|

Oldsmobile Overview Page

Conversion to Firepower

Oldsmobile WWII Plant Tour Guide

Book

Firepower is Our Business

The

Oldsmobile Division of General Motors in World War Two

Recognizing a Company

from my Hometown that contributed to winning World War Two

Lansing, MI

1897-2004

Rest in Peace

Updated 9-24-2021.

Other Lansing Companies that

contributed to winning World War Two

I grew up in Lansing, MI. My childhood and early adulthood

was dominated by the presence of Oldsmobile in the city.

Oldsmobile was the economic engine that drove the economy.

Oldsmobile provided

the jobs for many of the fathers of my school friends. Oldsmobile

was important to my family, even though my father worked for the nearby

Fisher Body Division of General Motors plant. Oldsmobile was still important to

our family, as my father's plant produced the automobile bodies for "The

Olds." Indirectly, Oldsmobile dominated my life and my family's as I

grew up. I have memories of new Oldsmobiles being driven past my

grade school to the nearby trucking companies, where they were loaded

onto

trailers, to be delivered to dealers around the country. The

Oldsmobile plant was just a half mile down the road from my school.

Oldsmobile in 1905 looking south east from

Division Street and Olds Ave. In 1905, Olds Avenue was Issac

Street.

The Olds Administration Building that served

the division during WWII. It was replaced by a more modern structure in 1965.

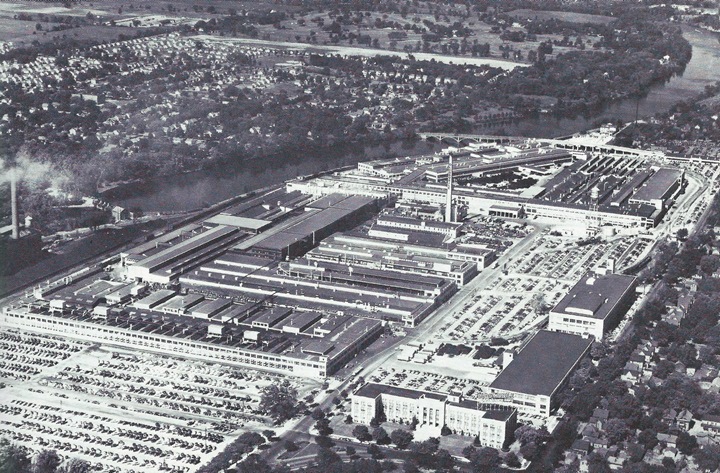

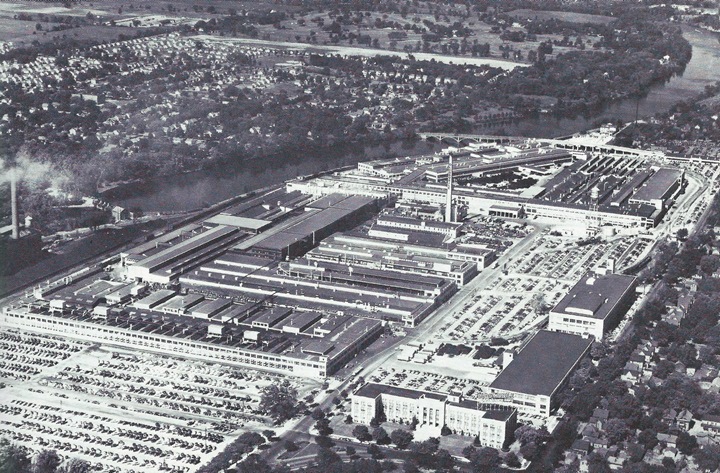

Oldsmobile in 1950 looking west. The

old administration building pictured above can be seen in the lower right

hand corner of the complex. I grew up in the neighborhood to the

south of the Grand River that bordered Oldsmobile. I fished and played in

Moores Park, on the south bank of the river.

Photo added 11-16-2015.

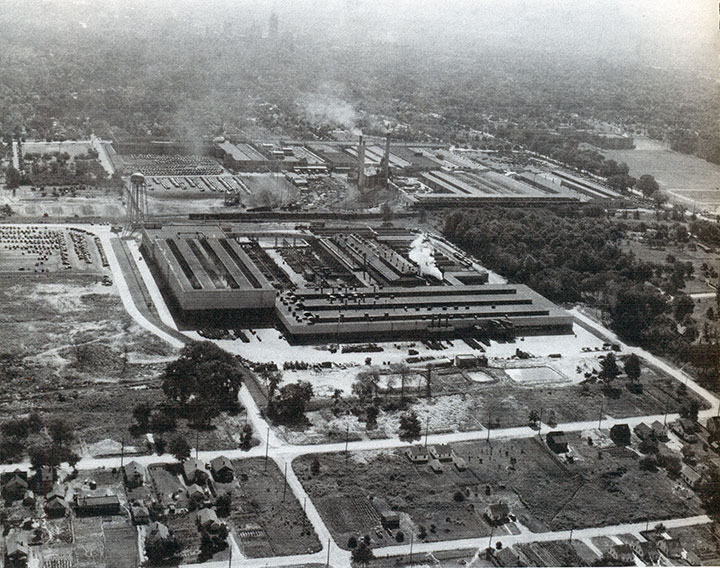

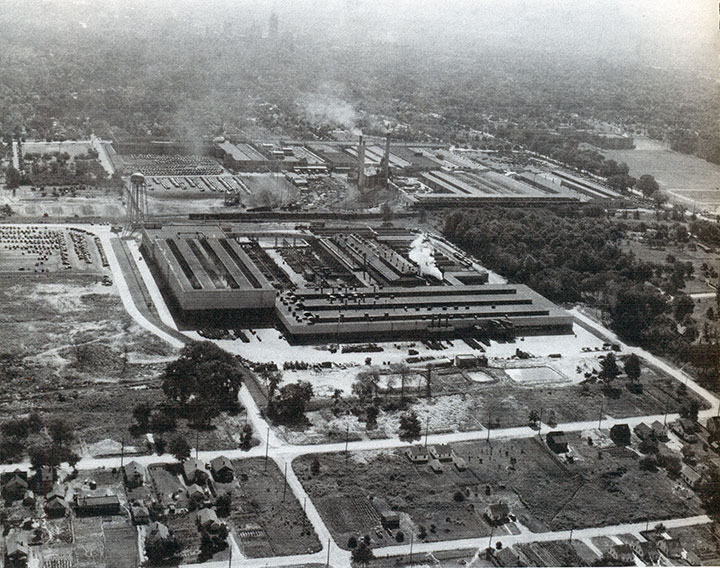

This post-1975 photo looking northwest in Lansing

shows the Olds Complex at its peak, before being dismantled after 2004.

In the background, one can see the Fisher Body / Olds Forge / Olds Jet

plants. A new administration building can be seen in the location

of the former one shown above. The new administration building

still exists today. In the foreground is the empty field where REO used to

be.

The Oldsmobile complex shown in the previous

two photos was replaced by the GM Grand River Assembly Plant.

Several of the older buildings from the Oldsmobile era still appear to

stand. The heat exchangers in the foreground along the Grand River

were opposite the side of the river where I fished while growing

up in Lansing. The plant now assembles the Cadillac CTV and ATV, and

the Chevrolet Camaro.

Oldsmobile Plant Number Two in 1945, looking

east with Lansing Fisher Body behind it. Up in the right hand corner

is the newly completed JW Sexton High School that I would attend 20

years later. Fisher Body plant's power house supplied steam to both plants.

Downtown Lansing is in

the distance through the smoky haze. The

capitol dome is not visible in this photo.

Today Oldsmobile is gone,

and most of the plants shown in the photos above have been razed.

Lansing and the surrounding area still has two GM Assembly plants,

building the Cadillac CTS and ATS, Chevrolet Camaro and Traverse, and

Buick Enclave. But it is not the same for those who grew up in

Lansing under the protective shadow of Oldsmobile. Oldsmobile then

had its headquarters and engineering staff along with its own forge and

engine plants in Lansing. Engineering advances were developed in

Lansing, not at the GM Warren, MI Technical Center, as they are today.

The aura of a GM auto town with its own auto division is no longer

present.

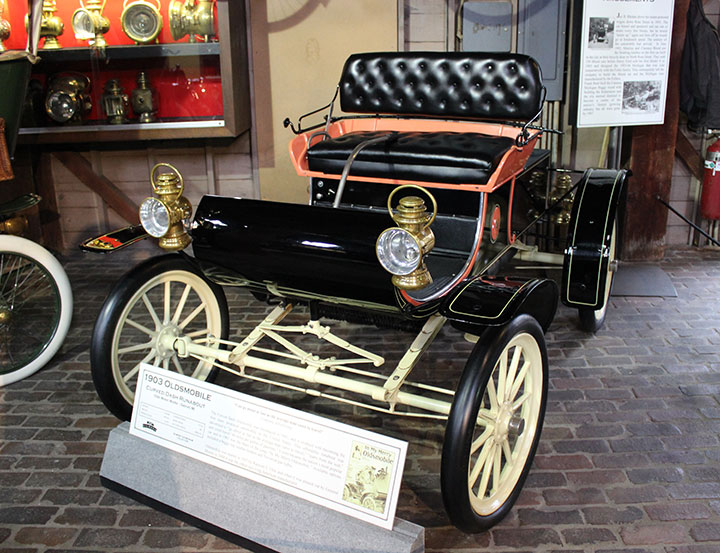

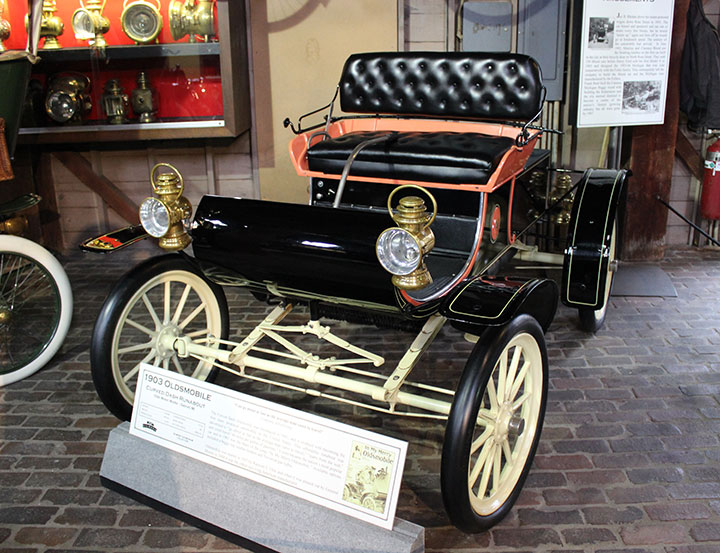

This 1903 Olds Curved Dash was first

introduced in 1901. It is considered to be the first mass produced

automobile. It was actually built by Olds in Detroit before a

fire destroyed the factory, and Olds moved back to Lansing.

Author's Photo from the Gilmore Car Museum in Hickory Corners, MI.

This 1910 Oldsmobile was the first motorized

fire truck in the state of Indiana. Author's Photo from the Terre

Haute Fire and Police Museum, Terre Haute, IN

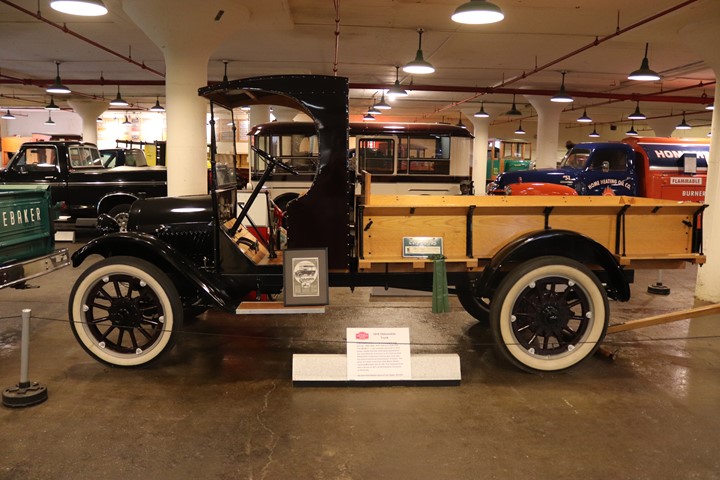

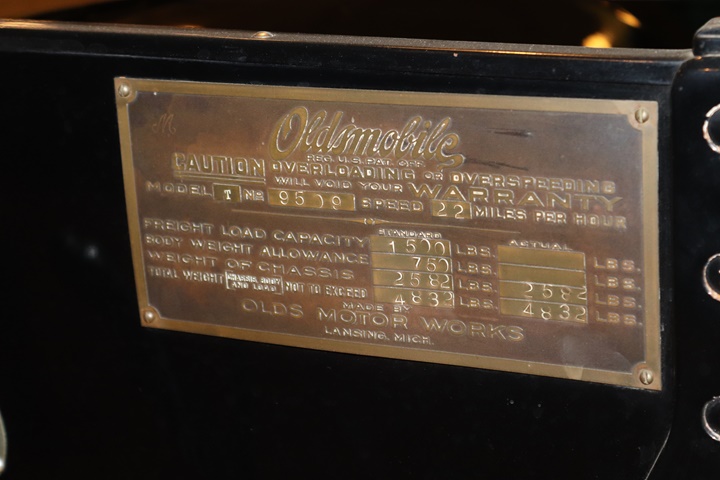

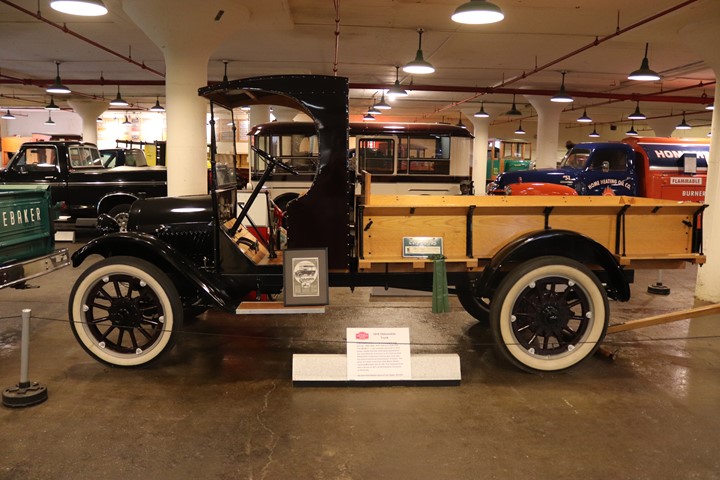

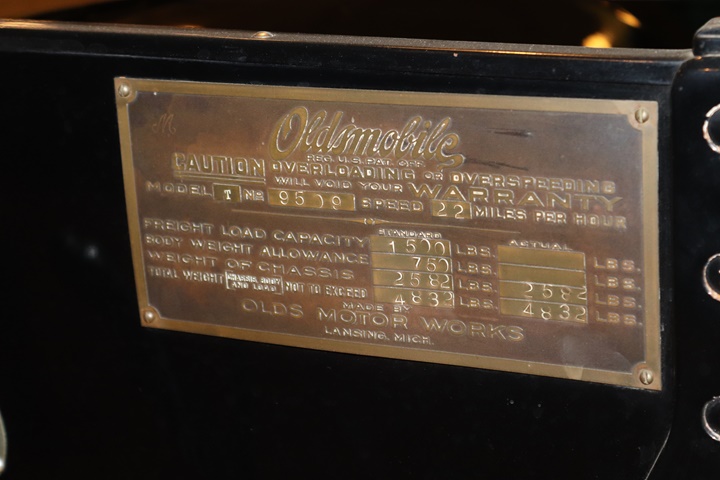

The next four photos are of a 1919 Model T

Oldsmobile 3/4-ton truck on display at the National Automotive and Truck

Museum in Auburn, IN. Author's photo added 1-7-2019.

Author's photo added 1-7-2019.

Author's photo added 1-7-2019.

Author's photo added 1-7-2019.

Many of the engine technologies developed

and built in Lansing are on display at the RE Olds Museum in Lansing,

MI. Olds developed many other automotive innovations in Lansing.

Author's photo added 4-29-2017.

Little did I know of

Oldsmobile's huge contribution to the winning of World War Two until I

started my research on the subject. Lansing Oldsmobile built

"Firepower" in the form of 125,527 cannons ranging in size from 20mm to

76mm, and 20,818,600 artillery shells ranging in size from 75mm up to

155mm. Oldsmobile's two borrowed GM plants in Janesville, WI, and

Kansas City produced another 24,919,390 shells ranging in size

from 75mm to 105mm. Total shells produced by all Olds operated

plants was 45,737,190.

This was the display of Olds military products

in the plant from the Second World War.

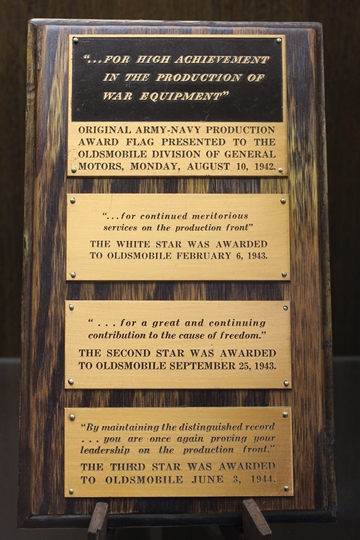

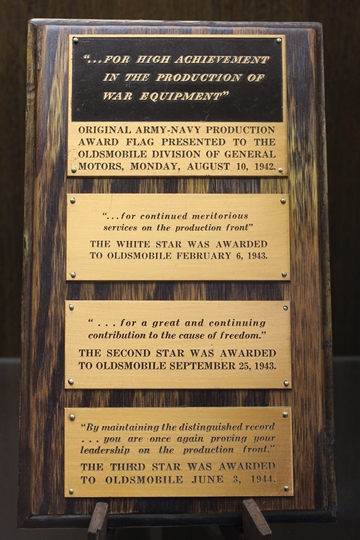

This is the original and extremely rare Army-Navy

"E" award flag that Lansing Oldsmobile won during World War

Two. The original flag was awarded on August 10, 1942.

Lansing Olds then won the award three more times, on February 6, 1943,

September 25, 1943, and June 3, 1944, denoted by the three stars on the flag . The "E" Award was the

most coveted award given to companies by the Army and Navy for

outstanding work in producing war material. This flag is very

rare. and is one of only a few original Army-Navy "E" award flags still

in existence in museums today. Author's photo taken at the RE Olds

Museum added 4-29-2017.

This plaque detailing the Lansing Oldsmobile

"E" Awards is also on display at the RE Olds Museum. Author's

photo added 4-29-2017.

Oldsmobile Janesville won its first Army-Navy "E" Award in December 1943. It won two more for a total of three.

Oldsmobile Kansas City won the Army-Navy "E" award four

times. The first time was October 5, 1943.

Oldsmobile World War Two Production Statistics for the Lansing, MI Home Plant

Cannons: 125,527 total units

77,010 20mm M2 aircraft cannon built from 10-16-1941 to 1-31-1944

2,779 37mm M4 aircraft cannon built from 7-12-1942 to 6-16-1943.

This was a Colt design that Olds built under license. The original

contract was for the Olds to build 6,195 M4 cannon. Colt built

8,667 M4 37. This weapon was used in the Bell P-39 Airacobra.

1,500 37mm M4E3 anti-aircraft cannon,

150 37mm M1A2 anti-aircraft cannon

2,930

37mm M9 anti-aircraft cannon built from 5-23-1943 to 5-16-1944,

5,129 75mm M6/T13E1 cannon - The T13E1 was used in the B-25H, and the

M6 was used in the M24 Chaffee tank

21,894 75mm M3 tank cannon built from 4-25-1942 to 2-4-1944

14,135 76mm M1A2 tank and tank destroyer cannon with production to

6-1-1945. Olds also built the M7 3 inch cannon used in the M10

tank destroyer. The weapons are similar in that 3 inches is

equivalent to the 76.2mm the 76mm size the cannon M1A2 actually was.

The M7 production numbers are included in the 14,135 quantity built.

Shells:

8,597,161 75mm M48 HE The 75 mm High Explosive round was

preferred by US tank crews, as it was superior to the 76mm HE round.

398,328 75mm M66

5,417,737 105mm M1 HE

316,362 105mm M67

3,740,678 75mm M61 APO

414,098 75mm M62A1

330,476 75mm M72 AP Shot

1,026,120 3 inch MK29APO Shot for the M10 tank destroyer and M5 towed

anti-tank gun

521,490 155 M101

56,150 75mm M61A1

Total amount of shells, projectiles and

shot produced at the Lansing operation was 20,818,600 from 8-19-42

until 6-30-45.

Oldsmobile World War Two Production Statistics for the Lansing, MI Home Plant

Misc.:

24,713 M2 Feeders

1,680 37mm M4E3 Magazines

30,672 .50 Cal. Gun Tubes

220,906 Pratt &WHItney Radial Aircraft Engine Piston Rods

7,050 4.5 inch T22 Rockets

231,198 4.5 inch T38 Rockets -These are also referenced as T22 in one

source. Both were 4.5 inch rockets.

? Propeller Spider Hub Forgings for Hamilton-Standard Three-Blade

Propellers - These may well have been supplied to Nash-Kelvinator

in Lansing that was building this type of propeller.

? Bomber Landing Gear Part Forgings

? Forged Crankshafts for Vauxhall

? Packard Rolls-Royce Merlin Aircraft Engine Crankshafts from 10-1944

to 6-1945

? Packard Rolls-Royce Connecting Fork Rods from 10-1944 to 6-1945

? Packard Rolls-Royce Rocker Arms from 10-1944 to 6-1945

? Packard Rolls-Royce Cylinder Liners from 10-1944 to 6-1945

? 37 Different Parts for 6-Ton 6x6 Truck Axles - This was for the

Timken-Detroit Company that built the axles.

? 33 Different Parts for 4-Ton 6x6 Trucks Axles - This was for the

Timken-Detroit Company that built the axles.

? 8 Different Parts for either the 6-Ton or 4-Ton 6x6 Trucks Axles -

This was for the Timken-Detroit Company that built the axles.

Oldsmobile World War Two Production Statistics for the Janesville, WI Plant:

Oldsmobile borrowed both the Chevrolet and

Fisher Body plants in Janesville, WI for World War Two production. Total amount

of shells, projectiles, and shot produced at the plant was 12,420,353

from 7-7-42 until 8-19-45.

4,088,757

3in M62 APC Projectiles, (Armor Piercing Capped) The shell had a

ballistic cap over the firing cap to reduce drag

270,000 3in M79 AP Projectiles (Armor Piercing) for the M10 tank

destroyer and M5 towed anti-tank gun

558,358 3in MK29 APC Shot (Armor Piercing Capped) for the M10 tank

destroyer and M5 towed anti-tank gun

196,315 M75 HE

Shells,

720,973 90mm M82 APC Shells, (Armor Piercing Capped)

6,585,950

105mm HE Shells, (High Explosive)

Oldsmobile World War Two Production Statistics for the Kansas City, MO Plant:

Oldsmobile borrowed this plant for the

war from the Fisher Body Div. of GMC. Total amount of shells,

projectiles, and shot produced at the plant was 12,499,237 from 8-19-42 until 6-30-45.

3,198,255 75mm M48 HE

Shells,

1,060,413 75mm M66 Shells,

182,498 75mm T39 HEAT Shells,

(High Explosive Anti-Tank)

1,122,287 3in M42A1 HE Shells for the M10 tank destroyer and M5 towed

anti-tank gun

1,980,994 90mm M71HE Shells,

3,149,516 105mm M67 HEAT Shells (High Explosive Anti-Tank)

1,805,274 105mm M1 HE Shells

36,860 81mm T19 Mortar Shell

The total amount of shells, projectiles and

shot produced at all Oldsmobile operations during World War Two

was 45,338,190.

Forgings:

The Oldsmobile Forge produced 37 different

forgings for the axles in this White 6-ton 6x6 Model 666 cargo truck.

Timken-Detroit was the supplier of the axles for this vehicle. The

forgings may have actually been delivered to the Reo Motor Company in

Lansing, because Reo built Detroit-Timken axles under sub-contract during

World War Two. Author's photo added 9-24-2021.

This is the rear axle on the White 666

truck. Many of the forgings in this axle were produced by the

Oldsmobile Forge. Author's photo added 9-24-2021.

The is the front axle on the White 666.

Author's photo added 9-24-2021.

This Diamond T 4-Ton 6x6 Wrecker was

photographed in Bath, MI. The Oldsmobile Forge produced 33

different axle forgings fifteen miles from this location for this type

of truck. Author's photo added 9-24-2021.

The Oldsmobile Forge produced landing gear

forgings for the Grumman FM-2 manufactured by the Eastern Aircraft

Division of General Motors. Author's photo added 9-24-2021.

Author's photo added 9-24-2021.

The Grumman F6F shot down more Japanese

aircraft during World War Two than any other aircraft and operated

primarily from the Essex Class Aircraft Carriers. Landing gear

forgings from Oldsmobile allowed the F6Fs to land safely during the

high-impact landings on the carriers. Author's photo added

9-24-2021.

The Boeing B-17 has become one of the most

famous bombers of World War Two, if not the most famous of those in

American

service during the war. Oldsmobile forged the propeller spiders

for the Hamilton-Standard three-bladed propellers for the B-17.

Both Nash-Kelvinator in Lansing, MI and Frigidaire in Dayton, OH built

B-17 propellers. Author's photo added 9-24-2021.

The Consolidated B-24 was the most widely

produced American bomber of World War Two, with over 18,000 being built

in five plants across the country. Lansing-built propellers were

supplied to the Ford Willow Run bomber plant in southeast Michigan.

Oldsmobile forged the Hamilton-Standard propeller spiders that were then

sent to Nash-Kelvinator across town in Lansing. Author's photo added

9-24-2021.

Projectiles and Weapons:

An M10 tank destroyer built "up the road" from Oldsmobile by Fisher

Body in Grand Blanc, MI fires it's Olds-built 3 inch M7 cannon in anger

in Normandy in July 1944. It could also be firing one of the

1,026,120 three inch shells built in Lansing. Photo added 11-10-2015.

An Oldsmobile M2 aircraft cannon is in the

back of the display case at the Museum of the United States Air Force in

Dayton, OH. This is one of 77,010 the division built during

World War Two. Author's photo added 4-29-2017.

Author's photo added 4-29-2017.

This collection of types of artillery shells Olds made during World War

Two is shown here in a glass display case at the RE

Olds Museum. Author's photo added 4-29-2017.

According to Oldsmobile's records, the

Division "only" produced 45,338,190 shells during World War

Two. The number

on this 155mm shell is a mystery. Author's photo added 4-29-2017.

This M4A3 Sherman tank built in the Fisher

Body Tank Arsenal in Grand Blanc, MI in March 1944 has an Olds-built

75mm M3 cannon. It is on display in downtown Bastogne, Belgium.

Olds was one of four companies building the cannon during World War Two

It supplied M4 tank production at the sister GM plant in Grand

Blanc, and the Chrysler Tank Arsenal in Warren, MI. Author's photo

added 10-31-2015.

This Fisher Body Grand Blanc, MI built M4A2

Sherman tank and its Oldsmobile built M3 75mm main gun landed with

Canadian tanks forces at Normandy, and survived the entire European

campaign. Holy Roller is on display at a park in London, ONT.

Author's photo.

This Grand Blanc, MI Fisher Body-built

M3A3(76)HVSS Sherman tank is armed with one of the 14,135 Olds-built

M1A2 76mm cannon. Author's photo taken at Bangert Park,

Florissant, MO added 4-29-2017.

This Grand Blanc, MI Fisher Body-built

M3A2(76)HVSS Sherman tank is also armed with one of the 14,135 Olds-built M1A2 76mm cannon. Author's photo taken at the

Oshawa Military and Industrial Museum, Oshawa, ONT added 4-29-2017.

The Cadillac-designed and built M24 Chaffee

light tank came with the one of the 5,129 M6 75mm cannons Oldsmobile

produced during World War Two. The M6 version was developed for

the Chaffee tank; and came with a thinner barrel wall and different

recoil mechanism than the M3 cannon used on the M4 Sherman. The

75mm gave the M24 tank crews increased firepower over the previous 37mm

cannon in the M5 series light tanks. Not

only did Cadillac build the M24, but Massey-Harris also contributed to

the 4,731 built. Author's photo taken at the tank park at the

First Division Museum in Wheaton, IL added 10-31-2015.

The Oldsmobile-built M7 3-inch cannon was used on Fisher Body-built M10 and Ford-built M10A tank destroyers, like this

Fisher M10 at the Patton

Museum at Fort Knox, KY. Olds also manufactured 1,026,120 shells

in Lansing for the weapon. Olds Janesville, WI produced 4,917,115

shells and shot for the 3-inch gun. The Kansas City Olds Plant

produced another 1,122,287 shells for it. Author's photo added

10-31-2015.

This is a 3-inch M5 anti-tank gun built by

the Rock Island Armory. It is on display on the front lawn in

front of the Vermillion County War Museum in Danville, IL.

Oldsmobile manufactured shot and shells that would have also been used

in this type of weapon that saw service with towed anti-tank battalions in

North Africa and Europe. The total number of 3-inch shells and

shot Oldsmobile produced during World War Two was 7,065,522. Author's photo added

10-31-2015.

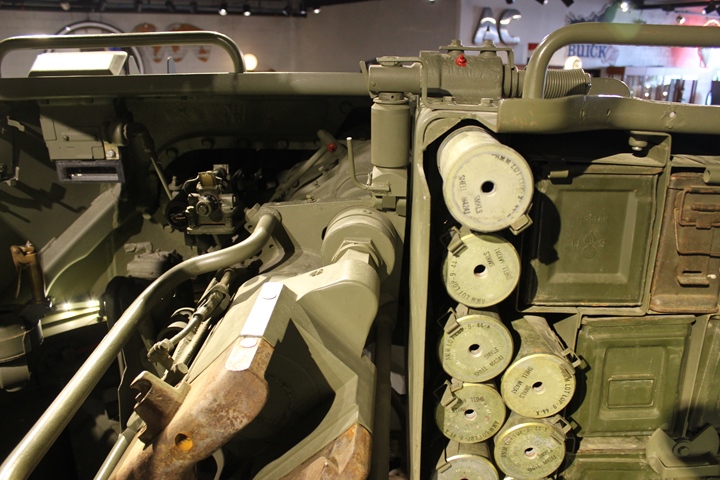

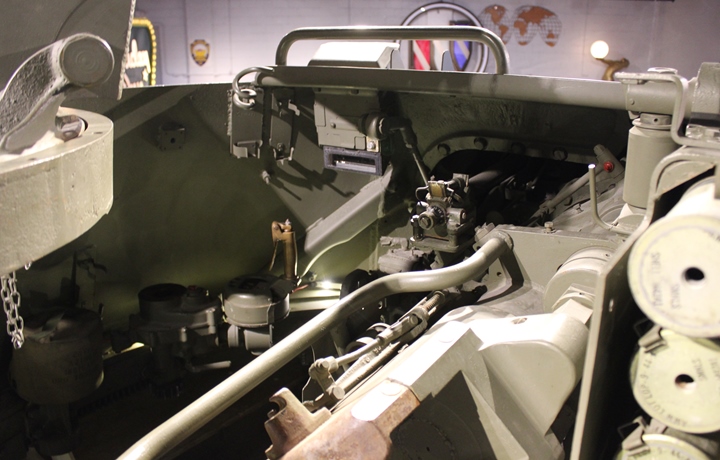

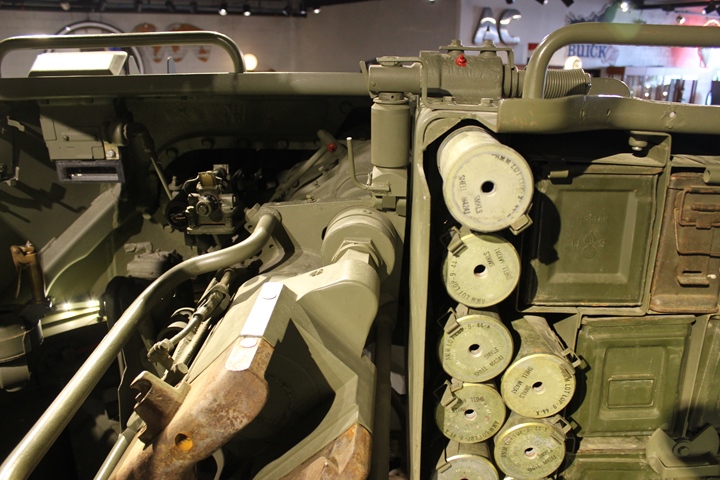

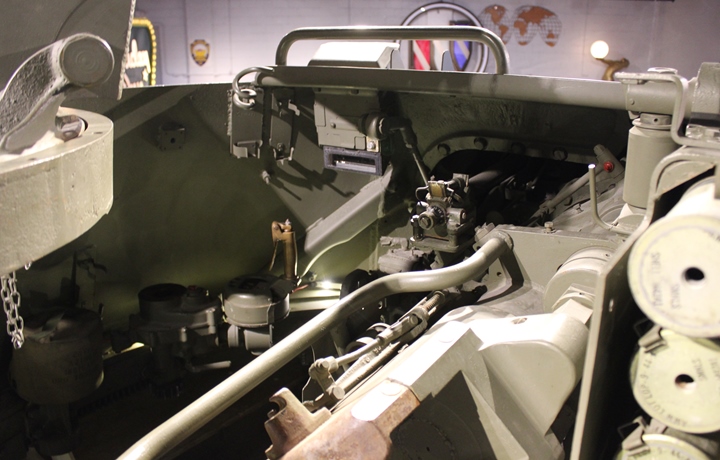

This Buick-built M18 at the Buick Museum in Flint, MI shows an excellent view of the Olds-built M1A2 cannon. Author's photo

added 10-31-2015.

In the M18, the loader sat to the right of

the 76mm cannon. Author's photo added 10-31-2015.

The gunner sat to the right of the Olds

built 76mm cannon. Author's photo added 10-31-2015.

This Autocar M15A1 is on display at the US

Army Basic Combat Training Museum at Fort Jackson, SC. It was equipped with

either an M1A2 or M9 37mm Oldsmobile anti-aircraft cannon. Author's

photo added 10-31-2015.

This photo shows the M1A2 or M9

37mm anti-aircraft guns mounted above the M2 .50 Browning machine guns.

Author's photo added 10-31-2015.

Elco PT-579 is on patrol in the Philippines

during the last two months of World War Two. Note an Olds 37mm aircraft

cannon that now resides on the bow of the boat. Oldsmobile-built cannons like

this were scavenged from derelict P-39s and mounted on the front decks

of PT boats to provide them more fire power. This was common for many PT

boats during the

war, and the weapon found a use for which it was never intended. Photo

added 11-10-2015.

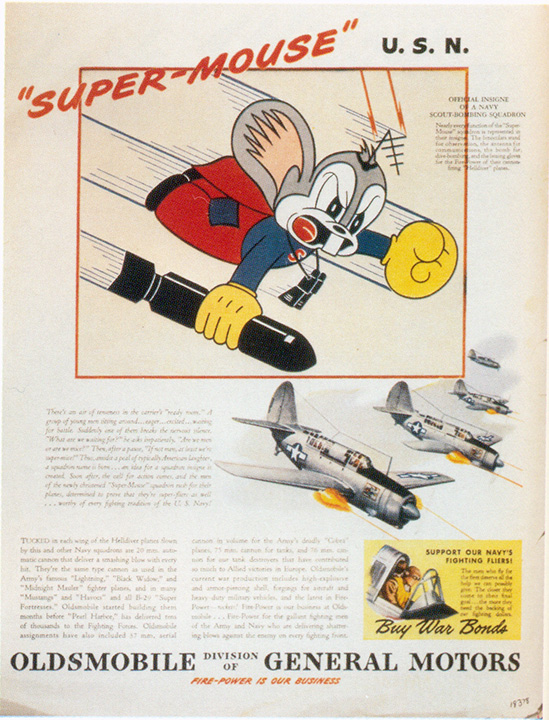

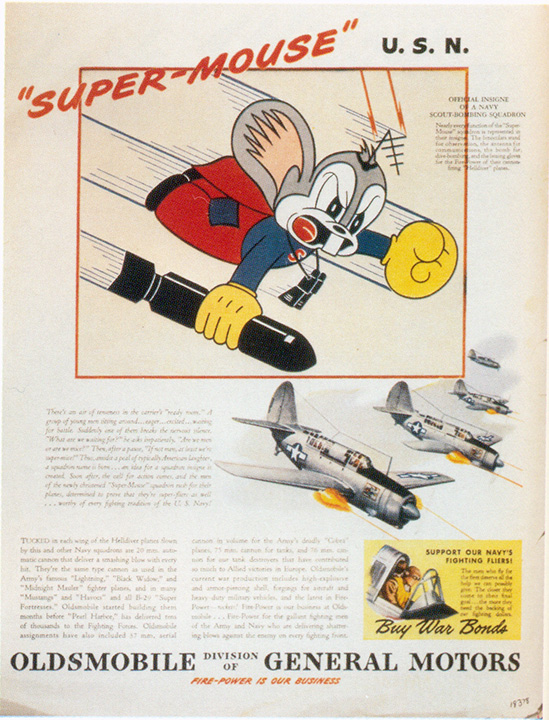

World War Two Magazine advertisements:

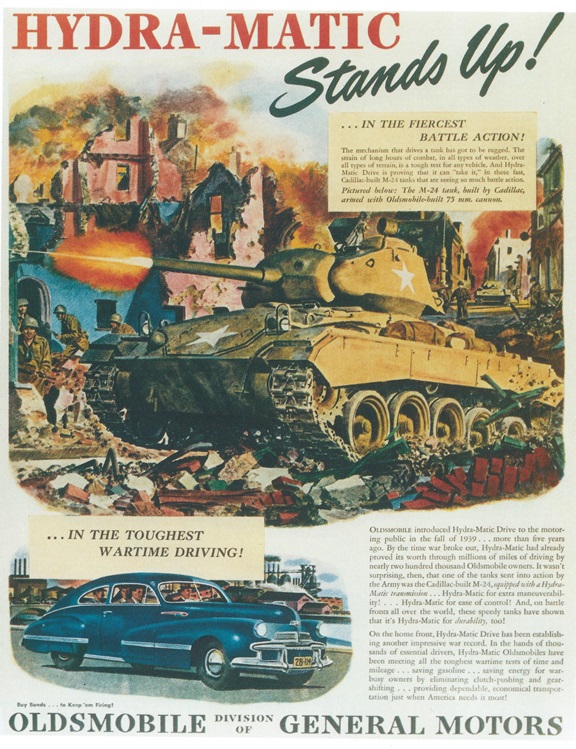

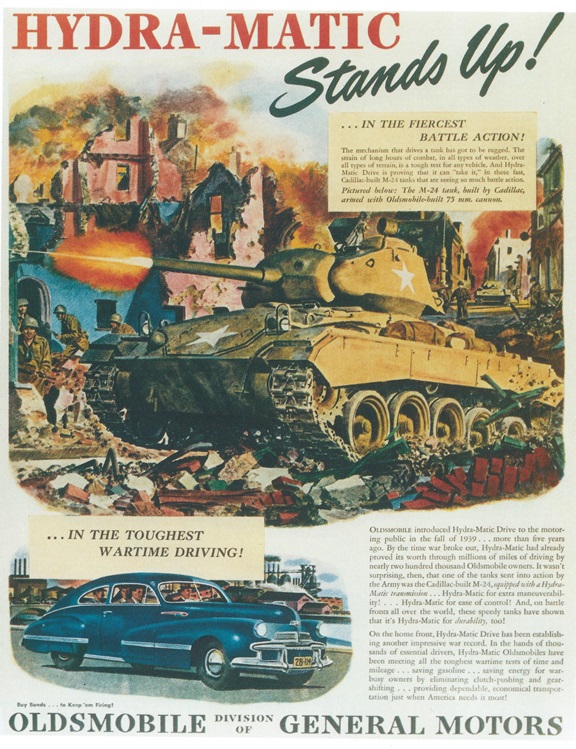

This Oldsmobile ad is touting the attributes

of the Hydra-Matic transmission, supplied before the war to Olds by

Detroit Transmission Division of GM. The Hydra-Matic transmission

was exclusive to Cadillac and Oldsmobile and became one of Oldsmobile's

marketing features to generate sales after the war.

Customers would not be purchasing the 75mm cannon, so it was more of a

side note in this ad.

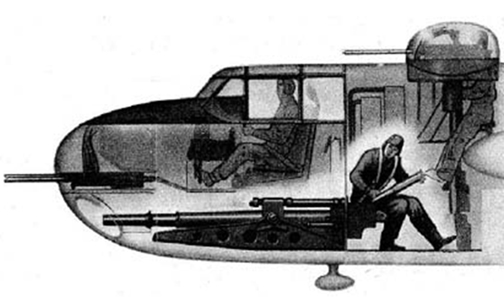

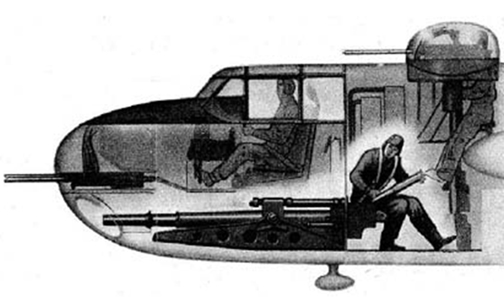

B-25H "Barbie III" as seen on display at the National Museum of

the United States Air Force in April 2017. "Barbie III" is an H model B-25

that carried the Olds 75mm T13E1 cannon as an anti-ship weapon.

Author's photo added 4-29-2017.

One can see the barrel of the Olds-built

T13E1 cannon in the lower left of the nose of the B-25. Of the B-25s

that are still flying, "Barbie III" is the only one with this cannon

configuration. Author's photo added 4-29-2017.

Author's photo added 4-29-2017.

Originally the Olds 75mm cannon was hand

loaded, which allowed for three or four shots per minute. Later, an

automatic feed system was developed that utilized the T9E1 75mm cannon

with an automatic feed system, which was not produced by Oldsmobile.

A Lockheed P-38 as shown in the ad above.

The 20mm cannon is the one on the left. The others are .50 machine

guns that could have also been manufactured by a GM Division.

The engines were supplied by the Allison Division of General Motors in Indianapolis, IN.

Olds-built 20mm aircraft cannons were the

main armament of the Northrop P-61 "Black Widow." There are only

four surviving P-61s. This one is on display at the Udvar-Hazy

Center of the National Air and Space Museum. Author's photo

added 4-29-2017.

This P-61 is on display at the National

Museum of the United States Air Force in Dayton, OH.

Author's photo added 4-29-2017.

Of the four remaining P-61s, none are

flightworthy. This one is being restored to flying condition by the

Mid-Atlantic Air Museum in Reading, PA. Author's photo added

4-29-2017.

The P-61's main armament was four Olds-built

20mm cannons. Barrels from three of the cannons can be seen.

Author's photo added 4-29-2017.

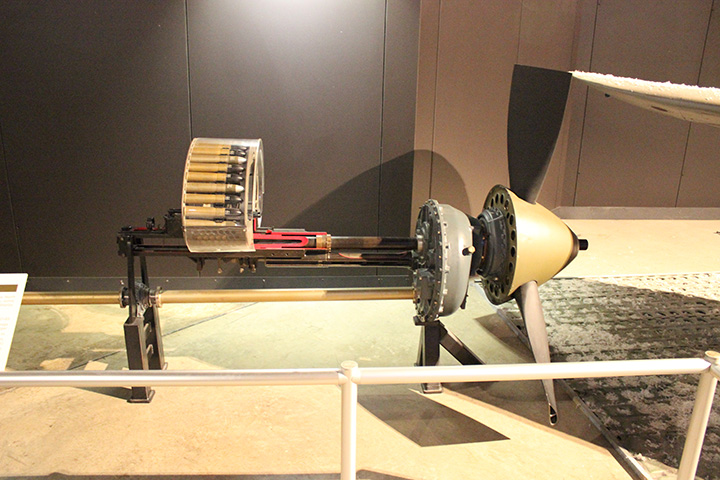

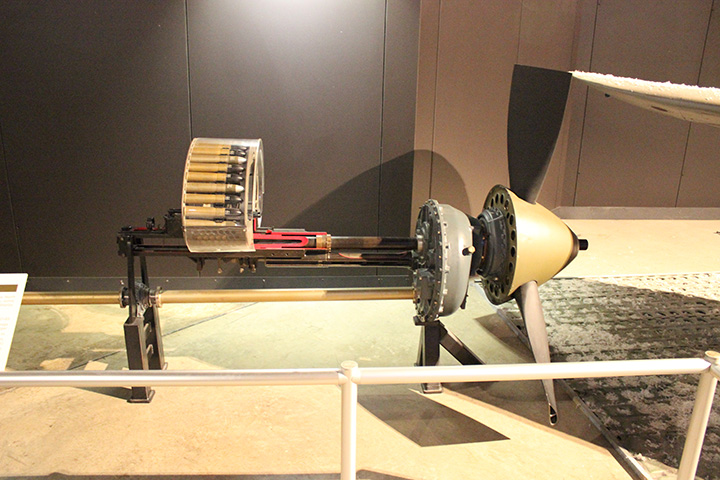

Oldsmobile provided the 37mm cannon that

fired through the propeller hub of Bell P-39 "Aircobra."

Author's photo.

The Bell P-63 also came with the Oldsmobile-built 37mm

cannon in the nose. The P-63 was a larger version of the P-39.

Author's photo added 4-29-2017.

Oldsmobile built 37mm feed mechanisms for

both the Bell P-39 and P-63. Author's photo.

The Olds-built 37mm cannon's barrel went

through both the gear reducer and the propeller hub.

Author's photo added 4-29-2017.

The Curtiss SB2C with an Olds-built 20mm cannon in each wing.

PT-658 You

Tube Deck walk around - In the first minute of this video an Olds-built 37mm cannon is shown. Normally these were scavenged off of

P-39 Aircobras.

Other Lansing Companies that

contributed to winning World War Two

|