|

NCR

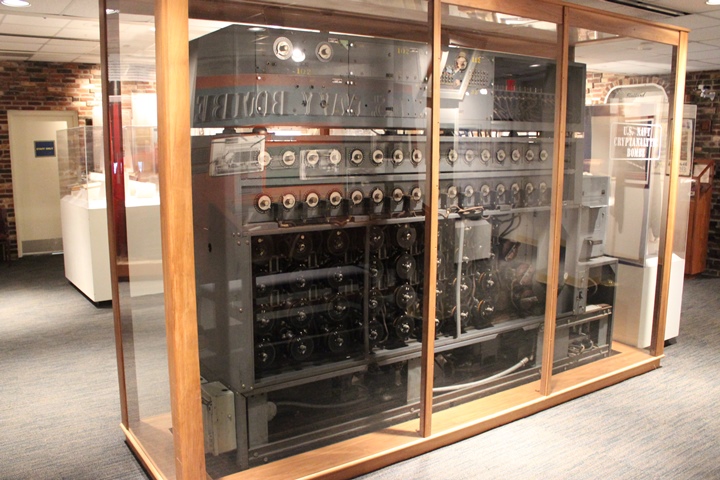

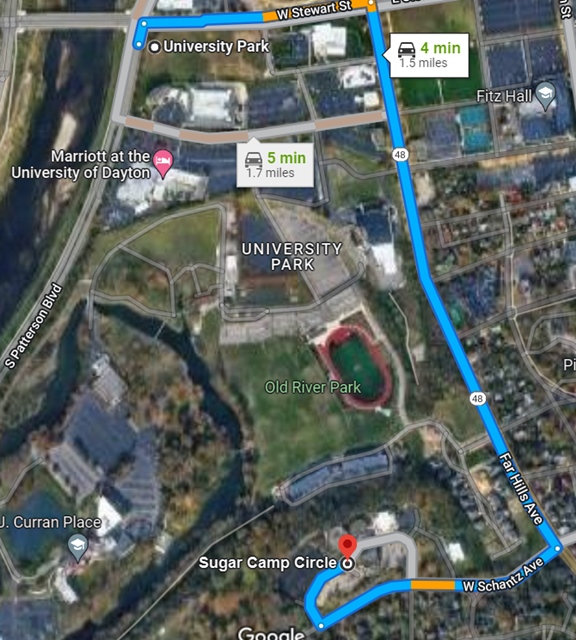

N-530 Bombe Enigma Decrypting Machine

National

Cash Register Company in World War Two

Dayton, OH

1879-1884 National Manufacturing Company

1884-1991 National Cash Register Company

1991-1997 as part of AT&T

1997-2009 NCR in Dayton, OH

2009-Present NCR in Atlanta, Georgia area

This page added 12-29-2022.

This is National Cash Register's signature

product for World War Two. However, because this was a top secret

computer that decoded the German's secret Enigma machine, knowledge of

this machine was not released to the public by United States Government

sources until 1993 when this went on display at the Smithsonian Museum

in Washington, DC. This is the only surviving NCR N-530 Bombe

Enigma Decrypting Machine of the 121 built for the U.S. Navy during

World War Two. It is on display at the National Cryptologic

Museum at Fort Meade, MD. Author's photo.

While today's military and NCR historians

focus on the N-530 when addressing what the company made during World

War Two, it was just a small, yet very important, part of a much larger

story of how NCR helped the United States military win World War Two.

Tables 1 and 2 below show the diversity of the products the company made

for the war effort.

This NCR webpage will be divided into two

pages. This page will focus on the non N-530 products. A

separate page linked at both the top and bottom of this page will

feature an extensive photo gallery of the NCR N-530 at the National

Cryptologic Museum.

An examination of the items listed in Tables 1

and 2 shows that they were mechanical and electro-mechanical in nature.

While the cash registers currently in use are electronic

devices, the cash registers prior to World War Two were mechanical

adding machines. National Cash Register was well equipped with

punch presses, screw machines, and other machinery to manufacture the fuzes, bombsights, magazines, gun sights, and other similar military

equipment required by the U.S. Army and U.S. Navy.

Shown in this and the next photo are some of

the many cash registers built by National Cash Register that are on

display at the Carillon Historical Park in Dayton, OH. Author's

photo.

Originally formed in 1879 as the National

Manufacturing Company to manufacture and market the first mechanical

cash register,

the company and patents were purchased by the Patterson Brothers of

Dayton, OH in 1884. They renamed the company National Cash

Register Company. Author's photo.

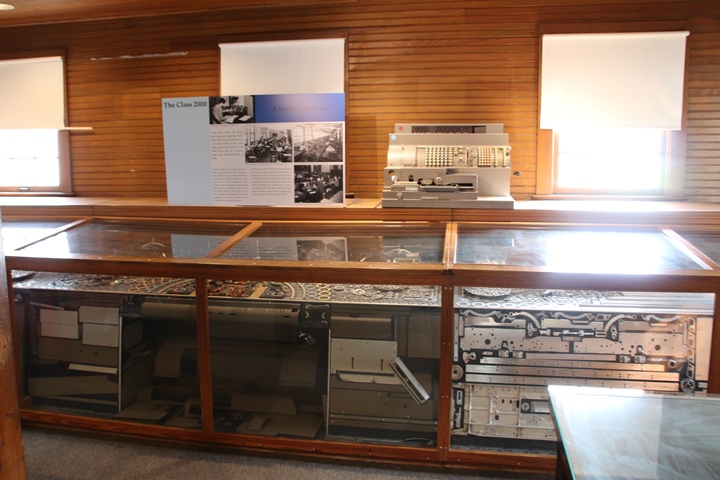

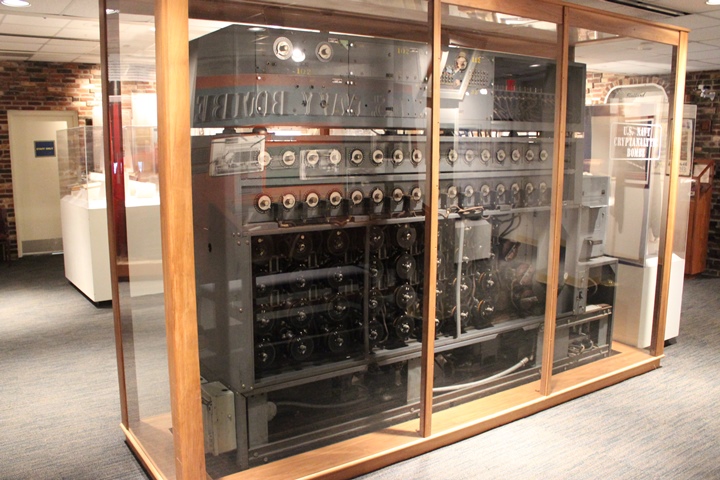

The Class 2000 Payroll Machine was built in

various models from 1922 through 1973. It was the forerunner of

many other business machines besides cash registers that the company built. The 20,143 parts that were hand assembled into the unit

are displayed in the display cases below the machine. The parts

display case takes up an entire wall in one of the out buildings at

Carillon Historical Park. Small parts are on the top shelves while

larger stamped pieces are shown along the front. Author's photo.

This display case has just a few of the many

stamped and other manufactured parts that National Cash Register

required in order to assemble the Class 2000. Today, business machines are

all electronic. Not so in the World War Two era. They were

all mechanical or electro-mechanical devices. This is why

National Cash Register was the proper company to make the military items

shown below. Author's photo taken at Carillon Historical Park.

Author's photo taken at Carillon Historical

Park.

National Cash Register won the Army-Navy "E"

award six times during World War Two.

The first time was January 28, 1942.

The second time was October 2, 1942.

The fourth time was September 1943.

The last and sixth award was March 12, 1945.

National Cash Register in World War Two:

The company had

$86,817,000 in major contracts as noted in Table 1. Note

that the company was contracted by both the Treasury and Navy

Departments to make cash registers and office equipment. These

were non-military products that both government agencies needed to keep

the bureaucracies running. The Navy may have needed the cash

registers to keep track of sales in its commissaries and BXs.

There are two Navy contracts labeled as

"Classified" totaling $2,400,000. These two contracts were awarded

too late in the war for the construction of the 121 N-530 Bombes the

company built, as work started on those early in the war and probably

cost more than $2,400,000. As this was a top secret project, the

funding may have been provided in another manner.

Table 1 - National Cash Register Company's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. |

|

Product - Customer |

Contract Amount |

Contract Awarded

Date |

Completion

Date |

| Shells - Army |

$770,000 |

11-1940 |

1-1942 |

| Housings - Army |

$427,000 |

1-1941 |

12-1941 |

| Fuzes - Army |

$174,000 |

2-1941 |

2-1942 |

| Ordnance Material

- Army |

$6,368,000 |

3-1941 |

4-1943 |

| Parts Fuze - Navy |

$1,491,000 |

4-1941 |

3-1942 |

| Fuzes - Army |

$287,000 |

6-1941 |

1-1942 |

| Fuzes - Army |

$245,000 |

6-1941 |

3-1942 |

| Metal Parts -

Navy |

$1,421,000 |

7-1941 |

4-1943 |

| Shells - Foreign

|

$318,000 |

7-1941 |

1-1943 |

| Fuze Parts - Army |

$658,000 |

10-1941 |

10-1942 |

| Office Equipment

- Treasury |

$97,000 |

10-1941 |

2-1942 |

| Ordnance Material

- Navy |

$228,000 |

11-1941 |

12-1942 |

| Parts - Shell -

Army |

$147,000 |

11-1941 |

3-1943 |

| Ordnance Material

- Navy |

$275,000 |

12-1941 |

6-1942 |

| Airplane

Equipment - Army |

$4,967,000 |

1-1942 |

12-1942 |

| Shells - Army |

$183,000 |

1-1942 |

8-1942 |

| Fuzes - army |

$156,000 |

1-1942 |

5-1942 |

| Ordnance

Equipment - Navy |

$1,074,000 |

2-1942 |

1-1943 |

| Fuzes - Army |

$658,000 |

2-1942 |

12-1942 |

| Shells - Army |

$137,000 |

3-1942 |

12-1942 |

| Shells - Army |

$341,000 |

4-1942 |

10-1943 |

| Fuzes - Army |

$191,000 |

4-1942 |

10-1943 |

| Fuzes - Army |

$555,000 |

4-1942 |

10-1943 |

| Airplane

Instruments - Army |

$2,018,000 |

4-1942 |

2-1943 |

| Fuze Parts - Army |

$60,000 |

5-1942 |

6-1943 |

| Fire Control

Equipment - Army |

$5,115,000 |

5-1942 |

5-1943 |

| Tracers -

Igniters - Navy |

$615,000 |

6-1942 |

10-1942 |

| Bomb Sights -

Army |

$4,975,000 |

7-1942 |

12-1943 |

| Machines Office -

Treasury |

$181,000 |

7-1942 |

9-1943 |

| Machines Office -

Treasury |

$119,000 |

7-1942 |

9-1943 |

| Machines Office -

Treasury |

$417,000 |

7-1942 |

9-1943 |

| Communication

Equipment - Navy |

$2,500,000 |

8-1942 |

5-1943 |

| Ordnance

Equipment - Navy |

$209,000 |

9-1942 |

5-1943 |

| Fire Control

Equipment - Army |

$4,662,000 |

9-1942 |

6-1943 |

| Airplane

Equipment - Army |

$875,000 |

9-1942 |

12-1942 |

| Fuze Parts - Navy |

$564,000 |

10-1942 |

6-1943 |

| Cash Registers -

Navy |

$167,000 |

10-1942 |

11-1943 |

| Airplane Parts -

Army |

$580,000 |

10-1942 |

8-1943 |

| Fuzes - Army |

$105,000 |

11-1942 |

5-1943 |

| Cash Registers -

Navy |

$93,000 |

12-1942 |

2-1943 |

| Airplane

Equipment - Army |

$2,330,000 |

12-1942 |

12-1943 |

| Fuzes - Army |

$2,523,000 |

12-1942 |

8-1943 |

| Magazines Fuze -

Navy |

$244,000 |

1-1943 |

11-1943 |

| Fuzes - Army |

$191,000 |

1-1943 |

10-1943 |

| Cash Registers -

Treasury |

$210,000 |

1-1943 |

12-1943 |

| Office Equipment

- Navy |

$78,000 |

4-1943 |

11-1943 |

| Electrical

Apparatus - Navy |

$131,000 |

4-1943 |

9-1943 |

| Machines Office -

Treasury |

$110,000 |

4-1943 |

12-1943 |

| Ordnance

Equipment - Navy |

$642,000 |

6-1943 |

3-1944 |

| Bomb Nose Fuzes -

Army |

$280,000 |

7-1943 |

3-1944 |

| Mechanical Time

Fuzes - Army |

$990,000 |

7-1943 |

4-1944 |

| Mechanical Time

Fuzes - Army |

$2,041,000 |

8-1943 |

4-1944 |

| Fuze Magazines

20mm - Navy |

$280,000 |

9-1943 |

7-1944 |

| Gun Sight

Assemblies - Army |

$1,112,000 |

9-1943 |

1-1944 |

| Computing Sight

Assemblies - Army |

$9,340,000 |

11-1943 |

7-1944 |

| Sight Parts -

Army |

$52,000 |

11-1943 |

6-1944 |

| Cash Registers -

Navy |

$59,000 |

11-1943 |

3-1944 |

| Metal Collars -

Navy |

$631,000 |

12-1943 |

11-1944 |

| Ship Equipment -

Navy |

$500,000 |

1-1944 |

6-1944 |

| Office Equipment

- Navy |

$1,000,000 |

2-1944 |

4-1945 |

| Airplane

Equipment - Army |

$100,000 |

2-1944 |

12-1944 |

| Classified - Navy |

$53,000 |

4-1944 |

11-1944 |

| Classified - Navy |

$1,850,000 |

5-1944 |

8-1944 |

| Cash Registers -

Navy |

$98,000 |

5-1944 |

10-1944 |

| Classified - Army |

$274,000 |

5-1944 |

5-1945 |

| Classified - Army |

$139,000 |

5-1944 |

5-1944 |

| Gun Sight

Assemblies - Army |

$930,000 |

5-1944 |

1-1945 |

| Metal Collars -

Navy |

$360,000 |

9-1944 |

4-1945 |

| Office Machines -

Treasury |

$90,000 |

9-1944 |

12-1944 |

| Carburetor Parts

- Navy |

$404,000 |

10-1944 |

7-1945 |

| Rocket Motors MK

4 - Navy |

$114,436 |

12-1944 |

12-1945 |

| Gun Sight

Assemblies - Army |

$99,000 |

1-1945 |

5-1945 |

| Gun Sight

Assemblies - Army |

$453,000 |

1-1945 |

6-1945 |

| Metal Collars -

Navy |

$877,000 |

2-1945 |

10-1945 |

| Classified - Navy |

$400,000 |

6-1945 |

6-1946 |

| Classified - Navy |

$2,000,000 |

2-1945 |

6-1946 |

| Communication

Equipment - Navy |

$107,000 |

7-1945 |

6-1946 |

|

Total |

$86,817,000 |

|

|

Table 2 lists the many products the company

built during World War Two. It does not give the actual number of

components or products produced. While it gives a "Maximum

Production per Month," it is unknown in most cases if that was the true

production rate or how long it was produced.

Table 2 - National Cash Register World War Two Products

This is from a National Cash Register Company Document

located at Dayton History, Dayton, OH. |

| Product |

Maximum

Production per Month |

Cost per unit at Maximum Production |

Months to reach initial production |

Months to reach Maximum Production |

|

M-48 P.D. Fuze |

135,000 |

$1.28 |

11 |

14 |

| 20mm Fuze |

5,451,000 |

$0.033 |

3 |

24 |

| M55, 37mm Shell |

62,350 |

$0.43 |

2 |

3 |

| Oerlikon Magazine |

55,000 |

$32.20 |

6 |

23 |

| Magazine Loading Frame |

16,100 |

$0.95 |

6 |

19 |

| Magazine Lever Handle |

16,000 |

$2.77 |

6 |

19 |

| Relay Igniting Chg. Housing |

730,000 |

$0.042 |

5 |

16 |

| M54, 37mm Shell |

93,964 |

$0.38 |

5 |

19 |

| M50 Dummy Fuze |

330,000 |

$0.145 |

3 |

10 |

| Shell Tracer and Igniter |

561,000 |

$0.275 |

9 |

12 |

|

D8 Bomb Sight |

1,800 |

$175.00 |

2 |

7 |

| M43 A3 Mechanical Time Fuze |

221,000 |

$3.24 |

6 |

11 |

| K3 Gun Sight |

586 |

$794.62 |

8 |

22 |

| K4 Gun Sight |

864 |

$803.23 |

8 |

22 |

| 58 CPB-4 Carburetor |

2,347 |

$410.00 |

17 |

16 |

| 1900 CPB-3 Carburetor |

4,535 |

$363.93 |

17 |

11 |

| S-1 Bomb Sight |

158 |

$7,160.00 |

12 |

5 |

| Metal Collars |

867,400 |

$0.30 |

5 |

20 |

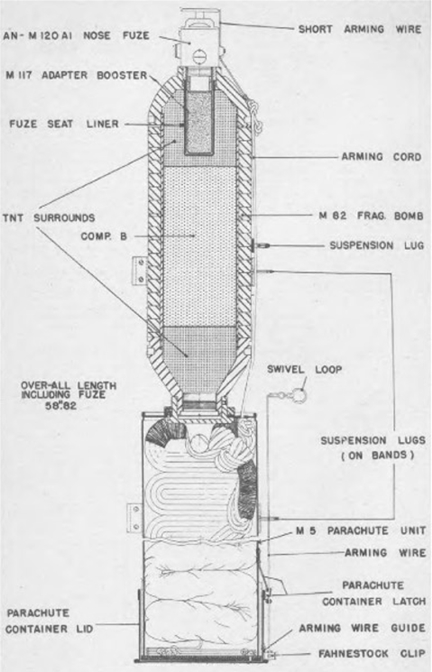

| M120 Bomb Nose Fuze |

82,975 |

$2.24 |

4 |

3 |

| M61 Mechanical Time Fuze |

25,280 |

$4.96 |

5 |

4 |

|

Rocket Motor |

50,674 |

$15.64 |

4 |

7 |

| 58 CPB-10 Carburetor |

54 |

$576.00 |

24 |

5 |

| |

|

|

|

|

| Carbide M1 Carbine Parts for Inland Division of

General Motors |

|

|

|

|

| Firing Pin |

117,382 |

$0.40 |

4 |

9 |

| Piston Nut |

111,985 |

$0.18 |

4 |

10 |

| Hammer Spring Plunger |

100,796 |

$0.16 |

4 |

8 |

| Operating Slide Pin |

224,000 |

$0.014 |

2 |

2 |

| Magazine Catch Ret. Safety Plunger |

391,906 |

$0.009 |

2 |

5 |

| Hammer Pin |

175,117 |

$0.026 |

2 |

3 |

| Hammer |

52,521 |

$0.89 |

2 |

9 |

| Extractor Spring Plunger |

142,990 |

$0.04 |

1 |

1 |

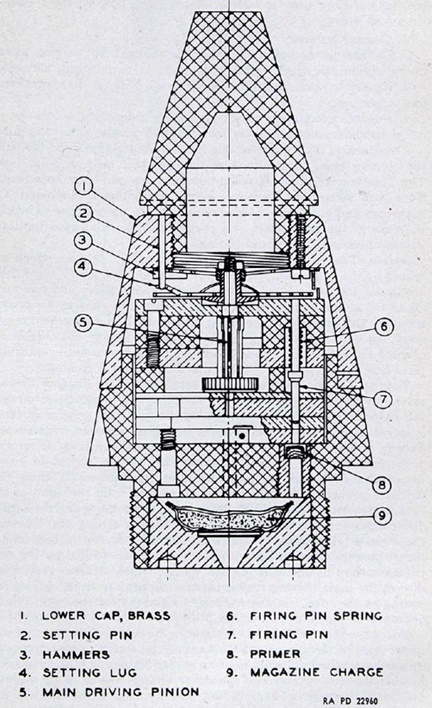

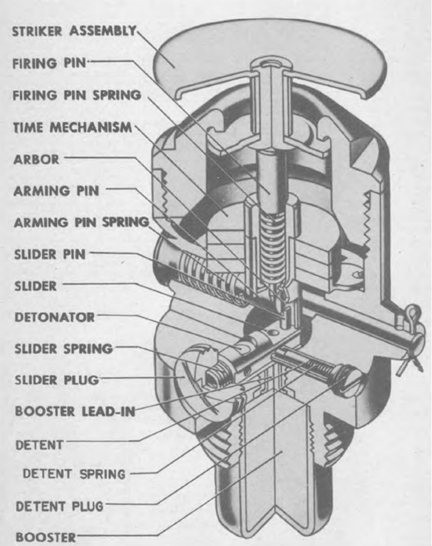

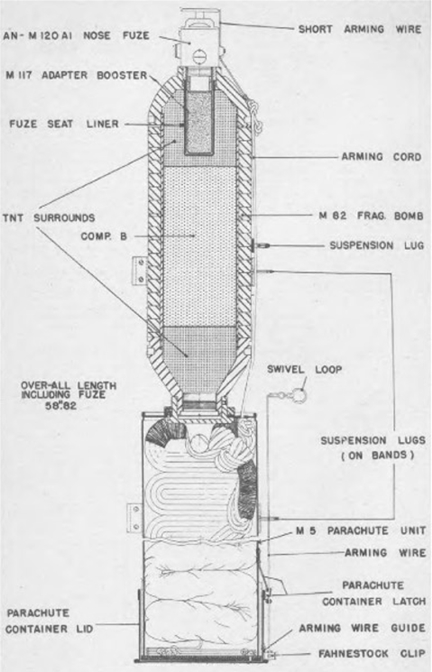

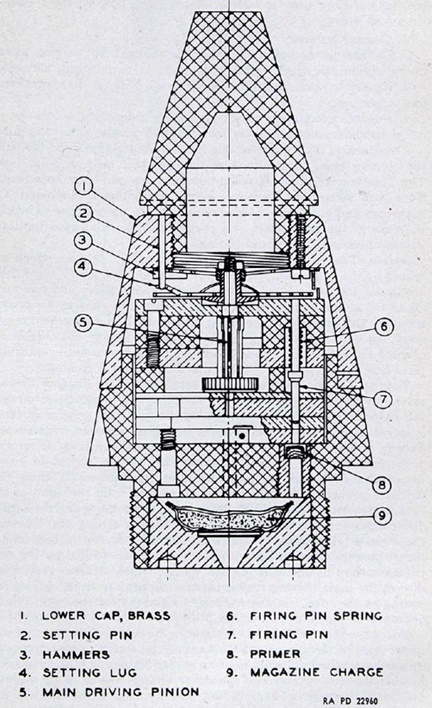

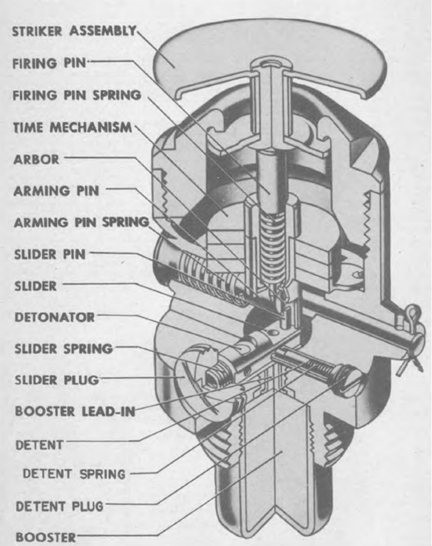

Fuzes: National Cash

Register produced the M48 P.D. Fuze, 20mm Fuze, M50 Dummy Fuze, M43 A3 Mechanical Time Fuze, M120 Bomb Nose Fuze, M120 Bomb Nose

Fuze, and M61 Mechanical Time Fuze during World War Two. The total

value of the company's fuze contracts was $8,116,000.

The

M43 fuze provided up to a 30 second delay for 90mm anti-aircraft shells.

This NCR-built

M43 fuze is on display at the Veterans Memorial Museum in Germantown, OH,

not far from the location of the former NCR complex in Dayton.

Author's photo.

The NCR-built M43 fuze was used on the

shells that were fired by the 90mm anti-aircraft gun. Author's

photo.

The Veterans Memorial Museum also has a cut-away example of an NCR-built

M120 fuze. This fuze was used in the 120lb parafrag bombs of the 5th

Air Force in the southwest Pacific during World War Two. Also in

the photo is a 20mm shell used by the U.S. Navy in its 20mm Oerlikon

anti-aircraft guns. NCR made the fuzes for the 20mm projectiles.

Author's photo.

Parafrags being put to good use by a B-25 in

the southwest Pacific. The parachutes allowed aircraft like the

B-25 and A-20 to make surprise low level attacks on Japanese airfields.

The combination of the parachute and the timer mechanism in the

NCR-built M120 fuze allowed the attacking aircraft to clear the area and

escape the bomb blast. This Imperial Japanese Navy Mitsubishi

G4M2a "Betty" long range bomber is about to have a bad day once the

NCR-built fuzes time out.

Also on display at the Veterans

Memorial Museum is this cut-away of an M61 mechanical time fuze for

120mm anti-aircraft projectiles. Author's

photo.

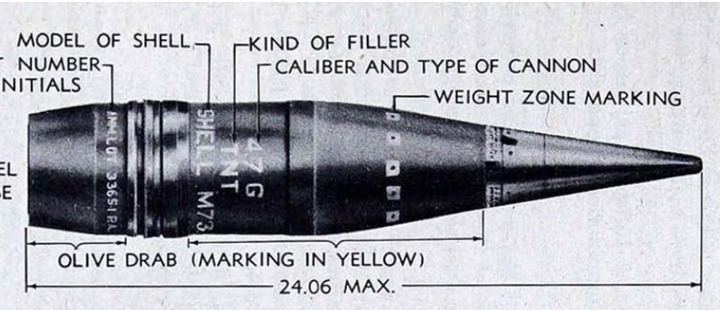

Author's photo.

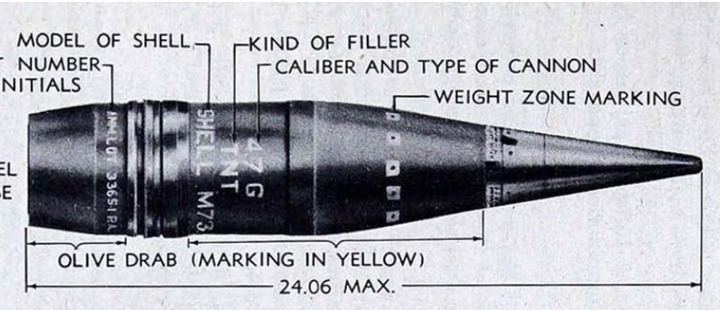

This image shows an

M61 fuze on 120mm HE M73 anti-aircraft shell.

This is one of the few surviving 120mm M1

anti-aircraft guns of the 550 built by Fisher Body Grand Rapids during

World War Two. It is on display at the USS Alabama in Mobile, AL.

Author's photo.

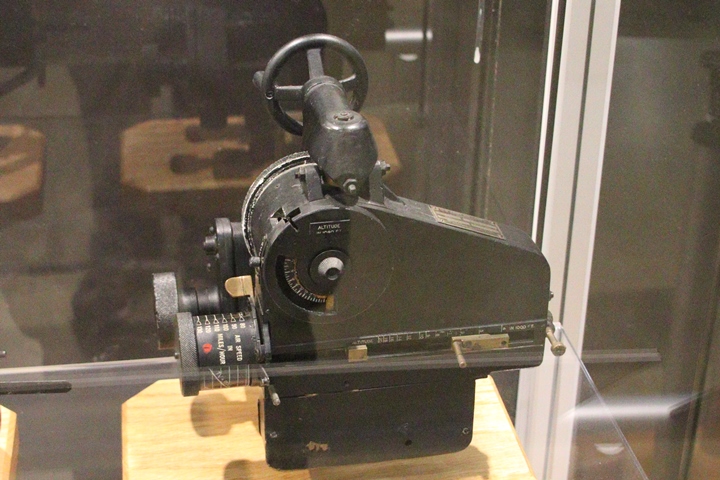

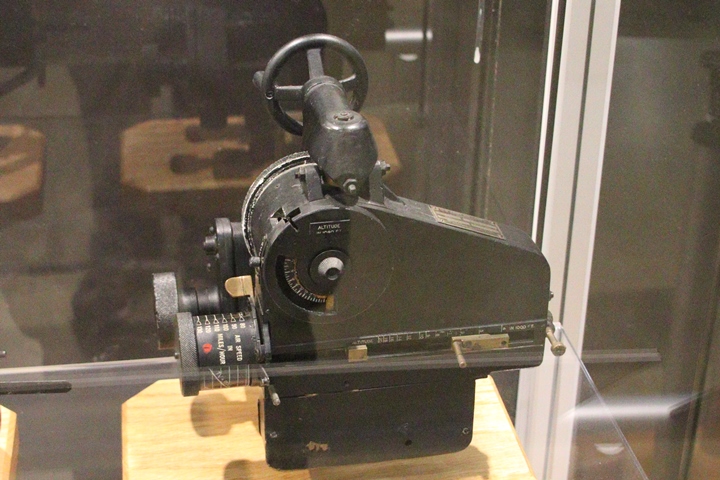

Aircraft Bombsights: National

Cash Register produced two of the three bombsights used by the U.S. Army

Air Forces in World War Two. These were the Estoppy D-8 and the

Sperry S-1. While the Norden M9 bombsight is the best known of the

World War Two bombsights, it was not necessarily the best American

bombsight, in spite of the myth that has been built up over the

years since World War Two. Many officers in the U.S Army Air

Forces considered the Sperry S-1 to have been the better bombsight.

However, politics and hype won the day for the Norden M9 and it became

the standard bombsight during World War Two.

Estoppy D-8 Bombsight: Until I

began researching the products that National Cash Register manufactured

to help win World War Two, I was unaware that there was such a bombsight

at the Estoppy D-8 used in World War Two. I even made a special

trip to the National Air and Space

Museum Steven F. Udvar-Hazy Center near Chantilly, VA to photograph the

one the museum has on display.

Mr. Estoppy began work in 1921 as a civilian engineer at McCook Field,

Dayton, OH, after he had immigrated from Switzerland. The first bomb sight he designed was

the D-1. Previous to Mr. Estoppy's invention of the D-1, the U.S.

Army and U.S. Navy used British bombsights. In 1926 he designed an

improved version known as the D-4. The D-4 was used until Mr.

Estoppy invented another improved version designated the D-8.

Production of the D-8 began with other companies in 1938, with National

Cash Register commencing production in February 1942 at a cost of

$233.05 each. When production ended in February 1943, the cost had

been reduced to $156.00. From National Cash Register's historical

records, full production appears to have been reached in July 1942.

At least 9,339 were built by NCR, which was

the primary contractor for this bombsight during World War Two.

This

D-1 is on display at the National Museum of the United States Air Force

in Riverside, OH. This is one of 114 that were produced.

Author's photo.

This

D-4 is also on display at the National Museum of the United States Air

Force. Author's photo.

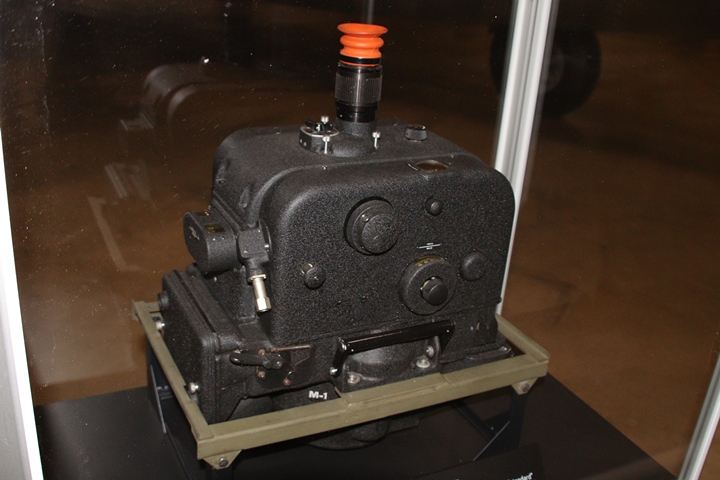

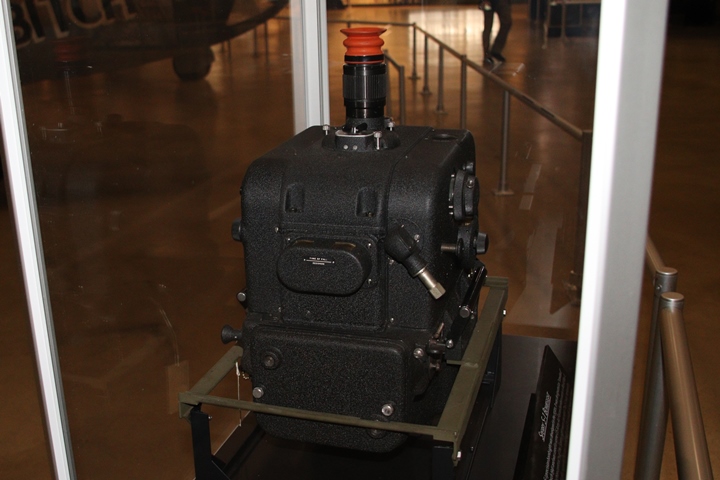

The Estoppy D-8 has a definite family

resemblance to the D-1 and D-8. Author's photo from the National Air and Space

Museum Steven F. Udvar-Hazy Center near Chantilly, VA.

Author's photo.

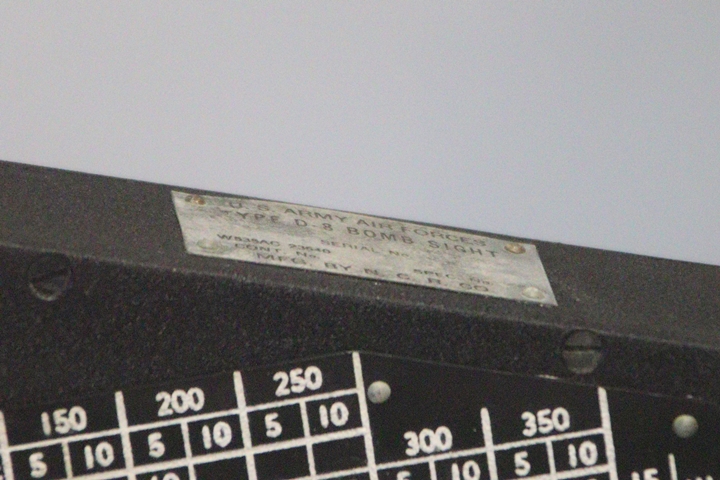

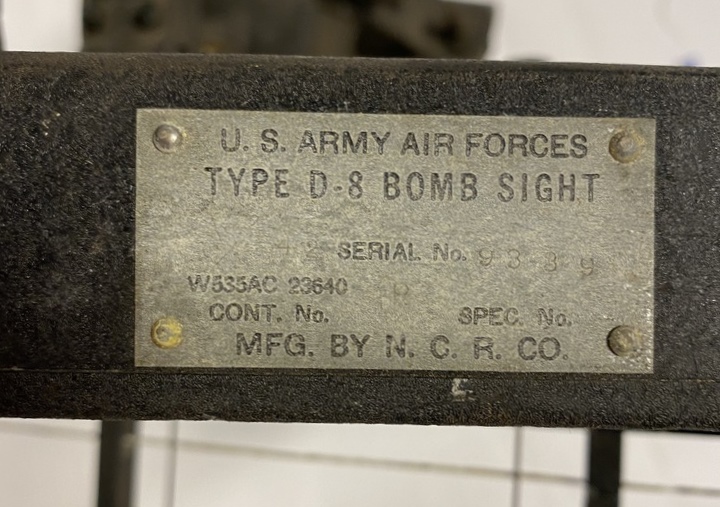

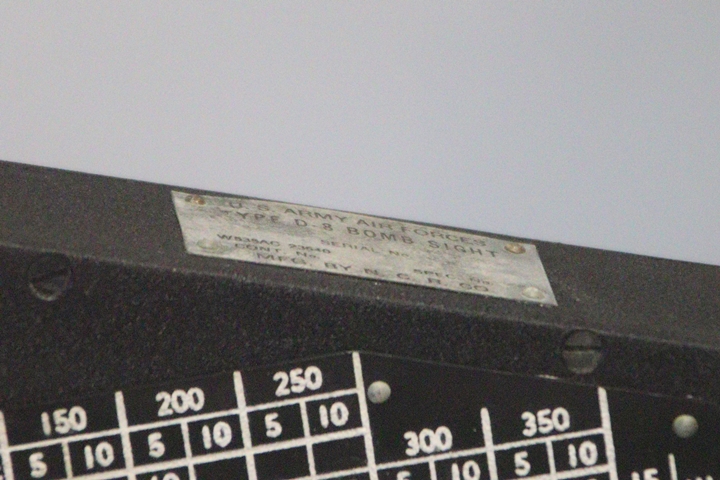

The data plate shows the D-8 was built by

National Cash Register Company. Author's photo.

Author's photo.

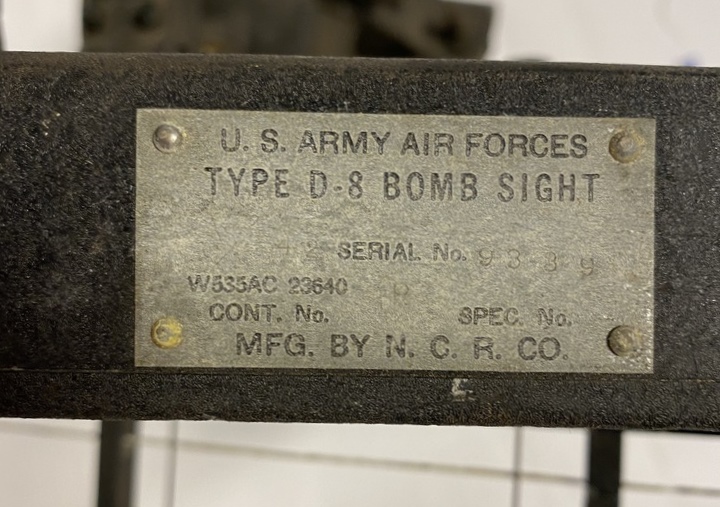

This photo is courtesy of the National Air and Space

Museum Steven F. Udvar-Hazy Center. This photo shows that it is serial

number 9339 which indicates the company built at least this amount. Contract W535 AC23640 is the

$2,018,000 contract for

Airplane Instruments awarded to National Cash Register in April 1942.

The D-8 was used on B-24s,

B-25s, B-26s, B-34s, and A-20s. It was not used on the B-17.

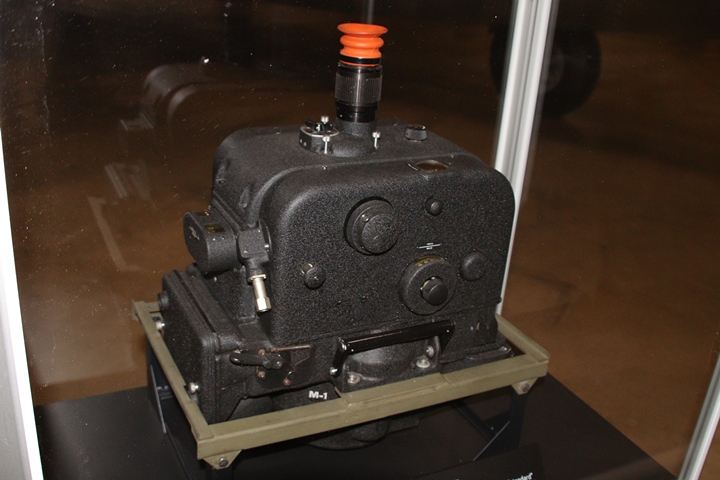

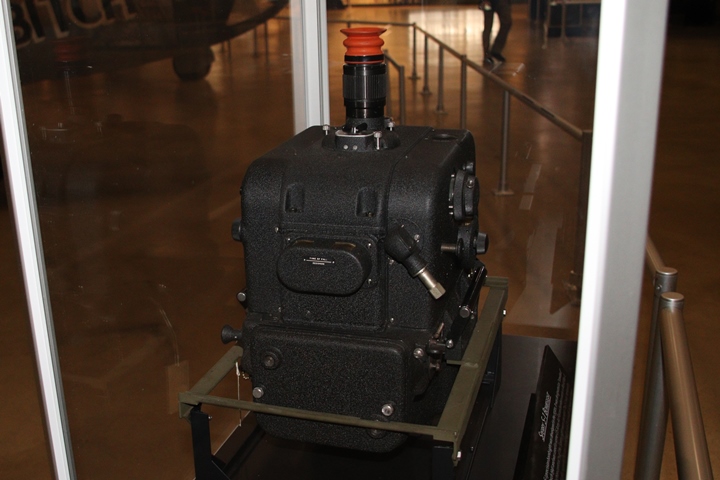

Sperry S-1

Bombsight:

The Army Air Forces awarded National Cash Register

contract number AC24608 for $4,975,000 in July 1942. While the

description in Table 1 is not very descriptive, the contract number

matches up with the contract number for this National Cash Register-built S-1 that is on display at

the National Museum of the United States Air Force. Author's

photo.

The Sperry S-1-designed bombsight was built

by Sperry, International Business Machines, and National Cash Register.

This S-1 is 5.64 miles from where it was

built at the former National Cash Register factory on the south side of

Dayton. Author's photo.

Author's photo.

Looking at the S-1 computing bombsight

shows that there was a sighting eye piece for the bombardier to view the

target and set up the bombsight. This was done with the several

rotating knobs on the exterior of the device. Author's photo.

Author's photo.

Author's photo.

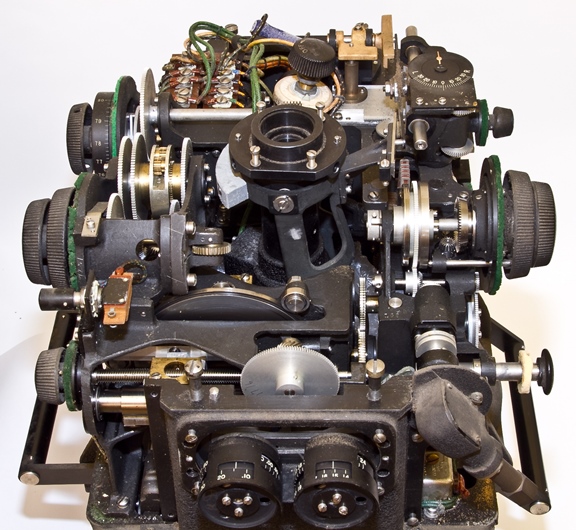

Once the cover is removed, it becomes very

obvious that the S-1 was a very complicated mechanical computer.

National Cash Register and International Business Machines were both

picked by the Army Air Force to build the S-1 due to their previous

experience in making similar devices for the civilian market.

Photo courtesy of www.glennsmuseum.com.

National Cash Register made four modifications

to the S-1 bombsight that were approved by the Army Air Force on August

30, 1943. The company made the modifications to improve both the

manufacturability and performance of the bombsight. A new style

of the clutching arrangement on the azimuth control system was

developed. The company also designed new tangent and degree scales

for the device. The bomb release was fitted with a new switch

relay. The last item, due to its complexity was being investigated

by Sperry as a better method. However, it may not have been

implemented due to the unexpected cancellation of the S-1 bombsight

program in favor of the better promoted, but not necessarily better, Norden bombsight. The entire program was terminated at the end of

1943. The last National Cash Register suggestion under

consideration by Sperry was a method to deposit a thin film of magnesium

fluoride in a high vacuum to the bombsight's optical surfaces.

This resulted in less reflection in the device and also increased the

amount of light transmission in it.

It is unknown how many S-1 bombsights National

Cash Register

made. According to Table 2, it was going to take 12 months to

reach initial production, which would have been July 1943. It was then going to

take another five months to ramp up to full production of 158 bombsights

per month, which would have been December 1943, when the contract was cancelled.

It probably built a couple of hundred units at most.

Sperry K-3/K-4 Automatic Computing

Gun Sights: Both gun sights were similar in construction and

use. The K-3 gun sight was used in the upper Sperry B-17 turret

which was operated by the fight engineer. The K-4 was used in the

Sperry lower ball turrets of the B-17 and the B-24. The reason the

K-3 was not used in the upper turret of the B-24 is that it was a Martin

turret that used a different gun sight.

The U.S. Army Air Forces awarded National Cash Register

four contracts worth $2,594,000 the

construction of the Sperry K-3 and K-4 automatic computing gun sights.

The contracts ran from September 1943 until June 1945.

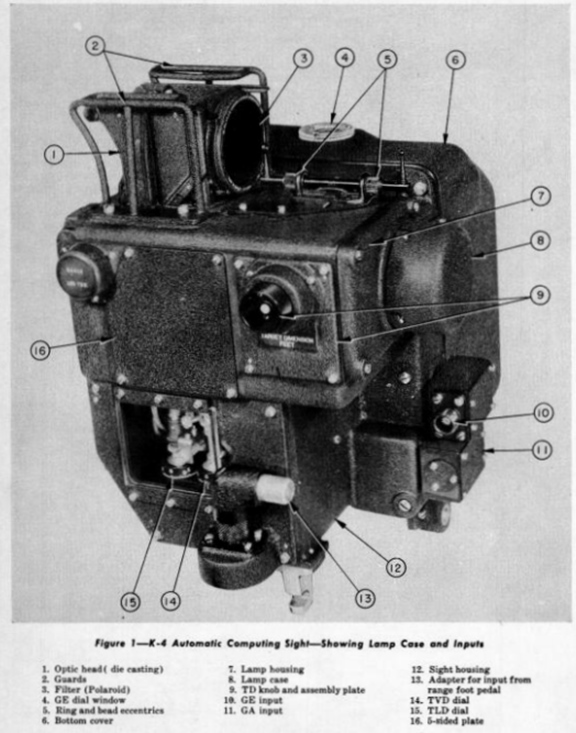

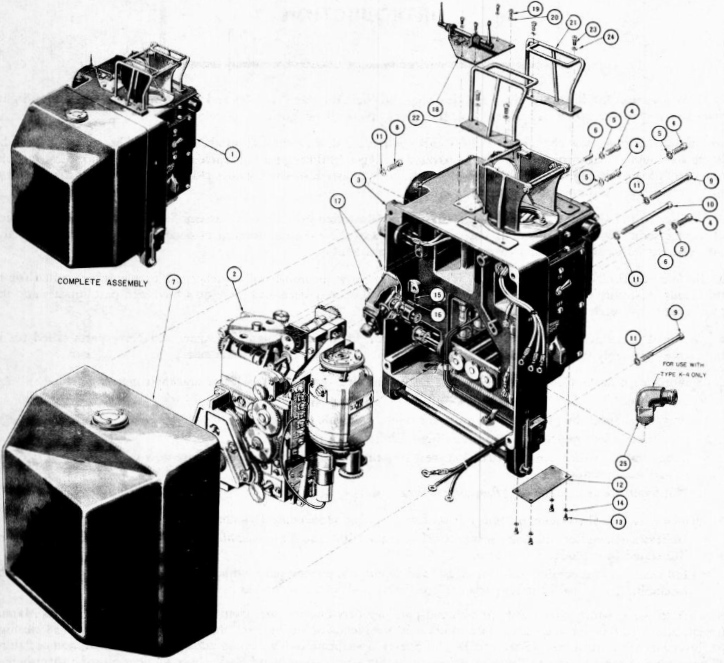

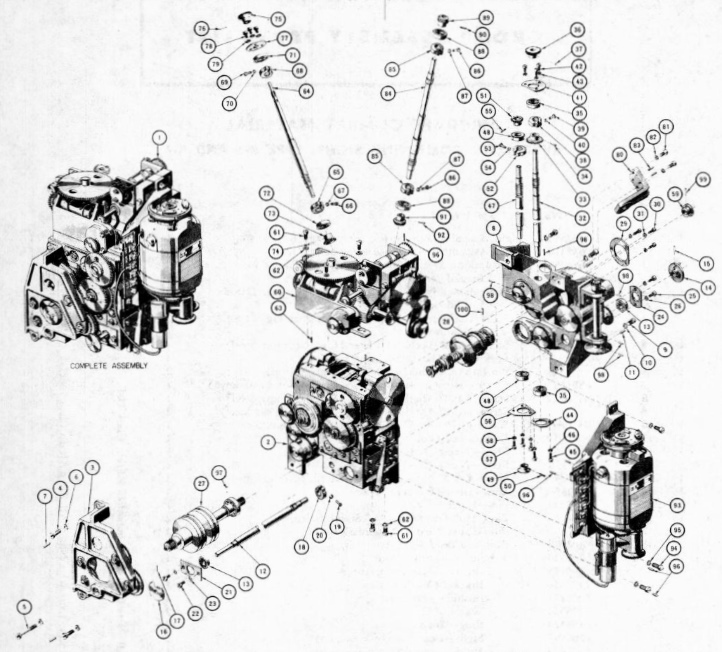

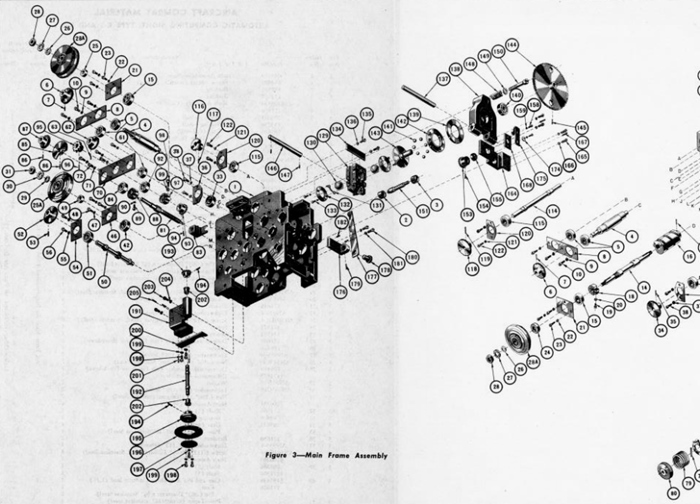

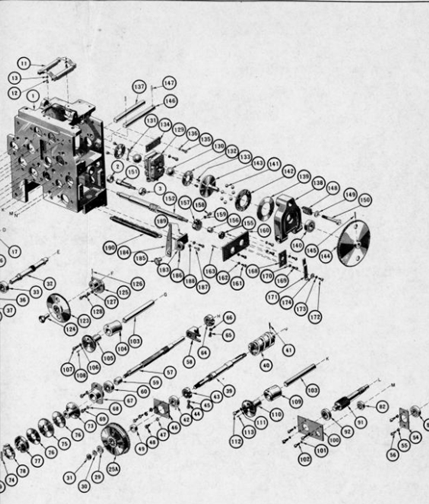

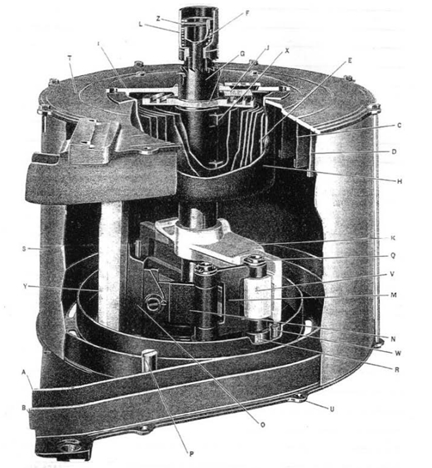

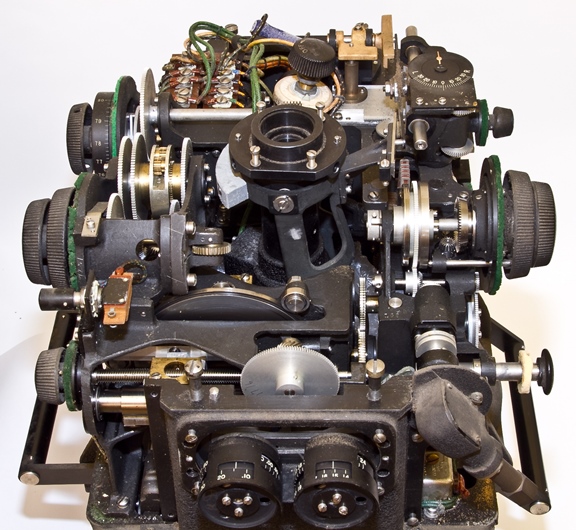

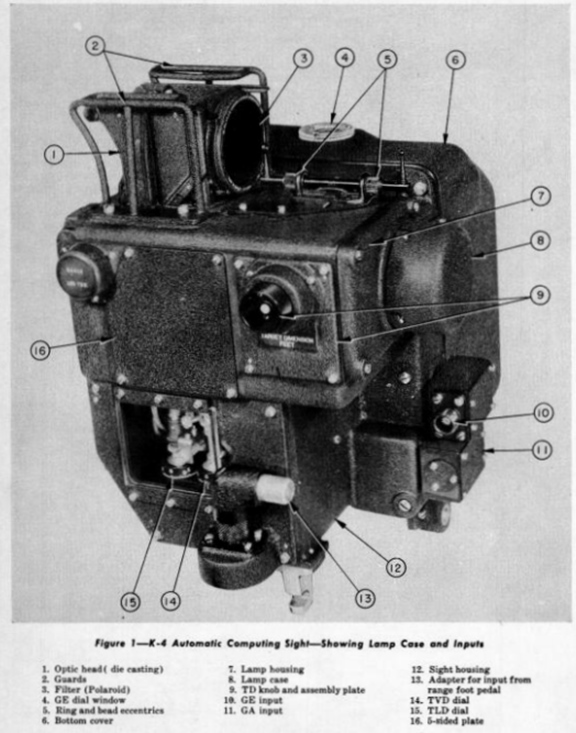

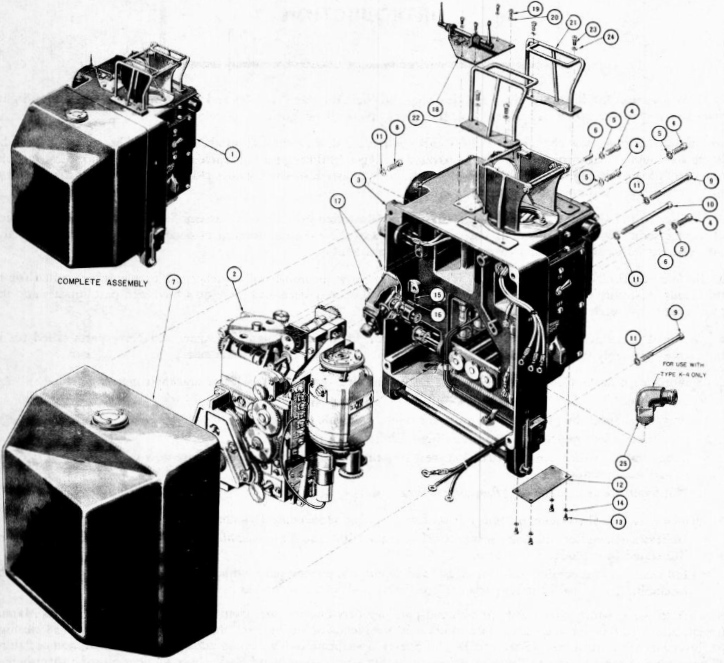

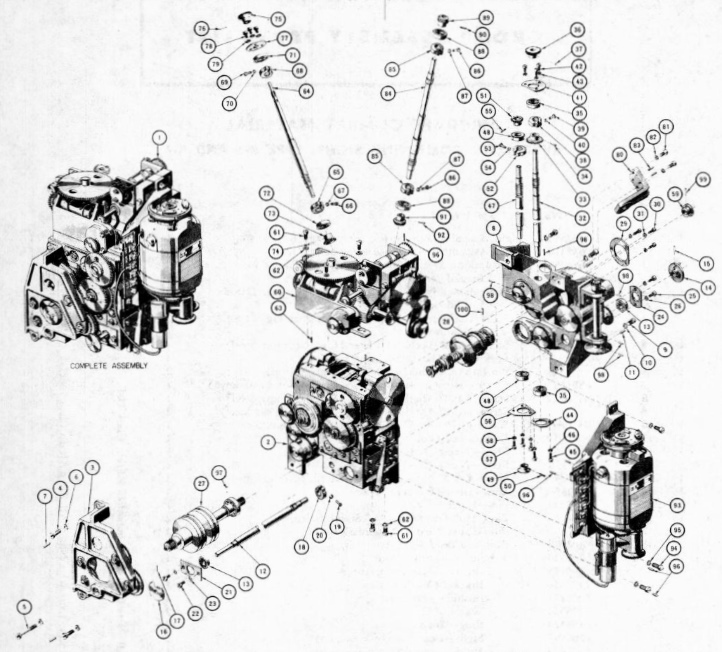

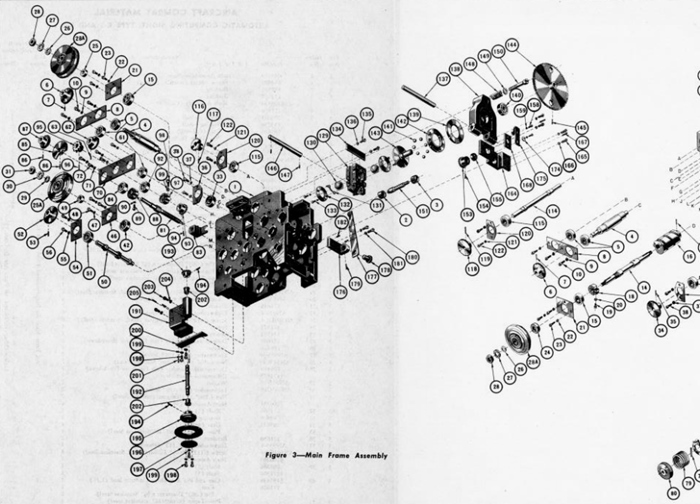

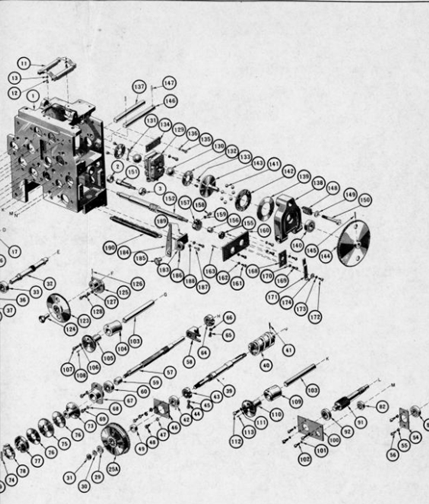

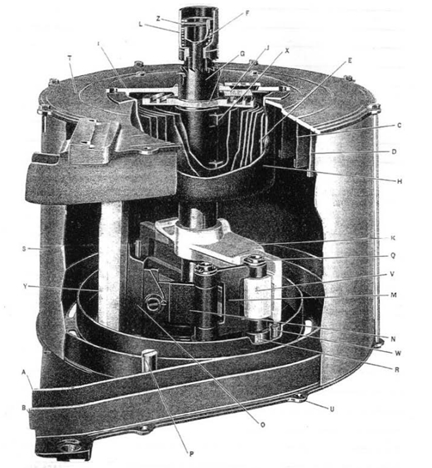

This and the next three images show the

complexity and all of the small parts used in the K-4 computing gun

sight.

This image shows the automatic computing gun sight

main assembly.

This image shows the computing mechanism assembly.

This image shows the main frame assembly.

NCR was well qualified to manufacture both the Sperry K-3 and K-4

computing gun sights. All of the small parts used in the gun

sights were similar to the parts and construction in the company's cash

registers of the era.

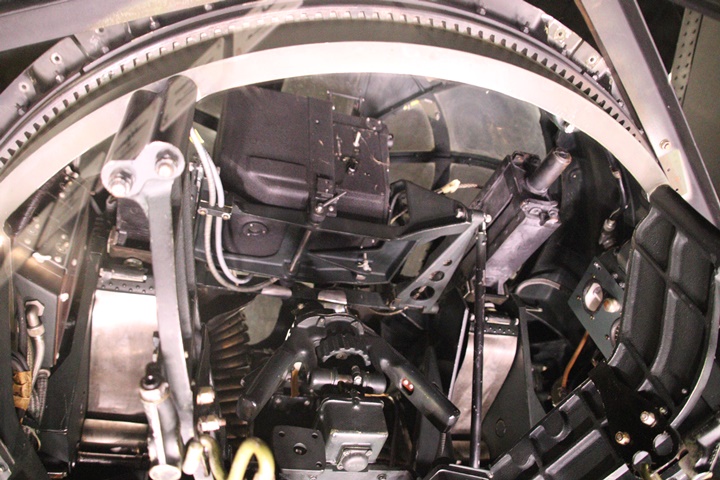

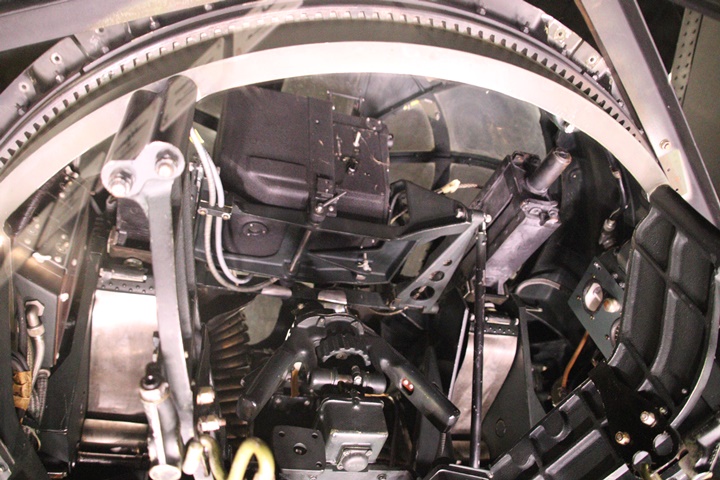

This is a Sperry-designed B-17 top turret

that is on display at the National Museum of the United States Air

Force. Author's photo.

Looking up into the turret, the back of the

K-3 gun sight can be seen in the upper left of the turret.

Author's photo.

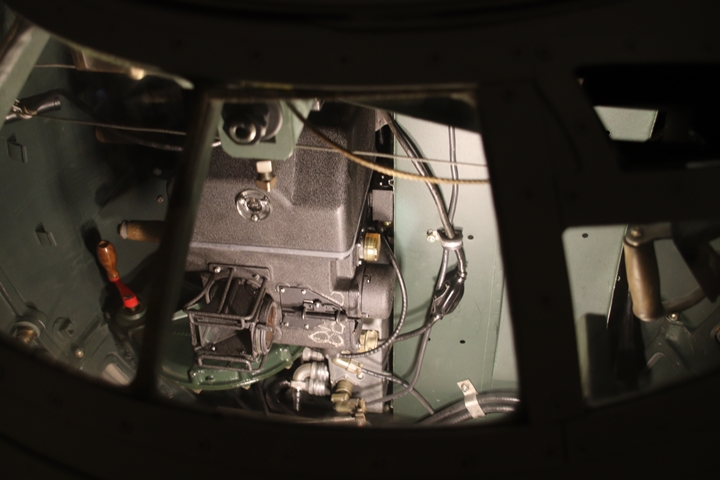

This is the B-17F Memphis Belle which is

also on display

at the National Museum of the United States Air Force. Author's photo.

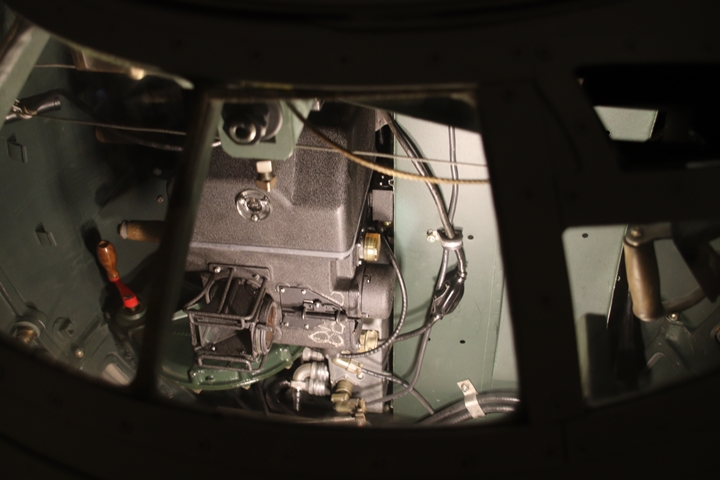

This is the Memphis Belle's Sperry-designed ball turret with a K-4 gun sight

installed. Author's photo.

The K-4 gun sight is in the center of the

turret. Author's photo.

Mark 4 Rocket Motors: In December

1944 National Cash Register was awarded a $114,436 Navy contract for Mark 4

five-inch High Velocity Aircraft Rocket (HVAR) rocket motors. The

rocket motor assembly did not include a propellant, as that would be

installed at an ordnance plant along with the warhead.

The U.S. Navy used the Mark 4 five-inch HVAR

in several aircraft during World War Two, including the TBM shown here.

Other Navy single engine aircraft that used the rockets were the F6F,

F4U, and SB2C. Author's photo.

Author's photo.

Author's photo.

The only Navy twin engine aircraft that used

the Mark 4 five-inch HVAR was the Lockheed PV-2 Harpoon. It could

carry four under each wing. Author's photo.

37mm M54 High Explosive Shell:

The size of the entire 37mm shell can be seen in relation to the World War Two

tanker's helmet in the photo. NCR made a high explosive shell

similar to the black painted shell in the photo. The nose fuze and

brass shell casing were made by another company. All of the

components were then assembled into the final product at an ordnance

plant. Author's photo.

The M5A1 series light tank was mounted with a 37mm main gun which used

the M54 high explosive shell. Author's photo.

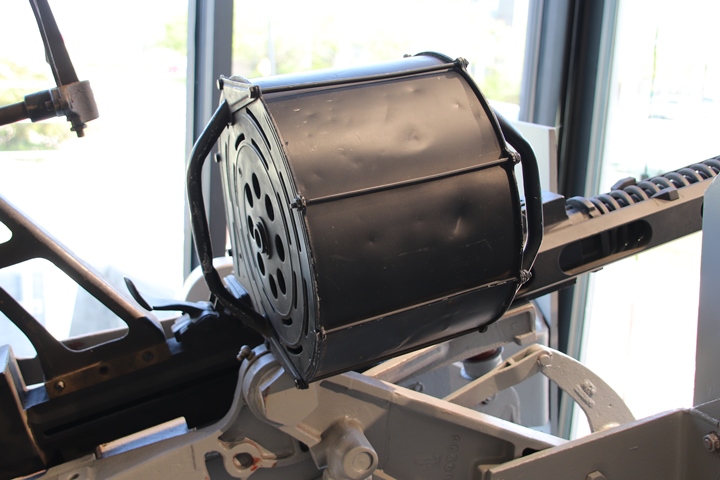

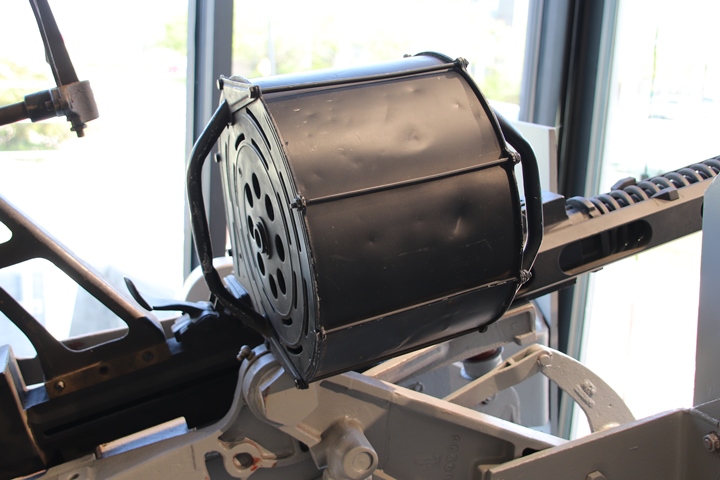

20mm Oerlikon Magazines:

This 20mm Oerlikon anti-aircraft gun is on

display at the LST-325 Museum in Evansville, IN. National Cash

Register built many of the 60 round magazines that were used on the

weapon. Author's photo.

There were 137,541 20mm Oerlikons

built during World War Two for the U.S. Navy, which was the company's

customer for the product. A total of 1,375,410 magazines would

have been required if it is assumed that each weapon required ten

magazines. It is unknown how many magazines the company built. Author's photo.

Author's photo.

Due to many changes that National Cash

Register made to make the magazines easier to manufacture, the selling

price for the magazines in May 1941 was $94.78. Over the next

29.5 months, the selling price dropped to $35.70 in eight

steps. Author's photo.

While it does not look like a very

complicated product from the outside, the 20mm magazines were assembled

using a

considerable number of components.

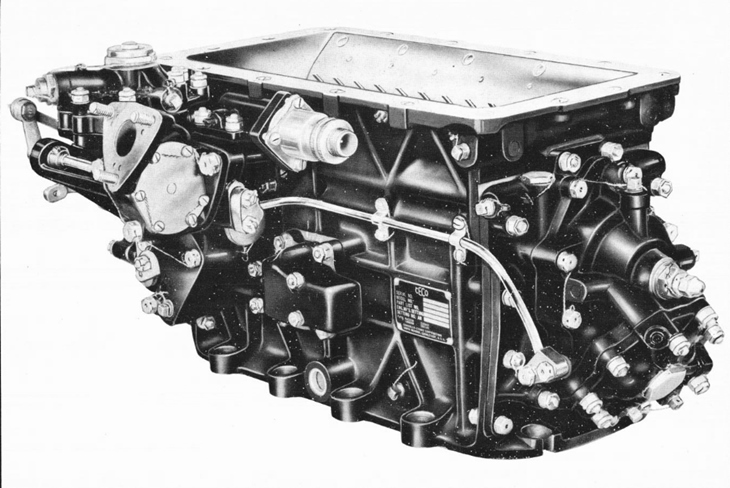

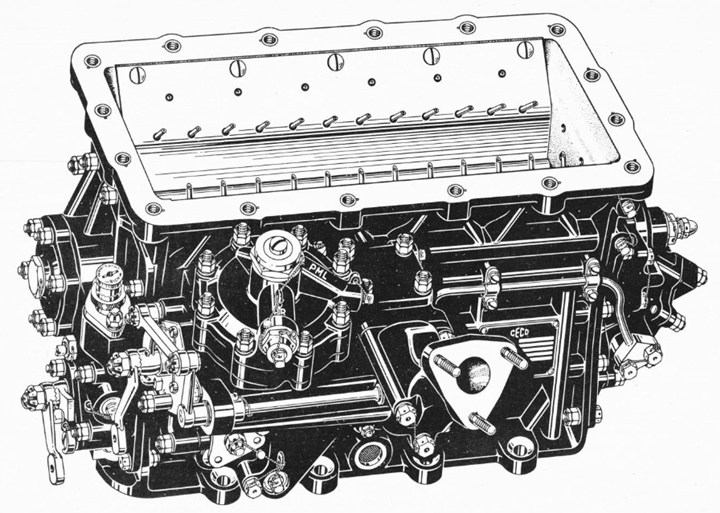

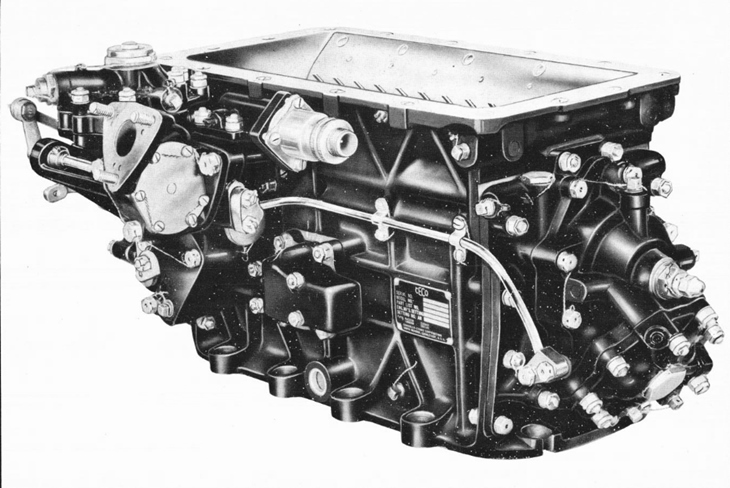

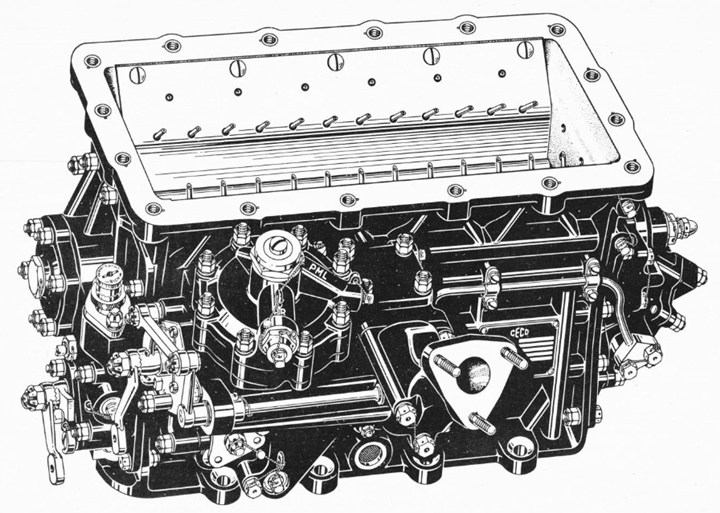

Chandler-Evans Carburetors:

Chandler-Evans produced a variety of military aviation components during

World War Two. The National Cash Register Company built three

different carburetors as a subcontract for Chandler-Evans during World

War Two.

The 58 CPB-4

and 58 CPB-10 carburetors were used on the Wright R-3350-35 engine which

were used on the B-29 Superfortress bomber.

The 1900 CPB-3 carburetors were used on the

Pratt & Whitney 1830-C4 engine which was used on a variety of aircraft

during World War Two.

This image and the one below show a 58 CPB-4

aircraft carburetor. The other two types of carburetors that NCR built

were similar.

M-1 Carbine Parts:

During World War Two the Inland Division of

General Motors was the largest manufacturer of the M-1 carbine.

The Inland Division was located on the west side of Dayton not far from

the NCR complex. Inland subcontracted with NCR to make firing

pins, piston nuts, hammer spring plungers, operating slide pins,

hammers, hammer pins, extractor spring plungers, and magazine catch

retaining safety plungers for the weapon.

This Inland-built M1 Carbine is on display

at Fort Macon State Park in North Carolina. Inland built 2.6

million of these during the Second World War. Author's photo.

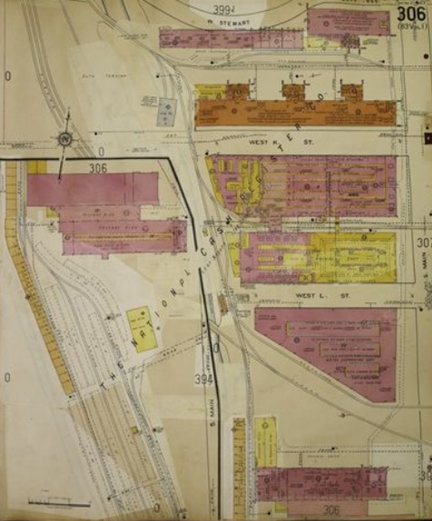

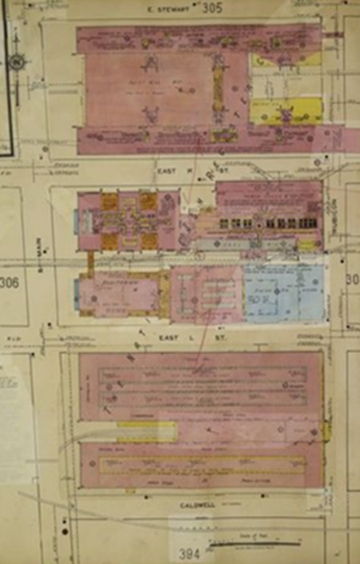

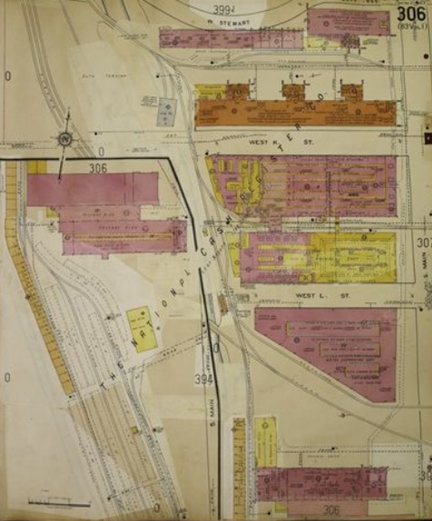

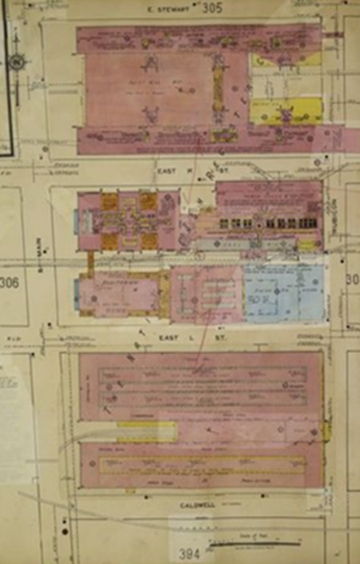

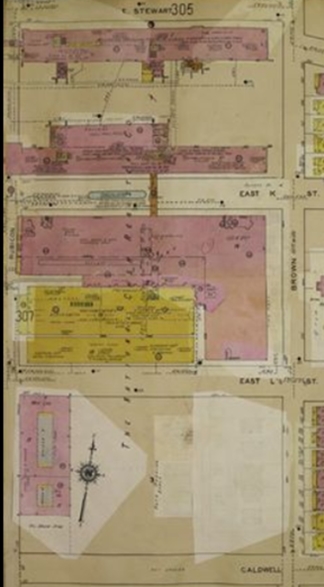

National Cash Register's Factory Complex:

The NCR factory complex was razed, and the land is now part of the

University of Dayton. Below is a Sanborn fire insurance map shows

the how big the complex was. The Google satellite photo below shows the same area today.

The University of Dayton now owns the former

NCR property. All of the former NCR buildings have been razed and

replaced by new university buildings and parking lots. There is no

trace of the former NCR complex.

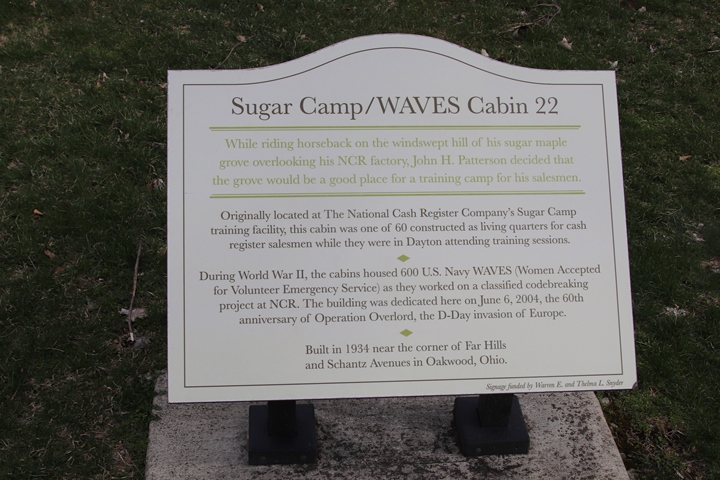

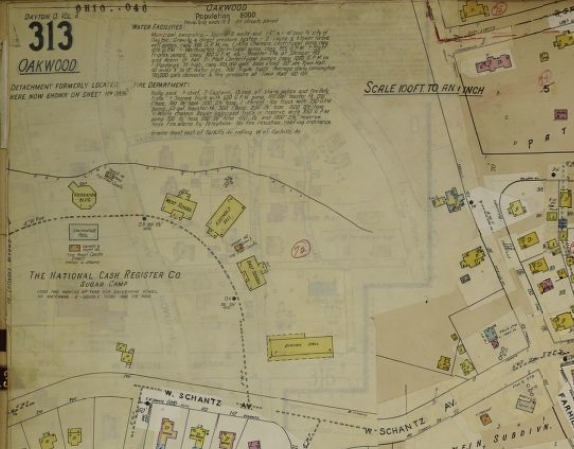

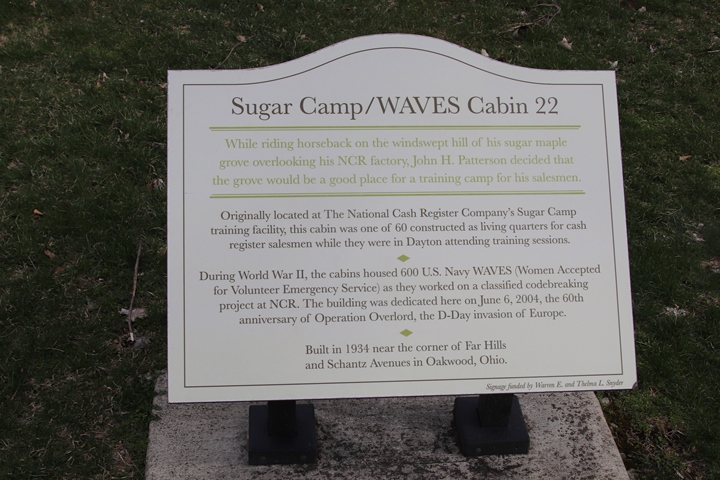

Sugar Camp:

This was an NCR-owned camp about a mile south

of the factory complex with a number of log cabins that were used for

off-site sales meetings. During World War Two, it was the living

quarters for the Navy WAVES that were assigned to NCR to assemble

components for the NCR N-530 Bombe Enigma Decrypting Machines.

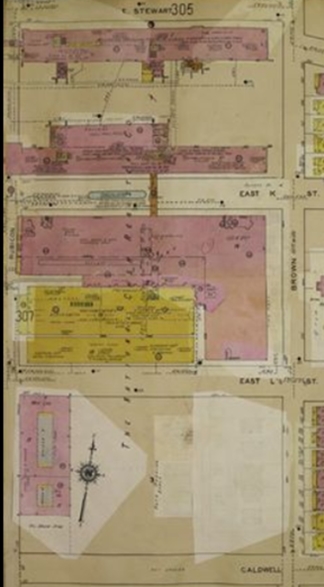

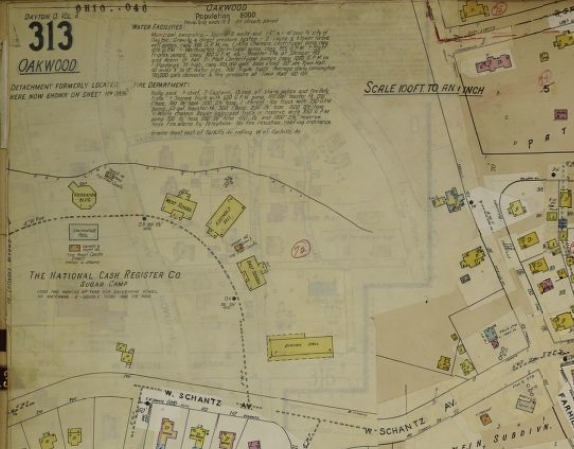

This is Sanborn map shows the layout of the

camp on West Schantz Avenue. This does not show the 60 cabins that

were used by 300 WAVES during World War Two.

Sugar Camp was also razed except for two

buildings. The location of the razed buildings has been repurposed

with several office buildings.

One building that was not razed was the

gatehouse to Sugar Camp located at the intersection of West Schantz

Avenue and Sugar Camp Circle. Author's photo.

This is the east side of the building.

Author's photo.

This is the south and west sides of the former

gatehouse. Author's photo.

This is the east and north sides with the

attached garage in the background. Author's photo.

The other building that was not razed was

Sugar Camp Cabin #22. In 2004, it was moved in one piece from its

former Sugar Camp home to Carillon Historical Park. It is now on

display less than a mile west of its original location. Author's

photo.

There are several different figures for the

number of WAVES at Sugar Camp.

With only 60 cabins, this would mean there were ten WAVES per cabin.

This would have resulted in an overcrowding issue. The cabins as

shown below had two rooms each with two beds per side. The cabins

were set up for four persons. With 600 WAVES, there was an

overcrowding issue. Some of this was relieved by the fact that the

WAVES worked two twelve hour shifts. Therefore, the WAVES used a

hot bunking system where one WAVE slept while the other went to work.

However, there still would have had to have been extra bunks

installed in the cabins to accommodate all of the WAVES. The first

winter the WAVES were located at Sugar Camp, there was no heat in the

cabins which made for very cold nights trying to sleep. Author's photo.

Carillon Historical Park's re-creation

of cabin's bedroom does not show the overcrowding that occurred. Author's photo.

Author's photo.

There were two sinks, one shower, and

one commode for up to ten WAVES. Author's photo.

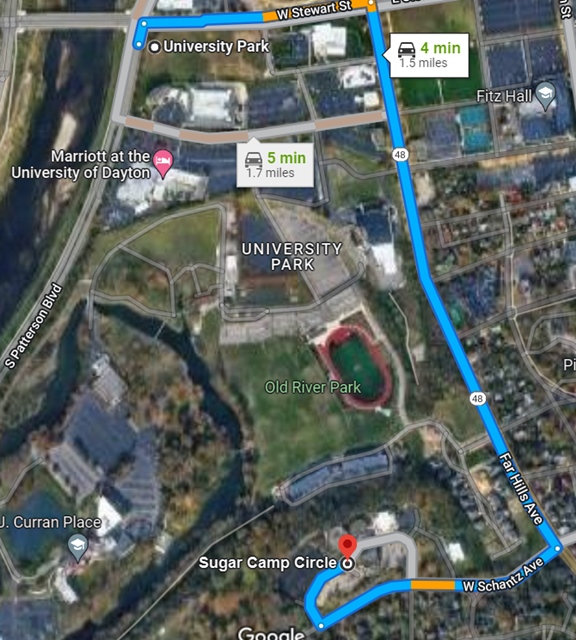

There are stories of the WAVES marching back

and forth from Sugar Camp to Building 26 where the Bombes were being

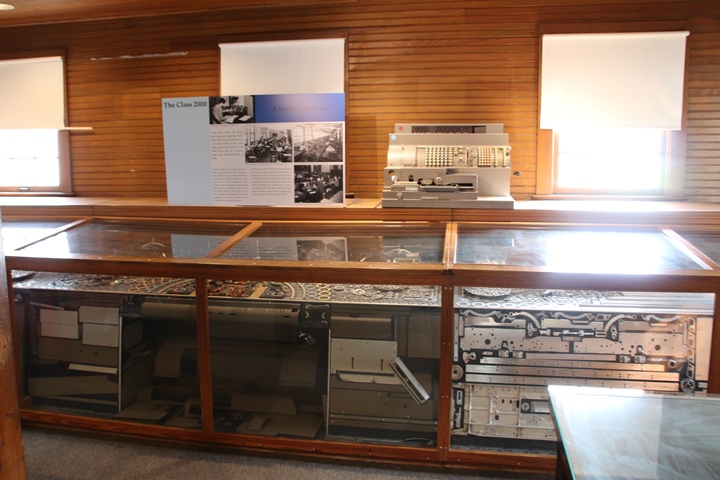

manufactured. This Google Satellite view shows the route they marched.

Author's photo.

Far Hills Avenue turns into Main Street

north of Schantz Avenue. The WAVES marched up Main Street and then

west on Stewart Street to NCR's Building 26 which was located at the

intersection of Stewart Street and South Patterson Blvd. With two

shifts, this happened twice a day. Dayton police closed the roads

when the WAVES were marching. They did this in all kinds of weather during

the year. Image courtesy of Google Maps.

There was

also a mess hall located at Sugar Camp where the WAVES stayed. In

spite of the over crowding in the cabins and the march each day back and

forth to work at NCR, the WAVES had it considerably better than the male

sailors assigned to NCR. This is an untold story and not much is

known about their involvement. However, the male sailors had

to find their own housing and meals. The sailors also

worked on building components for the Bombes and how to maintain them.

NCR N-530 Bombe Enigma

Decrypting Machine

|