|

Briggs &

Stratton in World War Two

Milwaukee, WI

1910-2020

2020-Present owned by KPS Capital Partners

This page added 5-30-2021.

Anyone in the United States who has owned a

gasoline powered lawn mower has had it most likely powered by a Briggs & Stratton

engine. In 1953 the company introduced light-weight aluminum

engines that were found on many mowers of the era. The first

gasoline powered mowers I used for mowing lawns were Briggs & Stratton.

To me, Briggs & Stratton was synonymous with lawn mower engines. I did not realize there were other manufacturers of

the same type engines. For the early mowers, the pull rope was

separate from the engine. To start it, the rope had to be manually wrapped

around the engine pulley.

With this sort of background, I expected to

find examples of small gasoline engines used for various

applications. The one that is most prevalent in restored military

equipment are Briggs & Stratton generators to power multiple gun mounts.

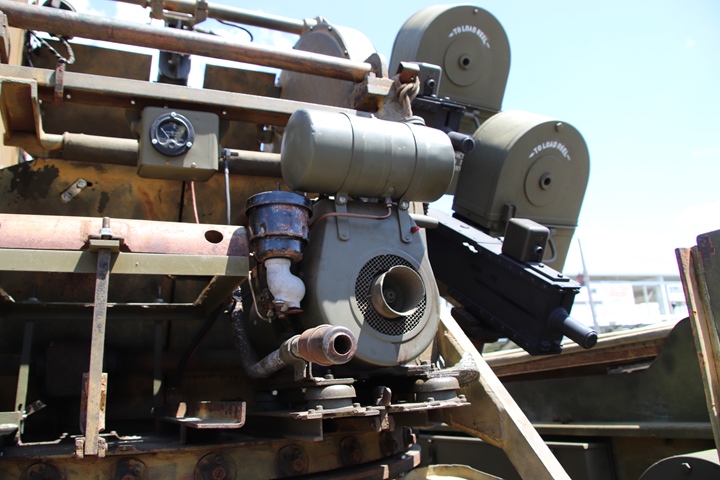

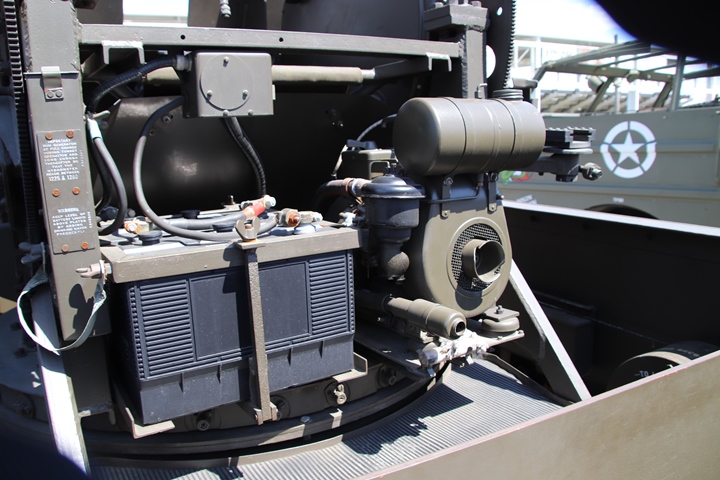

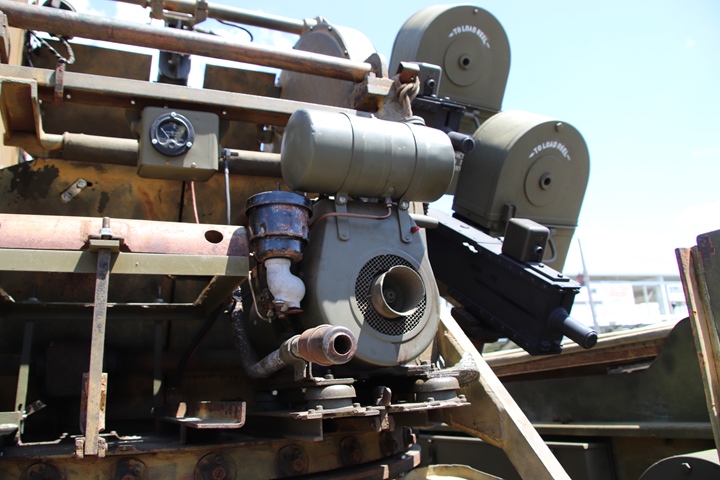

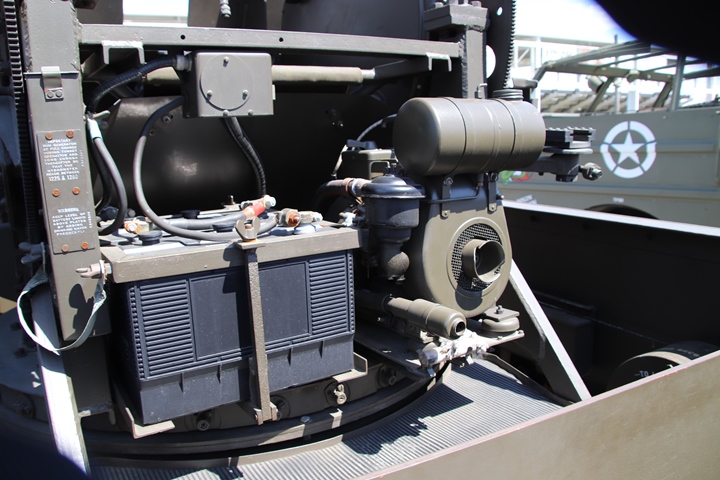

This is a Briggs & Stratton gasoline powered generator for an M45 Quad

Mount anti-aircraft gun. Author's photo.

Briggs & Stratton won the Army-Navy "E"

Award in August 1942.

Briggs & Stratton World War Two

Production: P.E. 75 120vac

at 22 amps 2400 watt engine model 223 generators, at least 2,160 Model

300 PC-1 12 VDC 300 watt generators, at least 13,070 Model 304 12 VDC 300 watt generators, 67,236 S18LG-P1 and S18RG-P1 General

Electric Aircraft Magnetos

M33 and M45 Gun Mounts

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946.

This table includes the type of Briggs & Stratton generator used in each type of gun mount. |

|

Mount Type |

Briggs & Stratton Generator |

1942 |

1943 |

1944 |

Total |

|

Multiple Caliber .50 Machine Gun Mount M33 |

Model 300 PC-1 12 VDC 300 Watt |

428 |

1,732 |

|

2,160 |

|

Multiple Caliber .50 Machine Gun Mount M45 |

Model 304 PC-1 12 VDC 300 Watt |

|

7,715 |

5,355 |

13,070 |

|

Total Combined M33 and M45 |

|

428 |

9,447 |

5,355 |

15,230 |

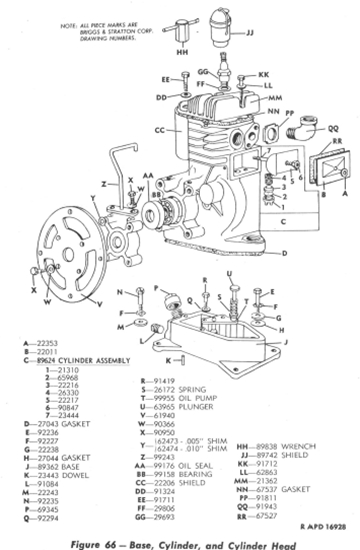

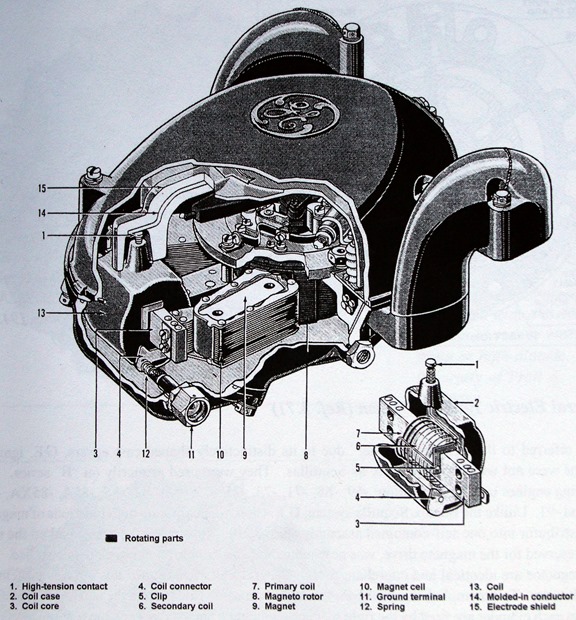

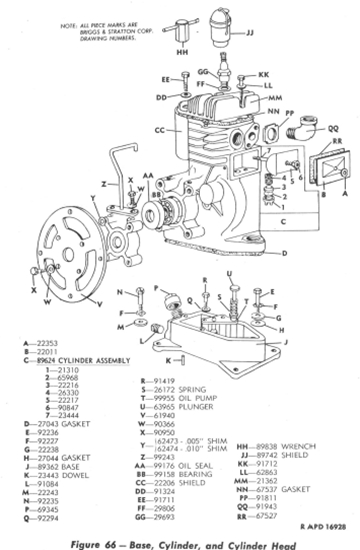

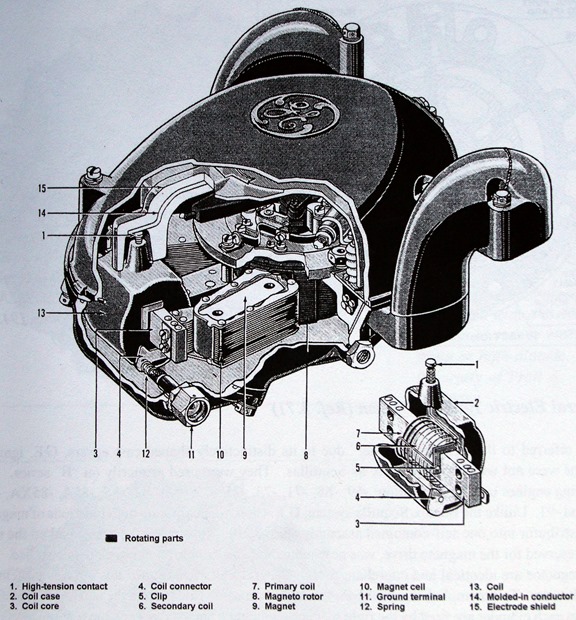

This is an exploded view of the Briggs &

Stratton one-cylinder gas engine used in the PC-1 series.

Image is from TM_9-1223.

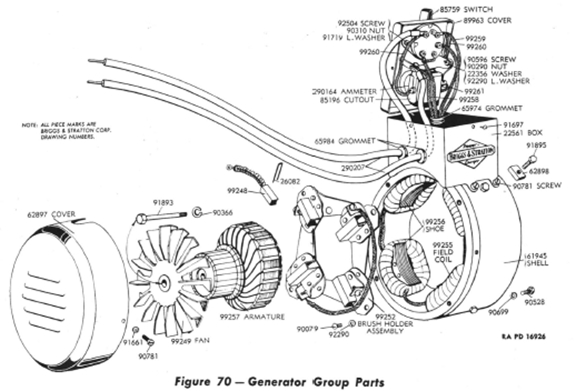

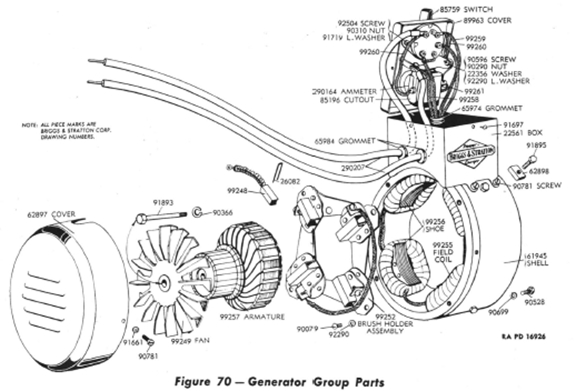

This is an exploded view of the Briggs & Stratton DC generator used

in the PC-1 series. Image is from TM_9-1223.

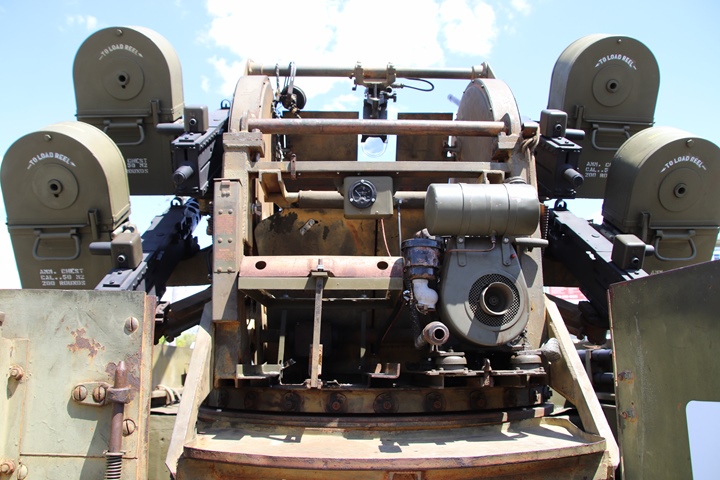

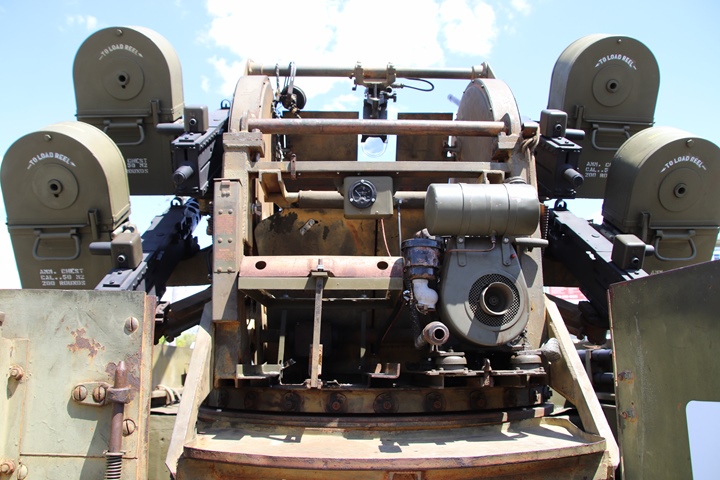

This M16 half-track was on display at the

2021 Findlay, OH Military Show. This particular M16, named "The

African Queen" by the owner, has been on display at the National Museum

of the United States Air Force since December 2020. For the

Findlay Military Show, the owner temporarily removed it from the museum

for it to be part of the Findlay event. This allowed me to obtain

photos of the gun mount and Briggs & Stratton engine not afforded me at

the National Museum of the USAF. Author's photo.

Author's photo.

Author's photo.

I was allowed to climb up into the rear of the vehicle that allowed a

photo of the top of the engine. Author's photo.

Author's photo.

The data plate for the Briggs & Stratton

engine on "The African Queen" shows that it is serial number 15519.

Author's photo.

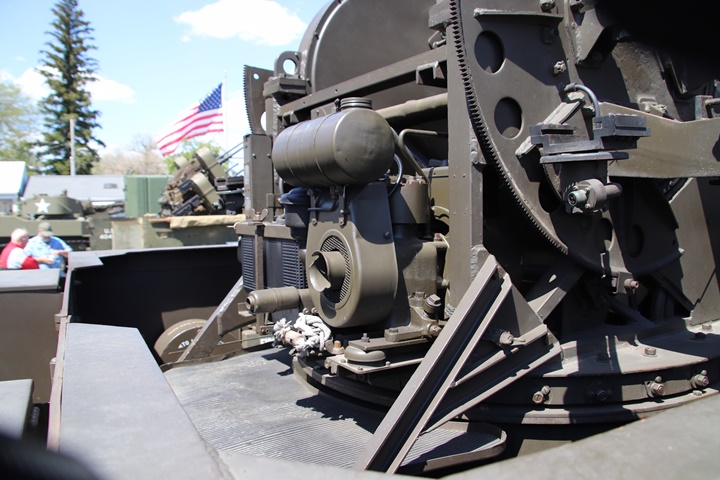

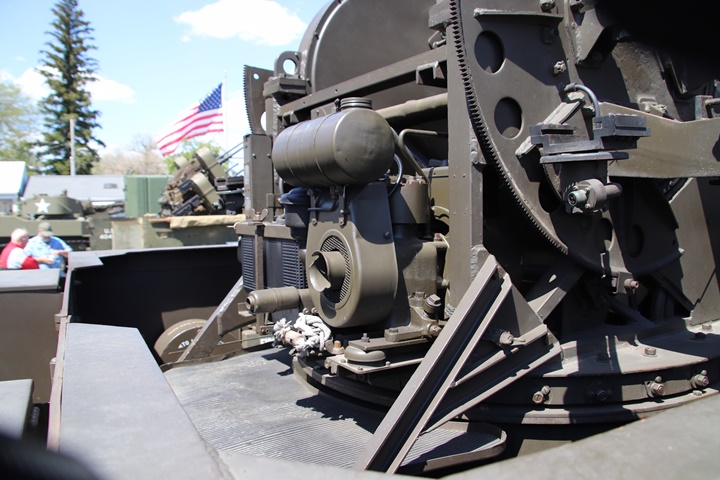

There was a second M16 at the 2021 Findlay

Military Show. Author's photo.

The M45 Quad Mount on this M16 is

operational and has a battery installed which used the Briggs & Stratton

engine and generator charged. The battery then operates the

traversing and elevation system on the gun mount. Author's photo.

The pull rope can is stowed just at the

bottom and rear of the engine. There is no data plate on this

unit. Author's photo.

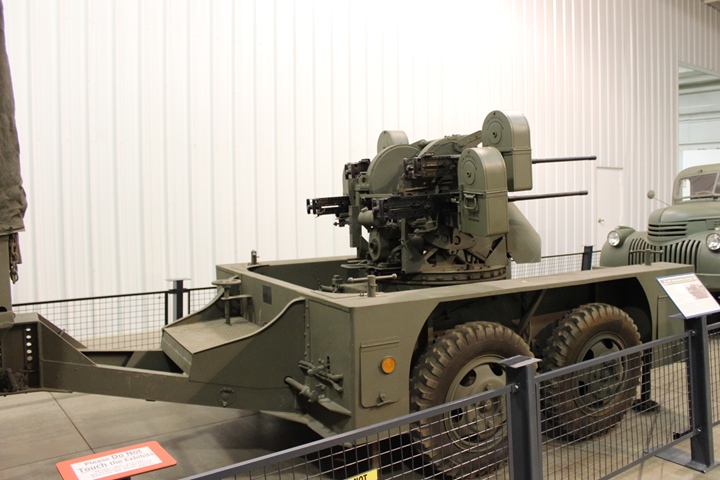

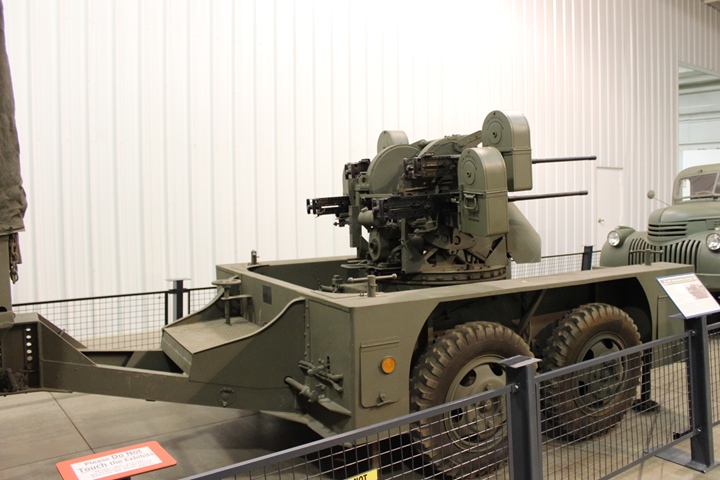

This Multiple Caliber .50 Machine

Gun Mount M45 is mounted on a small trailer and was used for fixed

anti-aircraft gun positions. The small wheels on the trailer

hindered the movement of the unit. The Briggs & Stratton engine

can be seen mounted in the rear of the gun mount.

The M17 trailer was another method of

transporting the M45 during World War Two. With the larger tires,

it had good mobility. The Briggs & Stratton engine is visible to

the rear of the gun mount. Author's photo.

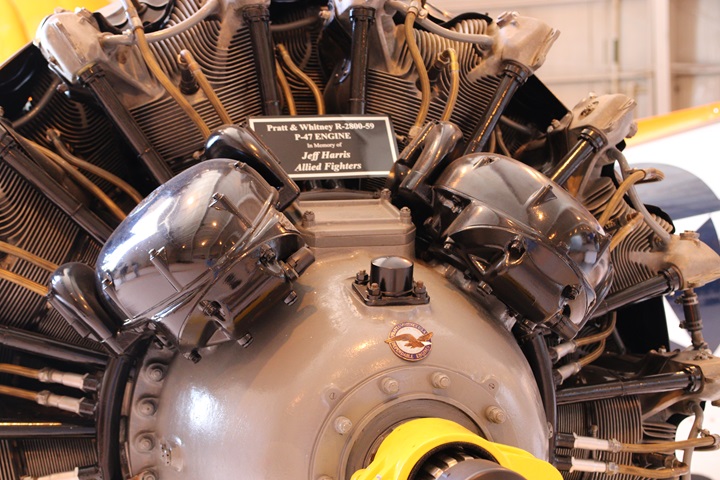

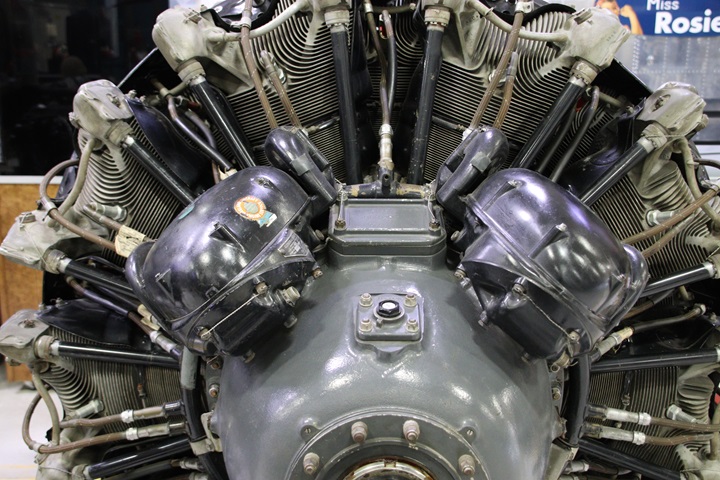

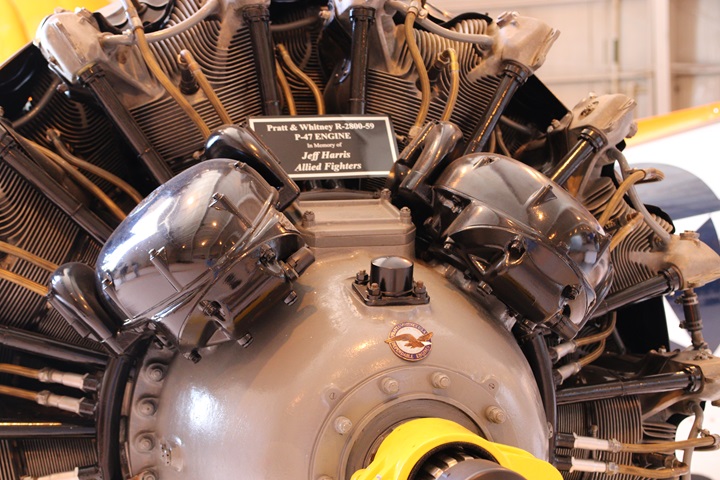

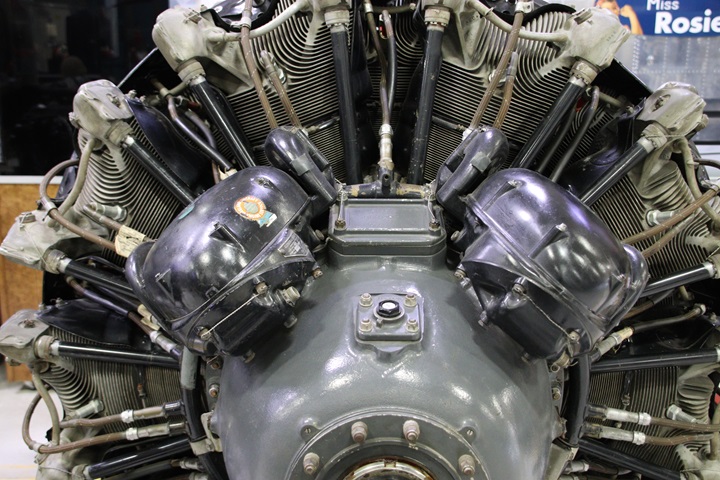

While small motor generator units like the

P-1 series used on M45 Quad Gun Mounts were adapted from Briggs &

Stratton's pre-war commercial product line, the manufacture of General

Electric aircraft magnetos were not. This R-2800-59 built by Pratt

& Whitney has two GE magnetos on it that were manufactured under license

by Briggs & Stratton. This engine and magnetos are on display at

the Evansville Wartime Museum in Evansville, IN. The P-47 in the

background was one of 6,225 that was built during World War Two just a

mile to the south of its current location. Author's photo.

The GE-designed magnetos are called

turtleback magnetos due their distinctive shape. Author's photo.

Author's photo.

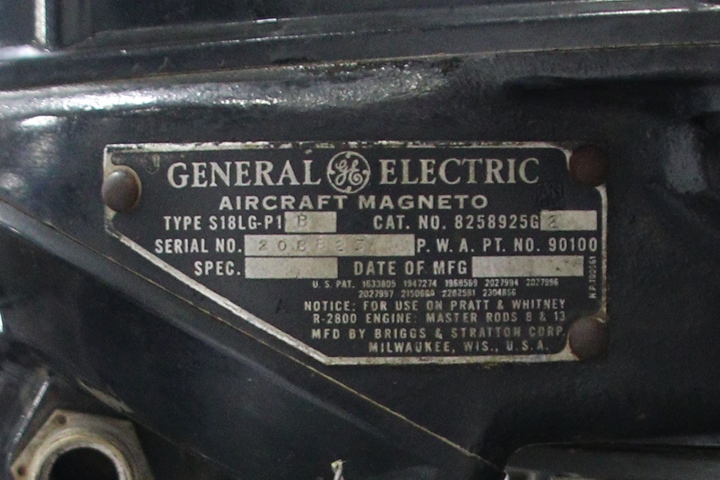

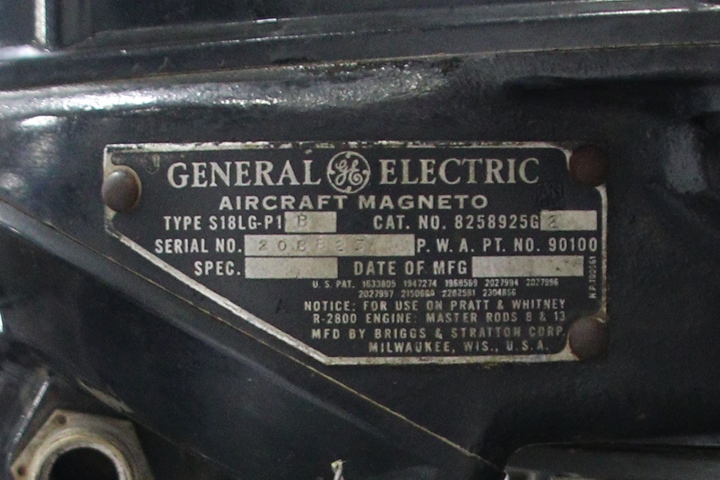

This is the General Electric magneto on the

right side of the engine. Author's photo.

I was completely surprised to find that a

company that is most well-known for its lawnmower engines had built

aircraft magnetos to help win World War Two. In 1947 General

Electric published a book that told of its efforts in assisting the war

effort. The book, entitled "Men and Volts at War" is very

comprehensive on all of the products that GE built during World War Two.

However, there is no mention of aircraft magnetos either being designed

or manufactured by the company. Obviously, GE designed aircraft

magnetos because the data plates on the magnetos note they are of

General Electric design. Apparently, with all of the other

products it needed to produce for the war effort, it did not have the

manufacturing capacity to build the magnetos, and the work was given to

Briggs & Stratton. With no evidence that GE built any magnetos,

this implies that Briggs & Stratton built all of them.

On this particular magneto, the serial number

and other information is not legible. Author's photo.

The left hand magneto is serial number 132724.

Both magnetos are Type s18LG-P1. Author's photo.

This is a cross sectional view of a GE

aircraft magneto.

|

Pratt & Whitney R-2800 Engines built with General

Electric-Designed S18LG-P1 and S18RG-P1 Aircraft Magnetos |

|

R-2800 Model |

Magneto Model |

Number of Engines Built |

Manufacturer |

Aircraft Type |

|

R-2800-59 |

S18LG-P1 |

592 |

Pratt

& Whitney East Hartford, CT |

P-47C, D, L |

|

R-2800-59 |

S18LG-P1 |

10,799 |

Ford

River Rouge, MI |

P-47C, D, L |

|

R-2800-65 |

S18LG-P1 |

1,292 |

Pratt

& Whitney East Hartford, CT |

P-61A,B |

|

R-2800-65 |

S18LG-P1 |

517 |

Nash-Kelvinator

Kenosha, WI |

P-61A,B |

|

R-2800-71 |

S18LG-P1 |

1,726 |

Ford

River Rouge, MI |

Douglas JD-1, A-26B, C |

|

R-2800-73 |

S18RG-P1 |

2,665 |

Chevrolet Tonawanda, NY |

P-61C, P-47N |

|

R-2800-75 |

S18LG-P1 |

8,042 |

Ford

River Rouge, MI |

C-46 |

|

R-2800-79 |

S18LG-P1 |

6,617 |

Ford

River Rouge, MI |

Douglas JD-1, A-26B |

|

R-2800-81 |

S18RG-P1 |

362 |

Pratt

& Whitney Kansas City |

P-47N |

|

R-2800-83 |

S18RG-P1 |

855 |

Chevrolet Tonawanda, NY |

Designed for the A-26D which was not produced. The

engine was later used in the

Vought AU-1 in Korea. |

|

R-2800-85 |

S18LG-P1 |

62 |

Chevrolet Tonawanda, NY |

Early C-82As |

| 95 |

S18RG-P1 |

9 |

Pratt

& Whitney East Hartford, CT |

C-118/DC-6 -President Truman's Independence |

| 103 |

S18RG-P1 |

80 |

Pratt

& Whitney East Hartford, CT |

C-131B |

|

Total Engines |

|

33,618 |

|

|

Every engine had two magnetos implying that

Briggs & Stratton built 67,236 magnetos for OEM engines plus spares and

spare parts.

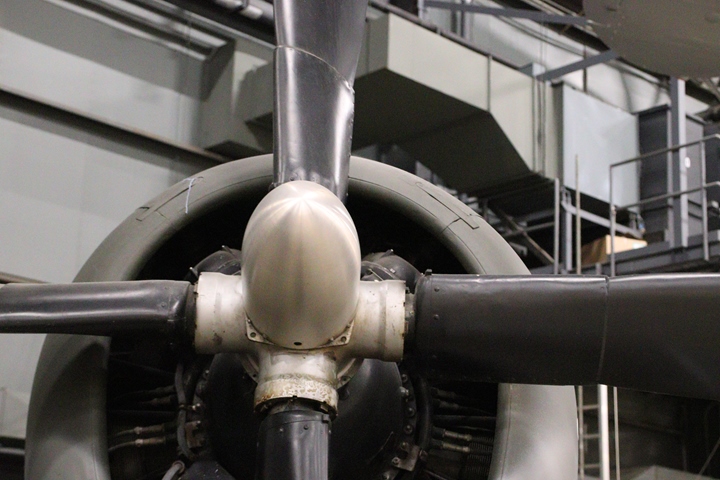

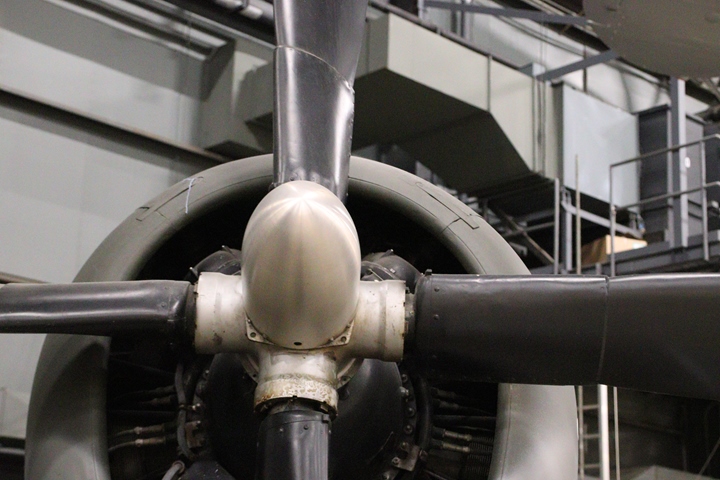

This Ford-built R-2800 is on display at the

Yankee Air Museum. The R-2800-7x is either an R-2800-71, 75, or 79

engine, as it is not possible to identify the last digit on the data

plate. It is one of these three types as it has the GE magnetos on it. Author's photo.

Author's photo.

Author's photo.

The right magneto is type S18LG-P1 and

serial number 212618. Author's photo.

The left magneto on the engine is serial number 208823 Author's photo.

This Chevrolet-built Pratt and Whitney

R-2800 engine is on display at the National Museum of WWII Aviation in

Colorado Springs, CO. It is equipped with Briggs & Stratton

magnetos. Author's photo.

The engine is part of a larger display

showing how the Republic P-47 super turbocharger system worked. Author's photo.

This P-47N is located at the Peterson Air and

Space Museum at Peterson AFB in Colorado Springs, CO. It has a

Chevrolet Tonawanda, NY-built R-2800-73 engine in it. Author's photo.

The left Briggs & Stratton-built magneto is

visible at the top of the engine. Author's photo.

This P-47D Razorback is on display at the

National Museum of the United States Air Force. It has either a

Pratt & Whitney or Ford-built R-2800-59 engine installed in it.

Most likely it is a Ford-built R-2800-59, as there were 20 times more of

them built than the Pratt & Whitney version. Author's photo.

The distinctive turtle back magnetos built

by Briggs & Stratton are visible at the top of the engine.

Author's photo.

This P-61B is undergoing restoration at the

Mid-Atlantic Air Museum in Reading, PA. Author's photo.

The R-2800-65 with the P-61 was built by

either Nash-Kelvinator or Pratt & Whitney. In either case, the

engine has Briggs & Stratton-built magnetos on it. Author's photo.

This P-61C is on display at the National

Museum of the United States Air Force. The P-61C featured the higher performance

R-2800-73 that Chevrolet was assigned to build and equipped with Briggs

& Stratton-built GE magnetos. Author's photo.

Ford built 6,617 R-2800-79 engines with the

Briggs & Stratton-built GE magnetos for the A-26B. Author's photo.

The Curtiss C-46 Commando was the largest

twin engine transport used by the US in World War Two. 8,042

R-2800-75 engines with Briggs & Stratton-built GE-designed magnetos were

built by the Ford Motor Company for the C-46.

Author's Photo.

|