|

Ford Victory Pictorial

Ford WWII Production Database

Ford M4A3 Sherman Tank Photos Ford

Highland Park Plant Photos

Ford Motor Car

Company in World War Two

Dearborn, MI

1903-Present

This page updated on

6-7-2025.

An Overview

Ford Motor Company is probably best known for its production of 6,790

B-24 Bombers at the US government financed and owned plant at Willow

Run, MI. Constructing the plant, finding and training the

required people, and acquiring the tooling and equipment to build the

aircraft consumed a considerable amount of Ford's resources and time

during the war. Lost in the B-24 story is the number and diversity of

other war items Ford built that contributed to the success of the US war

effort. Below I have attempted to capture the entire breadth of

what the Ford Motor Company produced during World War Two. This starts with the

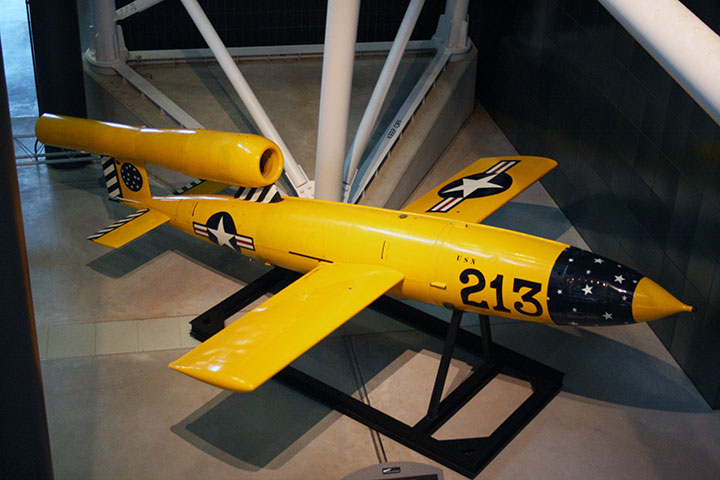

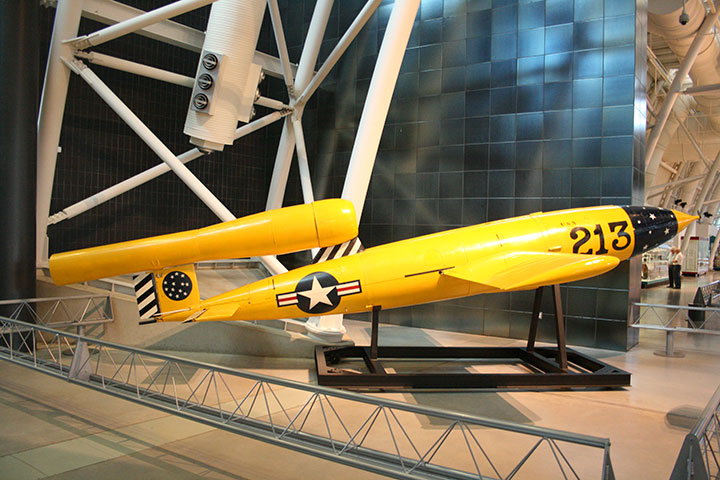

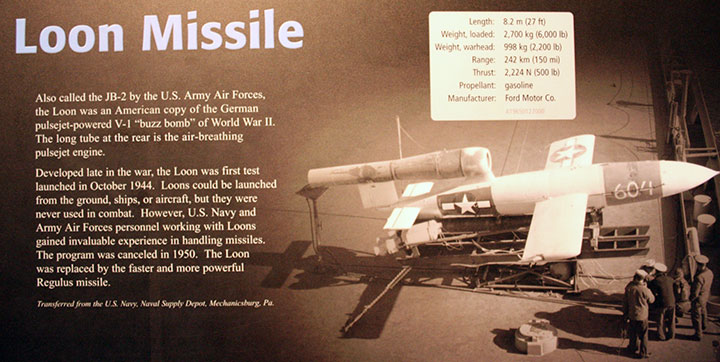

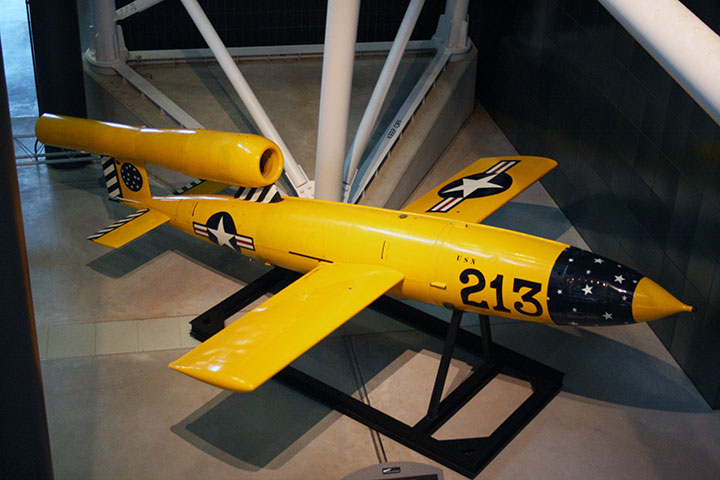

JB-2 Loon, the first US "cruise missile," which was a copy of the German

V-1 Buzz Bomb.

Also of significant note is the number and location of Ford's plants, not

only in the US but overseas as well. While several of the plants

were sold or loaned to the US government for war production, Ford's 42

domestic plants continued producing war goods. Some of these were

small "village" plants that produced many important parts for the larger

products.

In the years after World War One and leading up to World War Two, the

United States military establishment ignored the work of US rocket

inventor Robert Goddard, putting the defense of the country at risk in

doing so. While they were ignoring Robert Goddard, now proclaimed

the father of American rocketry, the German military was in the process

of funding its rocket scientists, resulting in the Vengeance Weapons,

the V-1, and V-2. The United States was therefore put in the

position of having to copy captured German V-1s as they became

available. The result was the JB-2 Loon as seen above.

Republic Aviation had the contract for the airframe, but Ford

Motor Company was chosen to produce the pulse jet engine. Check my Willys-Overland

page to see the significant contribution it made to this project when

Republic Aviation subcontracted all of the airframe

work to it. Author's Photo.

This 1903 Ford Model A runabout had its

engine and chassis supplied by the Dodge Brothers machine shop, setting

into motion two names in the US auto industry that still exist. This

was Henry Ford's third and lasting attempt to start a car company, the

second one became Cadillac after he left. Author's photo from the

Gilmore Car Museum.

Seven Ford plants won the Army-Navy "E"

Award a total of 14 times during World War Two.

|

Ford Motor Car

Company Plants that won the Army-Navy "E" for Excellence Award

during WWII |

|

Aircraft Engine Plant, Dearborn, MI on 3-12-1943 |

1 |

|

Glider Plant, Iron Mountain, MI |

3 |

|

Richmond Tank and Motor Vehicle Depot, Richmond, CA |

4 |

|

Somerville Branch, Somerville, MA |

2 |

| Twin

City Branch, St. Paul, MN |

1 |

|

Willow Run Bomber Plant, Ypsilanti, MI |

1 |

|

Ypsilanti Plant, Ypsilanti, MI |

3 |

|

Total |

14 |

Ford Motor Company World War Two Production Statistics:

Aviation Related - (56,870) Pratt & Whitney R-2800 Radial Aircraft

Engines, (6,790) B-24 Liberator

Bombers, (1,894) B-24 Knock Down Kits*, (75,166) P-1 Aircraft

Generators, (11,224) R-1 Aircraft Generators, (4,314) CG-4A Gliders, (87) 14A Gliders, (17,008) Aircraft Drop

Fuel Tanks, (2,501) Pulse Jet Engines,

(52,278) Turbo Superchargers, (5,475) Aircraft Rate of Climb Indicators

*Knock Down Kits - These

went to the Douglas Plant in Tulsa, OK and Consolidated Plant in Fort

Worth, TX for final assembly.

Vehicles - (12,782)

Amphibious Jeeps (Seeps), (282,354) Jeeps, (250) T17 Armored Cars,

(8,410) M-8 Armored Cars, (3,791) M-20 Armored Cars, (19,520) British

Axles, (26,086) British Engines, (1,690) M4A3 Sherman Tanks, (1,038) M10A1

Tank Destroyers, (26,727) Tank Engines, (5,475) Tank Gun Mounts,

(13,893) Universal (Bren Gun) Carriers, (7,053) GTBC 1-1/2 ton, 4x4 Bomb Service Trucks,

(77,915) G8T 2-1/2 ton 4x2 Trucks,

(8,218) GTB 1-1/2 ton 4x4 Cargo Trucks (Burma Jeep), (42,676) Army/Navy

Cargo Trucks (Standard Product), (12,420) 1-1/2 Pick-up Trucks (Standard

Product), (10,476) 1942 Automobiles, (3,025 or 10,877) Ford designed

Moto-Tugs.

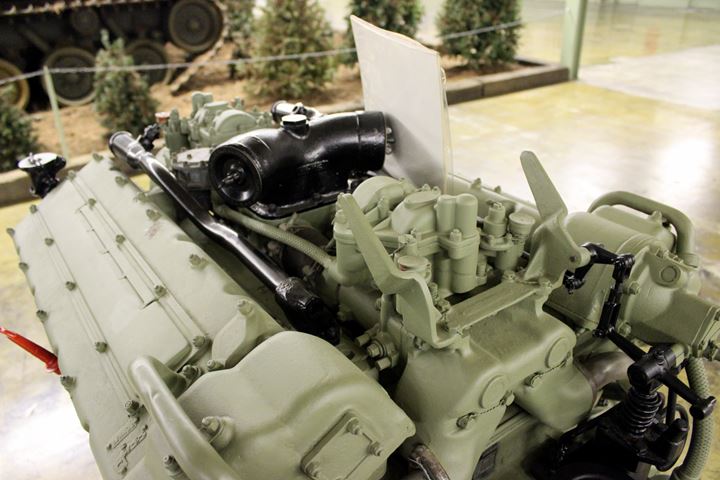

A note on tank engines:

Included in the total of 25,079 tank engines are 20,999 GAA, 3,688

GAF, 366 GAN and 26 GAY tank engines. The GAA was used in both the

Ford-built M4A3 tank built by Ford, Chrysler, and Fisher Body. It

was also used in the M10A1 tank destroyer built by Ford. The GAF

was used in the 2,202 T26E3/M26 Pershing tanks and the 185 T26E2/M45

105mm howitzer gun carriages. The GAN was used in the 250 T23

built by Chrysler at the Detroit tank arsenal.

A note on Jeeps:

The figure 282,354 includes 4,458 GP models with Ford engines and

277,896 GPW models with Willys engines.

Other - (802) M-7 Gun

Directors, (400) M-5

Gun Directors, (9,498) Squad Tents, (19,985) M34 and M34A1 Gun Mounts

for Sherman Tanks.

The numbers given above only

represent United States production. Foreign

production is listed on the Ford Database Page.

Editor's Note:

The information presented for Ford-built World War Two military production numbers was obtained from "Ford in the

Service of America: Mass Production for the Military During the

World Wars," by Timothy J. O'Callaghan published by McFarland and Co.

in 2009. This is an excellent book. Mr. O'Callaghan spent

considerable time researching Ford historical archives to tell the Ford

story during both World Wars. Production numbers above came from a

table that included three different ways the WWII production had been

tabulated: 1) Month by month production records from 1-1941

to 8-1945; 2) Fixed and Cost contracts from 1941 through

1945; 3) Flyer published September 1945.

Sometimes the numbers for a

particular product match between the three sources, and sometimes they

don't. I chose method "one," as this covers the war production that

ended with the termination of hostilities in August of 1945. In

other parts of the book, production numbers are given for individual

plants for particular products. As seen below, in several cases

where I have compared the two sets of numbers they do not reconcile. This is not unusual. I have found

conflicting or non-existent production numbers in many cases for many

of the companies presented on this website. The main thing to recognize is the vast scope

and large numbers of different products Ford

produced in the defense of the United States in World War Two.

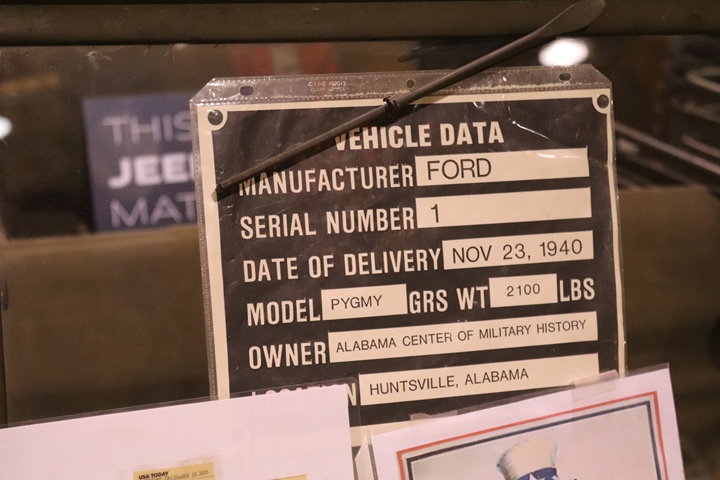

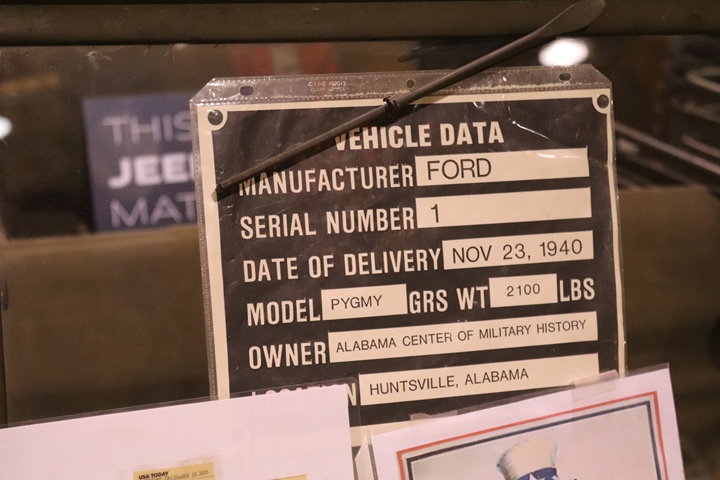

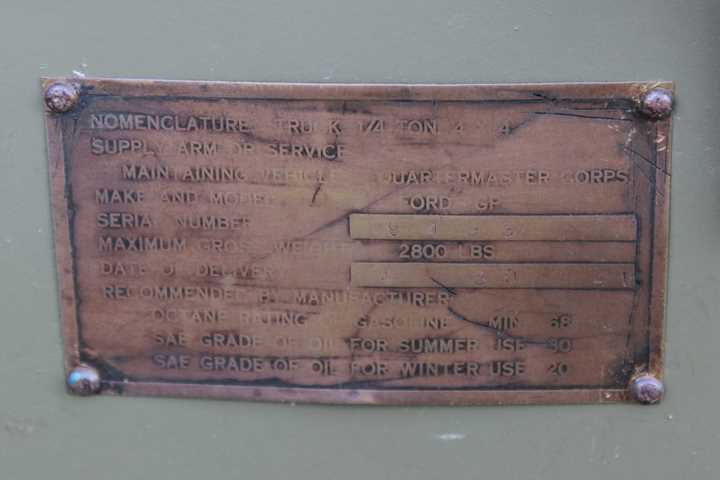

How cool is this? This is the original

prototype jeep that Ford built in 1940. It is the oldest Ford jeep in

existence, on display at the U.S. Veterans Memorial Museum

in Huntsville, AL. There are more photos and information in the

jeep section below. Author's photo added 2-27-2020.

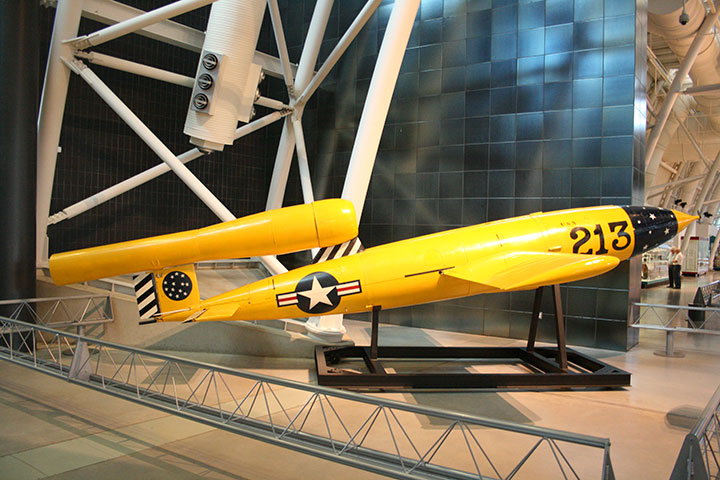

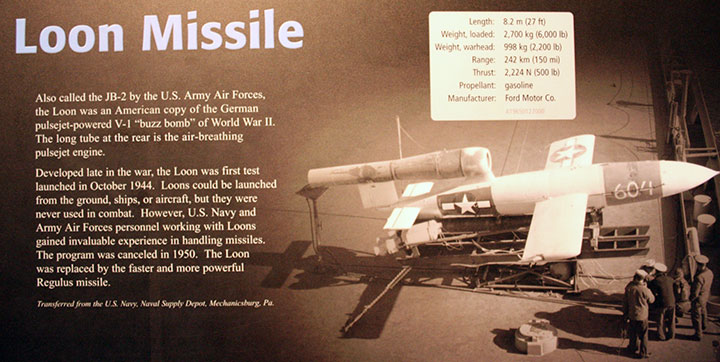

This JB -2 Loon is on display at the Udvar-Hazy Center in Virginia. Author's Photo.

The Udvar-Hazy Center is in error or misleading in

its identification of Ford Motor as the manufacturer, as it only

produced the pulse engine. Author's Photo.

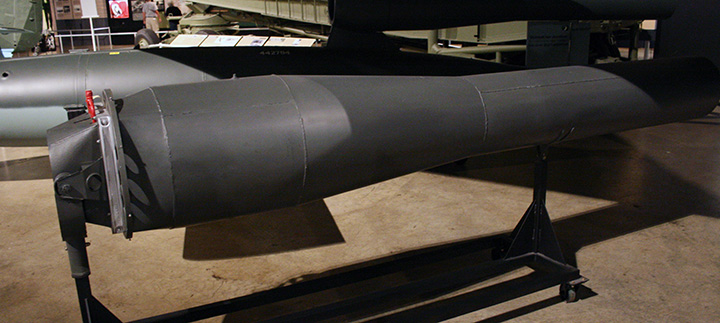

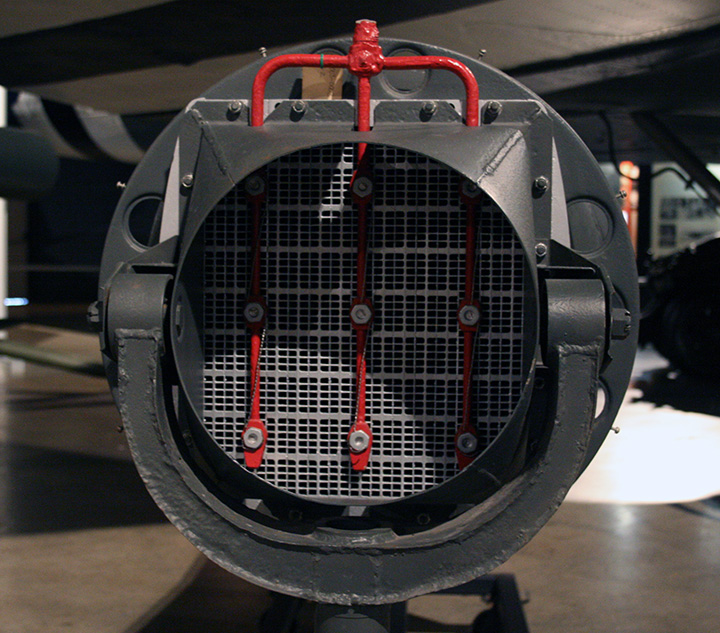

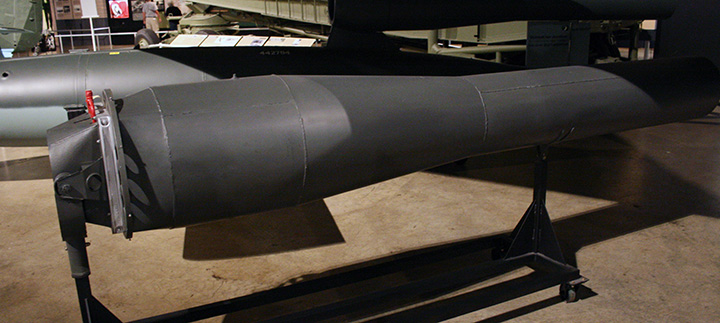

This Ford-built pulse jet engine is on display at the Air

Force Museum. Author's Photo.

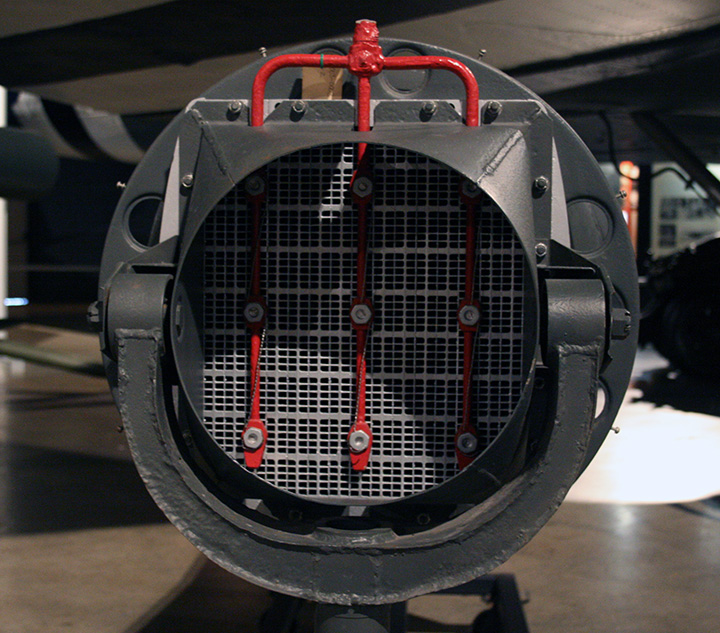

The red tubes are the fuel lines and injectors, which sprayed the fuel

into the combustion chamber. Author's Photo.

Ford-Built World War Two Ground Vehicles:

Below are photos of the many different types of vehicles Ford

manufactured for the war effort.

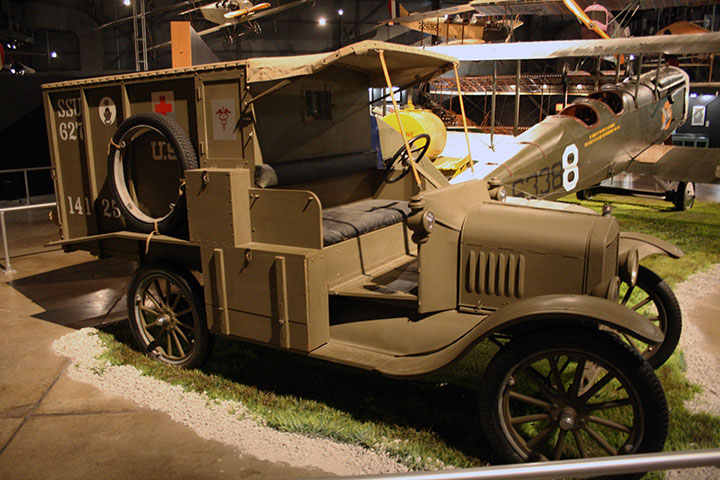

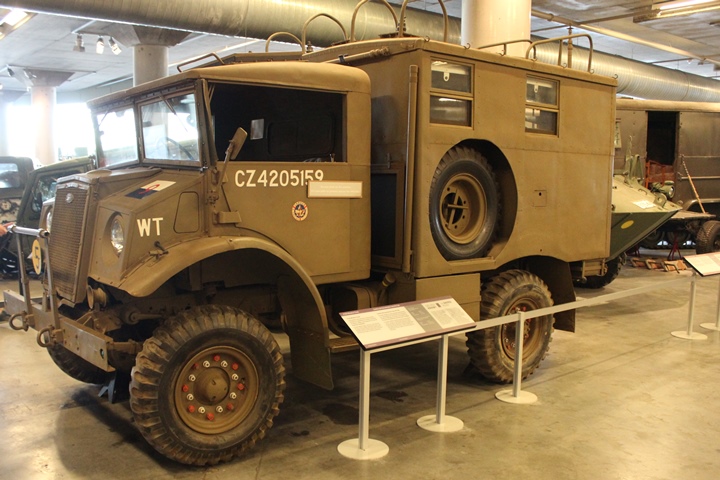

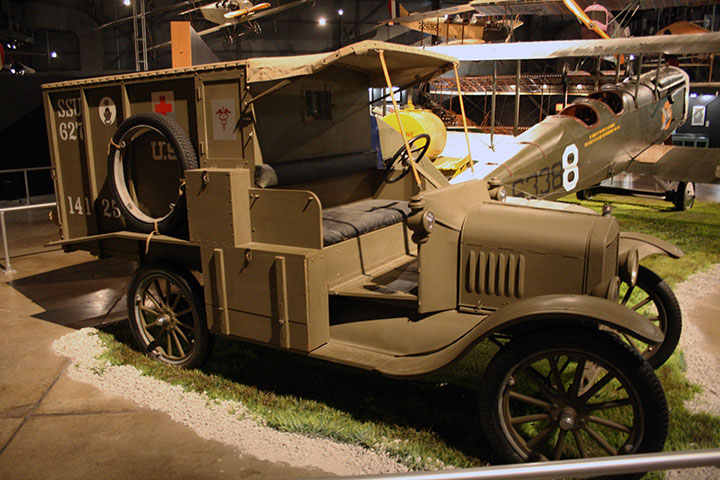

During World War One, the Model T was high tech. Ford shipped 4,362

ambulance models like this one to Europe during that conflict.

This was the predecessor to the many trucks it supplied during World War

Two, as

seen at the US Air Force Museum. Author's Photo.

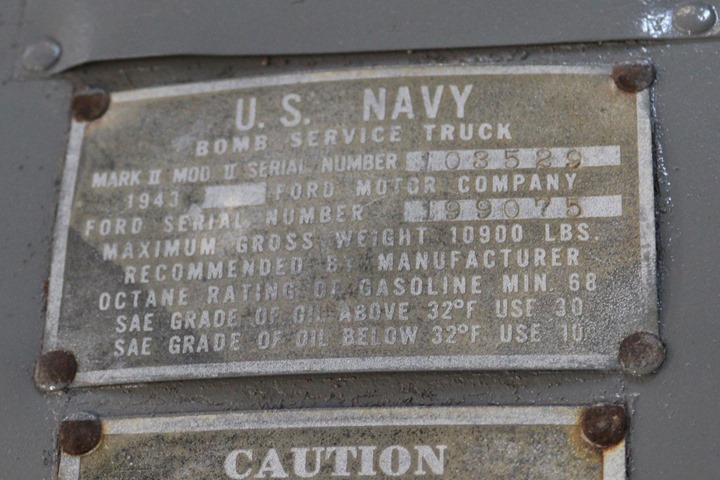

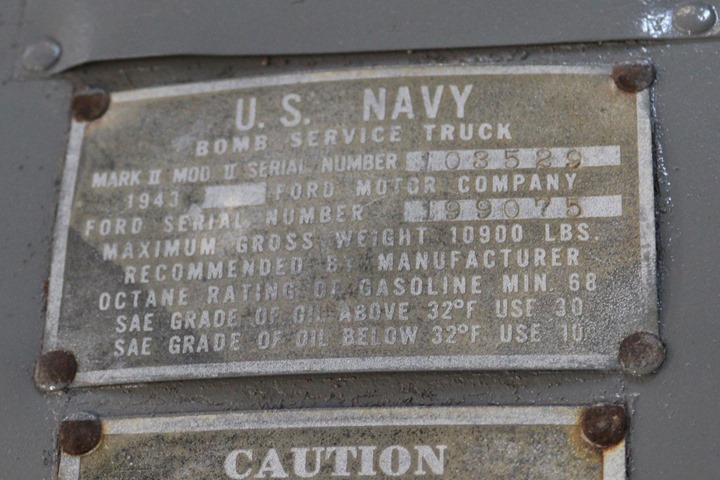

Seen here at the 2014 Indiana Military Museum's Salute to World War Two Veteran's

is a 1943 Ford 1-1/2 ton GTBC 4x4 bomb truck. Author's photo added

9-1-2014.

7,053 GTBCs were built, 4,292 at

the Edgewater, NJ plant and 2,750 built in Louisville, KY. These two

production numbers leave eleven units unaccounted for.

Author's photo added 9-1-2014.

Author's photo added 9-1-2014.

Author's photo added 9-1-2014.

Author's photo added 9-1-2014.

In US Navy parlance this is a Mark II, Model II with serial number

101709. The Ford serial number is 185548. The maximum gross

weight is 10,900 lbs. Author's photo added 9-1-2014.

This Ford bomb truck is on display at the Sam Werner Military Museum in Monteagle, TN. Author's photo added 2-27-2020.

Author's photo added 2-27-2020.

Author's photo added 2-27-2020.

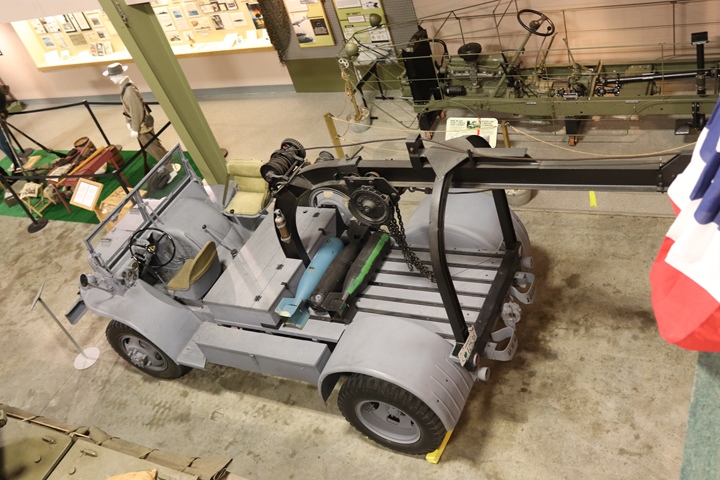

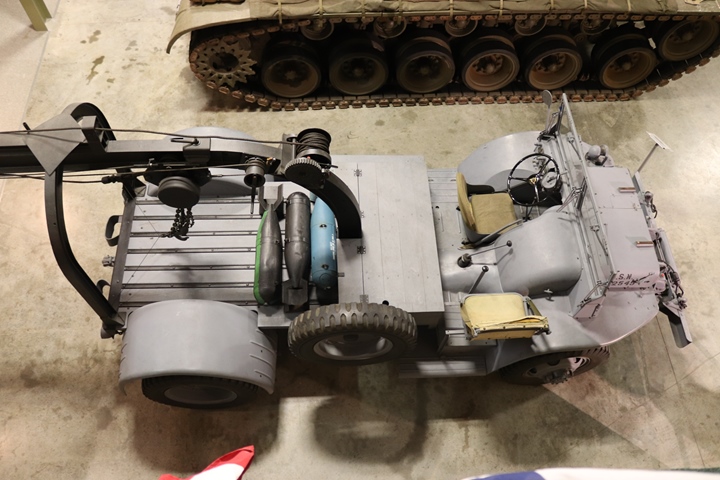

This Ford bomb service truck is on display

at the Wright Museum of World War II in Wolfeboro, NH.

Author's photo added 4-20-2020.

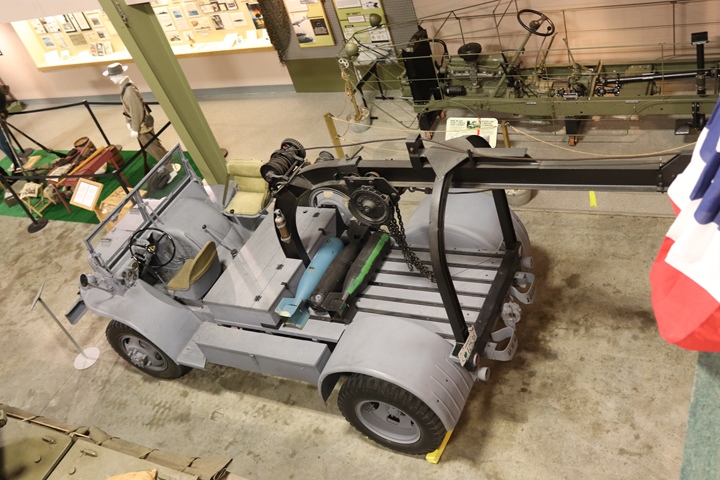

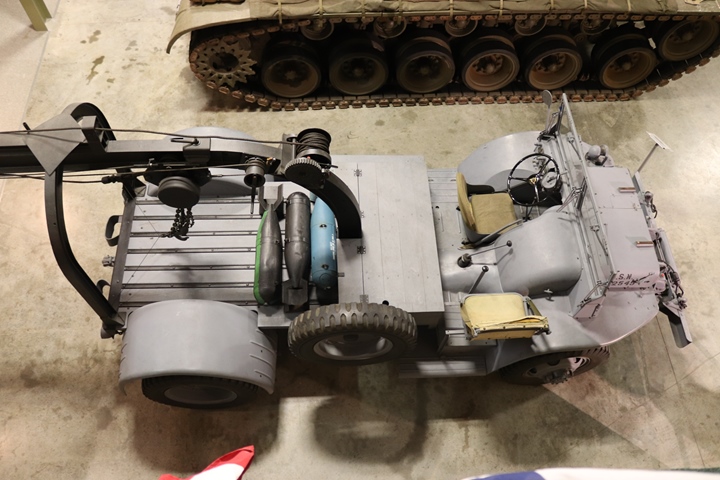

This photo from the balcony of the

museum provides a nice view down into the vehicle.

Author's photo added 4-20-2020.

This overhead photo provides another

view of the vehicle and how the bombs were transported.

Author's photo added 4-20-2020.

This GBT navy bomb truck is part of the

collection of the National Museum of Naval Aviation in Pensacola, FL.

Author's photo added 6-7-2025.

Author's photo added 6-7-2025.

Author's photo added 6-7-2025.

Author's photo added 6-7-2025.

Author's photo added 6-7-2025.

8,218 GTB 1-1/2 ton 4x4 Cargo Trucks

(Burma Jeep) were built by Ford during World War Two. This pristine example

was on display at the 2014 Aviation Day at the Columbus, IN Airport.

Note that the design is similar to the GTBC bomb truck shown above.

Author's Photo added 9-1-2014.

Author's Photo added 9-1-2014.

The GBT has the same sideways facing

passenger seat as the bomb truck. Author's Photo added 9-1-2014.

Edgewater, NJ built 5,951 GTB Cargo

Trucks, and Louisville 1,442 GTBA Cargo Trucks for a total of 7,393.

This leaves 825 units unaccounted for. Author's Photo added

9-1-2014.

On the move back at the end of the day.

Author's Photo added 9-1-2014.

Author's Photo added 9-1-2014.

This GBT was on display at at the 2025 MVPA

National Convention in Louisville, KY. It is marked as U.S. Navy

hood number 90148. Author's photo added 6-7-2025.

Author's photo added 6-7-2025.

Author's photo added 6-7-2025.

This is one of 77,915 G8T 2-1/2 ton 4x2 trucks built by Ford.

It

is basically the same as its civilian trucks. Author's Photo from the

2014 MVPA National Convention in Louisville, KY and added 9-1-2014.

Dallas, TX built 5,899 G8T and 314 GT8A Cargo Trucks, while

Edgewater, NJ built 71,350 G8T Cargo Trucks. In this case 352

trucks are not accounted for. Author's Photo added 9-1-2014.

G8T production continued from September 1942 until May 1945. Author's Photo added 9-1-2014.

Most of the trucks went to the Russians under Lend Lease but many

ended up on US farms in 1945 when the war ended. Author's Photo

added 9-1-2014.

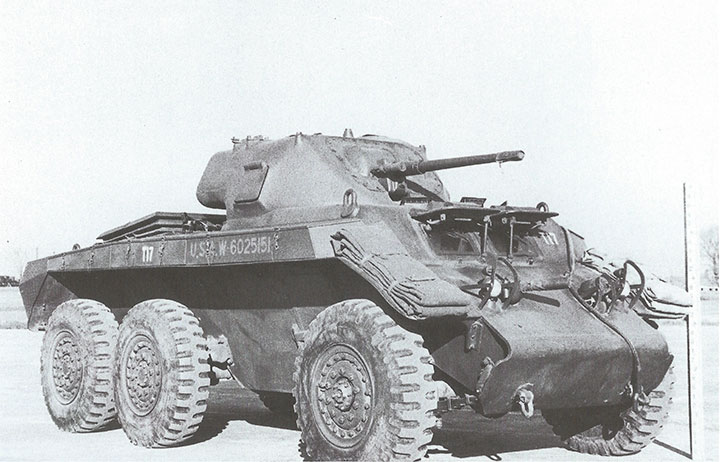

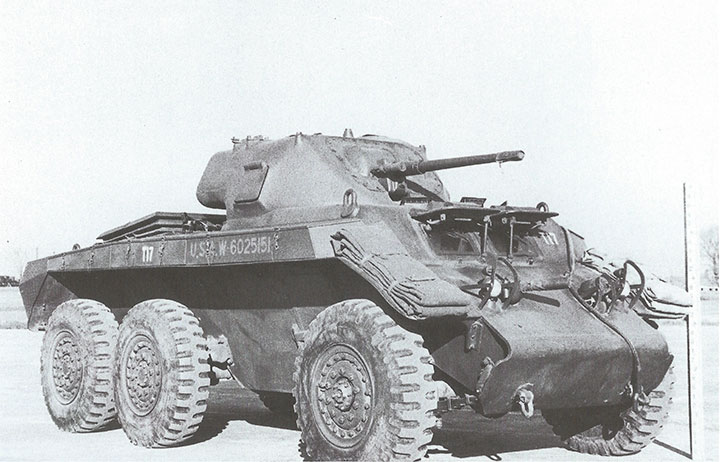

This World War Two-era photo shows one of 250

T17 armored cars produced by Ford Motor Company at the Aberdeen Proving

Grounds in Maryland. This 30-ton vehicle was to be supplied to the

British as the "Deerhound." For the U.S. Army, T17s were given to Military

Police units in the United States for use after the 37mm cannon was removed.

The U.S. Veterans Memorial Museum in Huntsville, AL has a unique and

historic collection of early World War Two jeeps. From left to

right is the original Ford prototype jeep, a 1941 Ford GP, a 1941 Bantam

BRC 40, and a 1941 Willy Model MA. For the jeep or military vehicle

historian, these are worth the trip to Huntsville themselves. But

these are just part of a great collection of military history and

vehicles at the museum. Author's photo added 2-27-2020.

Our interest for this page are the two Ford jeeps. Author's photo

added 2-27-2020.

Author's photo added 2-27-2020.

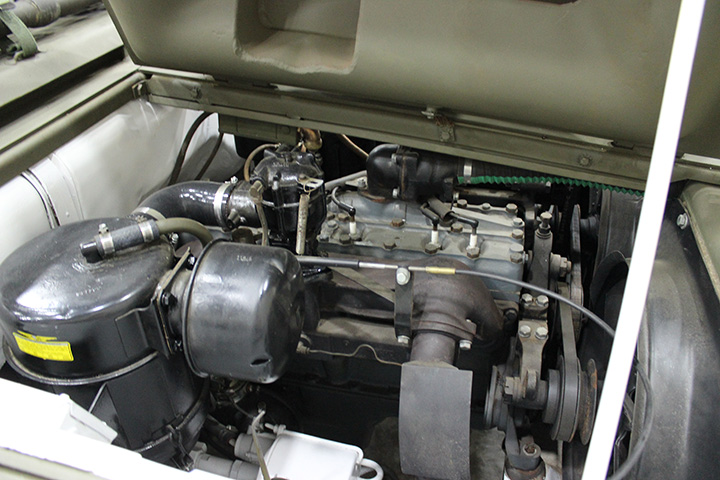

This is the very first jeep that the Ford Motor Company built in

response to the U.S. Army's request to provide samples for a 1/4-ton

reconnaissance car. This was the first of two prototypes built by

Ford. Both were Ford property and were returned to the company

when the testing was complete. This became part of the Henry Ford

Museum in Dearborn, MI and was purchased by the U.S. Veterans Military

Museum in 2015. The GP-1 was built by hand in Dearborn, MI and had

tractor tires, a 4-cylinder 46hp tractor engine and a Model A four-speed

transmission. Author's photo added 2-27-2020.

This is the oldest surviving jeep. Author's photo added 2-27-2020.

Author's photo added 2-27-2020.

Author's photo added 2-27-2020.

Author's photo added 2-27-2020.

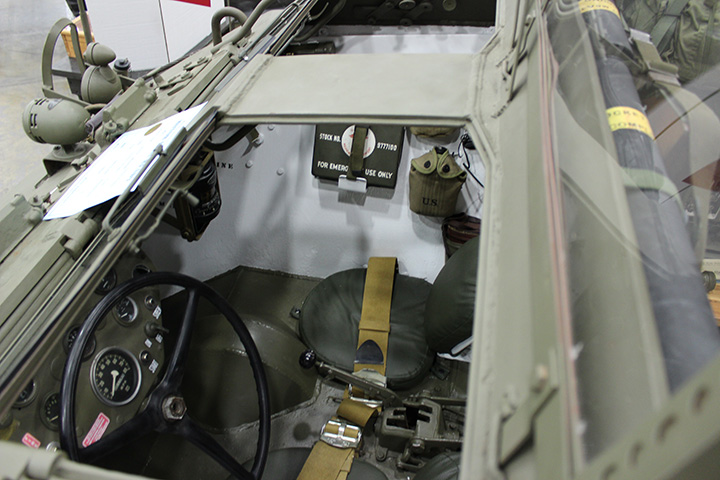

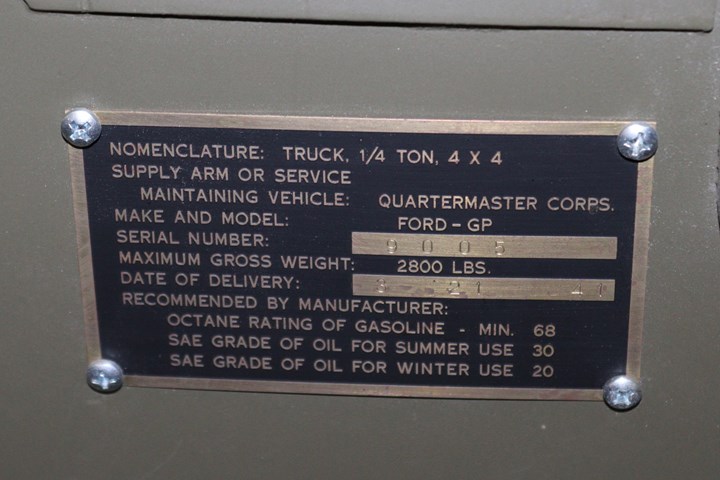

This is the 1941 Ford GP that is next to the

line of jeeps. It was built on May 8, 1941, with serial number

9911. Author's photo added 2-27-2020.

Author's photo added 2-27-2020.

This 1941 Ford GP is on display at the Sam

Werner Military Museum in Monteagle, TN. Author's photo added

2-27-2020.

Author's photo added 2-27-2020.

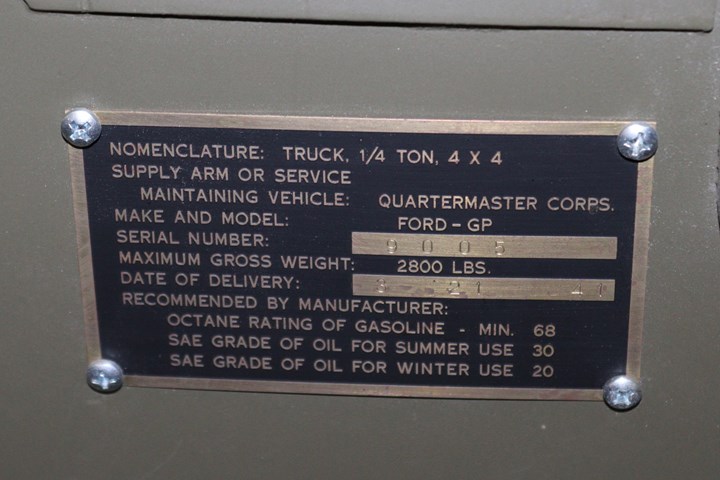

This jeep was built on 3-21-1941 and is serial number 9005.

Author's photo added 2-27-2020.

Ron Stauffer of Portland, IN is the owner of

this 1941 Ford GP. Author's photo added 2-27-2020.

Note that the Ford name is stamped into the rear of the vehicle.

Author's photo added 2-27-2020.

This was photographed at the 2014 MVPA show in Portland, IN.

Author's photo added 2-27-2020.

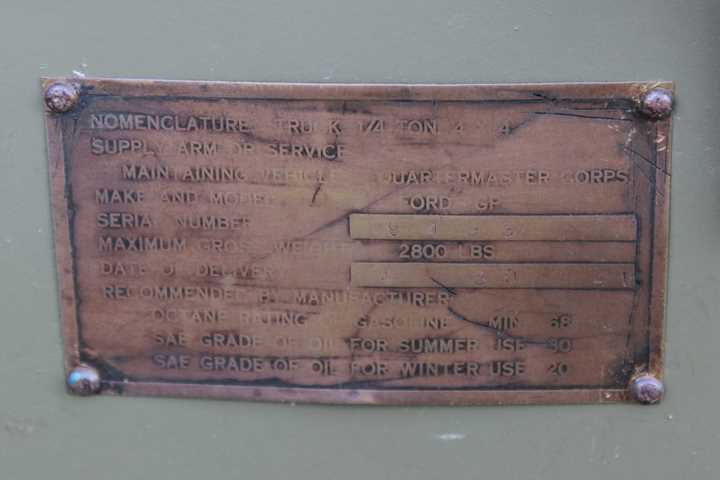

This vehicle is serial number 9493

and was built 4-20-1941. Author's photo added 2-27-2020.

A Ford-built GPW Jeep photographed at the

MPVA Rally at the now defunct Ropkey Armor Museum. Author's Photo.

The 277,896 number given above includes only

the GPW model with a Willys engine. Another 4,458 of the GP model

with a Ford engine brought the total to 282,354

Ford-built Jeeps during WWII. Author's Photo.

Author's Photo.

This Ford was delivered to the US Armed

Forces on May 3, 1943. It was seen at the 2013 Great Georgia

Airshow as the British Long Range Desert Group would have equipped it. Author's Photo.

This Ford GPA is one of

12,782 Amphibious Jeeps (Seeps) produced by Ford at the River Rouge.

It is on display at the 2017 MVPA National Convention at Cleveland, OH.

This previously belonged to a military museum in Auburn, IN. Author's photo

added 12-25-2019.

This is Serial Number 11563, built in 1943.

Author's photo added 12-25-2019.

Author's photo added 12-25-2019.

Author's photo added 12-25-2019.

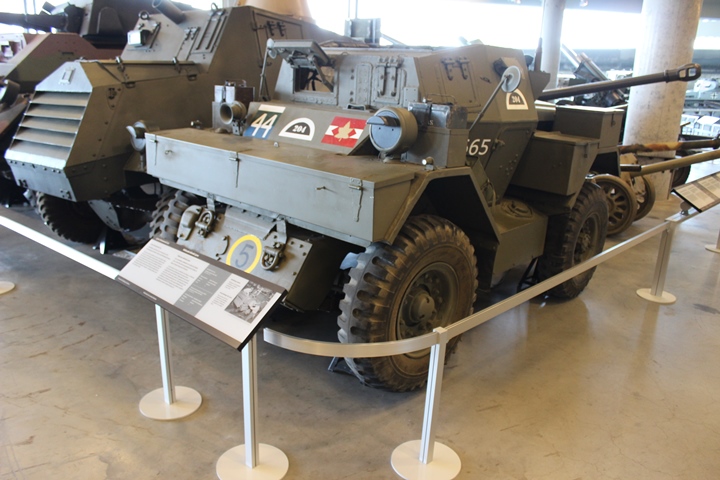

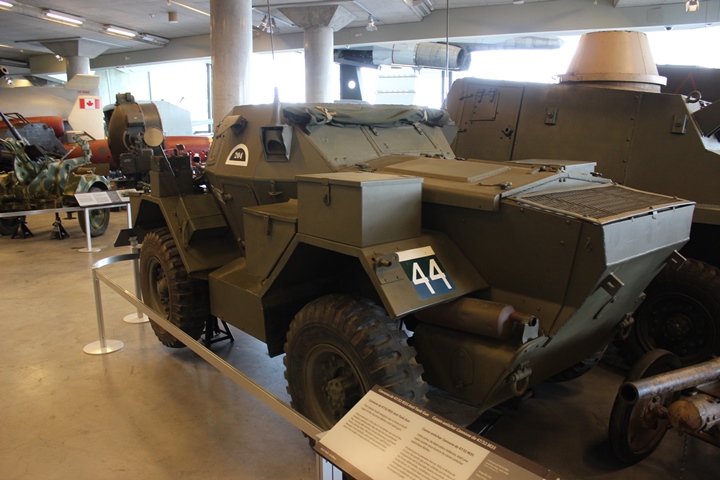

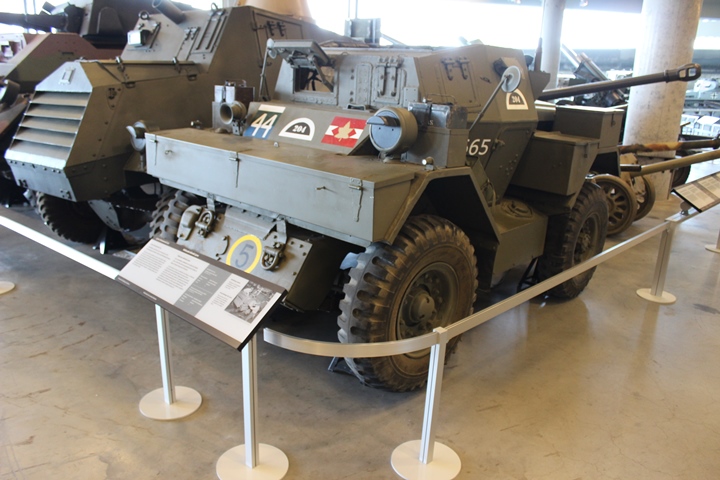

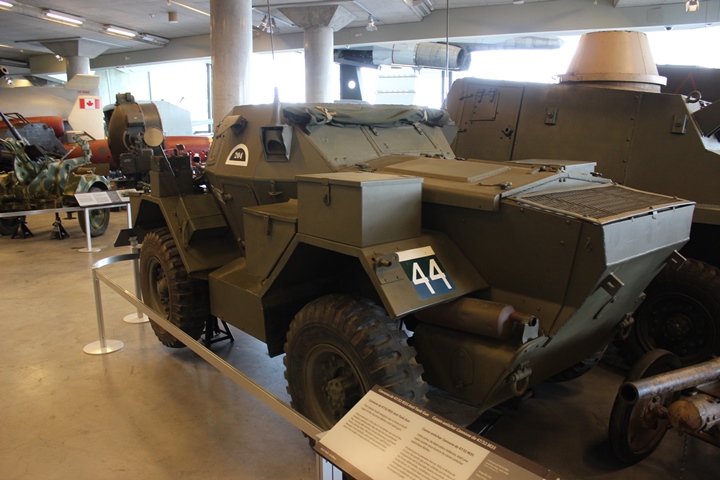

Ford built 8,410 of these M8 armored cars as the sole manufacturer of

the type. Ford's designation for it was GAK. This particular

one was built

either in St. Paul, MN or Chicago, IL. It was reported that 6,397

were built in St. Paul and 2,126 Chicago. However, the total from

the two plants differs from the overall reported total by 113 units. This one was seen at the Tico, FL Airshow in 2012. Author's Photo.

The M20 version of the Ford armored car came without the turret but

retained a .50 machine gun for defense. It was used primarily as a

command car with more radios. Ford built all 3,791 of these at its

Chicago, IL facility. Author's Photo from the 2013 Wings over Houston Airshow.

The M20 was used as either a command car

with an extra complement of radios or as an armored troop carrier.

Here we can see the bench seats along the sides. Author's Photo.

Author's Photo.

General Patton used an M20 for his command car when he was in

Europe. This is a re-creation of that vehicle. Author's

Photo from the 2014 MVPA National Convention in Louisville, KY and added

9-1-2014.

Under the windscreen is an M1 2.36 inch bazooka and four rounds of

ammunition. The radio and a Thompson submachine gun are on the

opposite wall. Author's Photo added 9-1-2014.

More bazooka ammunition on the back wall with three M1

carbines. Author's Photo added 9-1-2014.

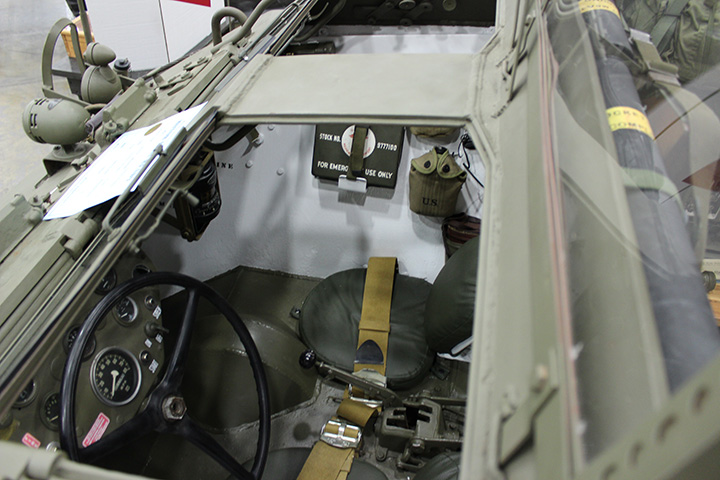

The driver's location. Author's Photo added 9-1-2014.

Another photo of the driver's location and the assistant driver's

seat. Author's Photo added 9-1-2014.

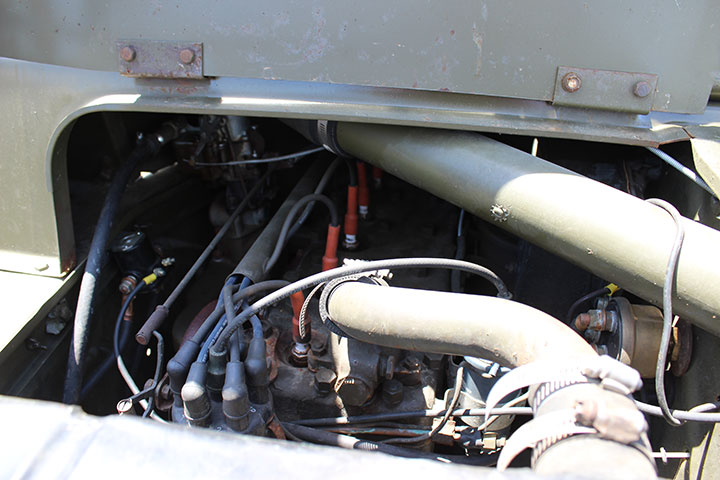

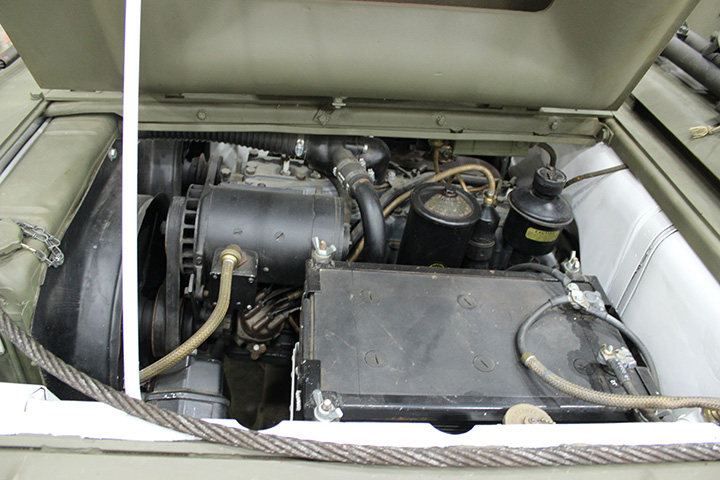

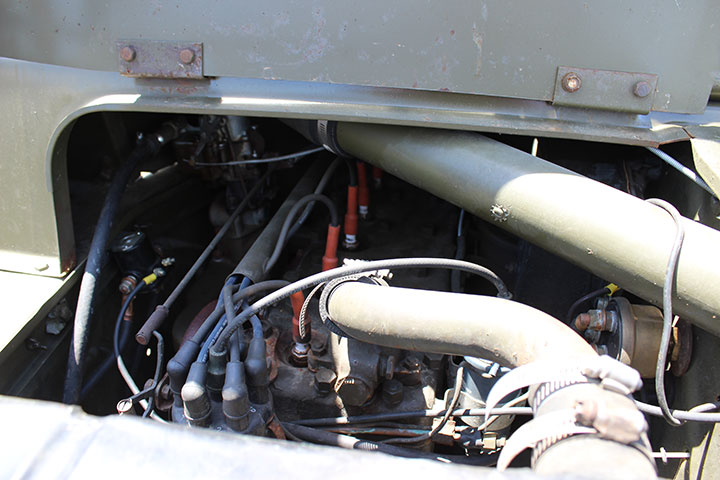

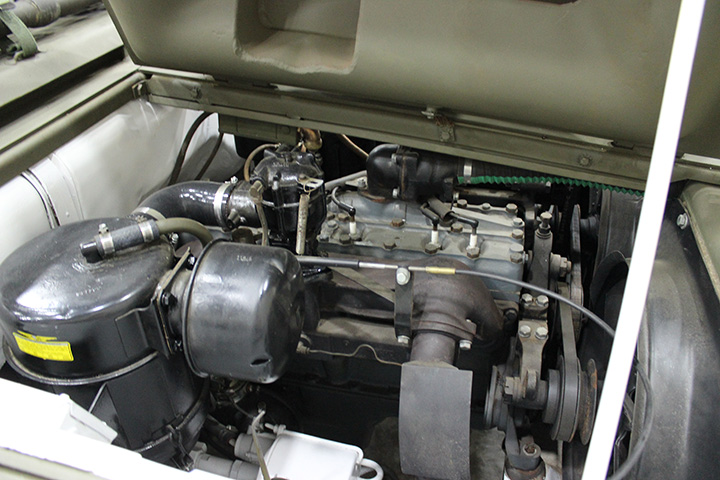

The M20 was powered by a Hercules JXD inline six-cylinder engine,

as seen here from the driver's side of the vehicle. The JXD could

produce 110 hp from 320 cu. in. The Author's Photo added 9-1-2014.

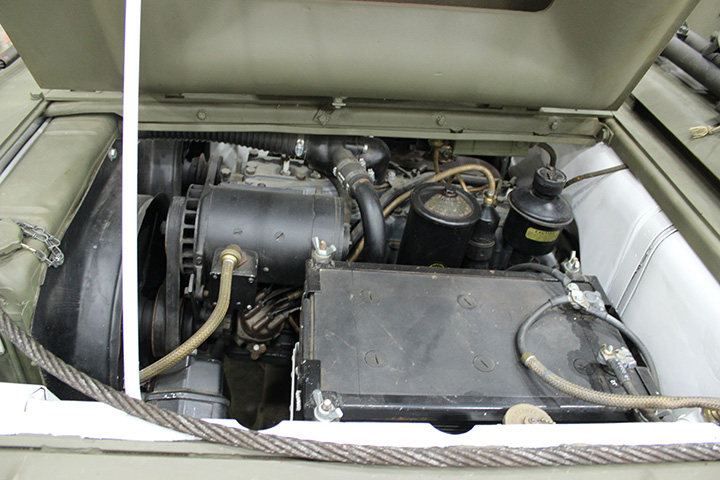

Here is the engine from the assistant driver's side with the

battery box in the foreground. Author's Photo added 9-1-2014.

Ford Motor Company built 1,690 M4A3 Sherman

Tanks and 1,038 M10A1 Tank Destroyers during World War Two. It

acquired previous experience in building tanks during 1918 at the end of

World War One. This is one of two surviving Ford-built Model 1918

tanks out of the fifteen that were built. The vehicle was designed in

two days, the first prototype was built in three weeks, and a 222 foot

by 530 foot building for mass production of the vehicle was built in 30

days. Ford was given a contract to build 15,000 units at a

rate of 100 per day. The end of World War One prevented the tank

from going into production. Author's photo from the National Armor

and Cavalry Tank collection at Fort Benning, GA added 9-22-2018.

The Ford 1918 tank was powered by two Ford

Model T engines and was armed with a .30 caliber machine gun. It

had a two man crew. Author's photo added 9-22-2018.

Author's photo added 9-22-2018.

Author's photo added 9-22-2018.

This is an extremely well restored

example of the 1,690 Ford-built M4A3 small hatch Sherman tanks

constructed at its Highland Park, Michigan plant. This was the only type of

Sherman tank Ford built; and was photographed at the WWII Museum in New

Orleans, LA.

The original small hatch M4 Sherman tanks,

like this Ford built M4A3, had the front glacis angled 57 degrees from

the vertical, to hopefully have enemy anti-tank shells deflect off the

glacis rather than penetrate it. However, this allowed for the

driver's and assistant driver's hatches to protrude forward of the

glacis, creating a weak spot in the armor. Steel plates were

welded in front of them in the field or at tank depots to increase armor

protection. The later large hatch tanks got away from this problem

by reducing the glacis angle to 47 degrees. This eliminated the

protruding hatch bulges. The glacis armor thickness was increased

to compensate for the smaller angle of deflection. Author's Photo.

The Ford-built M4A3 Sherman was powered by

Ford's GAA 500 hp engine as shown below. Sand bags were placed on

the front glacis to give more protection, not only against German tank

shells but the just as dangerous hand held Panzerfaust anti-tank weapon. Author's Photo.

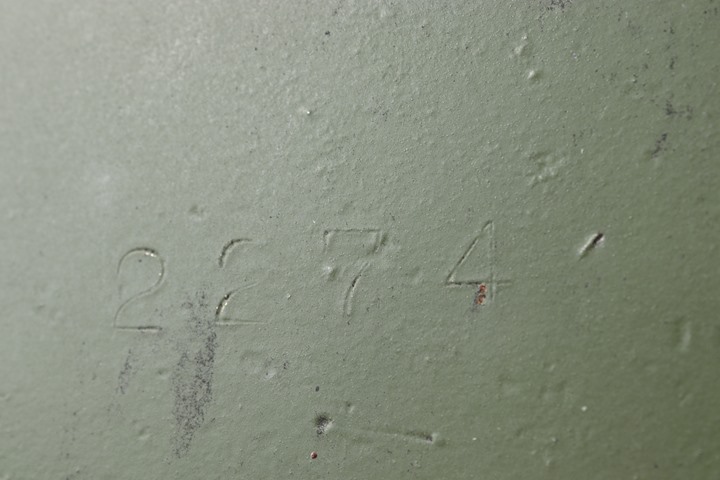

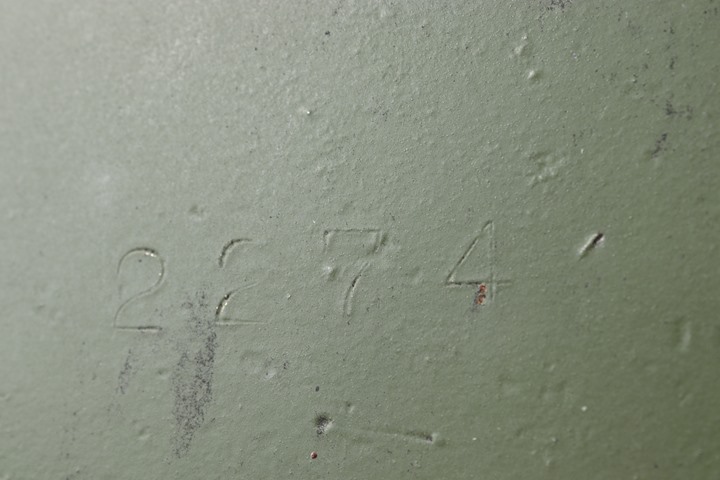

This M36 Jackson Tank Destroyer is on display at the U.S. Cavalry Museum

at Fort Riley, KS. It was originally built in April 1943 as a Ford M10A1 with serial number 2274. Author's photo added 4-27-2018.

Here are two American automotive industry products in the same photo.

The M36 built on a Ford M10A1 chassis is in the foreground and a Fisher

Body M4A3(75) is in the background. Author's photo added 4-27-2018.

The serial number 2274 is plainly stamped on the chassis in

several locations. Author's photo added 4-27-2018.

The Ford-built M10A1 tank

destroyers did not see overseas duty and were delegated to training

in the United States. This happened because it was powered by the Ford GAA

V-8 engine while the Fisher Body M10 version was powered by twin Detroit

Diesel engines. Five times the number of Fisher Body M10s were

available for combat duty versus the M10A1. The Army also did not

want two different type engines in the field. It therefore chose to have the Ford

stay in the US for training purposes. But the M10A1 did see combat

duty when converted to the M36 like the one shown above. The M10A1

was armed with a three inch main gun. The M36 was armed with

a larger 90mm main gun needed to penetrate the more heavily armored

German tanks that US forces were coming up against in Europe. It

also had a different turret for the 90mm main gun.

|

Ford built M10A1 Serial Numbers |

|

Serial Numbers |

Registration Numbers |

|

1803-2840 |

4046509-4047546 |

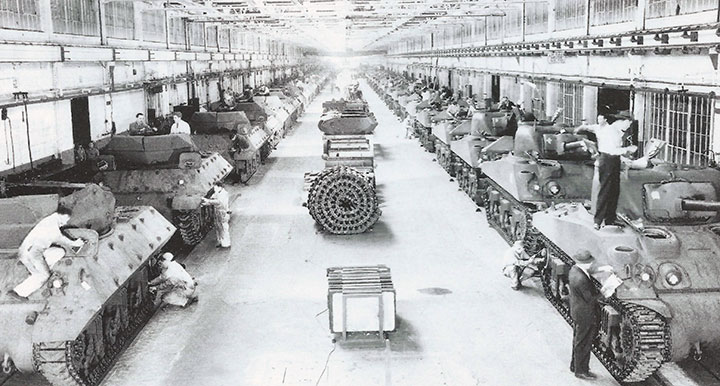

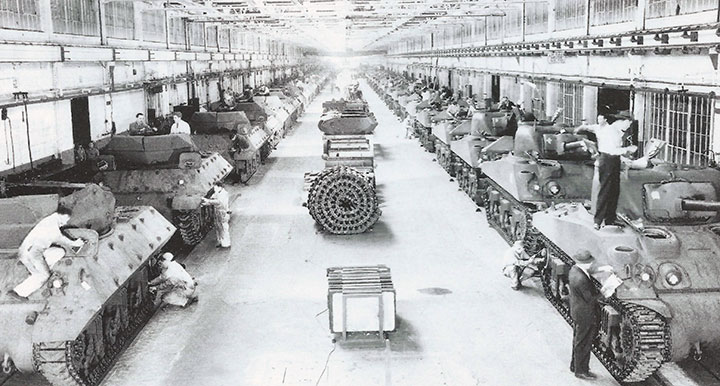

This photo shows both the M10A1 Tank

Destroyers and M4A3 Tanks coming down parallel production lines at the

Ford Highland Park assembly plant circa 1942-43.

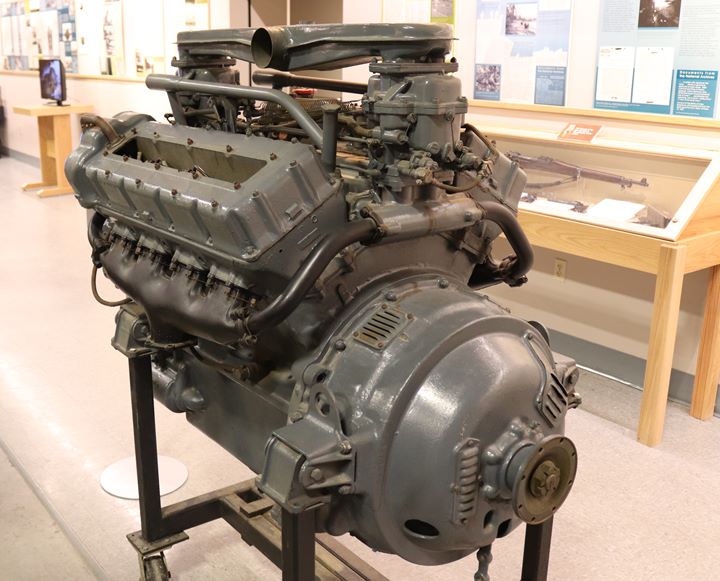

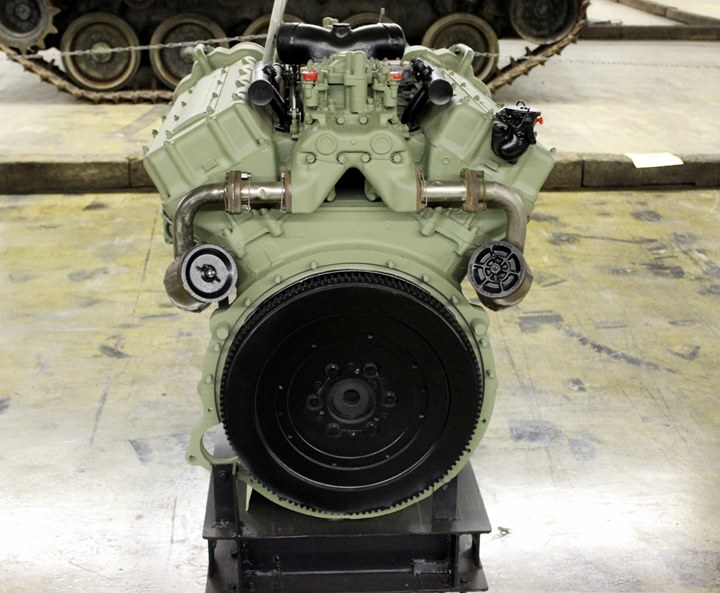

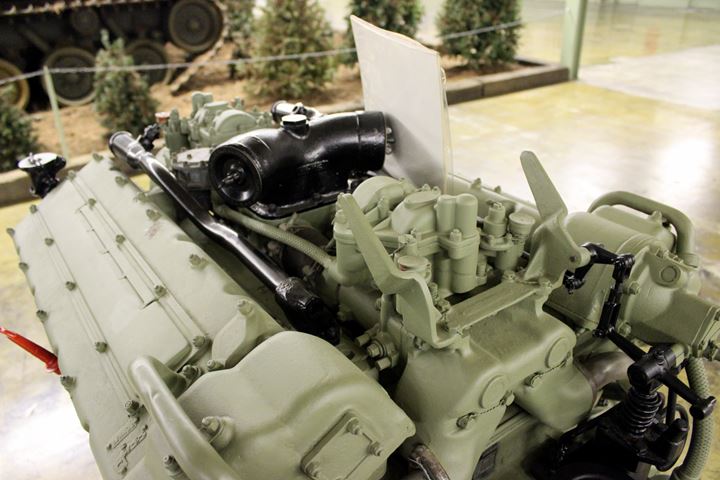

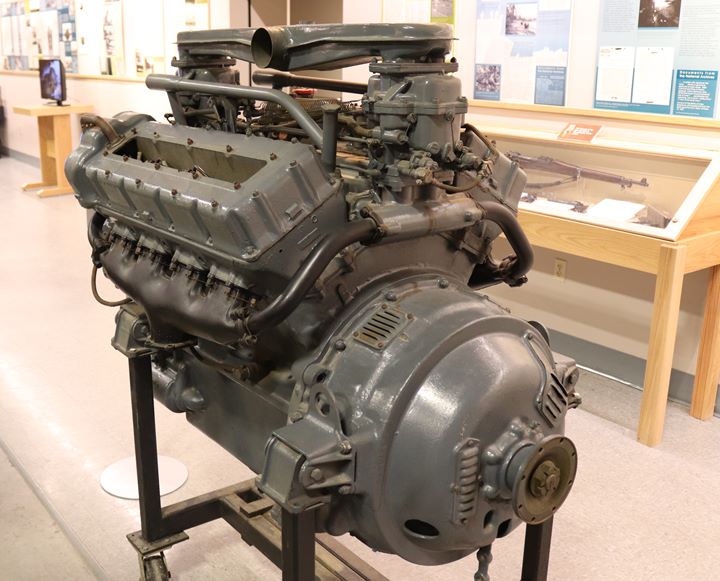

Ford built 20,999 GAA 1,100 cubic inch, 500 hp engines in its Lincoln

Plant in Detroit for use in the M4A3 Sherman tank, M10A1 Wolverine tank

destroyer, and later in the M26

Pershing. The engine block castings for the GAA were poured at the River

Rouge. Author's Photo taken at the Wright WWII Museum added

11-14-2017.

Another version of the GAA, the GAF, powered the M26 Pershing heavy tank

seen in the background. Author's Photo taken at the Wright WWII

Museum added 11-14-2017.

The engine had 32 valves and four overhead cams and weighed 1470 lbs. Author's Photo

taken at the Wright WWII Museum added 11-14-2017.

During operation, a sheet metal cover hides the spark plugs and sparkplug

wires. Author's Photo taken at the Wright WWII Museum added

11-14-2017.

Author's Photo taken at the Wright WWII Museum added 11-14-2017.

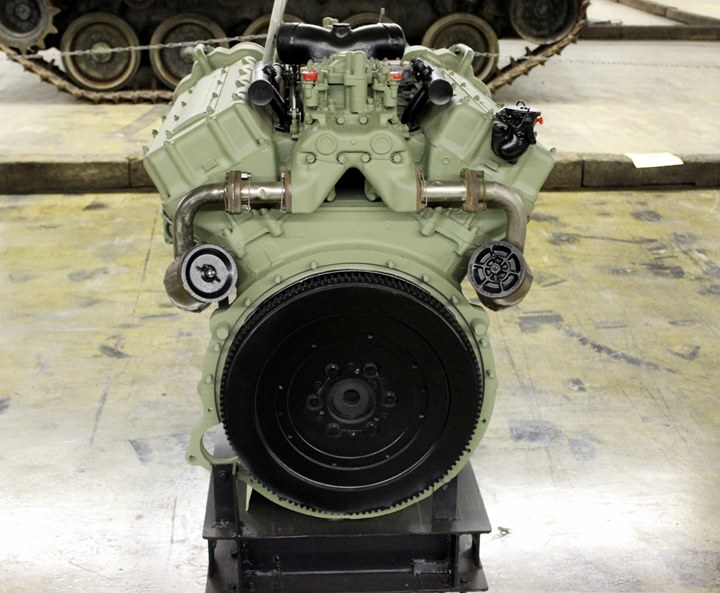

This is a one of 3,688 Ford GAF tank engines that were used in the M26

Pershing tank. Note the lower profile compared to the GAA above.

The lower profile was required to fit into the shorter engine bay of the

M26. The air filters were located off the engine with pipes

delivering the air to the carburetor. Author's Photo taken at the

AAF Tank Museum added 11-29-2017.

Author's Photo taken at the AAF Tank Museum added 11-29-2017.

Author's Photo taken at the AAF Tank Museum added 11-29-2017.

Author's Photo taken at the AAF Tank Museum added 11-29-2017.

Shown here is black intake from the detached air filters via piping.

Author's Photo taken at the AAF Tank Museum added 11-29-2017.

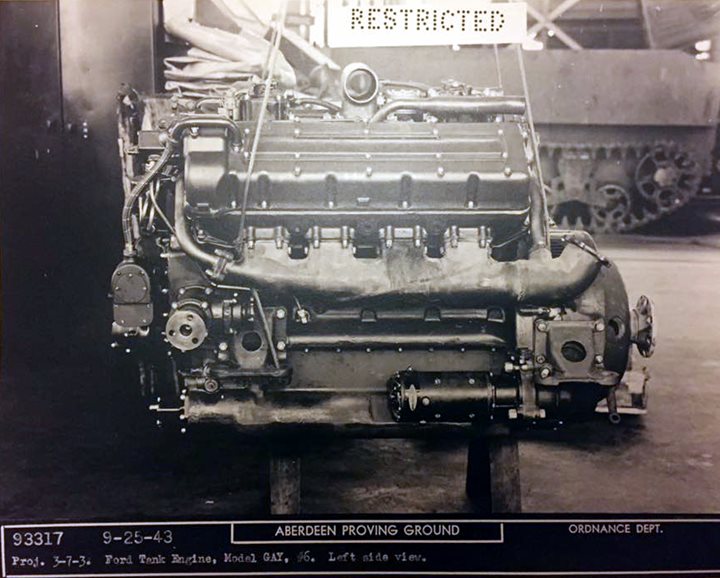

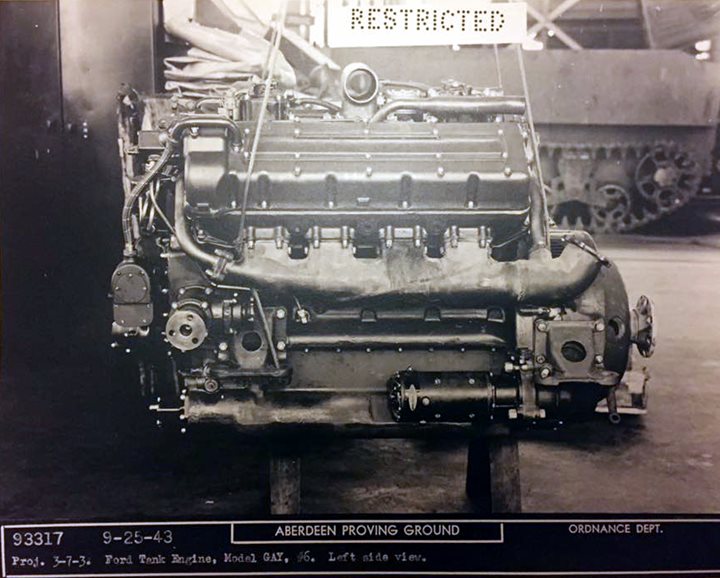

This World War Two era photo shows one of 26 GAY

tank engines built for possible use in a British tank. Photo added

11-29-2017.

Here is a World War Two-era photo of the tank engine

assembly at the Lincoln Plant.

Ford assembled 19,985 M34/M34A1 gun mounts

at the Highland Park plant from parts made at the River Rouge. Six

manufacturers of the Sherman tank then assembled them into the tanks.

Author's photo added 2-1-2018.

This 1941 Ford Fire Truck served at Hunter

Field in Savannah, GA during World War Two. As seen at the Mighty

Eighth Air Force Museum in Pooler, GA. Author's Photo.

This 1942 Ford/American LaFrance fire truck

served at Freeman Army Airfield in Seymour, IN during WWII. It

then served with the Seymour fire department after the airfield closed

in 1946. It can be seen on display at the Freeman Field Airfield

Museum at the Seymour, IN airport. Author's Photo added 3-1-2017.

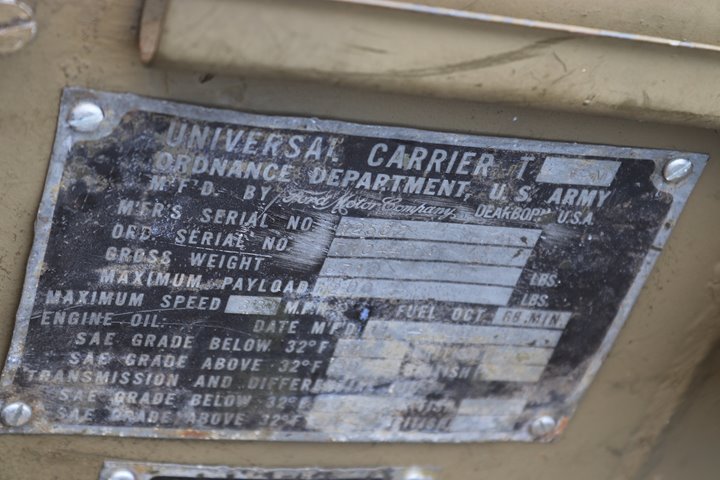

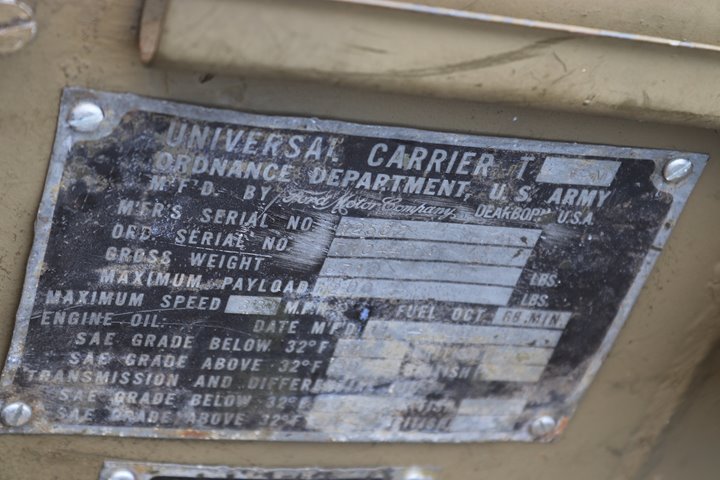

Ford Motor Company produced 13,893 Universal

Carries for British Commonwealth nations at its Somerville, MA remote

assembly plant. Ford of Canada in Windsor built another 33,988. The Universal Carrier

carried the Ford internal designation of GAU but was

better known a Bren Gun Carrier. This

very nicely restored GAU was at the 2018 World War II Weekend at Reading, PA.

Author's photo added 6-22-2018.

Author's photo added 6-22-2018.

This is the best restoration of the radio

equipment on a Universal Carrier that I have found. Author's photo

added 6-22-2018.

The Author's photo added 6-22-2018.

This Universal Carrier is Ford serial number

12502, Ordnance Department serial number T 10448-9 , and was built

in November 1944. Author's photo added 6-22-2018.

This Canadian Ford built Universal Carrier

from the Second World War was photographed at the 2014 Spirit of St.

Louis Air Show. Author's Photo.

Author's Photo.

Author's Photo.

Ford Canada:

This is one of 33,988 Universal Carriers

built by Ford at its Windsor, ONT plant. Author's photo added

2-11-2022.

"Ford Canada" is on a nameplate behind the

driver's location. Author's photo added 2-11-2022.

Author's photo added 2-11-2022.

This World War Two photo shows several of the 33,988

Universal Carriers on the railroad dock at the Windsor, ONT Ford plant.

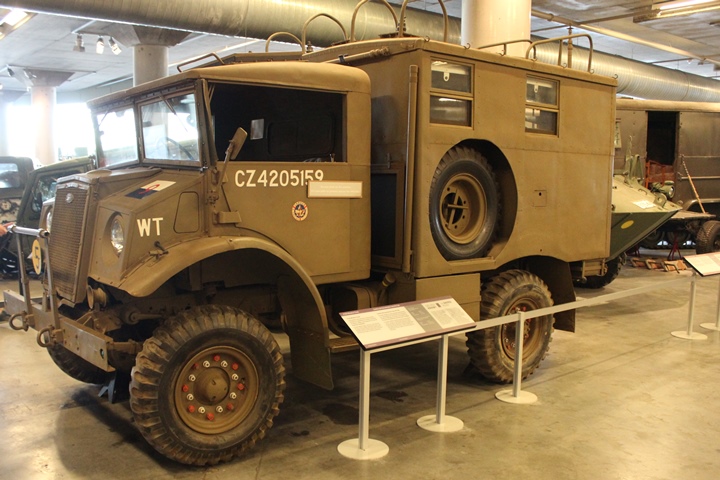

This is one of 209,000 Canadian Military

Pattern Trucks built by Ford of Canada and was photographed at the

National Military History Center in Auburn, IN. Author's photo.

This version carries a single Bofors

anti-aircraft gun. Both Chrysler and Pontiac made the 40mm weapon

during World War Two. For this version built in Canada, the 40mm

Bofors was built by Otis - Fensom Elevator, Ltd. in Hamilton, ONT.

The company modified the Bofors for use on the Ford truck. Author's

photo.

This Ford of Canada F15A wireless truck is on display at the Canadian

War Museum in Ottawa, ONT.

Author's photo added 2-11-2022.

Author's photo added 2-11-2022.

Author's photo added 2-11-2022.

This Ford of Canada CMPT truck is also on

display at the Canadian War Museum. Author's photo added 2-11-2022.

Author's photo added 2-11-2022.

Ford of Canada produced 3,200 Lynx armored

cars for the war effort. The Lynx was the Canadian version of the

British Dingo short range scout car. This one is on display at the

Canadian War Museum. Author's photo added 2-11-2022.

Author's photo added 2-11-2022.

Ford-Built Aircraft and Related Items:

A Northrop P-61 "Black Widow" at the National Museum of the Air Force.

Ford built 17,008 drop tanks like the one seen here for the P-38, P-47,

and P-61 during World War Two. Author's Photo added 9-1-2014.

Ford is best remembered, especially among

the aviation historians, for its contribution to the war effort for building

6,790 Consolidated B-24 Liberator four engine bombers in a huge, brand

new plant in Willow Run, MI. This was quite an endeavor and not

without a lot of pain and controversy. Once the plant got up to line

speed, it was producing one bomber an hour, like this Ford-built B-24J on display at the Barksdale Global Power Museum

at Barksdale AFB in Bossier City, LA. Not only was the Willow Run

Plant making parts for the bombers it was building, but it also built

1,894 Knock Down B-24s that were then shipped by truck to the Douglas

Plant in Tulsa, OK and the Consolidated Plant in Fort Worth, TX for

final assembly. The Willow Run Plant was one of five in the US during

World War Two that in total produced 18,140 B-24s, making it the

most produced aircraft in this country during the war. Author's Photo.

Author's Photo.

This is one of four B-24s built at the Ford

Willow Run plant that are on display. It is the only one on

display in the United States. One is in Canada and two are in the

United Kingdom. Author's Photo.

Author's Photo.

This is a Waco CG-4A Combat Glider that is

on display at the Silent Wings Museum in Lubbock, TX. Ford built

4,190 of these combat gliders at its Iron Mountain Plant in the Upper

Peninsula of Michigan. Ford was one of 17 companies that built a

total 13,903 CG-4As under license for the US Army Airborne Troop Carrier

Command and was the largest producer of this type of glider. Author's Photo.

This photo shows both the landing skids

and landing wheel. Author's Photo.

From inside, it is evident that the glider

is built with steel tubing wrapped by aircraft fabric and wood for

supports, benches, and the floor. Ford's Iron Mountain facility was

ideally suited for this task, as it had originally made wooden bodies

for the Model T. Author's Photo.

This photo shows the interior of the rear of

the CG-4A. More steel tubing, fabric, and wood. Author's Photo.

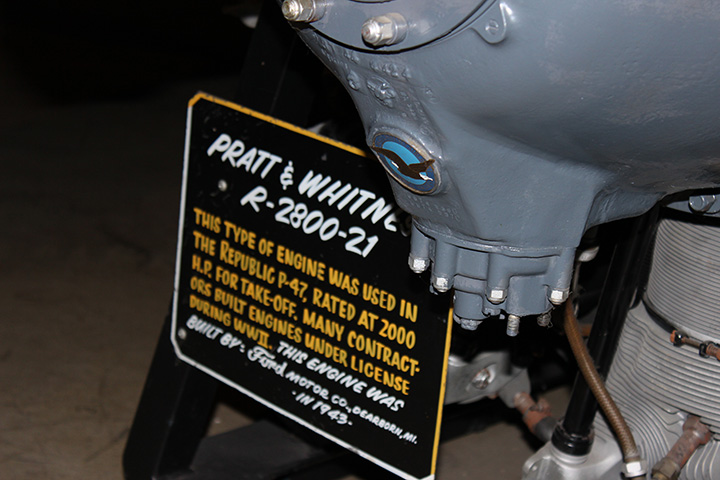

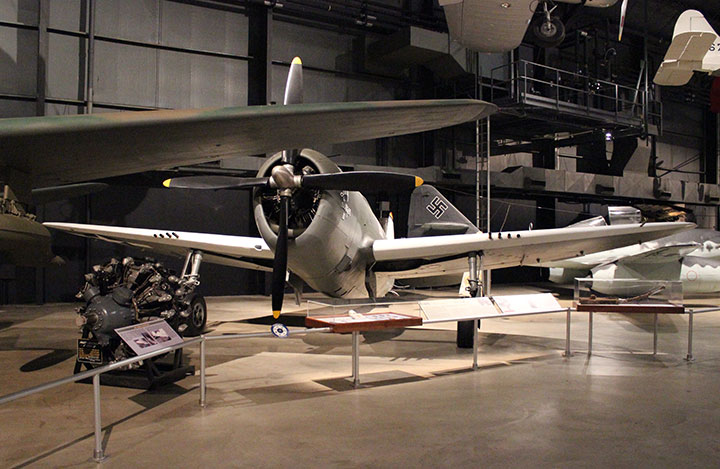

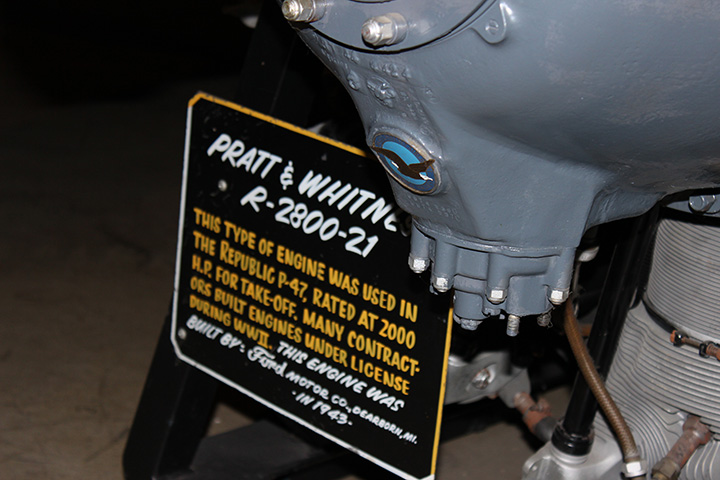

Ford Motor Company built 56,870 Pratt

& Whitney R-2800 Radial Aircraft Engines like this during the war, at a

new plant at the River Rouge. The Ford built R-2800 found

application on the Curtiss C-46, Douglas A-26, Martin B-26,

Northrop P-61, Republic P-47 and the Lockheed B-34. This is an

actual Ford-built R-2800-21 engine, on display at the Museum of the

United States Air Force. Author's Photo.

Ford built 4,671 R-2800-21 radial aircraft

engines to power the P-47 Thunderbolt. Author's Photo.

|

Ford-Built Pratt & Whitney

R-2800 Engines |

|

R-2800 Model |

Number of Engines Built |

Aircraft Type |

|

R-2800-5 |

954 |

B-23, B-26A,B |

| R-2800-21 |

4,671 |

Various P-47 |

| R-2800-27 |

262 |

JD-1, B-23,

A-26., F7F-1N |

| R-2800-31 |

6,088 |

PV-1, PV-2,

Rb-34A,B |

| R-2800-43 |

12,559 |

C-46, B-26 |

| R-2800-51 |

5,152 |

R5C, C-46 |

|

R-2800-59 |

10,799 |

P-47C, D, L |

|

R-2800-71 |

1,726 |

Douglas JD-1, A-26B, C |

|

R-2800-75 |

8,042 |

C-46 |

|

R-2800-79 |

6,617 |

Douglas JD-1, A-26B |

| Total |

56,870 |

|

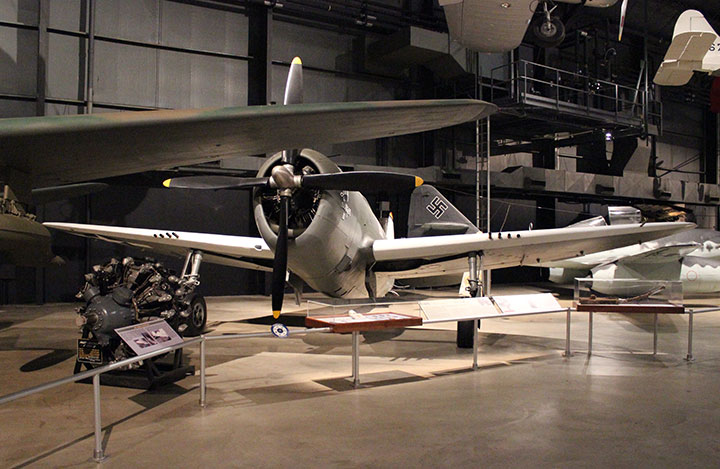

The Ford-built R-2800 can be

see next to one of the P-47s on display at the National Museum of the US

Air Force. Author's Photo.

A Republic P-47. Author's Photo.

This Lockheed PV-2D Harpoon photographed at

the 2013 Gathering of Warbirds and Legends still has its Ford-built

R-2800-31 engines in it. Author's Photo.

Author's Photo.

This Ford-built R-2800-31 was seen at the

2016 Warbird Expo at the Indianapolis Regional Airport. Author's

photo added 11-13-2016.

The ID tag shows the engine has a serial

number of FP-0-42-08-7. Author's photo added 11-13-2016.

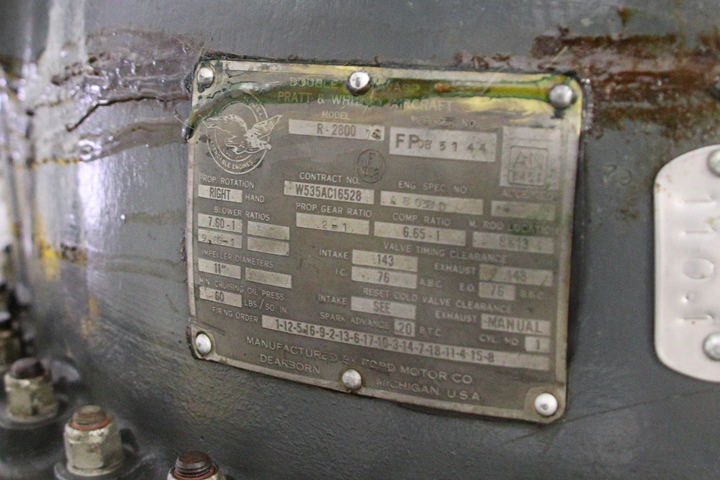

This Ford-built R-2800 is on display at the

Yankee Air Museum in Bellevue, MI. This engine is 22 miles from

where it was built. Author's photo added 5-17-2021.

Author's photo added 5-17-2021.

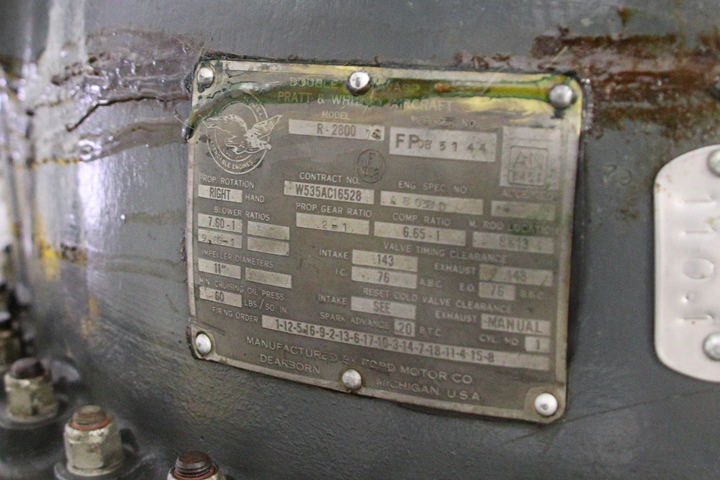

This engine is serial number FP-08-51-44.

This is either an R-2800-71, 75, or 79 engine, as it is not possible to

identify the last digit. Author's photo added 5-17-2021.

Ford was the exclusive manufacturer of the R-2800-51

engines that powered the

Curtiss C-46 Commando. Author's Photo.

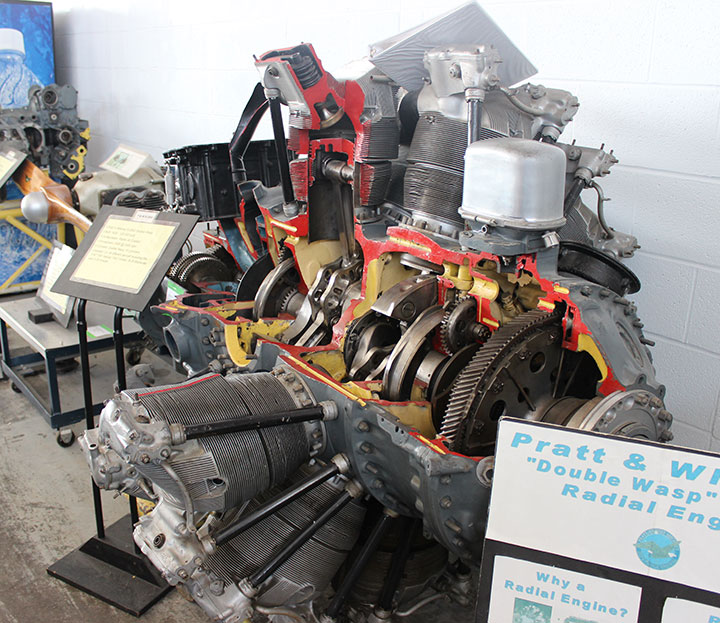

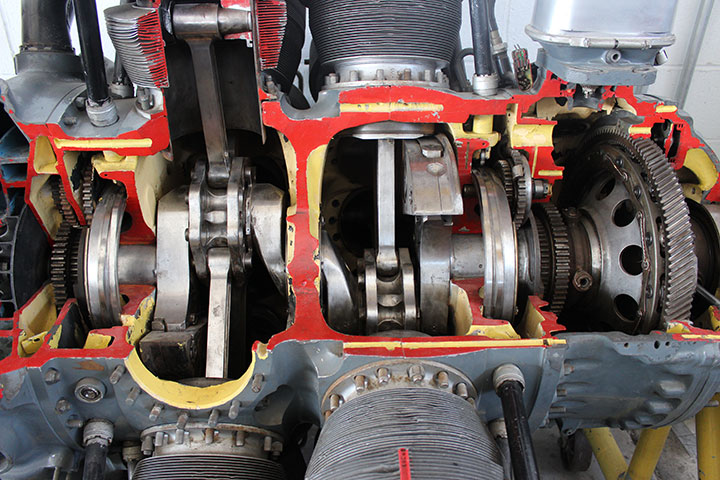

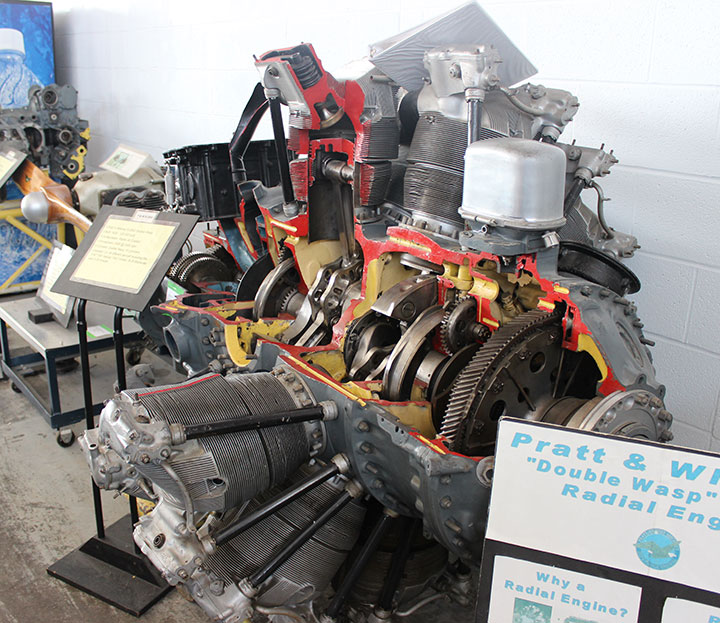

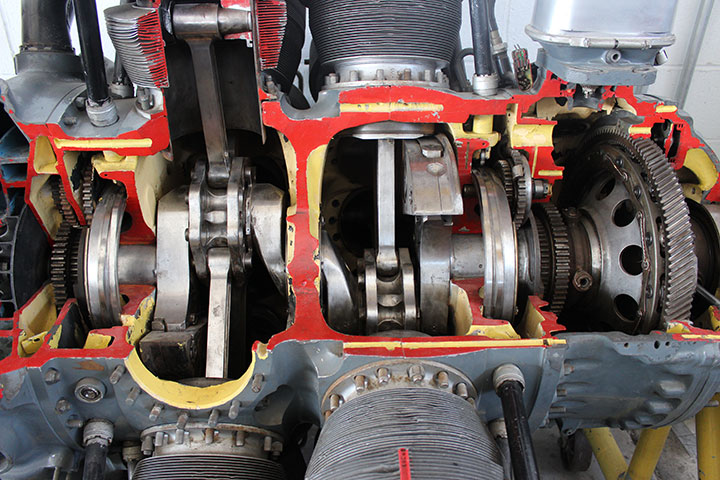

This cutaway on display at MAPS Museum is a

Ford-built R-2800-51 that powered the C-46 Commando as seen above.

Author's Photo added 5-6-2015.

Author's Photo added 5-6-2015.

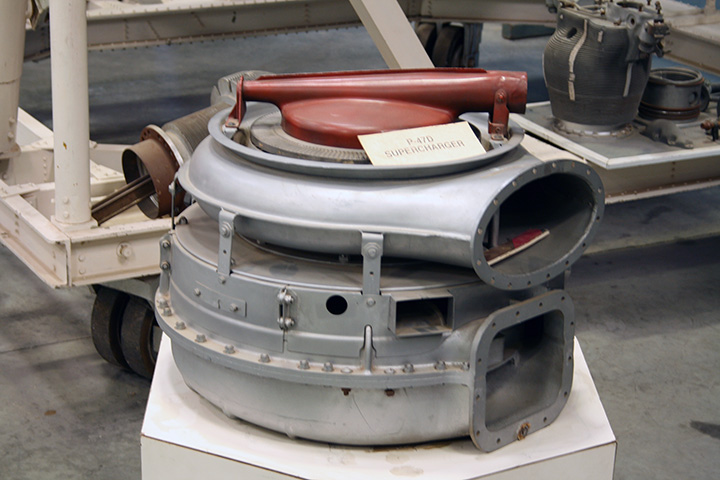

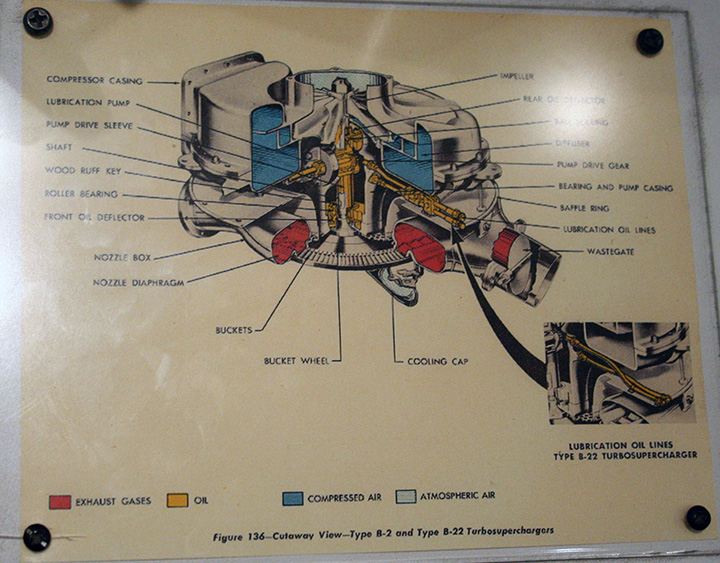

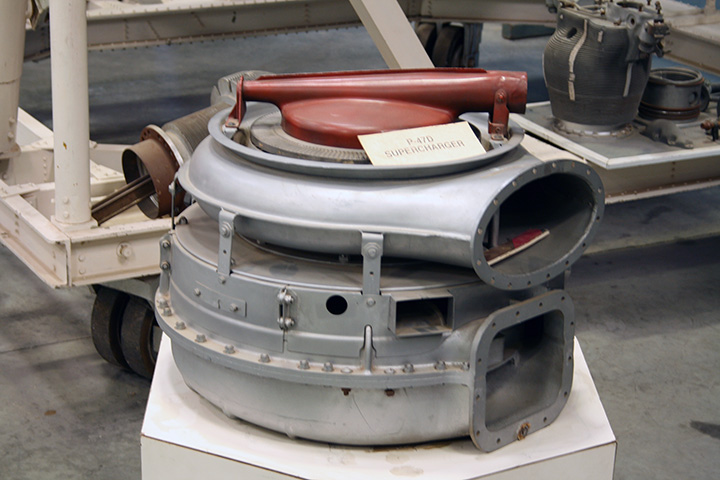

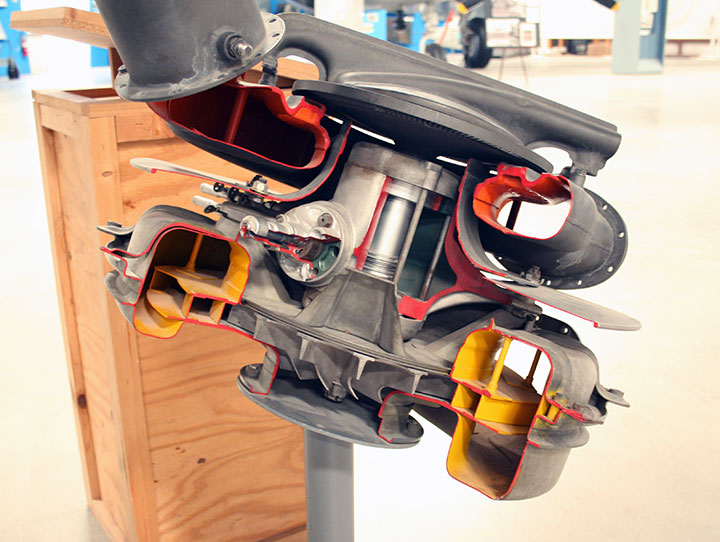

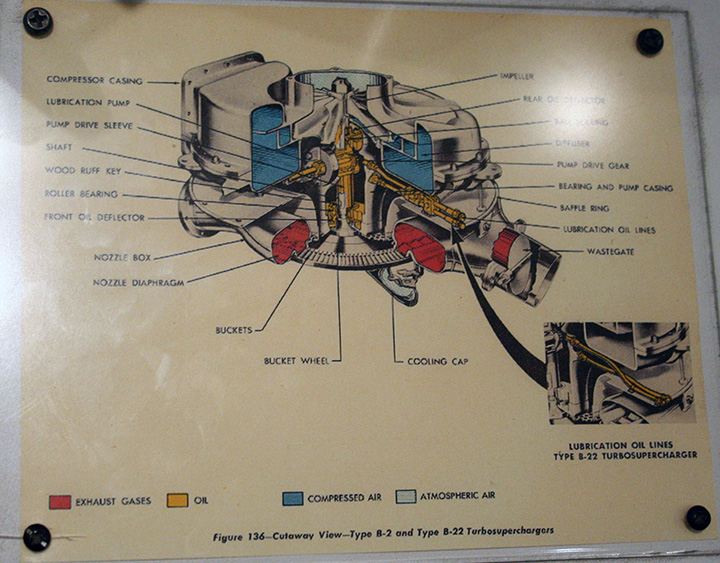

This is a General Electric turbo supercharger used on a Republic P-47

during World War Two. Ford Motor Company built 52,276 of similiar General

Electric turbo superchargers

at its River Rouge plant. These were used on B-17s and B-24s. Author's Photo.

Author's Photo.

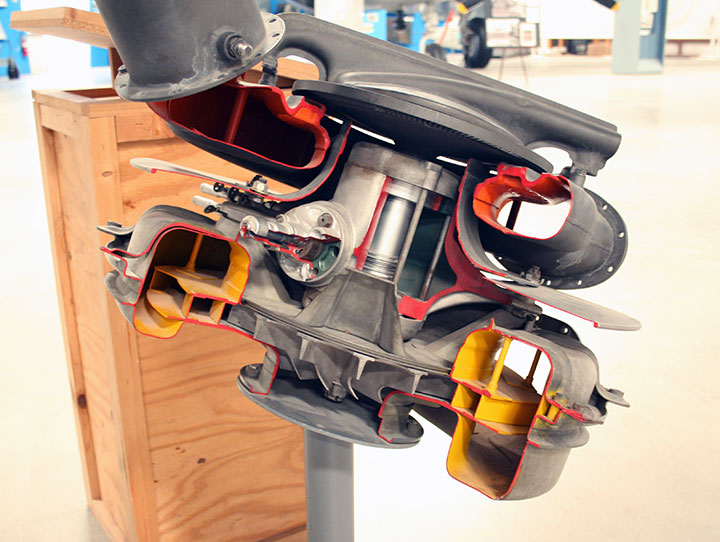

This cut-away of a turbo supercharger shows some of the internal parts. Author's Photo.

Author's Photo.

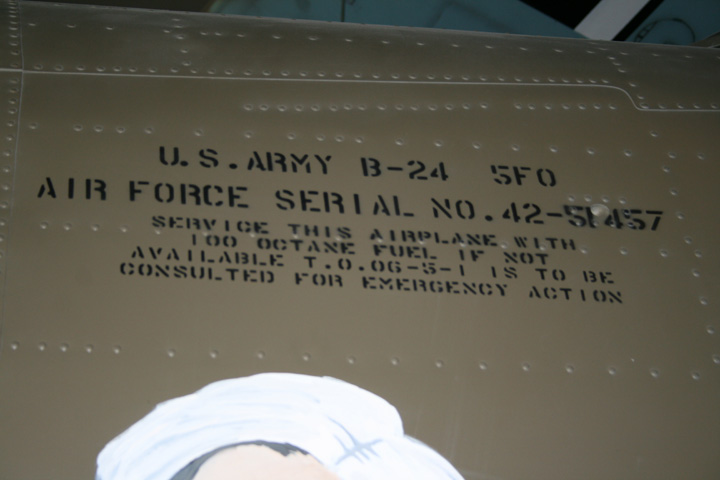

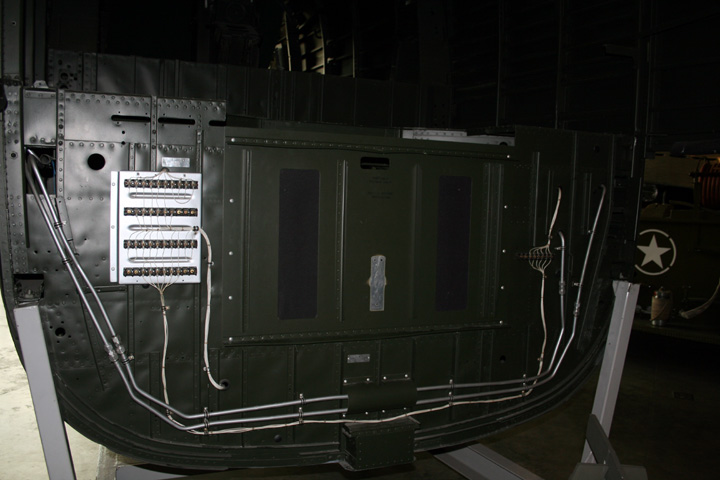

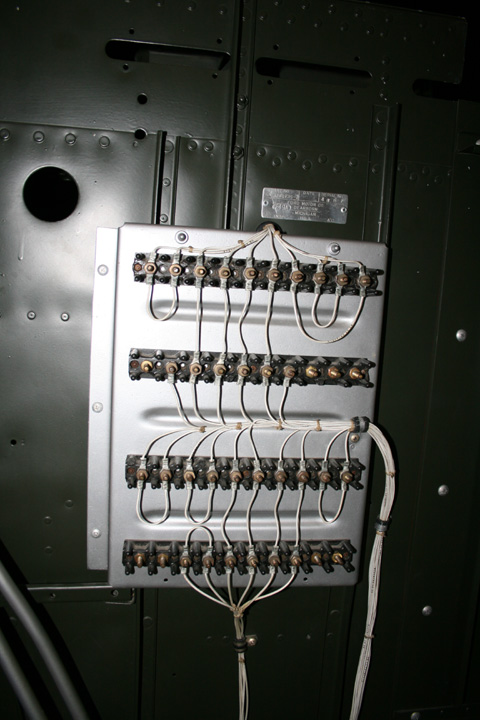

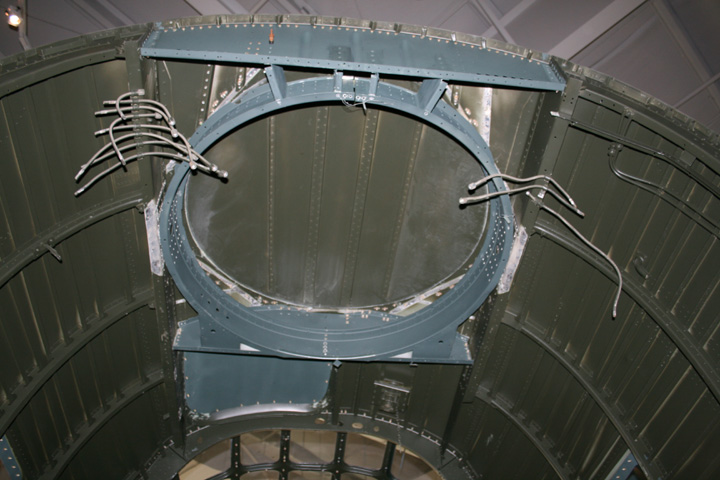

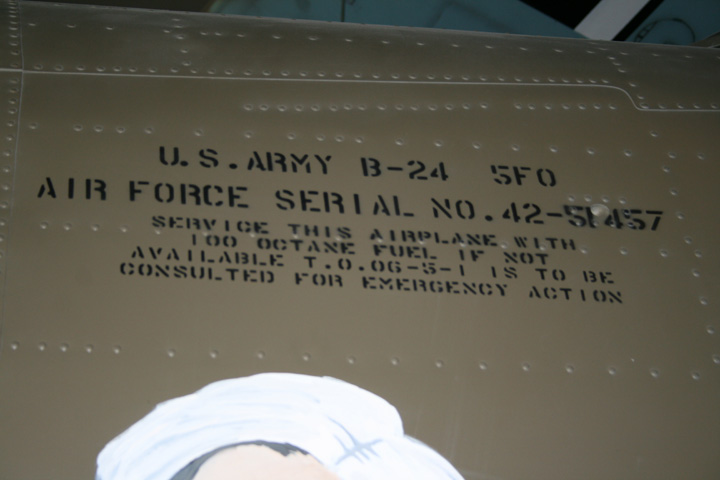

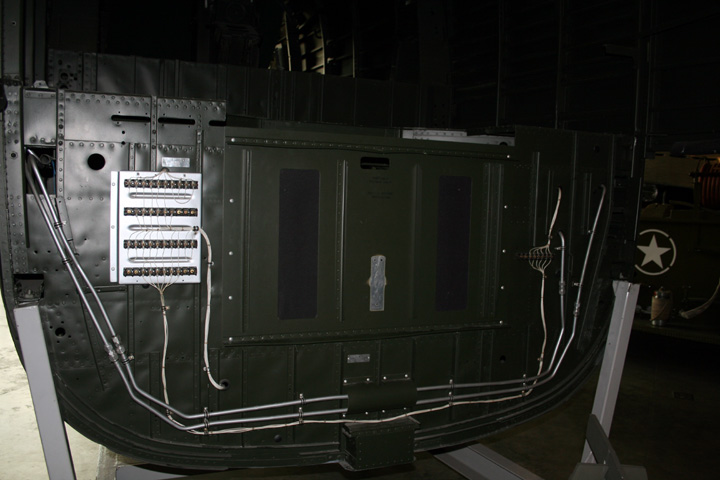

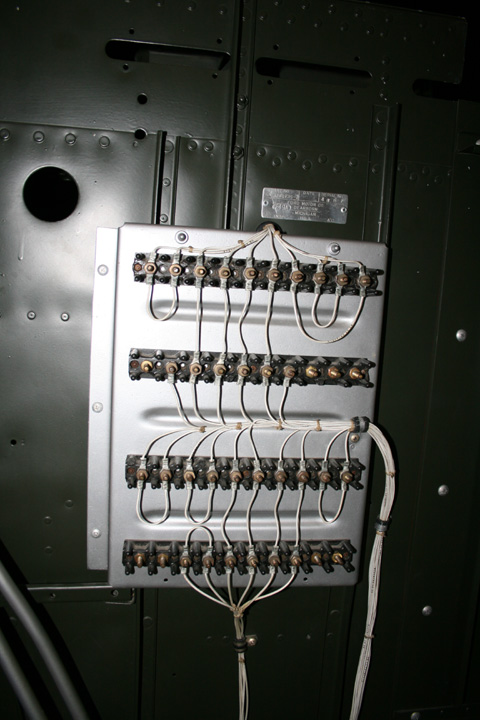

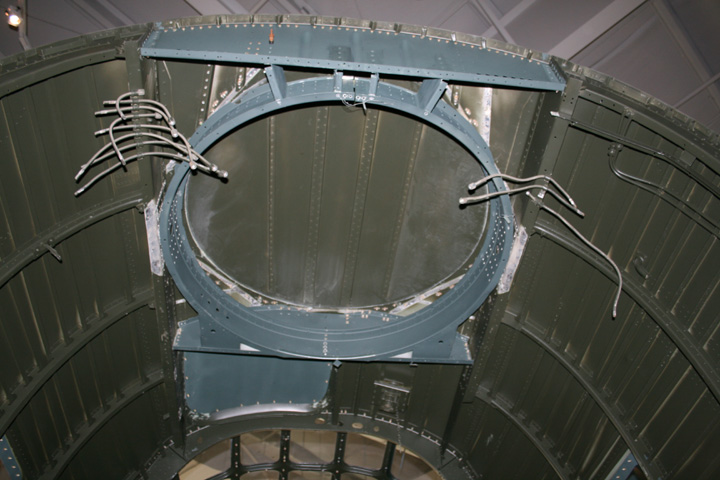

B-24 Nose Section Photos from the

Mighty Eighth Air Force Museum:

This Ford-built nose section is on display at the Mighty Eighth Air

Force Museum in Poole, GA. More photos of this nose section can be

seen at the bottom of this page. Author's Photo.

Author's Photo.

Author's Photo.

Author's Photo.

It was delivered 2-25-1942. Author's Photo.

Author's Photo.

Author's Photo.

Author's Photo.

Author's Photo.

Miscellaneous Ford built items:

High tech to low tech, Ford delivered to the

US Military. Squad tents like this one were very important to the

common service person, as the tentss protected them from the elements.

One would not think an automobile manufacturer would have the expertise

to make something like this. In today's world, they don't.

The seats and interior trim are now outsourced . But in the World

War Two era, Ford and other companies made their own seats and

sewed their own upholstery. The Ford Highland Park Trim

Department made 9,498 tents like this to protect the GIs from rain,

snow, and the cold. Author's Photo.

This Ford Moto-Tug can be seen at the Yankee

Air Museum. This particular one was used to pull aircraft off the

end of the assembly line at the Ford B-24 plant. Ford records are

unclear whether 10,877 Moto-Tubs were outsourced or built in-house by

Ford. Author's Photo added 2-16-2017.

Also at the Yankee Air Museum is this Ford built B-24L cockpit.

Author's Photo added 2-16-2017.

|