|

Crosley Cincinnati Plants Photo Page

Crosley Richmond, IN Plant Photo

Page Crosley

Motors Marion, IN Plant Photo Page

Crosley

Corporation in World War Two

Cincinnati, OH

1921-1956

Auto Production in Richmond, IN

1939-1942

Auto Production in Marion, IN as Crosley Motors

1946-1953

Rest in Peace

This page last updated

8-11-2020. The Crosley

Corporation was headquartered in Cincinnati, OH. Its founder, Powel

Crosley Jr., was an American inventor, industrialist, entrepreneur,

and pioneer in radio broadcasting. In 1920, Crosley's first radio was a

crystal radio named "HARKO". It was a roaring success and made radio

available to the masses. This life changing innovation earned Powel

Crosley, Jr. the reputation as "The Henry Ford of Radio." By 1923,

Crosley radio station (WLW) reached 500,000 watts, the most powerful

station in the world. By 1930, Crosley designed its own airplane called

the "Moonbeam" and was the first to broadcast radio from a plane.

Crosley manufactured radios, refrigerators, and as somewhat of a

sideline, automobiles before the Second World War. During the Second

World War, Crosley was the largest employer in Cincinnati with 10,000

employees. Powel, Jr. and Lewis Crosley sold their company to AVCO

on August 8, 1945. This included all the products except for

vehicles. AVCO would market the Crosley name until 1956.

Both Powel, Jr. and Lewis would build Crosley cars and trucks in Marion,

IN from 1946 until 1953 when they sold the Marion plant and remaining

car parts to General Tire Company.

The Crosley Corporation is a story of two brothers, Powell Crosley, Jr.

and his younger brother Lewis Crosley. Each were

successful in their lives before Lewis joined Powell's company in 1919,

after returning home from serving in Europe during World War One.

They were almost complete opposites. Powel, Jr. was the idea

person. He lived the high-life of the era with a mansion, several

vacation homes, yachts, and private aircraft. Lewis and his family

lived in a modest house, wore the same suit each day, and was always

home at 5PMfor dinner with the family. Powel, Jr. was foremost in

sensing new business opportunities, but it was his brother Lewis that

ran the factories that turned the opportunities into a marketable

product. Their synergy made the Crosley Corporation more than the

sum of their two individual efforts.

The Crosley Corporation did not win

the Army-Navy "E" Award during World War Two.

Normally, I do not make a

statement of this sort. If a company did not win the "E" award, I

do not bring up the subject. However, in the case of Crosley, it

did not win the "E" award because it was producing the Navy's very top

secret VT (Variable Timing) proximity fuze. This project was more

secret than the Manhattan Project, so much so that most persons still do not

know about it. There is no known evidence that the Russians were

aware of proximity fuze. Russia was well aware of the Manhattan

Project through its network of spies. The project was so secret

that the manufacturing of the components and final assembly of the

product was done in highly secured areas. Even the owners of the

Crosley company were not allowed in the area where proximity fuzes were

being assembled. The workers in any of the plants making parts and

doing final assembly were not told what they were making. For this

reason, the Navy could not award Crosley an "E" award, as it would have

had to reveal what was being made in the plant. Therefore, all of

the hard work to produce the original proximity fuzes and then make

5,205,913 of the finished units went totally unrecognized. This

was 23.6 percent of the 22,073,481 proximity fuzes built.

The VT proximity fuze program was one

of three top secret programs the United States had during World War

Two. It was the only one that remained secret during the war

and was never discovered by the enemy in action or through spies.

The Manhattan Project was penetrated by spies. The American

radar program was only secret in that it had the magnetron tube.

The Germans and other combatants had radar. The VT

program was so secret that VT fuzes were taken to the Lunken Airport

in unmarked trucks to be flown to their final destination. The

aircraft flew directly to military bases were the fuzes were then

attached to shells. If the fuzes were shipped by train in a

boxcar, a U.S. Marine guard would be in the boxcar at all times

until the load arrived at its final destination.

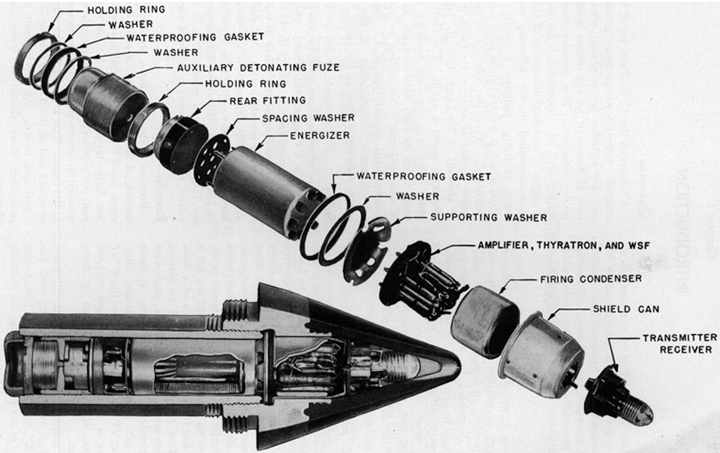

The VT fuze consisted of a small radio

transmitter and receiver of several miniature electronic tubes,

electronic components, and safety devices that were mounted in the nose

of anti-aircraft shells. When fired at an attacking aircraft, the

VT shell would detect a change in the received frequency when near an

enemy aircraft, and the VT fuze would detonate the shell. This was

far superior to the other method of pre-setting the time-to-detonation

of a fuze of an anti-aircraft shell before the shell was loaded in the

anti-aircraft gun. This was problematic at its best in attempting

to predict, in the heat of an aerial attack, how long it would take a

shell to reach the area of fast moving enemy aircraft.

For the U.S. Navy, the VT fuze is

considered to be one the main reasons it was able to progress so quickly

back across the Pacific during World War Two. It was shown at

Pearl Harbor and the sinking of HMS Repulse and HMS Prince of Wales

three days later that aircraft was the biggest threat to the American

fleet in the Pacific. With the aid of the VT fuze built by Crosley,

it is estimated that the U.S. Navy's Pacific campaign advanced months

faster than it would have without it. Many lives were saved and

fewer ships were sunk than if the VT fuze had not been produced by

Crosley and other companies.

The U.S. and British Navies were

the first users and the driving force behind the vast scientific,

engineering, and manufacturing project. When first used

in combat, they were only used on ships, so any duds would fall into the

ocean. In doing so, duds could not be recovered by enemy troops, reverse

engineered, and used against the Navy. Later, they were used over

land in defending Antwerp, Belgium from V-1 attacks. Another

version of the VT fuze was designed for artillery shells for air bursts

against enemy ground forces. This was first used very effectively

during the Battle of the Bulge.

Engineering and development of the VT

proximity fuzes was carried out at the Applied Physics Laboratories

(APL) of John Hopkins University.

|

Number of VT

Proximity Fuzes built by Crosley during World War Two

Primary Source: Bureau of Ordnance, U.S. Navy, History

of the Bureau of Ordnance, World War II, vol.2, pt 2.

T designations are U.S. Army, unless otherwise noted for British

Army.

Mk designations are U.S. Navy, unless otherwise noted for

British Navy. |

|

Fuze Type |

Number Built |

Number Shipped for Combat Use |

Number Tested |

Crosley Percentage of Total Number

Built |

| T74 -

90mm AA |

974,628 |

951,000 (97.6%) |

23,628 (2.4%) |

65% |

| T75 -

120mm AA |

621 |

333

(53.6%) |

288

(46.4%) |

100% |

| T98 -

3.7 in AA British |

628,068 |

615,574 (98.0%) |

12,494 (2.0%) |

100% |

| T149

- 3.7 in AA British Short Round |

124,238 |

122,592 (98.7%) |

1,646

(1.3%) |

100% |

| T152

- 90mm AA Short |

552,295 |

545,736 (98.8%) |

6,559

(1.2%) |

71% |

| Mk 32

- 5"/38 |

1,368,785 |

1,335,798 (97.6%) |

32,987 (2.4%) |

67% |

| Mk 40

- 5"/38 |

200,432 |

195,000 (97.3%) |

5,432

(2.7%) |

59% |

| Mk 45

- 3"/50 Mod 11 |

79,186 |

75,852 (95.8%) |

3,334

(4.2%) |

100% |

| Mk 47

- 6"/47 |

27,205 |

26,532 (97.5%) |

673

(2.5%) |

100% |

| Mk 53

- 5"/38 |

880,042 |

863,855 (98.2%) |

16,187 (1.8%) |

69% |

| Mk 56

- 3"/50 - British Navy |

121,610 |

119,624 (98.4%) |

1,986

(1.6%) |

100% |

| Mk 59

- 5"/54 |

32,414 |

31,635 (97.6%) |

779

(2.4%) |

100% |

| Mk 60

- British Navy |

216,389 |

213,021 (98.9%) |

3,368

(1.1%) |

100% |

|

Totals |

5,205,913 |

5,096,552 (97.9%) |

109,361 (2.1%) |

|

The only way to test VT fuzes was by

firing samples at an over water firing range. The Mk 32 would

be fired 12,000 yards down range where observers could see how many of a

sample group burst approximately 130 above the water. The

observers would also listen on a radio tuned to the frequency of the VT fuze to see whether it turned on. The testing of VT fuzes was

managed by APL during the war.

Crosley VT Timeline:

-

October 1941

- Crosley is contacted by the U.S. Navy

Bureau of Ordnance about a forthcoming "top secret-top priority"

project

-

October 28, 1941

- A U.S. Navy official and a scientist from the Applied

Physics Lab arrive at the Crosley factory. In a meeting with

several company officials in a locked room with the shades drawn on

the sixth floor, the Crosley officials were sworn to secrecy and

signed the Espionage Act. The company officials then had the

scope of the VT project explained to them. Crosley was chosen

as the first supplier of the VT fuzes due to its ability to make

high quality electronic equipment in large quantities. Did I

mention that the Navy official laid his sidearm on the table during

the meeting? This was serious business!

-

November 1941 -

Crosley allocated 600 square feet of secure factory space and

fifteen engineers to the project.

-

November 1941 - Late in the month, Crosley received a letter of intent from the U.S.

Navy.

-

December 1941 - A

long-term production contract for VT fuzes was made with the U.S. Navy.

This would not be executed until late 1942.

-

December 1941 -

First short-term contract for 500 VT fuzes.

-

December 1941 -

Production of the VT fuzes moved to a former Crosley refrigerator

plant on Arlington Street across the street from the main plant.

This became the Primrose Manufacturing Plant. The plant had

two sub-assembly rooms and one final assembly area. The

employees in each room were unaware of what components were being

assembled in the others.

-

1942 - A

correlation between the performance of the VT fuzes and the high

summer humidity

in Cincinnati was found. High humidity resulted in a higher fuze failure rate. Crosley installed air-conditioning in the Primrose

Plant.

-

January 1942 -

First four groups of ten Crosley VT fuses were tested by the U.S.

Navy at Stump Neck, MD. The fuzes were tested by placing them

in anti-aircraft shells. They were then fired out over a body

of water. Scientists from APL would listen on a radio receiver

for the tone of the VT transmitter. This told them that it was

working. The shell's trajectory would then fall back over the

water. A successful result was when the VT fuze detected the water

and detonated the shell.

|

Results of the

Crosley-built VT Fuzes at Stump Neck in January 1942 |

|

Group Number |

Results |

Engineering Differences |

| 1 |

10%

exploded over the water. |

Non-solid mounting of the antenna series capacitor.

|

| 2 |

40%

exploded over the water. 100% were heard on the radio

receiver. |

Solid

mounting of the antenna series capacitor. |

| 3 |

0%

exploded. |

Due

to the shortage of aluminum, brass was used for the nose of the

fuze. This caused them to tumble. Solid mounting of

the antenna series capacitor |

| 4 |

0%

exploded. |

Due

to the shortage of aluminum, brass was used for the nose of the

fuze. Solid mounting of the antenna series capacitor |

-

January 1942 - Solid mounting of the capacitor was an improvement. However, Crosley had made several changes all at one time. It was

agreed with APL that, moving forward, Crosley would only make one

change at a time and test it before another was made. All

changes, especially once production began, had to be approved in

advance. This is good engineering and manufacturing practice

for any product. Crosley was given the right to suggest

changes to existing VT fuzes and engineer designs of their own.

Crosley suggested many ideas during the war that improved the VT

fuzes.

-

August 13, 1942 -

Crosley-built Mk 32 fuzed 5"/38 rounds shot down three drones from

the USS Cleveland in Chesapeake Bay near Tangier Island. This

was an unheard of feat, as drones had never been shot down with

normal timed fuzes during navy anti-aircraft practice. There

were no more drones ready. From past experience, drones at most

came back with a few holes in them. The next day three more

drones were shot down and the test came to an end. There were

no more drones. The USS Cleveland was ordered directly to the

Pacific with the remaining proximity fuzes. This was done so

none of the 1,000 men on board could tell anyone of what they saw if

it had gone back to port. Crosley's VT Mk 32 had performed to

perfection, giving the U.S. Navy a secret advantage over Japanese

aircraft in the Pacific.

-

September 1942 -

Pilot line expands after several iterations of a resistor change to

reduce the sensitivity.

-

November 1942 -

Full production begins on the Mk 32 fuze.

-

January 5, 1943 -

The USS Helena shot down the first Japanese aircraft in combat with

a VT fuze. This was done with Crosley-built Mk 32 fuzes.

-

January 1945 -

German V-1s had been attacking Antwerp, Belgium since October 1944.

Crosley-built T-149 and T-152 fuzes were authorized for use over

land in December 1944 and primarily used at the Battle of the Bulge

and at Antwerp. The destruction in the V-1s increased with the

introduction of the VT fuzes. Normally a V-1 would fly at

2,300 feet, giving a 60 second window of opportunity for VT shells

to engage the target. The Germans modified the V-1 to fly as

low as 1,200 feet, after most were being shot down by VT fuzes.

With the lower altitude, the fuzes were not self-destructing after a

miss as they did not have enough time in the air. This meant

there were VT fuzes on the ground that could be recovered by the

enemy. In order to prevent enemy recovery and reverse

engineering of the V-T fuzes, Eastman Kodak started building new self-destruct

switches after two days of intensive around-the-clock design work by

APL. Once complete, the switches were flown to Crosley in

Cincinnati. Winston Churchill ordered special Lancaster

bombers to pick up the completed VT fuzes at Lunken Airport in

Cincinnati and fly them directly to the battlefield at Antwerp.

2,183 of 2,394 of the V-1s that attacked Antwerp were destroyed by

aircraft, normal timed fuze anti-aircraft shells, and VT fuzed

shells. After the release for use of the VT fuze at Antwerp,

most of the V-1s were destroyed by Crosley-built VT fuzes.

-

August 1945 -

Production of the VT fuze ceased at Crosley.

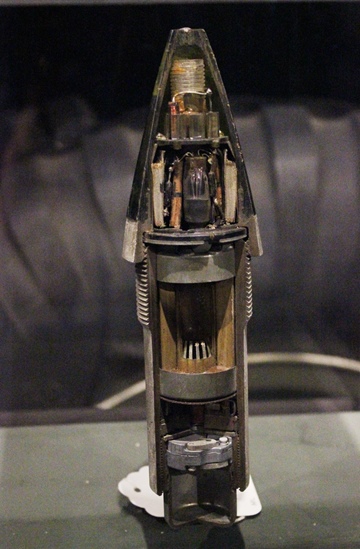

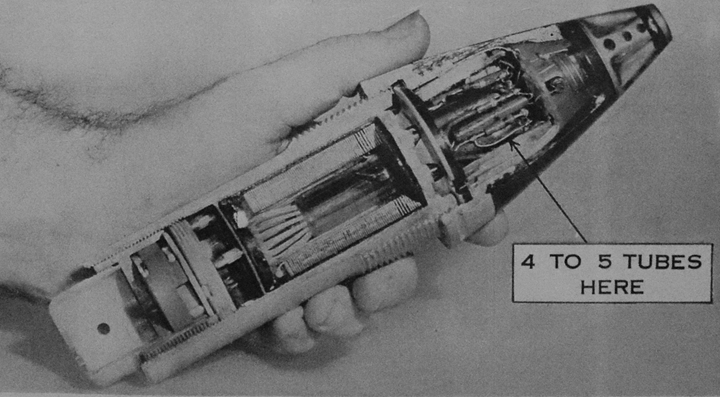

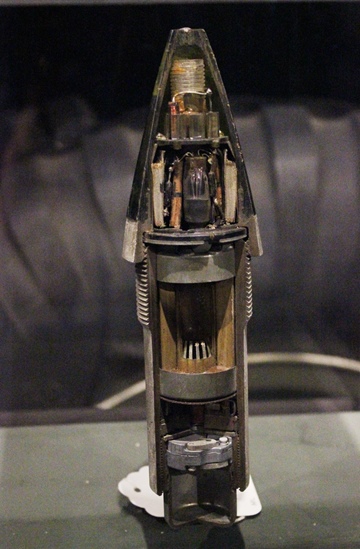

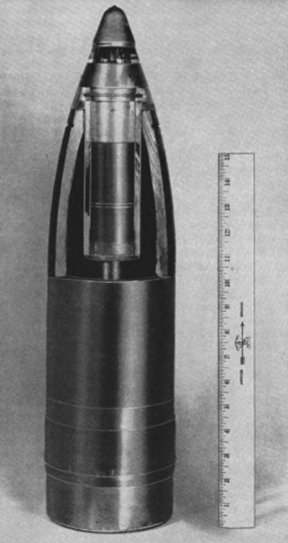

This cut-away of a VT fuze is on display at the National Electronics

Museum in Linthicum, MD. Crosley built 5,205,913 VT proximity

fuzes in thirteen different models similar to this for the U.S. Army,

U.S. Navy, British Army and British Navy. Author's photo added

5-22-2019.

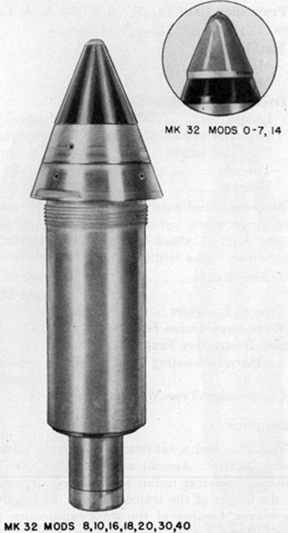

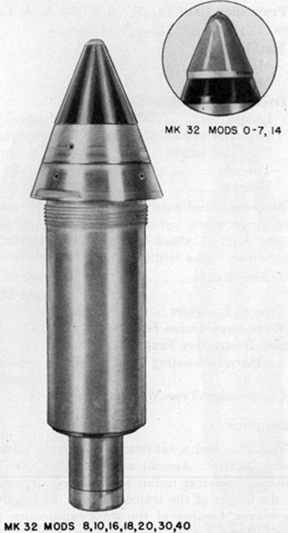

The Mk 32 was the first VT fuze used in the

Navy's 5"/38 dual purpose gun. It was 12 inches long, was 3.3

inches in diameter at its widest point, and weighed 6.81 lbs. It

would detonate within fifty feet of a target. When tested at an

over-water firing range, it would detonate 130 feet above the water.

Note the number of modifications the Mk 32 had over its lifetime and the

change in the shape of the antenna cap. It was a Crosley-built Mk

32 that shot down the drones in navy testing, and a Crosley Mk 32 was

the first VT fuze to shoot down a Japanese aircraft in the Pacific.

Crosley built 1,368,785 Mk 32s. Photo added 5-20-2020

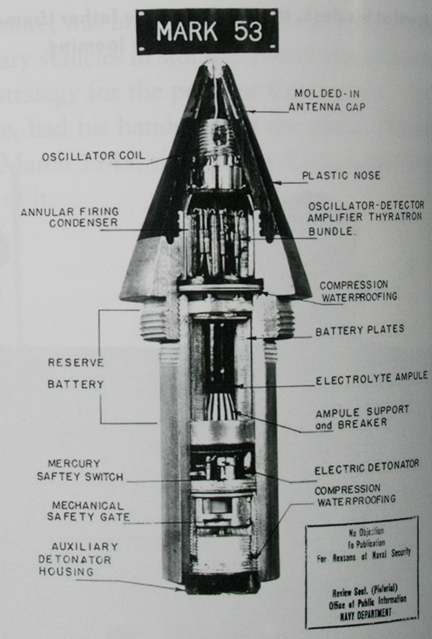

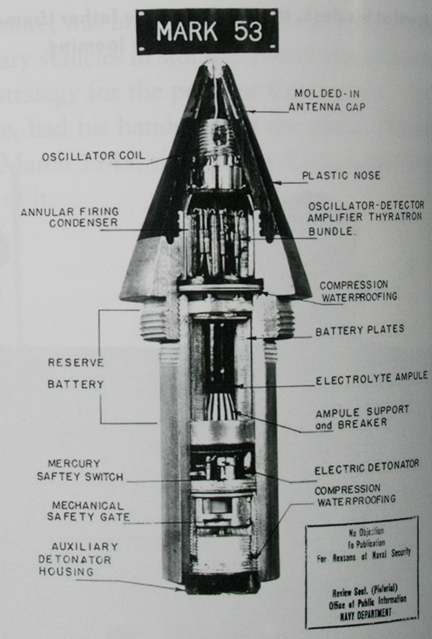

Crosley also built 880,042 Mk 53s for the

U.S. Navy's 5'/38 dual purpose gun. Previous to the Mk 53, Crosley

built the Mk 32 and Mk 40 for the same weapon. Different Mk

numbers were assigned as improvements were made in the design and they

were reduced in size. Crosley built 2,449,259 of all three types

combined for the U.S. Navy in World War Two. These were

instrumental in protecting American sailors and ships from Japanese air

attacks in the Pacific. The Mk 53 was nine inches long, was 3.3 inches

in diameter at its widest point, and weighed 4.89 lbs. Its smaller

size allowed for more explosive to be loaded into the shell.

Photo added 5-20-2020.

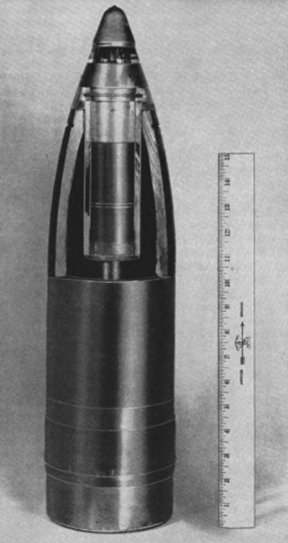

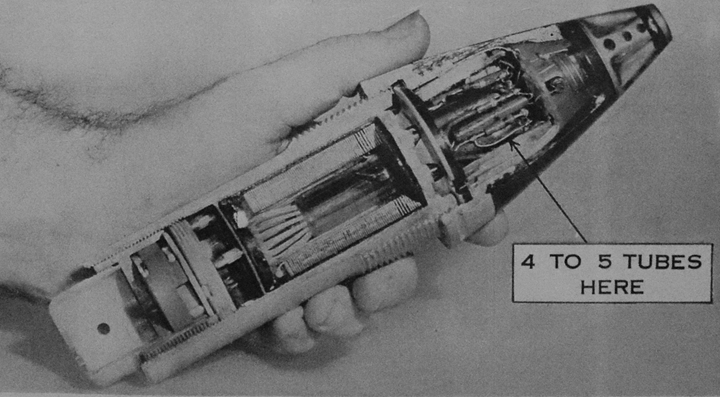

This shows how the VT fuze fit in a shell.

Photo added 5-20-2020.

The miniature tubes were held in place by

wax, to protect them from the intense g-forces when being fired from an

anti-aircraft gun. The wax also held them in place from the large rotational

g-forces of the shell. Sylvania produced over 100 million tubes

for the VT program. Photo added 5-20-2020.

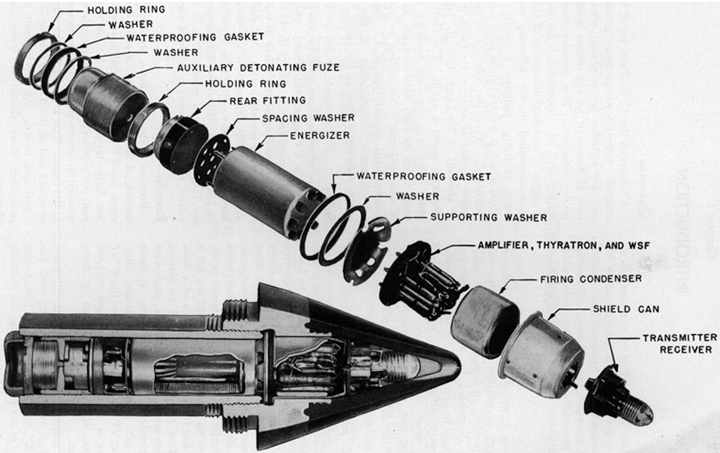

Crosley assembled the VT fuze from

components purchased from U.S. Navy authorized

suppliers. The original cost of a VT fuze in 1942 was $732.

By 1945 it had been reduced to $18. This is $11,514 and $256 in

2020 dollars, respectively. Photo added 5-20-2020.

The Richmond, IN Auto Plant:

From 1939 to 1942, Crosley built 5,757 automobiles in Richmond,

IN. After World War Two, the Richmond facility was sold to

Aviation Corporation, later AVCO, which returned the plant to refrigerator production.

Powel Crosley, Jr. kept the car making operation and moved it to Marion,

IN as Crosley Motors, where it remained in production until 1953,

producing another 83,539 vehicles.

|

Crosley Cars

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Car, 4-Passenger |

1 |

|

|

|

|

|

1 |

This one vehicle was purchased on P.O.

134-MV.

Products built at the Richmond plant for

the war effort included: Components for Walkie-Talkie Radios, IFR

Radio guidance equipment, air supply units for Sperry bombsites (used in

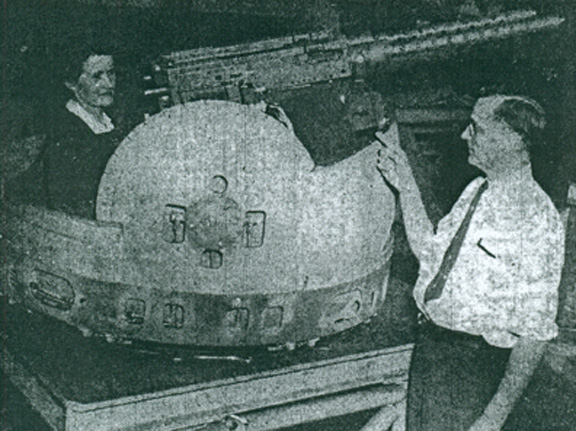

B-24s), air conditioning units, cooking stoves and Martin PBM Mariner bow gun turrets. The gun turret was the largest contract. Crosley had 1,400 employed at the Richmond plant during World War Two.

Crosley World War Two

Military products made at the Richmond, IN auto plant:

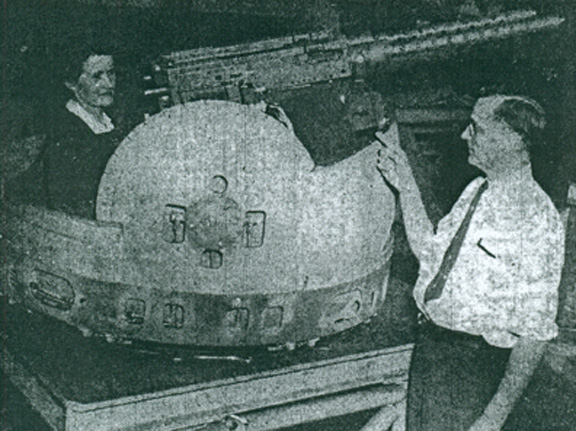

One of the World War Two products in the former Crosley auto plant was

this bow turret for the Martin PBM Mariner. 1,362 PBMs were built.

This photo shows the Crosley built bow

turret in the Martin PBM.

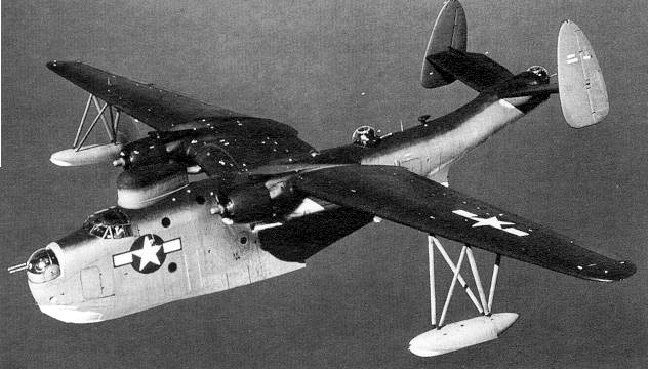

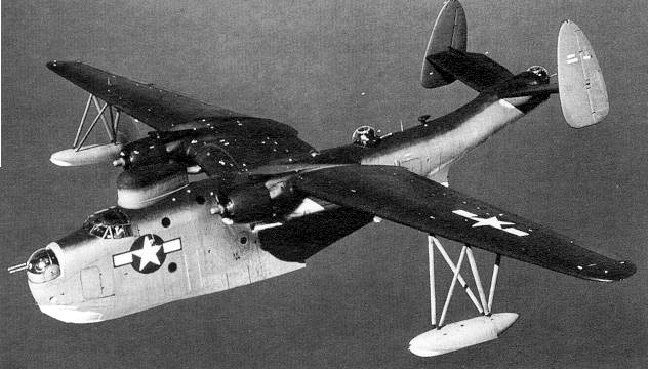

This is a Martin PBM-5A Mariner. It is the

only surviving PBM remaining in the world of the 1,366 built; and is at

the Pima Air and Space Museum in Tucson, AZ. This aircraft

unfortunately does not have any of the turrets on it, as it is a post-World War Two

model.

This is where the bow turret would go.

This is an interesting item. Each PBM

Mariner bow turret came with a tool box and tools. This one was

appropriated by a worker in the Richmond plant for his personal use.

Author's photo from the Museum of the Soldier in Portland, IN.

The next two photos show a Sperry S-1

Bombsight for which Crosley made parts in its Richmond, IN Plant.

Crosley World War Two Products built in

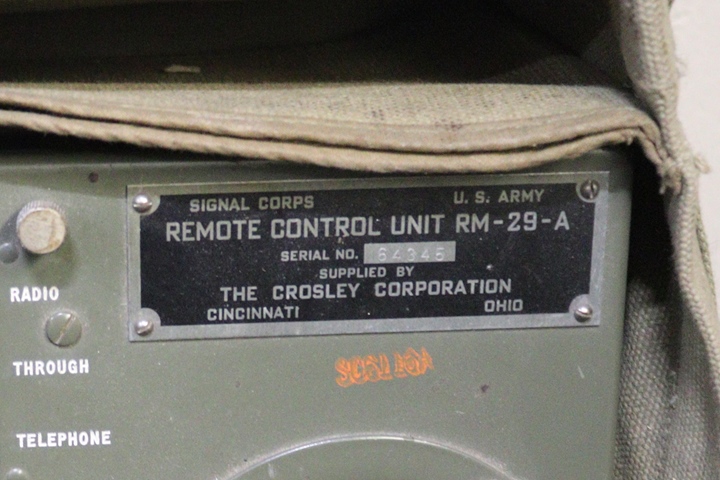

Cincinnati, OH: 63,972 SCR-284/BC-654 radios, 34 CT-3 Pup extra-light

jeeps, a portion of 85,000 Mark XIV anti-aircraft gun sights for

the U.S. Navy, aircraft bomb releases for the U.S. Army Air Forces,

Signal Corps RM-29-A remote control units, aircraft tracking radar equipment,

gun mounts, briefcase-sized radio direction finders, portable electrical

generators for the U.S. Navy, and 5 SCR-582 coastal radar installations.

-

The SCR-582 was a fixed

coast artillery microwave radar which consisted of 41 individual

units. Crosley received this order from the U.S. Army Signal

Corps in May 1942.

-

Crosley built all of the

63,972 SCR-284 radios during World War Two. The company built

13,585 in 1942, 28,618 in 1943, and 21,769 in 1944.

-

Crosley built an unknown

number of bomb releases. During conversation with Army

procurement officials, Lewis Crosley informed them that Crosley

could build the bomb releases for eight dollars. The Army was

currently being charged $30 a piece. Crosley was awarded the

business.

-

Crosley built a small

portable electric generator for the U.S. Navy that was made out of

18 stamped sheet metal which were brazed together and mated to an

aluminum crankcase. This four-cylinder engine weighed sixty

pounds. Crosley Corporation purchased the commercial rights

from the inventor, and then hired him during the war to work on the

engine. After the war this became the COBRA engine for the

Crosley automobile.

-

Crosley built several

other small experimental vehicles besides the CT-3 for both the U.S.

Army and Navy. These were the Bull, Pup, Crosley Snow Tractor,

and the Crosley Duck. None got beyond the experimental stage

of one unit.

A War Production Board Report

dated 9-30-1943 shows that Crosley was building 305 radios of all types

per day in its Cincinnati plant.

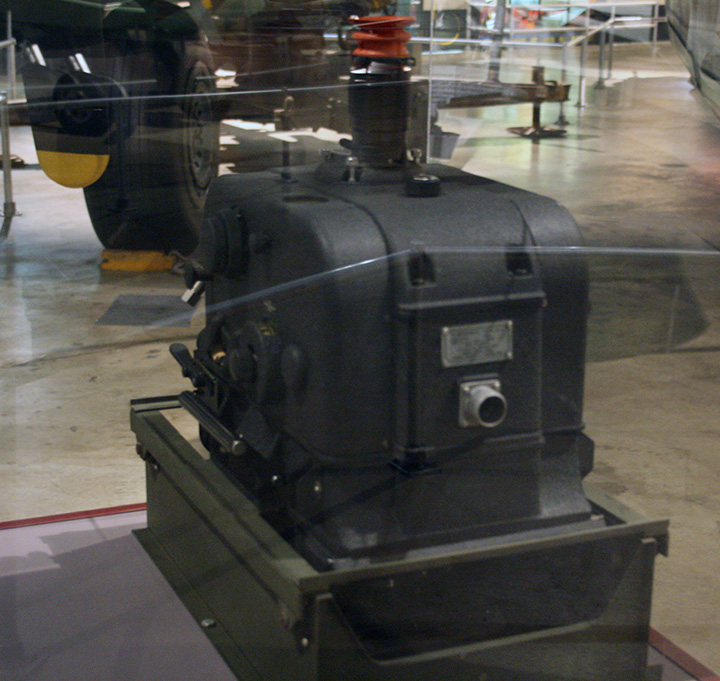

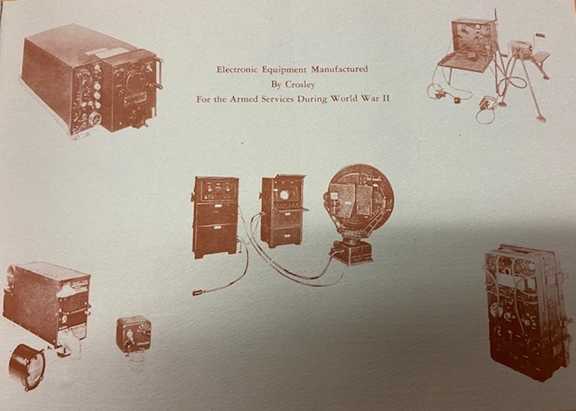

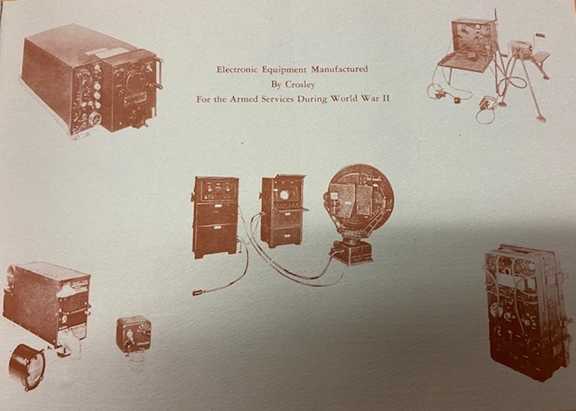

This page is from a post-World War Two

document published by the Crosley Division of AVCO. It shows five

pieces of equipment that the former Crosley Corporation produced during

the war. In the upper right is the SCR-284 radio for the U.S.

Signal Corps. The middle photo of a radar unit is most likely the

SCR-282. Image added 6-13-2020.

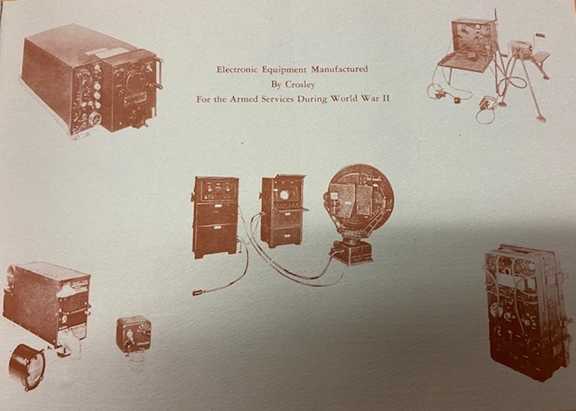

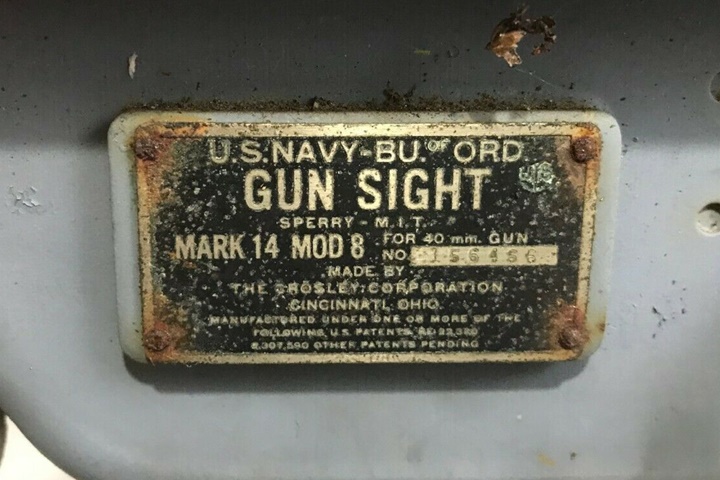

Mark XIV Navy Gun Sight for 20mm and 40mm

Anti-Aircraft Guns: The Mark XIV gun sight was designed by the

Massachusetts Institute of Technology at the request of Sperry Gyroscope

to assist Navy gunners to track high speed aircraft. Sperry became

the main contractor for the Mark XIV and Crosley built the gun sight

under contract. A total of 85,000 were built by all suppliers.

The War Production Board Report dated 9-30-1943

also

shows that Crosley was building 50 units per day. Initial

production began in February 1942 and obtained the rate as of May 1943.

Fifty gun sights per day is 1,500 per month. For the eight

remaining months Crosley built 12,000 Mark XIV gun sights. If this

rate continued to the end of World War Two, Crosley had the potential to

build 42,000 Mark XIV gun sights for the U.S. Navy. This was half

of the total built.

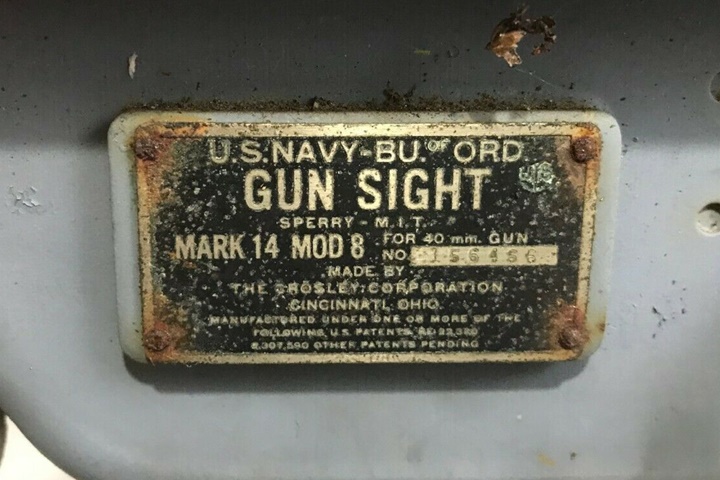

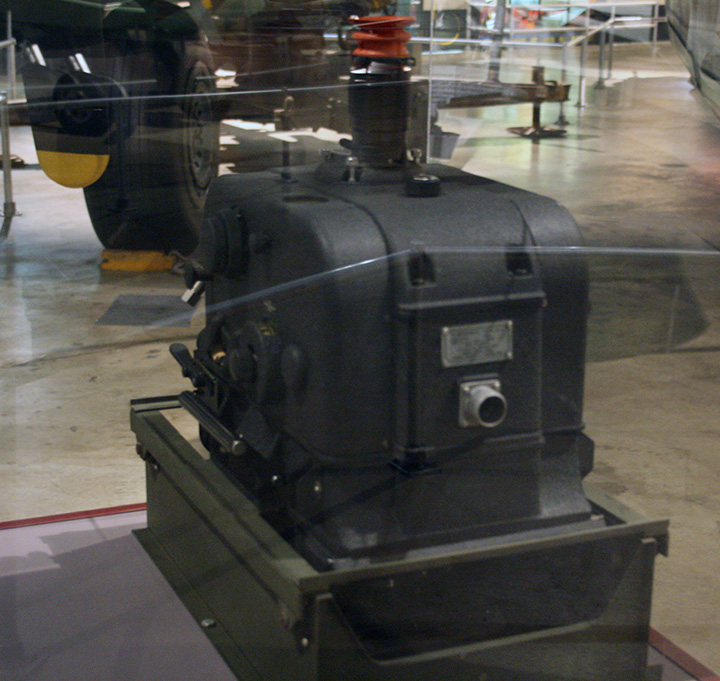

This is a Crosley-built Mark XIV Mod. 8 for

use on 40mm Bofors anti-aircraft guns. This is the side that faces

the gunner.

This is he side facing the enemy aircraft.

The weapon has been opened up and is viewed

from the target side unit. In the upper right-hand corner is the

where the image comes into the unit and is then displayed on the glass

for the gunner.

This view is form the gunner's side of the

sight. This was a very sophisticated piece of equipment for the

era.

The Crosley-built Mark XIV gun sight mounted

on 20mm Oerlikon anti-air guns. For those enemy aircraft that were

lucky enough to penetrate the Crosley V-T proximity fuzed five-inch

anti-aircraft shells, Crosley-produced Mark XIV gun sights aided the

short-range tracking and aiming of fast moving aircraft approaching the

ship. All of the 20mm anti-aircraft guns on the USS Slater, DE766

in Albany, NY have Mark XIV gun sights. This is the only World War

Two ship I have visited that have these sights mounted on the guns.

The USS Slater is the most well restored World War Two ship on display

in the United States. Author's photo added 6-13-2020.

Author's photo added 6-13-2020.

Author's photo added 6-13-2020.

Author's photo added 6-13-2020.

These two 20mm twin mounts have Mark XIV gun

sight under a weather proof covering. Author's photo added

6-13-2020.

Crosley built 150,000 of these BC 654 radios

during World War Two. Some of the parts may have been produced at

Richmond, along with other radio components made there. This example was on

display at the former Ropkey Armor Museum in Crawfordsville, IN.

High tech radio with low tech mule to

transport it with Merrill's Marauders during World War Two.

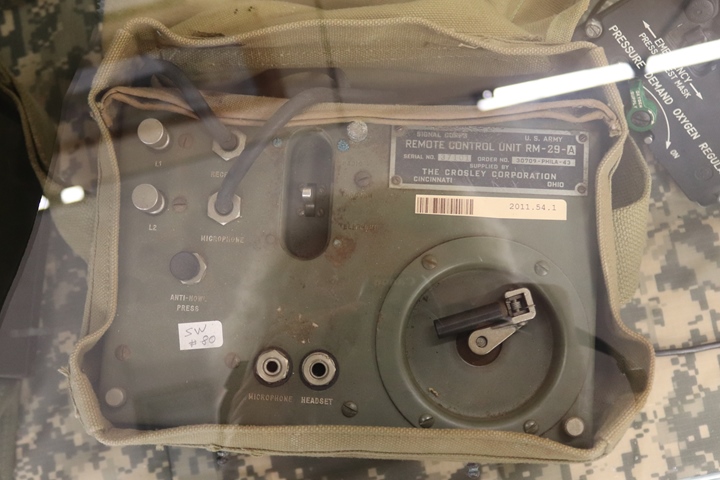

Crosley built RM-29-A Remote Control Units

for the U.S. Army Signal Corps. This unit allowed remote

communication from a field phone at a front line position to other

military units via radio transmission. The RM-29-A was the

interface between the phone switchboard and the radio set. The

unit could also be used as a field phone. Author's photo from the

Museum of Military History in Kissimmee, FL.

It is Serial Number 969. Author's

photo.

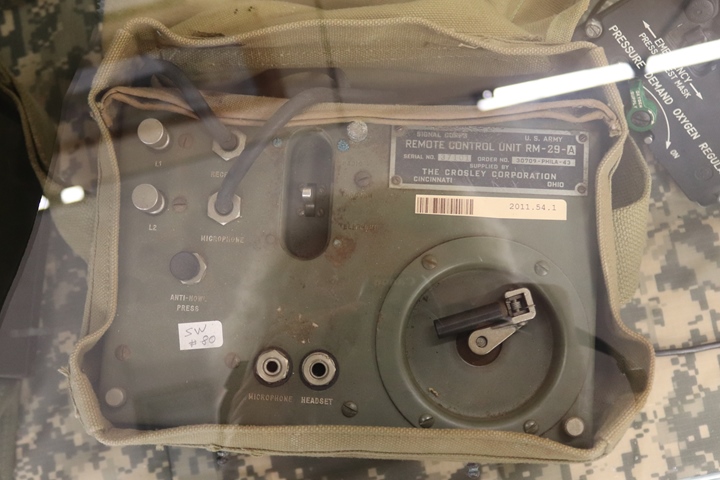

The Museum of Military History has two

RM-29-A's on display. This one is in its carrying bag and is

Serial Number 37101. Author's photo.

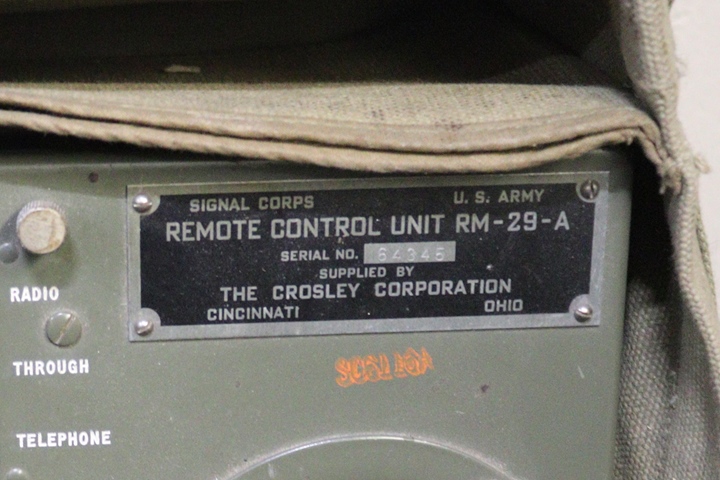

This Crosley-built RM-29A is on display at

the Military Veterans Museum in Oshkosh, WI and is serial number 64345.

Author's photo.

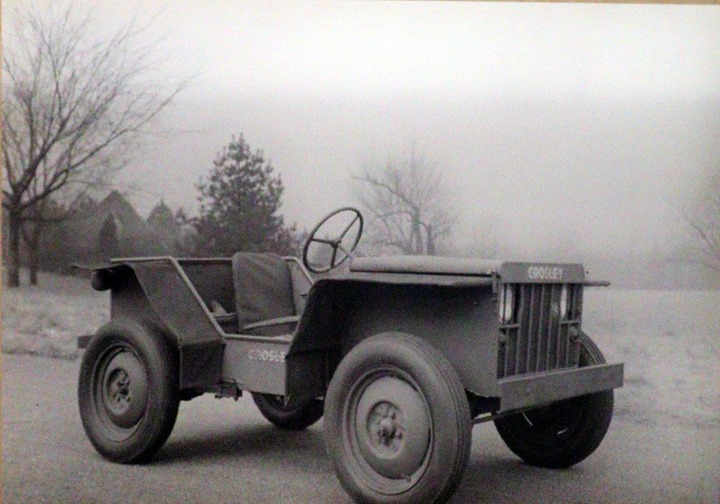

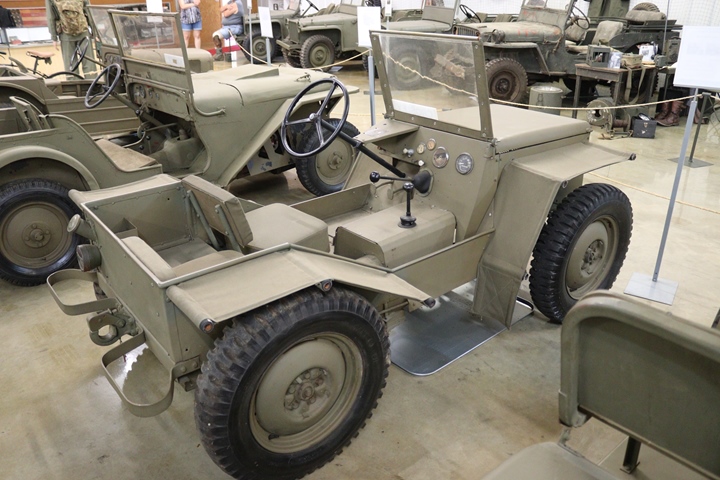

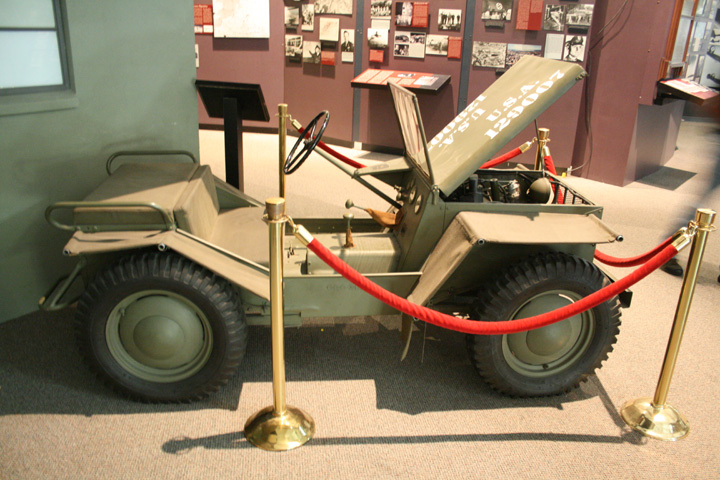

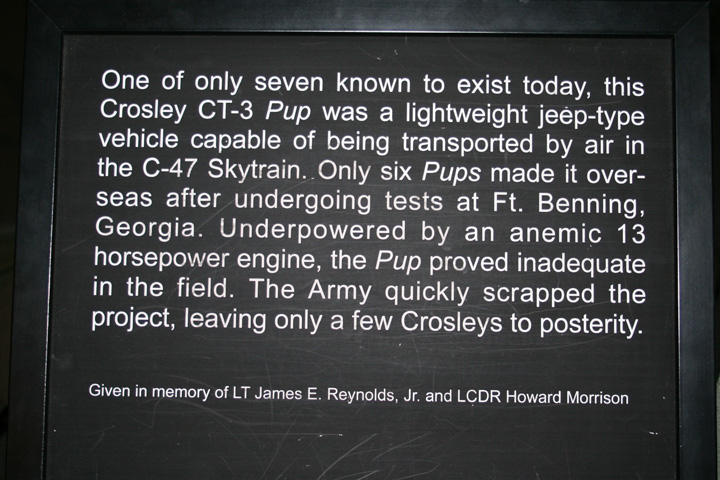

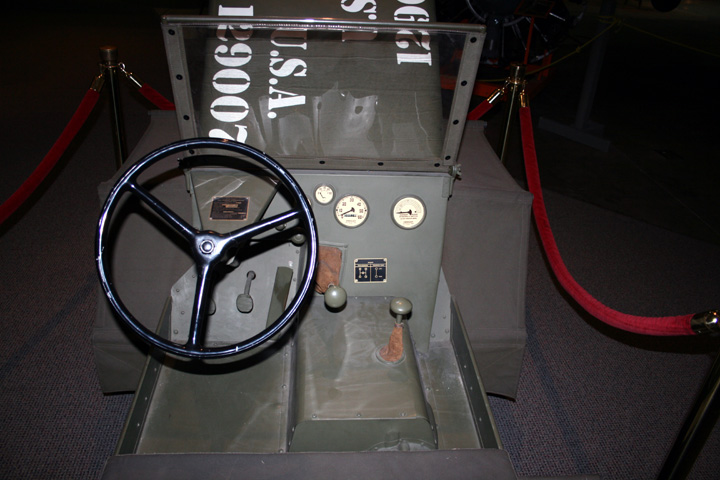

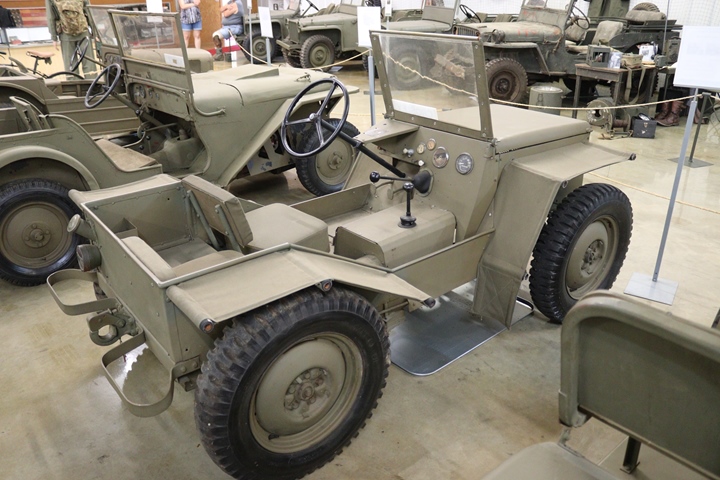

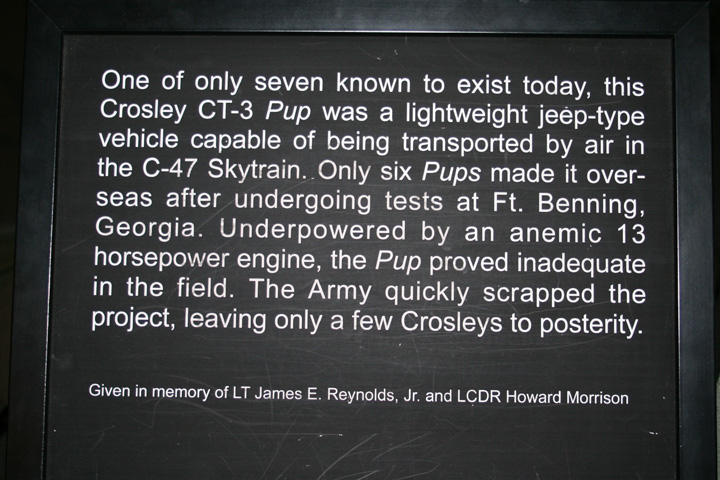

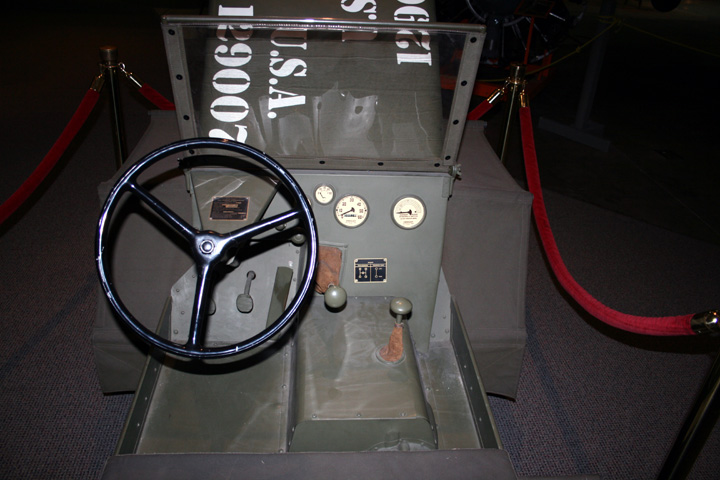

The Crosley Pup CT-3 Truck, 1/4-ton 4x4,

Extra Light: There were 37 CT-3s built by Crosley during World

War Two. Serial Number 137 is at the Sam Werner Military Museum in

Monteagle, TN. Serial number 133 is located at the National Museum

of the 8th Air Force in Pooler, GA and serial number 134 is at the

Airborne and Special Operations Museum in Fayetteville, NC. There

are photos of those three below. These are three of seven that are

still reported to exist.

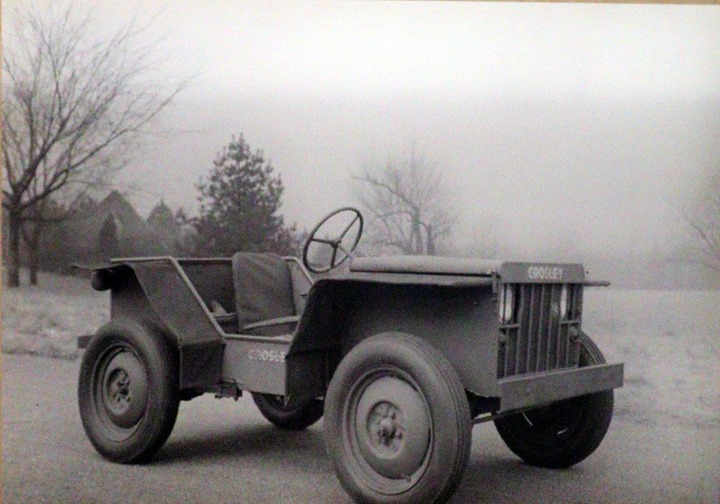

A Crosley CT-3 at an Army camp. Note

the pyramid tents in the background. This may be the first one, as

it does not have the all-terrain type tires on it. Photo added

5-22-2019.

The building of the CT-3 by Crosley was a

job shop operation. There are 16 of them in various states of

production in this photo. Photo added 5-22-2019.

It looks like a medic is working on the leg

of the driver who drove this CT-3 into the hole. Photo added

5-22-2019.

This is serial number 137. It is the

last CT-3 Pup of the 37 built. The serial numbers ran from

101-137 inclusive. It is at the Sam Werner Military Museum in Monteagle, TN as part of a display of four extra-light jeeps that were

built for the U.S. Army. Note the fenders are made of canvas.

Author's photo added 5-20-2020.

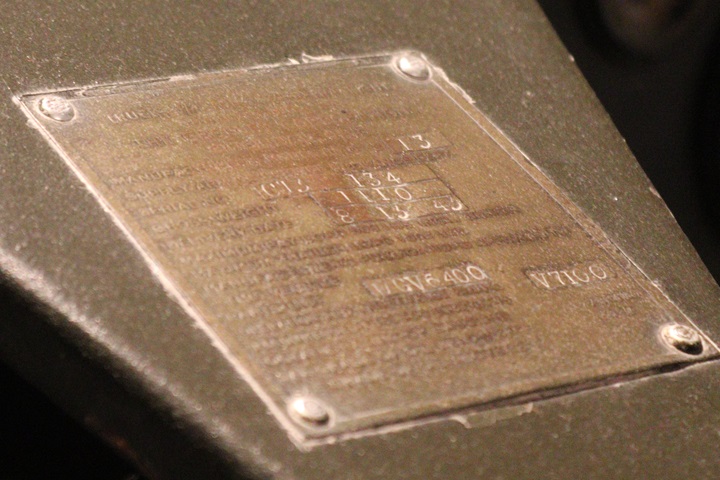

CT-3 serial number 137 was built on

8-20-1943.

Author's photo added 5-20-2020.

Author's photo added 5-20-2020.

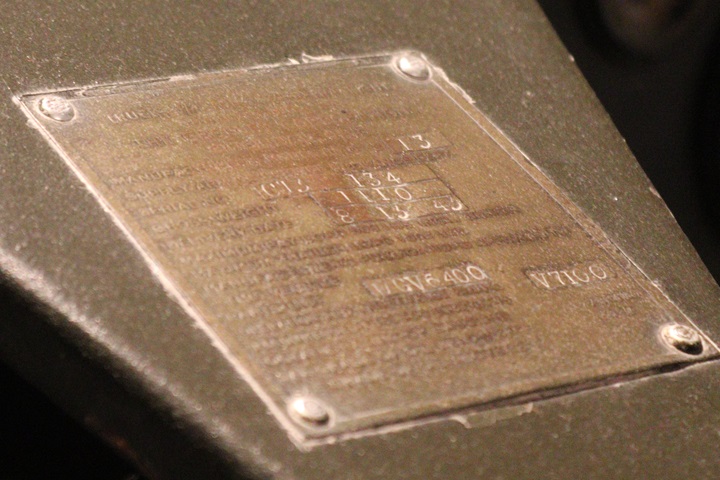

This is CT-3 serial number 134, dated

8-13-1943. It can be seen at the Airborne and Special Operations Museum

in Fayetteville, NC. Author's photo added 5-22-2019.

Author's photo added 5-22-2019.

Author's photo added 5-22-2019.

Author's photo added 5-22-2019.

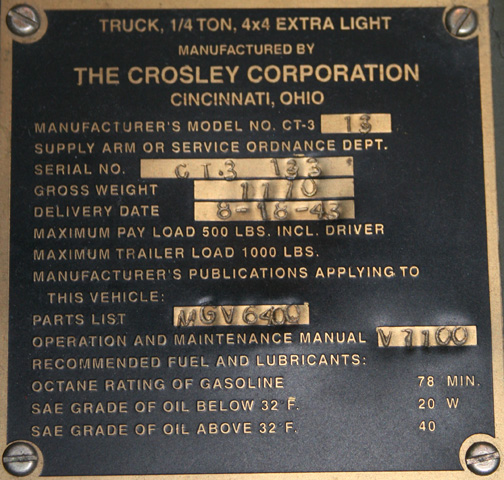

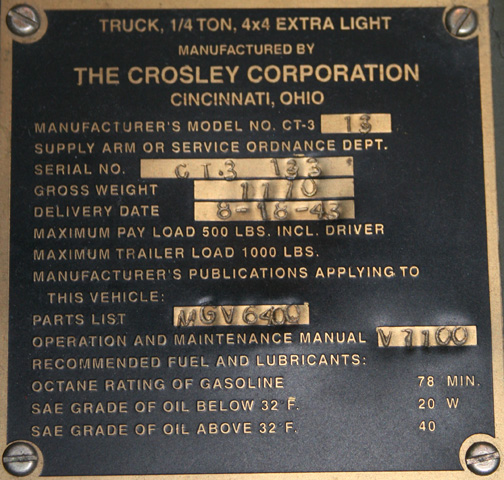

The data plate on this CT-3 shows serial

number 134, with a delivery date of 8-13-1943. Author's photo

added 5-22-2019.

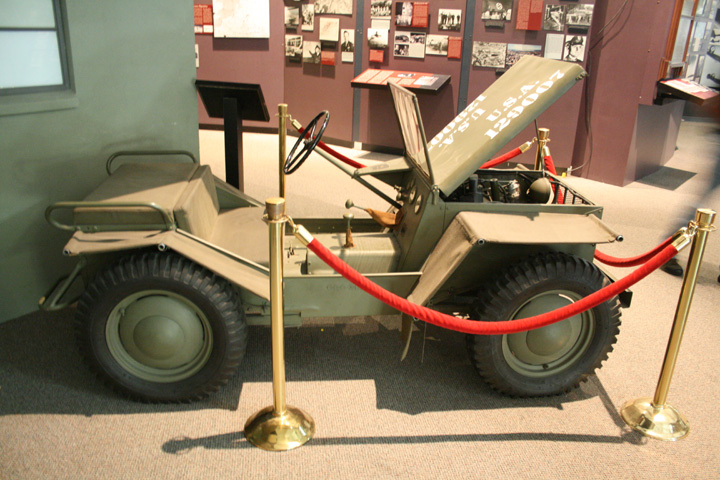

This CT-3 is located at the National Museum

of the 8th Air Force in Pooler, GA. It is serial number 133,

dated, 8-16-1943. This is three days later than serial number 134

above.

Other World War Two Plants: The War

Production Board Report dated 9-30-1943 shows that Crosley was building

shortwave broadcast transmitters in Butler County, OH. No quantity

was given.

Another facility is listed for Mason, OH with

only "Communication" as the description. This may have been a

radio broadcast station.

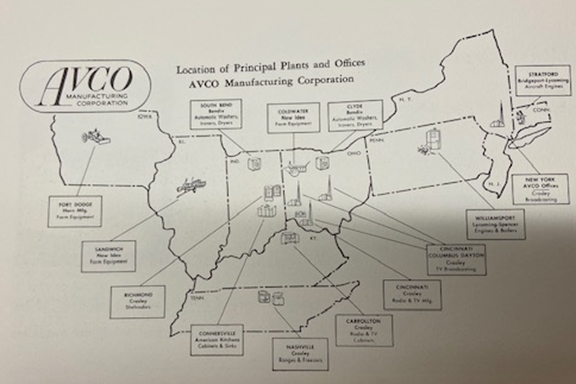

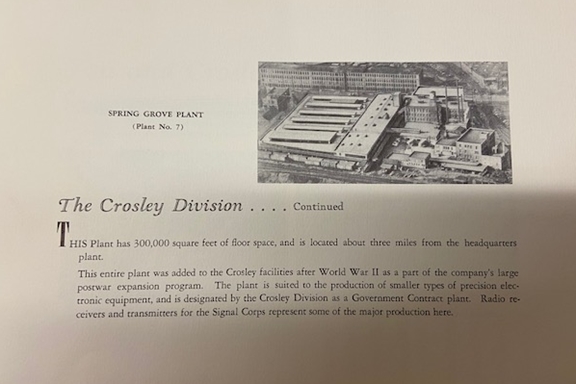

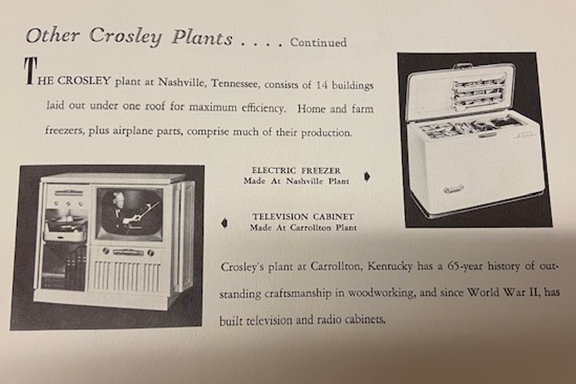

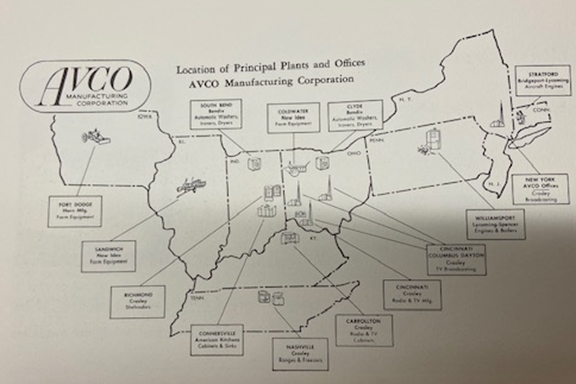

The Crosley Division of AVCO:

Below are several pages from "The Crosley Story" that was giving to new

hires as an orientation on what was expected of them when going to work

for the Crosley Division of AVCO. The pages below show that AVCO

purchased several new plants to expand production of the refrigerators

and electronic equipment. The document is circa early 1950s.

Document courtesy of the Cincinnati Public Library.

|