|

Torqmatic 900-T Hellcat Transmission Abstract: Even though Detroit Transmission developed what became one of GM's most recognizable products in the Hydra-Matic and later Turbo Hydra-Matic transmission, its name has been lost to history. In 1962 the name of the Division changed to Hydra-Matic, which is the name most persons familiar with the auto industry recognize. In 1990 Hydra-Matic was absorbed into GM Powertrain and was no longer an independent Division of GM. During WWII Detroit Transmission developed Hydra-Matic and Torqmatic transmissions that introduced the automatic transmission to American tanks. Tank automatic transmissions designed by GM Research and Detroit Transmission Division late in WWII have been standard equipment on American tanks ever since the end of the war. The complete story is below, including Detroit Transmission's 1944 wartime era booklet entitled "Teamwork in Peace and War".

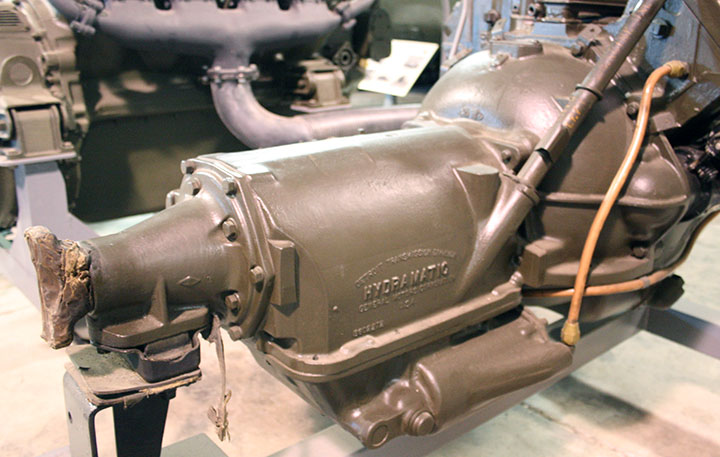

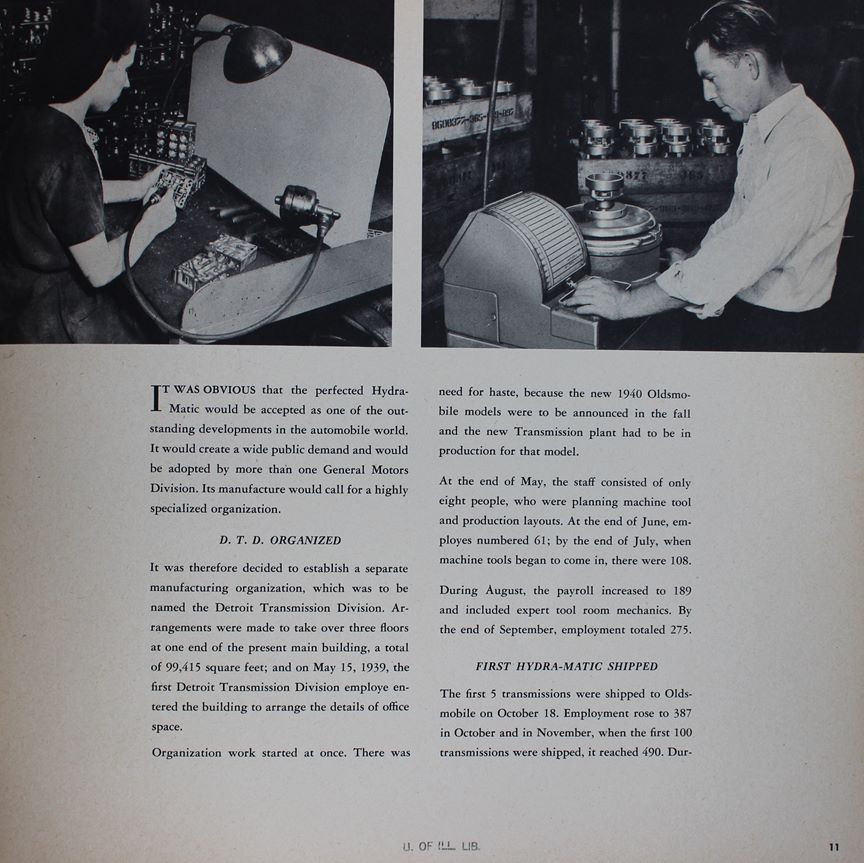

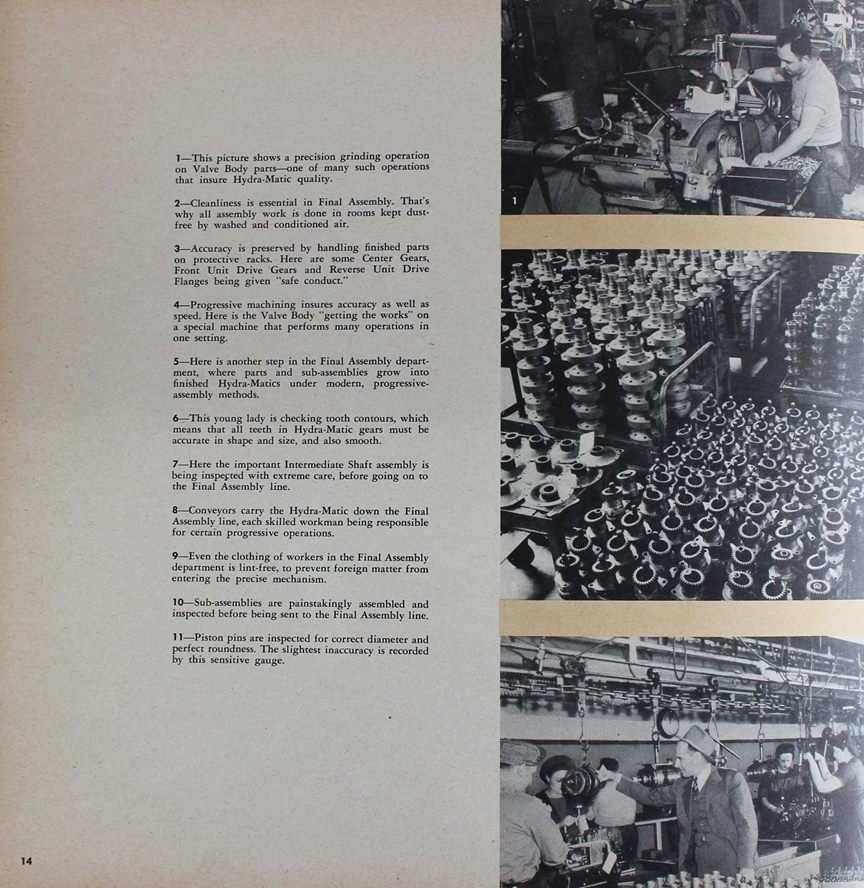

How the Hydra-Matic came to be named When Detroit Transmission was created, the Hydra-Matic transmission had not yet been developed, nor had it been named. When the development of the transmission utilized the hydraulic fluid that was in the hydraulic coupling to also flow through the body and valves of the transmission itself. It was named Hydra-Matic. This name stood for the hydraulic fluid that flowed through it, and for the fact that it now automatically shifted through the gears without any assistance from the driver. A General History of Detroit Transmission Division Detroit Transmission Division of General Motors began production in 1939 for the new self-shifting transmission, now known as Hydra-Matic, for introduction in the 1940 Oldsmobile. The following year, Cadillac introduced it on its vehicles. When automobile production stopped in February of 1942 for the duration of World War Two, 200,000 transmissions had been shipped to Olds and Cadillac. During the war, Hydra-Matics were used in various tanks and armored vehicles. It continued to increase sales after the war, as drivers switched from manual shifting to the ease of automatic shifting. On September 22nd, 1947, Detroit Transmission shipped its 500,000th Hydra-Matic.

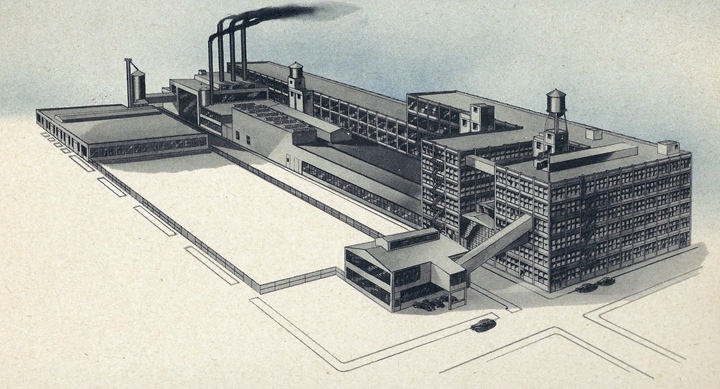

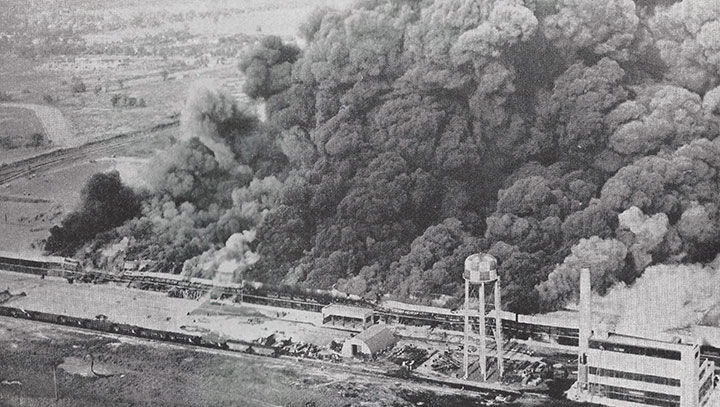

After World War Two, the Division moved from its original location on Riopelle Street in Detroit to a 34.5 acre plant in Livonia, MI. The Livonia plant was the scene of the August 12th, 1953 fire that destroyed the plant and shut down production of Hydra-Matics for twelve weeks. Not only were Cadillac and Oldsmobile Divisions affected but Pontiac, Nash, Hudson, Kaiser, and Lincoln were also offering the Hydra-Matic as an option on their vehicles. During this period, new equipment was made by all GM divisions, which had all tool rooms working seven days a week, twelve hours a day. Simultaneously, Detroit Transmission moved into the former Ford Willow Run bomber plant and made Hydra-Matics there until it was vacated by GM in 2010 during the Great US Automobile Industry Meltdown. When I worked Plant Protection for Lansing Fisher Body while working my way through college in the late sixties, the Detroit Transmission Division fire was still discussed. This event dictated much of what we did at Fisher Body. As a result of the fire, which was started by sparks from a welder igniting nearby flammable liquids, GM implemented standard policy which still requires on-location approval by a Plant Protection fire inspector before any welding or cutting is done. Fire prevention within GM was driven by the Livonia fire. When I arrived at Delco-Remy in 1973 and became a supervisor in one of many tool rooms, I heard stories from the "old timers" about working 7 days a week, 12 hours a day remaking the tooling to restart Hydra-Matic production. All GM tool rooms engaged in this massive tooling endeavor.

In 1962 Detroit Transmission Division became the Hydra-Matic Division of GM.

In 1990 Hydra-Matic Division of GM, as it was then known, was merged into GM Powertrain and lost its individuality and identity. World War Two:

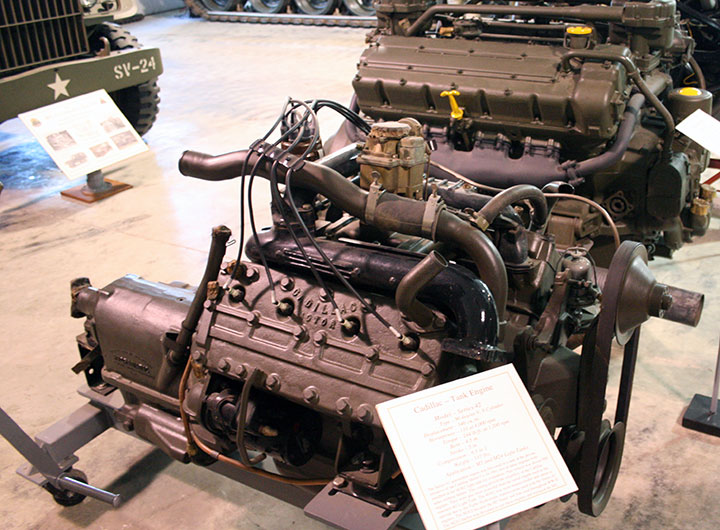

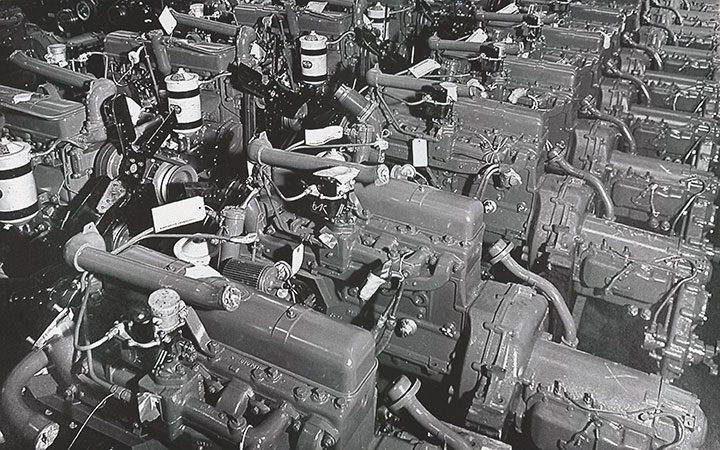

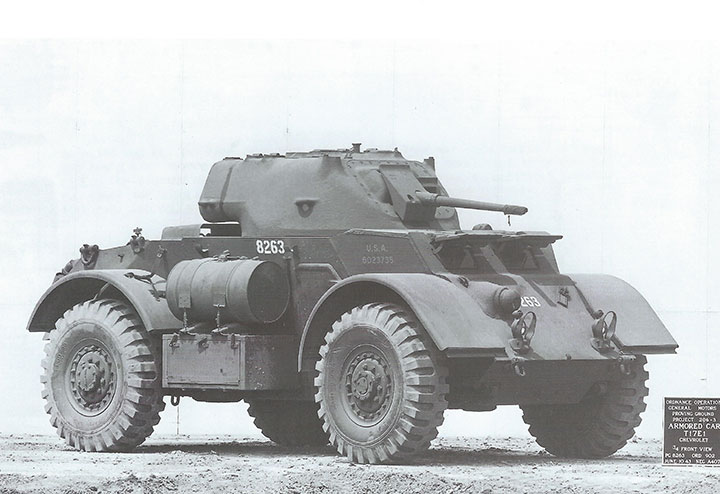

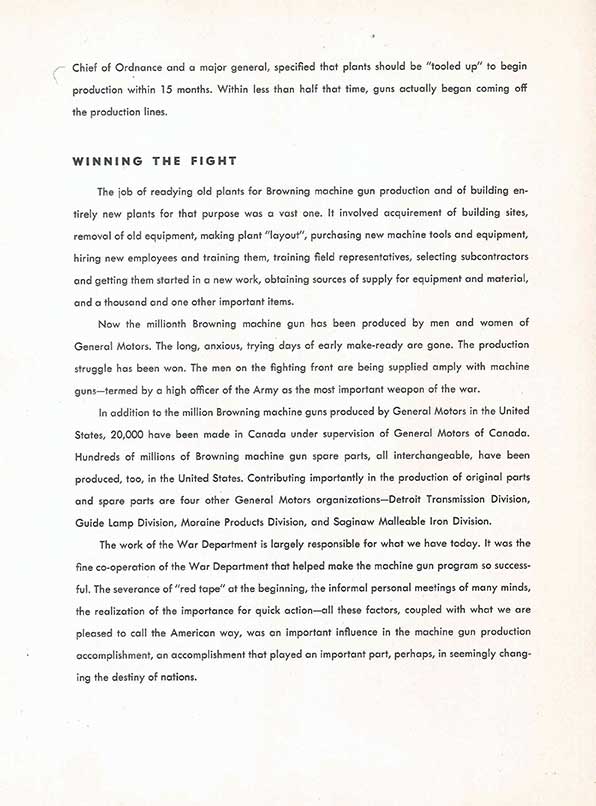

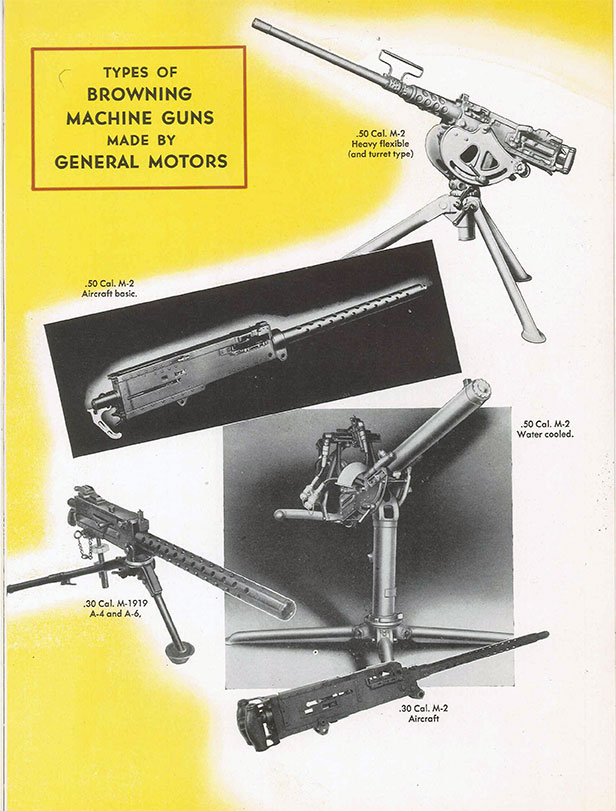

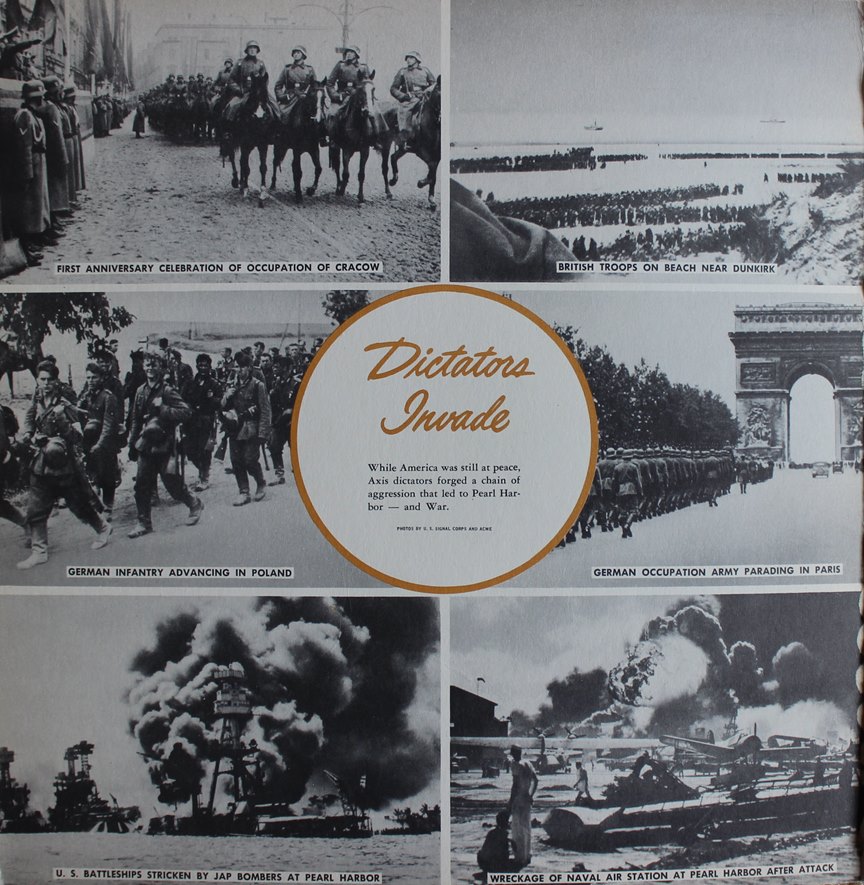

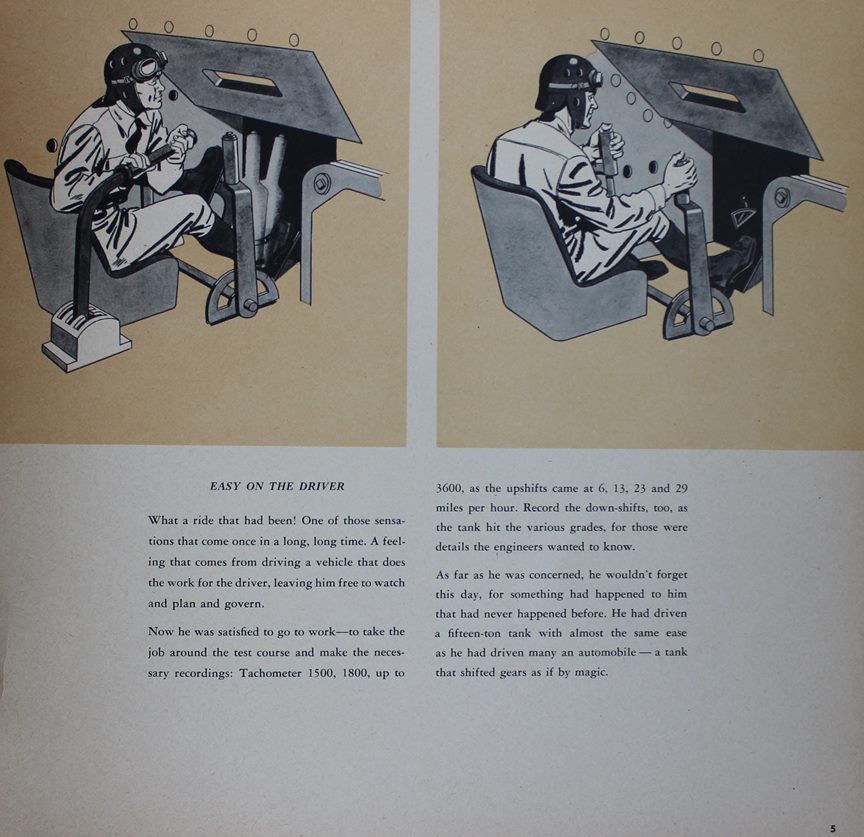

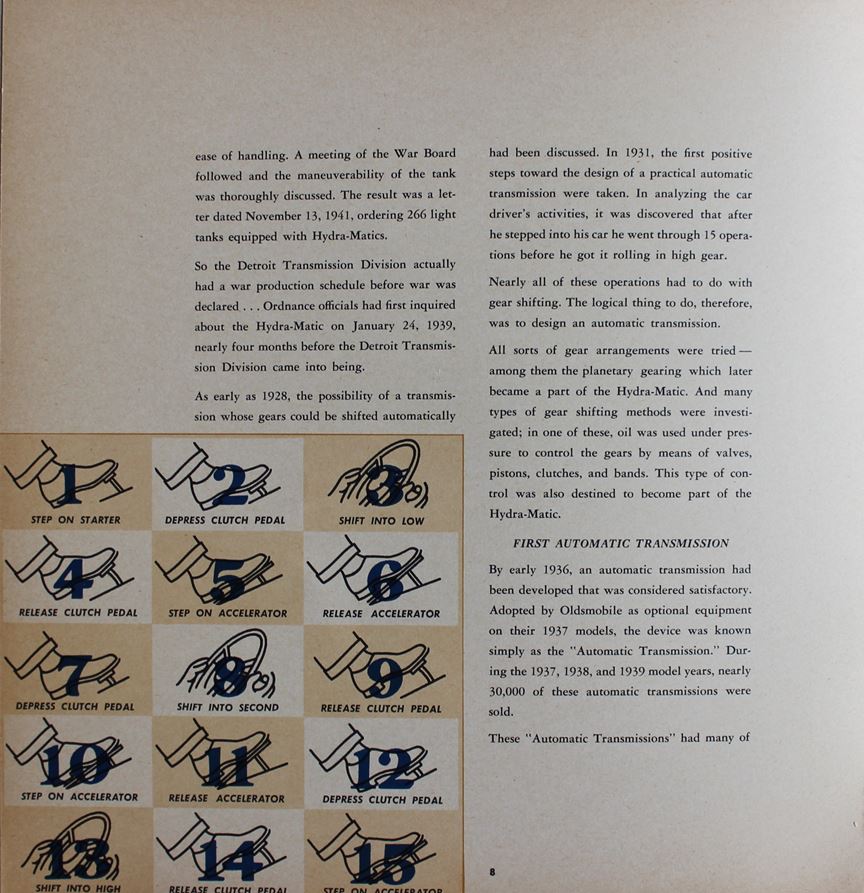

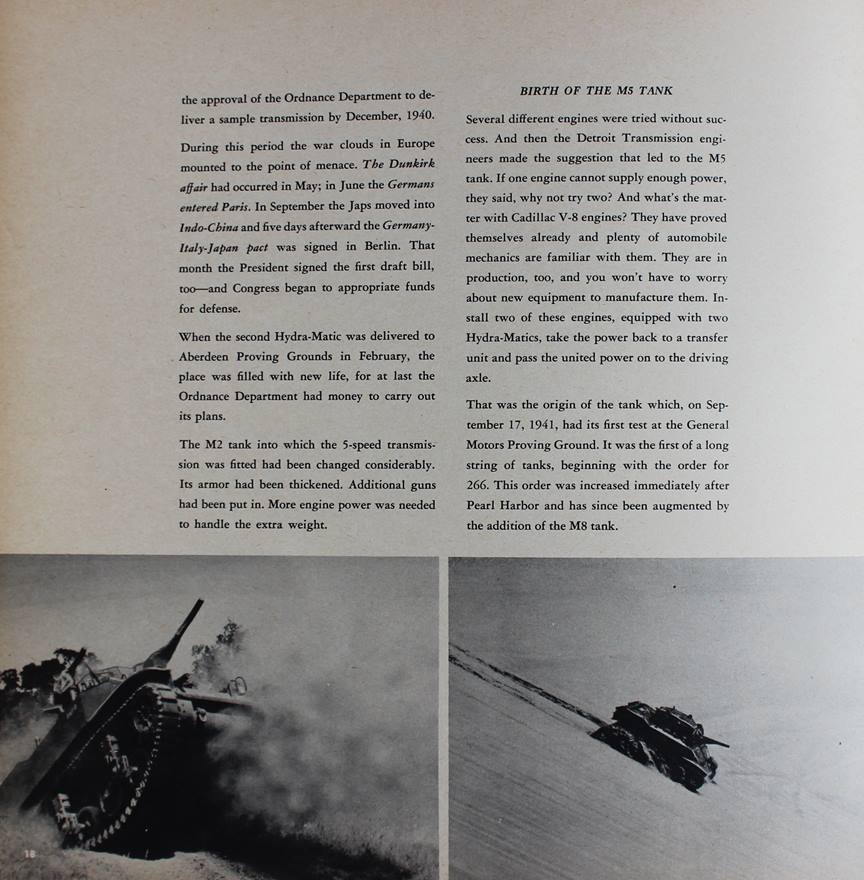

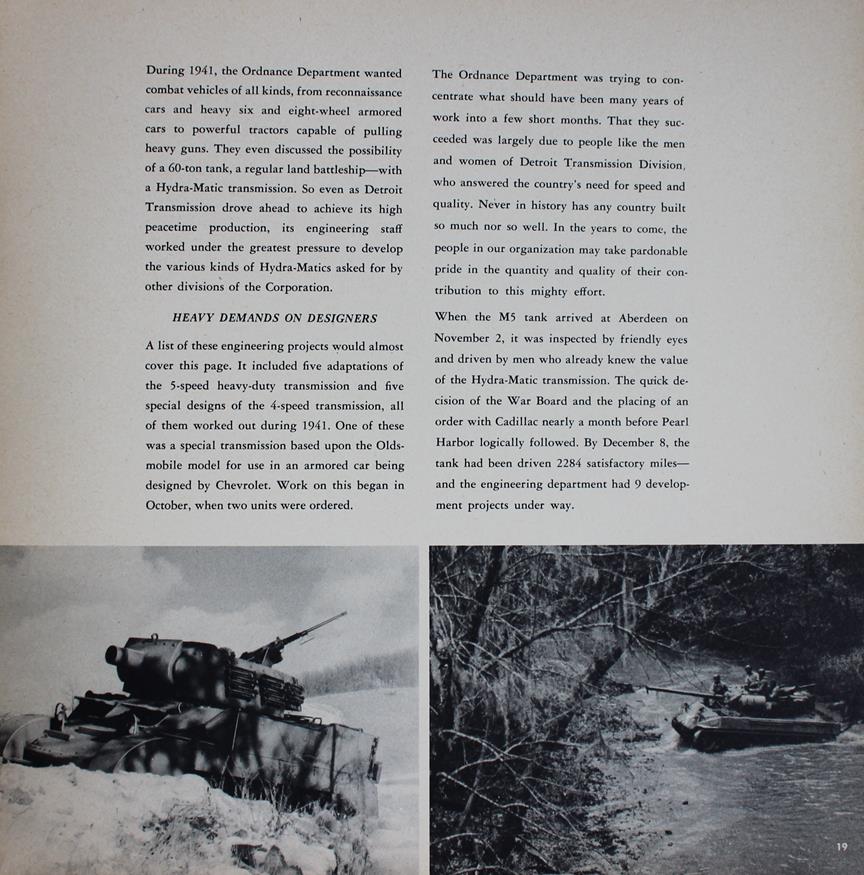

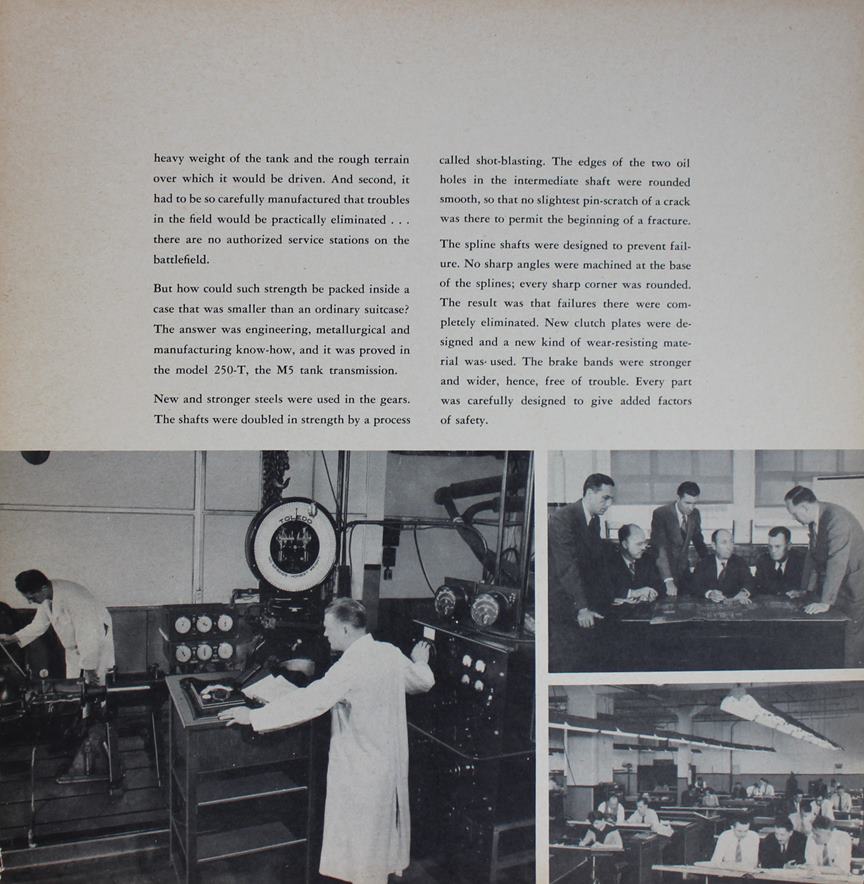

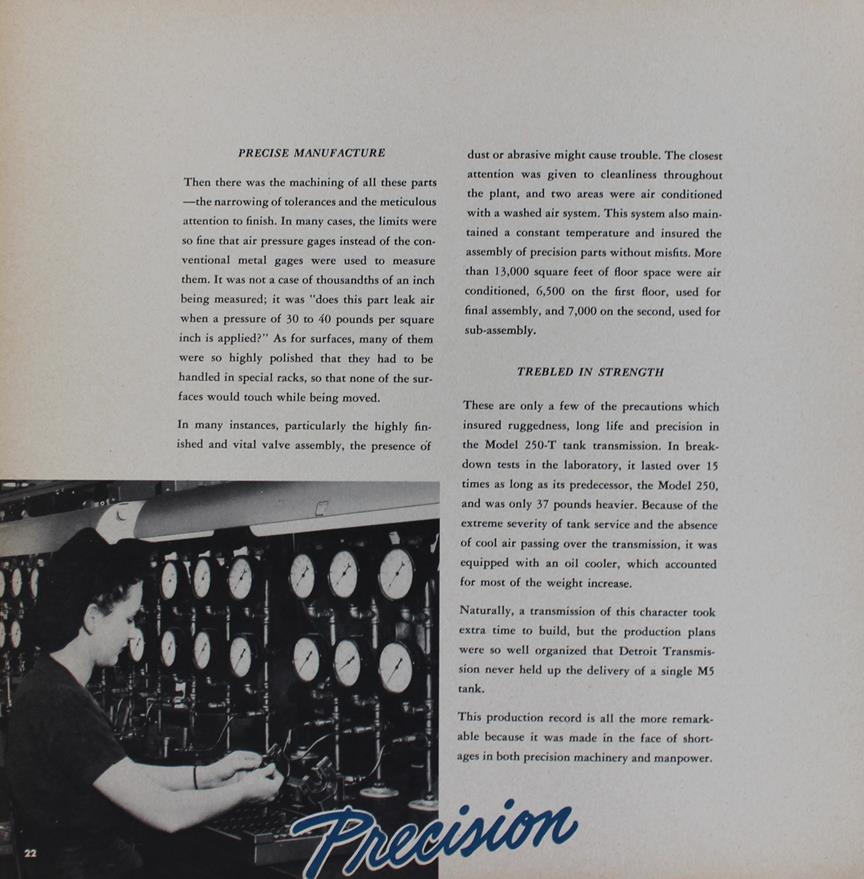

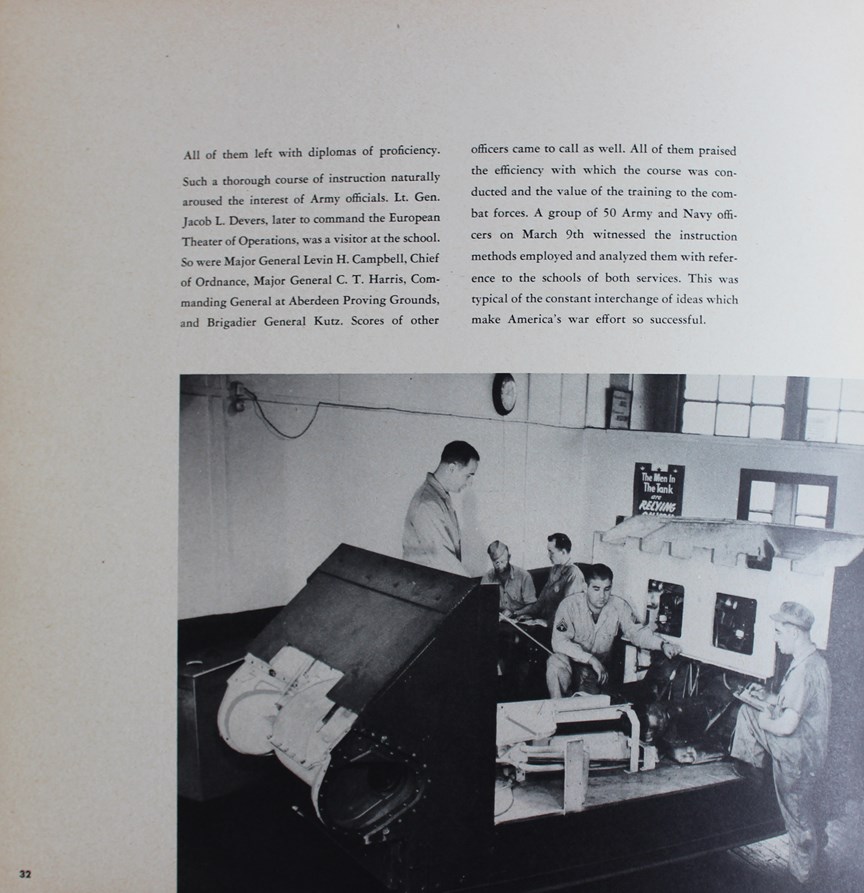

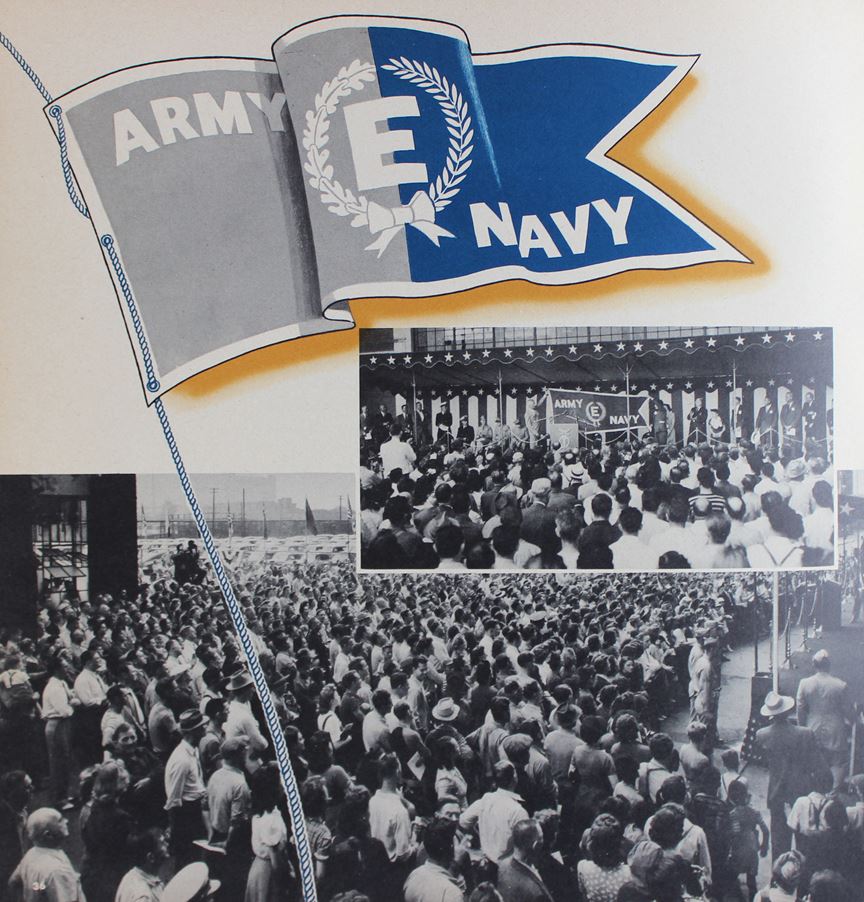

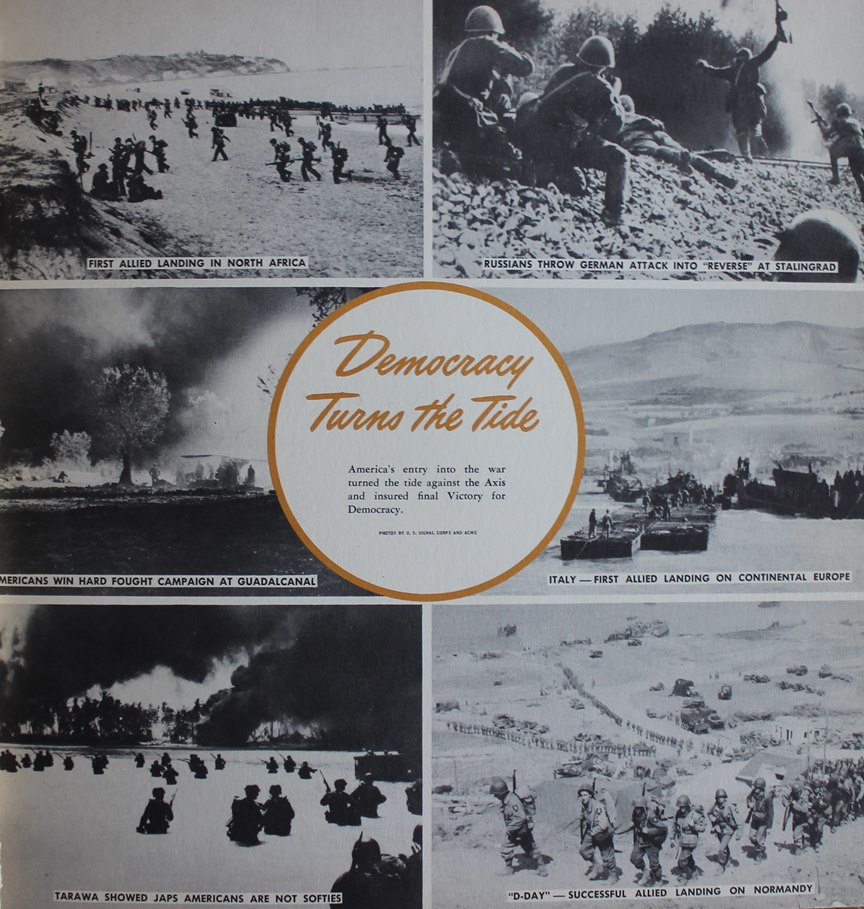

Detroit Transmission Division World War Two Production Statistics: Detroit Transmission Division of GM produced 54,991 Hydra-Matic and Torqmatic transmissions for tanks, tank destroyers, and armored cars. The Division also produced Browning machine guns parts for the 1,218,837 weapons that four other GM divisions built during the war. The Hydra-Matic Transmission in World War Two: The Detroit Transmission Hydra-Matic was the most utilized automatic transmission in armored vehicles during World War Two. Along with the Detroit Transmission Torqmatic also used in armored vehicles, they were the only two of their type used. The Hydra-Matic was also the first of its type to be used by the military in tanks and armored cars. Initial use of a Detroit Transmission Division was on May 29, 1939, when a Detroit Diesel Division powered M2 tank had a heavy duty four speed transmission installed in it. This was the first time an automatic transmission was installed in a tank. The advantages were immediately clear to the military ordnance officers: elimination of engine stalling as the fluid coupler did not mechanically lock up the engine to the transmission, use of full power under all conditions, elimination of the heavy shift lever, and best of all, the elimination of the clutch and the double clutching required every time the driver had to change gears. By eliminating the clutch and manual shifting of gears, the driver was able to concentrate on looking where the tank was going and not being distracted with manipulating the gears and clutch. Manual transmissions in tanks also had the severe disadvantage of slowing down on the battlefield when changing gears, making them easier targets to be hit by enemy fire. The new automatic transmission eliminated this tactical disadvantage. In February 1941, a newer, heavier duty five speed transmission was installed in the M2 tank, which was now heavier with added armor and weapons. The one engine was having problems moving the tank. According to page 18 in "Teamwork in Peace and War", it was Detroit Transmission engineers that suggested the use of two Cadillac V-8 engines matched with two Hydra-Matic transmissions that resulted in the M5 Stuart tank. If one refers to "Cadillac...From Peace to War" on the Cadillac page of this website, that Division notes that it broached the subject of a new light tank with two of its engines and Hydra-Matic transmissions to Army Ordnance. Which version is correct? Most likely both, as no doubt both Divisions were working with the Ordnance Department on projects to improve the tank by the use of their products. The first run of the new M5 Stuart tank with the new Hydra-Matic 250-T transmission took place on September 17, 1941, at the General Motors Proving Grounds in Milford, MI. Next the new tank went on a 560 cross country trip on public roads from Detroit to the Aberdeen Proving Grounds in Maryland. Drivers on the trip were able to easily negotiate the hills of Pittsburgh in with no driver fatigue. The dawn of a new era of tank transmissions had arrived. After more successful testing at the Aberdeen Proving Grounds the Army ordered the first 266 M5 Stuarts, the first of 1,824 M5s, and a total of 24,941 light tanks, armored cars and landing vehicle tanks equipped with the Hydra-Matic transmission during WWII. An aside: One can only wonder what civilians thought of the M5 as it drove through cities and towns across the eastern US in late 1941. The author remembers a similar type of incident in the Castleton area of Indianapolis after 9-11-2001. Allison Transmission was doing engineering development on a GM of Canada LAV and took it out on the local streets for a test run. Paranoid civilians thought the country was under attack because one armored vehicle was driving around, so they called the police. Needless to say, Allison did not do any more road tests in the area. Were the civilians in 1941 as paranoid as those in 2002? For the complete inside story of the development of the Hydra-Matic, not only military use in World War Two, and the early work for Oldsmobile and Cadillac, please read pages 1 through 25 of "Teamwork in Peace and War" at the bottom of this page.

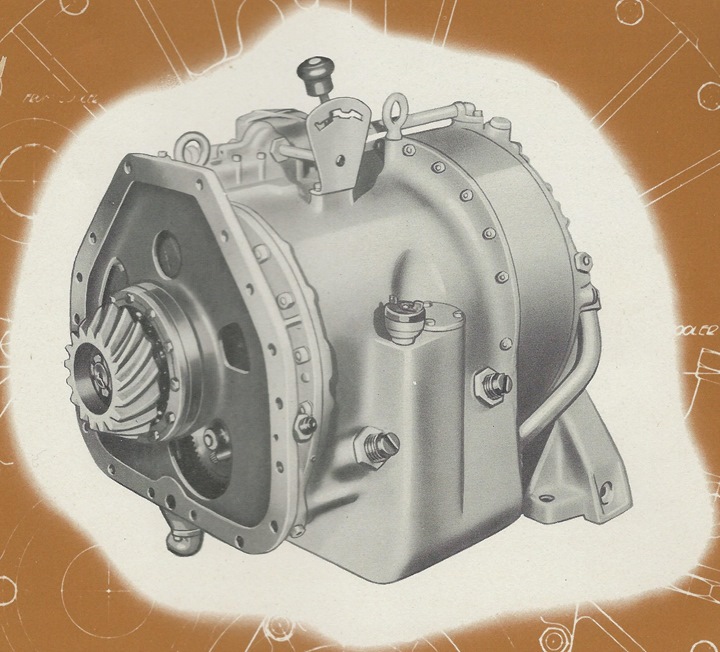

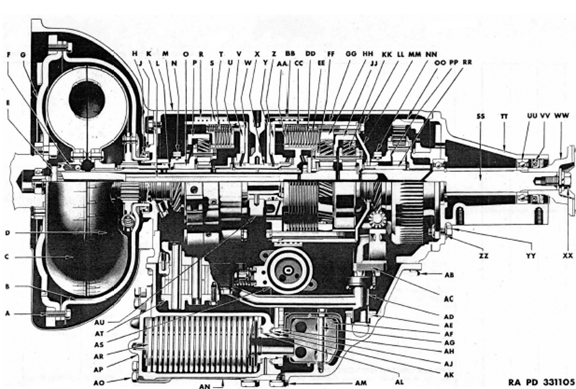

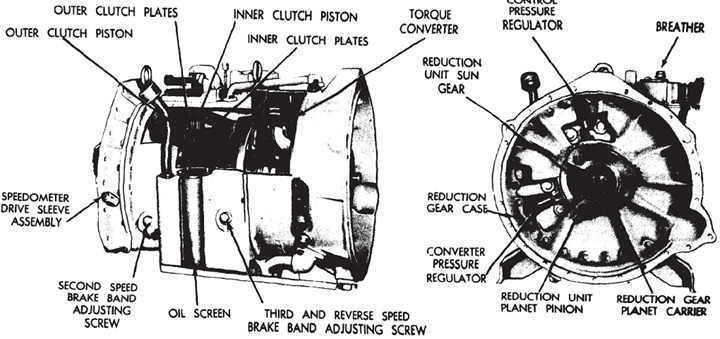

The Torqmatic Transmission in World War

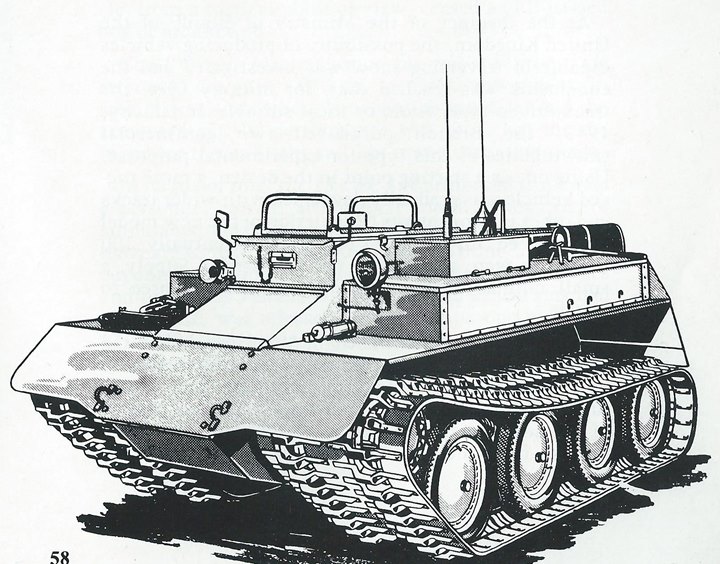

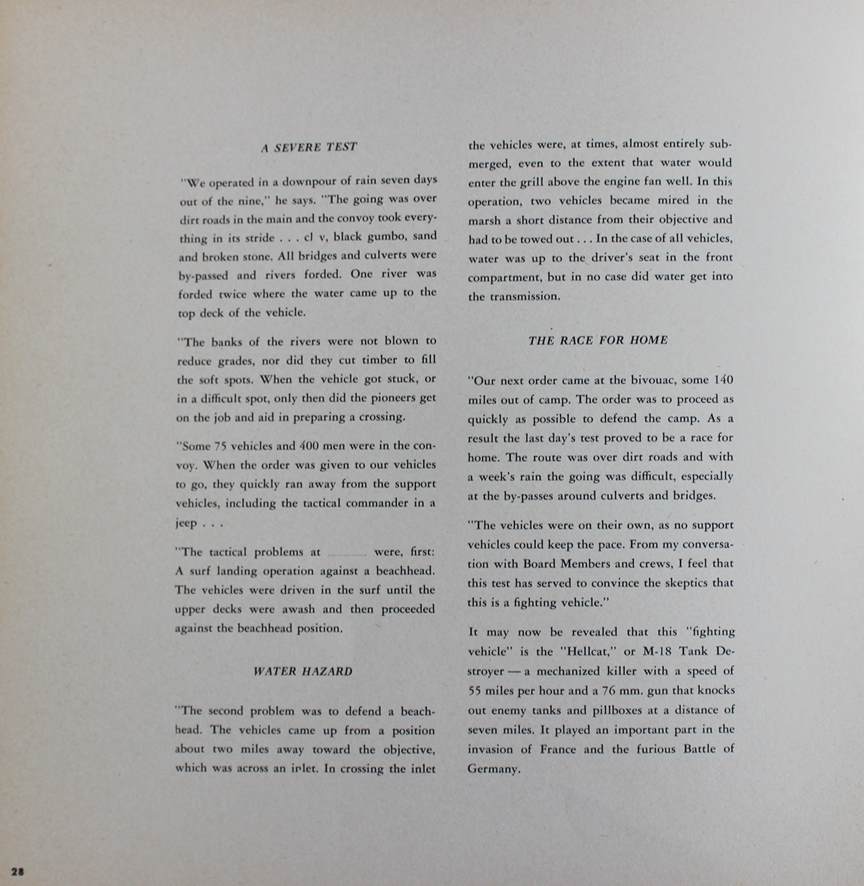

Two: The Torqmatic transmission was similar to the Hydra-Matic with the exception that it used a "Hydraulic Torque Converter" instead of the fluid coupling used in the Hydra-Matic. While similar in function, the torque converter has a stator that decreases slippage at low rpms, just what was needed to get tanks moving from a stop in a hurry. This was the first application of a torque converter in an automatic transmission. After World War Two, Detroit Transmission would incorporate the more costly and complex technology into its Hydra-Matics, and the term Torqmatic would disappear from use. But the torque converter has been a staple of automatic transmissions for 50 years. Detroit Transmission opened a second plant across the street from its original facility for the manufacture of the Torqmatic transmission, which was used in 2,507 Buick built M18 Hellcat tank destroyers. This transmssion had three forward gears and one for reverse. It was mated to a Continental R-976-C2 nine cylinder radial aircraft engine that produced 400 hp at 2,400 rpms. This was four times the horsepower that the Hydra-Matic 250-T saw in the Cadillac V-8 engine. Not only was this the first use of the Detroit Transmission Torqmatic transmission, but it was also the first use of a torque converter and the matching of an automatic transmission to an aircraft radial engine. The second and final Torqmatic transmission went into the T26E3/M26 Pershing built at the end of the war. The Perishing was powered by 500hp Ford V-8 engine, which was 20% more horsepower than the radial engine in the 18-ton M18 Hellcat. The M26 Pershing weighed in at 46 tons. Therefore, the Torqmatic for this tank had to be considerably larger and more capable than the one for the Hellcat. The Torqmatic with very little slippage at low rpms was key to getting and keeping the heavy tank moving with what was found to be an underpowered engine for its weight.

The Legacy of the Detroit Transmission Hydra-Matic and Torqmatic Tank Transmissions: During the latter part of World War Two, Army Ordnance, GM Research, and Detroit Transmission developed the Cross Drive Transmission which was completed in 1945. This all began in earnest in February 1943 when a representative of Detroit Transmission presented Army officers at the Tank Automotive Center in Detroit a set of engineering drawings of a new transmission and torque converter that included electric brakes and steering in one combined unit. After testing at the GM Proving Ground and changes that substituted oil cooled friction clutches, an experimental unit was installed on a Sherman tank. However, by that time in 1945, the war was coming to an end and the project ceased. However, a version designated the CD-850 was built by Allison in Indianapolis, IN after the war for use in the M46, M47, M48, and M60 tanks. Allison then developed the next generation tank transmission that is currently used in the M1 Abrams main battle tank. In 1946 General Motors made an internal technology transfer. Allison Division of General Motors, which had exclusively produced inline aircraft engines, such as the V-1710 used in the P-38 Lightning, was tasked by the Corporation with making heavy duty transmissions for not only tanks, but commercial vehicles such as trucks and buses. Detroit Transmission was then allowed to focus on the larger market of automotive passenger car applications using the trade name Hydra-Matic. Today Allison no longer produces aircraft engines as that product line was sold to Rolls-Royce. Allison Transmission is also no longer part of General Motors, but is the largest producer of heavy duty transmissions in the world. Since Allison Transmissions took over the heavy duty transmission business in 1946, its transmission for trucks and buses carries the trade name Torqmatic. Unfortunately, Allison Transmission does not acknowledge the pioneering engineering work done by Detroit Transmission and others prior to the 1946 technology transfer. In the history portion of its website, it shows that in 1946 it developed the CD-850 tank transmission. Technology this complicated did not just appear out of thin air as is implied on the website. It is unfortunate that Allison does not acknowledge where the technology came from with its roots in the Detroit Transmission Division and World War Two tanks. The Legacy of the Assistant Driver in American tanks: All tanks during World War Two had an assistant driver, who had the important task of watching where the tank or tank destroyer was going while the driver was distracted while shifting gears and double clutching. This was the case for the M3, M4, M10, and M36, but not for the tanks and tank destroyers with either Hydra-Matic or Torqmatic automatic transmission supplied by Detroit Transmission. In these vehicles. the assistant driver no longer needed to watch the road because with the gears shifting automatically and no clutching, the driver could now focus on the road ahead. However, Army Ordnance tank designers did not realize this until after World War Two, when the M41 Walker Bulldog and the M48 Patton tanks and finally eliminated the assistant driver.

Teamwork in Peace and War This gives an excellent insight into how the Hydra-Matic and Torqmatic transmissions were introduced into World War Two combat vehicles.

Link to: Torqmatic 900-T Hellcat Transmission

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||