|

Chevrolet Anderson, IN

1945 Open House

Chevrolet World War Two Truck

Database

Chevrolet Division of General Motors in World War Two

Flint, MI

1911-Current

This

page updated 4-29-2025.

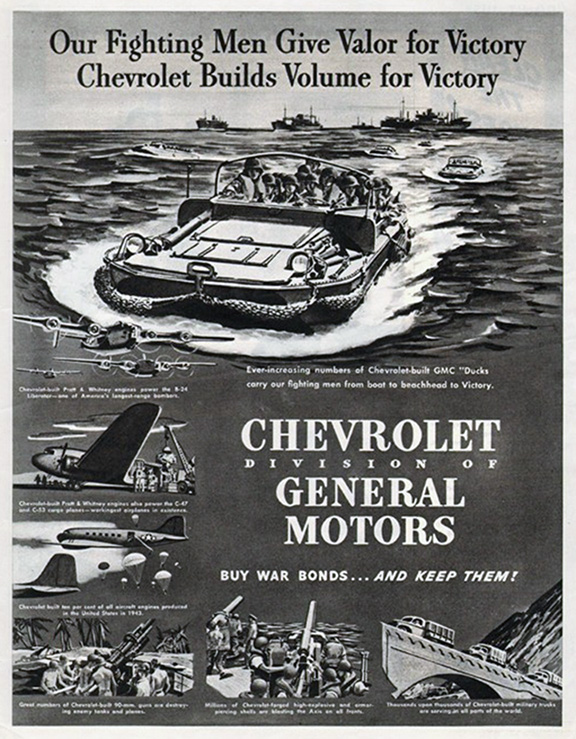

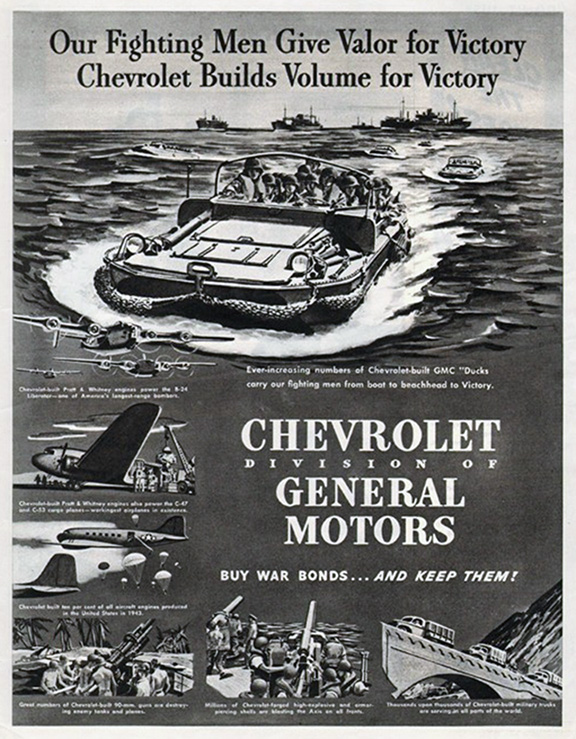

The Chevrolet Division was

General Motors' largest division during and after World War Two.

During the war, Chevrolet made a variety of products, with trucks and

radial aircraft engines being the two largest categories of products

produced to help win World War Two.

The Chevrolet Aviation

Plant No.2 in Tonawanda, NY won the Army-Navy "E" Award five times.

The Chevrolet Aviation Plant No.1 in Buffalo, NY won the Army-Navy "E" Award five times.

The Chevrolet Motor and Axle Plant in Tonawanda, NY won the Army-Navy

"E" Award five times.

The Chevrolet Motor Plant in Bay City, MI won the Army-Navy "E" Award two times.

The Chevrolet Motor Commercial Body Plant in Indianapolis, IN won the

Army-Navy "E" Award three times.

The Chevrolet Gear and Axle Plant in Detroit, MI won the Army-Navy "E" Award four times.

Chevrolet

World War Two Production Products:

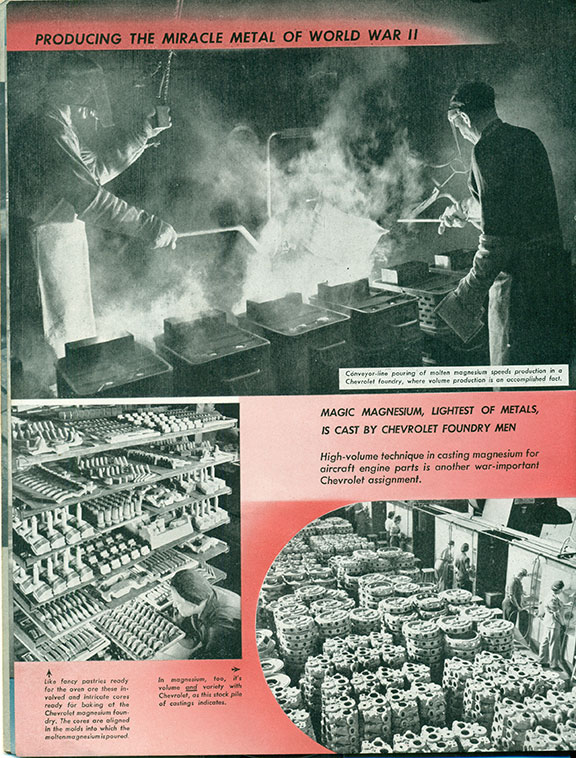

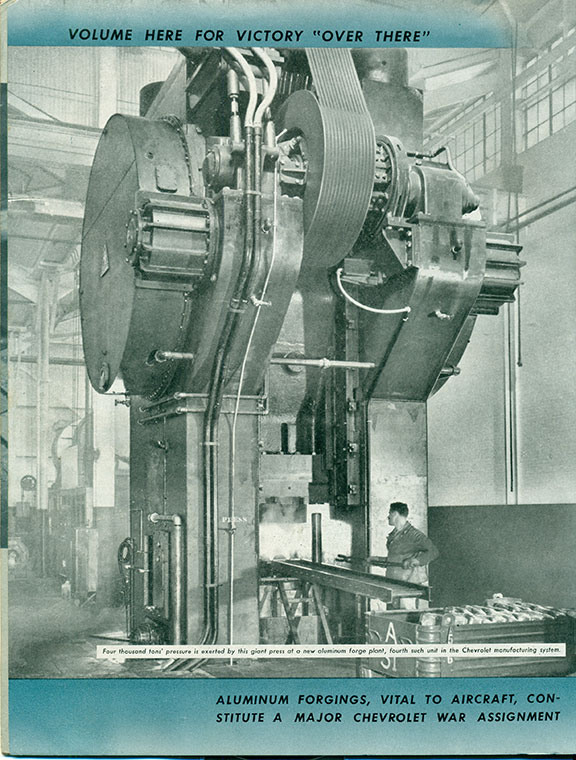

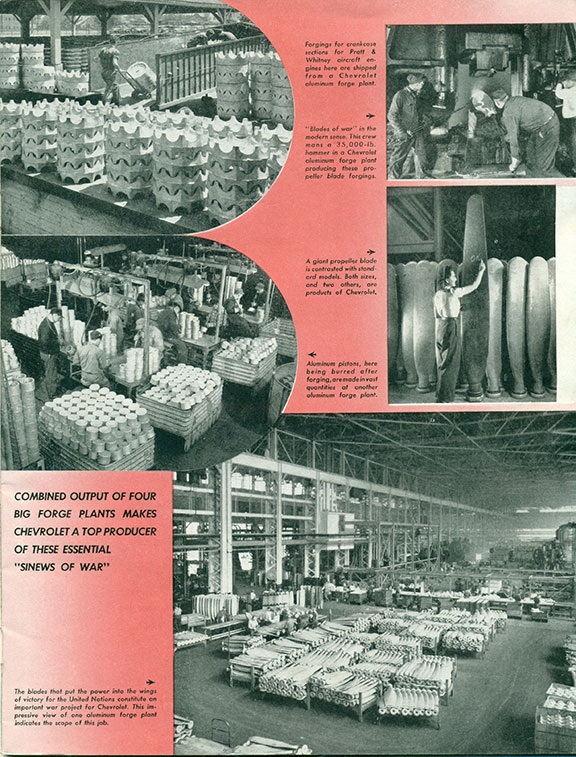

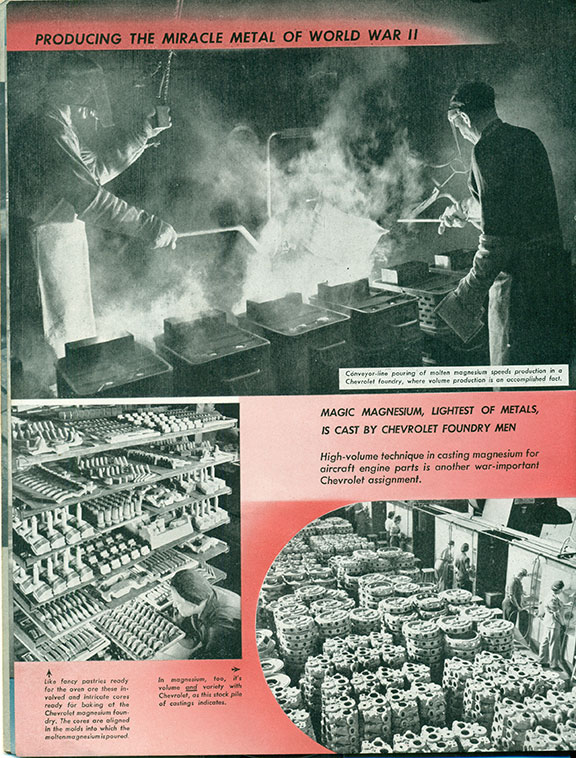

The division had $2,027,239,000 in major contracts during World War Two.

It produced: 439,893 Chevrolet and GMC trucks (See below

for the details.), 2,583 Passenger Sedans, 3,844 Staghound Medium

Armored Cars,

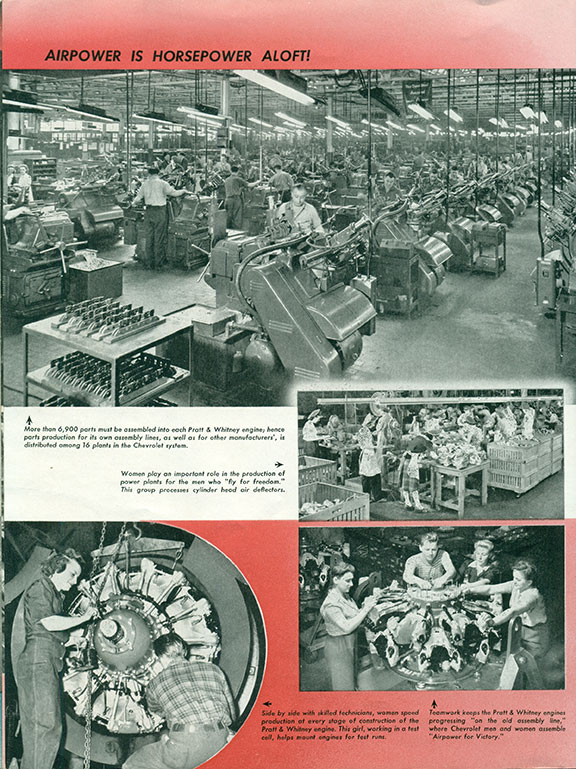

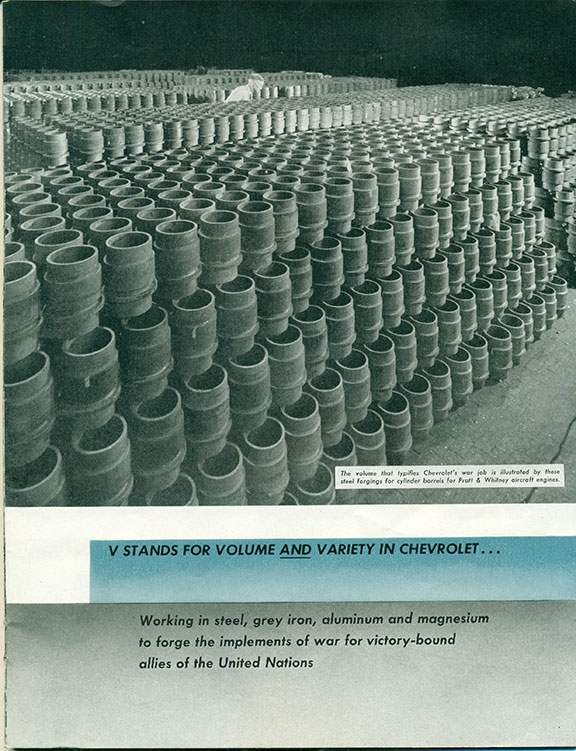

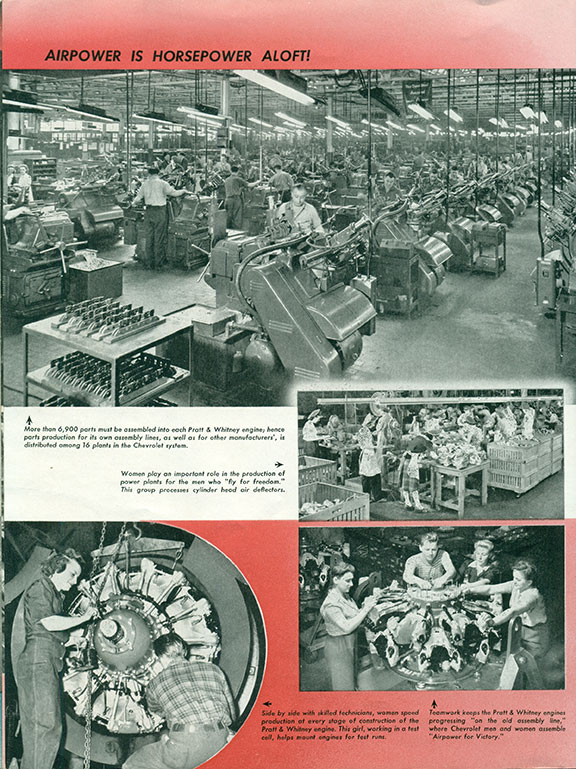

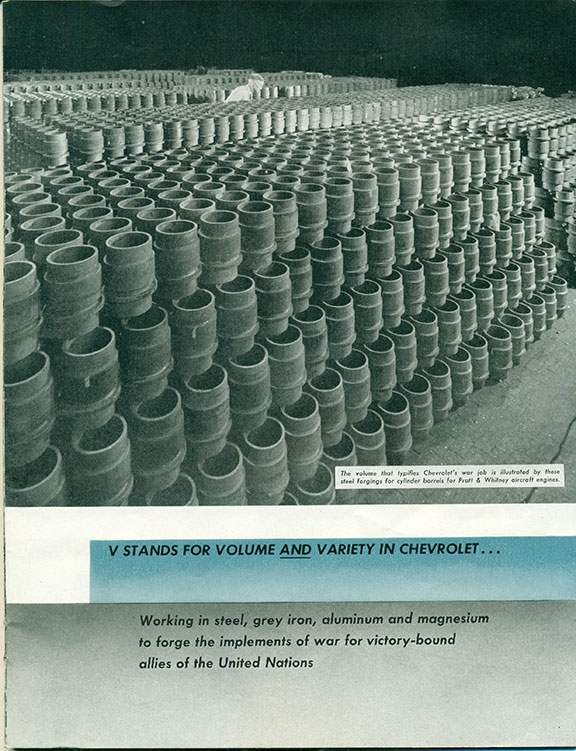

60,766 R-2800 and R-1830

Pratt & Whitney Radial Aircraft Engines (17 Chevrolet Plants

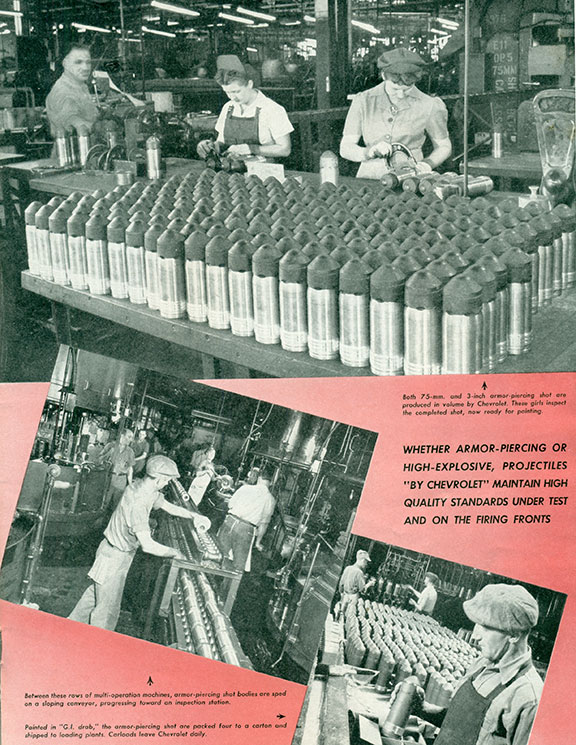

provided parts for final assembly at Tonawanda, NY), 75mm armor piercing and high

explosive projectiles, 3 Inch armor piercing and high explosive

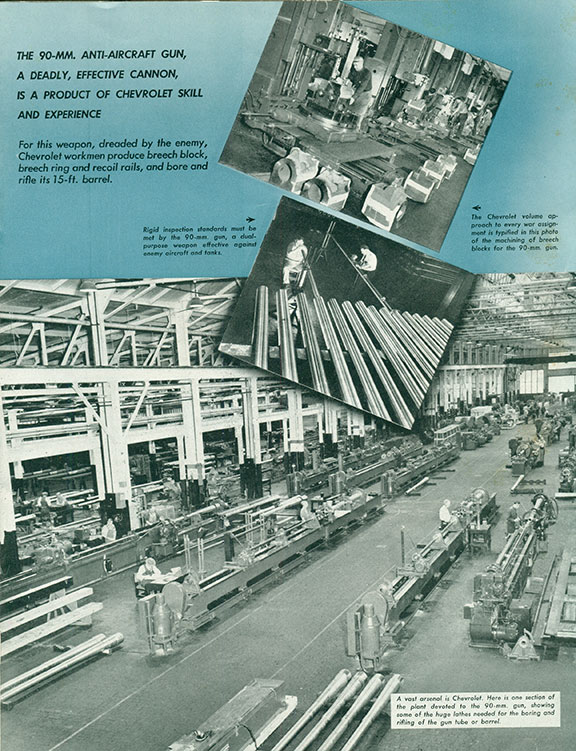

projectiles, 2,000 90mm Anti-aircraft gun tubes, breech ring and

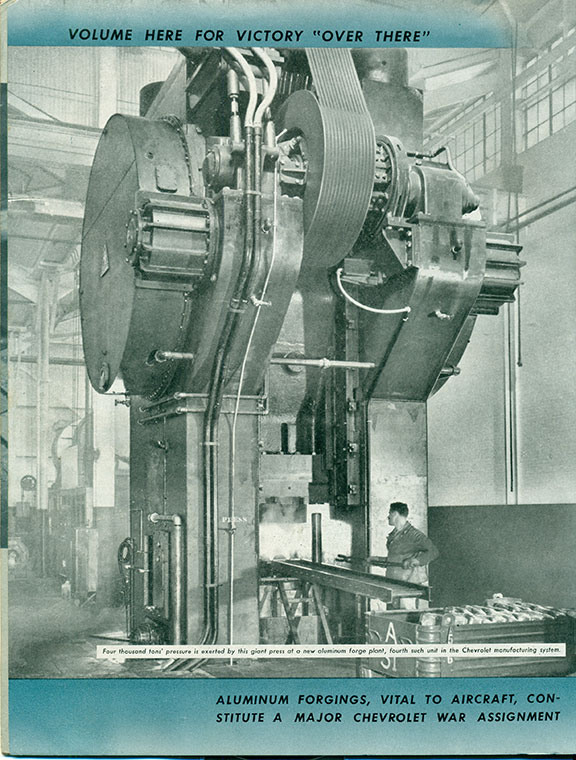

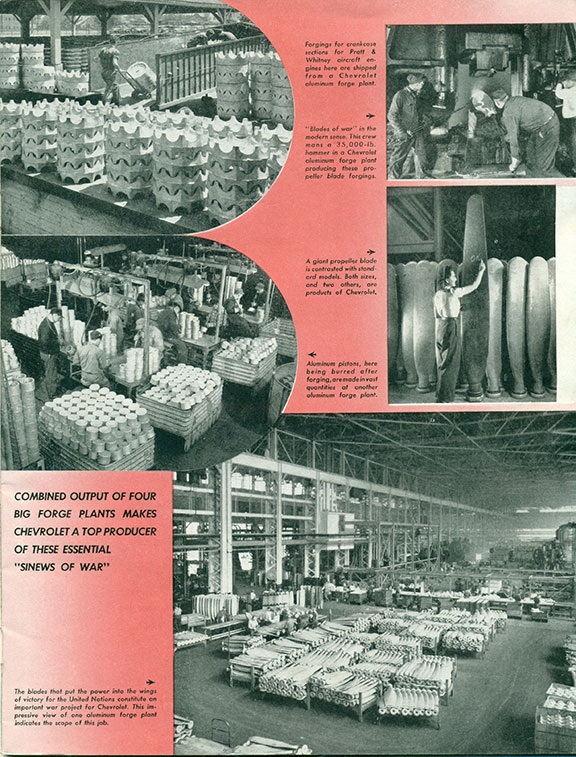

block, and recoil rails, 200 million pounds of aluminum forgings

included forged aircraft propeller blades from four plants, making it

the second largest producer of aluminum forgings in the world, 5.7 million pounds

of magnesium castings, and two billion pounds of grey iron castings and

aluminum castings.

|

Table 1 - Chevrolet

Division's Major World War Two Contracts This table

added 4-29-2025. |

|

Plant Location |

Contract Value |

Products |

Comments |

|

Atlanta, GA |

$55,541,000 |

Trucks |

|

|

Baltimore, MD |

$28,936,000 |

Trucks |

|

|

Bloomfield, NJ |

$28,936,000 |

Trucks |

|

|

Cleveland, OH |

$1,573,000 |

Trucks |

|

|

Detroit, MI |

164,074,000 |

Trucks, Motor Vehicle Parts, Ordnance Equipment, Cargo

Bodies, Drop Forgings, Shells, Automotive Light Sedan,

Automobiles, Drop Forgings, Bomb Service Truck M6, Armored

Car Parts, Gun Motor Carriages T27, Combat Vehicle Seals,

Tank Turret Models, Tank Turrets, Gun Mounts T4, Airplane

Equipment, Shot 76mm, Engineering Services |

|

|

Flint, MI |

$216,544,000 |

Trucks, Motor Vehicle Parts, Ordnance Equipment, 75mm Shot

AP,

90mm Anti-Aircraft Guns, Cars Light Sedan, Trucks Bomb

Service, Armored Cars T17E1, Winterization Kits, Gun Parts

90mm, Engine Parts |

t |

|

Janesville, WI |

$64,000 |

Trucks |

Loaned to Oldsmobile Division of GM |

|

Norwood, OH |

$76,022,000 |

Trucks |

|

|

Oakland, CA |

$16,773,000 |

Trucks |

|

|

Saginaw, MI |

$1,086,000 |

Gray Iron Castings, Piston Assemblies |

|

|

St. Louis, MO |

$18,529,000 |

Trucks, 105mm HE Shells |

|

|

Tarrytown, NY |

$54,886,000 |

Trucks |

|

|

Tonawanda, NY |

$1,364,275,000 |

Airplane Engines R1830, Airplane Engines R2800 |

|

|

Total |

$2,027,239,000 |

|

|

Note that the Tonawanda, NY

plant had half of the major contracts. Aircraft engines were expensiive.

Trucks:

A total of 281,570 Chevrolet

name plated trucks consisting of:

55,579 1/2 ton 4x2 trucks

128 3/4 ton 4x2 trucks

52,568 1-1/2 4x2 trucks

173,295 1-1/2 4x4 trucks

(See my Chevrolet WWII

Truck Database for more details.)

158,323 Chevrolet-built GMC branded

trucks consisting of:

151,575 CCKW 6x6 2-1/2 ton trucks.

This was 30% of all CCKWs built. 149,135 were built at

the Chevrolet St. Louis, MO plant and 2,650 in the Baltimore, MD

assembly plant. At the end of the war, all CCKW production had

shifted to St. Louis. In 1944 and 1945, the daily run rate for CCKWs

was larger at St. Louis than at the GMC plant in Pontiac, MI.

Therefore, while all of the nameplates on the CCKWs are GMC, if the

truck was built in 1944 or 1945, there is a greater than 50% chance that

it is the Chevrolet-built version. All CCKWs built in St. Louis, with

the exception of the last 1,000 units, had Chevrolet axles on them.

Chevrolet built both the CCKW-352 and 353; the

former being the 145 inch short wheelbase version with a nine foot bed,

and the latter being the 164 inch long wheelbase type with a twelve foot

bed. Both types came with or without a front mounted winch.

6,748 of the GMC-designed 6x6 Amphibious

Trucks (DUKW) were assembled by Chevrolet in its St. Louis, MO plant.

This was 32% of the total of 21,147 built. GMC supplied the

sheet metal "boat" section pre-assembled from its plant in Pontiac, MI.

GMC sub-contracted the work to Chevrolet and all DUKWs built carried a GMC ID tag, even though the final assembly was carried out by

Chevrolet. Therefore, it is impossible to determine whether a DUKW

was built by GMC or Chevrolet, just as with the CCKW.

Chevrolet components on GMC Trucks:

Chevrolet supplied the original closed passenger cabs, the open

soft top cabs, many of the axles which were similar to the ones used

on its 1-1/2 ton truck, and the engine cowlings for not only the CCKW,

but other GMC 2-1/2 trucks. St. Louis also helped build 37,803

cargo dump trucks, of which the last forty units built were

cargo dump trucks. Chevrolet also built 3,330 cabs and chassis

only for F3 750 gallon fuel tankers and L1 660 gallon lubricant tankers

for the Army Air Corps.

For Britain: 3,844 Staghound Medium

Armored Cars of which 2,844 were T17E1 with 37mm cannon and

1,000 were T17E2 with twin .50 machine gun anti-aircraft units.

During World War Two Chevrolet built the 1-1/2

ton trucks in ten assembly plants. Each one had a code which was the

first number in the serial number.

|

Table 2 - Chevrolet Vehicle Assembly

Plants |

|

Plant Number |

Location |

|

1 |

Flint, M |

| 2 |

Tarrytown, NY |

| 3 |

St.

Louis, MO |

| 5 |

Kansas City, KS |

| 6 |

Oakland, CA |

| 8 |

Atlanta, GA |

| 9 |

Norwood, OH |

|

14 |

Baltimore,

MD |

|

20 |

Van Nuys, CA |

|

21 |

Janesville, WI |

This Chevrolet truck was photographed at the

75th Anniversary of D-Day in Normandy, France. Photo courtesy of

Pierre-Olivier Buan.

Photo courtesy of Pierre-Olivier Buan.

This Chevrolet cargo truck was on display at

the 2019 MVPA Convention in York, PA. Author's photo added

11-20-2020.

This is a photo of a 1941 Chevrolet 4x4 1-1/2 ton cargo truck with a winch, as seen at the

2013 Houston Airshow. Author's photo.

It can be determined from the tables on the

Chevrolet WWII vehicle

production page that this is a type ZM truck and

that 6,770 were built in 1941. Author's photo.

Author's photo.

This 1943 GMC CCKW-353 2-1/2 ton truck with

winch was in the same display at Houston. It may very well

have come off the Chevrolet St. Louis production line. During 1943

GMC built 78,432 CCKWs and Chevrolet built 51,715. Note the similarity

in the engine cowling and grill with the previous Chevrolet truck.

They look very similar, as they came off of the same Chevrolet presses in

Flint, MI. Chevrolet also supplied many of the axles for the GMC,

which were similar to those on its own 1-1/2 ton series.

In 1943 Chevrolet St. Louis started building the open cab versions of the CCKW like this.

Prior to that time, it was building

the closed cab, like the one below. Author's photo added

12-24-2014.

The original CCKWs came with the closed cab,

which the Chevrolet Division supplied for all of the CCKWs built by both

itself and GMC in Pontiac, MI. Chevrolet produced 40,070 of the

closed cab type CCKWs, like this CCKW-353 with no winch, seen at the 2014

Columbus, IN Airport Appreciation Day. Author's photo added

12-24-2014.

This 1944 F-3 Army Air Corps 750 gallon Aviation Fuel

servicing truck built on a CCKW-353 chassis and cab was at the 2014 MPVA

National Convention. Chevrolet St.

Louis provided all of the 3,330 cabs and chassis for these type

vehicles. Author's photo added 12-24-2014.

Over 70 years after being built in 1942,

this Chevrolet 1-1/2 ton dump truck is still used occasionally for odd

jobs by owner

Rob Ellert. Note that this model has the front winch.

Photo courtesy of Rob Ellert. Photo added 2-14-2015.

This nice looking example of the NL series

dump truck was one of 5,098 built by Chevrolet in 1942 for the military. After being built for the Army, it eventually was obtained

by the Navy. Photo courtesy of Rob Ellert. Photo added

2-14-2015.

This Chevrolet dump truck was built between

1942 and 1944. Author's photo added 6-14-2017.

Author's photo added 6-14-2017.

Author's photo added 6-14-2017.

This Chevy dump truck was on display at the 2019 Findlay, OH Military

Show. Author's photo added 6-20-2019.

Author's photo added 6-20-2019.

Author's photo added 6-20-2019.

Author's photo added 6-20-2019.

This Chevrolet dump truck was on display at

the 2019 MVPA Convention in York, PA. Author's photo added

11-20-2020.

This 1942 Chevrolet 1/2 ton pickup truck

shows the Chevy styling of this type of vehicle at the time. The

truck is rare due to production of civilian vehicles being stopped in

early 1942. This vehicle was on display at the National Automotive and Truck Museum (Natmus) in

Auburn, IN. Author's photo.

This 1946 Chevrolet 1/2 ton, also at Natmus, shows the same basic styling as the prewar model. Author's photo.

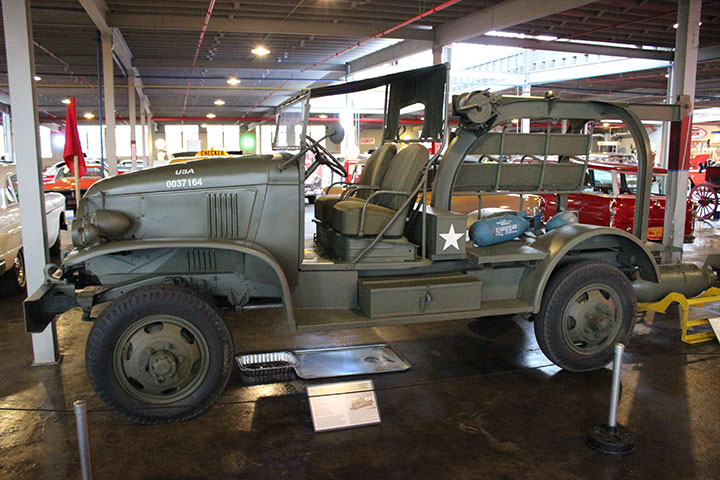

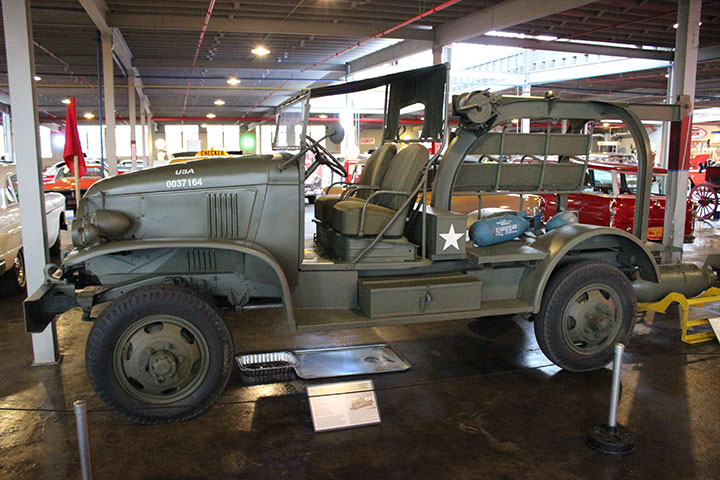

This is an example of one of the 7,857

Chevrolet-built 1-1/2 ton 4x4 bomb service trucks for the military

during World War Two. This was on display at the

National Automotive and Truck Museum in Auburn, IN. Author's

photo.

Author's photo.

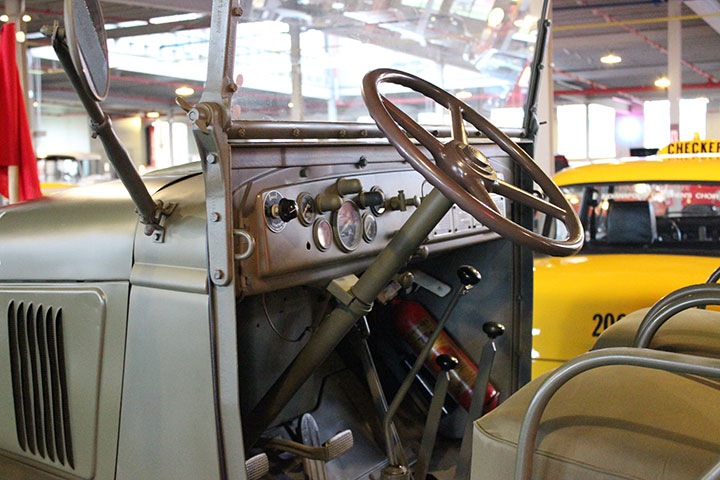

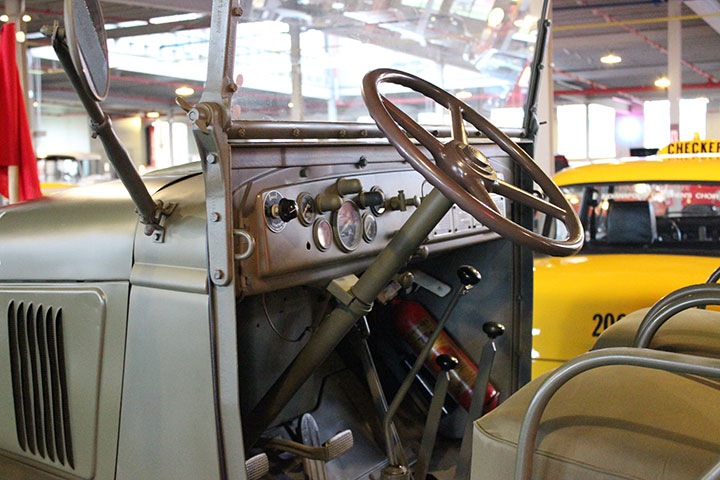

Note that there are three seats for crew

members on the passenger side of the vehicle. Author's

photo.

Author's photo.

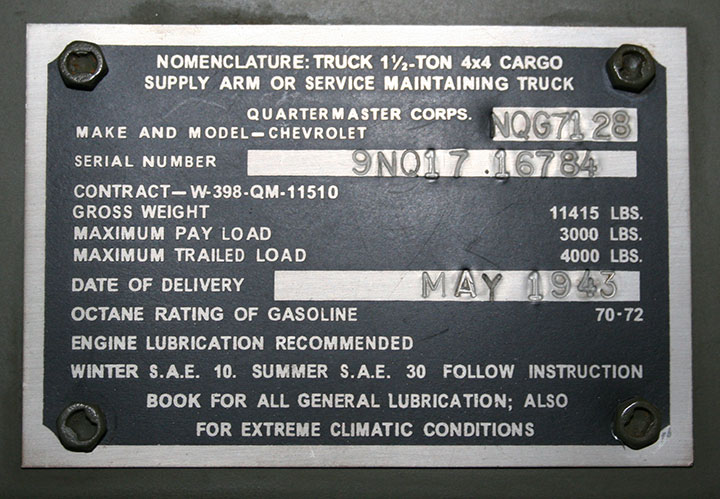

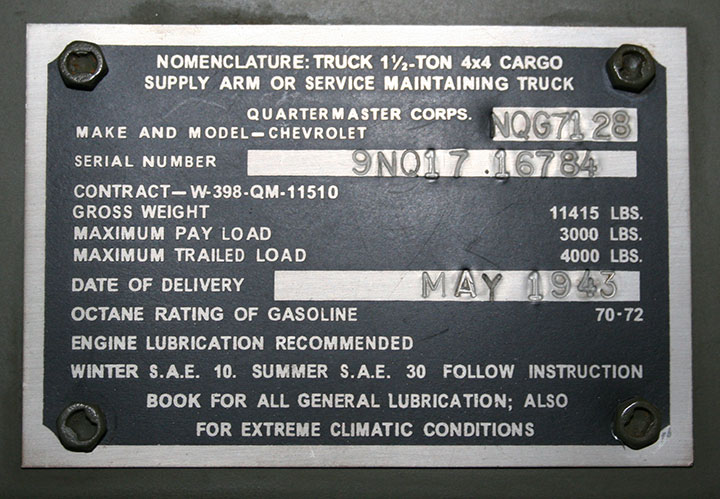

The first number 9 in the serial number

designates the Chevrolet Norwood, OH plant.

"NQ" designates it as a bomb service truck. Author's

photo.

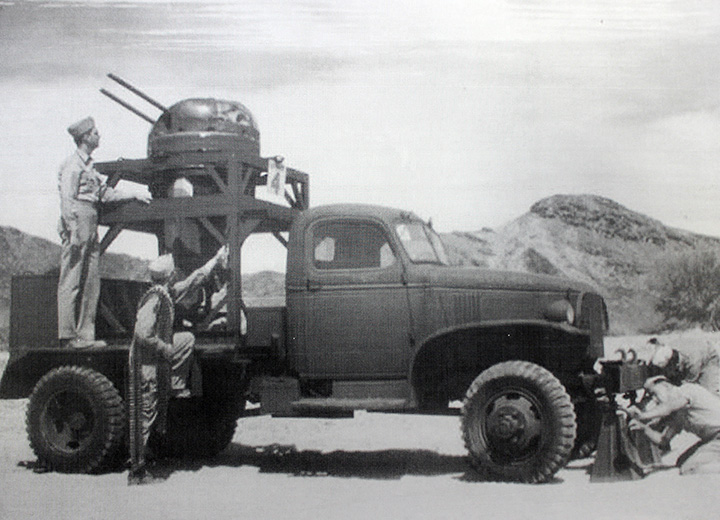

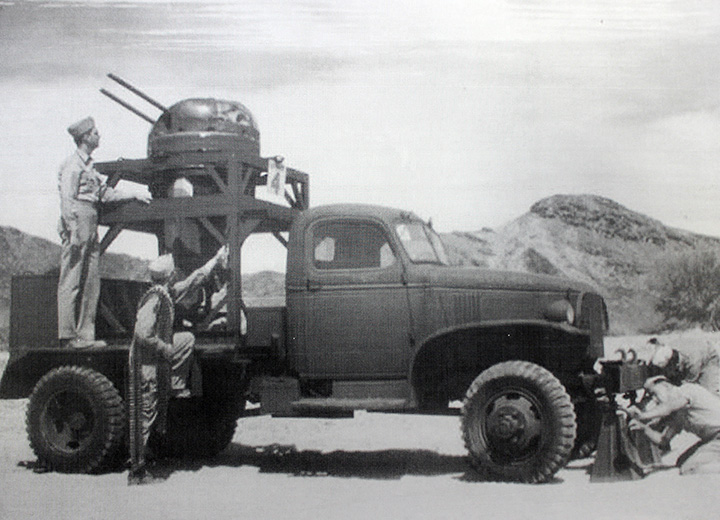

The next set of period photos shows Chevrolet

1-1/2 ton trucks being used to train Army Air Force aircraft turret

gunners, allowing the trainees to shoot at targets while moving on the

bed of the vehicles. This is a little known but important use for

Chevrolet trucks during World War Two.

The Army Air Force designated the turret

mounted truck as an E-5. The air gunnery ranges were located at

Buckingham Army Air Field, FL, Harlingen Army Air Field, TX, Las

Vegas Army Air Field, NV, Lowry Bombing and Gunnery Range, CO, Matagorda

Island Bombing and Gunnery Range, TX, Tonopah Bombing and Gunnery Range,

NV, Tyndall Army Air Field, FL and Williams Army Air Field, AZ. Photo added 2-12-2015.

This photo of the E-5 gun trainer was taken

at Buckingham Army Air Field, located east of Fort Meyers, FL. Photo added 2-12-2015.

Photo added 2-12-2015.

This is another example of the Chevrolet

1-1/2 ton 4x4 trucks built for the military during the Second World War.

This one is a telephone pole setter, formerly at the National Military History

Center in Auburn, IN. Author's photo.

Chevrolet built 1,719 of these during

World War Two. Author's photo.

This photo of a derelict Chevy 1-1/2 ton

truck was taken

at the Fort Economy Museum in Hallsville, OH. Author's photo added

9-2-2014.

Crash and Fire Trucks built on Chevrolet

4x4 Chassis:

Table 3 -

Chevrolet 1-1/2-ton 4x4 Military Crash and Fire Trucks

Information in this table courtesy of "Chevrolet G-506" by

David Doyle. |

|

Class |

Registration Number |

Quantity |

Apparatus Manufacturer |

Comments |

|

110 |

50702-50731 |

30 |

Holabird Quartermaster Depot |

Hale

pumps |

|

501274-501428 |

157 |

Holabird and Memphis Quartermaster Depot |

American LaFrance pumps |

|

503961-504000 |

40 |

Oren

Fire Apparatus |

|

|

503769-503918 |

150 |

Army

Corps of Engineers |

|

|

Total Class 110 |

|

377 |

|

|

|

135 |

506089-506138 |

50 |

W.S Darley |

|

|

5010139-5010238 |

100 |

|

|

506239-506338 |

100 |

Mack |

|

|

507843--597992 |

150 |

|

|

507347-507377 |

31 |

Oren Fire Apparatus |

|

|

508332-508431 |

100 |

|

|

507478-507527 |

50 |

Minnesota Fire Equipment Company |

|

|

5075780-507602 |

25 |

|

|

507528-507577 |

50 |

Central Fire Trucks Corporation |

|

|

5010029-5010088 |

60 |

American LaFrance |

|

|

Total Class 135 |

|

716 |

|

|

| 300 |

Unknown |

Unknown |

Central Fire Trucks Corporation |

These

were equipped with W.S. Darley Model F-300 front-mounted pumps

and carried a 250-gallon water tank. |

| 325 |

Unknown |

Unknown |

W.S

Darley, Detroit General Corporation, American Fire Apparatus,

Hahn, Oren, and Maxim Motors |

These

were equipped with Barton Model F-300 or W.S. Darley Model F-300

front-mounted pumps and carried a 300-gallon water tank. |

| 525 |

Unknown |

Unknown |

Oren

Fire Apparatus |

These

were equipped with W.S. Darley Model F-500 front-mounted pumps. |

|

Known Total U.S. Army |

|

1,093 |

|

|

|

U.S. Navy |

|

|

|

|

| U.S.

Navy |

|

103 |

Howe

Fire Apparatus Company |

|

|

Total U.S. Navy |

|

103 |

|

|

|

Known Grand Total |

|

1,196 |

|

|

Class 110

Crash and Fire Trucks built on Chevrolet 1-1/2 ton 4x4 Chassis:

As noted above, the 377 bodies were

built by the Holabird and Memphis Quartermaster Depots, Oren Fire

Apparatus, and the Army Corps of Engineers. It

is unknown which organization built the bodies in the photos below.

This Chevrolet-built 1-1/2 ton 4x4 Class 110 crash truck actually served at George

Army Air Field in Lawrenceville, IL during World War Two. The truck belongs

to the Indiana Military Museum in nearby Vincennes, IN, eleven miles away

from the old air field.

Author's photo added 9-2-2014.

Through the end of 1942, Chevrolet provided 306 of these crash truck

bodies

for the army.

Author's photo added 9-2-2014.

Author's photo added 9-2-2014.

The registration number on the hood does not

match any in the table above. If it were W-50731, the body

would have been built by the Holabird Quartermaster Depot. Author's photo added 9-2-2014.

This 1942 Chevrolet Class 110 crash truck was

photographed at the 2017 MVPA national convention in Cleveland, OH.

It is Serial Number N90212859. Author's photo added 12-25-2019.

Author's photo added 12-25-2019.

Author's photo added 12-25-2019.

Class 125 Crash and Fire Trucks built on

Chevrolet 1-1/2-ton 4x2 civilian truck chassis: The Chevrolet

class 125 crash truck shown below is an anomaly. According to the

historical record, only International Harvester Corporation provided the

chassis for the Class 125 crash truck. The example below shows

that they were also built on Chevrolet chassis.

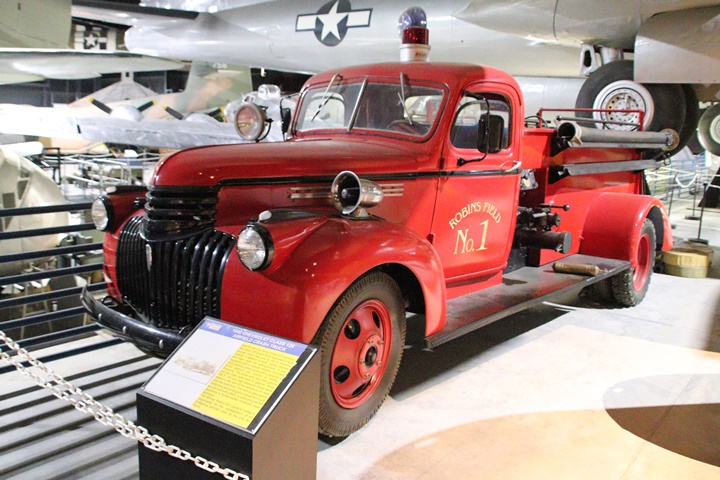

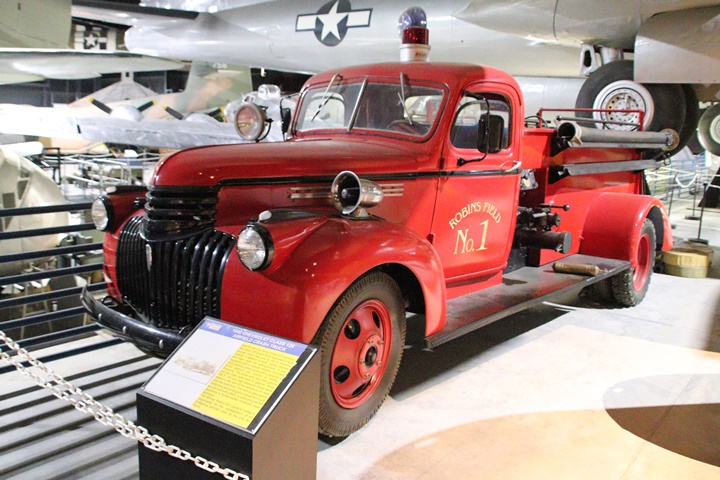

This 1942 Chevrolet truck was used as a

class 125 fire truck at Robins Field during World War Two. It is

on display at the Museum of Aviation at Robins Air Force Base, GA.

Author's photo added 6-14-2022.

Author's photo added 6-14-2022.

Author's photo added 6-14-2022.

Class 135 Crash and Fire Trucks built on

Chevrolet 1-1/2 ton 4x4 Chassis: As noted above, the 377 bodies

were built by W.S Darley, Mack, Oren Fire Apparatus, Minnesota Fire

Equipment Company, Central Fire Trucks Corporation, and American

LaFrance.

This 1943 Chevrolet 1-1/2-ton 4x4 Class 135 fire truck was on display at

the annual MVPA Convention at Louisville, KY in June 2014. The registration

number 508421 indicates the body was built by Oren Fire Apparatus. Author's photo added

9-2-2014.

Author's photo added 9-2-2014.

Author's photo added 9-2-2014.

Author's photo added 9-2-2014.

Author's photo added 9-2-2014.

This Class 135 is one of two Chevrolet World War Two

crash trucks on display at the Sam

Werner Military Museum. The second one is parked directly behind this one.

It is a Class 325.

Author's photo added 11-20-2020.

Author's photo added 11-20-2020.

Class 325 Crash and Fire Trucks built on

Chevrolet 1-1/2 ton 4x4 Chassis: As noted above, the bodies were

built by W.S. Darley, Detroit General Corporation (General Fire

Truck), American Fire Apparatus, Hahn, Oren, and Maxim Motors.

This is the second Chevrolet crash truck at

the Sam Werner Military Museum. It is a Class 325 with a General Fire Truck body. The USA

registration number is incorrect. It should start with a "50." Author's photo added 11-20-2020.

Author's photo added 8-26-2021.

Author's photo added 11-20-2020.

Amphibious Trucks (DUKW):

The Chevrolet St. Louis plant built (6,748) GMC name plated DUKWs.

This DUKW was on display at the National

Military History Center in Auburn, IN. It is no longer there. Author's photo.

Author's photo.

In this World War Two era photo, the DUKW shows its

versatility in a river crossing.

This DUKW is on display at the Indiana

Military Museum in Vincennes, IN. Author's photo.

Author's photo.

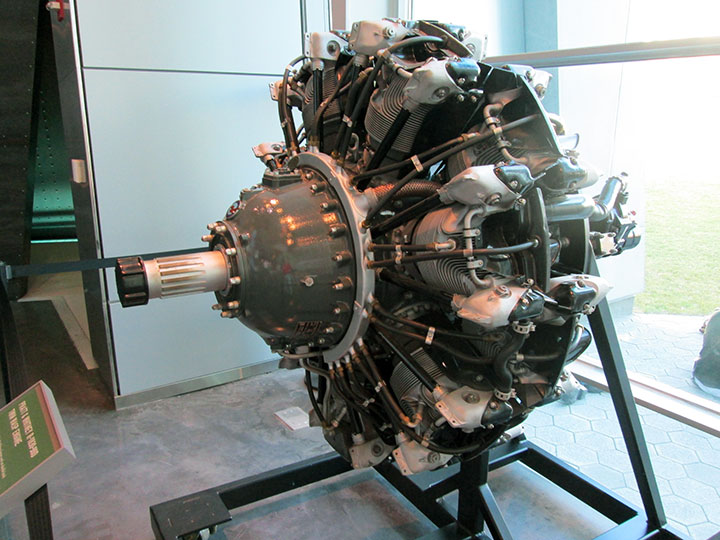

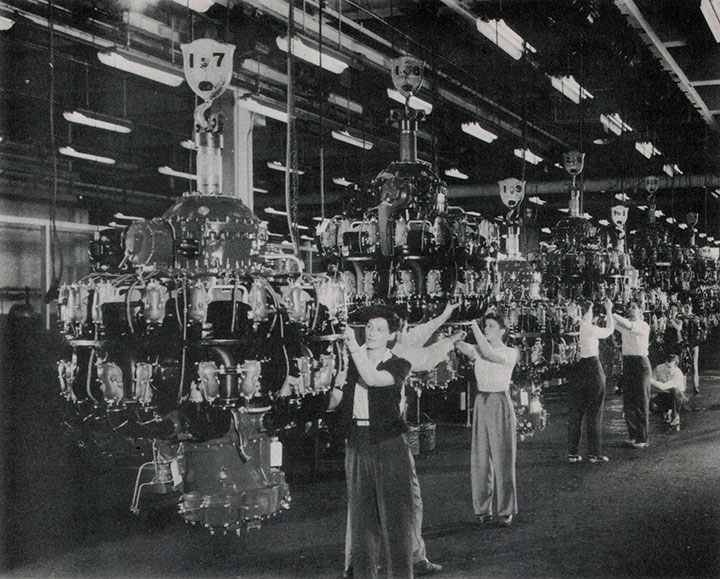

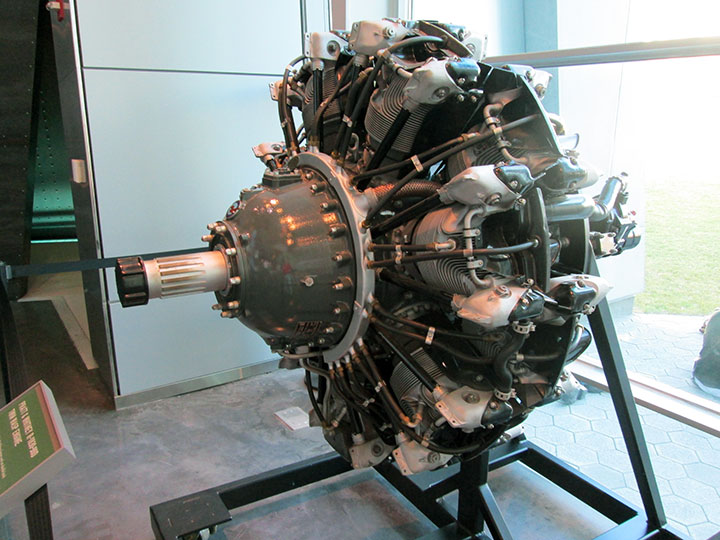

Aircraft Engines:

56,484 R-1830 and 4,282 R-2800 Pratt & Whitney

Radial Aircraft Engines. Seventeen Chevrolet plants provided

components that went into the final

assembly at Tonawanda, NY.

R-1830 - Chevrolet Tonawanda built the

first of 56,484 R-1830s on 3-20-1942 and continued to produce the engine

until 3-31-1945. During these three years, Tonawanda turned out an

average of 1,569 engines per month. Chevrolet built R-1830s that were used in the B-24, C-82, PBY, and A-28.

Buick also built the R-1830 during World War

Two. It produced 74,198 in a government-owned plant in Melrose Park, IL,

west of Chicago. Chevrolet and Buick combined to provide 130,682

R-1830s, which was 75% of the 173,618 built during the war. General

Motors was the largest producer of the R-1830 during World War Two.

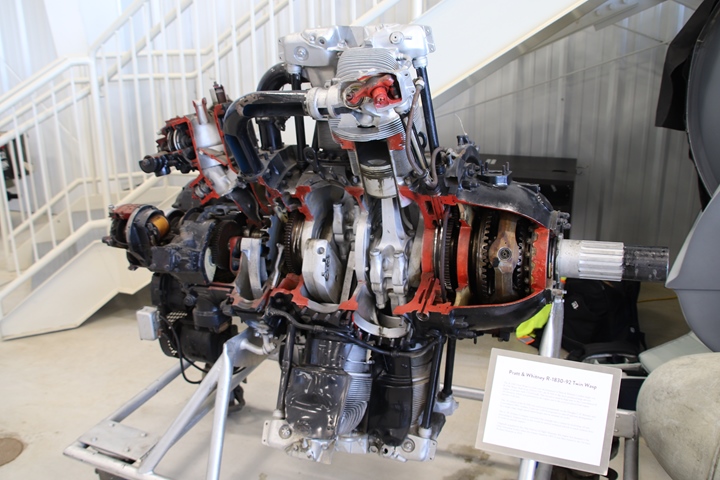

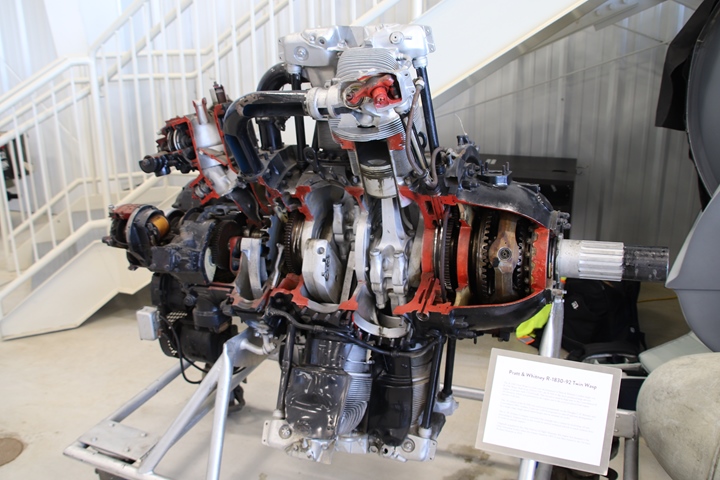

This is a Pratt & Whitney R-1830 engine,

as seen at the National Museum of World War Two in New Orleans, LA. Chevrolet Tonawanda built this

type of aircraft engine. Author's photo.

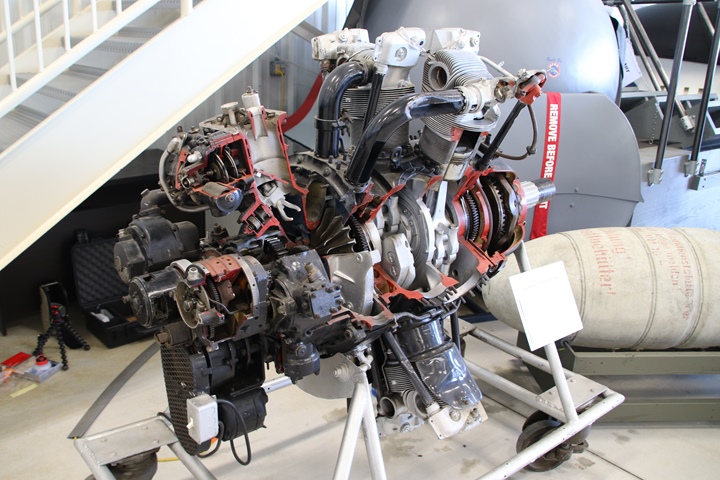

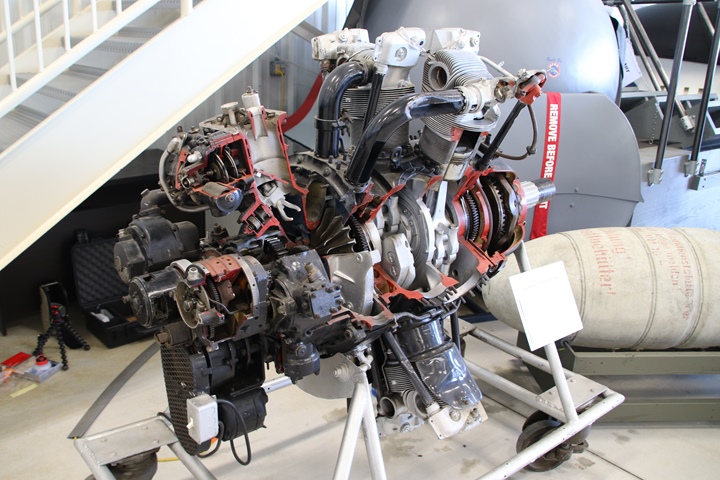

This R-1830 display at the Tri-State Warbird

Museum in Batavia, OH shows the complexity of the engine. Author's

photo added 11-20-2020.

Author's photo added 11-20-2020.

Chevrolet Tonawanda-built

Pratt & Whitney engines went into the Douglas C-47, the workhorse

transport aircraft for the United States during World War Two. Author's

photo.

Chevrolet-built R-1830s were used in the

B-24. The C-82 was the cargo version of the B-24. Author's

photo added 11-20-2020.

This is a USAAF OA-10, which was its

designation for a PBY. Tonawanda was only providing engines for the USAAF, so it was probably this version of the aircraft in which the

engines were used. Author's photo added 11-20-2020.

R-2800 - Chevrolet built the first of

4,282 R-2800 aircraft engines on 7-29-1944. It maintained a

production run of 356 per month until a year later when the war ended.

These were used on the P-47, P-61, A-26, C-46, and C-82. The first

engine was built in only five months and nineteen days from start to

final testing and acceptance. This was extremely fast for such a

complex engine.

|

Table 4 -

Chevrolet-Built Pratt & Whitney R-2800 Engines |

|

R-2800 Model |

Number of Engines Built |

Aircraft Type |

|

R-2800-57 |

200 |

P-61C,D; P-47M,N |

|

R-2800-73 |

2,665 |

P-61C; P-47N |

|

R-2800-77 |

500 |

P-61C,D; P-47N |

|

R-2800-83 |

855 |

This was for the A-26D which was cancelled due to the ending of

World War Two. The engine was later used in the

Vought AU-1 developed during the Korean Conflict. |

|

R-2800-85 |

62 |

C-82A.

Some were built during World War Two |

| Total |

4,282 |

|

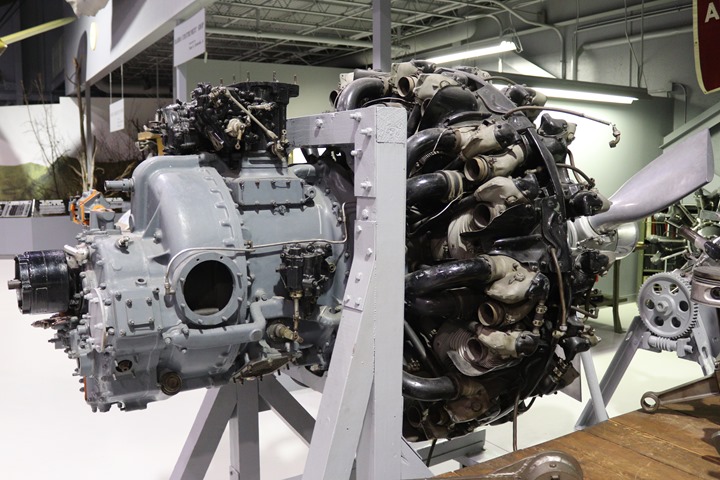

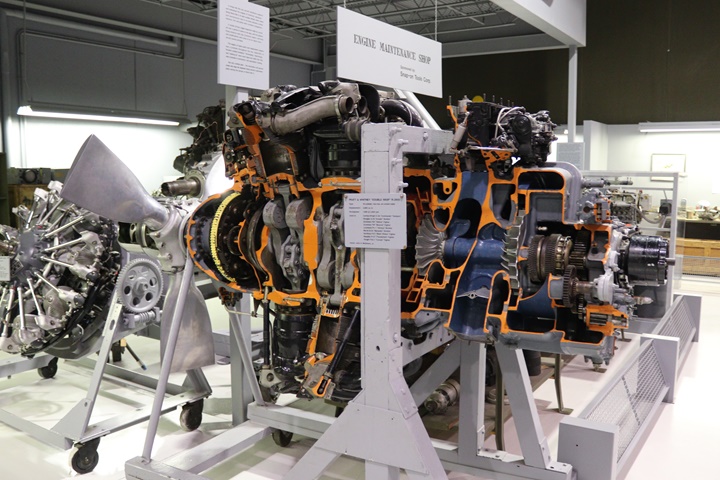

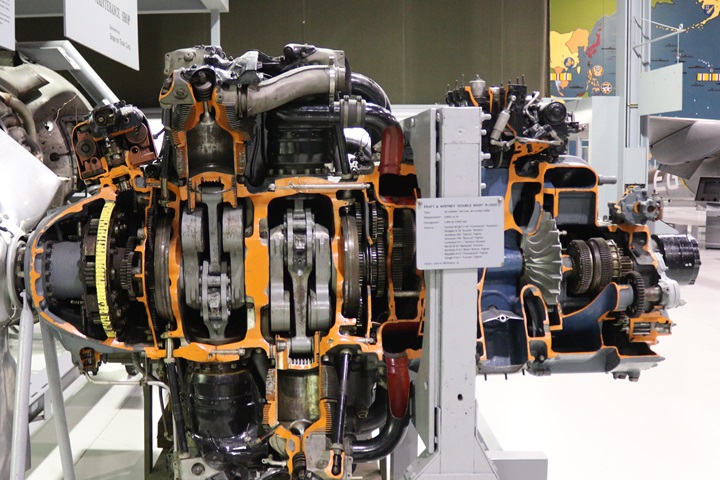

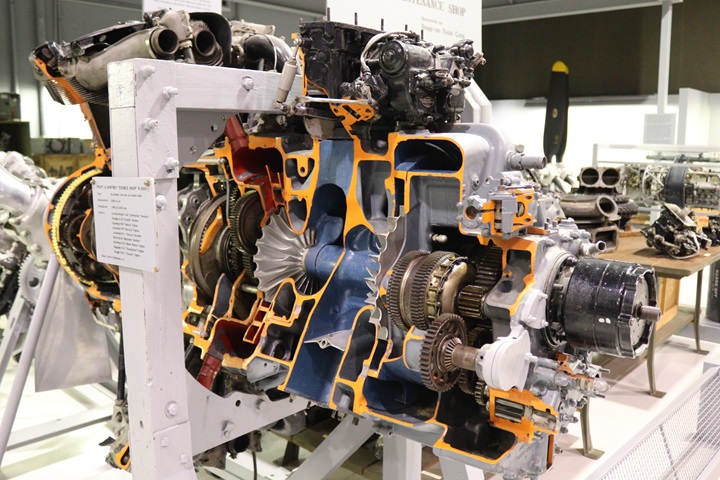

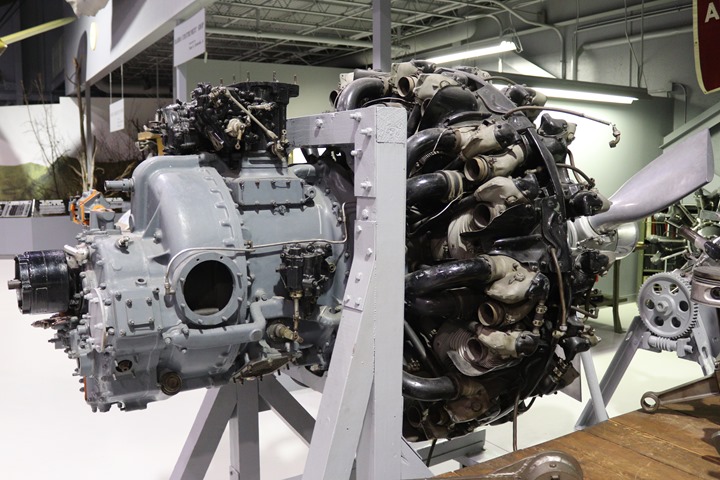

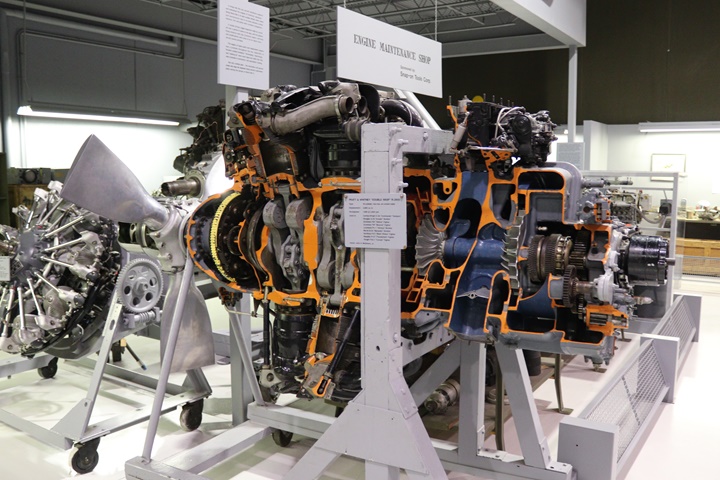

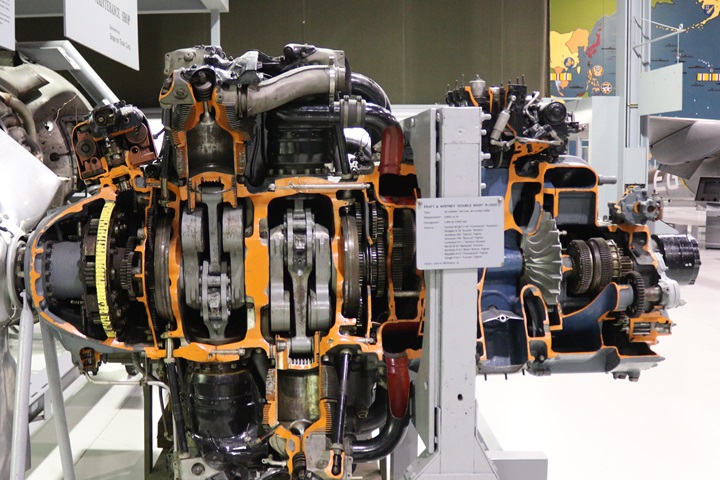

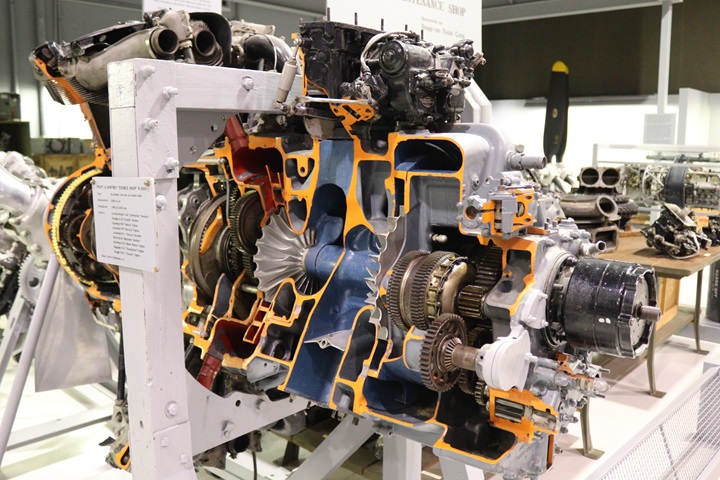

This R-2800 is on display at the EAA Museum

in Oshkosh, WI. While the R-1830 had a single row of nine

cylinders, the R-2800 had two rows of nine cylinders. The

accessory section of the R-2800 was a whole section of the engine which the R-1830 didn't have. The R-2800 was an order of

magnitude more complex to build than the R-1830. Author's photo

added 11-20-2020.

Looking at the other side of the display and

the interior of the engine, its complexity is obvious. Author's

photo added 11-20-2020.

The R-2800 was the most powerful radial

engine the U.S. military used in World War Two. The R-2800 was

used in both of the Navy's premier World War Two fighters, the F6F and F4U.

Author's photo added 11-20-2020.

Author's photo added 11-20-2020.

This Chevrolet-built Pratt and Whitney

R-2800 engine is on display at the National Museum of WWII Aviation in

Colorado Springs, CO. Author's photo added 10-7-2017.

The engine is part of a larger display

showing how the Republic P-47 super turbocharger system worked. Author's photo

added 10-7-2017.

Here is the Chevrolet bowtie on the engine's

nose housing. Author's photo added 10-7-2017.

This P-47 is located at the Peterson Air and

Space Museum at Peterson AFB in Colorado Springs, CO. It has a

Chevrolet Tonawanda-built R-2800

engine in it. Author's photo added 10-7-2017.

Author's photo added 10-7-2017.

This engine still has the data plate on it.

Author's photo added 10-7-2017.

The C-46. Author's photo added

11-20-2020.

The P-61C featured the higher performance

R-2800 that Chevrolet was assigned to build. Author's photo added

11-20-2020.

The A-26. Author's photo added

11-20-2020.

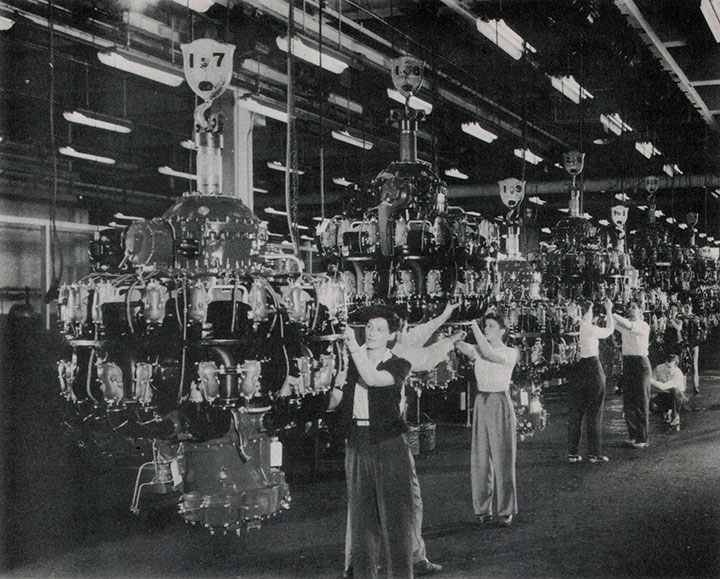

This is part of the Chevrolet Tonawanda, NY

Pratt & Whitney R-2800 radial aircraft engine production line.

Seventeen plants in the Chevrolet Division were involved in making

these aircraft engines. The Chevrolet Tonawanda plant is still

in production today. It is right along the Niagara River south of The Falls and north

of Buffalo.

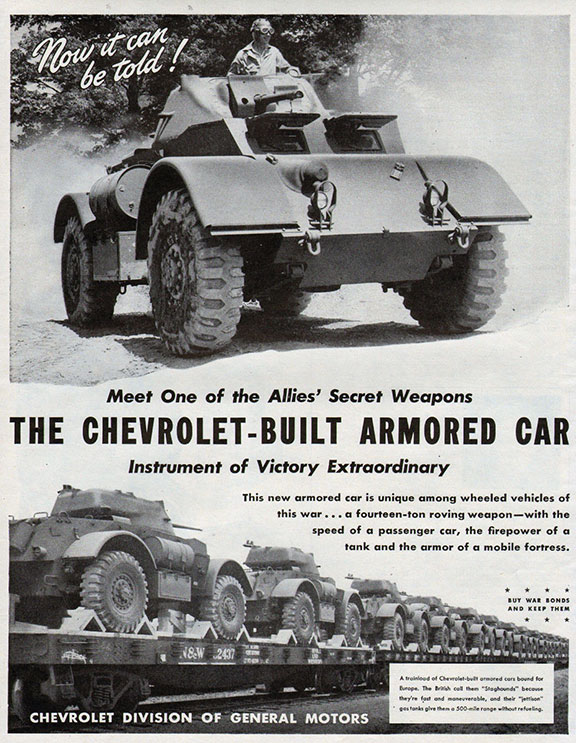

Armored Cars:

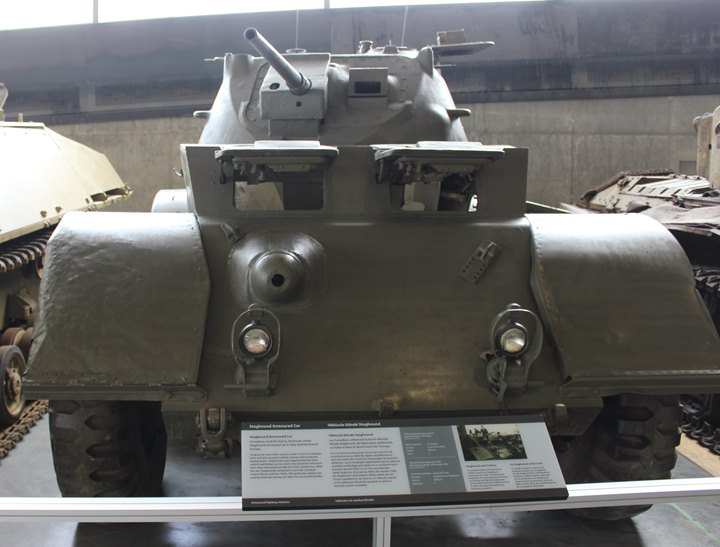

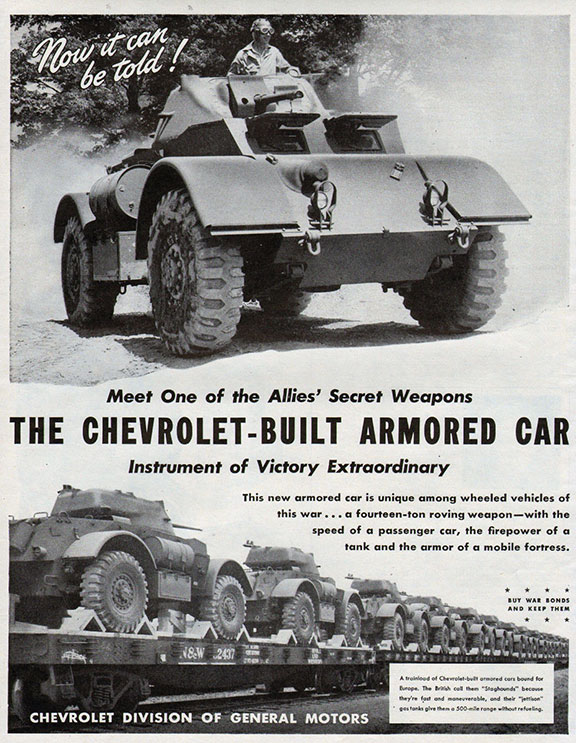

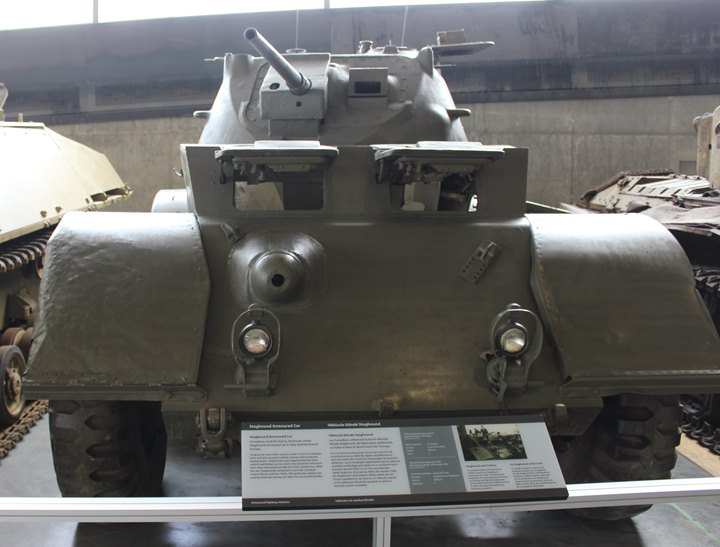

This photo of a T17E1 "Staghound" armored

car, as it appeared in the GM 1944 annual report. According to the annual

report, the Staghound was a closely guarded secret for three years.

There was also a T17E2 which replaced the 37mm cannon shown here with

two .50 caliber M2 machine guns in a Frazier-Nash turret as an

anti-aircraft mount.

This Chevrolet ad makes it known that its

Staghound was a secret weapon. Not only was its

production a secret; but due to the fact that it was not used by US

forces during the Second World War, it has been overlooked and somewhat

of a secret ever since. Staghounds were used by British

Commonwealth nations, especially the Canadians, during World War Two,

while Polish forces in Italy were the biggest user of it.

|

Table 5 -

Chevrolet Staghound and Boarhound World War Two Production |

| |

T17E1

Staghound |

T17E2

Staghound |

Comments |

| 1942 |

157 |

|

Production of the T17E2 started in October. |

| 1943 |

2,687 |

211 |

|

| 1944 |

|

789 |

|

| Totals |

2,844 |

1,000 |

Chevrolet produced a total of 3,844 of the T17armored cars

between October, 1942 and April, 1944 when production of all

types ceased. |

Author's Aside: The Staghound

and I go all the way back to when I was in early grade school. My

first set of plastic army men included a Staghound armored car. I played

with it until I outgrew playing with army men. However, I still

have that collection of army men with the Staghound. Now my

grandchildren play with it. The day the photo below was taken my

oldest grandson was playing with the set of army men.

Author's photo added 1-11-2023.

Staghound T17E1 Walk Around and Interior

Views:

The Staghound featured below is part of the superb collection of

World War Two vehicles at the Wheels of Liberation in Gettysburg, PA.

From all appearances, the interior seems to be original. The

Wheels of Liberation was still in the process of consolidating its

collection into one location when I visited in September 2022.

The machine gun mount on the turret is an

addition to the original vehicle. Author's photo added 1-11-2023.

Author's photo added 1-11-2023.

Author's photo added 1-11-2023.

The side door was open. This allowed

me to take some photos of the interior. It is very rarely that one

is able to view the inside of armored vehicles. Author's photo added

1-11-2023.

Author's photo added 1-11-2023.

The 7.62mm machine gun operated by the

assistant drive can be seen in the background. This indicates this

vehicle was in service after World War Two when the 7.62mm cartridge

became the standard for NATO countries. A photo further down in

the turret shows an ammunition box with 7.62mm marked on it.

Author's photo added 1-11-2023.

This and the next several images show the

inside of the turret. The breech for the 37mm cannon can be seen

in the upper left of the photo. Author's photo added 1-11-2023.

The radio is the type used by the British

and other Commonwealth countries. Author's photo added 1-11-2023.

Author's photo added 1-11-2023.

On the turret wall is the previously

mentioned ammunition can which is marked 7.62mm. Author's photo

added 1-11-2023.

Author's photo added 1-11-2023.

Author's photo added 1-11-2023.

Other Surviving T17E1

Staghounds:

This Chevrolet-built Staghound armored car

has a fresh coat of paint. It is temporarily stored outdoors while

awaiting placement into a new inside display area as part of the U.S.

Army Armor and Cavalry Collection, Fort Benning, GA. Author's photo added 9-21-2018.

Author's photo added 9-21-2018.

Author's photo added 9-21-2018.

Author's photo added 9-21-2018.

Author's photo added 9-21-2018.

This Chevrolet-built T17E1 Staghound is on

display at the Canadian War Museum in Ottawa, ONT. Author's photo

added 9-13-2016.

Author's photo added 9-13-2016.

Author's photo added 9-13-2016.

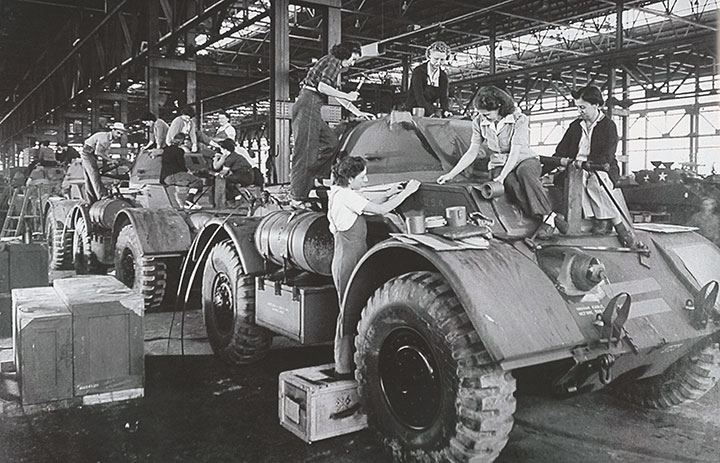

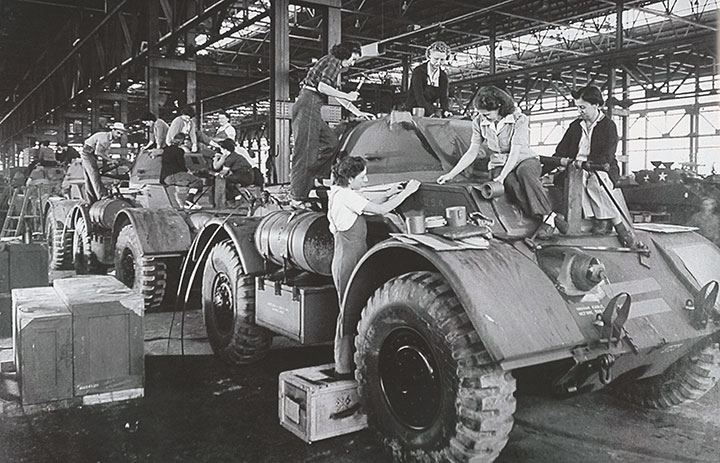

What a cool photo! Nine of the ten

persons in this photo preparing the first two Staghounds for shipment

overseas are women. Photo courtesy of the Military

History Institute in Carlisle, PA.

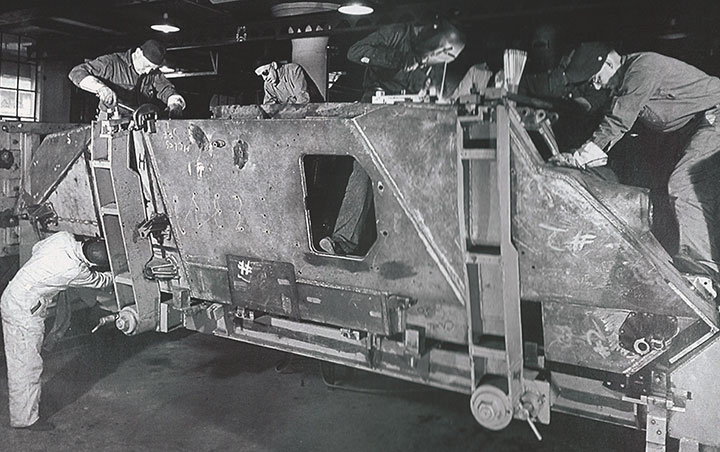

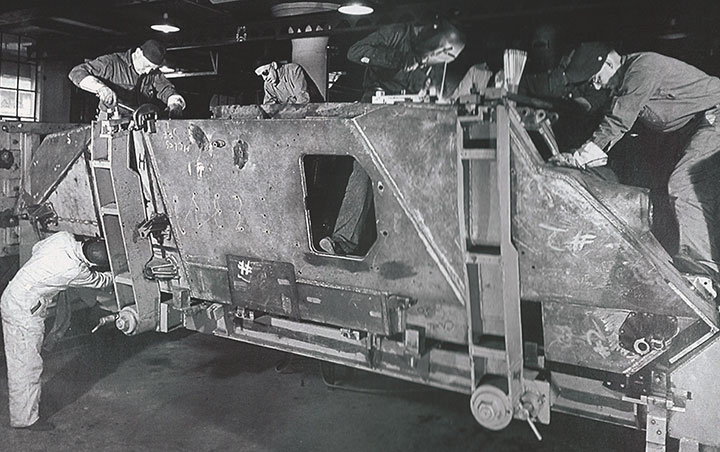

Here a Staghound hull is being welded.

Other Armored Cars:

This Fox Armored Car seen at 2009 Windsor,

Ontario Airshow was designated as a GM MK.1, but Chevrolet was the

Division that designed the chassis. Final assembly was done by GM

of Canada. Author's photo.

Author's photo.

Chevrolet began development on the M38

armored car in 1944 as a replacement for the M8 Greyhound.

Production on the new armored car did not get started until March 1945.

Only five pilot models were built due to the ending of the war in

Europe. The M38 was powered by a Cadillac V-8 engine mated to a

Detroit Transmission Hydra-Matic transmission. Photo added

1-8-2020.

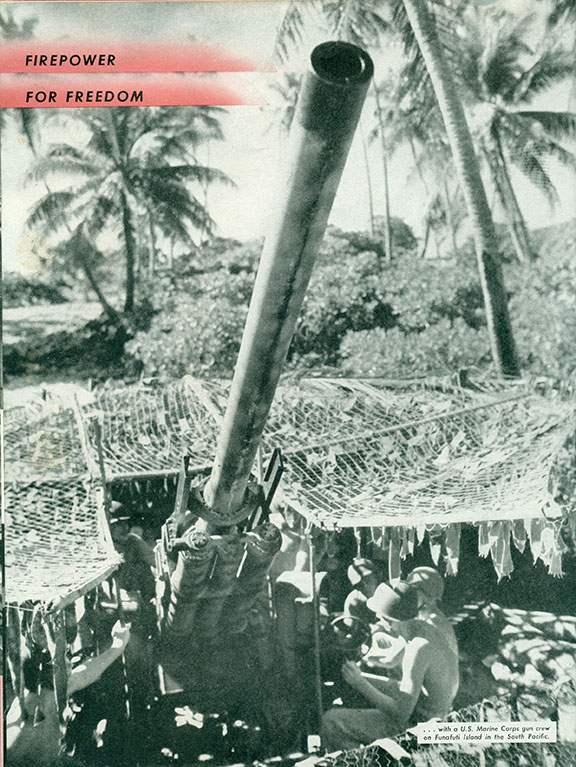

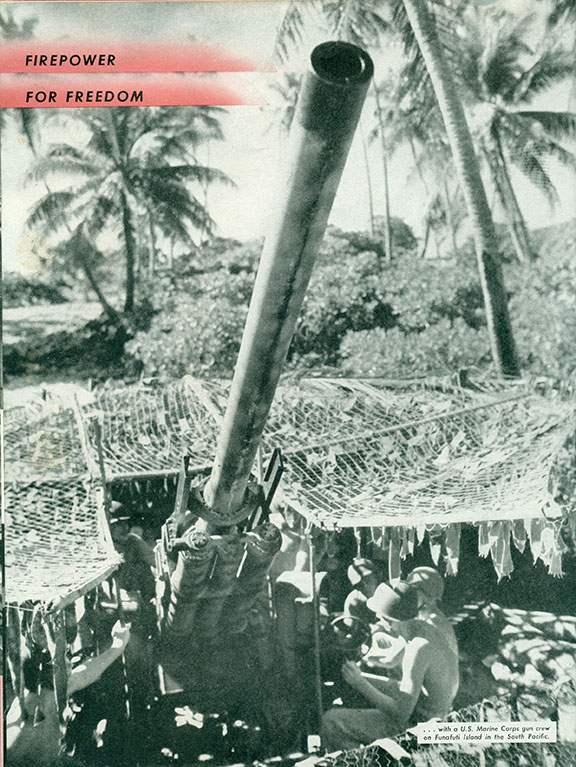

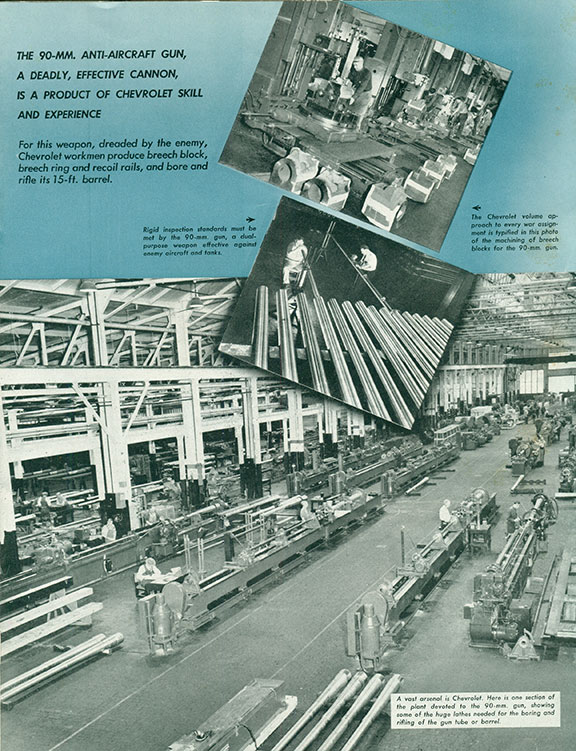

90mm Anti-Aircraft Gun Components:

Chevrolet built 2,000 gun tubes, breech ring

and block assemblies, and recoil rails for 90mm anti-aircraft guns like this one

seen at the Indiana Military Museum in Vincennes, IN. Author's photo.

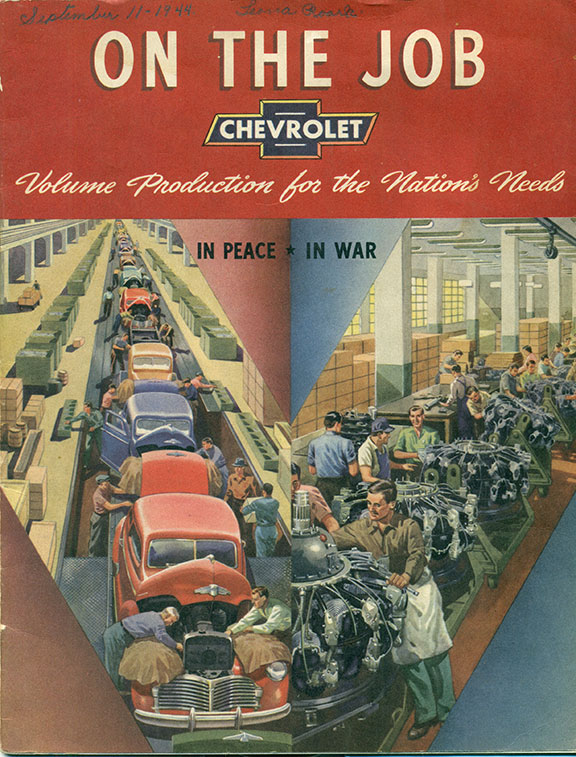

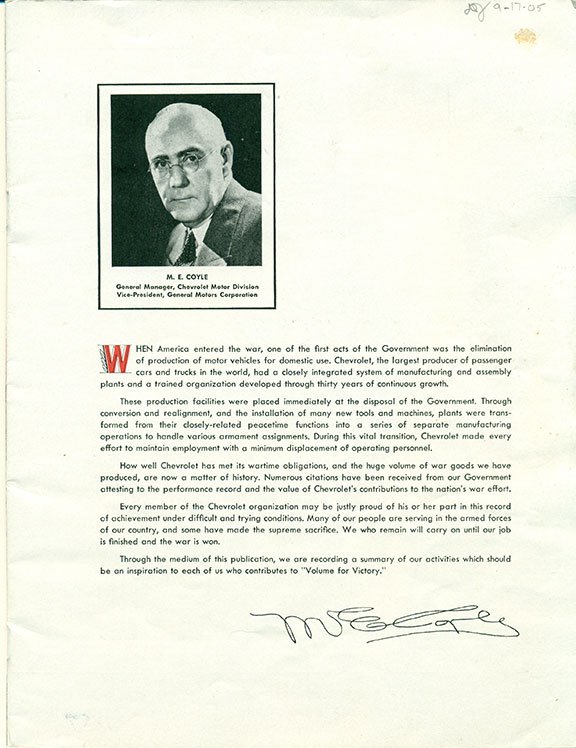

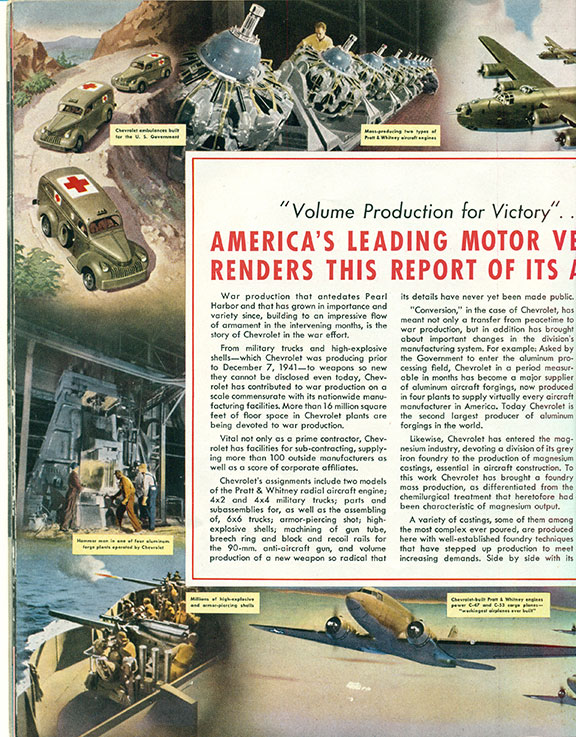

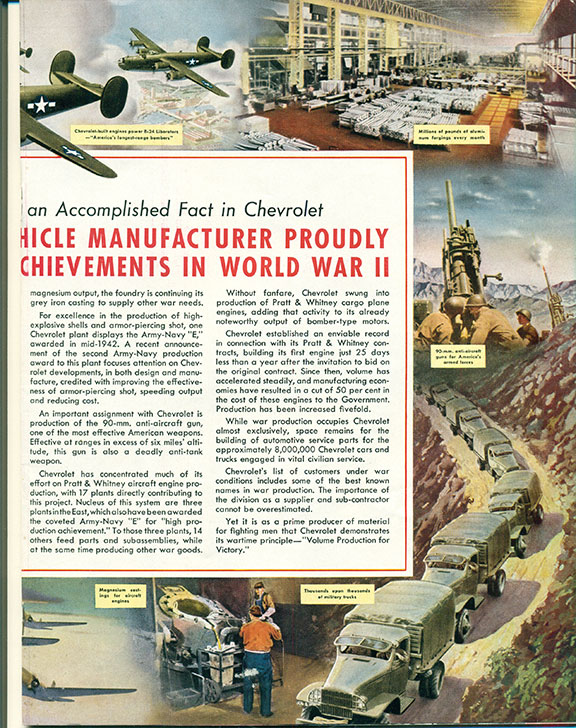

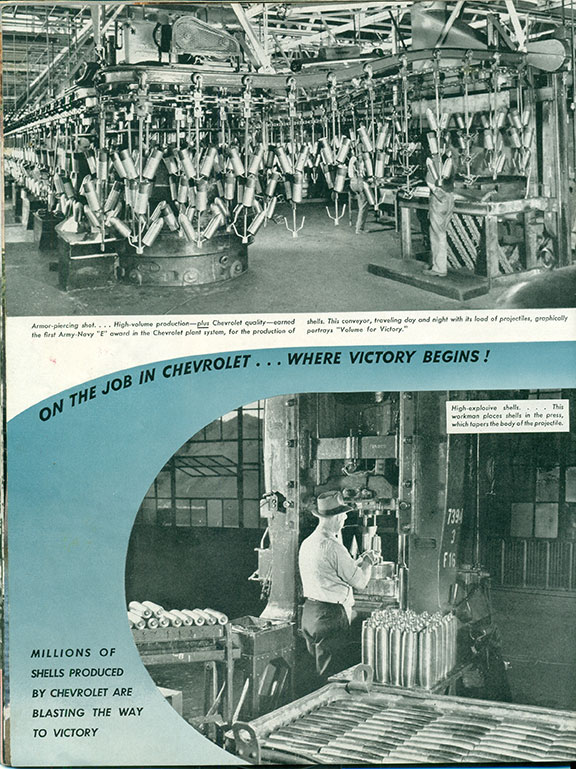

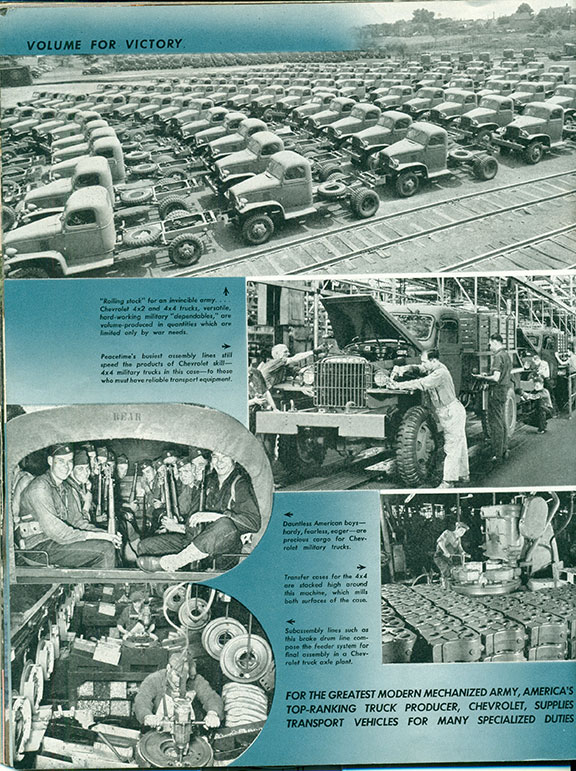

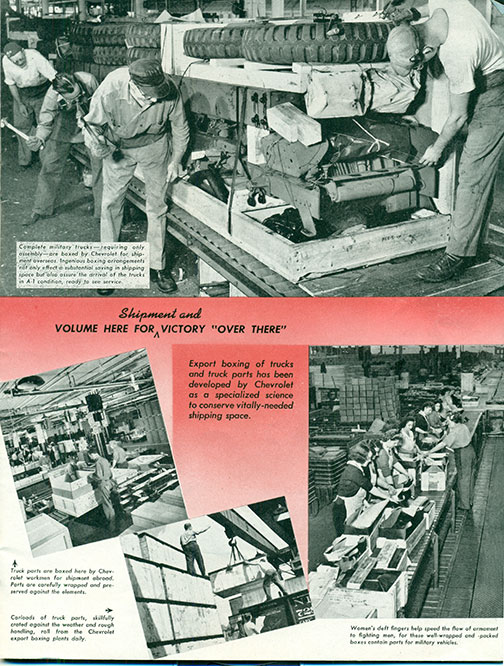

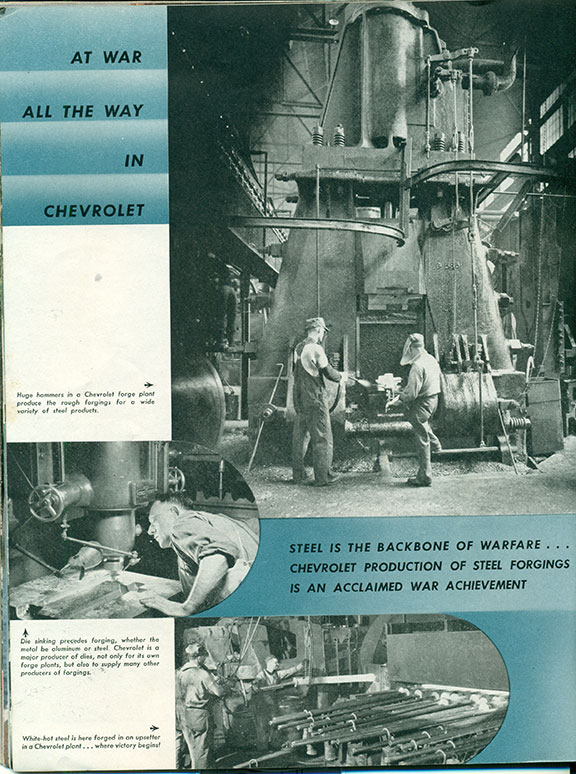

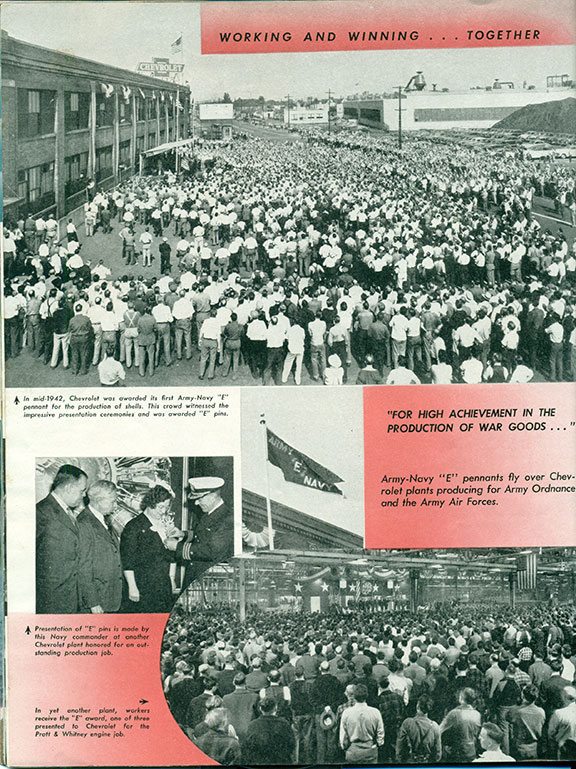

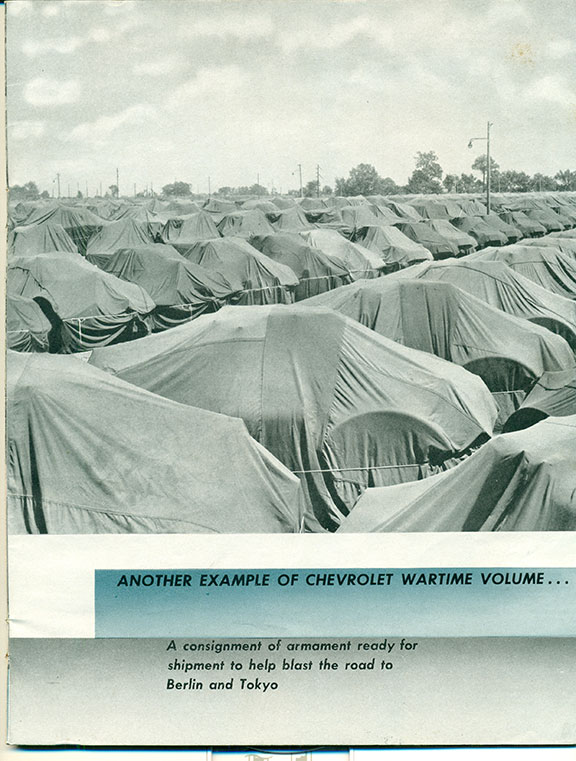

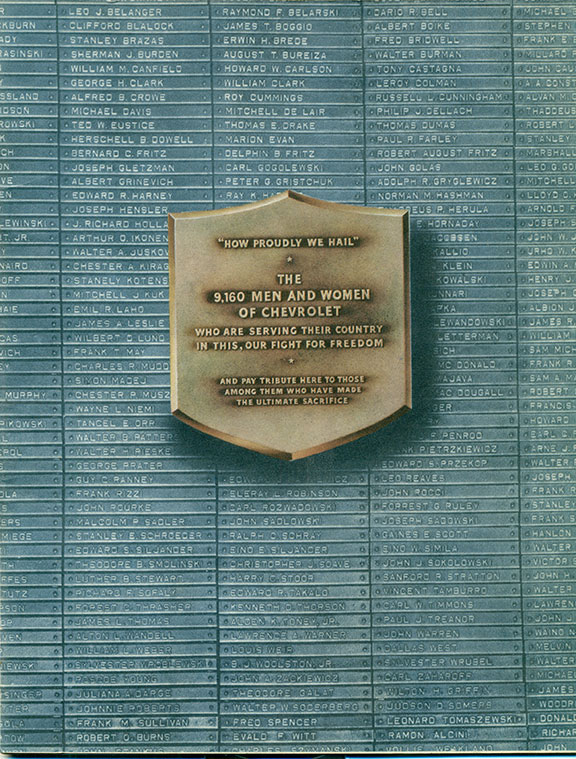

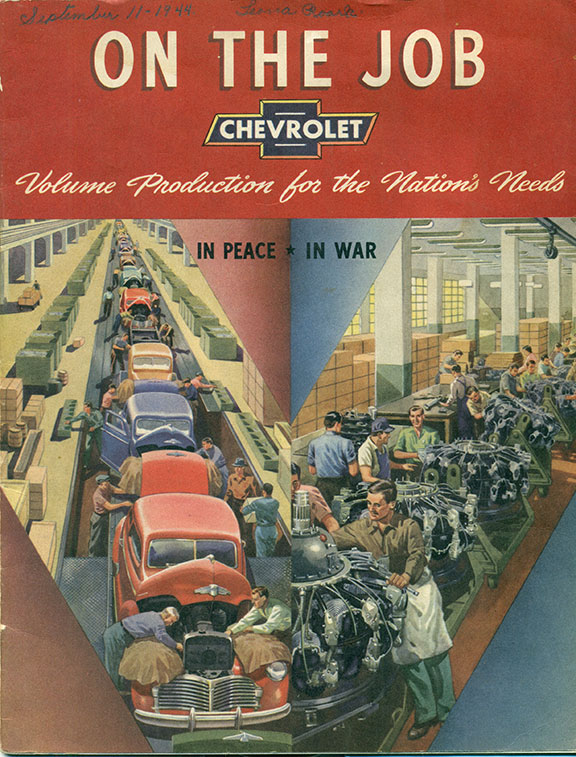

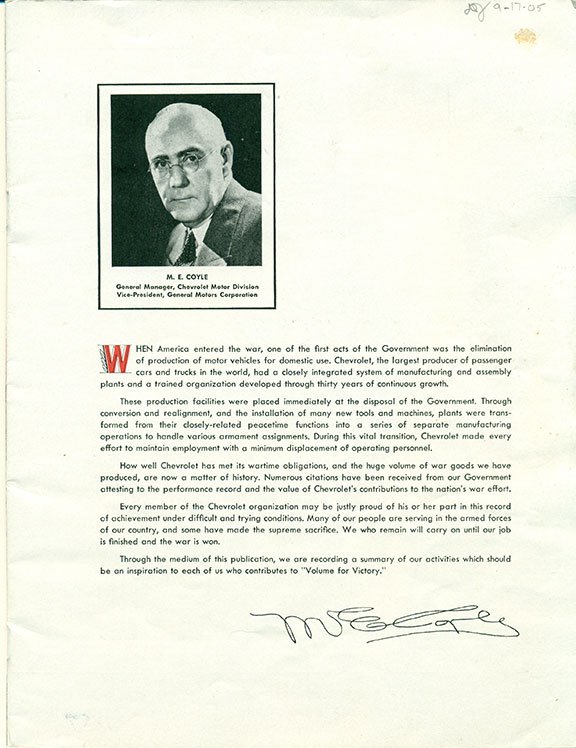

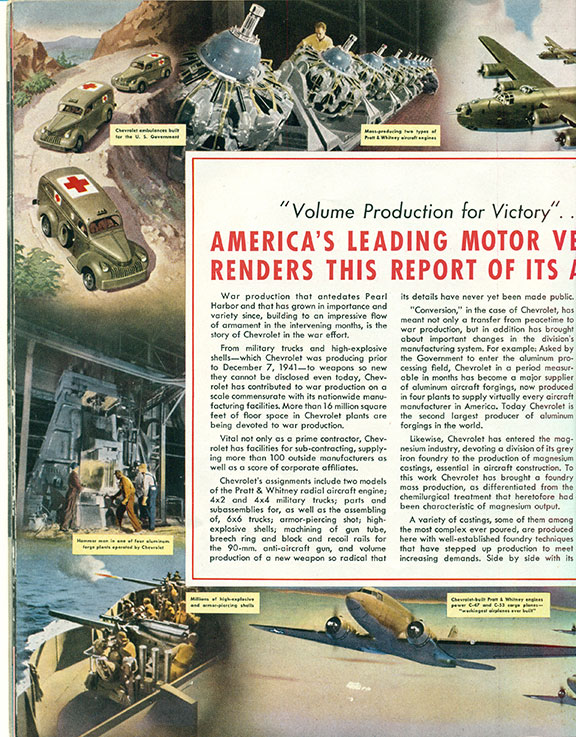

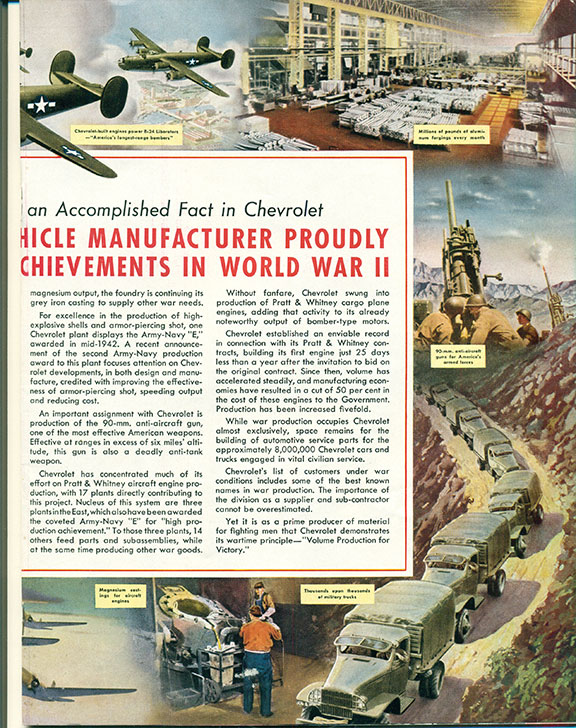

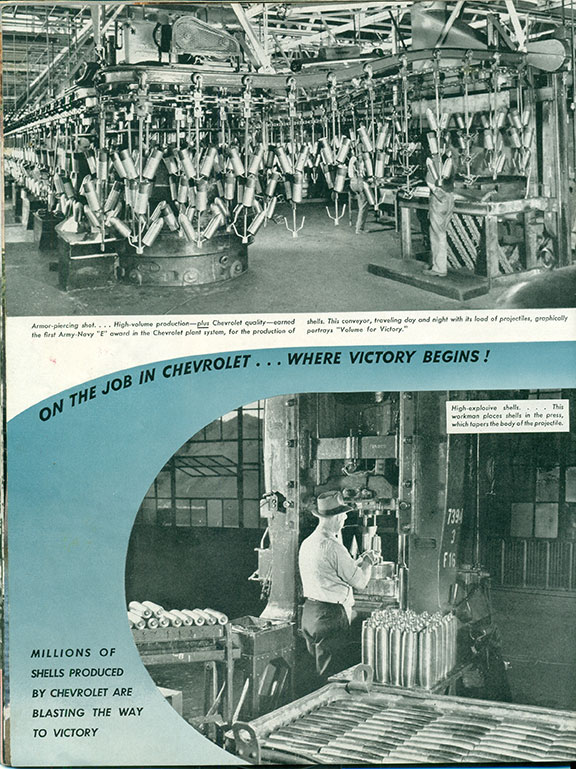

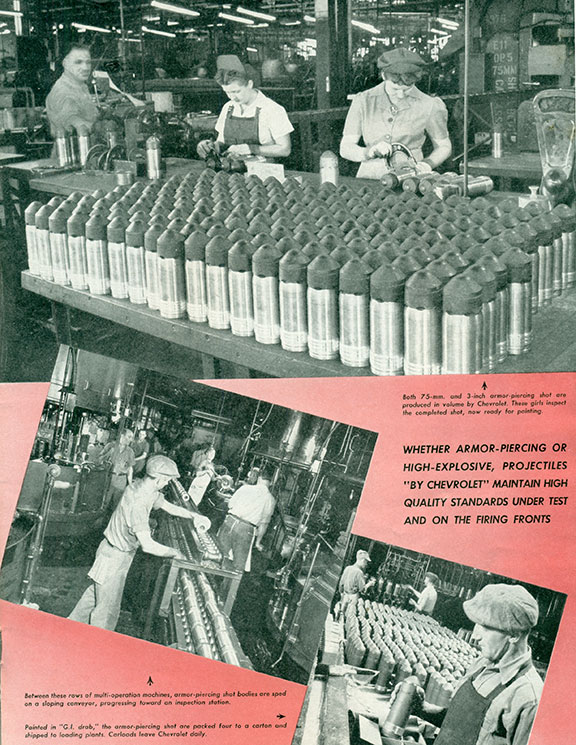

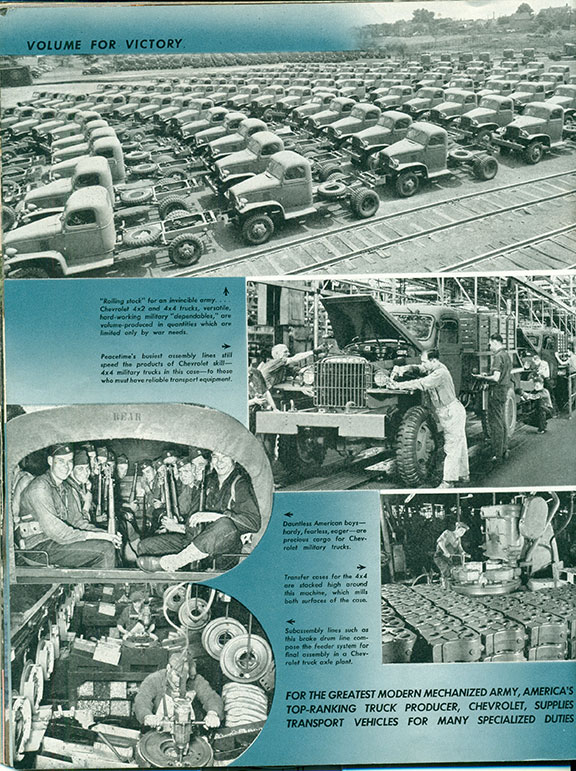

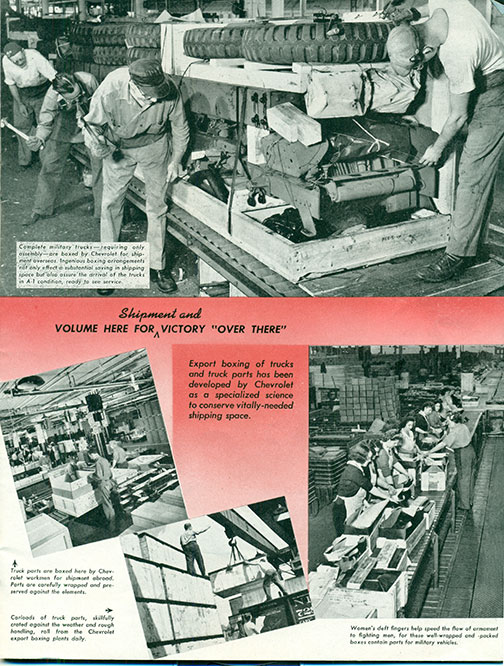

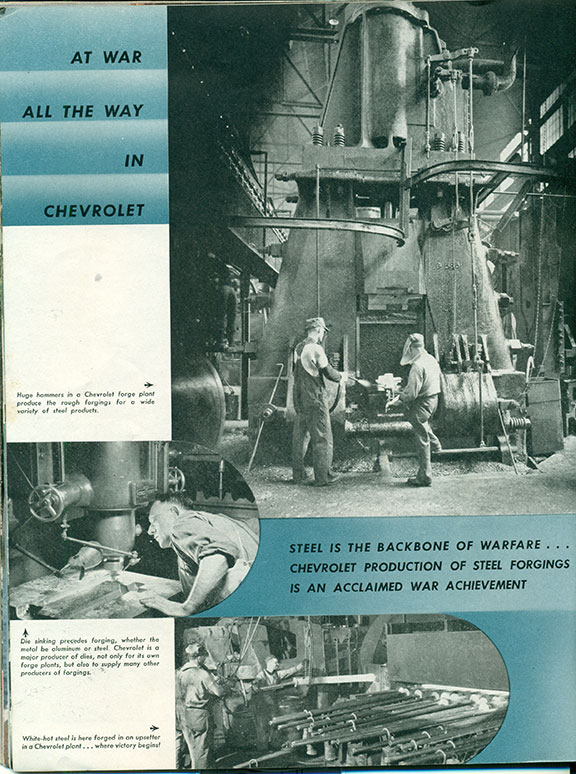

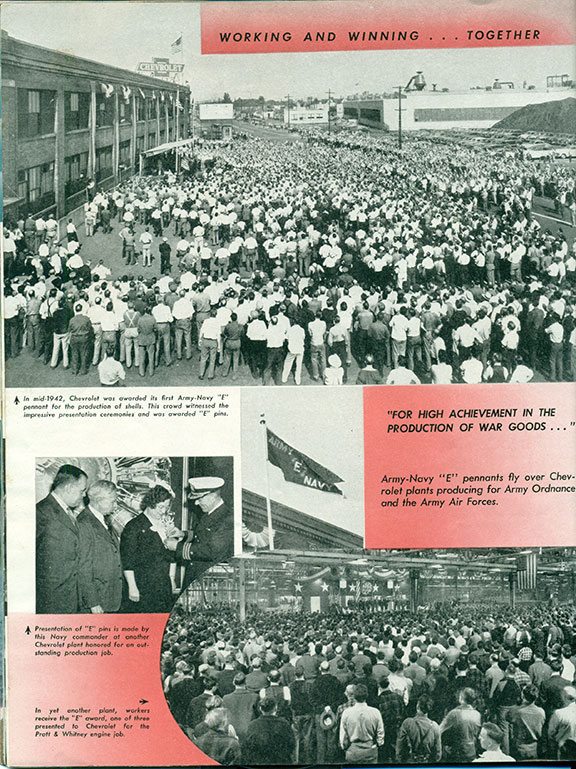

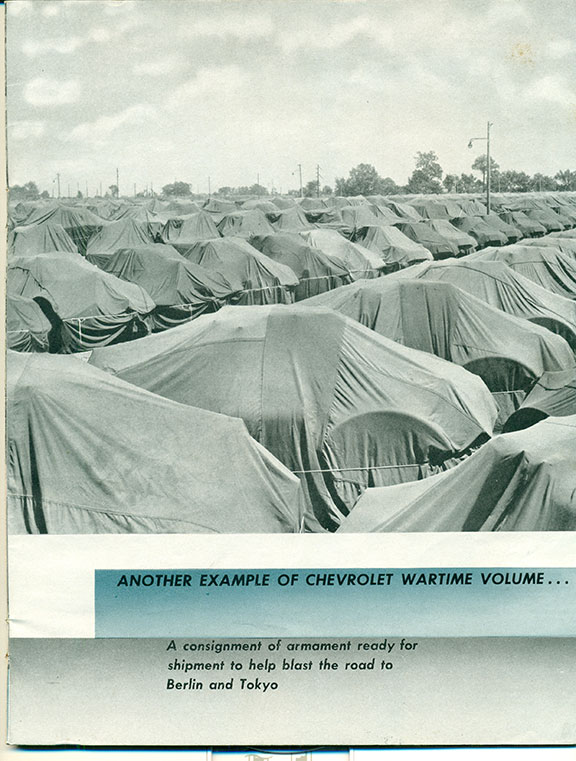

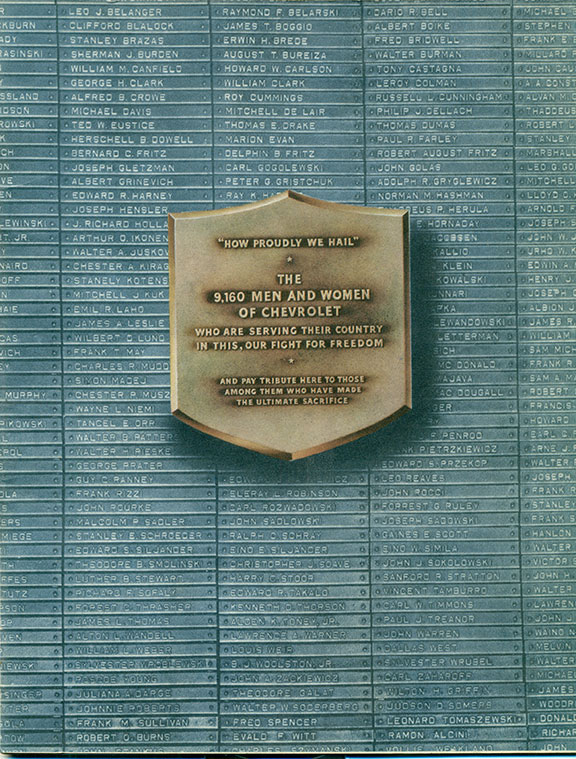

On the Job - Chevrolet

Volume Production for the Nation's Needs

This publication gives an excellent overview

of what Chevrolet did by those who worked there

during the Second World War. This was dated September 11, 1944.

|