|

Steel

Products Engineering Company in World War Two

Springfield, OH

1908-1996

1955-1973 as the SPECO Division of Kelsey-Hayes Company

1973-1987 as part of Fruehauf Corporation

1987-1989 as part of Grabill Aerospace

1989-1996 as part of SNECMA

This page added 6-23-2022.

It is not very often that I find an

Army-Navy "E" flag for a company for which I do a page. In this

particular case, I photographed this "E" flag two years before I wrote

this page. This Steel Products Engineering Company "E" flag is on

display at The Heritage Center of the Clark County Historical Society in

Springfield, OH. Steel Products Engineering Company was the first

company in Springfield, OH to win the "E" award for U.S. Army Air Corps

production. Author's photo.

This is the company's first flag, as it was

awarded one star six months after this one was awarded. This flag

was presented to the company on July 28, 1944, "for the splendid turrets

delivered by the thousands you have contributed to the magnificent

records of our Flying Fortresses times without number." These were

the words of Brigadier General Orval Cook as he spoke to 3,000 persons

gathered at the award ceremony. The turrets General Cook was

speaking of were the B-17 top deck turrets that was the main product of

the company during World War Two. Author's photo.

Author's photo.

The Steel Products Engineering Company is

one of the many unrecognized American industrial heroes that contributed

to the winning of World War Two. Its main World War Two product,

but not its only product for the war effort, was the license-built

Sperry Gyroscope Company's A-1, A-1A, A-1B, and A-1C B-17 top deck

turret. Steele Products Engineering is overlooked by historians

due to the fact that Emerson Electric in St. Louis, MO also built the

same turrets along with many other types of turrets in an immense

factory dedicated to turret production.

In 1908, Mr. Joe McAdams formed the

Steel Products Engineering Company in Springfield, OH as a tool and die

shop. As time progressed, the company took on contract work and

expanded its business into making special machinery and other industrial

products. In the 1920s and 1930s the company had contracts with

both the War Department Air Corps and the U.S. Navy. War

Department contracts included the manufacture of aircraft propeller hubs in

1920, the manufacture of winches for airships in 1923, and several

contracts in the late 1920s for the reconditioning of Liberty aircraft

engines. In the late 1930s the company had contracts from the Navy

for generators, an auxiliary power unit, engine cylinder assemblies, and

starter systems. Steel Products Engineering Company was no stranger

to contracting for different products when World War Two arrived.

In 1936 the company merged with Combustioneer,

Inc. of Springfield, OH, which was a company that produced automatic

coal burners and stokers. This was the era when many homes and

companies in the United States were heated with coal.

In 1955, the company was purchased by the

Kelsey-Hayes Company and focused on the manufacture of jet engine parts.

For Steel Products Engineering, this was a good move as American

households and commercial buildings were converting to natural gas to

replace coal for heating. The manufacture of coal stokers was a

product line with no future. I distinctly remember in the early

1950's when the house I lived in was converted as I remember having a

conversation with the technician that was doing the work. During

this period the company became known as the SPECO Division of

Kelsey-Hayes. Afterwards, no matter the owner of the company, it

was referred to as SPECO. During this period SPECO's employment

reached 2,200 employees as one its main products was gears for

helicopters used in the Vietnam War.

In 1973, with the end of the Vietnam War and

the end of gear making for war-time helicopters, Kelsey-Hayes sold its

SPECO Division to Fruehauf Corporation. In 1987, Grabill Aerospace

purchased SPECO. Grabill filed for bankruptcy in 1989 and sold

SPECO to SNECMA in 1992, which then closed the operation in May 1996.

The equipment in the manufacturing plants was sold to a California

company. In 2004, the company's former plant complex at 1205 West

Columbia Street was razed for redevelopment.

The Steel Products Engineering Company World War Two Products:

This company made a diverse number of products to help win World War

Two. Table 1 shows that Steel Products Engineering had $47,032,000

in major contracts from the U.S. Army and Navy during World War Two.

$43,820,000 was for gun turrets and gun turret assemblies, which was 93%

of its total contracts. These contracts were for the upper deck

gun turret for the B-17 bomber. The company also made variable

pitch propeller blade hubs, engines, and air conditioning units for the

U.S. Navy. For the U.S. Army it made several types of trailers and

bomb racks. The company also made bomb sight mounts, tools, dies, jigs,

and fixtures. It had another facility located in the

Springfield, OH area that did experimental aircraft work.

Table 1 - Steel Products

Engineering Company's Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Blades Hubs

Propeller - Navy |

$103,000 |

9-1940 |

2-1942 |

| Vacuum

Chamber Equip - Army |

$65,000 |

1-1941 |

12-1941 |

| Racks - Bomb

- Army |

$750,000 |

2-1941 |

6-1942 |

| Gun Turret

Assemblies - Army |

$14,588,000 |

10-1941 |

2-1944 |

| Cones

Nuts - Navy |

$95,000 |

3-1942 |

12-1942 |

| Air

Conditioning Units - Navy |

$231,000 |

3-1942 |

5-1942 |

| Trailers Semi

- Army |

$57,000 |

4-1942 |

6-1942 |

| Engines -

Navy |

$300,000 |

6-1942 |

12-1943 |

| Turret

Assemblies - Army |

$3,622,000 |

7-1942 |

7-1944 |

|

Airplane Equipment - Army |

$258,000 |

8-1942 |

8-1943 |

| Turret

Assemblies - Army |

$4,504,000 |

1-1943 |

12-1943 |

| Hand Turret

Controls - Army |

$441,000 |

5-1943 |

9-1943 |

| Adapter Kit

Assemblies - Army |

$100,000 |

6-1943 |

11-1943 |

| Gun Turret

Assemblies - Army |

$15,651,000 |

9-1943 |

9-1944 |

| Airplane

Equipment - Army |

$100,000 |

12-1943 |

6-1944 |

| Airplane

Modify Kits - Army |

$182,000 |

4-1944 |

10-1944 |

| Airplane

Parts - Army |

$50,000 |

6-1944 |

6-1945 |

| Airplane

Turrets - Army |

$5,455,000 |

6-1944 |

11-1945 |

| Airplane

Turret Parts - Army |

$480,000 |

10-1944 |

5-1946 |

| Total |

$47,032,000 |

|

|

While Table 1 shows the first contract for gun

turret assemblies was issued in October 1941, Steel Products Engineering

Company actually became involved with the manufacture of Sperry

Gyroscope Company's A-1 top deck turret for the B-17 bomber. In

December 1940, Sperry had a contract from the Army Air Corps for 540

units but did not have the manufacturing capability to make the heavy

castings and then machine them. The Steel Products Engineering

Company, started in 1908 as a tool and die shop, had the necessary

equipment. Sperry chose Steel Products Engineering as a

subcontractor to do this work. Steel Products had six A-1 partial

turrets done and ready to ship to Boeing in Seattle, WA by February

1941. Once the fire interrupter control units arrived from Sperry,

they were installed, and the complete units were sent to Boeing.

Because Steel Products Engineering Company

built the first 540 A-1s for the B-17, it was only natural that in

October 1941, Steel Products Engineering Company would receive an Army

Air Corps contract to build more A-1 top deck turrets under license from

Sperry.

The A-1, A-1A, and A-1B had six different

types of domes for the turrets, as shown in Table 2. From the

information in the Table 2, it is possible to obtain a minimum number of

turrets that Steel Products Engineering Company produced during World

War Two, which is 3,238. The table also shows that Steel Products

Engineering Company and Emerson Electric were each producing about half

of the turrets.

Table 2 - A-1, A-1A, and A-1B Upper Deck Dome and Turret

Serial Numbers - Emerson Electric Company and Steel Products

Engineering Company

The information in this table comes from the " AN

11-45C-5 Handbook of Operations and Service Instructions for

Upper Deck Turrets - A-1, A-1A, and A-1B date June 30, 1944,

with revision January 10, 1945. |

|

Dome Number |

Dome Serial Numbers |

Emerson Turret Serial Numbers |

Number of Emerson Turrets |

Steel Products Turret Serial

Numbers |

Number of Steel Products Turrets |

| 1 |

SG-959 |

- |

- |

SP1 - SP722 |

722 |

| 2 |

J210835 |

E1 - E2700 |

2,700 |

- |

- |

| 3 |

SG-938 |

- |

- |

SP723 - SP1640 |

918 |

| 4 |

SP-4530 |

- |

- |

SP1641 - SP2320 |

680 |

| 5 |

SP-4600 |

- |

- |

SP2321 - SP3237 |

917 |

| 6 |

AG-1100 and SP-4700 |

E2701 to end |

1+ |

SP3238 to end |

1+ |

| |

|

Totals |

2,701 |

|

3,238 |

The information below looks at two different

methods of estimating the total number of turrets Steel Products

Engineering Company produced during World War Two.

The historical record indicates that by April

1943, Steel Products was tooled up to produce 250 A-1 top deck turrets

per month. If the company ran at this rate for the next 27 months

until the end of B-17 production in July 1945, it could have produced

6,750 B-17 top deck turrets. The first contract for $14,588,000

was released in October 1941. At some point after this, the

company would have started ramping up production until it was fully

tooled to produce 250 units per month.

The original contract that Sperry was issued

in December 1940 for its A-1 turret was for a total of $3,879,000, or

$7,185 per turret. If the $7,185 is used as a rough estimate for

the amount Steel Products Engineering Company was paid for each turret,

($47,032,000/$7,7185) this would show that the company built 6,545

turrets. This number of turrets could be low, because as the war

continued and the company gained experience in building the devices, the

cost would have declined.

Two different methods show that Steel Products

Engineering Company built at least 6,000 B-17 top deck turrets during

World War Two. It supplied approximately half of the turrets

required for the 12,731 B-17s built during the war. This also fits

well with the information in Table 2 that indicated the company was

producing about half of the B-17 top deck turrets. Steel Products

Engineering Company was a significant supplier for turrets in World War

Two. These included the A-1, A-1A, A-1B, and A-1C, which was

exclusively built by Steel Products Engineering Company.

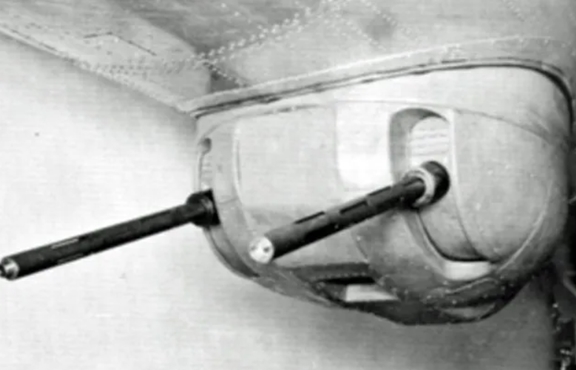

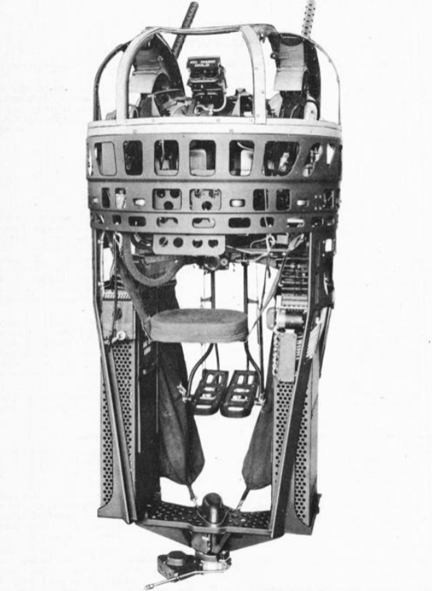

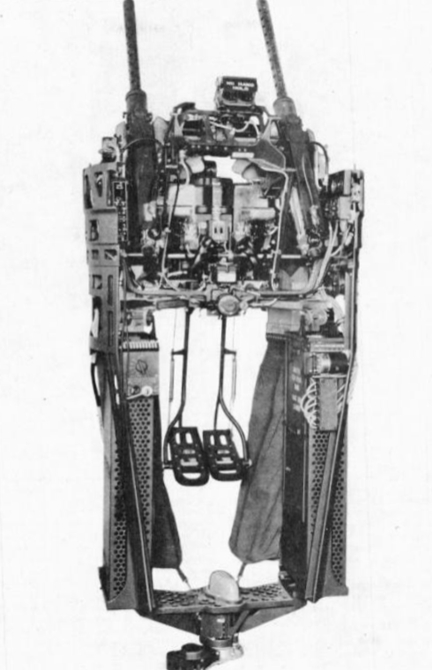

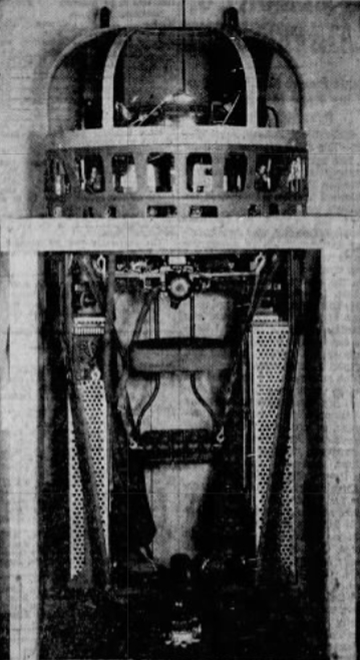

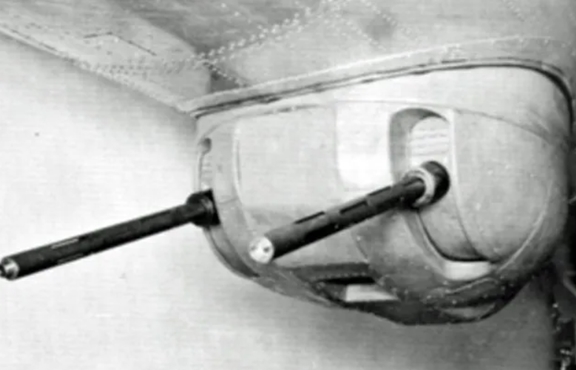

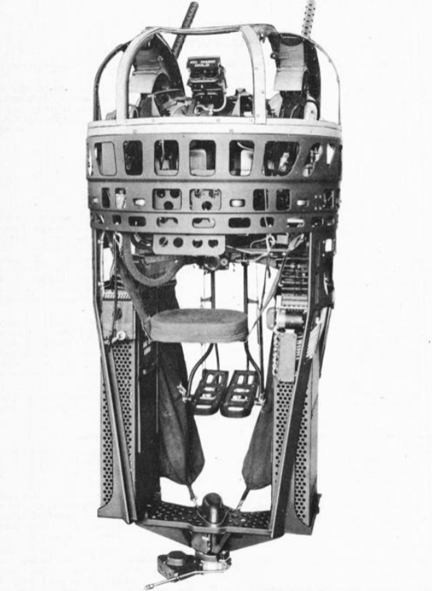

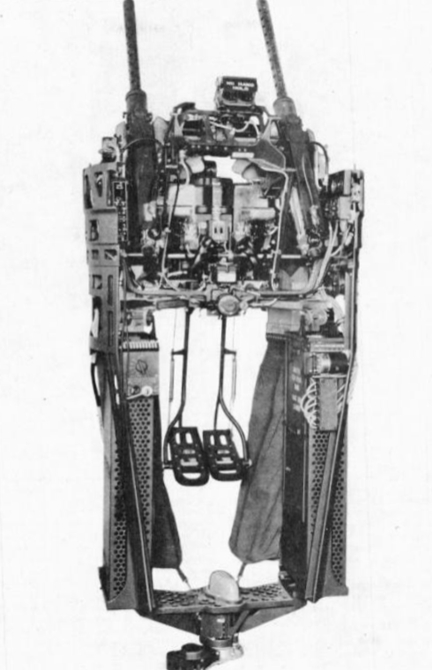

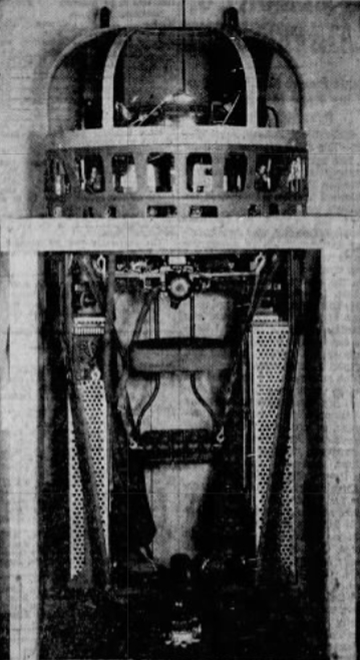

This A-1 upper gun turret is on display at

the National Museum of the United States Air Force. This

particular unit was manufactured by Emerson Electric, which was the

other supplier of the turret. Steel Products Engineering Company's

turrets would be identical. To make sure this happened, Steel

Products and Emerson Electric visited each other's plants on alternate

weeks to make sure the parts for their respective turrets were

interchangeable with the other company's parts.

The historical record shows that along with

the original six A-1 top deck turrets that Steel Products Engineering

Company sent Boeing in Seattle, WA, it also had also assembled Sperry

six lower remote control turrets, which were also shipped to Boeing.

By the end of 1941, Steel Products had

produced a total 111 top deck turrets and 91 lower remote turrets.

In total, Steel Products manufactured 112 lower deck remote turrets

installed in B-17Es, serial numbers 41-2393 through 41-2504. Many

of these B-17s were sent to the southwest Pacific. B-17E 41-2429

arrived over Pearl Harbor on the morning of December 7, 1941. It

later flew General MacArthur's staff out of the Philippines on March

25,1942. On August 7, 1942, it was shot down over Rabaul.

B-17E 41-2430 was also arrived at Pearl Harbor on December 7, 1941.

It was shot down on June 25. 1943 while on a night mission to Rabaul.

Steel Products Engineering Company built the

Sperry remote lower deck turret that was installed on B-17s 41-2393

through 41-2504.

There is a 50-50 chance that the B-17F

"Memphis Belle" had a Standard Steel Products Engineering-built top deck

turret when it did its famous 25 missions over Europe.

Table 3 - Steel Products

Engineering Company's Major World War Two Aircraft Gun

Turret Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. |

|

Product |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Gun Turret

Assemblies - Army |

$14,588,000 |

10-1941 |

2-1944 |

| Turret

Assemblies - Army |

$3,622,000 |

7-1942 |

7-1944 |

| Turret

Assemblies - Army |

$4,504,000 |

1-1943 |

12-1943 |

| Gun Turret

Assemblies - Army |

$15,651,000 |

9-1943 |

9-1944 |

| Airplane

Turrets - Army |

$5,455,000 |

6-1944 |

11-1945 |

| Total |

$43,820,000 |

|

|

This and the next two photos are more images

of the Sperry A-1 top deck turret on display at the National Museum of

the United States Air Force. Author's photo.

Author's photo.

Author's photo.

Steel Products Engineering Company made

improvements to the A-1 turret. The new turret was designated as

the A-1C, and Steel Products Engineering Company was the only producer of

this type. However, it was too late in the war to be introduced

into production.

This image from April 1945shows a Steel Products

Engineering Company-built turret in a department store display window in

Springfield, OH.

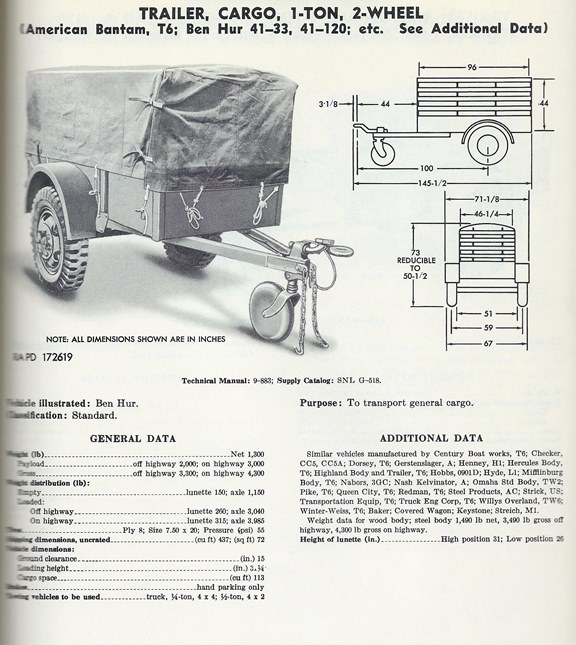

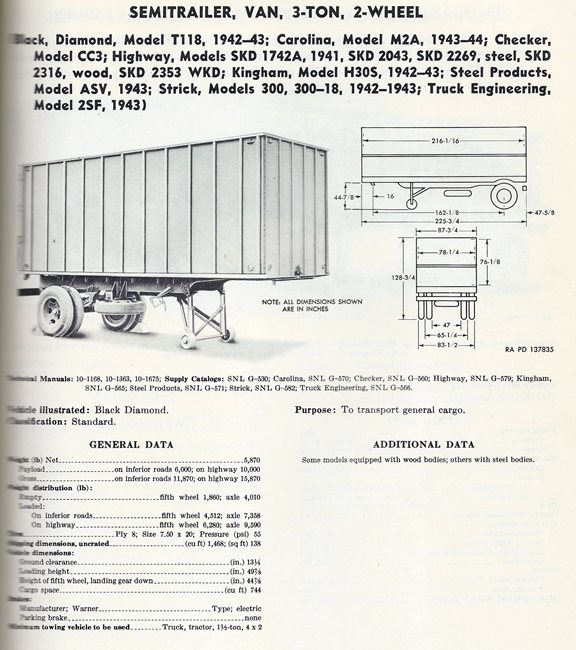

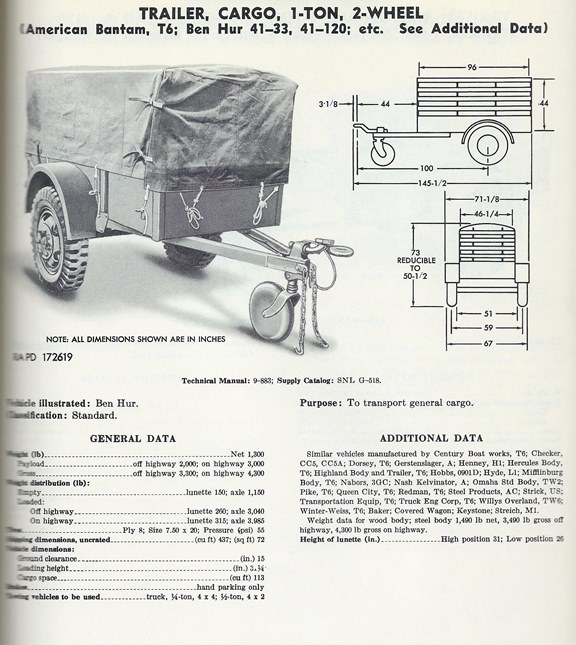

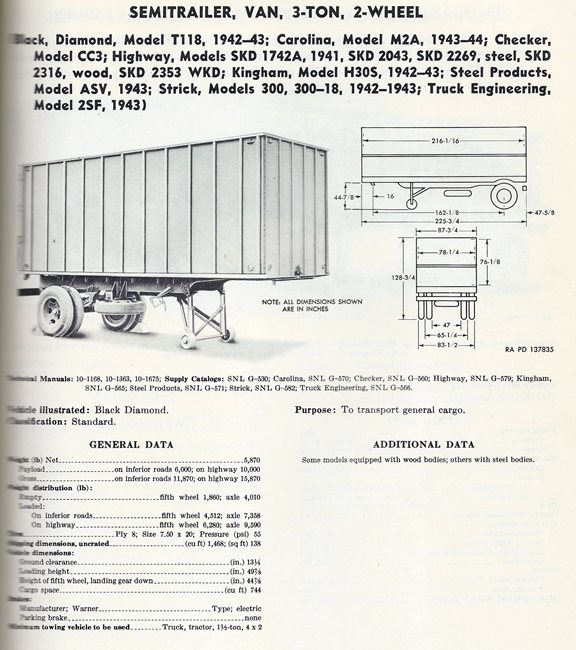

The semi-trailer contract in Table 1 for

$57,000 issued 4-1942 was Army Quartermaster contract 445L. Table

4 shows that Steel Products Engineering Company actually had four

different contacts for trailers of three different types. For

whatever reason, three of the contracts were not included in the Major

Contract Listing. The construction of trailers is another example

of the ability of Steel Products Engineering Company to make various

types of products for the war effort. The company built a total of

2,283 trailers for the war effort.

Table 4 -

Steel Products Engineering Company World War Two Trailers Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

Contract Number |

1942 |

1943 |

1944 |

1945 |

Total |

| Trailer, 1-Ton, 2 Wheel,

Cargo |

134-776 |

|

1,048 |

954 |

|

2,002 |

| Semi-Trailer,

12-ton, 2W, Low Bed |

DA445 |

44 |

|

|

|

44 |

| Semi-Trailer,

12-ton, 2W, Low Bed |

W489 |

|

36 |

|

|

36 |

| Subtotal |

|

|

|

|

|

80 |

| Semi-Trailer,

3-ton, 2W, Van |

W706 |

|

301 |

|

|

301 |

| Total |

|

44 |

1,385 |

954 |

|

2,383 |

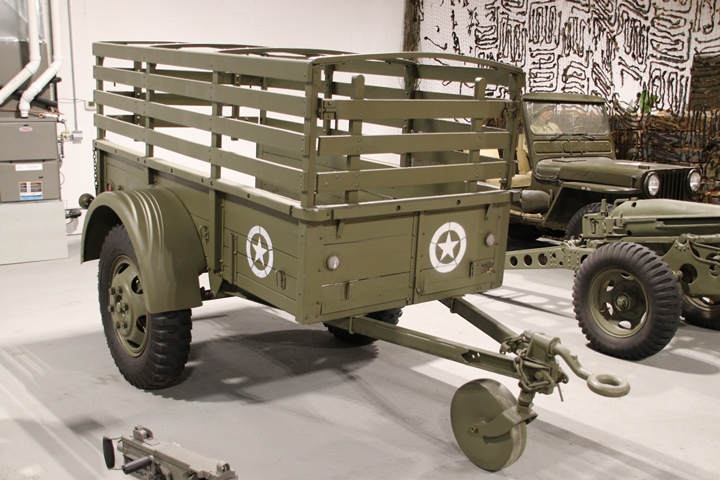

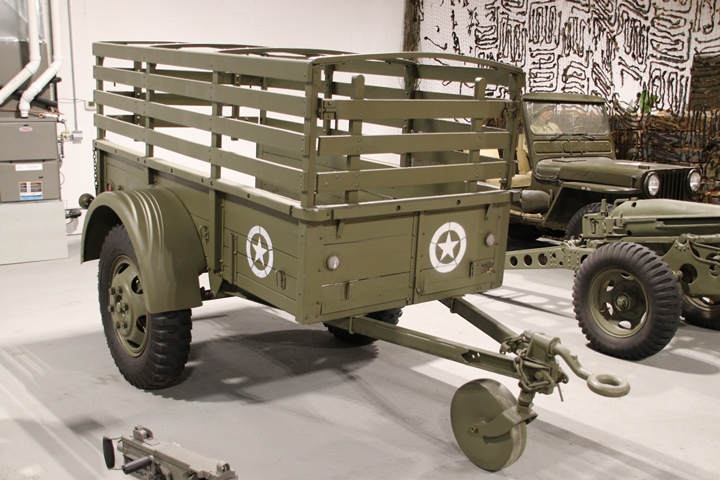

This is an example of a World War Two era

one-ton two-wheel cargo trailer like Steel Products Engineering Company

manufactured. Author's photo.

Steel Products Engineering Company built

2,002 one-ton

two-wheel cargo trailers during World War Two. It was one of

several companies that made this type of trailer.

Steel Products Engineering Company built 301

3-ton, 2-wheel semitrailers.

Steel Products Engineering Company was a

subcontractor for the Eastern Aircraft Division of General Motors.

Eastern Aircraft built 7,546 TBM torpedo bombers for the U.S. Navy.

Steel Products Engineering Company supplied four different part numbers

to Eastern Aircraft. These were fuel filler cap assemblies, part

numbers M34067, M34183, M34357, and M34056. Author's photo.

Steel Products Engineering Company

Factories:

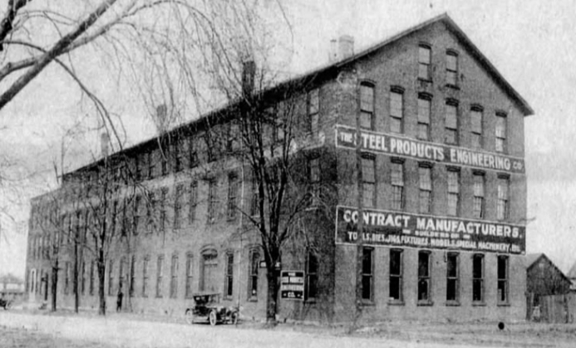

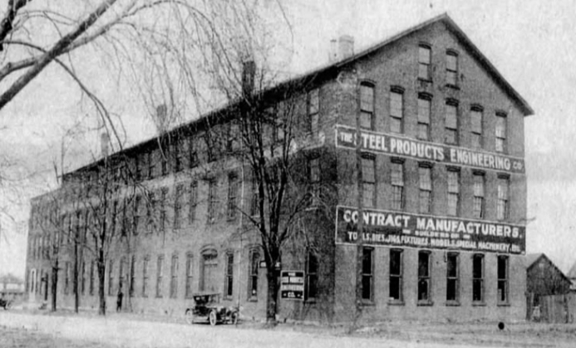

This is the original Steel Products

Engineering Company factory at the corner of Columbia Street and Dakota

Avenue in Springfield, OH. Built in 1917, the was 100 feet long building

was built of steel and brick to be fireproof. This

replaced another building the company had at this location.

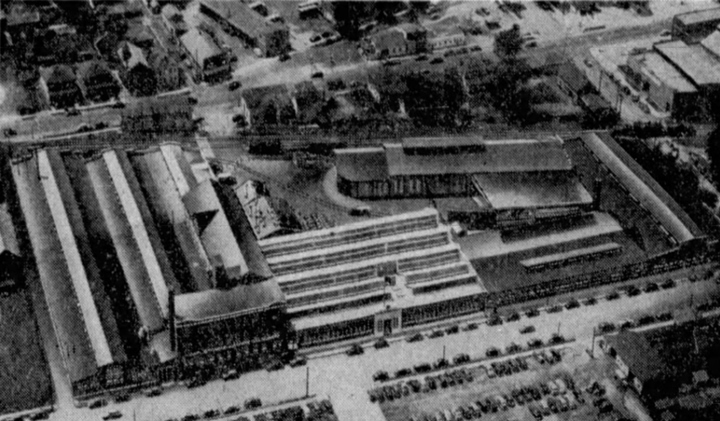

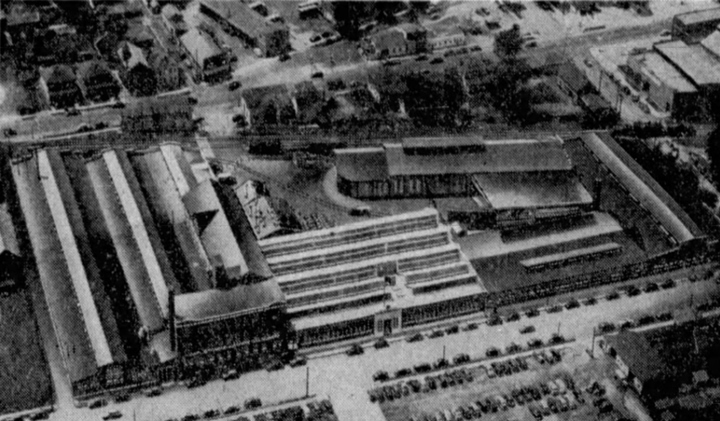

This is the main Steel Products Engineering

Plant in 1944. This was known as Plant 1 and covered 5.834 acres

at 1205 Columbia Street in Springfield, OH. The 1917-built

three-story plant is in the lower left hand corner.

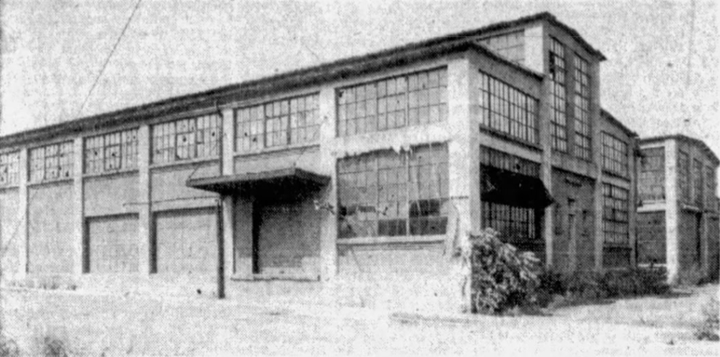

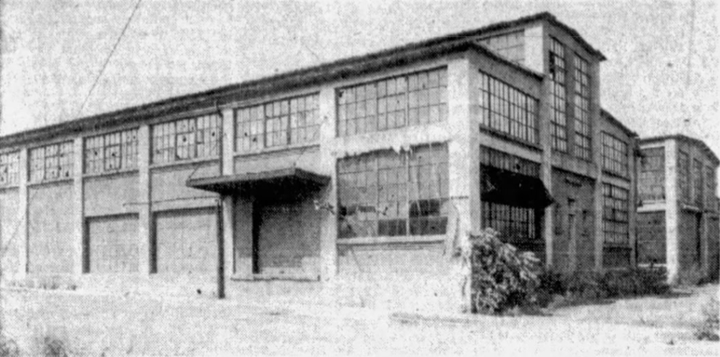

In August 1940 Steel Products Engineering

Company purchased the former C. and L.E. Traction Company plant in

Springfield, OH for future expansion.

During World War Two, the company utilized

the former C. and L.E. Traction company for War Production. It was

designated as Plant 2.

In the 1970s the company opened a third plant

on Baker Road on the west side of Springfield, OH. This was the

last location from which the company operated before its ultimate

closure in 1996.

Surviving B-17s: Forty six B-17s still

exist. Half of them should have top deck gun turrets made by Steel

Products Engineering Company.

Some of the B-17s are on static display like

this one at the USAF Armament Museum. Author's photo.

Others are undergoing restoration like this

one at the Museum of Aviation. Author's photo.

Author's photo.

A few B-17s still fly and can be seen at

flying events like the Spirit of St. Louis Airshow. Author's

photo.

|