|

Hudson

Motor Car Company in World War Two

Detroit, MI

1909-1954

Rest in Peace

This page updated on 1-30-2020. Hudson started production

in 1909. In 1954 it merged with Nash-Kelvinator to form

American Motors. The last Hudson, actually with a Nash

nameplate, was

produced in 1957. Hudson's Main Plant was located on East

Jefferson Avenue and Connors in Detroit, but no longer exists.

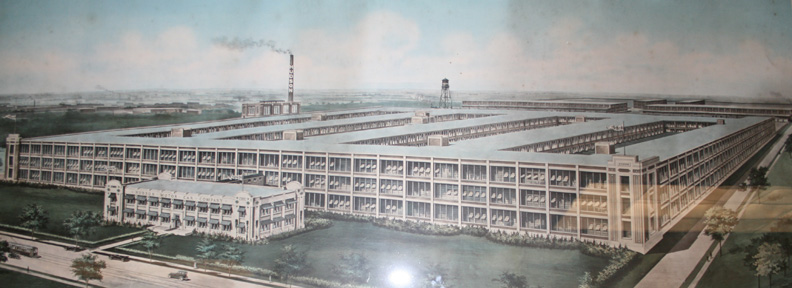

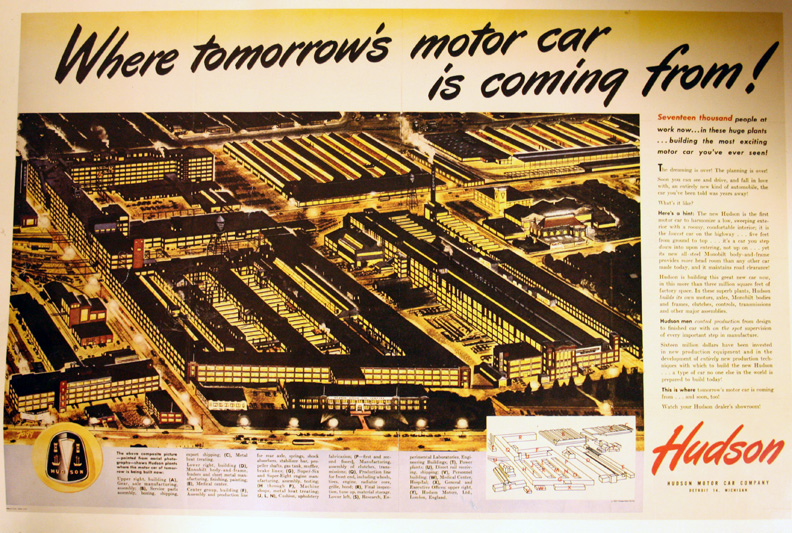

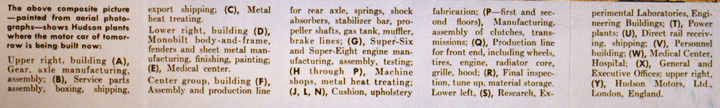

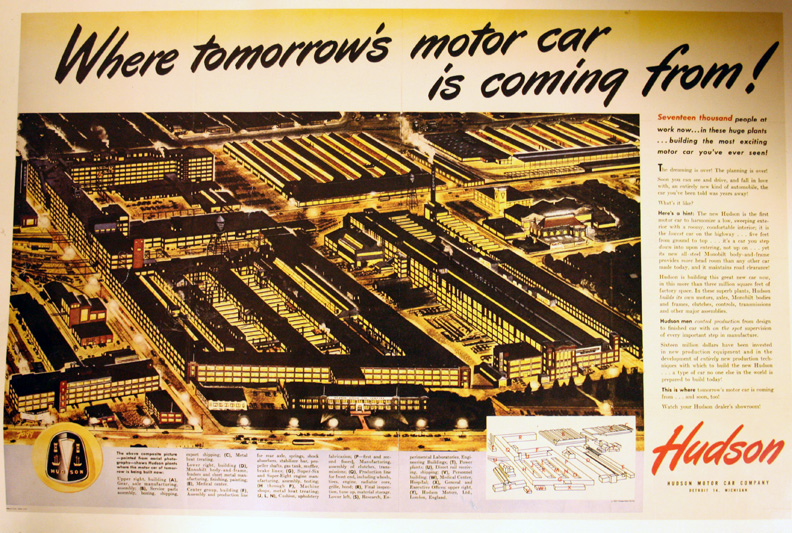

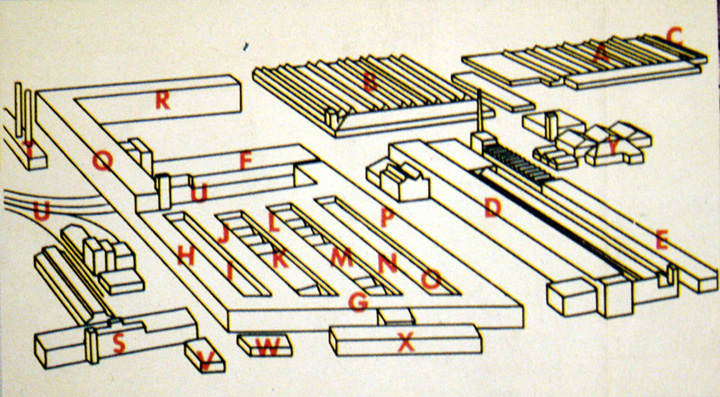

The Hudson Motor Car Company looking

Northwest. East Jefferson is the road in the foreground. This

is probably a pre WWII drawing.

Hudson Airplane Division, Main Plant, won the

Army-Navy "E"

Award twice during WWII.

Hudson Motor Car Company World War Two Production Statistics:

The World War Two production is shown below in the table,

chronologically listed by Hudson start date. Note that Hudson primarily made airframe components for the

B-26, SB2C, P-63, P-38 and B-29. The atmosphere on the production

floor at Hudson must have been intense, starting in mid-944 with the

added B-29 rear fuselage and wing production. In just over a

year's time, it had to produce enough B-29 components for 531

aircraft. This was the most expensive project of the war, being

more expensive than the Manhattan project. (See the Martin B-29

production schedule at the bottom of this page.) Hudson accomplished

this while also making P-38 and SB2C wings. This was a production

miracle on the part of the Hudson Motor Car Company in World War Two!

|

Hudson Motor Car Company World War Two Production Numbers |

| Dates |

Product |

Number built |

Comments |

| 2-41 to ? |

P-47 ailerons |

? |

The first aviation contract. |

| 7-41 to 10-43 |

20mm Oerlikon anti-aircraft guns |

(33,201) |

The contract was

abruptly

canceled by the US Navy and the contract given to Westinghouse. |

| 9-41 to 1-45 |

Aluminum pistons for Wright aircraft engines |

(1,030,000) |

|

| 9-41 to 1-45 |

Rocker arm assemblies

Wright aircraft engines |

(1,460,000) |

|

| 3-42 to 3-44 |

B-26 Marauder rear

fuselage sections |

(1,891) |

Fuselages

were supplied to the Martin plant in Omaha, NB, which built 1,585

B-26 Marauder twin engine bombers before converting to B-29

production in May 1944. |

| 6-42 to

9-42 |

37mm armor piercing shells |

(310,551) |

|

| 12-42 to

9-44 |

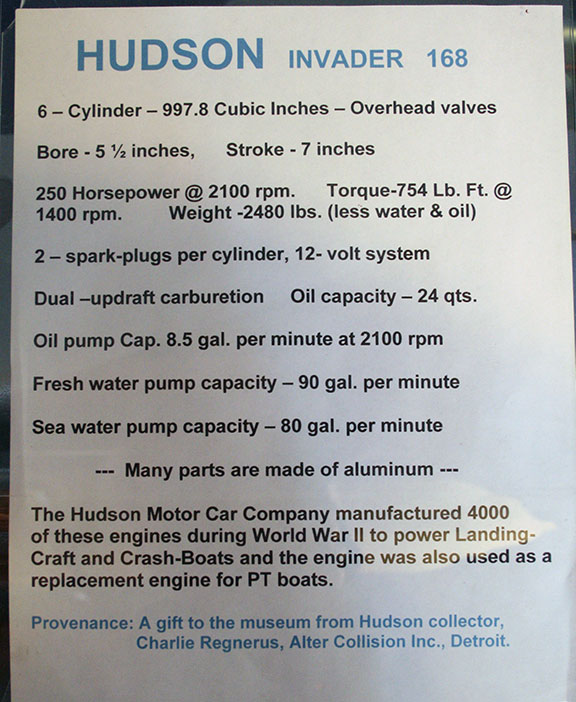

License built Hall-Scott 250 hp Invader Marine Engines |

(4,000) |

|

| 1-43 to 8-45 |

SB2C Helldiver wing sets |

(4,250) |

|

| 3-44 to 8-45 |

P-63 King Cobra cabins |

(3,041) |

|

| 7-44 to 5-45 |

P-38 Lightning Wing sections |

791 sets |

Records

stop at the end of May but production is assumed to have continued

through August 1945 so the number of P-38 wing sets would have been

at least 1,000. |

| 7-44 to 8-45 |

B-29 rear fuselages |

(802) |

Martin

built 531 B-29 bombers at Omaha, NB which at first glance would

indicate that Hudson built more than enough rear fuselage sections

for aircraft. However, information presented below shows that

the company provided three different sections as part of the rear

fuselage, which is a total of 1,593 total fuselage components. This would have

been an aggressive production program for Hudson. As also

noted below the first B-29 came off the production line at Omaha in

May 1944.

Hudson would have had to started shipping components in April for them to be available for Martin's Start of Production. |

| 7-44 to 8-45 |

B-29 outboard wing sections |

? |

As shown

below this included the leading edge, wing section, aileron and wing

tip. Hudson supplied the Martin B-29 plant in Omaha, NB where the

first of 531 B-29s came off the assembly line in May1944.

Hudson would have had to produced 1,062 of each wing component. This, along with the B-29

fuselage production by Hudson would have stretched its production

capability to the utmost. |

My research has uncovered references to Hudson building the following

parts during WWII. However, I have not yet been able to

substantiate that Hudson actually built them during WWII. The

unsubstantiated parts are: Hercules DNX

diesel engine components, ammunition boxes, aircraft engine starter

parts, tank components and fighter drop tanks.

This is the B-29 "Enola Gay", now on display at the Steven F. Udvar-Hazy Center of the Smithsonian Air and Space Museum in Chantilly,

VA. It is famous for being the aircraft that dropped the first atomic

bomb on Hiroshima, Japan. Significantly, the rear

fuselage sections, wing tips, outer wing sections, outer wing leading

edges and ailerons were built in Detroit, MI by the Hudson Motor Car

Company. As shown below, Hudson was one of many auto companies and

their suppliers to contribute major components to the B-29s built at

Martin's Omaha B-29 plant. Martin Omaha built the B-29

"Silverplate" nuclear bombers, including the "Enola Gay" and

"Bockscar", the Superfortress that dropped the second atomic bomb on

Nagasaki, Japan. In

the photo above, Hudson built the two fuselage sections that extend from

behind the wing to the tail gun position, and the outboard

wing sections, and leading edge wing sections.

The wing tip is not visible in this photo. Author's

photo added 11-12-2015.

This photo gives a view of the

Hudson built rear fuselage sections, the outer wing section, ailerons,

and the wing tip on the B-29 "Enola Gay". Author's

photo added 11-12-2015.

Prior to making the B-29 rear fuselage

section, Hudson had been supplying the same component for the Martin

B-26 Marauder. When Martin converted to

the B-29, the company contracted the same suppliers previously used for

the Marauder. For Hudson, moving to the larger and more

complicated B-29 rear fuselage was no trivial task. Ultimately,

Hudson provided at least 802 rear fuselages for the 531 B-29s built in Omaha.

As there are no known production numbers for wings components available,

it has to be assumed that Hudson provided B-29 outer wing components on time and in

the needed quantities. While it is immaterial 75 years later, I always try and clean up the loose ends.

I can not do it in

this case. If new information becomes available during my

research, I will update the page.

In any event, Hudson was taxed to the limit

to provide all of these complicated B-29 components.

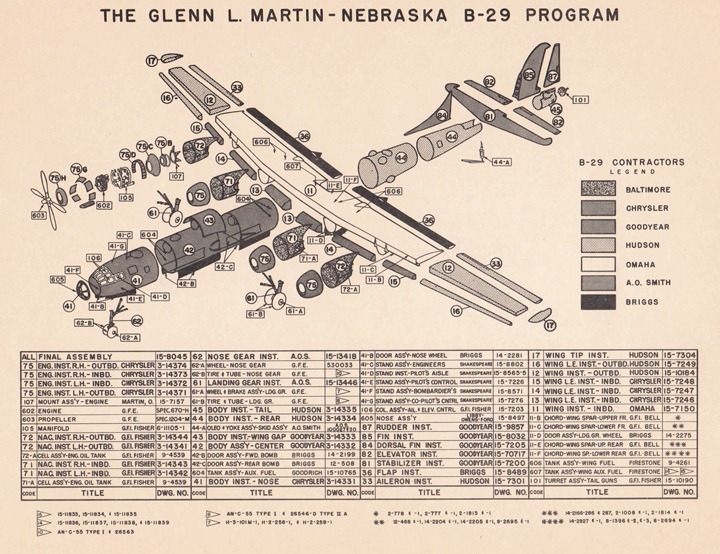

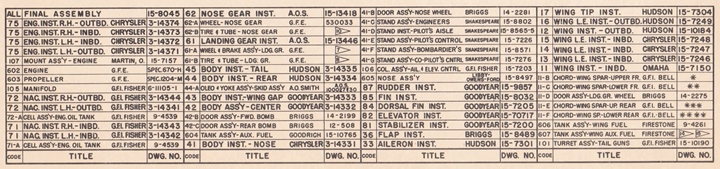

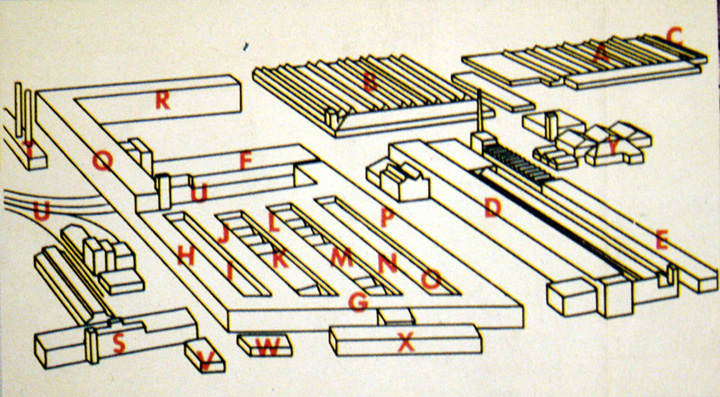

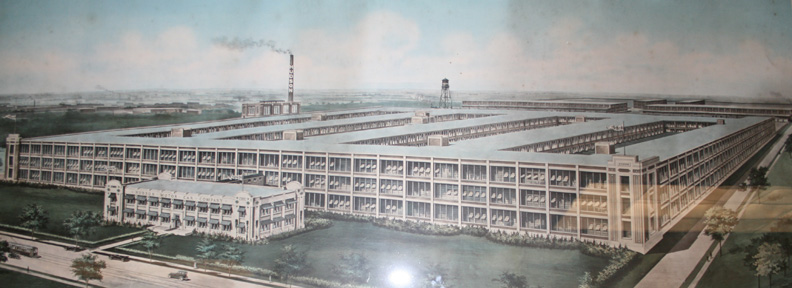

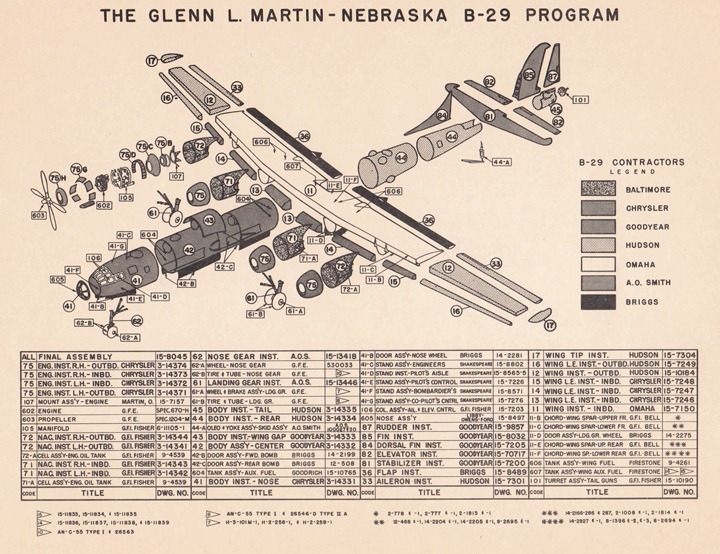

In this Martin supplier diagram Hudson is

shown as the supplier for components #12, #16, #17, #33 #44(2) and #45.

Hudson supplied these components as per the

Martin nomenclature.

#12 - Wing Inst-Outboard

#16 - Wing LE Inst - Outboard (Leading Edge)

#17 - Wing Tip Inst.

#33 - Aileron Inst.

#44 - Body Inst. - Rear (2 sections)

#45 - Body Inst. - Rear

With the Glenn

Martin Omaha, Nebraska B-29 Program diagram shown above, supplied by B-29

historian Chris Howlett of the UK, it is now evident that Hudson's

involvement as supplier for the Omaha, NB built Superfortress was significantly beyond what was previously known. It was a major supplier.

The following photos are in the order

from

the start of production.

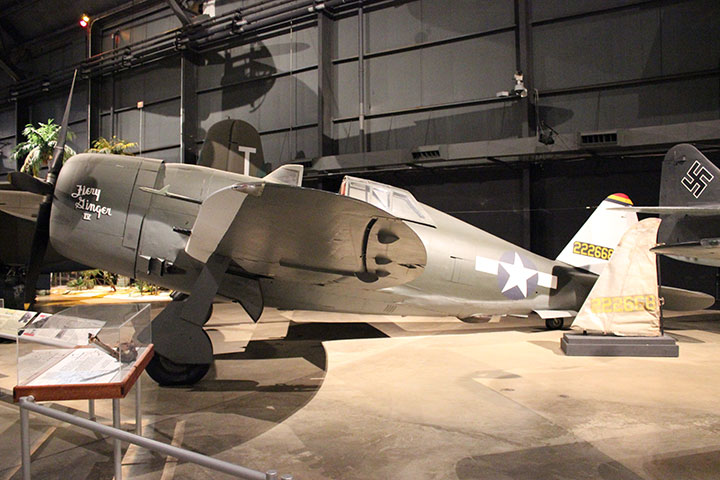

Hudson's first military contract starting

February 1941 was for Republic Aircraft P-47 ailerons.

They can be seen being constructed in the Hudson plant.

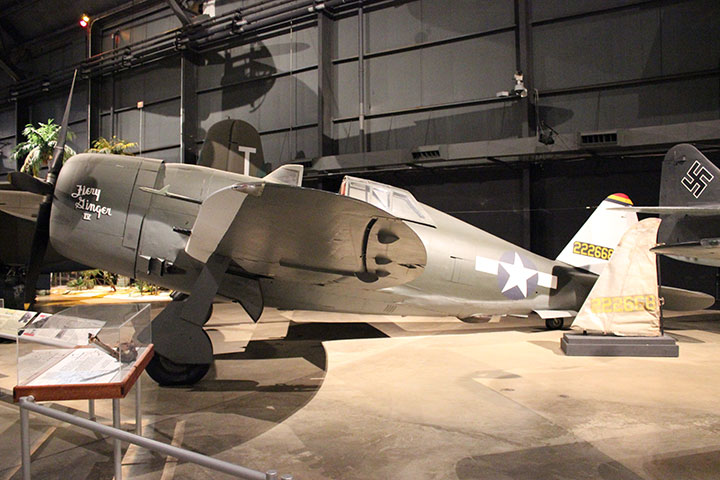

The wings on the Republic P-47 are

semi-elliptical, as can be seen in this photo. The ailerons,

located at the end of wings, have the same shape. Author's photo

from the National Museum of the US Air Force.

An unknown number of the P-47 ailerons were

produced by Hudson early in the war, or even before the US became

involved. Author's photo.

Author's photo.

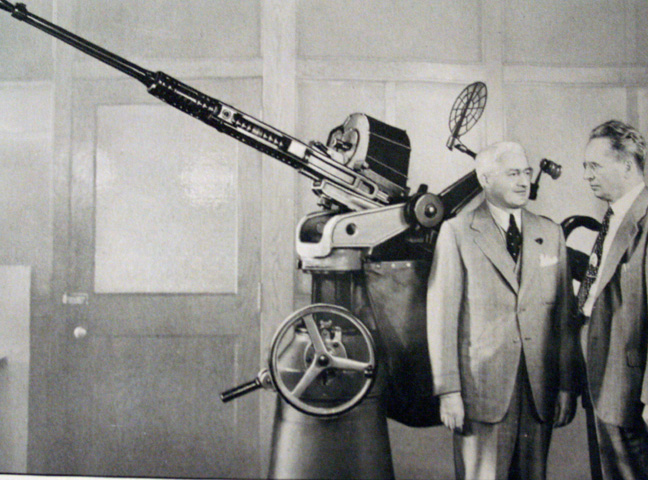

During the Second World War Hudson also operated a

Government built Navy Ordnance Plant in Centerline (Warren), MI for the manufacture of 33,201

20mm Oerlikon anti-aircraft guns. This was a $20,000,000 plant

built in 1941 that began production July. Originally it was a

400,000 square foot facility contained in 113 acres. During

construction, expanded to one million square feet. At the same time the acreage expanded to

135 acres. The original contract was for 8,000 guns for

$14,038,500 or $14,548 per gun. Something went wrong somewhere

because even though in 1942 Hudson was the largest producer of 20mm Oerlikon

guns and hit a peak production of 2,330 units in September 1943, the US Navy terminated the contract the next month.

The business was awarded to Westinghouse. Because the Centerline

Plant and equipment in the plant belonged to the US Navy, most

likely all of the 4,000 people working there, including probably most

of the supervision were Hudson employees one month and Westinghouse

employees the next. Today, this facility is the GM Powertrain Transmission

Plant located on Mounds Road at Nine Mile Road.

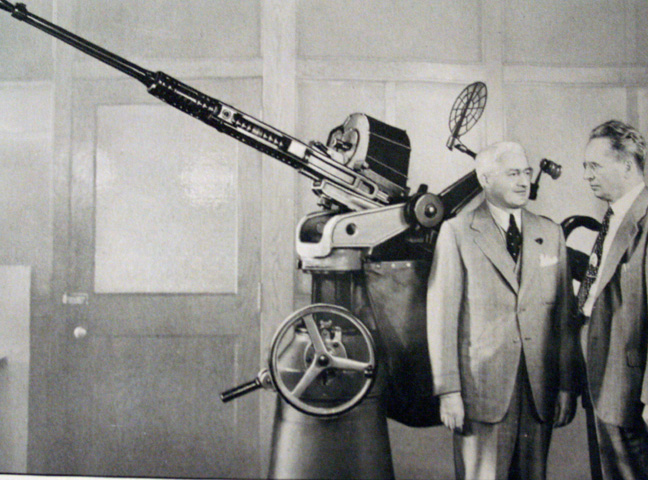

Here is one of the 33,201 20mm Oerlikon

anti-aircraft guns built at the Centerline, MI plant; first by Hudson,

and then by Westinghouse. Author's photo added 2-21-2017.

This is one of the great displays of items

built for defense by Michigan companies. It is located in The

Michigan Military Technical and History Society Museum in Eastpointe,

MI. Author's photo added 2-21-2017.

This is a Westinghouse built version, as it

has the "W" ID stamp on it. The Hudson versions were identical,

as they were produced by the same tooling, people, and plant. Only the top

management changed. Author's photo added 2-21-2017.

Some of the 33,201 20mm Oerlikon anti-aircraft

gums manufactured by Hudson at its Centerline, MI plant during WWII.

Pontiac also produced the same weapon for the Navy.

This 20mm cannon can be found on the LST-325

along the Ohio River in Evansville, IN.

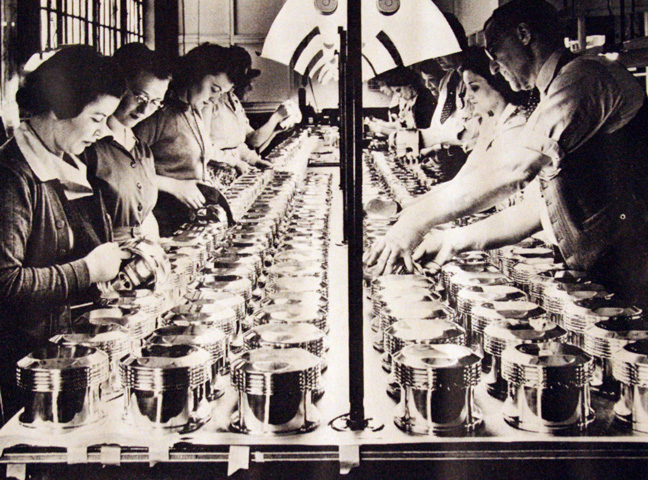

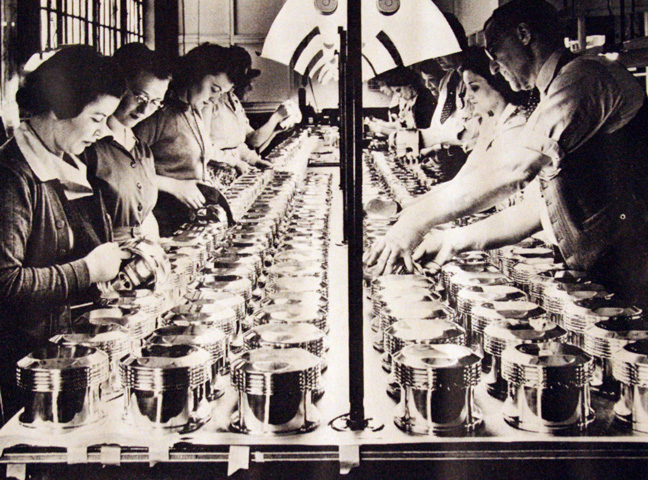

Hudson's third military contract was for aluminum pistons for Wright Cyclone

Aircraft Engines.

1,030,000 were produced at the Hudson East Jefferson plant between

September 1941 and the end of WWII.

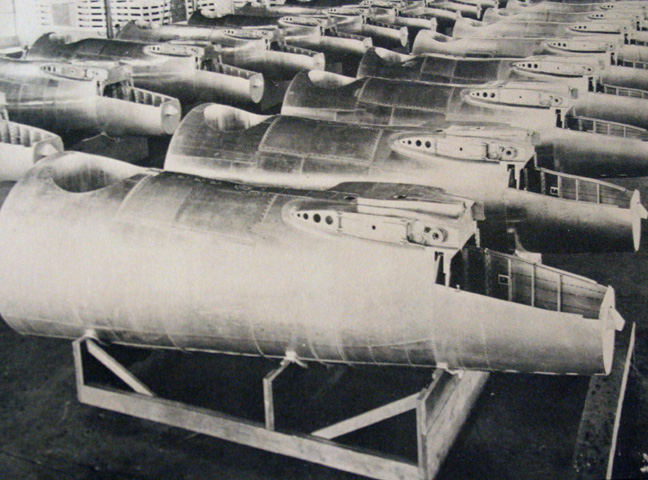

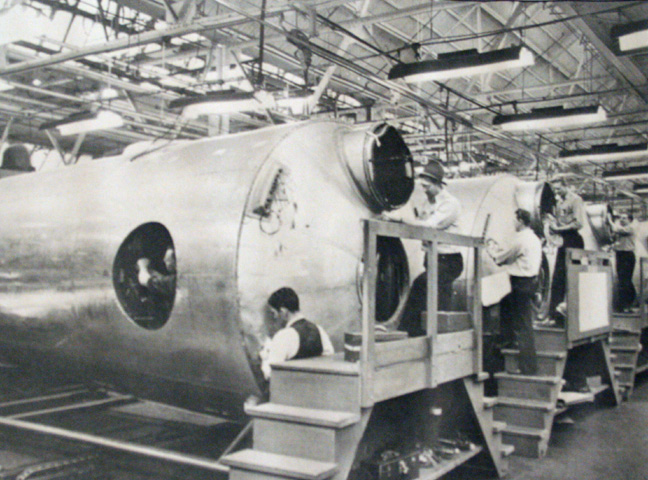

Rear fuselage sections for the Martin B-26

Marauder at the Hudson plant. The company produced 1,891 of the

airframe components during a two year period from March 1942 to March

1944.

The rear fuselage of the B-26 at the Air

Force Museum. This was the section Hudson made for the Martin Omaha

plant. Author's Photo.

The Martin B-26 at the Museum is one of two currently on display in the United States.

Both of them are in Ohio, with the second B-26 on display at the MAPS

Museum in Canton, OH.

Author's Photo.

Hudson advertised its association with the

B-26 in this World War Two advertisement. Note that the ad is

displaying the Army-Navy "E" for Excellence Award.

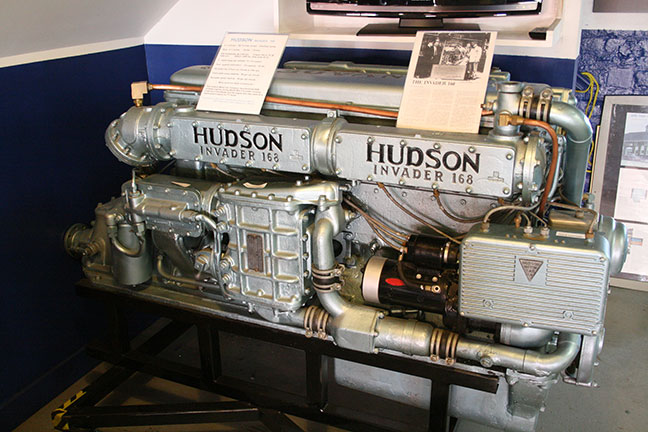

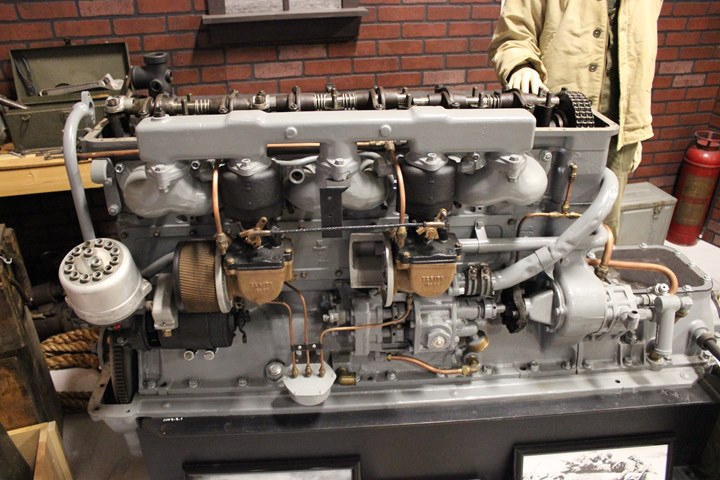

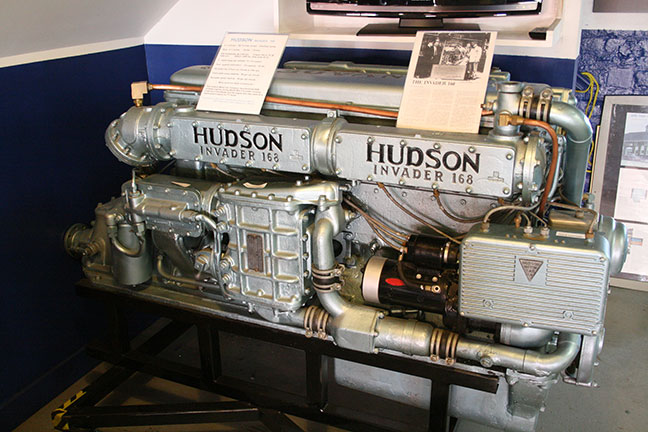

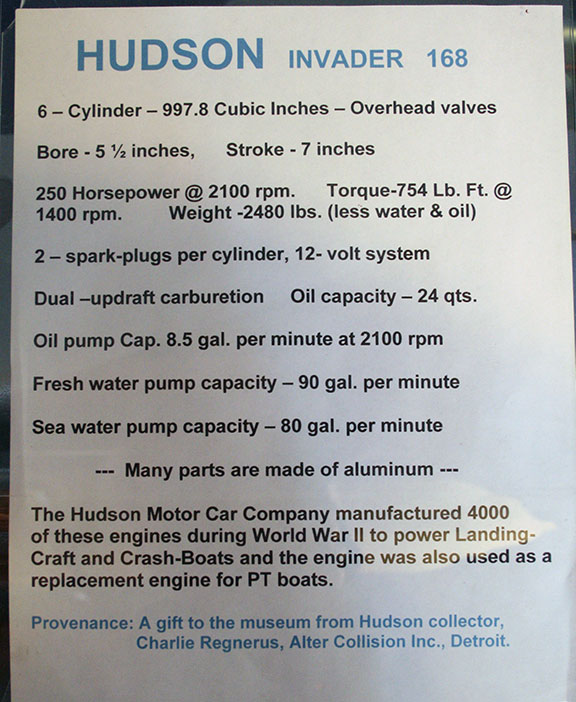

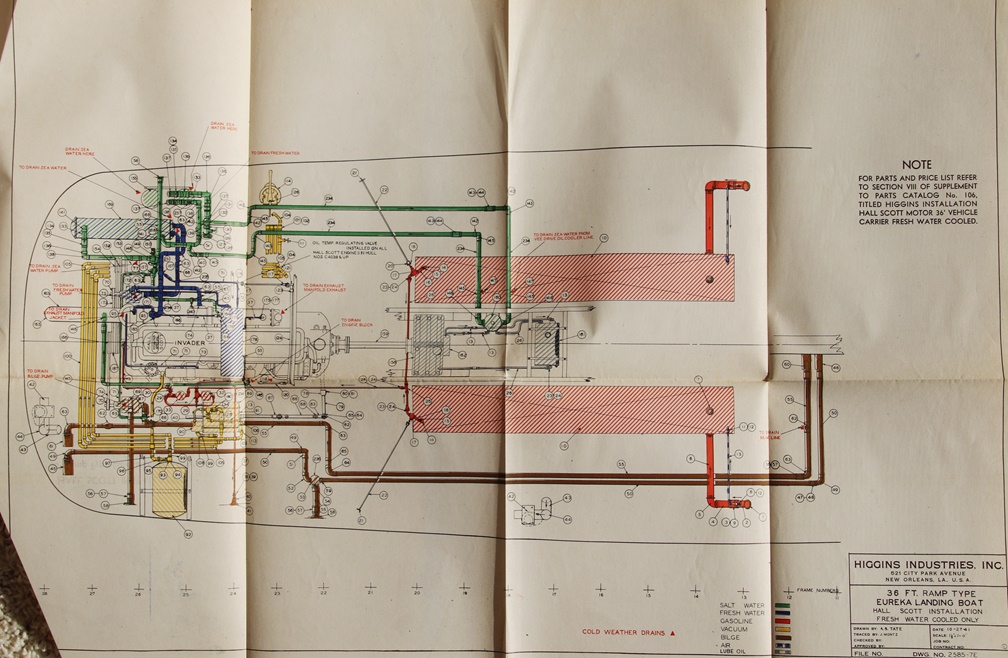

The 250hp Invader marine gasoline powered

engine shown above was a license-built Hall-Scott Motor Car Company

design. The Invader was the last engine designed by Elbert John

Hall before he left Hall-Scott in the early 1930s. Hudson took the

liberty of putting its name on the engine in several places which it

wasn't supposed to do. In the literature that specifies the

applications on the small landing craft where the engine was used, it is

identified as a Hall-Scott engine, not a Hudson. However, most Invader engines used in landing craft during World War Two were

built by Hudson. Production

of the engine ran from December 1942 until September 1944 during which time

4,000 were built for the US Navy.

Hall-Scott had been building the Invader

engine for marine applications since 1931. Once the United States

entered the World War Two in December 1941, Hall-Scott did not have the

capacity to produce the Invader engine along with the other engines the

military was needing from the company. Therefore, it made a deal

with Hudson to produce the Invader engine. The Navy specified that

the Hudson-built version of the engine obtain 250 horsepower.

Hudson's version of the engine exceeded this requirement and tested out

at 263.7 hp. The Invader Engine above is at the Ypsilanti

Automotive Heritage Museum Ypsilanti, MI. Author's Photo.

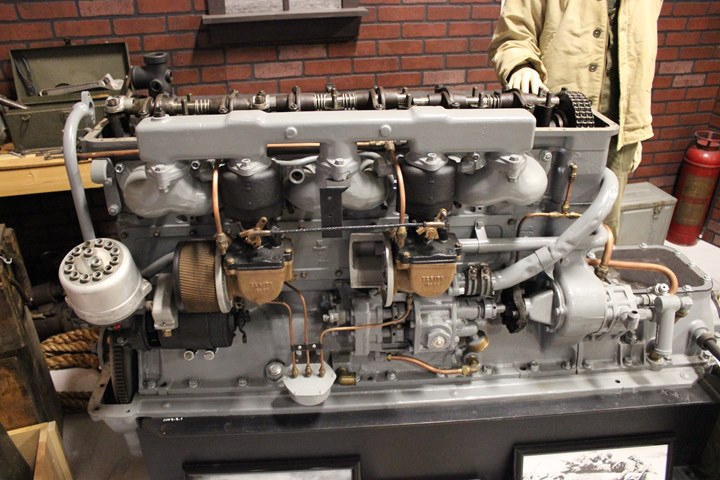

There were several differences between the original Hall-Scott Invader

and the Hudson version. The U.S. Navy required the Hudson version

to have a heat exchanger to better cool the engine, which for the Hudson

version fresh-water. Hall-Scott along with the rest of the marine

engine industry normally used salt-water cooling. In

order to manufacture the engine in its former auto assembly plant,

Hudson had to install over 6,000 fixture, quality control gauges, tools

and jigs that were shipped from the Hall-Scott plant in Berkeley, CA. It also converted 800 machine tools from its automobile

production to get tooled up between October 1942 and start of production

in December 1942.

The Michigan Military Technical and History

Society Museum has a fine example of the Hudson Invader engine on

display. Author's photo added 2-21-2017.

Author's photo added 2-21-2017.

Author's photo added 2-21-2017.

Partial Listing of Hudson-built

Invader Engines

The type landing craft the Navy ship serial numbers match-up

to is unknown. These 36-foot wooden landing craft were

LCP(L), LCP(R), LCV and LCVP. |

| Hudson Invader Engine Serial

Numbers |

U.S. Navy Bureau Of Ships Serial

Numbers |

Lot Number |

| HU-40001 to HU-40500 |

A-14729 to A-15228 |

1 |

| HU-40501 to HU-42000 |

A-16278 to A-17777 |

2 |

| HU-42001 to HU-43000 |

A-28387 to A-29386 |

3 |

| HU-43001 to HU-44000? |

?? |

4? |

The four types are shown below.

LCP(L) (Landing

Craft, Personnel, Large):

This 1944 Landing Craft, Personnel, Large (LCP(L))

was the first type of landing craft that Andrew Higgins designed.

This particular boat was built by Higgins Industries in New Orleans in

October 1944, and is currently on display at the National WWII Museum in New Orleans.

It has returned home for museum visitors to see. It is the

only one on display left in the world. Author's photo.

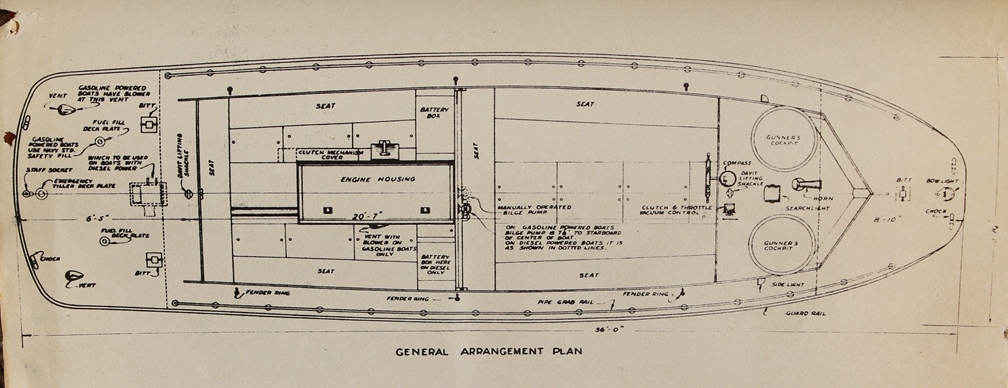

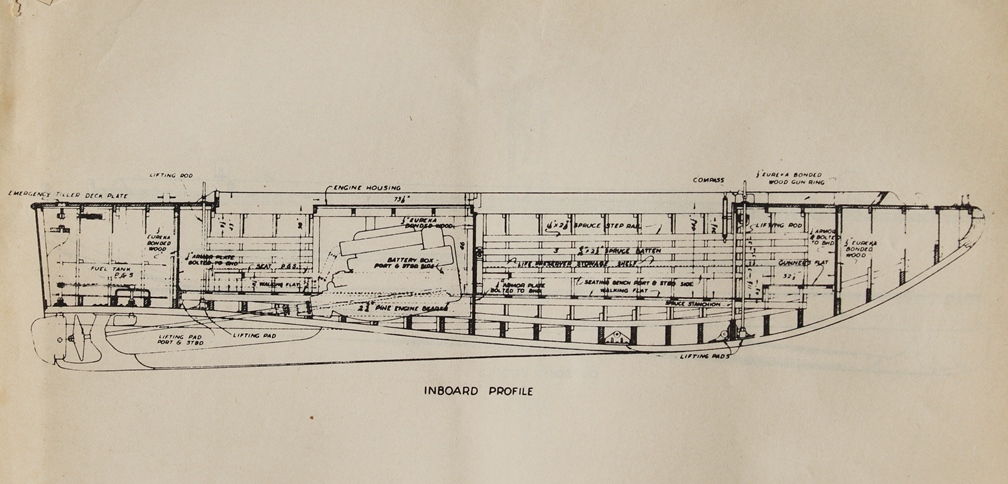

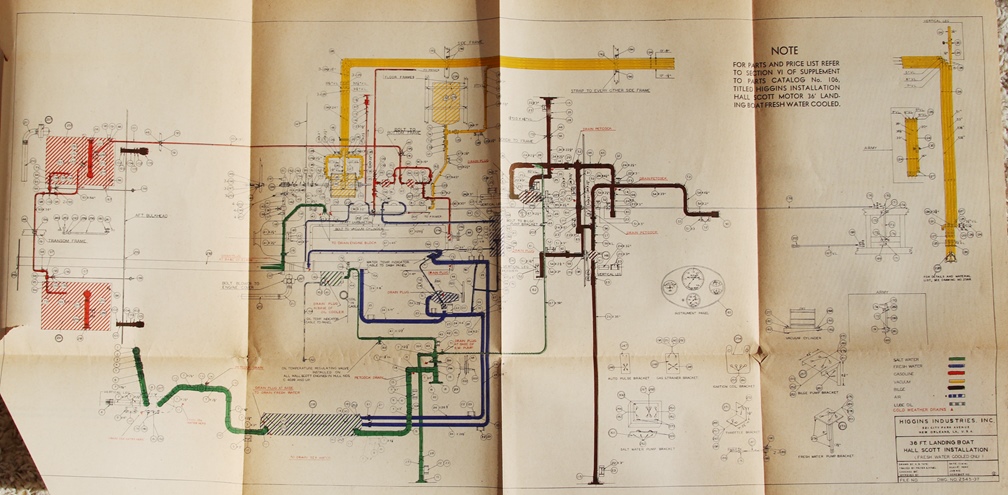

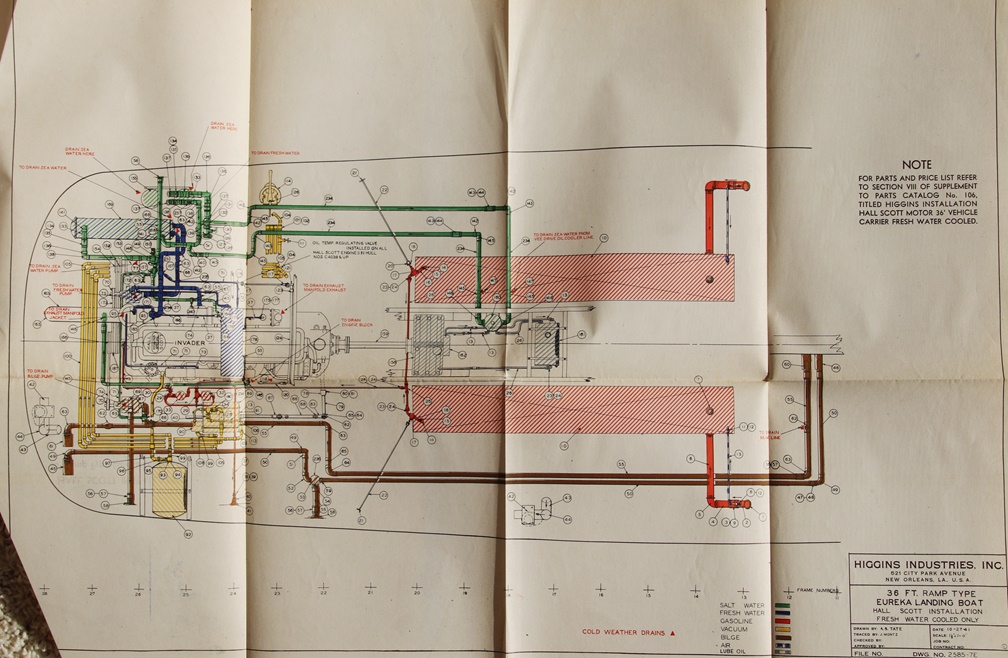

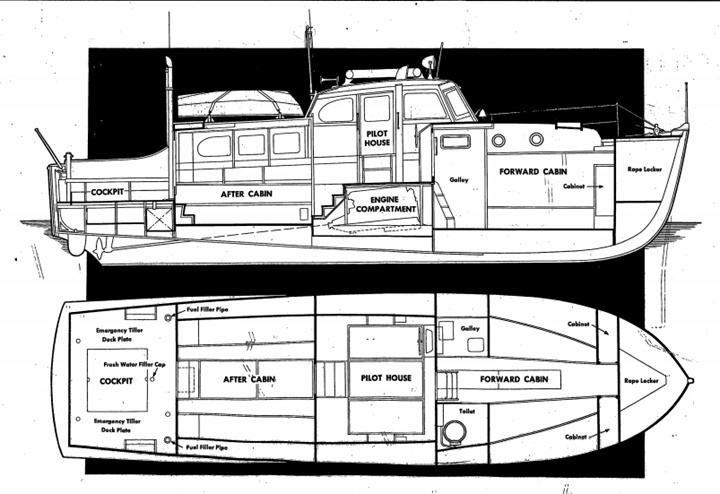

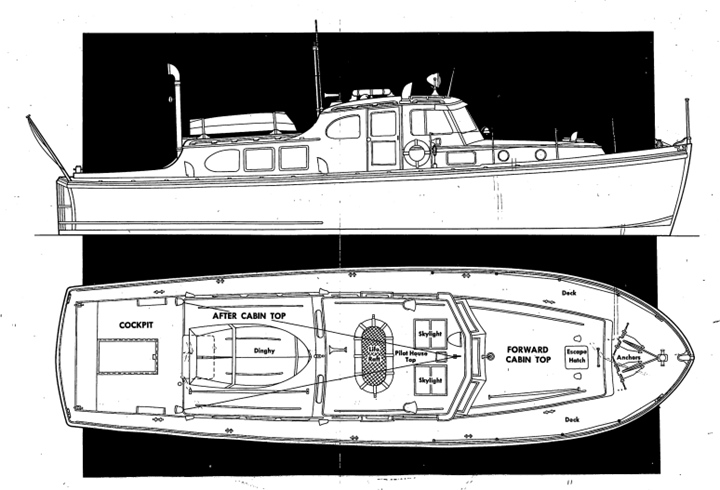

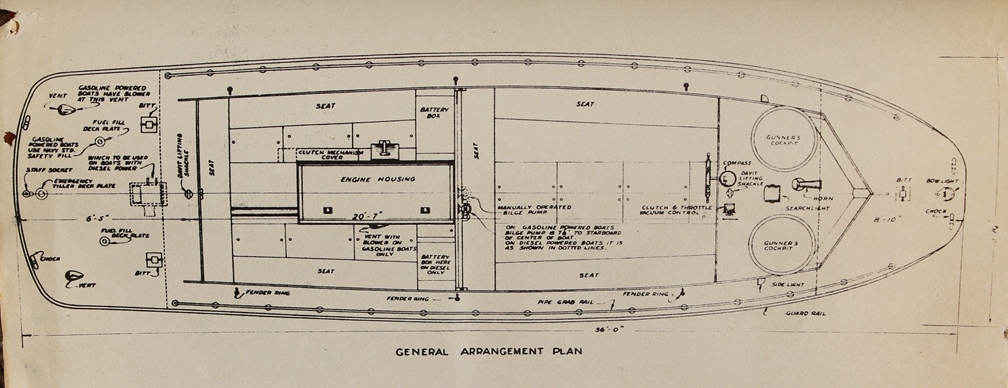

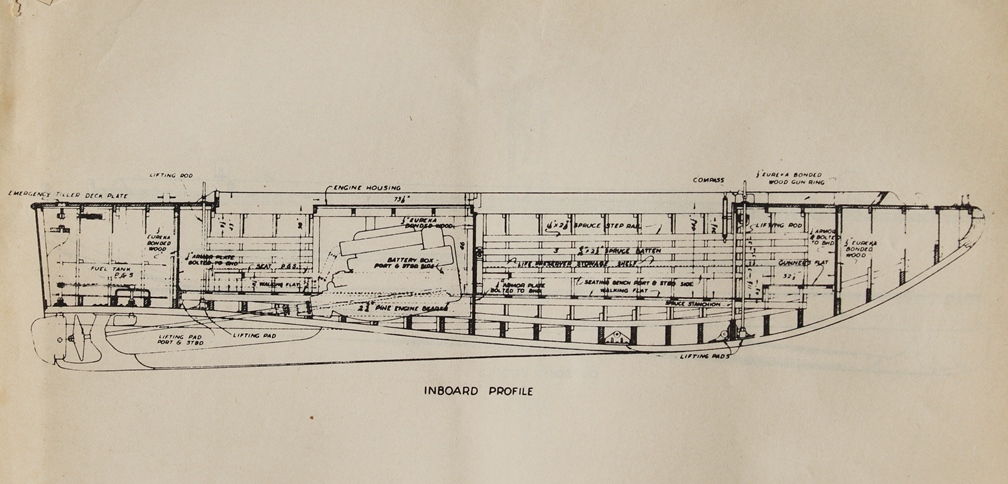

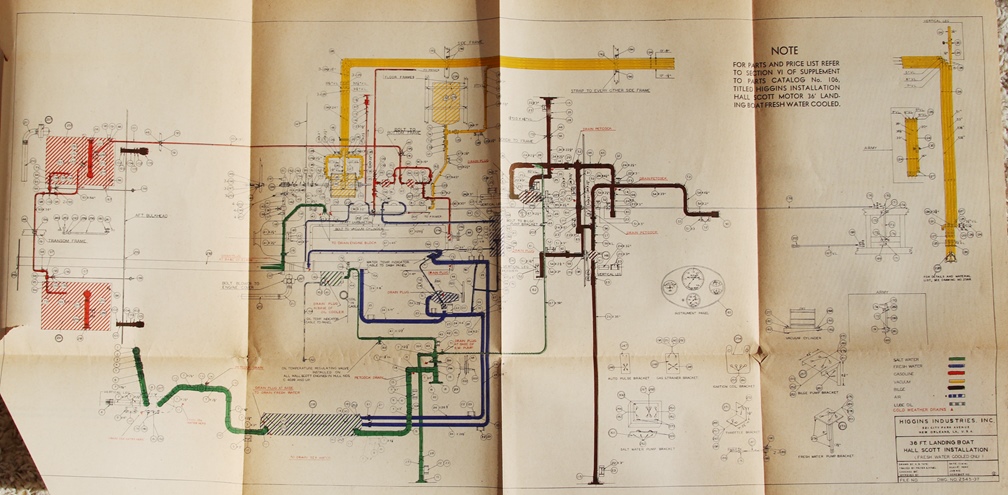

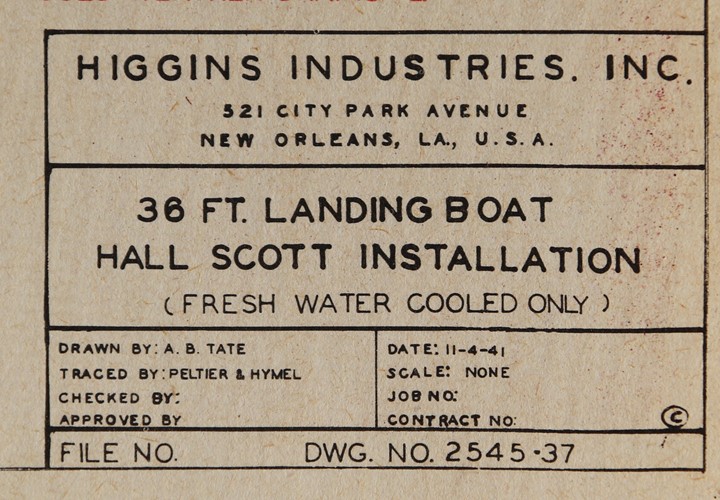

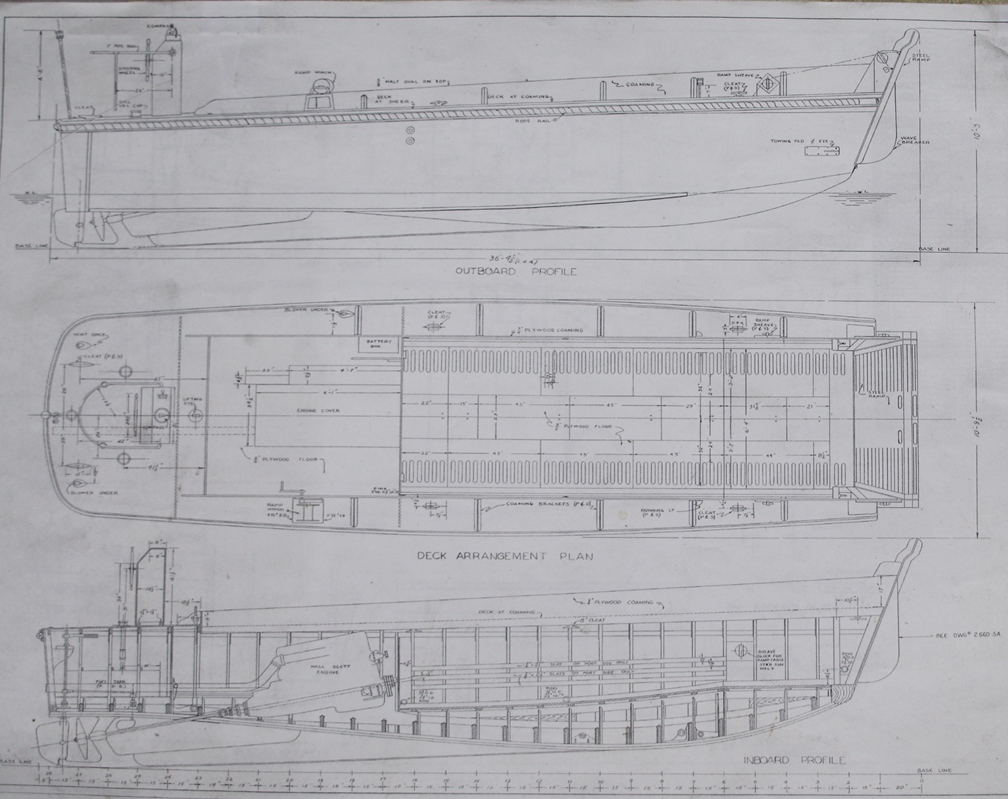

The engineering drawings below show the engine

placement in the LCP(L) and the plumbing for a Hall-Scott Invader fresh

water cooled engine. While the engineering drawings show the

engine as Hall-Scott, it was actually the Hudson-built Invaders that

were used in this landing craft. Hudson built the freshwater

cooled version of the Invader. The engineering drawings below were

drawn up when in late 1941 before Hudson became involved in the Invader

program.

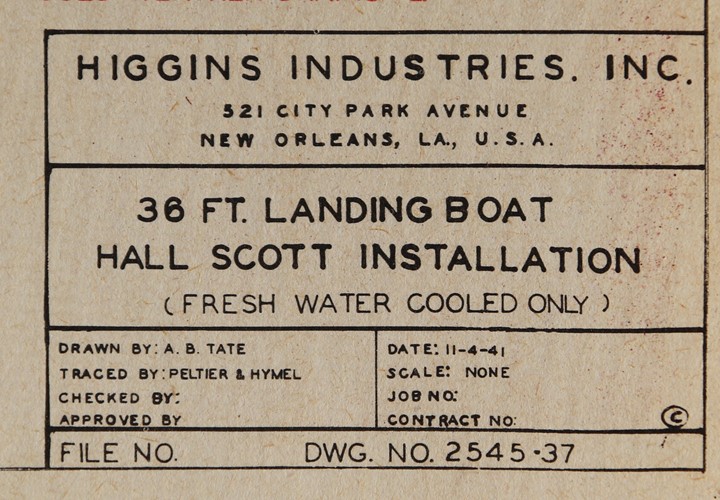

Engineering drawing added 1-30-2020.

Engineering drawing added 1-30-2020.

Engineering drawing added 1-30-2020.

Engineering drawing added 1-30-2020.

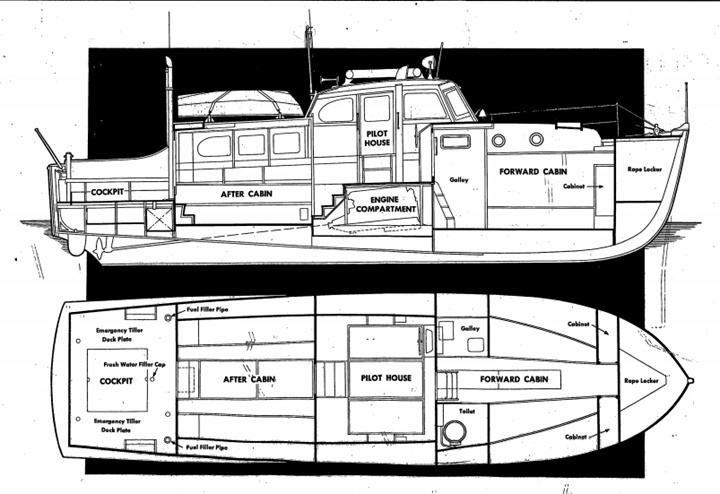

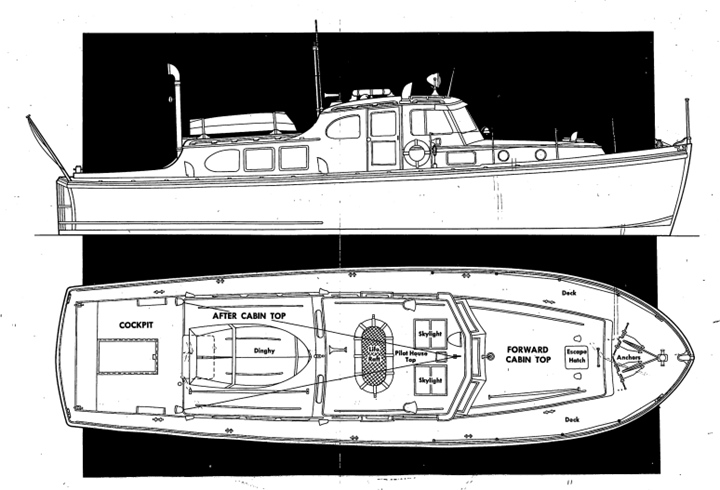

LCV (Landing Craft, Vehicle):

There were 2,633 LCVs built between 1941

and 1943 by Higgins Industries, Chris-Craft, Richardson, and Owens Yacht.

While not built in the

quantities of the LCVP, LCVs saw duty in early American invasions in

World War Two such as Guadalcanal and North Africa. It continued to be utilized even after the LCVP

became the dominant landing craft later in the war.

There are several key differences

between the original LCV and the later LCVP that can be seen in the

photo above and the outline drawing for the LCV shown below.

The most obvious is the coxswain's station, which on the transom of

the LCV. It was moved into the boat on the LCVP. Note

the ramp winch is also located in an exposed position on the port

side of the LCV. In later models of the LVCP it was moved down into the boat

to protect the crewman operating it from hostile fire.

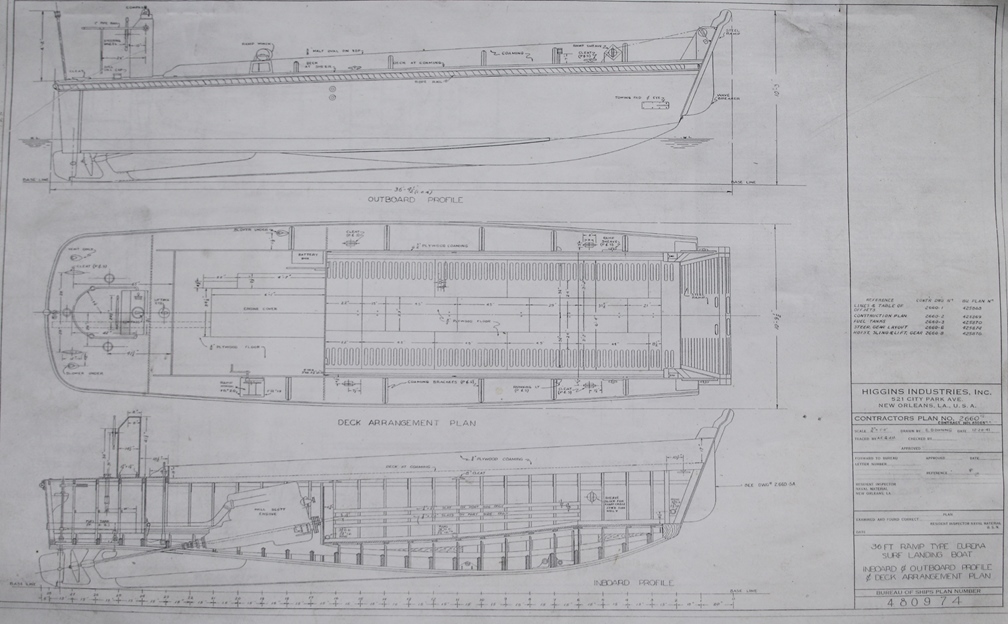

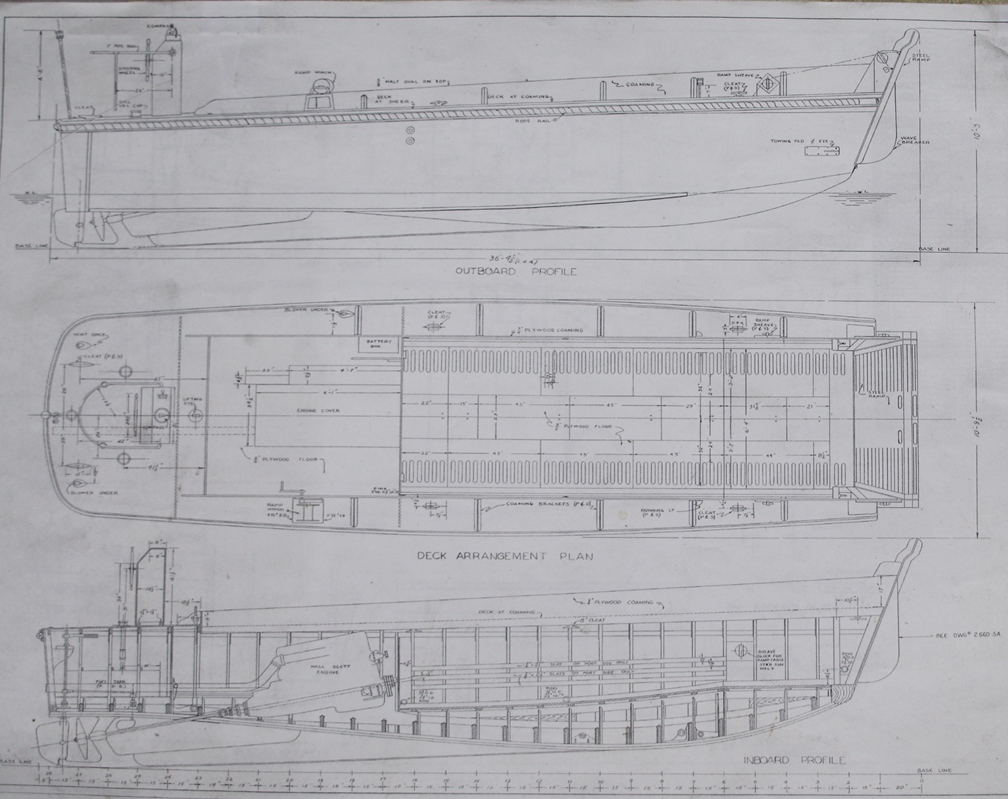

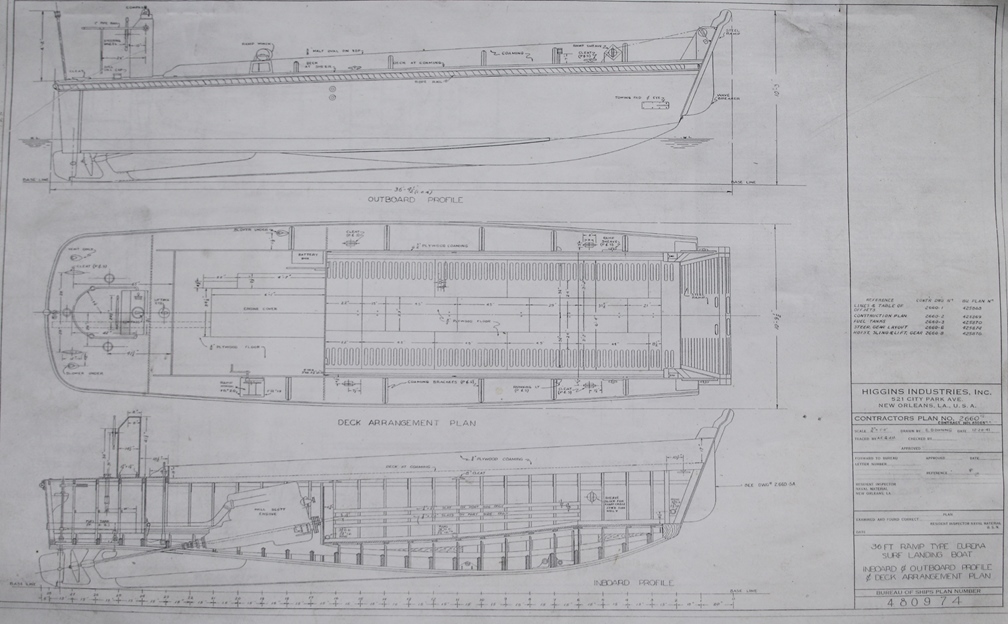

The name given to the LCV at the time of

this drawing on 12-29-1941 was 36 Foot Ramp Type Eureka Surf Landing

Boat. The drawing calls out for a Hall-Scott engine.

Because the date of the drawing is a year before Hudson began production

of the Invader engine the original drawings and engineering layouts were

done with Hall-Scott engines. Engineering drawing courtesy of C. Robert Gillmor added

1-30-2020.

The length of the boat was 36 feet and

4-1/2 inches. It was 10 feet and 9 inches in height, and 10

feet and 9-1/2 inches wide. The engine shown is a Hall-Scott

168 Invader six-cylinder gasoline powered engine. Engineering

drawing courtesy of C. Robert Gillmor added 1-30-2020.

Engineering drawing added 1-30-2020.

LCVP

(Landing Craft Vehicle Personnel):

Both the licensed Hall-Scott Invader engine

and the LCVP started volume production in 1943, so it would appear that

most of the Hudson Invader were used in the LCVP. However, there were 23,358 LCVPs built and only

4,000 Hudson-built Hall-Scott Invader gasoline engines, so they

were in the minority. For combat operations, the US Navy preferred

diesel engines, for which the Gray Marine/Detroit

225hp marine

engine was the engine of choice. LCVPs equipped with the Invader engine were used

extensively in the US

for training purposes.

This replica LCVP is located at the National World

War Two Museum in New Orleans, LA. Hudson license built Hall-Scott

gasoline powered marine engines were used when the preferred Gray

Marine/Detroit Diesel engines were not readily available. The Navy

preferred the diesel as it

was used to power its larger ships. Diesel is also not as volatile of a fuel as

the gasoline, making it safer. Landing craft like these with the

Invader engines would have been used in training on the US coasts

allowing the Gray Marine/Detroit Diesel engines to be allocated to the

combat zones. Author's Photo.

LCP(R) (Landing Craft, Personnel, Ramp):

There were 2,631 LCP(R)s built by Chris Craft, Richardson Boat,

and the Matthews Company. Higgins Industries did not build any and

was not responsible for the design of the boat. It was a U.S.

Navy/Chris-Craft design. Higgins considered it to be inferior to

the LCV and LCVP. Production ran from 1942 to 1945 for the LCP(R),

allowing for Hudson Invader engines to be used in this type craft.

There are no known LCP(R) landing craft

still in existence. This is a replica at the the National UDT-Seal Museum

in Fort Pierce, FL. Author's photo.

Also, my research did not produce evidence the

Invader Engine was used on PT boats as a replacement engine. PT

boats they were all powered by three Packard 4M2500 Marine engines that

produced between 1,200 and 1,500 hp each. One is not going to

replace a bigger engine with one that only gives 1/6th of the

horsepower, as that would be fatal in combat. Also, the Invader

engine would not fit the motor mounts and other connections would not

match. There was no reason to replace a Packard 4M2500 with a

smaller and less powerful engine. This seems to be one of those

old wives' tales that has taken on a life of its own without research or

logic.

There were several different sizes of Army

Air Forces crash boats during WWII. The smallest, a 42 foot

version like the model shown here, utilized either a Hudson built

Invader engine or a Kermath Sea Ranger 6 Marine engine. The AAF

Handbook for the 42 foot rescue boat calls out for either one. It

is unknown how many Invader engines were used in the 42 foot boats.

This model of a 42 rescue boat is on display at the Michigan Military

Technical and History Society Museum. Author's

photo added 2-21-2017.

Below are drawings of the 42-rescue boat.

Drawing added 1-30-2020.

Drawing added 1-30-2020.

The 63 foot crash boat, designated AVR-63

(Auxiliary, or Aircraft, Vessel Rescue), normally had twice the

horsepower of the Invader engine with either two Scott-Hall 650 or

Kermath 550 hp marine engines. Of the 740 built, 20 AVR-63s had

two Hudson Invader 250hp engines, due to shortages of the Hall-Scott

Defender engines. They were vastly underpowered, and were utilized for duty

other than crash rescue.

A 63-foot crash boat. Photo added

1-30-2020.

Hudson built 4,250 outer wing sets for the Curtiss SB2C Helldiver, manufactured in Columbus, OH. Production of the

wings ran from January 1943 to August 1945.

This is the world's only remaining flying

Curtiss SB2C Helldiver, as seen at the 2014 Tico Airshow. Hudson

built 4,250 of the outer wing sections like the ones seen

here. The pilot demonstrates the wing folding ability of the aircraft.

Author's Photo.

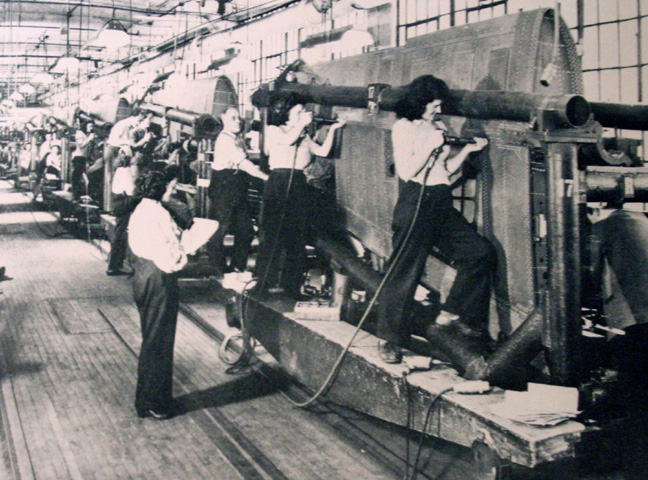

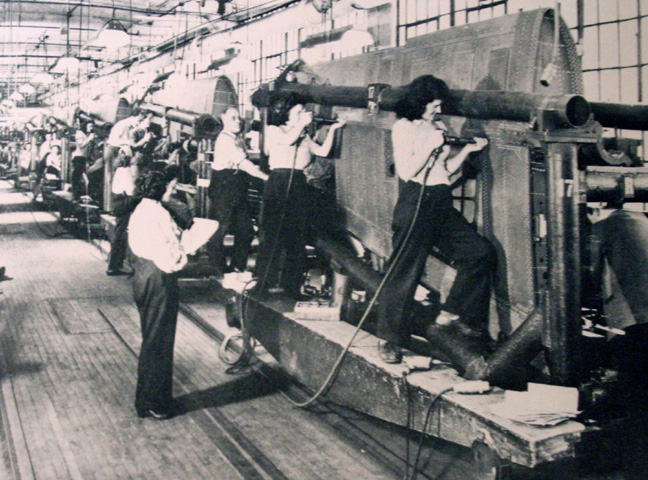

Hudson took on the contract for P-63 cabins

for Bell Aircraft in Niagara Falls, NY in March 1944 running through the end of the war.

The company built a total of 3,041 of the P-63 on an automotive type

production line as seen here.

The Bell P-63 King Cobra. The Hudson built cockpit section can be seen after being assembled into

the complete aircraft. The seam between the cockpit section and

the nose section is obvious. Author's

photo added 11-12-2015.

The P-38 is always popular at airshows due

to its unique design. Hudson built 791 wing sets for the Lockheed

Lightning starting in July 1944 and through May 1945. Author's

photo added 11-12-2015.

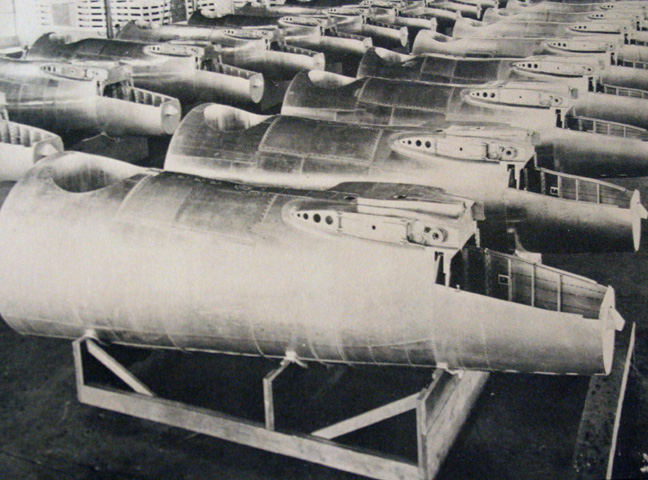

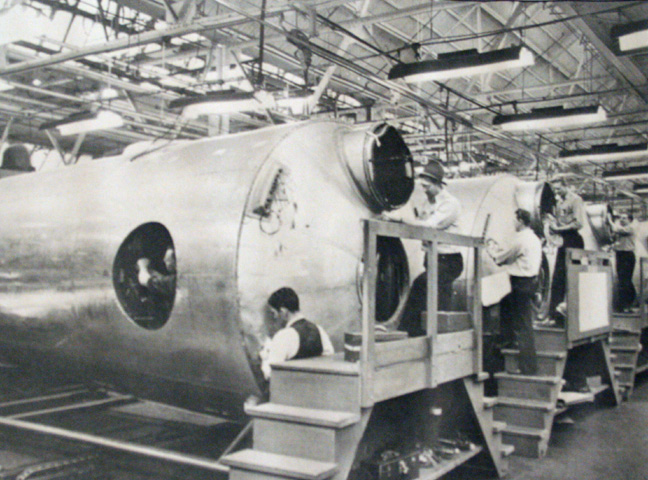

Pictured here are some of the forward B-29

Rear Fuselage Assemblies produced by Hudson. According to the Martin

information presented above, the company also produced two more sections

that were located behind this on the aircraft. Hudson would have

needed to build 531

of each for Martin Omaha production from May 1944 to the end of the war.

This would have been a huge task for Hudson, as the B-29 was a more

complicated and significantly larger aircraft than the previous B-26 for

which Hudson made parts.

This is Martin Omaha built B-29 "Bockscar",

the second nuclear bomber, as seen on display at the National Museum of

the United States Air Force in Dayton, OH. Just like the "Enola

Gay, it has Hudson built rear fuselage and outer wing sections. Author's

photo added 11-12-2015.

Here the Hudson wing components can all be

seen; the leading edge, wing tip, the wing itself, and the aileron. Author's

photo added 11-12-2015.

The three Hudson built rear

fuselage sections can be seen. Author's photo added 11-12-2015.

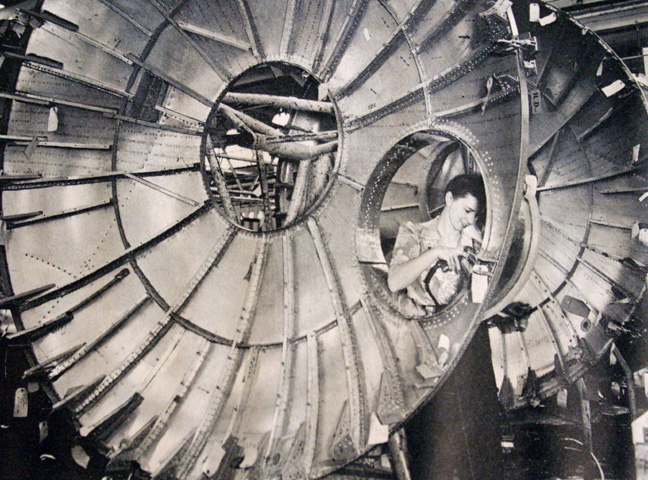

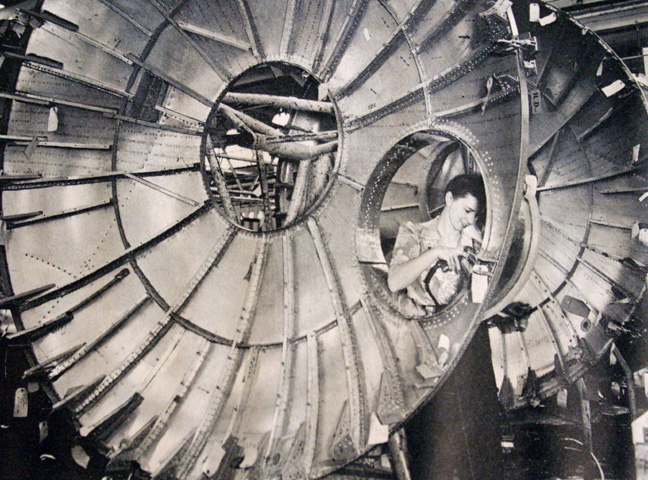

B-29 Bulkheads for the pressurized cabins in

the aircraft are being worked on.

The table below details the production

schedule that Hudson, and other suppliers, had to meet to supply components for the Martin Omaha, NB built B-29s.

Several months show no production, or at least no accepted

production. It could have been that there was a parts shortage

that did not allow the aircraft to be finished and accepted by the US

Army Air Force. I do think the work stoppages were intentional.

Aircraft in WWII were built in Block Numbers,

which had frozen designs and did not allow for any changes to the

aircraft while coming down the production line. This allowed mass

production of aircraft without having to make the constant changes and

improvements based on information coming back

from testing and operational units. When a new block was started,

it contained updates and improvements. Even then to

facilitate production, not all of the upgrades would be included.

Afterward, the aircraft would go to one of nineteen modifications

centers for the latest updates. The modification centers were

integral to the process of keeping the aircraft production

lines operating efficiently. In the case of Martin Omaha, it

had its own modification center.

Serial numbers reflect the year the aircraft

were ordered, as indicated by the first two numbers in the sequence.

The first B-29 built at Martin Omaha was the 65202nd aircraft ordered by

the US Army Air Force in 1942. The last one off the assembly line

in August 1944 was the 86273rd aircraft ordered in 1944.

MO designated that the aircraft was built at

Martin Omaha.

Of the four plants making B-29s during WWII,

Martin in Omaha, NB was chosen to build and then modify the operational

B-29s for the nuclear bomber "Silverplate" program. Martin was considered by the US Army Air Force to have the best

quality of the four plants. The first fifteen came directly off

the assembly line went to Wendover Army Air Field, Utah. Once

there, they were converted to the "Silverplate" configuration and then

used in training.

The fifteen operation "Silverplates" that went

to Tinian were also built at Martin and modified at the adjacent

modification center. Modifications included, but were not limited

to, replacing the Hamilton Standard propellers with Curtiss Wright

Electric reversible props, the elimination of all of the gun turrets,

gun sights, and gun control computers with the exception of the tail

turret, and modification of the bomb bays to accept the large atomic

devices.

|

Martin Omaha,

Nebraska World War Two B-29 Production Schedule |

|

Month |

Number built |

Block Number |

First Serial Number |

Last Serial Number |

Comments |

| 1944 |

|

|

|

|

|

| May

|

3 |

B-29-MO-1 |

42-65202 |

42-65204 |

|

| June |

7 |

B-29-MO-5 |

42-65205 |

42-65211 |

|

| July

|

0 |

|

|

|

|

|

August |

8 |

B-29-MO-10 |

42-65212 |

42-65219 |

|

|

September |

16 |

B-29-MO-15 |

42-65220 |

42-65235 |

|

|

October |

28 |

B-29-MO-20 |

42-65236 |

42-65263 |

|

|

November |

0 |

|

|

|

|

|

December |

50 |

B-29-MO-25 |

42-65264 |

42-65313 |

|

|

1944 Total |

112 |

|

|

|

|

| 1945 |

|

|

|

|

|

|

January |

69 |

B-29-MO-30 |

42-65315 |

42-65383 |

|

|

February |

18 |

B-29-MO-35 |

42-65384 |

42-65401 |

|

|

February |

67 |

B-29-MO-35 |

44-27259 |

44-27325 |

The B-29 "Bockscar"

was serial number 44-27297 and came off the Martin Omaha

assembly line in February 1944. |

| March |

0 |

|

|

|

|

| April |

0 |

|

|

|

|

| May

|

33 |

B-29-MO-40 |

44-27326 |

4-27358 |

|

| May

|

35 |

B-29-MO-40 |

44-86442 |

44-86276 |

|

| May

|

39 |

B-29-MO-45 |

44-86277 |

44-86315 |

The B-29 "Enola Gay"

was serial number 44-86292 and came off the Martin Omaha

assembly line in May 1944. |

| June |

55 |

B-29-MO-50 |

44-86316 |

44-86370 |

|

| July

|

55 |

B-29-MO-55 |

44-86371 |

44-86425 |

|

|

August |

48 |

B-29-MO- 60 |

44-86426 |

44-86473 |

|

|

1945 Total |

419 |

|

|

|

|

|

Grand Total |

531 |

|

|

|

|

The Hudson Plant on East Jefferson in Detroit,

MI. This is probably pre WWII drawing of the plant. Compare

to the 1947 version below.

This is the plant in 1947. Note the

expansion that has taken place to the Northeast of the original plant.

After the consolidation of Hudson with Nash-Kelvinator to form American

Motors, production moved to Kenosha, WI. The above plant was torn down

in 1961. Apparently a portion of the facility was spared and a

warehouse for the plant is still in use. From below, it would appear

that 17,000 jobs disappeared in Detroit with the 1954 merger.

|