|

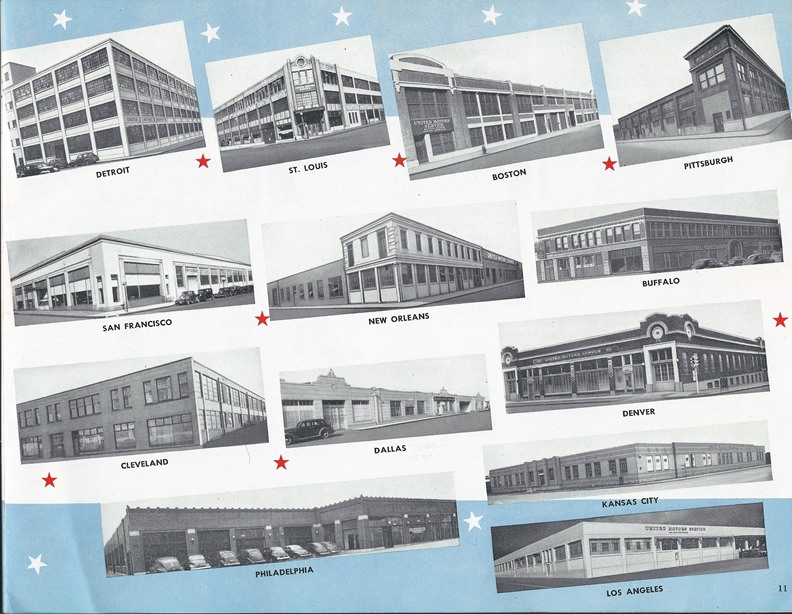

United

Motors Service Division of General Motors Corporation in World War Two

Detroit, MI

1918-1960

1960-1974 as United Delco

1974 to present as AC-Delco

The Lima Tank Depot in

World War Two

1942 to Current - Now as the

Lima Army Tank Plant

This page updated 2-10-2017.

The Lima Tank Depot was one of four tank

depots in the US during the Second World War. The other three were

in Richmond, CA, Chester, PA and Toledo, OH, which the Lima Depot

replaced. The Toledo Tank Depot was opened in January 1942 in

leased space at the New York Central Railroad yard. The Ordnance

Department placed Auto-Lite

Company in charge of the management of its operation. The Ford Motor Company was contracted to convert its

Chester, PA and Richmond, CA assembly plants into tank depots.

This strategy then allowed for a depot on each coast to facilitate shipments overseas.

The Ordnance also opened a depot in Montréal, Quebec, for equipment going to the

United Kingdom.

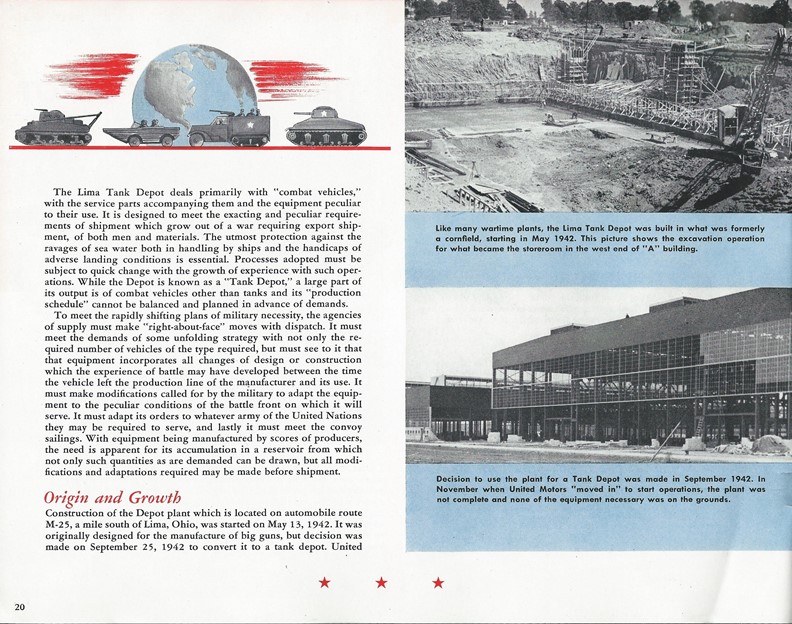

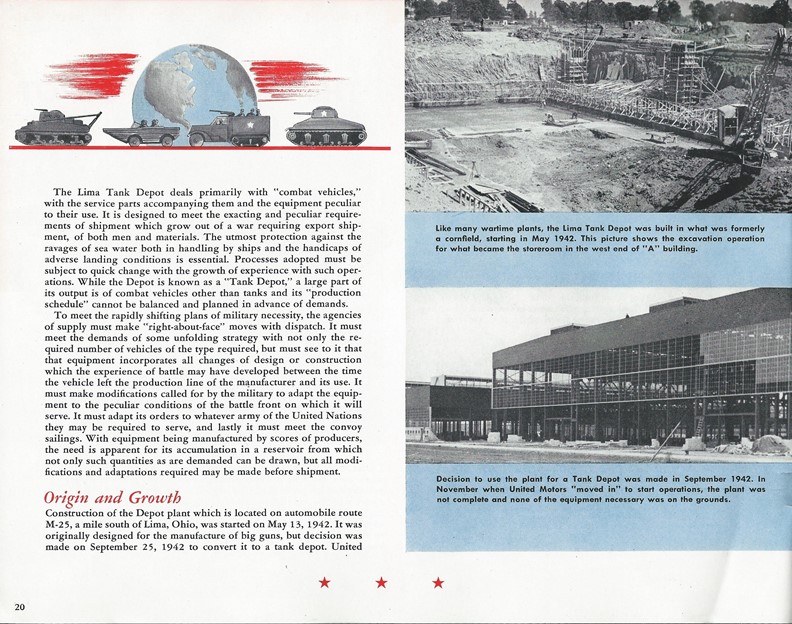

Construction on the Lima Tank Depot began

on May 13, 1942, on what originally was to be a plant for the manufacture of

heavy artillery. However, on September 25, 1942 the decision was made to

use the facility as a tank depot. With three fourths of the plant

complete, United Motors took control of the plant in November 1942.

United Motors Service Division, Lima Tank Depot, Lima, OH won

the Army-Navy "E" Award once.

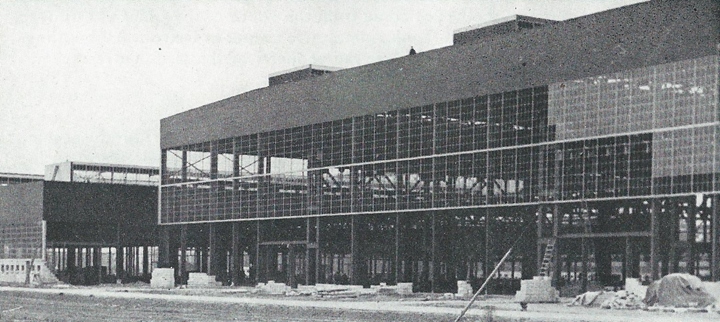

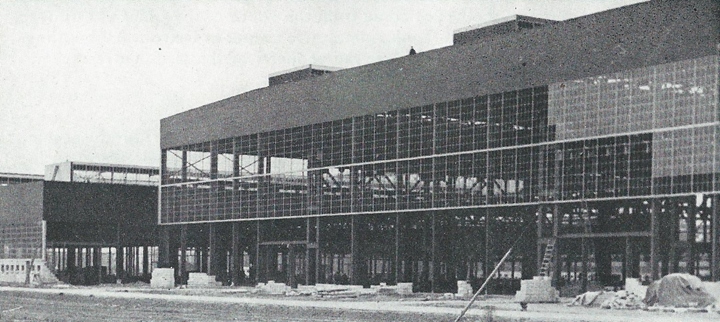

This photo shows the state of

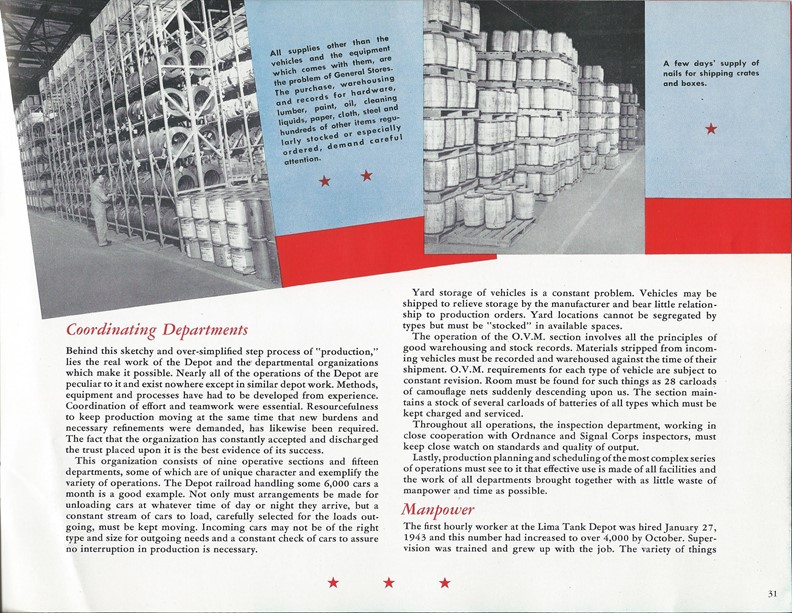

construction when United Motors Service took possession

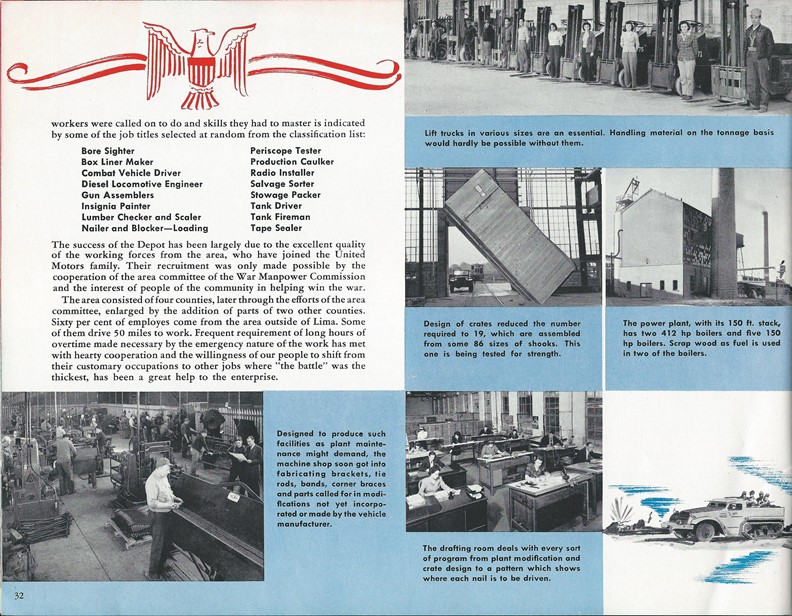

of the plant in November 1942.

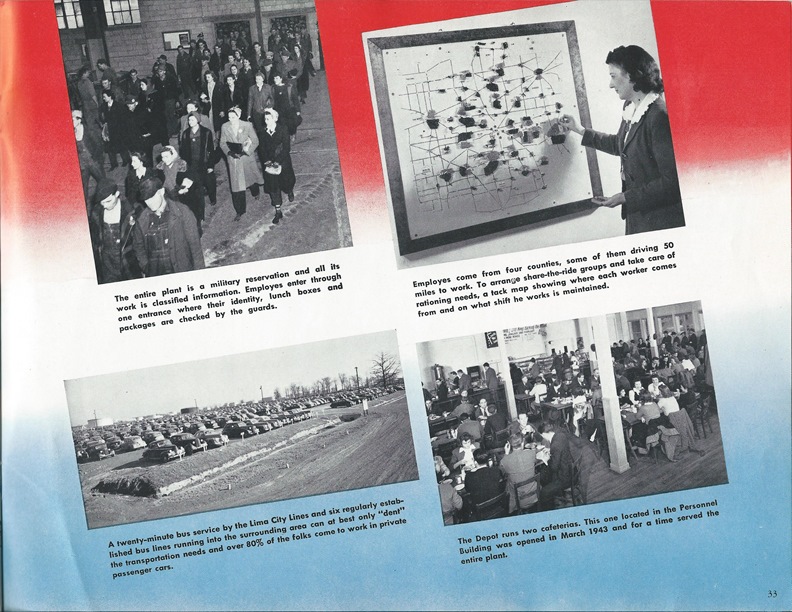

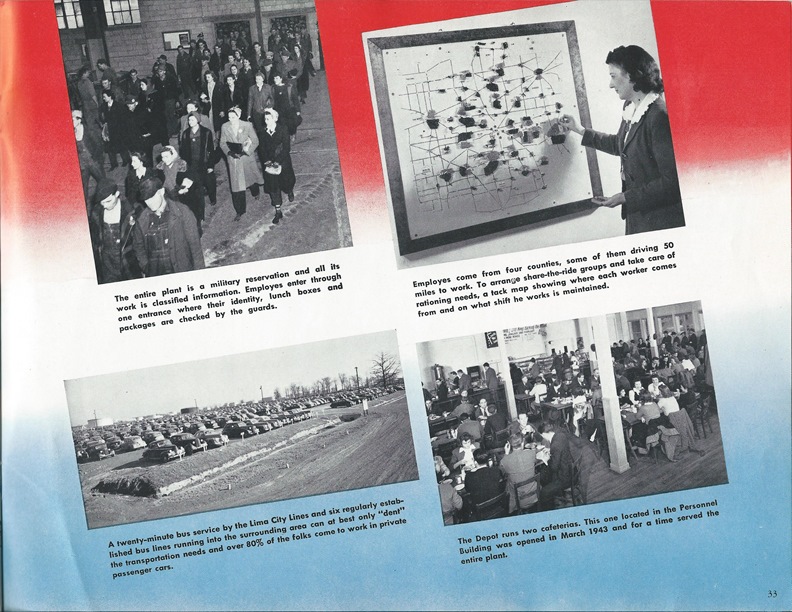

With the opening of the new and larger Lima

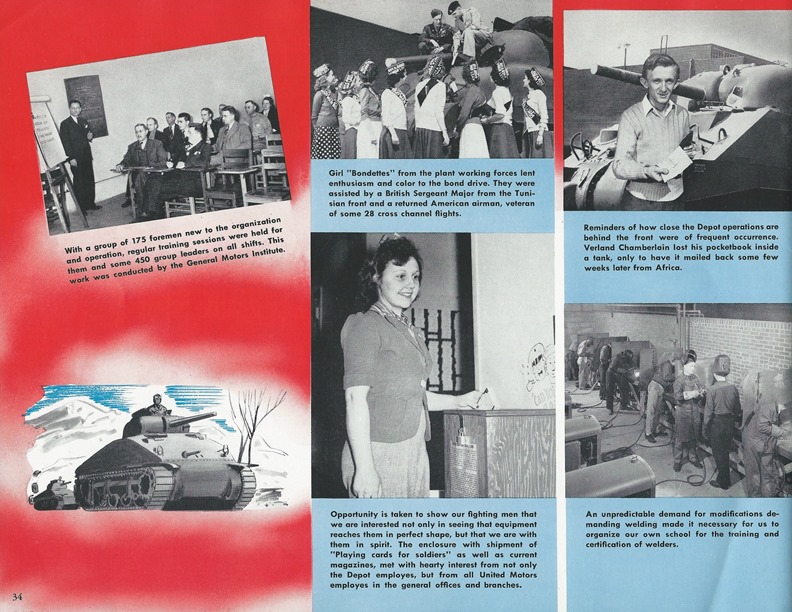

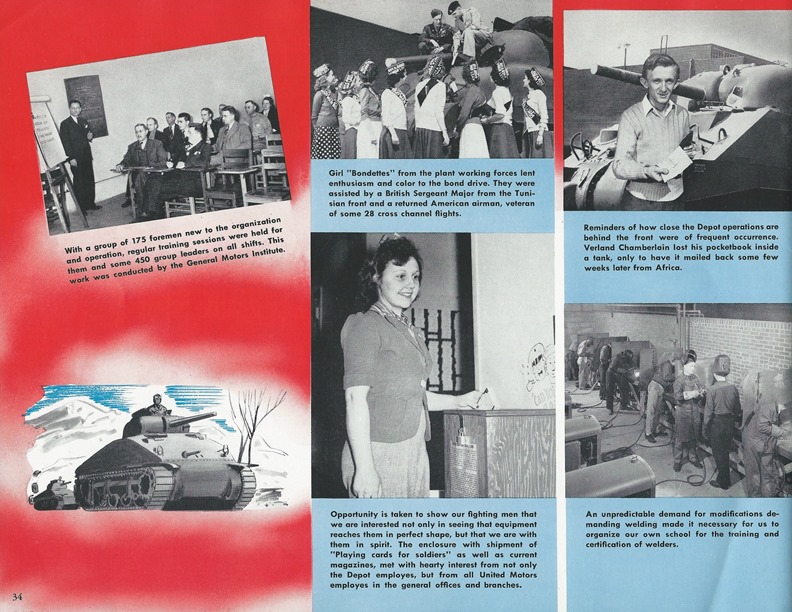

Tank Depot with 5,000 employees, the Toledo location closed on August 1,

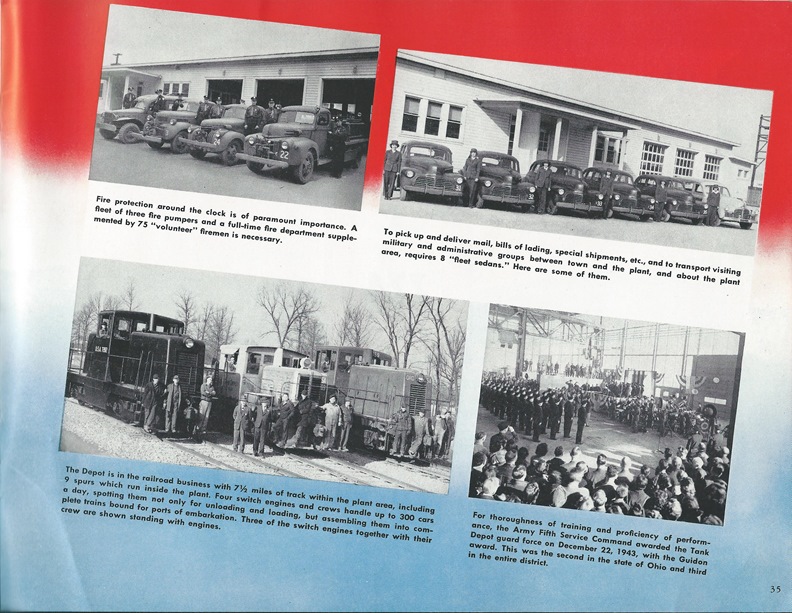

1943. A total of 100,000 vehicles were processed though Lima;

and were made ready for shipment to the European combat zones in North

Africa, Sicily, Italy and Europe. Tanks and other vehicles arrived

at the Lima Tank Depot without many of the items needed for combat; or

needing updates or changes to make them more combat fit that the factory

did not install. The vehicles then needed to be prepared for

shipment across the Atlantic Ocean on Liberty ships. This

preparation included applying corrosion resistant applications, and in

the case of non-tank vehicles, dismantling them for shipment in wooden

crates for protection from the elements, especially the salt-air

corrosion, theft, pilferage, and mechanical damage.

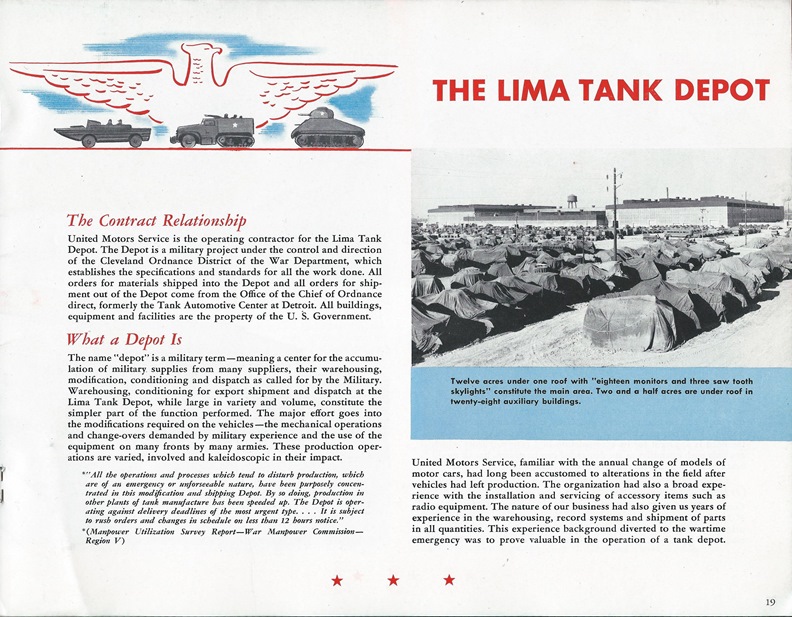

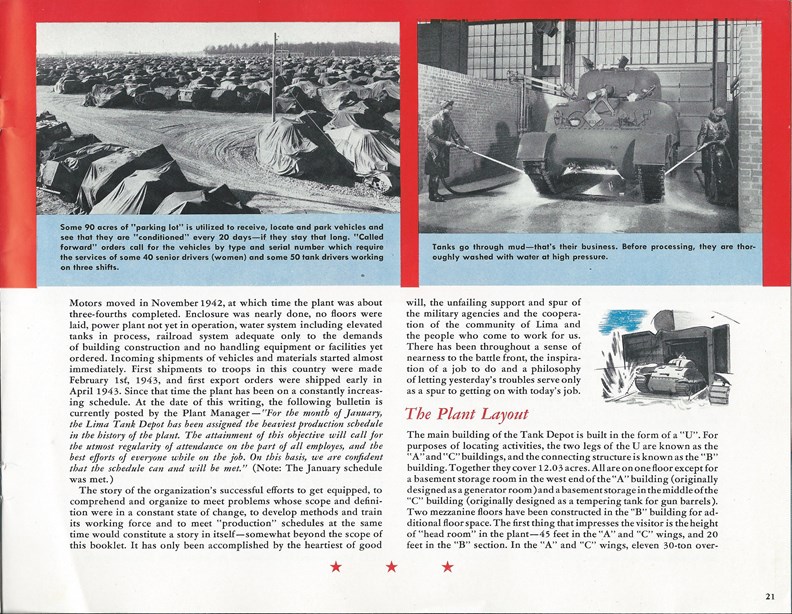

Just a few of the twelve

acres of vehicles waiting processing into the now completed tank depot

seen in the background. The vehicles are all covered to protect

them from the elements.

In many instances the Lima Tank Depot worked

under emergency conditions, when tanks were needed after large American tank losses

in Normandy and the Battle of the Bulge. Tanks had to be retrieved

and brought into the plant to be processed for immediate shipment.

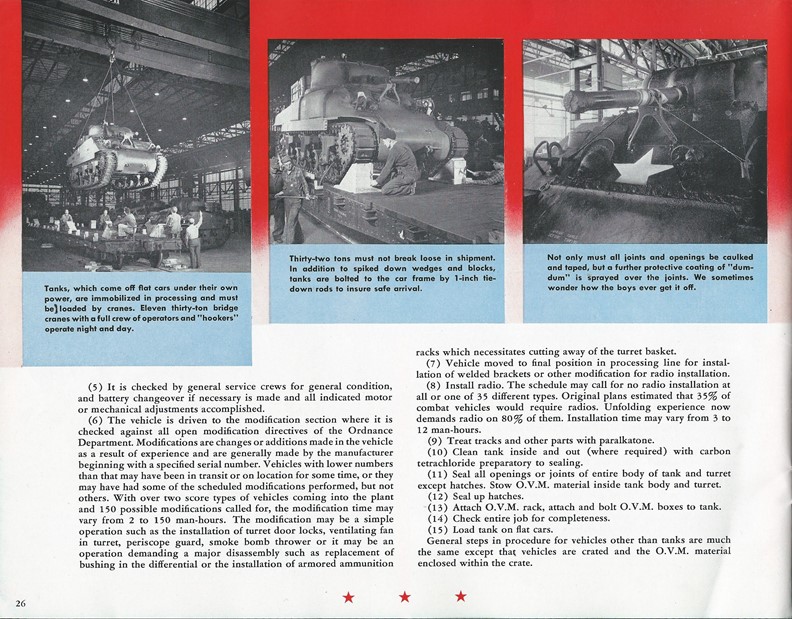

Steps for preparation of a tank or other

type vehicle to the combat zone:

1- Order placed by Ordnance with requirements

for each vehicle.

2- Vehicle is driven to the wash rack.

3- Vehicle lubricated.

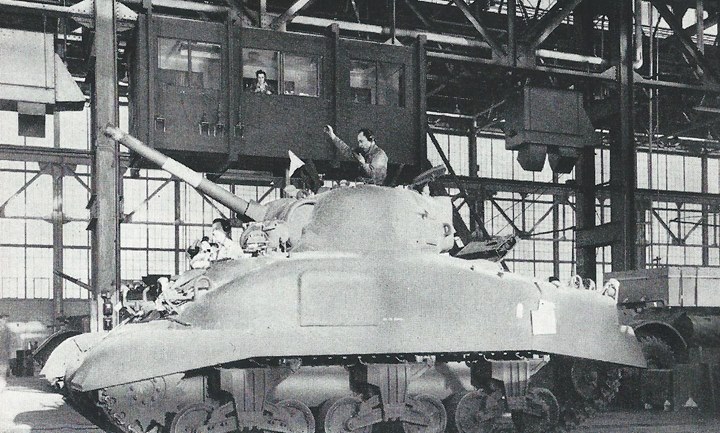

4- Vehicle moved to production floor and main gun and systems checked.

5- General condition of vehicle checked and battery replaced as

necessary.

6- Vehicle updated and modified per latest directives from the Ordnance

Department. For tanks this could include installing turret door

locks, ventilating fan in the turret, periscope guards or smoke

throwers. Modifications could be more intense, replacing or

updating parts in the engine or transmission or adding armor for the

ammunition racks inside the tank. The more than 25 different

vehicles created over 150 different modifications, which could take

between 2 and 150 man-hours to complete. This was the

central focus of the Lima Plant Depot, and its reason for being.

7- Any necessary welding of modifications made.

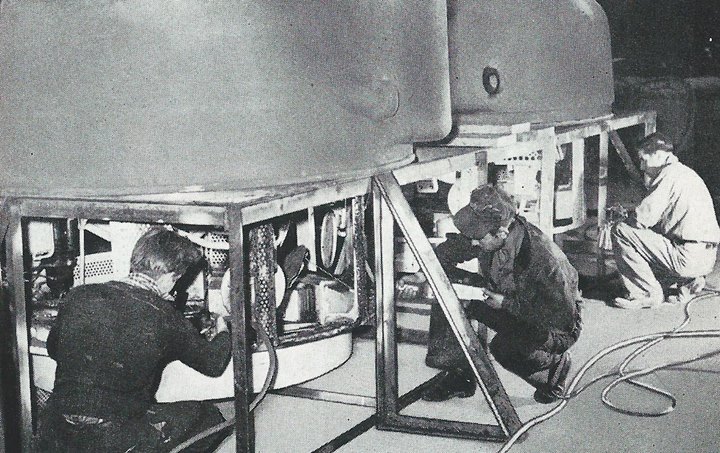

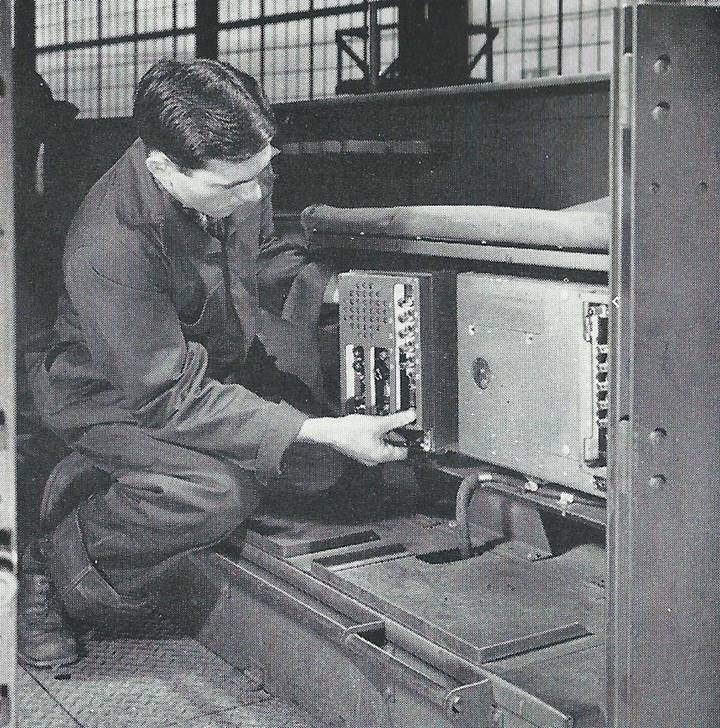

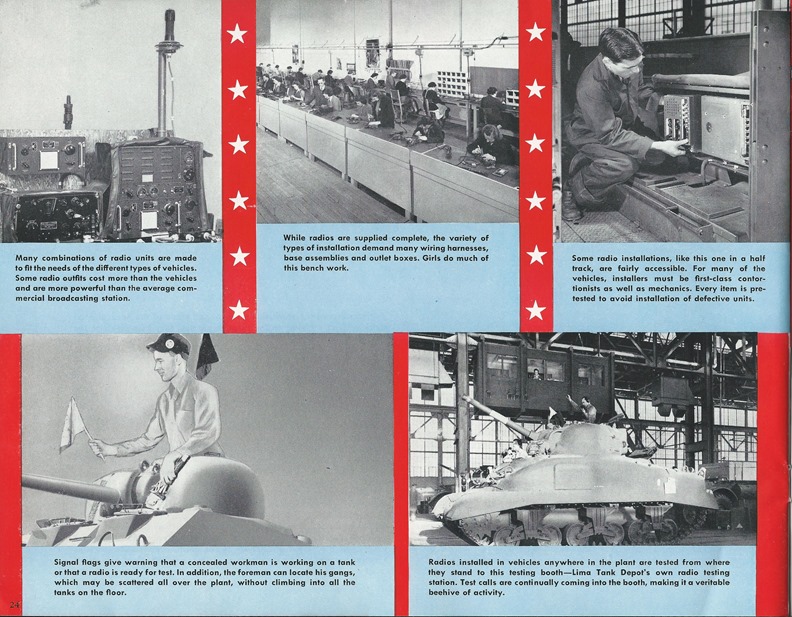

8- Install radios. There were 35 types of radios. At the

beginning of the war, 35% of the vehicles needed one or more installed.

By the end of the war, 80% of the vehicles needed a radio installed.

This operation

took 3 to 12 man-hours each.

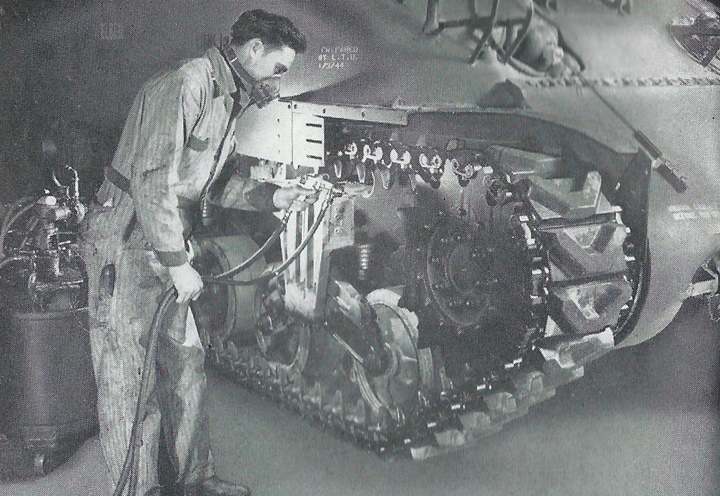

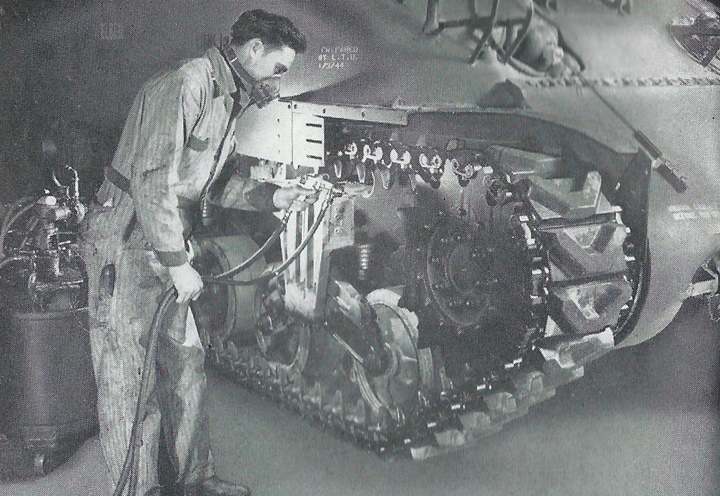

9- Treat tracks with paralkatone, a preservative.

10- Clean tank for prior to sealing.

11- Seal all openings and joints except for hatches. Stow OVM (On

Vehicle Equipment.) inside the tank. (See photo below for more information.).

12- Seal up the tank hatches.

13- Attach OVM rack and attach OVM boxes to tank.

14- Check for completeness of required tasks.

15- Load tank on railroad flat car.

For non-tank vehicles, OVM equipment would be

enclosed with the vehicle inside its shipping crate.

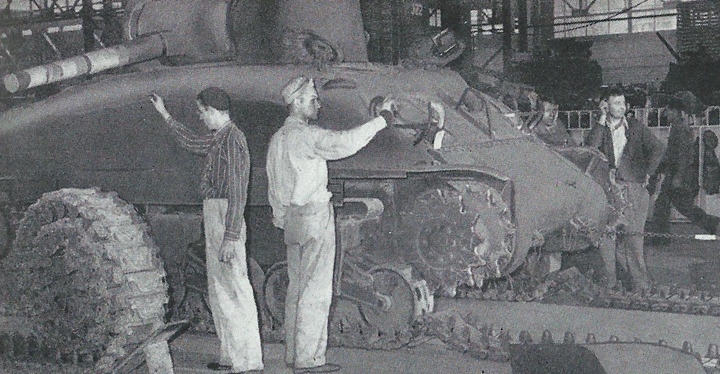

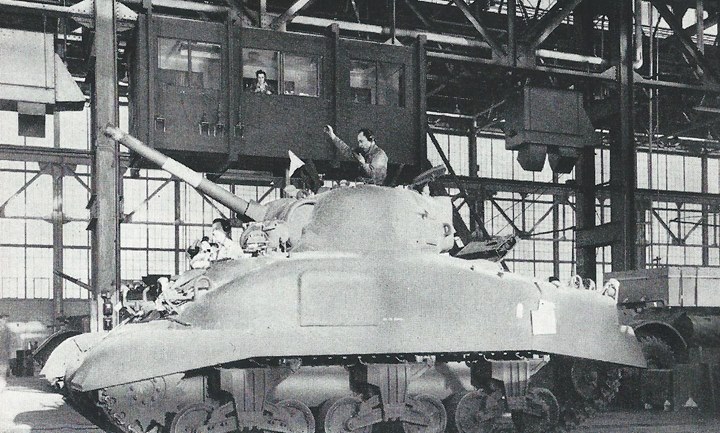

The photos below show some of the actions

described in the 15 steps.

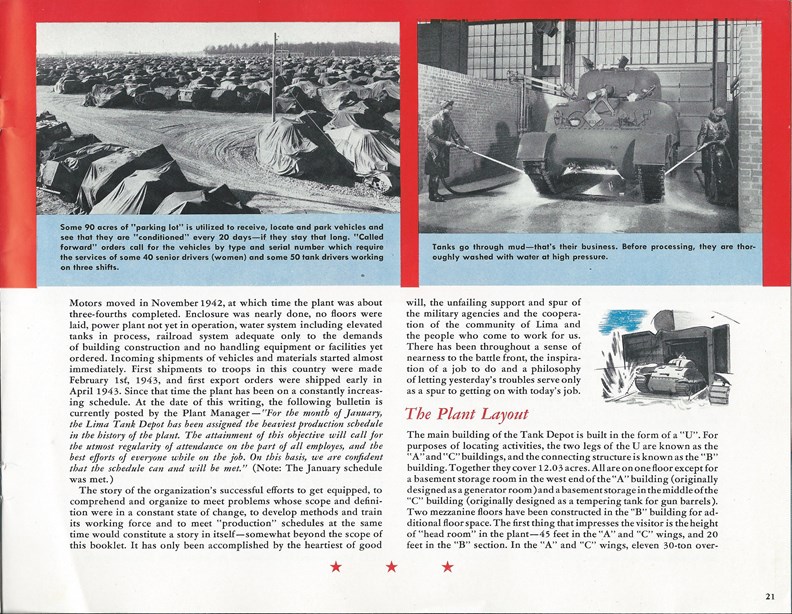

All of the tanks arriving at the depot

were given a complete wash. After being built at the manufacturer,

each tank was driven around a test track for 50 miles to make sure

everything worked properly. This wash was to make sure any dirt not removed at

the manufacturer was cleaned off before the tank was prepped for

shipment. Shown here is an M4A1 Sherman, which could have been one

of the 1,658 produced by the local Lima Locomotive Works.

Once the tank is cleaned up all critical

moving parts received a protective coating.

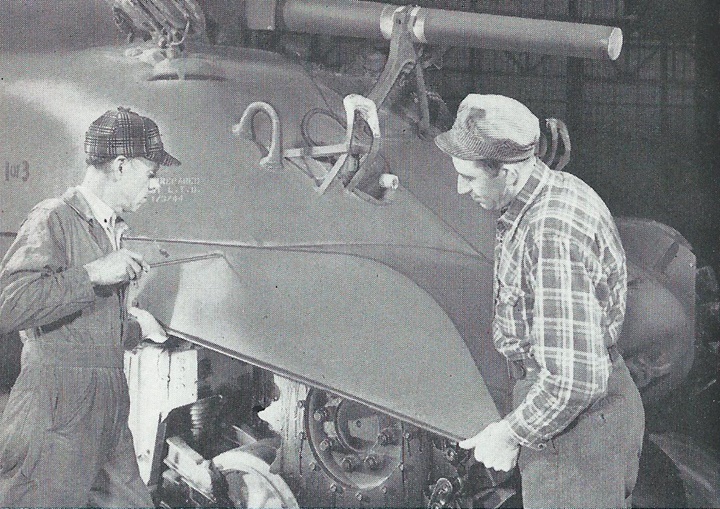

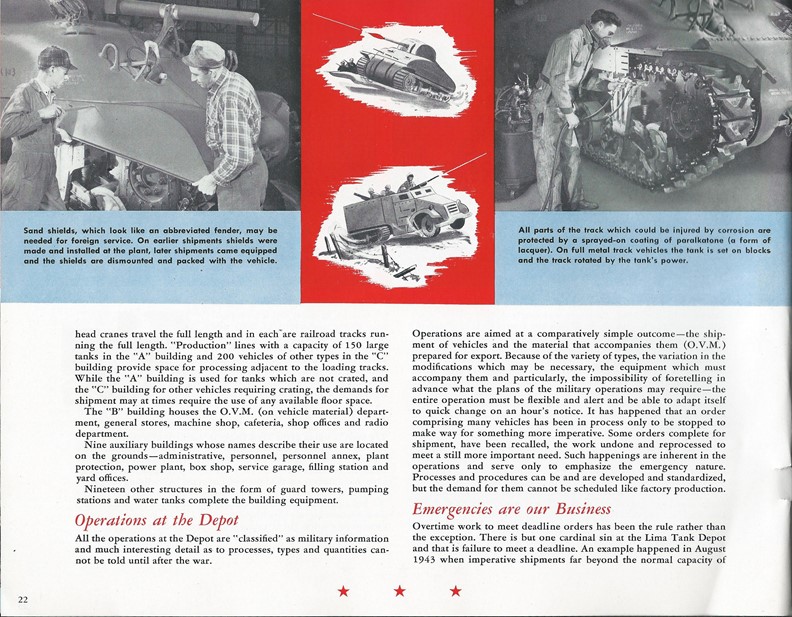

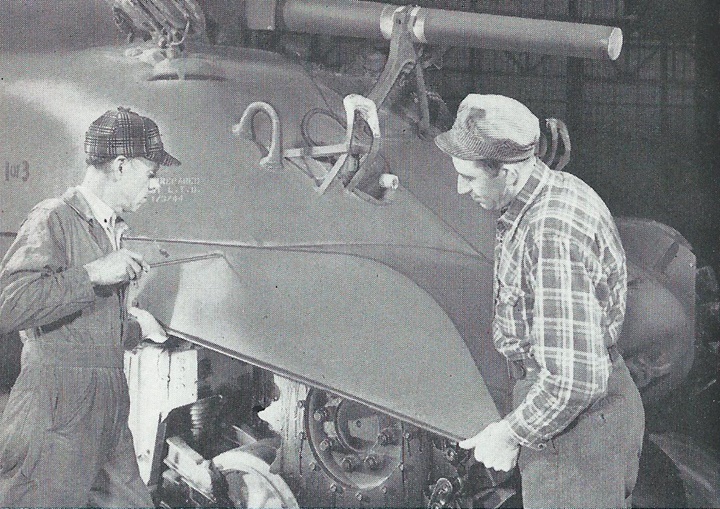

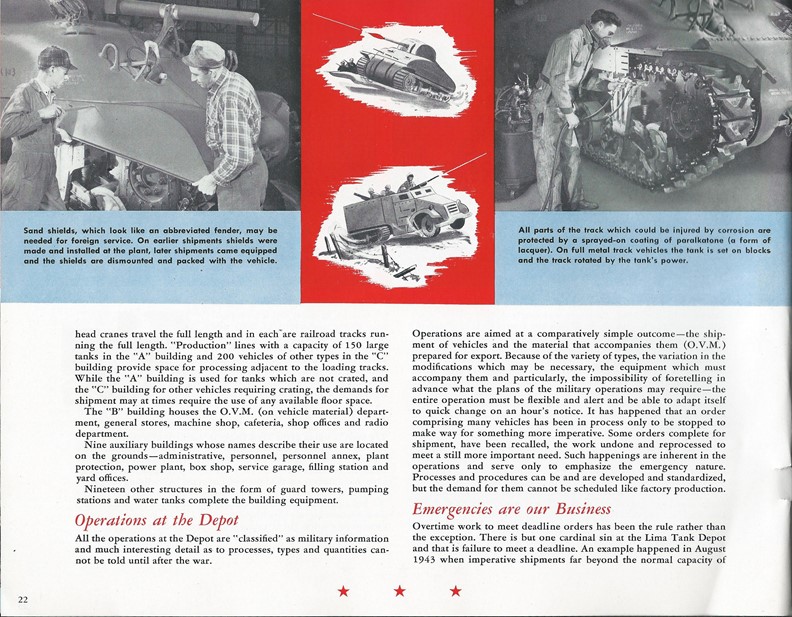

For M4 tanks going to North Africa, sand

shields were added if they did not come so equipped from the

factory.

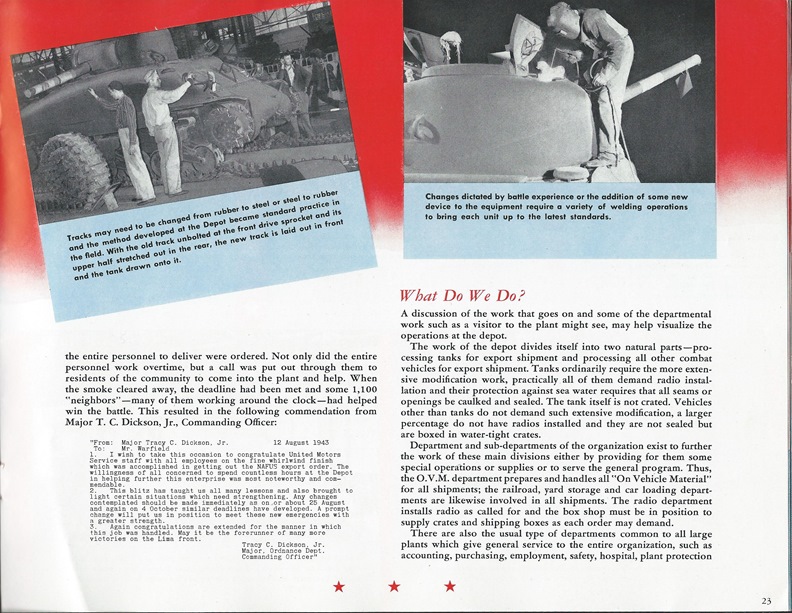

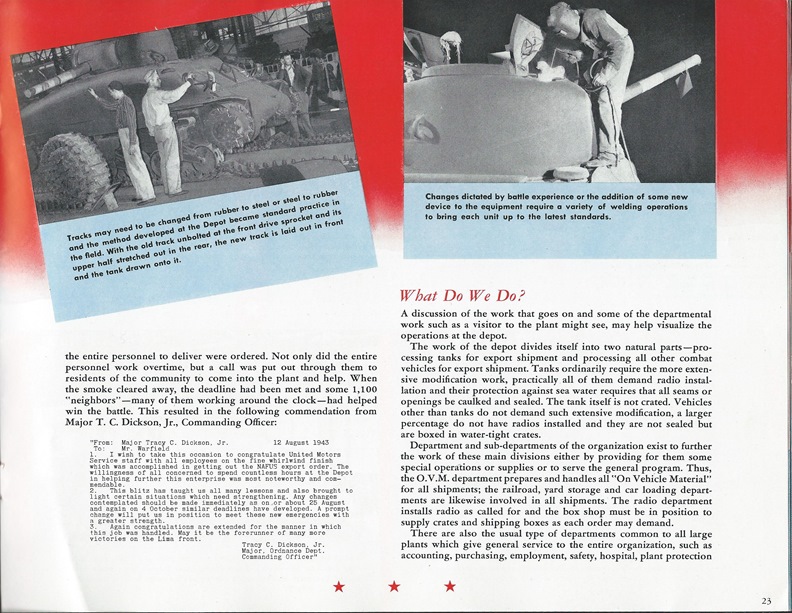

There were two types of tracks used on tanks

during WWII; all metal and metal with rubber pads. The M4s could

come with either, depending on what was originally ordered by the

Ordnance Department. The tracks often had to be changed

before shipment to meet the needs of the units in the field.

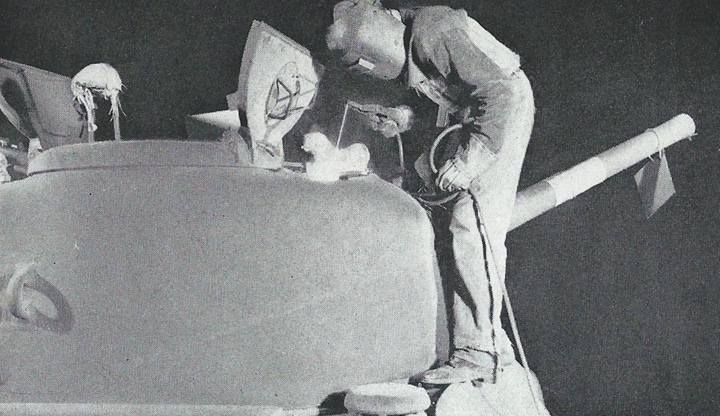

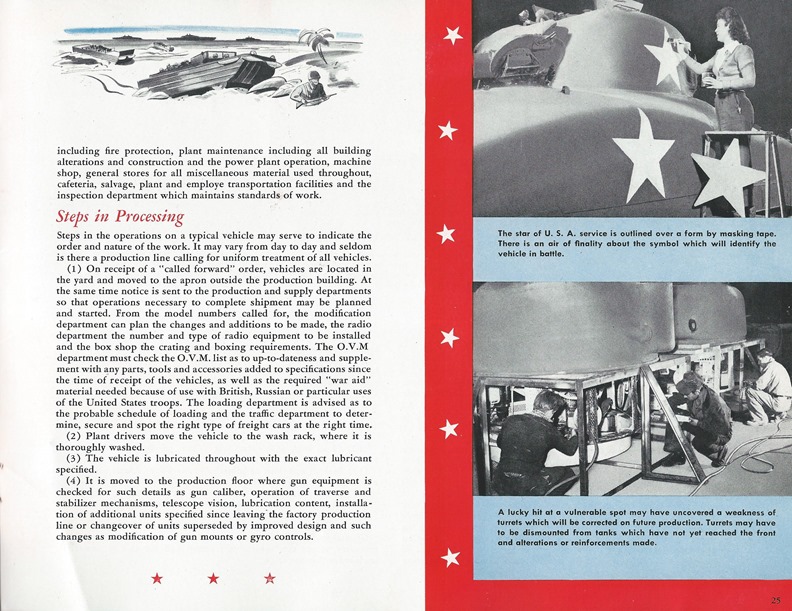

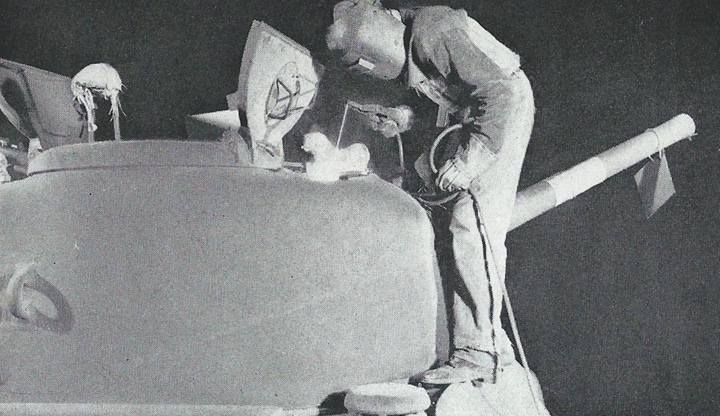

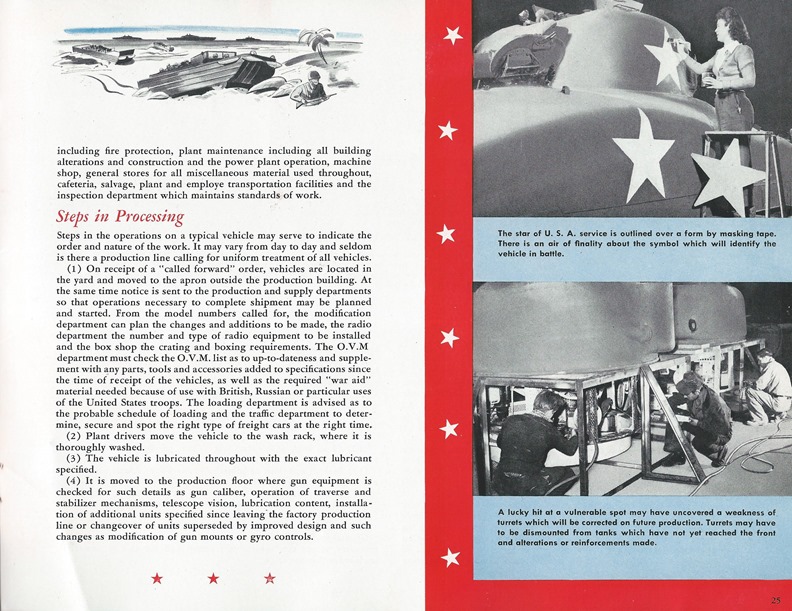

As reports of needed additions to the tanks

came in from the combat zones, modifications not only needed to be

welded to the outside of the tank, but to the inside as well.

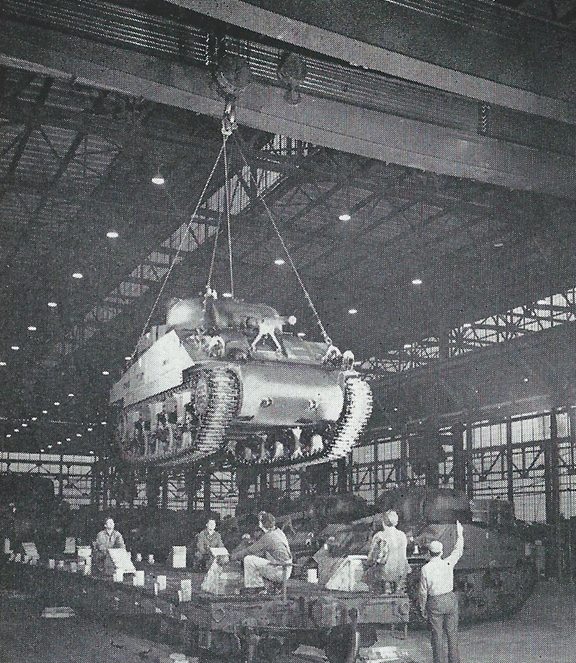

Lima Tank Depot had

to remove the M4 tank turrets from the tank to update the turret

basket with reinforcements. The tanks from which these turrets came out

of were manufactured before it was known at the factories to build them

with reinforcements. Making important improvements to tanks

and other vehicles before being prepared for shipment was one of the

most important tasks assigned to the 5,000 employees in Lima.

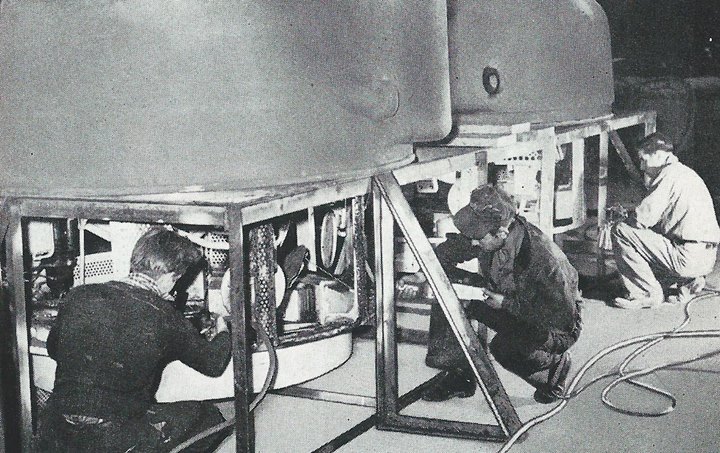

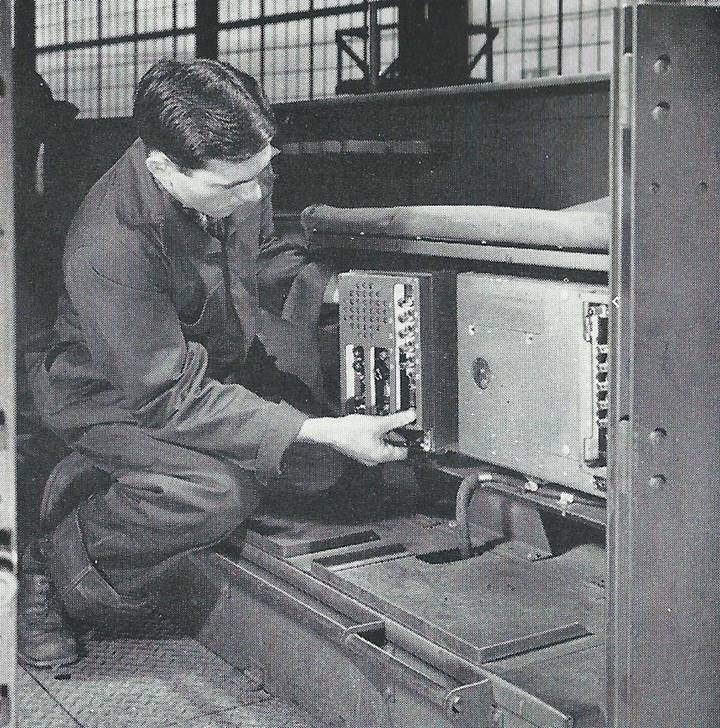

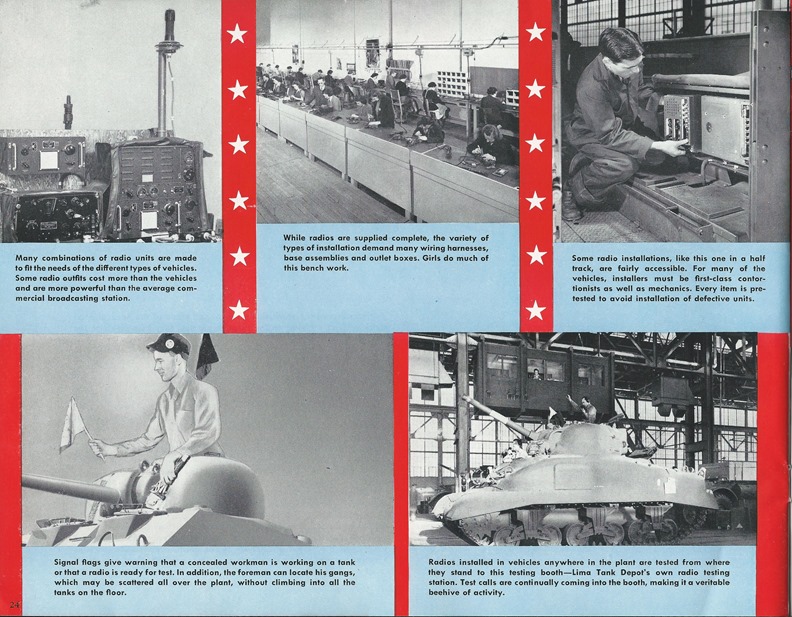

Radios were not installed at the tank

factories, so the Lima Tank Depot would performed this important task and

installed the proper radios depending on the function of the tank.

A company commander's tank received one

SCR508, which had one transmitter and two receivers. Platoon

commander's tanks would have an SCR228 with one transmitter and one

receiver. Originally, the remainder of the tanks had installed an

SCR538 with no transmitter. As the war progressed it became

obvious that all tanks needed a transmitter. So the SCR228 was installed

in all tanks except for the company commander's tank.

In the photo above, the radio has been

installed in the rear of the turret on this M4A1, and the new radio is

undergoing transmission and receiving tests from a central radio test

center.

An SCR series radio is being installed by a

Lima Tank Depot employee in the right rear of a half-track.

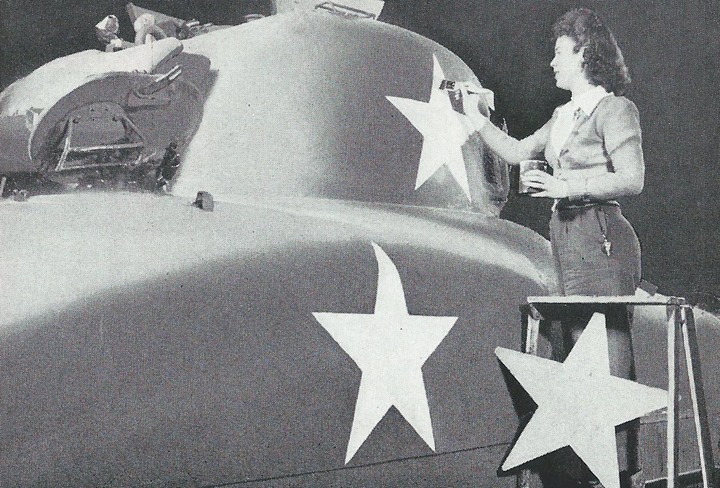

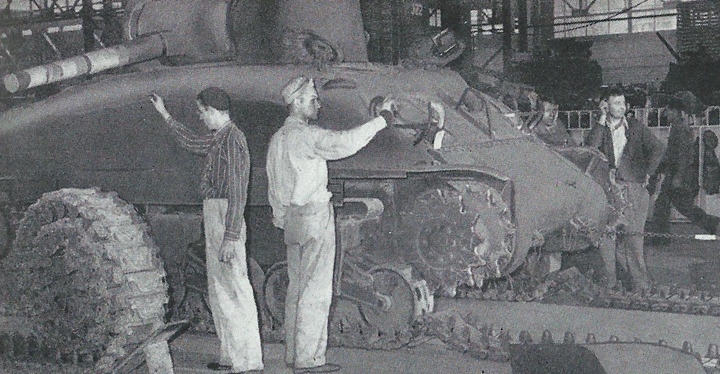

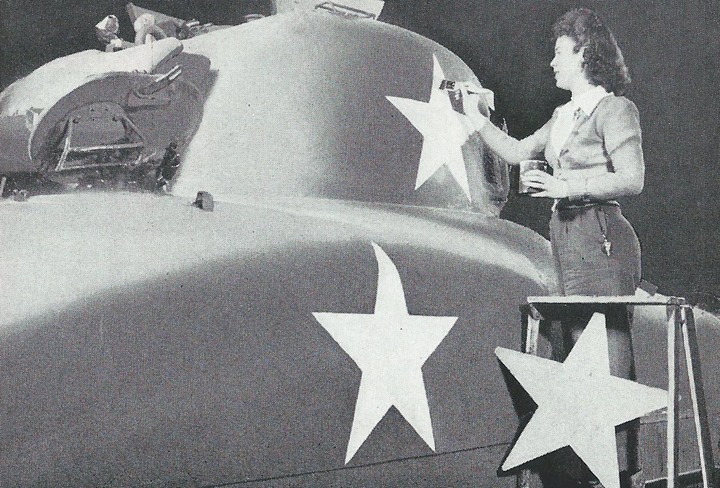

The star was painted on tanks and other

vehicles as they were processed through the Lima Tank Depot.

Although the stars identified the vehicles as American to prevent

fratricide, but they were also excellent aiming points for German tanks and

anti-tank guns.

This photo shows the many items stored

inside or on the tank itself, including weapons and 75mm or 76mm shells.

Items like the pioneer tools shown at the left of the photo, tools to

make repairs to the engine and tracks, and the tow cable shown across

the top all needed to be stowed in the tank before it left the Lima

Depot. These items were not provided by the manufacturing plant,

so the Lima Tank Depot was tasked with adding all

necessary items. This assured that when the tank arrived in the

combat zone it was ready to go. These items were known as "On

Vehicle Equipment" or OVM. Only weapons and ammunition would be supplied in the field.

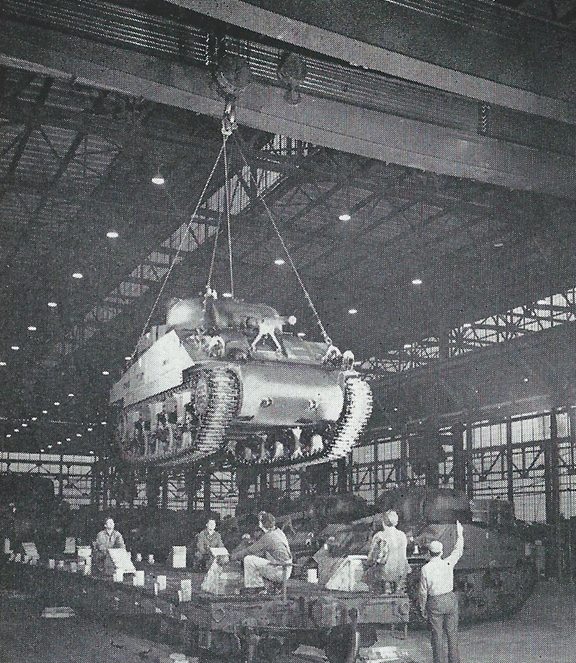

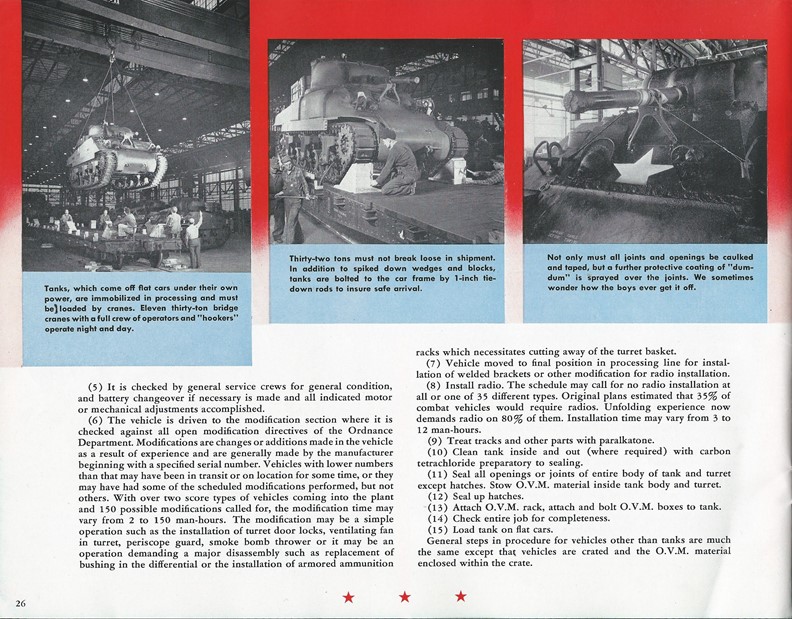

A 30 ton M4 Sherman tank is loaded on

to a railroad flat car. While the tanks arrived at the Lima Tank

Depot and were able to run under their own power, the overseas

preparation of the tanks disabled the engines for shipment.

Therefore they were all loaded on to flat cars by overhead cranes and then secured for travel.

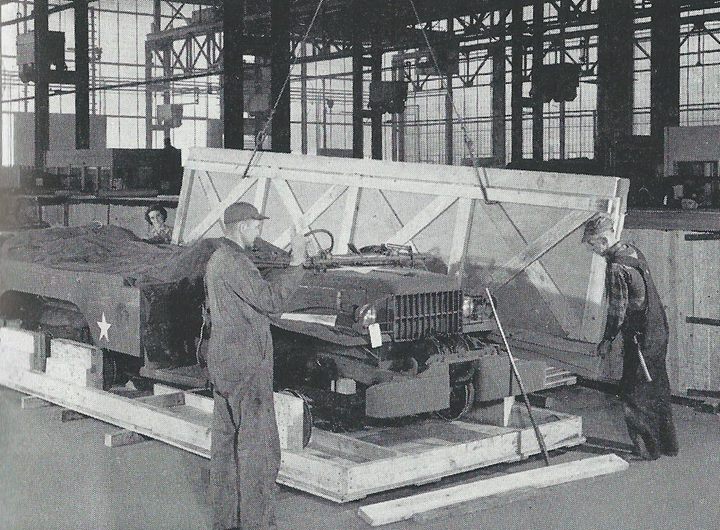

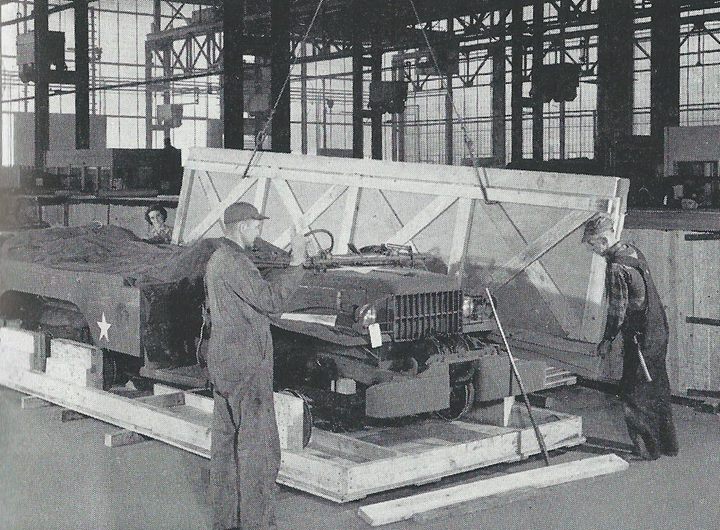

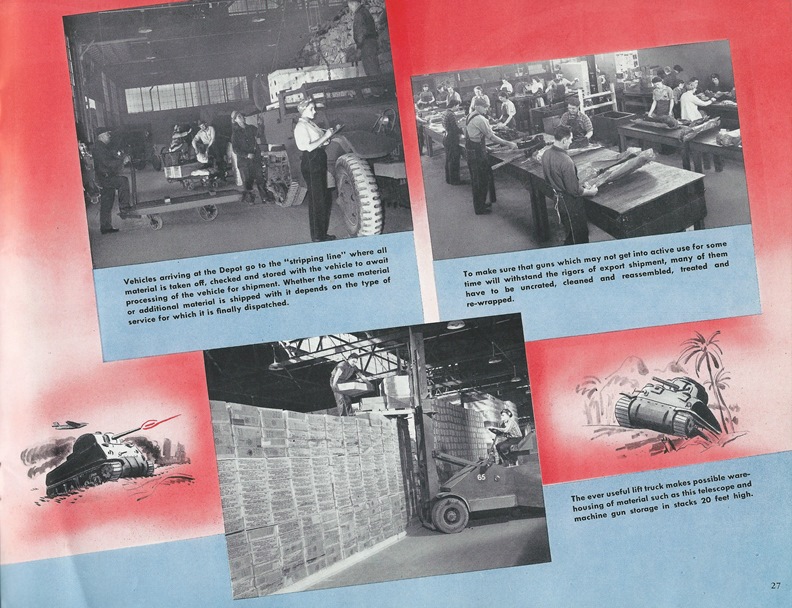

Other vehicles were treated against

salt water corrosion, partially disassembled, and then

completely boxed for shipment. Completely boxing equipment, like

this Dodge WC-51 truck, protected it from the elements, damage, and theft of parts while in transit. It also allowed for

the secure transport of OVM items.

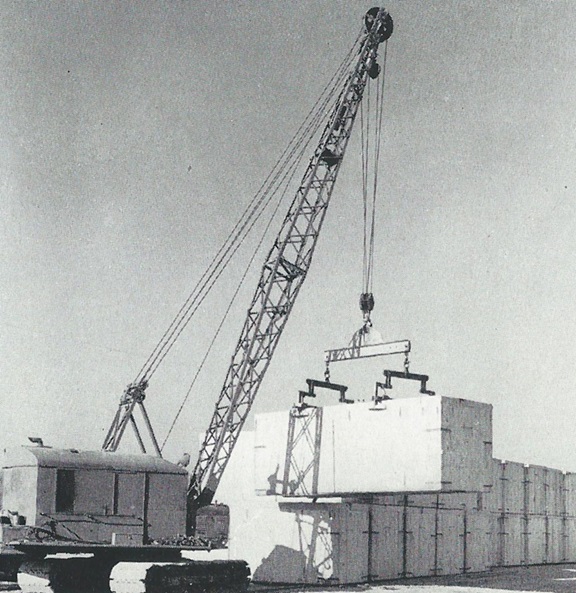

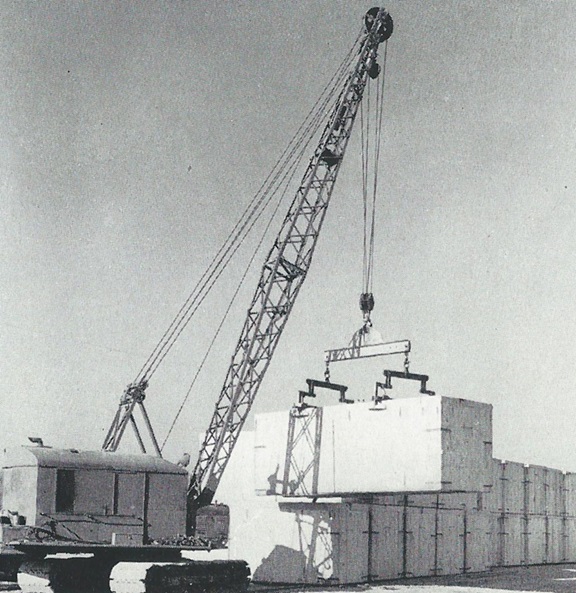

Here is a small group of boxed trucks awaiting shipment to the war

zone after being prepared by the Lima Tank Depot.

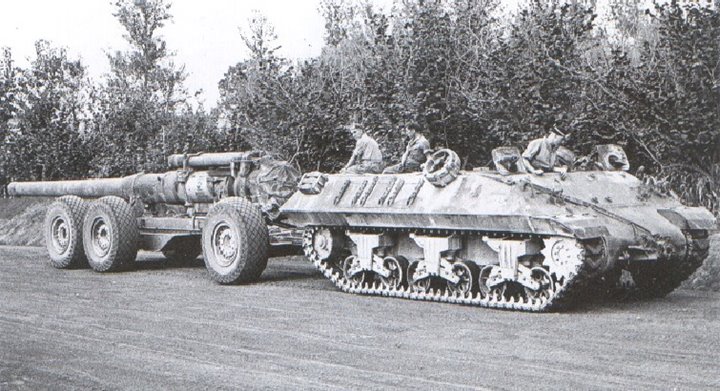

M35 Prime Mover Project

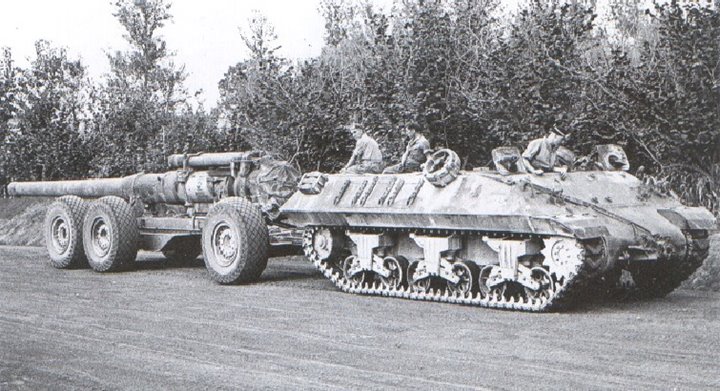

Starting in January 1944 the Lima Depot

converted 209 M10A1 Wolverine tank destroyers into M35 prime movers.

Work included removing the turret, ammo racks, and equipment not needed

for use as a prime mover. The Lima Tank Depot also fitted the

vehicles with air compressors for the air brakes on the towed artillery

they would be pulling.

This M35 is pulling a bulldozer in Kyll

Germany in March 1945 has had a hard top with windshield added. It

also has a ring mounted .50 caliber machine gun. These were not

standard on the M35. See the photo below for the standard M35.

Photo added 1-17-2017.

Photo added 1-17-2017.

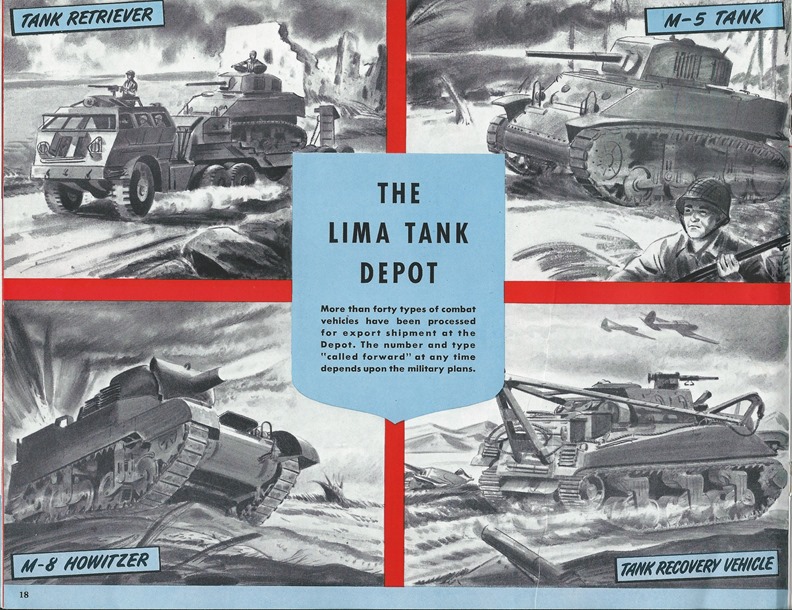

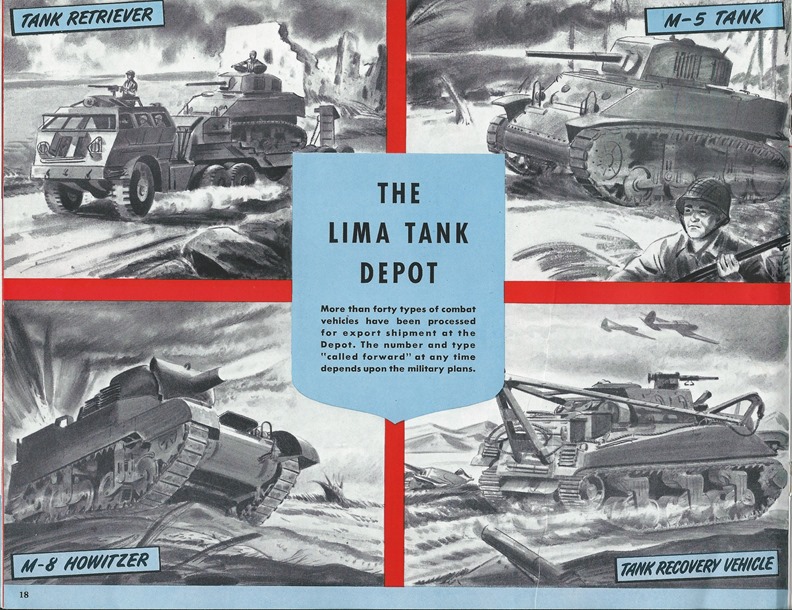

Below are a photos of a few of the over 25

types of tanks and other military vehicles that came through the Lima

Tank Depot.

The M7 Priest was a 105mm gun carriage built

on a Sherman tank chassis. 4,315 were built by three different

companies starting in April 1942, and continued through the end of the

war. Author's photo from the Patton Museum.

This Fisher Body built M4A3 is one of 49,234 Sherman tanks built by ten

different manufacturers during World War Two. Many of the M4s came

through the Lima Tank Depot to be processed on their way to battle

fronts in North Africa, Sicily, Italy, and then Europe. As battles

raged and M4 losses became heavy in Europe, the Lima Tank Depot was

called upon to expedite the processing and shipping of replacement tanks

for the troops on the battle front. Author's photo.

Pacific Car and Foundry in Renton, WA

produced 1,327 M26 and M26A1 "Dragon Wagons" like this M26A1. The

vehicles were used extensively in Europe to pull trailers while

retrieving disabled M4 tanks on the battlefield. The Lima Tank

Depot prepared these vehicles for overseas shipment. Author's

photo.

This is one of 53,733 half-tracks built

during WWII in various models and configurations. Half-Tracks

manufactured by Auto-Car in Ardmore, PA, Diamond-T in Chicago, IL,

International Harvester in Springfield, OH and White Motor Company in

Cleveland, OH would have been processed for combat duty at the Lima Tank

Depot. Author's photo.

This Dodge WC-51 is the type shown above

being boxed for shipment. The Lima Tank Depot would have prepared

many of the 404,817 Dodge trucks built in various configurations during

the war. Author's photo.

The first M26 Pershing tanks built by the

Fisher Body Tank Arsenal in

November and December 1944 were

expedited for emergency shipment to the battle front in Europe by the

Lima Tank Depot in January 1945. M26 tanks were desperately needed

to combat the German Tiger and Panther tanks that were decimating

American Sherman tanks on the battlefield. This was especially

true after large American tank losses during the Battle of the Bulge.

Author's photo.

Both Massey-Harris and Cadillac built the M5

and M5A1 Stuart light tank. The Lima Tank Depot would have prepared

them for North Africa and later European combat fronts. Author's

photo.

First used in the invasion of Sicily, the

GMC DUKW amphibious truck was considered by General Dwight D Eisenhower

to be one of the most important weapons fielded by the US in WWII.

The Lima Tank Depot would have processed many of the 21,147 DUKWs

produced by both GMC and Chevrolet on their way to Sicily, Italy and

France. Author's photo.

Post WWII

The M1A1 Abrams Main Battle Tank was built by the

Lima Tank Depot along with the Warren Tank Arsenal. It is unknown

whether this was built at Lima. Currently all M1A1s are rebuilt at

Lima. Author's photo added 2-10-2017.

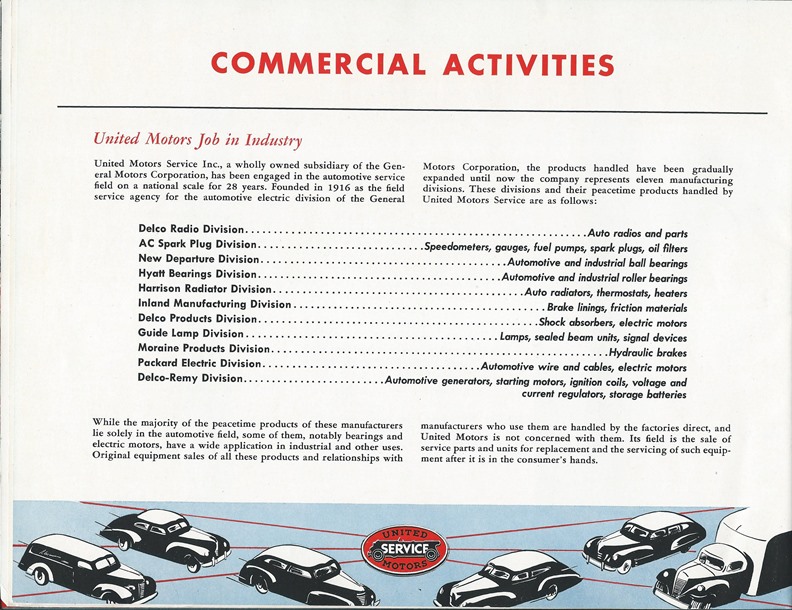

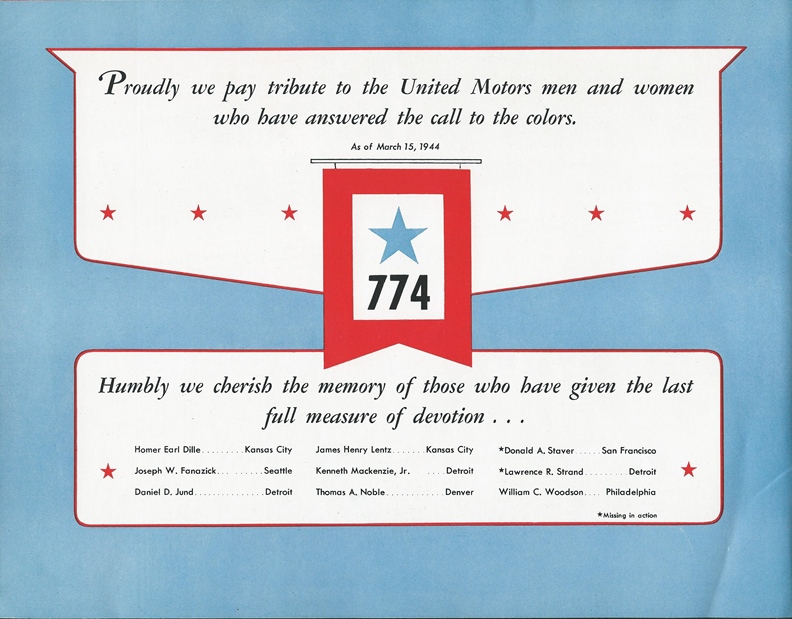

"The Wartime Story of United Motors

Service"

This 37 page booklet

published in 1944 not only tells the story of the Lima Tank Depot as

managed by United Motors Service, but how the GM Division provided

service parts and rebuilt automobile components to keep civilian cars

running during WWII.

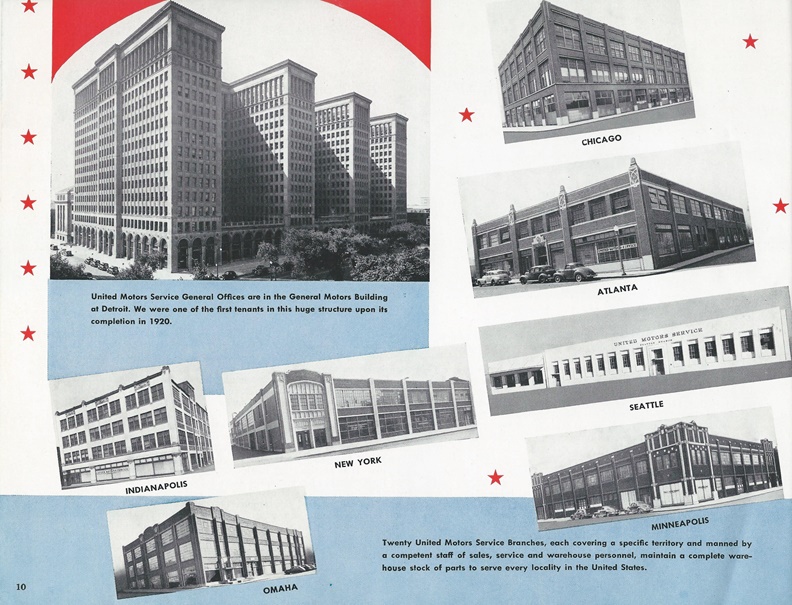

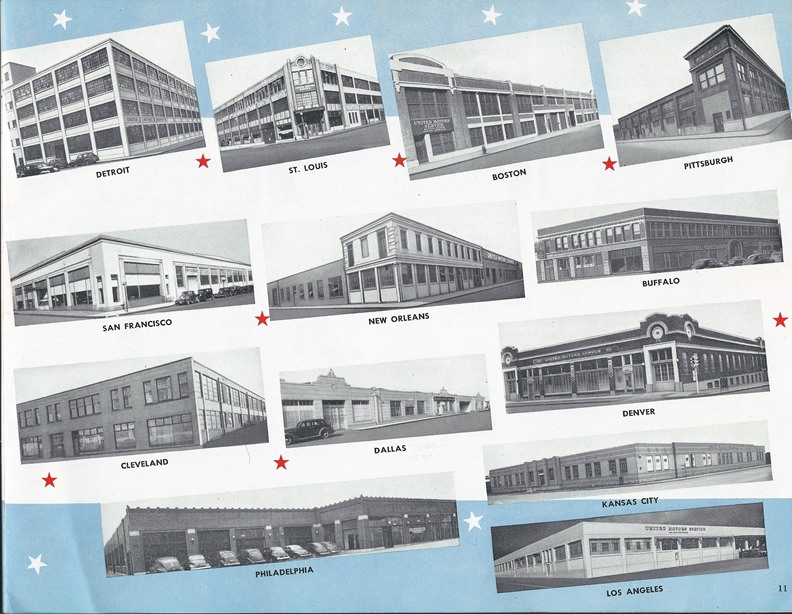

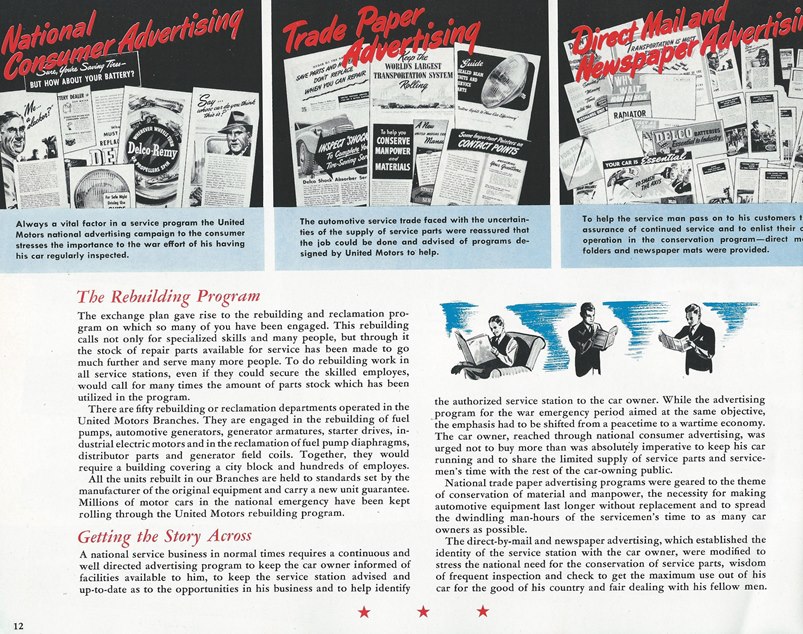

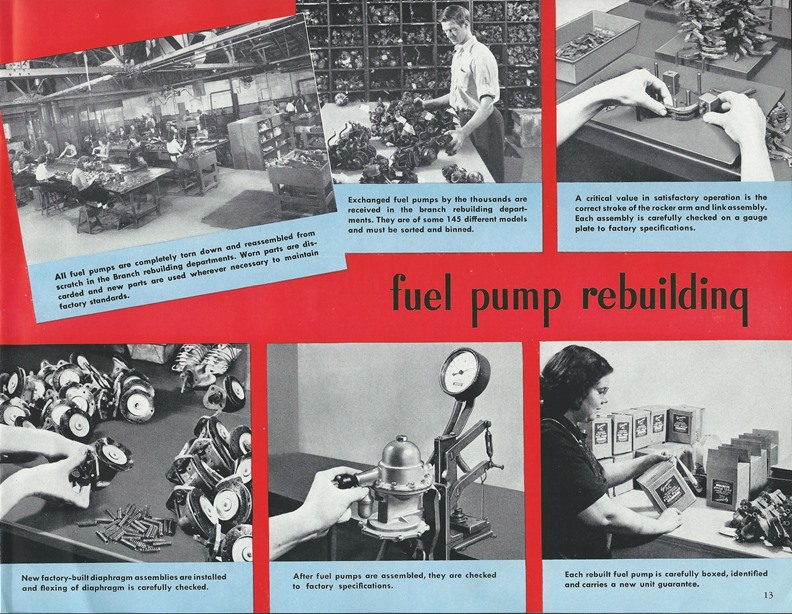

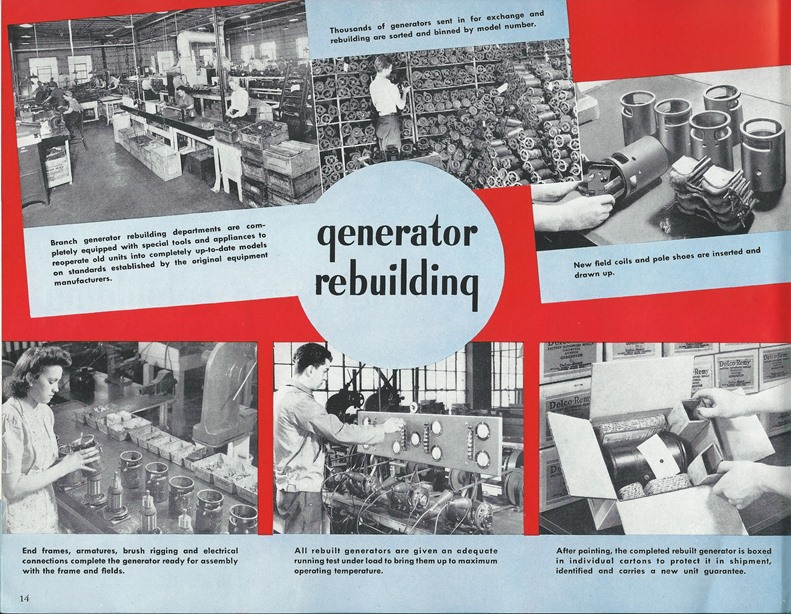

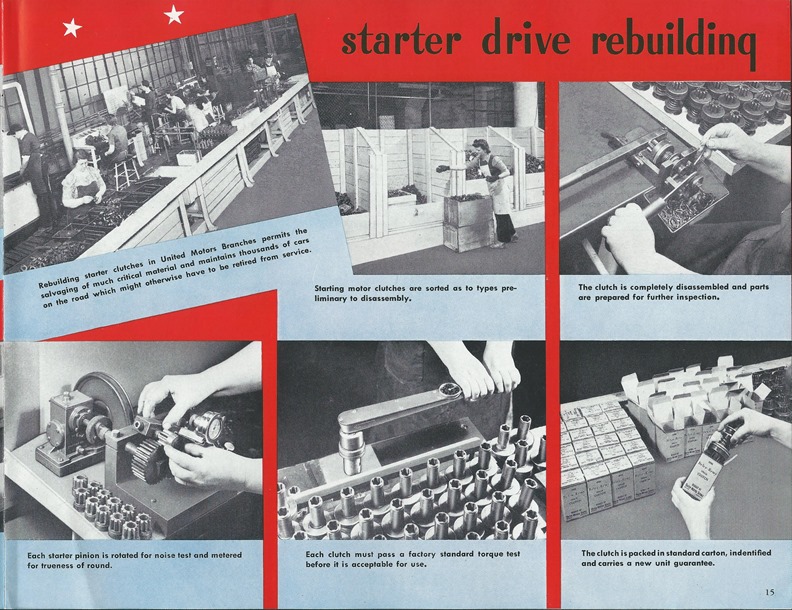

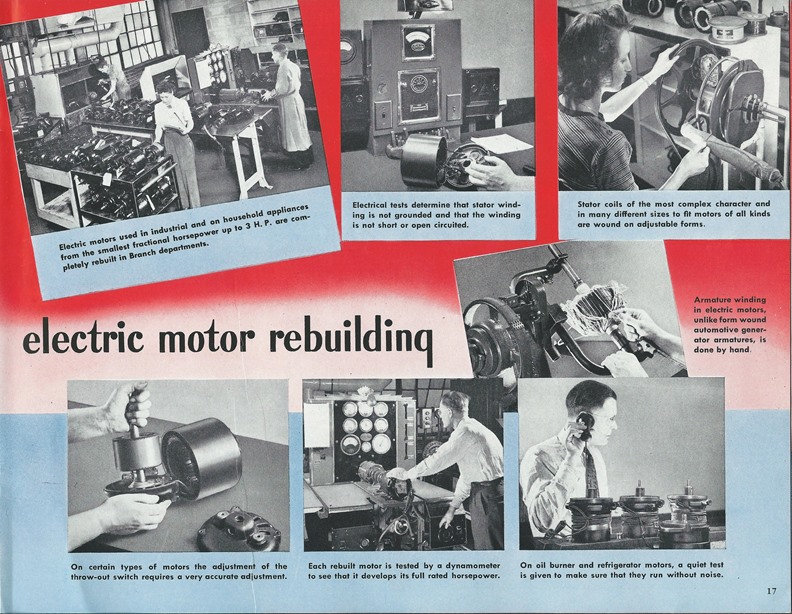

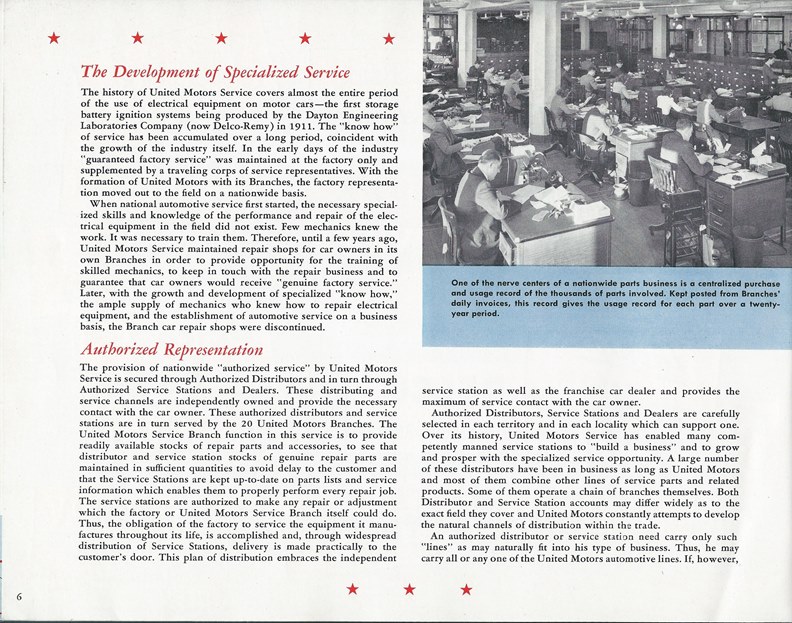

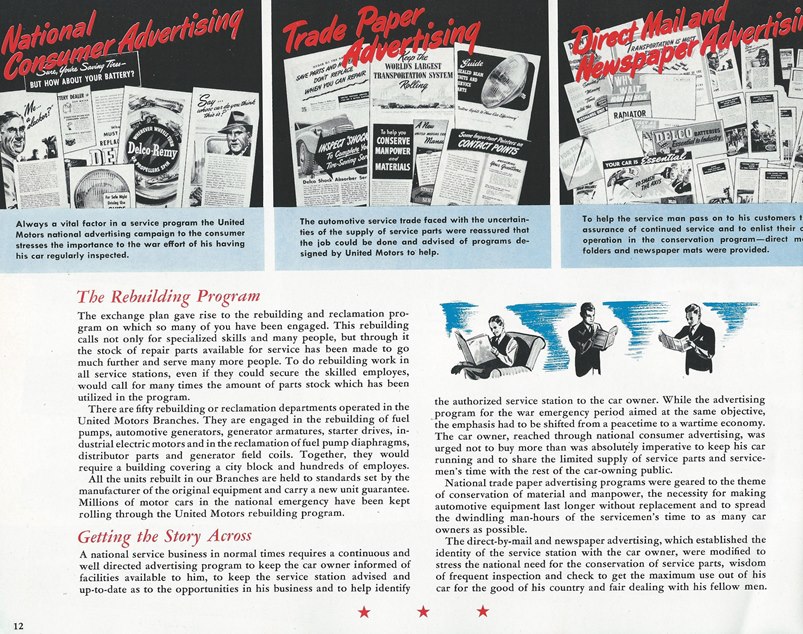

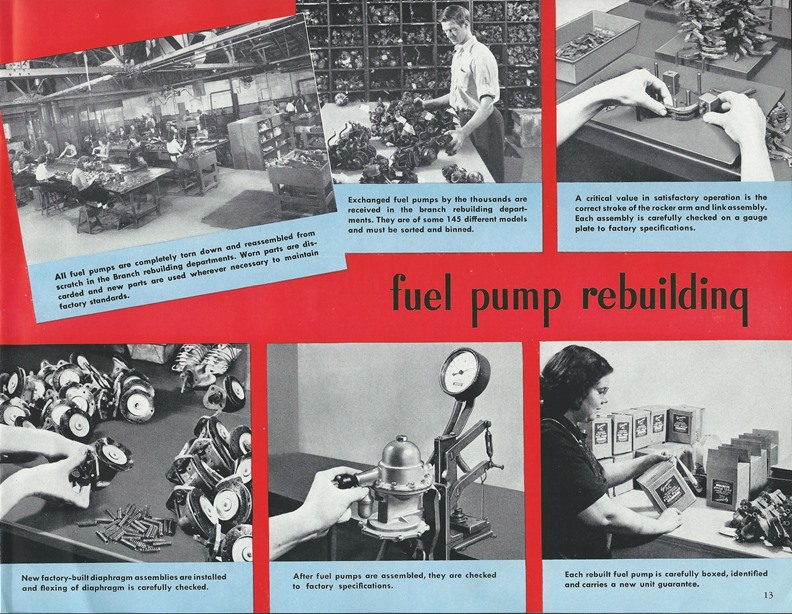

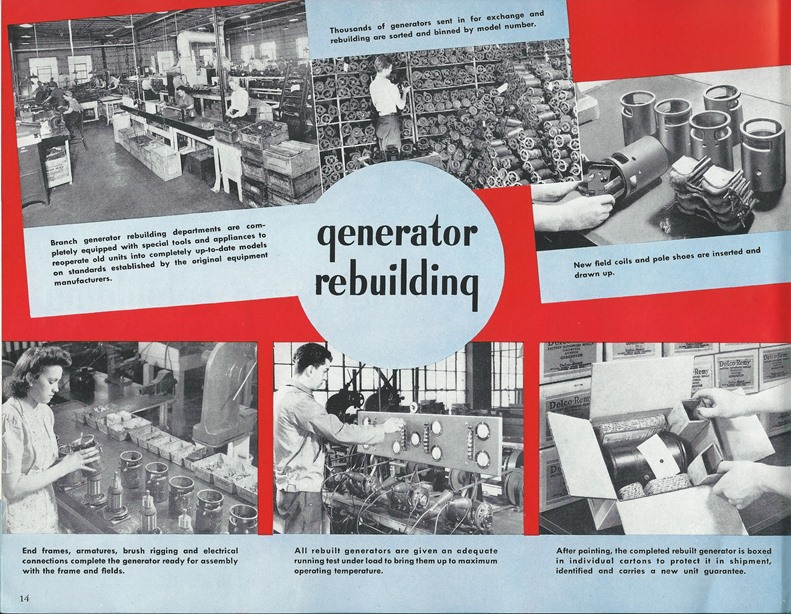

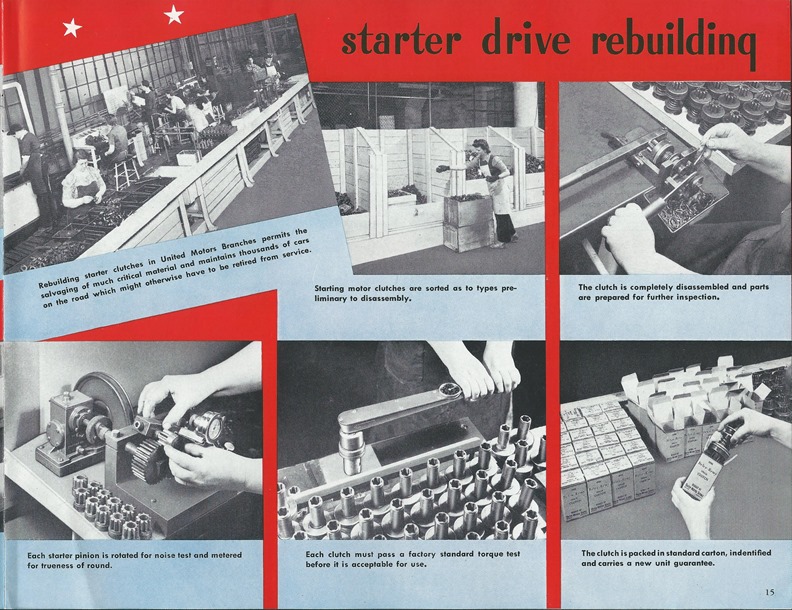

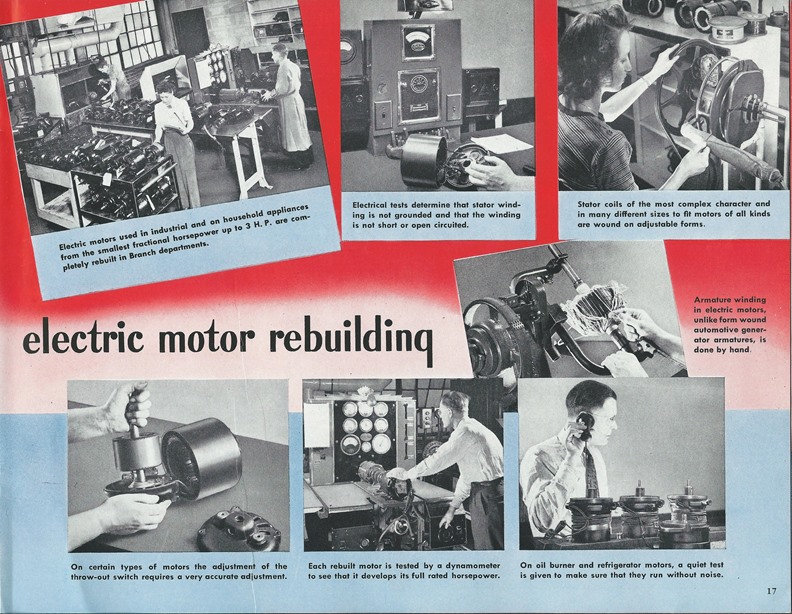

Pages 4-17 tells how United Motors Service provided parts for civilian

vehicles by rebuilding starters, generators, and

fuel pumps.

From pages 18 to the end,

the complete wartime story of the Lima Tank Depot is detailed. This

is the best and most definitive account available of what a tank depot did in

World War Two. It is well worth the reading time.

One will not find anything more informative on World War Two tank depots

than that provided below.

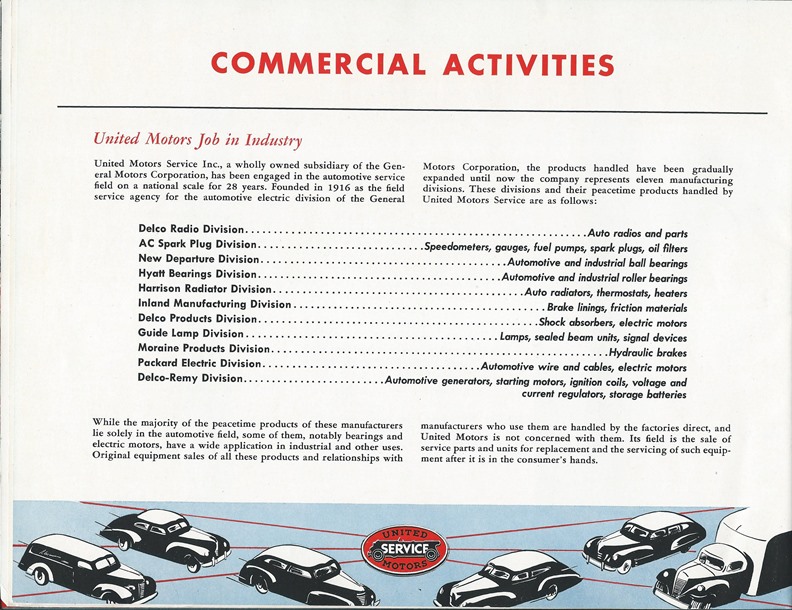

Page 4.

Page 18. The section below is the best

description of the workings of a WWII tank depot.

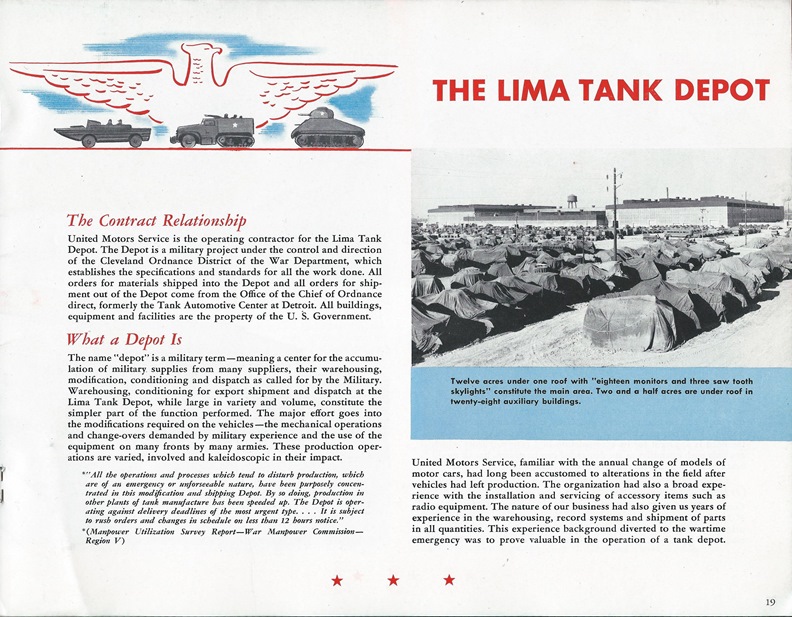

Page 19 gives a general description of a

tank depot.

Page 22. "Emergencies are our

business" illustrates one of many times the Lima Tank Depot pulled out

of all of stops to get needed equipment ready and on the way to the

battlefield.

Page 23. Starting with "What Do We

Do?" explains in detail how the Lima Tank Depot prepared vehicles for

final shipment.

|