|

Delco

Products Division of General Motors Corporation in World War Two

Dayton, OH

1929-1992

This

page updated 12-10-2024.

Delco Products became a Division of General

Motors in 1929. It was rolled into the newly formed Delco Chassis

Division that also included Delco Moraine in 1992. It later became

part of Delphi Automotive Systems in 1999. Surviving portions of

the division were sold to Tenneco in May 2008.

This is a rare but interesting ID tag of a Delco Products-manufactured

nose-strut for a North American B-25. It is rare because normally

more than 75 years after manufacture the ID tags have disappeared off of

the aircraft after many owners, rebuilds, and restorations. It is

curious that the Delco Products "War Diary" below, makes no mention of

making landing gears for the B-25. However, Delco Products did build the B-25

main and nose struts in the borrowed Fisher Body plant in Norwood, OH. Author's photo.

Here is more of the nose landing gear on the

B-25. Author's photo.

This B-25N was built in 1944 at the North

American Aviation plant in Fairfax, KS. The B-25 is currently

owned and operated by the Liberty

Aviation Museum in Port Clinton, OH. Author's photo.

Delco Products Division of GM

World War Two Products:

The Dayton, OH plant had $51,721,000 in major contracts during the war.

Its Detroit, MI plant had $2,073,000 in major contracts and its Norwood,

OH plant had another $952,000.

During the war the Delco Products Division produced 40,000,000 20mm, 37mm, and 40mm projectiles and fuses, 7,000,000 shock absorbers

for army trucks, gun carriages, tank destroyers and other armored

vehicles,

1,000,000 electric motors to include windshield wiper motors for US

aircraft, fuel booster pumps for aircraft, Selsyn motors for

anti-aircraft guns and truck steering gears, 2,500,000 link assemblies

tank treads,

23,000,000 spark plug shells for AC-Sparkplug (This must have been

production after April of 1943 as it is not mentioned in the "War Diary"

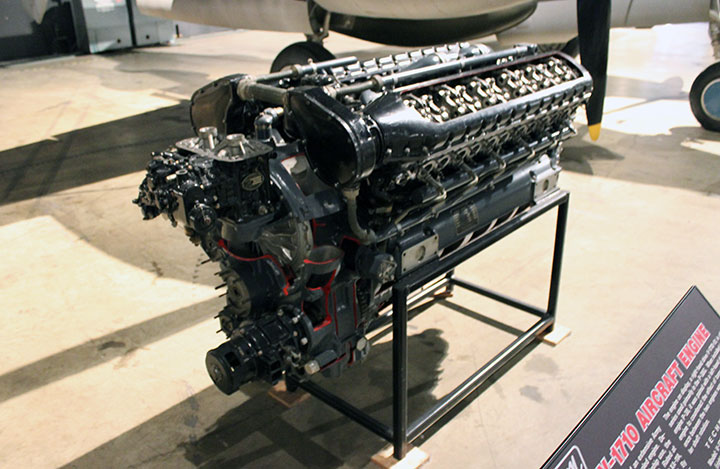

below,) 6,500,000 miscellaneous items to include shafts and gears

for the Allison V-1710 aircraft engine,

250,000 units of hydraulic actuating

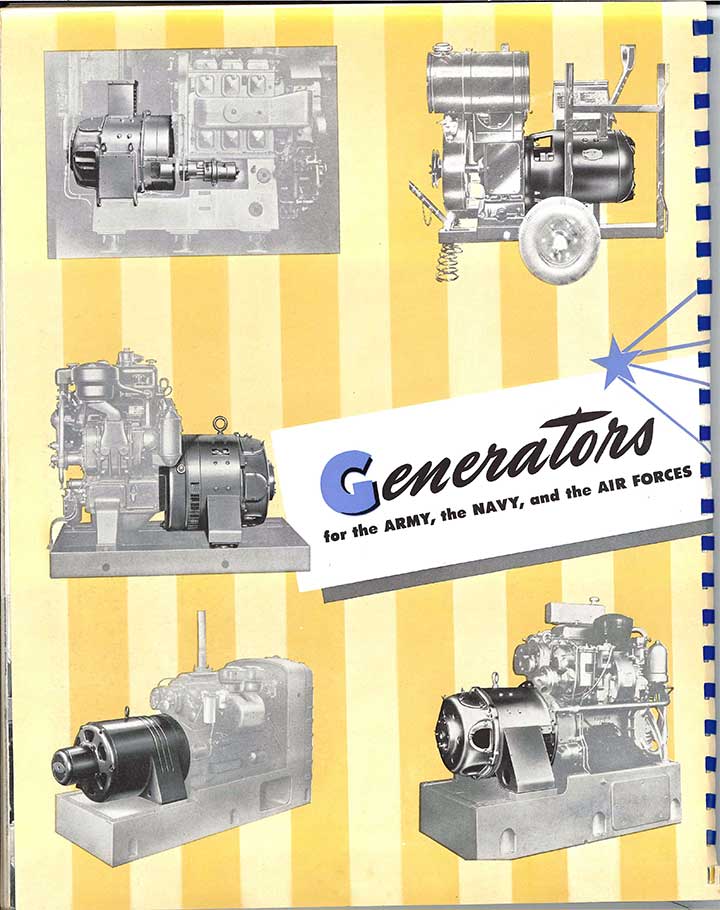

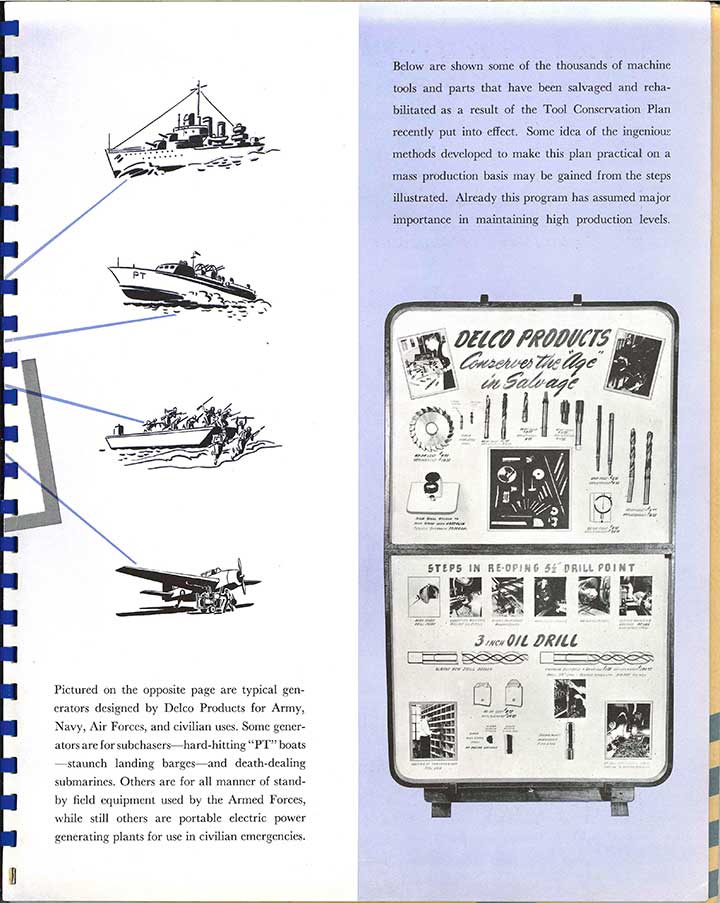

devices for Grumman aircraft, 25,000 generators to include

those for large searchlights and applications on navy ships, 24,000 sets of aircraft landing gears

for B-24, B-25 and B-26,

and 250 electric actuators.

A War Production Board Report dated 9-30-1943

shows that Delco Products was building the following products in its

Dayton, OH plants:

-

5,300

Allison V-1710 engine part units

per month

-

755 hydraulic activating

units per month

-

120,000 M-52 fuzes per

month

-

450,000 40mm projectiles

per month

-

$3,000,000 worth of Navy

diesel generators per month

-

An unreported amount of

Selsyn motors

-

An unreported amount of

synchronous transmitters

During World

War Two, Delco Products borrowed the Fisher Body Plant in Norwood, OH for

the manufacture of war products. Norwood is a suburb of

Cincinnati. The War

Production Board Report dated 9-30-1943 shows that Delco-Products was

building the following products:

-

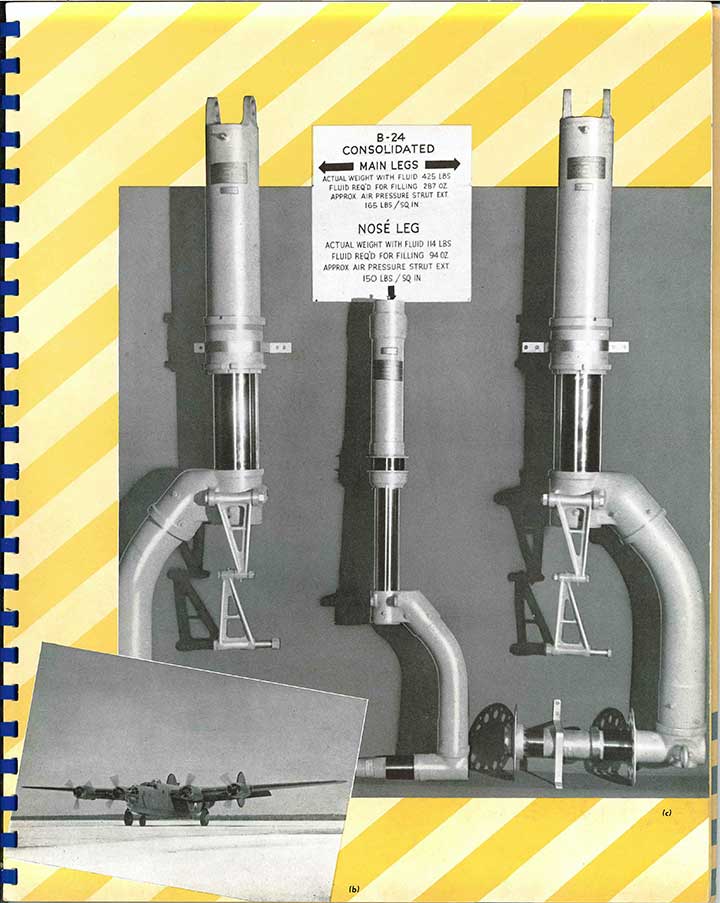

460 sets per month of

B-24 main and nose oleo struts

-

415 sets per month of

B-25 main and nose oleo struts

-

497 sets per month of

B-26 main and nose oleo struts

-

415 sets per month of

B-25Axles, outer cylinders, and drag arms

Neither of the two reports include

all of the products the division was making, as there were too many for a

complete accounting.

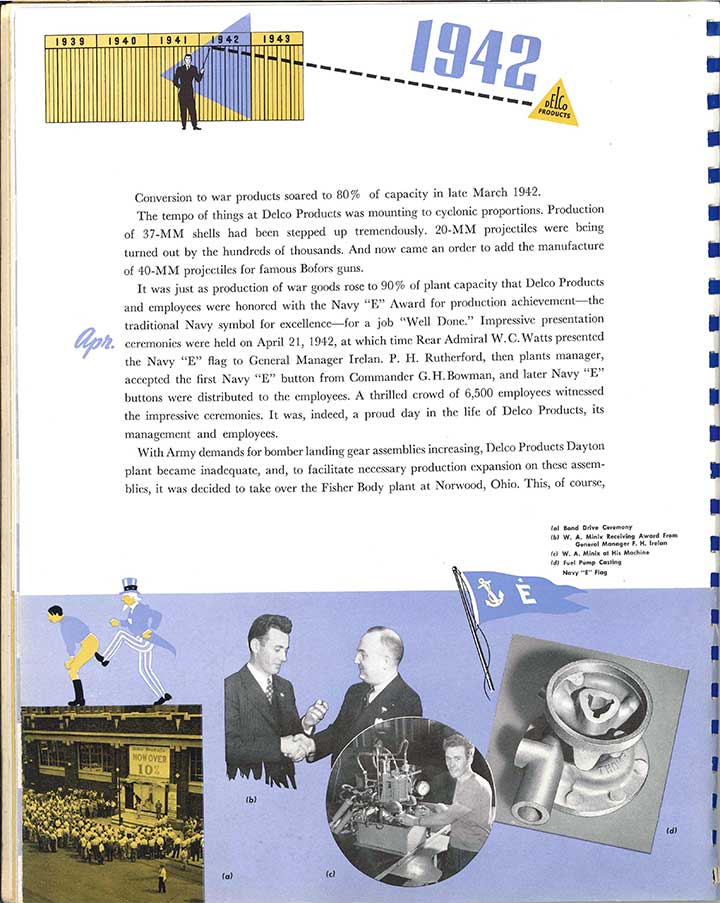

Delco Products

won the Navy "E" Award on April 21, 1942.

In September 1942, Delco Products won the Army-Navy "E" Award. It

later won three more awards.

Delco-Products converted its Navy "E" Award to the Army-Navy "E" Award

which gave it a total of five awards during World War Two.

This is the B-24 on display at the

Air Force Museum in Dayton, OH. There is a good chance that the landing

gear on this aircrat was built a few miles away at Delco

Products or at the borrowed Fisher Body plant in Norwood, (Cincinnati)

OH. Author's Photo.

This is the left main landing gear on the B-24.

The weight of the gear without tire and wheel is 425 pounds. In 1943

Delco Products was building 460 of these a month. It was also

building 460 right main landing gears and 460 nose gears per month. Author's

Photo.

One gets a better view of the main

gear from the opposite side. Author's Photo.

Author's Photo.

Delco Products also built landing gears for

the Martin B-26. This one is also on display at the Air Force Museum. Author's Photo.

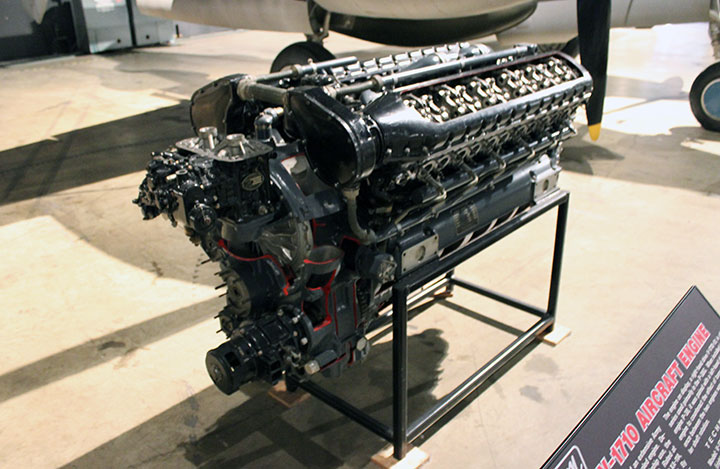

Delco

Products built shafts and gears for the Allison V-1710 aircraft engine.

Author's Photo from the Air Force

Museum.

Delco Products built Selsyn motors for the

remote control of anti-aircraft guns. It would be used for weapons like

this 40mm Bofors gun, as seen on LST-325 in Evansville, IN. The

motors would rotate the gun's position to the same position as that of a

remote gun director. It could be the motors pictured here are from

Delco Products. Author's Photo.

Delco Products built 7 million shock

absorbers for all sorts of vehicles during the Second World War such as

this Chevrolet 1-1/2-ton truck seen at the 2013 Houston Airshow. Author's photo.

This Chevrolet dump truck was on display at

the 2019 MVPA Convention in York, PA. Author's photo added

1-21-2021.

In total, Chevrolet built 281,570 trucks for

the war effort. Author's photo added 1-21-2021.

This is a post mid-1943 CCKW-352 with a winch.

Author's photo added 1-21-2021.

This CCKW-353 is owned by the Indiana

Military Museum in Vincennes, IN. Author's photo added 1-21-2021.

GMC built 7,232

of the AFKWX, which was a cab over engine design with a longer cargo bed

for transporting bulky loads. It had the same wheelbase as the

CCKW-353 and had a 15 or 17 foot bed which was three or five feet

longer than the 353 series truck. In total, GMC

built 571,053 trucks during World War Two. Author's photo added

1-21-2021.

The GMC DUKW needed Delco Product shock

absorbers that could operate in a salt water environment. DUKWs

were used extensively during invasions to bring supplies ashore and then

deliver them directly to the fighting fronts where they were needed.

21,147 were built during World War Two. Author's photo added

1-21-2021.

Delco-Products supplied GM of Canada which

built trucks for the British Commonwealth. The truck was designed

by Chevrolet and badged as such. 201,000 were built.

Author's photo added 1-21-2021..

This armored GM of Canada-built armored

truck needed heavy-duty Delco Products shock absorbers. This

example is one of 3,961 built. Author's photo added 1-21-2021.

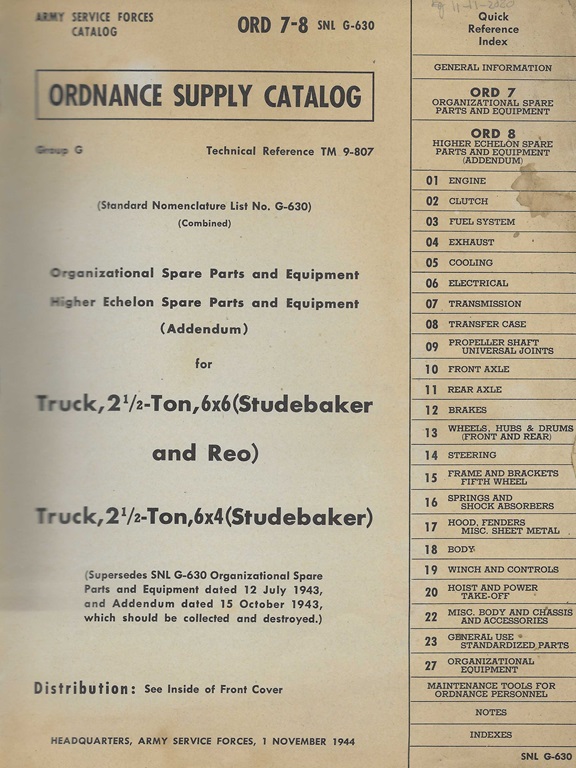

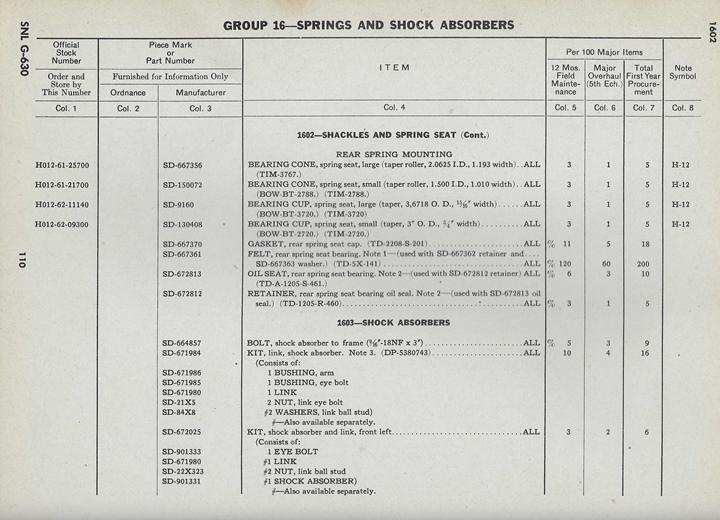

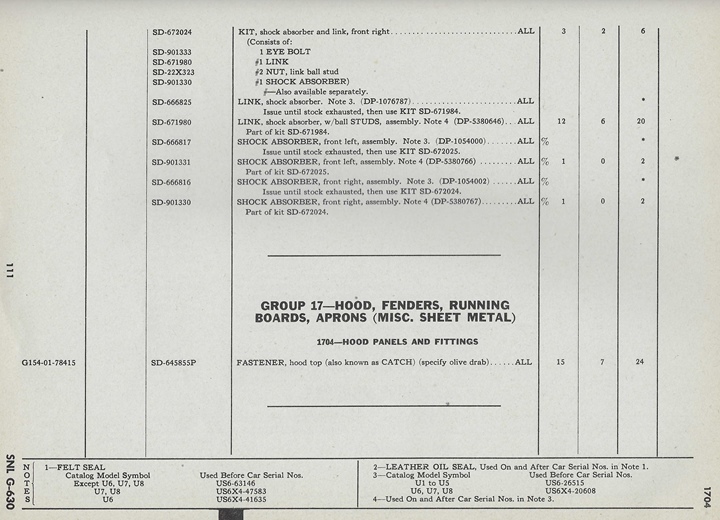

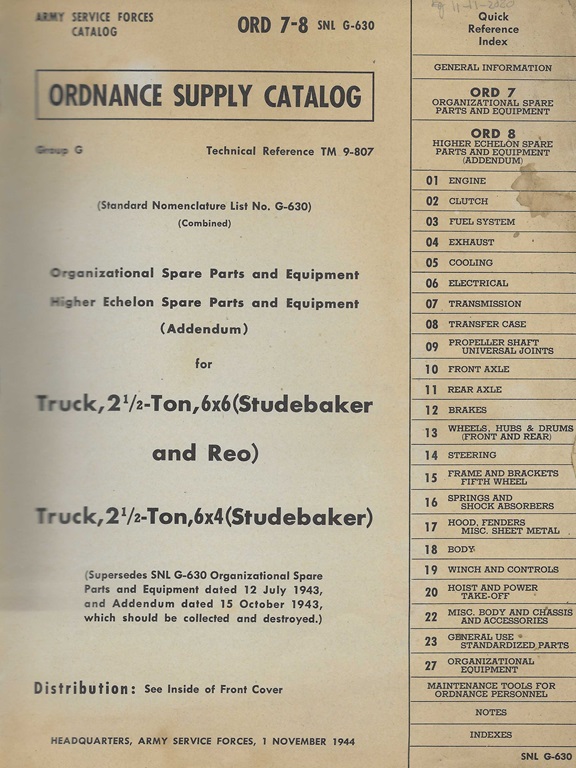

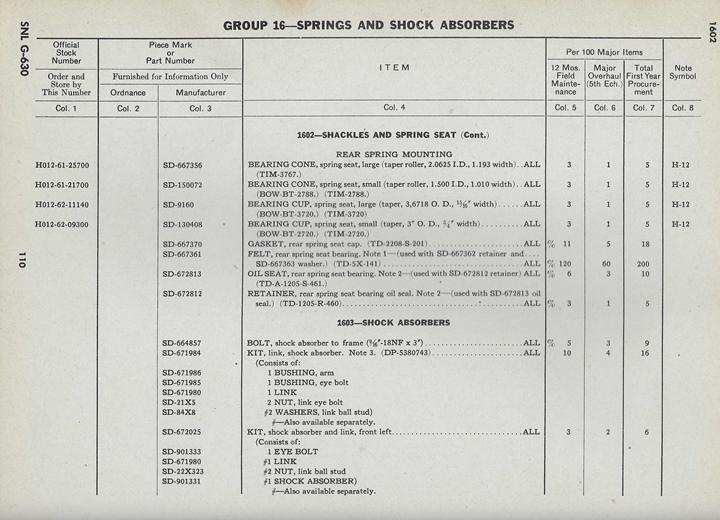

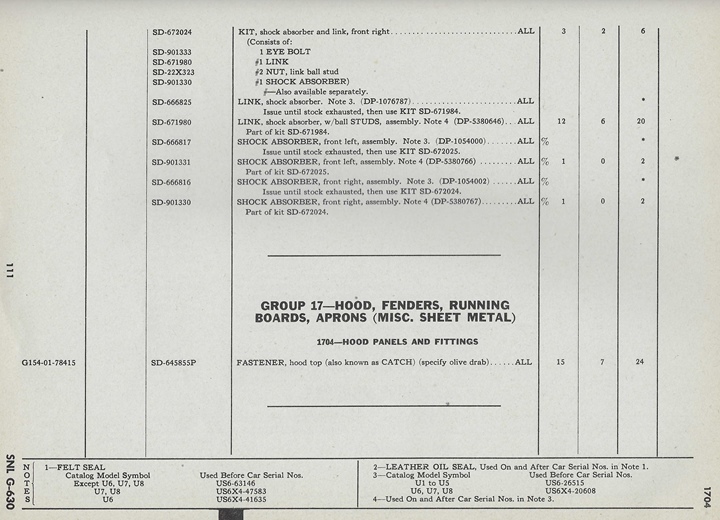

This looks like a GMC CCKW, but it is not.

It is the Studebaker-built US6 version of the 6x6 2-1/2-ton truck which

had some minor differences from the GMC, including a different engine.

Studebaker built 197,678 and Reo built another 22,204. What was

the same as the GMC CCKW is that it came equipped with Delco

Products shock absorbers. Below are several pages from the

Ordnance Supply Manual that show Delco Products supplied the shock

absorbers for this non-GM truck. Author's photo added 1-21-2021.

Image added 1-21-2021.

The Delco Products DP part numbers are shown

for both OEM and repair kits. Image added 1-21-2021.

Image added 1-21-2021.

250,000 hydraulic actuators were supplied

for Grumman aircraft, such as this TBM Torpedo Bomber. The Eastern

Aircraft Division of General Motors built the Grumman designed TBM.

It was logical to choose a sister division to supply the

hydraulic actuators for the aircraft. Author's

photo from the 2009 Chino Airshow.

Eastern Aircraft also built the Grumman F4F-4 Wildcat under the GM

designation of FM-1. Delco Products also supplied the hydraulic

actuators for this aircraft. Author's photo added 1-21-2021.

This is an Eastern Aircraft FM-2 which

utilized hydraulic actuators from Delco Products. Author's photo

added 1-21-2021.

The Fisher Body Division of General Motors

was first into production with the M26 Pershing Heavy tank. It

also utilized the torsion bar suspension with four Delco Products shock

absorbers per side. Fisher Body and Chrysler built 2,202 Pershings

at the end of World War Two. Author's photo added 1-21-2021.

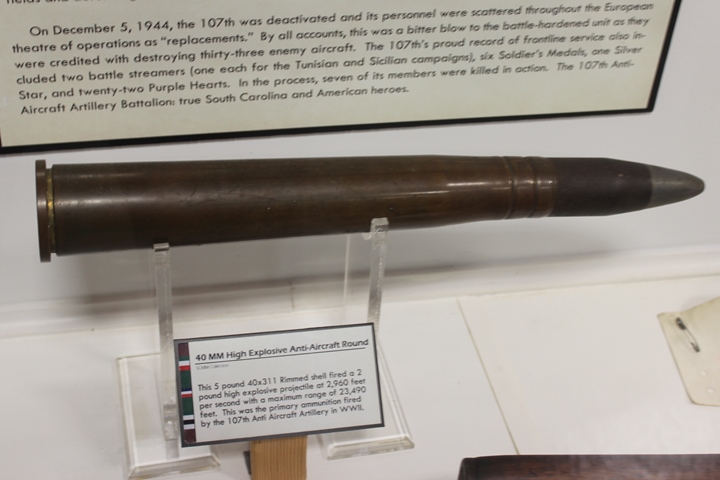

Delco Products built 40,000,000 projectiles

and fuzes during World War Two. Many of the projectiles were for

the 20mm round. Author's photo added 1-21-2021.

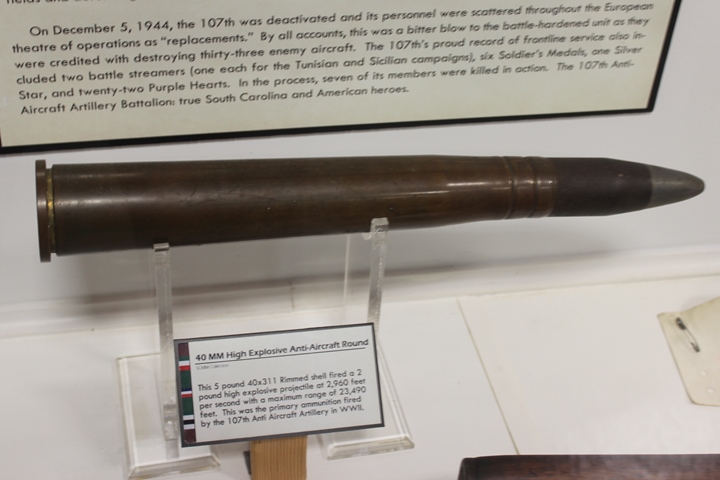

In 1943 Delco Products was building 450,000

projectiles per month for the 40mm anti-aircraft round. When

complete, the projectile head weighed two pounds. Author's

photo added 1-21-2021.

During 1943 Delco Products was producing 120,000

M52 mortar fuzes per month for use in both the 60mm and 81mm mortars.

The silver and white fuse on the dark brown 60mm mortar is an M52 fuze.

It could be set to time the mortar round to explode above ground for

maximum fragmentation effect. Author's photo added 1-21-2021.

Shown here is a 60mm mortar round with the

black fuze. Author's photo added 1-21-2021.

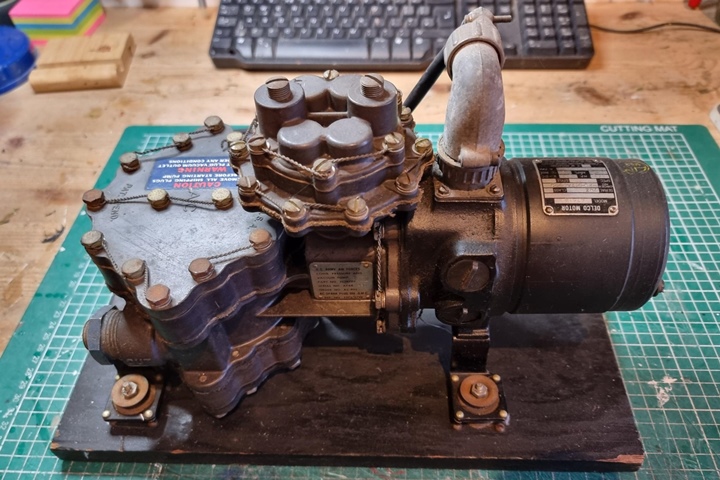

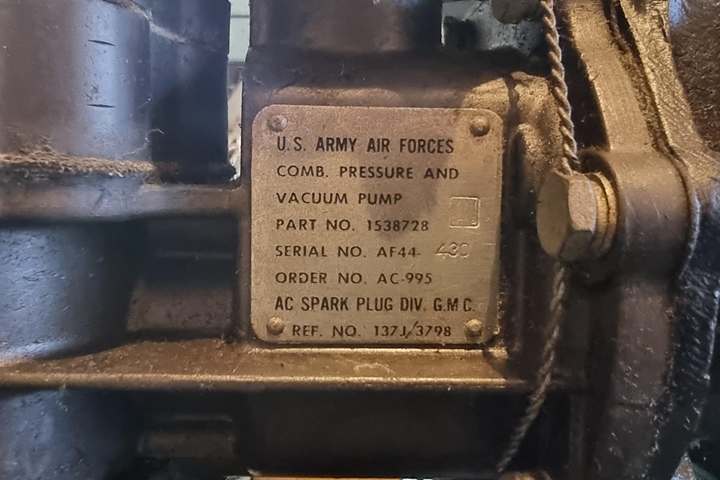

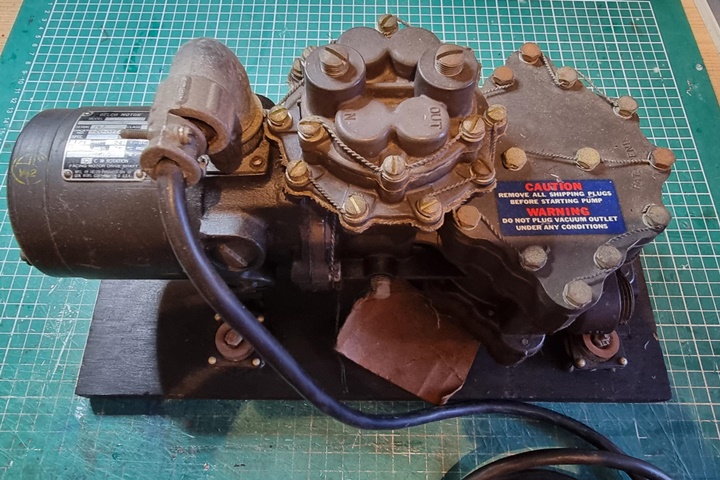

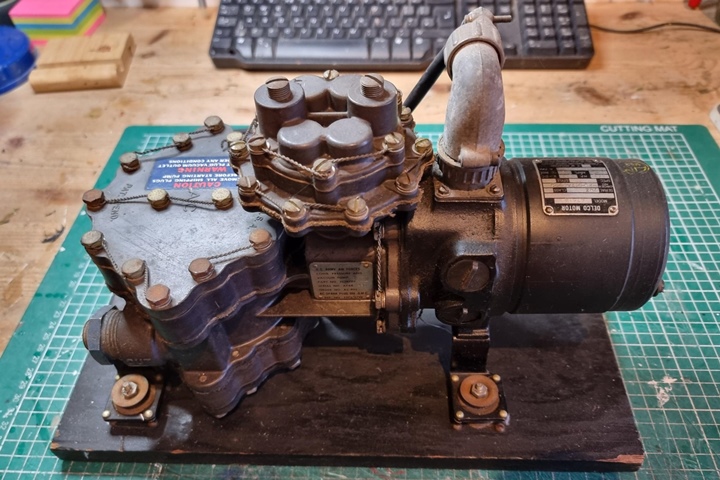

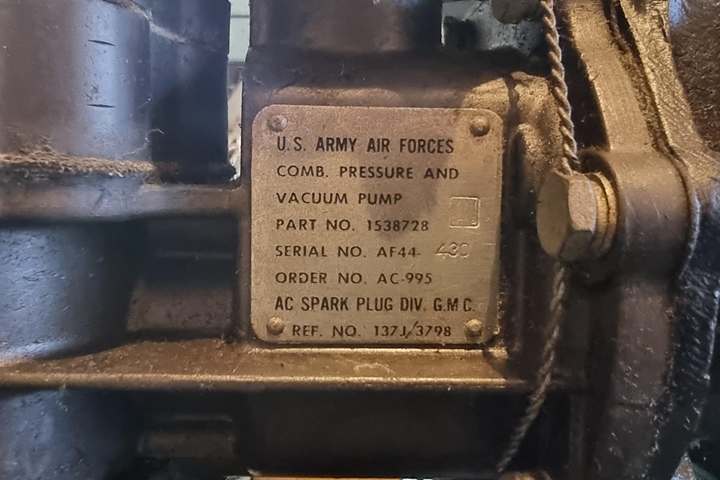

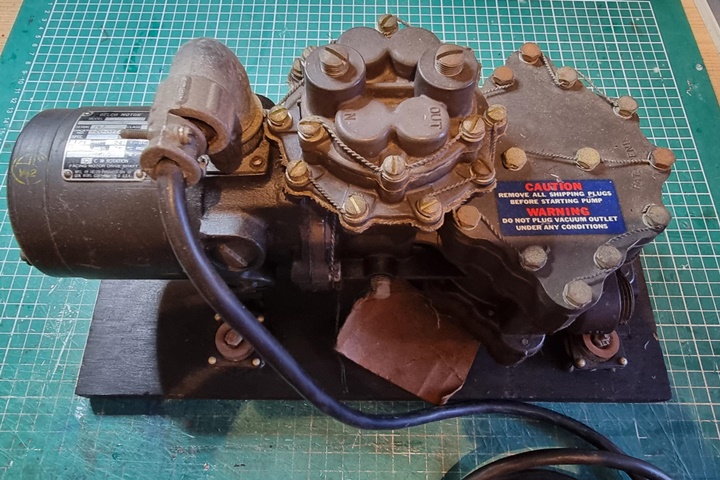

During World War Two the AC Spark Plug

Division of General Motors built combination pressure vacuum pumps for

the USAAF. It obtained the 24 VDC motors from the Delco Products

Division of GM. This was keeping with GM policy of sourcing

components from within the corporation. This pressure vacuum pump is

part of the collection of Mr. Lee Smithson. Photo courtesy of Lee

Smithson added 12-10-2024.

Photo courtesy of Lee Smithson added

12-10-2024.

Photo courtesy of Lee Smithson added

12-10-2024.

Photo courtesy of Lee Smithson added

12-10-2024.

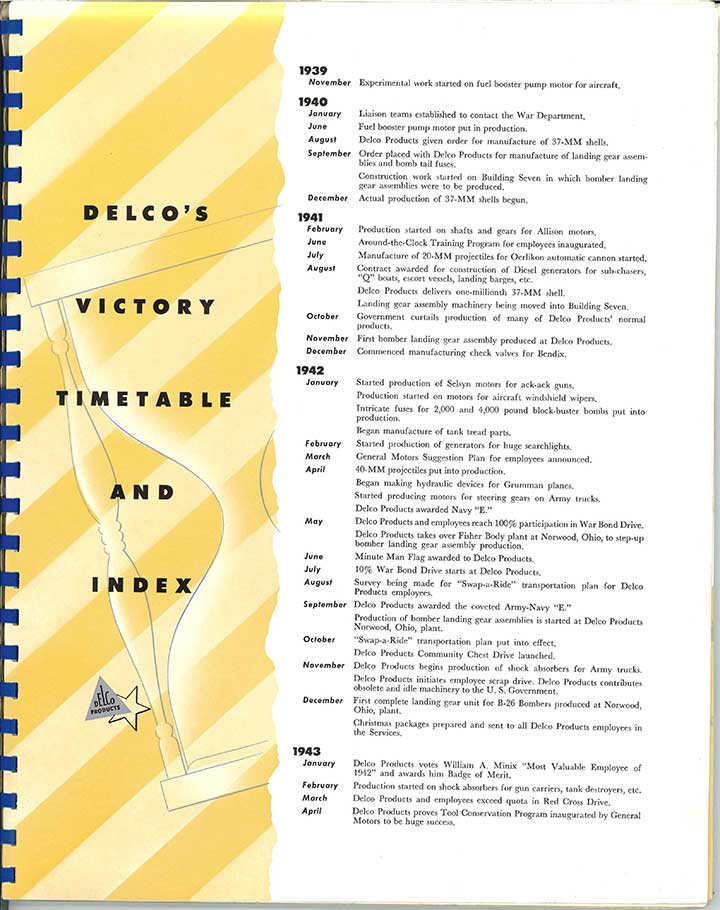

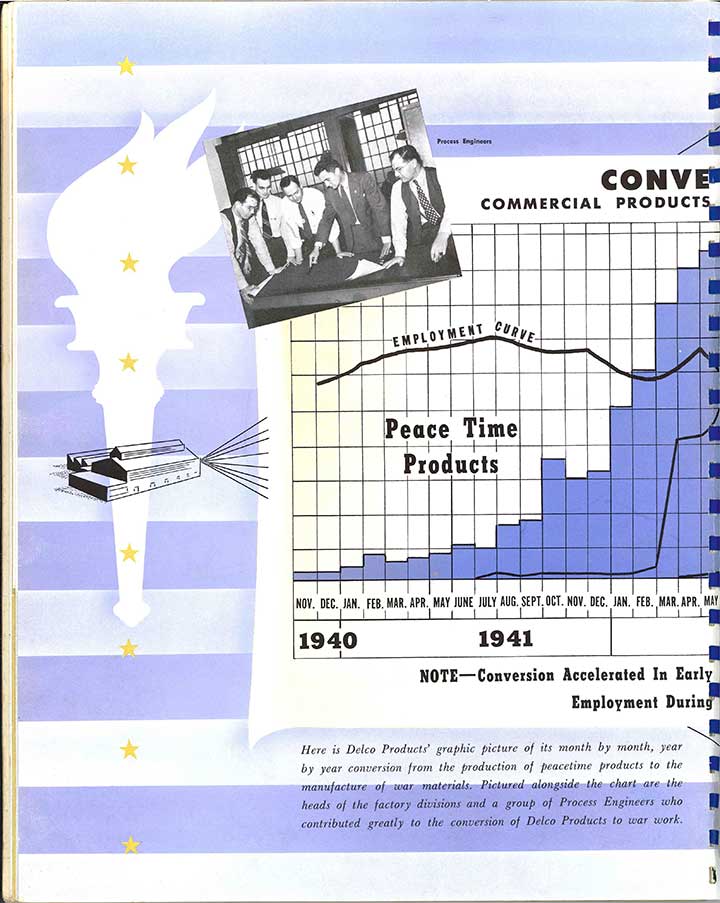

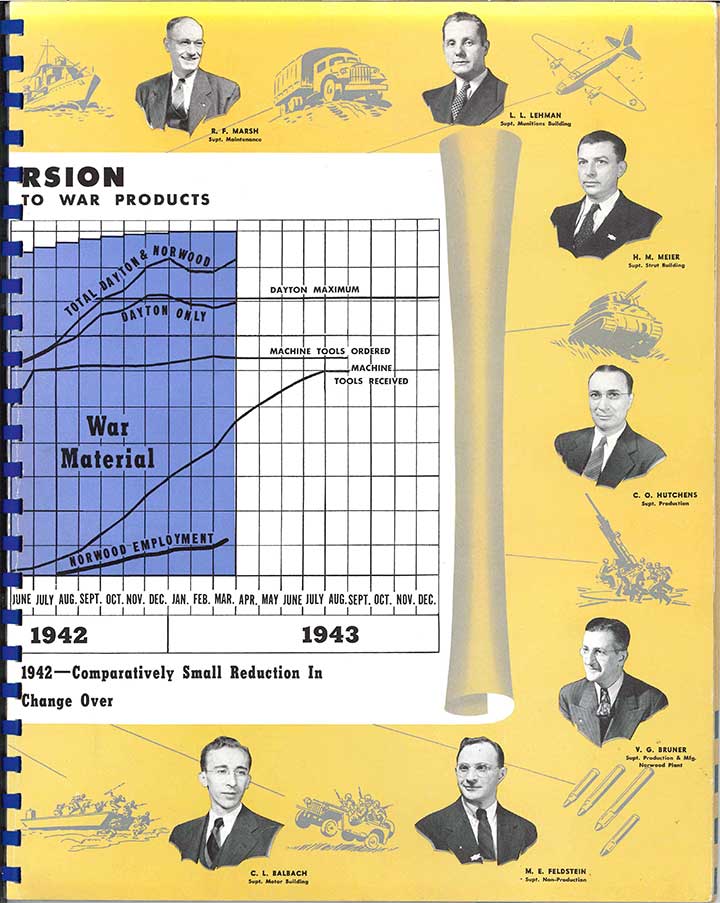

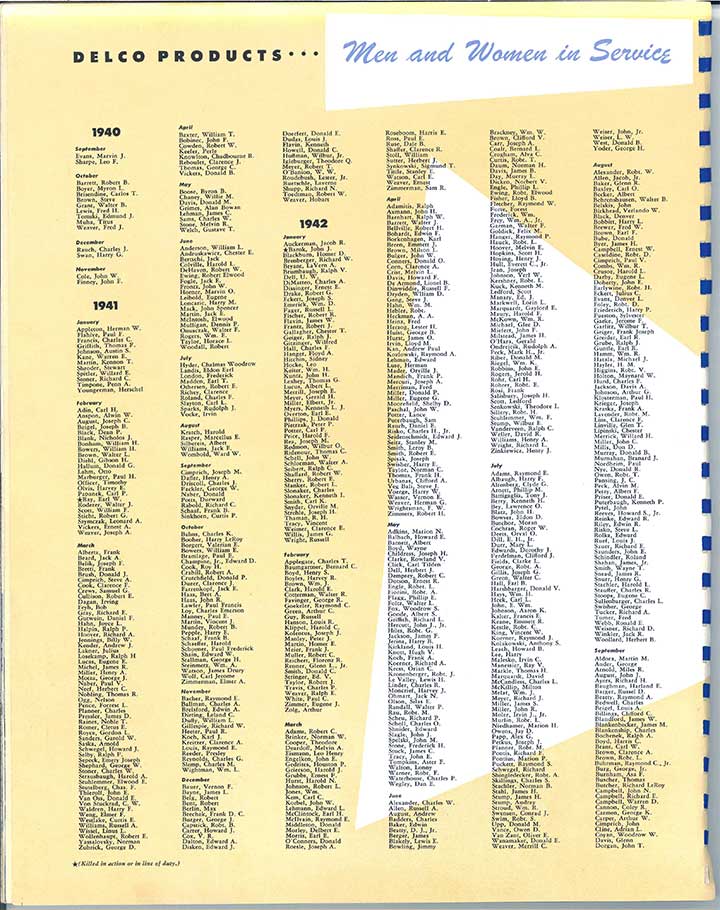

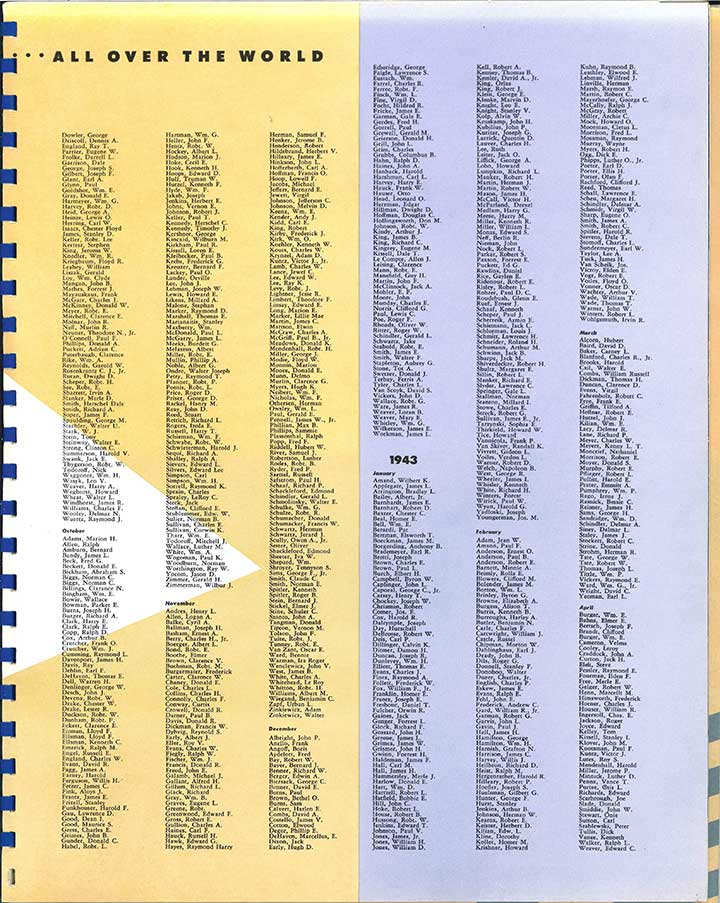

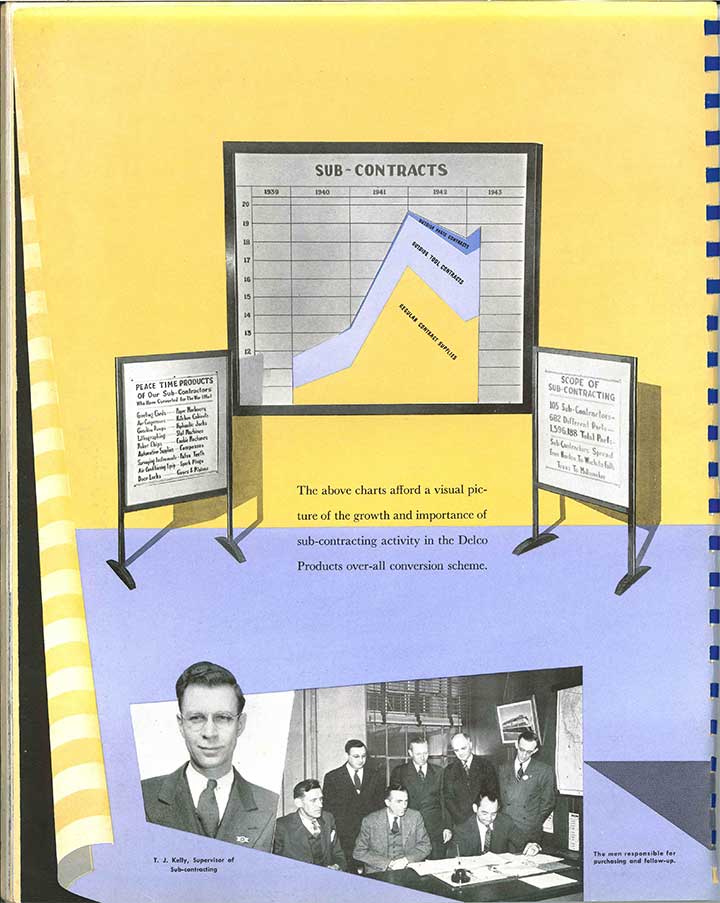

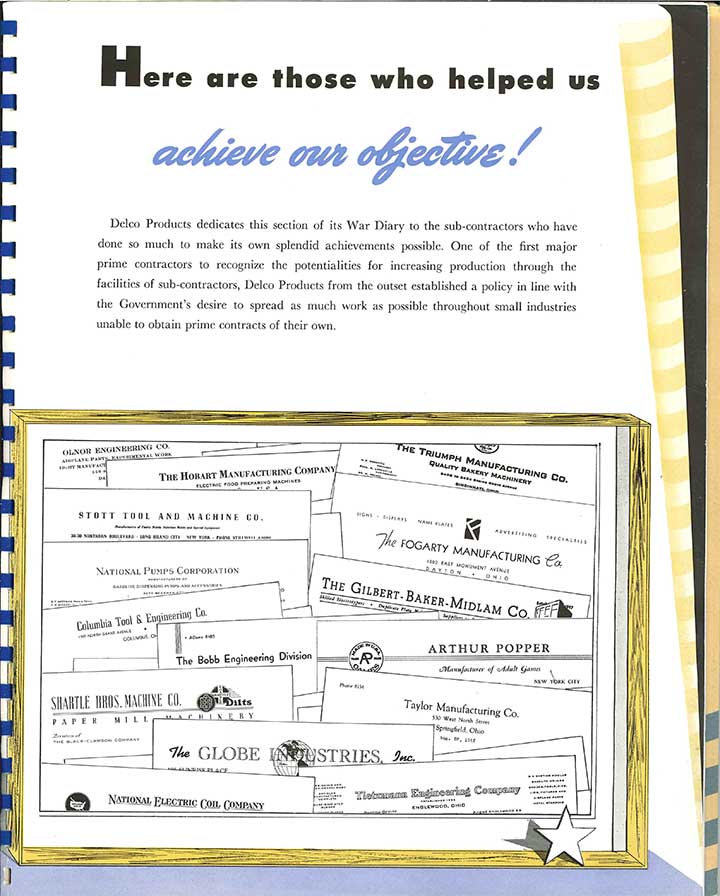

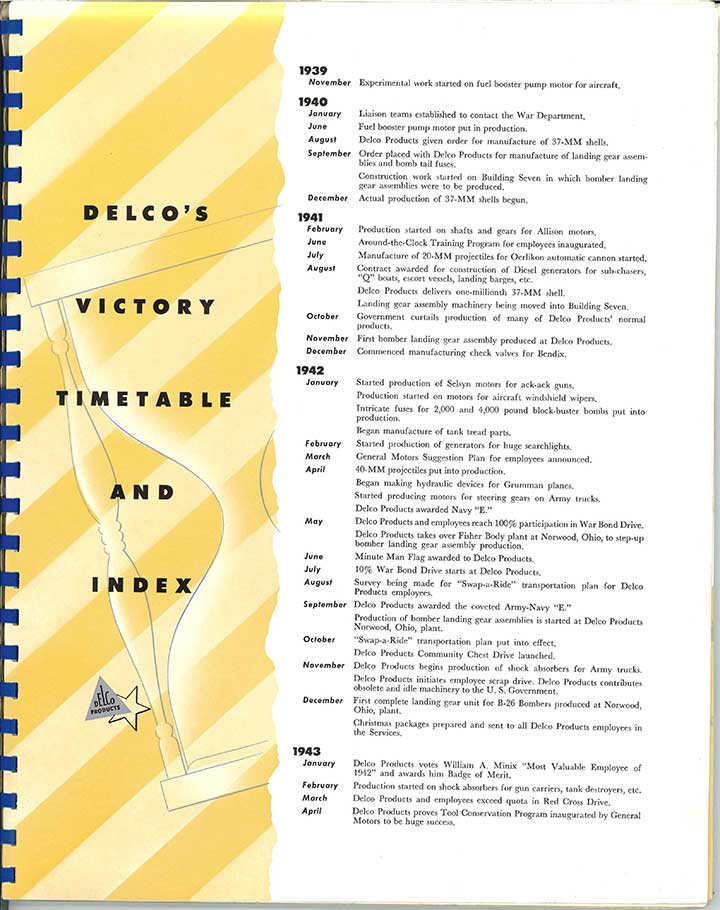

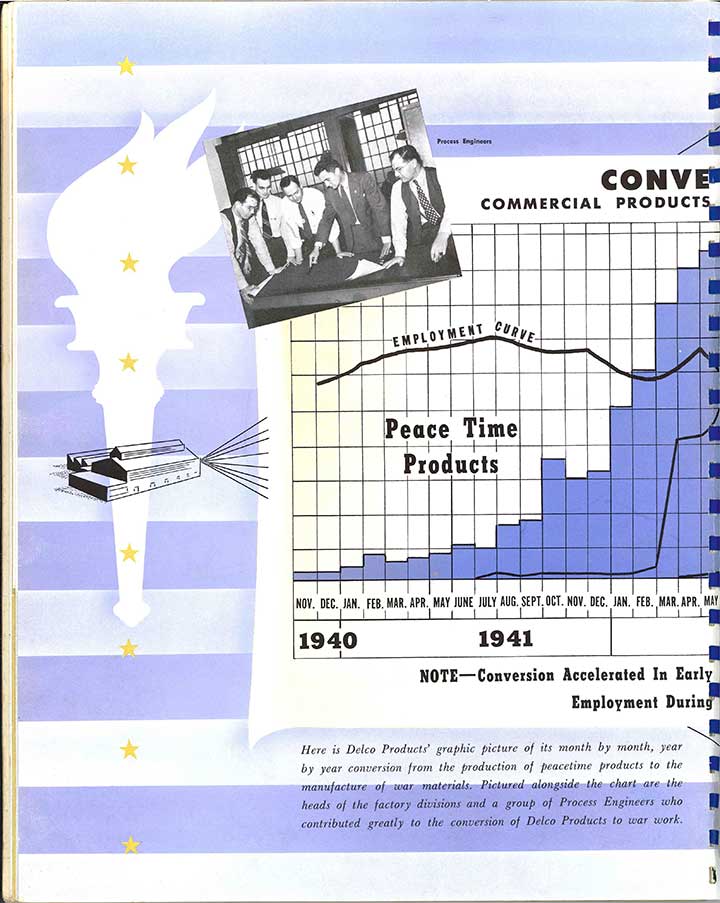

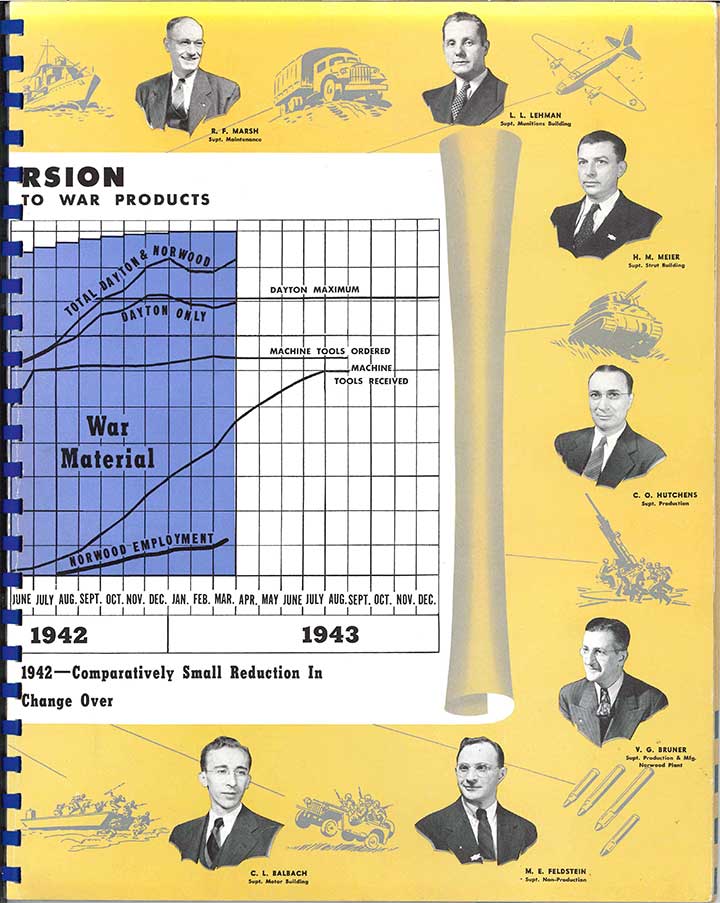

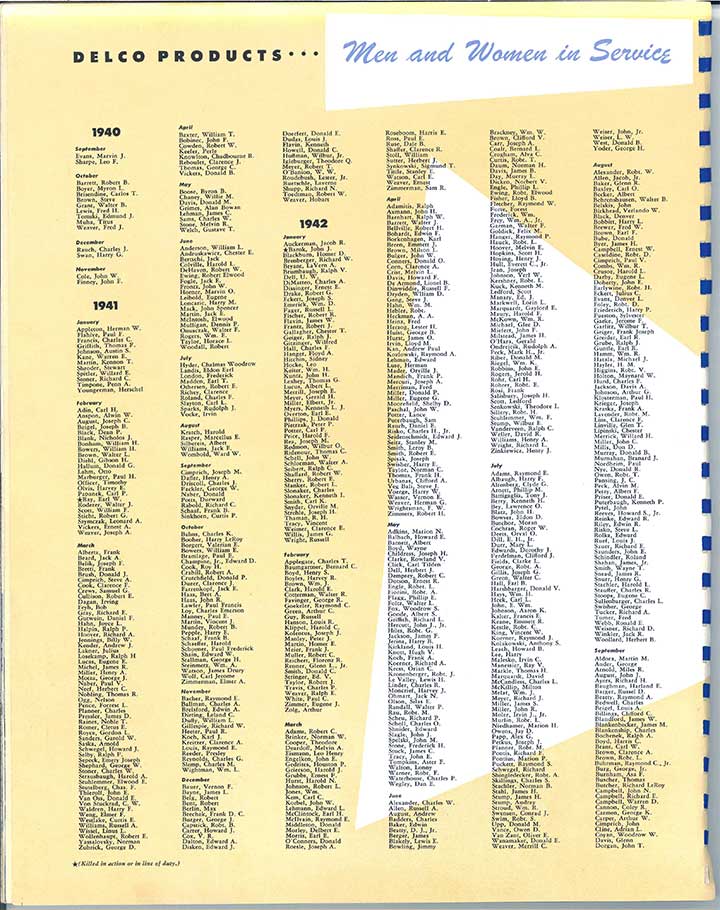

Below is the

war goods production chronology starting in 1940 through February 1943,

as documented in the Delco Products "War Diary." The information

below helps support the production numbers shown above that I found on

"Dayton History Books Online." Between both sources, we get a

clearer picture of what Delco Products produced during the Second World

War. Unfortunately, "War Diary" ends in April of 1943, when there

were still over two years of the war

remaining. Products could have been added during that time that

went unrecorded.

SOP = Start of Production

More information about the dates below can be found on page 6 below.

1940

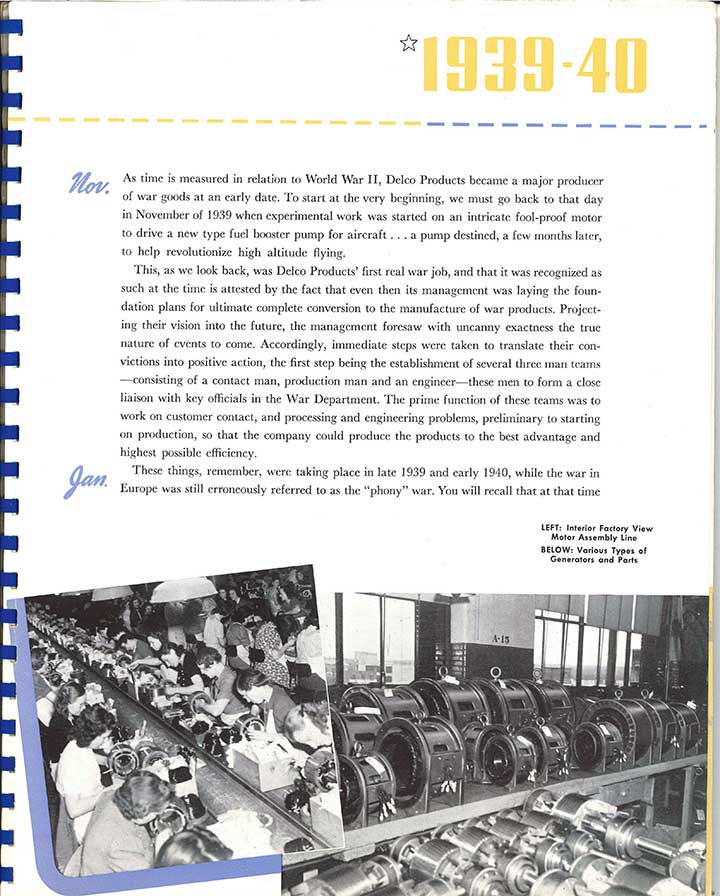

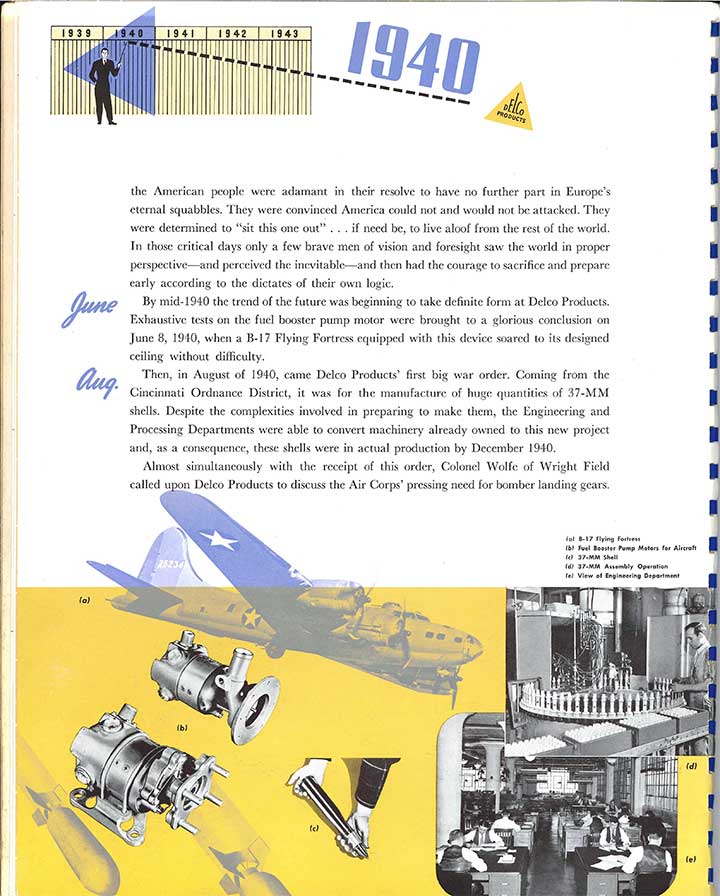

June - SOP of Aircraft fuel booster pump motor

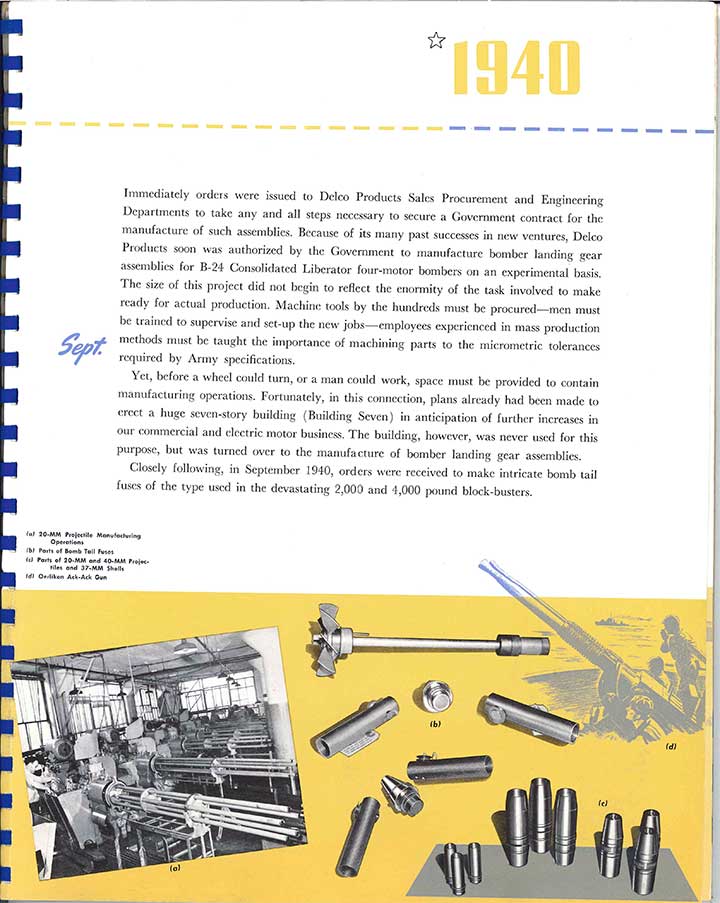

September - Tail bomb fuses ordered

December - SOP of 37mm shells

1941

February - SOP of shafts and gears for Allison V-1710 aircraft

engine. Delco Products was one of many GM Divisions that

manufactured components for the V-1710.

July - SOP of 20mm shells. This would be a Navy order as the Army

did not use the 20mm cannon.

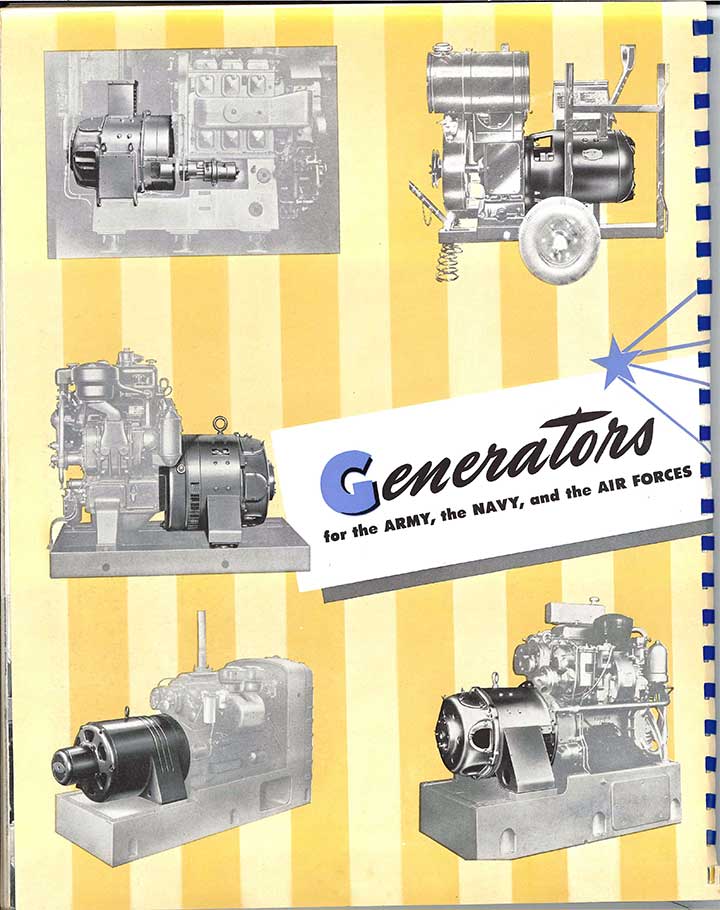

August - Contract awarded for naval generators for sub chasers, Q boats,

landing craft.

August - One millionth 37mm shell produced. This was the first million of 40 million

total of all sizes produced during the war.

November - SOP of landing gears. Production was in the new

Building Seven. A total of 24,000 sets were produced. Production was earmarked for landing gear sets for the Consolidated

B-24 bomber.

December - SOP of check valves for Bendix.

1942

January - SOP of Selsyn motors for anti-aircraft guns - The literature

below states the motors were for the 20mm anti-aircraft cannon. However,

that was a manually controlled weapon. The Selsyn motors were used

for remote control rotation of a weapon making it more likely it was for

a the 40mm cannon which were remotely controlled on Navy ships by gun

directors.

January - SOP of aircraft windshield motors.

January - SOP of tail fuses for both 2,000 and 4,000 lb. bombs.

January - SOP of tank tread parts.

February - SOP of generators for searchlights.

April - SOP of 40mm cannon shells. Part of the 40 million shells of all

sizes.

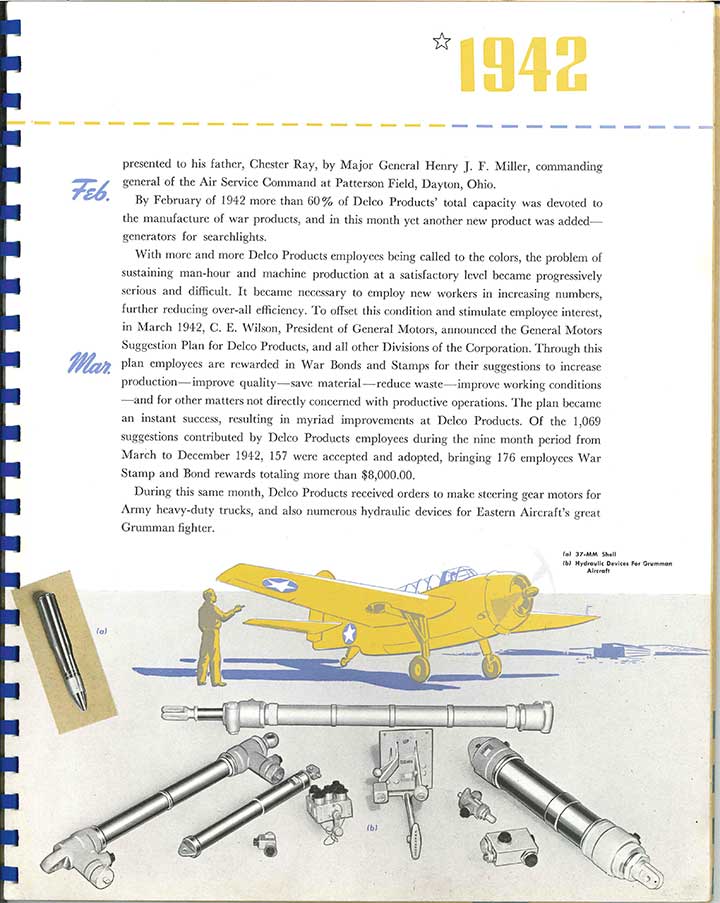

April - SOP of hydraulic actuators for Grumman aircraft. This may

actually have been for Eastern Aircraft Division of GM that was formed

about this time for the manufacture of Grumman TBM Torpedo Bombers and

FM-1 and FM-2 Fighters.

April - SOP army truck steering gear motors.

April - Awarded the Navy "E" for Excellence Award.

May - Delco Products takes over the Norwood (Cincinnati), OH Fisher Body

plant for the production of aircraft landing gear struts.

September - Awarded the Army-Navy "E" for Excellence Award.

September - SOP for bomber landing gears at the Norwood (Cincinnati), OH

Fisher Body plant.

November - SOP for army truck shock absorbers.

December - SOP of Martin B-26 landing gears at Norwood, OH.

1943

February - SOP of shock absorbers for gun carriages, tank destroyers

and other armored vehicles.

April - Last entry in Delco Products War Diary. It appears to have

been published not long after April 1943.

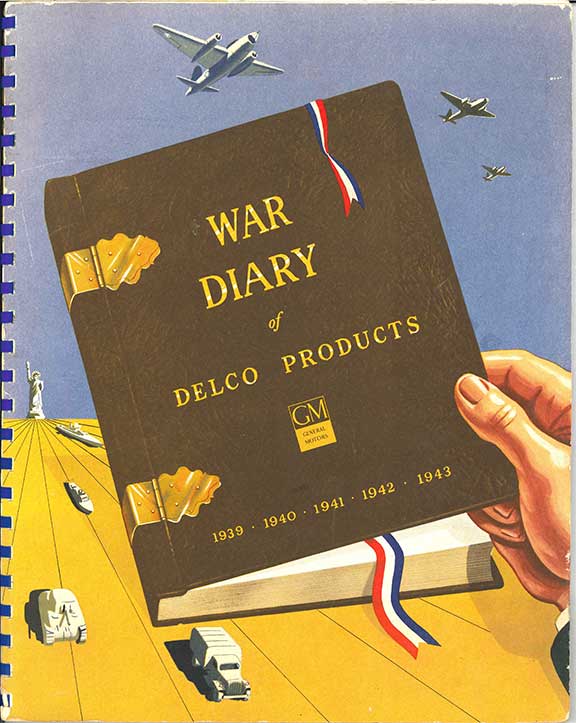

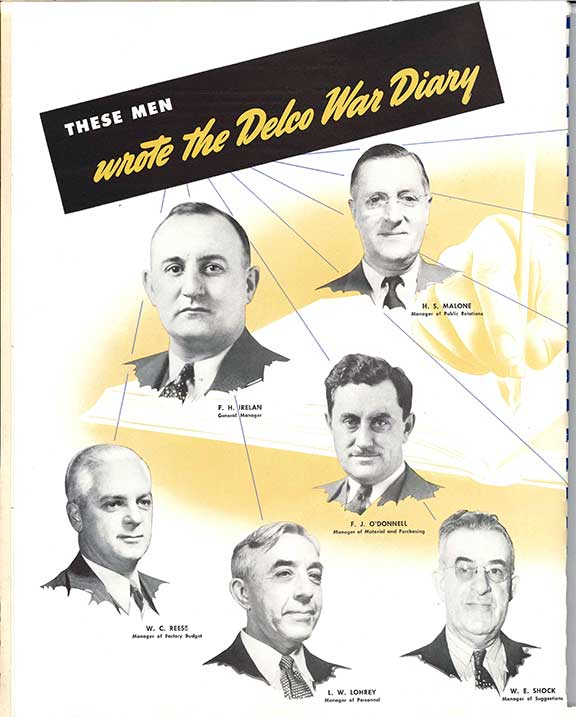

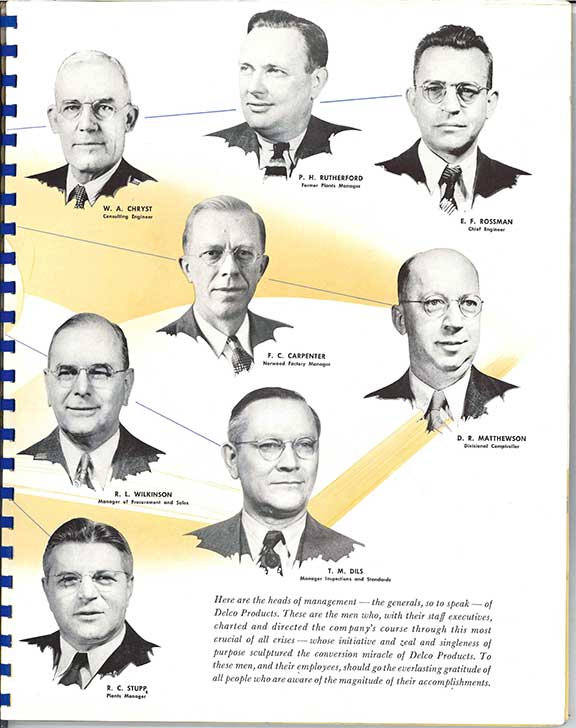

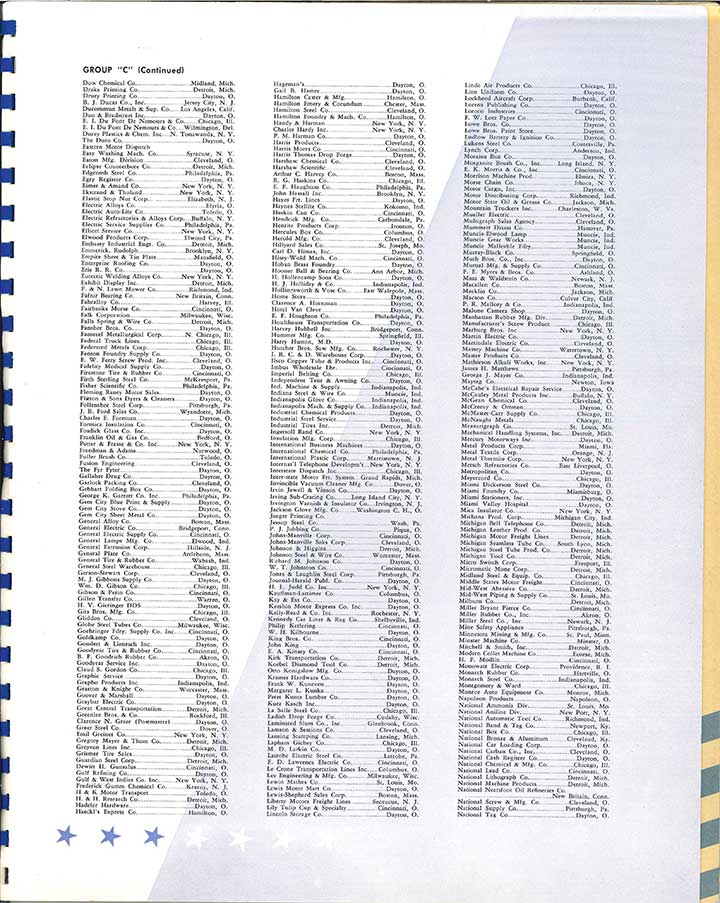

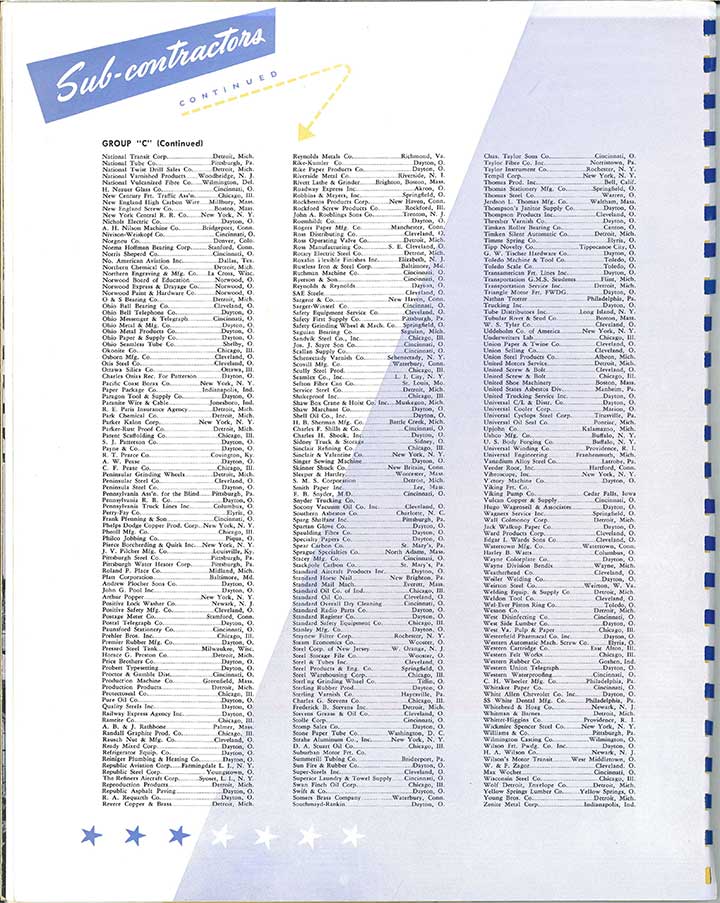

War Diary of Delco Products

- 1939, 1940, 1941, 1942, 1943

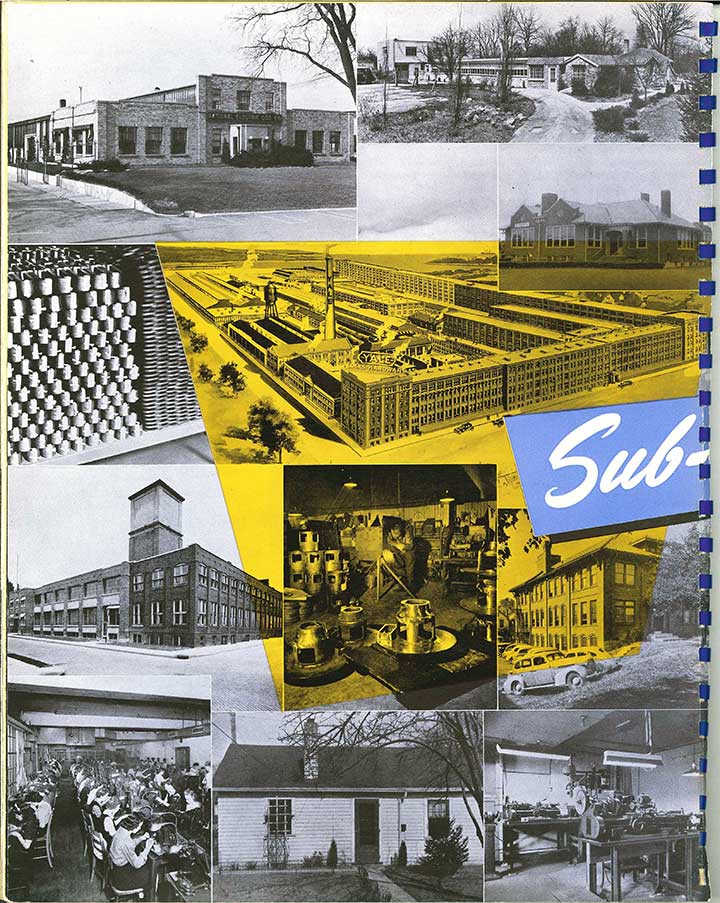

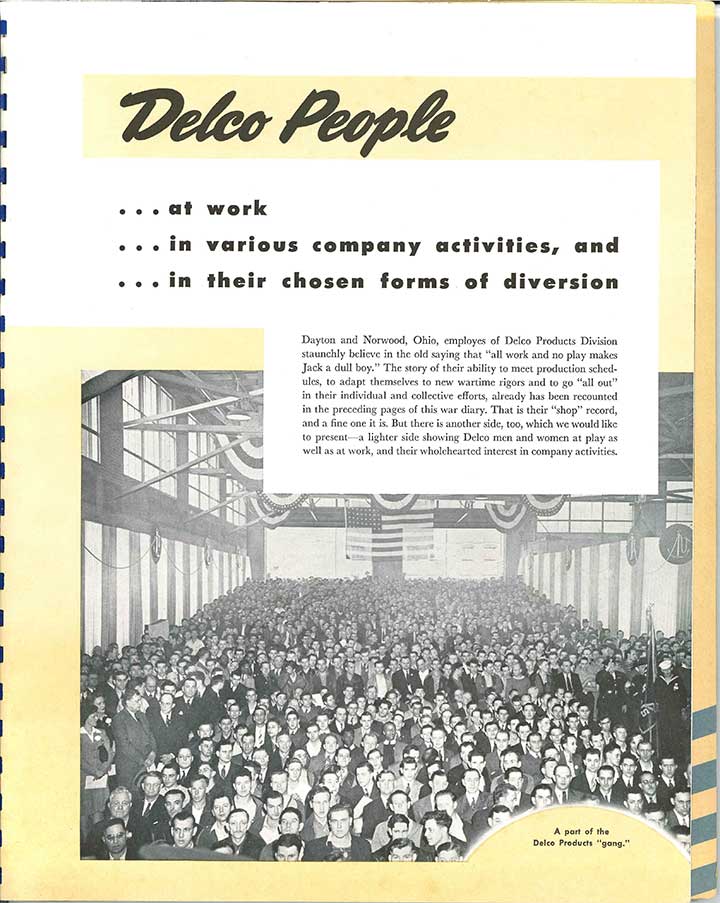

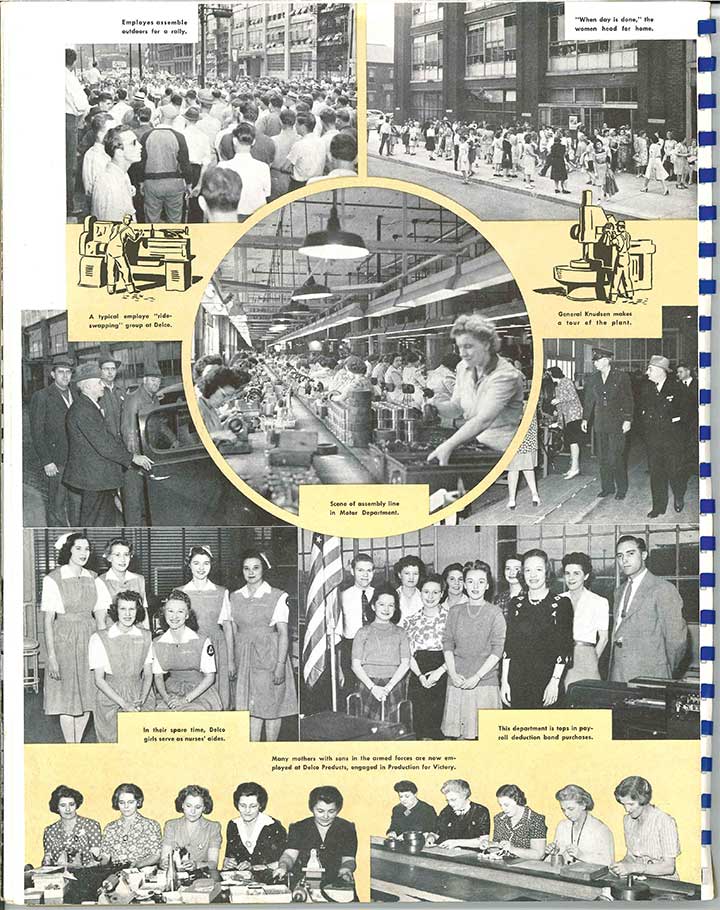

Reading the 1943 Delco Products

story of its participation in World War Two is most informative to the

historian or those interested in what this GM division built during

that period. The book is 50 pages plus front and back cover. Pages

10 through 32 are most informative as to the products built by Delco

Products.

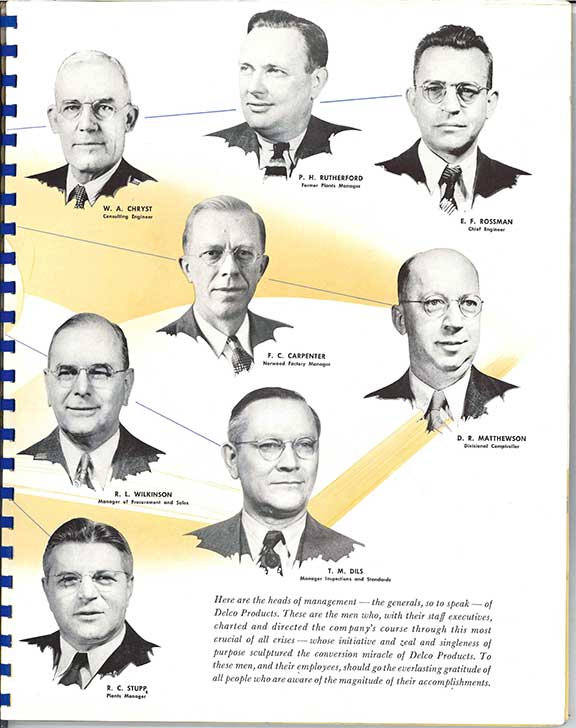

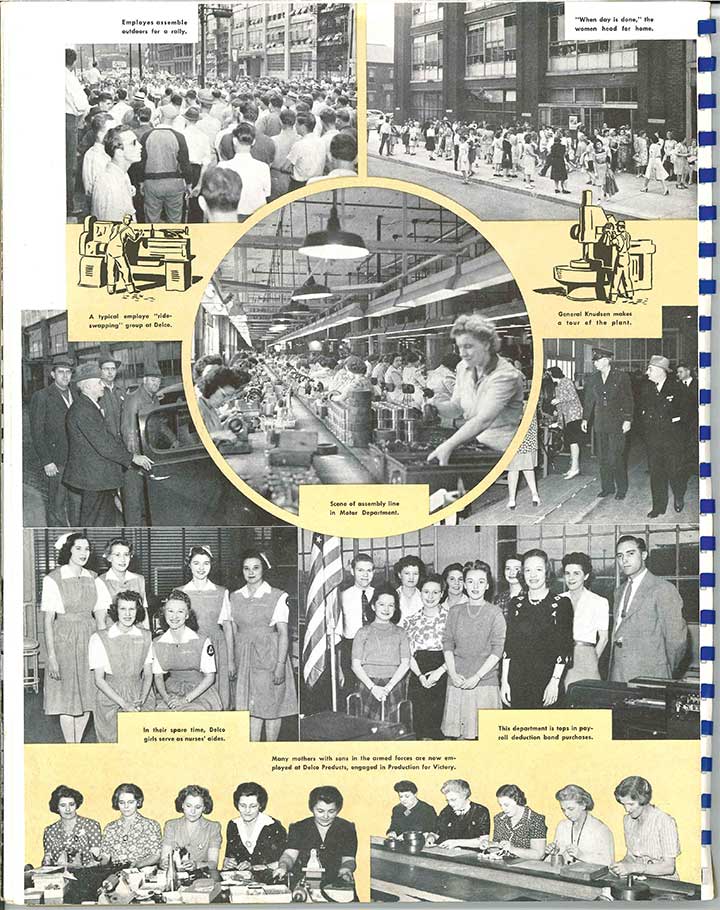

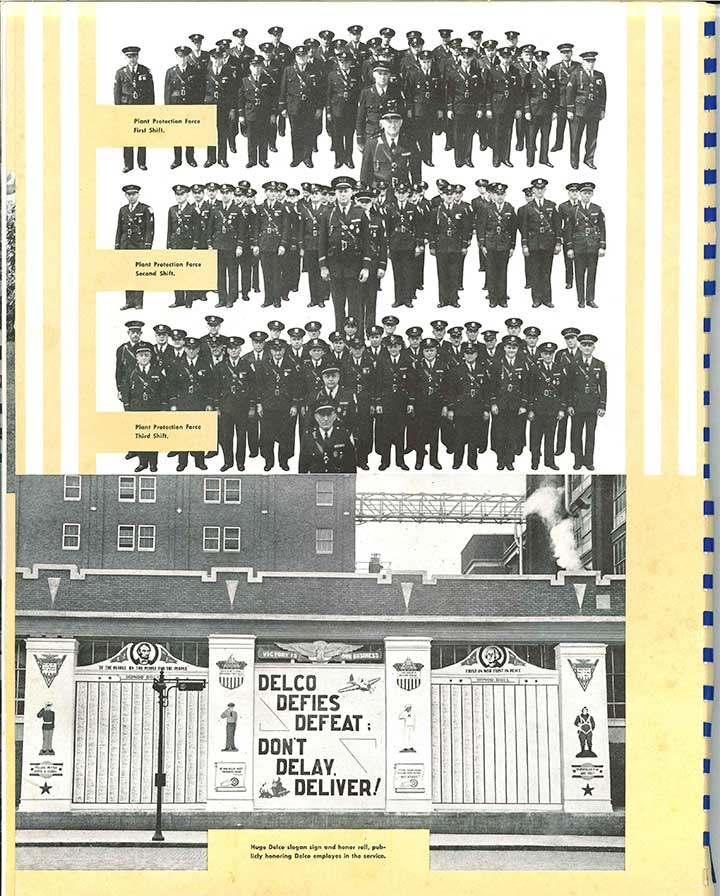

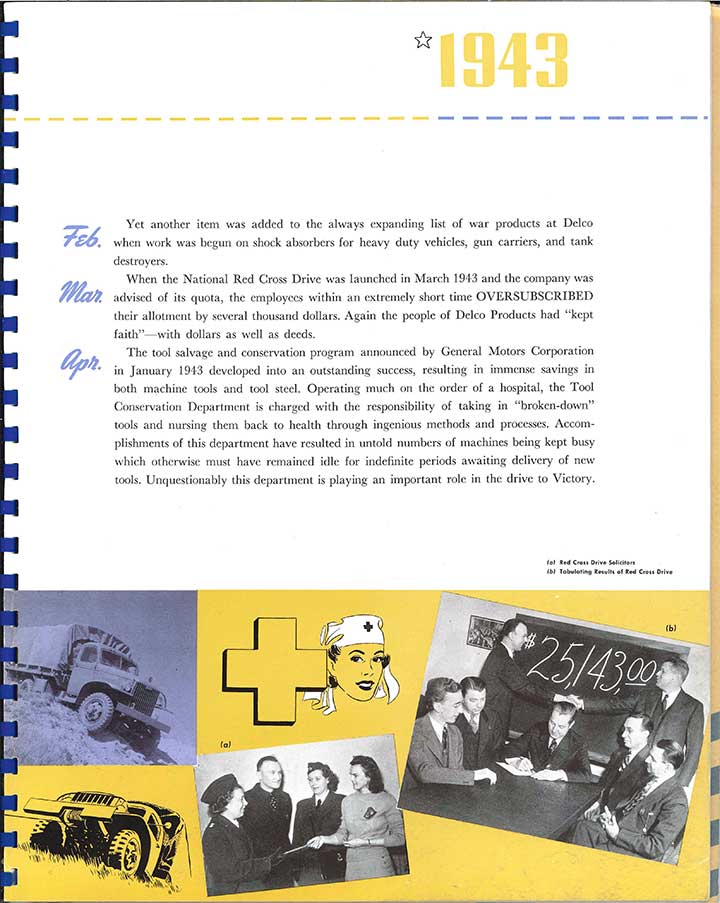

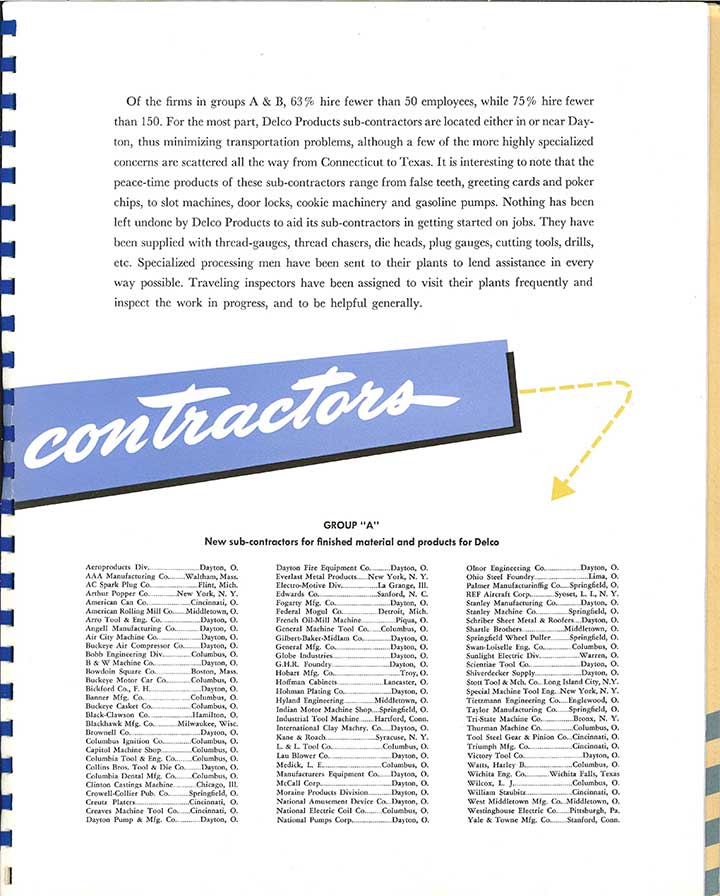

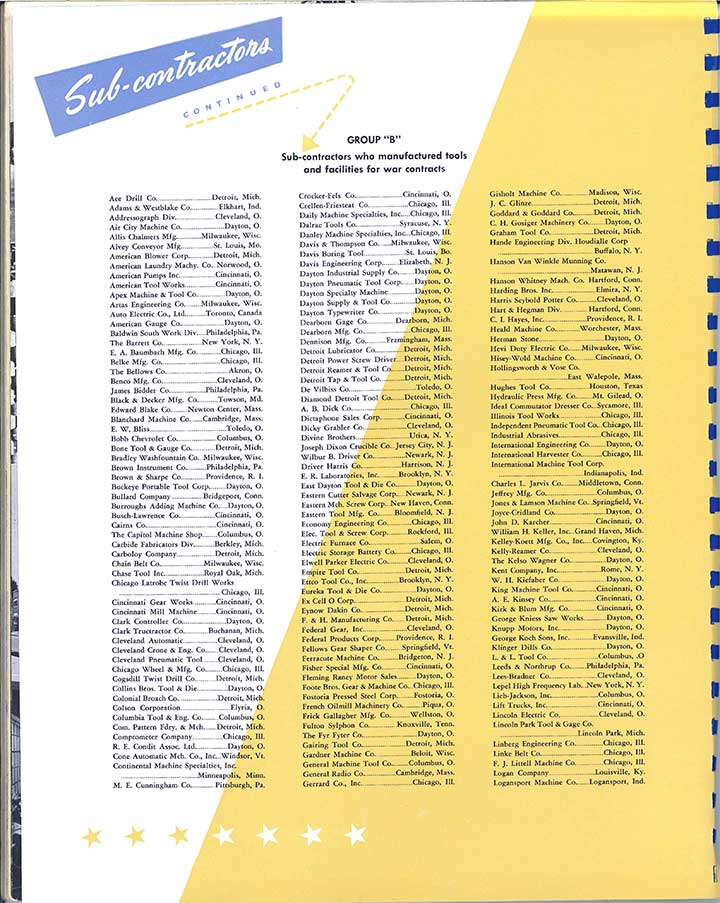

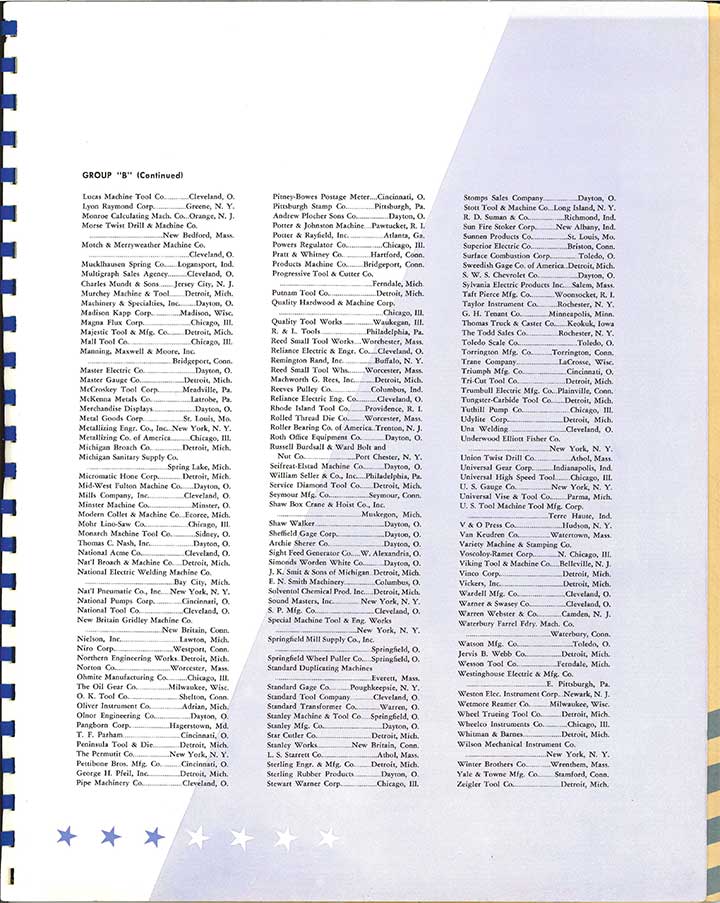

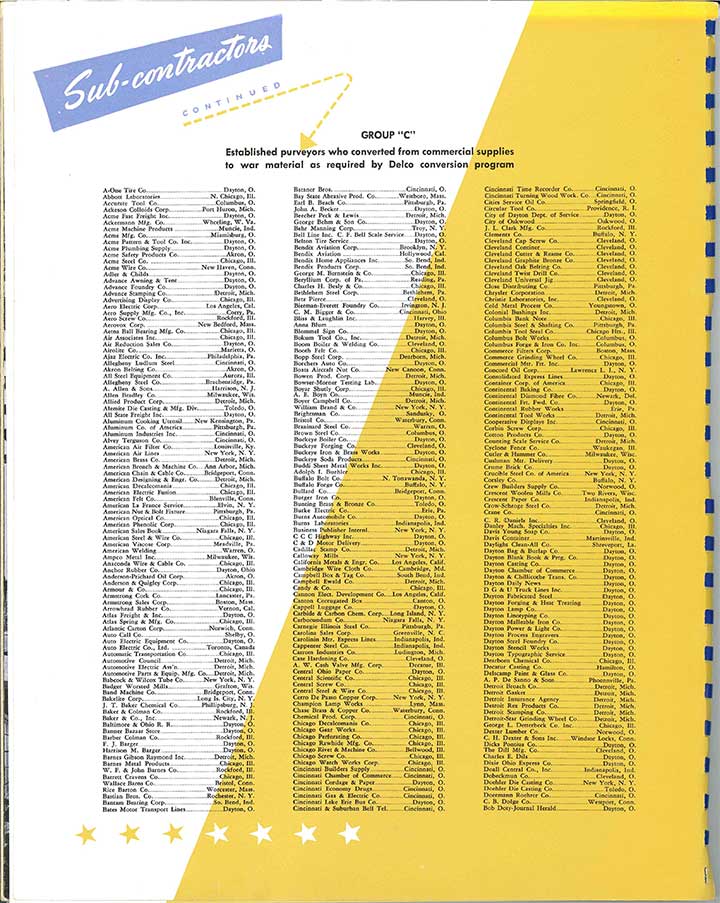

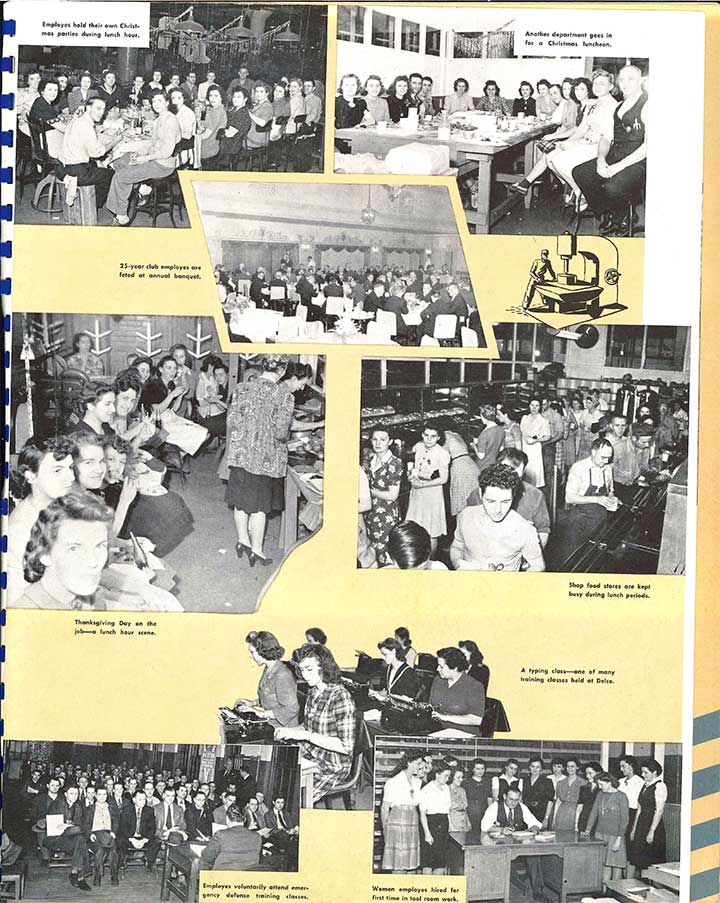

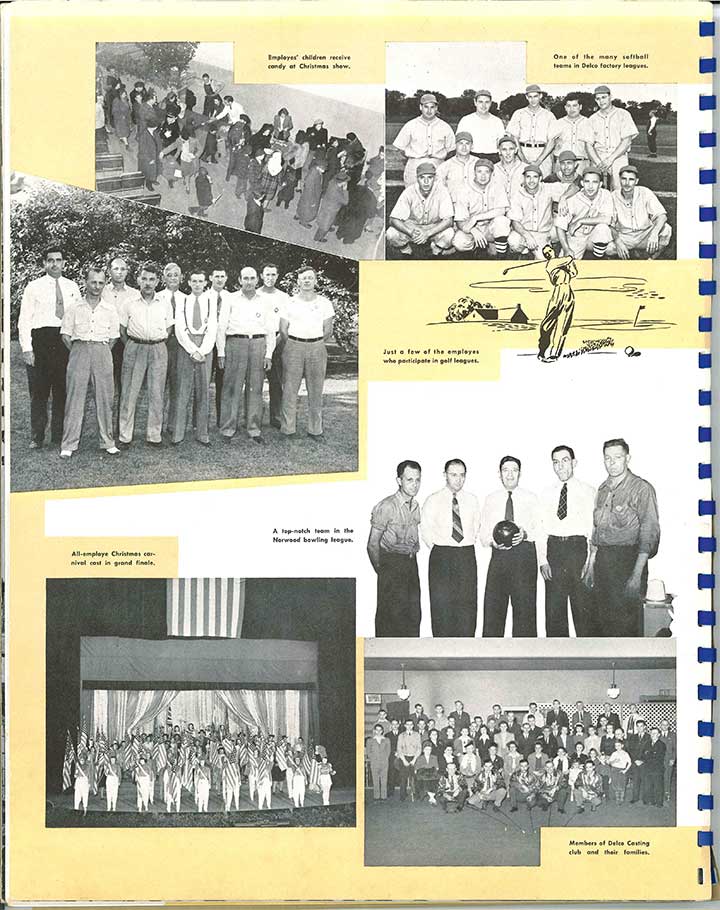

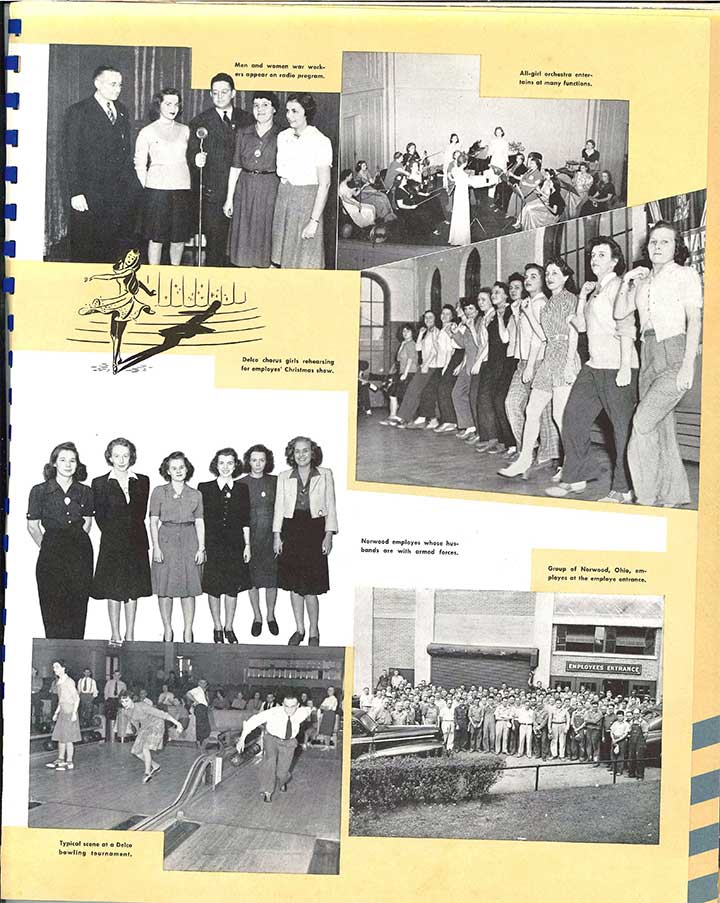

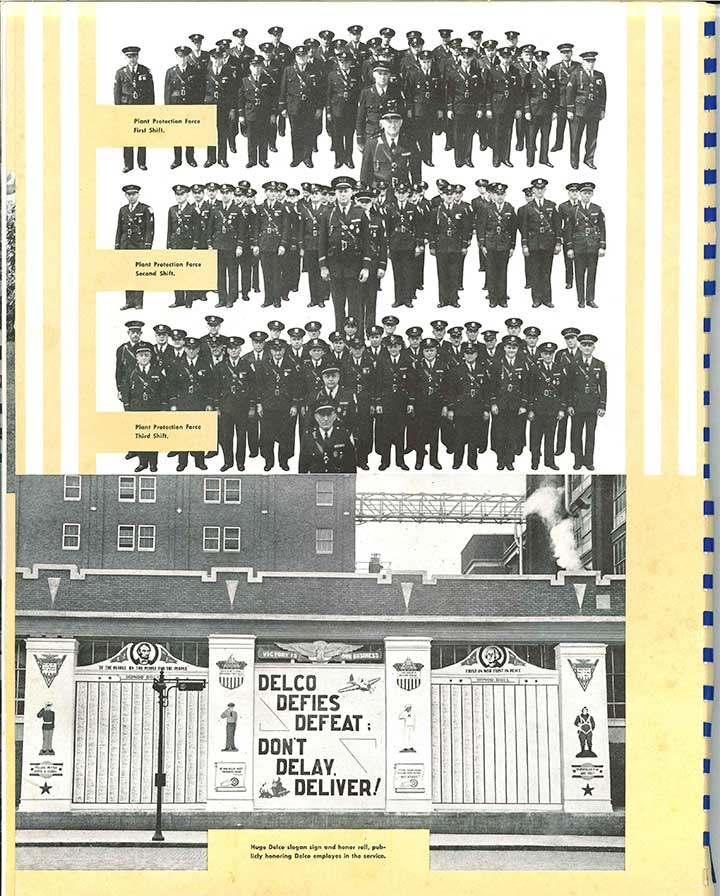

Page 6.

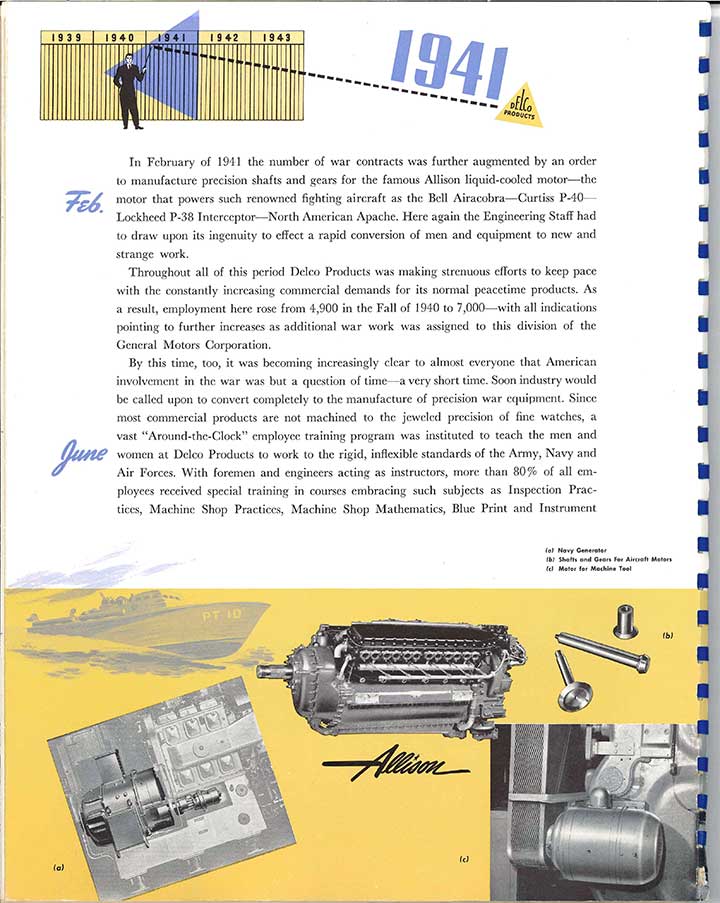

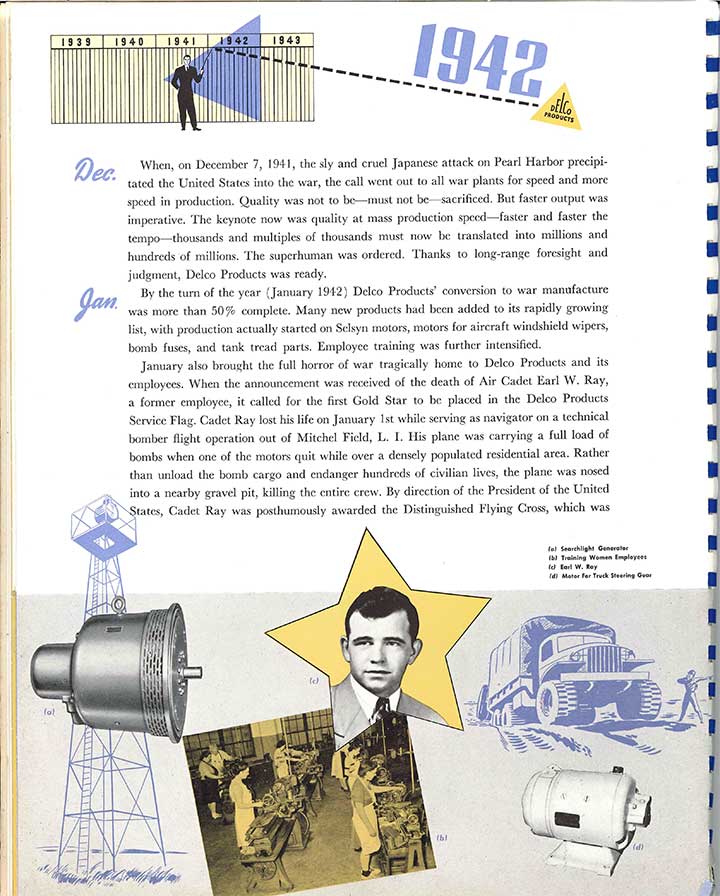

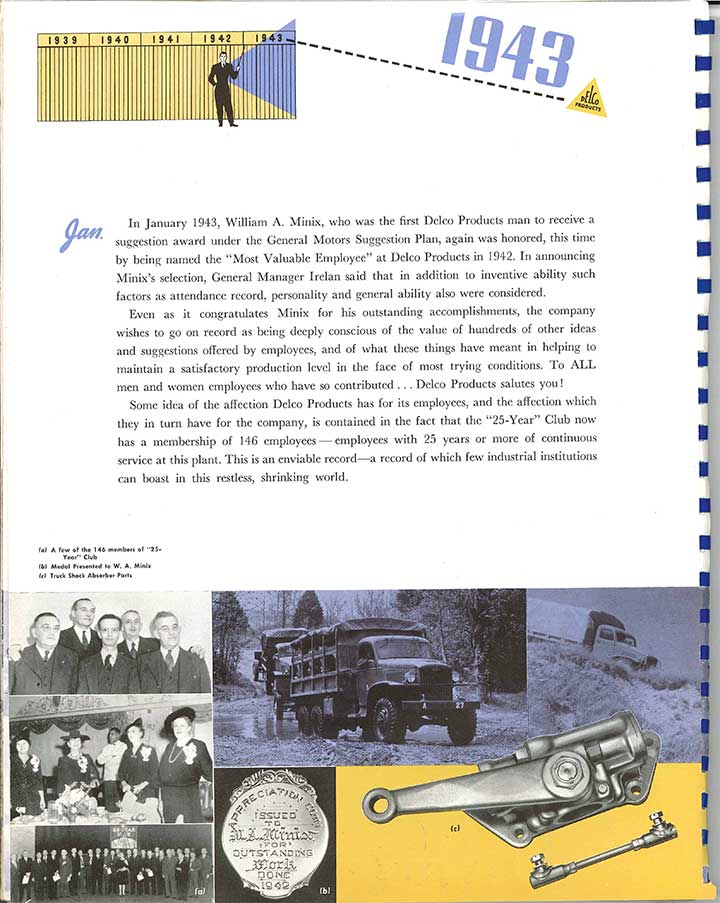

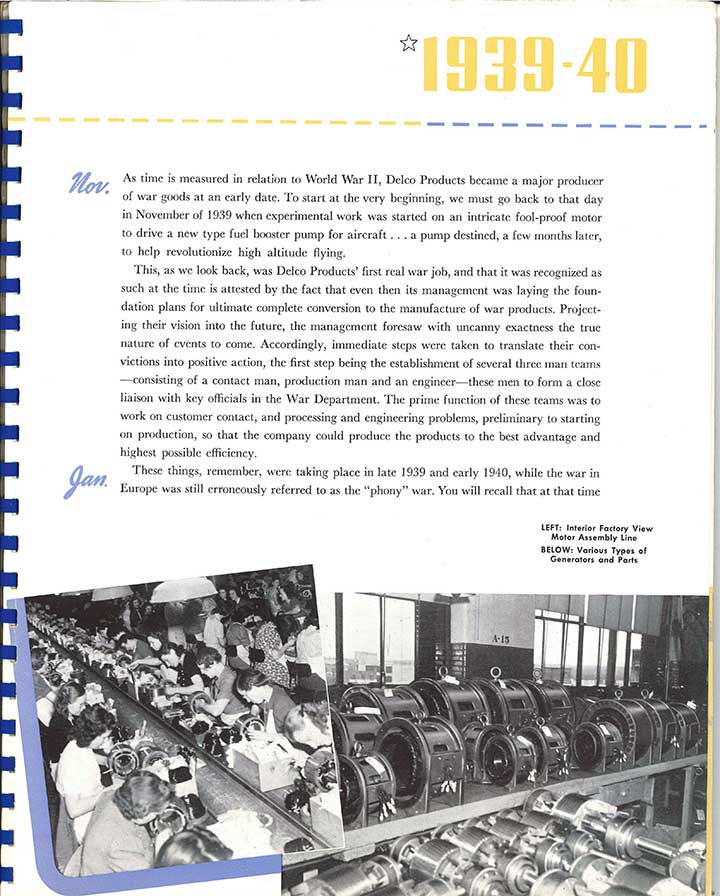

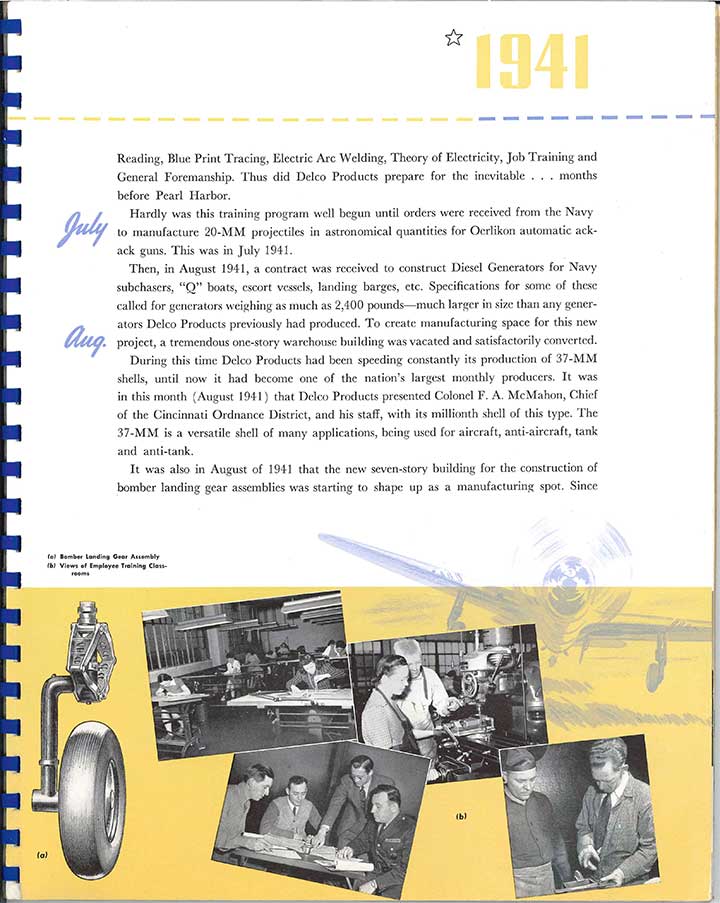

Page 10.

Page 11.

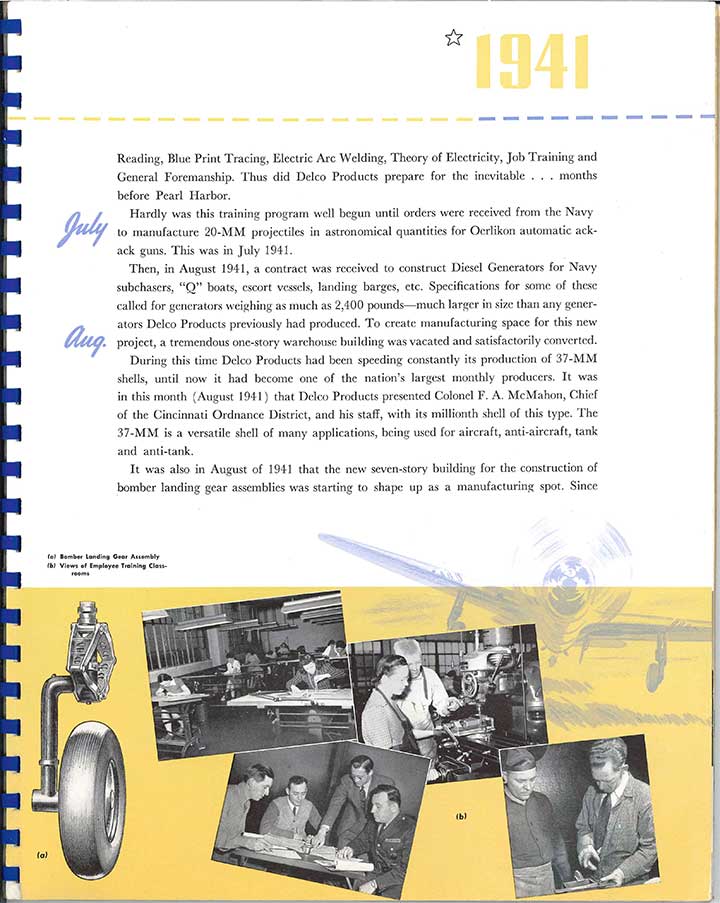

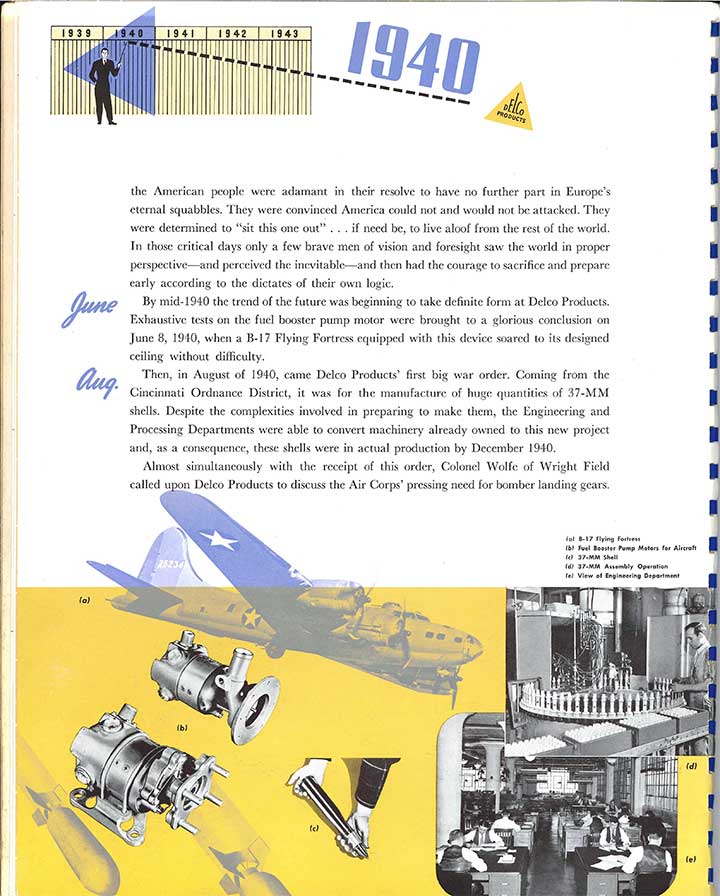

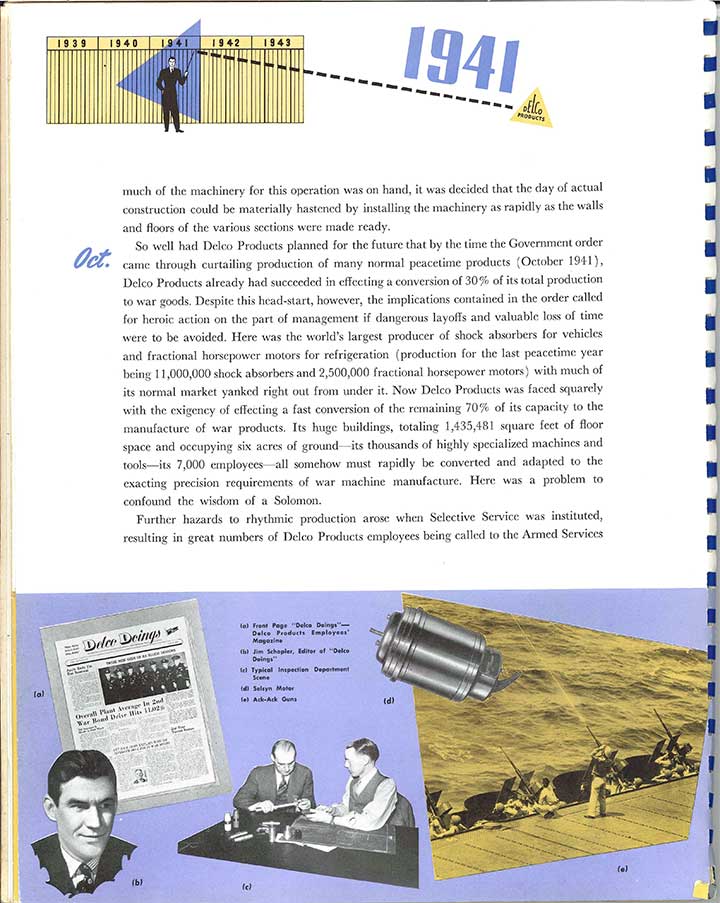

Page 12. Picture (d) is not a 20mm

Oerlikon but a 40mm Bofors.

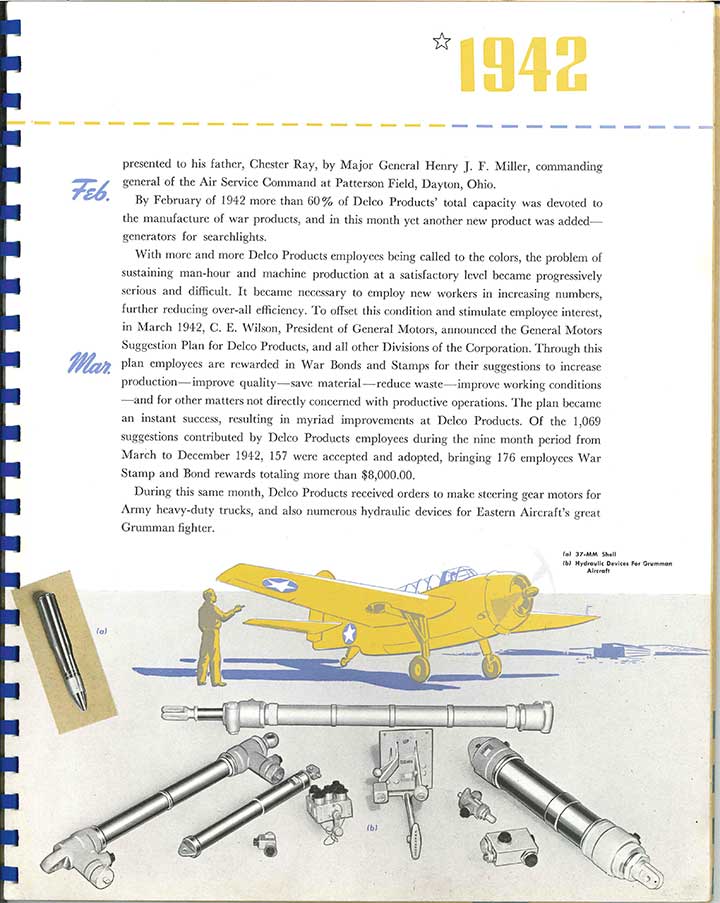

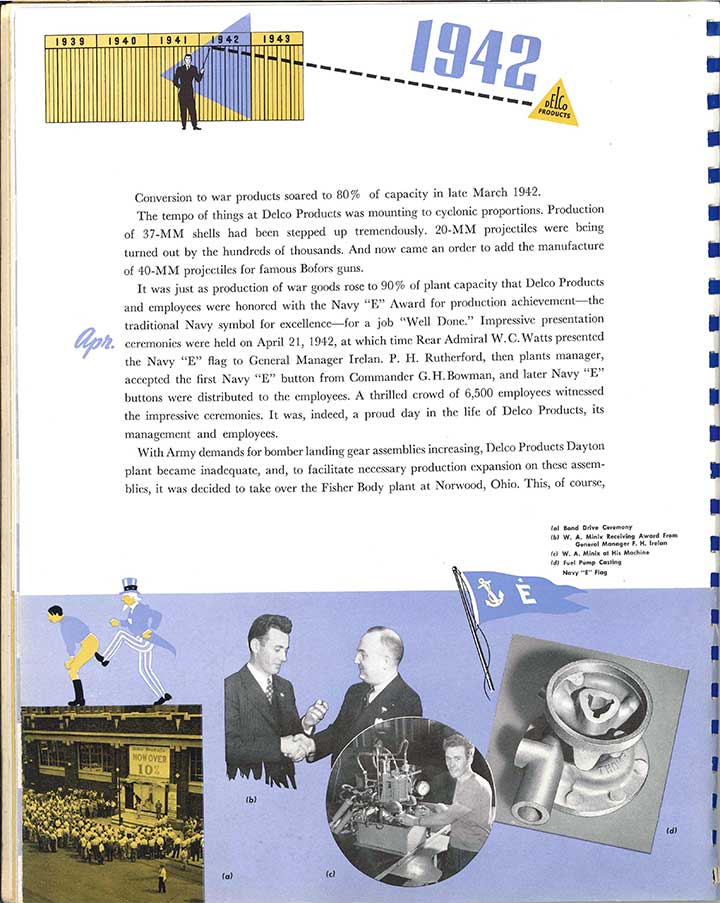

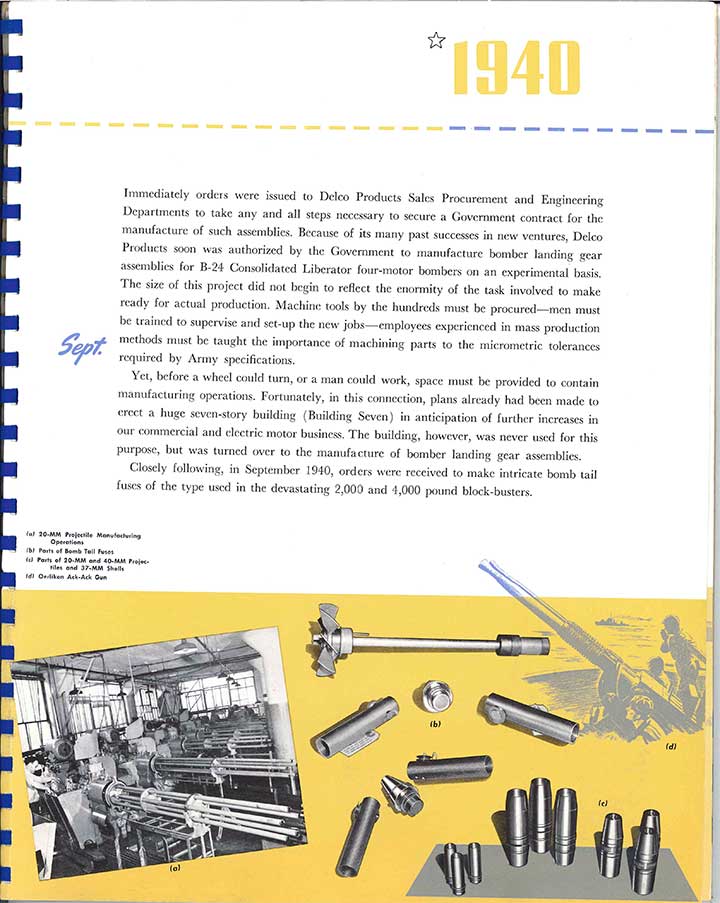

Page 13.

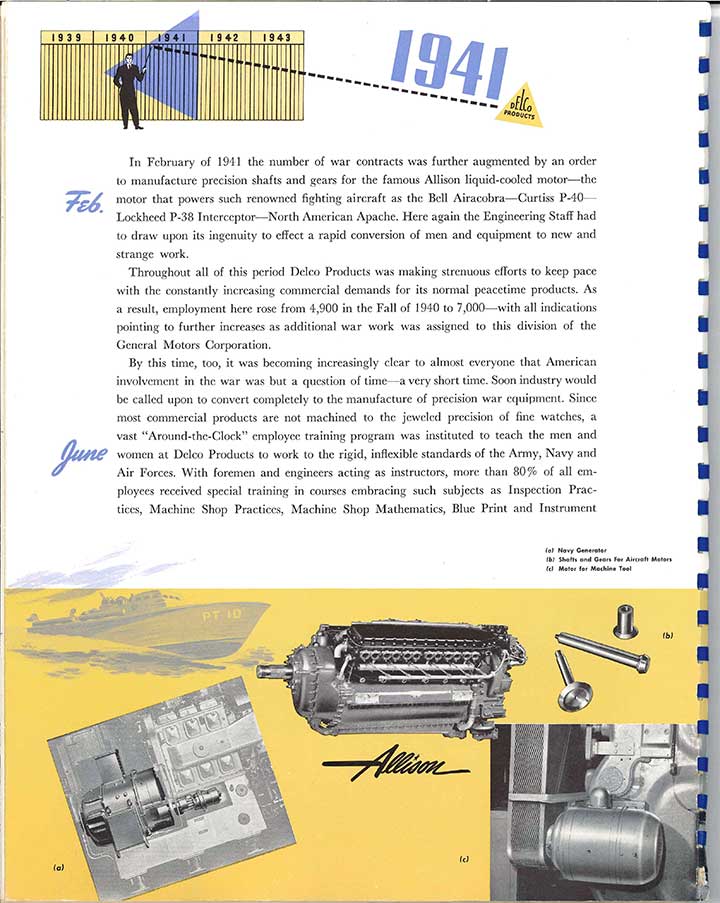

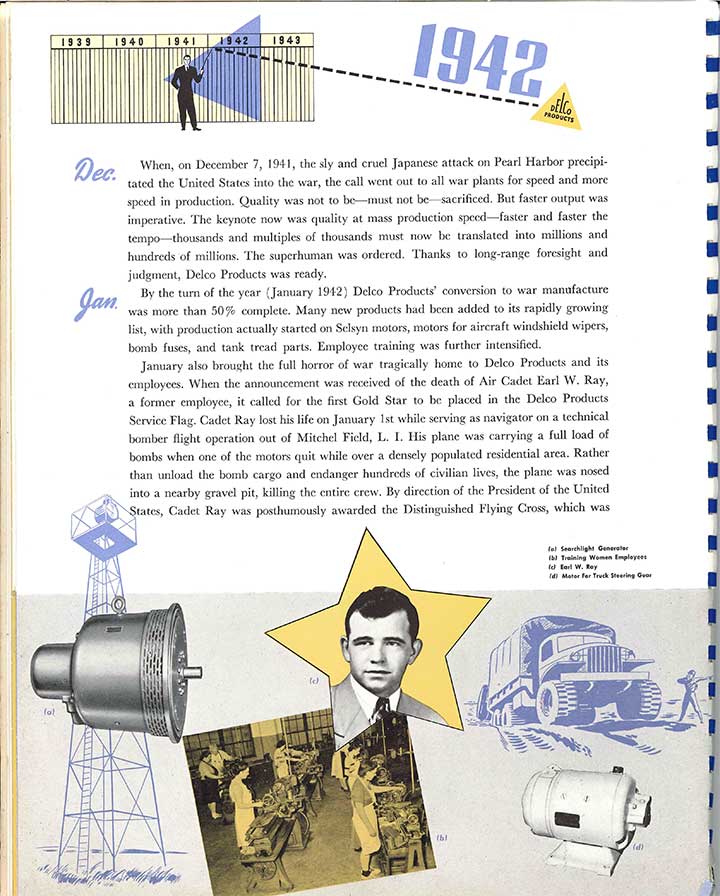

Page 14.

Page 15.

Page 16.

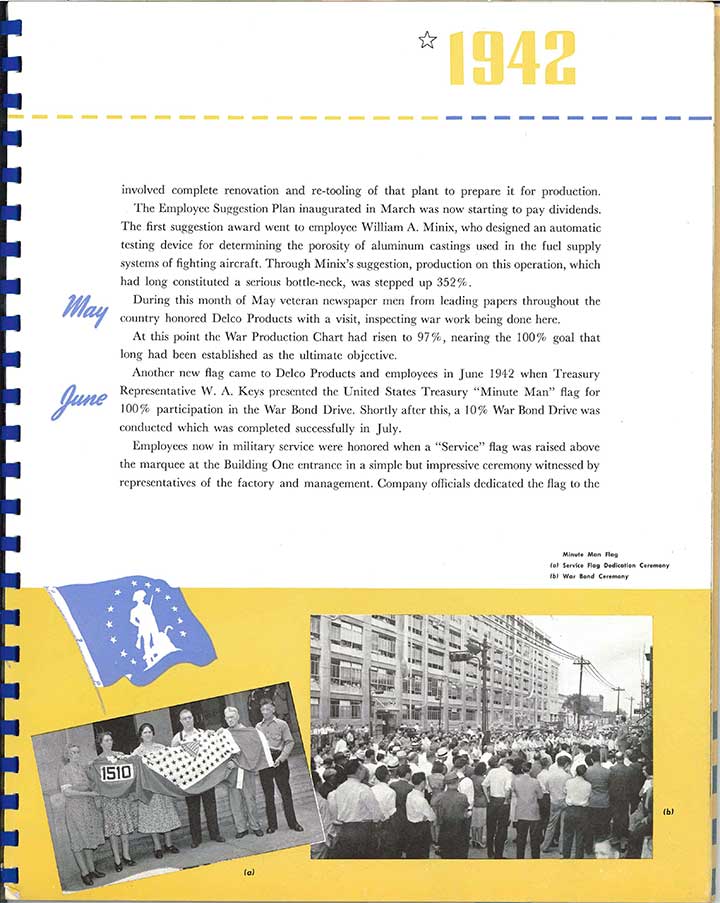

Page 17.

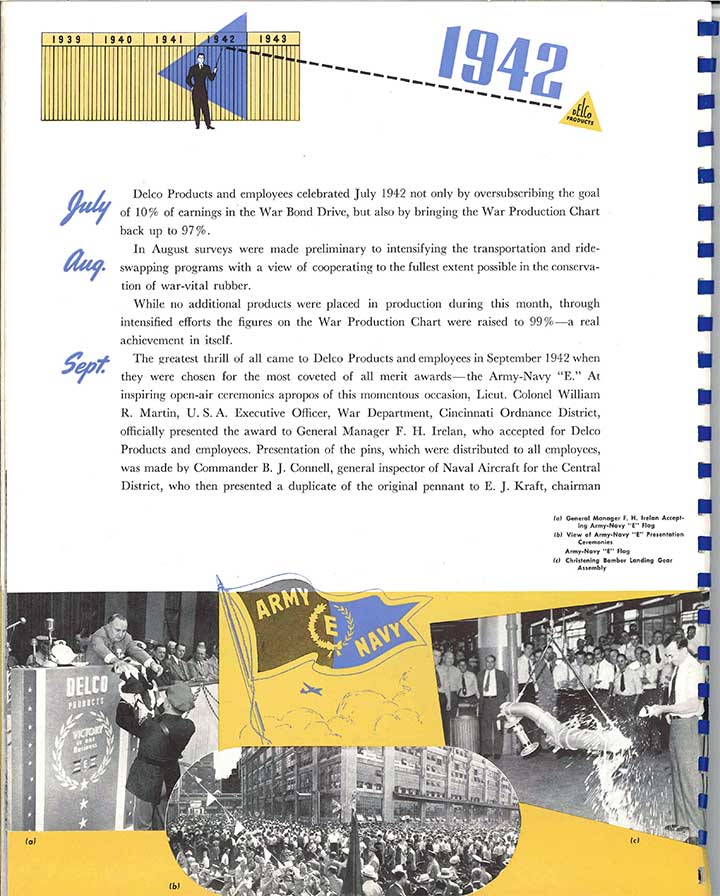

Page 18.

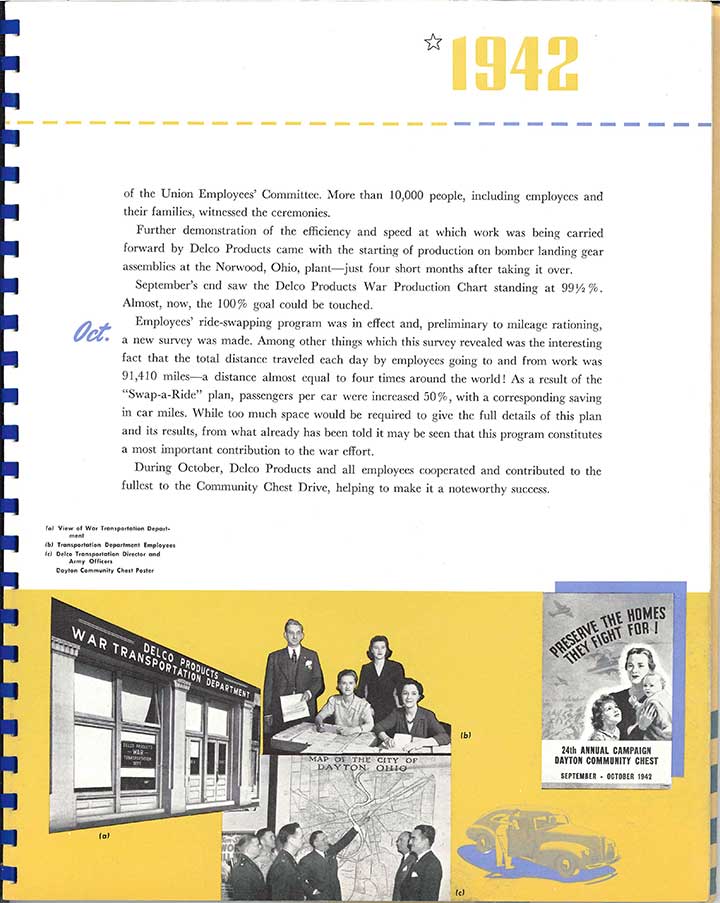

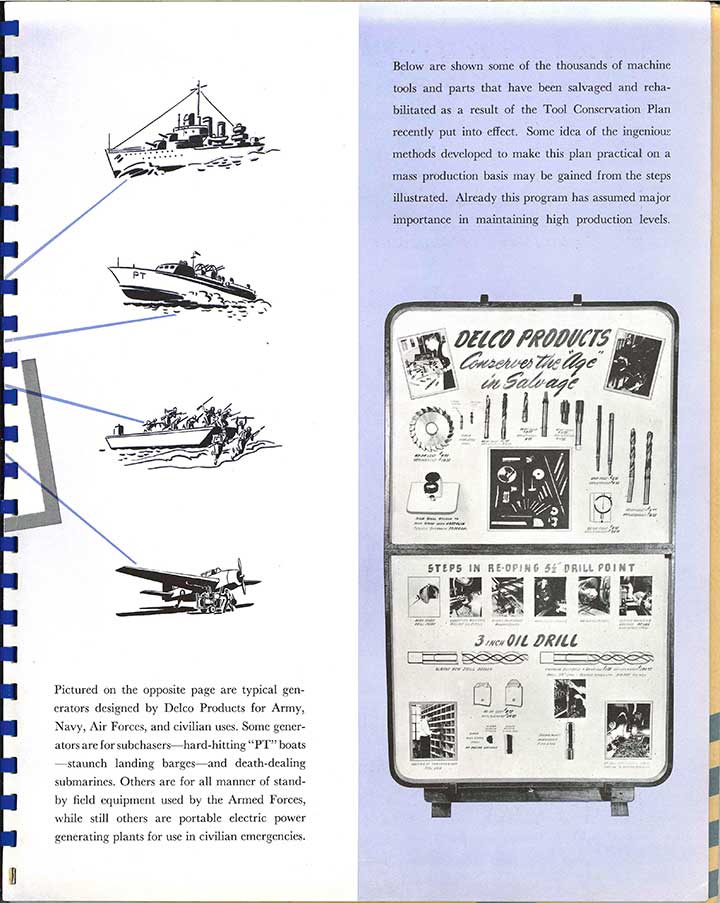

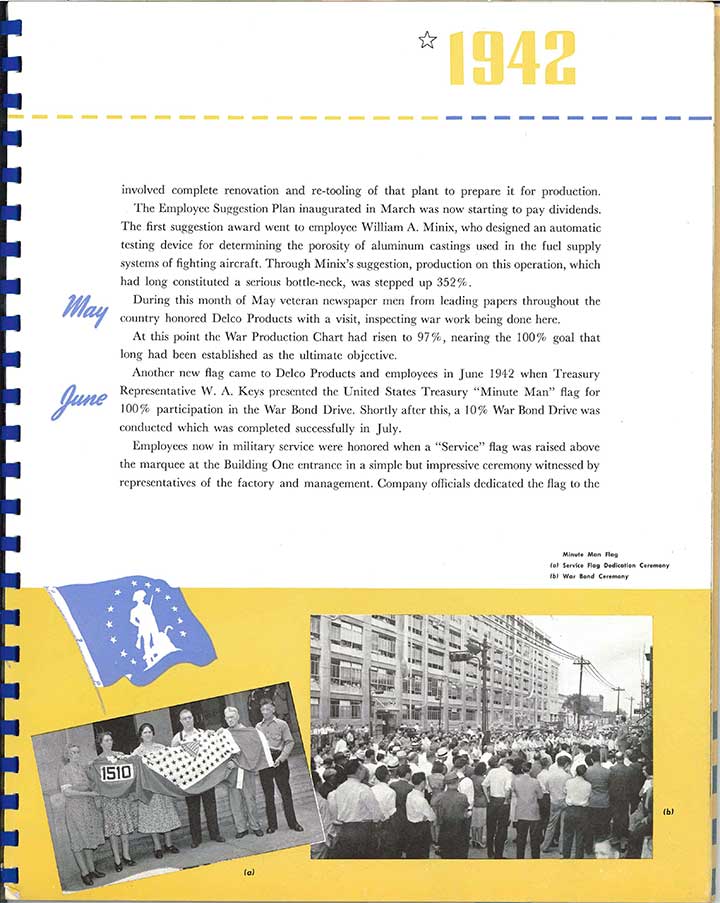

Page 19.

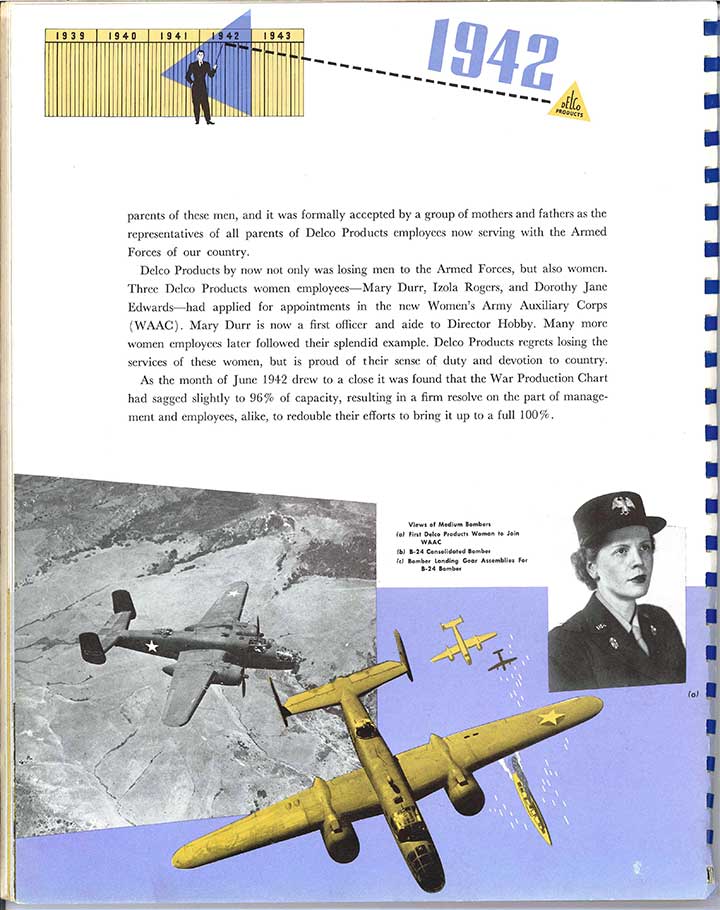

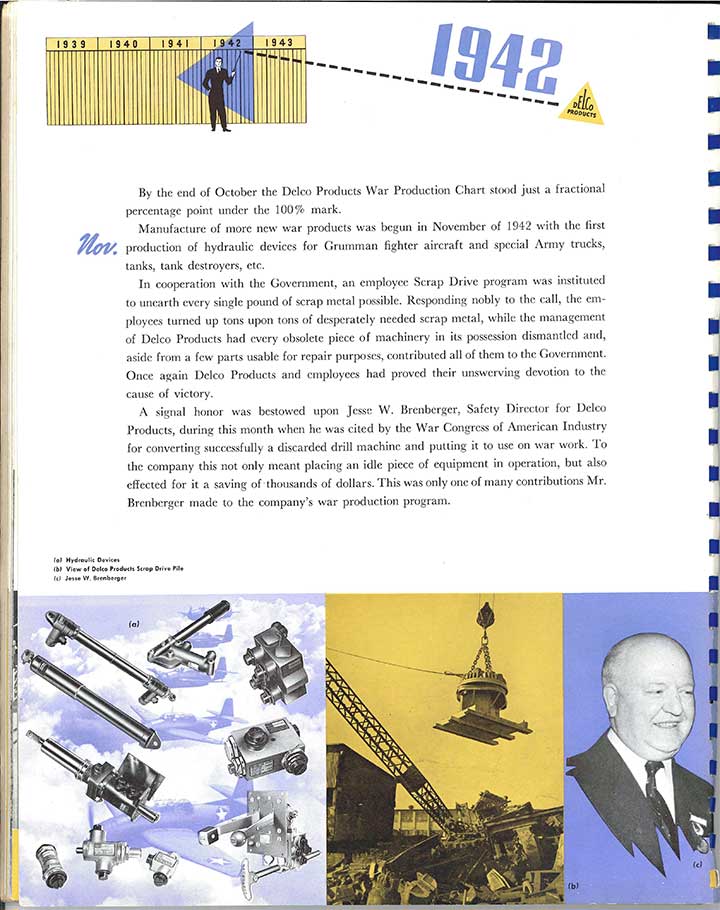

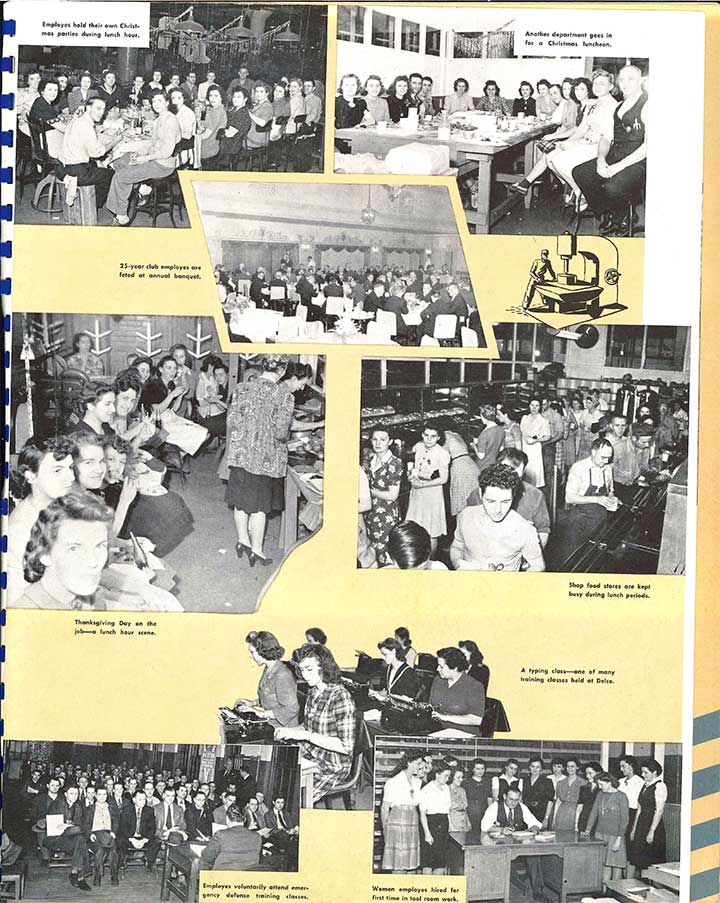

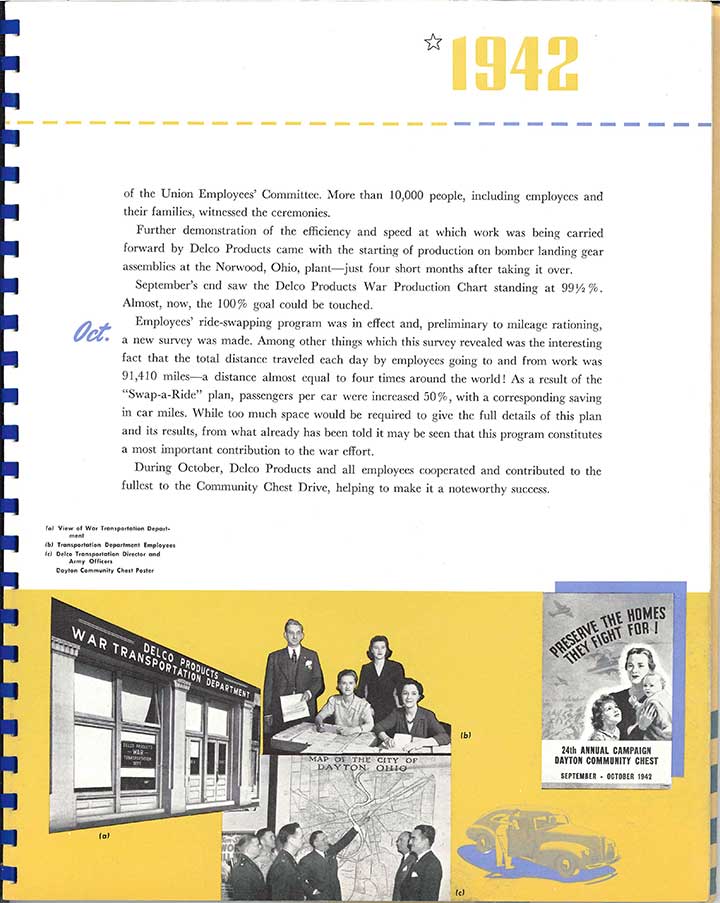

Page 20.

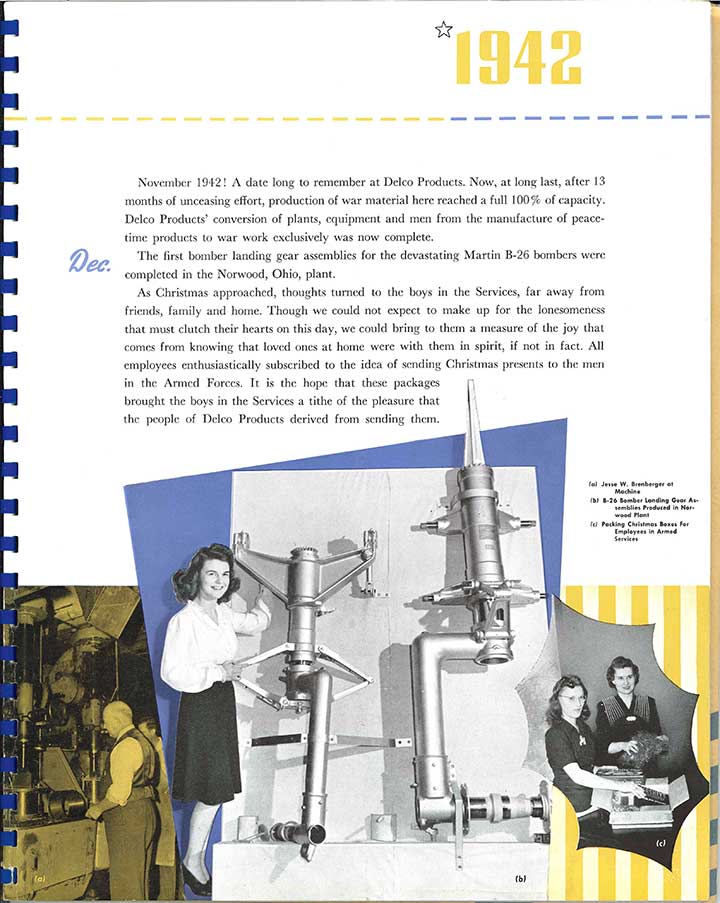

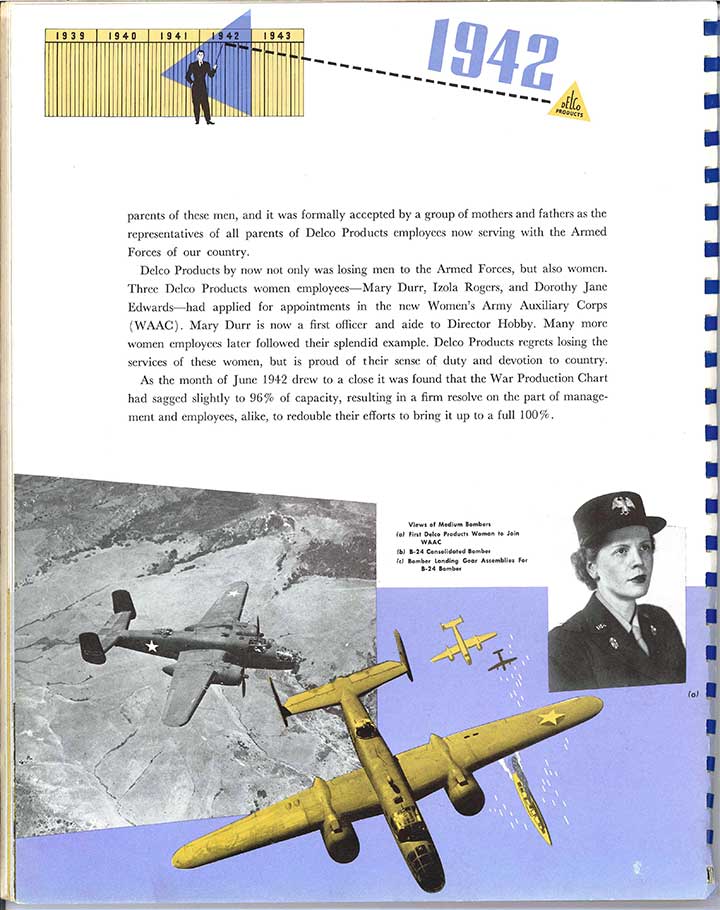

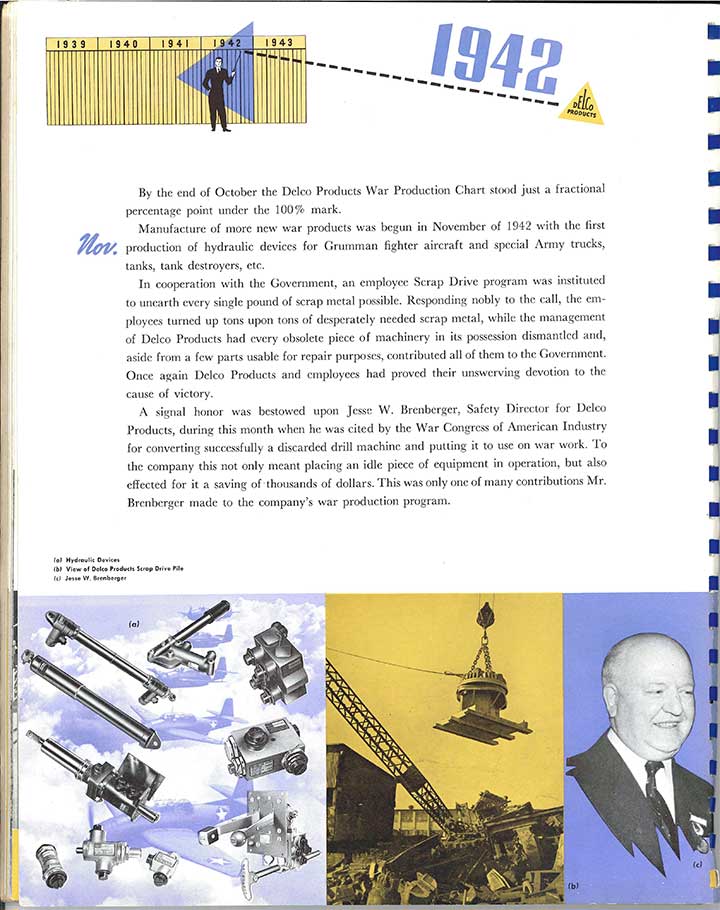

Page 21.

Page 22.

Page 23. Once again, the photos do not

match up with the text. All the aircraft here are B-25s, not B-24s

which were four-engine bombers.

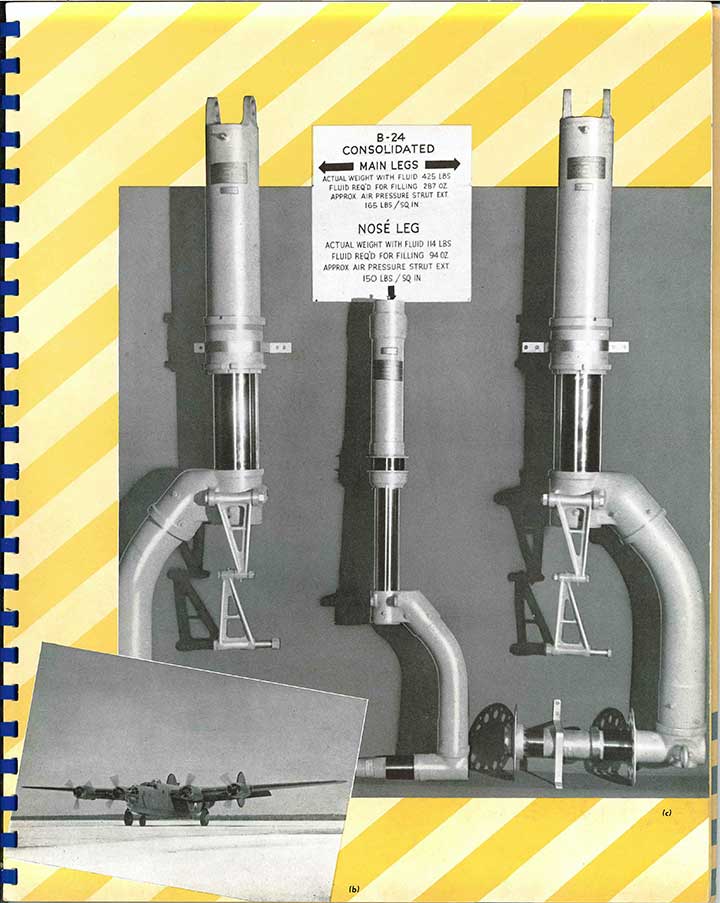

Page 24. Note that the B-24 main

landing gear produced by Delco Products weighed 425 lbs. and the nose

gear 114 lbs.

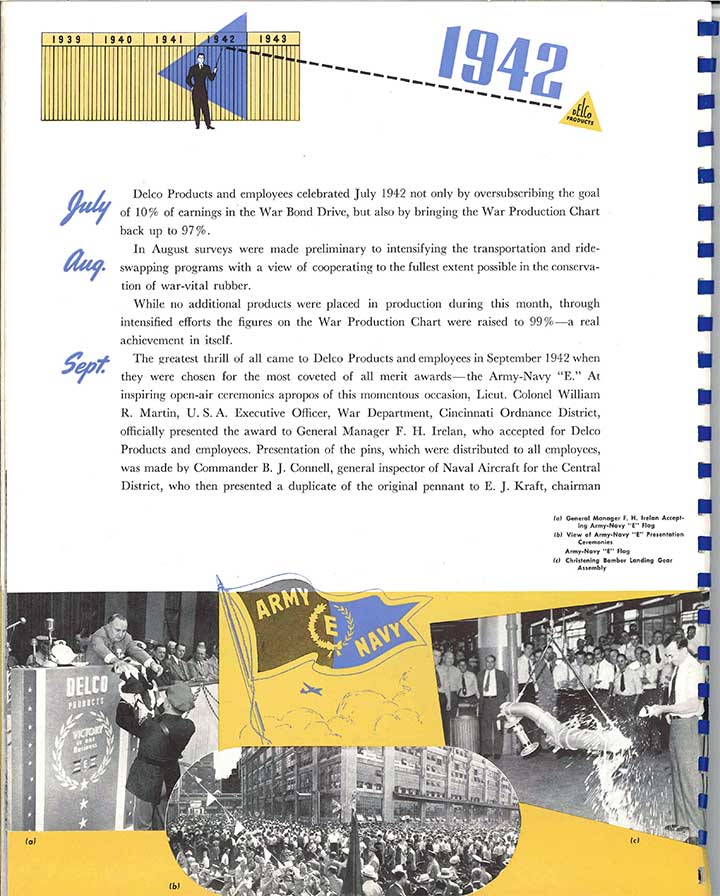

Page 25.

Page 26.

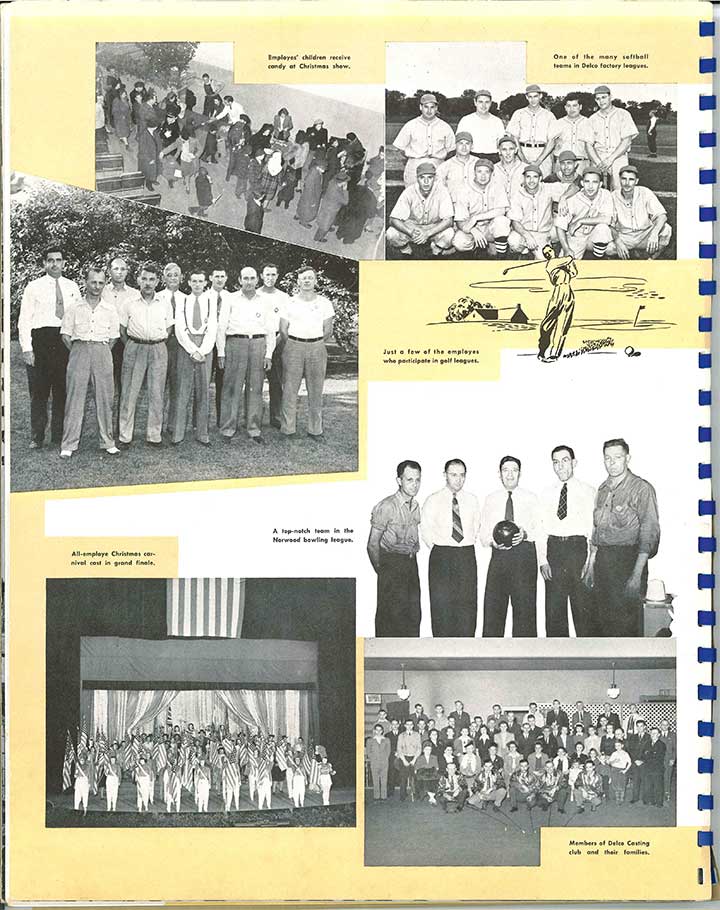

Page 27.

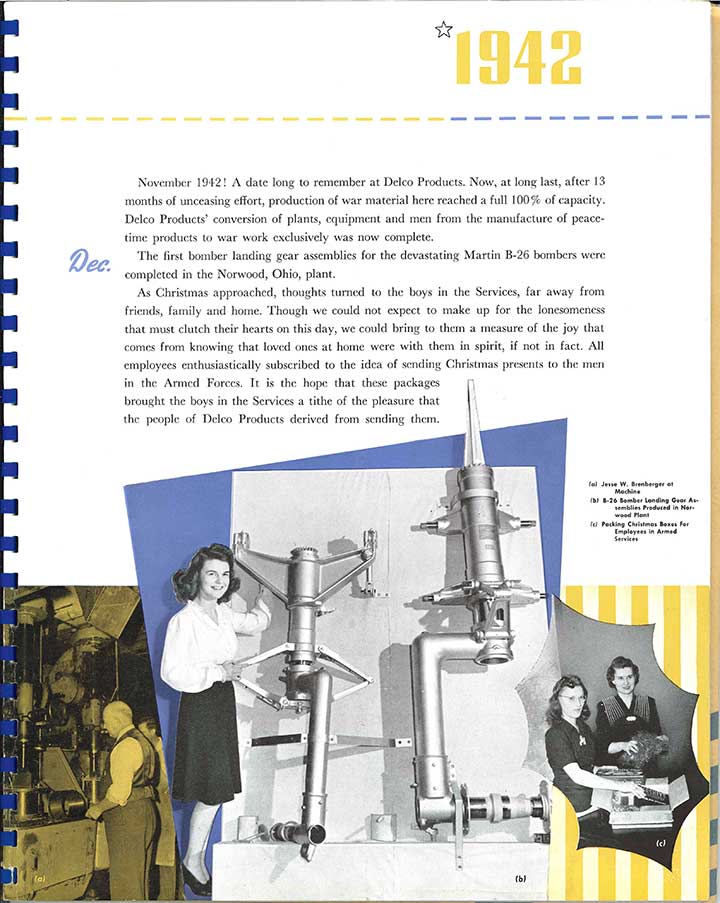

Page 28. Note the size of the Martin

B-26 Marauder landing gears in comparison to the young lady. She

is standing next to a nose gear. These were produced at the

borrowed Fisher Body Plant in Norwood (Cincinnati.), OH.

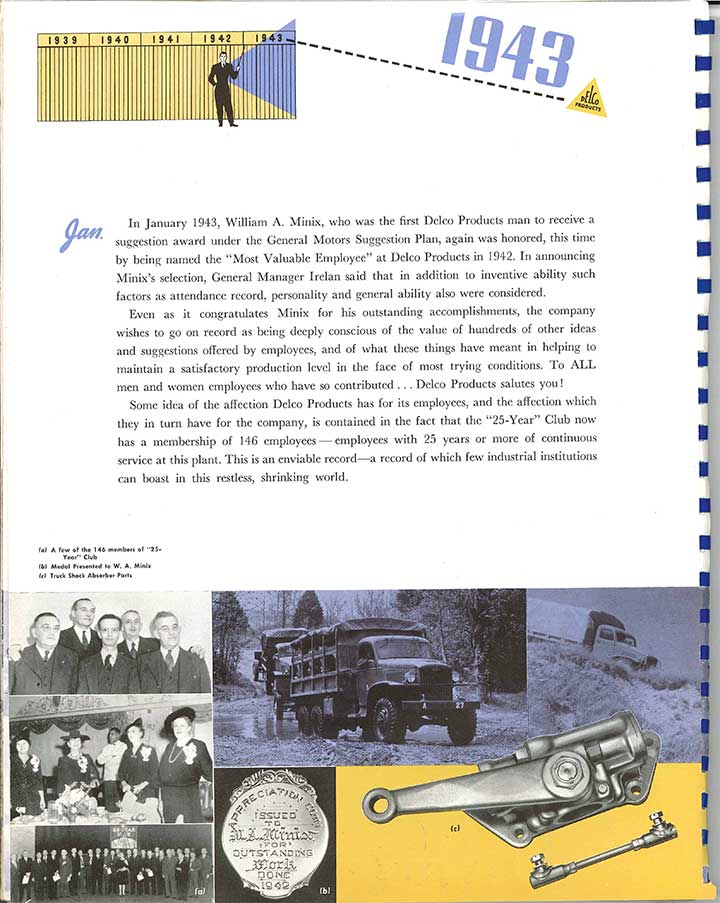

Page 29.

Page 30.

Page 31.

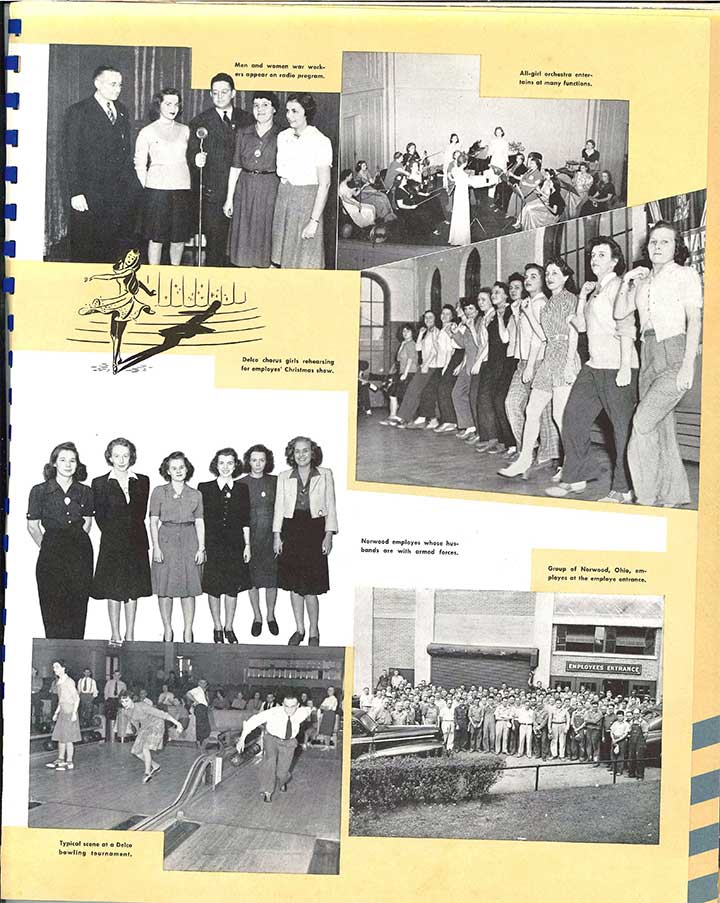

Page 32.

|