|

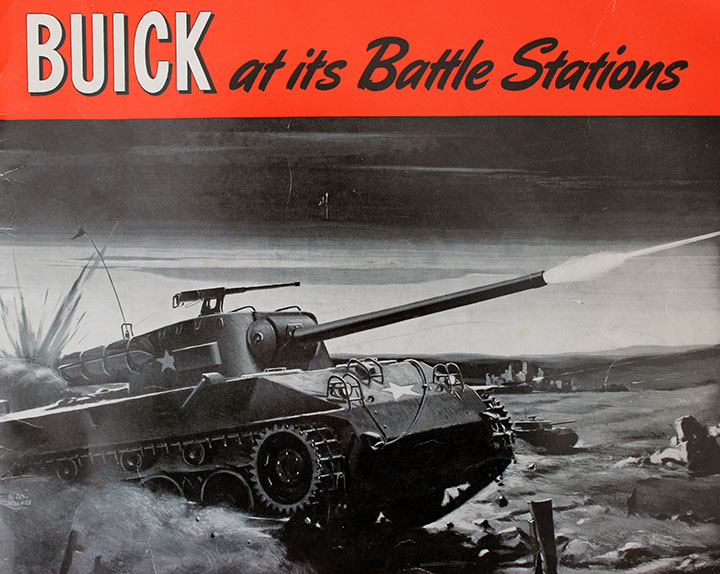

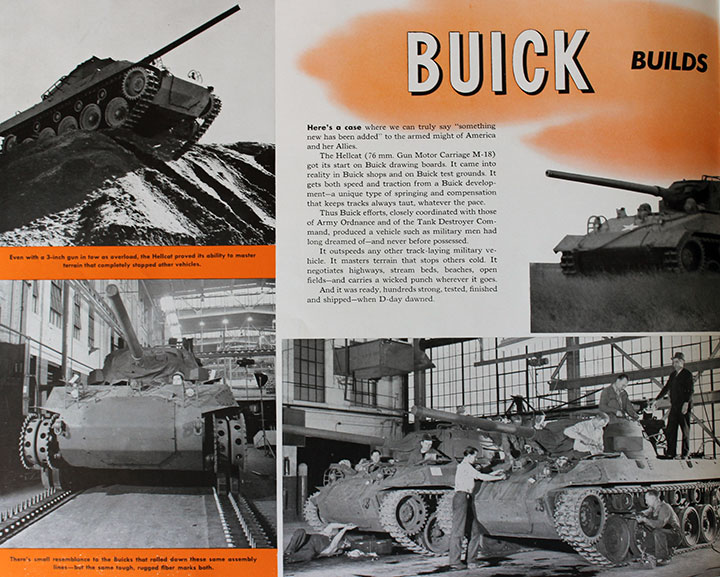

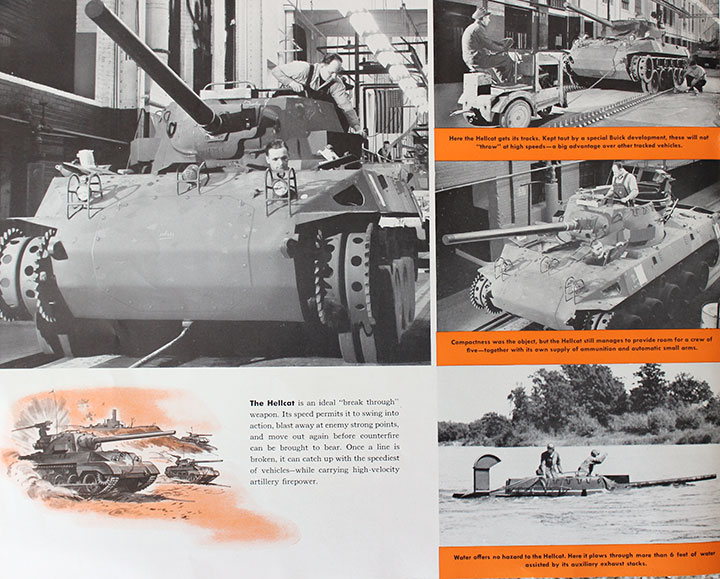

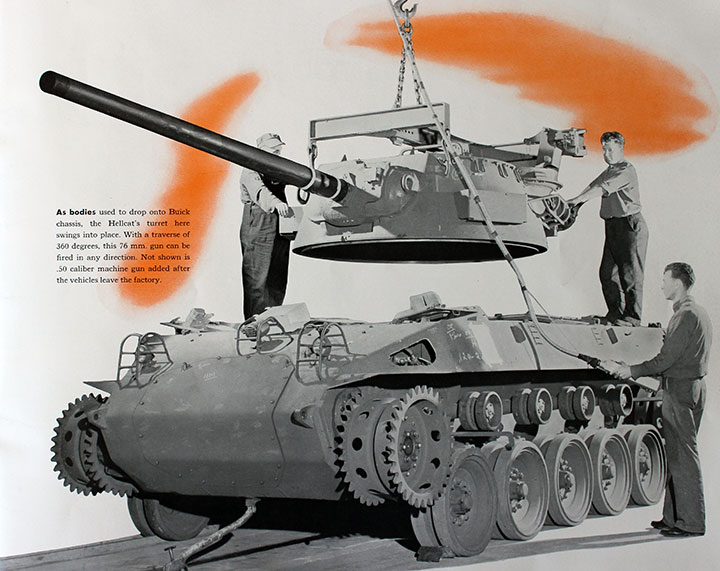

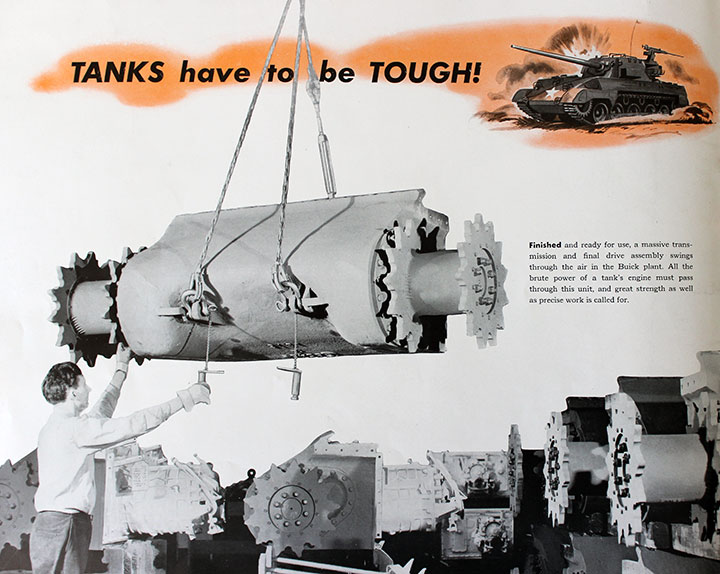

Buick Built M18 Tank

Destroyer Photos

Buick Motor Division of General Motors Corporation in World War Two

Flint, MI

1903-Present - (Now located in Warren, MI)

This page updated 11-20-2020.

The first races at the Indianapolis Speedway

were held in August of 1909 and included both 10 mile and 250 mile

events. Buick entered three cars, including this one. Indianapolis

Motor Speedway Hall of Fame Museum. Author's Photo.

Author's Photo.

In the 1909 races, a driver by the name of

Louis Chevrolet won the ten mile race. He led for 52

miles in the main 250 mile race, which was won by one of the other Buick

vehicles. Author's Photo.

This pre-World War Two 1940 Buick Limited

Series 80 passenger car was used by the U.S. Army as a staff car.

It was Serial Number 38315128. It was on display at the 2017 MVPA

National Convention in Cleveland, OH. Author's photo added

12-25-2019.

Author's photo added 12-25-2019.

Author's photo added 12-25-2019.

Author's photo added 12-25-2019.

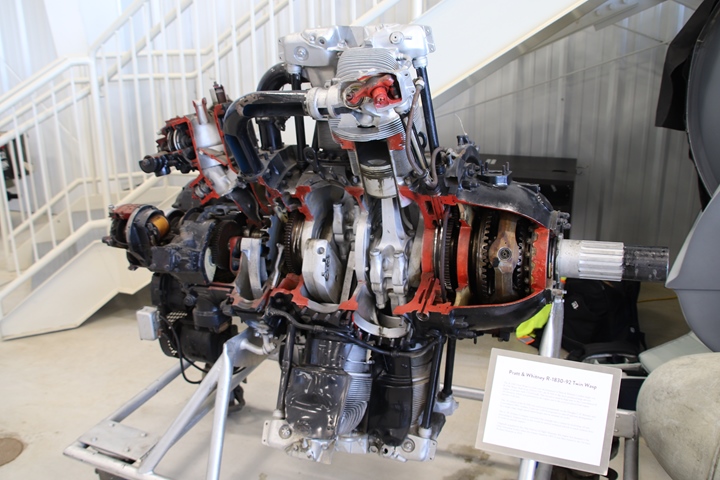

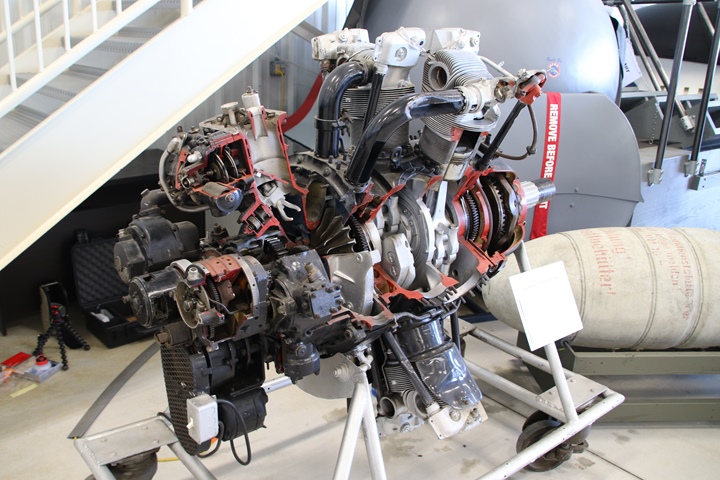

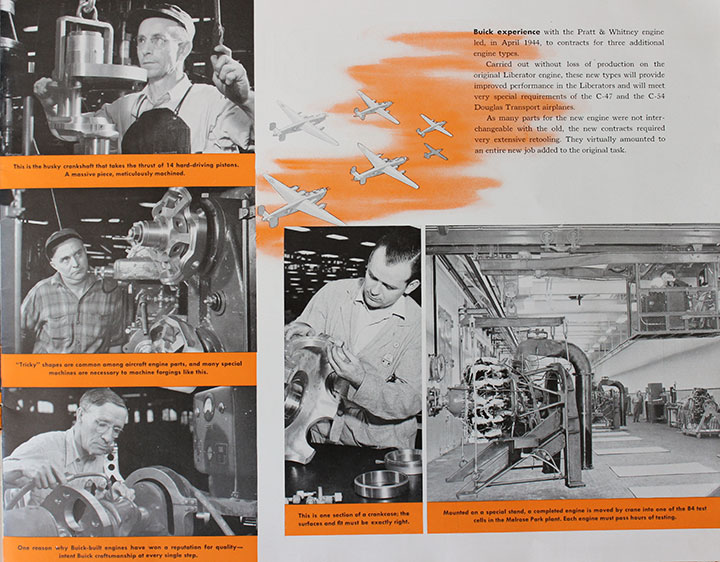

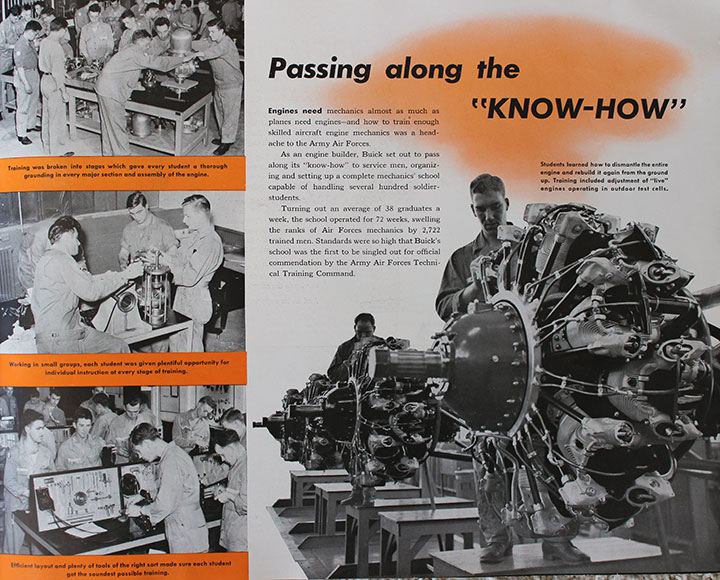

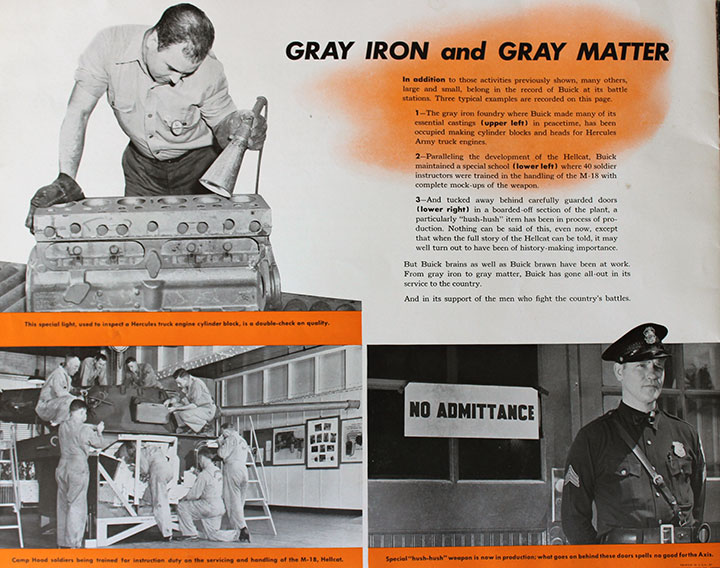

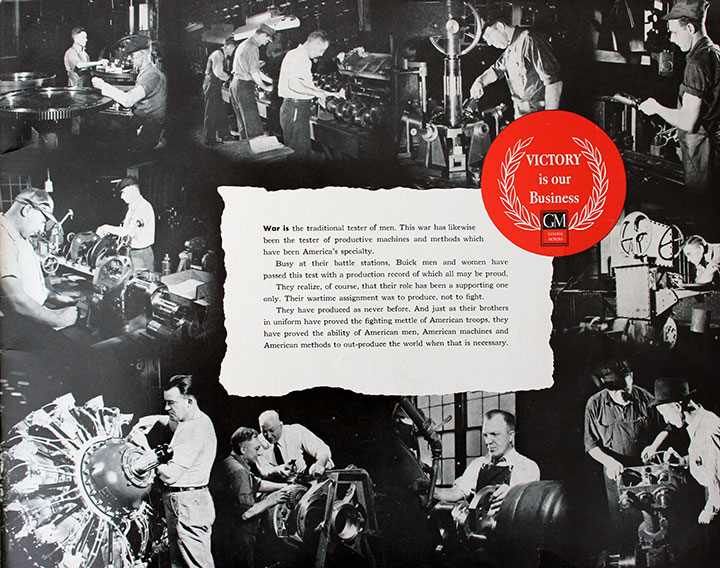

Buick Motor Division of GM

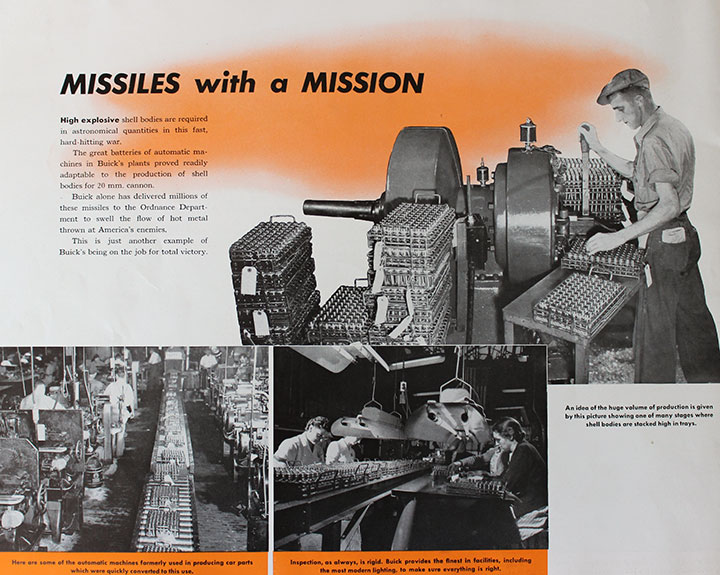

World War Two Production Statistics: (71,874) Pratt & Whitney

R-1830 and (2,548) R-2000 radial aircraft engines, (2,507)

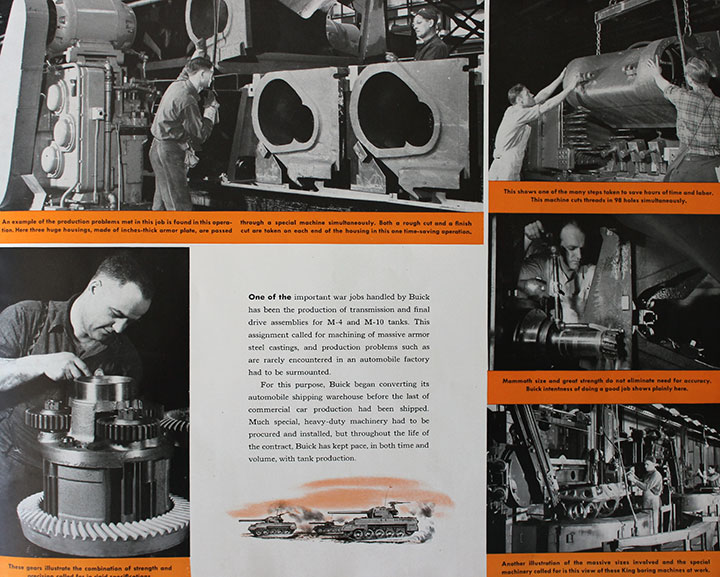

M18 Tank Destroyers, (640) M39 Armored Tractors, (19,928) M4, M10, and M26 transmissions and final

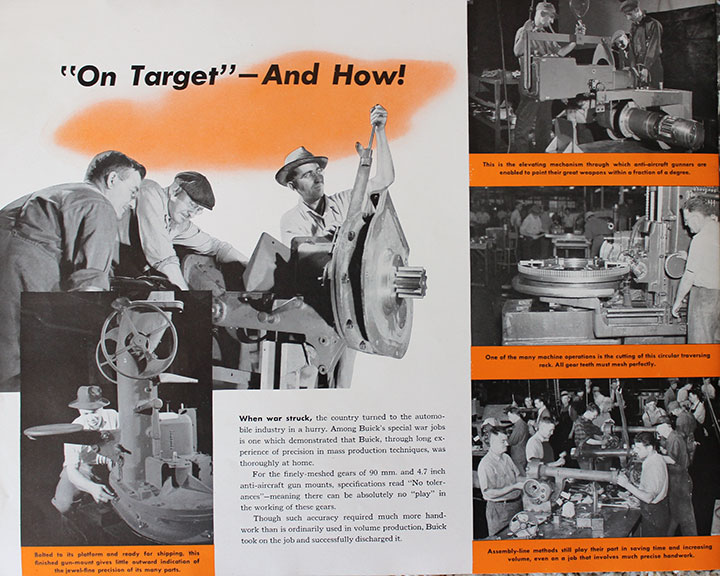

drive assemblies, (2,952) 90mm and 4.7 Anti-Aircraft Gun Mounts,

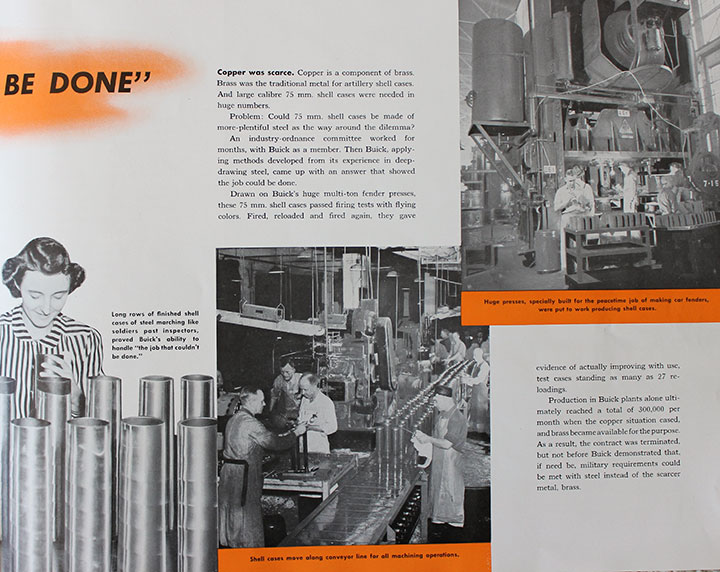

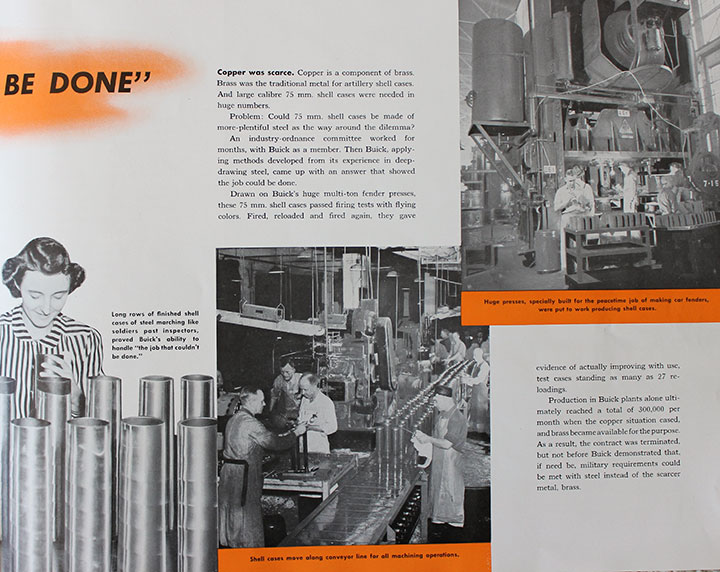

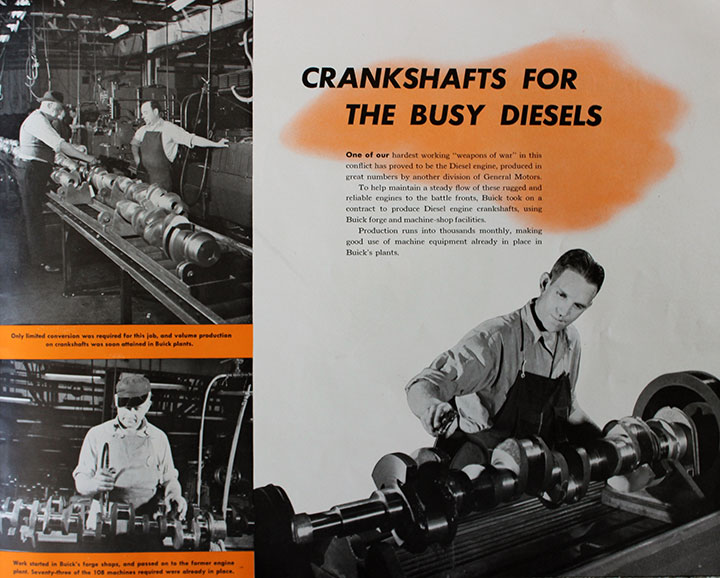

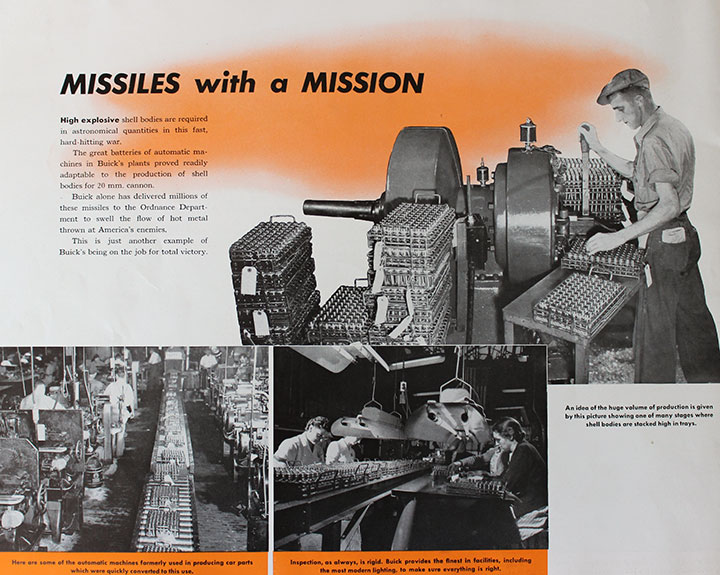

(148,196) Diesel Engine Crankshafts, (2,424,000) 75mm steel cartridge

cases, (1,149,300) 57mm shell bodies, (9,719,000) 20mm shell bodies,

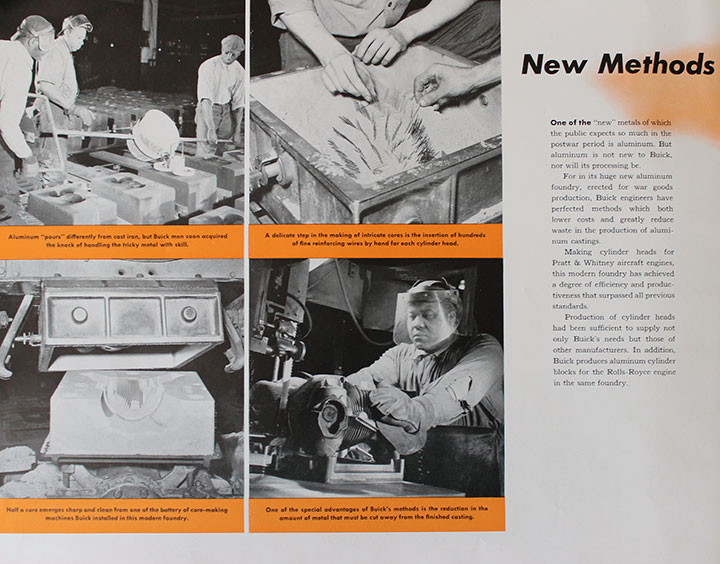

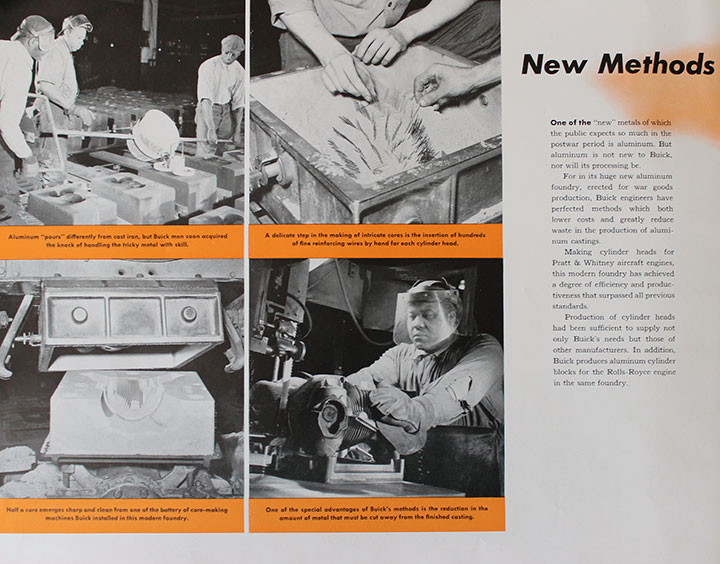

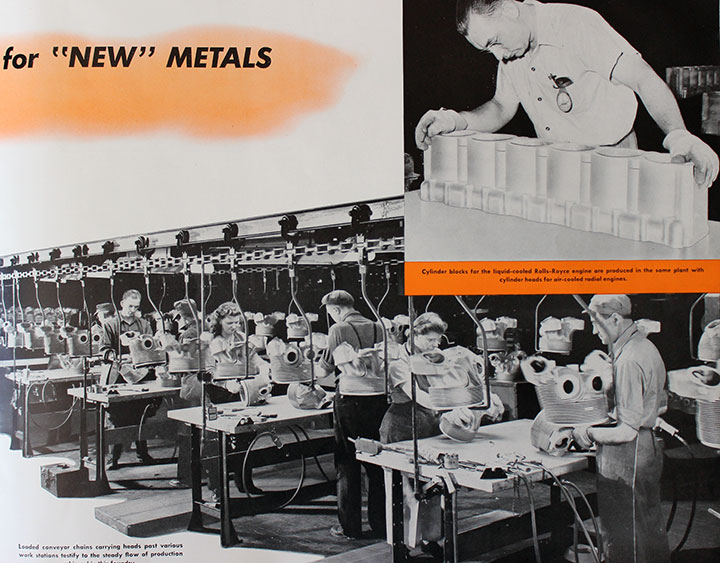

(3,120,000) Pratt & Whitney R-1830 Aluminum Cylinder Heads, (52,200) Aluminum Cylinder Blocks

for the Packard-built Rolls-Royce Merlin aircraft engine, 204,500 Cylinder

Blocks and Heads for Hercules

engines, and (3,120,000) Cylinder Heads for the Pratt & Whitney aircraft

engines.

Notes: Final assembly of the

Buick R-1830, which was used exclusively in the Consolidated B-24 bomber

up through April 1944, was done at its plant in Melrose Park, IL, with

the machining and fabrication of components being shared between Melrose

Park and Flint operations. In April 1944, Buick signed a contract

to continue building the R-1830 for the B-24. It also began

building the R-1830 model for the C-47, which was slightly different

than the B-24 R-1830. It also started producing the R-2000 engine

for use in the Douglas C-54. Production and assembly of the R-2000

was undertaken at the Buick home plant in Flint starting in February

1945.

Several sources erroneously indicate that the C-54 was

powered by R-2800 engine instead of the R-2000, which then leads to the

wrong assumption that Buick built R-2800 engines. Page 132 of the

1950 Pratt & Whitney published book entitled "The Pratt & Whitney Story"

clearly states that Buick built the R-2000, not the R-2800.

Only the C-54 used the R-2000 during World War Two.

The 640 M39 Armored Tractors were conversions

of previously built M18 Hellcat Tank Destroyers. Buick had the

contract from Army Ordnance to do the work, but subcontracted all of the

work to the nearby Fisher Body Grand Blanc plant, which did all of the

work.

Buick Flint, MI won the Army-Navy "E" Award three times during World War Two.

Buick Melrose, IL won the Army-Navy "E" Award five times during World War Two.

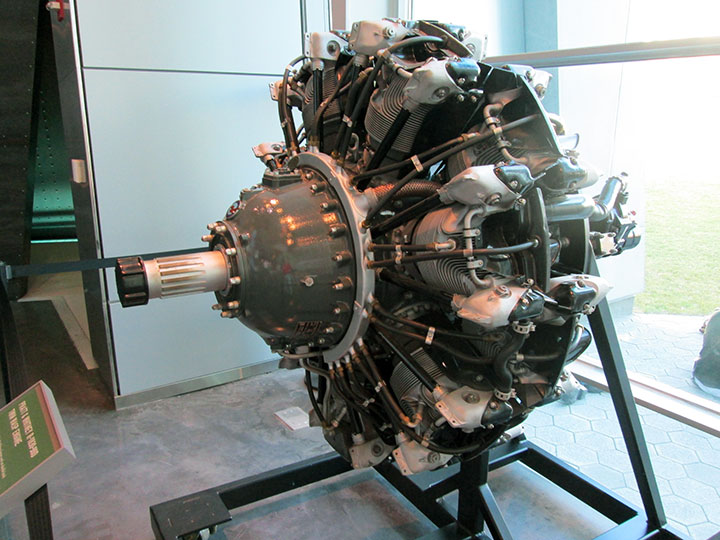

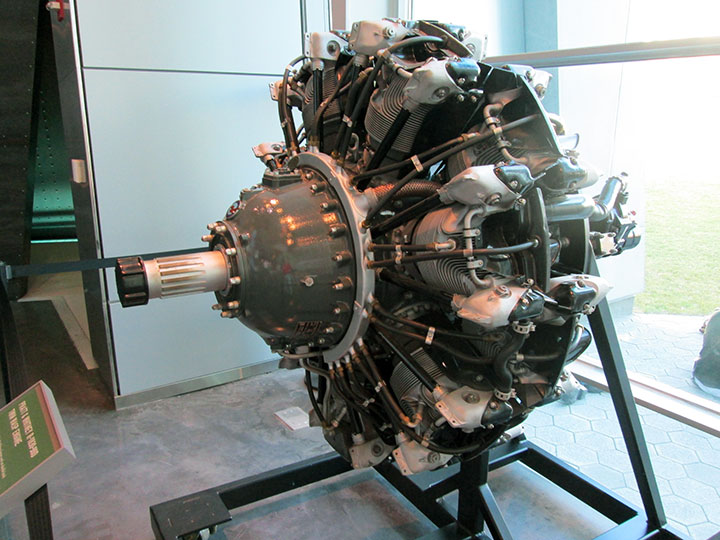

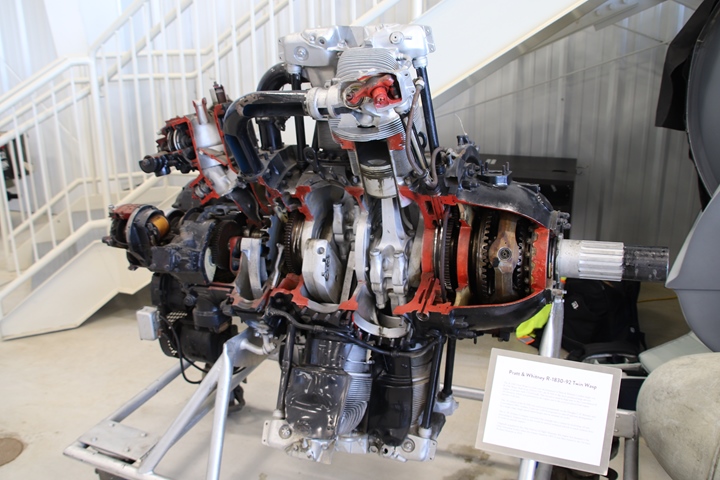

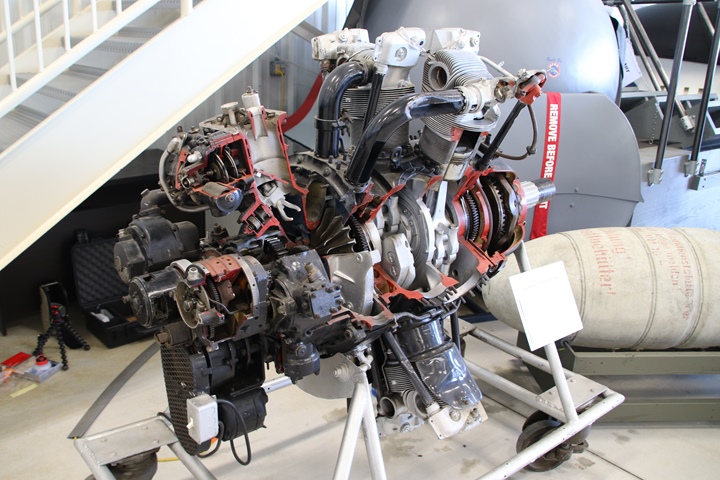

The Pratt & Whitney R-1830 1,200 hp radial

aircraft engine was on display at the National World War Two Museum in

New Orleans, LA. Out of the total 173,618 R-1830s built during the

war, Buick made 71,874 of them in the government

owned plant in Melrose Park, IL, west of Chicago. This was 43% of

the total. Buick-built engines were used exclusively on the 18,190 Consolidated B-24s

until April 1944, when Buick was contracted to build R-1830s for the C-47

as well. It should be noted that Chevrolet also built

R-1830s for the B-24 and C-47. Author's photo.

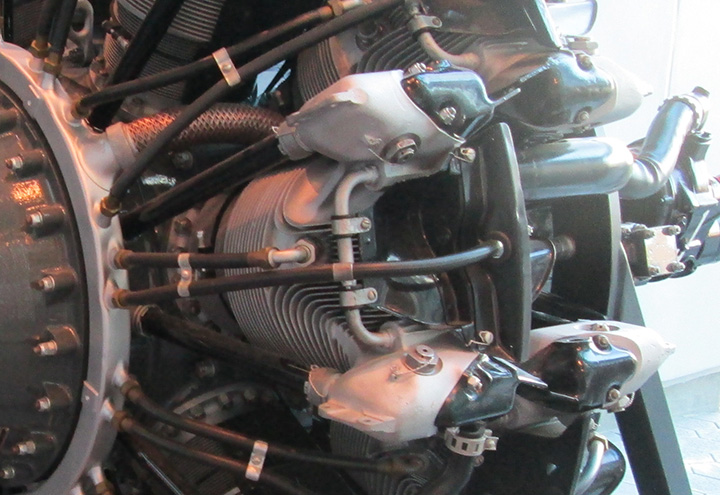

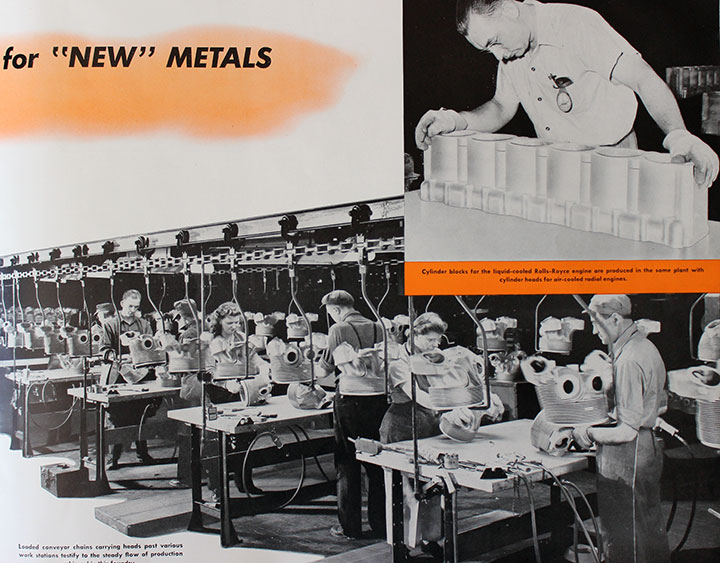

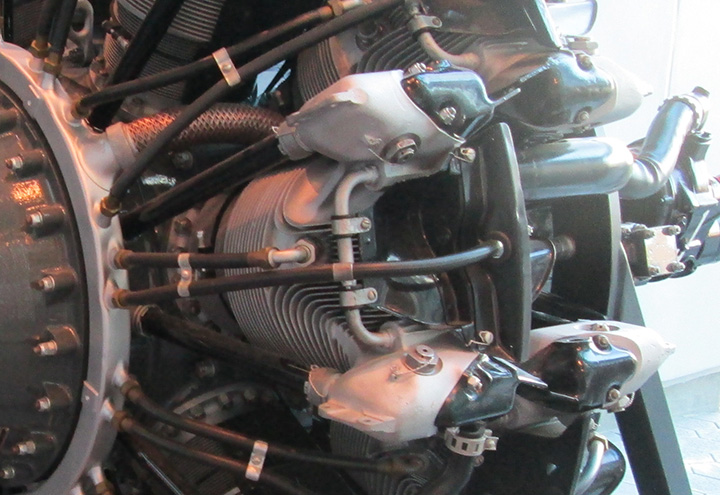

This shows a close-up of one of the fourteen

cylinders on the R-1830 with its cooling fins. During the

course of the Second World War. Buick built over 3.2 million cylinder

heads for Pratt & Whitney radial aircraft engines. Only 1,038,772

of the cylinder heads would be needed for Buick's own engine production.

After sparkplugs, which were changed sometimes after every combat

mission, cylinder heads were next on the list of components

replaced on a radial engine. So, an adequate number of spares would

have been required. See pages 2-3 and 12-13 below in "Buick at its Battle

Stations" for more information on this. Note how labor intensive

it was to make the fins on the castings.

This R-1830 display at the Tri-State Warbird

Museum Batavia, OH shows the complexity of the engine. Author's

photo added 11-20-2020.

Author's photo added 11-20-2020.

This photo shows a couple of Buick-built engines are

running on the B-24J Witchcraft. Author's photo from the 2011 Wings of

Freedom tour stop at Indianapolis Regional Airport.

Here, Witchcraft powered by Buick-built R-1830 engines, does a fly-by. Author's photo.

Many C-47s built in the last year of the war

were powered by Buick-built R-1830 engines. Author's photo.

This World War Two era photo gives an aerial view of

the Melrose Park, IL, plant looking northwest. The photo below was

taken from the parking lot, looking in the same direction from the

parking lot on the east side. The complex covered 126 acres.

This is a contemporary photo of the former Buick

aircraft engine plant in Melrose Park, IL, where 71,874 Pratt & Whitney

R-1830 radial aircraft engines were assembled and tested before being

installed in B-24s and C-47s during the last year of the war. Engines would have been shipped from this

location to B-24 assembly plants at Willow Run, MI, Tulsa, OK, Dallas,

TX, Fort Worth, TX and San Diego, CA. C-47s were built at Long

Beach, CA, and Oklahoma City, OK. Author's photo.

When Buick operated the plant, its name was

on the front. During World War Two the plant employed 10,000

persons.

With the landscaping that has been

added, one cannot get the same photo as above. Author's photo.

The Melrose Park plant was one of nineteen

government owned plants that General Motors operated during World War

Two. These facilities were built specifically for the production of war material.

In 1946, the 2,030,000 square foot plant was sold to

International Harvester by the War Assets Administration.

Since that time, International Harvester, now Navistar, has manufactured

six cylinder diesel engines in the facility. Author's photo.

The Douglas C-54. Beginning in

February 1945, Buick built 2,548 Pratt & Whitney R-2000 engines

for this type of aircraft. Author's photo added 1-24-2015 from the

2014 St. Louis Airshow.

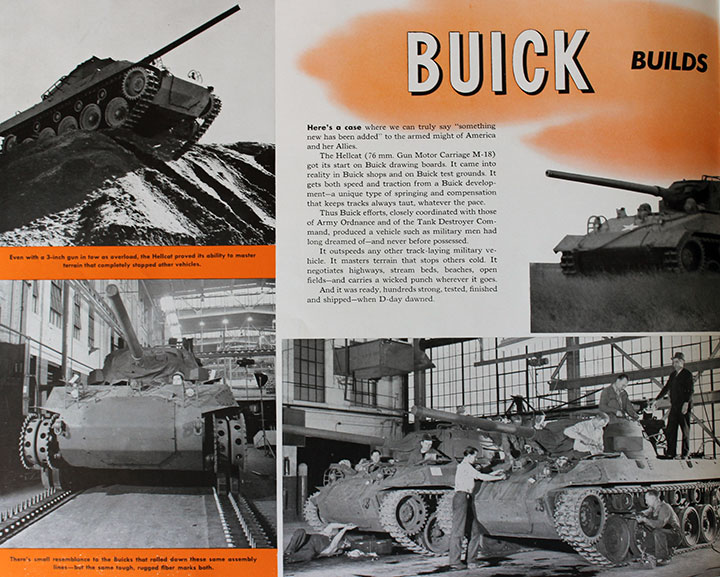

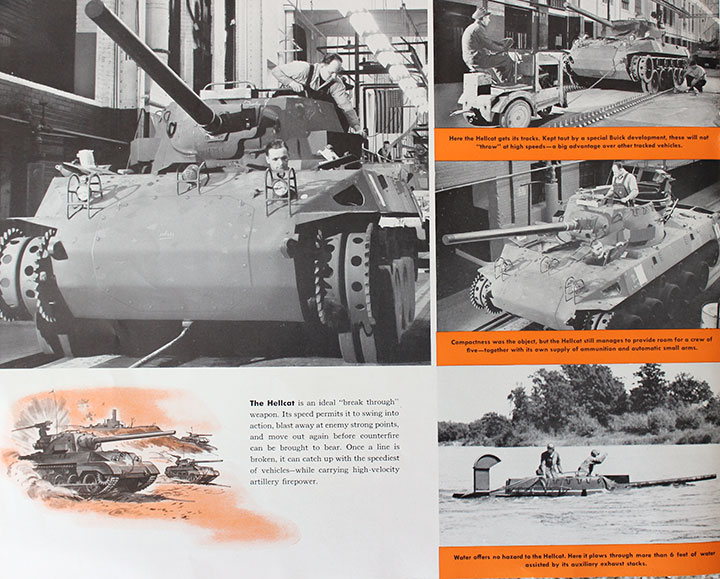

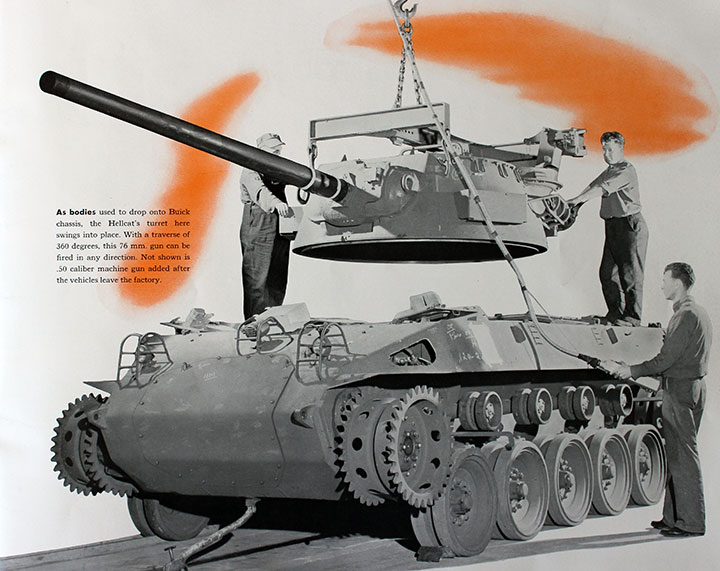

This pristine example of a Buick-built M18

"Hellcat" tank destroyer was previously on display at the now closed

National Military Historical Center in Auburn, IN. This M18 is now

in Florida as of 2017. Author's photo.

Buick built 2,507 of these at its plant in Flint, MI. Author's photo.

Author's photo.

Author's photo.

Author's photo.

|

Buick M18 Hellcat Production |

| 1943 |

Jul |

Aug |

Sep |

Oct |

Nov |

Dec |

1944 |

Jan |

Feb |

Mar |

Apr |

May |

Jun |

Jul |

Aug |

Sep |

Oct |

| |

6 |

83 |

112 |

150 |

267 |

194 |

|

250 |

218 |

170 |

150 |

150 |

150 |

150 |

150 |

150 |

157 |

|

Buick M18

Hellcat in Europe 1944-1945 - Strength and Losses |

| |

Jun44 |

Jul44 |

Aug44 |

Sept44 |

Oct44 |

Nov44 |

Dec44 |

Jan45 |

Feb45 |

Mar45 |

Apr45 |

May45 |

Total |

|

Strength |

146 |

141 |

176 |

170 |

189 |

252 |

306 |

312 |

448 |

540 |

427 |

427 |

Losses |

|

Losses |

0 |

0 |

6 |

6 |

14 |

7 |

44 |

27 |

16 |

21 |

55 |

21 |

217 |

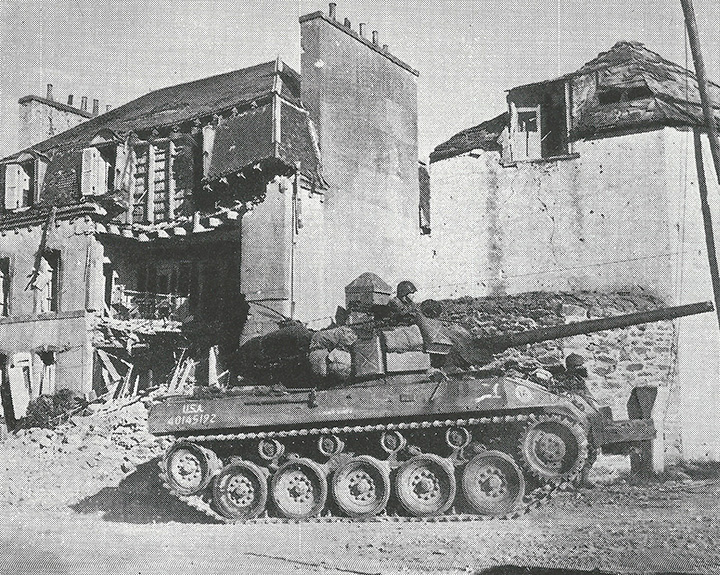

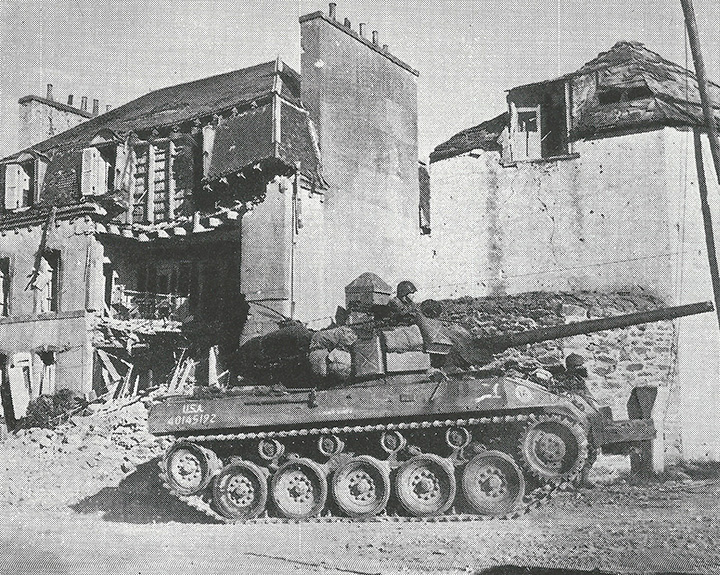

A Buick built M18 "Hellcat" is in action

in Europe.

This M18 can be seen at the Buick Museum in Flint, MI, just a couple of

miles away from where it was built. The factory that built it no

longer stands. This particular "Hellcat" was found in a junk yard

in Europe after having served in conflicts in the Balkans at the end of

the 20th century. Author's photo.

See pages 3-7 below in "Buick at its Battle Stations" for more

information on the M18.

This M18 Hellcat tank destroyer is on

display at the AAF Tank Museum in Danville, VA and came to the museum

after also serving in Bosnia. Author's photo.

Author's photo.

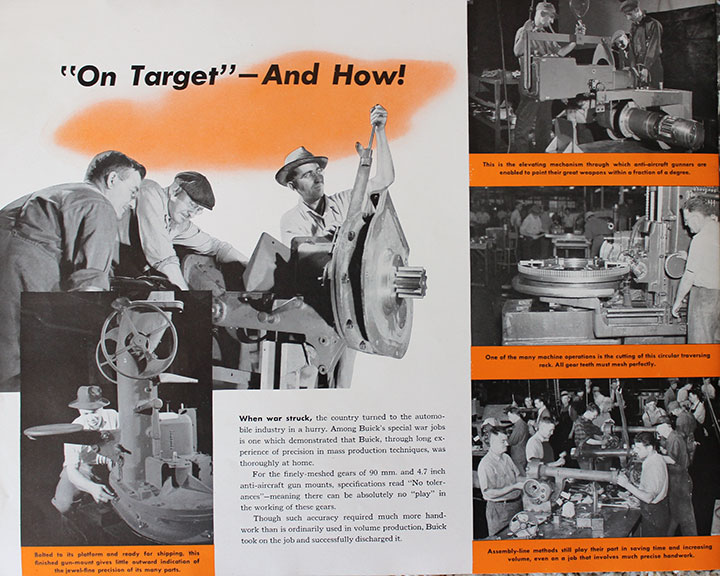

Buick built 2,952 mounts for 90mm anti-aircraft guns like this one. See page 14 below in "Buick at its Battle Stations" for more

information.

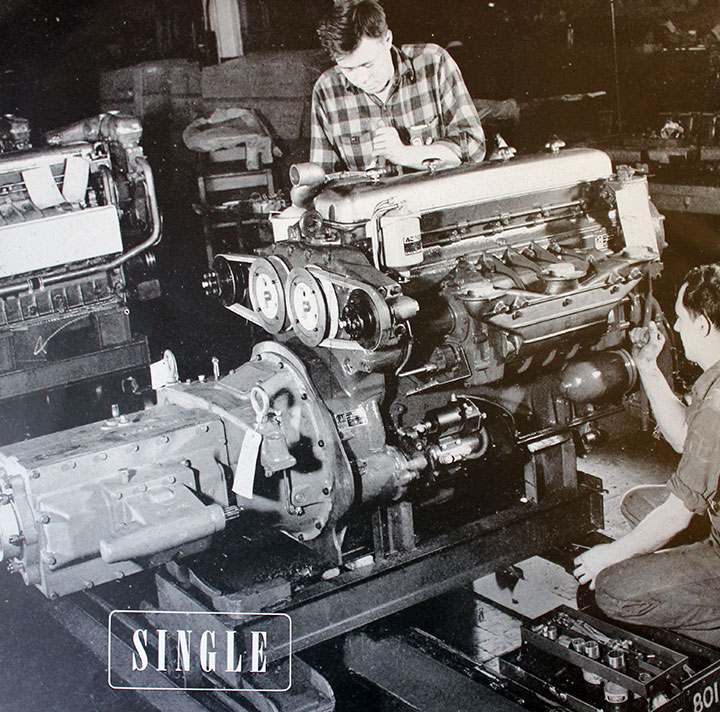

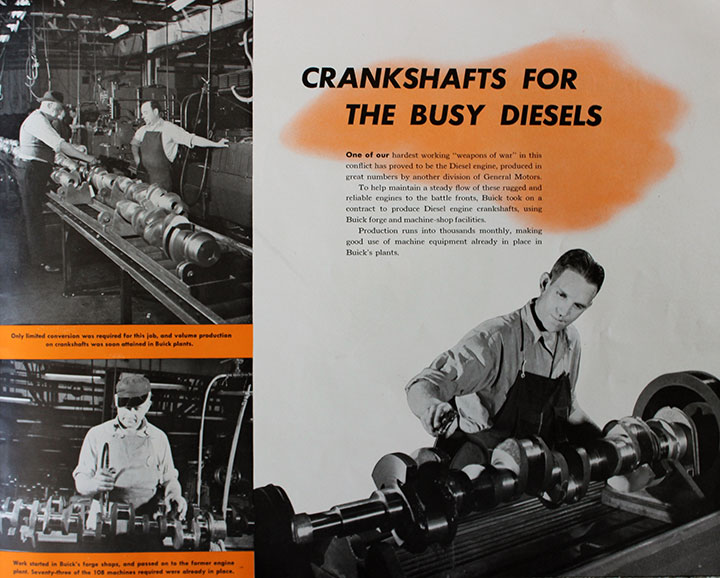

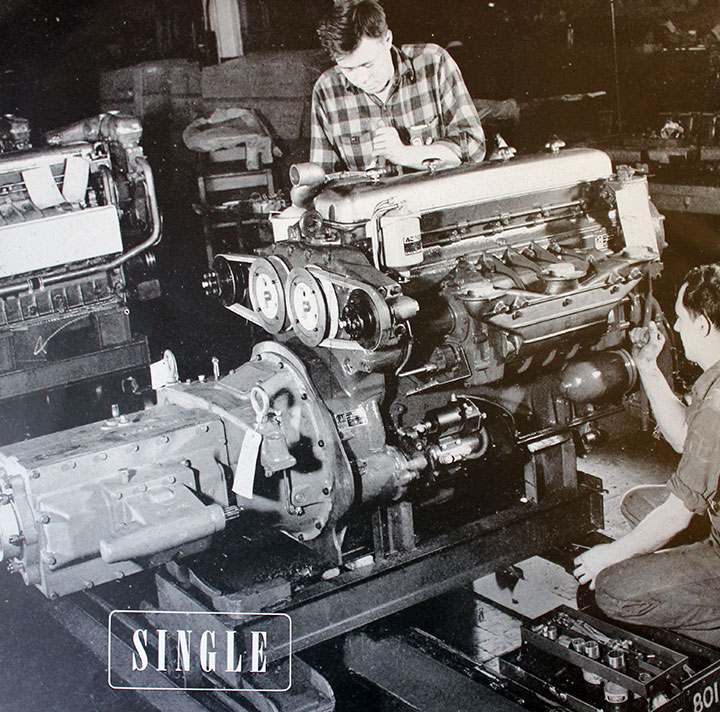

This is a photo of a Detroit Diesel 6-71 engine. Buick supplied

148,196 crankshafts for the approximately 190,000 engines built.

See page 15 below in "Buick at its Battle Stations" for more information

on the diesel crankshaft production.

Detroit Diesel 6-71 engines were installed in 19,353 LCVP landing craft like this

one seen at the First Division Museum at Cantigny in Wheaton, IL. Buick built crankshafts

for the 6-71 engines which were instrumental in many American amphibious landings, especially

the famous one at Normandy. Author's photo added 10-12-2015.

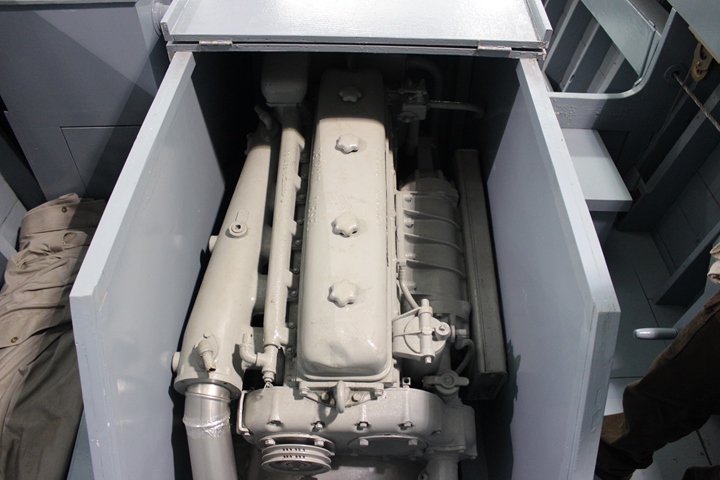

Buick built148,196 crankshafts for the 6-71.

So, this engine must have had a Buick crankshaft in it. Author's photo added

10-12-2015.

Detroit Diesel can be seen stamped on the

valve cover. Author's photo added 10-12-2015.

Not only did Buick-manufactured crankshafts end up in landing craft, but

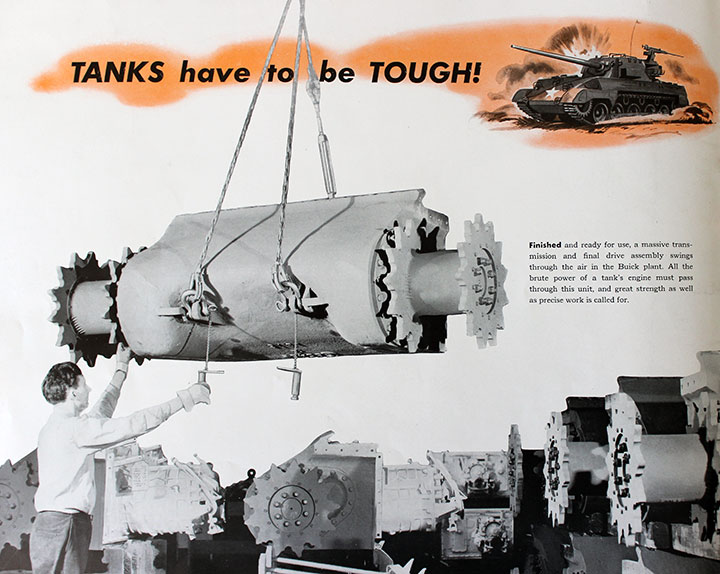

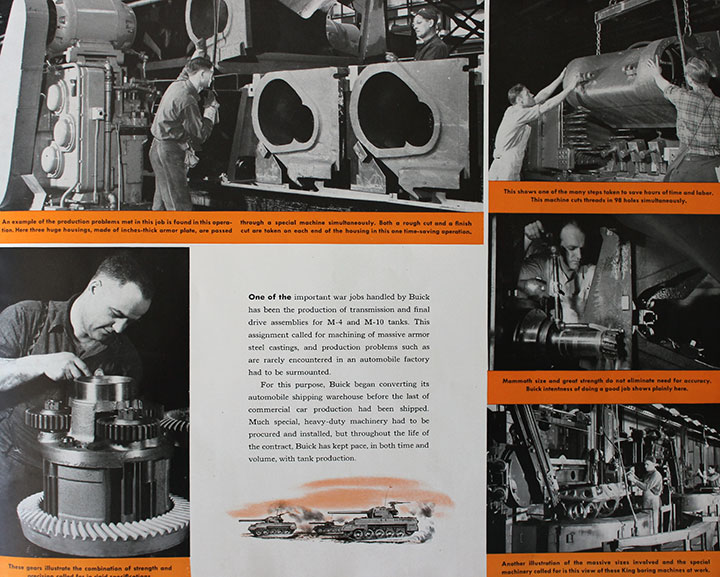

also in M4A2 Sherman tanks with Detroit Diesel engines. Buick also

supplied 19,928 transmissions that not only powered the Fisher Body-built M4A2 and M4A3, but the M10 tank destroyer and M26 Pershing tank as

well. Author's photo.

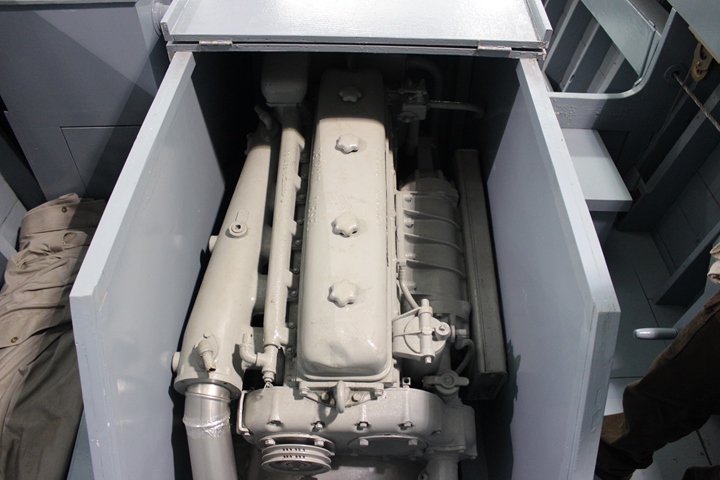

The engines were in the rear of the M4A2s and M4A3s Sherman tanks, as well as the M10 Wolverine and M36

Jackson tank destroyers. The driveshaft came up through the center of the tank to drive the treads from the

front axle. Buick built transmissions that transferred the power from

the driveshaft to the front axle like on this M10 tank destroyer. See

page 9 below in "Buick at its Battle Stations" for more information on

the diesel crankshaft production. Author's photo.

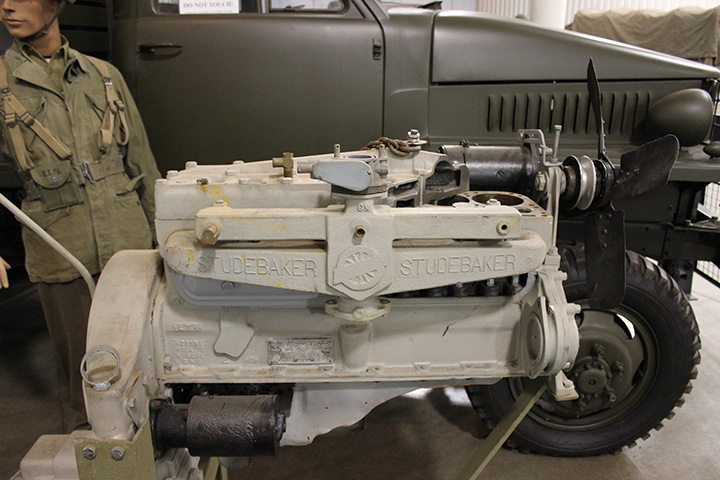

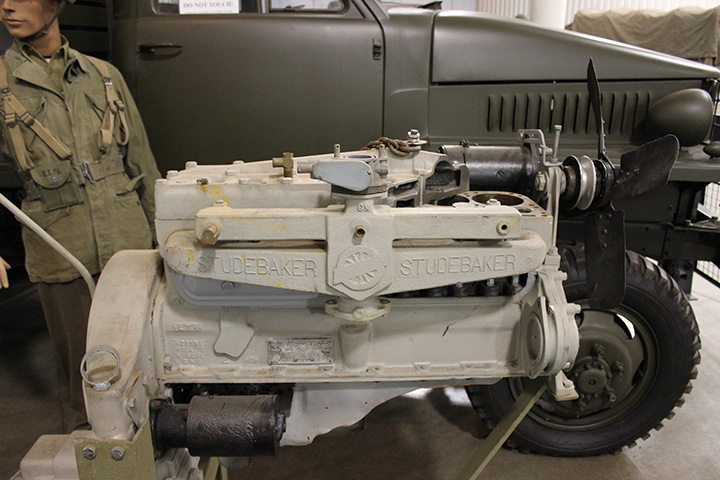

Buick produced 204,500 cylinder heads and

engine blocks for Hercules truck engines. One application of the

Hercules engine was this six cylinder JXD model that was used in the

Studebaker 2-1/2-ton truck. Studebaker obviously had its name on

the intake manifold. The 320 cu. in. engine could produce 86 hp.

Author's photo from the National Military Historical Center, Auburn, IN

Author's photo.

This Studebaker 2-1/2-ton truck was on display at

the now closed National Military Historical Center. This vehicle is no longer

at this location as of December 2017. Author's

photo.

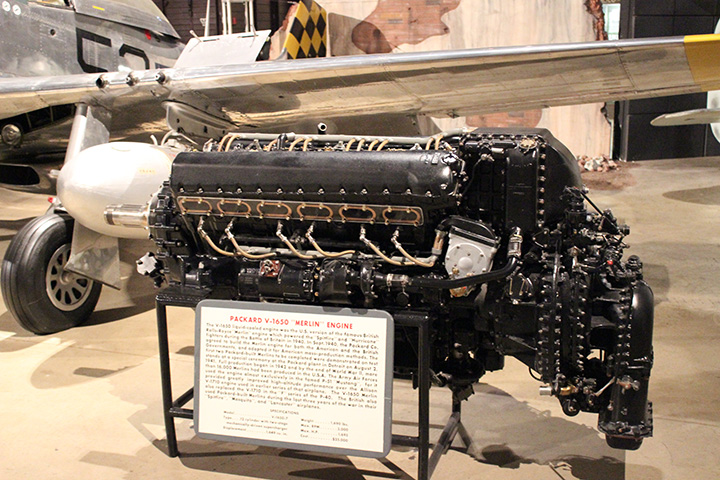

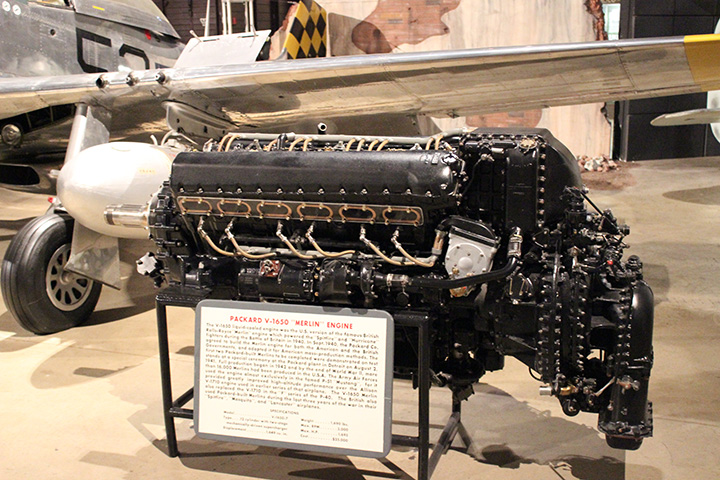

This Packard Rolls-Royce V-1650 Merlin in front of a P-51 Mustang was

one of 54,714 engines that Packard built at its Detroit plant during the

Second World War. Buick supplied 52,200 aluminum cylinder blocks

of the 109,428 needed for the engines. Each engine had two blocks

of six cylinders that mounted on the crankcase. Author's photo at

the National Museum of the US Air Force in Dayton, OH.

With around 150 Mustangs still flying in the US, most likely many

of them have Buick-built cylinder heads in their engines. The

Merlin was the best inline aircraft engine of WWII. Author's photo

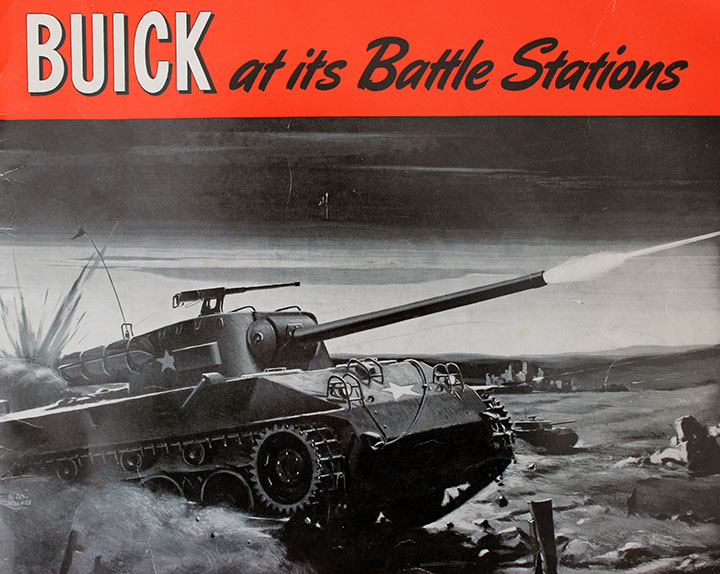

Buick at its Battle Stations

November 1944

Front Cover.

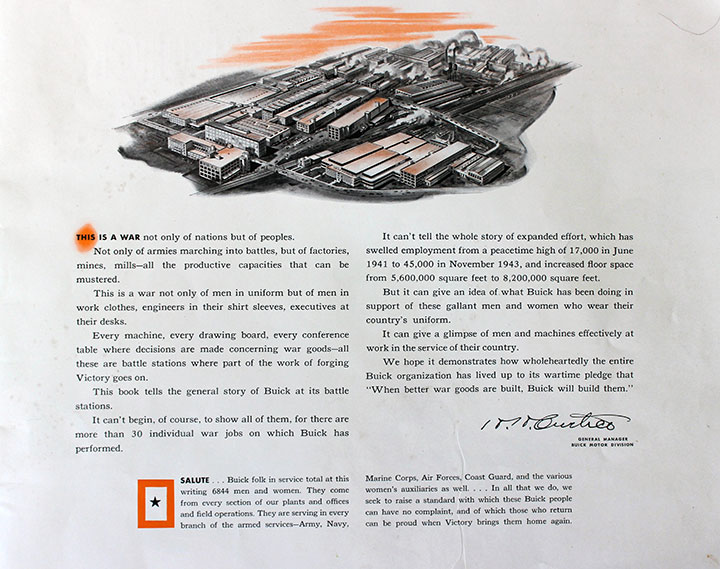

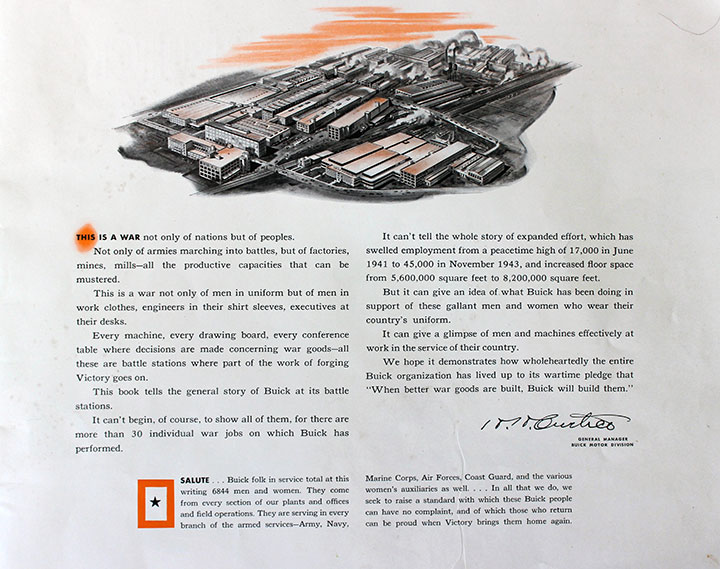

Inside Front Cover.

Page 1.

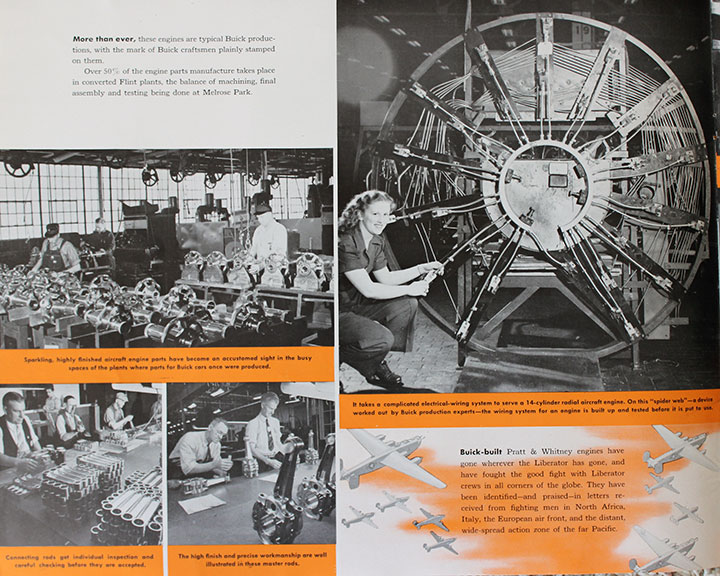

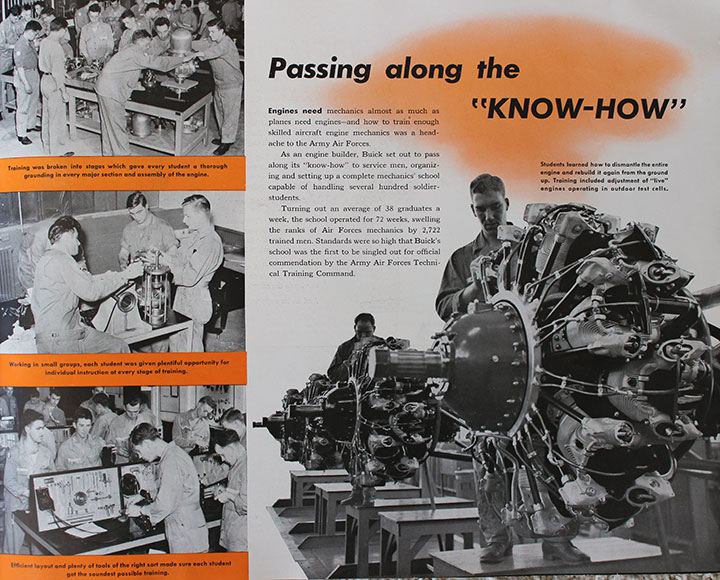

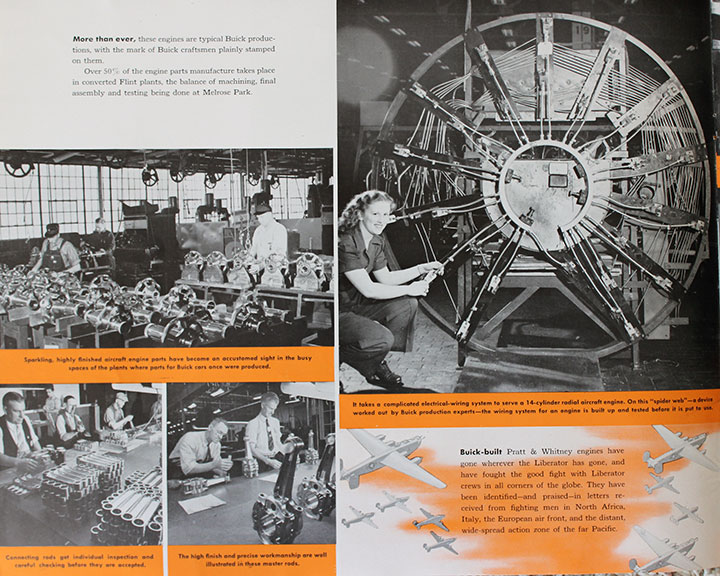

Page 2.

Page 3.

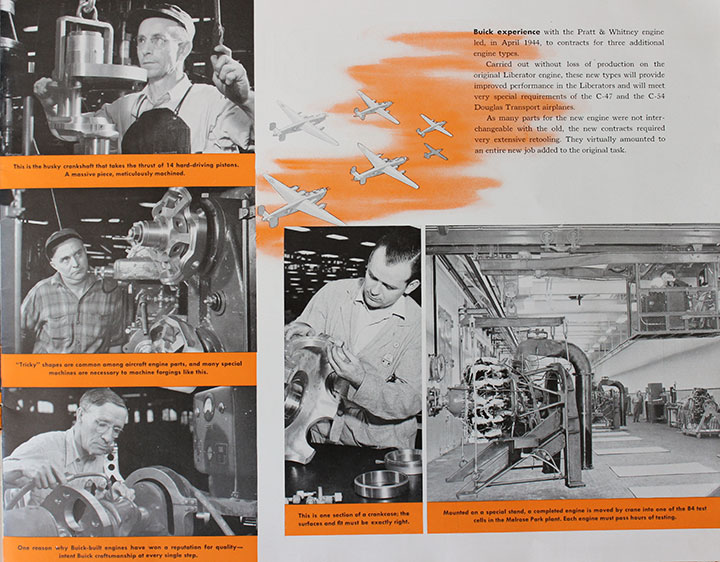

Page 4.

Page 5.

Page 6.

Page 7.

Page 8.

Page 9.

Page 10.

Page 11.

Page 12.

Page 13.

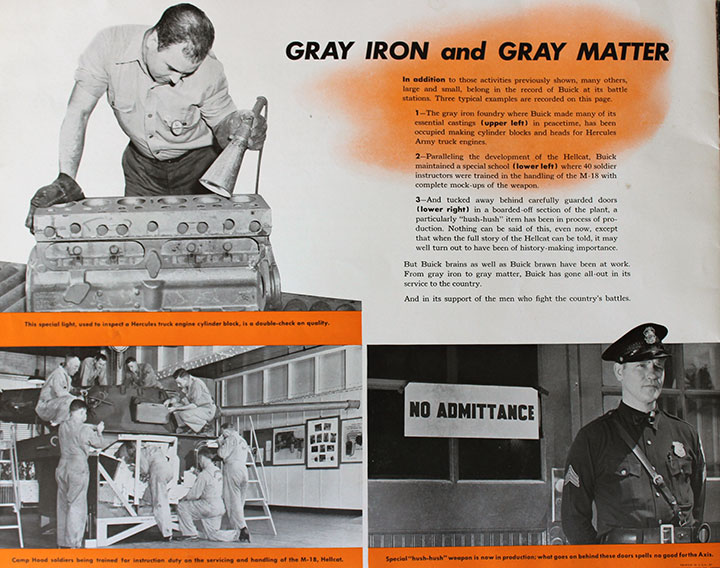

Page 14.

Page 15.

Page 16.

Page 17.

Page 18.

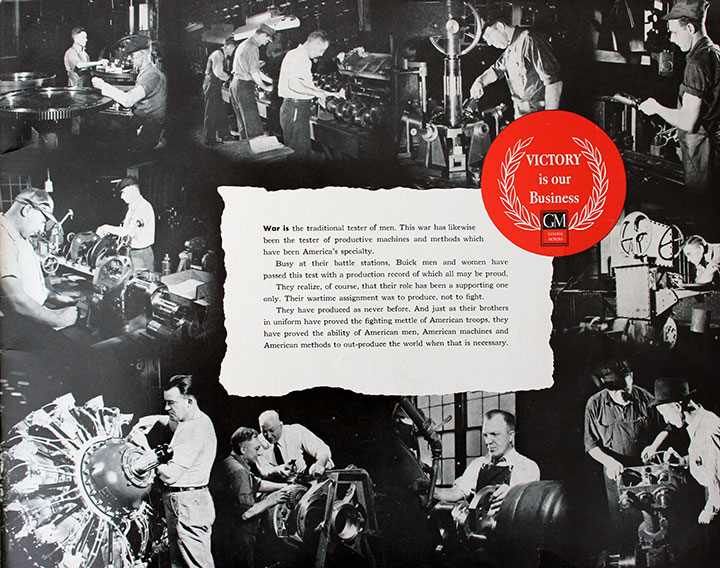

Inside of Back Cover.

Back Cover.

Find out more about Buick in WWII by visiting

my links page.

|