|

Southern

California Division of General

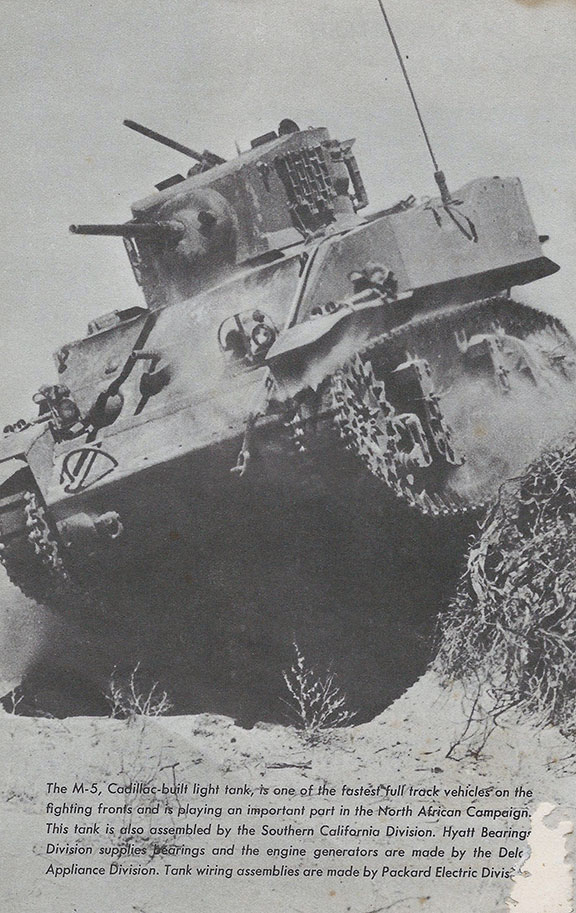

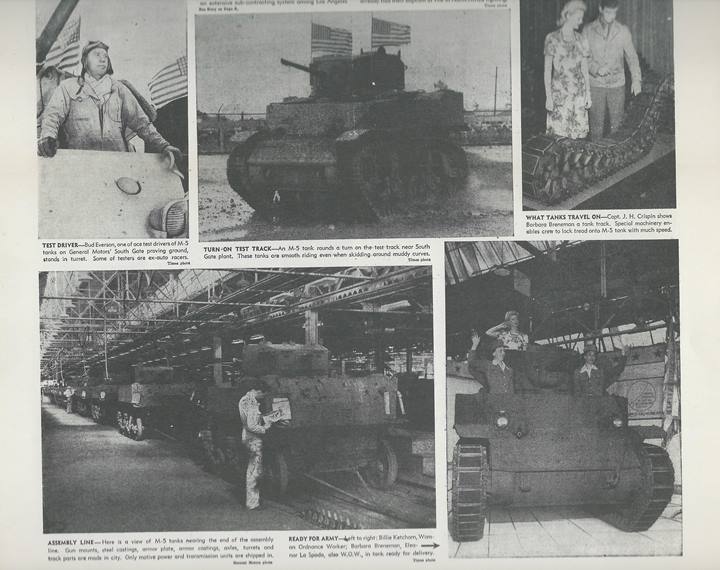

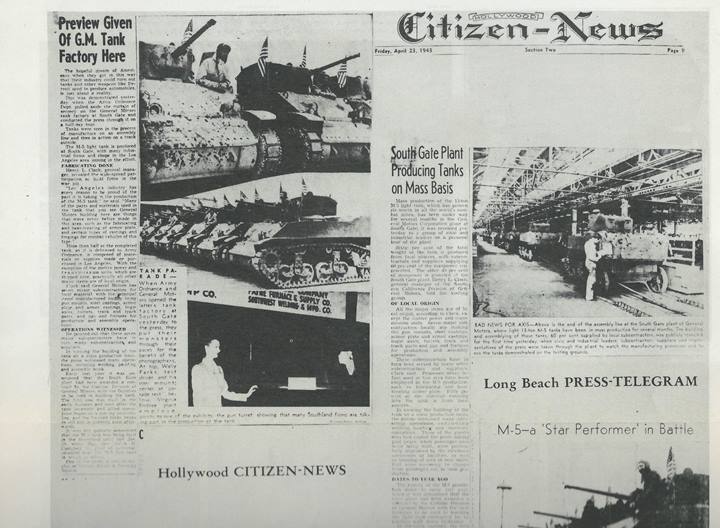

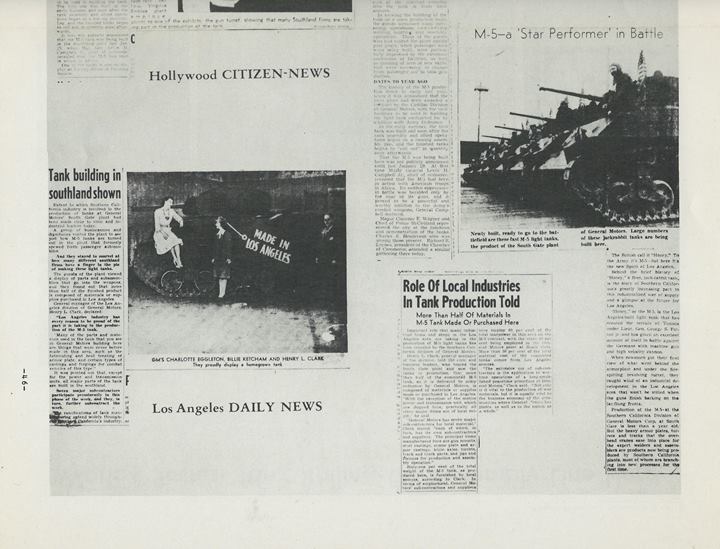

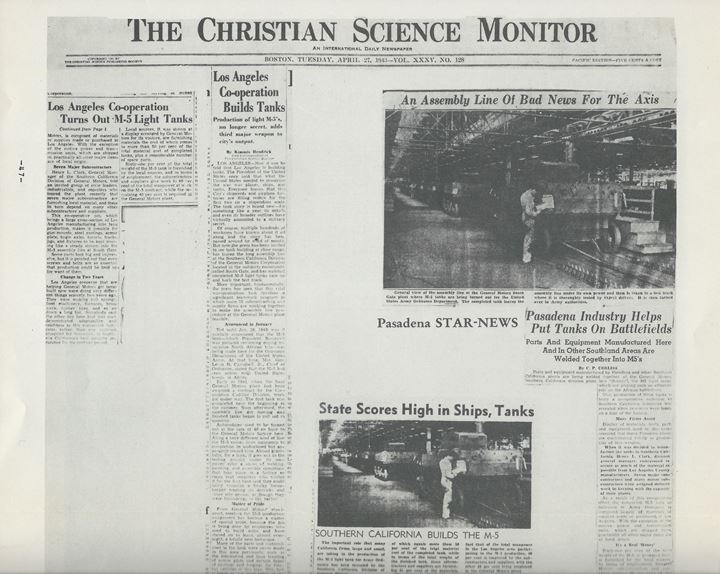

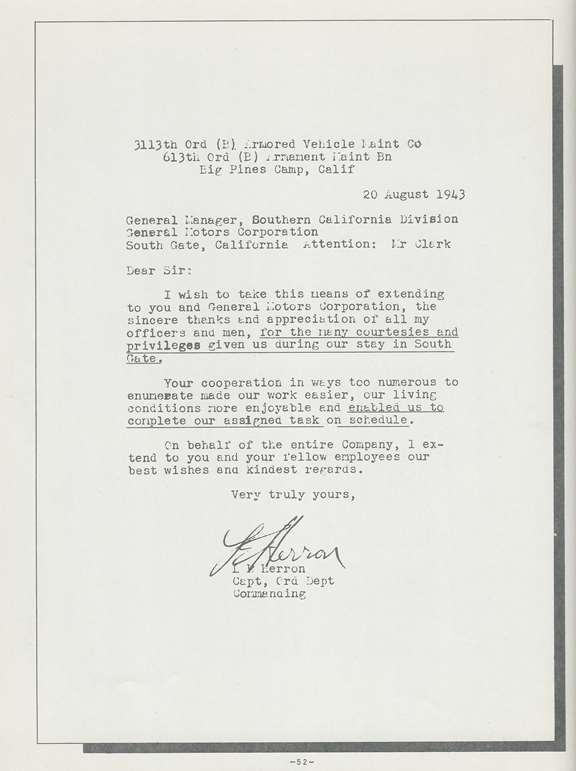

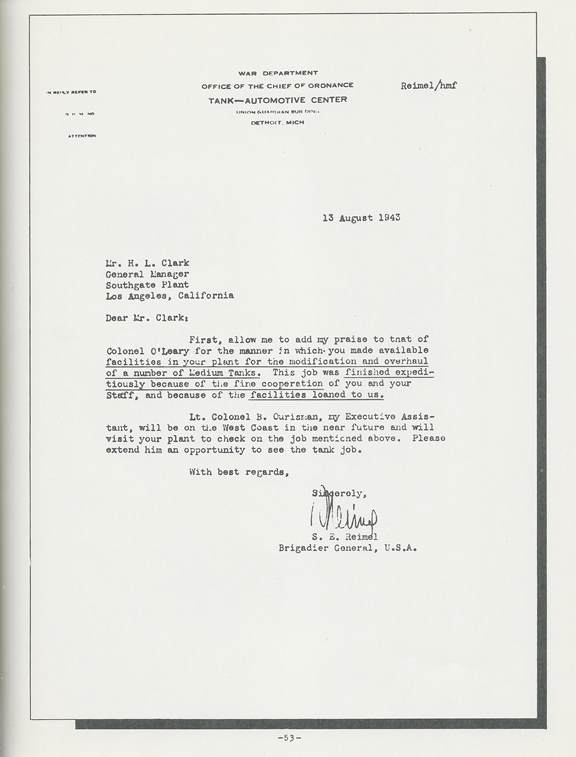

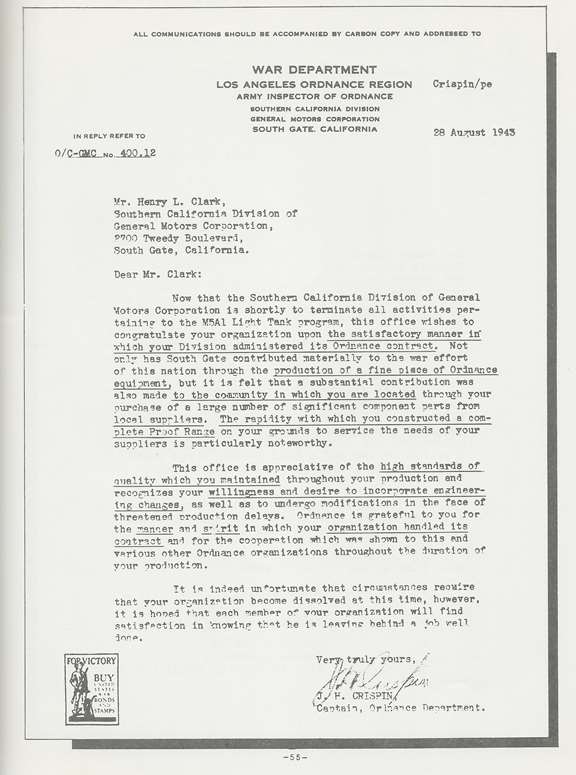

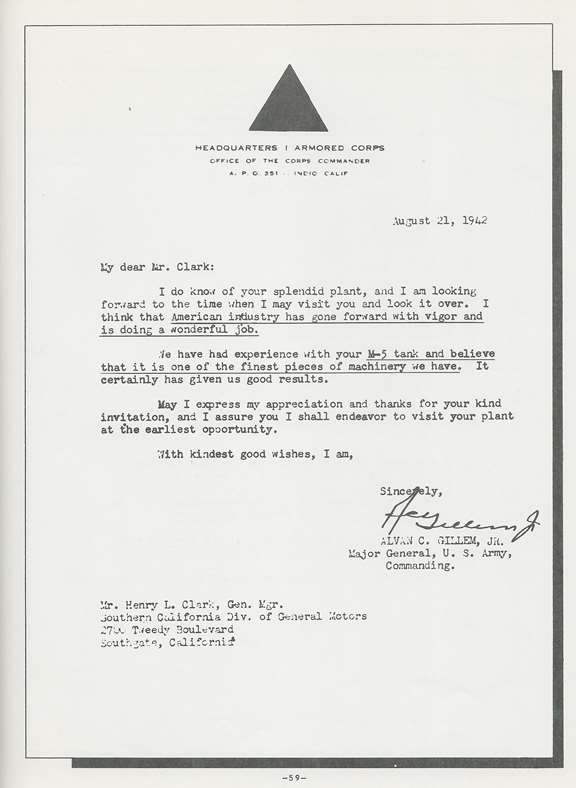

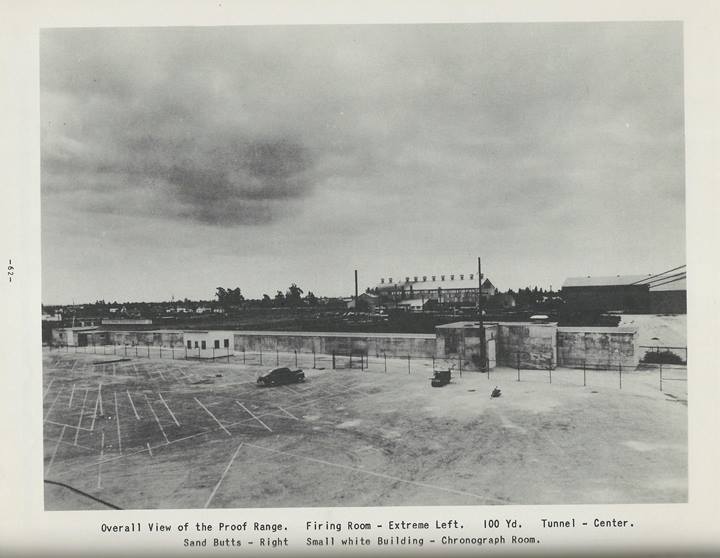

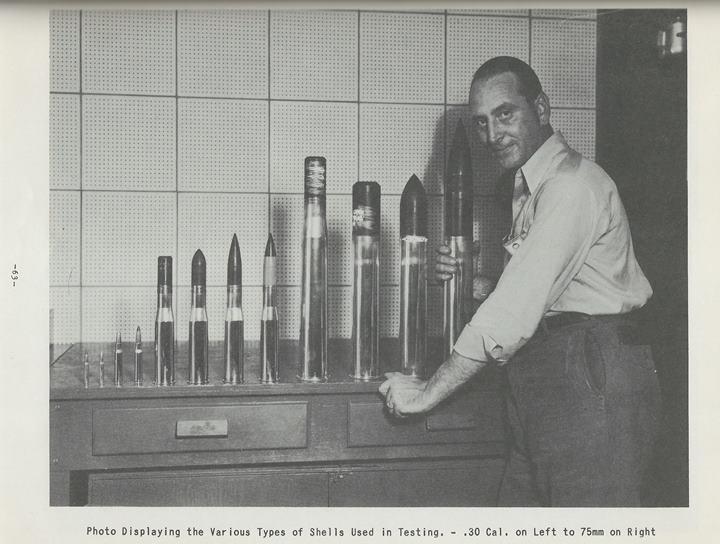

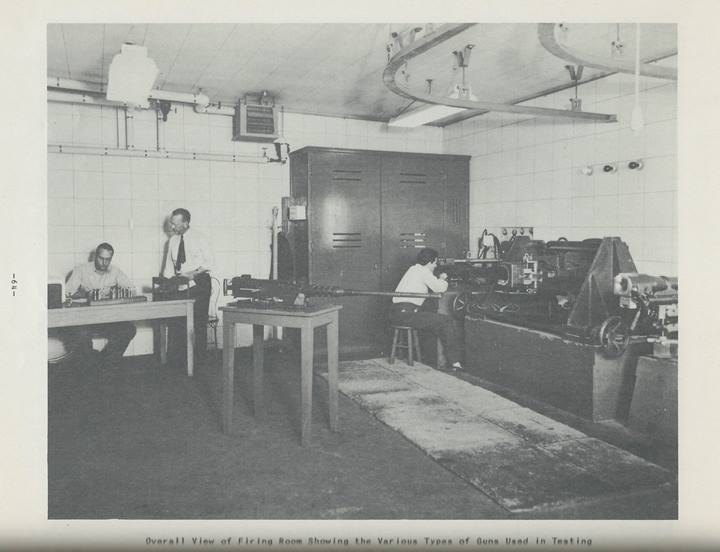

Motors Corporation in World War Two The GM South Gate Assembly Plant was opened in 1936 as the GM's first plant west of the Mississippi River in order to have a production source close to the growing market in southern California, hence the divisional name of Southern California Division. During the 1941 model year the plant produced 80,046 vehicles. From July 1942 through August 1943 General Motors produced the M5 and M5A1 Stuart tanks at the plant. It also provided a proof range for Army Ordnance to test various types of machine gun and cannon shells. Space was also provided for Army Ordnance to modify M4 medium tanks. When M5A1 production ceased in August 1943, the plant was leased Douglas Aircraft until the end of the war for aircraft part production. From 1945-1982 the South Gate Assembly Plant was first part of the Buick-Olds-Pontiac Division (BOP), and then the General Motors Assembly Division (GMAD). The plant closed in 1982 and today is the location of several schools. At least it wasn't turned into a shopping mall! The GM 1942 annual report on page 46 specifically mentions that the Southern California Division was tasked by the Corporation to assemble the M5 Stuart tank. It is also the last year Southern Californian Division is mentioned in the annual reports as a Division. Nine hundred persons worked at the plant producing tanks from 1942-1943.

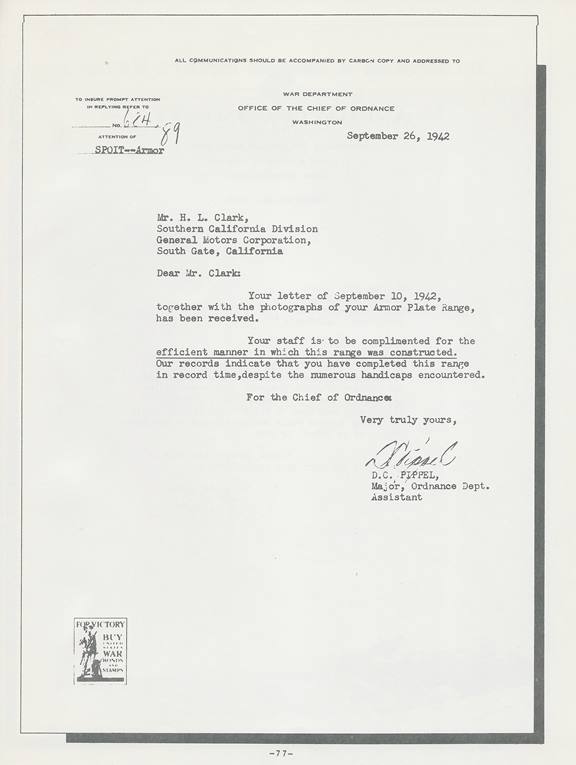

Southern California Division of GM World War Two Production Statistics: (354) M5 Stuarts from August-December, 1942, (1,196) M5A1 Stuarts from December, 1942 through August 1943. A small amount of gun shields were produced for the US Navy. Deck houses were also fabricated in small lots for the US Maritime Commission. For two months space was provided for the modification of M4 Sherman tanks by Army Ordnance personnel. In addition in September 1942 the plant finished construction of an on-site proof range for the San Francisco Army Ordnance Department. Author's Note: Some sources credit the M5 and M5A1 Stuart tanks built by the Southern California Division of General Motors at South Gate, CA to the Cadillac Division of GM. This is incorrect, as the Southern California Division of GM was its own entity within the GM corporate family. The Southern California's War Division's "War Production History" shown on this page shows that it was a contractor to Army Ordnance, and was not a part of or being managed by Cadillac Division.

The table below provides production

information on the M5/M5A1 series tanks produced during WWII by the

Southern California Division of General Motors.

This information has been painstaking researched and gathered by Joe DeMarco. We thank Joe for allowing this website to use this

information.

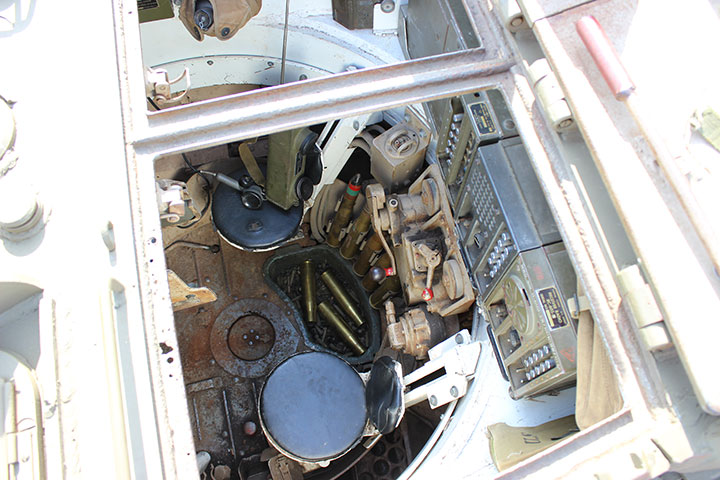

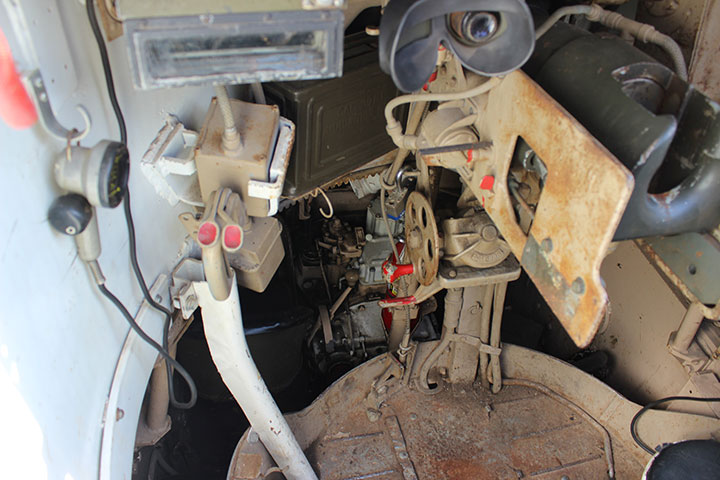

The M5/M5A1 Stuart Tank Photo Collection from 2014.

Spirit of St. Louis Airshow, May 2014.

Military Vehicle Preservation Association National Convention, Louisville, KY, June 2014.

Thunder over Michigan Airshow, Belleville, MI, August 2014.

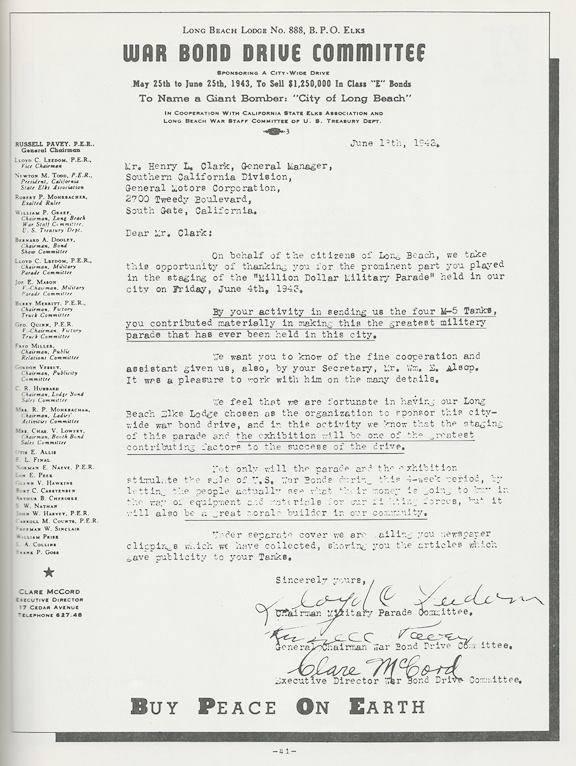

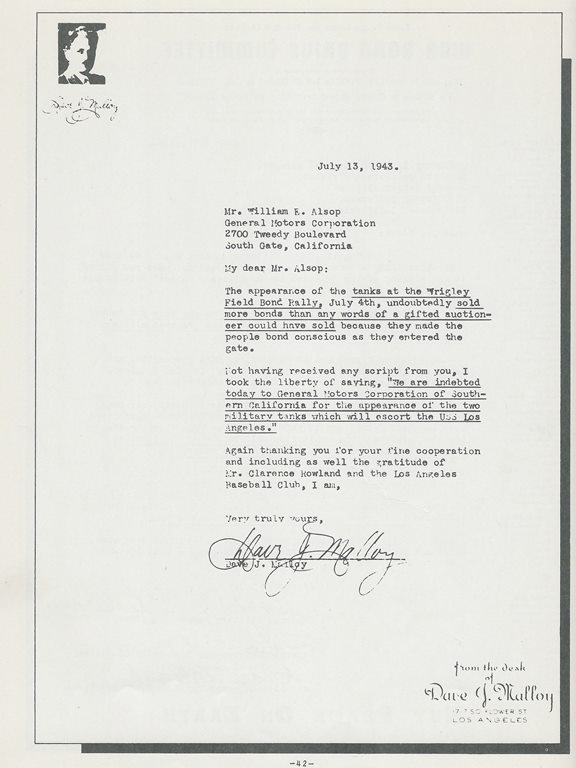

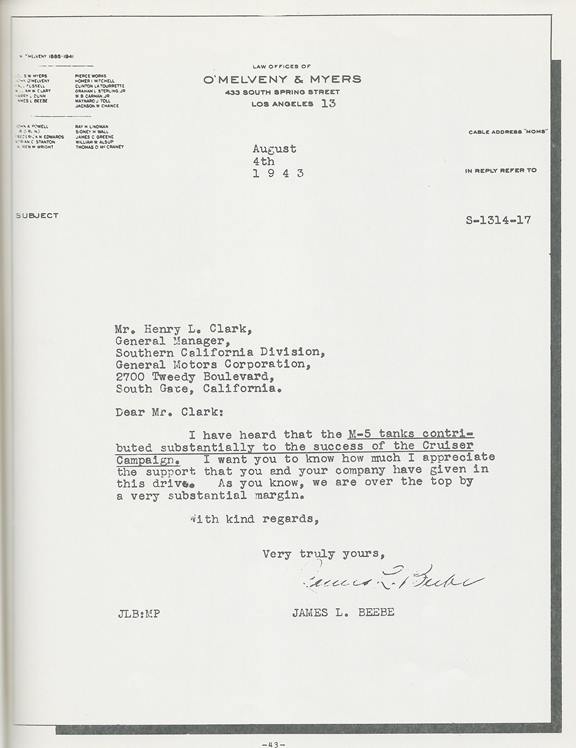

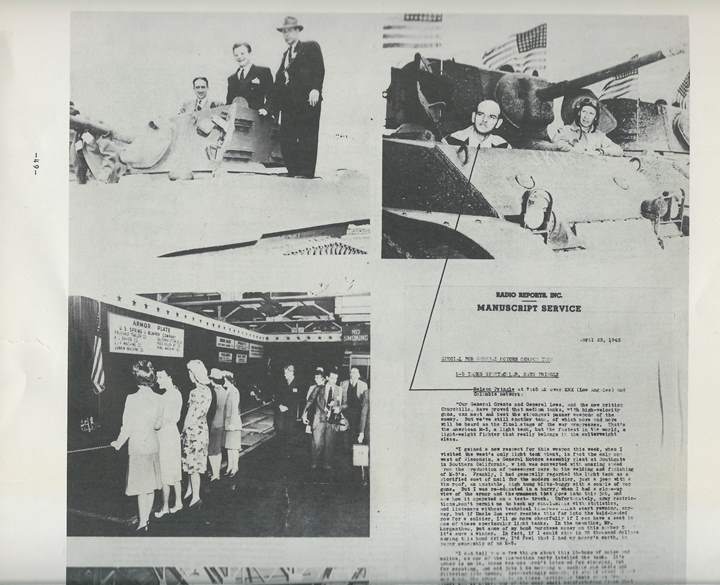

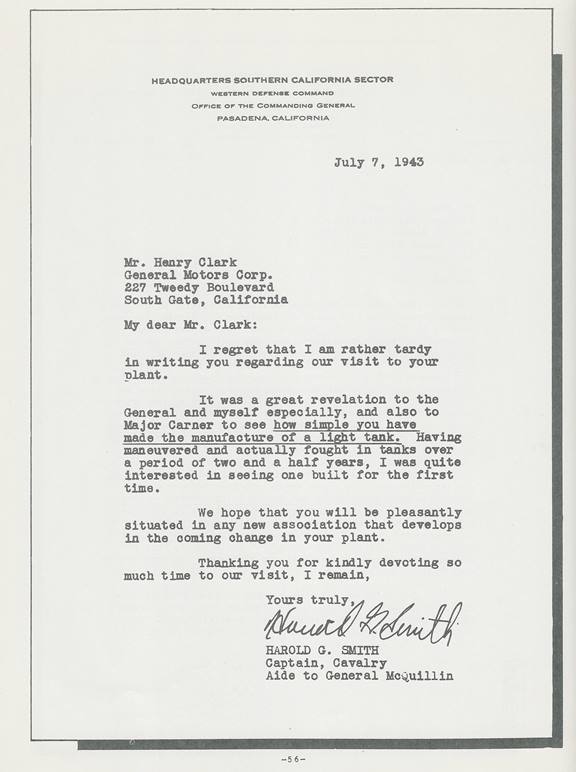

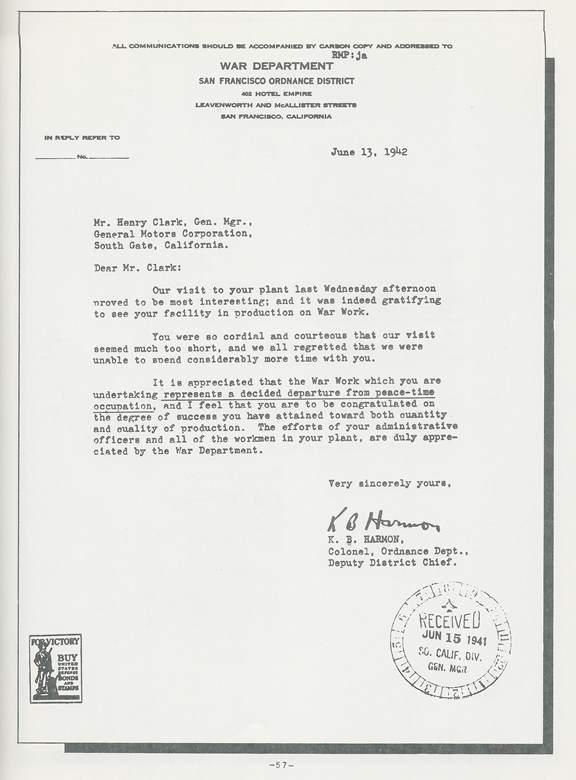

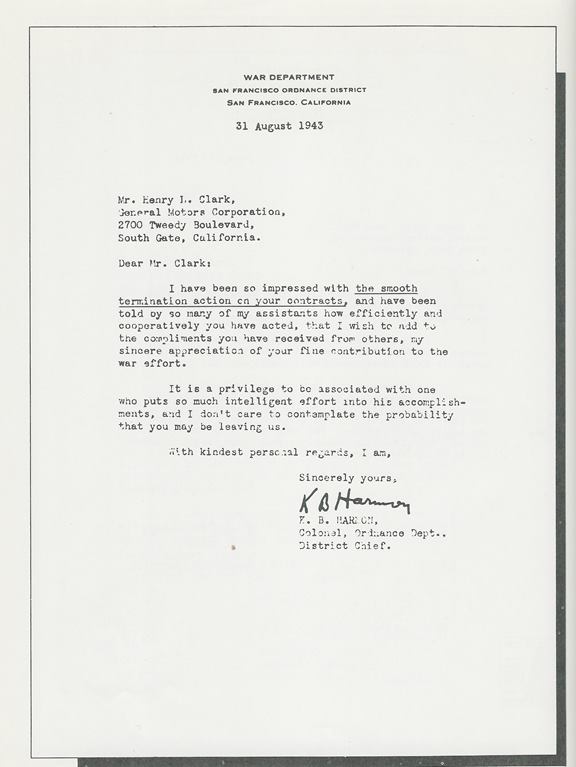

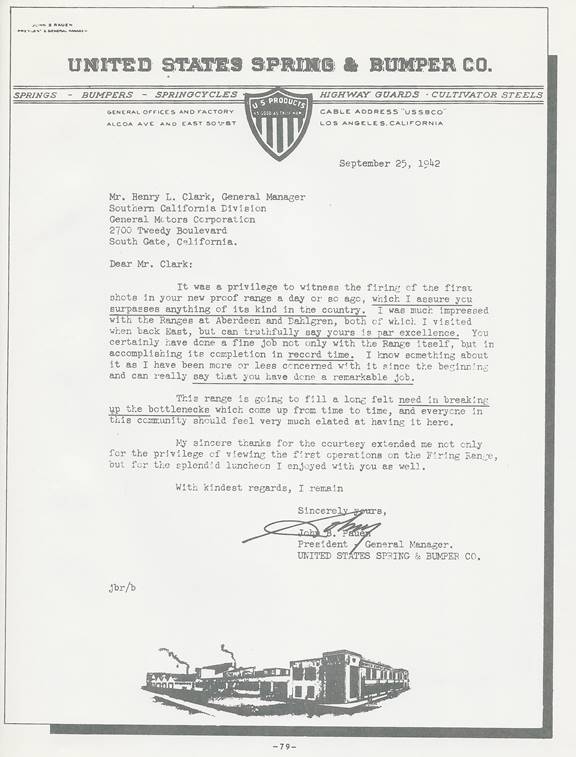

War Production History Below are over 80 pages of information that the Southern Californian Division produced at the end of 1943 when it ceased tank production. There is very good information contained on the conversion of an auto plant into a tank arsenal and an Army Proof range. Included are rare photos of the M5 tank components and how they were assembled into a tank. This is a fascinating document for those interested in the M5 and M5A1 Stuart tank.

Below is the history of the GM Southern California Division's World War Tank Production.

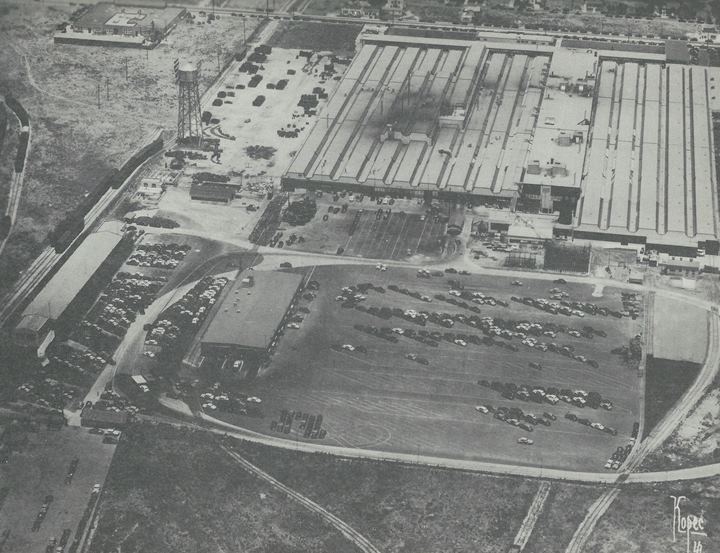

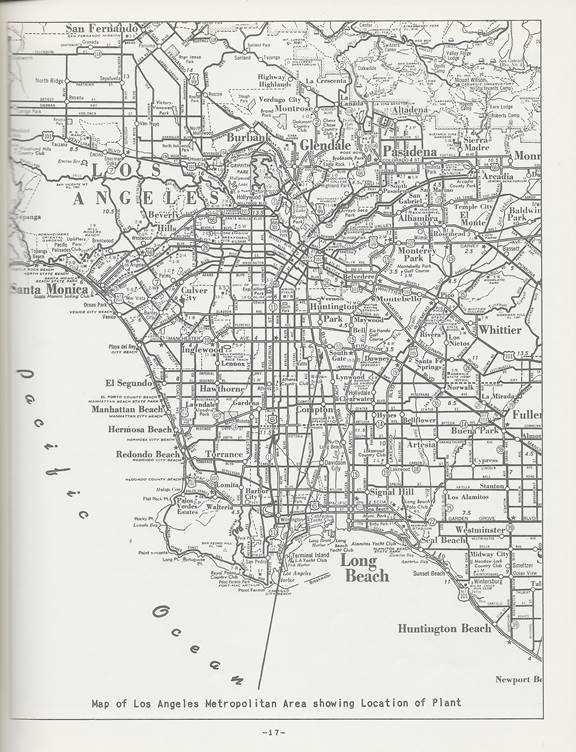

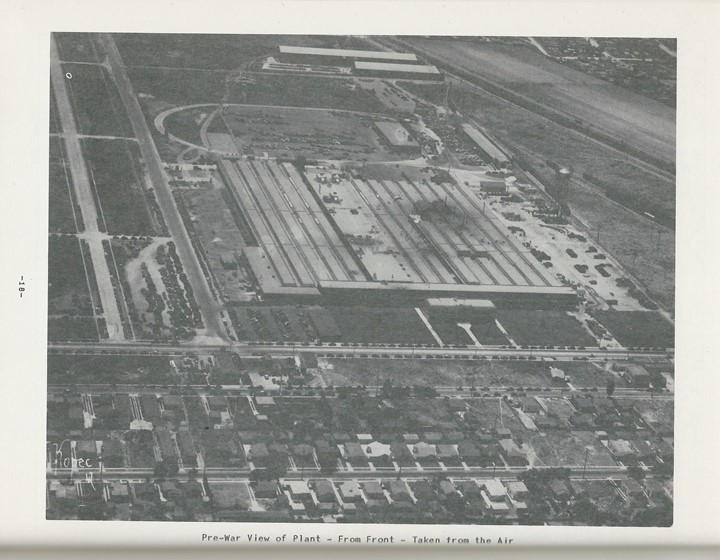

Below are photos and maps of the GM Southern California Division's Plant at South Gate, CA.

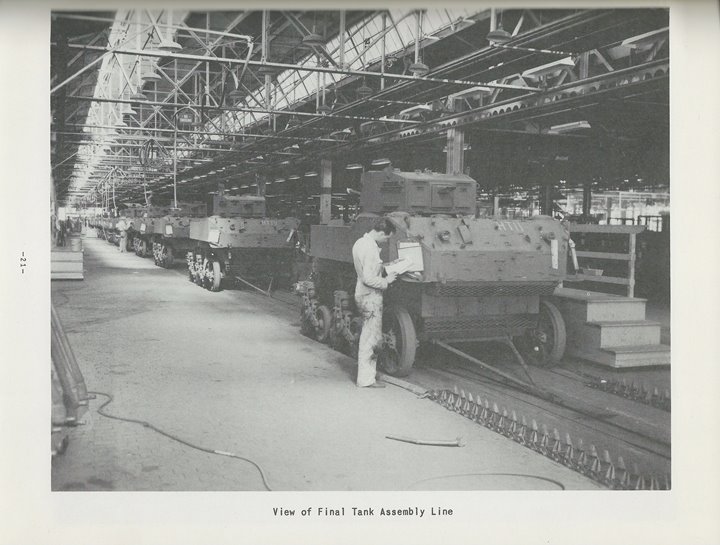

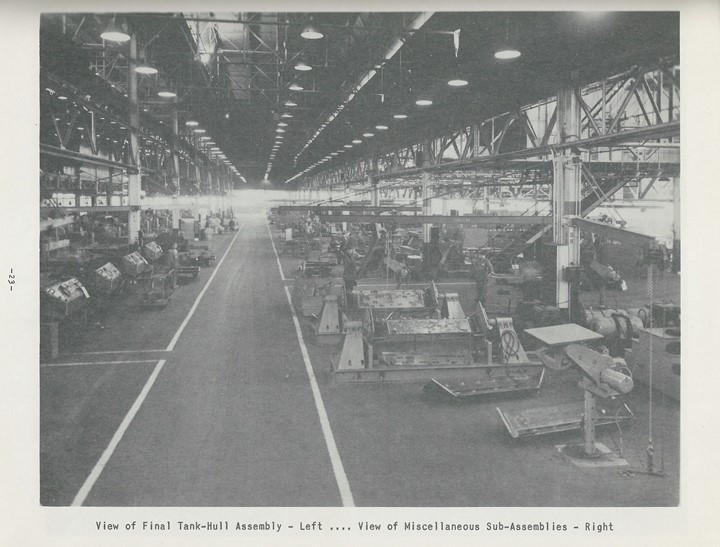

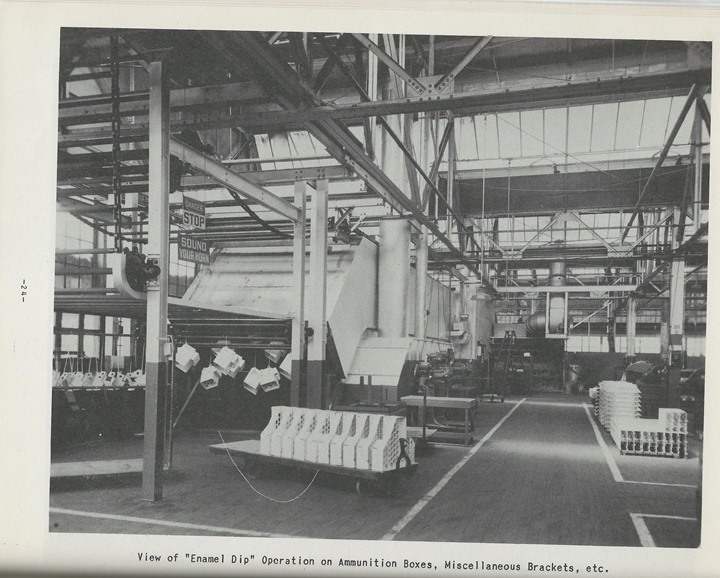

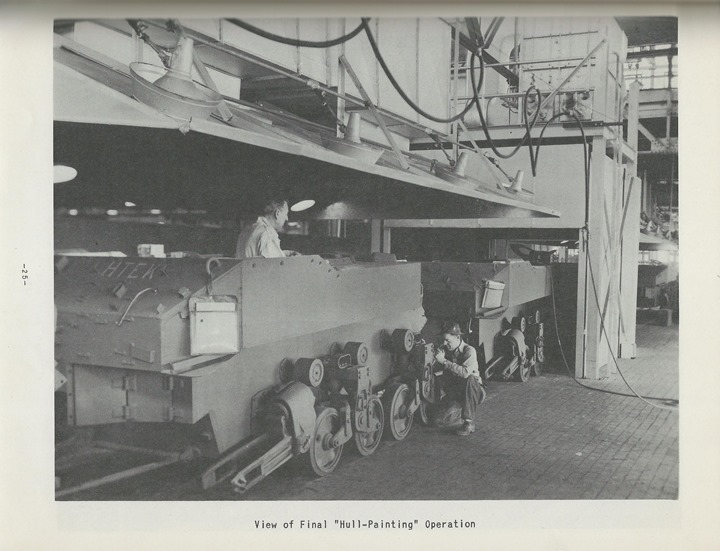

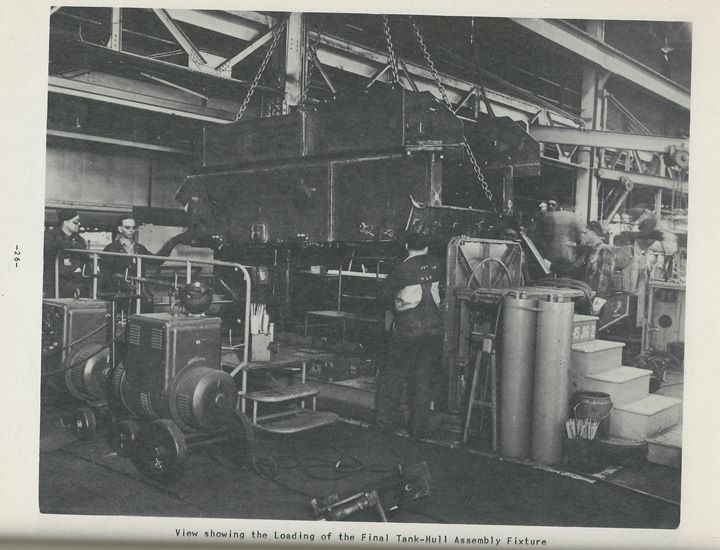

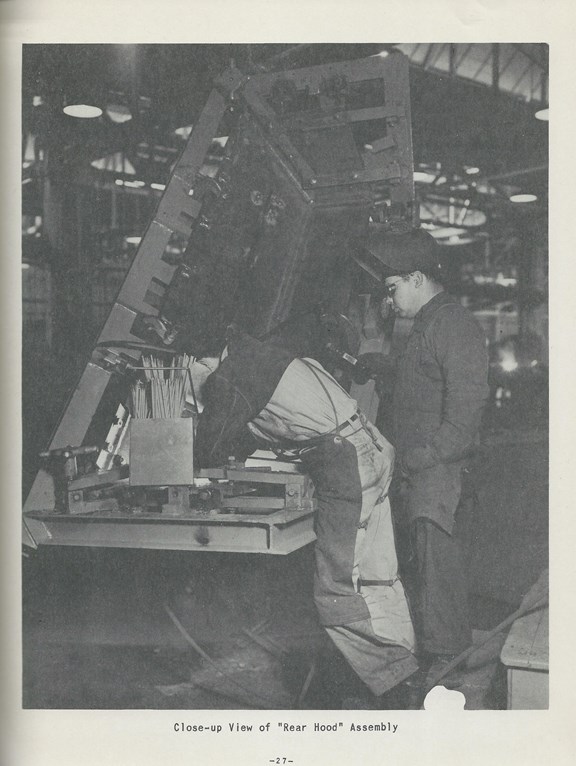

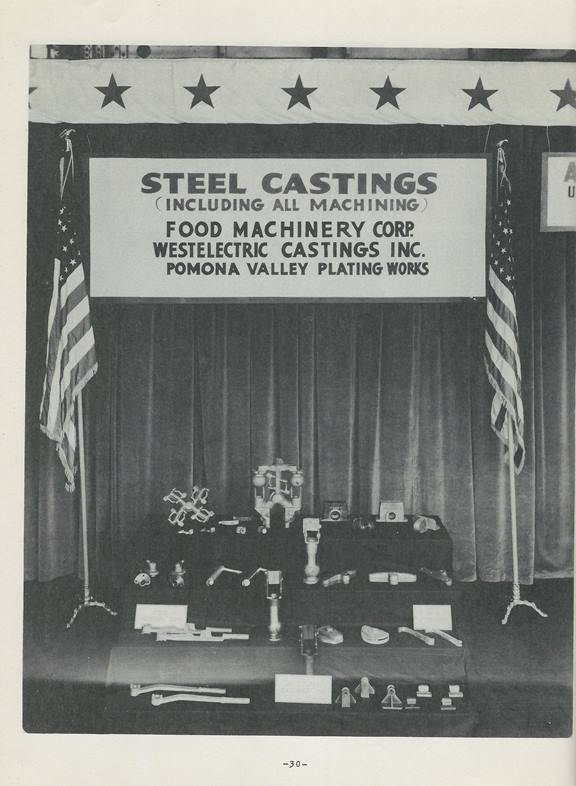

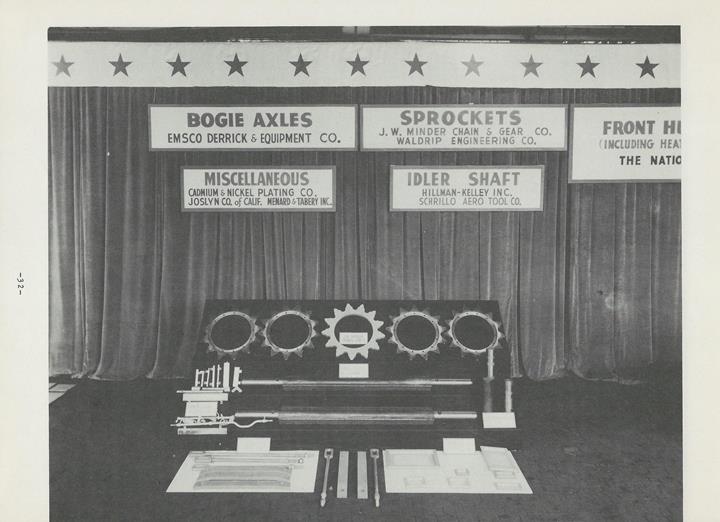

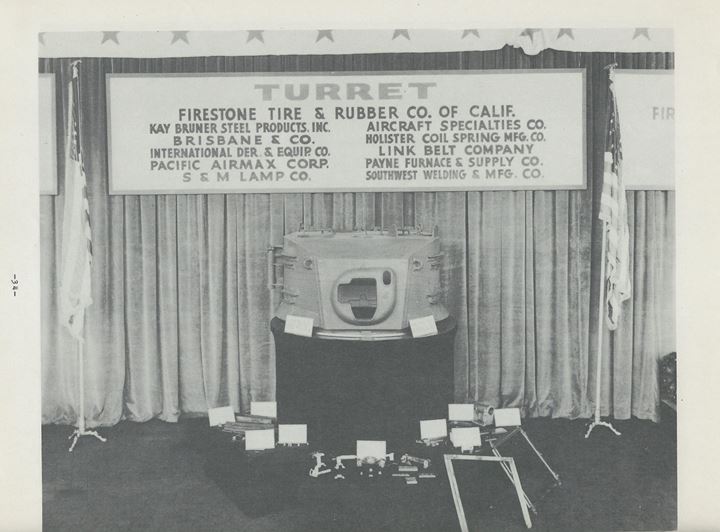

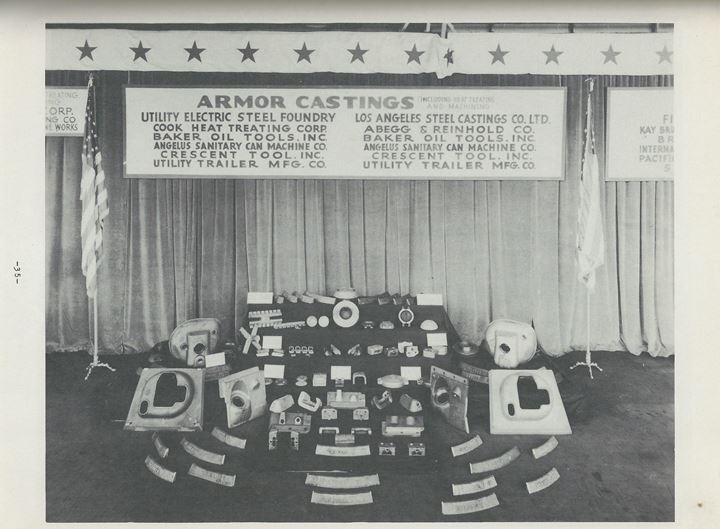

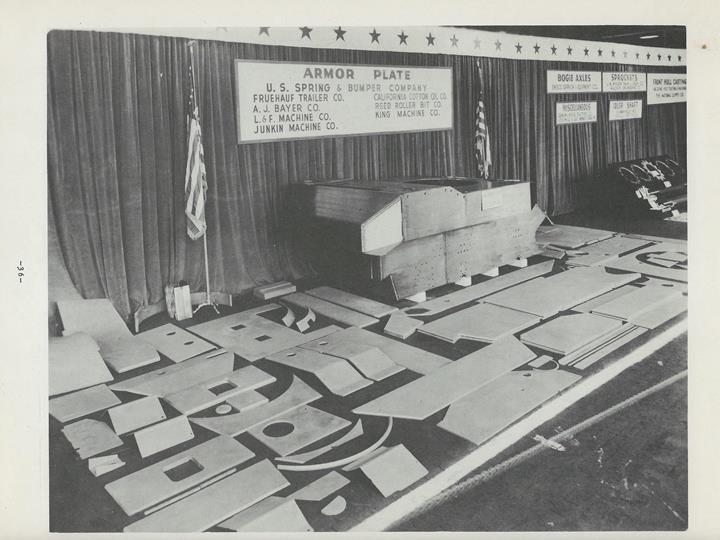

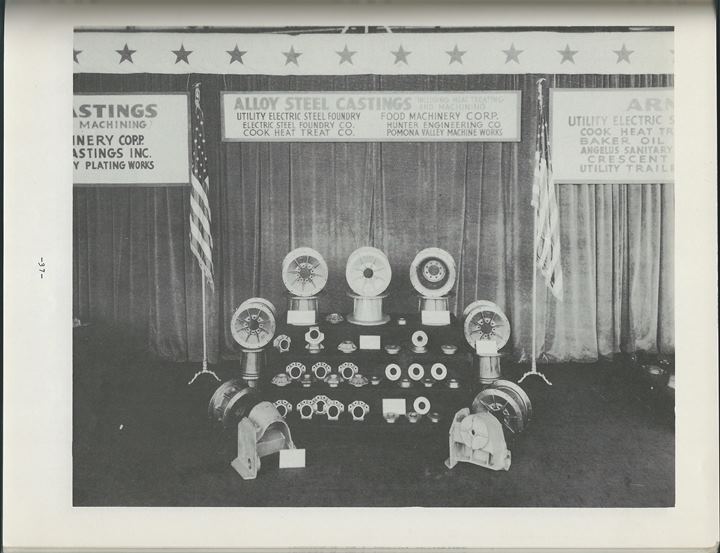

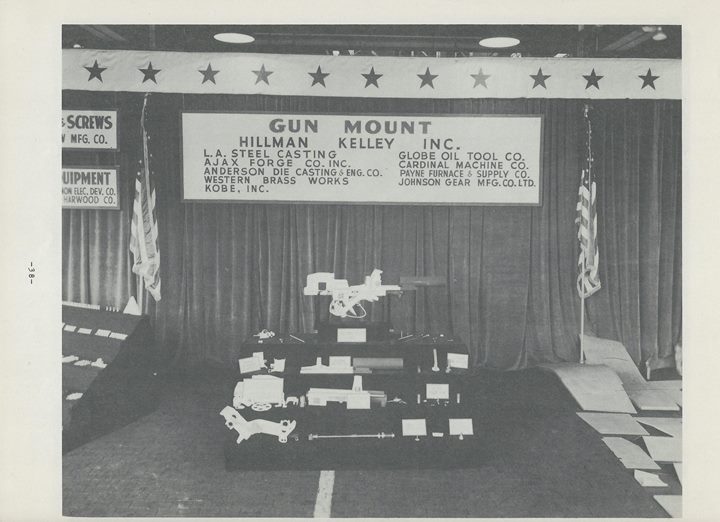

Below are excellent photos of how the M5 and M5A1 tanks were built at South Gate, CA during World War Two. Note that the Southern California Tank Arsenal had to weld up all of the supplied armor plate, and then assemble the rest of the components into a working tank.

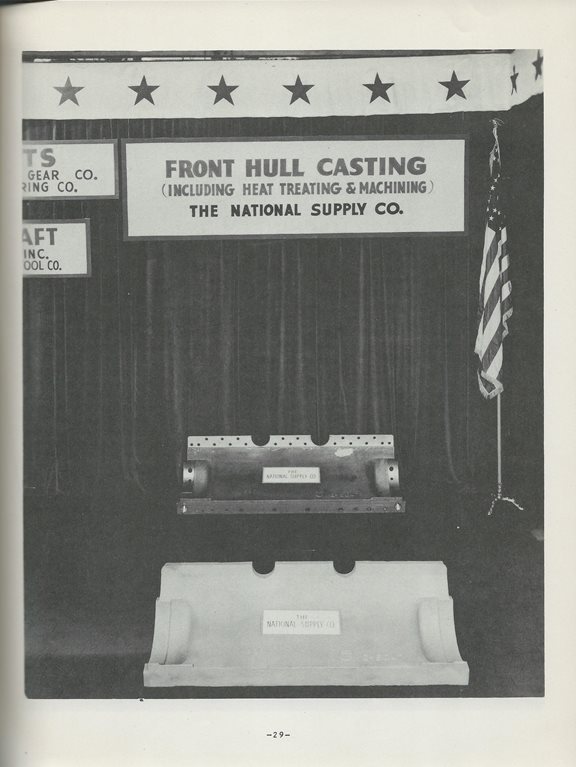

South Gate was an assembly plant. It turned to many of its previous auto suppliers to provided the needed M5 tank components for assembly. Note that the Southern California Tank Arsenal purchased all of the basic components. Then it had to weld up all of the supplied armor plate, and then assemble the rest of the components into a working tank.

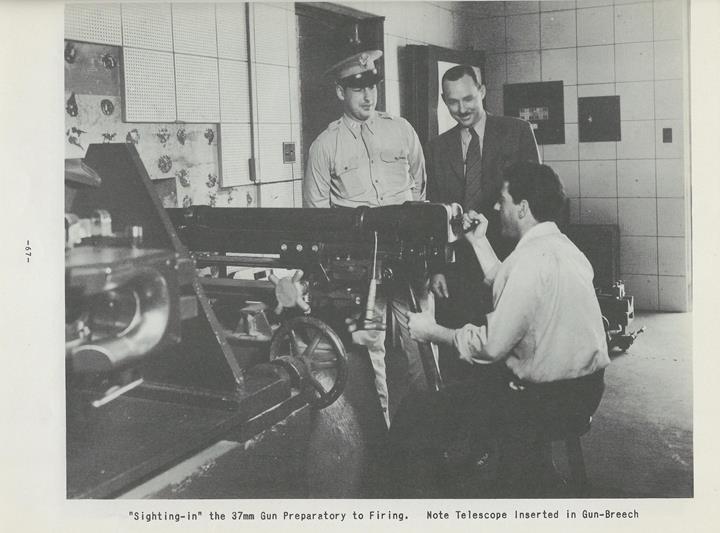

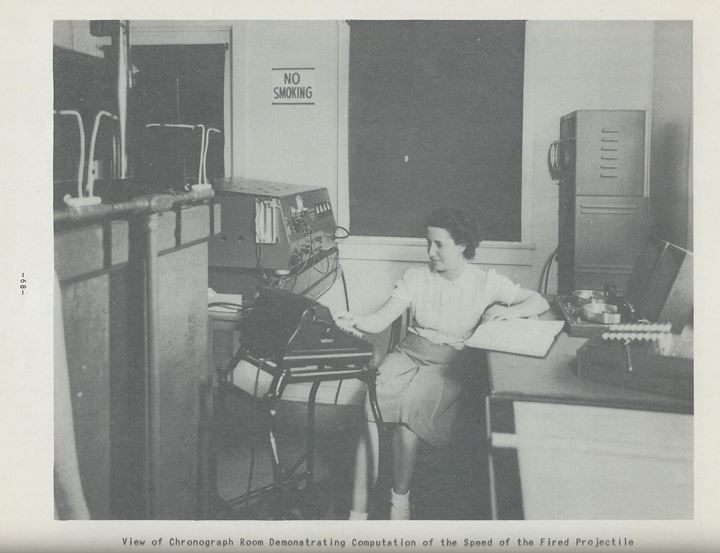

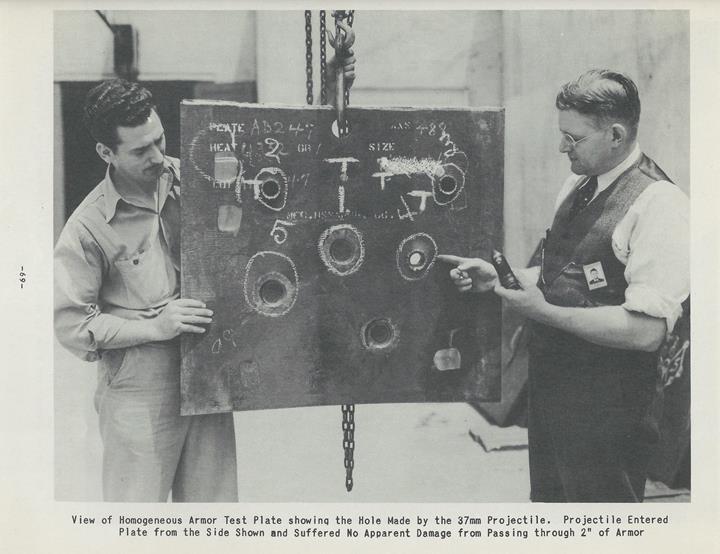

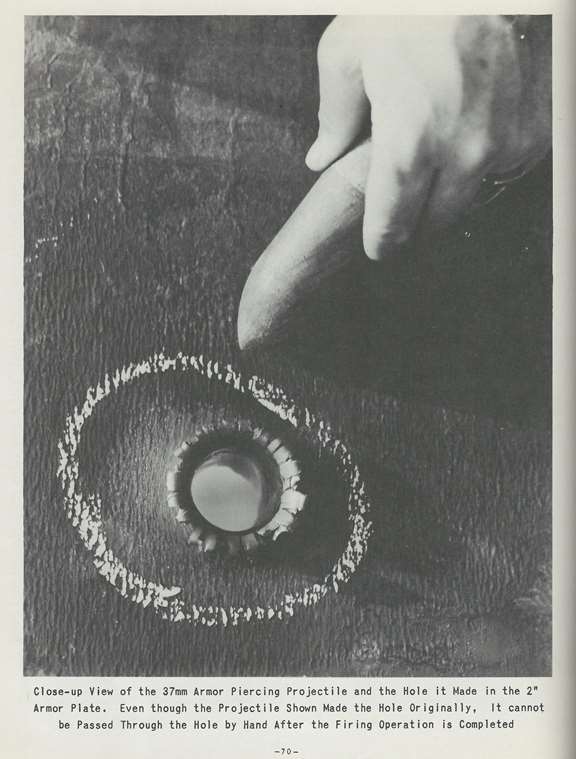

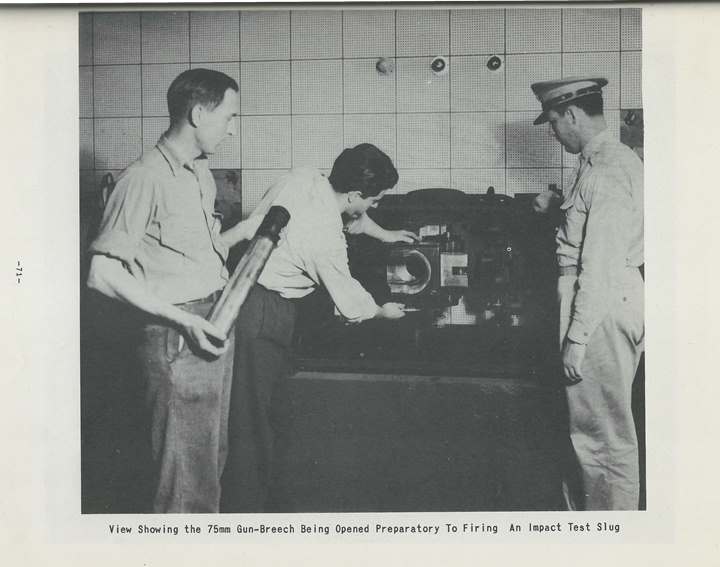

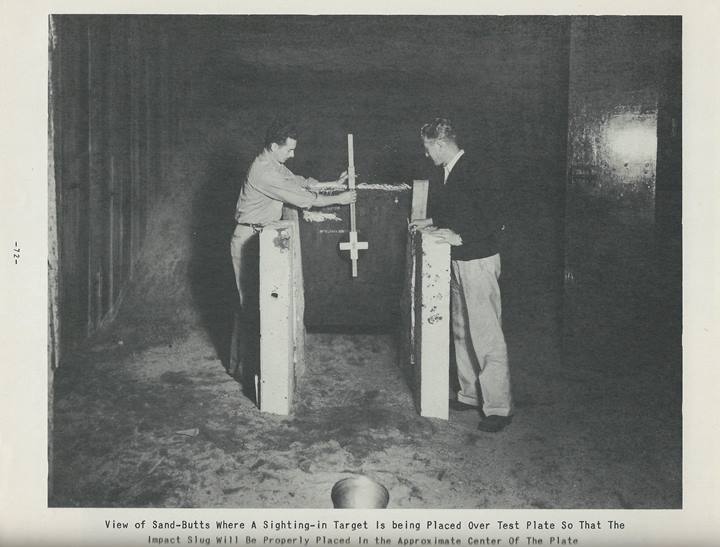

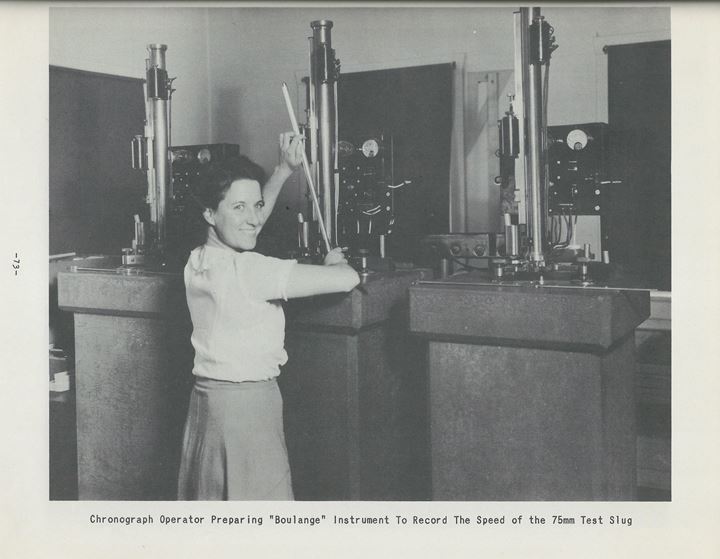

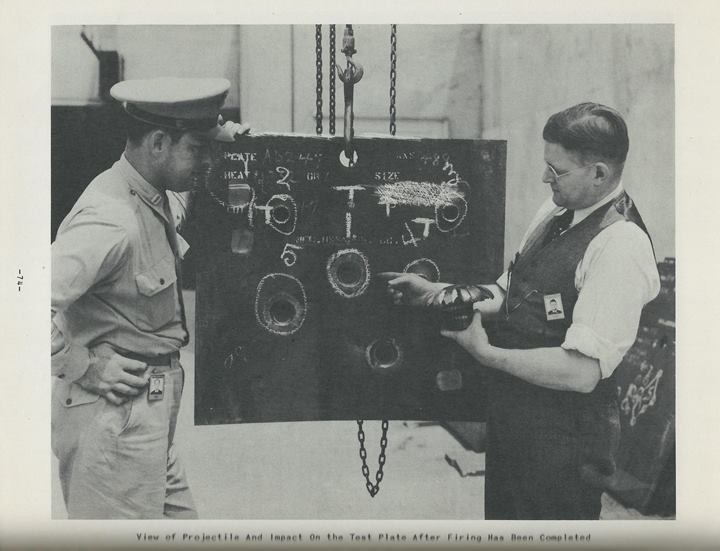

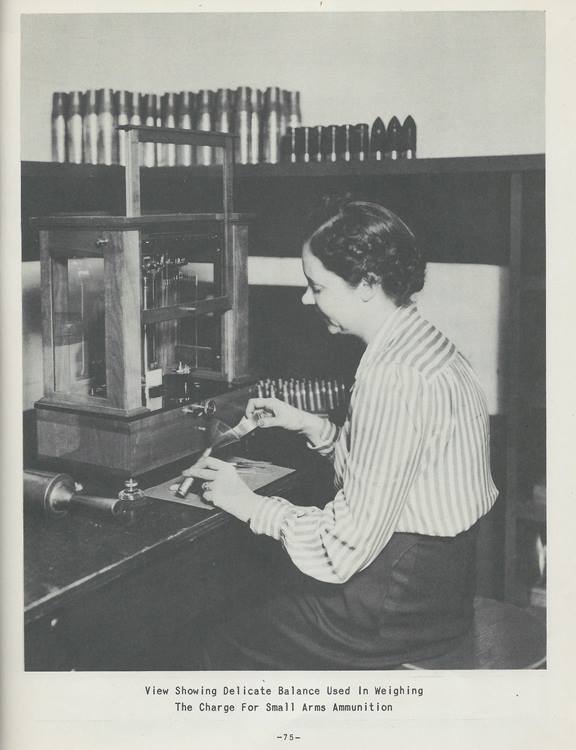

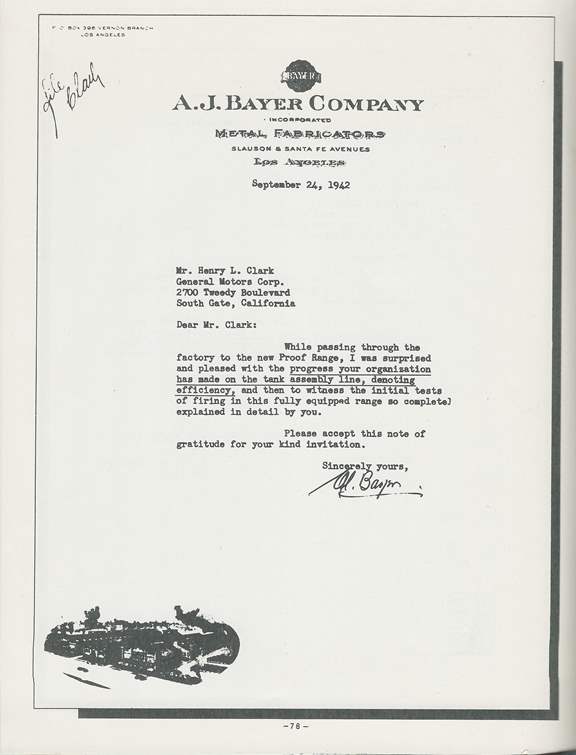

Below are photos of the Proof Range at South Gate during World War Two.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||