|

Studebaker Main Page

Studebaker Proving Ground

Studebaker South Bend Plant Photos

Studebaker

World War Two Vehicle Photos

Studebaker in World War One

Studebaker R-1820 Aircraft

Engines on the B-17 "Yankee Lady"

Studebaker World War Two Fort Wayne

Plant

Studebaker Pacific Corporation

Studebaker in World War Two

South Bend, IN

1852-1963

Automobile production in the U.S. at South Bend stopped in 1963.

Other diversified parts of the company survived for years afterwards.

Rest in Peace

Studebaker World War Two Fort Wayne Photo page added 2-7-2018.

Studebaker R-1820 Aircraft Engines on the B-17 "Yankee Lady" page added

6-12-2016.

Studebaker Proving Ground and Studebaker South Bend Plant Photo pages

added 1-25-2015.

Studebaker in World War One and Studebaker World War Two Vehicle Photos

pages added 2-12-2015.

This page last updated

12-29-2022.

Studebaker had 17,000 employees during

World War Two and had production facilities in South Bend, IN, Fort Wayne, IN,

and Chicago, IL after having moved out of its facilities in Detroit during the Great

Depression. The company's total contract value for the war was

$1.2 billion.

In South Bend there was the main

automotive complex of several plants that produced truck engines, trucks,

and the M29 Weasel. This was the main Studebaker complex that

built automobiles and trucks before and after the war until the company

went out of

business.

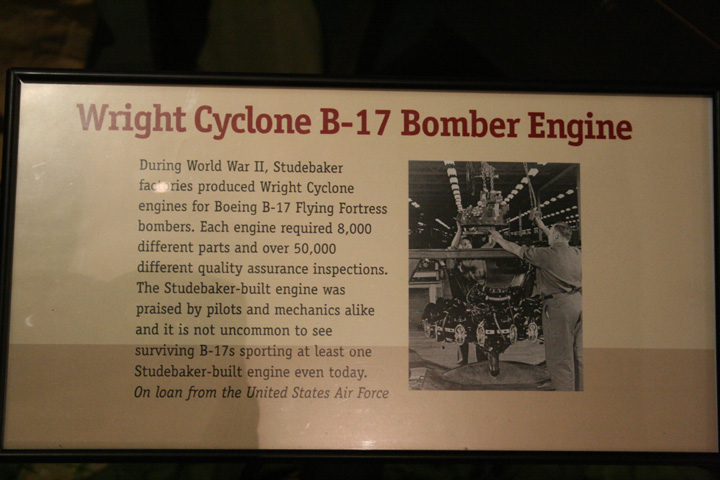

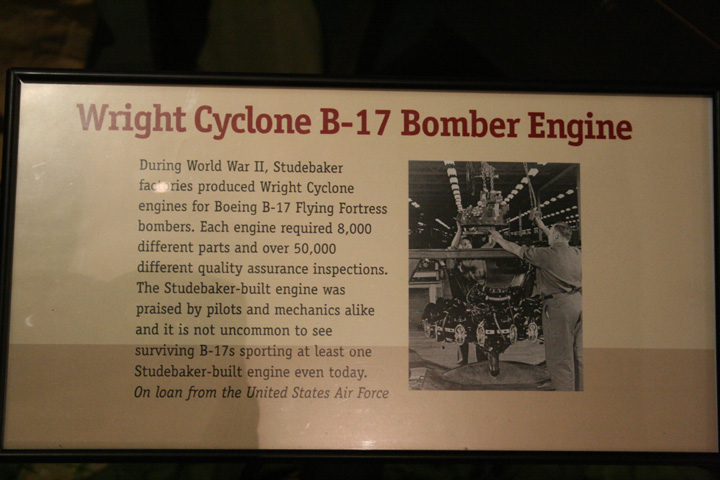

The Studebaker plant on the south side of

South Bend at 701 West Chippewa Avenue was utilized for the final assembly of license-built Wright R-1820 aircraft engines for the B-17 Flying Fortress.

During World War Two, this 1,560,000 square foot plant was on five parcels of land

totaling 318 acres. This was a government owned plant.

The plant on the southwest corner of

Archer and Cicero Avenues in Chicago, IL was an 850,000 square foot plant on 50

acres to produce components for the Chippewa Street final assembly

plant. The Chicago plant still exists today as a logistics center.

This was a government owned plant during World War Two.

The Studebaker Fort Wayne, IN plant also

produced components for Chippewa Street. This 500,000 square foot

building is currently located at 4410 New Haven Avenue in Fort Wayne

and was a government owned plant during the war. During World War

Two its

address was 4300 New Haven Avenue. It appears that after the war the magnet wire

plant currently owned by Rea Magnet Wire took the vacant property to the west of the former aircraft parts plant, and the address for

the former Studebaker plant changed.

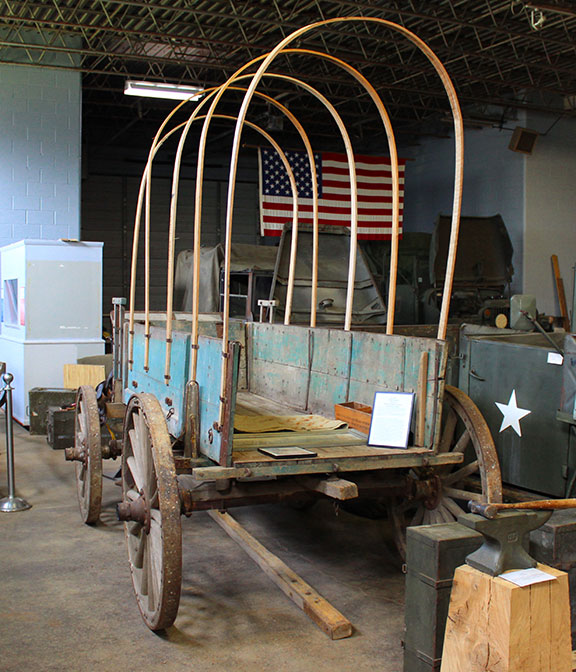

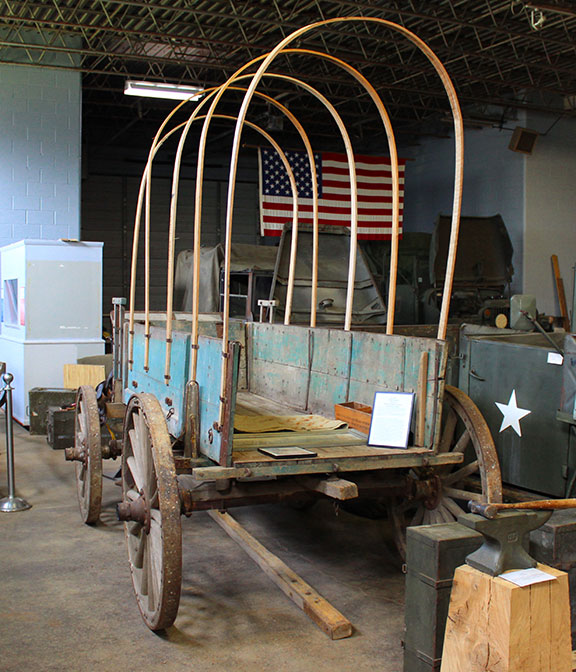

Studebaker started as a wagon manufacturer

in South Bend, IN in 1852, before making the conversion to trucks and

automobiles in the early 20th century. Seen here at the Museum of

the Soldier in Portland, IN is a Studebaker Wagon Company built Army

Escort Wagon 1899-1917. Author's photo added 9-30-2014.

This type of Escort Wagon was pulled

by four mules and accompanied soldiers in the field by carrying their

personal belongings, food, and other essentials and suppliers.

Author's photo added 9-30-2014.

The Five Studebaker plants were awarded a

total of 17 Army-Navy "E" Awards during WWII.

The Studebaker Aviation Plant in Chicago, IL won three Army-Navy "E" Awards.

The Studebaker Aviation Plant in South Bend, IN won four Army-Navy "E" Awards.

The Studebaker Automotive Plant in South Bend, IN won three Army-Navy

"E" Awards.

The Studebaker Aviation Plant in Fort Wayne, IN won four Army-Navy "E" Awards.

The Studebaker Pacific Assembly Plant in Los Angeles, CA won three Army-Navy "E" Awards.

This is the B-17F Memphis Belle on May 17,

2018, 74 years to the date from when she completed 25 combat missions over

Europe. This photo was taken several hours after the dedication of

the Memphis Belle at the National Museum of the United States Air Force.

Three of the engines currently on the Memphis Belle, which is one of the

most famous aircraft of World War Two, were built by Studebaker. Author's

photo added 5-21-2018.

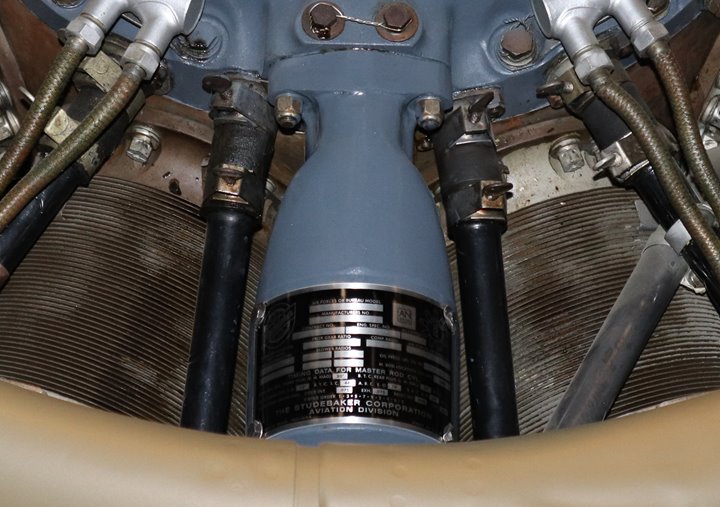

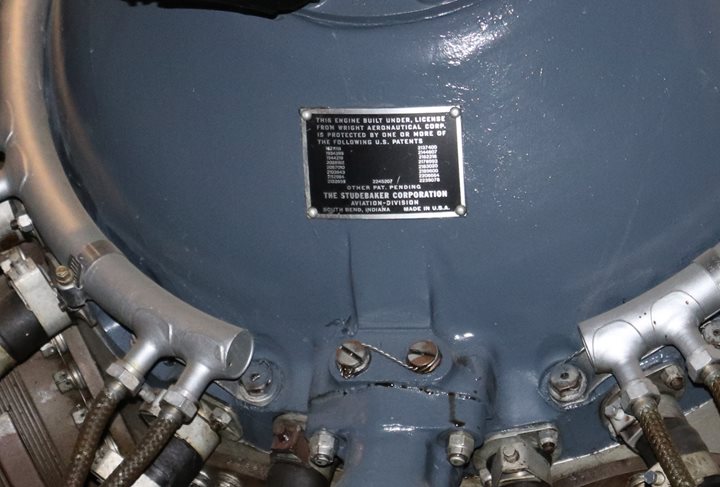

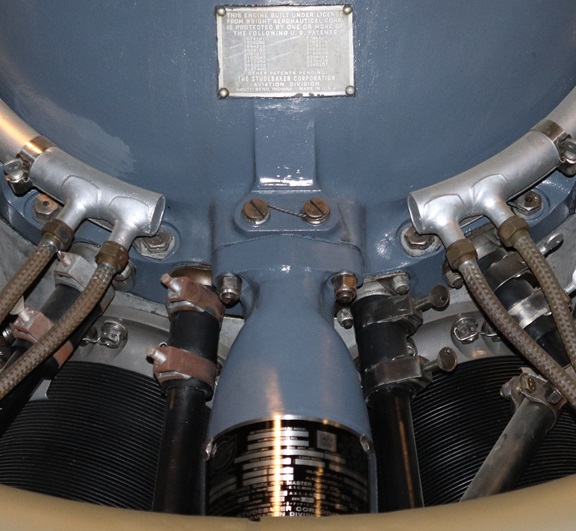

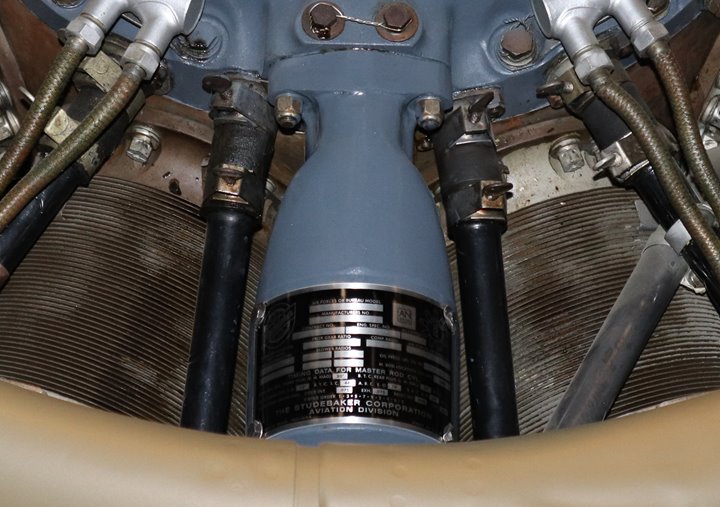

The number three engine, nearest the

fuselage, has an engine with a new Studebaker data plate. The number

four engine, closest to the end of the wing, has an unreadable

Studebaker data plate, but an original "built under license" tag.

Author's photo added 5-21-2018.

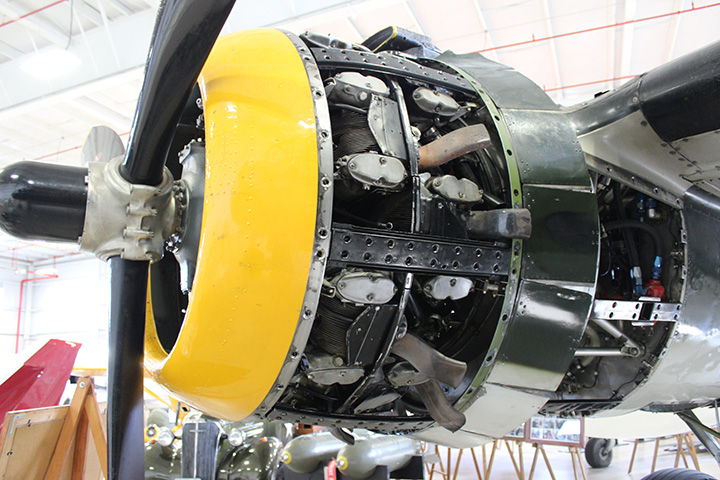

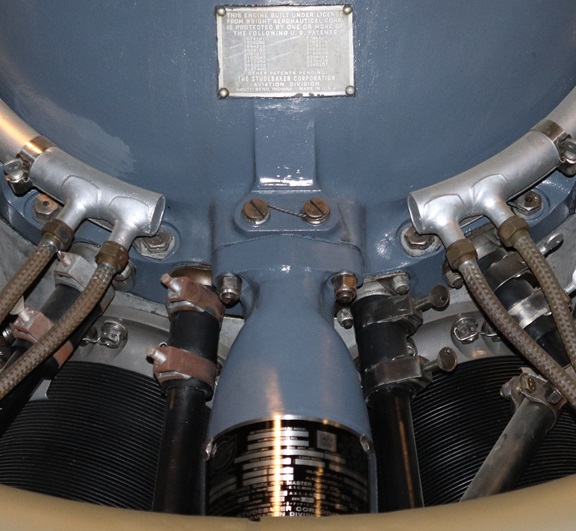

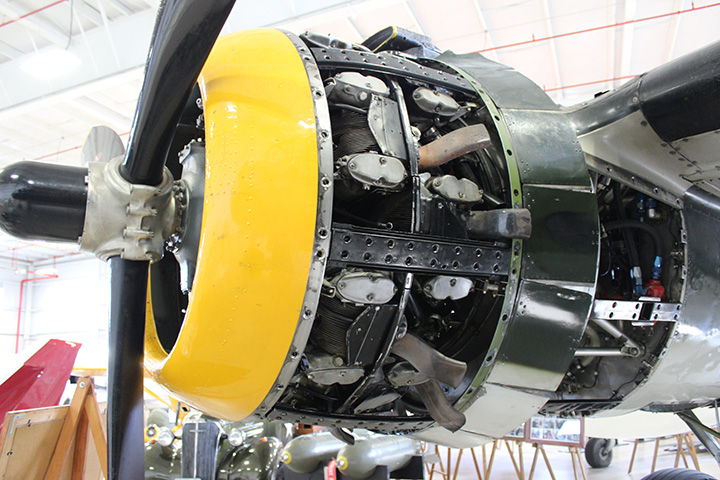

Engine number three. All of the

Studebaker production of radial aircraft engines went into the Boeing

B-17 Flying Fortress. All B-17s manufactured after January 1944 came

equipped with Studebaker-built R-1820 engines, with the last engines

coming off the South Bend, IN assembly line in June 1945.

Author's photo added 5-21-2018.

Engine number four. Author's photo

added 5-21-2018.

Engine number one also has a Studebaker

engine. Author's photo added 5-21-2018.

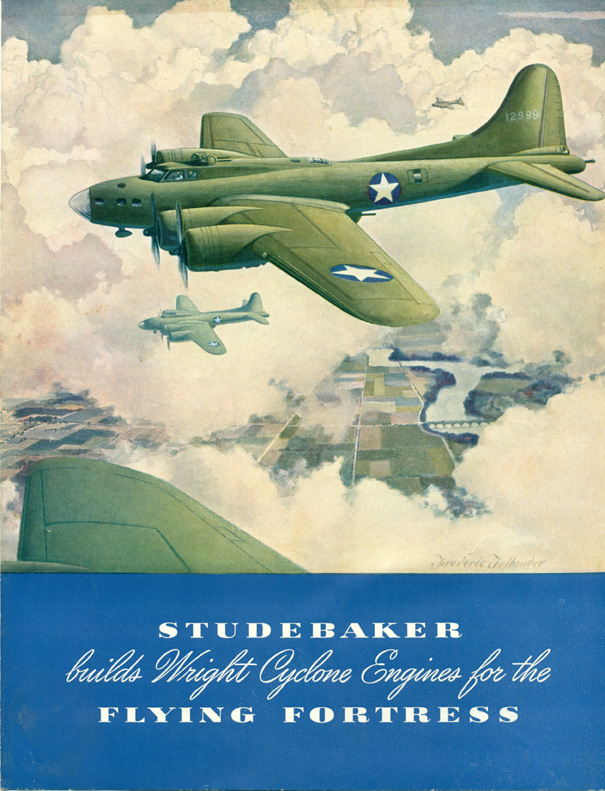

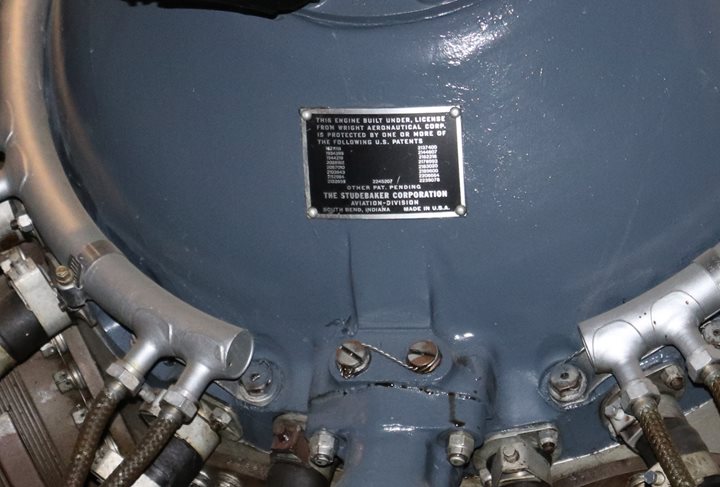

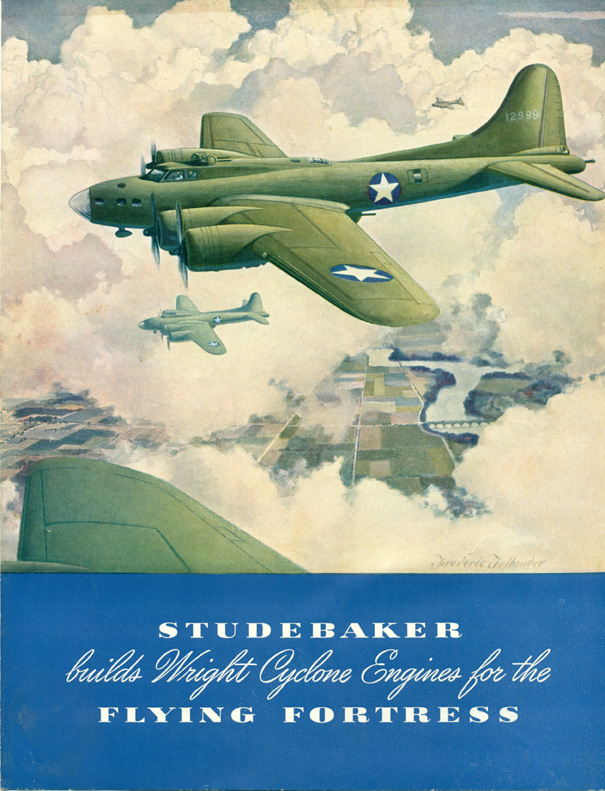

Studebaker built 63,789 Wright R-1820

Cyclone aircraft engines under license from the Wright Aeronautical

Company. Author's photo added 5-21-2018.

This 1931 Studebaker fire truck is on

display at the Liberty Aviation Museum in Port Clinton, OH.

Author's photo added 4-22-2019.

Author's photo added 4-22-2019.

The chassis was by Studebaker, and the fire

apparatus was built and installed by Boyer of Logansport, IN.

Author's photo added 4-22-2019.

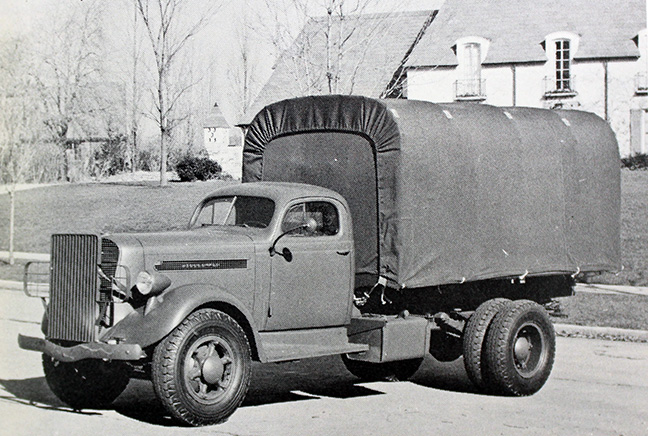

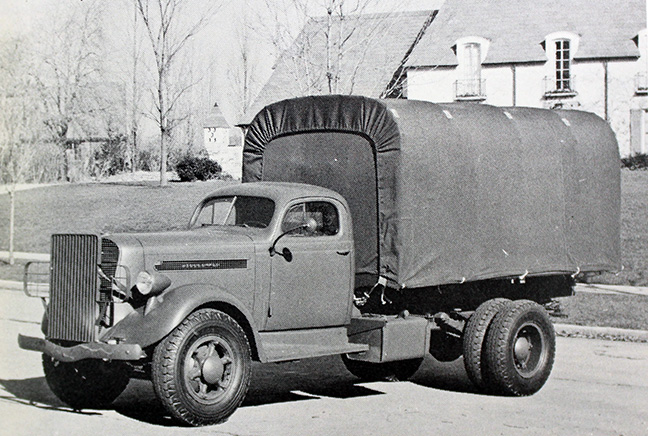

Long before the US became involved in World

War Two,

Studebaker was supplying 4x2 1-1/2 ton K-Series trucks to the

Netherlands, France, and Belgium. Most were captured by the Germans

and used by them during the conflict. Photo added 2-12-2015.

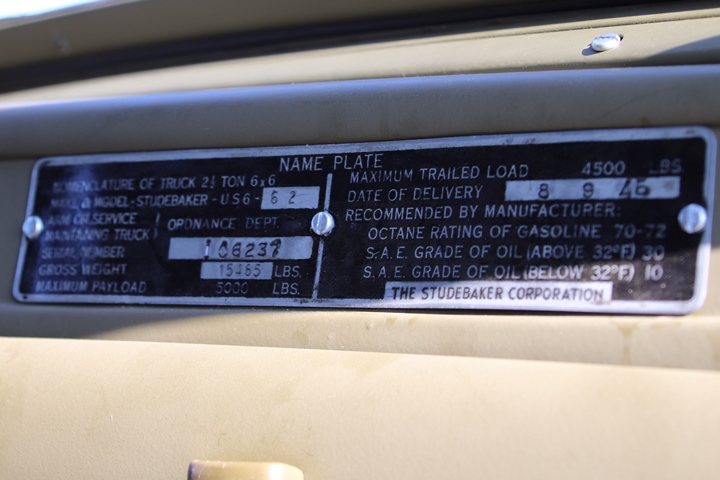

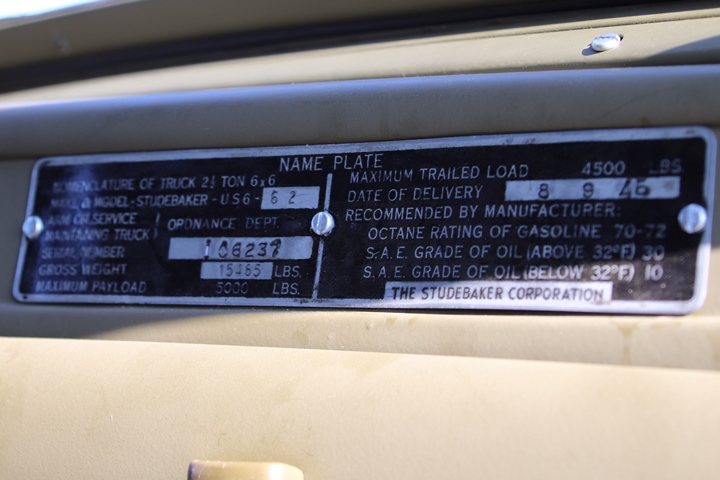

Studebaker built 103,739 US6 2-1/2-ton 6x6

trucks without a winch during World War Two. This truck is part

of the excellent collection of the Wheels of Liberation in Gettysburg,

PA. Author's photo added 12-29-2022.

This US6 is seral number 106237 and was

delivered on 8-9-1945. Author's photo added 12-29-2022.

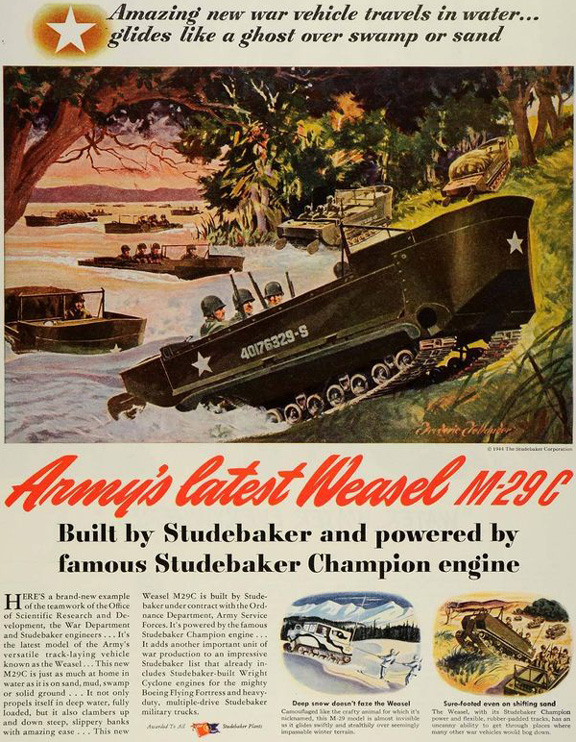

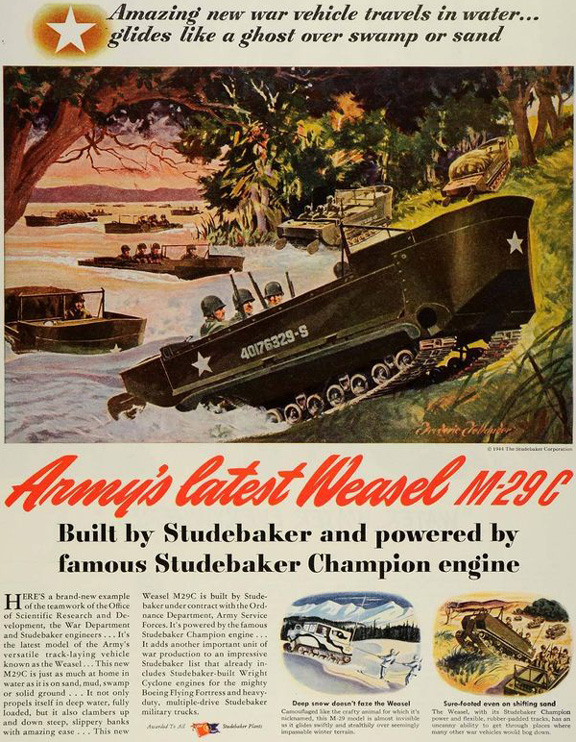

Another important product of Studebaker

during World War Two was the M29 Weasel. This M29C was photographed at the National

MVPA Convention in Louisville, KY in June of 2014. It is in the

markings of the USMC at the Iwo Jima landings.

Studebaker World War

Two Production:

63,789 of the

Wright R-1820 Cyclone aircraft engines were used exclusively in the Boeing

B-17 Flying Fortress Bomber. Starting in January of 1944 and

continuing to the end of B-17 production in the summer of 1945,

Studebaker supplied all of the engines installed the B-17s.

For production of the radial

aircraft engines, the Defense Plants Corporation provided $50,000,000

for a new plant on Chippewa Avenue on the south side of South Bend, the

ground breaking ceremony taking place in January 1941.

Studebaker did not need the facility after World War Two as it

was too large for its intended car production. However, during

the Korean War it assembled post war M35 2-1/2 ton military trucks in

the facility. After Studebaker went out of business, Kaiser-Willys

purchased the product line and the plant. When American Motors

purchased the Jeep and M35 product lines from Kaiser-Willys, the South

Bend plant and M35 trucks became part of the newly named AM General

subsidiary of American Motors. All during the name changes, the

M35 series trucks were built in the same plant on Chippewa Avenue on the

same assembly line by the same production workers. Only the name

on the front of the building and on the paychecks changed.

16,089 Light Cargo

Carriers (Weasels): The Light Cargo Carrier was invaluable to the

military as it had the ability to move through sand, mud and snow and

negotiate up, down and sideways across hills.

It was totally designed and built by Studebaker in its main plant in

South Bend.

80 Sleds for M28:

Studebaker Light Cargo Carriers and Sleds

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch.

January 21, 1946. |

|

Type |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Carrier,

Cargo, Light, M28 (T15) |

|

|

306 |

460 |

|

|

766 |

| Cargo,

Carrier, Light, M29 (T24) |

|

|

|

1,525 |

2,951 |

|

4,476 |

| Cargo,

Carrier, Light, M29C (T24) |

|

|

|

|

4,401 |

6,446 |

10,847 |

| Totals |

|

|

306 |

1,985 |

7,352 |

6,446 |

16,089 |

| |

|

|

|

|

|

|

|

| Sleds, To be

used with M28 |

|

|

|

80 |

|

|

80 |

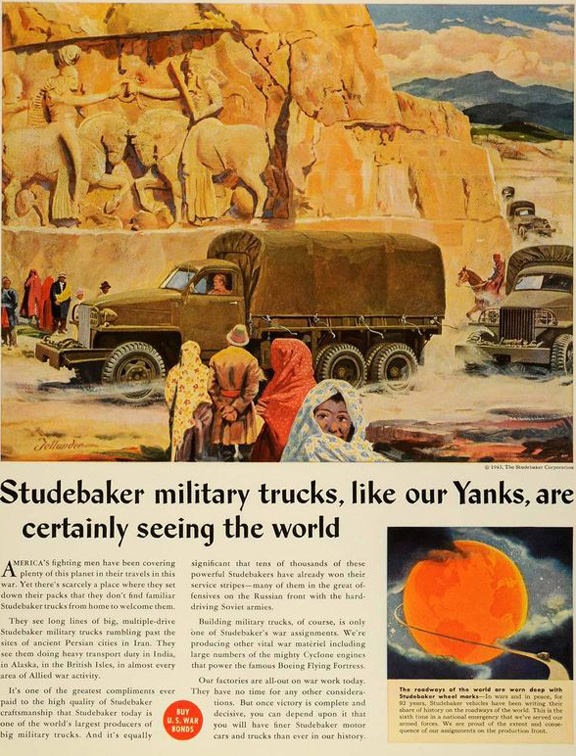

218,863 US6 / M16A 2-1/2 ton 6x6 and 6x4 trucks:

Most of the production went

to Russia which desperately needed good reliable heavy duty trucks.

In appreciation for the supply of trucks, Joseph Stalin sent Studebaker

an official letter of thanks. The trucks came in either a 148 in.

or 162 in. wheelbase. There was also a 6x4 version that was rated

at 5 tons but this was for over the road use only. The 6x6 was

rated 2 1/2 tons for off road travel and five tons for over the road travel. Around

10,000 trucks were manufactured as open cab starting in December of 1942,

but production reverted back to the covered cab in March 1943, after

the Russian Army expressed its dissatisfaction with the change.

It gets cold in Russia in the winter! Studebaker US6 trucks were not only manufactured as cargo trucks but

as 750

gallon water tankers, semi-tractors (6x4), and dump trucks.

Studebaker Trucks

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch.

January 21, 1946. |

|

Type |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| 2-1/2 -Ton,

6x6, Cargo, wo/w |

|

1,953 |

17,596 |

24,568 |

35,452 |

24,170 |

103,739 |

| 2-1/2 -Ton,

6x6, Cargo, w/w |

|

523 |

2,440 |

5,111 |

6,513 |

4,192 |

18,779 |

| 2-1/2 -Ton,

6x6, Cargo, SWB, wo/w |

|

425 |

|

|

|

|

425 |

| 2-1/2 -Ton,

6x6, Cargo, SWB, w/w |

|

779 |

|

|

|

|

779 |

| 2-1/2 -Ton,

6x6, Chassis, wo/w |

|

|

338 |

1,361 |

|

|

1,699 |

| 2-1/2 -Ton,

6x6, Dump, wo/w |

|

|

|

300 |

|

|

300 |

| 2-1/2 -Ton,

6x6, Dump, w/w |

|

|

|

100 |

|

|

100 |

| 2-1/2 -Ton,

6x6, Tank, 750 Gal. Gas (Complete Unit) |

|

232 |

268 |

|

|

|

500 |

| 2-1/2 -Ton,

6x6, Tank, Chassis for 750 Gal. |

|

|

|

|

|

1,800 |

1,800 |

| Total 6x6 |

|

3,912 |

20,642 |

31,440 |

41,965 |

30,162 |

128,121 |

| |

|

|

|

|

|

|

|

| 2-1/2 -Ton,

6x4, Cargo, wo/w |

|

|

13,696 |

16,320 |

26,340 |

13,642 |

69,998 |

| 2-1/2 -Ton,

6x4, Cargo, w/w |

|

|

2,376 |

2,880 |

4,646 |

2,202 |

12,104 |

| 2-1/2 -Ton,

6x4, Tractor |

|

|

2,094 |

2,868 |

2,270 |

1,408 |

8,640 |

| Total 6x4 |

|

|

18,166 |

22,068 |

33,256 |

17,252 |

90,742 |

| |

|

|

|

|

|

|

|

| Total 6x6

and 6x4 |

|

3,912 |

38,808 |

53,503 |

75,221 |

47,414 |

218,863 |

2 Prototype T27 eight wheeled armored cars:

What didn't happen:

Originally the Chippewa Street Plant was to produce the Wright

R-2600 engine for the North American B-25. After much of the

tooling was built the Army Air Corp had a more urgent need for the

R-1820 for the B-17. The original tooling was scrapped and the

process started over to tool up for R-1820 production.

B-25 "Champaign Gal" at the Champaign Air

Museum in Urbana, OH. Studebaker originally was contracted to

build the engines for this type of aircraft. Photo added 2-12-2015.

The R-2600 had two rows of cylinders vs. the

one row in the R-1820. Photo added 2-12-2015.

Studebaker went on to build the Wright R-1820

as described in the article below.

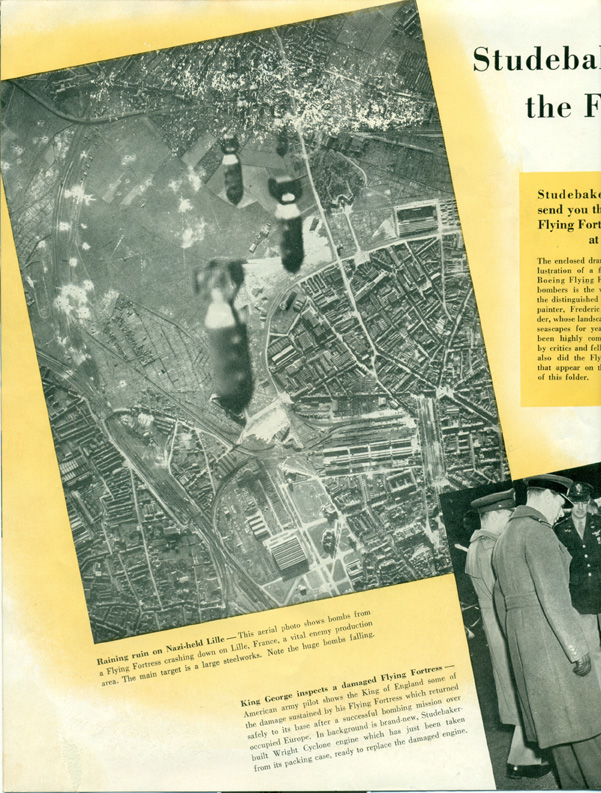

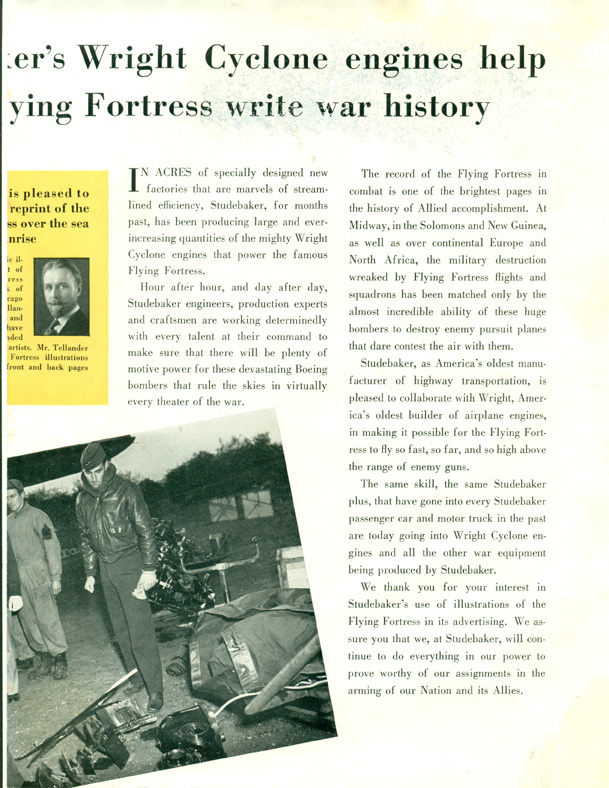

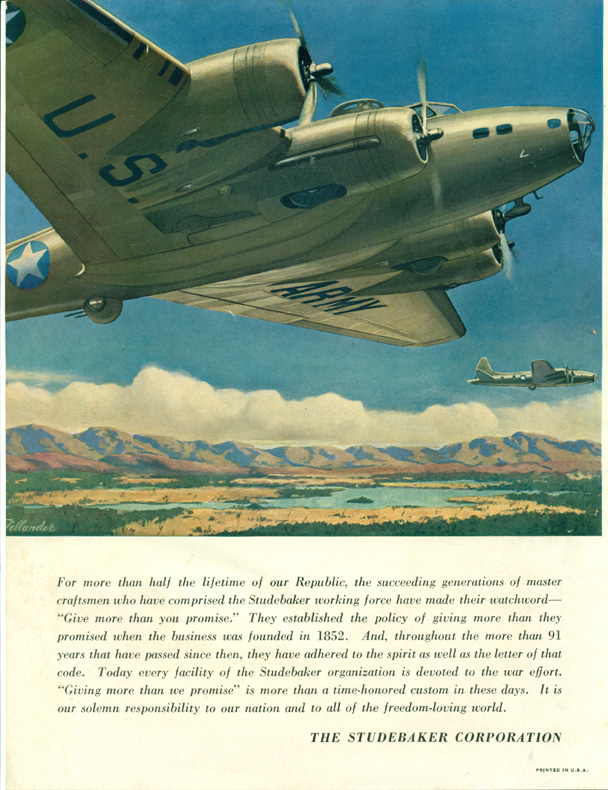

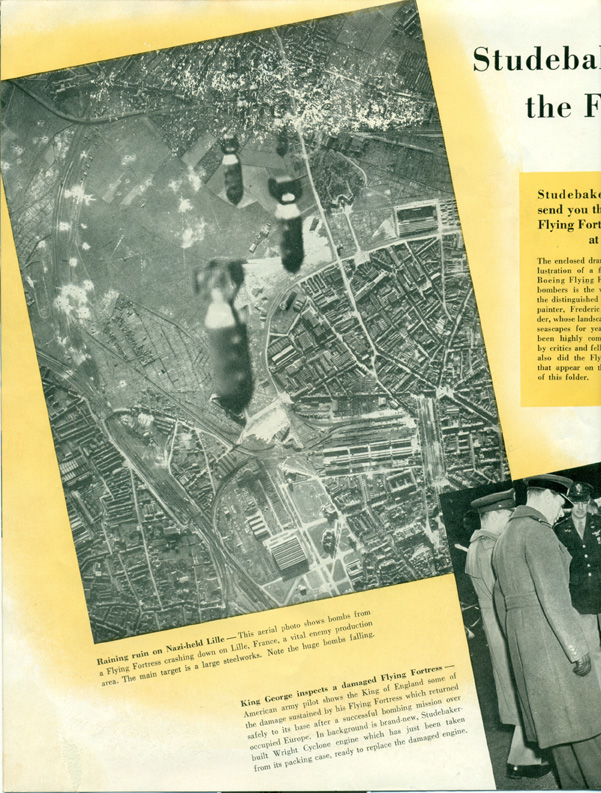

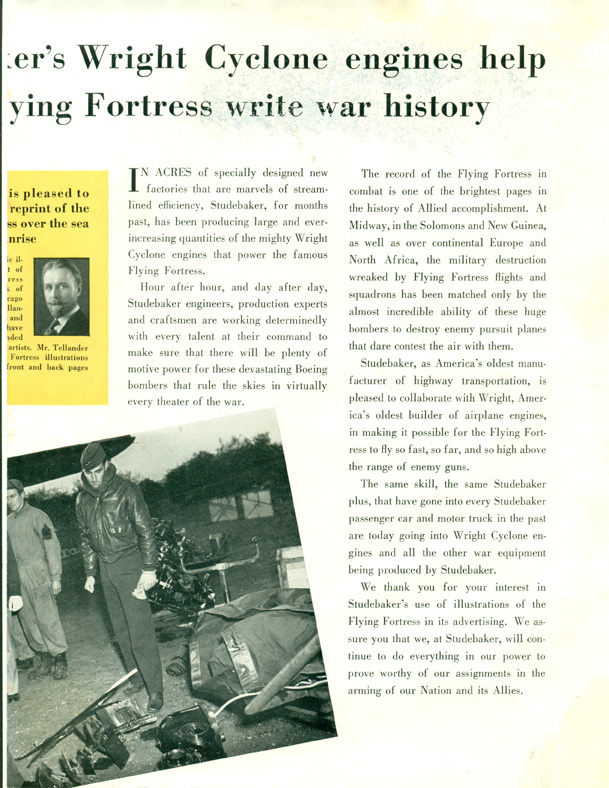

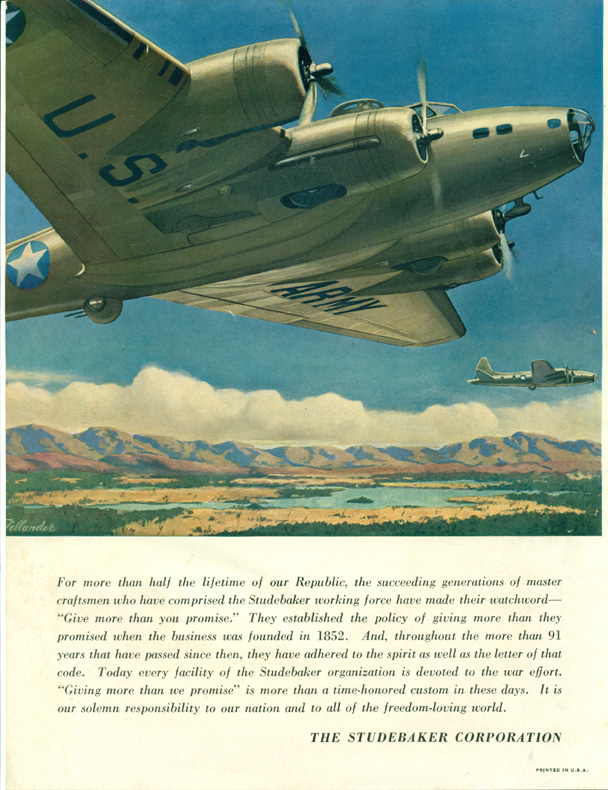

This undated four page brochure on Studebaker's contribution to the war

effort would appear to be 1943.

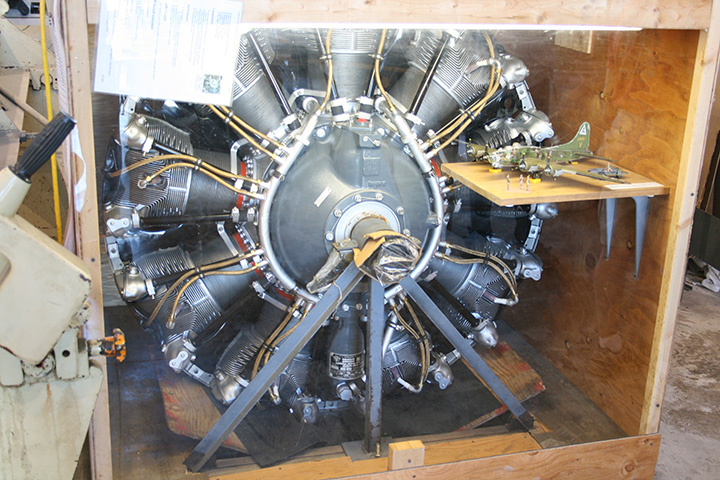

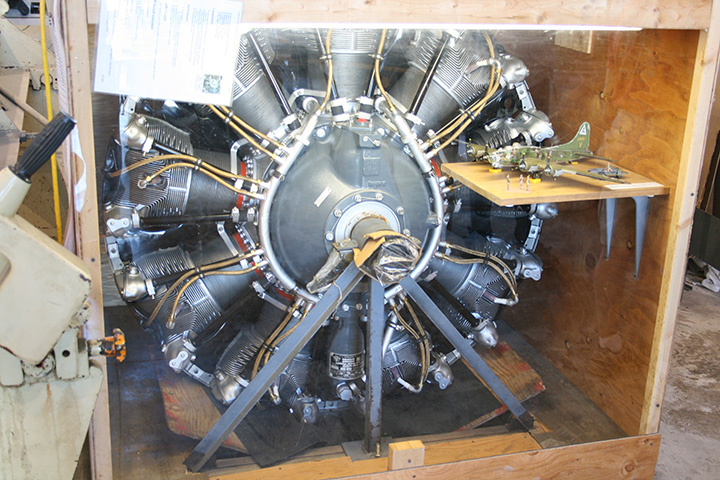

This is a Studebaker-built R-1820 engine

that is at the Champaign Aviation Museum in Urbana, OH. It will end up

as one of the four power plants that will go onto the B-17 "Champaign Lady"

when she is fully restored to flying condition by the Museum.

Here, a Studebaker-built M29 Weasel is

pulling troops on skies tethered by a tow rope in Italy in early

1945.

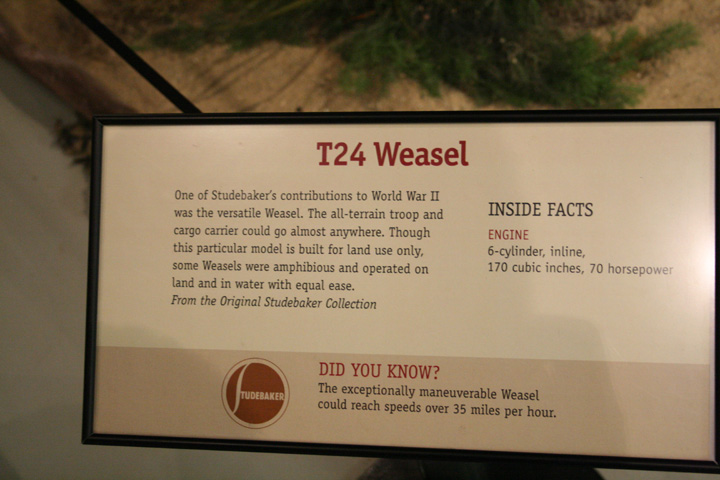

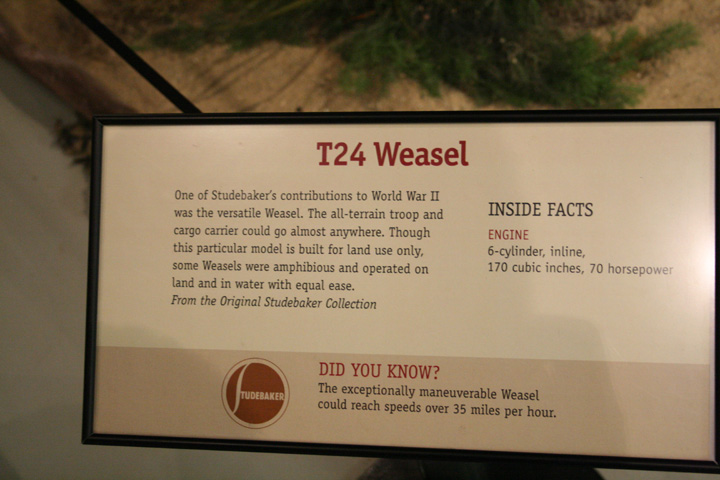

Photos from the Studebaker Museum in South

Bend, IN. This is an excellent museum and is well worth the trip

to South Bend to visit it. Consiting of three floors, there are all

sorts of vehicles in this brand new facility. The World WAr Two items are in the

basement which is a combination display and storage area for vehicles as

they are rotated through the main museum displays.

The M29/T15/T24 Weasel:

The Wright 1820 Radial Aircraft Engine:

There is no US6 truck on display but there was this photo of one.

See photo below.

Post-World War Two:

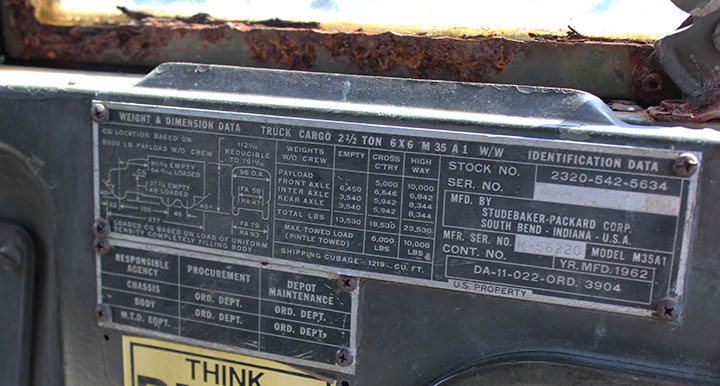

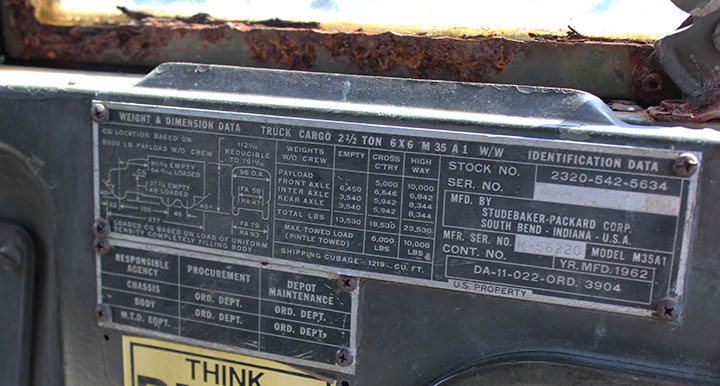

In the early 1960s, Studebaker, actually

Studebaker-Packard, was still turning out military trucks. This

M35A1 was built by the company in South Bend, IN in 1962. A year

later the company was gone. Author's photo from the 2014 MVPA

Portland, IN gathering added 9-30-2014.

During World War Two Studebaker designed the

US6, which Reo in Lansing, MI then also manufactured. After World

War Two, Reo then designed the M35 which not only

Studebaker built, like this one, but other companies built as well.

Author's photo added 9-30-2014.

Author's photo added 9-30-2014.

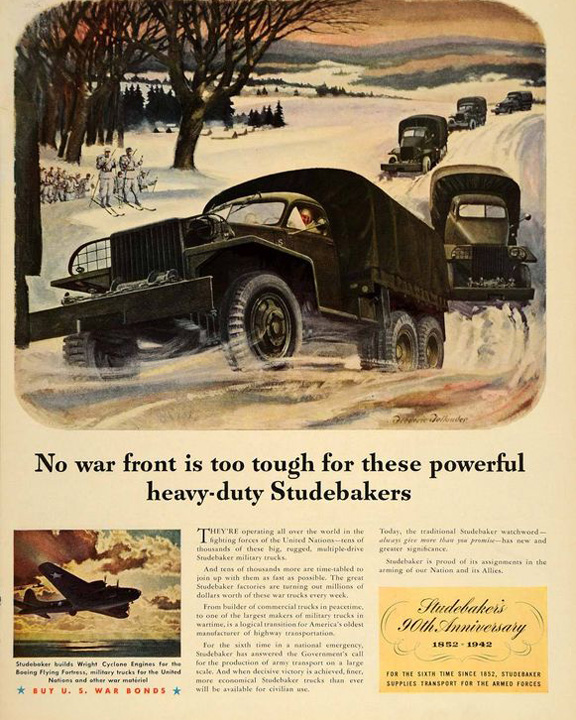

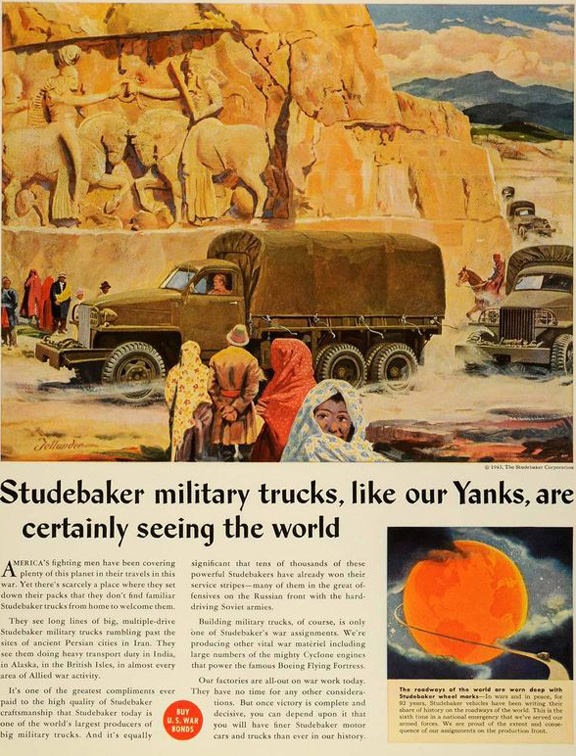

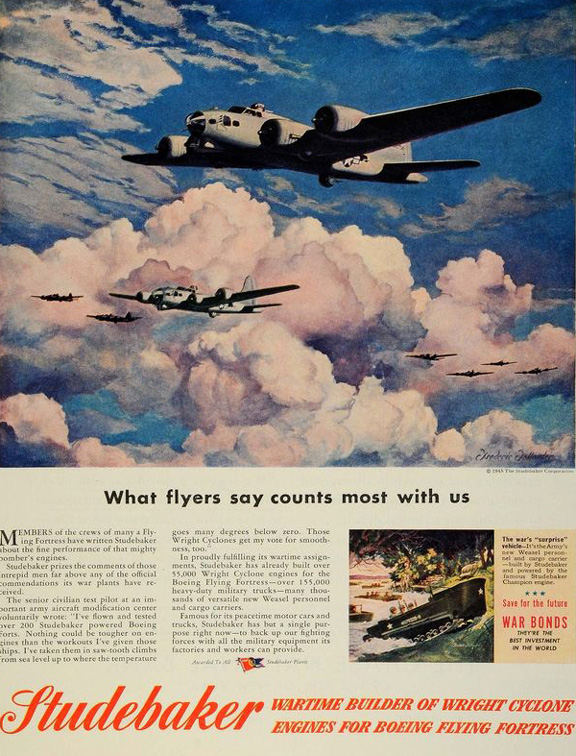

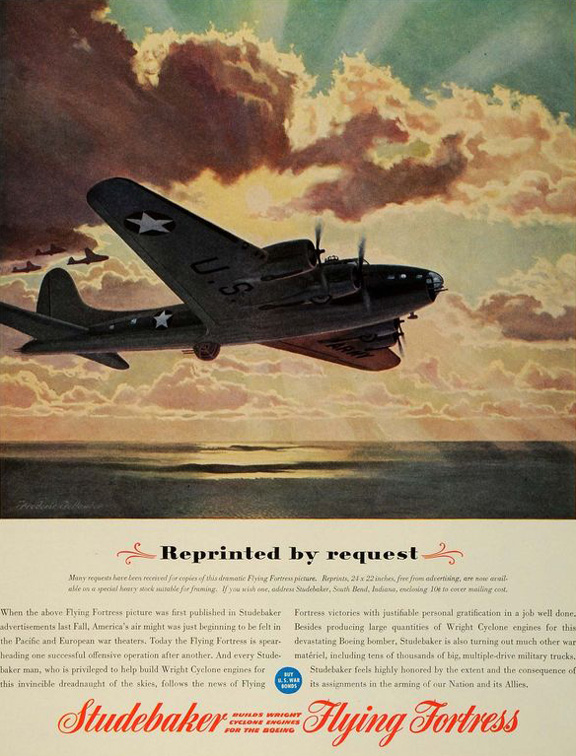

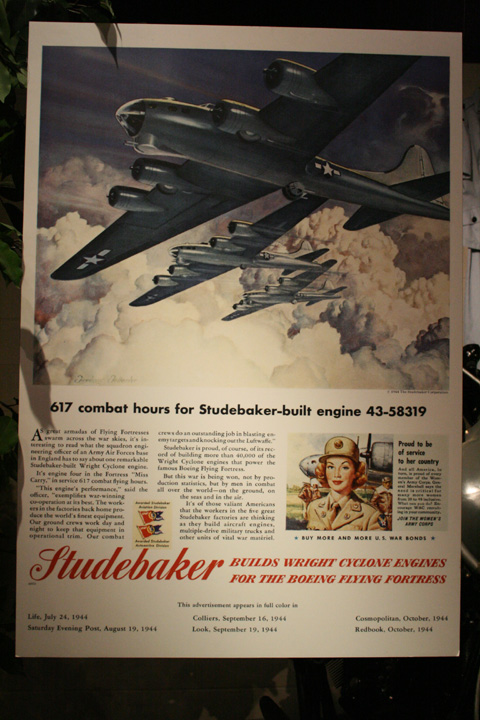

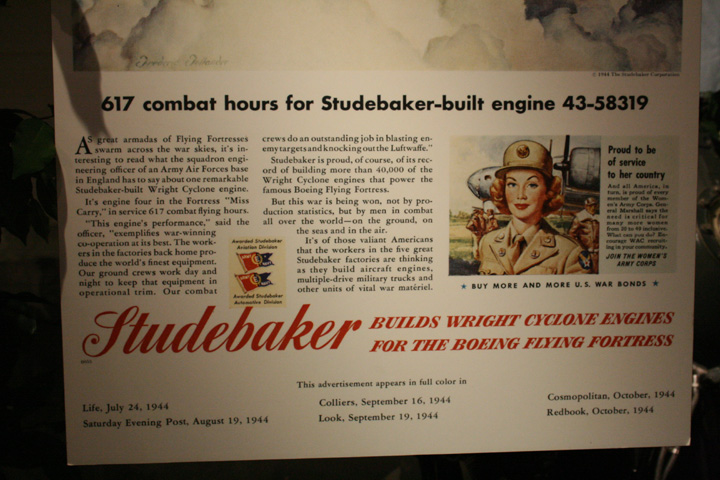

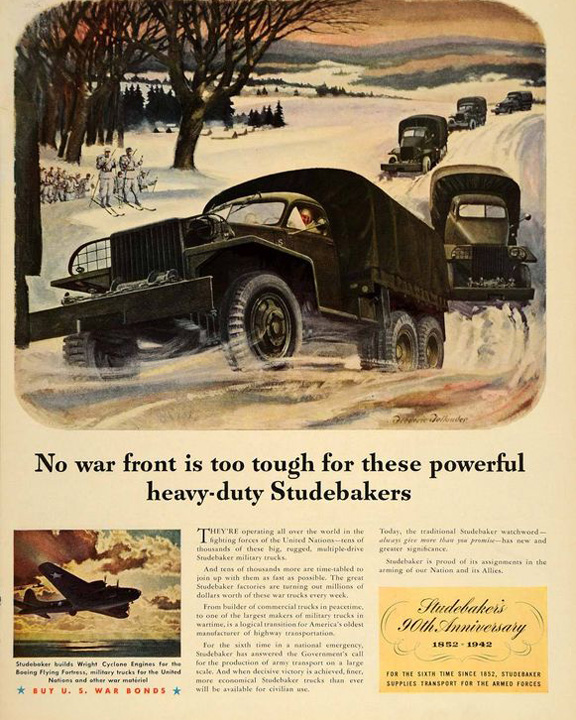

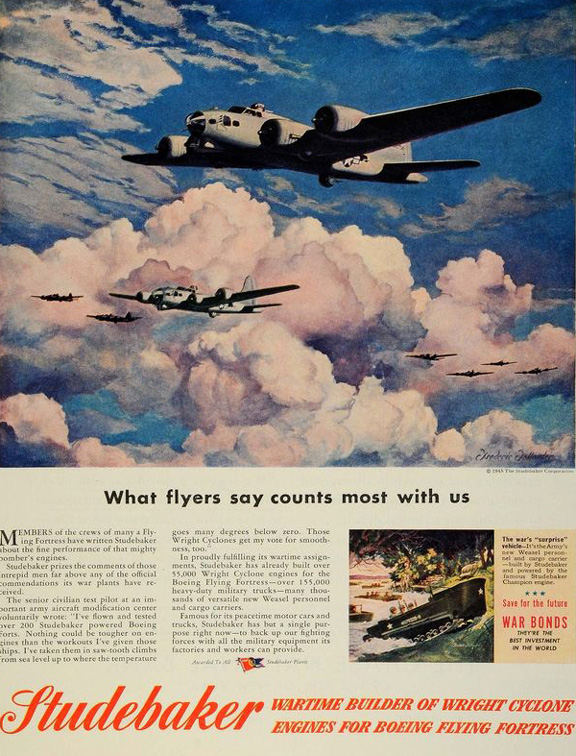

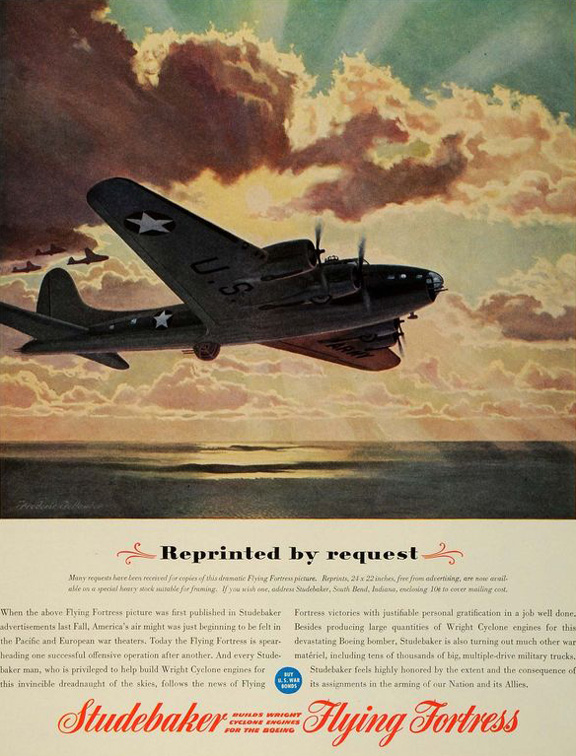

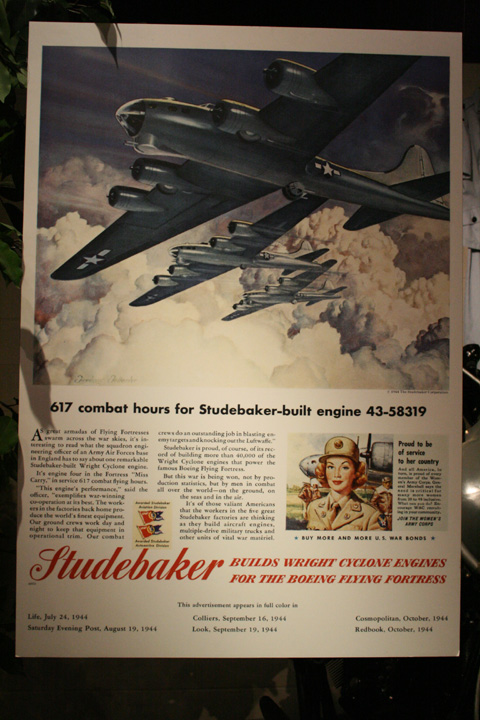

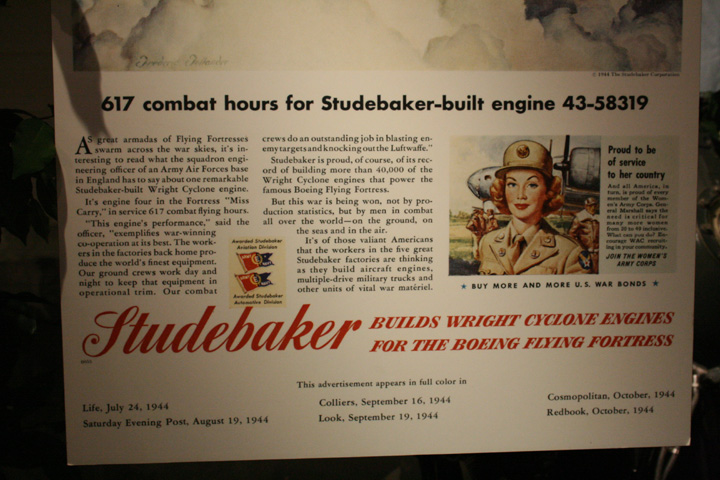

Magazine Advertisements - Studebaker is

one of the manufacturers that elected to advertise its war effort in the

magazines of the period to keep its name in front of the car buying

public, knowing there was going to be pent-up demand for automobiles after

hostilities ceased. Looking at the ads helps give more insight into the

war products produced.

This ad from October of 1944 gives some

Studebaker production numbers to that date. 45,000 R-1830 aircraft

engines out of a total of 63,789 and 135,000 trucks out of 197,678 had

been produced by that date. It is interesting that Studebaker

published the production numbers, as this was considered to be

classified information.

Studebaker built 197,678 trucks during WWII,

most of them going to the Soviet Union as part of the Lend-Lease program.

15,124 M29 Weasels were produced during World

War Two.

This was a Studebaker design, and it was the only company to manufacture

them.

You can see real Studebaker US6

Trucks below:

YouTube

Video of seventeen Studebaker Trucks in Queensland, Australia, 2007

|