|

Marmon-Herrington Company in World War Two

Indianapolis, IN -

1931-1963

Louisville, KY - 1963 to present

This page updated 11-28-2024.

Fifty-five years after

Marmon-Herrington closed its plant in Indianapolis, one of the two

remaining factory buildings still has Marmon-Herrington

painted on it. The rest of the plant has been torn down

and repurposed as the headquarters for the IndyGo municipal bus

service. The name Marmon-Herrington on the side of the building

shows no weathering. It looks so good that it would appear IndyGo

has repainted the name and maintained it. Either that, or the painting has been

done by an Indianapolis industrial historian. Author's photo added 9-29-2019.

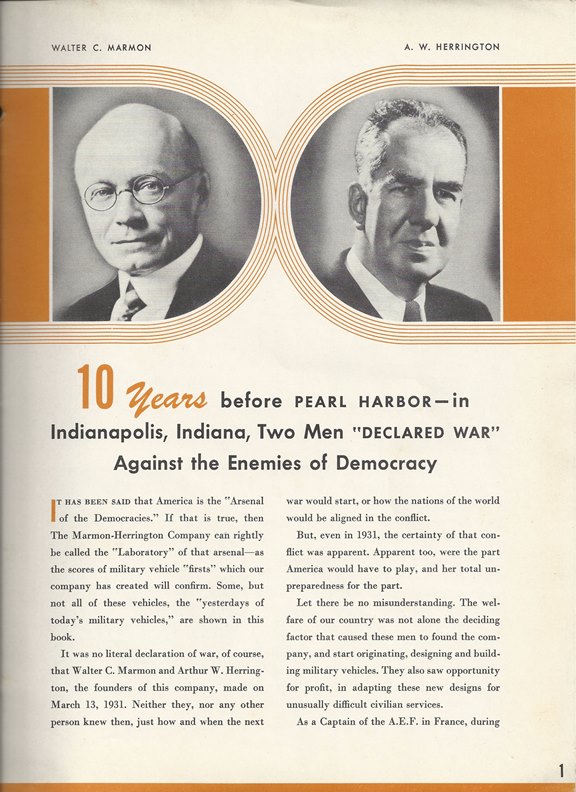

From 1902 to 1933, the Marmon Motor Car Company built automobiles.

Marmon-Herrington was formed in 1931 by Walter Marmon and Walter

Herrington, focused on building all-wheel drive trucks. Marmon-Herrington was especially successful in

converting Ford trucks into all-wheel drive. Today, the company

continues to provide all-wheel drive components to the heavy-duty

trucking industry.

Indianapolis historians have overlooked

Marmon-Herrington's contribution to the winning of World War Two.

At the main military museum in downtown Indianapolis, there is no

mention of the company among other noted local firms. And yet,

Marmon-Herrington was one of a select group of 17 American companies that

built tanks during World War Two. The tanks were built on the west side

of Indianapolis at West Washington Street and Harding Avenue, just 2.6

miles away from the downtown military museum.

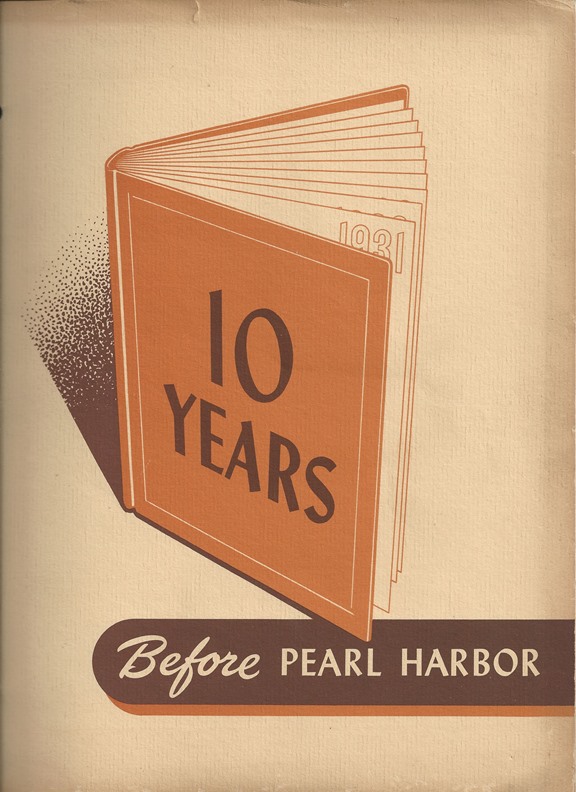

Towards the bottom of this page is a 1944

Marmon-Herrington publication entitled "Ten Years Before Pearl Harbor."

It covers the time period from the company's birth in 1931 to 1944.

This publication has photos of all of the products it built for military

applications during that time period. It shows an aggressive

company that produced a prolific number of different products for an

international customer base.

This website shows Marmon-Herrington's

contribution to the winning of World War Two which has been overlooked

until this time.

The Marmon "Wasp" that won the very first

Indy 500 in 1911 is on display at the Indianapolis 500 Hall of Fame

Museum in Speedway, IN. The author viewed the vehicle at a

local big box electronics retailer in Fishers, IN in March 2017.

The museum loans out the "Wasp" on a regular basis.

Author's photo.

This photo was taken in 1964 about the time

the plant closed. The view is to the south-east with West

Washington Street (US-40) along the bottom of the photo. Harding

Street runs north and south in the middle of the complex.

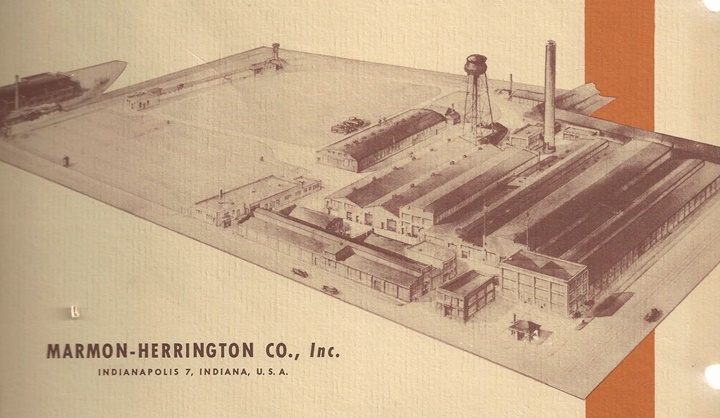

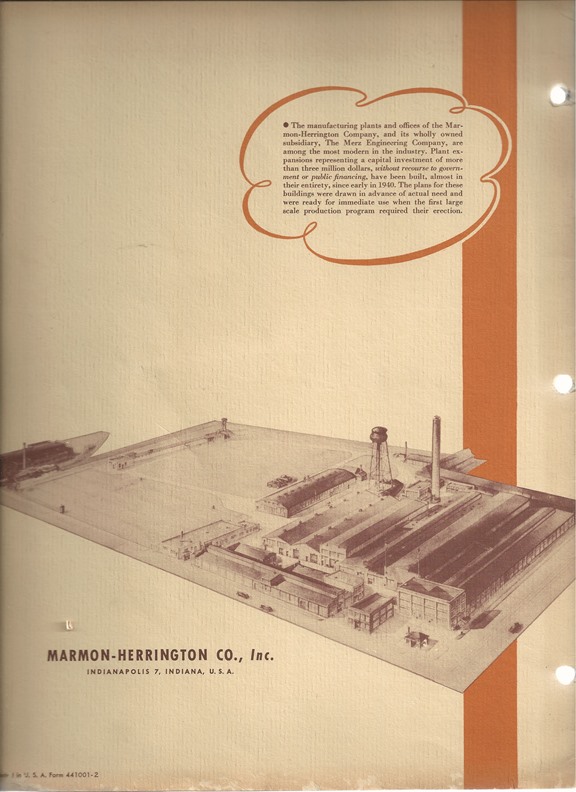

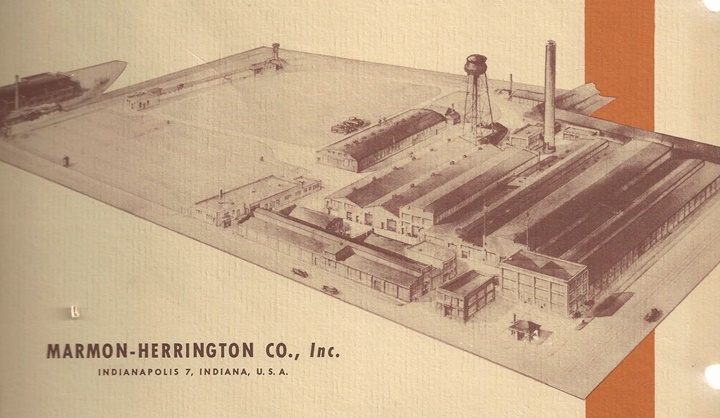

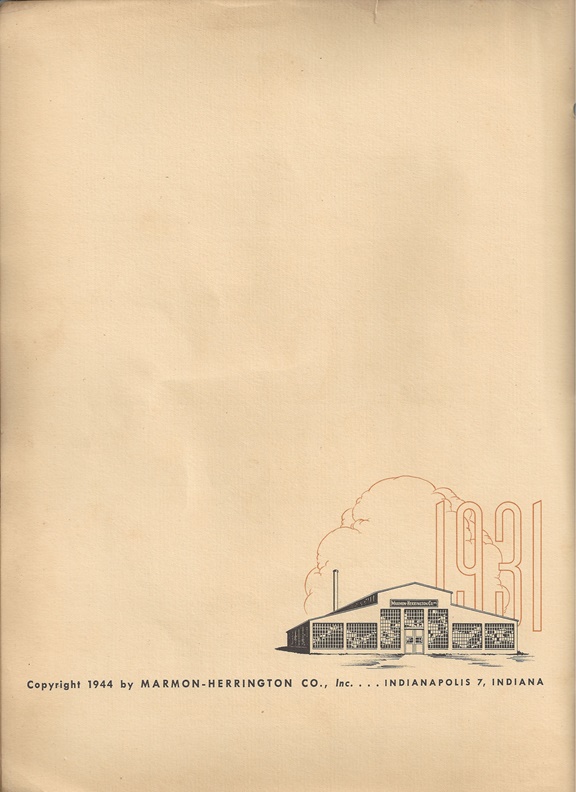

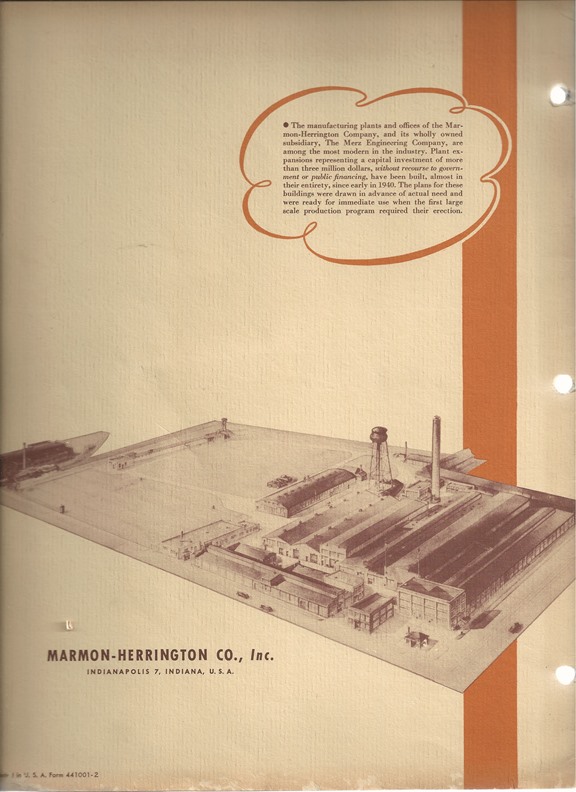

This artist's rendition of the

Marmon-Herrington plant, 1511 West Washington Ave. in Indianapolis, is from the

company's 1944 publication "10 Years Before Pearl Harbor." The

drawing is looking southwest with Washington Ave. along the right and

Harding Street along the front. The long building facing Harding

Street has had a section removed and is now two buildings, as shown

below in my contemporary photos.

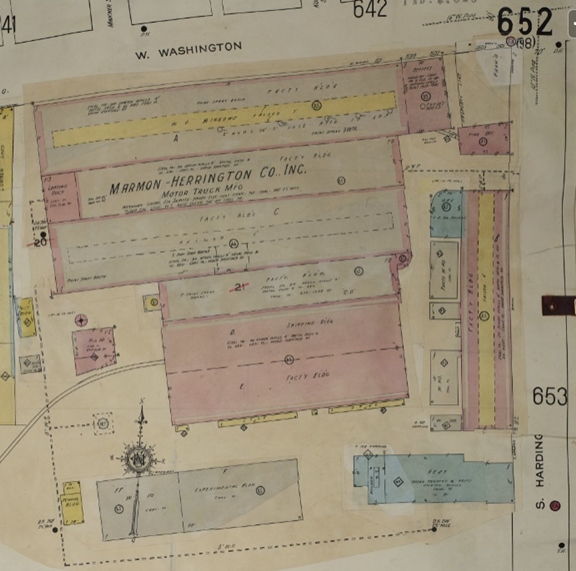

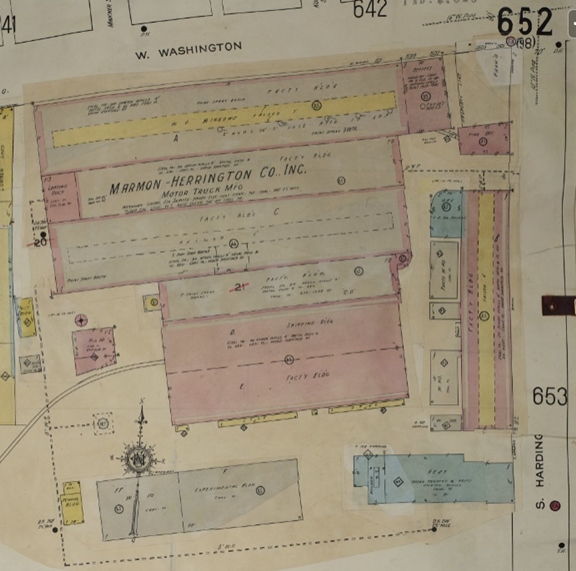

This Sanford map shows the Marmon-Herrington

factory in 1950. Imaged added 5-11-2022.

The orientation of this photo is looking

north along Harding Street towards West Washington Street. Along

Harding Street is an original factory building, which has had a section

removed as noted above. Author's photo added 9-29-2019.

This is the smaller section of the original

factory building. Author's photo added 9-29-2019.

This is the second portion of the original

building. There is a courtyard where a section of the original

building has been removed. Work is being done on the interior of this building to

repurpose it for IndyGo offices. Author's photo added

9-29-2019.

This is the north face of the north building. Duesenberg

Motors was the previous occupant of the factory at this

location. When it went out of business, Marmon-Herrington moved

in. Again, it appears someone has painted the name on the

building. It is doubtful Marmon-Herrington would have left the

name Duesenberg on the building, so this has most likely been painted by

an Indianapolis industrial historian or IndyGo. Also, this was not the

building nearest Washington Ave. The office building was in the grassy area,

which most likely would have had the company name on it.

The new brick building in the right-hand side of the photo is the IndyGo

bus terminal and maintenance building. This is where most of the

factory was. Author's photo added 9-29-2019.

This 1945 Marmon-Herrington-converted

H-542-H11C was seen at the World War II American Experience Museum in

Gettysburg, PA. It was on outside display for an open house at

this excellent museum. This vehicle was originally built as an

H-542-H1C 5-ton 4x2 light duty tractor. This is one of 1,200

H-542-H1C light duty tractors Marmon-Herington converted into the

H-542-H11C heavy duty configuration. Author's photo added

9-27-2022.

Author's photo added 9-27-2022.

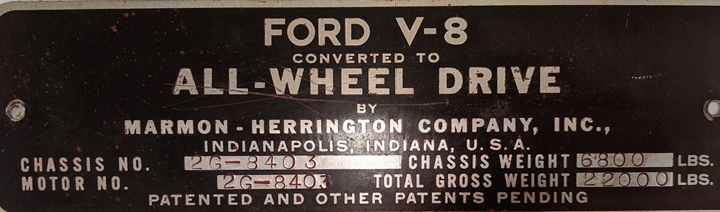

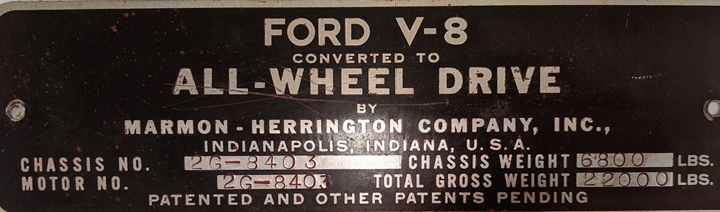

The data plate indicates that this is a 5-ton

4x2 heavy duty tractor Model Marmon-Herrington H542-IIC. At the

bottom of the data plate, it shows that it was converted from a light duty

HIC. The vehicle is serial number 4672. Author's photo added

9-27-2022.

The photos were taken on a sunny September

afternoon. Author's photo added 9-27-2022.

This forlorn looking Ford/Marmon-Herrington

four-wheel drive truck sitting among the weeds and derelict cars in a

junk yard is one of only 79 built by the company. Once the

Marmon-Herrington added the four-wheel drive to the vehicle, it was

shipped to Michigan City, IN where the Sullivan Machinery Company

installed the air compressor unit. Image courtesy of Jeff Lakaszcyck

added 11-28-2024.

Image courtesy of Jeff Lakaszcyck added

11-28-2024.

This Ford/Marmon-Herrington truck is on

display at the National Museum of Military Vehicles in Dubois, WY.

Mounted on the truck is a Klauer Manufacturing Company "Snogo" snow

blower. Author's photo added 11-28-2024.

The truck is identified as being a

Marmon-Herrington All Wheel Drive truck. Author's photo added

11-28-2024.

Author's photo added 11-28-2024.

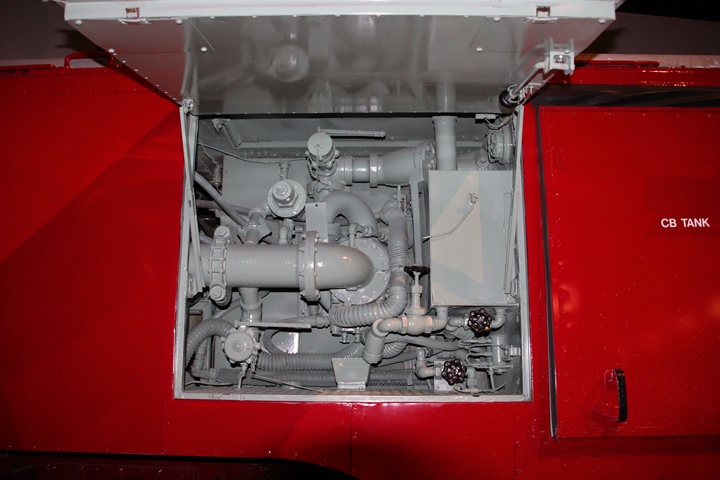

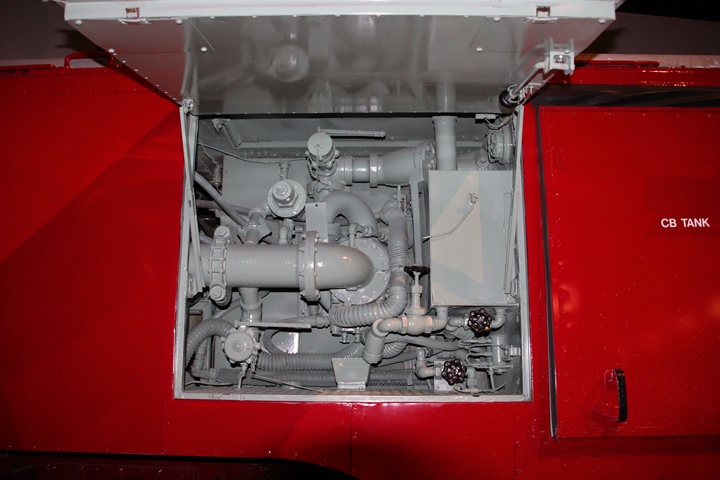

The gasoline engine mounted on the rear of

the truck provides the power to the snow blower unit. Author's

photo added 11-28-2024.

Author's photo added 11-28-2024.

The power from the engine is input into this

power takeoff which transfers the power to the transfer case below the

truck. Author's photo added 11-28-2024.

A look underneath the vehicle shows the

transfer case in the foreground and two propeller shafts running to the

front of the vehicle. The propeller shaft on the driver's side runs to the

snow blower and the other one on the passenger side runs to the front axle.

Author's photo added 11-28-2024.

This image taken from the passenger side of

the vehicle shows the propeller shaft running underneath the front axle

and out to the snow blower. Author's photo added 11-28-2024.

This photo taken from the driver's side of the vehicle also shows the

power from the engine mounted on the back of the truck running

underneath the front axle. Author's photo added 11-28-2024.

This photo shows the propeller shaft

continuing out to the snow blower unit. Author's photo added

11-28-2024.

How cool is this? When I did the

original research on Marmon-Herrington, I discovered that the

company built trolley buses after World War Two. However, I

did not have any photos to publish of a Marmon-Herrington-built trolley.

This was in April 2017. Then five years later, in March 2022, I was

at Dayton History in Carillon Park, Dayton, OH researching another company where

I found this 1949 Marmon-Herrington electric trolley. Author's

photo added 5-11-2022.

This is a Model TC-48, purchased by

the City Railway Company of Dayton, OH in May 1949. Between 1949

and 1988, when it was retired, it traveled a million miles over the

streets of Dayton powered by electrical power supplied by overhead

cables. The electrical trolleys in Dayton were ahead of their

time. Currently, municipalities are returning to electric powered

buses to reduce greenhouse gases and for quieter operation on city

streets. Author's photo added 5-11-2022.

Author's photo added 5-11-2022.

Trolley Number 515 was known as the "Queen

of the Fleet." She was one of twenty trolleys Marmon-Herrington

produced for the City Railway Company of Dayton, OH.

Author's photo added 5-11-2022.

Marmon-Herrington won the Army-Navy "E"

award once during World War Two.

Marmon-Herrington

Company World War Two Production: The company produced

$89,951,000 of military products during the war.

Table 1 -

Marmon-Herrington Military

Vehicles

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945"

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946 (Date on document is 1945. However,

this appears to be an error as the summary has 1945

acceptances.) |

|

Type |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

|

Light tank, 7-ton (most likely CTLS) |

|

|

240 |

|

|

|

240 |

|

M22 (9TE1) |

|

|

|

680 |

150 |

|

830 |

|

5-ton 4x2 tractor heavy duty SWB (120 inch WB) (Same as

International Harvester H542-9. M425 in Army

Nomenclature) |

|

|

|

|

2,000 |

1,200 |

3,200 |

|

Total |

|

|

240 |

680 |

2,150 |

1,200 |

4,270 |

Author's Note and Disclaimer:

The Detroit Office of Ordnance of the U.S. Army was the primary

purchasing entity for vehicles for the U.S. Army during World War Two.

It also purchased vehicles for the USMC, US Navy, and Lend-Lease.

However, there were other organizations that also purchased vehicles

including the Army Corps of Engineers, Navy Bureau of Ordnance, Navy

Bureau of Aeronautics, and foreign countries making direct purchases.

The above information only reflects what

Army Ordnance purchased. In the case of Marmon-Herrington, it had

many contracts from foreign companies leading up to World War Two.

Historical information indicates the U.S. Army purchased 240 CTLS tanks

for use in Alaska. This matches with the 240 7-ton light tanks

accepted by Army Ordnance in 1942. As shown below in Table 2,

Marmon-Herrington produced vehicles not accepted by Army Ordnance early

in the war. Most of the tank production was taken over by the U.S.

Army as the intended customers were under Axis control. Table 2

gives a full view of what the company did during World War Two.

Table 2 -

Marmon-Herrington Military Products 1940-1944

The information in the table below come from the 1944

Marmon-Herrington document entitled "10 Years before Pearl

Harbor." This document is published in its entirety at

the bottom of this webpage. |

|

Model |

Description |

Customer |

Year built |

Number built |

Comments |

| |

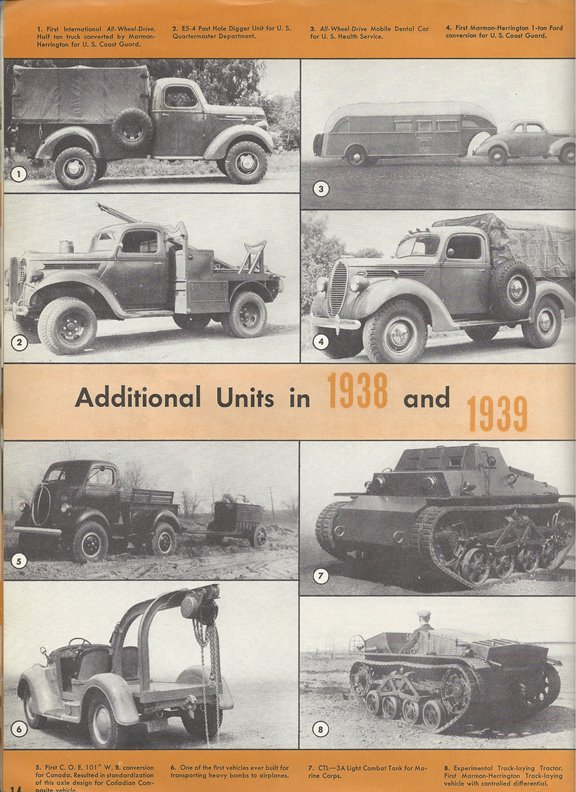

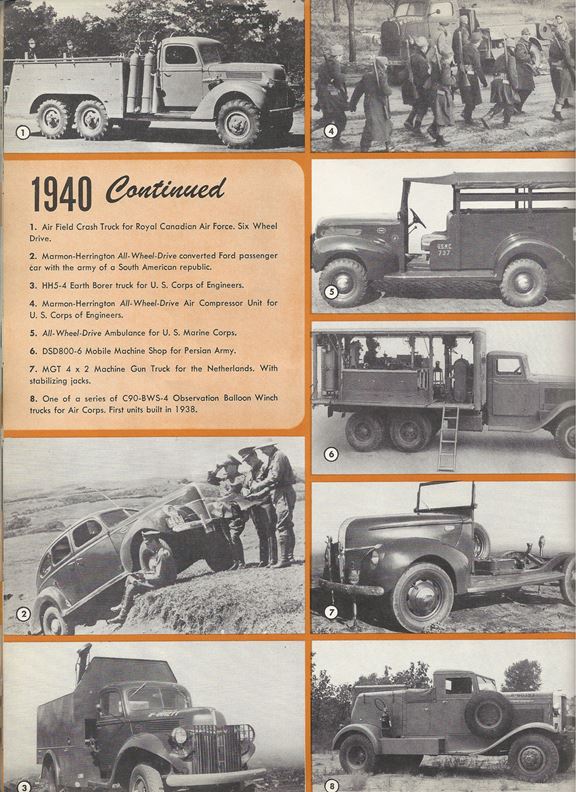

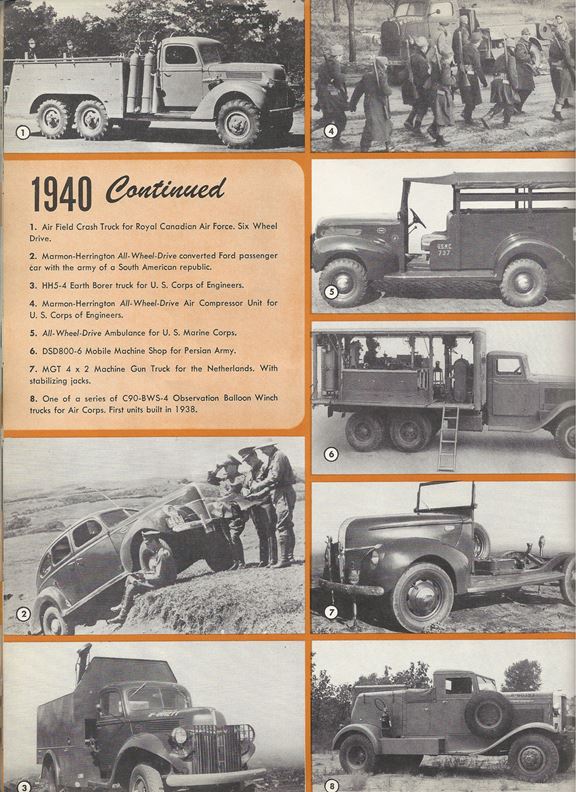

Air Field Crash Truck, 6-wheel Drive |

Royal Canadian Air Force |

1940 |

|

|

| |

All-wheel drive Ford passenger car |

Unknown South American Army |

1940 |

|

|

| HH5-4 |

Earth Borer Truck |

U.S. Army Corps of Engineers |

1940 |

|

|

| |

All-wheel drive Air compressor truck |

U.S. Army Corps of Engineers |

1940 |

79 |

|

| |

All-wheel drive Ambulance |

USMC |

1940 |

|

|

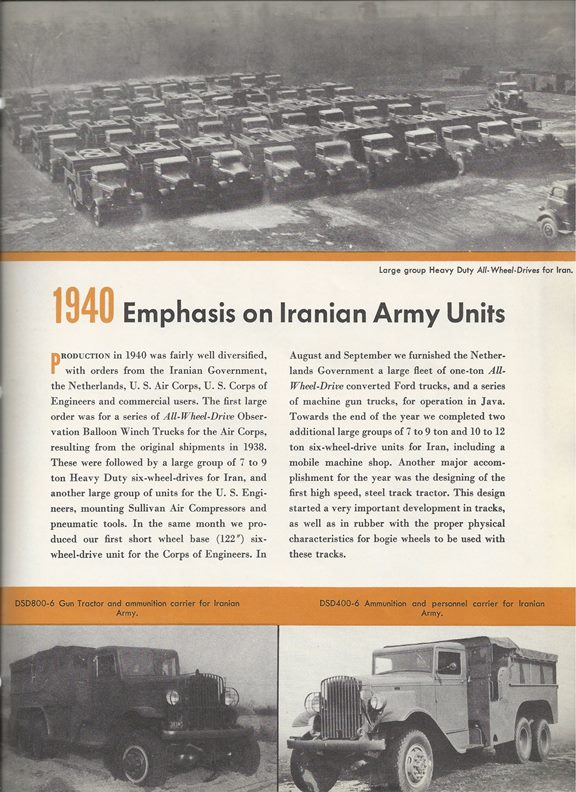

| DSD800-6 |

Mobile machine shop |

Persian Army |

1940 |

|

|

| DSD800-6 |

Gun Tractor and Ammunition Carrier |

Persian Army |

1940 |

|

|

|

DSD400-6 |

Ammunition and Personnel Carrier |

Persian Army |

1940 |

At Least 40 |

On the page in "10 Years before Pearl Harbor" showing the

year 1940, there are 40 DSD400-6 trucks awaiting shipment.

This may or may not be the entire order. |

| MOT |

Machine gun truck, 4x2 |

The Netherlands |

1940 |

|

|

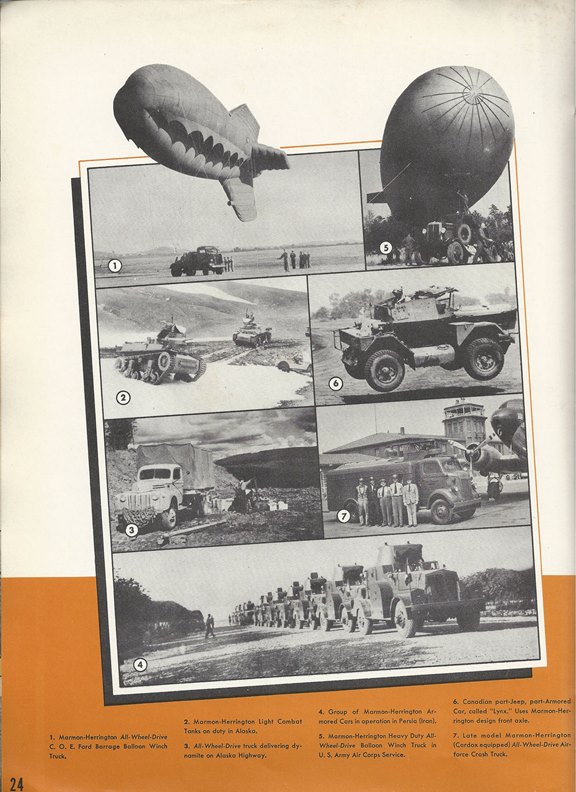

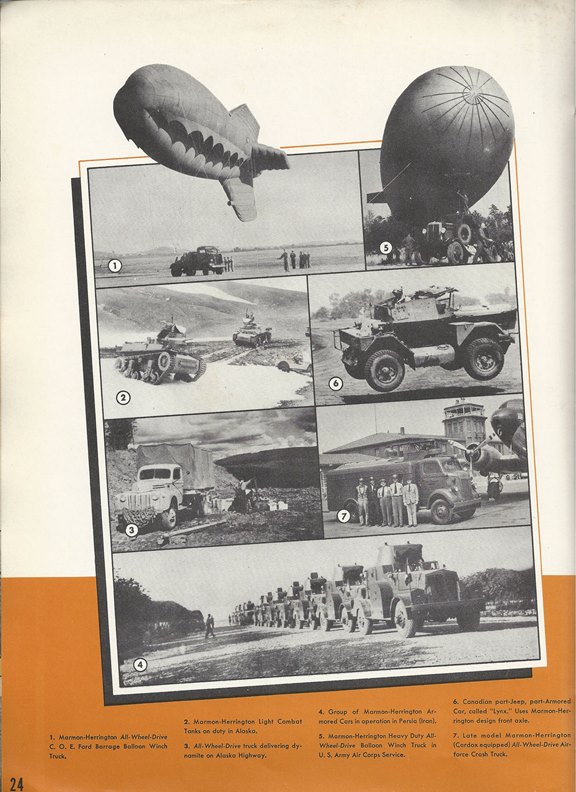

| 90-BWS-4 |

Observation Balloon Winch Truck |

U.S. Army Air Corps |

1940-1941 |

|

This is interesting. Observation balloons

should have been obsolete by this time. Imagine

one on the western front in Europe in 1940 with Me-109s

roaming the sky. The life expectancy of the observer

would be counted in minutes. |

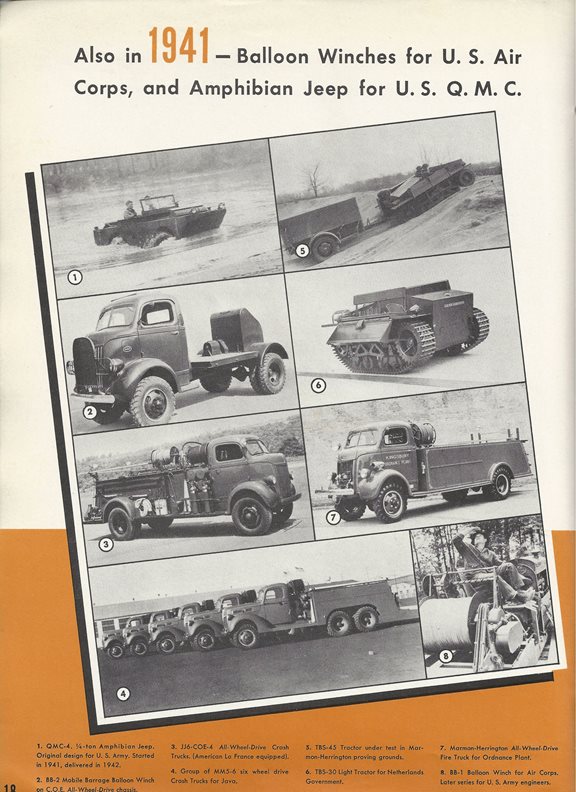

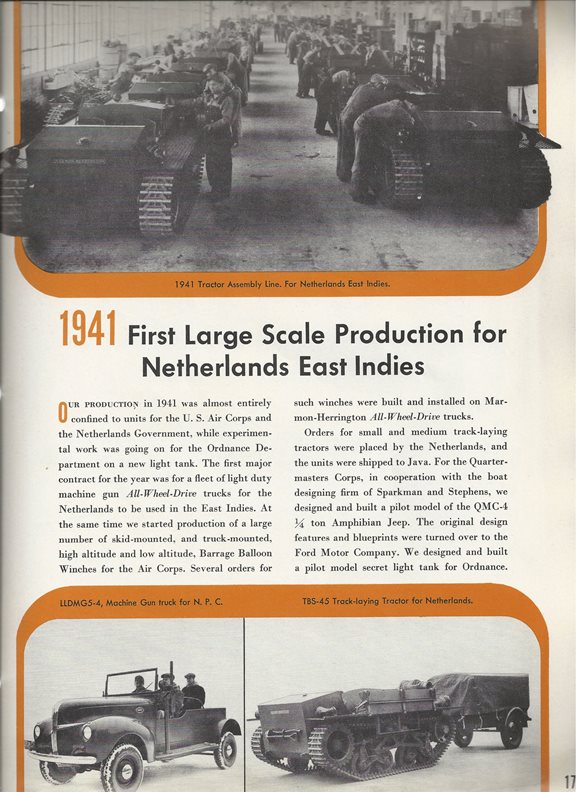

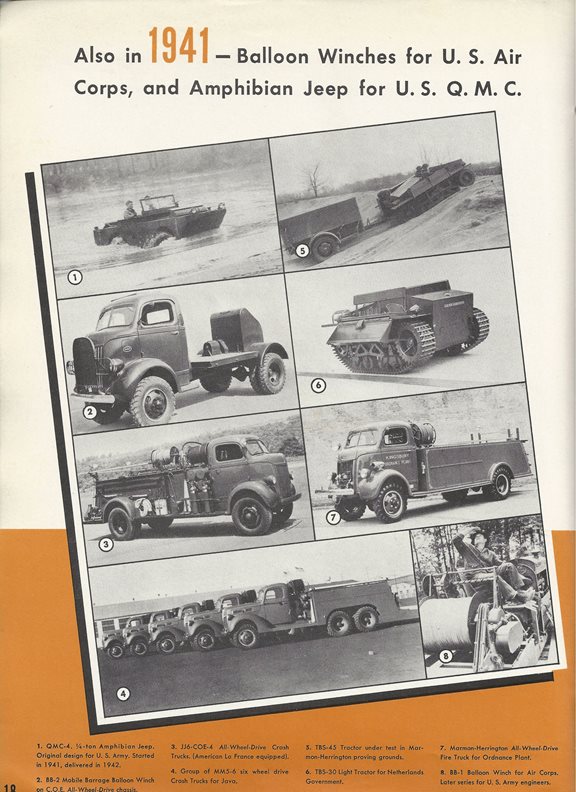

| |

1/4-ton amphibious jeep prototype |

U.S. Army Quartermaster |

1941-1942 |

1 |

Lost in competition to Ford Motor Company. See more

information below. |

|

BB-2 |

4x4 COE Barrage Balloon Winch Truck |

U.S. Army Air Corps |

1941 |

|

|

|

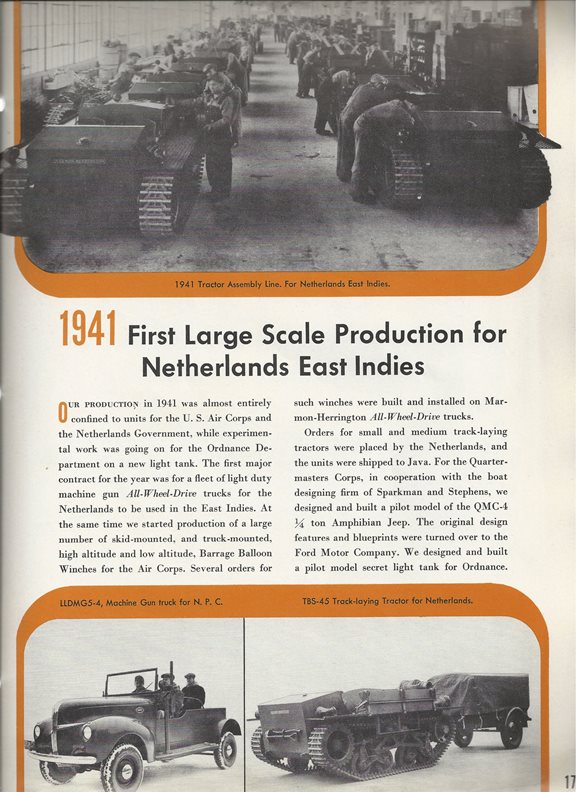

LLDMG5-4 |

4x4 Machine Gun Truck |

NPC |

1941 |

|

|

|

TBS-45 |

Track-laying Tractor |

The Netherlands |

1941 |

|

|

|

JJ6-COE-4 |

4x4 COE Crash Trucks |

U.S. Army Air Corps ? |

1941 |

56? |

These trucks had American-LaFrance fire apparatus.

Records show that American-LaFrance built 56 pumpers in 1941

for the U.S. Army Air Corps. There is no chassis

manufacturer identified. They may well have been the

Marmon-Herrington JJ6-COE-4 |

|

MM5-6 |

6x6 Crash Trucks |

Java |

1941 |

5? |

Five trucks are shown in the photo. This may be the

entire production. |

|

TBS-5 |

Prototype track-laying Tractor |

|

1941 |

1 |

|

|

TBS-30 |

Two-man Light Track-laying Tractor |

The Netherlands |

1941 |

|

These are similar to British Universal Carrier, although

there appears to be no armament. They were intended as

small prime movers. |

|

TBS-45 |

Track-laying Tractor |

The Netherlands East Indies |

1941 |

|

Same as above. |

| |

4x4 long-wheel base fire truck |

Kingsbury Ordnance Plant, LaPorte, IN |

1941 |

1 |

|

|

BB-1 |

Balloon Winch |

U.S. Army Air Corps,

then U.S. Army Corps of Engineers |

1941 |

|

This is the winch and drive motor only. No truck is

shown or specified in the document. |

|

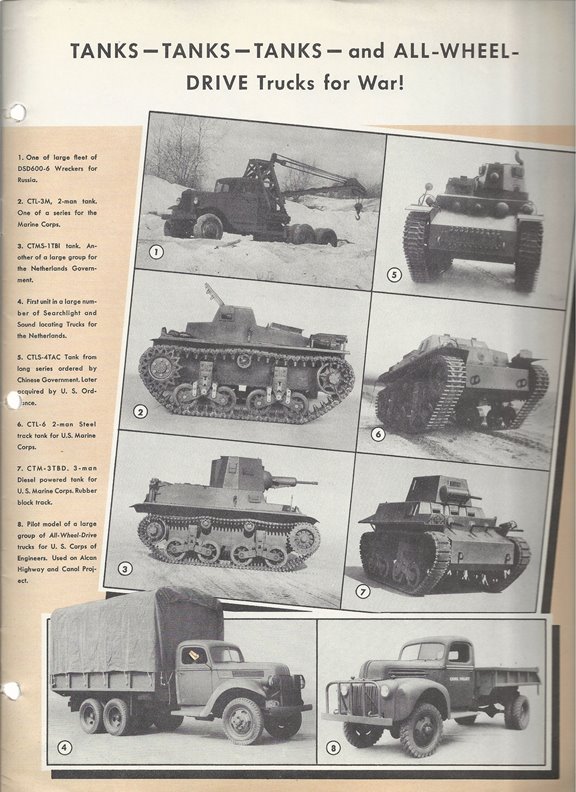

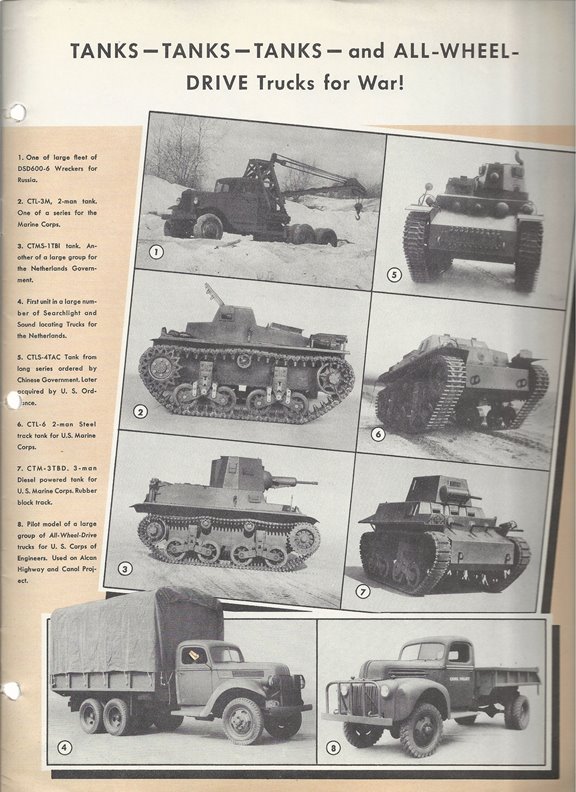

DSD600-6 |

6x6 Wrecker |

Russia |

1942 |

"A large fleet." |

This appears to be the Marmon-Herrington Wrecker that later

became the Ward-LaFrance M1 10-ton Wrecker. |

|

CTL-3M |

2

man tank |

USMC |

1942 |

|

|

|

CTMS-1TB1 |

3-man Tank with 360 degree rotating turret |

The Netherlands |

1942 |

"A large group." |

|

| |

6x6 Searchlight and Sound Locating Truck |

The Netherlands |

1942 |

"A large number." |

|

|

CTLS-4TAC |

Tank with single offset turret |

China |

1942 |

|

Order taken over by U.S. Army Ordnance |

|

CTL-6 |

2

man tank with no turret |

USMC |

1942 |

|

|

|

CTM-3TB3 |

3-man tank with diesel engine and rubber block tracks |

USMC |

1942 |

|

|

|

MTLS-1G14 |

4-man tank with turret |

|

1942 |

|

|

| |

4x4 truck |

U.S. Army Corps of Engineers |

1942 |

|

Used on the Alcan Highway and in the Canal Zone |

|

M22 |

M22 Locust Airborne Tank |

U.S. Army Ordnance |

1943-1944 |

830 |

|

|

M426 |

5-ton 4x2 tractor heavy duty SWB 120 inch WB.

(International-Harvester H-542-11) |

U.S. Army Ordnance |

1944-1945 |

3,200 |

These used Timken axles. IH used its own axles.

|

|

M426 |

Conversion of M425 to M426 specifications |

U.S. Army Ordnance |

1945 |

1,200 |

When complete, the trucks were designated as H-425-11-C for

conversion. H-425-11 was the IH designation for the

M426. The M426 could pull heavier loads than the M425.

|

Table 3 shows that

Marmon-Herrington had $89,951,000 in major government contracts

during World War Two. What is of special interest and not

normal for most American companies in the World War Two era is the

number of United States Military contracts the company had before the U.S. became involved in the war in December 1941.

43% of Marmon-Herrington's major contracts were issued in 1940 and

1941. This is another indicator that the company was

aggressively pursuing military contracts from both domestic and

foreign sources.

There are two contracts

for the T9E1/M22 Locust light tank. These two contracts

totaled $28,849,000 for 830 tanks. This is an average cost of

$34,757 per tank. Marmon-Herrington also supplied $114,000 in

spare parts for the M22.

There were three

contracts issued in 1943 and 1944 for a total of 3,200 M426 5-ton

4x2 tractor/trucks. The first contact was awarded October 1943

for $4,500,000. This was Army Ordnance contract number

33-008-215. The second contract was Army Ordnance contract

33-008-215S for $10,199,000 dated March1944. These two

contracts were for a total of 3,000 vehicles at a unit cost of

$4,900.

The third and last

contract for building new M426 trucks was Army Ordnance contract

33-008-1638 for $1,054,000 awarded November 1944. This was for

200 vehicles at a unit cost of $5,270.

Marmon-Herrington was

issued a contract in January 1945 for the conversion of 1,200 M425

trucks to M426. This contract was for $1,224,000 or a

conversion cost of $1,020 per truck.

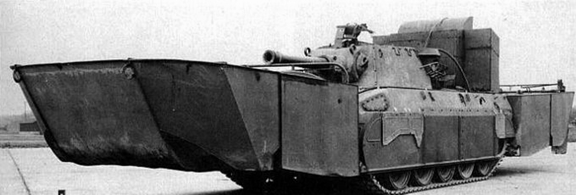

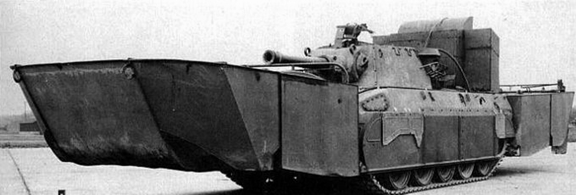

In February 1944

Marmon-Herrington was issued a Navy contract for $374,000 for "Tank

Hull Assemblies." This was a conversion of an M18 Hellcat tank

destroyer into an amphibious vehicle. The Navy may have

thought the M18s could be used as armed amphibious vehicles to

assist in its island invasion campaign in the Pacific, providing

fire support both in the water and after landing. There were two

different versions of this. The first, designated as the T86,

used the original fourteen inch treads for propulsion.

A second M18 was

converted and designated T86E1. This version used a twin

propeller system to propel the vehicle through the water.

Tests of both types of vehicles in the water indicated the treads

worked better for propulsion.

The basic layout for the T86 and T86E1

Marmon-Herrington also

converted a third M18 Hellcat tank destroyer into an amphibious

vehicle with a 105mm howitzer. This used the tracks for

propulsion. All three types of vehicles Marmon-Herrington

worked on were still undergoing tests when the war ended. The

projects were then cancelled.

This is the T87 with the 105mm howitzer

installed.

The U.S. Army issued a $352,000 contract in January 1945 for "Gun

Motor Cars T-87." This appears to have been for 250 sets of

detachable pontoons for the a 105mm armed M18. They were never

used.

|

Table 3 - Marmon-Herrington

Company's Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. Table added 5-22-2022. |

|

Product |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Ordnance

Material - Navy |

$65,000 |

6-1940 |

7-1940 |

| Tanks - Navy |

$606,000 |

6-1940 |

3-1941 |

| Tanks -

Foreign |

$4,720,000 |

6-1940 |

3-1942 |

| Tanks -

Foreign |

$3,654,000 |

8-1940 |

9-1942 |

| Cars Command

- Foreign |

$116,000 |

8-1940 |

1-1941 |

| Tractors -

Foreign |

$315,000 |

8-1940 |

7-1941 |

| Tractors -

Foreign |

$1,467,000 |

8-1940 |

12-1941 |

| Tractors -

Foreign |

$105,000 |

8-1940 |

11-1940 |

| Winches -

Army |

$79,000 |

9-1940 |

12-1940 |

| Trucks - Army |

$62,000 |

10-1940 |

3-1941 |

| Winches -

Army |

$163,000 |

12-1940 |

4-1941 |

| Winches -

Army |

$86,000 |

12-1940 |

3-1941 |

| 1940 Total |

$11,438,000 |

|

|

| Tanks -

Foreign |

$823,000 |

1-1941 |

9-1942 |

| Trucks - Army |

$100,000 |

1-1941 |

3-1941 |

| Tanks -

Foreign |

$275,000 |

3-1941 |

7-1942 |

| Tanks -

Foreign |

$5,689,000 |

3-1941 |

12-1942 |

| Motor

Vehicles - Foreign |

$160,000 |

3-1941 |

6-1941 |

| Tanks -

Foreign |

$796,000 |

4-1941 |

3-1942 |

| Tanks -

Foreign |

$1,977,000 |

4-1941 |

2-1943 |

| Tanks -

Foreign |

$1,628,000 |

4-1941 |

12-1942 |

| Tractors -

Foreign |

$1,390,000 |

4-1941 |

4-1942 |

| Tractor Parts

- Foreign |

$322,000 |

4-1941 |

6-1941 |

| Aircraft

Material - Army |

$2,032,000 |

6-1941 |

3-1942 |

| Tractor Parts

- Foreign |

$66,000 |

6-1941 |

9-1941 |

| Tank

Equipment - Foreign |

$99,000 |

7-1941 |

1-1942 |

| Tanks - Army |

$78,000 |

10-1941 |

1-1942 |

| Tanks - Light

|

$6,218,000 |

10-1941 |

7-1942 |

| Tanks - Parts

- Foreign |

$66,000 |

11-1941 |

4-1942 |

| Winches -

Army |

$4,962,000 |

11-1941 |

7-1942 |

| Tank Parts -

Foreign |

$166,000 |

12-1941 |

3-1942 |

| Tank Parts -

Foreign |

$467,000 |

12-1941 |

4-1943 |

| Tank Parts -

Foreign |

$114,000 |

12-1941 |

8-1943 |

| 1941 Total |

$27,428,000 |

|

|

| 1940 and

1941 Total |

$38,866,000 |

|

|

| Tanks - Army |

$135,000 |

1-1942 |

6-1942 |

| Light Tanks

T9 - Army |

$19,500,000 |

1-1942 |

1-1943 |

| Trucks -

Treasury |

$55,000 |

2-1942 |

9-1943 |

| Tractors -

Army |

$60,000 |

1-1942 |

8-1942 |

| Kits

Conversion - Army |

$504,000 |

1-1942 |

7-1942 |

| Auto Parts -

Army |

$341,000 |

4-1942 |

8-1942 |

| Car Parts -

Army |

$65,000 |

4-1942 |

6-1942 |

| Light Tanks

T9E1 - Army |

$9,349,000 |

4-1942 |

3-1944 |

| Tank Parts -

Foreign |

$85,000 |

4-1942 |

8-1942 |

| Vehicle Parts

- Army |

$251,000 |

5-1942 |

9-1942 |

| Trucks -

Treasury |

$784,000 |

7-1942 |

9-1943 |

| Truck Parts -

Army |

$165,000 |

9-1942 |

12-1942 |

| Trucks - Army |

$58,000 |

12-1942 |

1-1943 |

| Winch Parts -

Army |

$111,000 |

12-1942 |

1-1943 |

| Tank Parts -

Foreign |

$94,000 |

12-1942 |

1-1943 |

| Tank Parts

T9E1 - Army |

$114,000 |

2-1943 |

6-1944 |

| Motor

Vehicles - Army |

$116,000 |

3-1943 |

6-1943 |

| Truck

Assemblies - Army |

$409,000 |

5-1943 |

5-1944 |

| Tank Parts -

Foreign |

$63,000 |

9-1943 |

10-1943 |

| Trucks - Army |

$4,500,000 |

10-1943 |

12-1944 |

| Tank Hull

Assemblies - Navy |

$374,000 |

2-1944 |

5-1944 |

| Trucks - Army |

$10,199,000 |

3-1944 |

5-1944 |

| Motor Vehicle

Parts - Treasury |

$91,000 |

4-1944 |

11-1944 |

| Tractor

Trucks - Army |

$1,054,000 |

11-1944 |

6-1945 |

| Gun Motor

Cars T-87 - Army |

$352,000 |

1-1945 |

4-1945 |

| Ordnance

Equipment - Army |

$100,000 |

1-1945 |

8-1945 |

| Truck Tractor

Convern - Army |

$1,224,000 |

1-1945 |

6-1945 |

| Spring

Assemblies - Army |

$55,000 |

4-1945 |

8-1945 |

| Trucks -

Treasury |

$600,000 |

8-1945 |

2-1946 |

| Truck

Tractors - Treasury |

$277,000 |

8-1945 |

1-1946 |

| Total |

$89,951,000 |

|

|

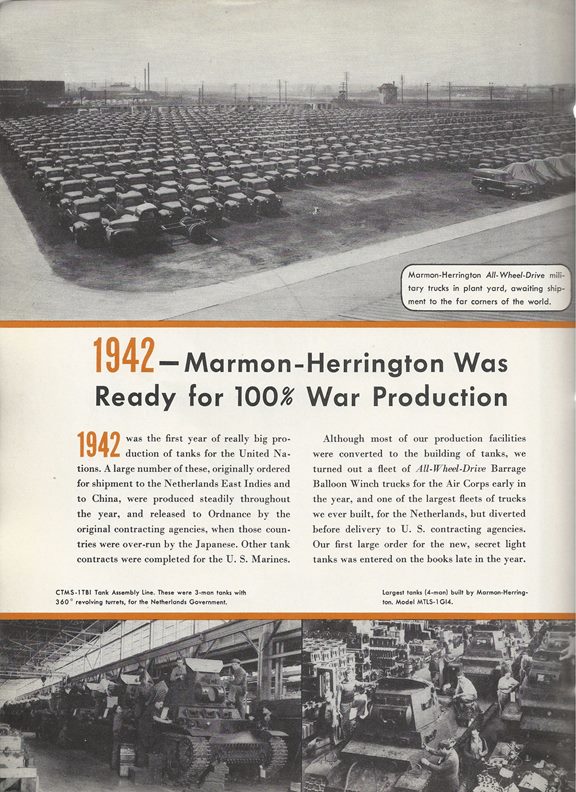

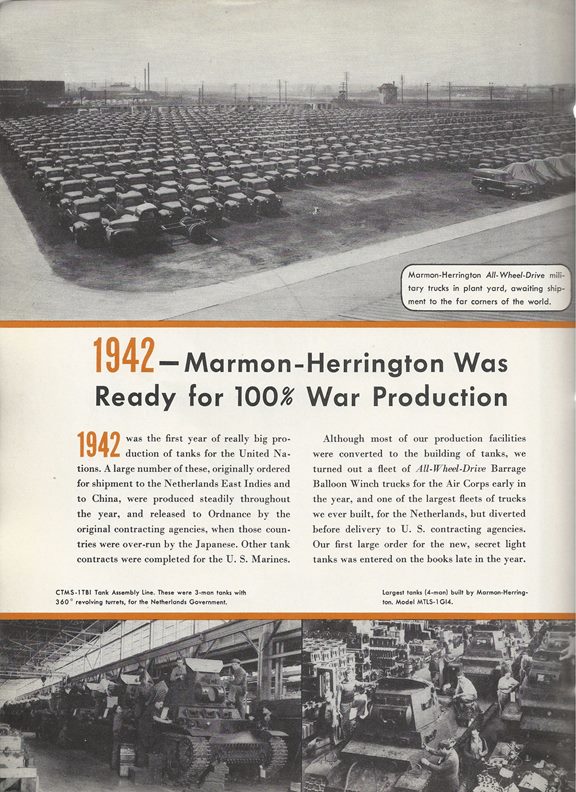

In

1942 the Marmon-Herrington parking lot was filled with 4x4 trucks.

Most, if not all, of the vehicles were Ford-built commercial trucks

converted to four-wheel drive by the company at its Indianapolis plant.

I count approximately 700 trucks awaiting shipment in this photo.

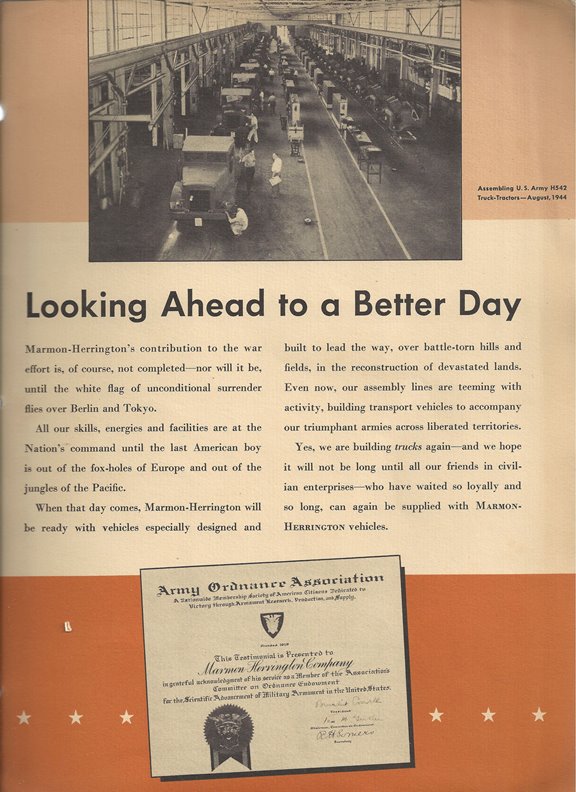

Marmon-Herrington of Indianapolis has the distinction of being the only

American company to have both tanks and trucks come down the same

assembly line. In this 1943-44 era photo, M22 Locust light

tanks are coming down the assembly line.

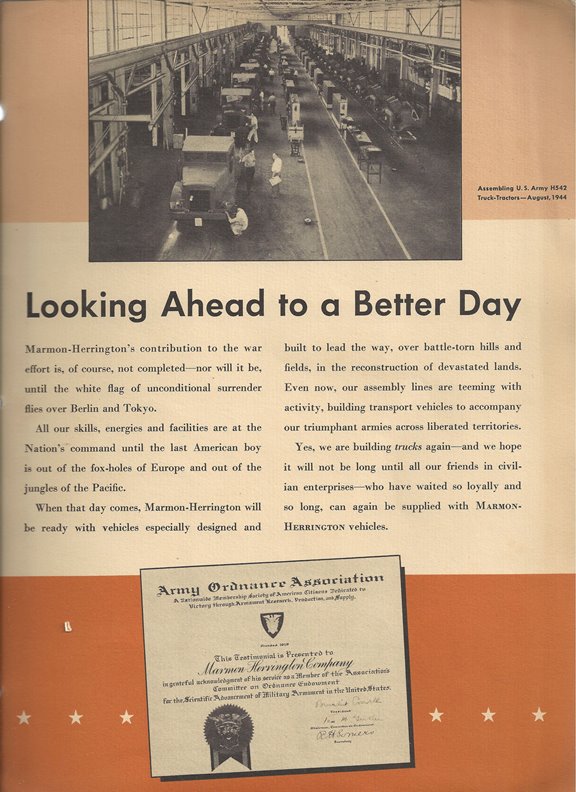

In this 1944 era photo, there are now M426 five-ton 4x2 tractors coming down the same assembly line.

These were International Harvester H-5-11 tractors built by

Marmon-Herrington under license. In 1945 Marmon-Herrington would

convert 1,200 IH-built M425 light duty tractors into M426 heavy duty

tractors.

Marmon-Herrington and Ford Motor Company

competed against each other for the production of what became the Ford

GPA. Marmon-Herrington was chosen to compete with Ford, which

already had contracts for the Jeep, again because of its experience in

four-wheel drive vehicles. Its design was composed of a unibody

construction that ended up being 400 pounds heavier than the Ford entry,

which won the competition. During the competition, the vehicle was

called the QMC-4 1/4-Ton Truck Light Amphibian.

Here is the Marmon-Herrington

version, which lost the competition during testing.

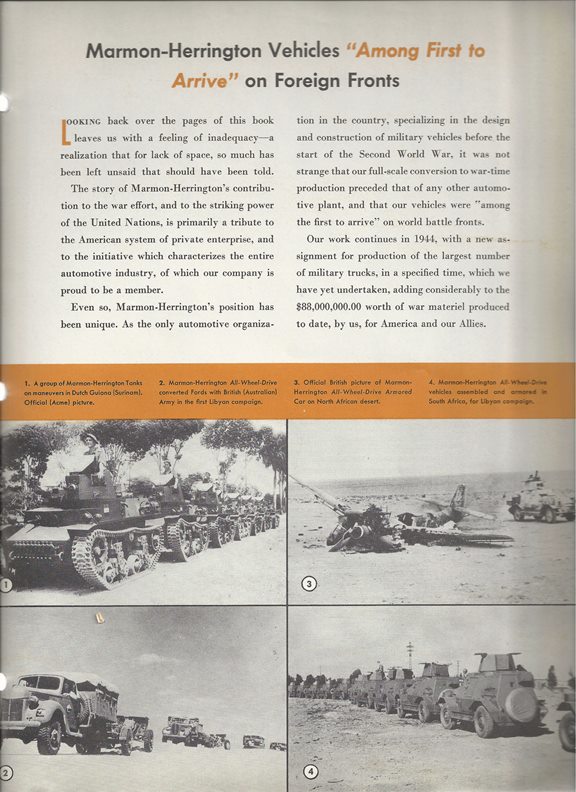

Four-Wheel Drive Components

- Marmon-Herrington supplied four-wheel

drive trains to convert Ford trucks for the British Commonwealth.

Armored Cars - The

Marmon-Herrington Armored Car consisted of a Canadian-built Ford 3-ton

truck that was then shipped to South Africa. There, they were fitted with

a Marmon-Herrington four-wheel-drive train, and had the necessary armor

and armament added. The vehicles were known as Marmon-Herrington

Armored Cars, even though the company only supplied the four-wheel-drive

train. A total of 5,746 armored cars in several versions were built by the

South Africans. Today 33 still exist, all

outside the United States. They served not only in World War Two, but also in

the Indonesian National Revolution, the 1948 Arab-Israeli War, the

Turkish Invasion of Cyprus, and the Rhodesian Bush War.

A Marmon-Herrington Mark III Armored Car manned by Indian troops during

WWII.

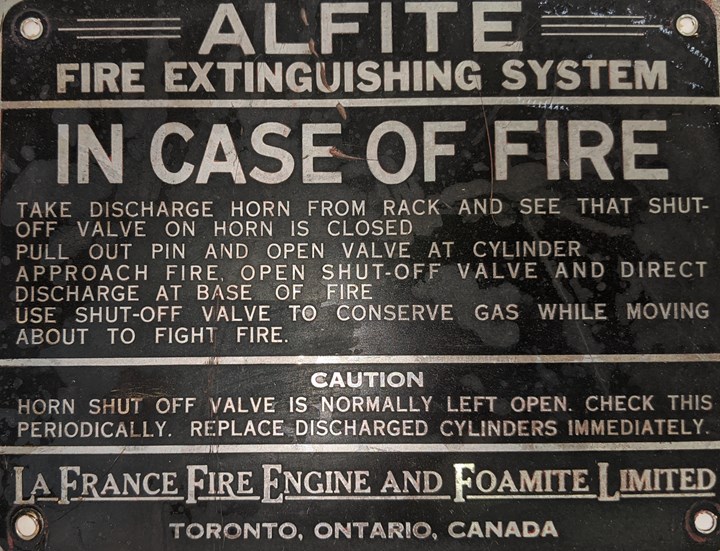

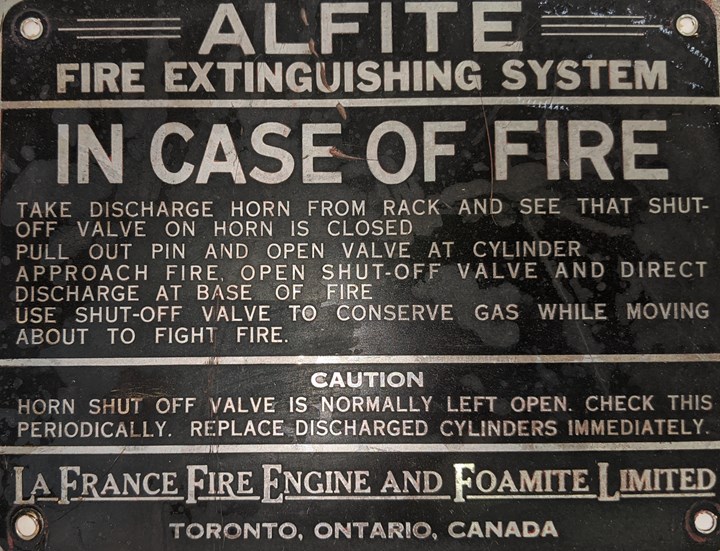

World War Two Ford Truck Conversions -

This 1940 Ford V-8 truck is in storage

awaiting restoration at the Nokomis & District Museum in Nokomis, SK,

Canada. During World War Two it served as a crash truck at the

R.C.A.F. base in Defoe, SK. This was home of the No. 5 Bombing and

Gunnery School between 1941-1945. After Ford built the truck, it

was shipped to Marmon-Herrington in Indianapolis, IN where it was

converted to an all-wheel configuration. Once this was complete,

it was then shipped to LaFrance Fire Engine and Foamite, Ltd in Toronto,

ON where the rear body and emergency equipment was installed. Then

it was shipped to Defoe, SK where it served during the war. Photo

and information courtesy of Michael Marb.

Photo courtesy of Michael Marb.

Photo courtesy of Michael Marb.

Photo courtesy of Michael Marb.

Pre-World War Two Tanks 1935-1942 - Marmon-Herrington built seven

different styles of tanks similar to the CTMS tank shown below, displayed at

the New Jersey National Guard Annex in Lawrenceville, NJ. About

300 total tanks were built; being sold to the US Marine Corp, The

Netherlands for service in the Dutch East Indies, and several Latin

American countries. The US Marines purchased 15; and 240 were

taken by the US Army, which were used for training in Alaska.

Today, only seven of the tanks remain worldwide. Five are in the

United States, one in Guatemala, and one is at an unknown location.

The Marmon-Herrington CTMS-1TB1 Light Tank

This is serial number 791, located in the artillery and armor

section of the New Jersey National Guard Museum Annex at

Lawrenceville, NJ. This formerly served with the Guatemalan

Army. Author's photo.

This design is typical of the pre-World

War Two light tank design. Differences in the other tanks

included crew size, armament, and location of the turret.

Author's photo.

The information on the museum placard

for this particular tank is incorrect. It states that the CTMS

tank served with American forces in Alaska. The American Army

in Alaska used the CTLS, and the turret was offset to the right, or

left, of the tank. Author's photo.

Author's photo.

Author's photo.

This CTLS light tank operated by the US

Army in Alaska had the turret offset to the right side of the tank.

The Marmon-Herrington CTL-3A did not

have a turret. Five CTL-3As were delivered to the USMC in 1939

and were taken out of service in 1943.

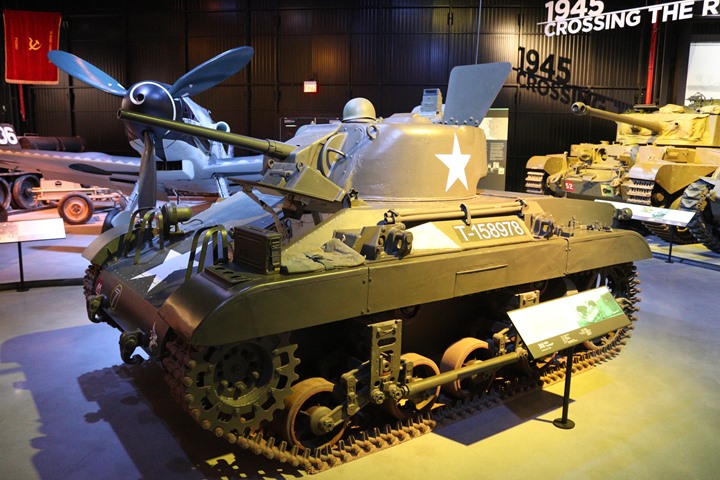

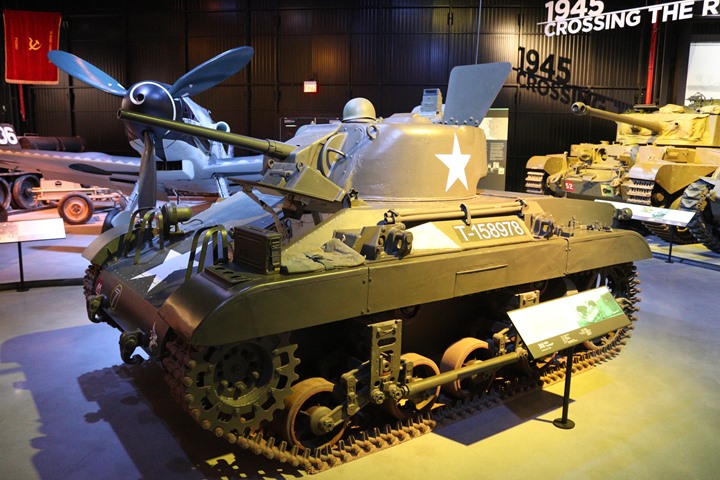

World War Two M22 Locust Tank -

Marmon-Herrington's largest tank production run was the M22 Locust

Light Tank. The company built 830 during 1943 and 1944.

While the M22 was not assigned to any operational units with the US

Army, 260 were shipped to Great Britain under Lend-Lease, where

eight were involved on the British attack on the Rhine River.

After World War Two, the Egyptians used a sizeable number of them in the 1948 Arab-Israeli War.

How small is an M22 Locust light tank

compared to a M4A3(76)HVSS Sherman medium tank? Pretty small,

as seen here at the Rock Island Arsenal in IL. Author's photo

added 8-12-2019.

This Marmon-Herrington M22 Locust light

tank was on display at the 2021 Findlay Military Show in Findlay,

OH. This tank was just recently restored, and this was its

public debut. Author's photo added 5-16-2021.

Author's photo added 5-16-2021.

Author's photo added 5-16-2021.

The next three photos are of a

Marmon-Herrington M22 Locust light tank that is on display at the

American Heritage Museum in Hudson, MA. Author's photo added

8-12-2019.

Author's photo added 8-12-2019.

Author's photo added 8-12-2019.

This M22 Locust tank is on display at

the Museum of American Armor in Old Bethpage, Long Island, NY.

It is one of many World War Two era armored vehicles and trucks the museum has, all of which are in running condition. Author's

photo added 6-12-2018.

Author's photo added 6-12-2018.

Author's photo added 6-12-2018.

Author's photo added 6-12-2018.

This M22 Locust tank is owned by the

Roberts Armory in Rochelle, IL. The author's photograph was

taken at the 2015 Rockford, IL WWII reenactment. Note its size

compared to the on-looking spectators.

Author's photo.

Author's photo.

The M22 squeezed a three-man crew into

the vehicle. There was the driver and tank commander/loader

seen here, along with a gunner for the 37mm cannon. Author's

photo.

Author's photo.

Author's photo.

The relative size of the M22 to its

supporting infantrymen is evident. Author's photo.

Author's photo.

This M22 Locust is part of the Armor and

Cavalry collection at Fort Benning, GA. Author's photo added

9-21-2018.

Author's photo added 9-21-2018.

This M22 Locust light tank is on display

at the Rock Island Arsenal in IL. Behind it is an M4A3 Sherman

tank. Author's photo added 8-12-2019.

Author's photo added 8-12-2019.

The M22 was designed with the intention of

being a light tank that could support airborne troops upon landing.

One of the methods of delivering the M22 to the airborne battlefield was

to remove the turret, and then hook the turret and body of the tank to

the bottom of a C-54. Then after the paratroopers secured a

suitable landing field for the C-54, the M22 tanks could be delivered

and re-assembled for support. British troops found that they could

attach the turrets to the tank in about ten minutes using the C-54's

internal hoist. Ten minutes is a long time under fire to be

putting a tank together. All of this assumed that the paratroopers

target area would include a landing field large enough to land the C-54.

It no doubt sounded like a good idea at the time. It was never

implemented. Author's photo.

What could have been...

The Ward-LaFrance M1 wrecker owes its

heritage to the 1935 Marmon-Herrington TL31-6 wrecker. The later DSD600-6 wrecker

was designed by

Marmon-Herrington, which was produced for Russia. Corbitt Truck

Company built the first three prototypes. Then Ward-LaFrance won

the production contract. It has to be assumed that

Marmon-Herrington was included in the bidding due to its all-wheel drive truck experience. It could have been a victim of its own success

in obtaining several different contracts for tanks and trucks in the

late 1930's and early 1940's. Its assembly lines were busy with

orders for a multitude of products for several countries. At the

same time, the United States started ramping up its purchase of military

products. Marmon-Herrington also missed out on building the

half-track with a powered front axle, which it invented in 1936. Four

other truck manufacturers began production of the halftrack in 1941. It wasn't

until 1943 that it had the capacity to start production of the American M22 tank.

Author's photo added 9-29-2019.

Post-World War Two Military Fire

Apparatus:

This is American LaFrance O-11A fire and

crash truck which is on display at the Museum of Aviation at Robins AFB,

GA. The O-11 was used by the United State Air Force starting in

1952 and continuing up into the 1970s. It was the main fire and

rescue truck at Air Force bases world wide including Vietnam.

Author's photo added 6-14-2022.

Marmon-Herrington also built an unknown number

of these units for the U.S. Air Force.

There was an O-11, O-11A, and O-11B in the

series each of which had various upgrades to the equipment.

Depending on the source, there was either 1,100 or 1,800 units built by

both American LaFrance and Marmon-Herrington. Author's photo

added 6-14-2022.

Author's photo added 6-14-2022.

Author's photo added 6-14-2022.

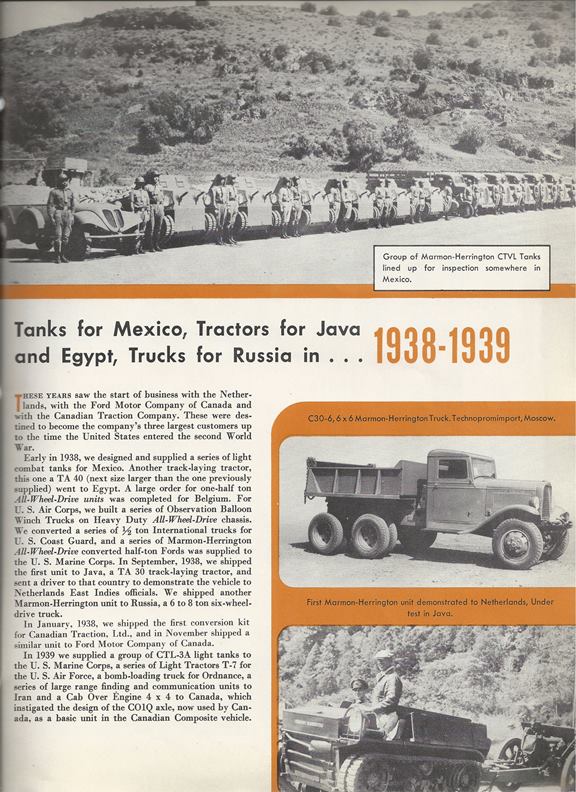

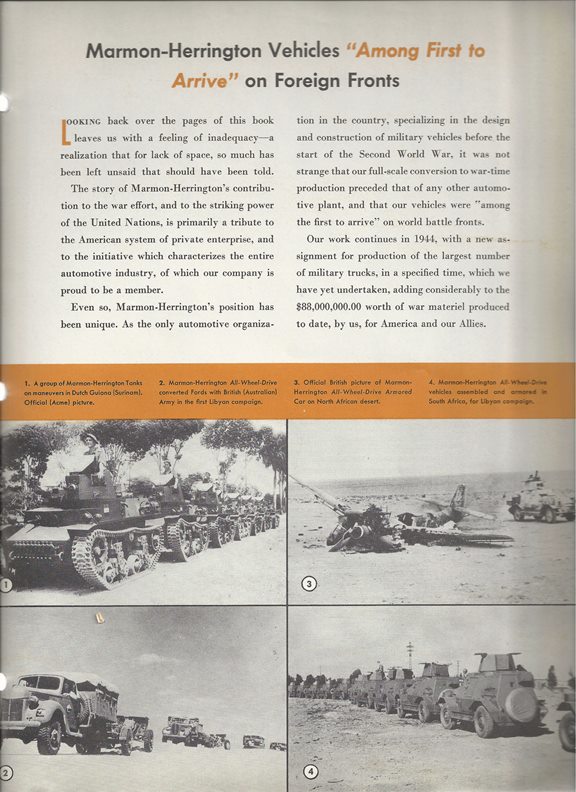

"Ten Years Before Pearl Harbor"

This 1944 booklet published by

Marmon-Herrington gives excellent insight into the company's preparation

before World War Two, and the many different products it produced during

the war. Being written by Marmon-Herrington, it is a primary

source document.

Thank you to Bill Kreiner for sending this to me. This has been

such a revelation, as in the past it has been hard to find information

on Marmon-Herrington. It has become a forgotten and ignored company

by local Indianapolis historians. It is as though the company was

writing the information below just so I could publish it 75 years later.

Not only does it tell its story during World War Two, but also how it

prepared for the war starting at its inception in 1931.

This is a must read for the serious

Marmon-Herrington historian! It is a fascinating story.

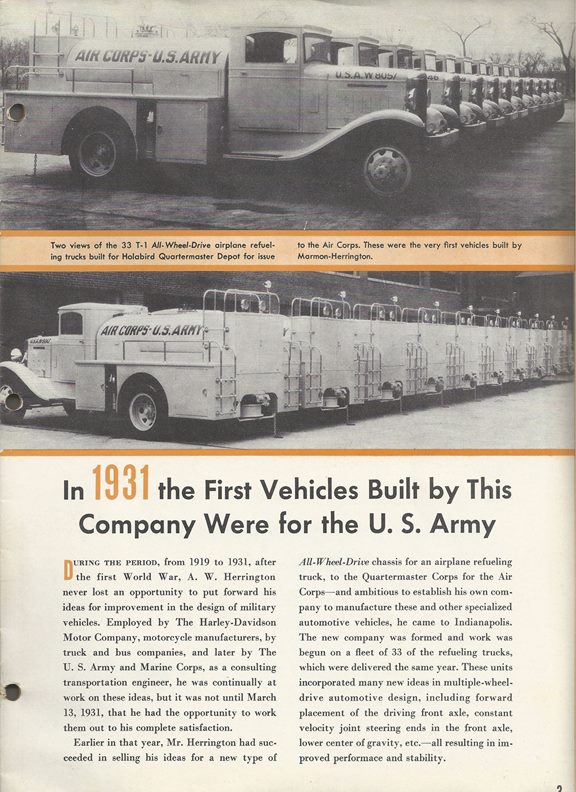

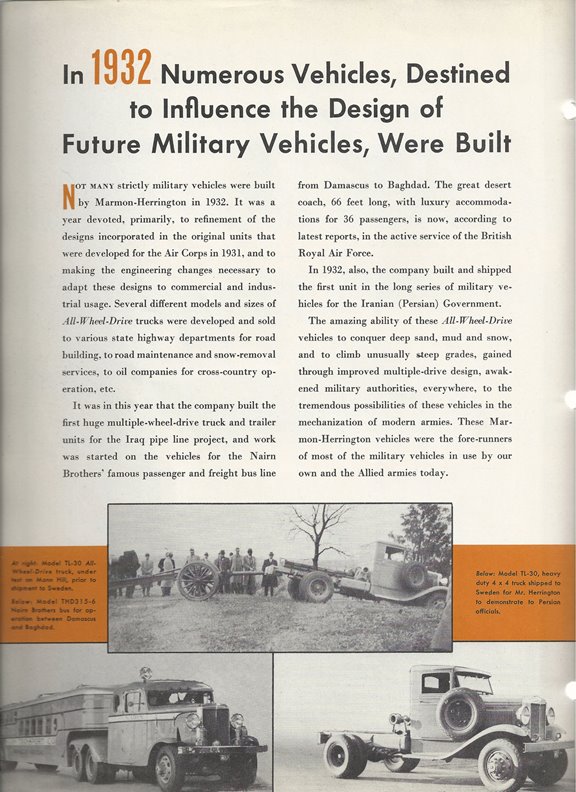

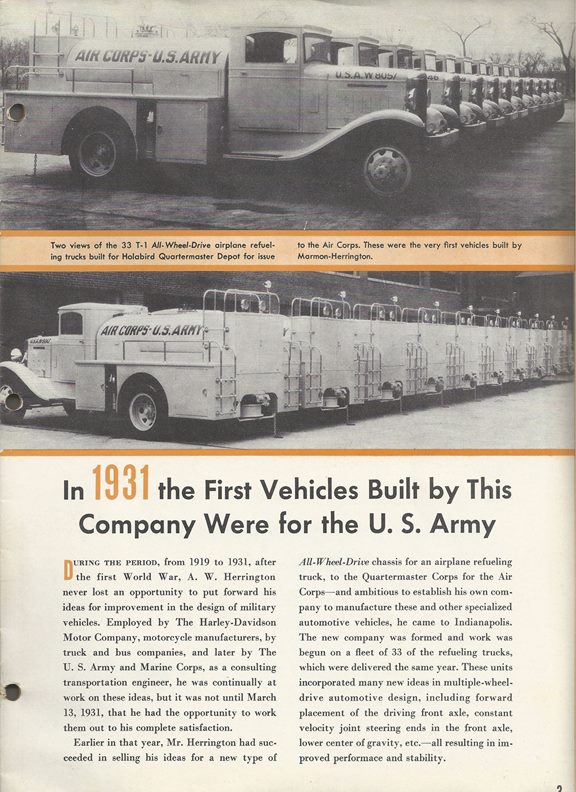

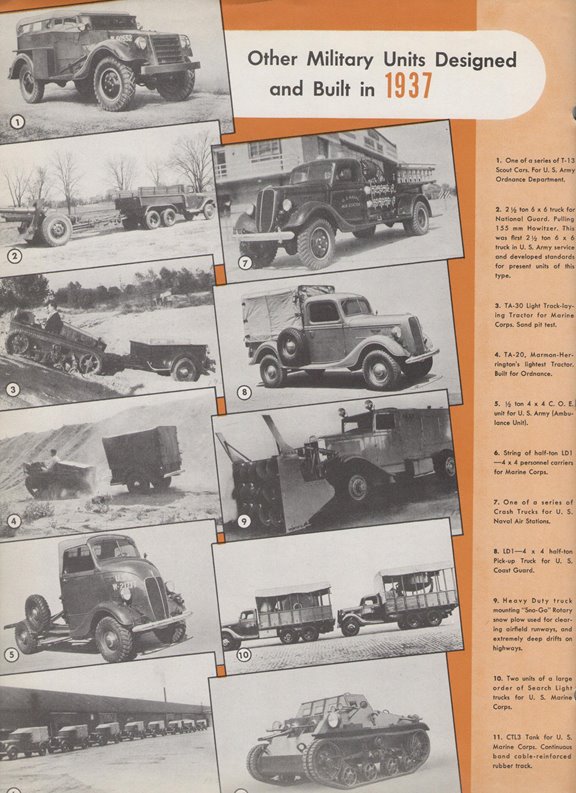

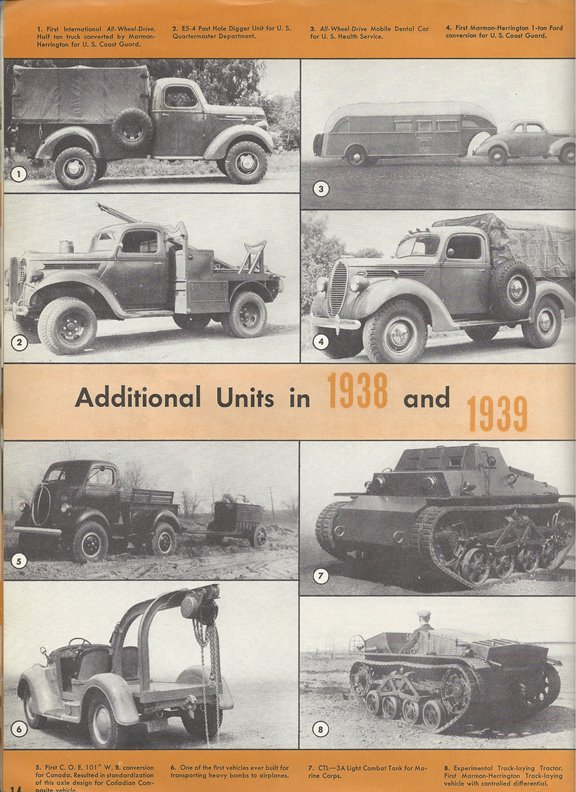

This page explains that the first 33 vehicles

built by the new Marmon-Herrington

Company in 1931 were all-wheel drive refueling

trucks for the Army Air Corps.

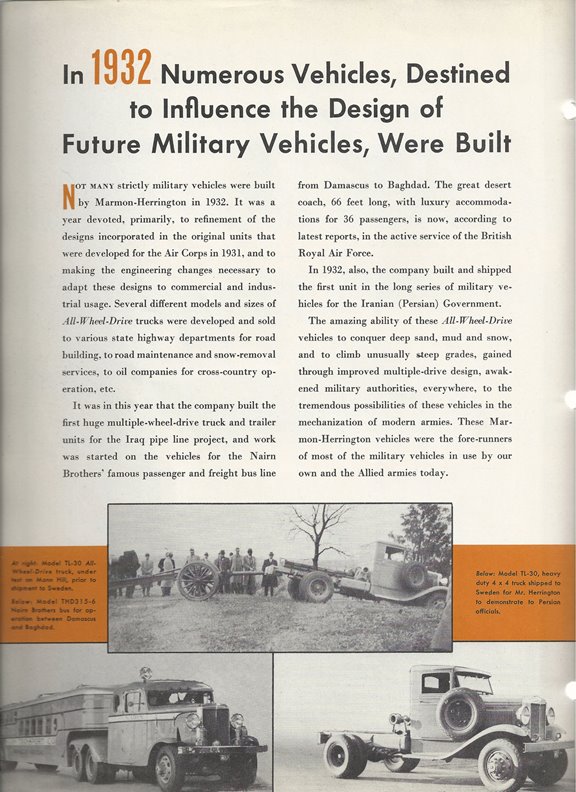

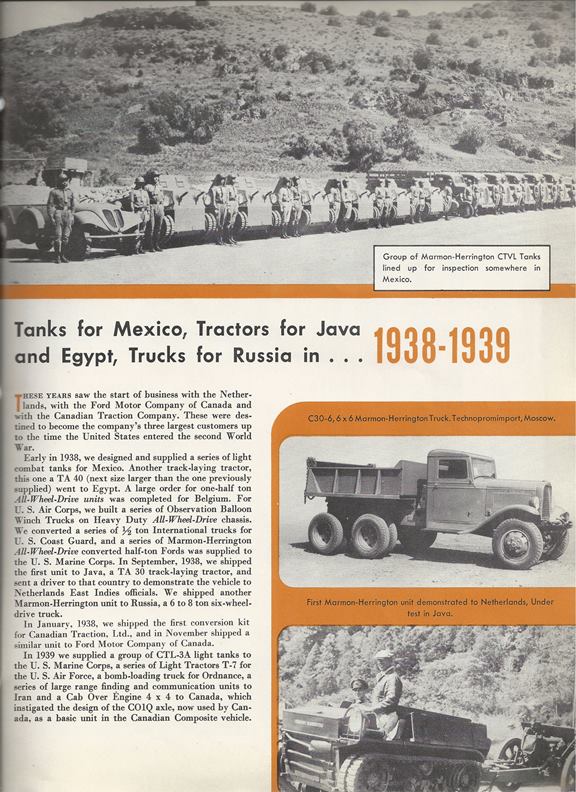

Marmon-Herrington very aggressively pursued foreign customers. In 1932 Iran became a long lasting and

important customer of the company's products.

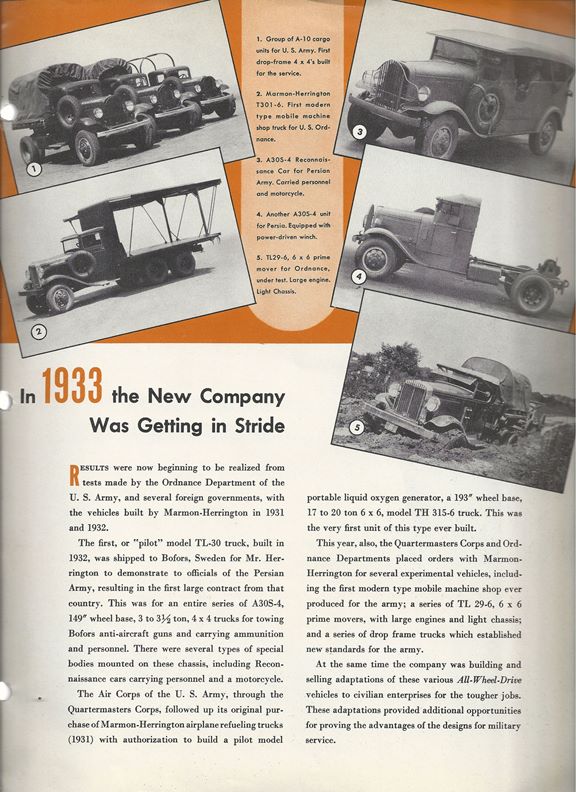

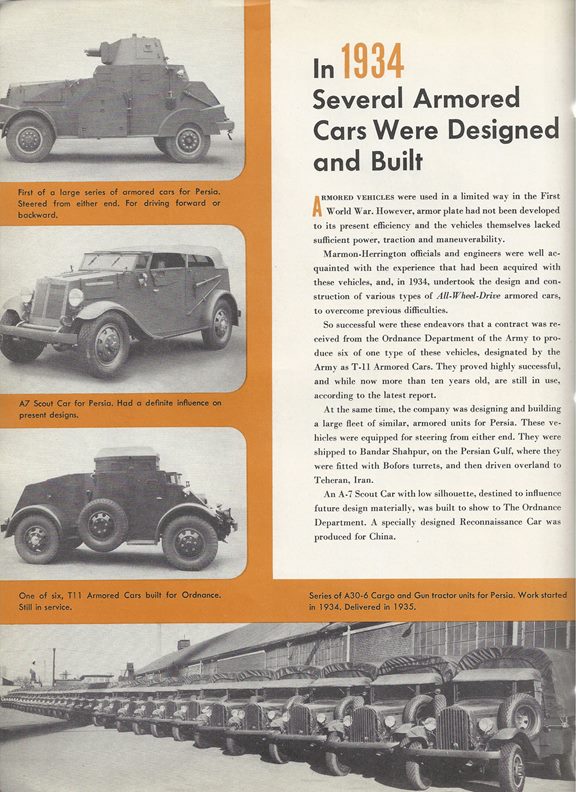

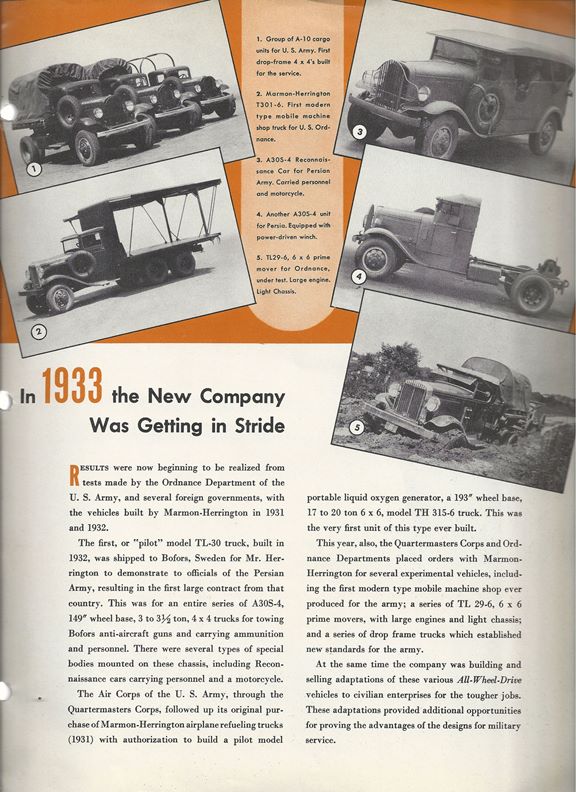

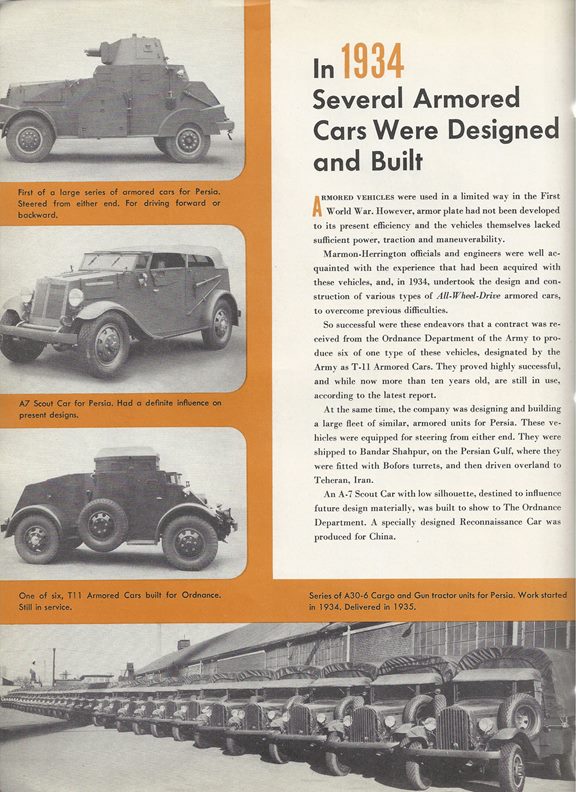

In 1934 Marmon-Herrington designed and then

built six T-11 4x4 armored cars for U.S. Army Ordnance. This was

one of several types of armored cars it developed in 1934.

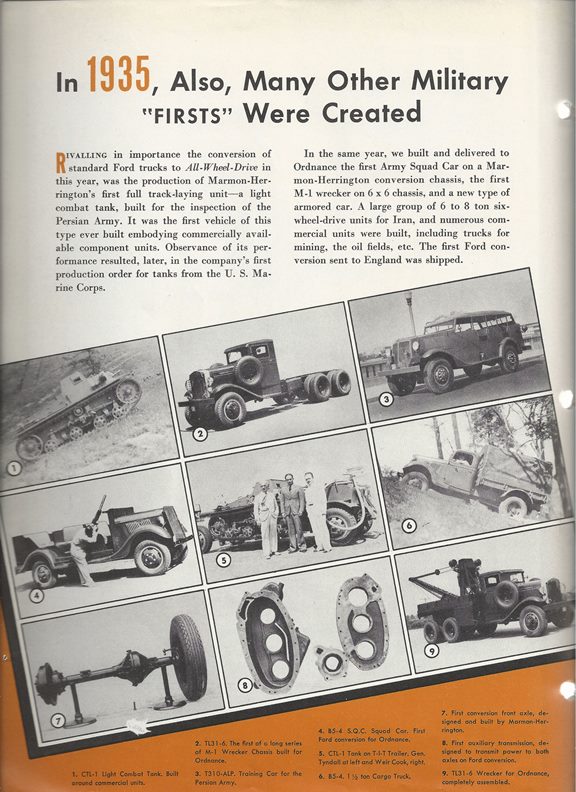

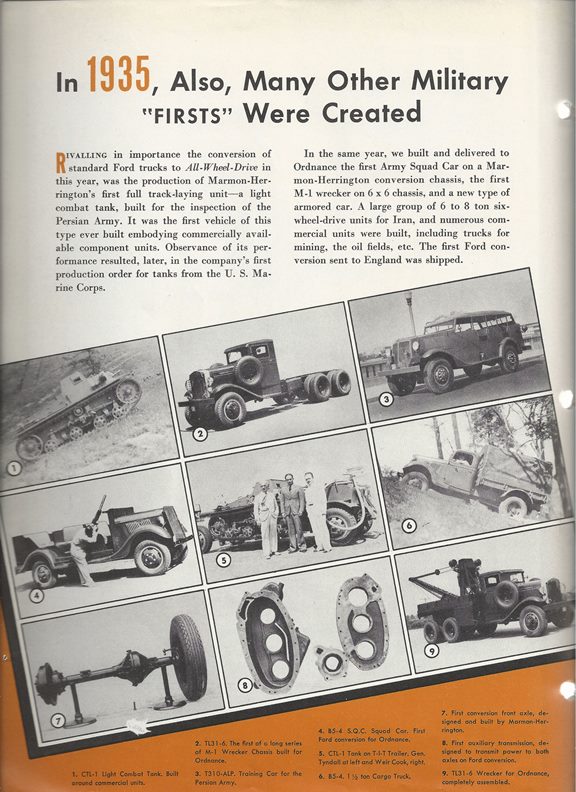

In 1935 Marmon-Herrington All-Wheel Drive is

officially introduced for military products.

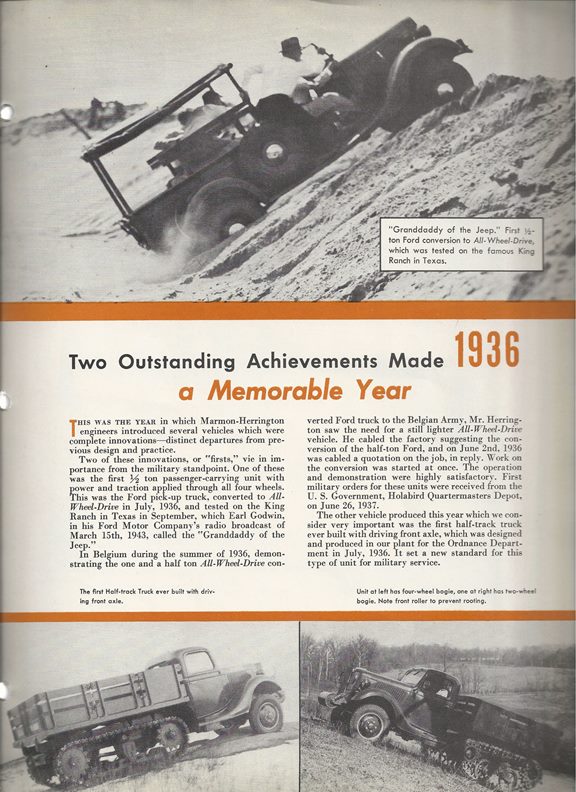

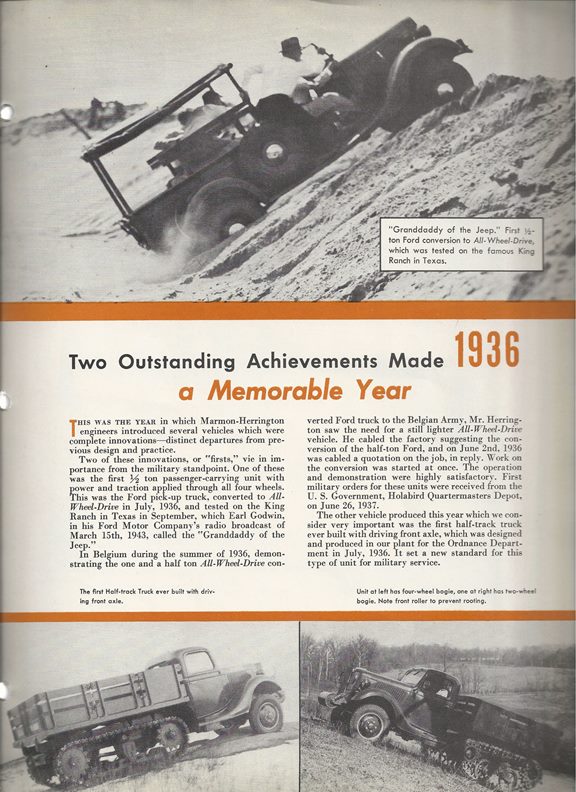

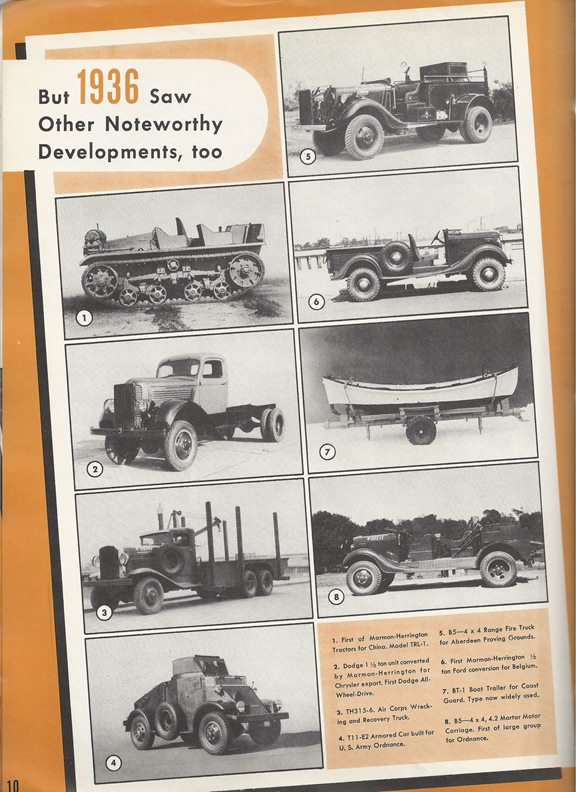

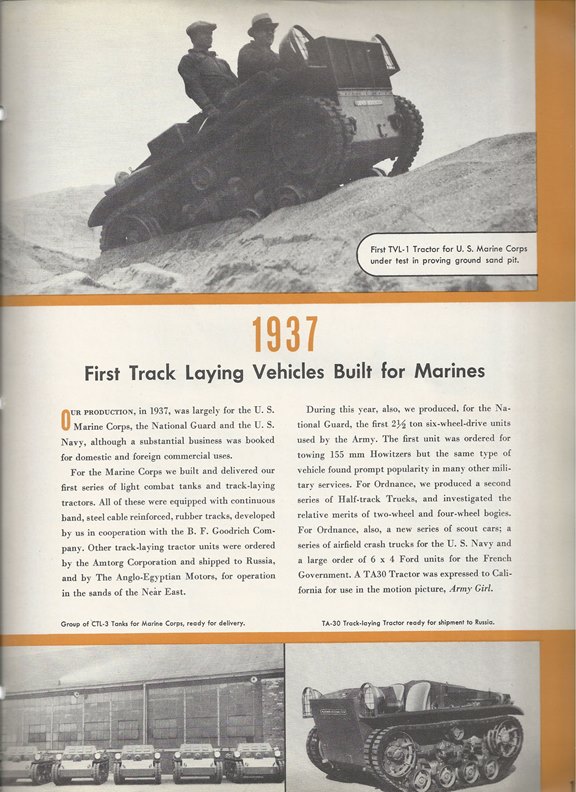

1936 was an important year for

Marmon-Herrington, as it designed and built the first half-track with a

powered front axle. It also converted a 1/2-ton Ford truck to

All-Wheel Drive. This eventually led to the Jeep and the

many other four-wheel drive trucks that were produced during World War

Two.

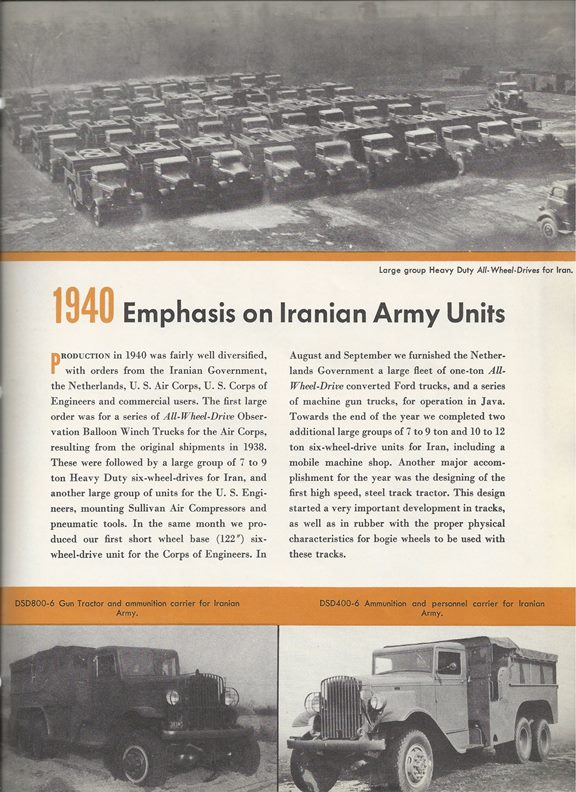

There are 42 trucks shown in the photo at the

top of the page. Forty of them are the DSD400-6 Ammunition and

Personnel Carriers for Iran.

Building the CTMS-1TB1 tank in 1942 for the

Netherlands did not make any sense. The Dutch East Indies was

under the control of the Japanese, and the Netherlands was

occupied by the Germans. The tanks were taken by the United States

military but were of little practical use. On the other hand,

while the rest of the United States was just starting to become really

engaged in war production, Marmon-Herrington was already in the war.

During the years leading up to World War Two, its military sales to

foreign countries gave employment to many men in the Indianapolis area

who might otherwise have been unemployed.

|