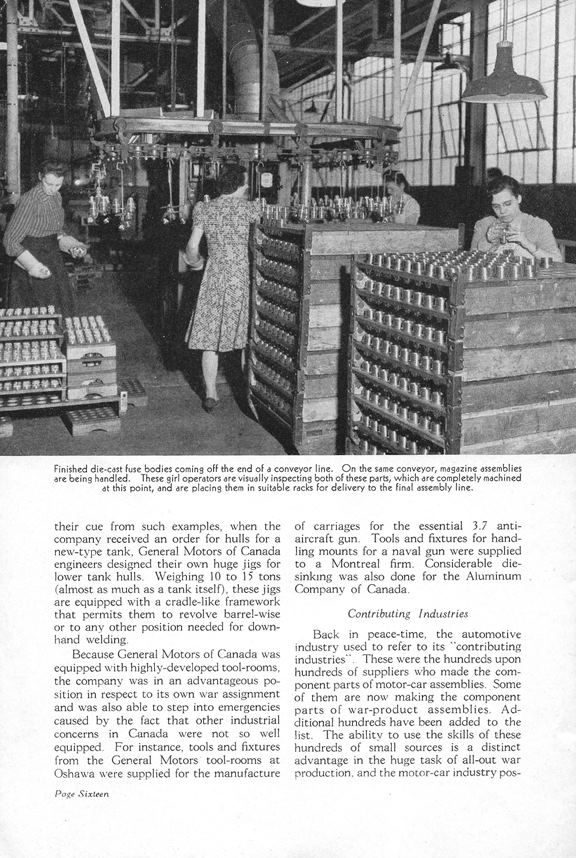

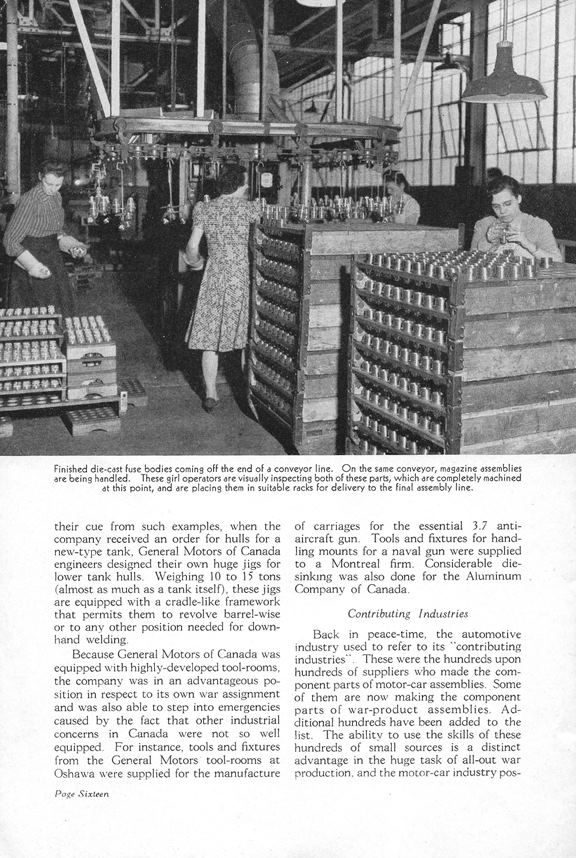

This 1942 photo shows the fuze final

assembly line at McKinnon Industries. It had a run rate of 375 units per hour.

This is one of two conveyors producing fuses for the

military at a combined output of 750 per hour.

Truck chassis and Otters are seen here after

coming off the assembly line at Oshawa.

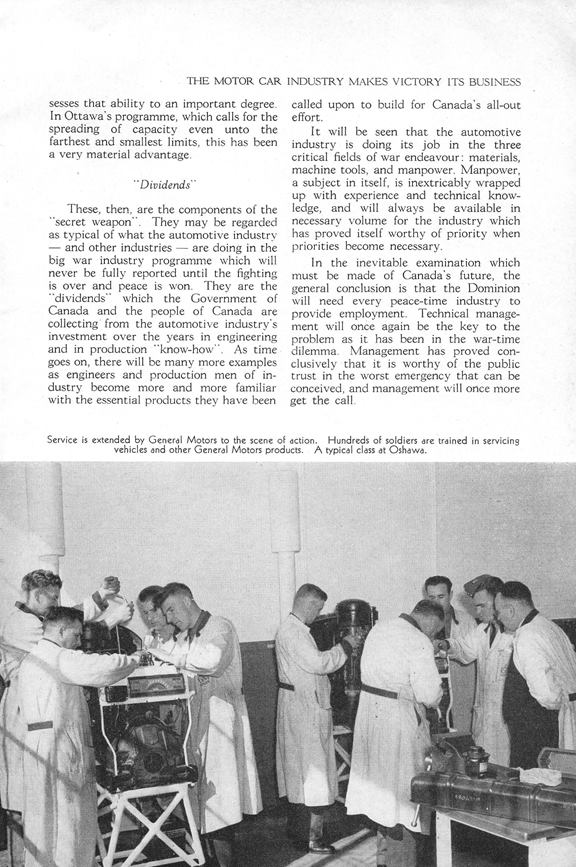

|