|

Packard

Electric Division of General

Motors Corporation in World War Two / WWII

Warren, OH

1890-Current

(As Delphi Packard)

Despite all the changes and consolidations of GM and then Delphi

Divisions that Packard became part of, it has still maintained its

identity.

This page updated on 4-28-2014

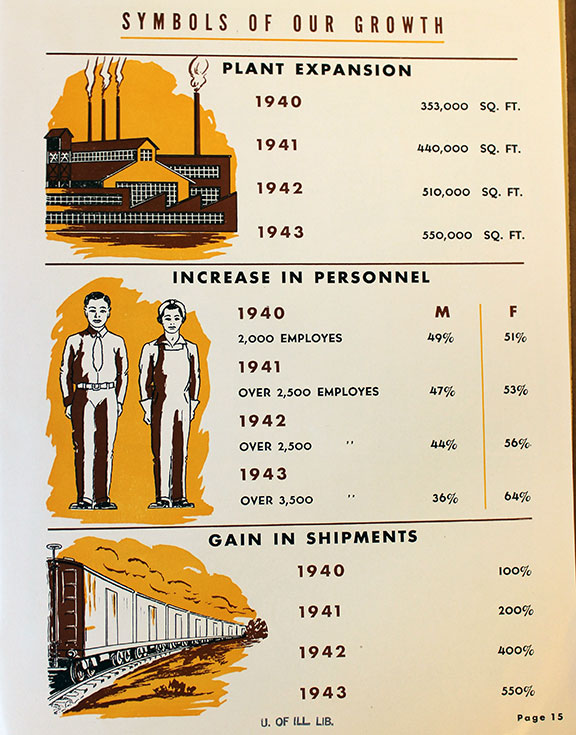

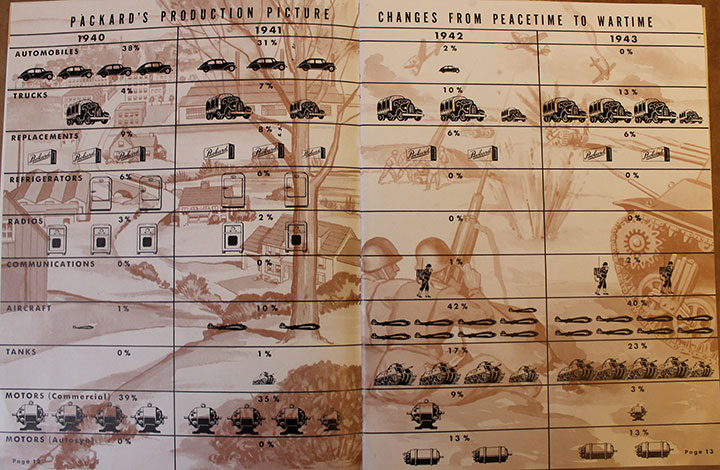

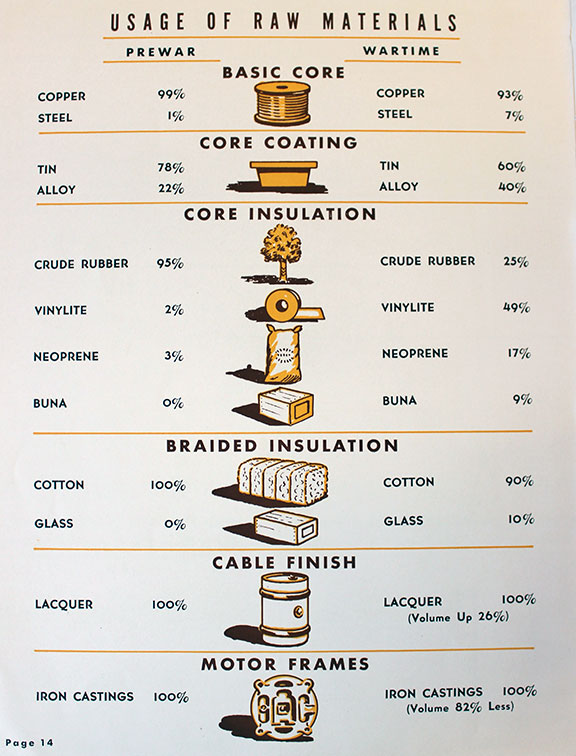

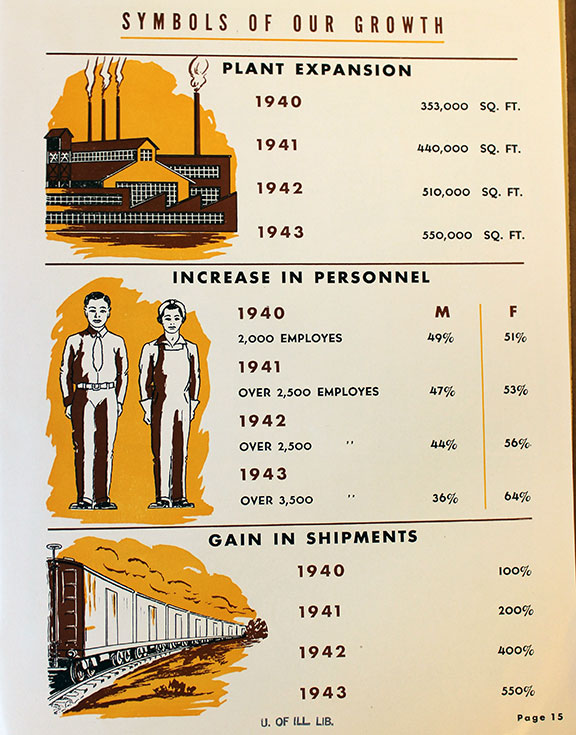

Packard Electric Division

World War Two / WWII Production Numbers / Statistics:

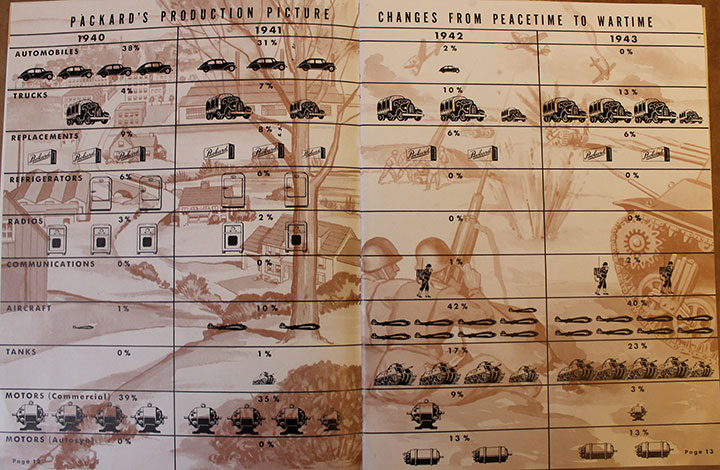

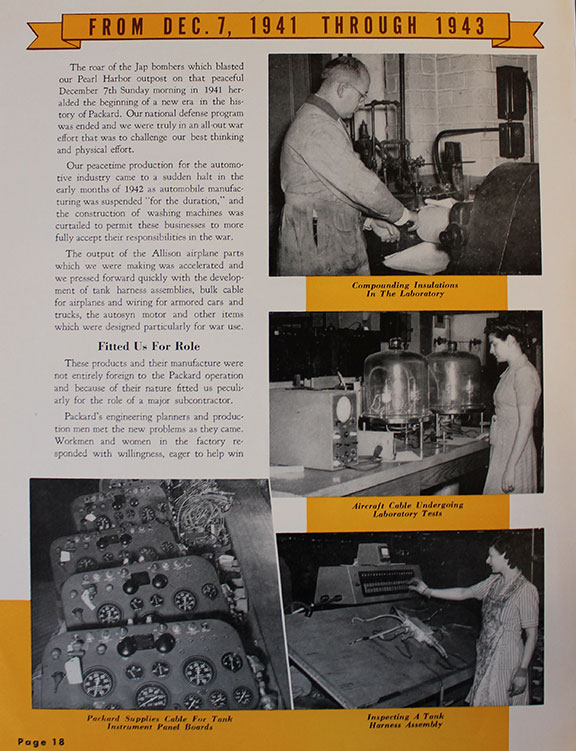

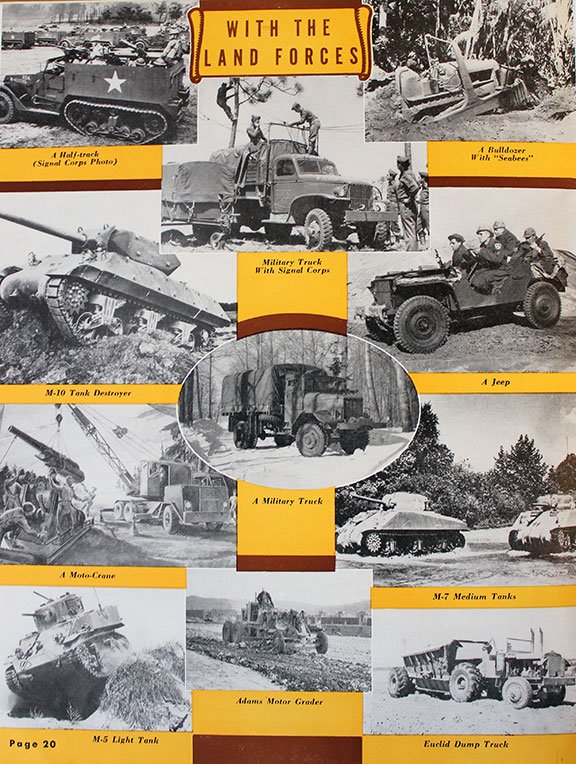

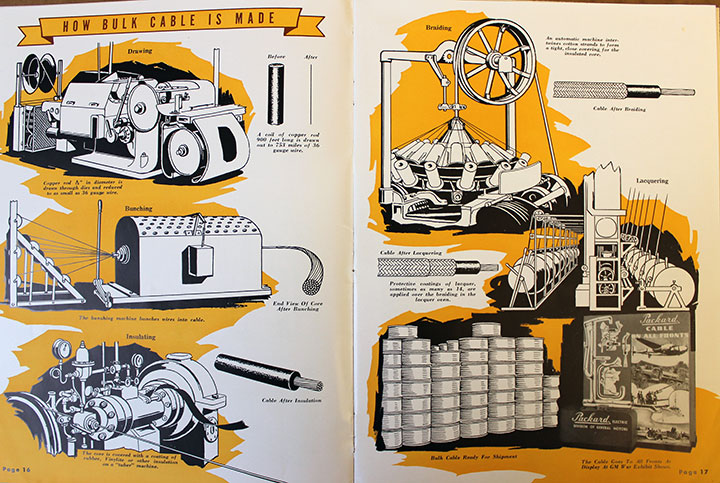

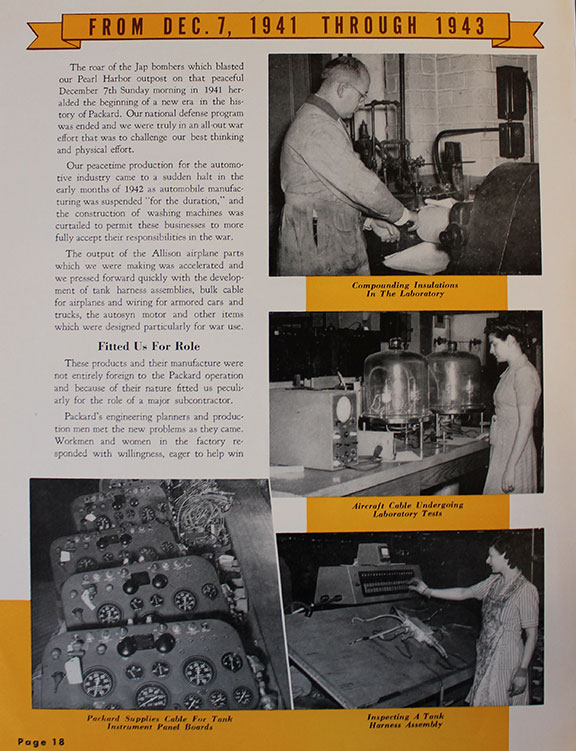

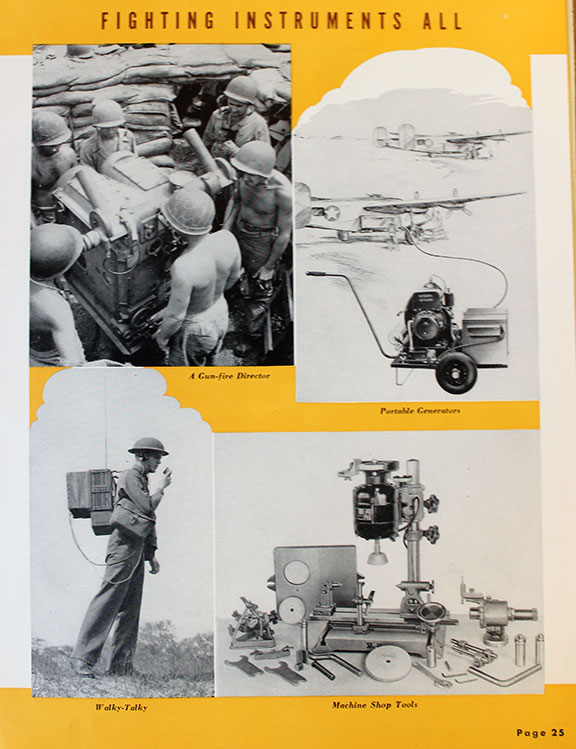

Electrical cable (wire) from Packard Electric was used for the wiring a

multitude of military applications during the Second World War.

Electrical wiring is ubiquitous. It is used

everywhere there are electrical circuits, but it is usually never given

much thought as it is never seen. There was a considerable amount

of engineering and manufacturing expertise needed to get the correct

electrical insulation for the military application. Packard Electric

was able to provide that expertise for the war effort. Packard cable was used in

land vehicles, aircraft, ships, engines and various military instruments

and electrical equipment. It should be noted that WWII was

previous to the invention and use of the circuit board. Electrical

equipment all used point to point wiring that needed copious amount

cable and wire to make it work.

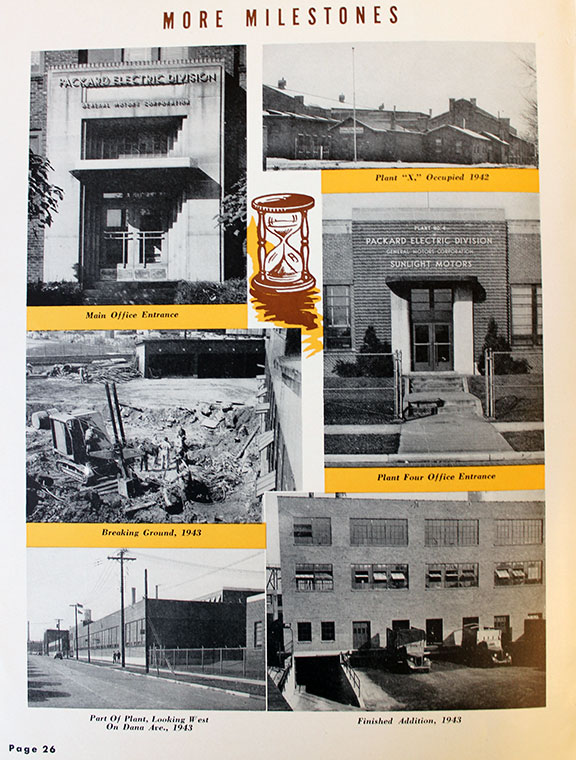

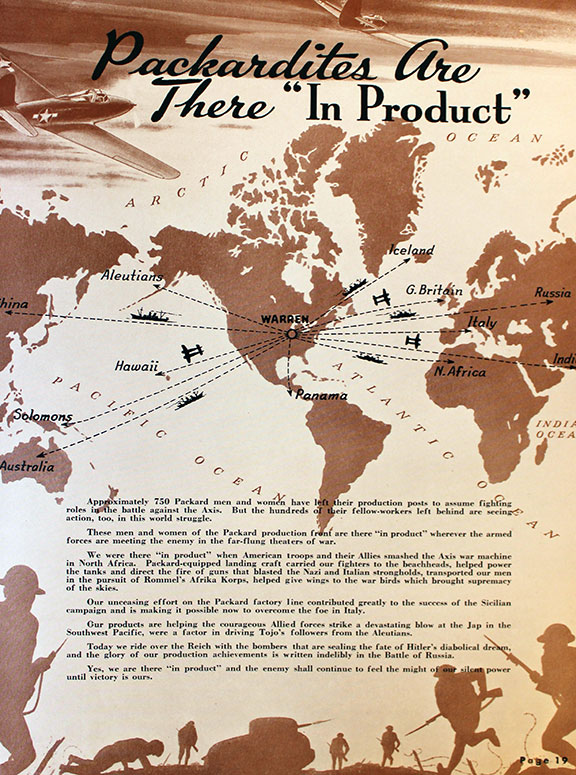

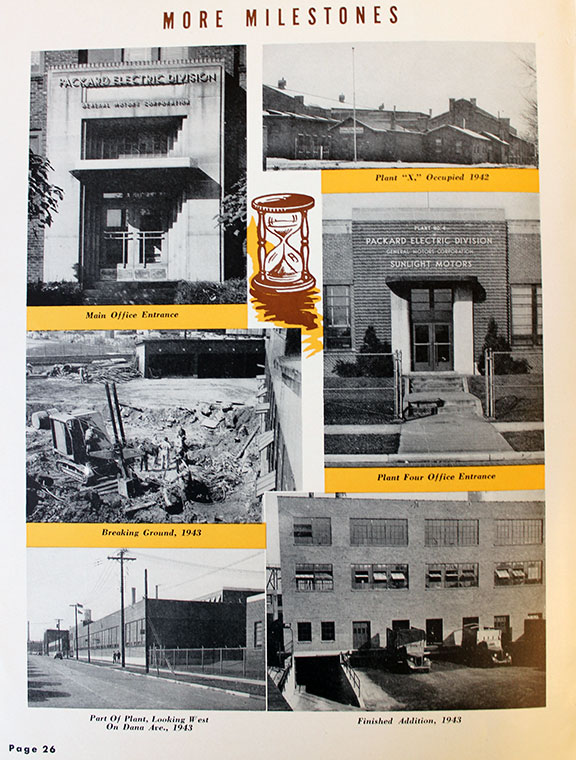

It should be noted from pages 5-6 of the

"Background for Victory" below that in July of 1943, Packard Electric

took over the Sunlight Division of GM, and assumed responsibility for

the manufacture of autosyn motors. These are also known as slo-syn

motors and one widely used application was the remote control of many

anti-aircraft aircraft guns by a sight remote gun sight.

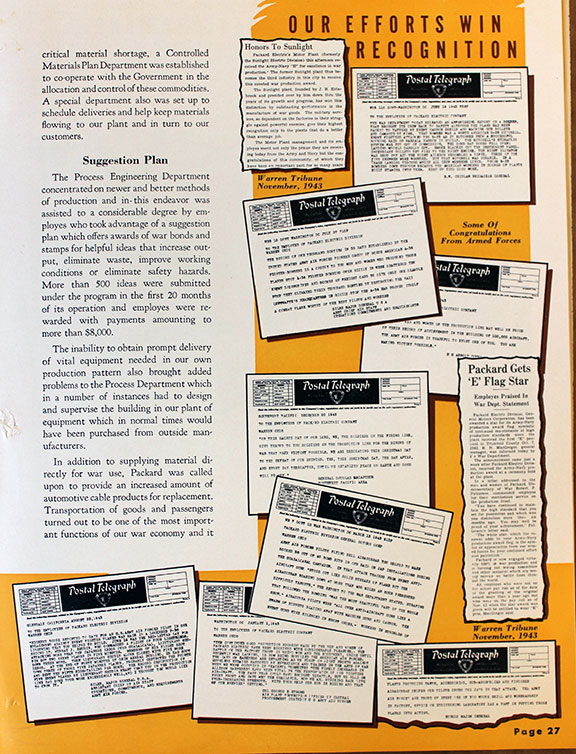

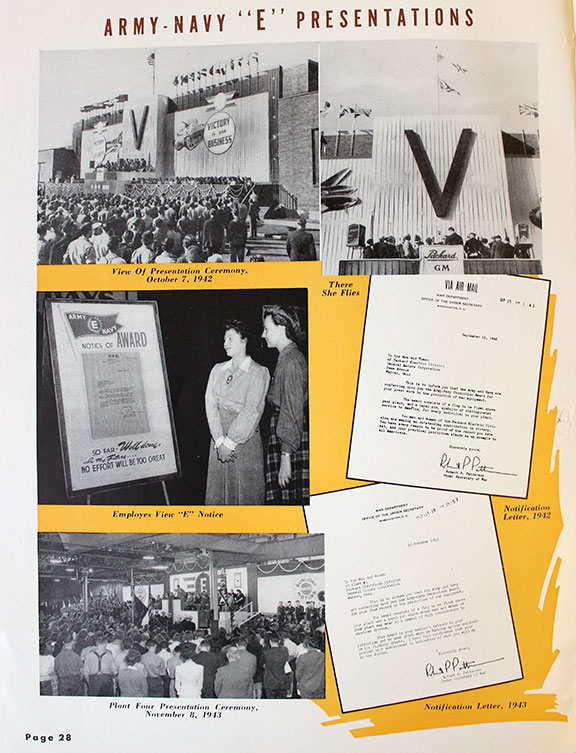

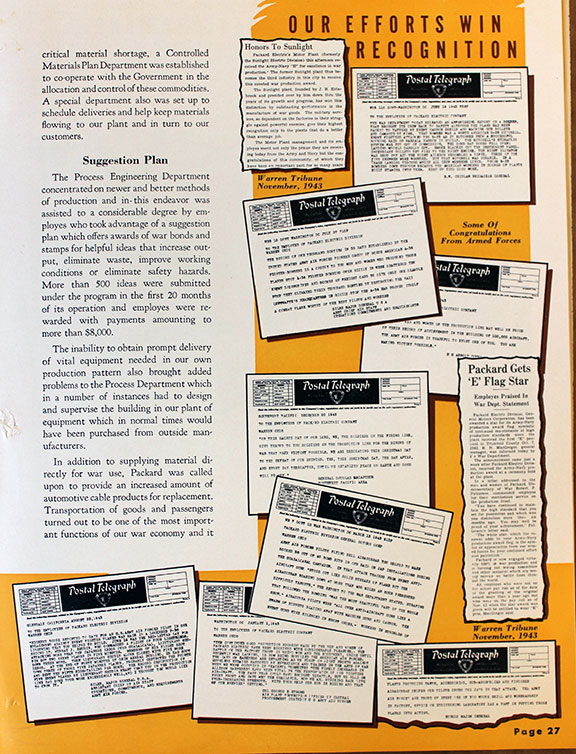

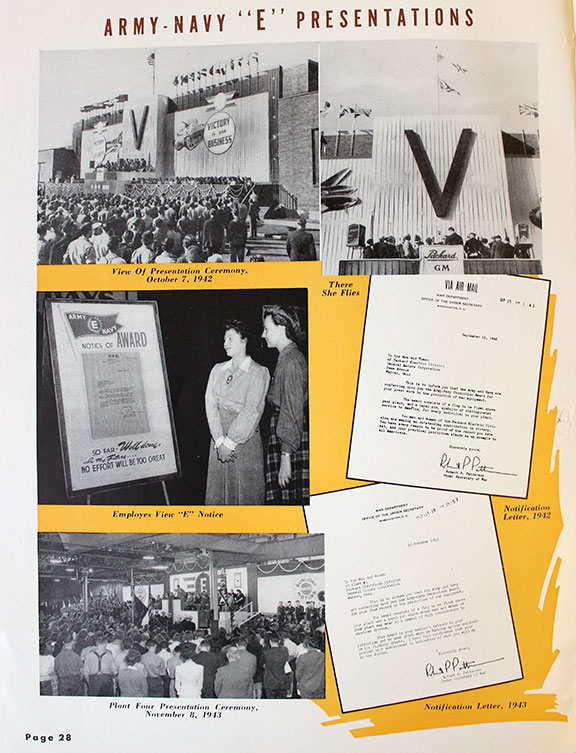

Packard Electric Division won its first

Army-Navy "E" award on September 12, 1942, with the

presentation on October 7th of that year. It won three more awards

for a total of four.

The next year Plant 4 of the Packard

Division won its own "E" award on October 16, 1943. The

the plant was awarded two more awards for a total of three.

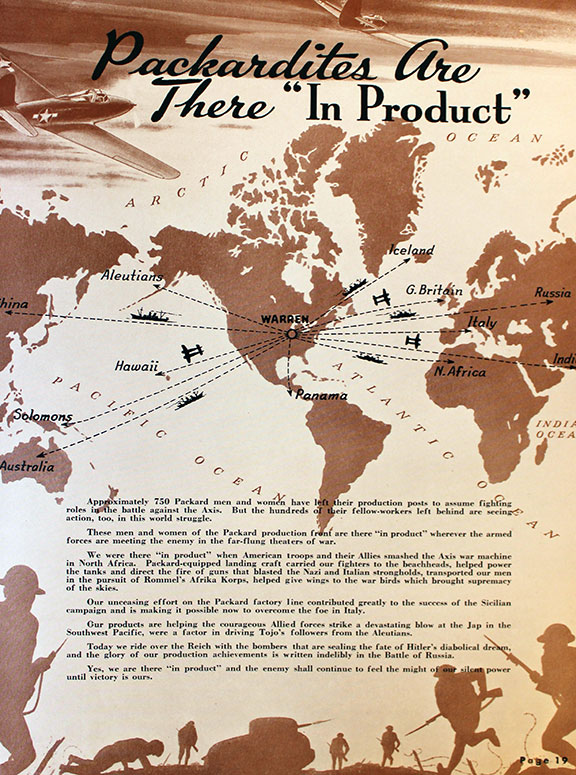

Packard Electric was one of seventeen GM

Divisions that was involved and supplied parts for the Boeing B-29

Superfortress during the Second World War. The B-29 was the most

expensive of the wartime projects taken on by the US, and combined with

the second most expensive Manhattan Project, ended the war with the

dropping of the atomic bombs. Packard supplied high altitude

ignition cable for the B-29 engines. No doubt its wring was used

in much of the on board electrical and electronic equipment also.

Author's photo from the 2013 World War Two Weekend Airshow.

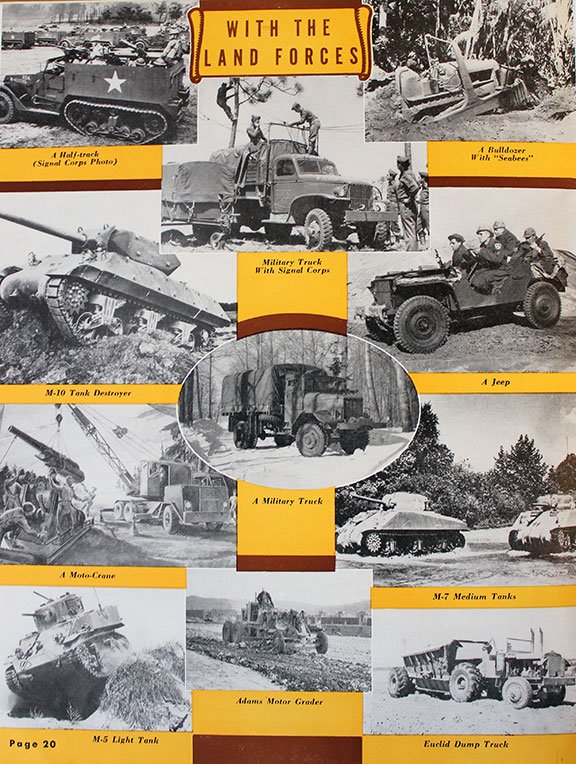

In the 1942 General Motors annual report it

was noted that Packard Electric was supplying wiring assemblies for the

Cadillac built M-5 tank. It is also shown along with other land

vehicles on page 20 of "Background for Victory" below. Author's

photo from the 2013 Thunder over Michigan Airshow.

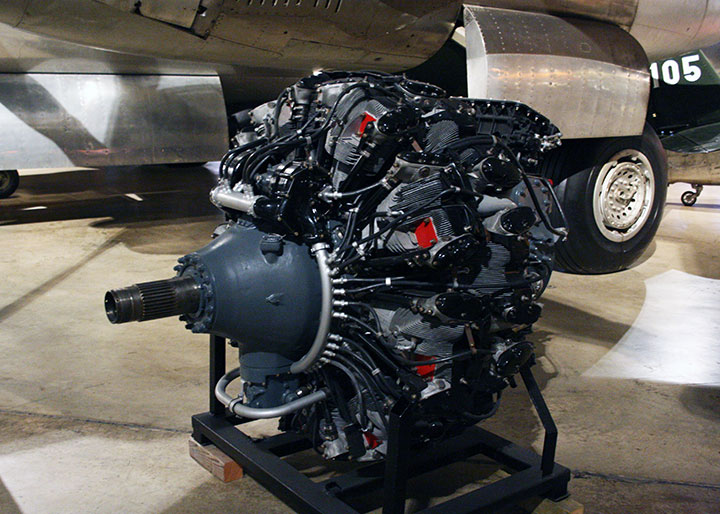

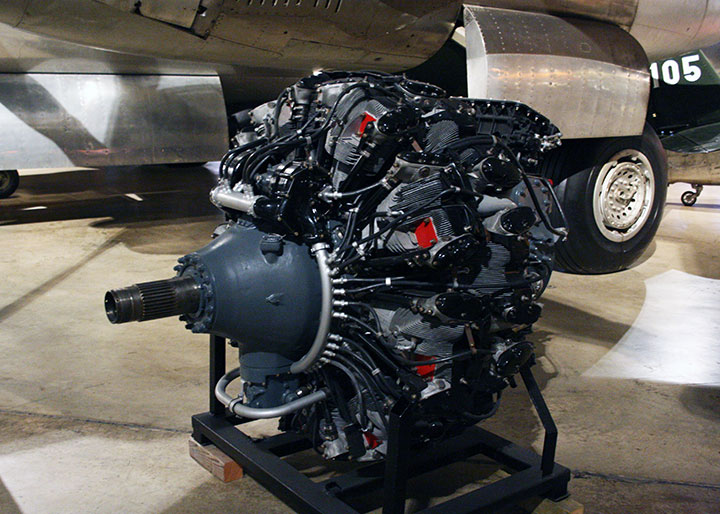

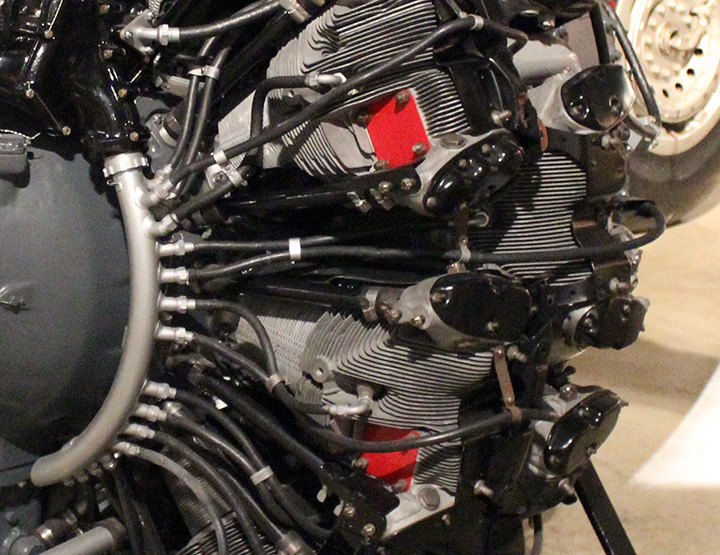

This is an example of the Wright R-3350

radial aircraft engine that powered the Boeing B-29. Note the

sparkplug wires coming out of the main wiring conduit and then making

their way to each of the eighteen cylinders. Each cylinder on an

aircraft engine has two sparkplugs. Author's photo from the

National Museum of the United States Air Force.

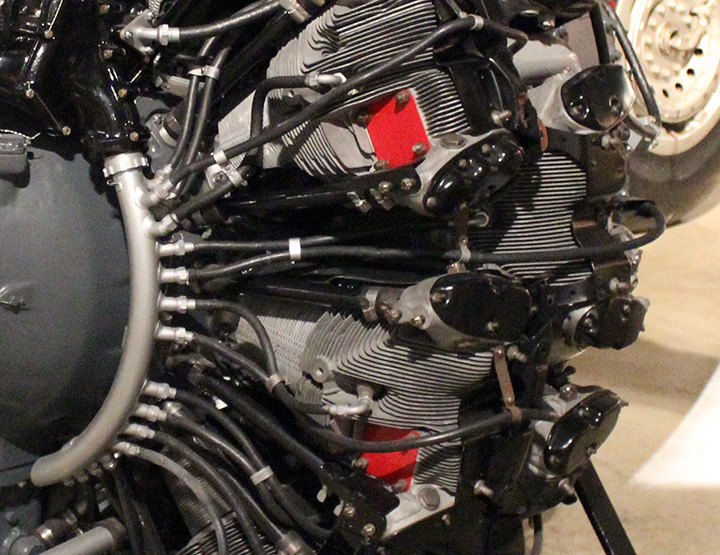

Author's photo from the National Museum of

the United States Air Force.

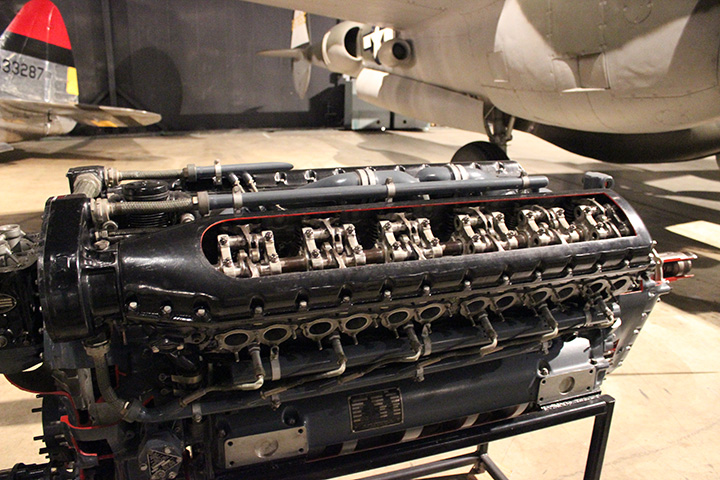

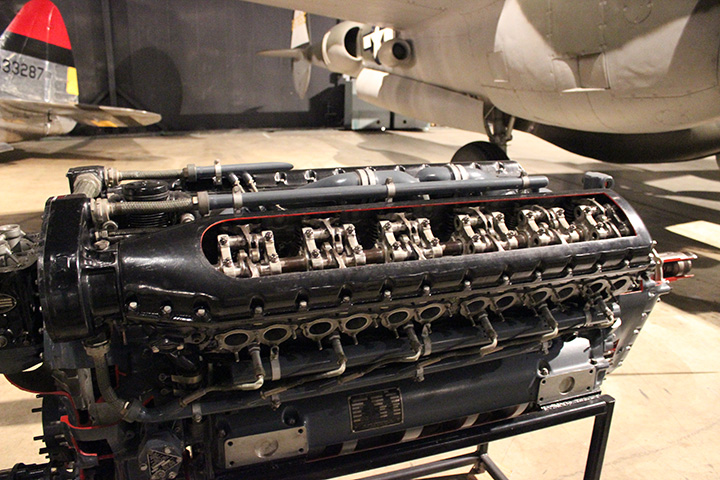

One can see the sparkplug wires on this

Allison V-1710 aircraft engine. Author's photo from the National Museum

of the United States Air Force.

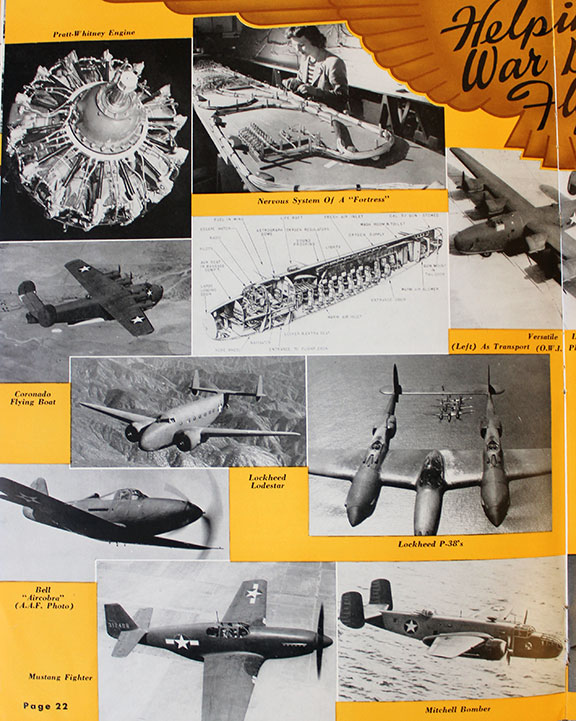

The Allison V-1710 with its Packard Electric

sparkplug wires was used in several World War Two fighters but the most

famous and iconic was the Lockheed P-38 "Lightning". Author's

photo from the 2013 Chino Airshow

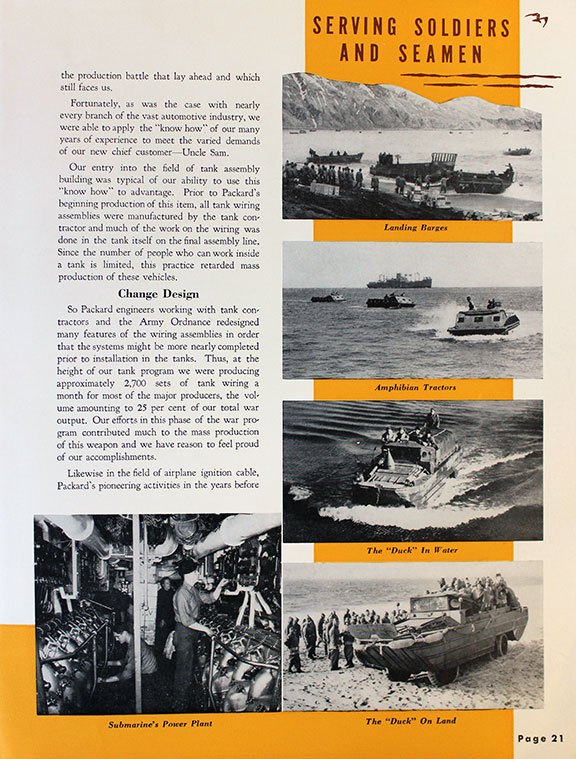

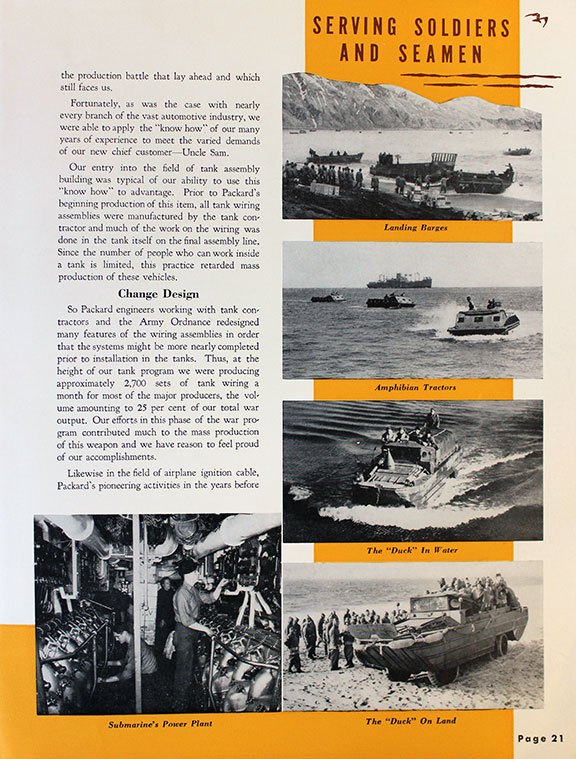

On page 21 below of "Background for Victory"

the DUKW (Duck) is shown. One of the outstanding logistical

innovations of WWII was this amphibious version of the GMC 2 &

1/2 ton 6x6 truck. In landing operations it could carry supplies

from the ship and deliver them directly to the combat troops in need of

them. Also it was instrumental in cross river landings, especially

in Europe.

This DUKW is on display at the Indiana Military Museum in Vincennes, IN. Author's photo.

Ford Motor Company was one of eleven

companies that built the M4 Sherman tank during WWII using Packard

Electric built wiring harnesses in the final assembly. This

example is one of 1,690 M4A3 Shermans that Ford built. Author's

photo photograph from the WWII Museum in New Orleans, LA. .

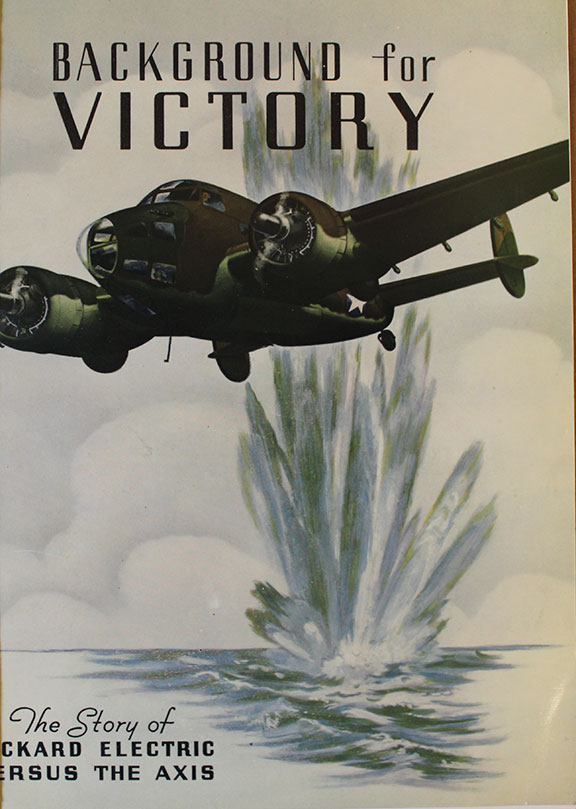

Background for Victory

The Story of Packard Electric against the

Axis

The aircraft shown here is a Lockheed

B-34/B-37 Bomber which was the US Army Air Force's version of the more

numerous PV-1 "Ventura" that the Navy used as a patrol bomber and sub

hunter.

The M7 medium tanks are misidentified.

They are actually M4 Sherman tanks, of which over 45,000 were built

during the war. As noted on the page below, Packard Electric was

producing 2,700 sets of pre-wired cable harness per month for the M4

Sherman tank. There were a total of eleven different companies

that built the tank.

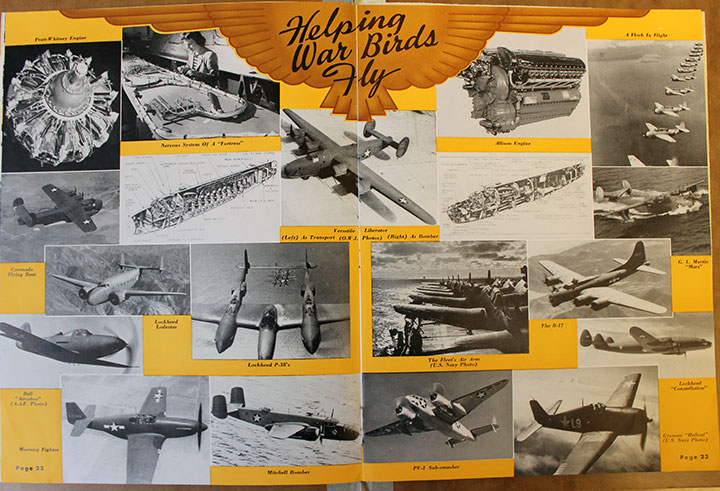

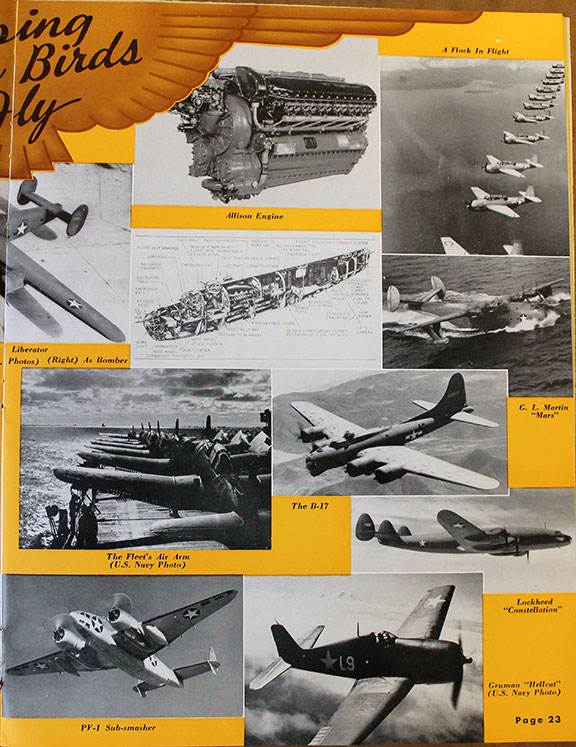

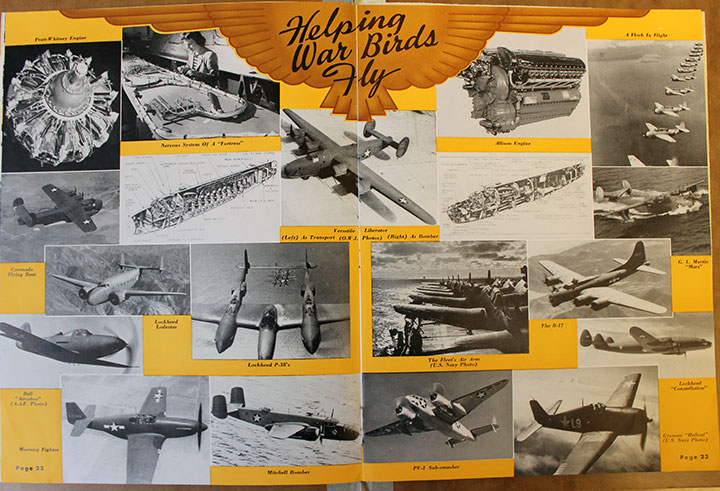

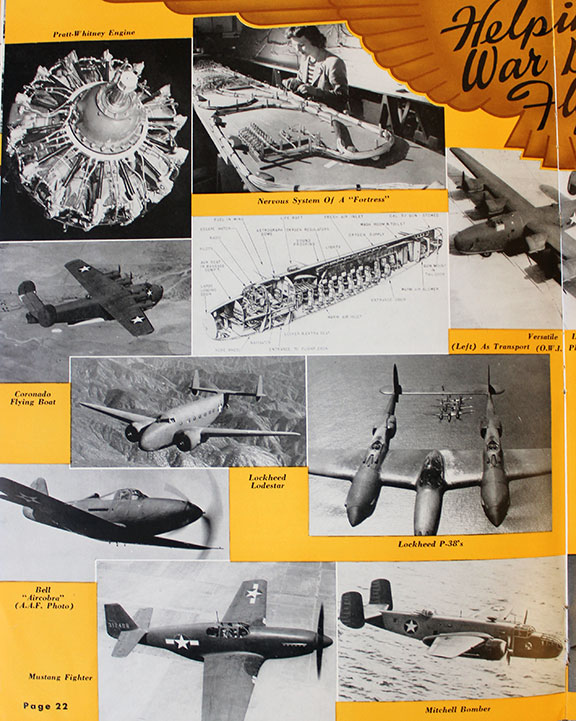

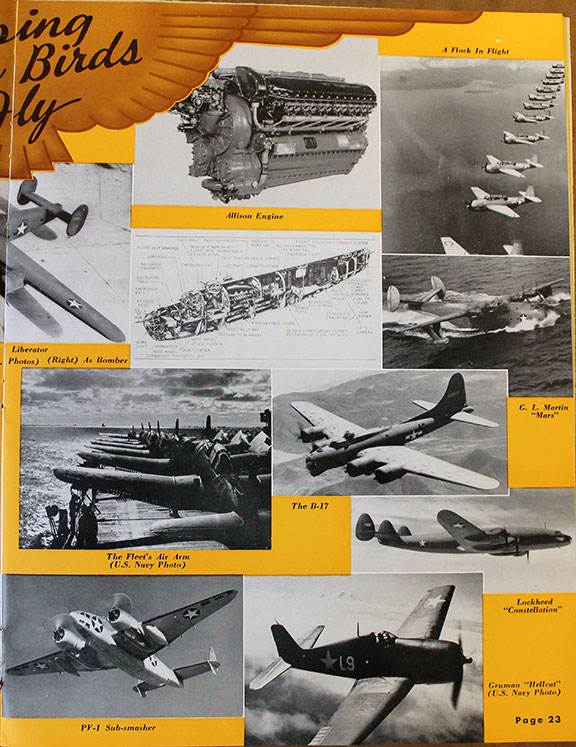

The next pages show an excellent sample of

many of the great US military aircraft and engines from WWII. This

is an aircraft

"Who's Who" from the Second World War.

This and the next page show an excellent

sample of many of the great US military aircraft and engines from WWII.

This is an aircraft

"Who's Who" from the Second World War.

Pictured in the lower right hand corner is

the Grumman F6F "Hellcat", which shot down more Japanese aircraft than

any other warplane in WWII. During initial testing the engine

would cut out at high altitudes. After being informed by the

engine manufacturer, Pratt&Whitney, that there was an ignition wire that

would prevent this, Grumman installed the new wire and the problem

disappeared. One has to assume this was the Packard Electric high

altitude wire the Division had developed.

|