|

Aeroproducts Division of General Motors in World War Two

Vandalia, OH

1935-1960

Rest in Peace

This page updated

11-30-2017.

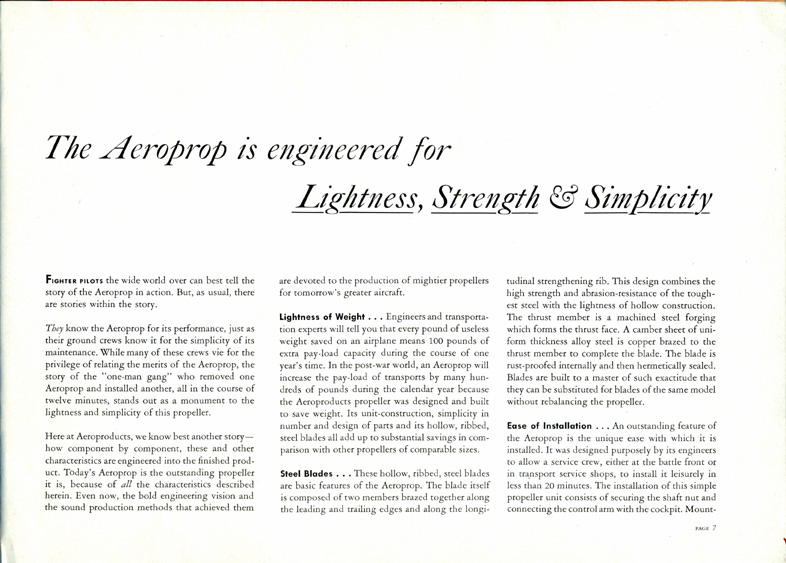

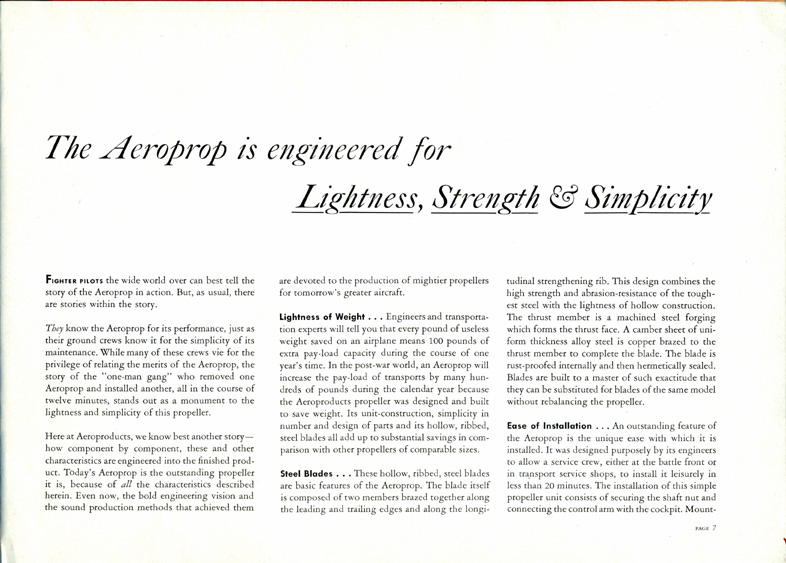

Author's Photo.

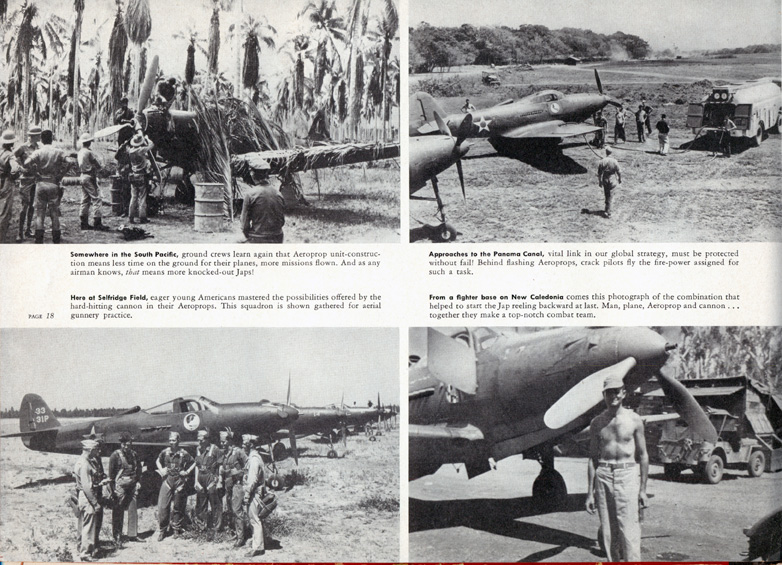

Aeroproducts is one of the more

obscure and now forgotten General Motors Divisions. In its day, it

was a prime contributor to the American World War Two effort as a

manufacturer of aircraft propellers. The last Aeroproducts

propeller was built in Indianapolis, IN in 1977 after Aeroproduct became part of the Allison Division of GM. The

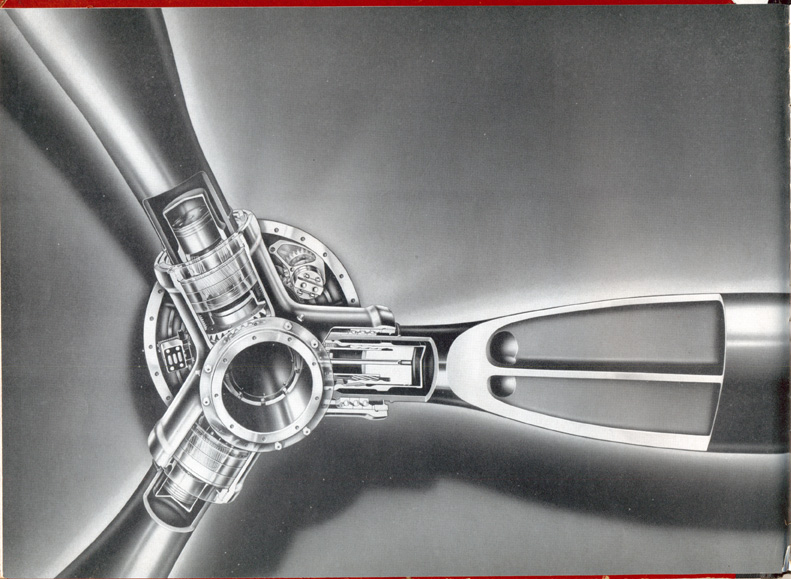

particular design of the propeller allowed for an Oldsmobile-built

37mm cannon to fire through the hub on the Bell P-39 and P-63.

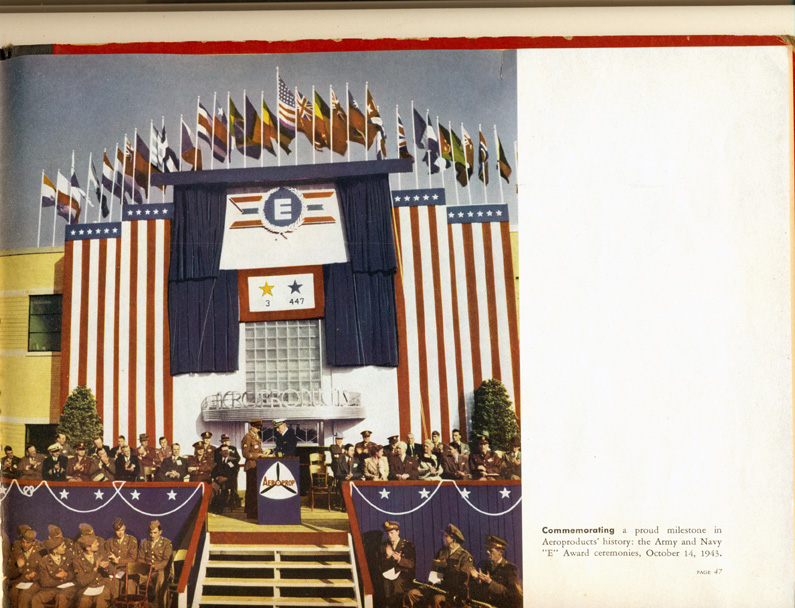

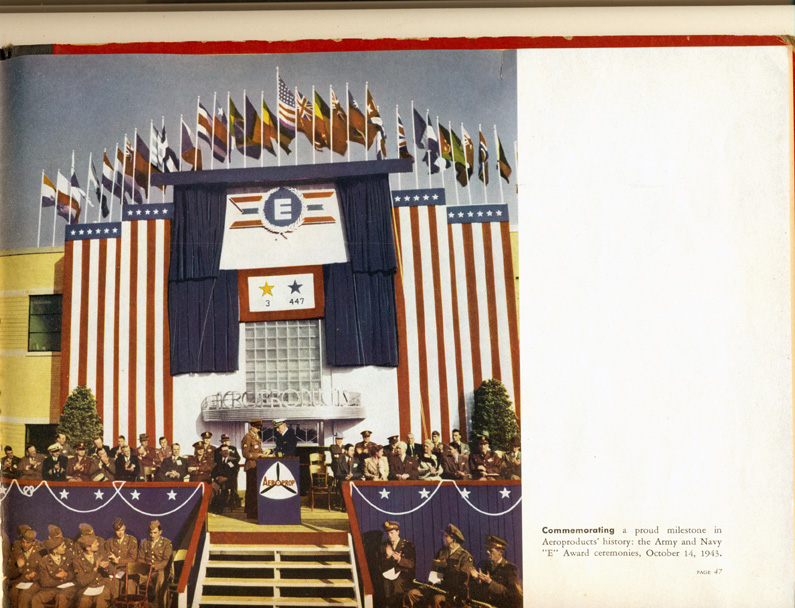

The Aeroproducts Division

of General Motors won the Army-Navy "E" Award on October

15, 1943.

The award ceremonies took place on October 15, 1943 at

the front entrance to the Aeroproducts Plant in Vandalia, OH.

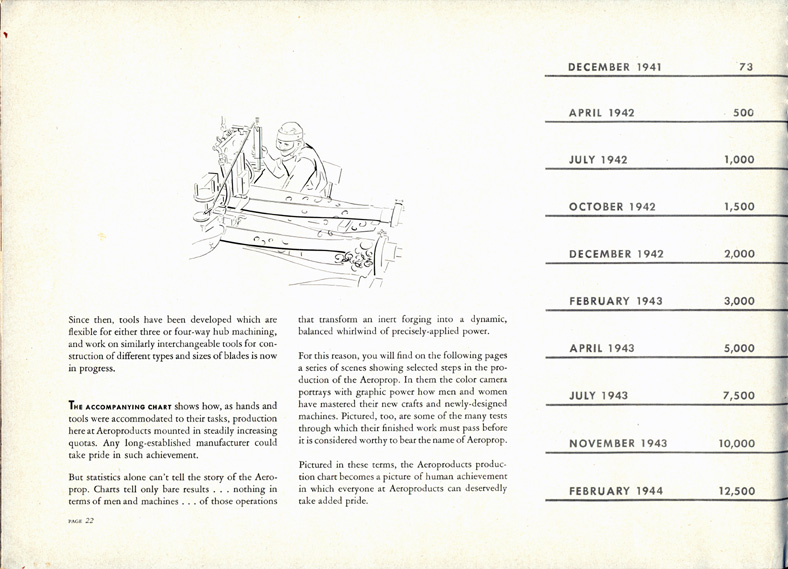

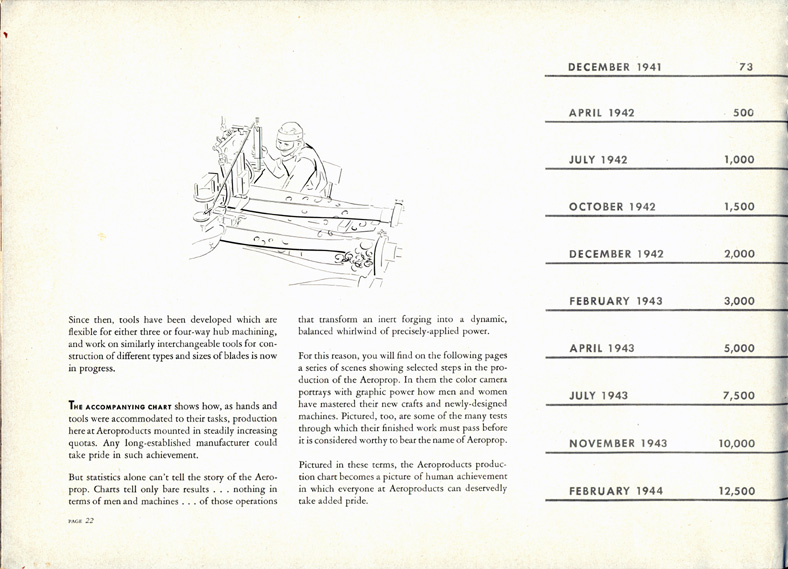

Aeroproducts

World War Two Production Statistics:

(20,773) Aircraft Propellers - For F8F, P-39, P-63, XP-75, P-75A, P-51K

and P-51H. During the war Aeroproducts had 2,500 employees.

|

Aeroproducts

WWII Propeller Applications - There may be others due to the

deficit of applications as shown below. |

|

Aircraft |

Propeller Designation |

Number of Blades |

Diameter in Feet |

Dates |

Number of Aircraft |

Comments |

| Bell

P-39F |

A632S |

3 |

10.3 |

1941 |

231 |

|

| Bell

P-39K-1 |

A632S |

3 |

10.3 |

First

Delivery in July of 1942 |

210 |

|

| Bell

P-39K-5 |

A632S |

3 |

11.6 |

|

|

This

is included in the 210 number. |

| Bell

P-39Q-21 |

A632S |

4 |

? |

SOP

March 1943 |

109 |

109

P-39Qs had the four bladed props and were sent to Russia.

I |

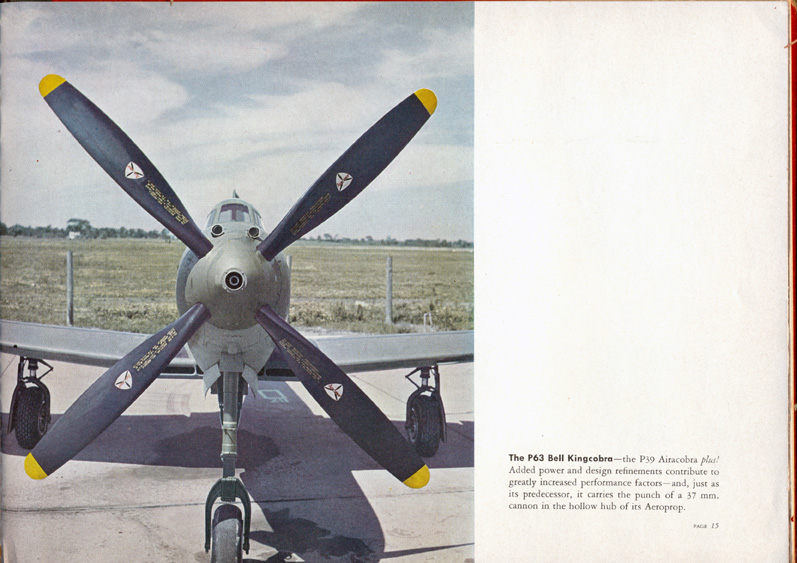

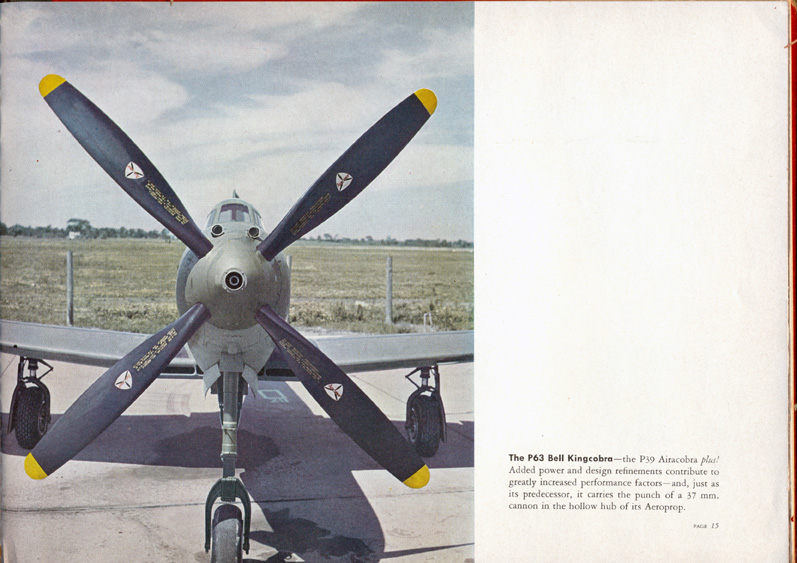

| Bell

P-63A |

A642S-D1, D3, E1, E2 |

4 |

11.0 |

First

flight 12-7-1942 |

3,303 |

|

|

Fisher XP-75 and P-75 |

AD7562-X5 |

6 |

12.6 |

First

flight 11-17-1943 |

14 |

|

|

Republic P-47B |

AD6462-X1 |

6 |

|

1943 |

1 |

AD

designated dual rotation in Aeroproducts nomenclature. In

1943 there was only one test flight of a P-47B with the

Aeroproducts AD6462-X1 counter rotating propeller. The

propeller was found to de-stabilize the aircraft, and it was the

only test flight ever made with the Thunderbolt and Aeroproducts

propeller. Added 5-5-2015. |

| Bell

XP-77 |

A5215 |

2 |

9.5 |

First

Flight 4-1-1944 |

2 |

|

|

Vought XF4U-4 |

AD7562-X5 |

6 |

12.6 |

6-1944 to 8-1944 |

1 |

Testing indicated the AD7562-X5 resulted in the XF4U-4 being ten

MPH slower, the climb rate reduced by 300 FPM while weighing 203

lbs more than than a standard four blade propeller. Added

5-5-2015.

|

|

Republic XP-72 |

AD7562-14 |

6 |

|

First

Flight 6-26-1944 |

1 |

The

end of the war cancelled the 100 place production run.

Added 11-30-2017. |

|

Grumman F8F-1 |

A642-G1 |

4 |

12.6 |

First

Flight 8-31-1944 |

658 |

|

|

Grumman F8F-2 |

A642 |

4 |

12.6 |

|

100 |

|

| North

American P-51F/G |

|

3 or

4 |

|

|

5 |

|

| North

American P-51K |

A542S |

4 |

11.0 |

|

1,500 |

|

| North

American P-51H |

A542-B2 |

4 |

11.0 |

First

Flight 2-3-1945 |

555 |

|

| North

American P-82 |

A542 |

4 |

11.0 |

First

Flight 6-16-1945 |

272 |

Twin

Engine aircraft |

|

Boeing XF8B-1 |

AD7562-XB |

6 |

13.5 |

First

Flight 12-27-1944 |

3 |

|

|

Total |

|

|

|

|

6,965 |

There

is a deficit of known applications for 13,810 propellers. |

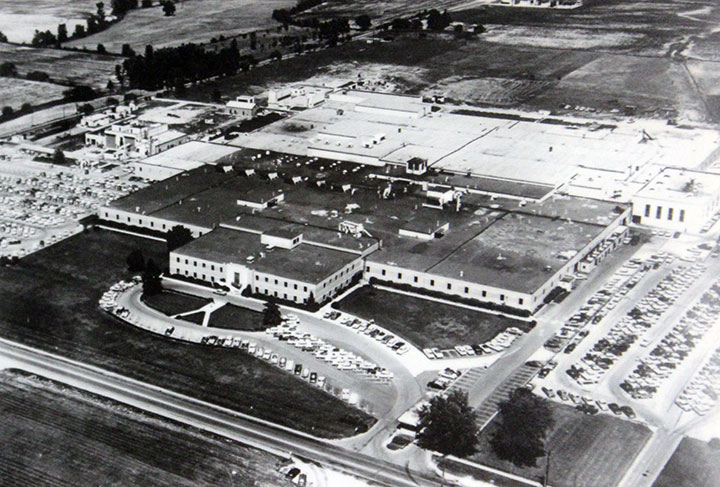

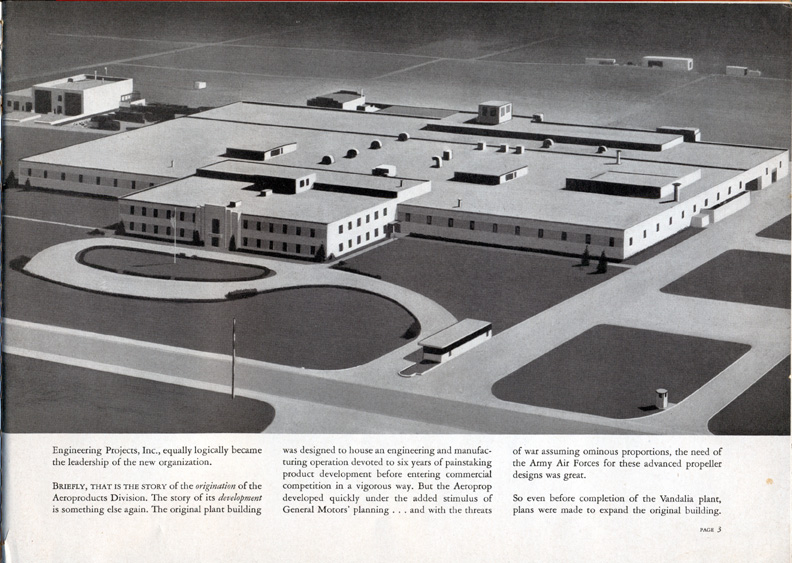

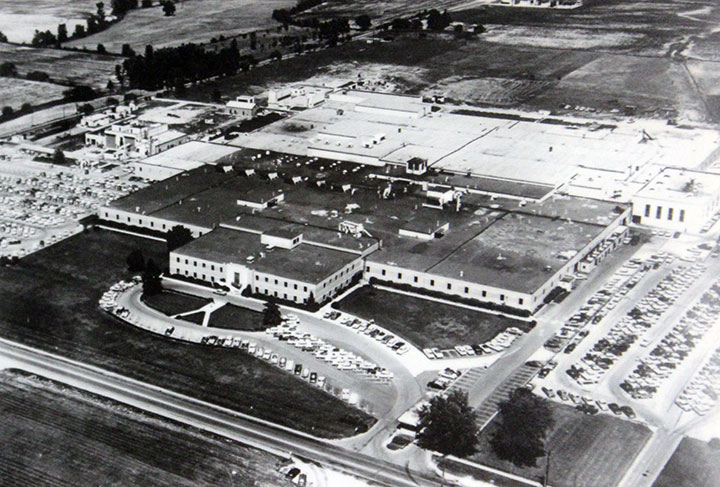

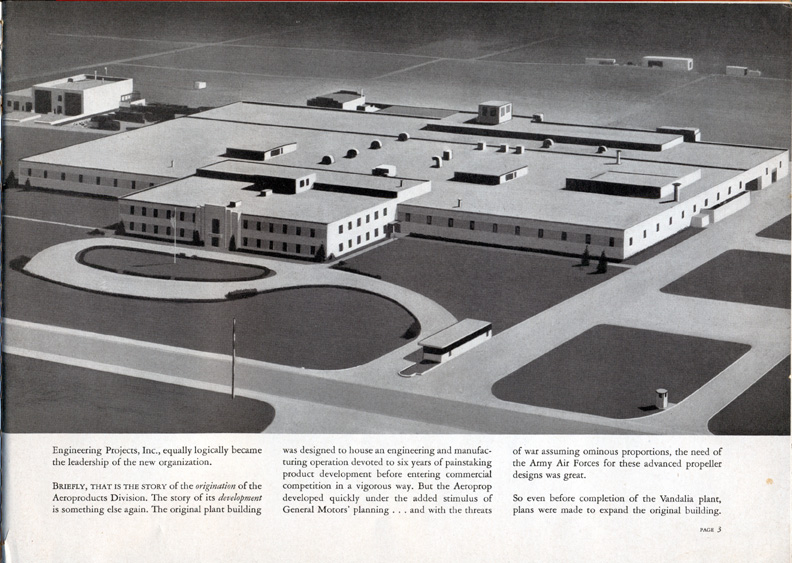

The Aeroproducts plant in

during World War Two. This Aeroproducts plant produced 3%

of the total propellers

made during World War Two. Photo added 2-27-2015.

This is the Aeroproducts

administration building as it stood before being razed in 2008.

When the product line went to Allison Division in 1960, Inland Division

of GM then took over this building and the related manufacturing

facilities. This was located just across the street from the Dayton

International Airport. The "E" for Excellence Award ceremonies

took place at the main entrance in October 1943 as shown above. Author's

photo.

Author's photo.

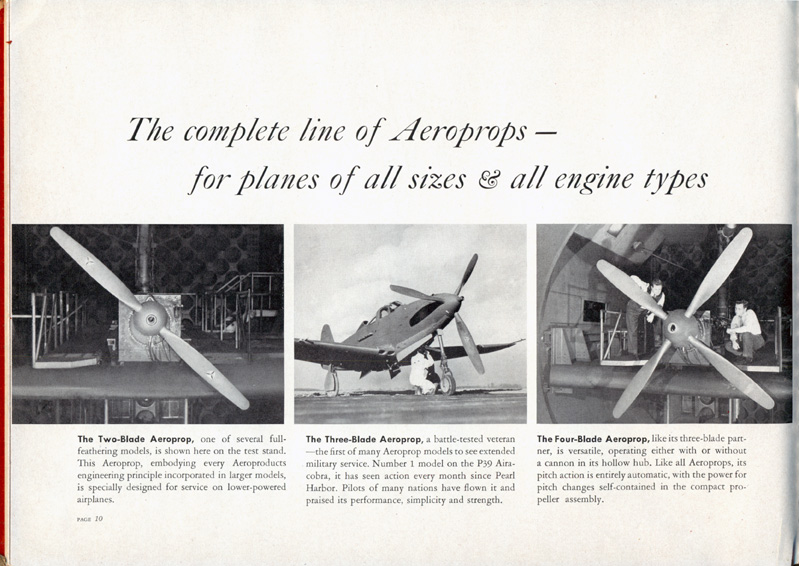

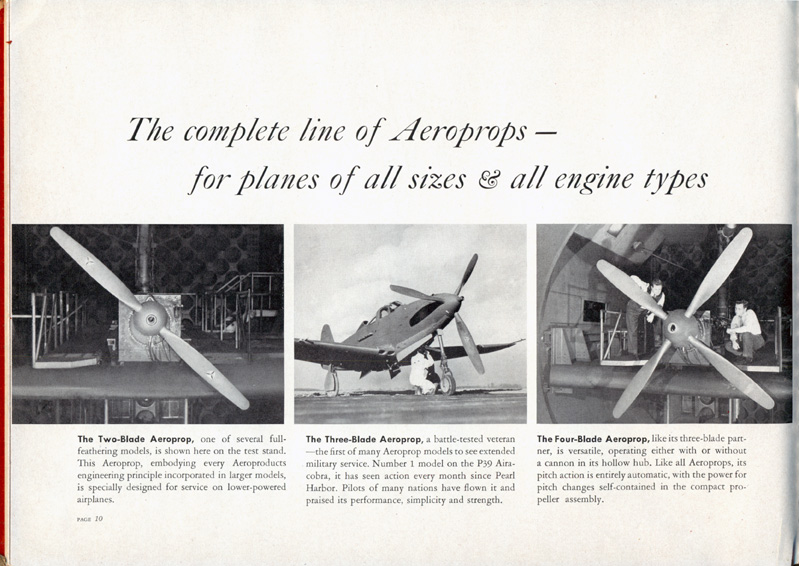

This ad is from 1944.

The Aeroprop emblems can be seen on this

Grumman F8F Bearcat. The diameter of the propeller is 12 feet and

seven inches. Author's photo from the 2009 Chino Airshow, Chino,

CA.

Here a Grumman F8F Bearcat climbs for

altitude at the 2013 Houston Airshow. The Aeroprop emblems can be

seen as blurs in this photo. Author's Photo.

The Aeroprop emblems can again be seen as

blurs in this photo at the 2013 Houston Airshow. Author's Photo.

This Fisher Body XP-75 on

display at the National Museum of the United States Air Force has an

Aeroproducts counter rotating prop. Author's Photo.

The first flight of the

Fisher XP-75 took place on 11-17-1943. Author's Photo.

The Aeroproducts Counter Rotating Props were also used on these World

War Two experimental aircraft: Republic XP-72, Boeing XF8B-1and

the Curtiss XBCT-2. Author's Photo.

This photo shows the Aeroprop

four-bladed propeller on a Bell P-63E displayed at the National Museum of

the United States Air Force. Author's Photo.

Author's Photo.

This is not an Aeroproducts

propeller on this Bell P-30Q. This photo does show

how it is possible to have the barrel of an Oldsmobile 37mm cannon

installed in either the Curtiss Electric or Aeroproducts propeller hub. Author's photo from

the National Museum of the United States Air Force.

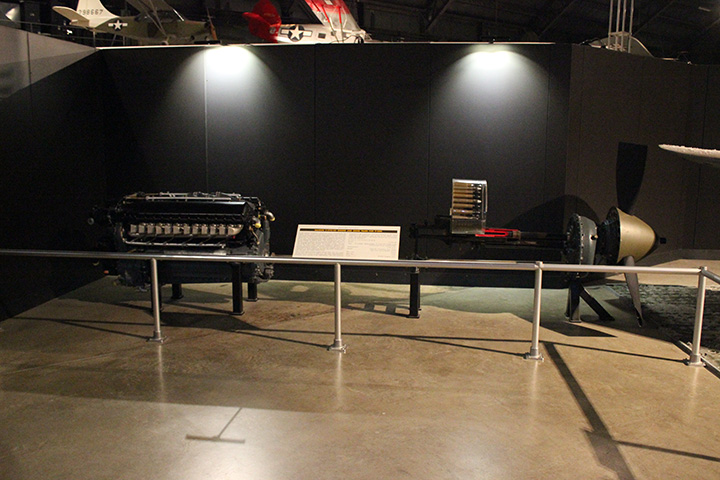

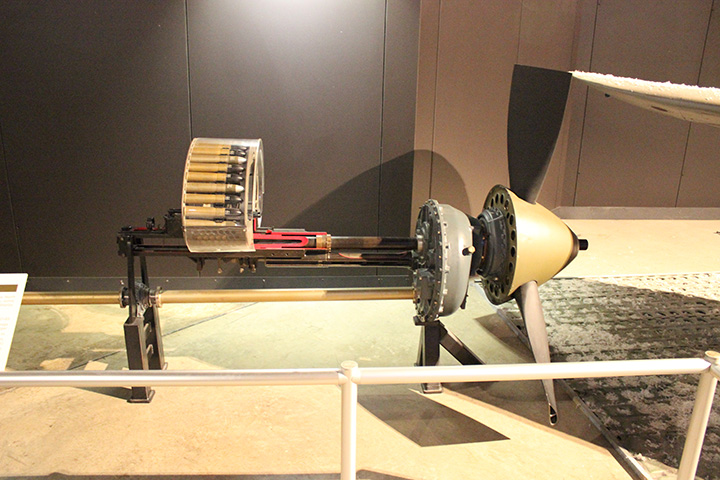

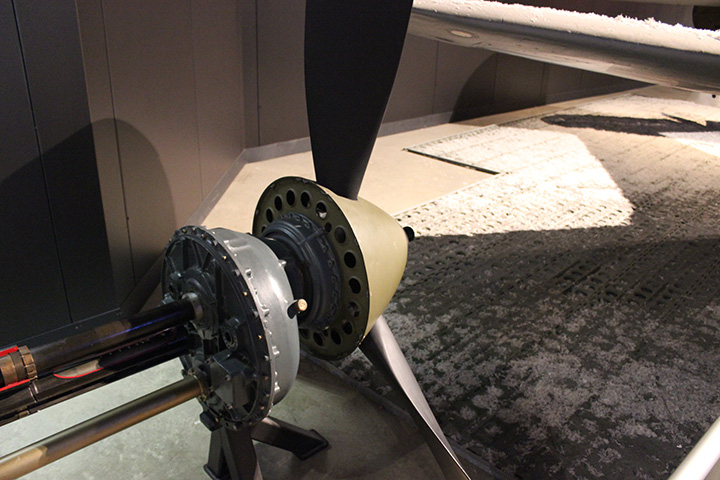

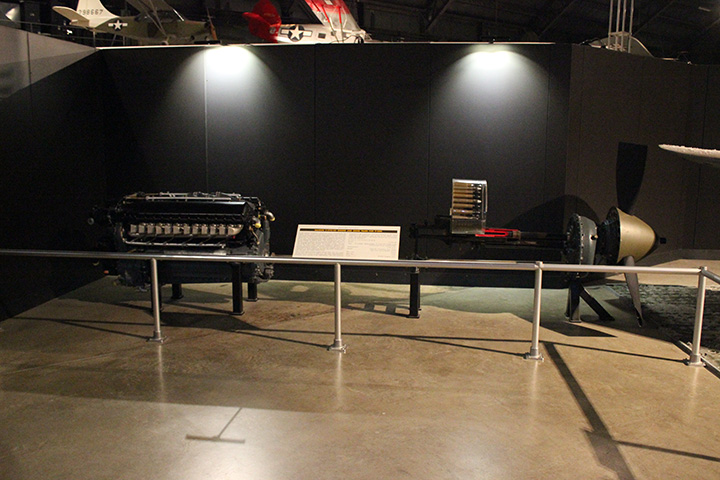

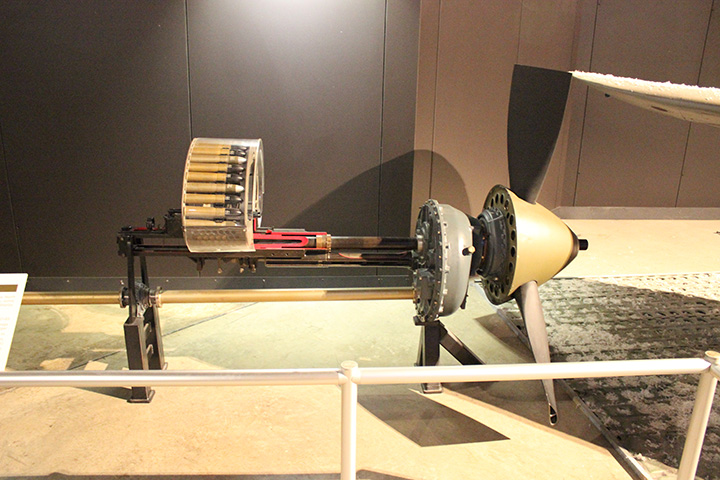

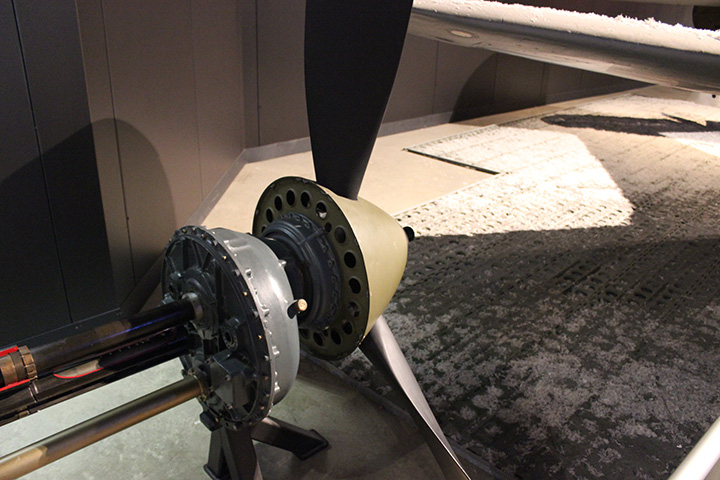

This photo shows the entire P-39 drive train with

General Motors Divisions' components. On the left is the Allison

V-1710 engine, then the Oldsmobile built 37mm cannon, the Cadillac gear

reduction unit, and then the Aeroproducts propeller. The engine was

behind the pilot and the driveshaft went between the pilot's legs.

This

allowed the cannon to fire out of the center hub of the prop.

Author's photo from the National

Museum of the United States Air Force.

Author's Photo.

Author's Photo.

This P-39Q shows the aircraft type

that is similar to the 464 P-39 aircraft that the Aeroproducts prop went

into. Note that the engine exhaust

stacks are behind the pilot where the GM Allison V-1710 engine was

located. Author's Photo.

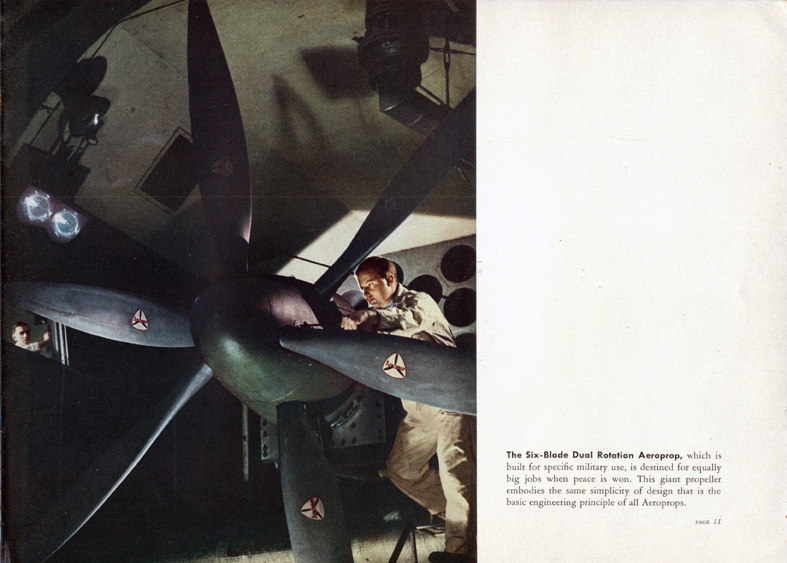

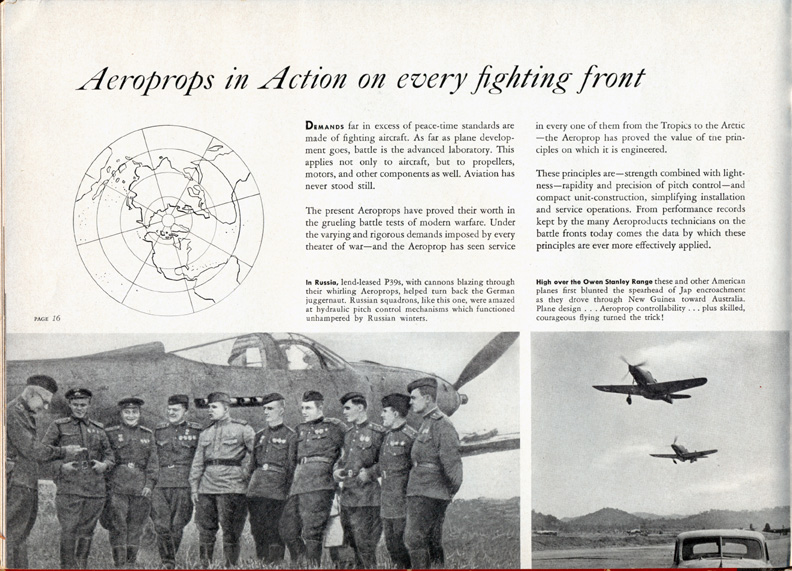

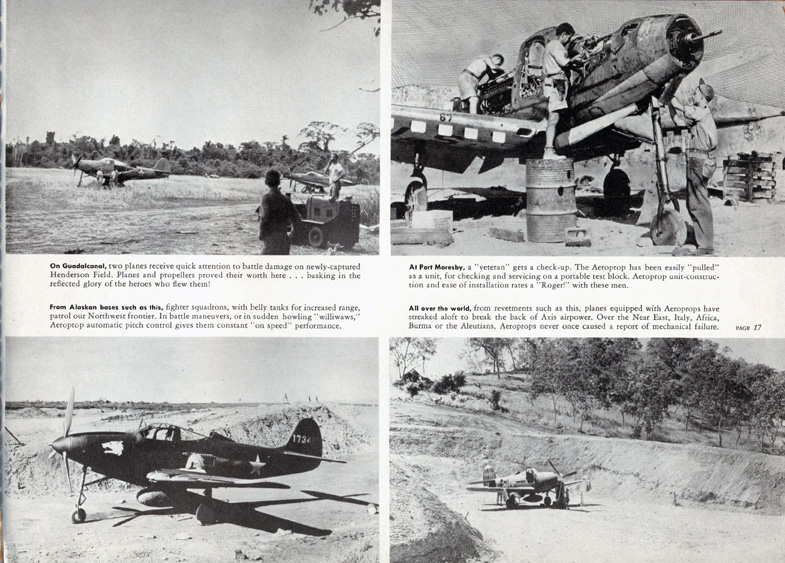

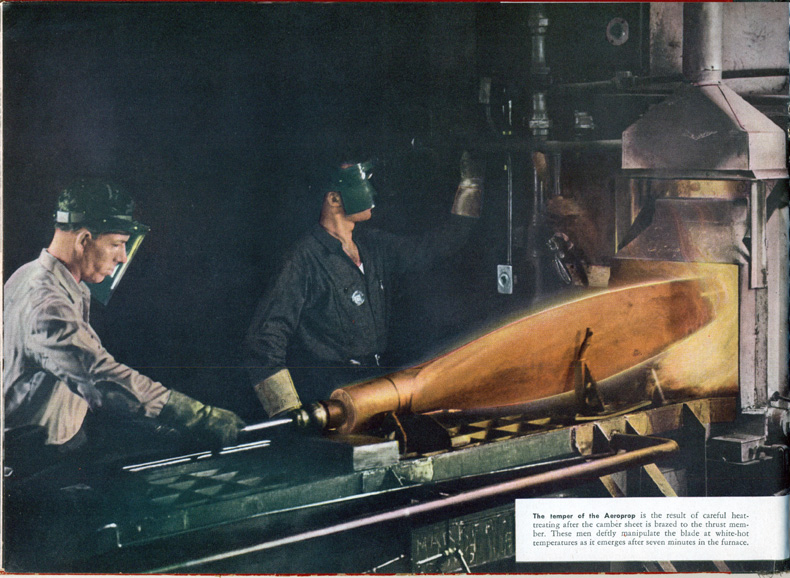

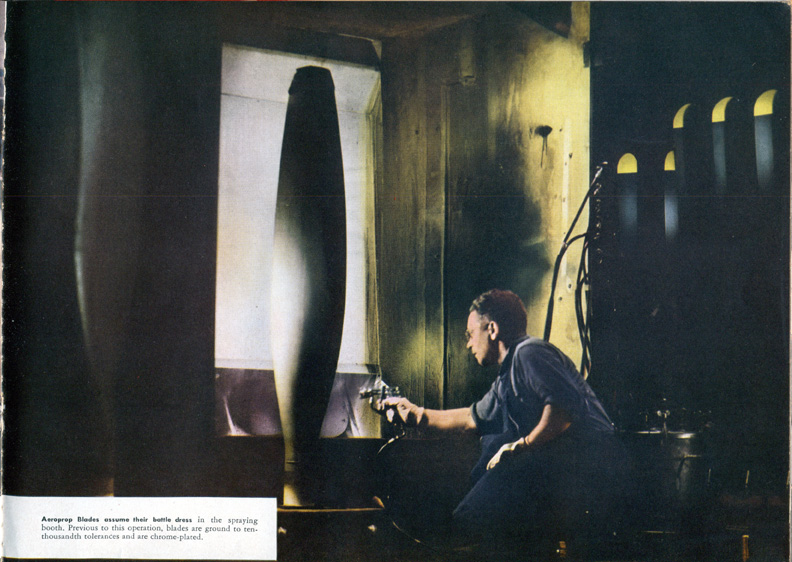

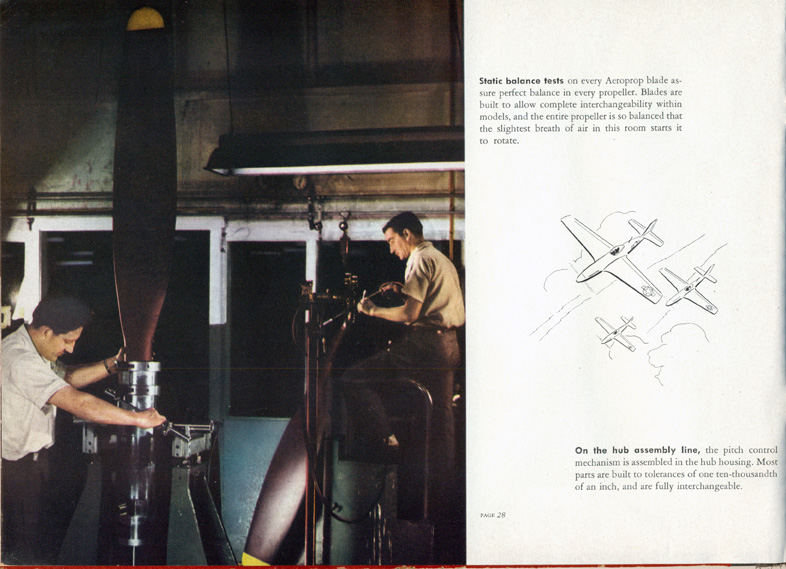

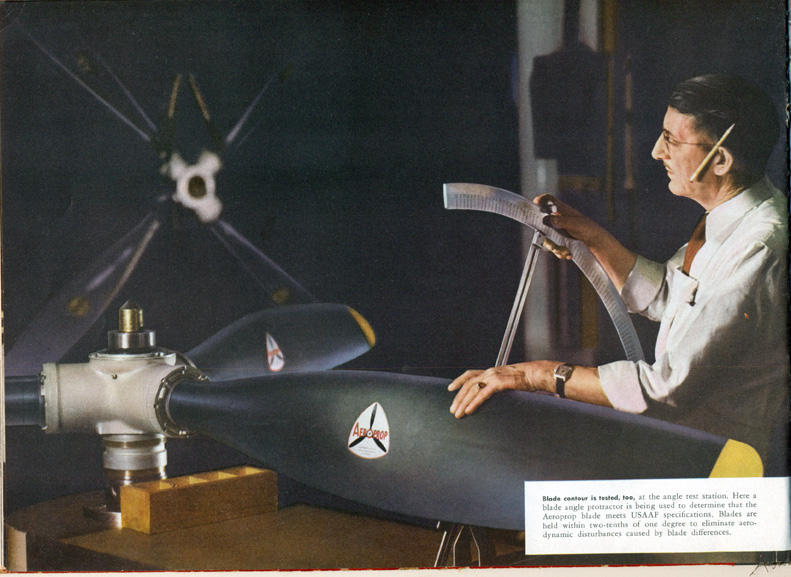

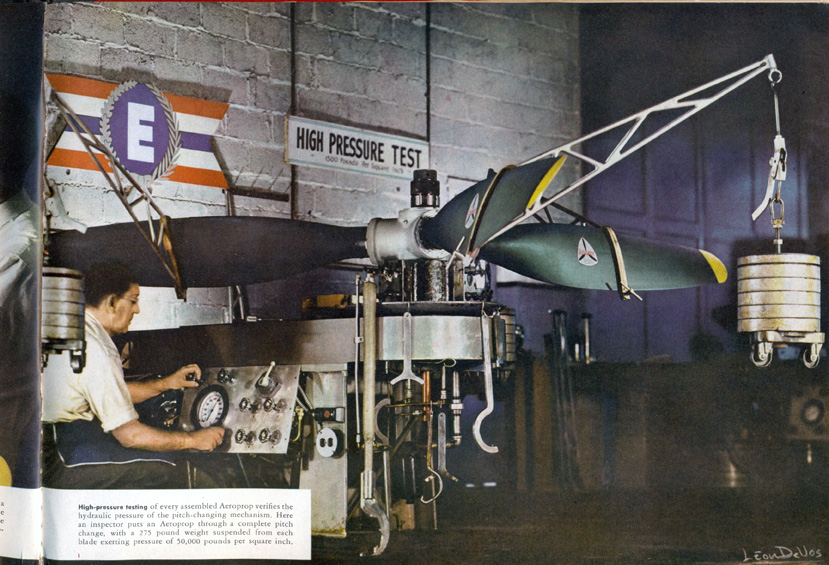

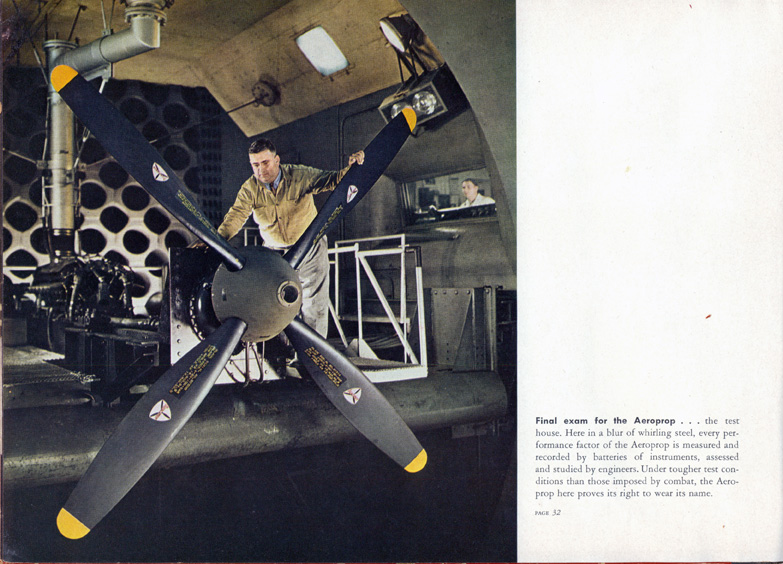

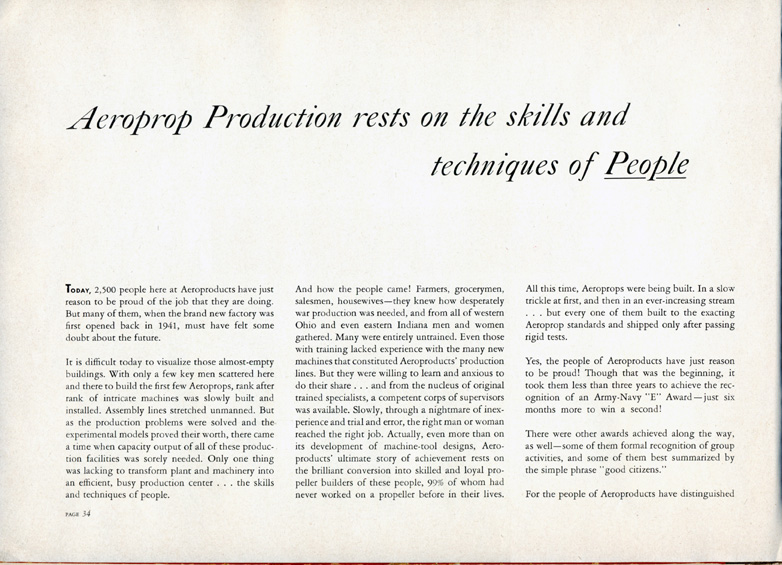

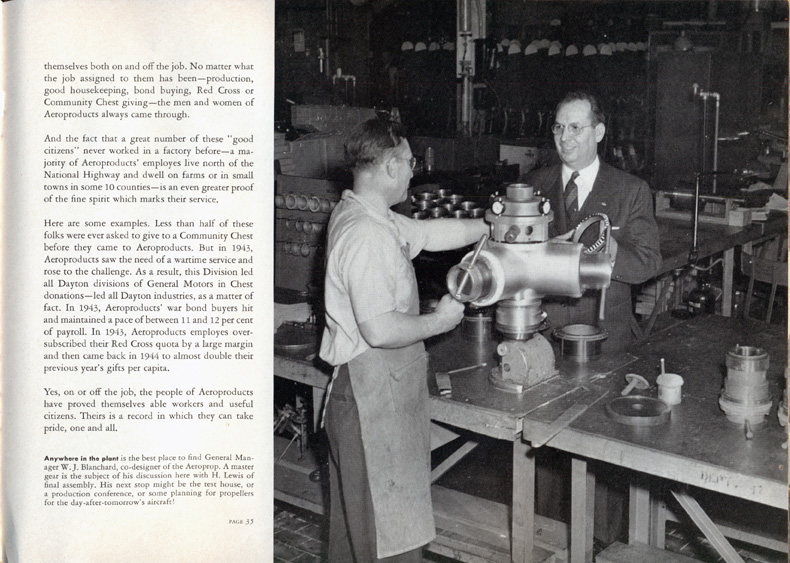

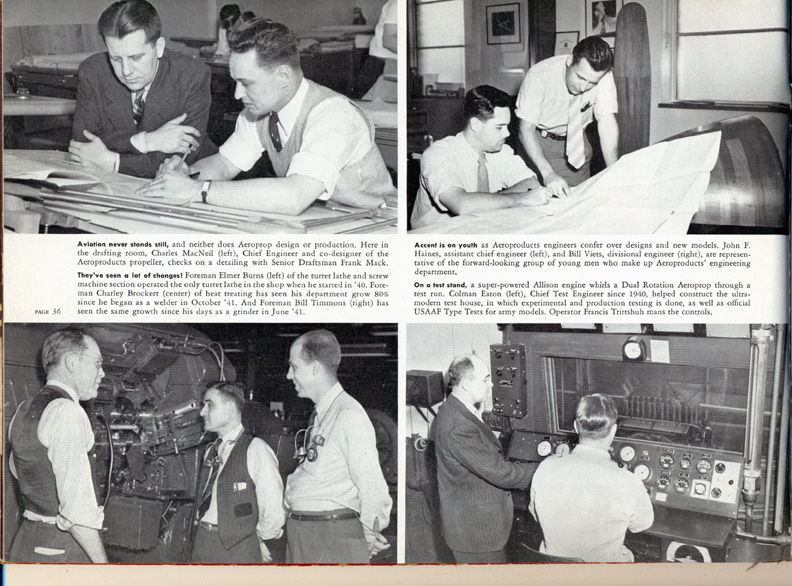

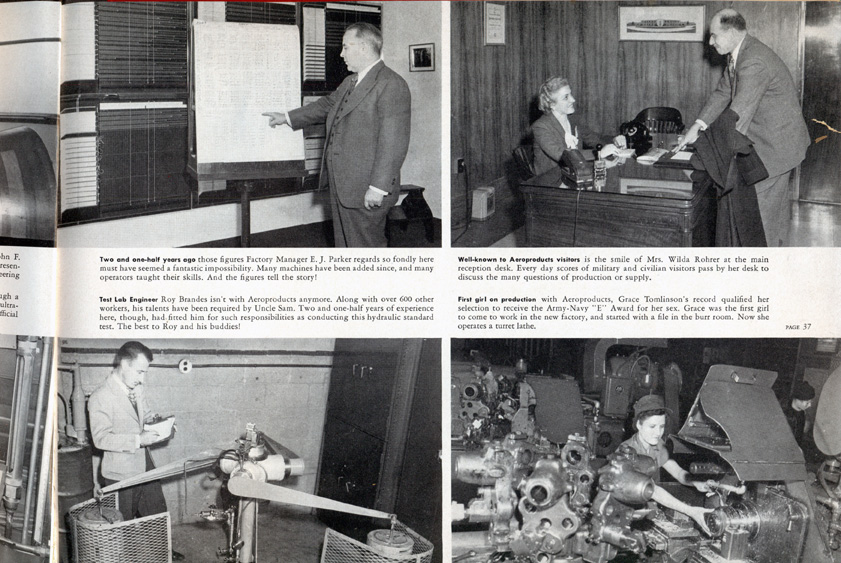

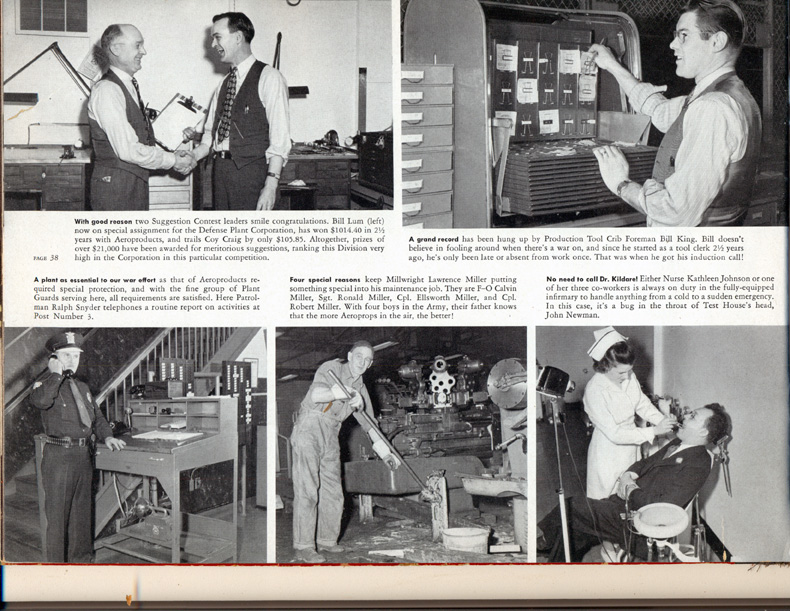

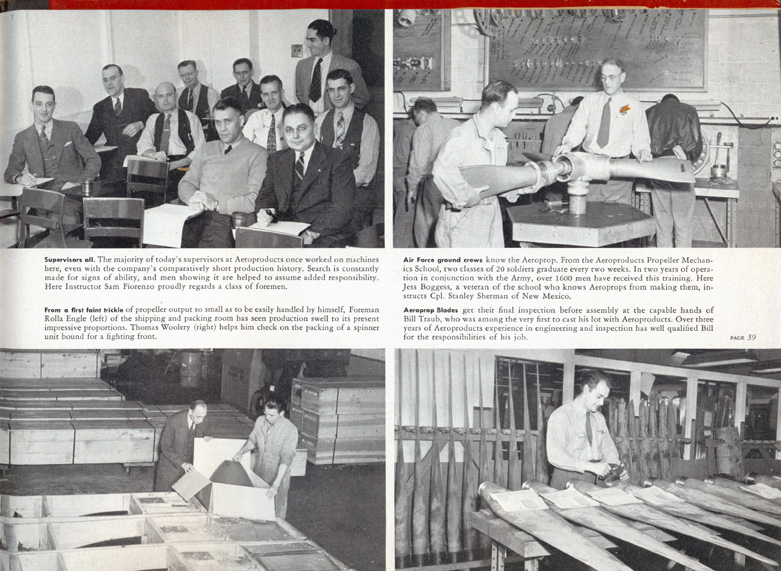

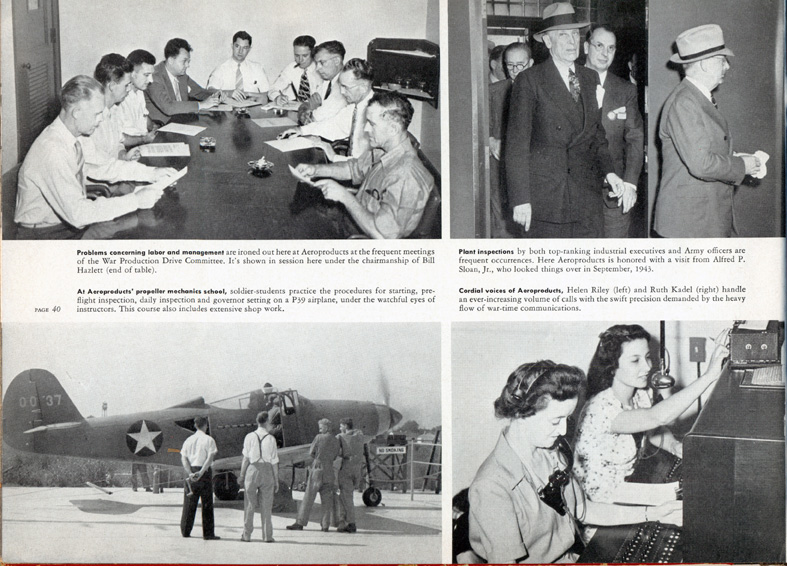

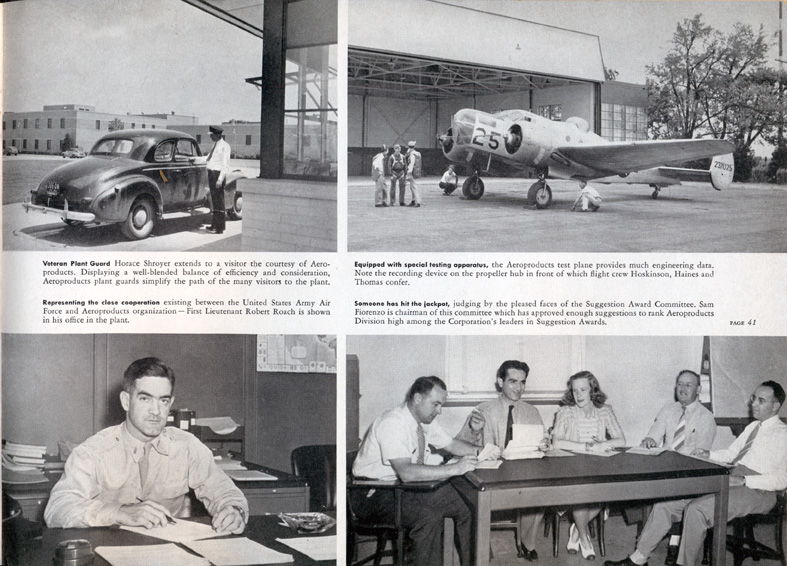

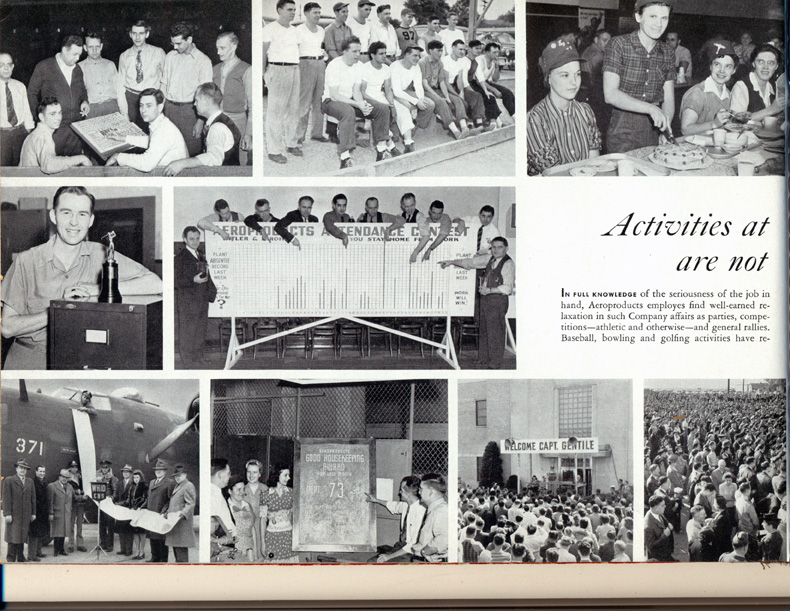

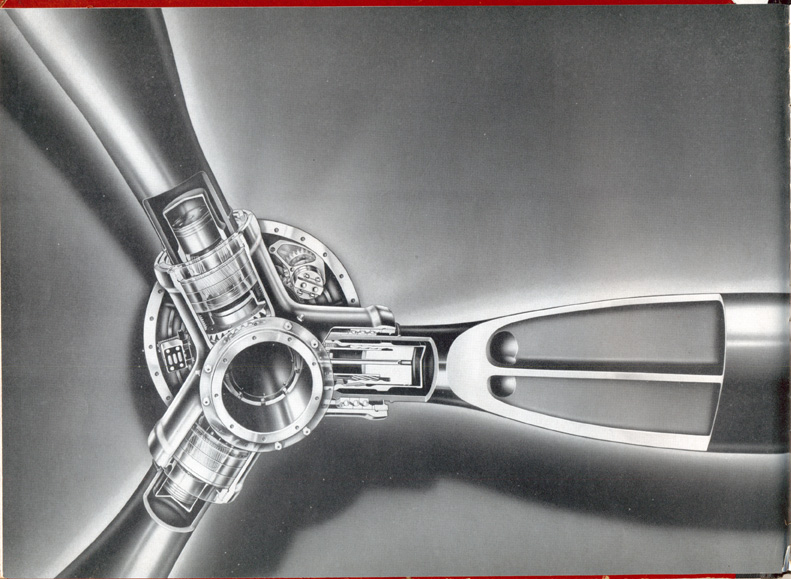

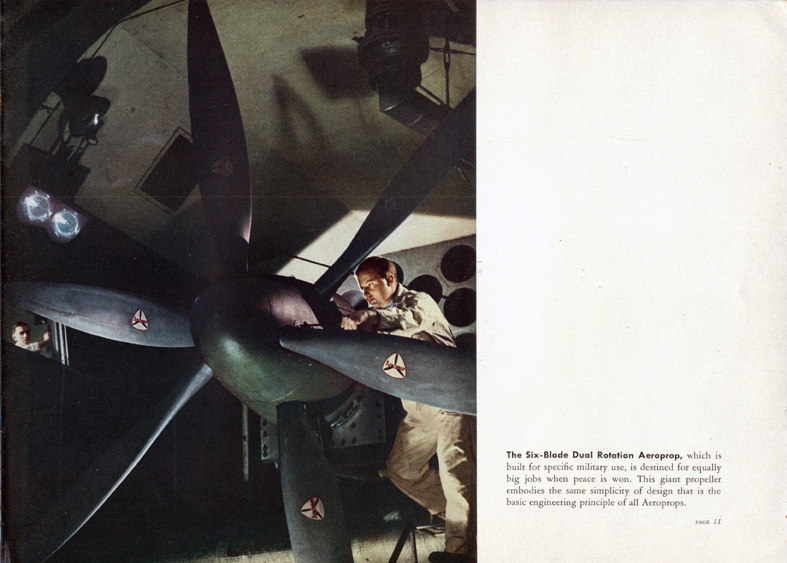

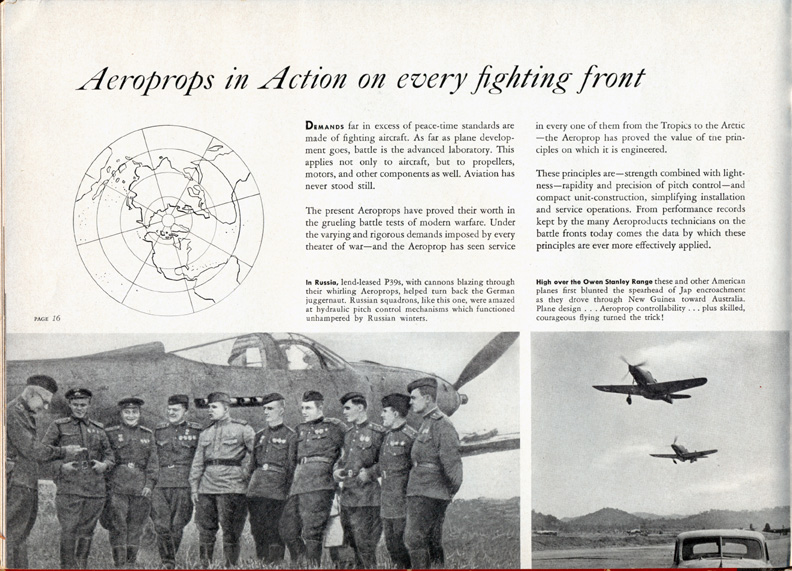

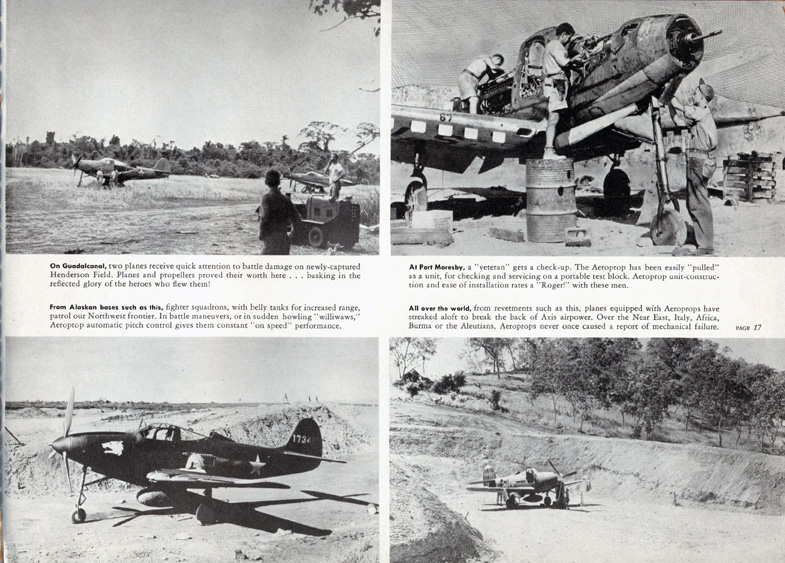

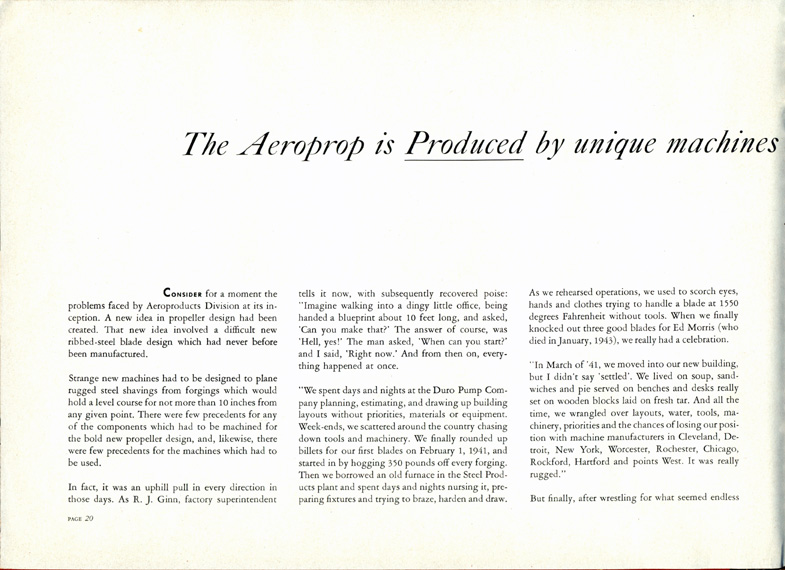

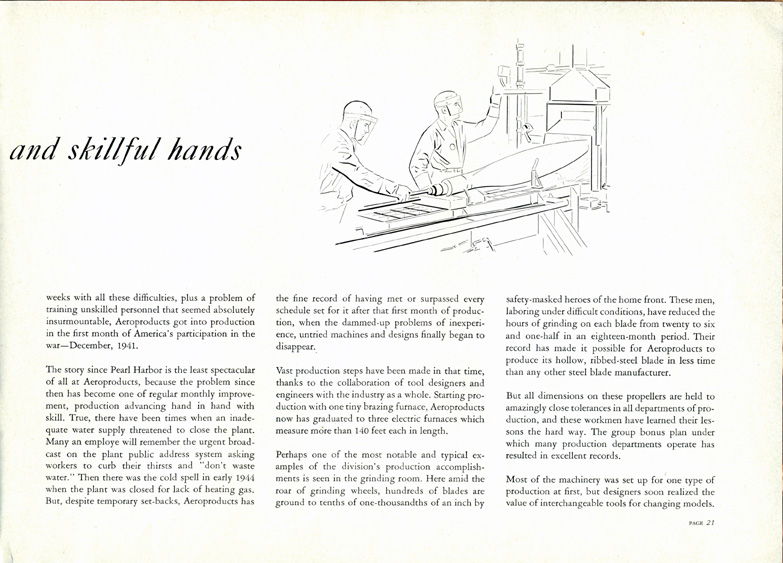

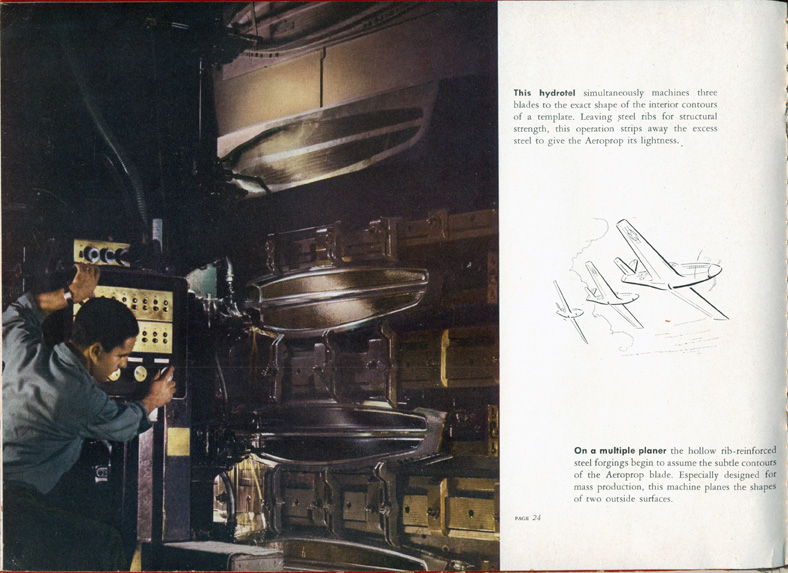

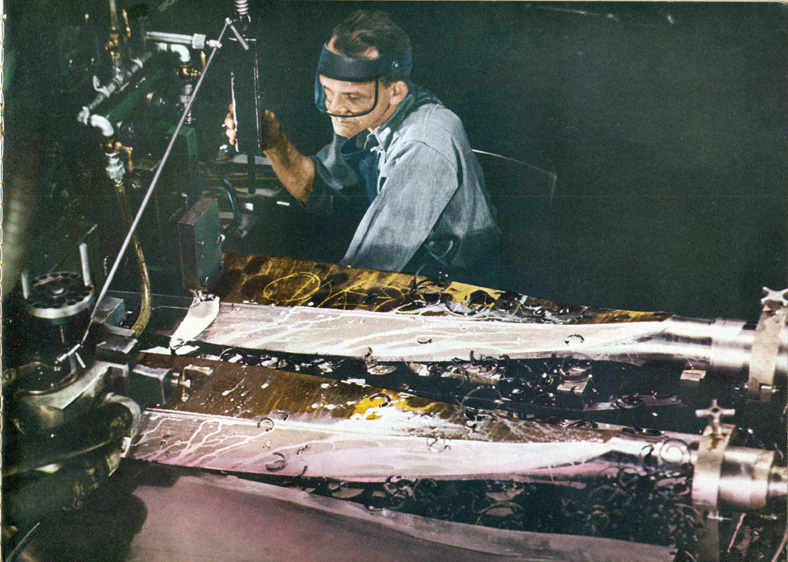

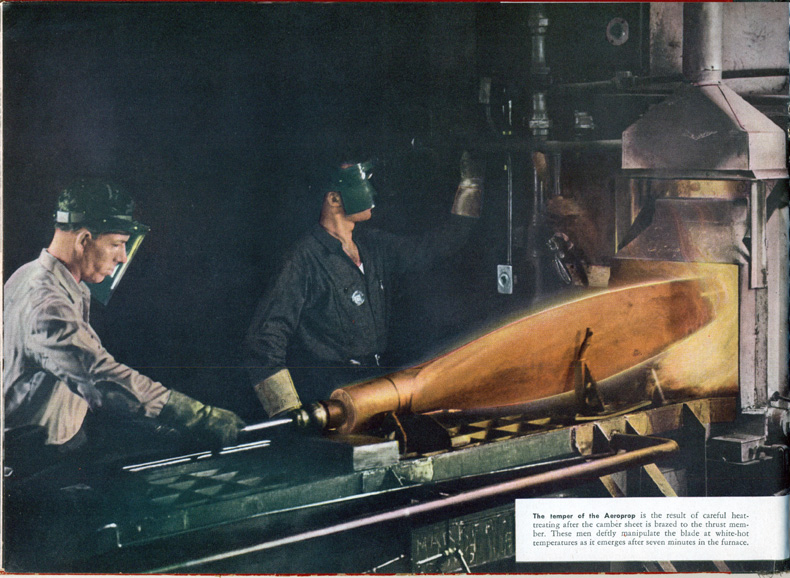

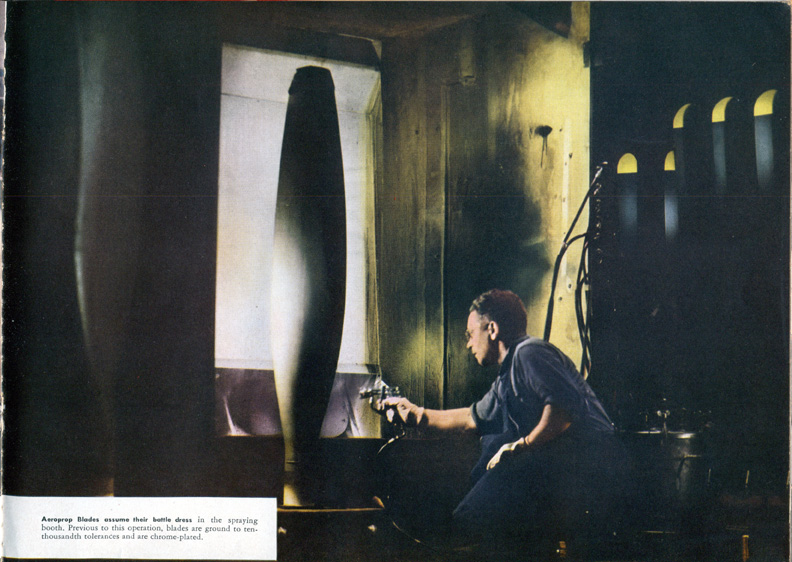

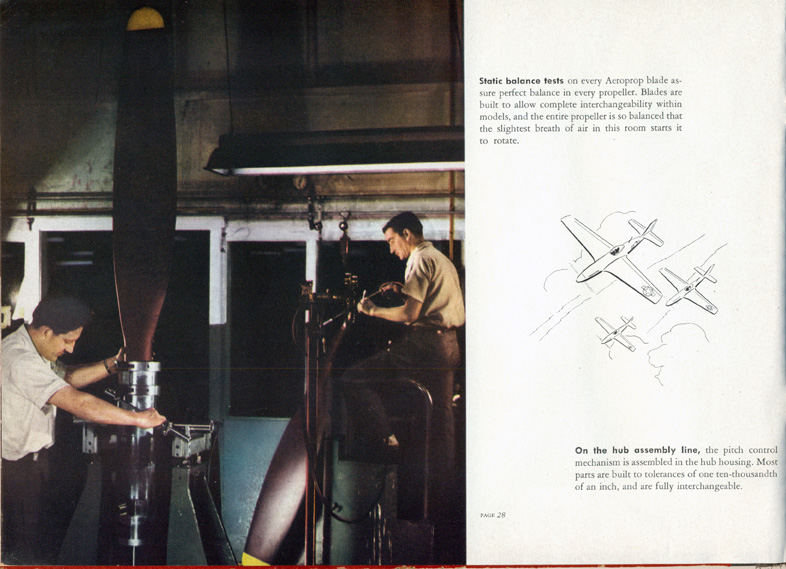

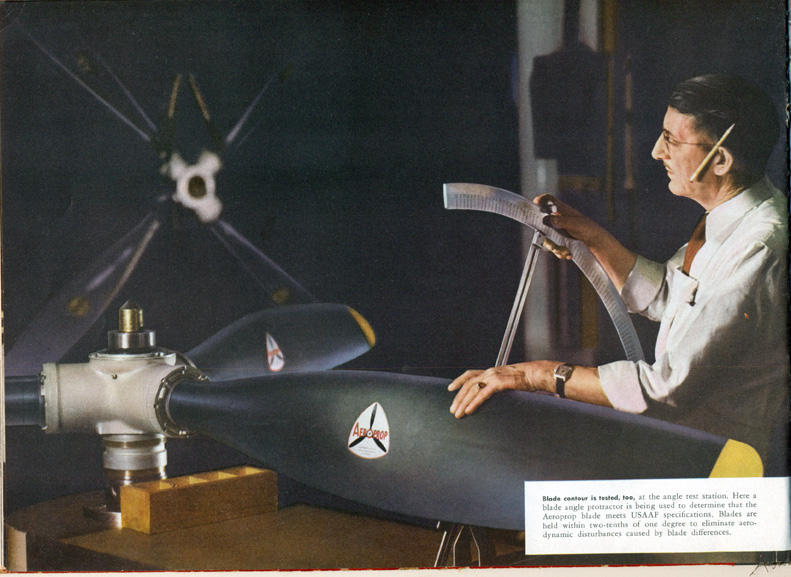

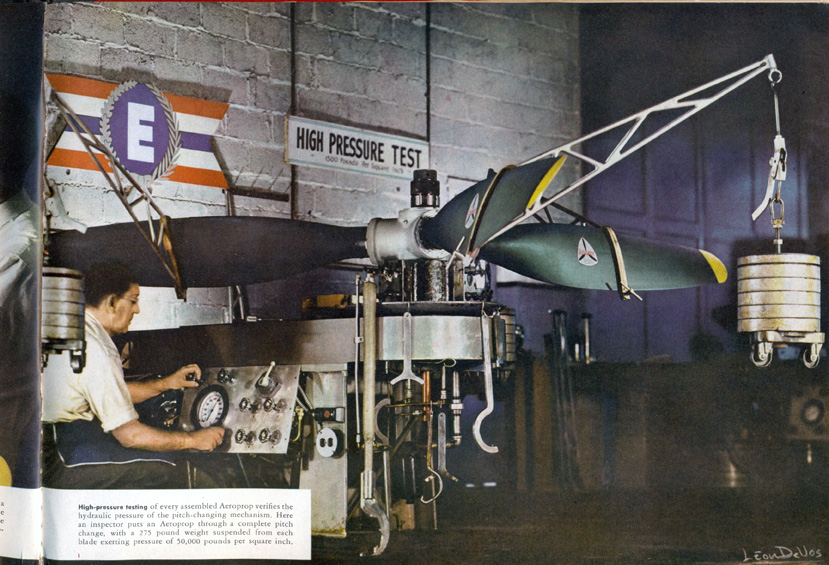

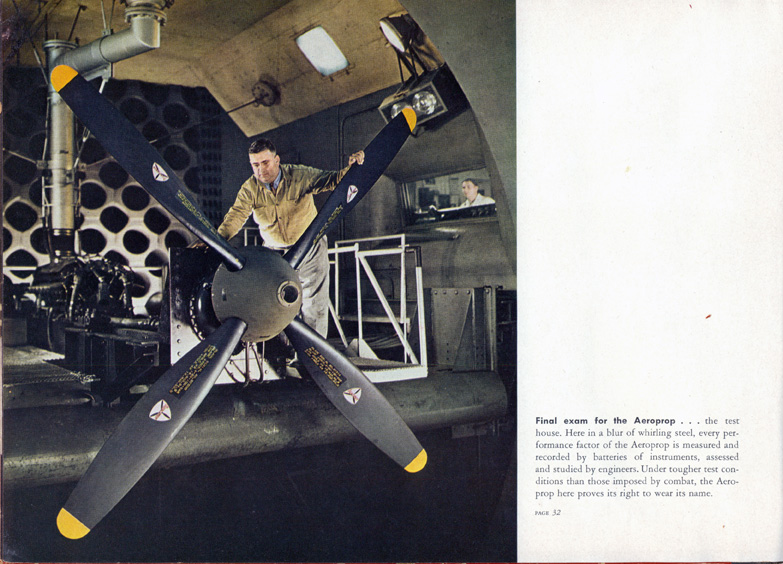

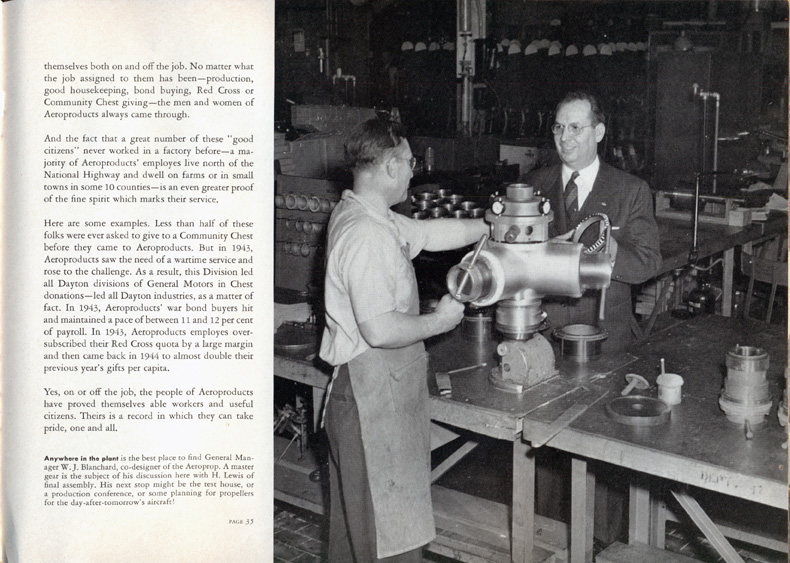

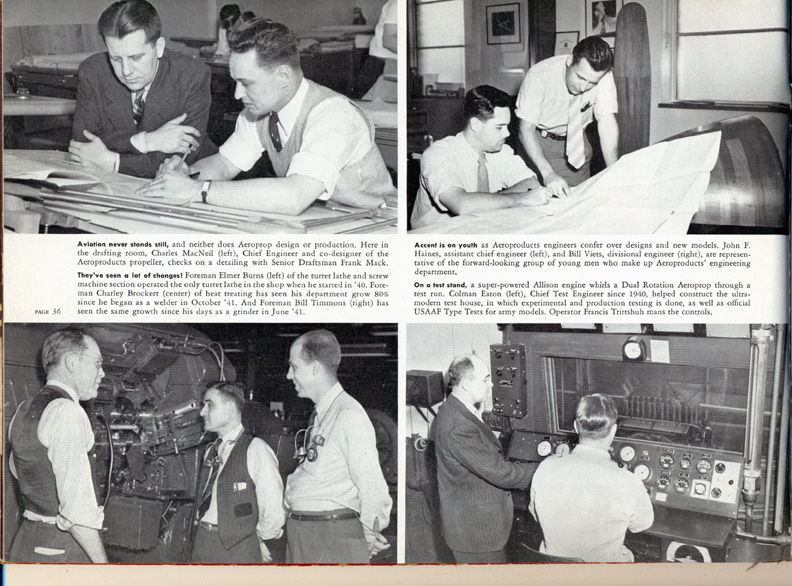

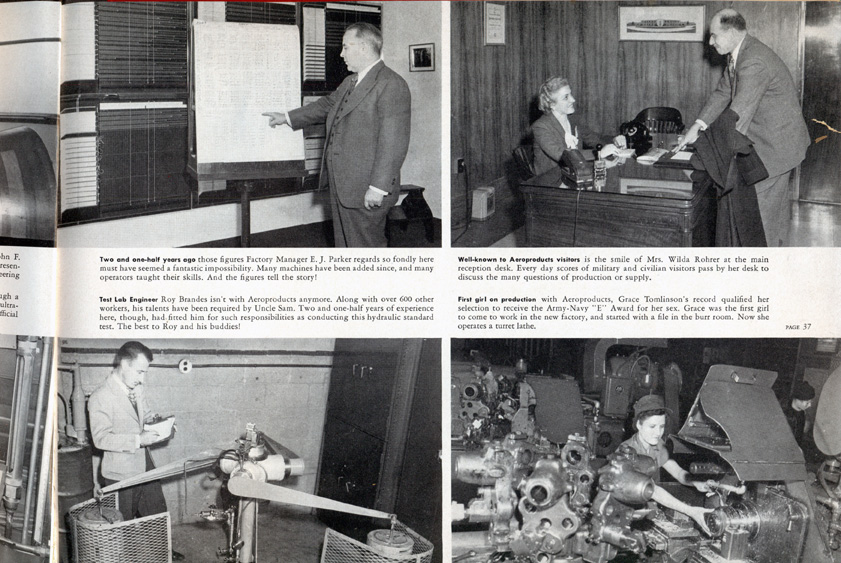

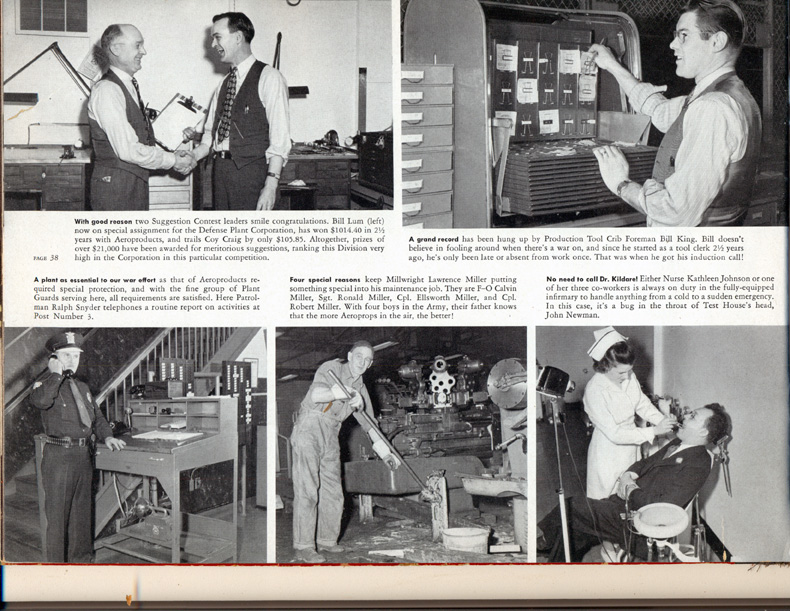

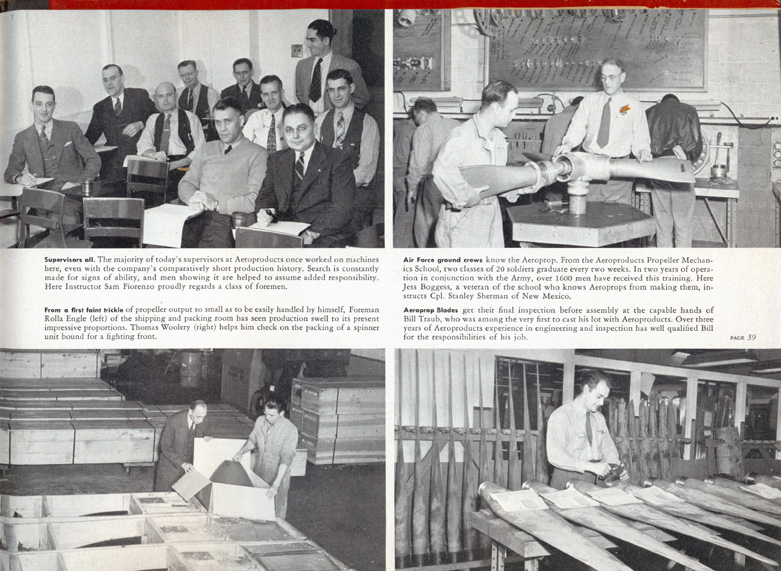

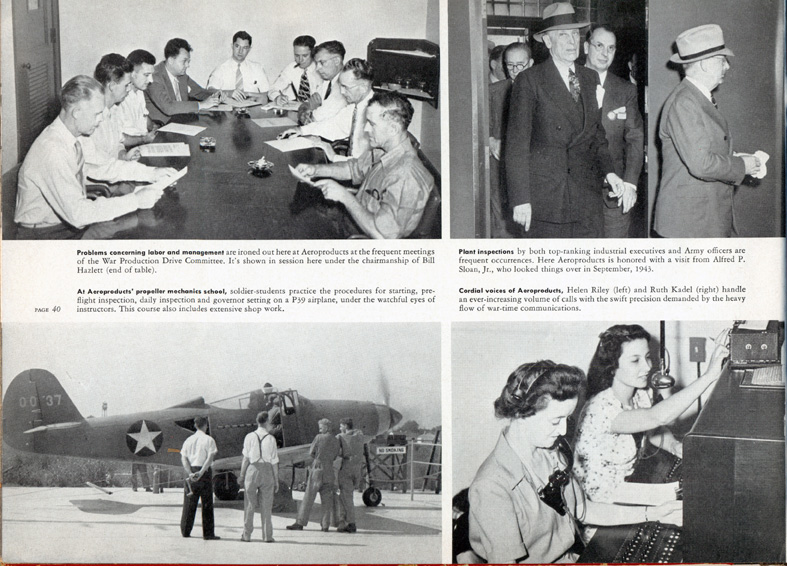

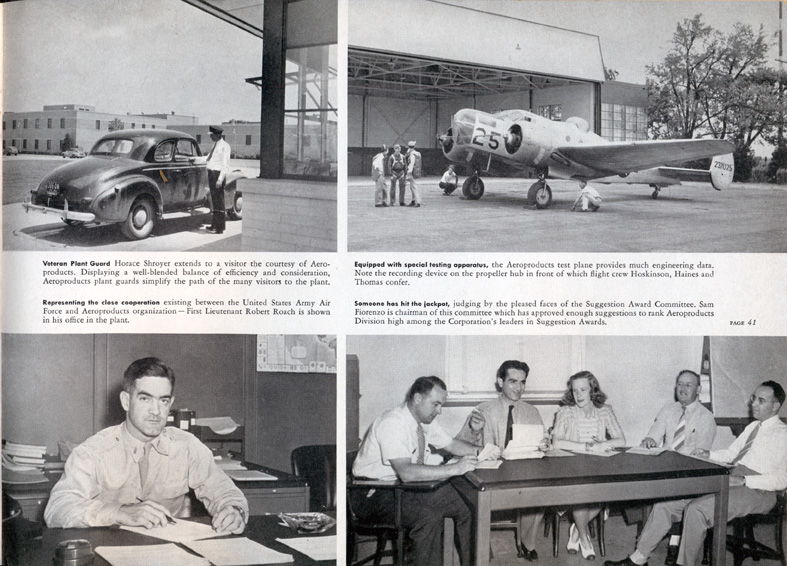

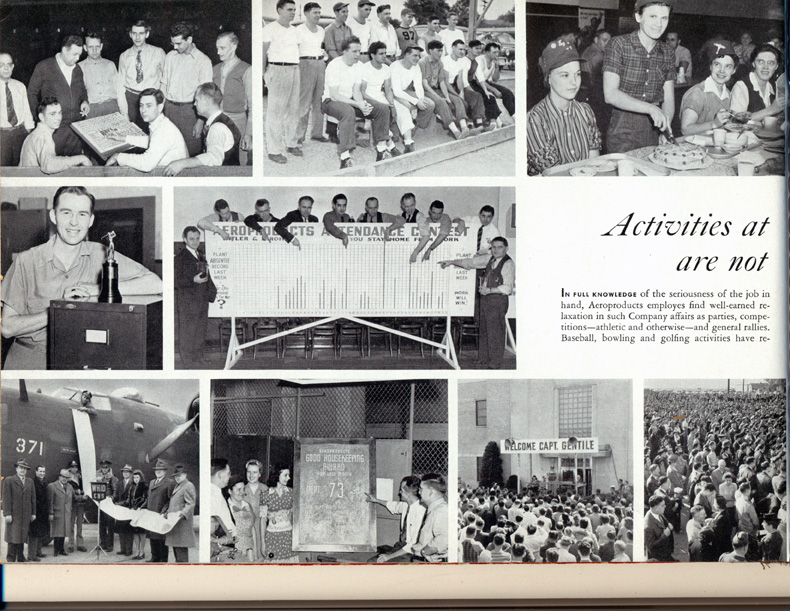

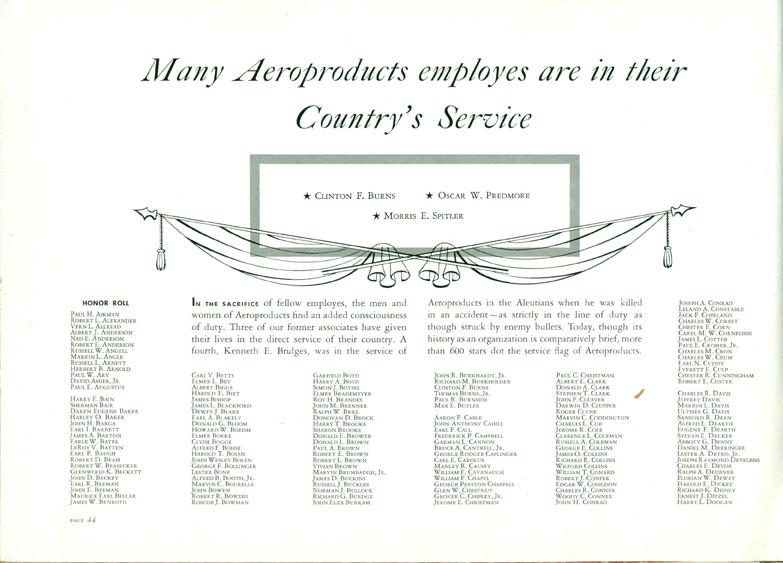

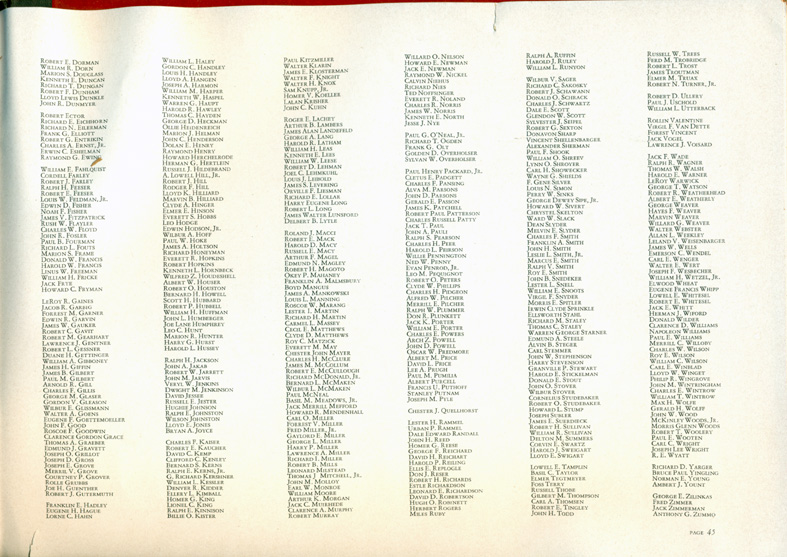

Blades for Victory - The Story of the

Aeroproducts Propeller & the Men & Women who build it

This booklet gives an excellent overview

of what and how the Aeroproducts propeller was made and those who made it

during the Second World War.

|