|

Producing More for

Victory

Progress in

Technology

One Million Browning

Machine Guns

Toward Victory This page updated on 1-14-2025. An Overview

Table 1 only includes contracts over $50,000. Not comprehended in Table 1 are any contracts less than $50,000. Also not comprehended are all of the parts and components the divisions were supplying to each other on internal company contracts, but also components supplied to outside truck companies for their vehicle manufacture. These amounts were significant, and the components vital to the manufacture of armored vehicles and trucks. An example of this would be the half-tracks built by Autocar, Diamond T, and the White Motor Car Company. These vehicles had components in them supplied by A-C Spark Plug, Delco-Remy, Guide Lamp, and Harrison Radiator.

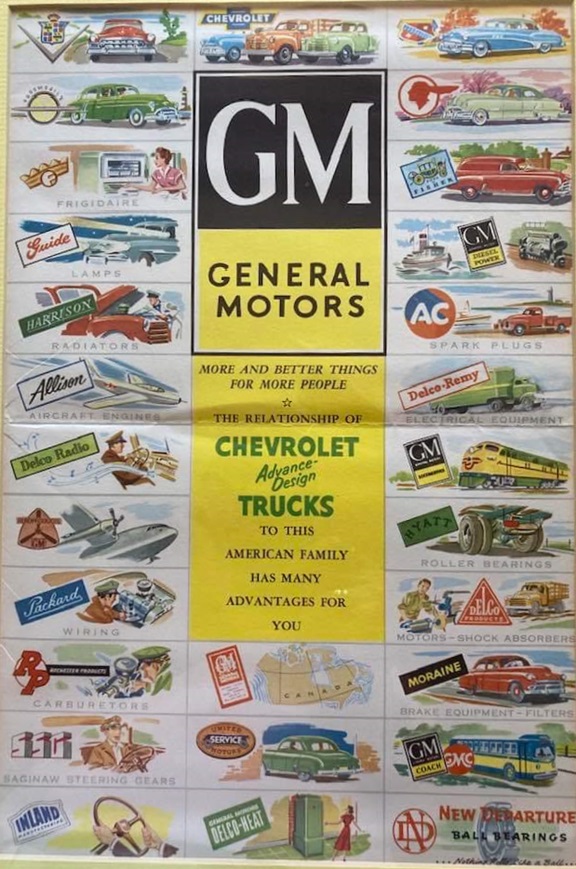

General Motors World War Two Products: According to the 1945 GM Annual Report, the company produced the following production totals during the Second World War: 119,562,000 Shells, 39,181,000 Cartridge Cases, 206,000 Aircraft Engines, 13,000 Naval Fighters and Torpedo Bombers, 97,000 Aircraft Propellers, 301,000 Aircraft Gyroscopes, 38,000 Tanks and Tank Destroyers, 854,000 Trucks, 190,000 Cannon, 1,900,000 Machine Guns and Sub-Machine Guns, 3,142,000 Carbines. 3,826,000 Electric Motors, 11,111,000 Fuses, 360,000,000 Ball and Roller Bearings and 198,000 Diesel Engines. These numbers are not inclusive of all products but give an understanding of the types and numbers produced. More can be learned by looking at the individual divisions.

The World War Two products built by General Motor are detailed below by Division, in alphabetical order. Many of the divisions listed below have their own page with more information above in the General Motors Category.

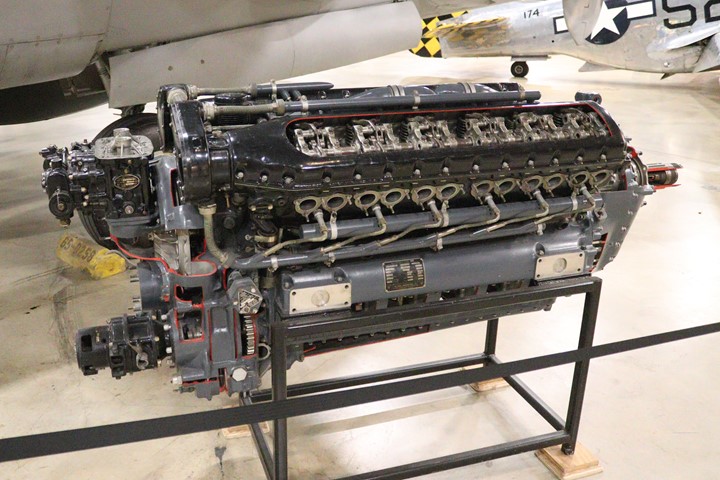

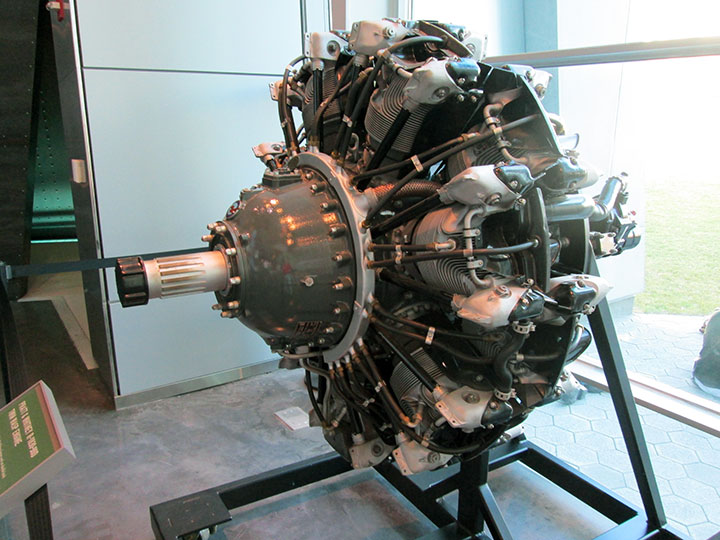

AC-Sparkplug Division: Aircraft Parts - Air Cleaners, Air Cleaner Replacement Elements, Aircraft Coolant Pressure Relief Valves, Sperry Automatic Pilots, Bombsights, Cable Terminal Connectors, Carbon Stack Insulators, Carburetor Intake Silencers and Air Cleaners, Crankcase Breathers, Crankcase Ventilating Valves, Die Castings, Diesel Engine Intake Silencers, Electric Pressure and Vacuum Pumps, Engine Bearings for Aircraft, Tanks, and Trucks, Firing Pins for Anti-Aircraft Shells (Should this be for Anti-Aircraft Guns?), Flame Arrestors, Flexible Shafts and Cables, Fuel Pumps -Electrical and Mechanical, Fuel and Vacuum Pumps, Fuel Pump Repair Kits, Gas Tank Pressure Caps, Gasoline Strainers, Ignition Cable Terminals, Instrument Panels for Tanks, Armored Cars, Trucks, and Marine Craft, (containing: Ammeters, Fuel Gauges, Indicator Lights, Oil Indicator Switches, Oil Pressure Gauges, Speedometers, Tachometers, Water Temperature Gauges, Voltmeters), Machine Guns - Browning .50 Caliber, Oil Filters - Lubricating and Fuel, Oil Filter Replacement Elements, Oil Temperature Gauges, Oxygen Pressure Gauges, Radiator Pressure Caps, Shell Magazines, Spark Plugs - Automotive and Aircraft, Spark Plug Cleaners, Spark Plug Gaping Tools, Speedometers Drive Adaptors, and Torpedo Directors. For more information see the dedicated AC Spark Plug page above. Aeroproducts Division: 24,000 or 20,773 Aircraft Propellers depending on the source - For F8F, P-39, P-63, XP-75, P-75A, P-51K and P-51H. For more information see the dedicated Aeroproducts page above. Allison: Aircraft Engines - 69,305 V-1710, V-3420, 297 J-33, 16 J-31engines for P-38, P-39, P-63, P-40, P-51A, A-36, P-59, XP-75, P-75A and P-80. Buick-Oldsmobile-Pontiac Assembly Division (BOP): BOP first showed up as a division in the 1945 GM annual report. BOP was a post-war division active in the 1950s and early 1960s for the assembly of automobiles at locations away from the home plants. The Southern California Division plant in Southgate, CA became part of this division after making tanks for Cadillac. Brown-Lipe-Chapin Division: A portion of 193,566 .30 caliber M2 Aircraft Machine guns, .50 caliber M2 Aircraft Machine guns, and .30 M1 carbine barrels. For more information see the dedicated Brown-Lipe-Chapin page above. Buick Motor Division: 74,198 Pratt & Whitney R-1830 and R-2000 aircraft engines (Final assembly for the R-1830 was done at the Buick plant in Melrose, IL and Flint for the R-2000. Machining of components was shared between Melrose and Flint.), 2,507 M18 Tank Destroyers, 640 M39 Armored Tractors (M18 chassis converted, not new production), 19,928 M4, M10 and M26 transmissions and final drive assemblies, 2,952 90mm and 4.7 Anti-Aircraft Gun Mounts, 148,196 Diesel Engine Crankshafts, 2,424,000 75mm steel cartridge cases, 1,149,300 57mm shell bodies, 9,719,000 20mm Shell Bodies, 3,120,000 Pratt & Whitney R-1830 Aluminum Cylinder Heads, 52,200 Rolls-Royce Aluminum Cylinder Blocks ( We have to assume these were for the Packard built Rolls-Royce Merlin engine, 54,714 V-1650 Merlin engines were built by Packard), 204,500 Cylinder blocks and heads for Hercules engines. For more information see the dedicated Buick page above. Cadillac Motor Car Division: 1,824 M5 Stuart tanks, 4,726 M5A1 Stuart tanks, 1,778 M8 3 inch howitzer motor carriages, 3,592 M24 Chaffee tanks, and at least 10,572 V-8 engines to other manufacturers of armored vehicles. Cadillac built all 1,824 M5 Stuart tanks and 3,530 of the M5A1 Stuarts in its Detroit plant. The remaining 1,196 M5A1 tanks were built in the Southern California Division plant in South Gate, CA. Most likely the 1,778 M8s were built at South Gate also. Cadillac also built 175 different parts for Allison V-1710 aircraft engines including crankshafts, camshafts, connecting rods and piston pins, supercharger rotator vanes, and gear reduction assemblies. Chevrolet Motor Division: 439,893 Chevrolet and GMC trucks, 2,583 Passenger Sedans, 3,844 Staghound Medium Armored Cars. Chevrolet also built Aircraft Engines. 60,766 R-2800 and R-1830 Pratt & Whitney Radial Aircraft Engines. Seventeen Chevrolet Plants were involved with building components, with final assembly being at Tonawanda, NY. R-1830 engines were used on C-47s, C-53s, and B-24s. Production of R-2800 was a project started in 1944, with the engines intended for the P-61 and P-47. Other component parts included 75mm armor piercing and high explosive projectiles, 3 Inch armor piercing and high explosive projectiles, 2,000 90mm anti-aircraft gun tubes, breech ring and block, and recoil rails. Chevroletís foundriesí 200 million pounds of aluminum forgings included forged aircraft propeller blades from four plants, making it the second largest producer of AL forgings in the world. Chevrolet foundries also produced 5.7 million pounds of magnesium castings, and two billion pounds of grey iron and aluminum castings. For more information see the dedicated Chevrolet page above. Cleveland Diesel Engine Division: At least 8,920 150-2,000 hp diesel engines. Applications for the Model 278A 16 cylinder, 1600 hp, two-cycle engine included 70% of the US World War Two submarine fleet and also were used for destroyer escorts, fleet and harbor tugs and landing craft. The combined diesel engine production of Cleveland Detroit Diesel, Detroit Diesel, and Electro-Motive Divisions was 198,000 during World War Two. For more information see the dedicated Cleveland Diesel Engine Division page above.

Delco Appliance Division: Small electric motors for various military

applications such as aircraft flap motors, and marine engine ignition

cut-out motors. For more information see the dedicated Delco

Appliance page above. Delco Products Division: 40,000,000 20mm, 37mm and 40mm projectiles and fuses, 7,000,000 shock absorbers for military trucks, gun carriages, tank destroyers, and other armored vehicles, 1,000,000 electric motors including windshield wiper motors for US military aircraft, fuel booster pumps for aircraft, Selsyn motors for anti-aircraft guns and truck steering gears, 2,500,000 link assemblies for tank treads, 23,000,000 spark plug shells for AC-Spark Plug Division (This must have been production after April 1943 as it is not mentioned in the "War Diary" below), 6,500,000 miscellaneous items to include shafts and gears for the Allison V-1710 aircraft engine, 250,000 units of hydraulic actuating devices for Grumman aircraft, 25,000 generators to include those for large searchlights and applications on navy ships, 24,000 sets of aircraft landing gears for B-24, B-25 and B-26, 250)electric actuators. For more information see the dedicated Delco Products page above. Delco Radio Division: Anti-Radar Devices (Radar Jammers) , IFF (Identification, Friend, or Foe) radio equipment for identification of aircraft, Ignition testers, Oxygen Flow Indicators, Radios for Tanks, Interphone Amplifiers, Aircraft Radio Components and Two-Way Field Radios (Walkie-Talkies.). For more information see the dedicated Delco Radio page above. Delco-Remy Division: Electrical Components for Military Trucks - Generators and generator regulators, starting motors, ignition distributors and coils, switches, and batteries; Electrical Components for Military Tanks and Armored Vehicles - Generators and generator regulators, starting motors, ignition distributors and coils, apparatus boxes, and batteries; Electrical Components for Military Aircraft - Generators and generator regulators, magnetos, and batteries; Automatic Aircraft Engine Controls; Solenoids for Sperry Autopilots; Automatic Trim Tab Controls; Electrical Components for Military Marine applications - Generators and generator regulators, starting motors, ignition distributors and coils; Marine propeller pitch controls for landing craft and submarine chasers; Marine diesel equipment - pistons, blowers, pre-heaters and pre-heater fuel pumps, governors; Tubing - for electrical, fuel, brake, air conditioning, oil and air lines; Allison V-1710 engine castings - Various; Aircraft engine machined parts - Various; 1,000,000 20mm shell bodies; Various solenoids for starting motors, aircraft bomb release racks, guns and overdrive controls. For more information see the dedicated Delco-Remy page above. Detroit Diesel Engine Division: Detroit Diesel built an estimated 193,000 diesel engines during the World War Two for armored vehicles and landing craft. It also supplied built up engines to Gray Marine that modified the engines for use in landing craft by adding a water to water heat exchangers for cooling. The combined diesel engine production of Cleveland Detroit Diesel, Detroit Diesel and Electro-Motive Divisions was 198,000 during World War Two. For more information see the dedicated Detroit Diesel Engine Division page above. Detroit Transmission Division: At least 49,862 Hydra-Matic Automatic transmissions for M5 Stuart and M26 Tanks, LVT(3) Landing Craft, Staghound and Boarhound Armored Cars and M8 Motor Carriages. It also provided parts for Browning machine guns produced by other GM divisions. For more information see the dedicated Detroit Division page above. Diesel Equipment Division: This division was created in the middle of the war in 1943 and given divisional status on January 1, 1944, to provide diesel engine components to the three expanding GM diesel engine divisions. Eastern Aircraft Division: 1,060 FM-1 and 4,777 FM-2 Fighter Aircraft, 7,546 TBM Torpedo Bombers. Electro-Motive Division: Diesel Engines for LSTs, 180 Foot Patrol Craft Escorts, Army DPC 86 foot Tugboats, 110 Foot Sub-chasers along with Components for LCI(L)s and Naval ship board Generators. The combined diesel engine production of Cleveland Detroit Diesel, Detroit Diesel and Electro-Motive Divisions was 198,000 during World War Two. For more information see the dedicated Electro-Motive Division page above. Fisher Body Division: Fisher Body was a supplier of aviation components to the aircraft industry. At the beginning of World War Two Fisher Body supplied 5,214 B-25 Bomber Assemblies to the North American Plant in Fairfax, KS. This was 55% of the content in these B-25s. It also supplied 13,772 B-29 Engine Nacelles, 68,612 B-17 exhaust collector systems, 46,748 B-17 fixed engine cowlings, 40,228 B-17 removable engine cowlings, 20,000,000 Dzus Fastener Blanks, 85,600 150 Gallon Drop Tanks for the US Navy, and 53,600 Drop Tank Mounting Kits. The Fisher Body Ternstedt Division produced 4,724 analog computers, 4,716 pumps, and 9,425 right angle drives for the Bendix Air Position Indicator. It also supplied 168,400 Gyro Horizons, 124,700 Directional Gyros, 46,615 Compass Transmitters, and 76,291 Compass Indicators under contract to the USAAF. Fisher Body also manufactured 11,358 M-4 Tanks, 5,368 M-10 Tank Destroyers, 487 M-36 Tanks, 1,200 M-26 Tanks; 2,359 90mm AA guns, 550 120mm AA Guns, 6,342 Breech Housings for 5in Naval guns, 480 5 inch gun mounts, 9,459 3 inch Naval Guns, and 888 Parts for Heavy guns, For the Oldsmobile Division of General Motors Fisher Body produced 1,500,000 Parts for 20mm Cannons 551,772 155mm shells, 2,000,000 incendiary bomb noses, and 200,000 4.5 inch rocket fins. Fisher Body also produced 9,353 crankcases for marine Diesel engines,140 planers, 250 vertical boring machines, 48 horizontal mills, 25 drilling and tapping machines; and 50,000 cutting tools. For more information see the dedicated Fisher-Body page above. Fisher Body-Ternstedt Division: This shows up for the first time in the 1945 GM annual report as a distinct division. Its contributions to the war effort are detailed under Fisher Body. Frigidaire Division: 363,000 .50 Caliber Browning M2 Machine Guns, 1,000,000 spare .50 Caliber Machine Gun Barrels - First Contract was in June 1941. Frigidaire engineers made over 500 design and manufacturing changes and reduced the cost of the machine gun to 25% of the original cost using mass manufacturing techniques. Chambering of one million FP-45 "Liberator" pistols to .45 caliber. Frigidaire also produced 21,263 three blade Hamilton Standard Propellers for the C-47, B-17, B-24, PB4Y and C-87. It also made 54,737 four Blade Propellers for the B-29 and P-47. Frigidaire also built components for both three and four bladed propellers for Aeroproducts, which was another GM Division located in nearby Vandalia, OH. These propellers were installed on the Bell P-39 and P-63. Components supplied by Frigidaire were the blades, hub, regulator assembly, blade thrust member, and other parts. Various components including the long range fuel tanks for the famous Doolittle Raiders' B-25s, components for the Hispano-Suiza 20mm aerial cannon, diesel cylinders and heads the Cleveland Diesel Division of GM that were installed in Sub Chasers, carburetor bodies for radial aircraft engines, 20mm Oerlikon cannon parts and millions of .50 caliber bullet cores. For more information see the dedicated Frigidaire page above. Frigidaire Products of Canada: This appears for the first time as a distinct division in the 1945 GM annual report. Frigidaire had a plant in Leaside, ONT, a Toronto suburb since 1937. It is not known what contributions it made to the war effort. General Motors Institute (GMI): GMI was GM's own in-house four year college with a mission to produce engineers and managers for its world wide operations. During World War Two, GMI provided industrial training to 17,500 men and women to help them learn the skills needed to produce military products in GM plants. Over 10,000 military personnel were trained there on GM wartime products. For more information see the dedicated GMI page above.

General Motors of Canada, Ltd.:

1,506 Mark 1 Fox Armored Cars, Modified

Canadian Military Pattern Trucks, 201,000 Canadian

Military Pattern Trucks (CMPT), 1,032 De Havilland Mosquito aircraft

fuselages, gun sights, gun mounts and 20,000 plus machine guns. For more information see the dedicated

General Motors of Canada, Ltd. page above. General Motors Parts Division: This division supplied the replacement parts needed to keep the civilian cars and trucks operating during the Second World War. A limited number of spare parts were manufactured during the war which became extremely important as no new cars were being built. General Motors Proving Ground: This is also known as the Milford Proving Grounds. It was the test location for many new World War Two vehicles such as trucks, tanks, and tank destroyers. Over 900 vehicles from all manufacturers were tested during the Second World War. For more information see the dedicated General Motors Proving Grounds page above. GMC Truck and Coach Division (Yellow Truck & Coach Manufacturing Company): 528,829 6x6 trucks, 55,096 other types of multi-drive vehicles, 32 armored cars and busses for military use. In 1944 limited civilian truck production resumed to provide transportation for the US war industry. GMC did not become a GM Division until September 30, 1943. Previous to that it was part of the assets of Yellow Truck & Coach Manufacturing Company that was owned by GM, but not a division. For more information see the dedicated GMC page above. Guide Lamp Division: 8,500,00 total of headlamps, tail lamps, dome lamps, blackout lamps and signal lamps; 3,400,000 Stimsonite reflector units; 22,000 Bell Aircraft P-39 Aircobra spinner noses; 1,000,000 water jacket sleeves for Allison aircraft engines; 36,750,000 cartridge cases for 37mm, 90mm, and 105mm constructed of both brass and steel; 1,600,000 .50 caliber Browning machine gun barrels; 682,163 complete M3 and M3A1 submachine guns. This was a GM Inland Division design with Guide doing all the final assembly. For more information see the dedicated Guide Lamp page above. Harrison Radiator Division: Radiators and oil coolers for tanks, aircraft, and various other military applications. For more information see the dedicated Harrison page above. Hyatt Bearing Division: Roller bearings for various military applications. For more information see the dedicated Hyatt page above. Inland Manufacturing Division: The Inland Division during World War Two is most identified with the M1 carbine. The division produced 1,984,189 M1 carbines, 140,000 M1A1 carbines, 500,000 M2 carbines, and 811 M3(T3) carbines. Inland also

manufactured a number of component parts: 4,000,000 tank shoes, 142,708

tank tracks, 40,000 gun sights and 13,688 shoulder rests for Oerlikon

20mm anti-aircraft cannons, 2,000,000 M-1 helmet liners, 846,000

clutches of all types, 8.8 million various rubber parts for military

vehicles, aircraft, and ships, and unknown numbers of truck steering

wheels and brake linings built for Chevrolet and GMC trucks. For more information see the

dedicated Inland page above. Moraine Products Division: M-1 Anti-Tank Mine Fuse, M-64 Relay Igniter Housing, M-20 Booster for powder charges, Tank Track Assemblies, Spinner assemblies for Aeroproducts propeller, .50 caliber cores, M-57 fuse, parts for .50 caliber machine guns, aircraft hydraulic fittings, Brake components for military trucks, Connecting rod bearings for various military engines, Bearings and bushings, Porex parts, and Powdered Metal parts. For more information on the combined Division see the dedicated Moraine Products page. New Departure Division: New Departure continued to make roller bearings, the same product line it was producing prior to the World War as it did previously. Available data shows that in 1942 it made 67,376,111 bearings and in 1943 it made 85,321,043 bearings for the war effort. Estimating that it made another 85 million in 1944 and then 50 million in 1945 as the war contracts were cancelled in August 1945 New Departure probably made approximately 287 million bearings for thousands of different uses in World War Two. More can be learned about those military applications and some of its earlier history by visiting the dedicated New Departure page listed above.

Oldsmobile Division:

Oldsmobile also produced 24,713 M2 Feeders, 1,680 37mm M4E3 Magazines, 30,672 .50 Cal. Gun Tubes, 220,906 P&W Piston Rods, 27,050 4.5 T22 Rockets, and 231,198 T38 Rockets. The 75mm, 105mm, 155mm and 3 inch shells were produced in the Olds Plant 2 Forge Plant which was about a mile northwest from the main Olds complex. Total amount of shells, projectiles and shot produced at the Lansing operation was 20,418,600 from 8-19-1942 until 6-30-1945. These included 8,597,161 75mm M48 HE, 398,328 75mm M66, 5,417,737 105mm HE, 316,362 105mm M67, 3,740,678 75mm M61, 414,098 75mm M62A, 330,476 75mm M72, 1,026,1200 3 inch, 121,490 155 M101, and 56,150 75mm M61A1 shells.

Oldsmobile World War Two Production Numbers for the Janesville, WI Plant Oldsmobile borrowed both the Chevrolet and Fisher Body plants in Janesville, WI for World War Two production. Total amount of shells, projectiles and shot produced at the plants was 12,420,353 from 7-7-1942 until 8-19-1945.

Oldsmobile World War Two Production Numbers

for the for Leeds, MO Plant (Kansas City, MO area) Oldsmobile borrowed this plant for the war from the Fisher Body Div. of GMC. Total amount of shells, projectiles and shot produced at the plant was 12,499,237 from 8-19 -1942 until 6-30-1945. For more information see the dedicated Oldsmobile page above. Packard Electric Division: Electrical cable (insulated wire) from Packard Electric was used for the wiring of a multitude of military applications during the Second World War. Electrical wiring is ubiquitous as it is used everywhere there are electrical circuits but it is usually never given much thought as it is never seen. There was a considerable amount of engineering and manufacturing expertise needed to get the correct electrical insulation for the military application that Packard Electric was able to provide for the war effort. Packard cable was used in land vehicles, aircraft, ships, engines and various military instruments and electrical equipment. It should be noted that World War Two was previous to the invention and use of the circuit board. Electrical equipment all used point to point wiring that needed copious amount cable and wire to make it work. For more information see the dedicated Packard Electric page above. Pontiac Motor Division: 47,026 20mm Oerlikon anti-aircraft cannon, 39,275 single 20mm Oelikon mounts, 5,760 twin 20mm Oerlikon mounts, 4,526 Mark XIII aerial torpedoes, 155mm artillery shells, tank axles for the M-5 Stuart and M24 Chaffee tanks built by Cadillac, parts for Detroit Diesel to include fly-wheel housings, connecting rods and cylinder liners, truck engine castings for GMC to include six Cylinder blocks for all GMC and Chevrolet built GMC 270 engines, some but not all engine heads for GMC 270 engine, oil pump housings, bearing caps. Pontiac produced 4,900 40mm Bofors anti-aircraft gun mechanisms and 17,892 40mm Bofors gun tubes through March 1944. It was the first auto manufacturer to win the Army-Navy "E" Award from the Navy on January 20,1942, which was the first of five. For more information see the dedicated Pontiac Motor Division page above. Research Laboratories Division: Research support for the manufacturing divisions. One important development coming out of the GM Research Labs in 1942 was the 16 cylinder 2 cycle pancake diesel engine that was then manufactured by Electro-Motive Division and was used to power 243 110 foot Navy Subchasers. The lab also developed the balancing and polishing machine used by Electro-Motive for the brass propellers on the LCI(L), Landing Craft Infantry (Large). Rochester Products Division: 75 types of Aircraft generators, 60 types of relays, controls, radio filters, and carbon pile and contract voltage regulators, naval alternators, voltage boosters, 60 types of aircraft starting motors, hydraulic pump motors, tank generators, starters and control units. For more information see the dedicated Rochester Products page above. Saginaw Malleable Iron Division: Armasteel for various military applications including Browning machine guns manufactured by other GM divisions. For more information see the dedicated Saginaw Malleable Iron page above. Saginaw Steering Division: 517,213 M1 .30 Caliber Carbines, 412,384 .30 Caliber Machine Guns, 13,377,152 37mm and 148,981 57mm projectiles. Of the 412,384 .30 caliber machine guns produced by Saginaw Steering Division, 43,479 were M1919A6. For more information see the dedicated Saginaw Steering Division page above.

Southern California Division:

This was last shown as a separate Division in the 1942 GM annual report and was the South

Gate, CA assembly plant. It was loaned to Cadillac for the war

effort and then at the end of the war became part of the new

Buick-Olds-Pontiac assembly division. United Motors Service, Inc.: This was the distribution division to provide both parts and service to GM vehicles. In November 1942 United Motors took over management of the Lima, OH Tank Depot which during the war prepared many vehicles for the war in Europe, including the M-5 light tank, the T-26 Pershing tank, and the M4 Sherman amphibious tank that was used on D-Day. See the United Motors Service page for more information on it and the Lima Tank Depot. The following General Motors divisions were new in 1945, and therefore made no contribution to the war effort: General Exchange Insurance Corporation General Motors Acceptance Corporation Motors Holding Corporation Motors Insurance Corporation Yellow Manufacturing Acceptance Corporation

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||