|

Inland

Manufacturing Division of General Motors in World War Two

Dayton, OH

1918- 1989

Rest in Peace

This page updated 5-4-2023.

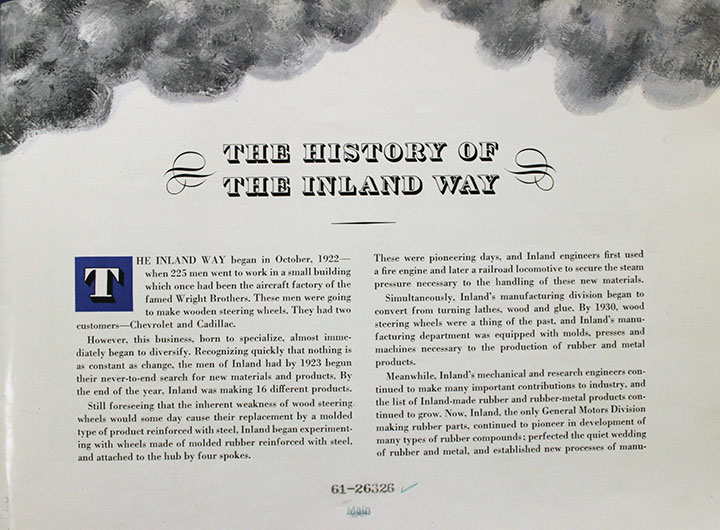

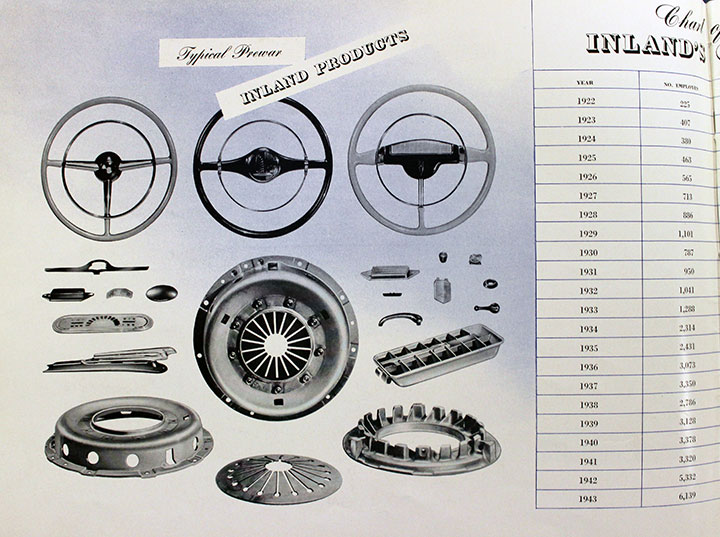

Inland Manufacturing

Division was formed on January 6, 1923. General Motors formed the

division to produce an automotive steering wheel consisting of an iron

spoke covered with a glued-on wood veneer. That was a new

technology at the time for producing this product. One of Inland's

many contributions to the World War Two war effort were steering wheels

for military trucks,

along with control yokes for military aircraft. The division's

original automotive steering wheel expanded to many other types of

products. By the time

of its 50th anniversary in 1973, the product line had expanded to 224

products produced by 7,000 employees.

Of special note is that when the new division started producing its new type

of steering

wheels in 1923, it did so in the buildings previously occupied by the

Dayton Wright Airplane Company. Inland also employed many of the same persons

that during World War One built components for 3,500 DeHavilland DH-4

military aircraft assembled in Moraine, OH. The two buildings,

called Plant 3 by the Dayton Wright Airplane Company, had originally been

built by the Wright Brothers in 1910 and 1911.

When the original Inland

complex was razed in the early 21st century, the original Wright

Brothers' buildings were spared and are being preserved for future

generations as the historic

buildings that they are. They will be open to the public

at some date in the future.

This is the original Wright Brothers factory

at the former Inland Division location that was not razed with the rest

of the buildings. It awaits restoration as a historic museum.

Author's photo taken in February 2015 and added

10-21-2015.

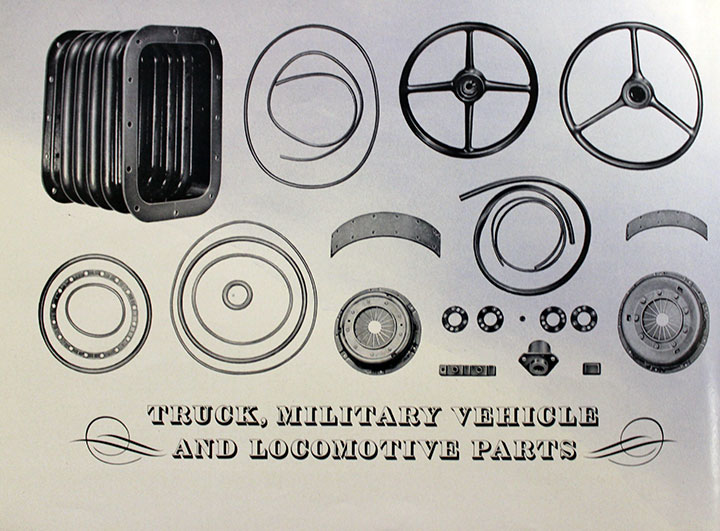

Inland Division of GM

World War Two Products:

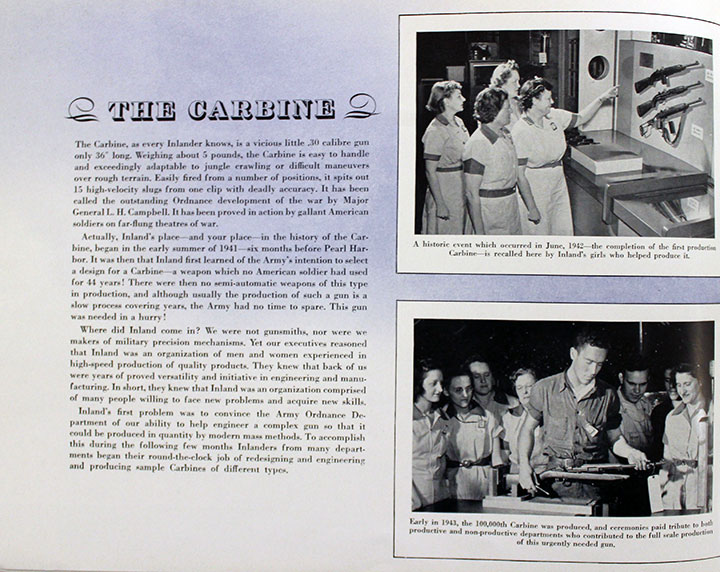

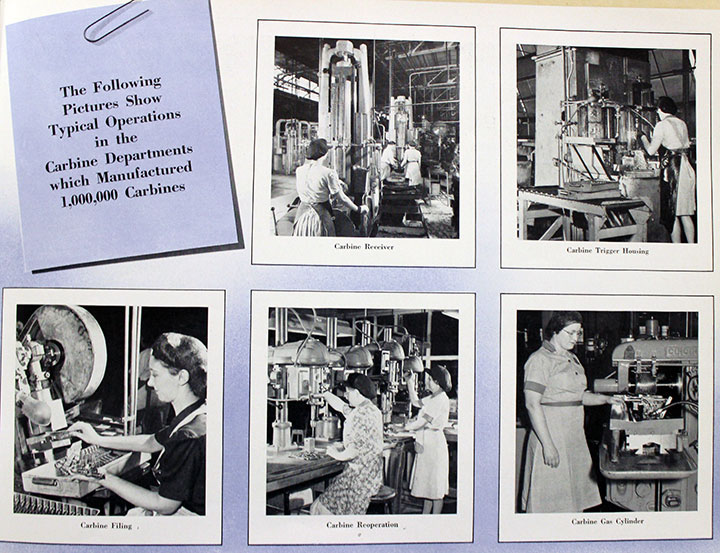

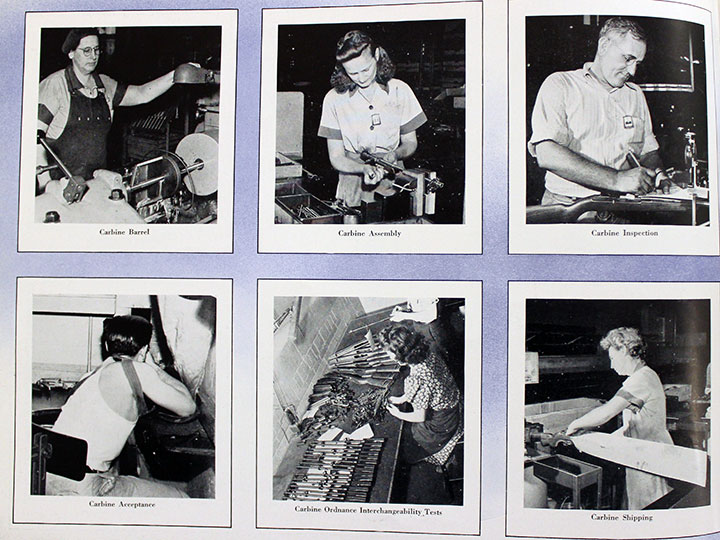

The .30 caliber Carbine:

The M1 carbine is most identifiable with the Inland Division.

During World War Two it produced 1,984,189 M1 Carbines, 140,000 M1A1

Carbines, 500,000 M2 Carbines, and 811 M3(T3) Carbines.

The M1 carbine became a weapon of the US Armed Forces on October 22,

1941, and Inland Division was the first of ten manufacturers to receive

an order one month later in November 1941. It was one of

only two companies still producing carbines when the war ended in 1945.

Of the 6,110,730 carbines of all types built during the conflict, Inland

made 2,625,000 or 43% of the total. Combined with the 517,212 that

its sister GM Division Saginaw Steering Gear manufactured, General

Motors produced 51% of all carbines made. Inland was the only

manufacturer of the M1A1 folding stock, paratroop version, and was one

of two companies that made the M2 version with selective fire. It

also was one of two companies that made the M3(T3) carbine with infrared

night sight and was the only supplier that made all four types of

carbines. Inland Division of GM truly was the king of the carbine

manufacturers!

Inland had the first and last series of serial numbers issued

for the .30 caliber carbine.

1 to 5; 11 to 999,999; 2,912,520 to 3,212,519; 4,879,526 to 5,549,921;

6,219,689 to 6,449,867; 6,629,884 to 7,234,883; 7,369,661 to 8,069,660.

Not all serial numbers were used.

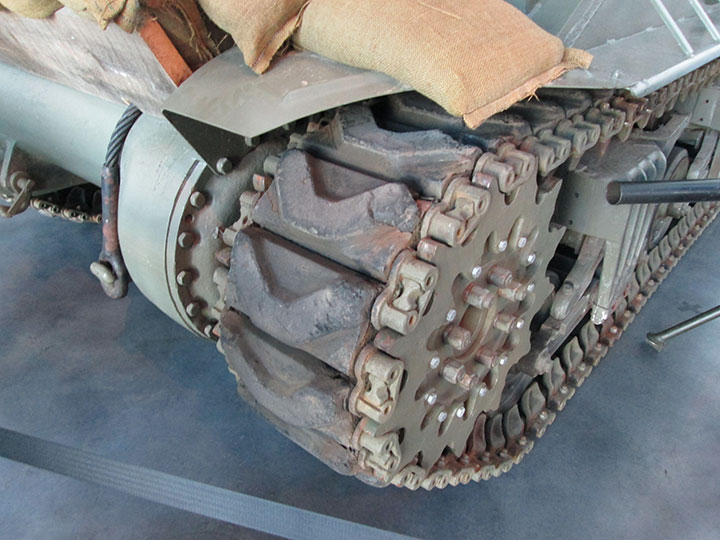

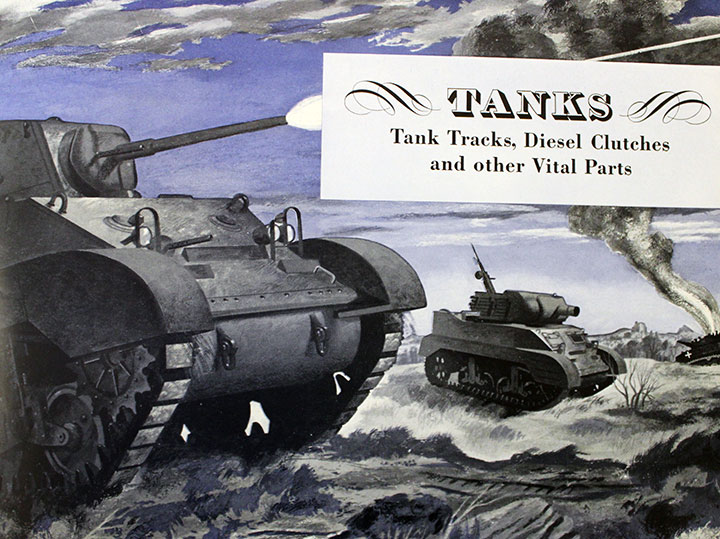

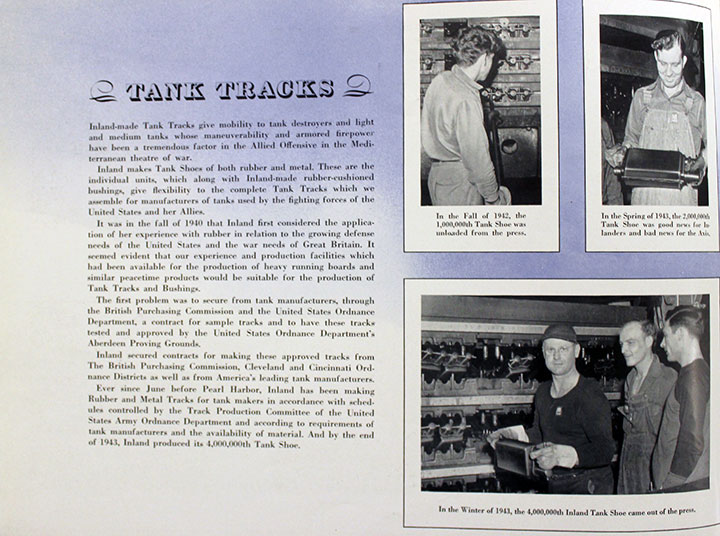

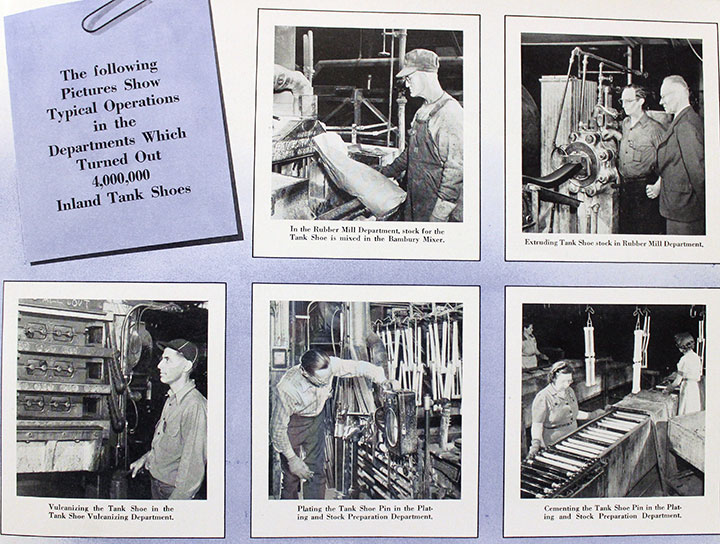

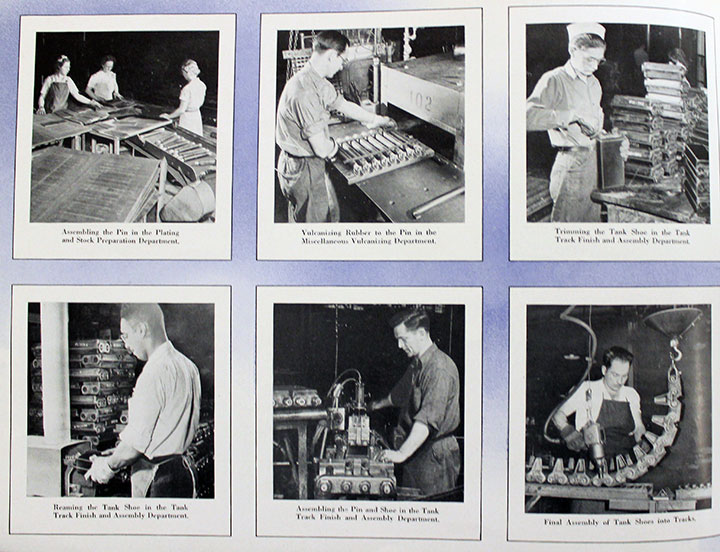

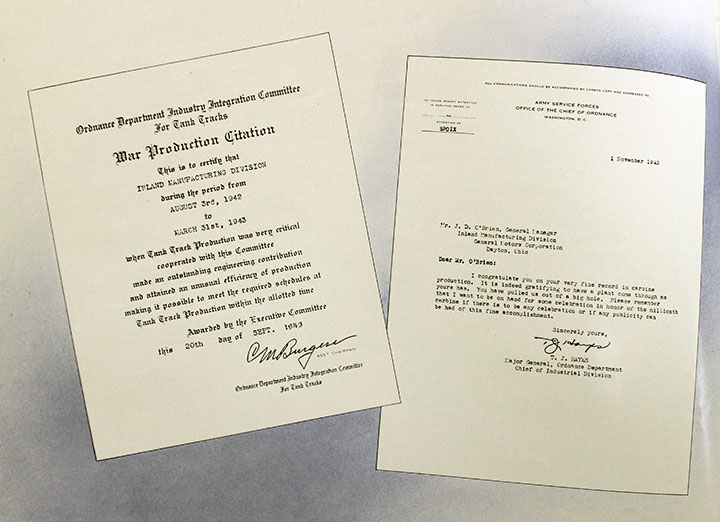

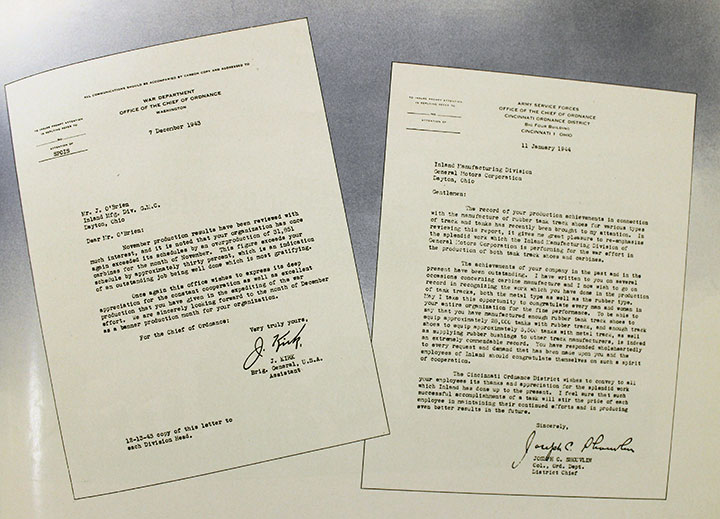

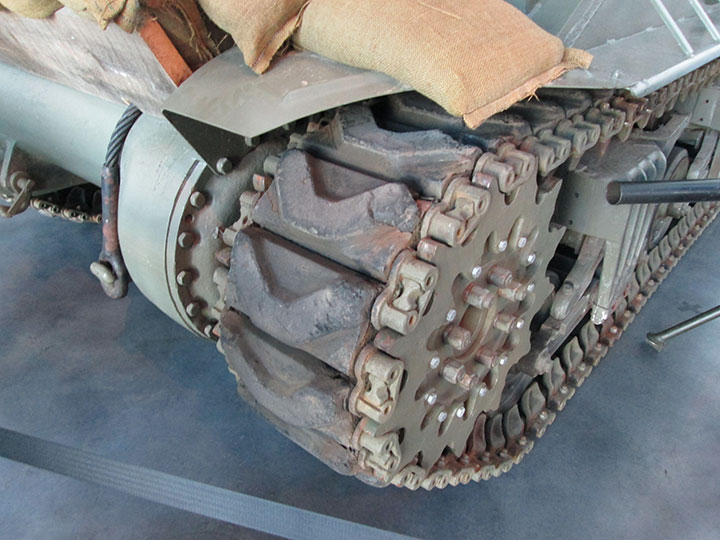

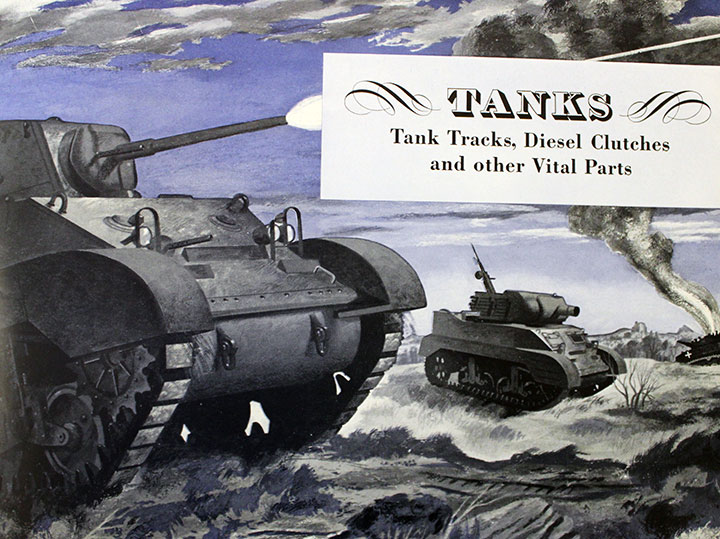

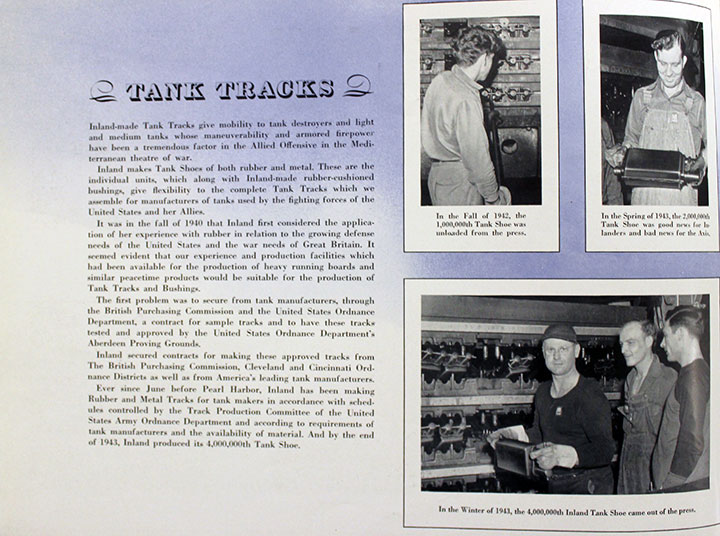

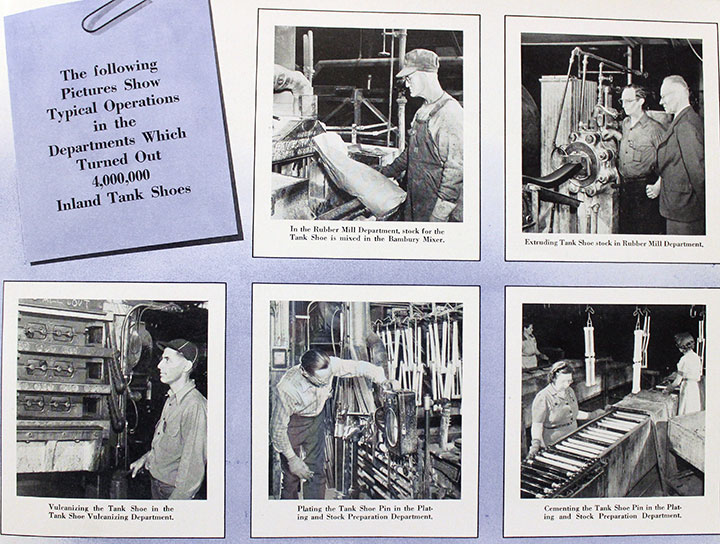

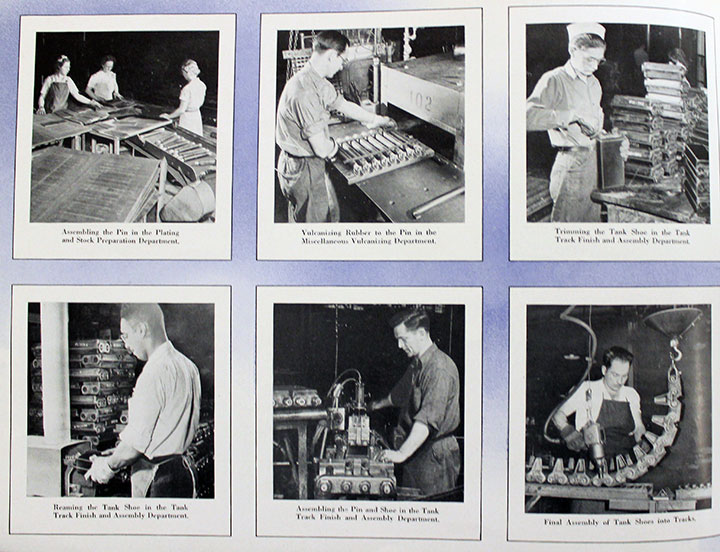

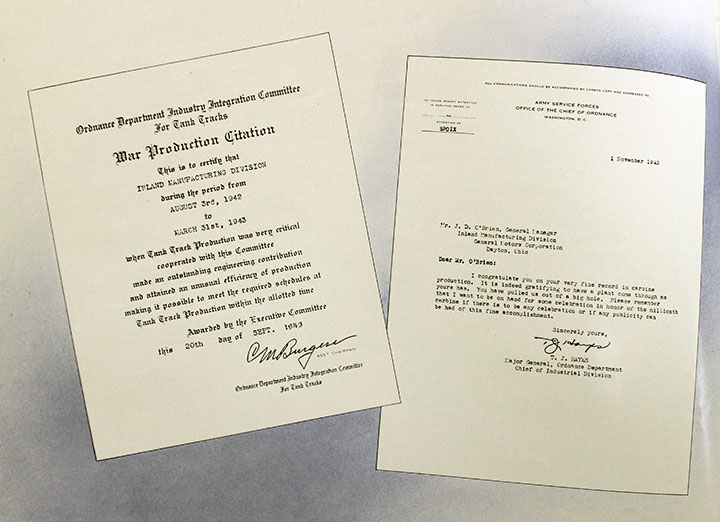

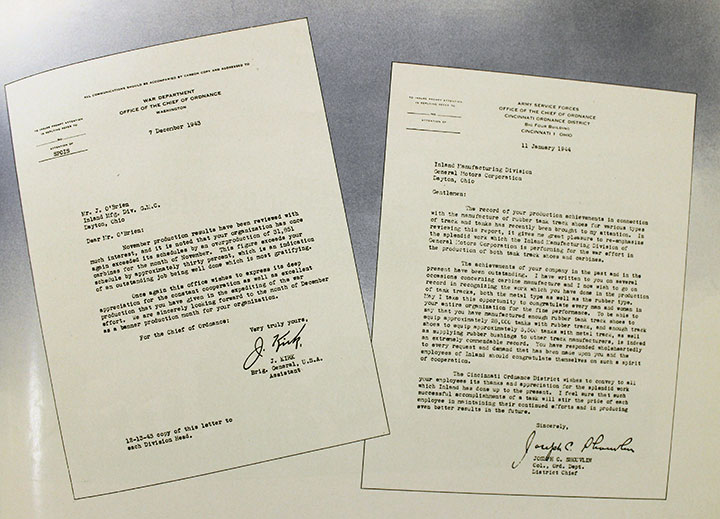

Tank Shoes: 4,000,000 rubber and metal tank shoes

were manufactured by Inland. They were then assembled into tank

tracks as of December 31, 1943, according to page 18 of the "The Inland

Way at War Today" below. With almost two more years of war to fight, this would

imply that many more were built before the end of the war.

Tank Tracks: 142,708 were built during the war. These would have been able to

equip all of the 49,234 M4 Sherman tanks built during World War Two. That is a lot of tank tracks.

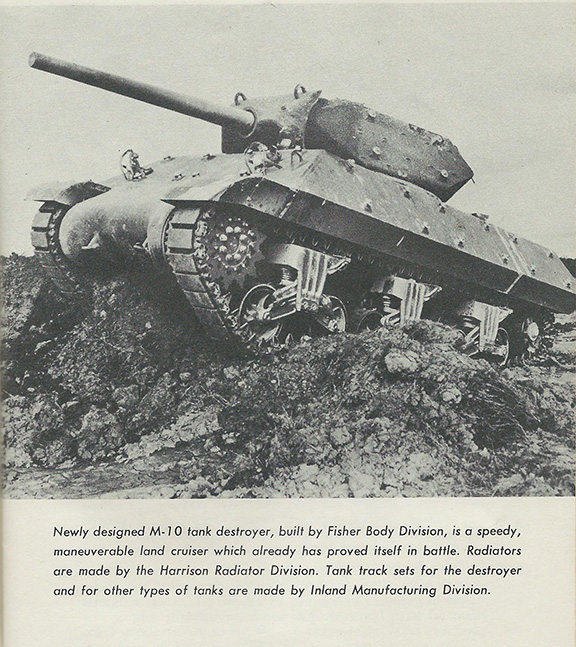

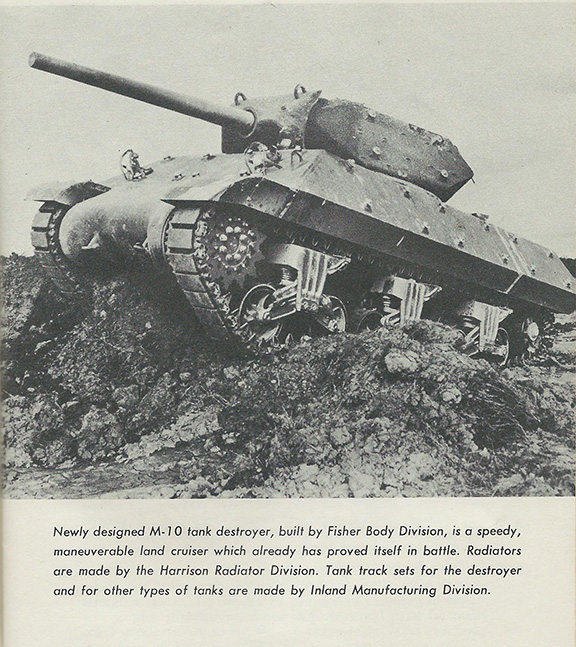

According to pages 16-19 of "The Inland Way at War Today" below, the tank

tracks were used on light and

medium tanks and tank destroyers. Pictured on page 16 is the M5

Stuart and its sister the M8 three inch Howitzer Gun Carriage. The

M4 Sherman was the main U.S. medium tank of World War Two, while the M10

and M18 Tank destroyers were the two fully tracked types built during

the war.

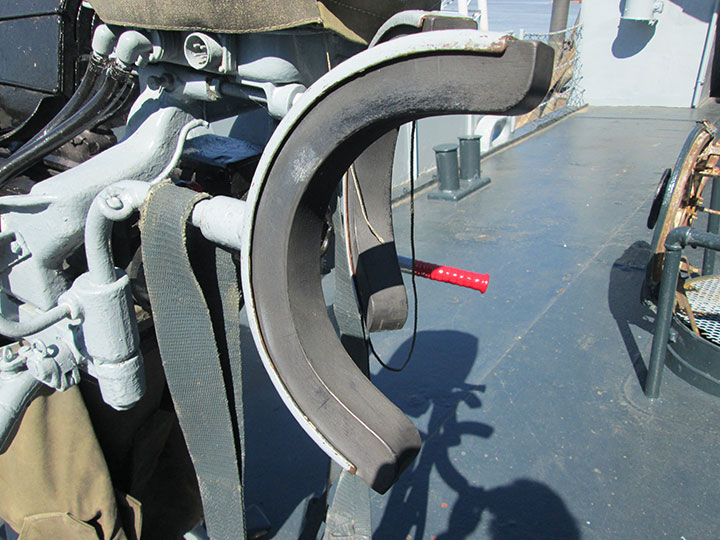

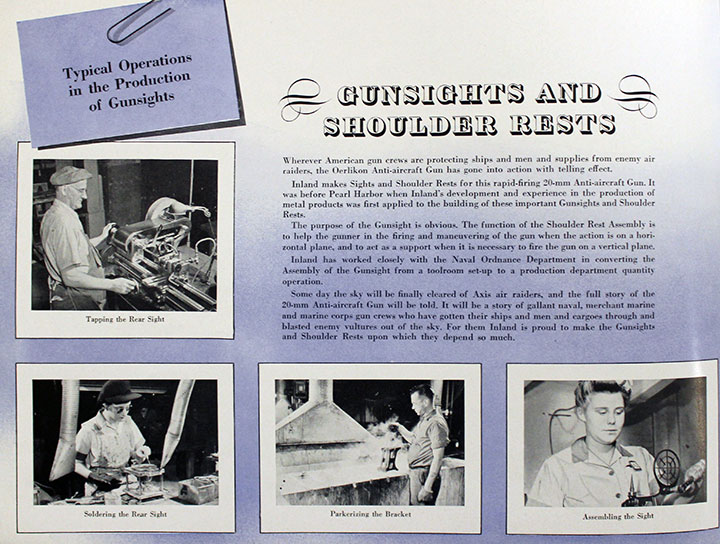

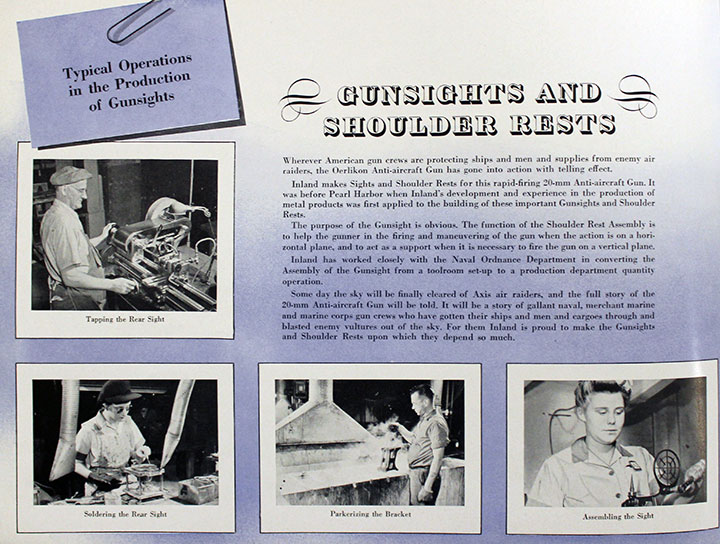

Gun sights and Shoulder

rests for Oerlikon 20mm anti-aircraft cannons: Inland built

40,000 gun sights and 13,688 shoulder rests for this weapon. These

weapons were used as a close range anti-aircraft weapon on U.S. Navy

ships. Pages 22-23 of "The Inland Way at War Today" below have more information.

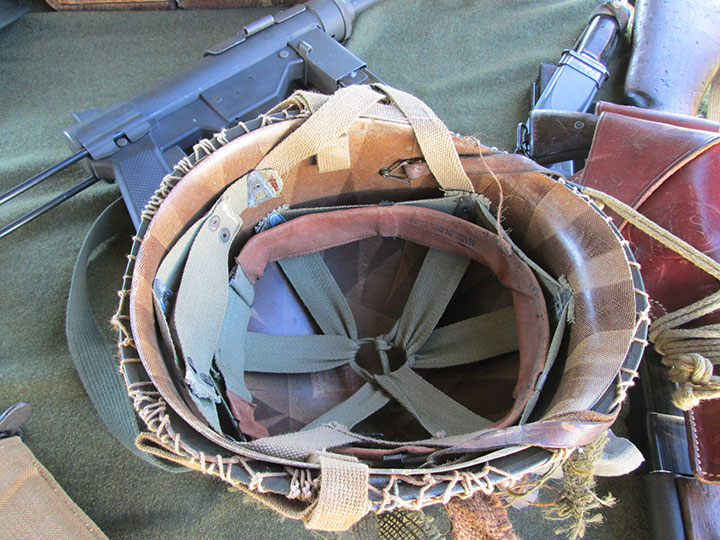

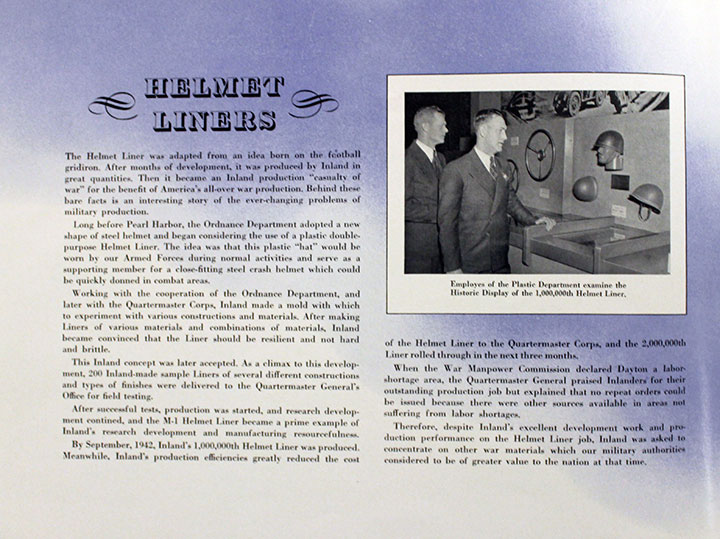

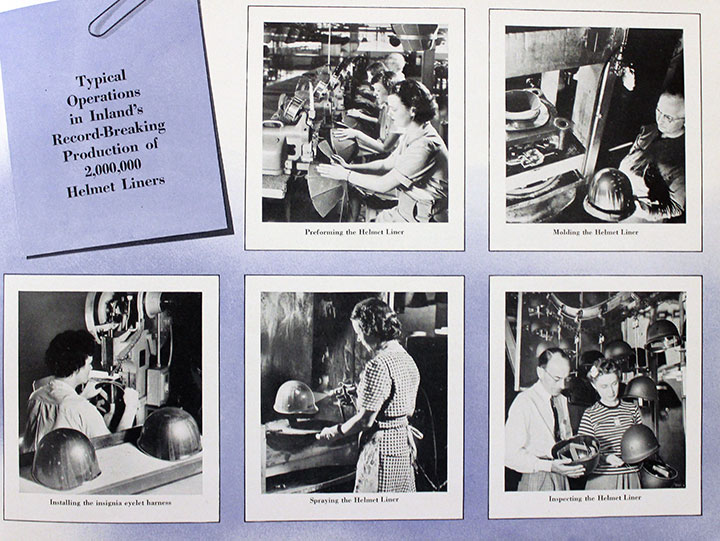

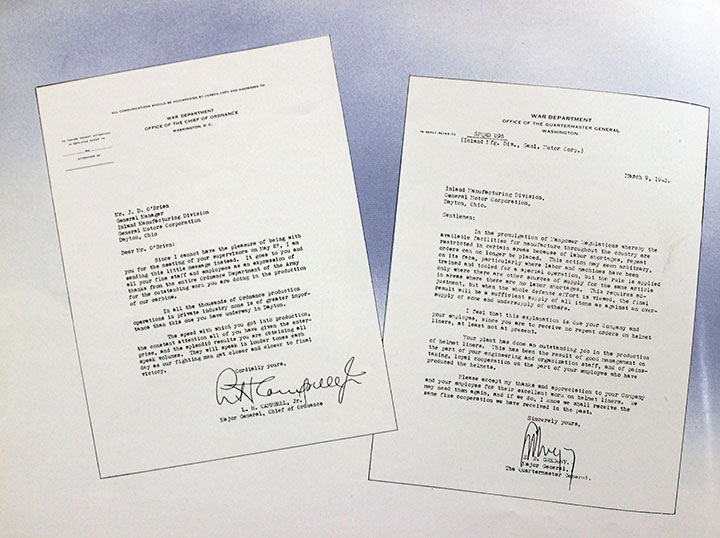

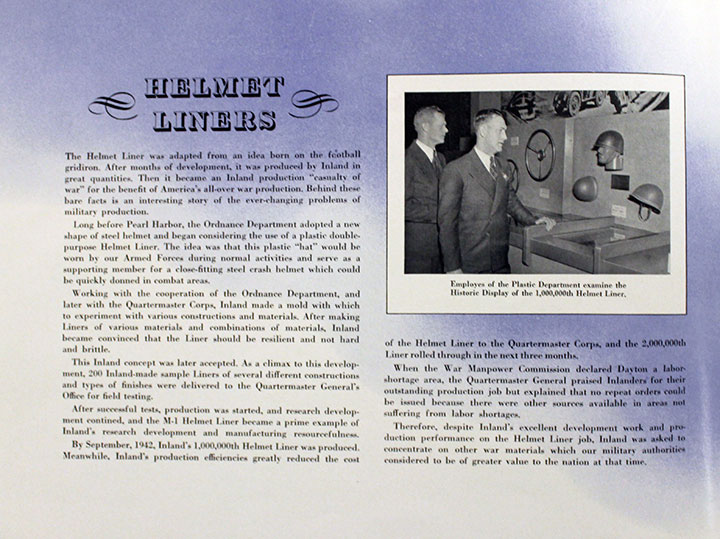

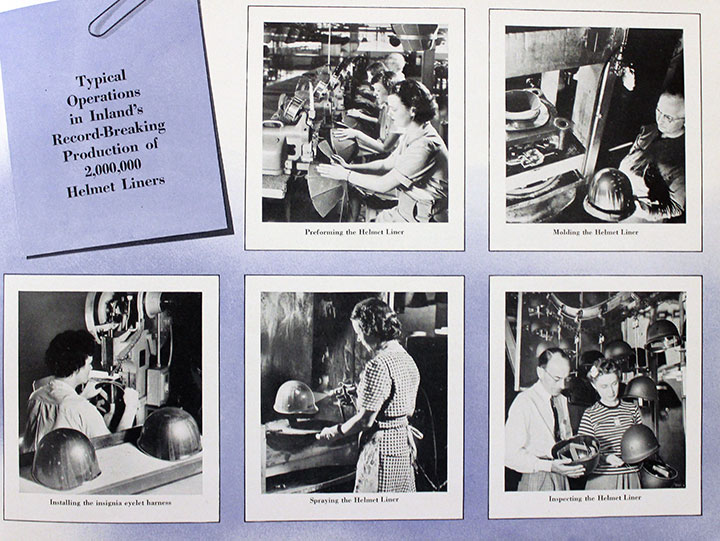

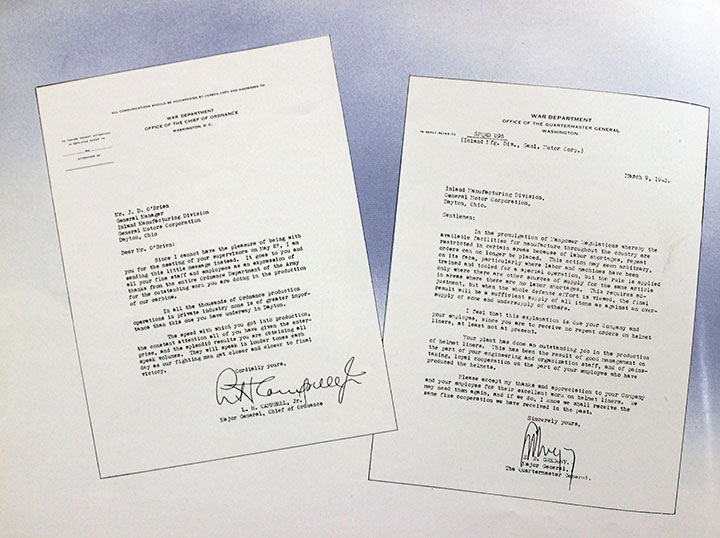

M-1 Helmet Liners:

By the end of December 1942, Inland manufactured 2,000,000 M1 helmet liners,

but then stopped production due to a labor shortage in the Dayton area.

See pages 24-26 in "The Inland Way at War Today" for more. Also on

page 52 below is a copy of the letter dated March 1943 from the War Department to Inland

explaining the reason for pulling the business.

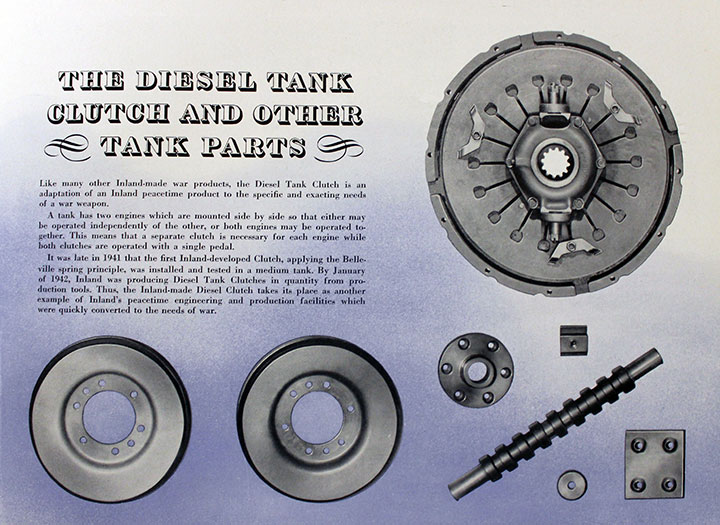

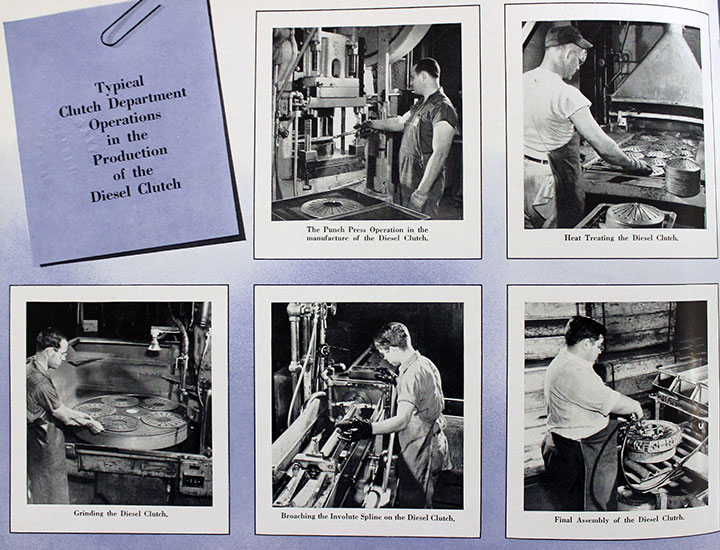

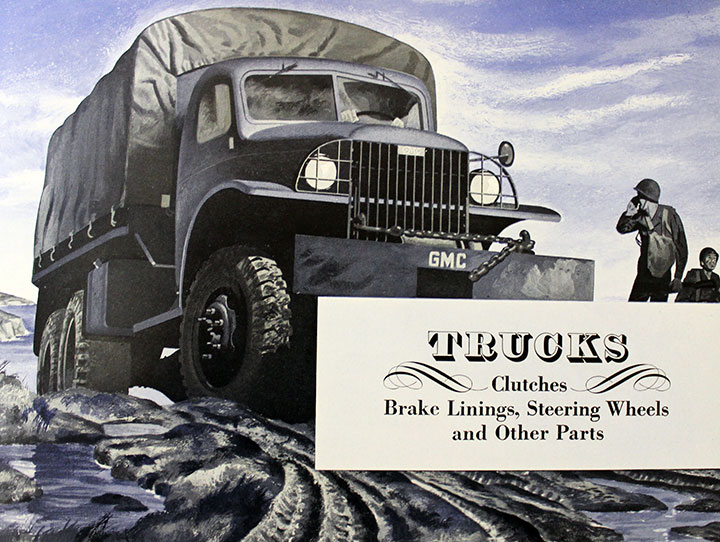

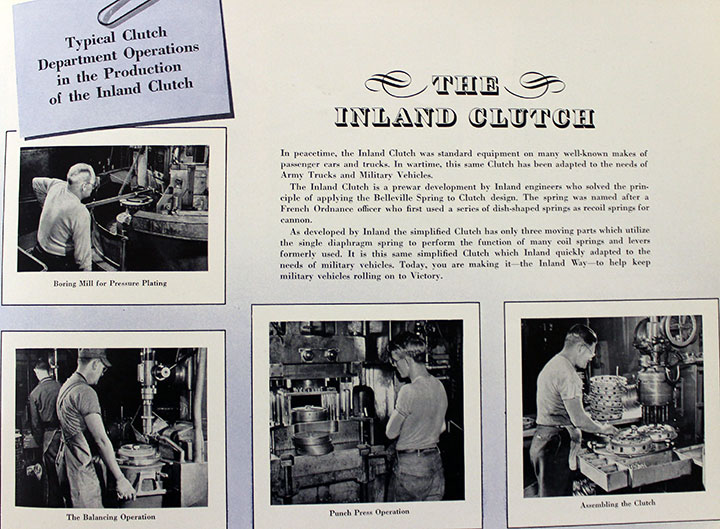

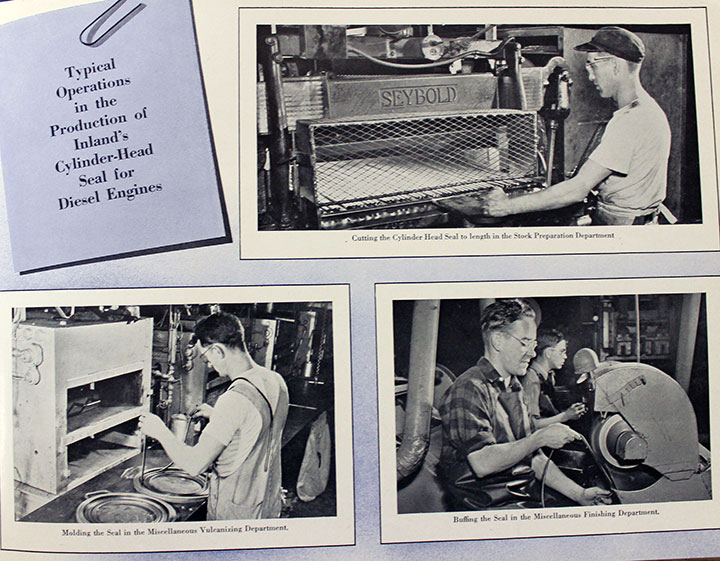

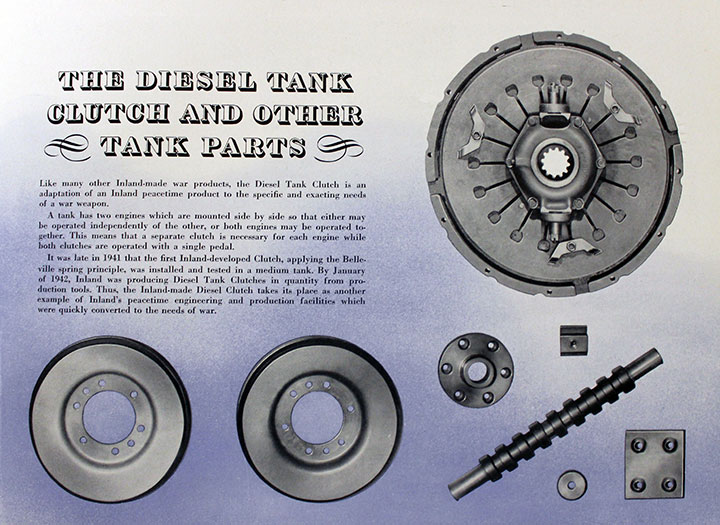

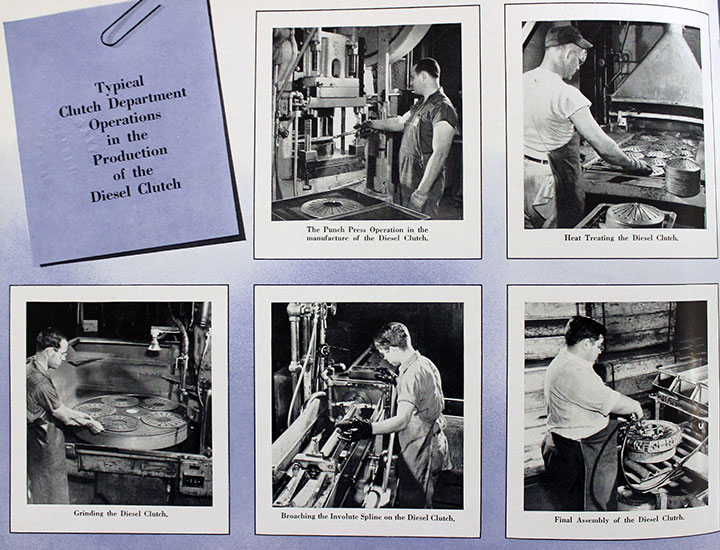

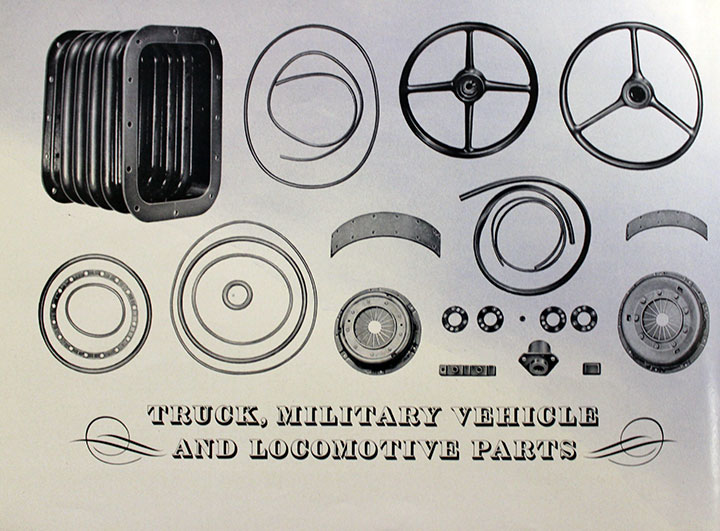

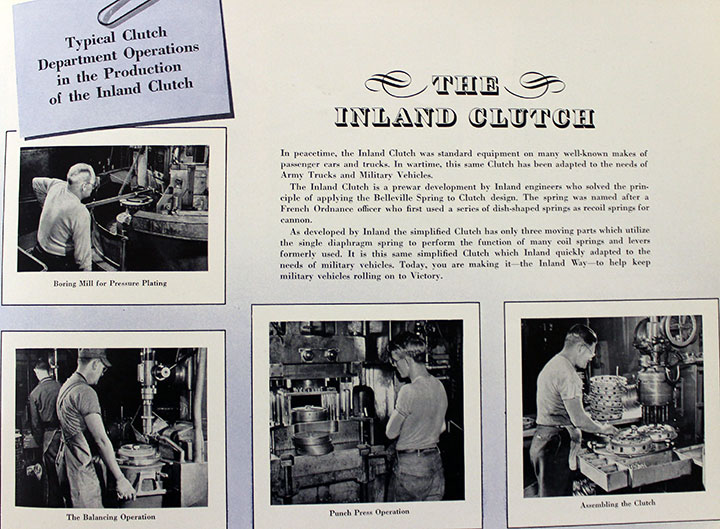

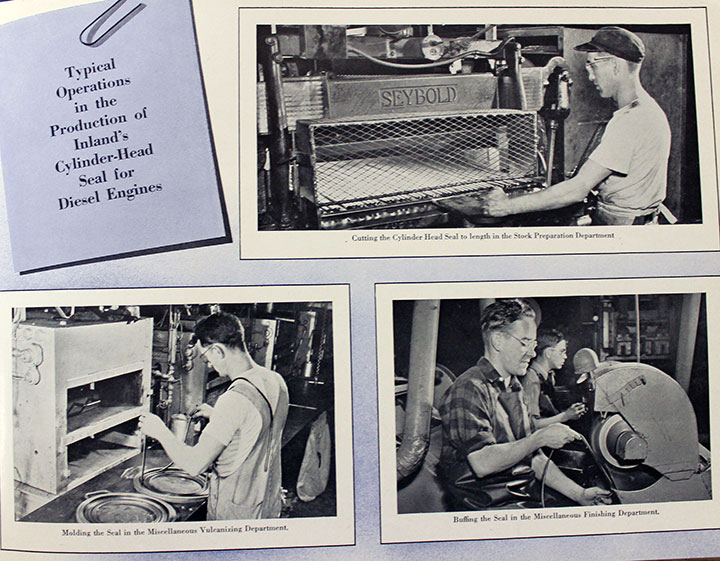

Clutches: 846,000

of all types. Pages 20 and 21 of "The Inland Way at War

Today" specifically talk about clutches and other parts for diesel

tanks but gives no quantities. The Detroit Diesel Division of

General Motors provided all of the diesel engines used in American-built

armor during World War Two. The engines went into 3,981 Canadian-built Valentine tanks, 913 M3 tanks,

8,053 M4A2 tanks, and 6,706 M10 tank destroyers, totaling 19,653 armored

vehicles.

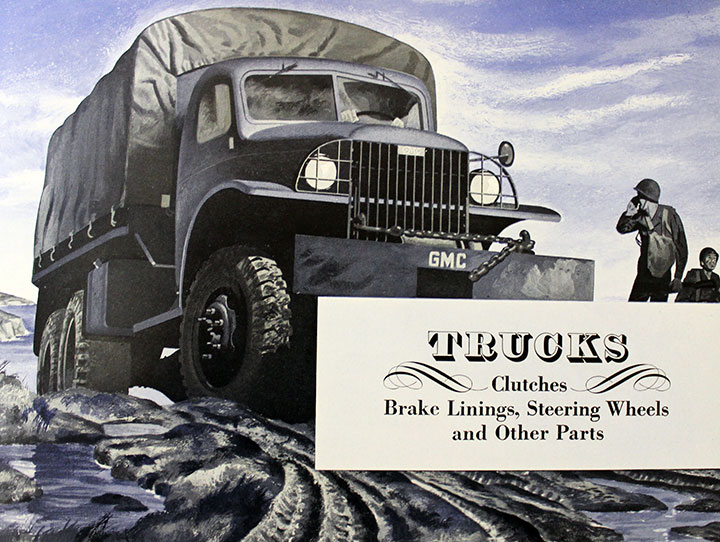

Pages 32-34 below discuss

the Inland Clutch that was used in military trucks. Page 32 shows a

drawing of a well-marked GMC 2-1/2 ton 6x6 truck. (Note that the

artist missed putting the double set of wheels and tires on the rear

axles. All GMC's built during the war had four wheels and tires on

the rear axles.) During World War Two Chevrolet and GMC built 854,000

gasoline powered trucks for the war effort. Inland clutches were used extensively in these vehicles.

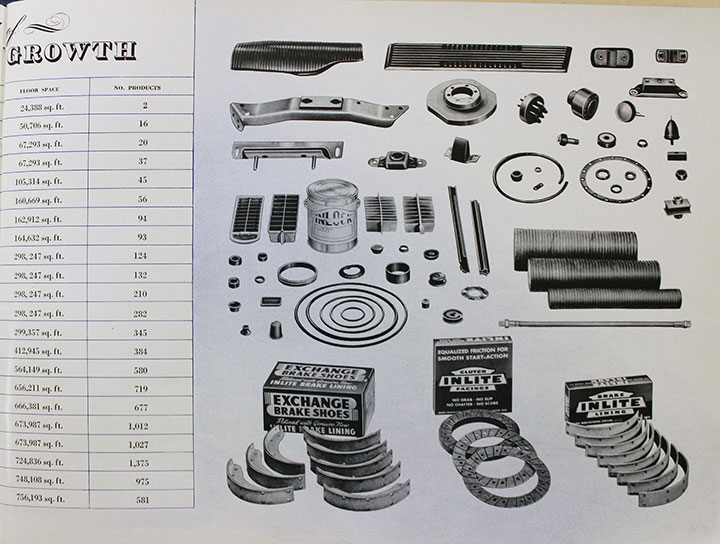

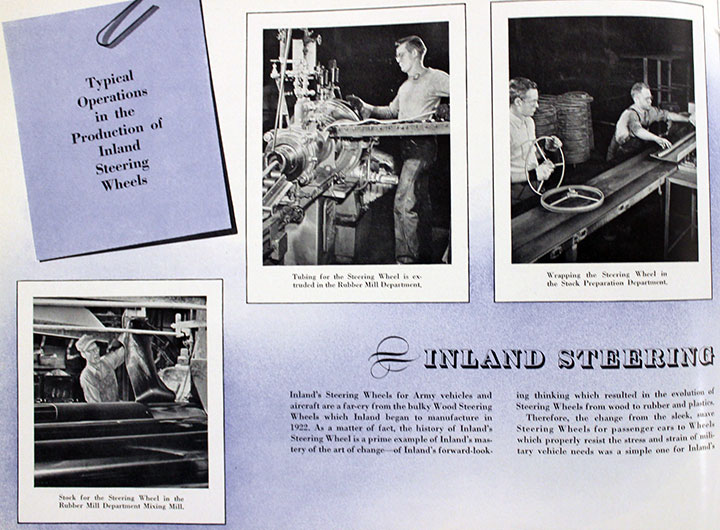

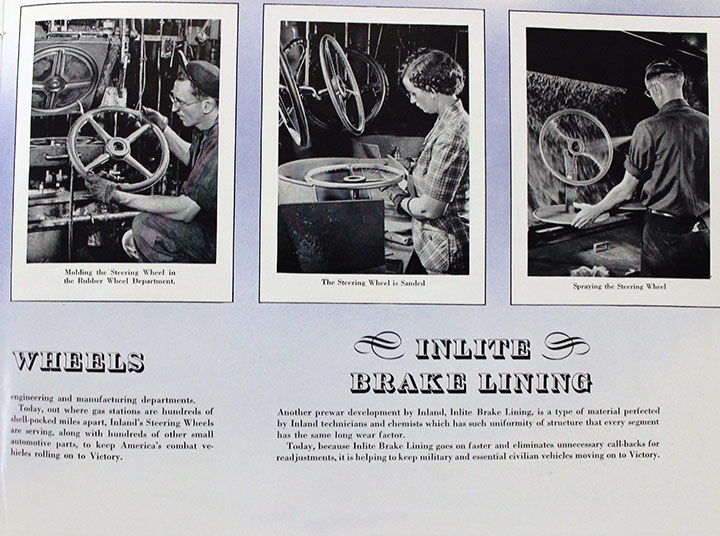

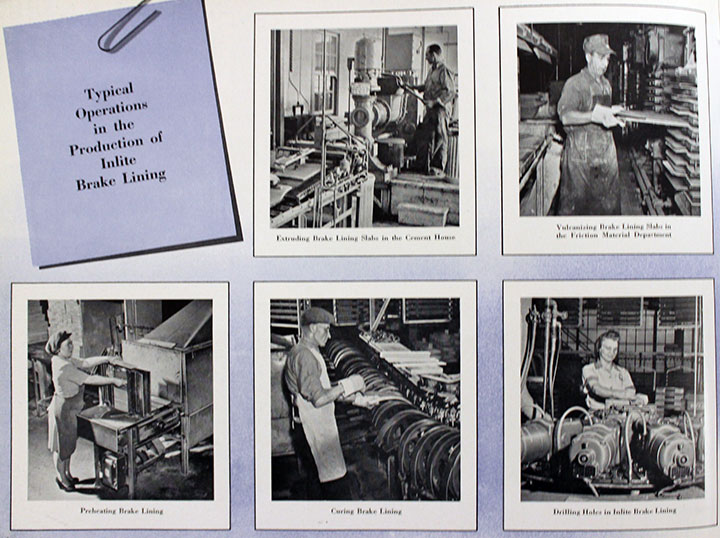

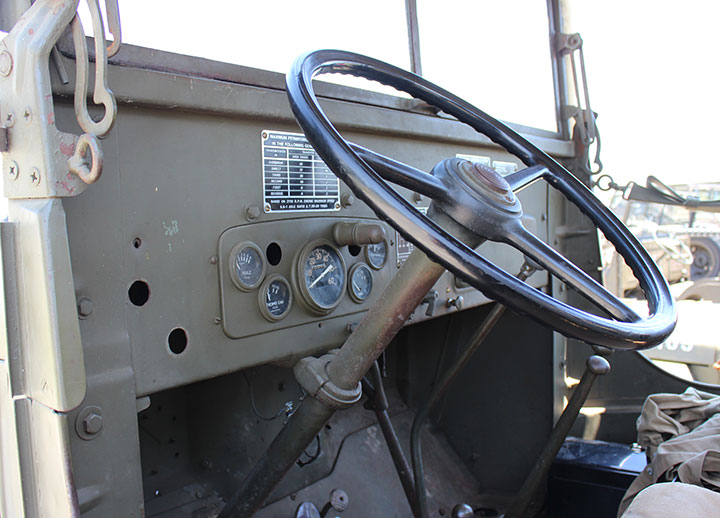

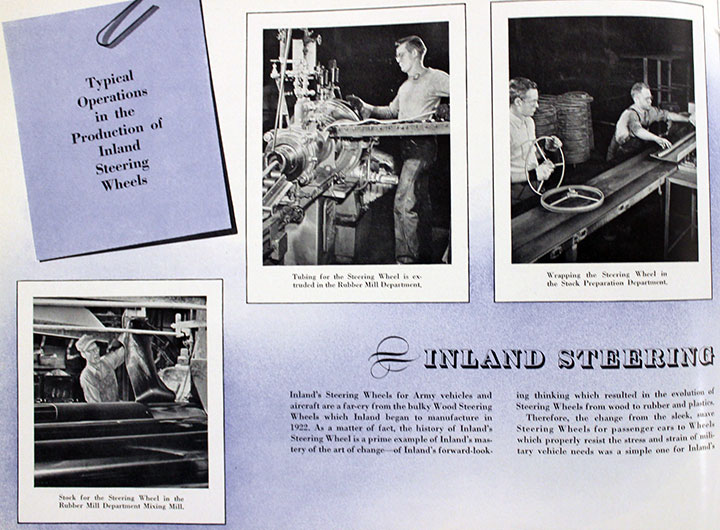

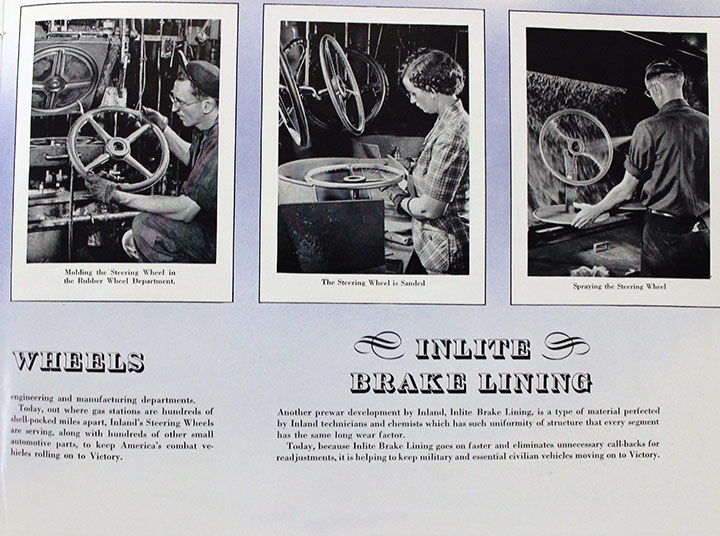

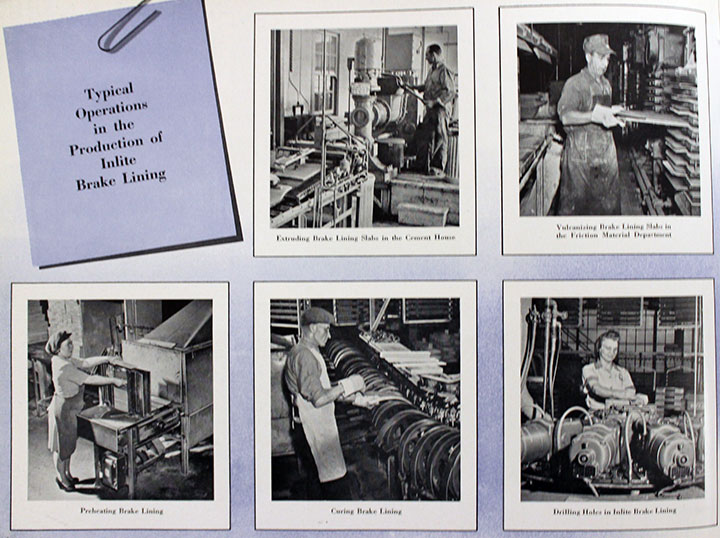

Truck Steering Wheels and

Brake Linings: Unknown numbers of these were built for

Chevrolet and GMC trucks. See pages 35-36. During this time,

Inland Division marketed its brake linings under the trade name Inlite.

Steering wheels, like the clutches, were used on GMC and Chevrolet

military trucks.

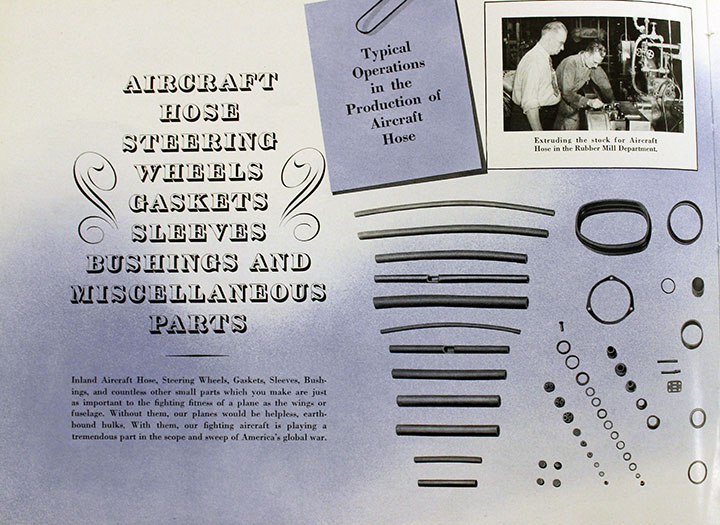

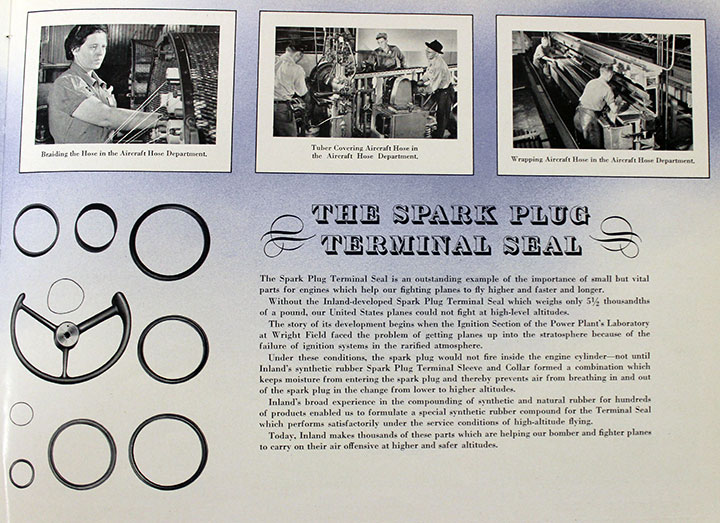

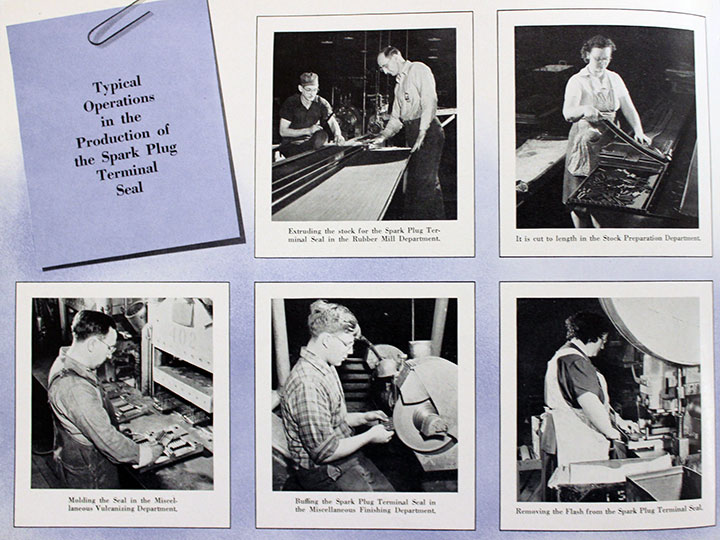

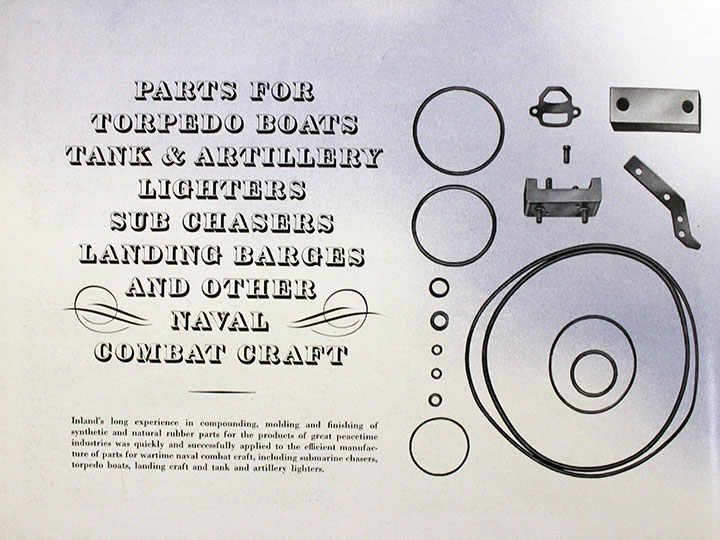

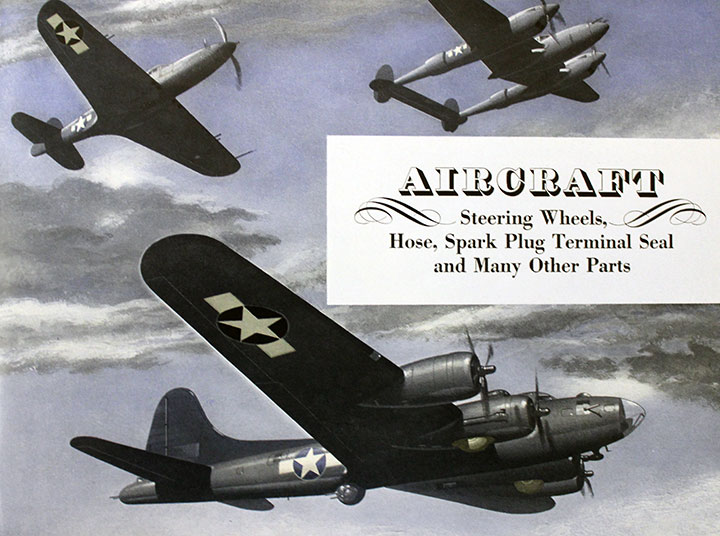

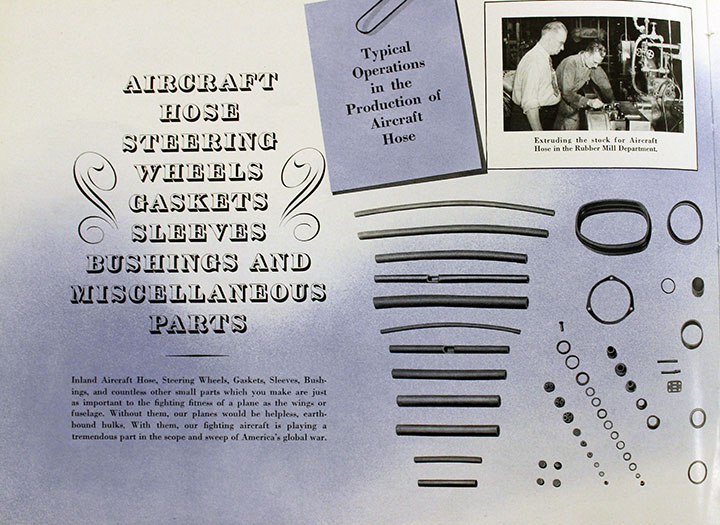

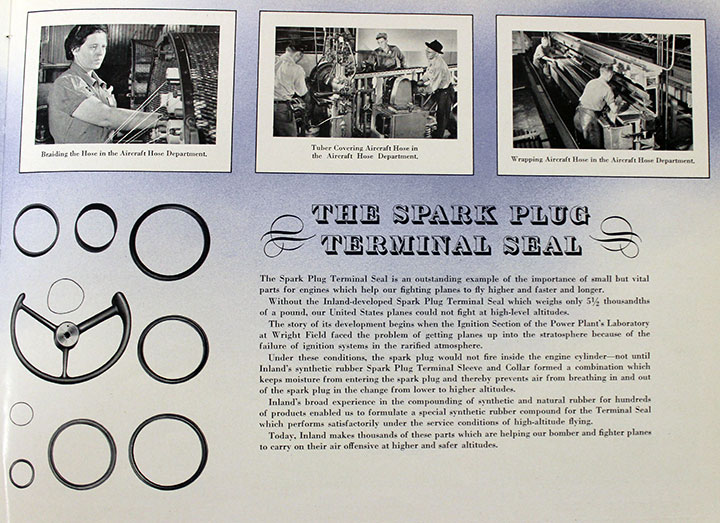

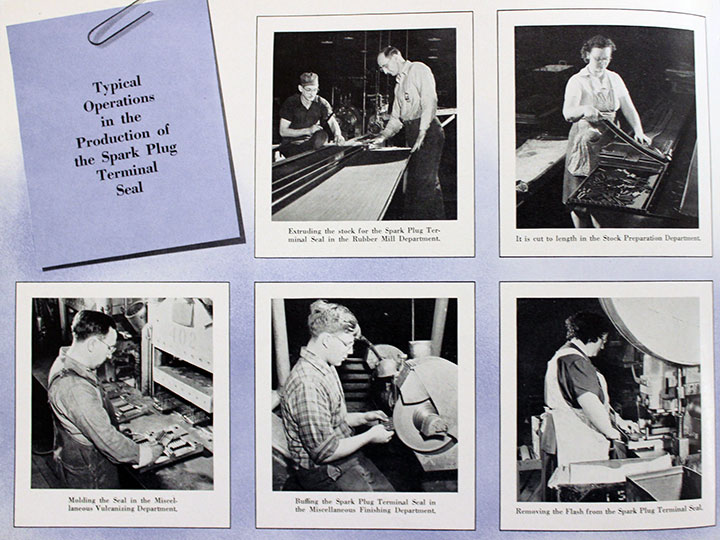

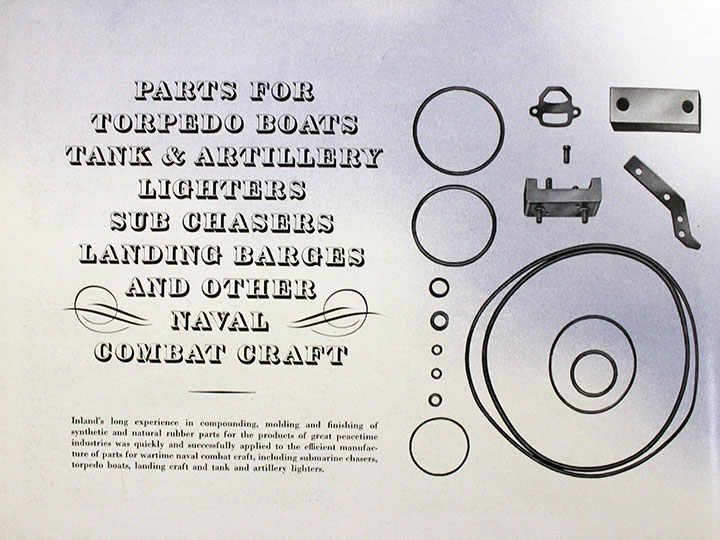

Rubber Parts:

68.8 million various rubber parts were produced for military vehicles, aircraft, and

ships. One of the major rubber products was aircraft sparkplug

boots that prevented the ignition system from grounding out at the low

temperatures at high

altitudes. See page 30 below for the whole

story.

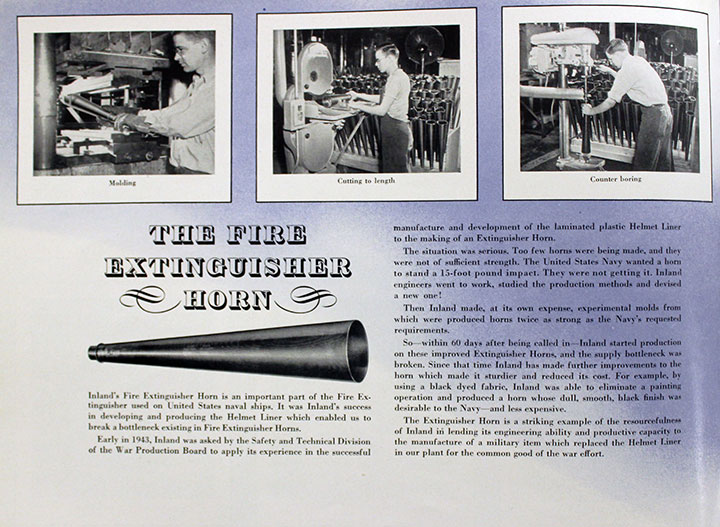

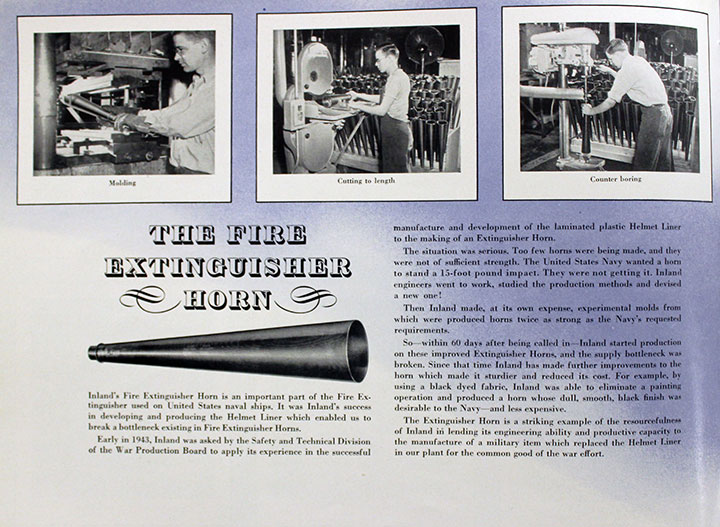

Fire Extinguisher Horns:

See page 27 for the entire story of this important product for U.S.

Navy ships during World War Two.

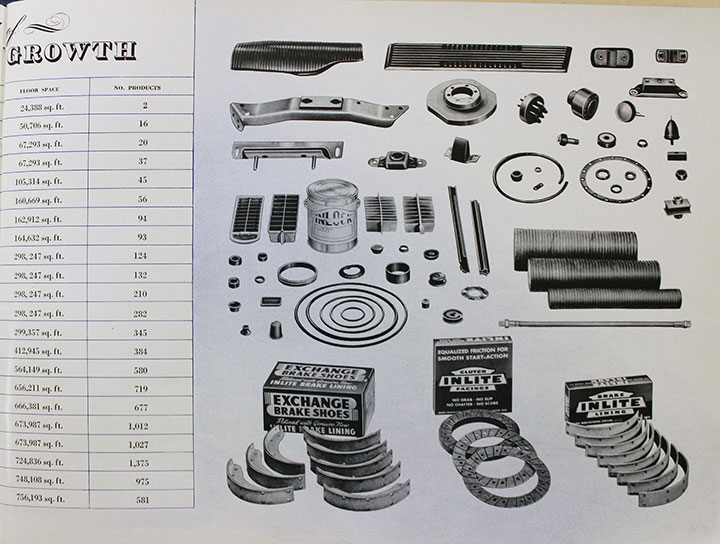

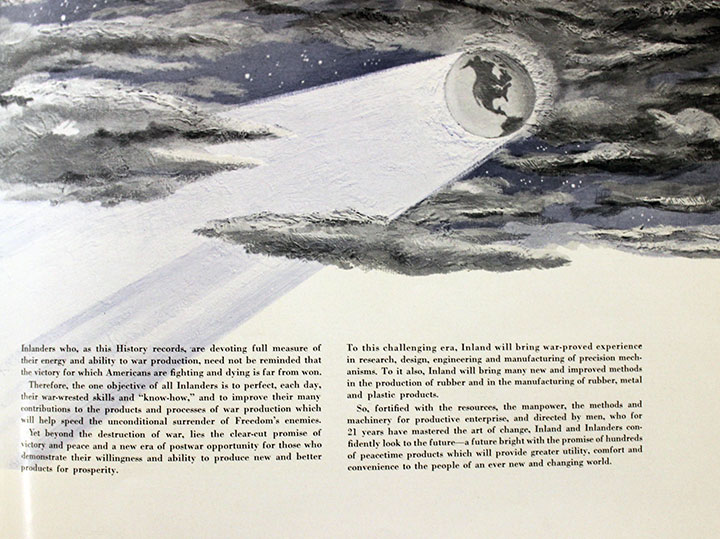

On December 31, 1943, Inland

had 6,339 employees producing 581 different products for the war effort

in 756,193 square feet of factory space.

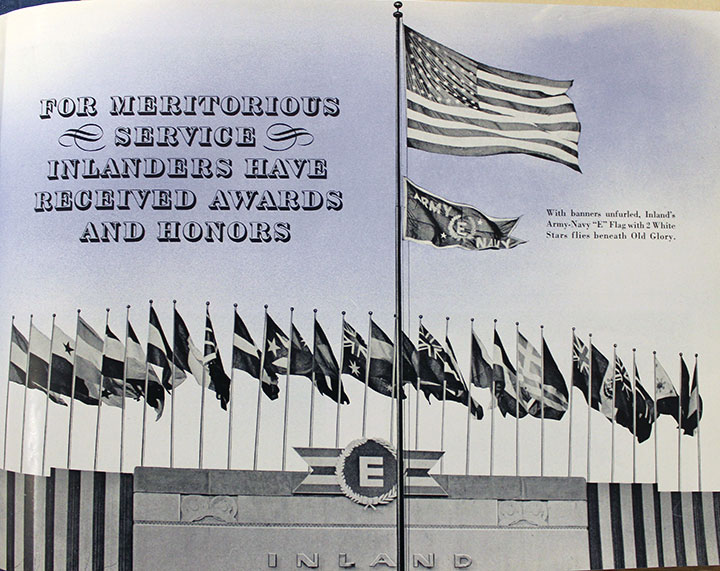

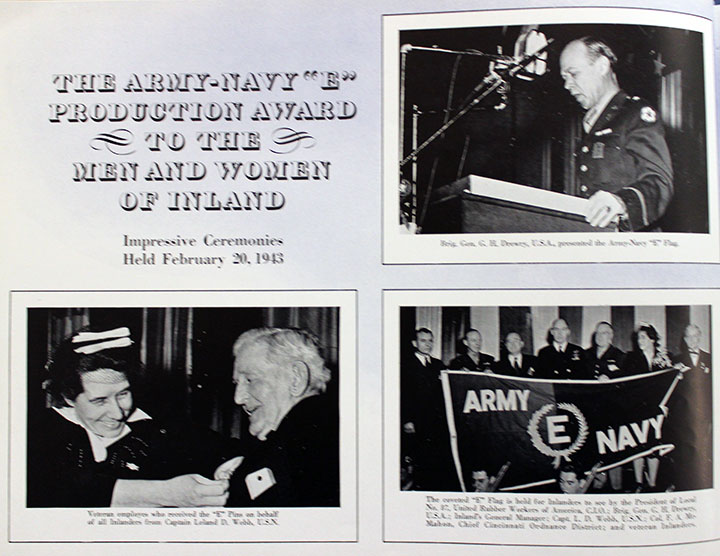

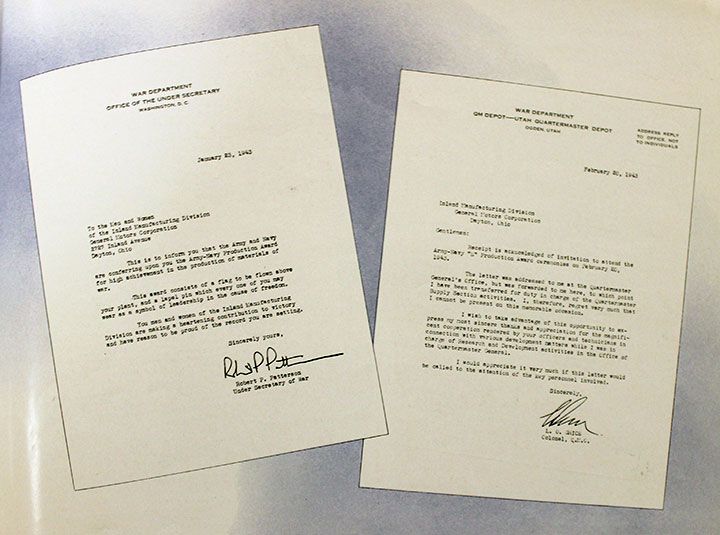

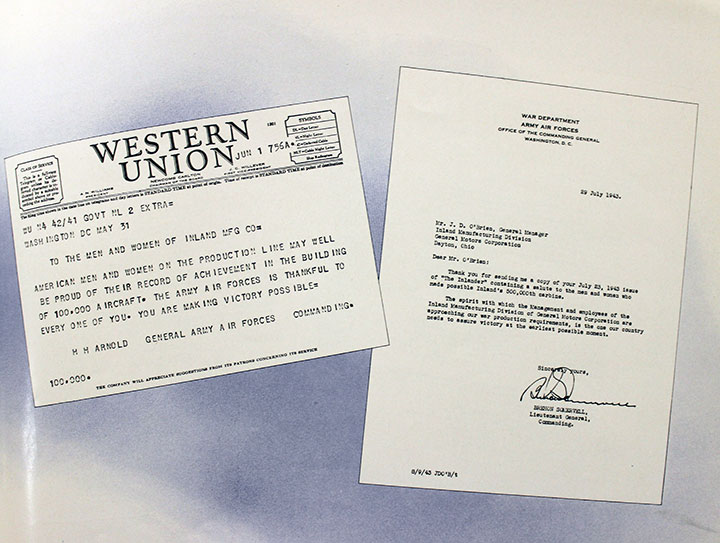

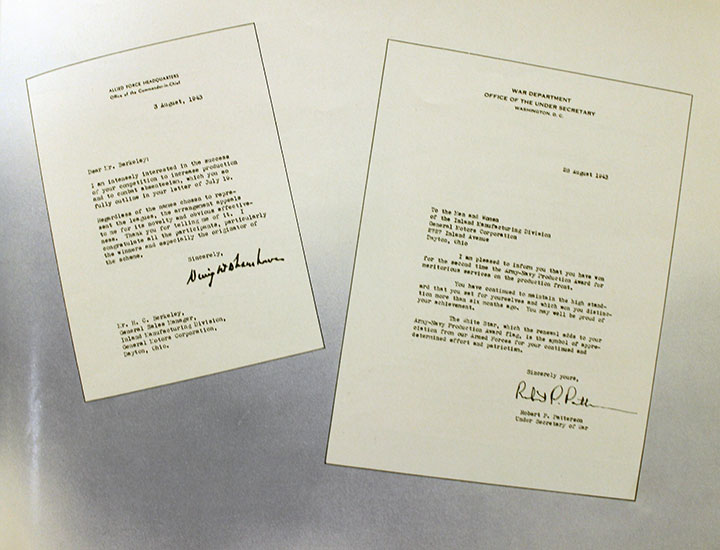

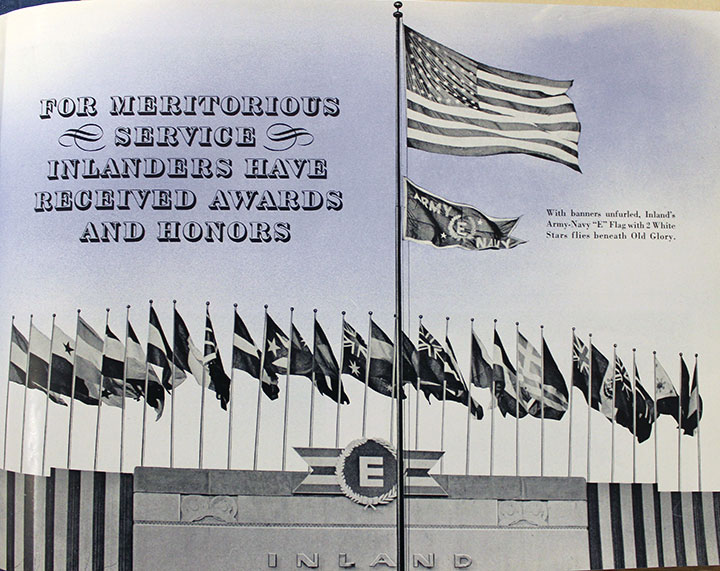

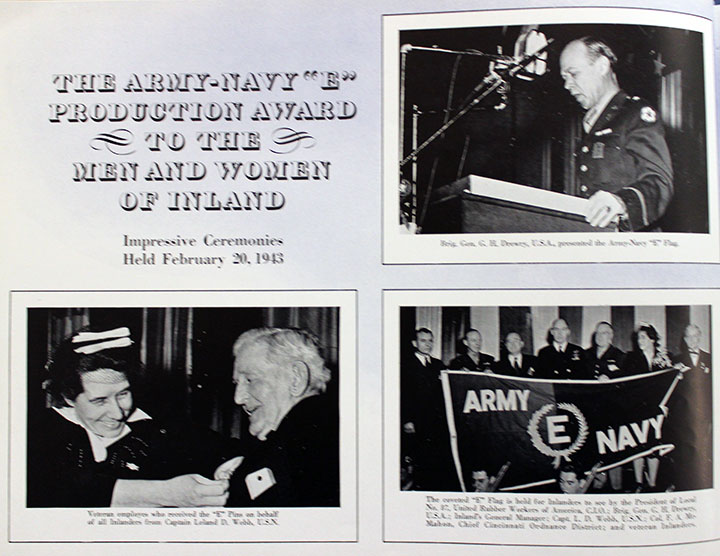

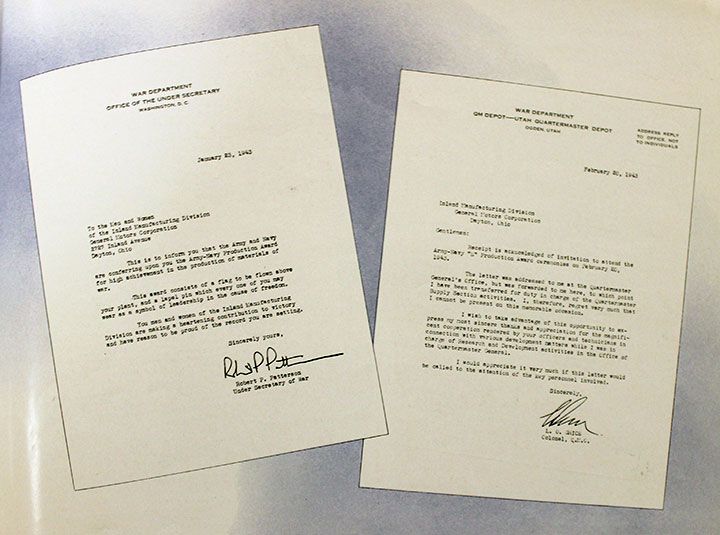

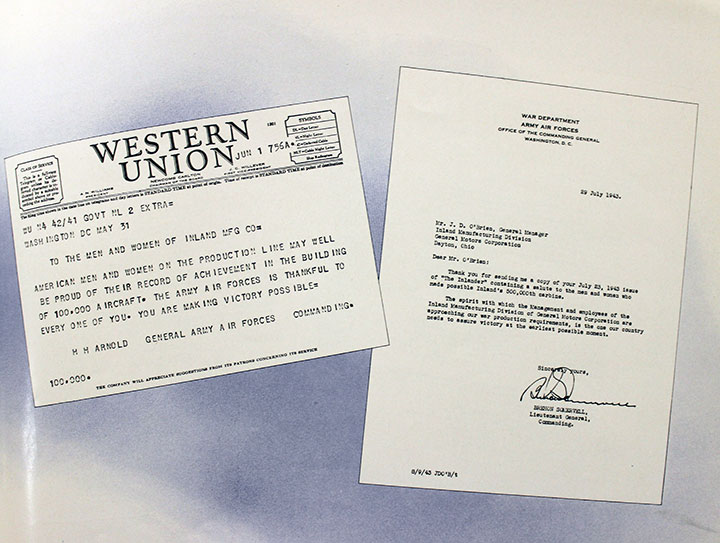

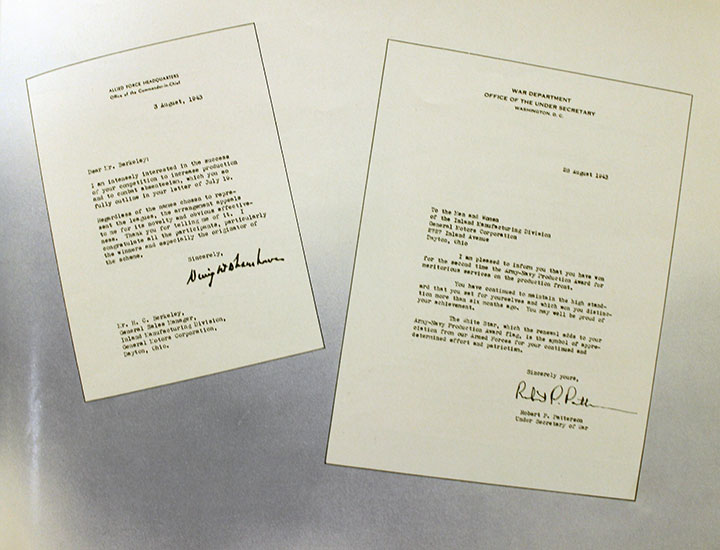

Inland received its first Army-Navy "E"

award on February 2, 1943. It received its second on August 20,

1943. It won three more awards on unknown dates for a total of five.

This Inland-built M-1 Carbine is on display at the Patton Museum at Fort

Knox, KY. Inland built 2.6 million of these during the Second

World War. Author's photo.

It is hard to see, as the photo was taken through Plexiglas, but the name

Inland is stamped onto the receiver just ahead of the sight.

Author's photo.

This Inland-built M1 Carbine is on display

at Fort Macon State Park in North Carolina. Author's Photo added

1-14-2017.

The Inland stamp is easier to read than on

the previous carbine and is serial number 210736. Author's Photo

added 1-14-2017.

Inland Division of GM built 811 out of the

1,919 T3 infrared carbines during WWII.

This example of an

M3 infrared Sniperscope is on display at

the Museum of the USMC in Triangle, VA. Author's photo added

1-24-2017.

Inland made 4 million tank shoes for the war effort and then assembled

them into 142,708 tank tracks. The pins that held the tracks

together were manufactured by another GM Division in Dayton, the Delco

Products Division. These are

steel shoes and tracks on an M4 tank. Author's photo.

Inland also made rubber tank shoes as seen here. Author's photo.

This Fisher Body-built M4A3 tank was photographed

in May 2008 by the

author in the square in Bastogne, Belgium. It was hit by enemy fire on

January 2, 1945. It went into combat with tracks made in Dayton,

OH built by the Inland Manufacturing Division of General Motors.

Author's photo added 1-7-2015.

Inland also assembled tracks for the M5

Stuart series of tanks during WWII. Author's photo added 1-7-2015.

This M10 Tank Destroyer photographed at the

Bastogne Historical Center in Belgium in May 2008 had a Detroit Diesel

engine for which Inland supplied the clutch. The tracks

were also supplied by the Inland Division. Author's photo added

1-7-2015.

This page from the 1942 GM Annual Report

shows Inland Division providing tank tracks for the M10 tank destroyer.

Photo added 2-13-2014.

Buick built the M18 tank destroyer with

Inland tracks. Author's photo added 12-25-2020.

Cadillac manufactured this M8 self-propelled

75mm howitzer with Inland tracks. Author's photo added 12-25-2020.

Late in World War Two, Cadillac built the M24

light tank with Inland tracks. Author's photo added 12-25-2020.

The Fisher Body Grand Blanc, MI tank plant

built this M26 heavy tank with Inland tracks. Author's photo added

12-25-2020.

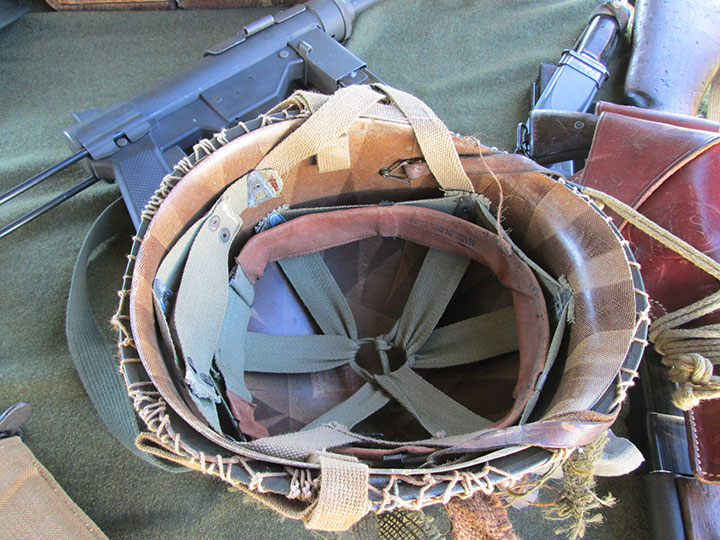

This is an authentic World War Two era M-1 helmet. After making over two

million helmet liners

for this type of helmet, the work

was transferred to another location in 1943, due to a shortage of skilled labor

in Dayton. Author's photo.

Inside the steel pot was a thermoset and fiber helmet liner as seen

here. Inland made two million helmet liners during World War Two.

Author's photo.

On March 5, 1944, Malvin Pike was wearing

this M-1 helmet in Europe when it took the bullet strike shown here.

The helmet liner cracked and imbedded in Mr. Pike's scalp, but the steel

pot and liner kept him alive. The medic that worked on him sent

the helmet and liner home for Mr. Pike, as he had thrown both in the

trash. Note the rivet heads on the liner to hold the internal

webbing in place. The liners were painted with a friction paint to

help keep the steel pot from coming off of it. As seen at the USS

Kidd Museum in Baton Rouge, LA. Author's photo.

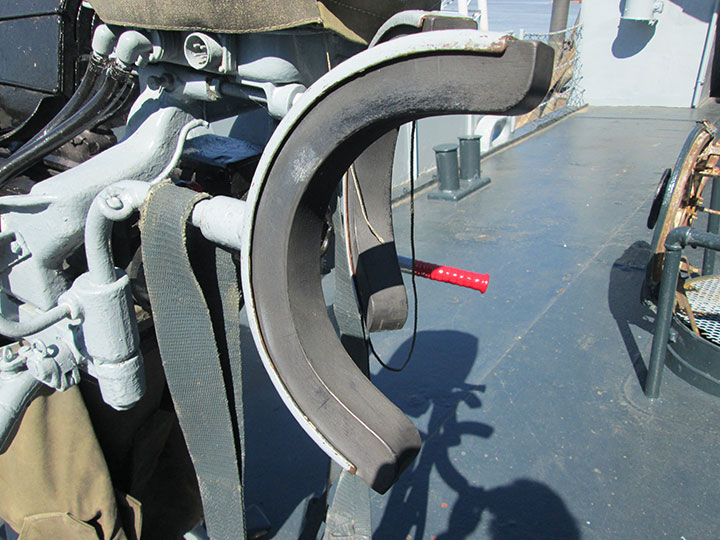

This is a 20mm cannon, as seen on the USS

Kidd in Baton Rouge, LA. During World War Two, Inland made the

rubber shoulder pads for the gunner of these weapons. Author's

photo.

Author's photo.

Pontiac built 20mm Oerlikon cannons for the

U.S. Navy. This one on display shows both the Inland-built rubber

shoulder pads and the large circular gun sight. Author's photo

added 12-25-2020.

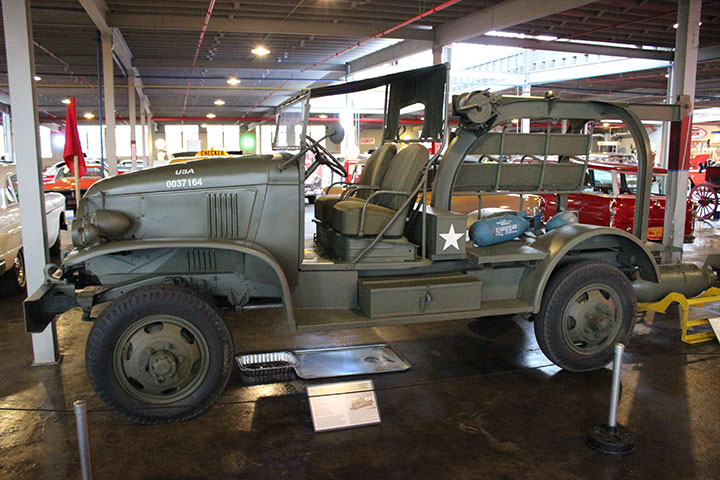

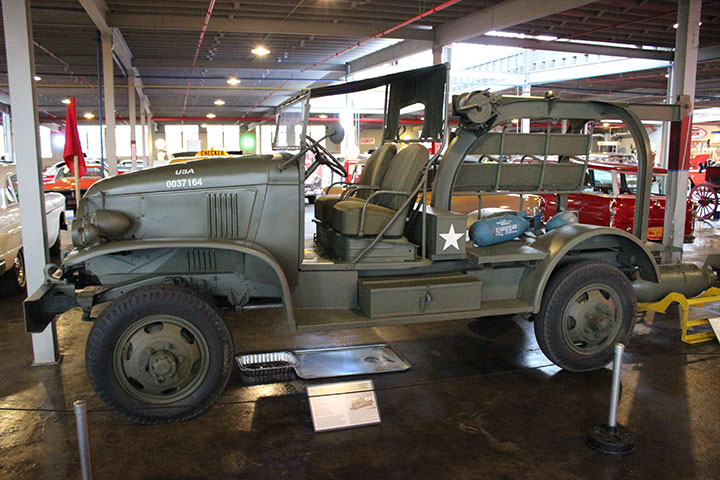

Inland supplied parts for Chevrolet 1-1/2 ton 4x4 trucks like this one

seen at the 2013 Houston Airshow. Author's photo added

1-7-2015.

This is a Chevrolet World War Two era Bomb

Truck on display at the National Automotive and Truck Museum in Auburn, IN.

Author's photo added 1-7-2015.

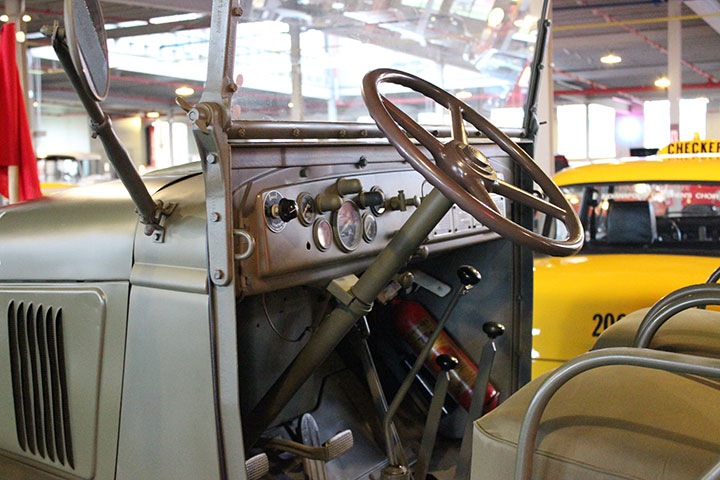

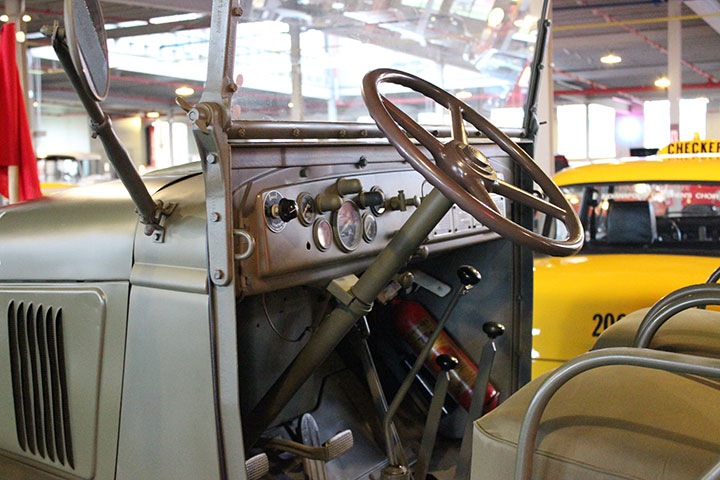

Chevrolet used four spoke steering wheels

supplied by Inland. Author's photo added 1-7-2015.

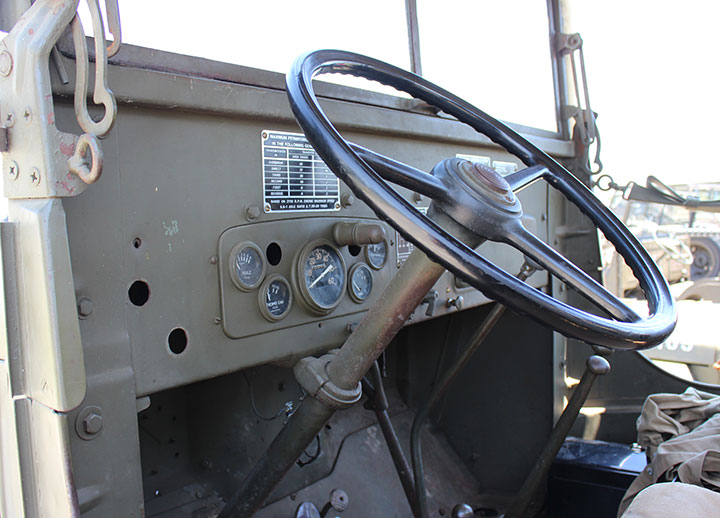

Inland also supplied parts for GMC 2-1/2 ton

6x6 trucks like this one seen at the 2014 Columbus Aviation Day Open

House. Author's photo added 1-7-2015.

Specifically, Inland supplied three spoke steering wheels like this one

for the GM CCKW series of trucks. Author's photo.

Pictured here is a Pratt & Whitney R-2800

radial aircraft engine, which was used on such aircraft as the F4U Corsair,

the P-47 Thunderbolt, and the F6F Hellcat, to name a few. Inland

sparkplug boots were instrumental in letting these fighters operate at

high altitudes. Author's photo added 1-7-2015.

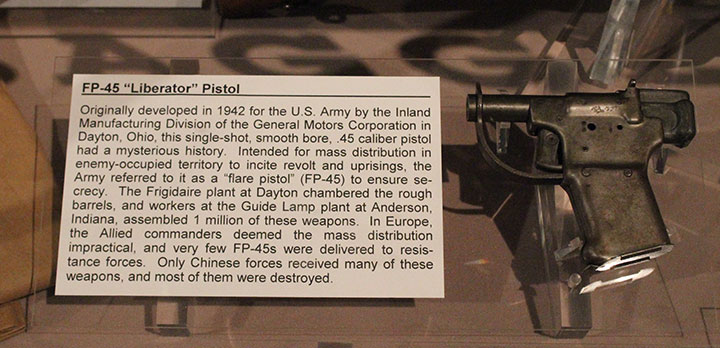

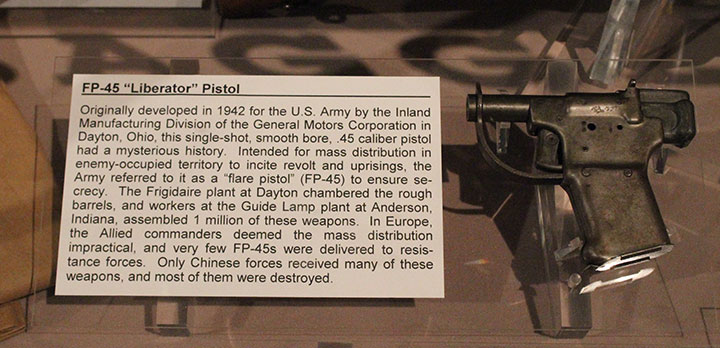

Inland designed the FP-45 .45 caliber

"Liberator Pistol" but the Guide Lamp Division built the weapon.

It is on display at the Museum of the United States Air Force in Dayton, OH.

Author's photo.

Author's photo.

This fire extinguisher was photographed by

the author on the USS Kidd in Baton Rouge, LA. While this is not a

World War Two era fire extinguisher, due to fire regulations, it shows the type

of "horn"

that Inland made for the Navy. This project was considered to be

more important than the helmet liner work which was transferred to

another location. Inland got the critical jobs when engineering

development was needed.

Plant Photos:

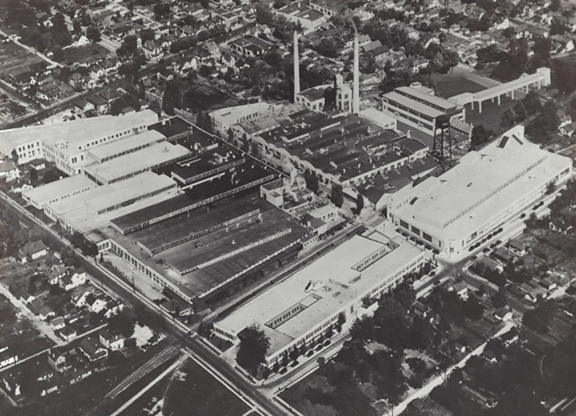

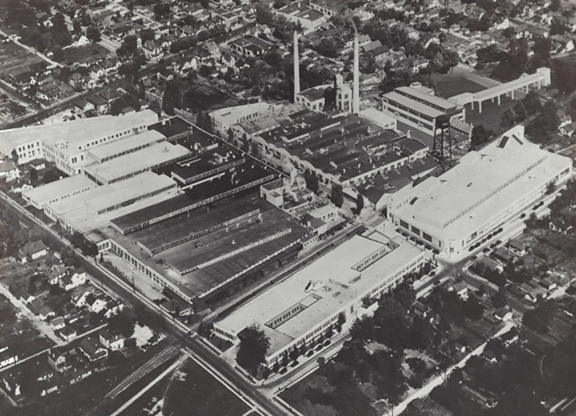

This is a 1945 aerial photo of the Inland

factory complex on Home Avenue. The long, elevated structure

located in the upper far right of the photo is the indoor test range for

the M1 carbine built at the plant during World War Two. Photo

courtesy of Mr. Ron Dalhamer added 5-1-2023.

Inland had to build an indoor test

range to test fire each of the 1,984,189 M1 Carbines, 140,000 M1A1

Carbines, 500,000 M2 Carbines, and 811 M3(T3) Carbines built at the

facility. The insert is the view of the five down range targets.

Photo courtesy of Mr. Ron Dalhamer added 5-1-2023.

This image shows the backside of four of the

five targets. The target paper was automatically forwarded for

each new carbine that was tested. This kept workers from having to go

down range and change targets with each new weapon tested. There

was also a method of collecting the spent projectiles. This was a

very sophisticated and automated system. Photo courtesy of

Mr. Ron Dalhamer added 5-1-2023.

The next three photos show the now razed Home Avenue Inland plant in

Dayton.

Author's photo.

Author's photo.

Author's photo.

This Google street view shows the new Dayton

branch library on the left at the location of the former Inland office

building. In the right side of the photo is the former Wright

Brothers factory that is awaiting funding for restoration as a National

Park Historical Site. Image added 5-1-2023.

It was a dreary day in late March 2023 when

I re-visited and photographed the former Wright Brothers Plant located

at the former Inland factory site. This was not long after there

was a fire in this building. This photo was taken from the north

side of the new branch library looking north. If I had wanted to,

I could have walked right up to and into these buildings. I found

it unsettling that such historic buildings were not secured by fencing.

Someone has dropped the ball here. Previously, this was fenced in

and somewhat secured. When the new library was built, all of the

fencing on the north side of the complex was removed. New fencing

needs to be re-installed to better protect this historic Wright Brothers

Plant. Author's photo added 5-4-2023.

This photo was taken from the south side of

the complex looking north. On this side, the old fence remains in

place. Also, the former Inland gate house is still standing.

Author's photo added 5-4-2023.

This closer view shows that there are

several open doors to the building. Author's photo added 5-4-2023.

Having a fence with an open gate is not very

effective security. I don't think anyone who really wants to get

inside and create mischief is going to pay any attention to the "No

Trespassing" sign. I did, but I don't think vagrants and vandals

have or will in the future. Author's photo added 5-4-2023.

The fire damage appeared to be restricted to

the southeast corner of the building. At least that is what I

could observe from my location outside of the fence. Author's photo

added 5-4-2023.

Post-World War Two Military Products:

In 1953 Inland was instrumental in the

development of what was later designated the M60 machine gun. This

is the final T161E3 version developed by Inland and was chambered for

7.62mm ammunition. The original T161 was chambered for 30.06

ammunition, as was the later T161E2. Inland produced twenty T1616E2s for

testing which were converted to the E3 modification in 1955.

Another 100 were also manufactured for testing and evaluation. At

this point, another company took over the final development of Inland's

work. It is not known why this happened. Author's photo

added 12-10-2020 from the South Carolina Military Museum.

This is Inland T161E3 serial number 2 and is

on display at the Virginia War Museum. Author's photo added

12-10-2020.

Author's photo added 12-10-2020.

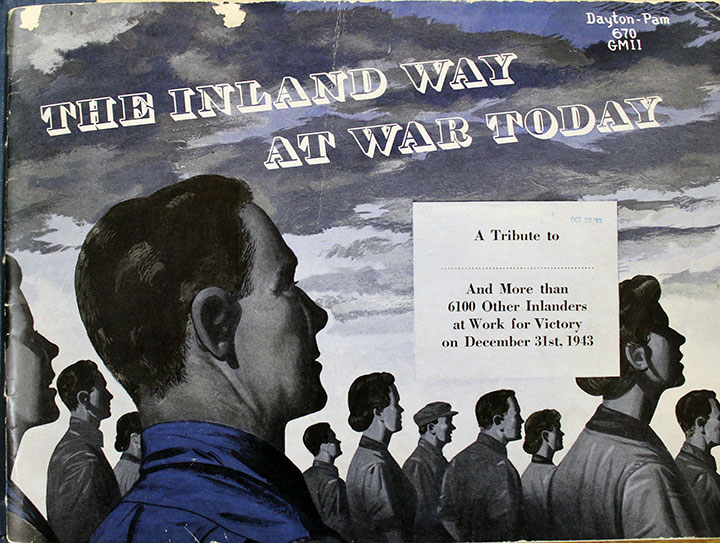

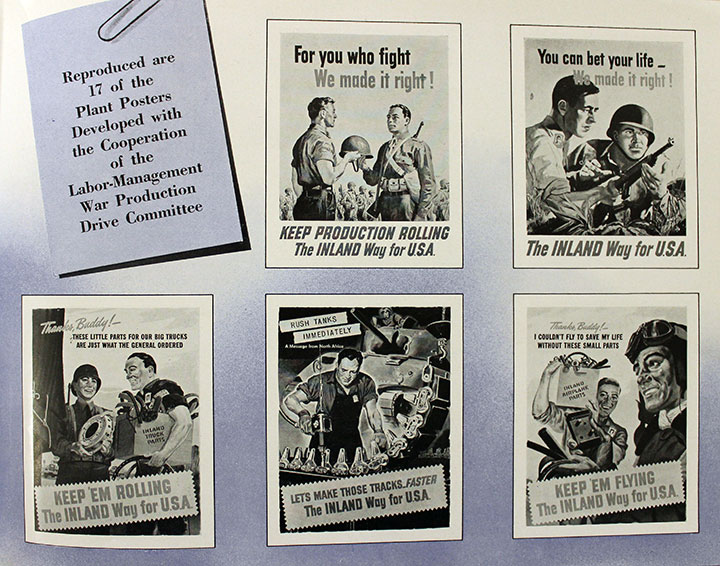

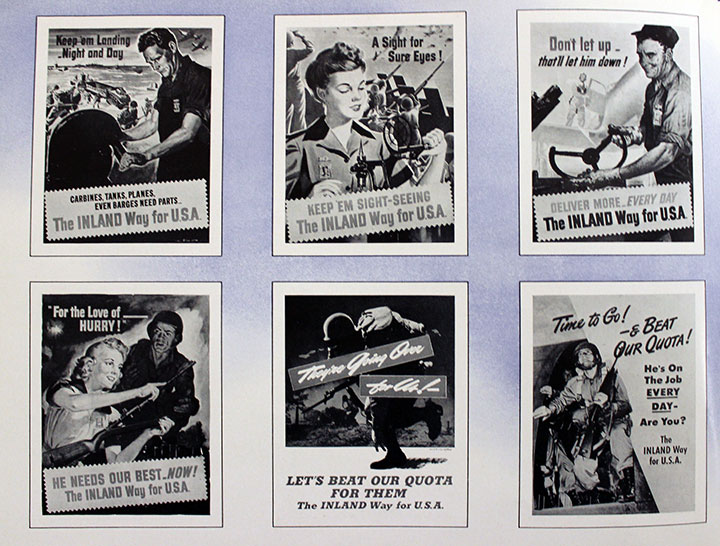

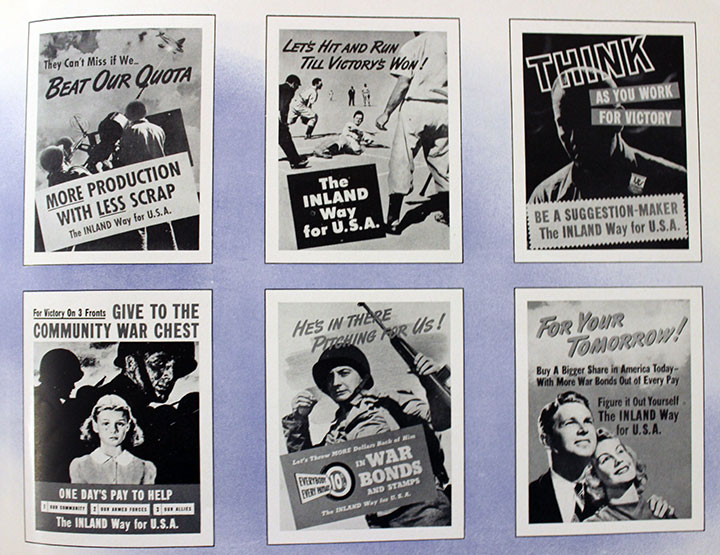

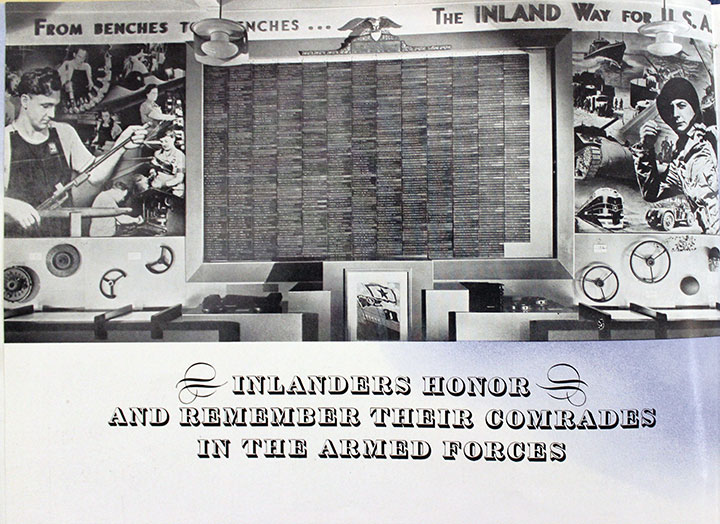

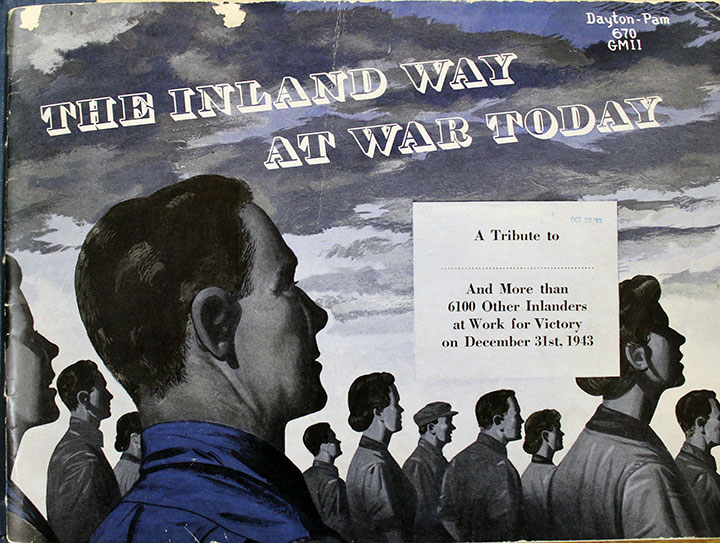

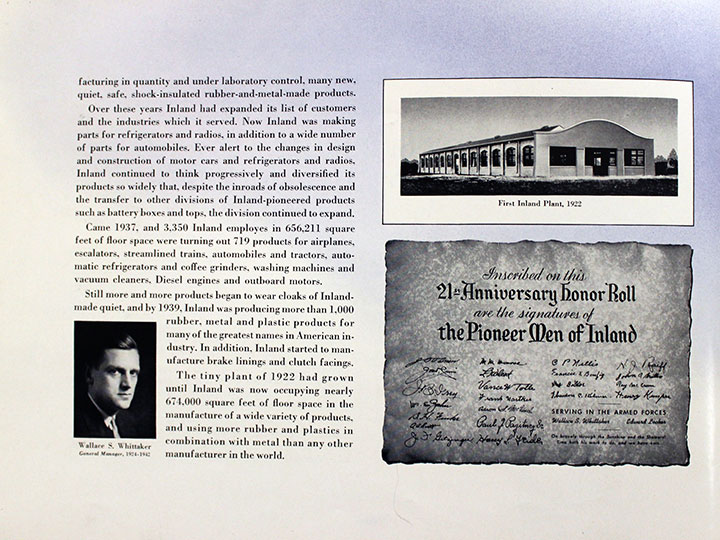

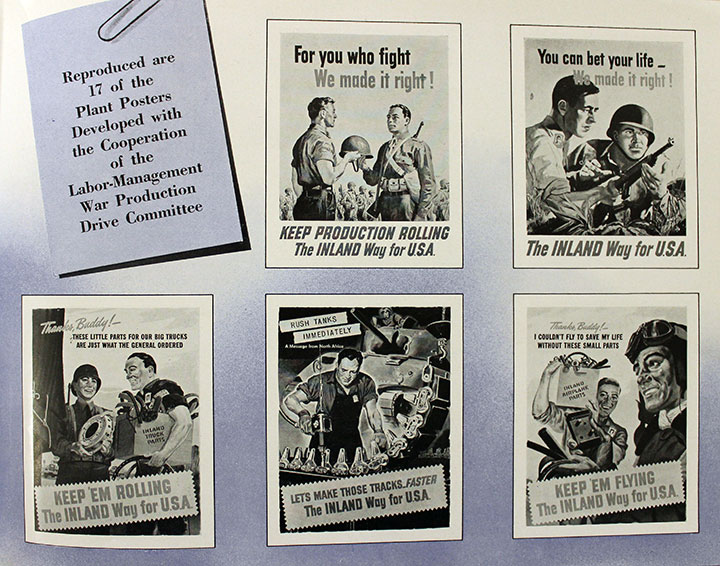

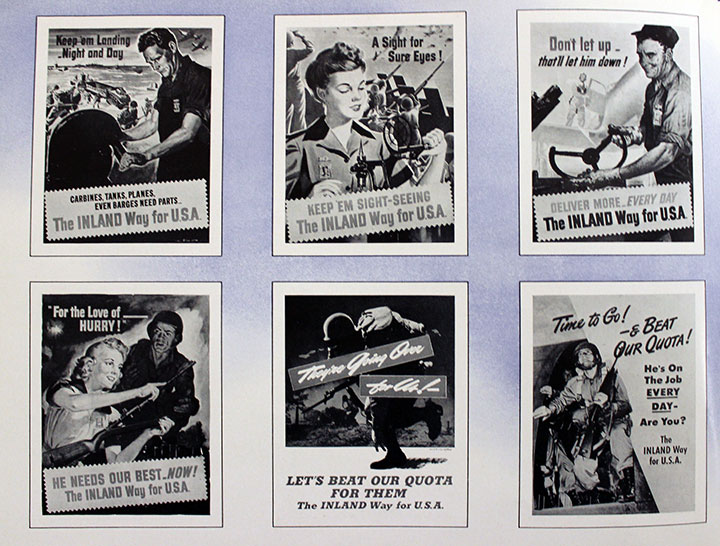

"The Inland Way at War Today"

Added 1-7-2015.

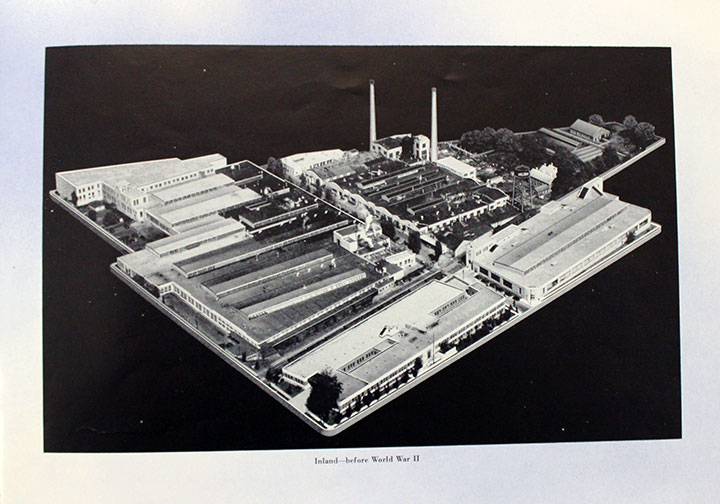

Cover.

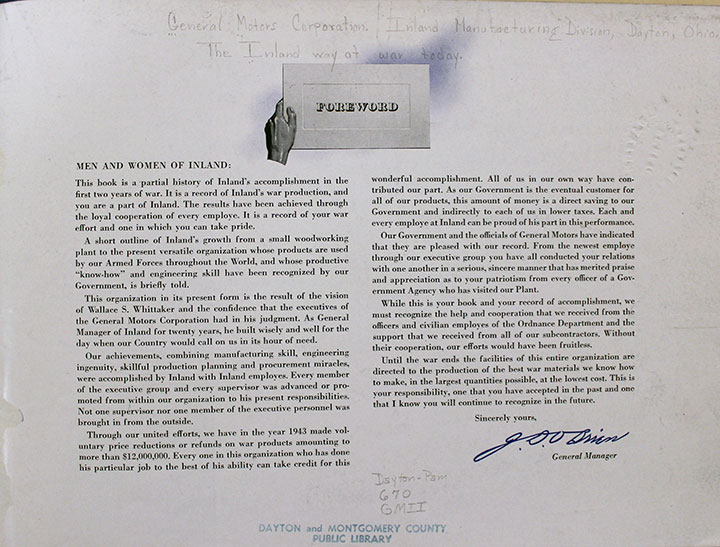

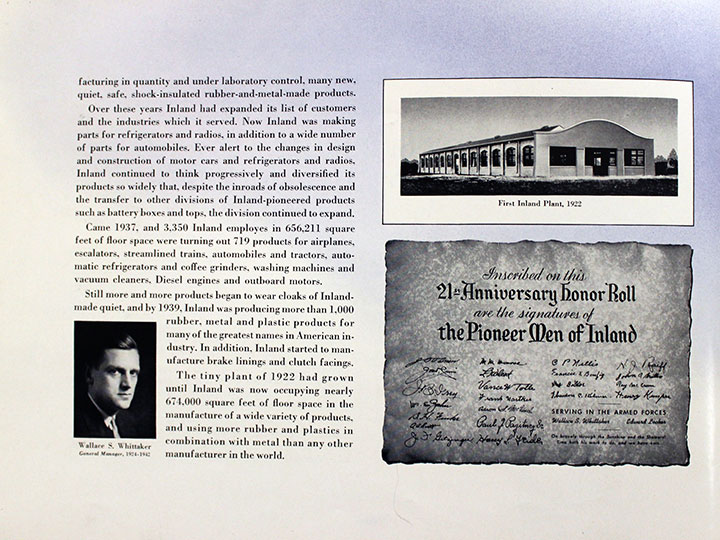

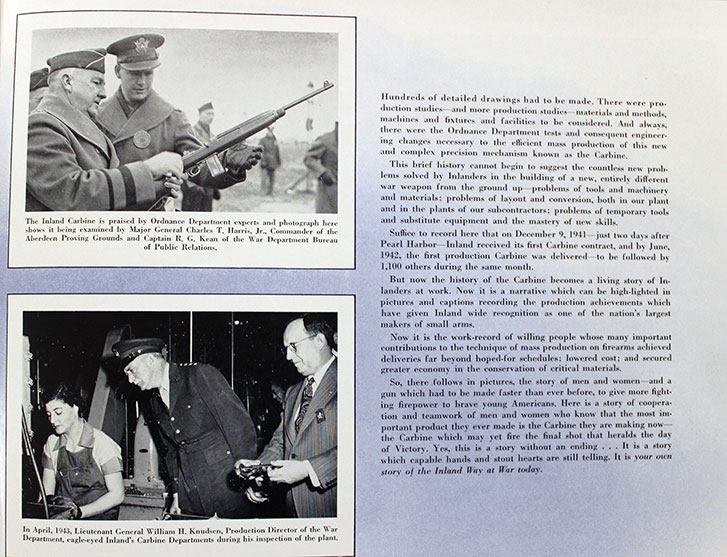

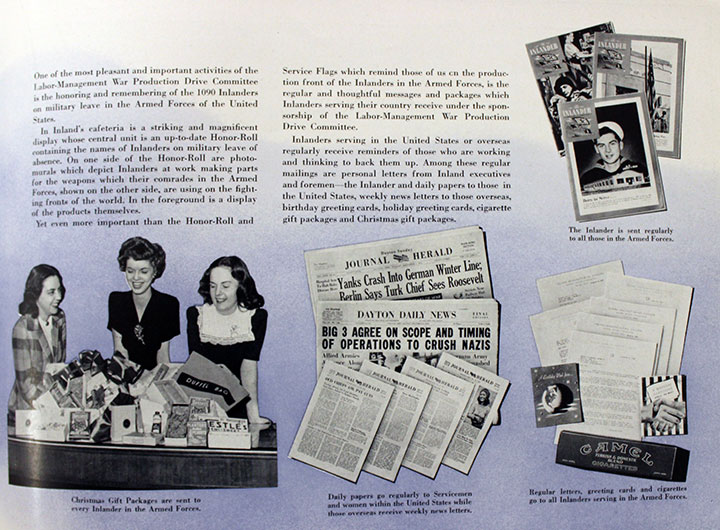

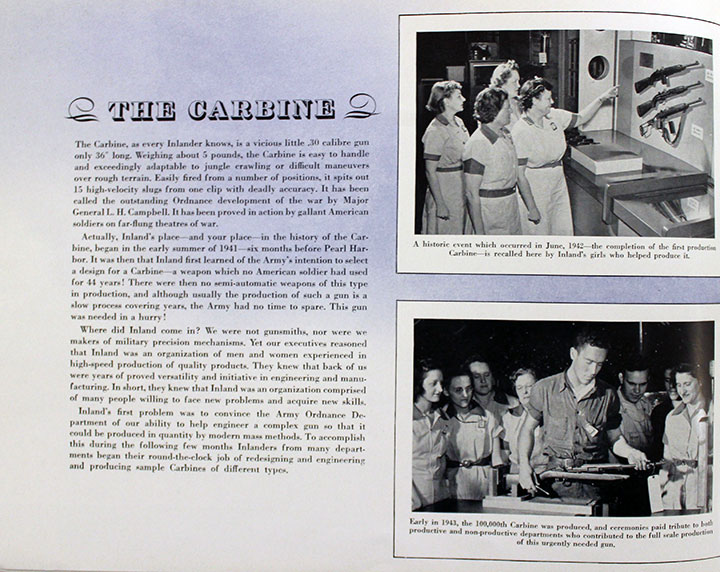

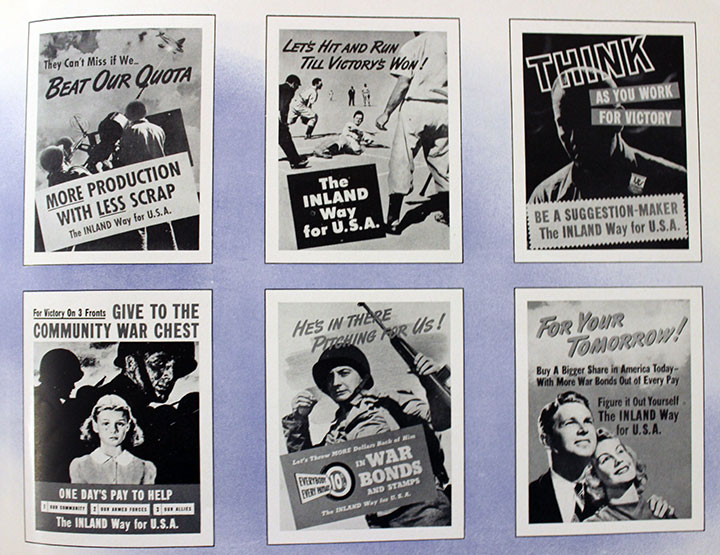

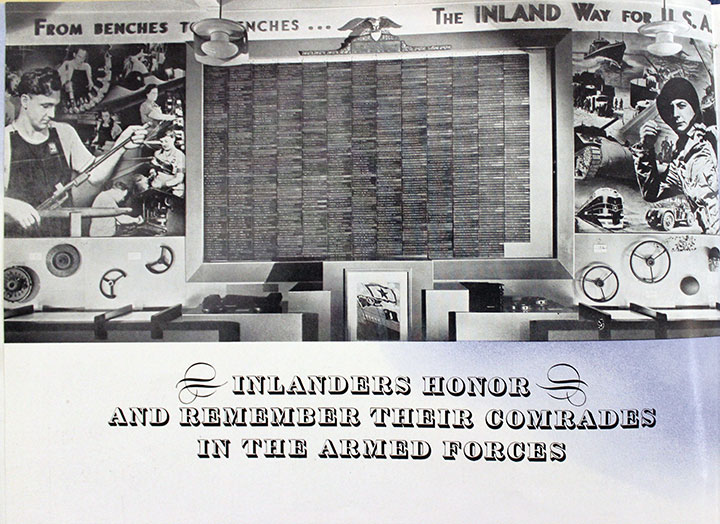

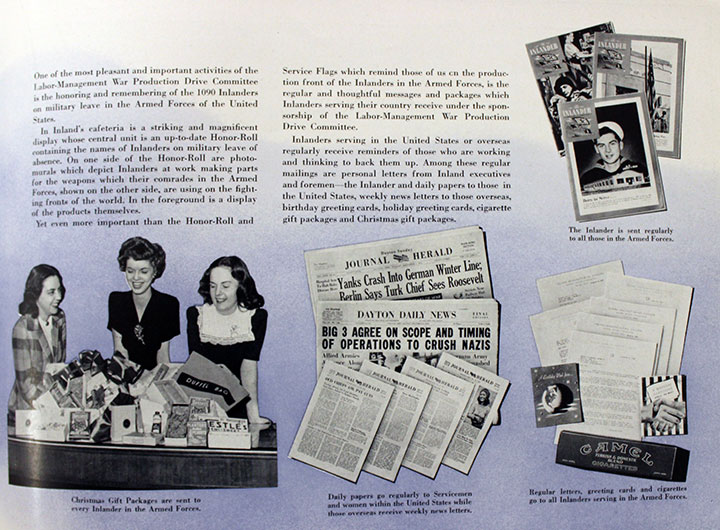

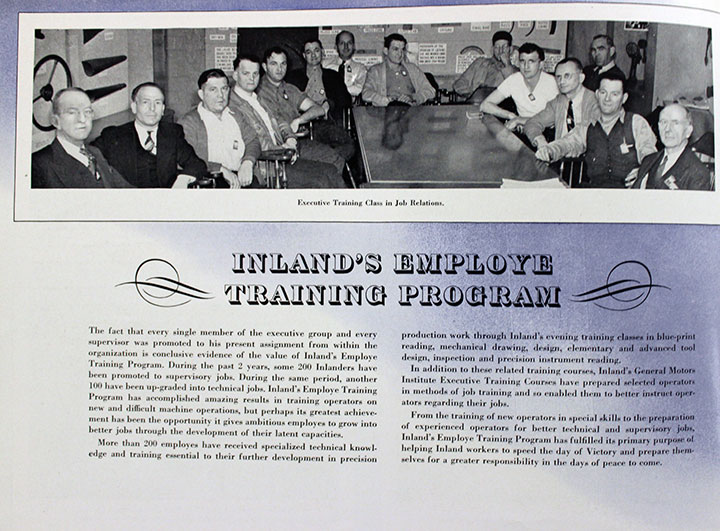

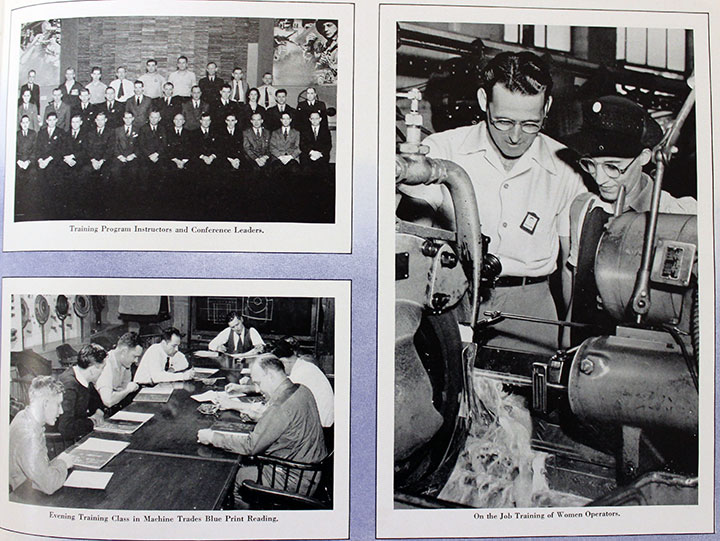

Page 1.

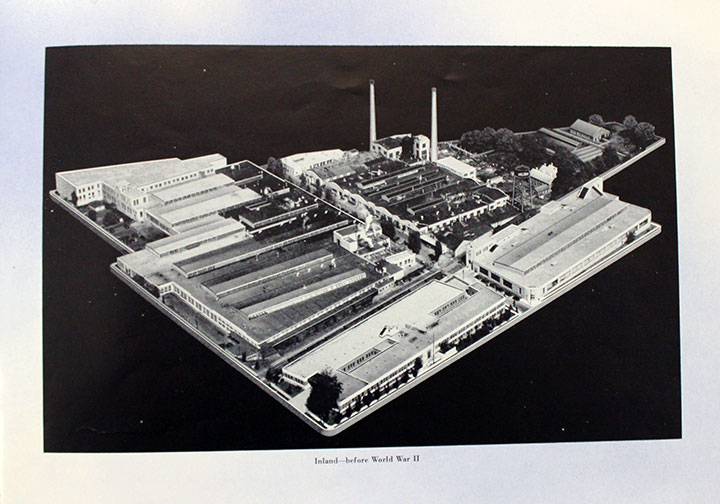

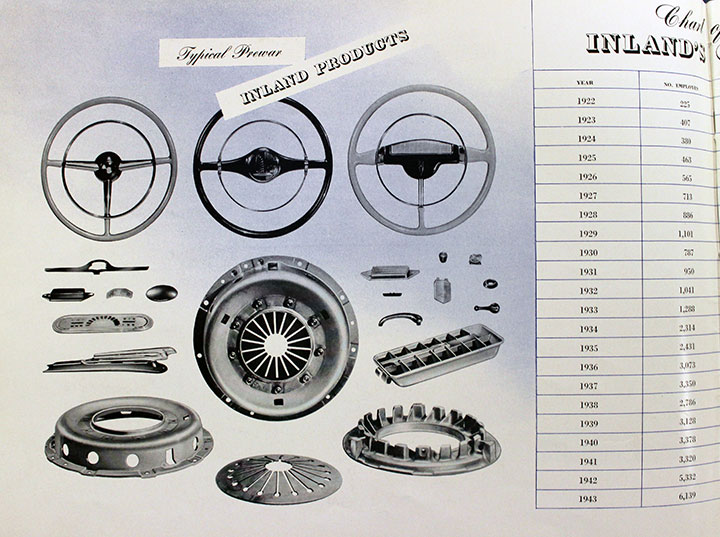

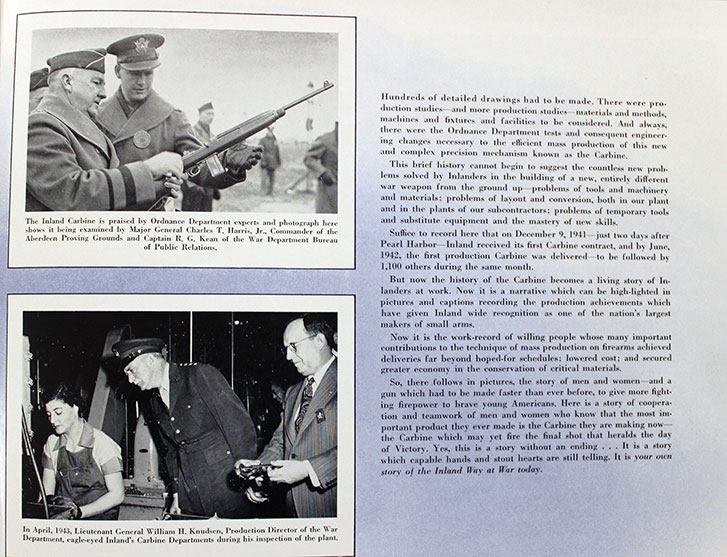

Page 2.

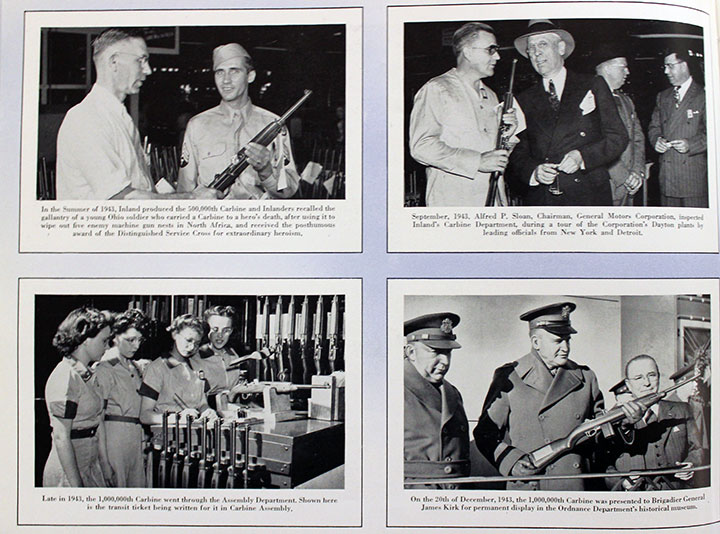

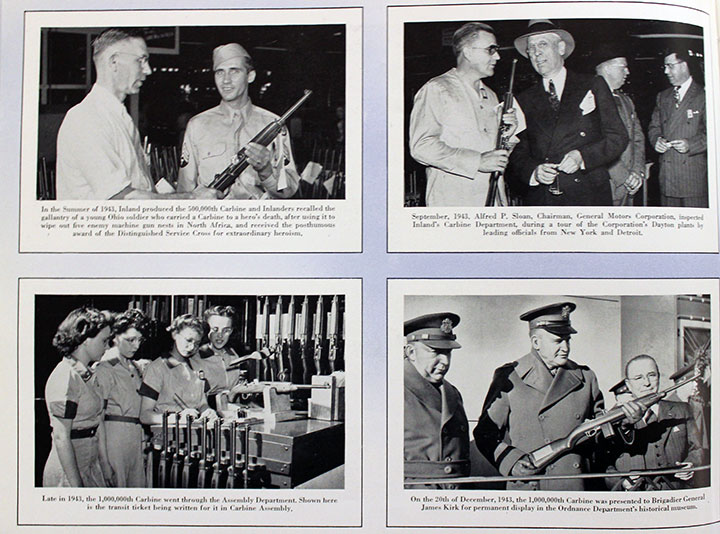

Page 3.

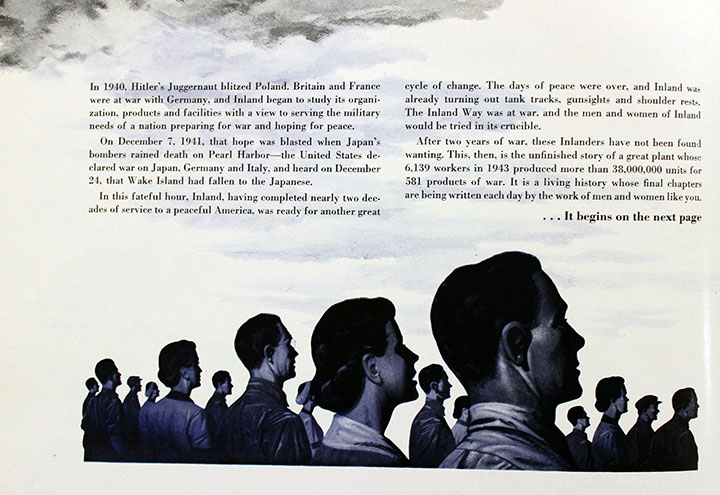

Page 4.

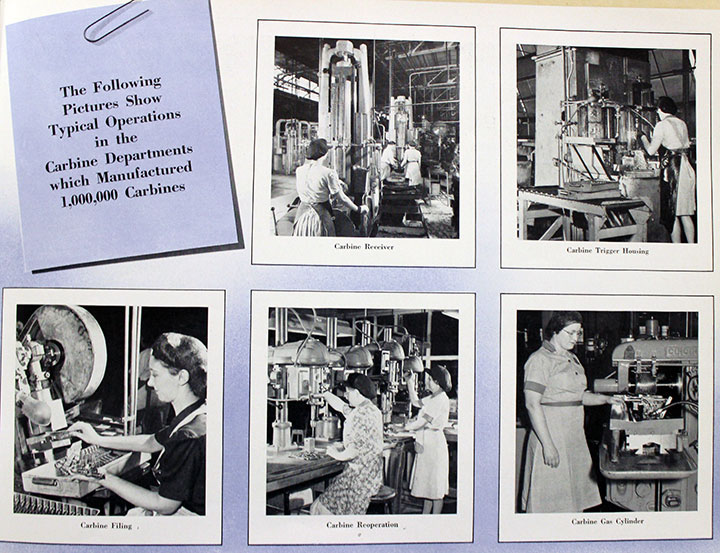

Page 5.

Page 6.

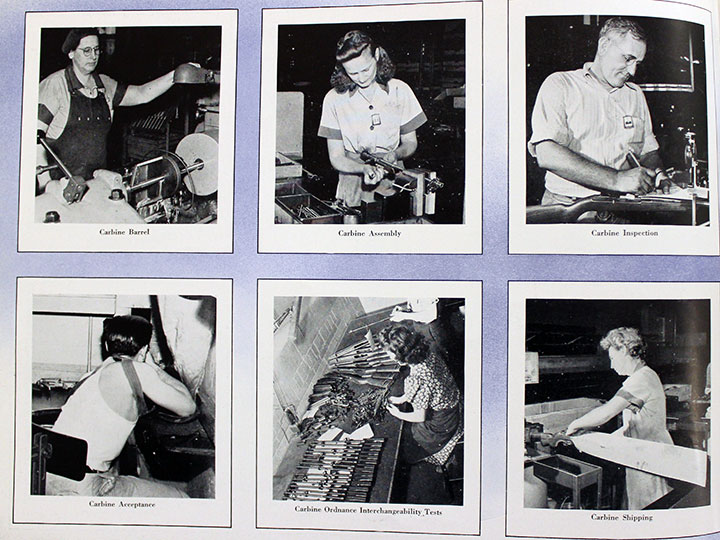

Page 7.

Page 8.

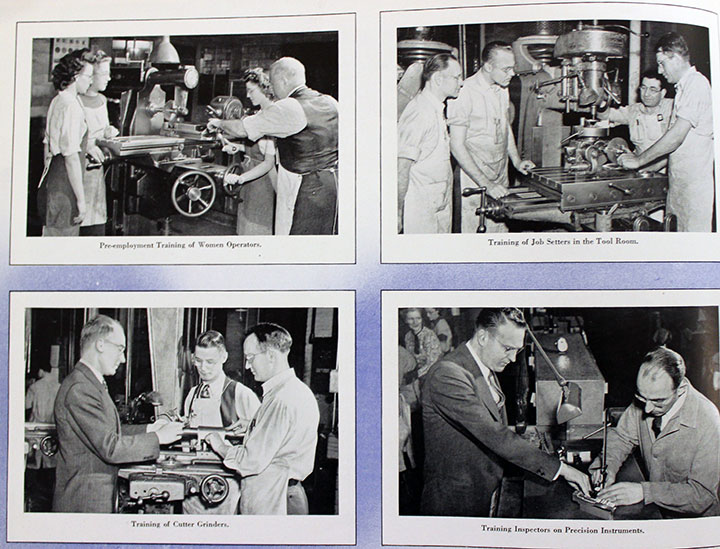

Page 9.

Page 10.

Page 11.

Page 12.

Page 13.

Page 14.

Page 15.

Page 16.

Page 17.

Page 18.

Page 19.

Page 20.

Page 21.

Page 22.

Page 23.

Page 24.

Page 25.

Page 26.

Page 27.

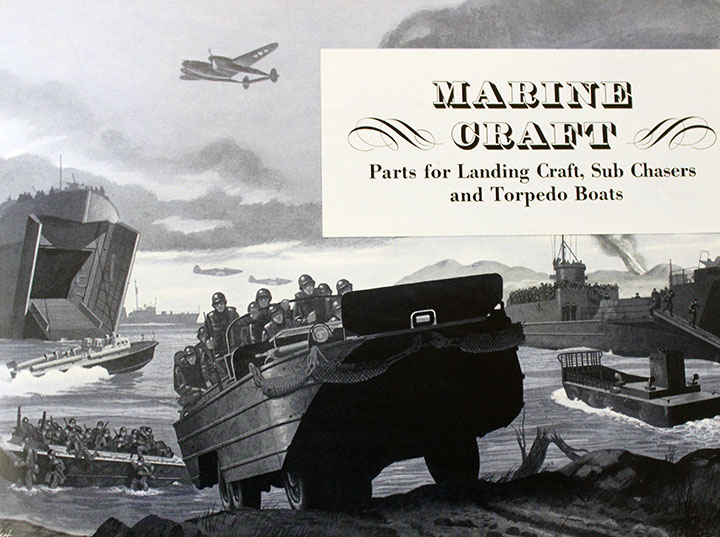

Aircraft do not have steering wheels; they

have control yokes. Page 28.

Page 29.

Page 30.

Page 31.

GMC 6x6 trucks had dual tires on the rear

axles during World War Two, not singles as show here. However, the artist

was 60 years ahead of his time because the 21st Century U.S. military

trucks

now have single tires on the rears. Page 32.

GMC steering wheels were three spoke and

Chevrolet four spoke. Page 33.

Page 34.

Page 35.

Page 36.

Page 37.

Page 38.

Page 39.

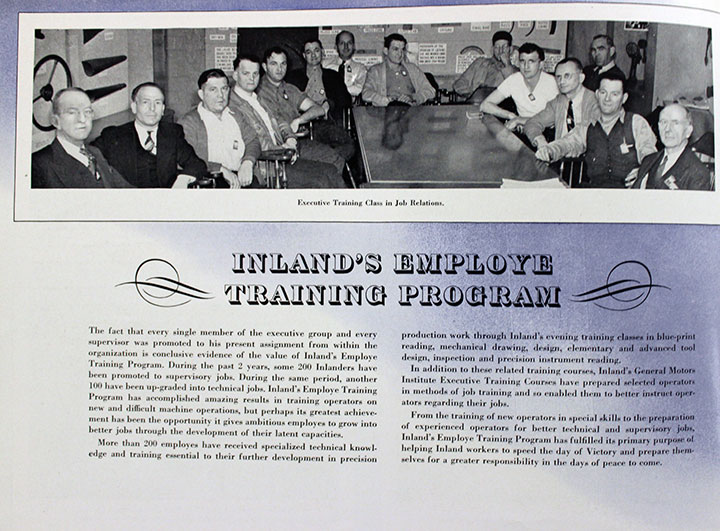

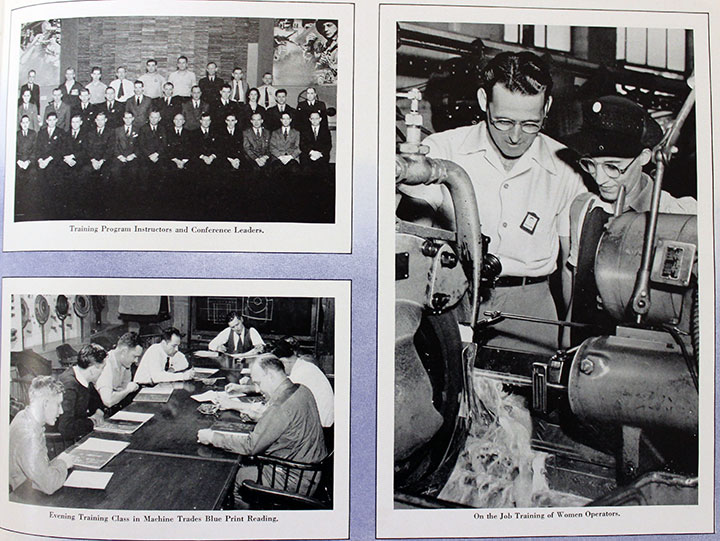

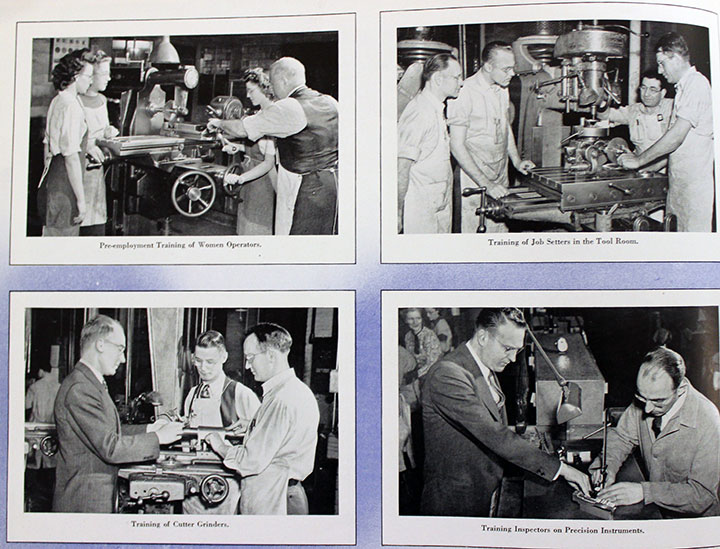

Page 40.

Page 41.

Page 42.

Page 43.

Page 44.

Page 45.

Page 46.

Page 47.

Page 48.

Page 49.

Page 50.

Page 51.

Page 52.

Page 53.

Page 54.

Page 55.

Page 56.

Page 57.

Page 58.

Page 59.

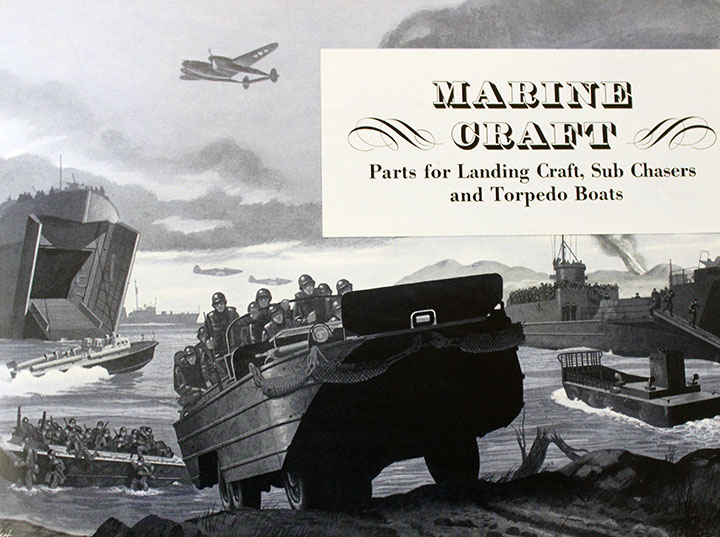

|