|

Briggs

Manufacturing Company in World War Two

Detroit, MI

1909-1954

This page updated 5-6-2022.

Briggs Manufacturing Company was one of

several automotive body suppliers to the American automobile industry

during the first half of the 20th century. While the larger

vehicles manufacturers like General Motors had its own captive body

manufacturer with the Fisher Body Division, smaller vehicle

manufacturers like Chrysler and Packard purchased their automobile

bodies from Briggs. Other small vehicle manufacturers used other

dedicated body manufacturers.

Walter O. Briggs founded the company in 1909

after working for several coach builders and carriage upholstery

companies. Briggs Manufacturing got its big order in 1910 when

Ford Motor Company purchased 10,000 Model T bodies. In 1922 Briggs

introduced the first enclosed car body, a revolutionary idea at the

time. After that, it became a mass producer and specialty

body builder for many of the Michigan vehicle manufacturers of the early

automobile age. Ford was a big Briggs customer early on,

purchasing Ford Model T and A truck beds, enclosed Ford truck

cabs, and Model A bodies. Briggs supplied bodies for all of Ford's east

coast assembly plants from its Cleveland plant. Other customers

over the years included Hudson, Graham-Paige, Packard, DeSoto, Plymouth,

Dodge, Stutz, Marmon, and Pierce-Arrow. As the years progressed,

Ford became less of a customer while Chrysler became more important to

Briggs as its main customer.

After many years as Chairman of the Briggs

Manufacturing Company, Walter O. Briggs passed away in early 1952.

In 1954 the Briggs family sold the remaining share of its stock in Briggs

Manufacturing to Chrysler, which was its largest customer. This

gave Chrysler its own in-house body supplier. At the same time, the

Briggs Manufacturing Company passed into history and has been largely

forgotten. But between 1909 and 1954 it was the largest and most

influential of the independent body manufacturers in Detroit. Upon

his death, Walter O. Briggs was the richest person in Detroit.

Briggs Manufacturing World War One Military

Products:

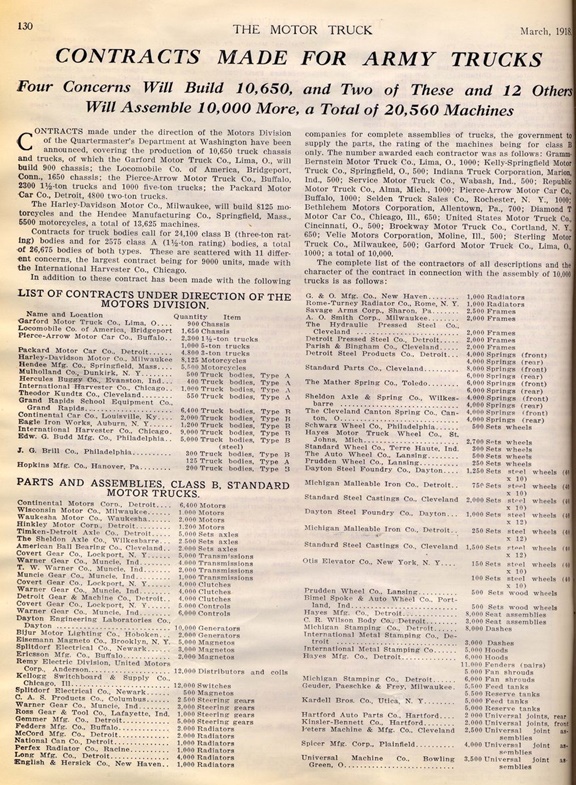

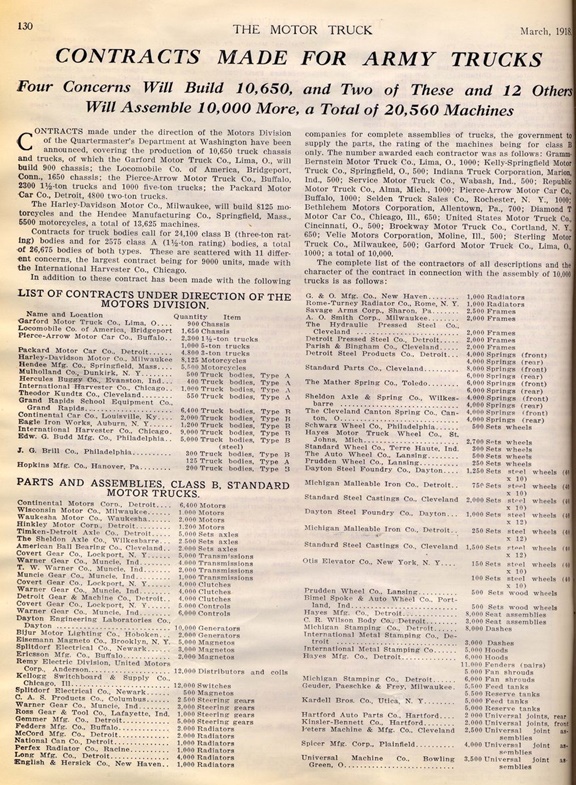

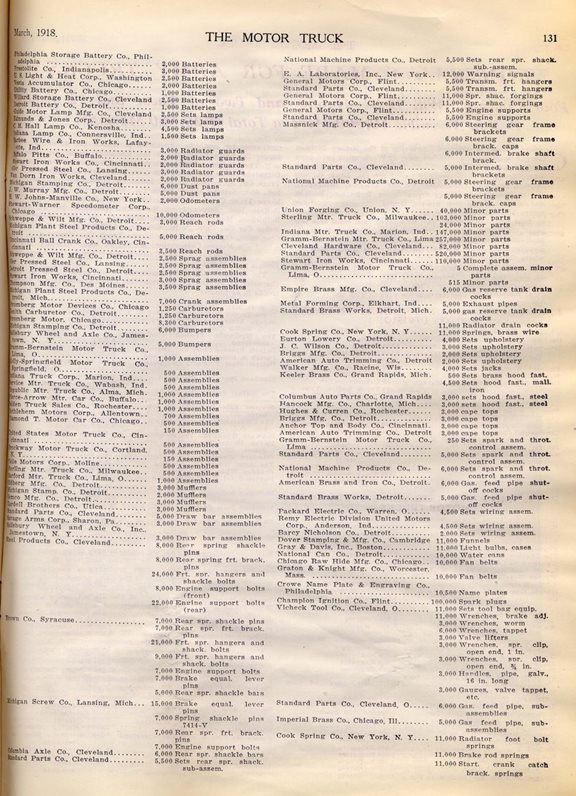

The two pages below are from the March 1918 issue of "The Motor Truck."

This provides invaluable information that reveals the types, numbers and

suppliers of motor vehicles and components that the U.S. Army

Quartermaster contracted for in World War One. The document shows

that Briggs was originally contracted for 2,000 sets of upholstery and

3,000 cape tops for the Class

B Liberty Truck..

The contracts were only partially fulfilled with the end of the war in

November 1919.

Document courtesy of Warren Richardson added

12-26-2020.

Document courtesy of Warren Richardson added

12-26-2020.

This

World War One Class B Liberty Truck has been restored to operating condition

by the First Division Museum in Wheaton, IL. The cape top over the

driver's seat is tied to the firewall with leather straps. Author's

photo added 12-26-2020.

This photo shows the cape top in more

detail. The seat is leather. Author's

photo added 12-26-2020.

For those unfamiliar with the automotive

technology of the early auto industry, the car bodies were normally

assembled in a separate body plant, often by a different company than where the final assembly of the vehicle

took place.

This came about due to the way the auto industry evolved in Michigan.

Inventors like R.E. Olds and Henry Ford were most concerned with the

drive train and the mechanical aspects of the vehicle. The auto

makers turned to the former coach and wagon makers in Michigan for the

building of the passenger body. Prior to the coming of the

automobile as a dominant industry in 20th century Michigan,

the state had been home to a large coach industry. Therefore, many

of the former coach builders became the builders of the original wooden

bodies for the fledgling car companies. Later, the technology turned to

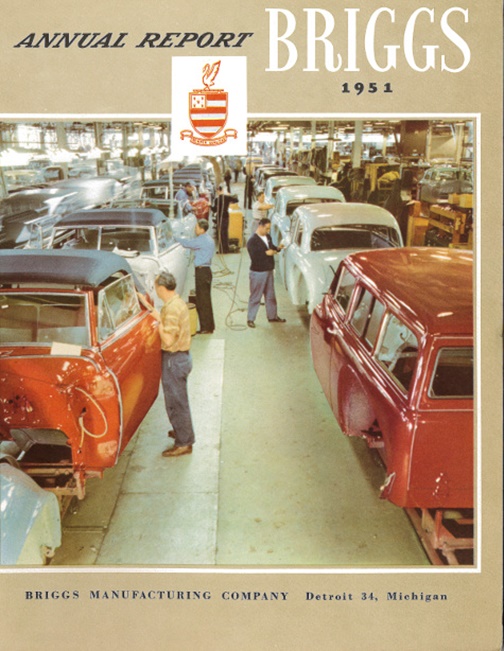

the steel bodies that are seen in the photo above.

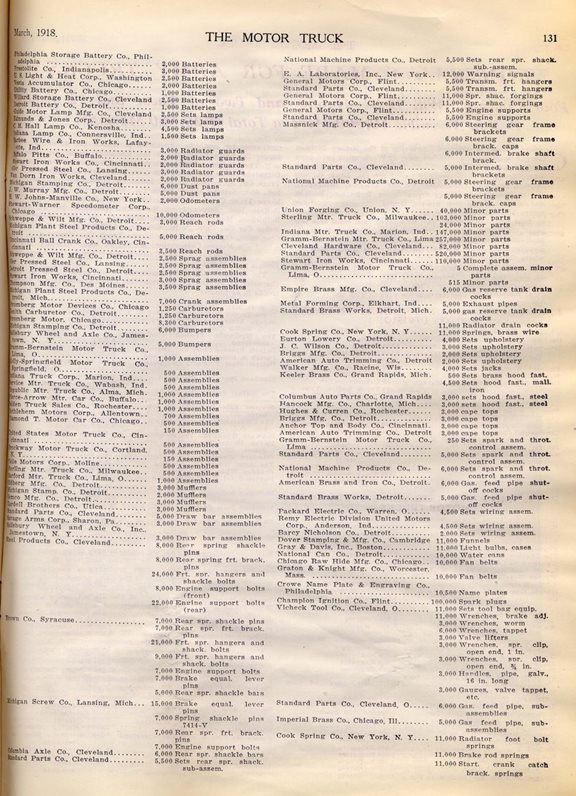

The photo above shows a typical body line in

the trim shop that could have been in any one of many body manufacturers

at the time. The line on the left appears to be all convertibles,

while the one on the right has a station wagon with several sedan bodies on it. Once completed,

the bodies would be loaded on a truck and transported to the vehicle

assembly plant. When ready, the body would be mated to the chassis

in a body drop.

This former display at the Studebaker Museum

illustrates the body drop. The body manufacturers installed all of the

carpeting, seats, door hardware, and windows along with all of the

upholstery. While a person may have been driving a Chrysler

vehicle prior to 1954, he was sitting in a

Briggs-build body. Author's photo.

In 1935 Briggs Manufacturing converted 200

Ford sedans into Ford Deliveries. These may have been the first

SUVs. The back seats could be removed for a flat area for carrying

cargo. Author's photo from the Ford V-8 Museum in Auburn, IN.

Author's photo.

Briggs and other body manufacturers would

have huge stamping presses for all of the body parts which would be welded together in the body shop. The assembled body

then would be moved to the paint shop and then proceed to the trim shop,

where all the upholstery would be installed. The body

manufacturers would have entire departments, or even plants, that were

responsible for the building of the seats that went into the vehicles.

To me, growing up in Michigan in the 1950s,

Briggs meant Briggs Stadium where the Detroit Tigers played baseball.

Walter O. Briggs was sole owner of the Detroit Tigers from 1935

until his death in 1952. His son sold the Tigers in 1956. I was unaware until I

started working on this page that Briggs Stadium was connected to a Briggs Manufacturing

Company.

Back when I was in grade school, my father would take me once or twice

per summer to a Detroit Tiger's baseball game at Briggs Stadium in

Detroit. This was before the days of interstate travel. I still remember my dad

driving Grand River Avenue,

a three lane road. from Lansing to Detroit and back. The middle

lane was for passing. Each direction of travel had a specified

alternating section to pass in. It was not as dangerous as trying

to pass on a two lane highway of the era, but it still could make for

some exciting times trying to get around a vehicle before the passing

zone ended.

I still remember some of the Detroit Tiger

baseball players from the era: Al Kaline was the big hitter for

the team and local superstar of the era. He played in the outfield

with Charlie Maxwell and Harvey Kuenn. Who could forget Rocky

Bridges at third base, Chico Fernandez at short stop, Hank McAuliffe at

second base, and Norm Cash at first base? I guess if there were

ever "good old days," going to Briggs Stadium with my father to watch my

favorite Detroit Tigers baseball player would be them.

The Briggs Stadium, later renamed Tiger

Stadium, was torn down in 1999 and replaced by a new stadium with new

owners. It will always be Briggs Stadium to me.

One of the Briggs Manufacturing Company's

main plants was at 11631 Mack Avenue in Detroit. It still exists

today as Chrysler's Mack Avenue Plant. Engines were produced there until 2012.

The plant is currently undergoing renovation to produce the next

generation Jeep Cherokee.

For several years, Briggs leased the former

Ford Highland Park Model T Plant when one of its plants was destroyed in a

fire. Briggs not only assembled Ford bodies in the plant, but

Chrysler bodies also. During World War Two, Ford built M4A3 Sherman

tanks and M10A Wolverine tank destroyers in the plant.

Briggs Manufacturing received the Army-Navy

"E" Award two times.

Briggs Manufacturing Company World War Two Military

Products: Briggs

Manufacturing Company had $173,559,000 in major war contracts during

World War Two from the U.S. Army and the U.S. Navy. Of the total

amount, $130,407,000 was for aircraft turrets for Army Air Force

multi-engine bombers. This was 75% of the total amount of major

contracts the company received. The first contract for aircraft

turrets was issued January 1942 and the last one was issued June 1944

and was completed in July 1945. Briggs Manufacturing was an

important suppler of aircraft turrets for the Army Air Force.

$4,074,000, or 2.3% of the

contracts were from the U.S. Navy.

The company also received a vast amount of

subcontracts from several aircraft manufacturers for airframe

components. These companies included Douglas, Goodyear, Grumman,

Martin, and Vought.

The 31,000 persons who worked at Briggs

Manufacturing Company during the war produced a multitude of components

to help win World War Two. It also made B-29 landing gear and bomb

bay doors, B-29 elevators, B-29 flaps, B-29 engine cowl sections,

and B-29 rudders. In 1945 it built 3,500 Knock-Down WC-64

ambulance bodies.

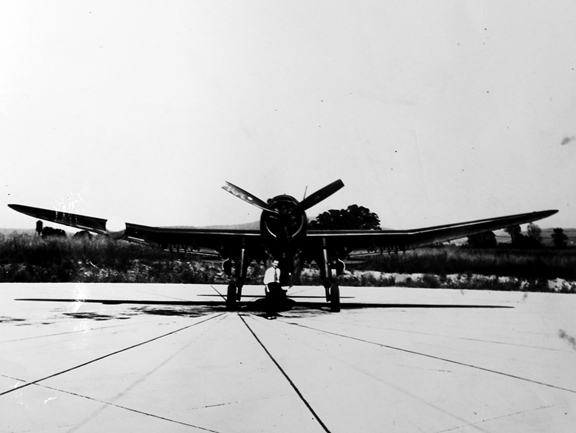

Briggs Indiana Corporation: This

body plant in Evansville, IN did final assembly on wings for several

Navy aircraft. Many, if not all of the components were fabricated

in the Detroit plant and shipped to Evansville for final assembly.

At the end of the war the Evansville plant had 4,000 employees making

wings for the FG-1 Corsair.

Table 1 - Briggs Manufacturing Company's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. This table added 5-6-2022. |

|

Product - Customer |

Contract Amount |

Contract Awarded

Date |

Completion

Date |

| Gun Turret

Assemblies - Army |

$29,912,000 |

1-1942 |

1-1943 |

| Cases

Cartridge - Army |

$5,248,000 |

1-1942 |

1-1942 |

| Model Engines

- Navy |

$55,000 |

6-1942 |

3-1943 |

| Tools - Army |

$8,603,000 |

7-1942 |

3-1943 |

| Turret

Assemblies - Army |

$133,000 |

7-1942 |

10-1942 |

| Cups - Army |

$995,000 |

8-1942 |

9-1943 |

| Gun Turret

Assemblies - Army |

$26,690,000 |

8-1942 |

11-1943 |

| Gun Turret

Assemblies - Army |

$10,226,000 |

9-1942 |

9-1943 |

| Training

Services - Army |

$519,000 |

10-1942 |

6-1944 |

| Cases

Cartridge - Army |

$1,204,000 |

10-1942 |

6-1943 |

| Tools Machine

Used - Army |

$104,000 |

11-1942 |

11-1942 |

| Welding

Equipment - Army |

$1,159,000 |

11-1942 |

5-1943 |

| Airpl Turret

Assemblies - Army |

$3,440,000 |

11-1942 |

3-1943 |

| Tools Machine

- Army |

$52,000 |

2-1942 |

3-1943 |

| Retraction

Mechanisms - Army |

$469,000 |

3-1943 |

5-1943 |

| Flame

Dampener Assys - Army |

$3,664,000 |

3-1943 |

12-1943 |

| Turret

Assemblies - Army |

$124,000 |

4-1943 |

4-1943 |

| Gun Turret

Assemblies - Army |

$12,561,000 |

5-1943 |

1-1945 |

| Droppable

Fuel Tanks - Navy |

$468,000 |

7-1943 |

9-1943 |

| Technical

Services - Army |

$120,000 |

8-1943 |

6-1945 |

| Droppable

Fuel Tanks - Navy |

$543,000 |

10-1943 |

12-1943 |

| Airplane

Turrets - Army |

$141,000 |

10-1943 |

11-1943 |

| Airplane

Parts - Army |

$150,000 |

10-1943 |

6-1944 |

| Fuel Tank

Assemblies - Navy |

$1,269,000 |

12-1943 |

5-1944 |

| Fuel Tanks -

Army |

$15,358,000 |

1-1944 |

5-1945 |

| Gun Turret

Assemblies - Army |

$2,556,000 |

1-1944 |

1-1944 |

| Airplane

Turrets - Army |

$9,818,000 |

1-1944 |

4-1945 |

| Dropbl Fuel

Tanks - Navy |

$1,026,000 |

1-1944 |

8-1944 |

| Airplane

Turrets - Army |

$70,000 |

2-1944 |

6-1945 |

| Gun Turret

Assys - Army |

$20,471,000 |

2-1944 |

4-1945 |

| Modify Gun

Turrets - Army |

$53,000 |

6-1944 |

10-1944 |

| Airpl Turret

Assys - Army |

$3,500,000 |

6-1944 |

3-1945 |

| Airplane

Turret Parts - Army |

$94,000 |

6-1944 |

4-1945 |

| Airplane

Turrets - Army |

$10,765,000 |

6-1944 |

7-1945 |

| Technical

Services - Navy |

$84,000 |

7-1944 |

6-1945 |

| Technical

Services - Navy |

$75,000 |

7-1944 |

6-1945 |

| Dropbl Fuel

Tanks - Navy |

$554,000 |

8-1944 |

8-1945 |

| Airplane

Turret Rprs - Army |

$90,000 |

12-1944 |

6-1945 |

| Cart Storage

Cases M13 - Army |

$781,000 |

1-1945 |

6-1945 |

| Rocket Band

Assemblies - Army |

$236,000 |

1-1945 |

3-1945 |

| Termination

Charges - Army |

$59,000 |

3-1945 |

8-1945 |

| Total |

$173,559,000 |

|

|

This Briggs Manufacturing Company data plate

is on a rebuilt wing for an FG-1 Corsair restoration at the Tri-State Warbird

Museum in Batavia, OH. The data plate appears to

be an unused example, and not the original that was on the wing.

However, this is an excellent example of a Briggs Manufacturing Company

data plate. Also, the data plate may only indicate that the

components were fabricated in Detroit, as Evansville, IN was the final

assembly point for the FG-1 wings. Author's photo.

Aircraft Gun Turrets:

Table 2 - Briggs Manufacturing Company's

Major World War Two Aircraft Gun Turret Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. This table added 5-6-2022. |

|

Product - Customer |

Contract Amount |

Contract Awarded

Date |

Completion

Date |

| Gun Turret

Assemblies - Army |

$29,912,000 |

1-1942 |

1-1943 |

| Turret

Assemblies - Army |

$133,000 |

7-1942 |

10-1942 |

| Gun Turret

Assemblies - Army |

$26,690,000 |

8-1942 |

11-1943 |

| Gun Turret

Assemblies - Army |

$10,226,000 |

9-1942 |

9-1943 |

| Airpl Turret

Assemblies - Army |

$3,440,000 |

11-1942 |

3-1943 |

| Turret

Assemblies - Army |

$124,000 |

4-1943 |

4-1943 |

| Gun Turret

Assemblies - Army |

$12,561,000 |

5-1943 |

1-1945 |

| Airplane

Turrets - Army |

$141,000 |

10-1943 |

11-1943 |

| Gun Turret

Assemblies - Army |

$2,556,000 |

1-1944 |

1-1944 |

| Airplane

Turrets - Army |

$9,818,000 |

1-1944 |

4-1945 |

| Airplane

Turrets - Army |

$70,000 |

2-1944 |

6-1945 |

| Gun Turret

Assys - Army |

$20,471,000 |

2-1944 |

4-1945 |

| Airpl Turret

Assys - Army |

$3,500,000 |

6-1944 |

3-1945 |

| Airplane

Turrets - Army |

$10,765,000 |

6-1944 |

7-1945 |

| Total |

$130,407,000 |

|

|

Sperry A2B Ball Turret for the B-17: This was the defensive

gun position in the belly of the B-17.

This is the B-17F Memphis Belle on display

at the National Museum of the United States Air Force. Author's

photo added 5-6-2022.

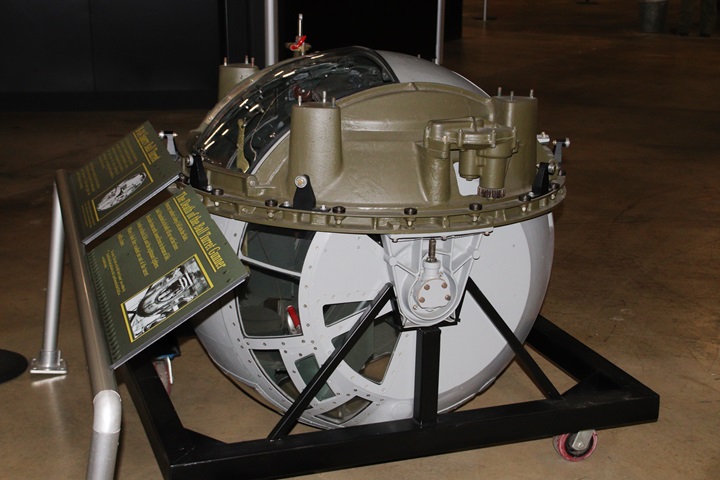

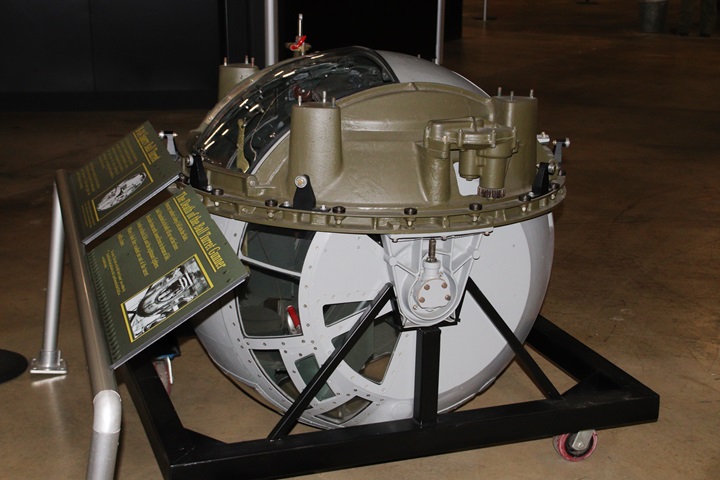

This is a Sperry A2B lower gun turret like

Briggs manufactured. Author's photo added 5-6-2022.

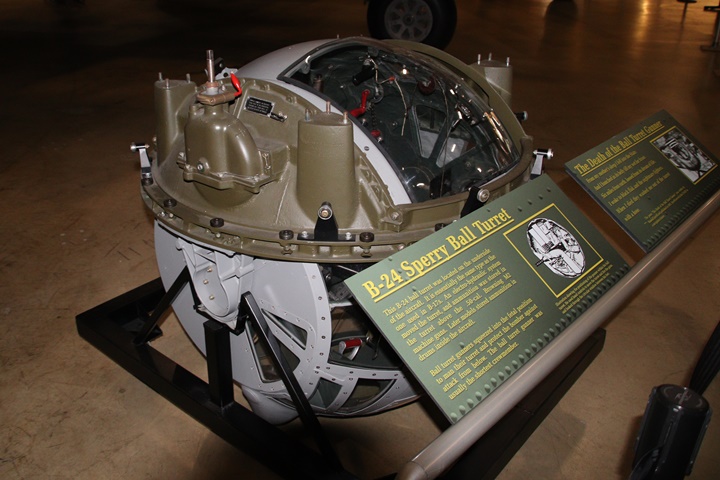

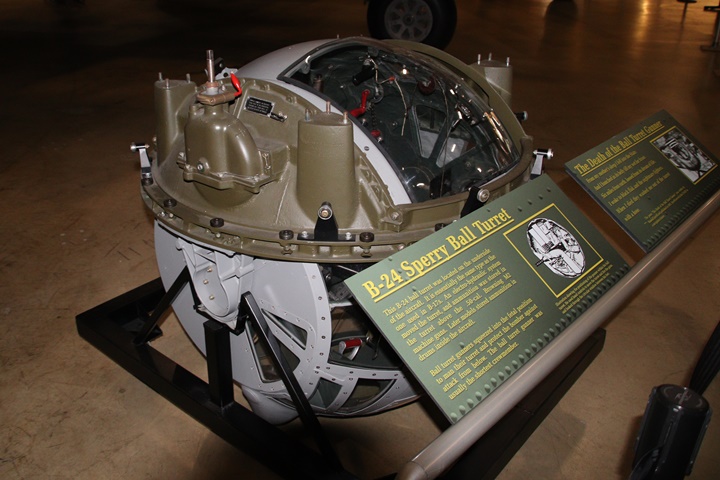

Sperry A13 Ball Turret for the B-24: This was the defensive gun position in the belly of the B-24. It

was located inside the aircraft during take-offs and landings. It

was then lowered once the aircraft took off.

There was not enough clearance for the aircraft to take-off or land with the turret

in the lowered position.

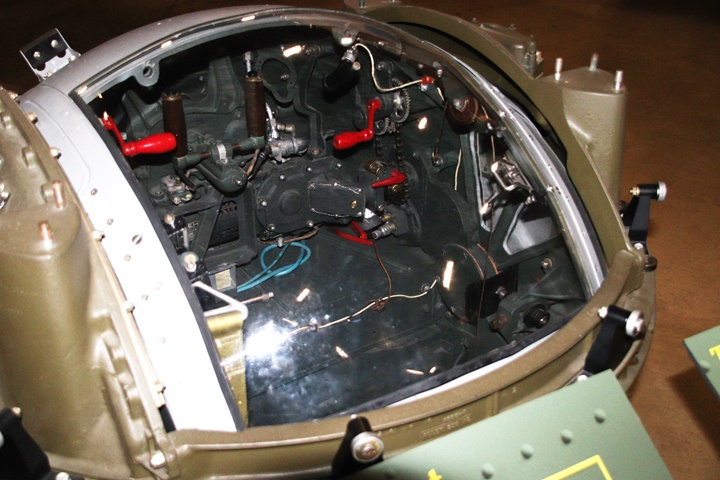

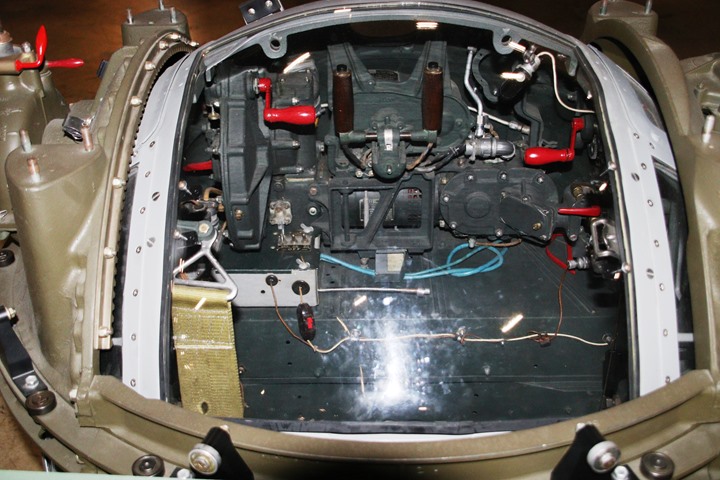

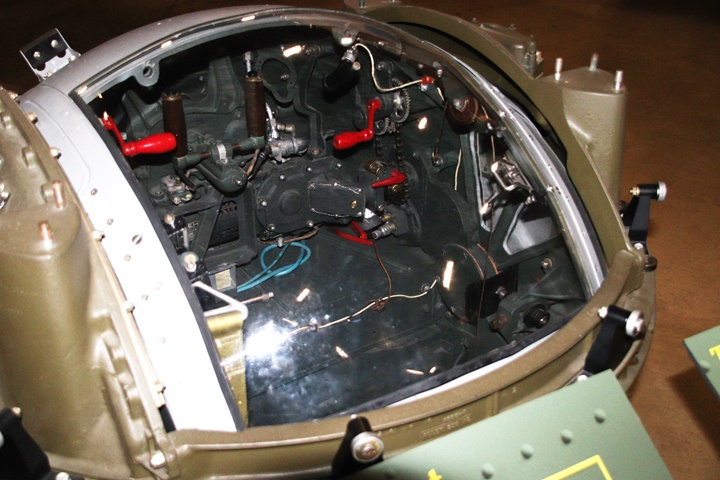

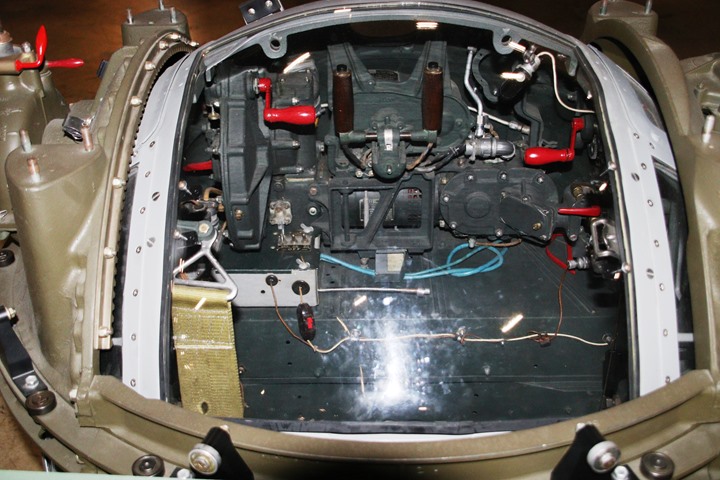

The following photos show two Sperry ball turrets at the National Museum

of the United States Air Force Dayton, OH. The first two photos

show them in the restoration area where they were being worked on.

The rest of the photos show one of them on display on the museum floor.

It is unknown whether Sperry, Briggs, or some other company built these.

The photos do show the detail and complexity of the turret.

Author's photo.

Author's photo.

Author's photo.

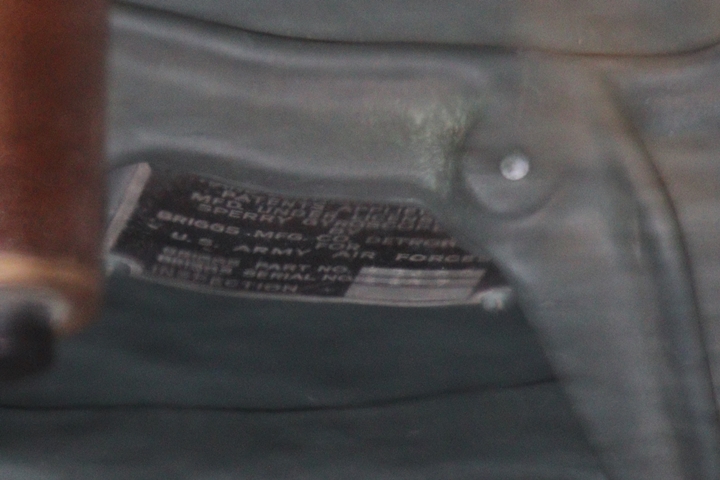

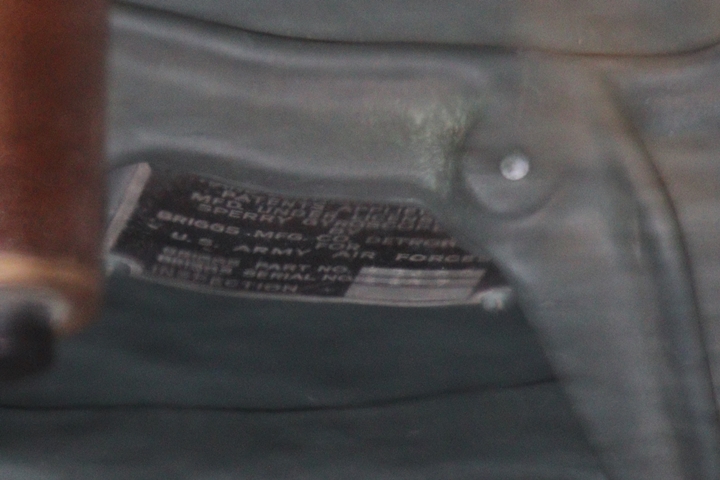

Looking all the way to the front of the

turret between the brown control handles is a data plate. Author's photo.

A 180 degree rotation of a close-up photo of

the data plate reveals that this turret was built by Briggs

Manufacturing Company. Author's photo added 5-6-2022.

Author's photo.

Author's photo.

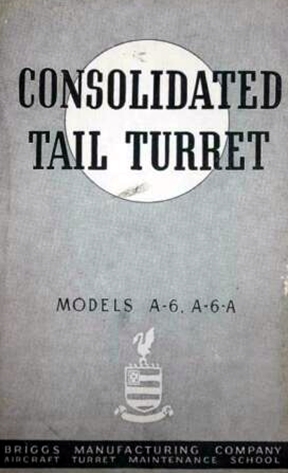

Consolidated Tail Turret A-6 and A-6A -

Historical evidence shows that Briggs held training sessions for the

Consolidated tail turret. This implies that the company was also

building this turret for the B-24. Both the Sperry and

Consolidated turrets were installed in the B-24s being built by

Ford at Willow Run, MI.

The Consolidated B-24 tail gun turret on this Ford-built B-24J

on display at the at the Barksdale Global Power Museum at Barksdale AFB

in Bossier City, LA looks very much like one in the photo above.

Ford built 6,790 B-24 at its Willow Run, MI plant outside of Detroit.

It was the nearest B-24 assembly plant to Motor Products Corporation.

Most likely Motor Products Corporation was the main supplier of A6 and

A6Arear

turrets to Ford. Author's photo added 5-6-2022.

Author's photo added 5-6-2022.

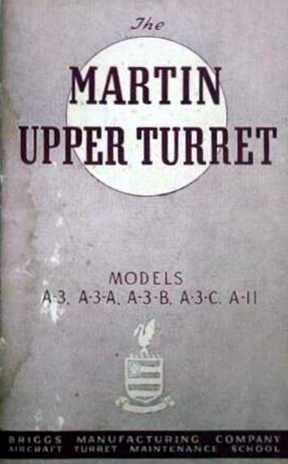

Martin Upper Turret A-3 Series:

Historical evidence shows that Briggs held training sessions for the

Martin upper turret. This implies that the company was also

building this turret for the B-26.

This Martin B-26 turret is under restoration

at the MAPS Museum in Canton, OH. It will be installed in the

museum's B-26. Author's photo added 5-6-2022.

When fully restored, the turret will go in

the location of the patch on the aircraft. Author's photo added

5-6-2022.

Aircraft Components:

B-17G: Outer wings, wing tips, stabilizers, fins, ailerons,

flaps, ducts, ducting for air flow for the turbocharger system, and bomb bay

doors. Each bomb bay door used six

hundred parts and 5,400 rivets

Author's photo.

A-20G: Outer wings, wing tips, ailerons

A Douglas A-20G on display at the National

Museum of the United States Air Force Dayton, OH. Author's photo.

This photo shows the Briggs-built wing tip,

wing, and aileron. Author's photo.

B-26C: Bomb bay doors, bulkheads,

Martin top turrets

A Martin B-26 is on display at the National Museum

of the United States Air Force Dayton, OH. Author's photo.

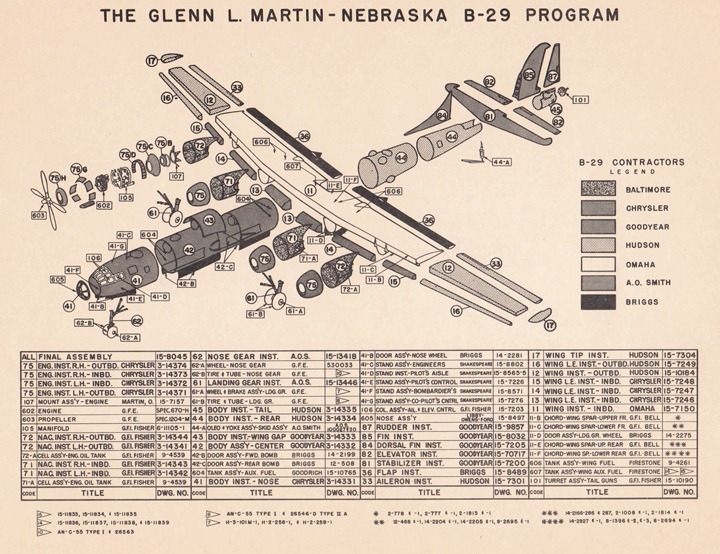

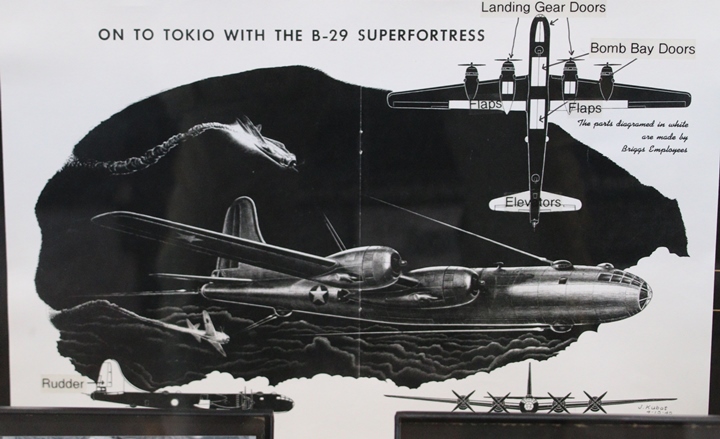

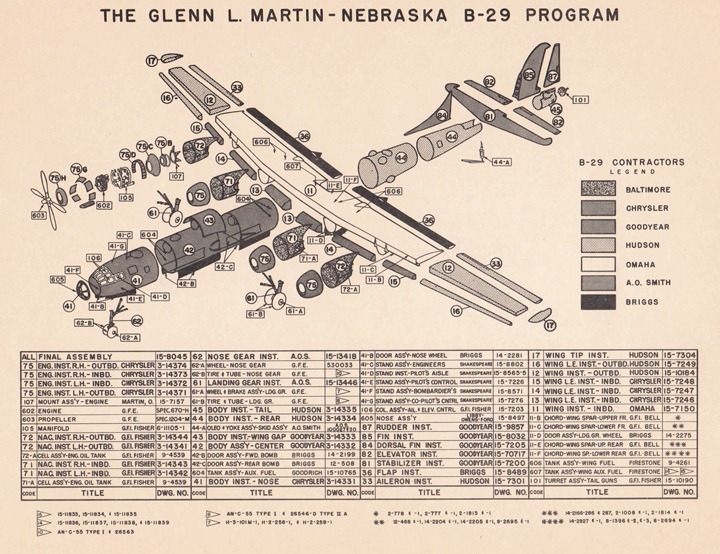

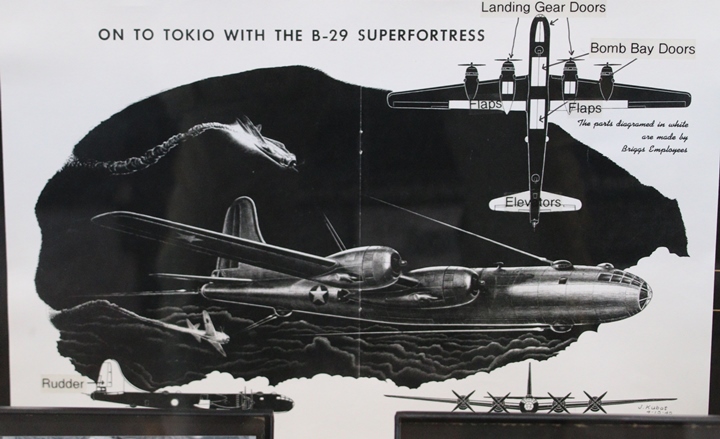

B-29: Flaps, forward and aft bomb bay doors, nose wheel doors, outer

wings, dorsal fins, and stabilizers.

Briggs supplied the forward and rear bomb bay door assemblies, the nose

wheel door assemblies, the main landing gear door assemblies, and the

flaps to the Martin B-29 plant in Omaha, NE. The Omaha B-29 plant

built and modified all of the B-29s that were designated to carry the

new atomic bomb. Briggs Manufacturing-built B-29 components were

on the aircraft that bombed Hiroshima and Nagasaki.

This World War Two Briggs document indicates

that the company was also building B-29 elevators and rudders.

There were three other final assembly plants besides the Martin plant in

Omaha, NE that produced the B-29 that Briggs could have supplied these

airframe components to. Image added 5-6-2022.

This is the Enola Gay at the Udvar-Hazy Center at Dulles Airport in

Virginia. The Briggs-built flaps can be seen in the down position

along the rear of the wings. Author's photo.

This photo gives a view of the starboard

side flap from the rear. The flap is almost as long as the P-47

underneath it. Author's photo.

This is the B-29 "Bockscar" that dropped the

second atomic bomb in World War Two and is on display at the National

Museum of the United States Air Force. In this photo, the

Briggs-built nose gear doors and forward bomb bay doors can be seen.

Author's photo.

This shows the rivet pattern on the exterior

of the Briggs-built main gear door. Author's photo.

The inside of the main gear door was also covered with aluminum.

Author's photo.

This is a close-up photo of the forward bomb

bay doors. Author's photo.

OS2N-1: Wings

In 1942 Briggs supplied 300 sets of wings for the

Naval Aircraft Factory's version of the Vought OS2U Kingfisher.

This OS2U-3 is on display at the Udvar-Hazy Center of the National Air

and Space Museum. There are no surviving Naval Aircraft

Factory-built OS2N-1s still in existence. Author's photo added

9-29-2021.

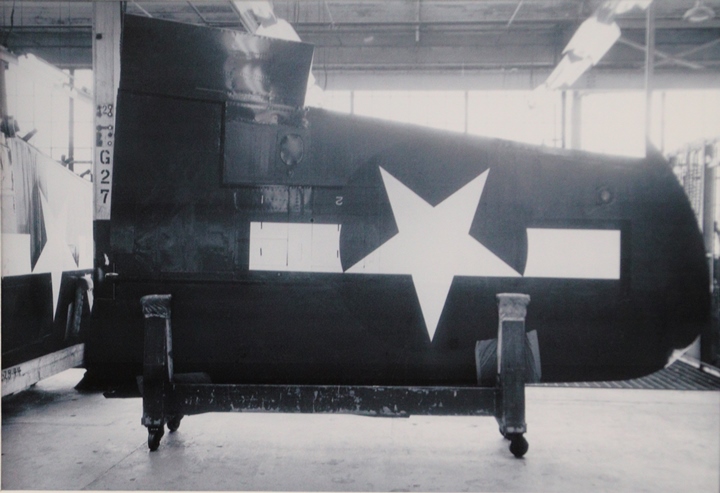

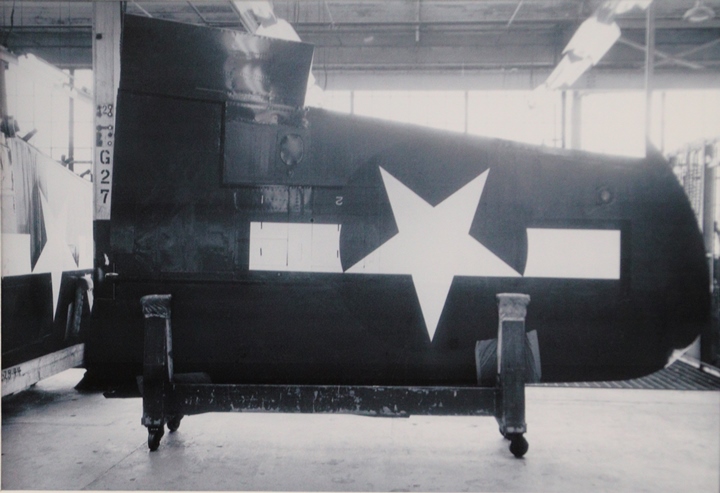

FG-1: Wings

The FG-1 wing components appear to have been

built in the Detroit plant and then assembled by Briggs Indiana

Corporation in Evansville, IN. The data plate below specifically

denotes that the associated wing was built by the Airplane Parts

Division of Detroit, MI.

The Vought F4U Corsair was flown by the U.S. Navy and USMC. Goodyear built the Corsair under license

as the FG-1. Author's photo.

This Corsair is in long-term restoration at

the Tri-State Warbird Museum in Batavia, OH. The wing in the

background has the Briggs data plate on it. Author's photo.

This photo shows that Briggs was building

wings for Goodyear of Akron, OH. It stands to reason, as both were part

of the auto industry. If

Briggs built all of the wings for the Goodyear FG-1s, it would have

been able to provide 4,007 wing sets. Author's photo.

The data plate can be seen about one-third

of the way up in the wing end. Author's photo.

Aircraft Drop Tanks: Briggs had

four contracts from the Navy and one from the Army Air Force for

disposable drop tanks.

The drop tanks Briggs made would have been

similar to this. Author's photo added 5-6-2022.

Truck body parts: Unspecified cabs, tops, and ambulance bodies

- Dodge was the primary builder of military ambulances during World War

Two.

The WC-64 was the Army's replacement for the

WC-54. The concept was to provide a field ambulance that did not

take as much room to ship overseas. The steel cab of the WC-54 was

replaced with a fold-down windshield and canvas roof. Briggs

developed the ambulance body that was shipped as a knock-down.

When it arrived in the theater of operations, the ambulance body was

assembled. With this configuration, more WC-64s could be stacked

inside a ship's cargo area. Briggs built 3,500 of these in

1945. Author's photo added 10-27-2020.

This is the only WC-64 I have found to

date. The WC-64 arrived too late to serve in World War Two.

It was provided extensively to American allies after World War Two.

This rare example was on display at the Indiana Military Museum's 2014

World War Two Days. The Briggs design had a wider body which

allowed for easier loading and unloading of litter patients that the

previous WC-54. Author's photo added 10-27-2020.

Author's photo added 10-27-2020.

The Briggs design used threaded fasteners to

assemble the body. Author's photo added 10-27-2020.

Author's photo added 10-27-2020.

M26 Pershing Heavy Tank: Tank hulls (90mm and 105mm models)

- The historical record shows Briggs making M26 tank hulls during the

war. This does not make sense, as this does not fit into the company's specialized

expertise. It stamped out sheet metal and then welded or riveted it

together for automobile, truck bodies, or aircraft parts.

Fabricating tank hulls would have required a foundry operation which

would have been considerably outside the expertise and experience of the

company.

There is nothing in the historical record that indicates the Briggs

Manufacturing Company ever purchased or operated a foundry. If it

actually did get into the foundry business, the hulls would have been for the Chrysler Tank Arsenal, as they included

hulls for the 105mm howitzer version. Only Chrysler built this

model. Also, Chrysler was Briggs most important non-war customer.

Chrysler eventually purchased Briggs in 1954.

This is a Chrysler-built M26 Pershing.

The manufacture of the hull was outside the specialized expertise of the

Briggs Manufacturing Company. Author's photo.

Briggs Motor Bodies, Ltd. in the United

Kingdom during World War Two: Briggs had two plants in England

during World War Two. One was at Dagenham and the other at

Doncaster. Briggs was in the U.K. initially to supply bodes to the

local Ford Motor Company plant. It also produced bodies for

Austin, Chrysler and others. During World War Two Briggs in the

U.K. manufactured at a minimum steel helmets and jerry-cans.

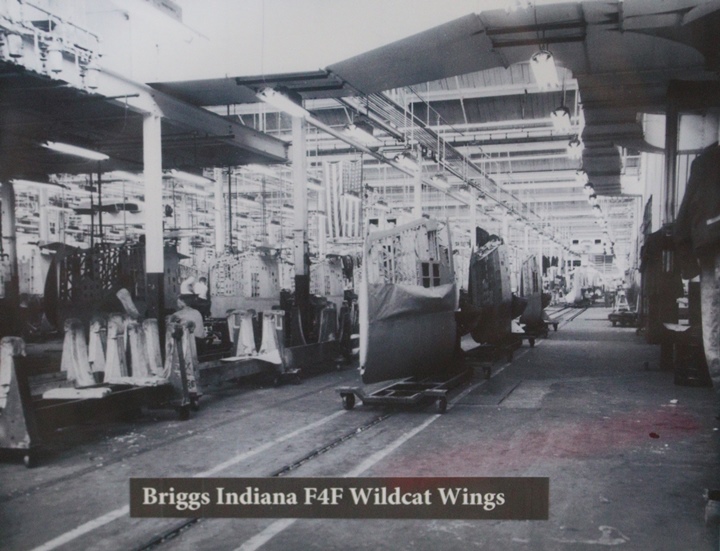

Briggs Indiana Corporation: This

plant was located in Evansville, IN to provide bodies for the Chrysler

Plymouth car assembly plant located there. During World War Two,

the Briggs Evansville plant assembled wings for the PBY, TBY, FG-1, and

F4F U.S. Navy aircraft.

This information was unknown to me until I

visited the Evansville War Time Museum in April 2022. The

information at the museum shows that many of the aircraft components

associated with the parent company's plant in Detroit were actually

assembled in Evansville. The production line photos of the Briggs

Evansville Corporation plant are from displays at the Evansville War

Time Museum.

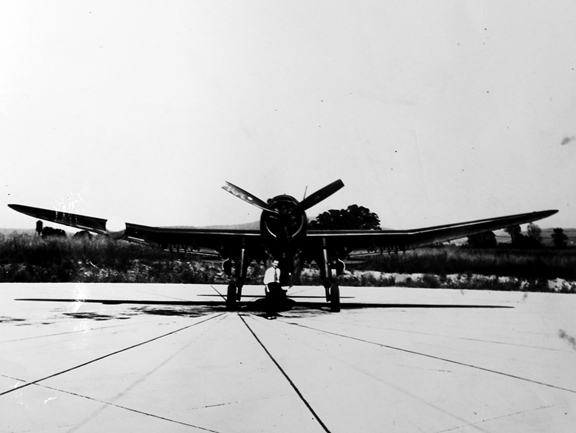

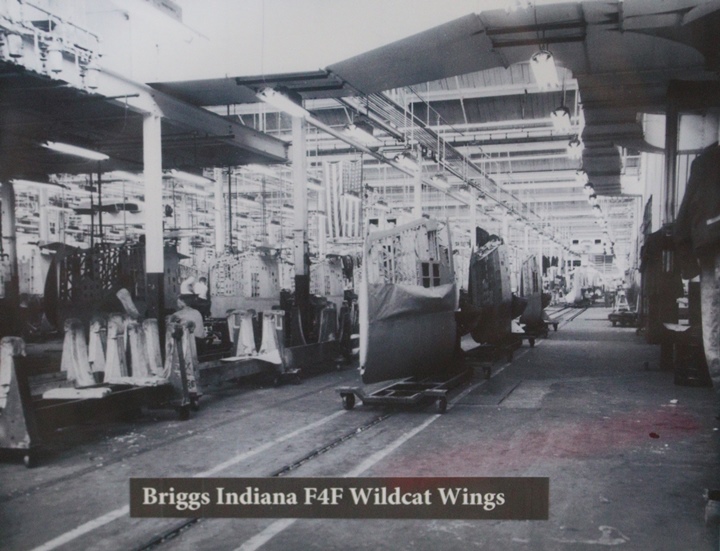

Early in World War Two Briggs Indiana produced

wings for the Grumman F4F Wildcat. Production would not have

started until mid or late 1942 due to having to build the tooling.

Production of the F4F wings would have then run until mid 1942 when

Goodyear would have been ramping up production of the FG-1. Briggs

Indiana Corporation ended F4F wing production and started FG-1 wing

production. In March 1945, Briggs Detroit was supplying parts to

Evansville for the FG-1 and TBY. In August 1945, 4,000 Evansville

employees were assembling wings for the FG-1.

F4F Wildcat: Table 2 shows the

F4F Wildcat production starting in July 1942 and ending February 1943.

Briggs would not have been ready any sooner than July 1942 to build the

wings in order to tool for mass production. In March 1943, Grumman

stopped building the F4F when the Eastern Aircraft Division of General

Motors took over the production. Briggs built approximately 991

wing sets for the Grumman Wildcat.

|

Table 2 - Grumman F4F Wildcat Production |

| Date |

Quantity |

| 7-1942 |

100 |

| 8-1942 |

135 |

| 9-1942 |

127 |

| 10-1942 |

163 |

| 11-1942 |

197 |

| 12-1942 |

175 |

| 1942 Total |

897 |

| |

|

| 1-1943 |

38 |

| 2-1943 |

54 |

| 1942 Total |

94 |

| Grand

Total |

991 |

This F4F-3 with Briggs Indiana

Corporation-built wings is on display at the Cradle of Aviation Museum

in Long Island, NY.

Author's photo added 5-6-2022.

This F4F-3A is on display in the hangar deck

of the USS Yorktown at Patriots Point in South Carolina. The wings

were built in Evansville, IN by Briggs. Author's photo added

5-6-2022.

This photo shows the F4F wing assembly

lines. Image added 5-6-2022.

Grumman produced the F4F Wildcat series

aircraft until early 1943 when the Eastern Aircraft Division of General

Motors took over production as the FM-1 and FM-2. Image added

5-6-2022.

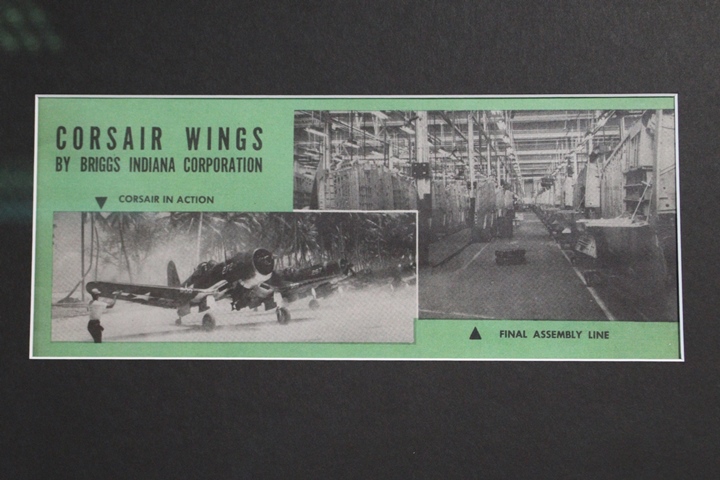

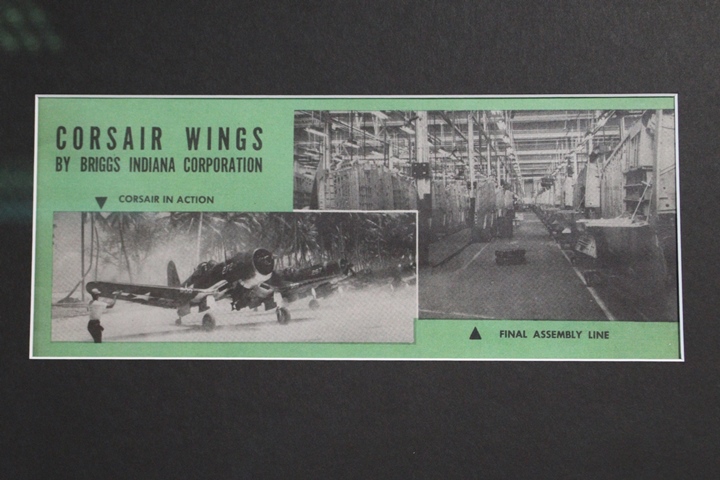

FG-1: In the 1945 Goodyear built

1,521 FG-1 Corsairs for the Navy. This averaged out to 190 wing

sets per month Briggs Indiana Corporation built to keep the Goodyear

production line running.

This image from a Briggs Indiana Corporation

Document shows the final assembly line for Corsair Wings. It

appears to be from the same location as the previous photo of the F4F

line. Image added 5-6-2022.

The Corsair wings were last product

made by the company in World War Two. Production continued until

the war ended in August 1945. Image added 5-6-2022.

Image added 5-6-2022.

Author's photo added 5-6-2022.

TBY: Only 180

Consolidated TBYs were built in Allentown, PA during World War Two.

By the time the TBY went into production, the General Motors-built TBM

had established itself as an effective torpedo bomber, of which

sufficient quantities were available. Also, the U.S. Navy was

running out of Japanese naval targets to attack. Therefore, Briggs

Indiana Corporation only built wing sets for 172 TBY aircraft.

|

Table 3 - TBY Production |

| Date |

Quantity |

| 11-1944 |

1 |

| 12-1944 |

1 |

| 1-1945 |

8 |

| 2-1945 |

6 |

| 3-1945 |

11 |

| 4-1945 |

14 |

| 5-1945 |

20 |

| 6-1945 |

33 |

| 7-1945 |

31 |

| 8-1945 |

41 |

| Total |

174 |

Photo courtesy of the Mack Museum.

The folded wings on the TBYs coming down the production line show the

size of its wing in Allentown, PA with Evansville, IN-built wings. Photo courtesy of the Mack Museum.

PBY:

Briggs Indiana built an unknown number of

outer wing sections for the Consolidated PBY. Author's photo.

The Plant: The Briggs Indiana

Corporation was located at 830 East Columbia Street in Evansville, IN.

This was not far from the Plymouth plant for which it supplied bodies to

in peacetime. In 1954 the plant became part of Chrysler

Corporation when it purchased the Briggs Manufacturing Company of

Detroit.

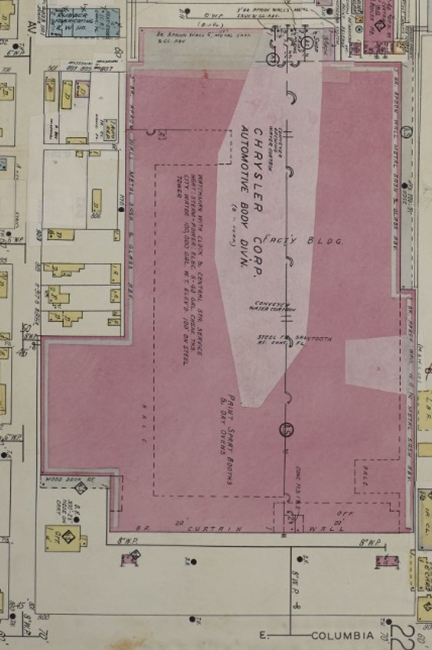

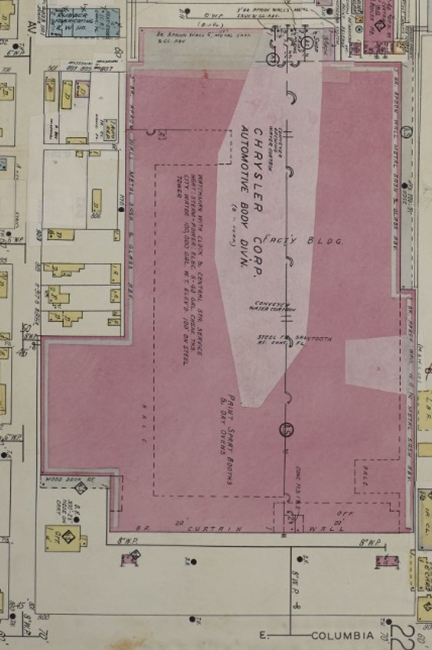

This 1962 Sanborn maps shows the 820 East

Columbia Street location of the former Briggs Indiana Corporation plant.

Image added 5-6-2022.

This Google Maps satellite image shows the

factory is still standing and in use today. Image added 5-6-2022.

Eighty years after the former Briggs Indiana

Corporation built wings for several U.S. Navy aircraft to help win World

War Two, the plant still looks good. Google Maps image added

5-6-2022.

|