|

The B-29

and the US Auto Industry in World War Two

This page added 6-15-2016.

The B-29 project was the largest and most

expensive project undertaken during World War Two. It was even

more expensive than the Manhattan Project. The American Automobile

Industry was instrumental in supplying airframe components and engines

for the B-29. Below are the automobile companies and their

suppliers known to have participated in the building of the most complex

aircraft to date.

The US Auto Industry's involvement in the B-29

was immense yet has been unheralded and forgotten. The auto

industry supplied everything from bearings for the remote control gun

systems to the major fuselage and wing components, and engines.

Boeing's initial work on the concept of a

long range bomber started with the February 5, 1940 receipt of

specification "R-40B" from the

U.S. Army Material Command at Wright Field in Dayton, OH. The specification was

written for a

long range four engine bomber with a range of 5,333 miles with the speed

and bomb load of a B-17. Boeing had been expecting the proposal,

and had been working on several conceptual bomber

models starting in 1939. The Model 341, which Boeing felt met the

requirements, was submitted in March 1940.

In late March the Army Air Corps

realized that the requirements needed to be changed. A supplementary

specification went to Boeing which included more bomb capacity, leak

proof fuel tanks, and more defensive armament. Due to these

requirements, the Model 341 evolved into the Model 345. The Model

345 added seventeen more feet of wing span than the Model 341 and was

eight feet longer. Each Wright radial engines had 200 more

horsepower at take-off than the engines designated for the Model

341. The Model 345 would have a maximum bomb load of 16,000

pounds, a crew of twelve, four remote controlled turrets, a rear

turret, and a maximum speed of 382 MPH at 25,000 feet. This was then

designated the XB-29.

As with all military designs, weight of the

B-29 went up over time with the addition of new requirements by the

military. The final B-29

design had grown to an aircraft with a design gross weight of 105,000

pounds, while the XB-29's design gross weight was 100,000 pounds, the

Model 345 was 97,700 pounds, and the Model 341 76,000 pounds. The

added requirements caused the weight to increase by 29,000 pounds over three years, while

the airframe and engines remained constant since the Model 345.

When it came time for production of the

B-29 in 1943, the US Auto Industry was deeply involved as suppliers of

airframe components, engines, and many of the internal components of the

aircraft. General Motor had seventeen of its divisions providing

parts and structural components. They were: AC Sparkplug,

Allison, Brown-Lipe-Chapin, Buick, Chevrolet, Delco Appliance, Delco

Products, Delco Radio, Delco-Remy, Fisher Body, Frigidaire, Harrison

Radiator, Hyatt Bearings, Moraine Products, New Departure, Packard

Electric, and Rochester Products. Chrysler's DeSoto, Dodge, and

Plymouth divisions contributed heavily to the B-29 project. Hudson

was the third automaker to supply B-29 components. Auto suppliers

contributing to the construction of the B-29 were Briggs Manufacturing,

Firestone, Goodyear, Goodrich, and Libby-Owens Ford.

The US Auto Industry and the B-29 "Enola

Gay": The first three Silverplate nuclear bombers were

built at the Boeing Wichita, KS plant. The "Enola Gay" and the of

remaining 43 Silverplate nuclear bombers were all built at the Martin

Omaha, NE B-29 plant. All were modified for the nuclear mission at

Martin Omaha.

As the Martin information from World War Two shows,

the US auto industry was the major supplier of airframe and structural

components to Omaha.

The B-29 "Enola Gay" is currently on display

at the Steven F. Udvar-Hazy Center of the National Air and Space Museum

at the Dulles International Airport in Virginia. Author's photo.

Author's photo.

The bombardier's front Plexiglas nose

section was built by Libby-Owens-Ford, a prime supplier of glass to the

US auto industry. The front eighteen foot fuselage section was

built by Chrysler's DeSoto Division on Warren Avenue in Detroit.

Author's photo.

The Fisher Body Plant # 1 in Cleveland, OH

built the rear turret and gun assembly. Goodyear built the rudder,

the vertical stabilizer and the leading edge to the vertical stabilizer.

It also built the horizontal stabilizer and elevators on the "Enola

Gay". Goodyear had aviation plans in Akron, OH and

Goodyear, AZ. The three rear fuselage sections behind the

wings, to include the tail gunner's location, were built the Hudson Motor

Car Company in Detroit. Author's photo.

Goodyear produced the two bomb bay fuselage

sections. Chrysler furnished the engine cowlings and the leading

edge sections for the wing center section. Fisher Body Cleveland

#1 or Fisher Body Lansing built the engine nacelles and inside the

nacelles the Fisher Body furnished the engine exhaust manifolds and the

engine oil tanks. Hudson provided the ailerons, outer wing

sections, outer wing leading edges and wing tips. Briggs supplied the flaps

and bomb bay doors. Inside the wings were four Firestone

fuel tanks. The engines are shown as Government Furnished

Equipment. Dodge in Chicago produced Wright R-3350 engines.

Author's photo.

The name "Enola Gay" is written on the

Chrysler DeSoto Division built nose fuselage section. The eighteen

foot long section parting line can be seen about two feet behind the

square window. Chrysler workers installed 50,000 rivets, four miles of wiring and

8,000 different types of parts in the nose section. Behind the nose section are two

Goodyear built bomb bay fuselage sections. On normal B-29s built

there was provision for a Goodrich built auxiliary fuel tank in the rear

bomb bay. For the nose gear and main landing gears the doors were

produced by Goodrich. Author's photo.

Because modifications were made to the

Silverplate B-29s, several of components supplied by the American auto

industry were not included. The bomb bay doors were modified to

accept the large atomic weapons. The bomb bay doors normally

supplied to Omaha B-29s were not used or were modified. It is

unknown. Also, the Silverplate aircraft used

Curtiss reversible electric propellers, and not the normal Hamilton

Standard propeller built by Frigidaire Division of GM .

Nose Section: The photos below

are of the interior of the nose section from B-29A 44-62139 at the

National Museum of the Air Force in Dayton, OH. This A model nose

section is representative of all nose sections built. Most likely

this one was built at the Boeing Renton, WA plant. B-29s built in

Marietta, GA by Bell and Boeing in Wichita, KS had Chrysler built

nose fuselage sections. The photos below show some of the 50,000

rivets, 8,000 parts and four miles of wiring. All of the displays

are behind Plexiglas.

Author's photo.

The left or port side of the bombardier's

station. Author's photo.

The pilot's station. Author's photo.

The flight engineer's station.

Author's photo.

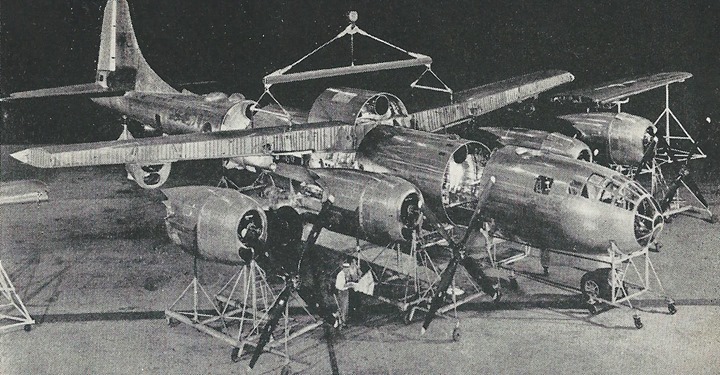

Factory Photos:

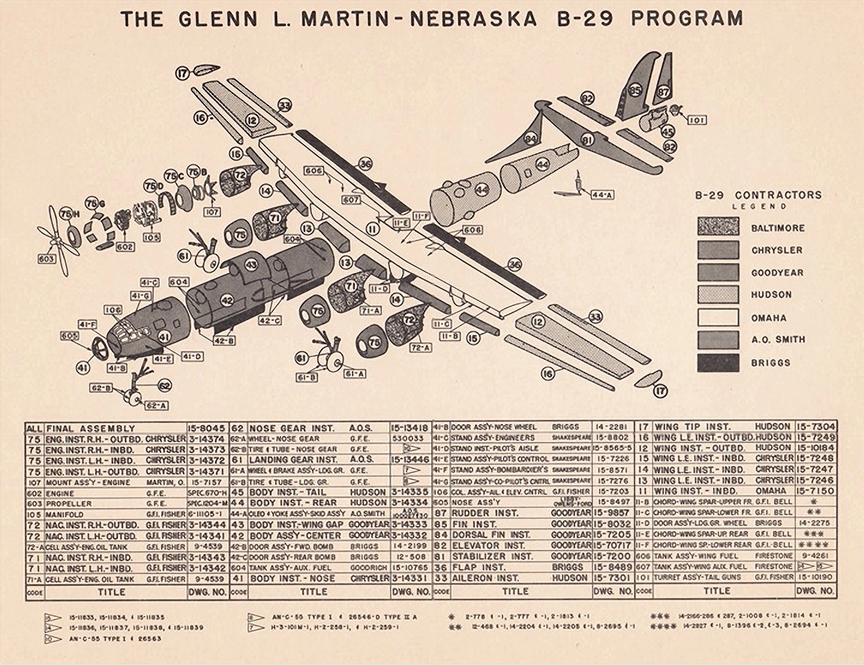

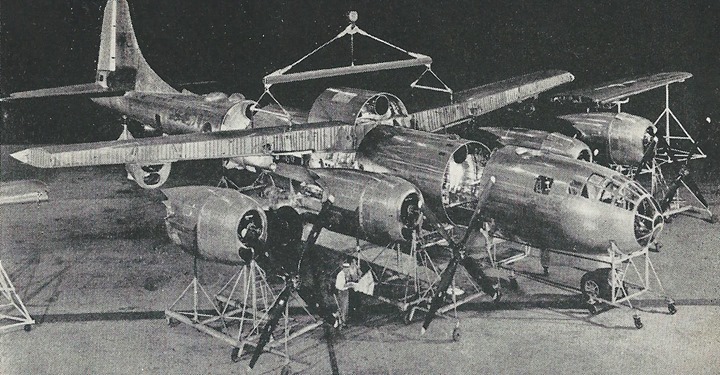

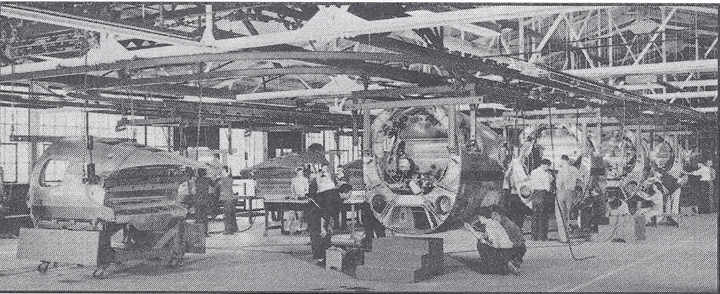

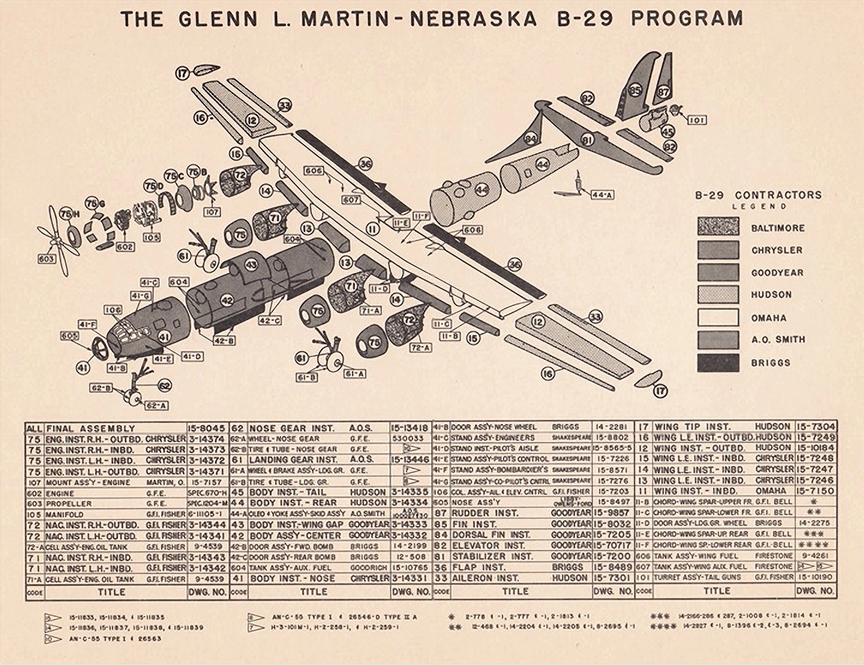

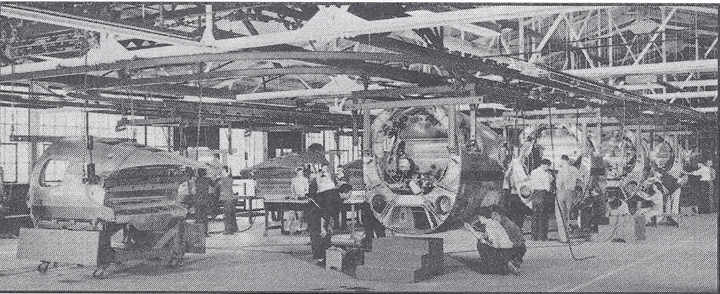

This photo is an exploded view of an actual

B-29, showing many of the main components. The Chrysler DeSoto

nose section is separated from the Goodyear built bomb bay fuselage

sections. The Hudson built rear fuselage sections with the

Goodyear vertical and horizontal tail and control surfaces can be seen.

The main wing center section was built by Martin Omaha but the outer

wing section components built by Hudson are visible. The Fisher

Body engine nacelles have Chrysler built engine cowlings attached.

Frigidaire props are off the Dodge built engines.

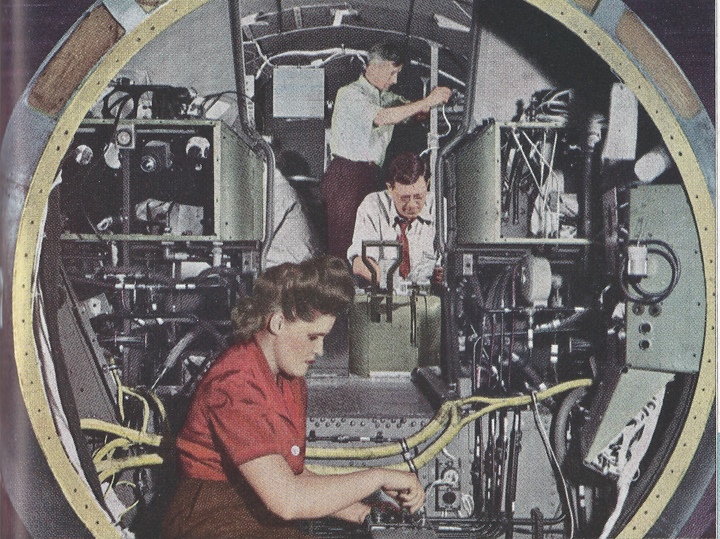

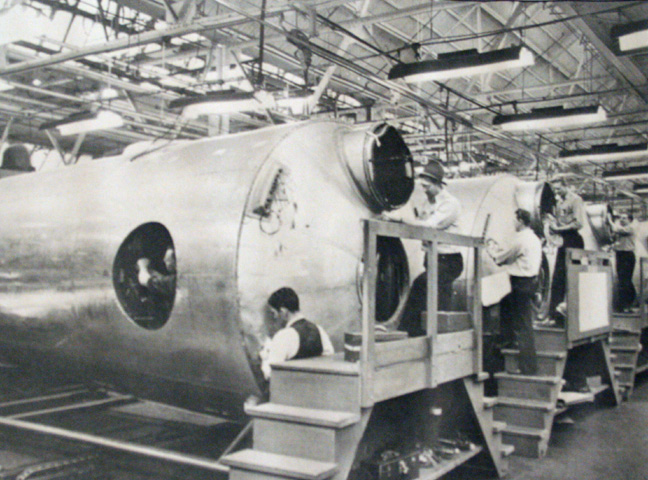

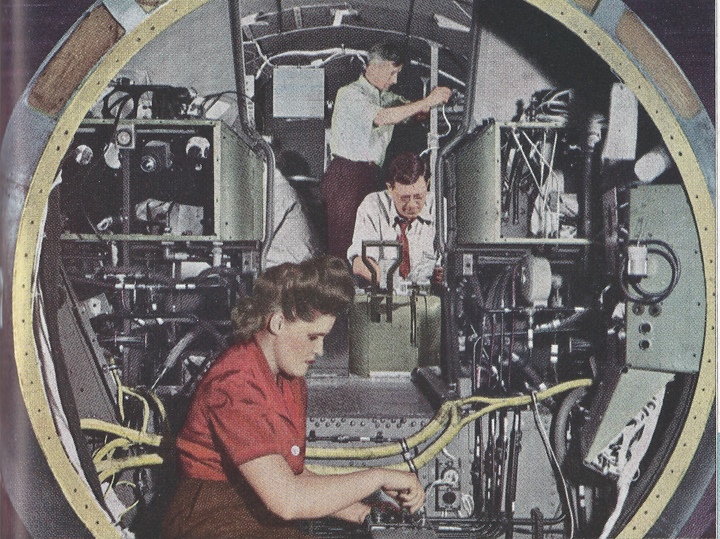

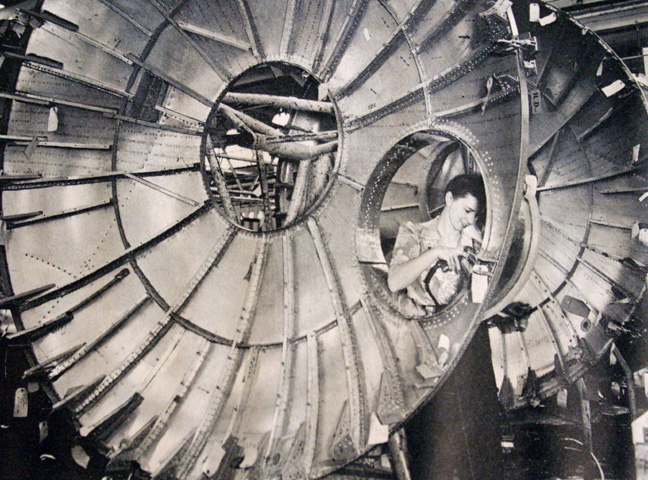

There was more to just stamping out the

aluminum sheet metal pieces and then riveting them together with 50,000

rivets to make the fuselage. DeSoto-Warren assembled all of the

interior of the B-29 nose section, which included four of the eight

miles of wiring in the B-29. The workers shown above are installing

some of the 8,000 parts that went into the construction of the

Superfortress fuselage. The B-29 was the first insulated and

soundproofed bomber and the insulation can be seen in this photo The

fuselage sections were shipped via rail to Omaha using oversized

boxcars, which were foot wider and one and a half foot taller than the

normal boxcar of the period.

Working on B-29 engine cowlings at the

DeSoto Warren Plant in Detroit.

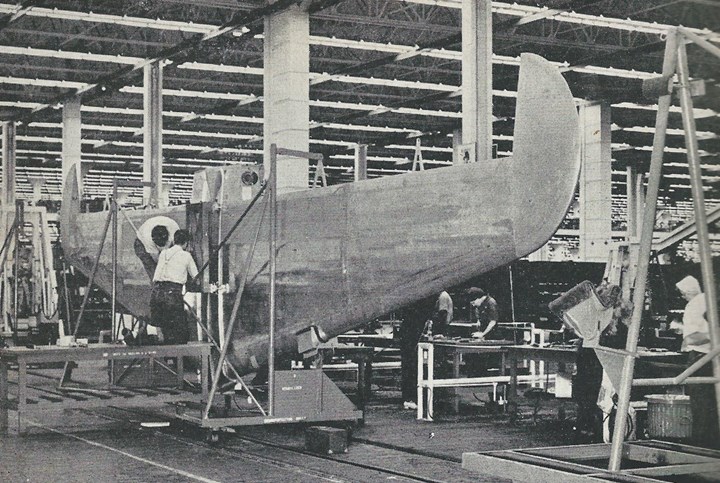

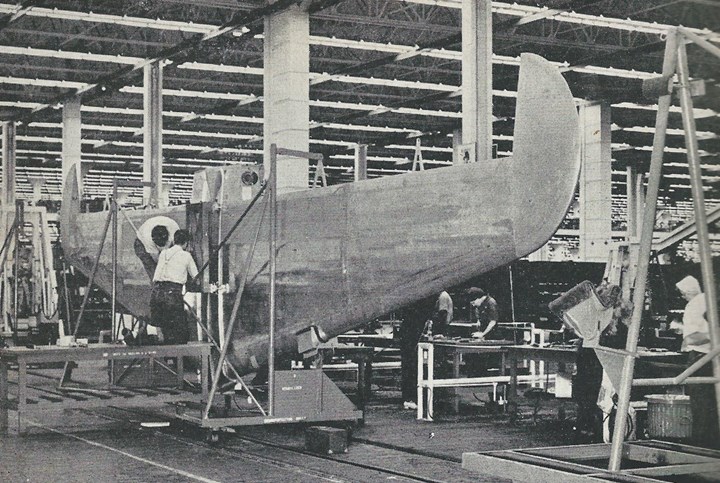

This is the Fisher Body Cleveland plant #2

making horizontal stabilizers. Fisher Body either made them along with

Goodyear, or was a sub-contractor to Goodyear for these particular B-29

components.

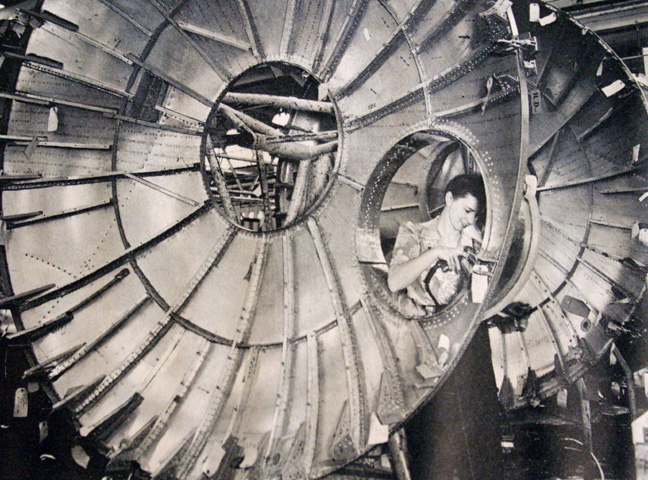

B-29 engine nacelles on the assembly line at

Lansing Fisher Body. My mother worked in this plant during World

War Two. Photo courtesy of UAW Local 602.

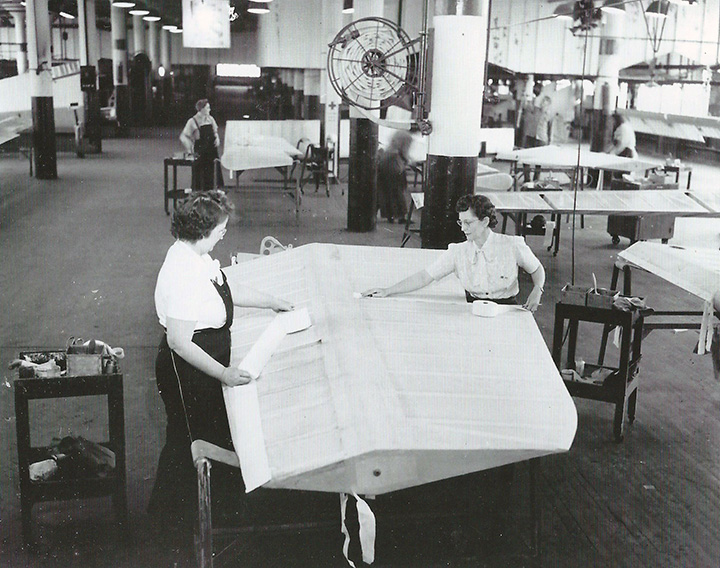

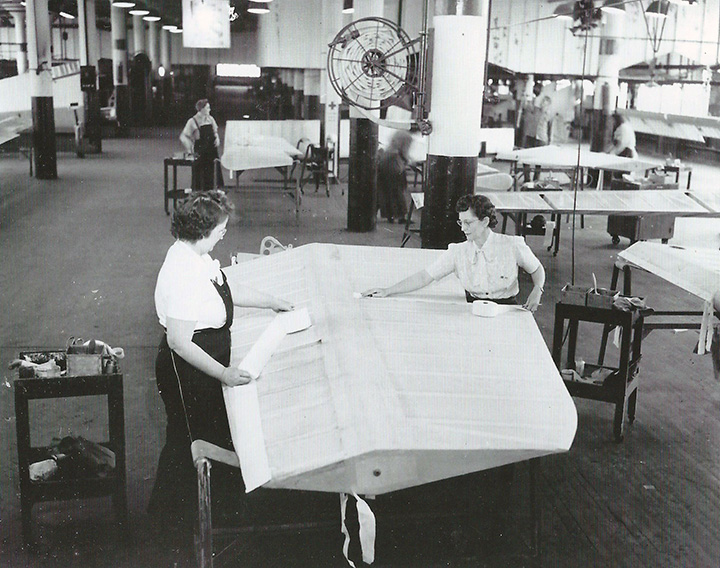

These women are working on a B-29 fabric covered rudder on the Lansing

Fisher Body plant floor. The woman on the left is applying tape

over the stitching that holds the fabric to the aluminum superstructure.

The stitching down the center has already been taped over. Once

this process is complete, a water-proof varnish is applied and then

cured.

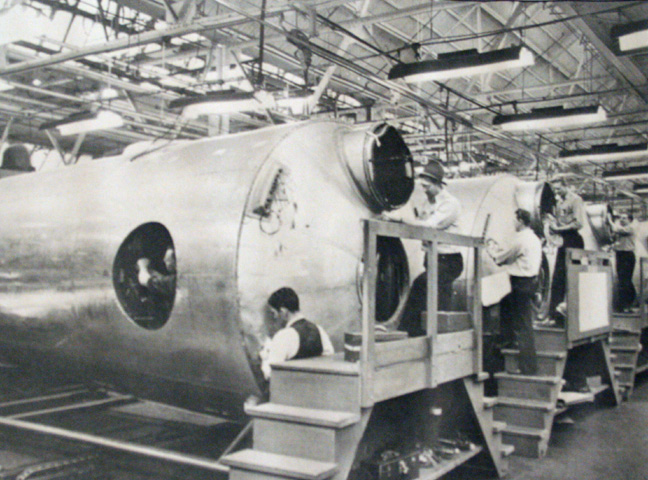

Hudson workers building B-29 rear fuselage

sections.

B-29 rear fuselage end caps under

construction at the Hudson plant.

|

B-29 Components

built by the US Automobile Industry in World War Two |

| Manufacturer |

B-29 Components |

Location |

Comments |

|

| Briggs Manufacturing |

Aft bomb doors and

forward bomb doors, nose wheel doors, and outer wings. |

31,000 employees in

ten Detroit plants, one in Youngstown, OH and one in Evansville,

IN produced parts for the B-29.

Besides B-29 components the company

also provided parts for the A-20, B-17 and many other war

products. |

Briggs components were supplied to the Martin Omaha, NE

plant for final assembly into B-29s including the "Enola

Gay" and "Bockscar".

Briggs was also a supplier to the

other three B-29 final assembly plants. |

|

| Chrysler - DeSoto

and Dodge |

(568) fuselage nose

sections, (559) leading edges, (4,752) engine cowling sets, and

(18,413) R-3350 radial aircraft engines. |

The airframe

components were built by DeSoto on Warren Ave. in Detroit and the R-3350s were built Dodge

in a new, dedicated plant in Chicago. |

DeSoto provided

airfrafme components for the Martin Omaha, NE plant for final assembly into B-29s

including, the "Enola Gay" and "Bockscar". DeSoto also supplied all of the engine cowlings for the B-29

assembly plants in Renton, WA and Marietta, GA.

Dodge

built R-3350 engines went to all four B-29 assembly plants.

Before supplying B-29 parts to

Martin it had previously provided (1,586) nose and fuselage

sections for assembly into the B-26 Marauder. |

|

| Firestone |

Wing Fuel tanks

|

The Coshocton, OH

plant built disposable auxiliary fuel

tanks for the B-17, B-24 and B-29, |

The outer wing fuel

tanks consisted of seven cells and held 1,320 gallons of

aviation fuel, while the inner tanks consisted of four cells and

held 1,425 gallons of fuel. |

|

| Fisher Body Div of

GM |

(13,772) B-29 Engine

Nacelles - These were the most complex component of the B-29 and

had 1,300 sub-assemblies in them.

Horizontal stabilizers, vertical

stabilizers, rudders, elevators, outboard wing sections, flaps,

exhaust collectors, engine cowlings, tail gun assemblies and rudder pedals, engine oil tanks along with many

other miscellaneous B-29 parts. |

Nacelles were

produced at the Cleveland, OH Plant #1.

Flaps,

vertical and horizontal stabilizers were produced at the

Cleveland, OH Plant #2.

Elevators, nacelles and tail

sections were made in the Lansing, MI

plant.

Parts and Assemblies - Grand

Rapids, MI, Pontiac, MI Ternstedt in Detroit, MI, Cleveland, OH Plant #1, Fleetwood,

MI, Memphis, TN, Central Development, Detroit, MI, Experimental Unit,

Detroit, MI, and

the Detroit Aircraft Unit.

Fixtures, jigs and tooling - Flint #1, Detroit Die

and Machine Unit and Detroit Stamping Unit. |

Fisher Body Division

of GM provided the following components to the Martin Omaha, NB

B-29 assembly plant. For

each engine: Exhaust manifold or exhaust collectors, the

engine nacelles, engine oil tanks.

Fisher Body also supplied the

rear turret assembly, which on the "Enola Gay", "Bockscar" and

the other Silverplate B-29 nuclear bombers was the only method of self

defense. All of the other gun turrets and sighting equipment

was removed to reduce weight.

Many of the B-29 components built

by Fisher Body were supplied to Martin in Nebraska by other

suppliers indicating that Fisher Body B-29 built components were

being provided to the other three B-29 plants, or subcontracted

to the first tier suppliers. These

components would include the engine nacelles as Fisher Body

built enough to supply 86% of the 3,970 B-29s built and Martin

only used 2,124 or 15%. Also horizontal stabilizers, vertical

stabilizers, rudders, elevators, outboard wing sections, flaps

would have been supplied to Bell in Marietta, GA and Boeing in

Wichita, KS and Renton, WA. |

|

| Goodyear |

Forward and rear bomb bay fuselage sections,

rudder, vertical stabilizer, dorsal fin assembly, elevator

assembly, and horizontal stabilizer assembly |

Akron, OH |

|

|

| Hudson |

(802) rear

fuselages, bulkheads, wing tips, rear turrets |

Detroit, MI |

|

|

| Frigidaire Div. of

GM |

(54,737) four Blade

Propellers for both the B-29 and P-47. |

Dayton, OH |

|

|

| B-F. Goodrich |

Fuel Tanks |

Akron, OH |

|

|

| Libby-Owens-Ford |

Bombardier's glass nose section |

Toledo, OH |

|

|

| New Departure

Division of GM |

1,417 roller

bearings for B-29 Fire control system |

Bristol, CT |

|

|

| Packard Division of

GM |

Packard supplied

high altitude ignition cable for the B-29 engines. |

Warren, OH |

|

|

In the table below is the production schedule

that the auto companies had to meet for the supply of components for the

Martin Omaha, NB built B-29s. Note that in several months there is

no production or at least no accepted production. It could have

been that there was a parts shortage that did not allow the aircraft to

be finished and accepted by the US Army Air Force. I do think the

work stoppages were intentional.

Aircraft in World War Two were built in Block Numbers,

which had frozen designs and did not allow for any changes to the

aircraft while coming down the production line. This allowed mass

production of aircraft without having to make the constant changes and

improvements that were needed due to information that was coming back

from testing and operational units. When a new block was started

it contained updates and improvements. However, even then to

facilitate production, not all of the upgrades would be included and

afterwards the aircraft would go to one of nineteen modifications

centers for the latest updates. The modification centers were an

important part of the process needed to keep the aircraft production

lines operating in a timely manner. In the case of Martin Omaha it

had its own modification center.

Serial numbers reflect the year the aircraft

were ordered as indicated by the first two numbers in the sequence.

The first B-29 built at Martin Omaha was the 65202nd aircraft ordered by

the US Army Air Force in 1942. The last one off the assembly line

in August of 1944 was the 86273rd aircraft ordered in 1944.

Of the four plants making B-29s during WWII,

Martin in Omaha, NE was chosen to build and then modify the operational

B-29s for the nuclear bomber Silverplate program. Martin was considered by the US Army Air Force to have the best

quality of the four plants. The first fifteen came directly off

the assembly line and went to Wendover Army Air Field, UT, where they

were converted to the Silverplate configuration and then used in

training.

The fifteen operational Silverplates that went

to Tinian were also built at Martin and modified at the adjacent

modification center. Modifications included but were not limited

to replacing the Hamilton Standard Propellers with Curtiss Wright

Electric reversible props, eliminating all of the gun turrets, gun

sights, and gun control computers with the exception of the tail turret,

and modifying the bomb bays to accept the large atomic

devices.

The Martin Plant received the Army-Navy "E"

for Excellent Award on December 13,1943 and then later 3 stars for

on-time delivery. The awards were given for the previous B-26 production

at the plant.

|

Martin Omaha,

Nebraska World War Two B-29 Production Schedule |

|

Month |

Number built |

Block Number |

First Serial Number |

Last Serial Number |

Comments |

| 1944 |

|

|

|

|

|

| May

|

3 |

B-29-MO-1 |

42-65202 |

42-65204 |

|

| June |

7 |

B-29-MO-5 |

42-65205 |

42-65211 |

|

| July

|

0 |

|

|

|

|

|

August |

8 |

B-29-MO-10 |

42-65212 |

42-65219 |

|

|

September |

16 |

B-29-MO-15 |

42-65220 |

42-65235 |

|

|

October |

28 |

B-29-MO-20 |

42-65236 |

42-65263 |

|

|

November |

0 |

|

|

|

|

|

December |

50 |

B-29-MO-25 |

42-65264 |

42-65313 |

|

|

1944 Total |

112 |

|

|

|

|

| 1945 |

|

|

|

|

|

|

January |

69 |

B-29-MO-30 |

42-65315 |

42-65383 |

|

|

February |

18 |

B-29-MO-35 |

42-65384 |

42-65401 |

|

|

February |

67 |

B-29-MO-35 |

44-27259 |

44-27325 |

The B-29 "Bockscar"

was serial number 44-27297 and came off the Martin Omaha

assembly line in February 1944. |

| March |

0 |

|

|

|

|

| April |

0 |

|

|

|

|

| May

|

33 |

B-29-MO-40 |

44-27326 |

4-27358 |

|

| May

|

35 |

B-29-MO-40 |

44-86442 |

44-86276 |

|

| May

|

39 |

B-29-MO-45 |

44-86277 |

44-86315 |

The B-29 "Enola Gay"

was serial number 44-86292 and came off the Martin Omaha

assembly line in May 1944. |

| June |

55 |

B-29-MO-50 |

44-86316 |

44-86370 |

|

| July

|

55 |

B-29-MO-55 |

44-86371 |

44-86425 |

|

|

August |

48 |

B-29-MO- 60 |

44-86426 |

44-86473 |

|

|

1945 Total |

419 |

|

|

|

|

|

Grand Total |

531 |

|

|

|

|

Below are two other B-29s built by Martin

built with US Auto Industry fuselage and wing components.

This Martin built B-29 42-65281, seen here at the Travis AFB Heritage Center, came off the assembly line at Omaha,

NE in December 1944. Author's Photo.

This Martin built B-29 44-27343, seen here at the Tinker AFB Heritage Display, came off the assembly line at Omaha,

NE in May 1945. Author's Photo.

Martin built B-29 44-86408 is also displayed at

Hill AFB in Ogden, UT. Five of the 531 Martin B-29s therefore

still

survive. |