|

Nash-Kelvinator Lansing Michigan

World War Two Propeller Plants

Nash-Kelvinator in World War Two

Detroit, MI

1937-1954

(1916-1937 as Nash Motors)

Rest in Peace

This page last updated

12-25-2022.

Nash-Kelvinator came into being in 1937, when

Nash Motors, an automobile manufacturer in Kenosha, WI since 1916,

merged with Kelvinator Appliance, a maker of home appliances in Detroit,

MI. Even though Nash was the senior partner in the merger,

company headquarters were in Detroit rather than Kenosha, because the

CEO was from Kelvinator and wanted to remain there.

In 1954, Nash-Kelvinator merged with Hudson to became American Motors.

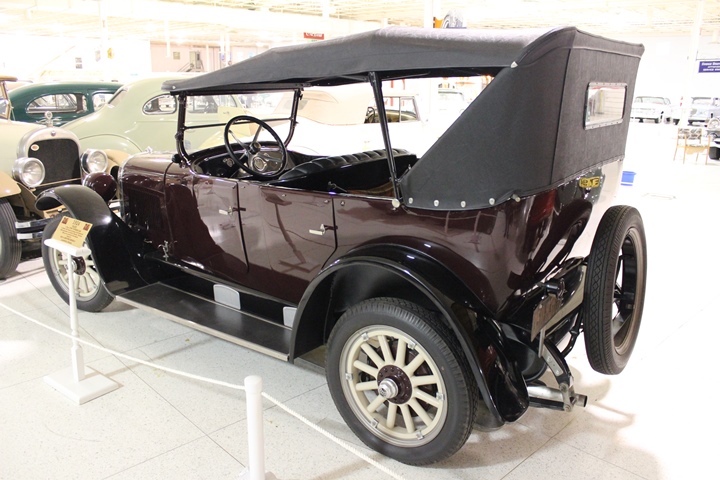

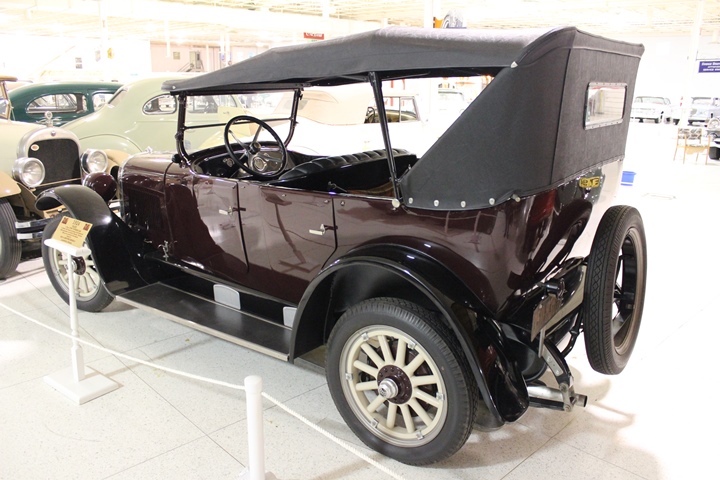

This 1924 Nash touring car was photographed

at the former Kokomo Automotive Museum in Kokomo, IN. Author's

photo.

Author's photo.

A Nash Statesman Super police car. Author's photo added 8-30-2018.

With the exception of one-ton truck trailers, Nash-Kelvinator did not manufacture products related to its

pre-war product lines during World War Two. In fact, it was one of only

three American automobile manufacturers to build complete aircraft, in

this case the Sikorsky R-6A helicopter. In fact, Nash-Kelvinator

built more helicopters during World War Two than Sikorsky and the rest of the

aviation industry combined.

Nash-Kelvinator was the largest producer of

American helicopters during World War Two.

It built the most advanced Sikorsky helicopter design of the war, the

R-6A Hoverfly II, which is shown above at the Air Force Museum in

Riverside, OH. Author's photo.

The Nash-Kelvinator Plant in Lansing, MI won

the Army-Navy "E" Award on September 17, 1943.

The Nash-Kelvinator Ranco Division in Columbus, OH won the Army-Navy "E" Award in January 1943.

Nash-Kelvinator World War Two Production: 650,000 bomb fuzes,

204,000 rocket motors, 200,000 M3 6x30 binoculars and cases. There

was also an unknown quantity of M13

Nash-Kelvinator-built 6X30 type binoculars. The company also

produced 44,628

one-ton two-wheel cargo trailers. Other products included aviation

fuel pressure gauges.

Nash-Kelvinator was 27th among United States

corporations in the value of World War Two production contracts.

Table 1 - Summary of

Nash-Kelvinator Company's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. Table added 4-10-2022. |

|

Plant |

Total Contract Amounts |

|

Detroit, MI |

$26,945,000 |

|

Kenosha, WI |

$402,017,000 |

|

Lansing, MI |

$539,433,000 |

|

Racine, WI |

$10,388,000 |

|

Ranco Division, Columbus, OH |

$32,512,000 |

|

Total |

$1,011,295,000 |

Table 2 - Nash-Kelvinator

Company Detroit, MI Plant's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. Table added 4-10-2022. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Ordnance

Material - Navy |

$8,089,000 |

6-1941 |

8-1943 |

| Refrigerators

- Army |

$221,000 |

7-1942 |

7-1942 |

| Refrigerators

- Army |

$220,000 |

9-1942 |

1-1943 |

| Bomb Fuzes -

Navy |

$4,812,000 |

3-1943 |

5-1944 |

| Helicopters

R6 - Army |

$12,560,000 |

6-1943 |

10-1945 |

| Refrigerators

- Army |

$185,000 |

10-1943 |

2-1944 |

| Rocket Motors

- Navy |

$535,000 |

2-1944 |

9-1944 |

| Rocket Motors

MK9 - Navy |

$123,000 |

8-1944 |

12-1944 |

| Total |

$26,945,000 |

|

|

Table 3 - Nash-Kelvinator

Company Kenosha, WI Plant's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. Table added 4-10-2022. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Airplane

Engines R2800 - Navy |

$15,311,000 |

3-1942 |

3-1943 |

| Drop Forgings

- Treasury Dept. |

$58,000 |

3-1942 |

6-1942 |

| Forgings -

Treasury Dept. |

$62,000 |

8-1942 |

1-1943 |

| Airplane

Engines R2800 - Navy |

$179,253,000 |

12-1942 |

3-1944 |

| Airplane

Engines R2800 - Navy |

$135,326,000 |

7-1943 |

3-1945 |

| Airplane

Engines R2800 - Navy |

$1,734,000 |

6-1944 |

10-1944 |

| Airplane Engs

R2800 - Navy |

$33,916,000 |

8-1944 |

6-1945 |

| Airplane Engs

R2800 - Navy |

$36,357,000 |

12-1944 |

8-1945 |

| Total |

$402,017,000 |

|

|

Table 4 - Nash-Kelvinator

Company Lansing, MI Plant's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. Table added 4-10-2022. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Airplane Prop

Assys - Army Air Force |

$11,738,000 |

6-1941 |

8-1942 |

| Airplane Prop

Assys - Army Air Force |

$19,599,000 |

10-1941 |

2-1943 |

| Airplane Prop

Assys - Army Air Force |

$66,679,000 |

1-1942 |

8-1943 |

| Airplane Prop

Assys - Army Air Force |

$26,922,000 |

7-1942 |

9-1943 |

| Airplane Prop

Assys - Army Air Force |

$27,104,000 |

7-1942 |

7-1943 |

| Airplane Prop

Assys - Army Air Force |

$20,548,000 |

8-1942 |

10-1943 |

| Airplane Prop

Assys - Army Air Force |

$86,375,000 |

10-1942 |

7-1945 |

| Airplane Prop

Assys - Army Air Force |

$47,-78,000 |

12-1942 |

8-1944 |

| Airplane Prop

Assys - Army Air Force |

$18,430,000 |

9-1943 |

2-1944 |

| Airplane Prop

Assys - Army Air Force |

$73,068,000 |

5-1943 |

1-1945 |

|

Airplane Prop Assys - Army Air Force |

$6,401,000 |

6-1943 |

10-1944 |

| Airplane Prop

Assys - Army Air Force |

$12,550,000 |

8-1943 |

8-1944 |

| Airplane Prop

Assys - Army Air Force |

$23,871,000 |

12-1943 |

3-1946 |

| Airplane Prop

Assys - Army Air Force |

$65,049,000 |

3-1944 |

8-1945 |

| Airplane Prop

Assys - Army Air Force |

$34,021,000 |

6-1944 |

6-1945 |

| Total |

$539,433,000 |

|

|

Table 5 - Nash-Kelvinator

Company Racine, WI Plant's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. Table added 4-10-2022. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Trailers -

Army |

$4,174,000 |

12-1940 |

10-1941 |

| Trailers -

Army |

$212,000 |

10-1941 |

3-1942 |

| Trailers -

Army |

$453,000 |

11-1941 |

4-1942 |

| Trailers -

Army |

$5,549,000 |

1-1942 |

8-1942 |

| Total |

$10,388,000 |

|

|

Table 6 - Ranco Division of

Nash-Kelvinator Company Columbus, OH Plant's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. Table added 4-8-2022. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Optical

Equipment - Army |

$8,817,000 |

10-1941 |

4-1943 |

| Optical

Equipment - Army |

$2,631,000 |

10-1941 |

4-1943 |

| Gages - Army |

$823,000 |

4-1942 |

2-1943 |

| Optical

Equipment - Army |

$1,425,000 |

8-1942 |

2-1944 |

| Airplane

Instruments - Army |

$4,890,000 |

9-1942 |

5-1945 |

| Binocular

Parts - Army |

$433,000 |

9-1943 |

2-1944 |

|

Binocular Assemblies - Army |

$378,000 |

2-1943 |

5-1944 |

| Binoculars -

Army |

$494,000 |

5-1943 |

12-1943 |

| Binoculars -

Army |

$1,540,000 |

8-1943 |

6-1944 |

| Binoculars -

Army |

$3,546,000 |

11-1943 |

6-1944 |

| Binocular

Parts M3 - Army |

$51,000 |

3-1944 |

3-1944 |

| Pressure

Gages - Army |

$275,000 |

5-1944 |

5-1945 |

| Binocular

Parts M7 - Army |

$86,000 |

8-1944 |

1-1945 |

| Binoculars

M13 - Army |

$5,300,000 |

10-1944 |

4-1945 |

| Pressure

Gages - Army |

$604,000 |

10-1944 |

7-1945 |

| Binocular

Parts M7 - Army |

$234,000 |

11-1944 |

12-1944 |

| Binoculars

M13 - Army |

$4,350,000 |

11-1944 |

12-1945 |

| Binocular

Parts M6 - Army |

$64,000 |

12-1944 |

1-1945 |

| Binocular

Parts M3 - Army |

$1,586,000 |

1-1945 |

6-1945 |

| Pressure

Gages - Army |

$258,000 |

2-1945 |

9-1945 |

|

Pressure Gages TO2 - Army |

$143,000 |

3-1945 |

9-1945 |

| Pressure

Gages - Army |

$372,000 |

4-1945 |

2-1946 |

| Fuel Pressure

Gages - Army |

$98,000 |

5-1945 |

6-1946 |

| Pressure

Gages - Army |

$114,000 |

5-1945 |

10-1945 |

| Total |

$32,512,000 |

|

|

18,082 R-2800 Pratt & Whitney Radial

Aircraft Engines: These included the R-2800-8 for the Vought F4U Corsair,

the R-2800-10 for the Grumman F6F Hellcat, and the R-2800-65 for the

Northrop P-61 Black Widow. Production of the R-2800 actually began in

late 1941 in the former

Reo Truck plant at Mt. Hope Ave. and Washington Street in Lansing, MI.

Due to increased production demand for both the R-2800 and Hamilton-Standard

propellers

being built by Nash-Kelvinator in

Lansing, the engine manufacturing was transferred to Kenosha, WI.

Lansing concentrated on propeller production. The Defense Plant Corporation

spent $31.4 million in Kenosha on a new 204,800 square foot plant and equipment to produce

the Double Wasp engine. An average of 9,125 employees worked at the

plant during the war, with peak employment reaching 11,500.

158,134

Hamilton Standard Propellers: Original production began in

the former Reo plant on South Cedar Street, to the east of the main Reo

complex. After the war, the plant became John Bean.

Production later expanded to another former Reo Truck plant at Mt. Hope

and Washington. This plant became propeller manufacturing and

final assembly for Nash-Kelvinator during World War Two.

Motor Wheel used it for a while after the war. Then about 1960, it

became the site of the first big box discount store in

Lansing.

Beyond the 158,134 propeller assemblies completed here were another

85,656 spare blades. My grandfather was in charge of propeller

balancing at this plant, which produced the second highest quantity of

American propellers during World War Two. Both three and four

blade configurations were produced, including the four bladed type for the Vought F4U-4

Corsair and Douglas A-26 Invader.

219 R-6A Sikorsky Helicopters:

Nash-Kelvinator built more helicopters than any other company built during the

Second World War.

|

Table 7 -

Nash-Kelvinator YR-6A and R-6A Helicopters built during World

War Two |

|

Type |

USAAF Serial Numbers |

Quantity |

|

| YR-6A |

43-45316 through 43-45341 |

26 |

|

| R-6A |

43-45342 through 43-45534 |

193 |

Twenty-five were transferred to the British Army. Four

were transferred to the U.S. Navy. |

|

Total |

|

219 |

|

Another view of the Nash-Kelvinator-built

R-6A Hoverfly II at the Air Force Museum. Author's photo.

Author's photo.

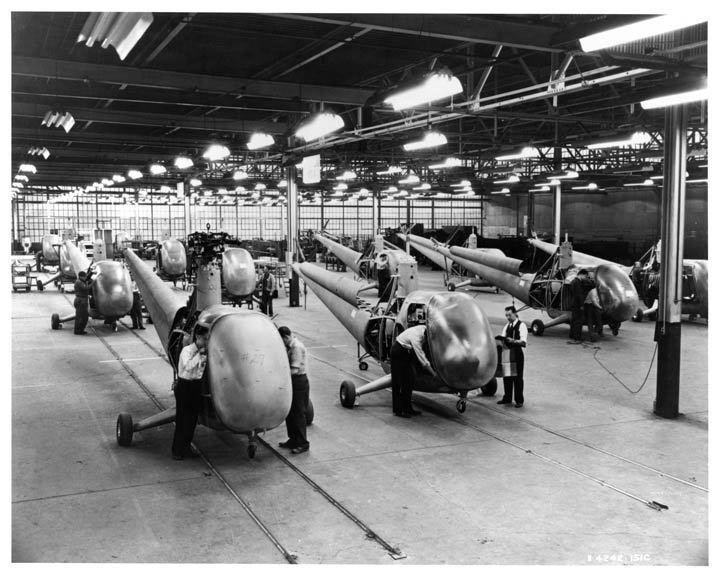

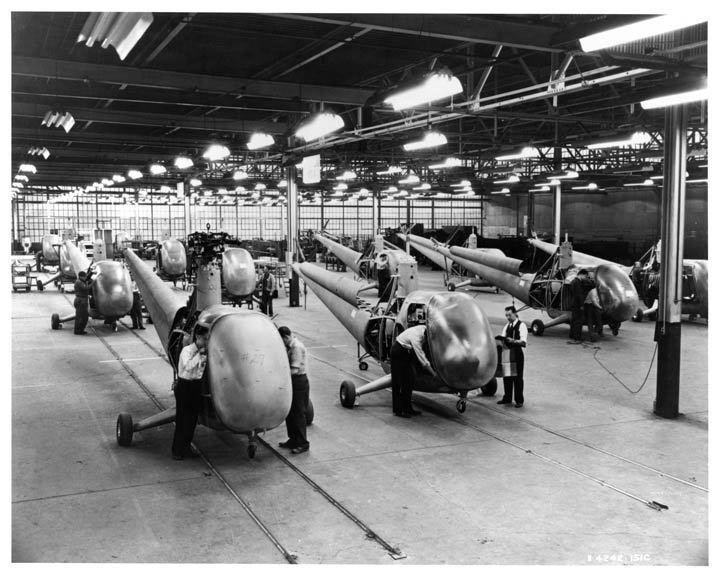

Eleven R-6 helicopters are under

construction in this World War Two era photo of the Nash-Kelvinator

Plant on Plymouth Road in Detroit, MI. Nash-Kelvinator was the

largest manufacturer of

helicopters during the war, producing 219. Sikorsky built 151 helicopters during

the war.

Three Nash-Kelvinator-built Sikorsky R-6

helicopters are airborne at the same time in 1944. Photo courtesy of

Ken Schroeder added 3-14-2016.

Table 8 -

Nash-Kelvinator World War Two Trailers Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| 1-Ton, 2 Wheel,

Cargo |

|

20,000 |

24,628 |

|

|

|

44,628 |

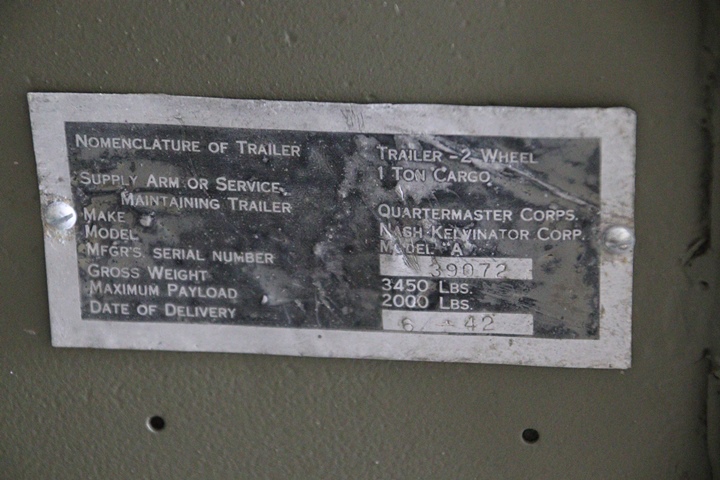

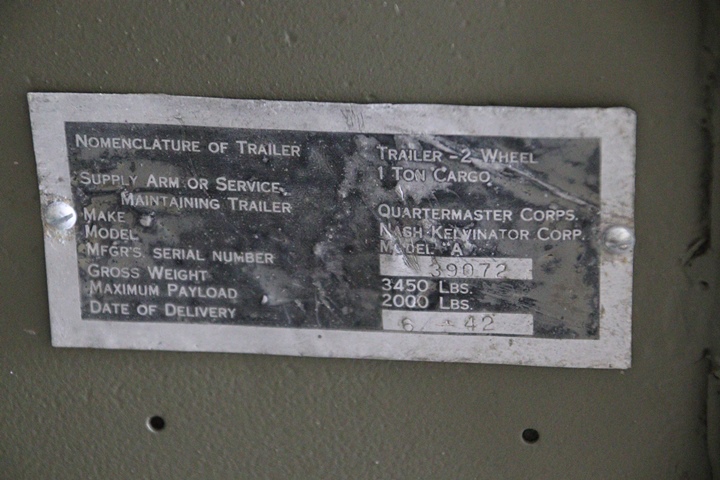

This Nash-Kelvinator-built 1-ton, 2 wheel

cargo trailer is part of the collection at the World War II American

Experience in Gettysburg, PA. I originally published the

Nash-Kelvinator page in September 2013. It took me nine years,

until September 2022, to find a Nash-Kelvinator-built World War Two

trailer. Author's photo added 12-25-2022.

Table 8 shows that Nash-Kelvinator built

44,628 trailers in 1941 and 1942. This one is serial number 39072

and was delivered in June 1942. Author's photo added 12-25-2022.

Author's photo added 12-25-2022.

Author's photo added 12-25-2022.

Binoculars:

This is a Nash-Kelvinator-built pair of M13 6X30

binoculars for the World War Two war effort. All of the

documentation shows that Nash-Kelvinator made M3 6X30 Binoculars.

Very little information can be found on the M13, and no information can

be found on the difference between the two types. Looking at

online auctions, both types were made and are for sale.

Author's photo.

This pair was on sale for $79.50.

Author's photo.

On display at the Vermillion County

War Museum is this pair of 1943 Nash-Kelvinator M3 6x50 binoculars, one

of 200,000 made at the Ranco Division in Columbus, OH. Author's

photo added 11-2-2015.

Author's photo added 11-2-2015.

The Ranco Division also made the binocular cases

along with aviation items, including altitude controls

and pressure gauges. Author's photo added 11-2-2015.

The binocular cases were manufactured in

the Nash-Kelvinator body plant in Milwaukee, WI. Photo courtesy of

Ken Schroeder added 3-14-2016.

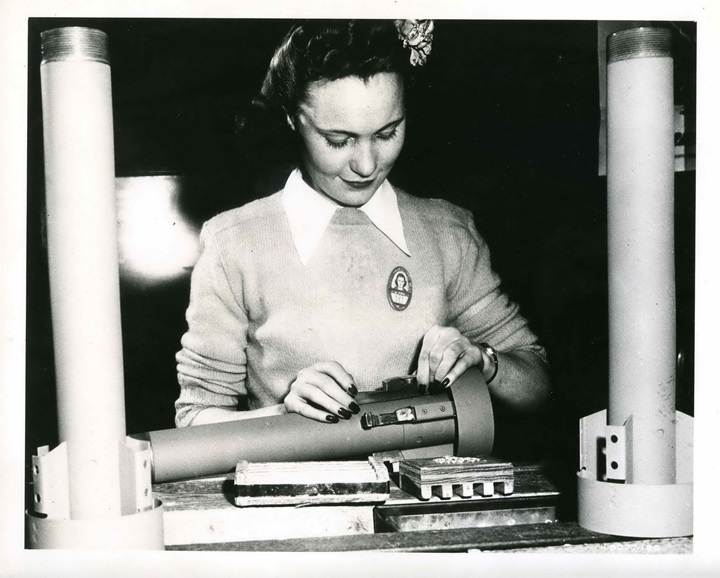

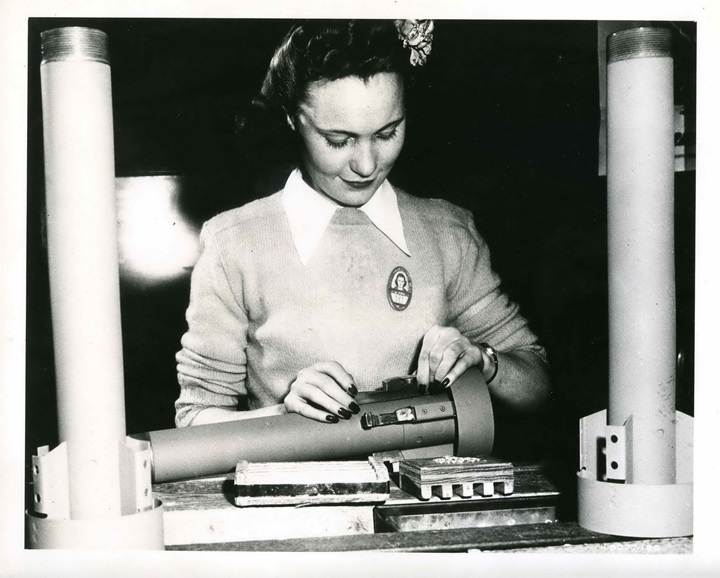

This worker is building one of 204,000

rocket motors manufactured by Nash-Kelvinator during World War Two. Photo

courtesy of Ken Schroeder added 3-14-2016.

This Nash-Kelvinator publicity photo

shows the warhead added to its rocket motors, ready

to fire on a beach landing in the South Pacific. Photo courtesy of

Ken Schroeder added 3-14-2016.

This rocket on display at the Indiana

Military Museum in Vincennes, IN has a rocket motor similar to that

which

Nash-Kelvinator built. Author's photo added 1-22-2018.

Nash-Kelvinator

(Mt. Hope Ave Plant) in Lansing, MI - See the link above for a

complete story on the company's Lansing propeller operation during World War

Two.

Author's photo.

Author's photo.

This photo shows the American automotive industry's

significant contribution to the construction of this late model B-24 (J,

L, or M model). Firstly, this is a Ford-built B-24 at the Willow

Run, MI plant. The Lansing, MI Nash-Kelvinator plant built the

propellers being installed, and the 100,000th milestone was

reached. My grandfather, Frank Dominik, while not in the photo,

played an important part in this. He was the supervisor of the

propeller balancing department back in Lansing. It was his

responsibility to assure that the engines on this B-24 were not affected

by vibration issues due to out-of-balance blades. The engines on this aircraft were also provided by U.S. auto companies.

Both Buick and Chevrolet built the Pratt & Whitney R-1830 engines that

powered the Liberator. The .50 caliber machine guns that defended

this aircraft against attacking fighters could have been manufactured by

any one of three General Motors Divisions: AC Spark Plug, Frigidaire, or Saginaw Steering

Gear.

The Pratt & Whitney R-2800 Engine:

|

Table 9 - Nash-Kelvinator-Built Pratt &

Whitney R-2800 Engines |

|

R-2800 Model |

Number of Engines Built |

Aircraft Type |

| R-2800-8 |

1,709 |

F3A-1, FG-1,

F4U-1,1C; F4U-2 |

| R-2800-8w |

3,094 |

F4U-1P(-8W) |

|

R-2800-10 |

1,690 |

P-60A,

XP-60E, F6F-3E,F,H,N,P; F6F-5, P-61, P-61A |

|

R-2800-10W |

9,900 |

F6F-5E,N |

|

R-2800-52 |

334 |

R6D |

|

R-2800-65 |

517 |

P-61A,B |

|

R-2800-99 |

842 |

Post World

War Two Aircraft |

| Total |

18,086 |

|

Nash-Kelvinator-built R-2800 engines were

instrumental in winning the Naval aerial war in the Central Pacific.

Grumman F6F-3 and F6F-5 Hellcats swept the Japanese aerial naval forces

from the sky. The Hellcat shot down more Japanese aircraft than

any other American aircraft during World War Two. This totaled

5,160 aircraft. Author's photo added 5-18-2021.

Nash-Kelvinator built 18,086 Pratt & Whitney

R-2800's, like this one shown at the P-61 display at World War Two Weekend

in Reading, PA. They were built in a

new government plant in Kenosha, WI during World War Two. The models

built by Nash-Kelvinator, first built in Lansing, MI and then Kenosha,

WI, went into the Hellcat, Corsair and Black Widow fighters. The

R-2800-65 version of the 2,000 hp engine was on display with the

Black Widow restoration in 2011. Author's photo.

This is one of only four Northrop P-61s "Black

Widows" that still exist in the world, and the only one that will ever

fly again. This P-61 is being rebuilt by the Mid Atlantic Air

Museum in Reading, PA, and was seen on display at the Museum's annual

WWII Weekend in June of 2011. The engine to the left could

very well be a Nash-Kelvinator-built R-2800-65 Model that the company built for the

"Black Widows" during the Second Word War. Author's

photo.

The Vought F4U Corsair with

Nash-Kelvinator-built R-2800 engines destroyed 2,140

Japanese aircraft. The

Corsair was second in the destruction of Japanese aircraft in aerial

combat during the war. Author's photo added 5-18-2021.

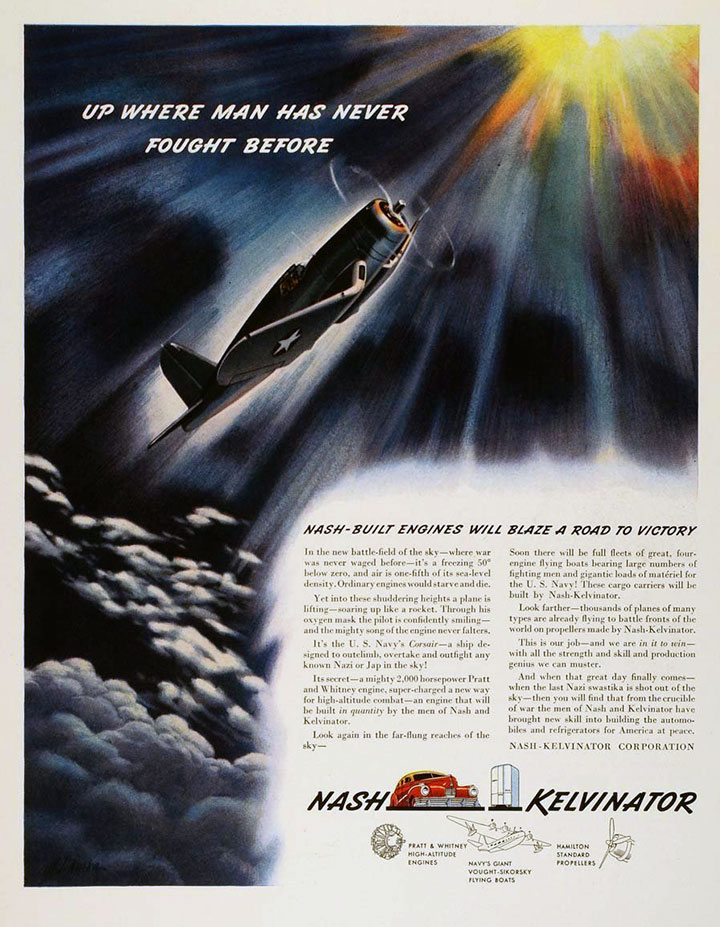

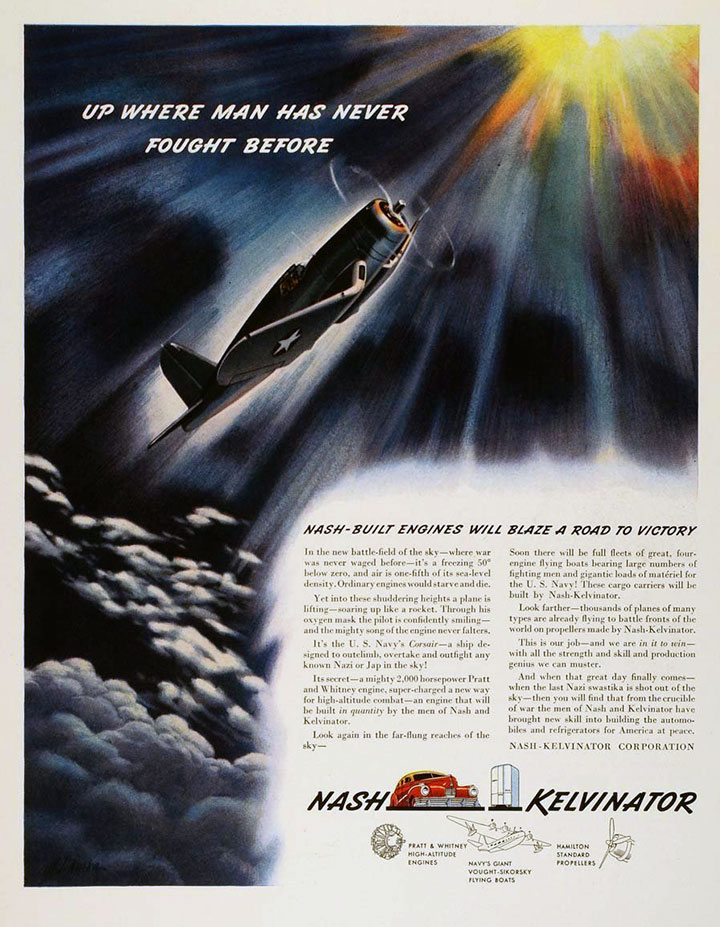

A World War Two era ad shows the Vought F4U Corsair

climbing towards the sun, powered not only by a Nash-Kelvinator-built R-2800

engine, but quite possibly a propeller built in Lansing, MI by my

grandfather.

Sikorsky SJRK-1:

Early in the war, plans called for Nash-Kelvinator to build a Sikorsky-designed four engine sea plane under a licensing agreement. All or

most of the World War Two

magazine advertisements indicated that this was one of the product lines

along with aircraft engines and propellers. Due to

changing military requirements, the need for this type

of aircraft decreased, and the project was dropped. The aircraft had

an experimental designation of XJRK-1. It would have carried 37

passengers. Artist's renditions, as shown below in the

advertisement, are the Sikorsky JR2S that was in production and not a

military secret. Final assembly of the SJRK-1 aircraft would have

been in New Orleans, where the assumption was that it would have been

built adjacent to Lake Pontchartrain and then launched from the lake.

Sub-assemblies would have been made in Grand Rapids, MI and Kenosha, WI.

This ad, along with other Nash-Kelvinator ads,

show and make reference to a Sikorsky four engine flying boat that

Nash-Kelvinator was to build, with final assembly being done in a new plant in New

Orleans, LA. The need for this type of aircraft diminished as the war

progressed, as more and larger aircraft carriers were built. The aircraft pictured

here is a JR2S.

Despite the fact that Nash-Kelvinator

never actually produced the proposed flying boat, it did spend a lot

of time and money on this wooden mock-up at its Milwaukee plant.

Photo courtesy of Ken Schroeder added 3-14-2016.

|