|

Willys-Overland War

Production Record

Willys-Overland Plant Photos

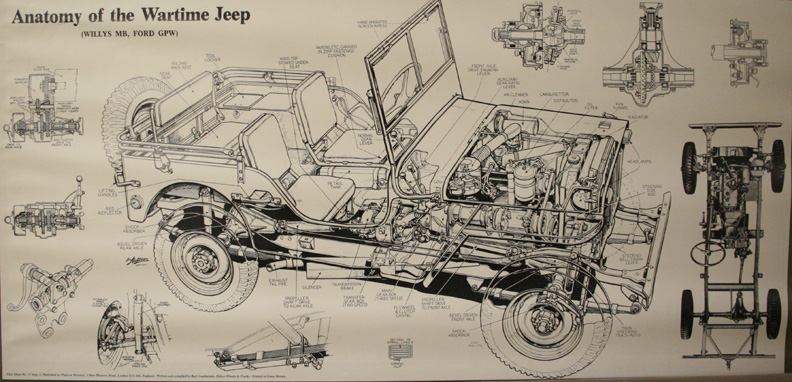

Willy Jeep

Willys-Overland Motors in World War Two

Toledo, OH

1903-1952

(Willys-Overland ceased as a company in 1952, but the Jeep has remained

and has been built by several companies in Toledo.)

Rest in Peace

This page last updated 3-11-2025.

Willys-Overland is best known for

its Jeep. It continues to be produced today in Toledo, OH, although in

a

newer plant than the one used during World War Two. Over the years since the

Second World War, the owners of the Jeep name have

changed several times. However, if one looks at the photos below

and in the War Production Record above, it becomes very obvious that Willys-Overland

had a very diverse product line beyond the Jeep. In fact, as shown

below, it was one of the four US automakers during World War Two

to make airframes. But what was special about the Willys-built

airframe is that it was the United States' first cruise missile.

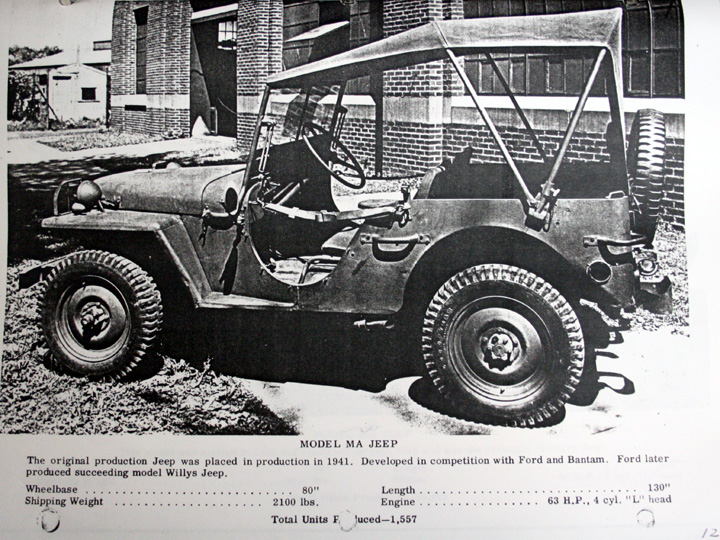

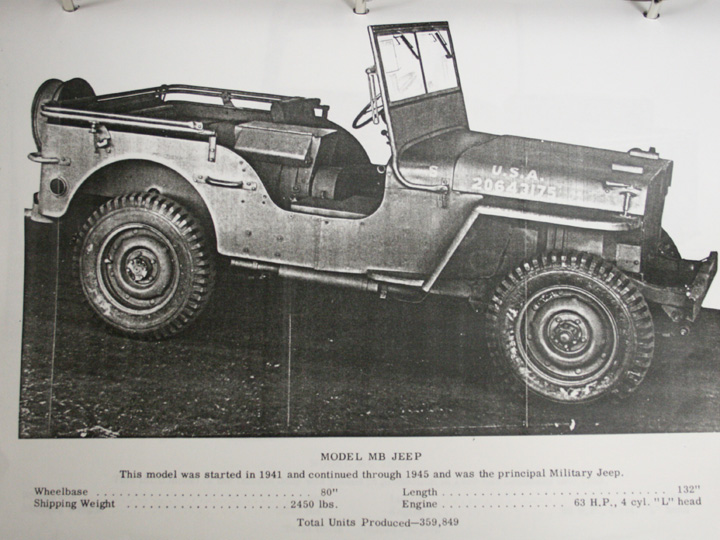

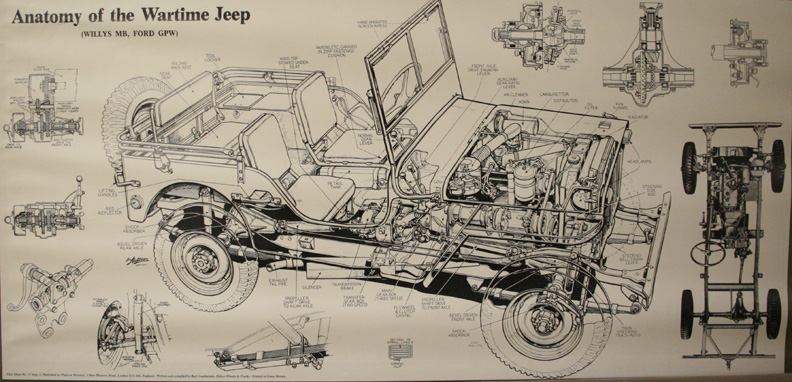

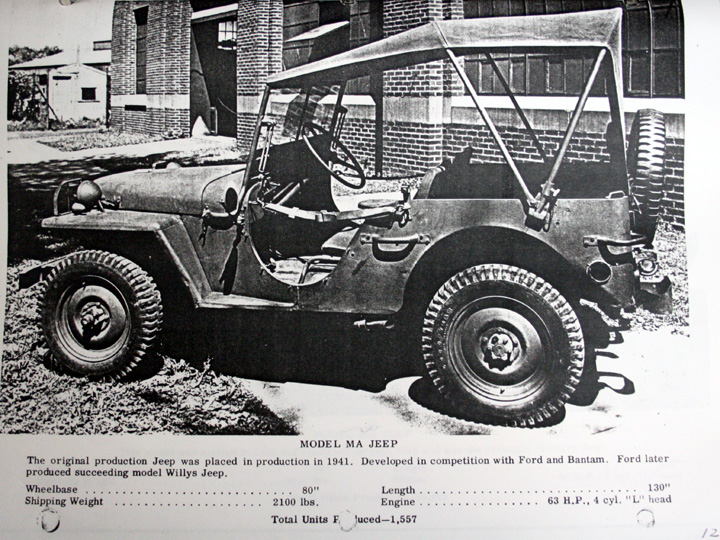

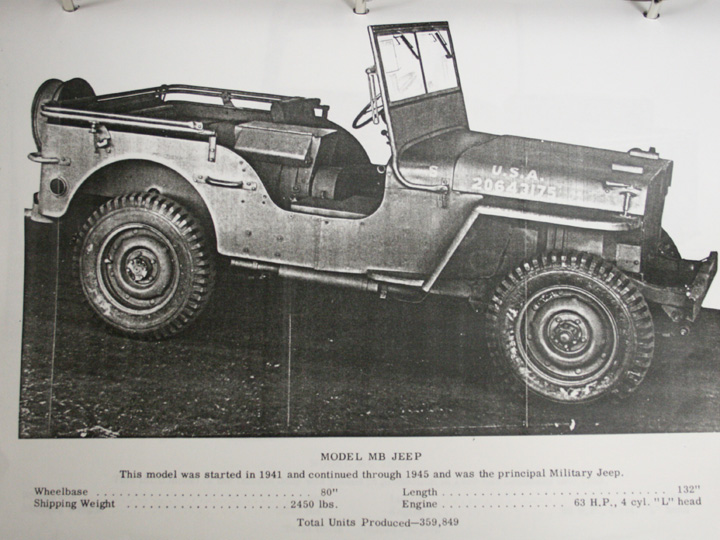

How many Willys-Overland Jeeps were

built? We have included official Willys-Overland photos and

documents from the World War Two era, and they do not agree. Below one can

note that 1,557 MA models and 359,849 MBs were built for a total of

361,406 Jeeps. Looking at page two of the "Willys-Overland War

Production Record" linked at the top of this page, the quantity of

353,941 is reported, but we assume that to be a typo and should have been

358,941. Then on page 3 of the same document, the quantity of 358,941 is reported. However, if one

actually adds up the numbers, it comes out to 359,941. It appears that

the fire trucks for the Navy were subtracted, as they were not Jeeps.

Only the Jeep chassis were used. To add to the confusion, Table 1

shows that Army Ordnance only accepted 350,349.

It should be noted that body

production was outsourced and was built in Connersville, IN. The

Jeep engine and final assembly were done in Toledo. Based on 359, 941, the average

cost of a Willys MA/MB Jeep and fire truck was $1,291.78 in World War Two dollars.

As noted above and can be seen from the

information below, Willys-Overland produced a whole plethora of war

goods besides Jeeps for the US Military. Total wartime sales for

the company were $734,148,706

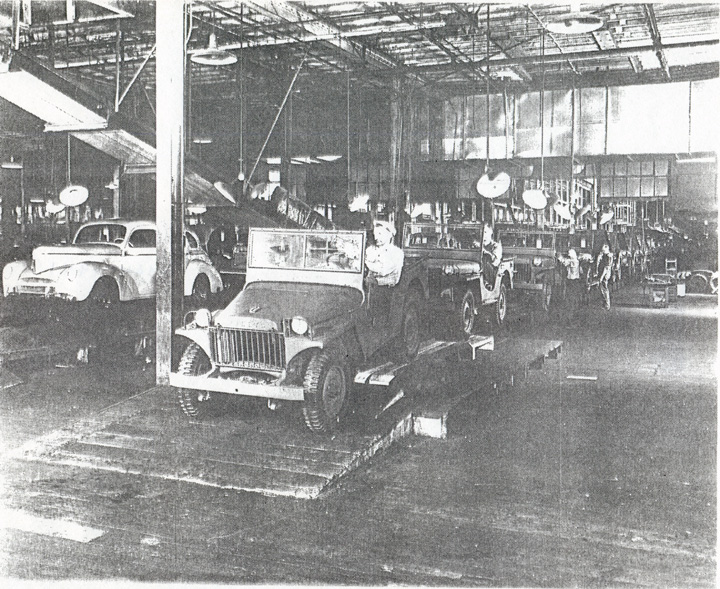

for the 19 major projects it undertook. At peak production, the

company employed 15,000 workers and was turning out a Jeep

every two minutes. All of the production was at one plant

complex on Central Avenue in Toledo.

Normally histories on the US Auto

Industry during World War Two are Detroit-centric and forget Willys-Overland down to

the south, just across the Ohio-Michigan state line. Hopefully,

this page provides a full accounting and credit for what Willys did

during World War Two.

Willys-Overland in

World War One:

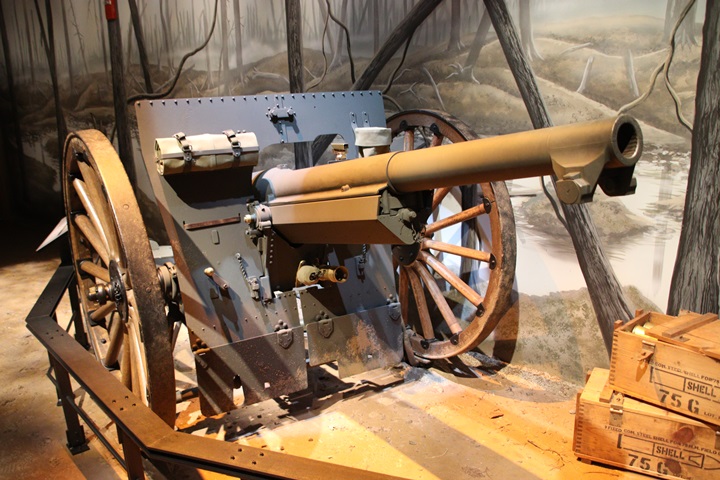

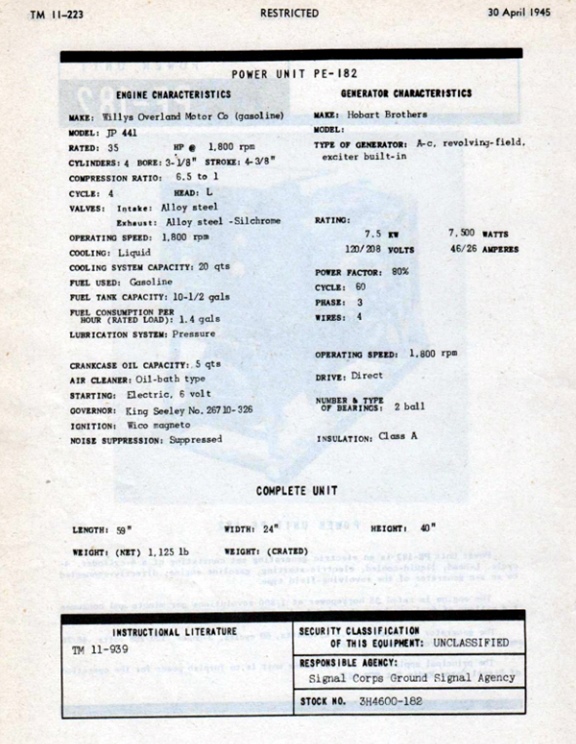

There were 1,500 French 1897 75mm field guns built under license in

the United States. Willys-Overland built many or all

of the gun carriages for this weapon. Author's photo added

1-2-2022.

This carriage is on display at the

National Museum of the USMC, which is serial number 501. Author's photo

added 1-2-2022.

Editor's note: None of what

is shown here would have been available without the help of Jeep Historian Emeritus Ron

Szymanski of Toledo, OH.

Mr. Szymanski is the former Curator of the Jeep Museum and is a virtual

encyclopedia of information on the entire history of the company and

product line. He voluntarily spent an entire day with me in January 2012,

providing information and photos that make this history of Willys-Overland

in World War Two so complete.

Willys-Overland won the Army-Navy "E" two

times during World War Two.

Willys-Overland World War

Two Products:

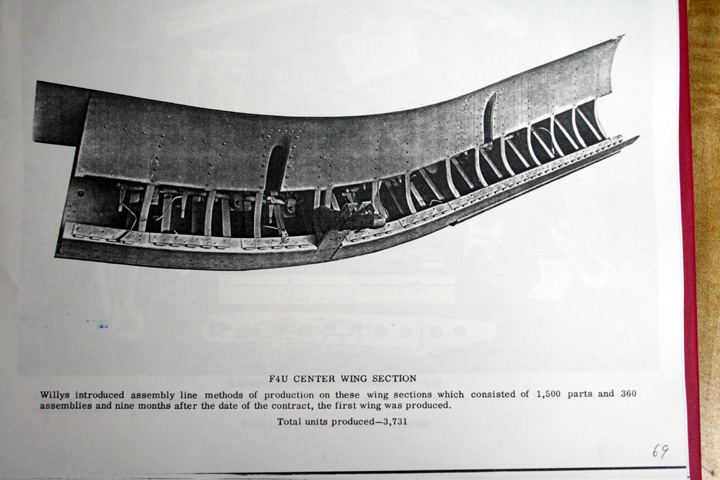

The company had $609,498,000 in major contracts during World War

Two. These contracts included the following products: 358,941 Model MA and MB

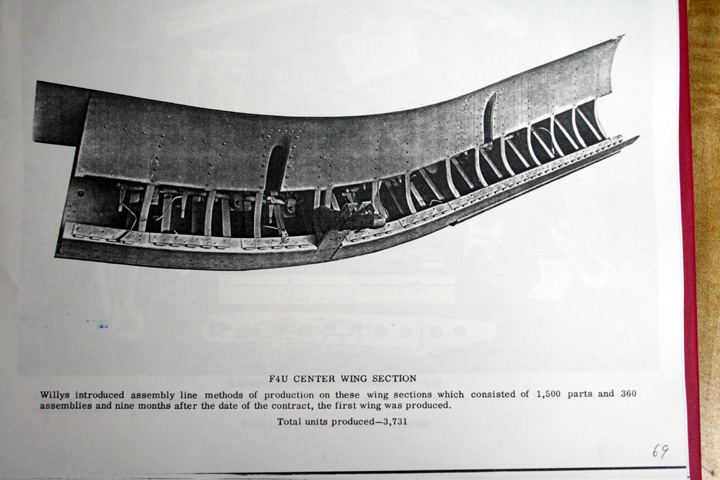

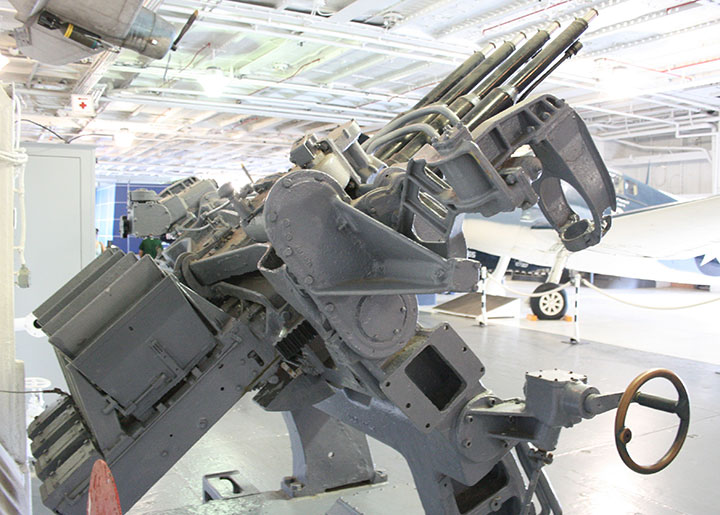

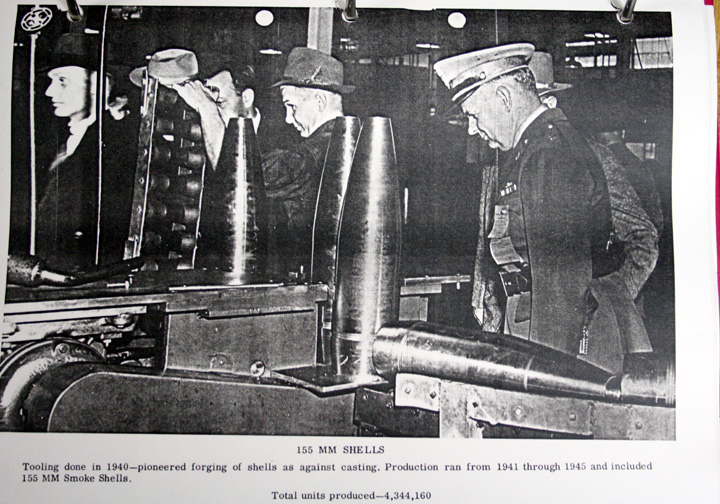

Jeeps, 15 MT Tugs, 4,344,160 155mm shells, 3,374 Breech Housings and Recoil

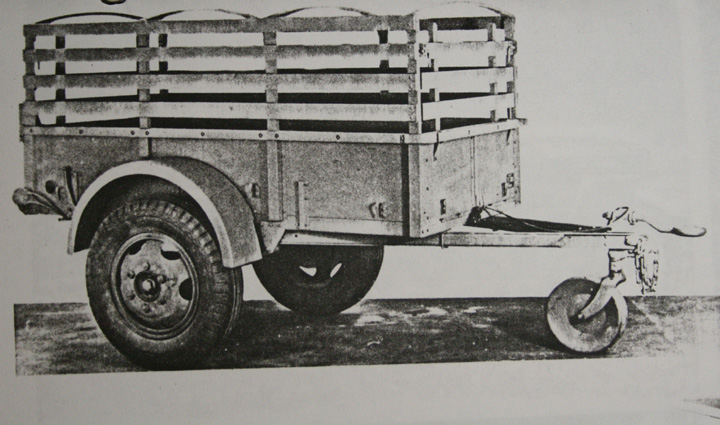

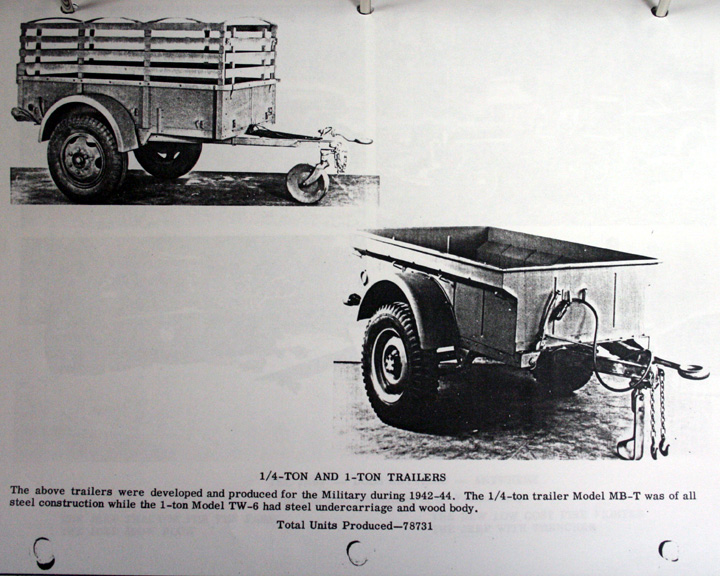

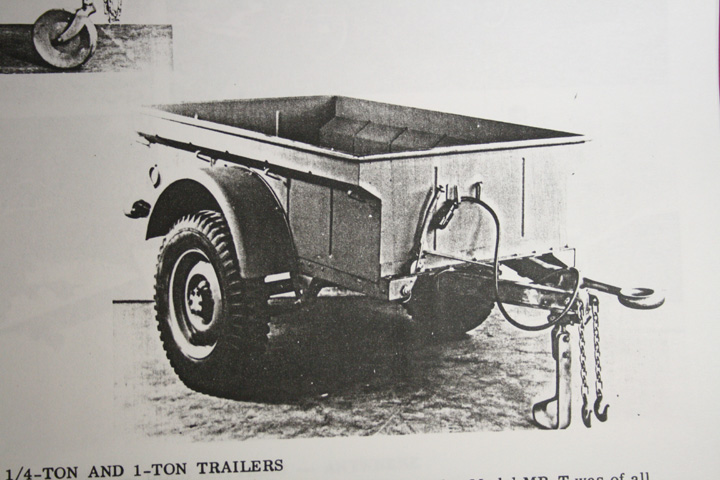

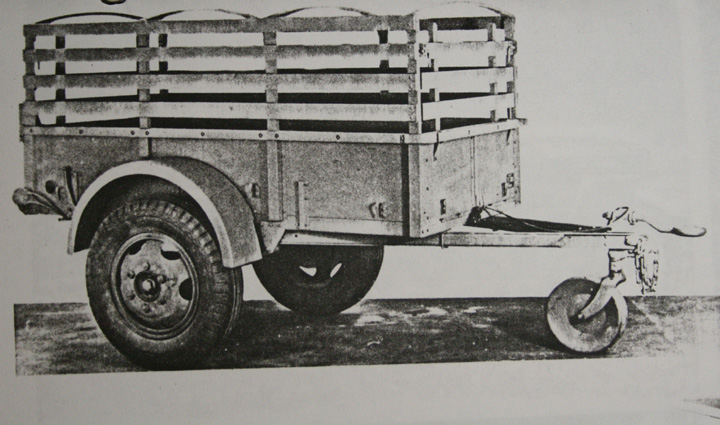

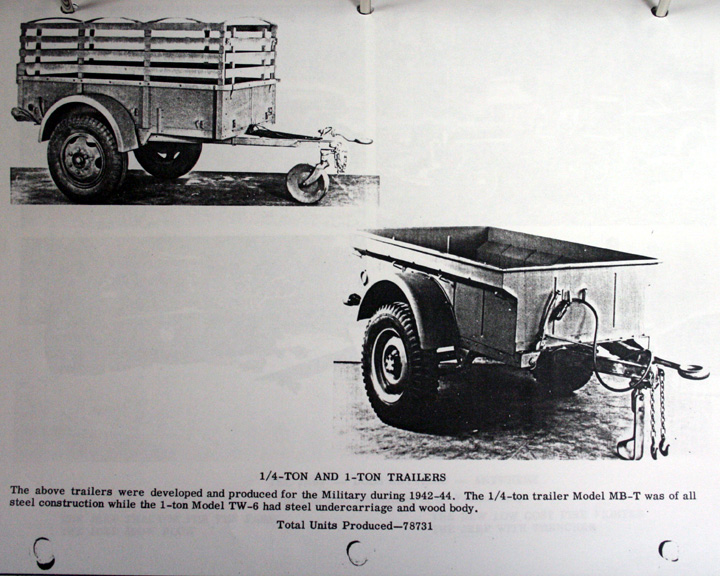

Cylinders for 1.1 inch anti-aircraft guns, 78,735 1/4 and 1 Ton Cargo Trailers, 415 Powder and

Projectile Hoists for US Navy ships, 253,072,519 40mm Primers and Parts, 2,000,460

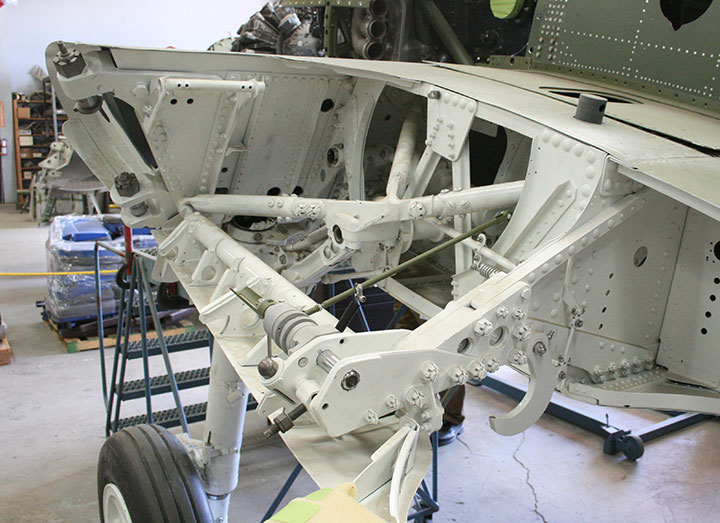

20mm Shells, 6,096 Grumman F6F Landing Gears, 849 Carburetor Air

Scoops for Curtiss-Wright (Unknown type aircraft.), 3,605 C-46 Wing

Fuel Tanks, 37,500 Bomb Cluster Shipping Bands, 1,087,277,247 .30

and .50 bullet cores, 3,731 Vought F4U Wing Center Sections, 1,292

JB-2 Airframes.

Table 1 -

Willys-Overland World War Two Vehicles

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Truck, 1/4-ton,

4x4, Command |

|

9,129 |

83,739 |

91,955 |

108,806 |

56,720 |

350,349 |

| Truck, 3/4-ton,

6x6, Tractor |

|

|

|

15 |

|

|

15 |

| Trailer, 1/4-ton,

2-Wheel, Cargo |

|

|

16,527 |

34,037 |

9,392 |

|

59,956 |

| Trailer, 1/4-ton,

2-Wheel, Flat Bed |

|

|

3 |

|

|

|

3 |

| Trailer, 1-ton,

2-Wheel, Cargo |

|

|

|

9,502 |

5,274 |

|

14,776 |

|

Total |

|

9,129 |

100,269 |

135,509 |

123,472 |

56,720 |

425,099 |

Author's Note

and Disclaimer: The Detroit Office

of Ordnance of the U.S. Army was the primary purchasing entity for vehicles for the U.S. Army during WWII. It also purchased

vehicles for the USMC, US Navy, and for Lend-Lease. However,

there were other organizations that also purchased vehicles

including the Army Corps of Engineers, U.S. Army Air Force, U.S.

Army Signal Corps, Navy Bureau of Ordnance, Navy

Bureau of Aeronautics, and foreign countries making direct

purchases. In this case it is known that the Signal Corps

ordered its own trailers from Checker, and they are not comprehended in

the numbers above.

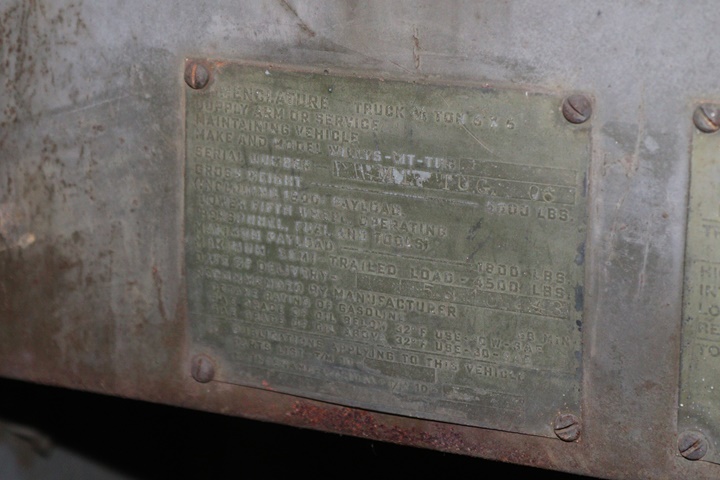

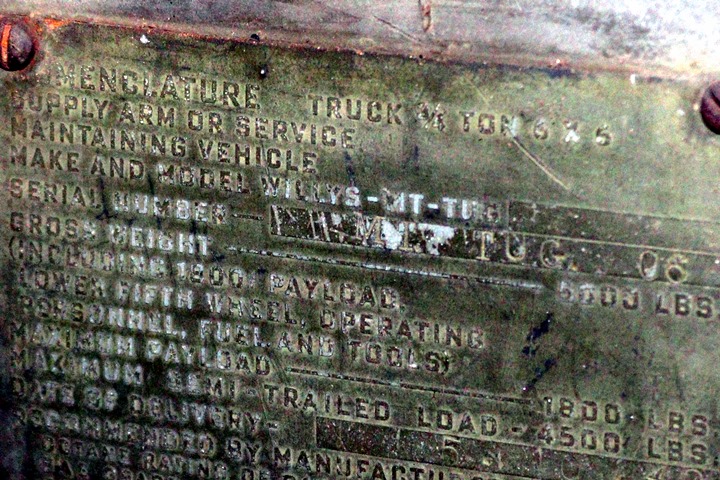

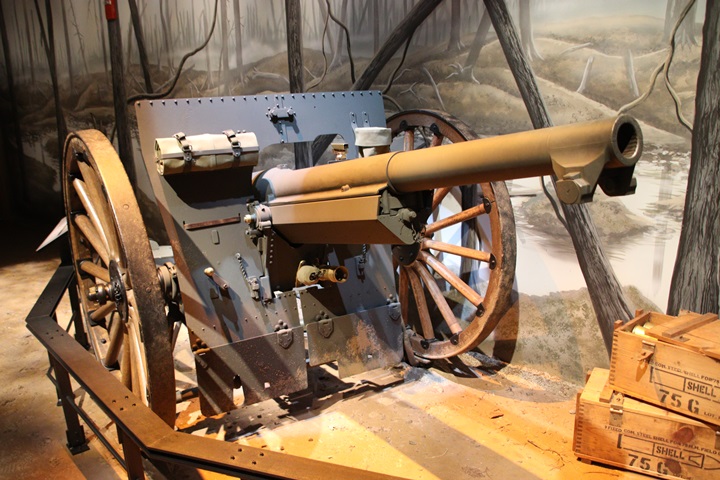

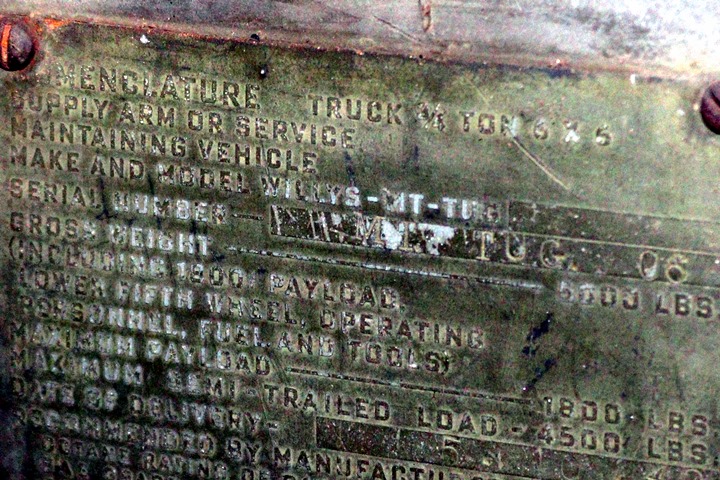

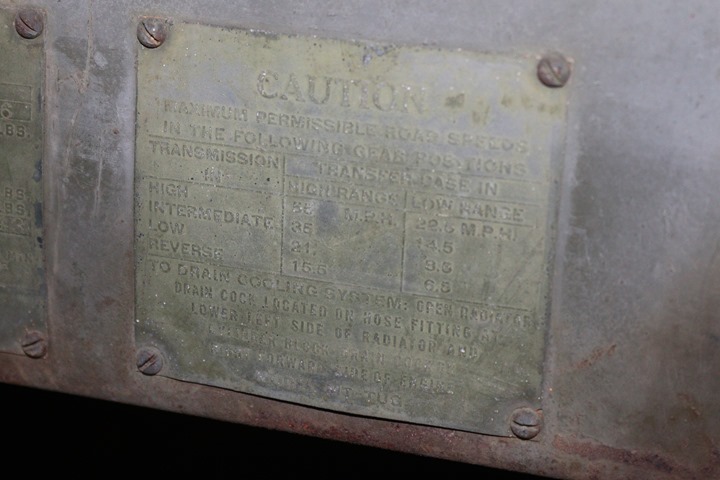

The Willys-Overland MT-Tug:

Army Ordnance describes this vehicle in the above table as the Truck, 3/4-ton,

6x6, Tractor. Willys-Overland described it as the MT-Tug,

as shown on the data plate below. Of the fifteen that were

produced in 1943, there appears to be three still in existence.

This is not a bad percentage for a World War Two vehicle. One of

the survivors is Serial Number 6, which is located at the Sam Werner

Military Museum in Monteagle, TN. While not restored, it is

original, with the data plate still attached to the vehicle. Some

collectors have been known to modify a standard jeep into the 6x6

configuration. This is the real deal at the Sam Werner Military

Museum.

The U.S. Army tested them and decided it

did not want it. However, the Army Air Force took the vehicles

and used them to tow aircraft at its airfields.

Photo added

7-29-2019.

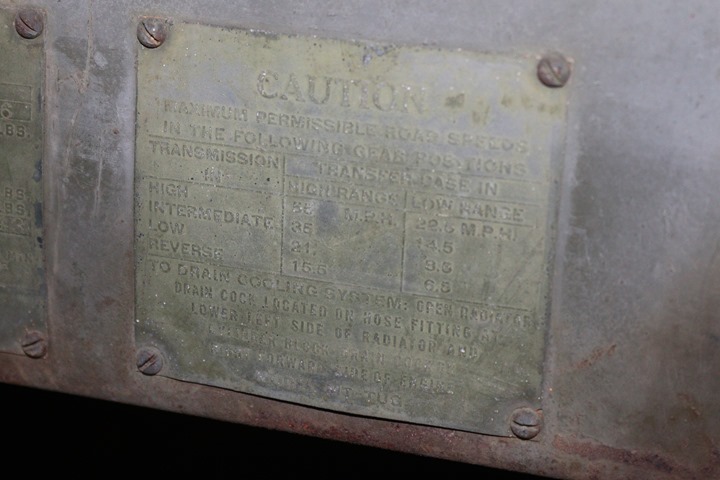

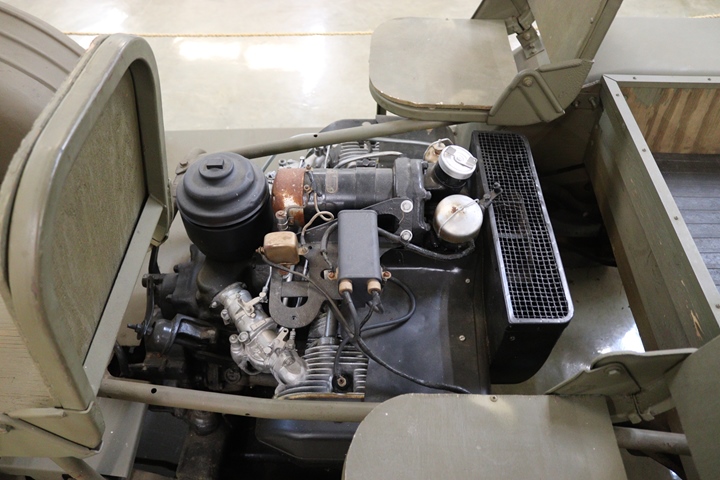

One feature of the Willys-Overland MT Tug is

that the steering wheel folds down parallel to the top of the vehicle.

This was a design feature so the units could be stacked for shipping.

After the windshield is folded down, the tires removed and stored

in the bed of the tub, the vehicles could be stacked one on top of

another for efficient shipping overseas. Photo added 7-29-2019.

The gas tank is located next to the driver.

While this may have aided shipping by not being under the vehicle,

this location is not the best location for it. Photo added 7-29-2019.

Photo added 7-29-2019.

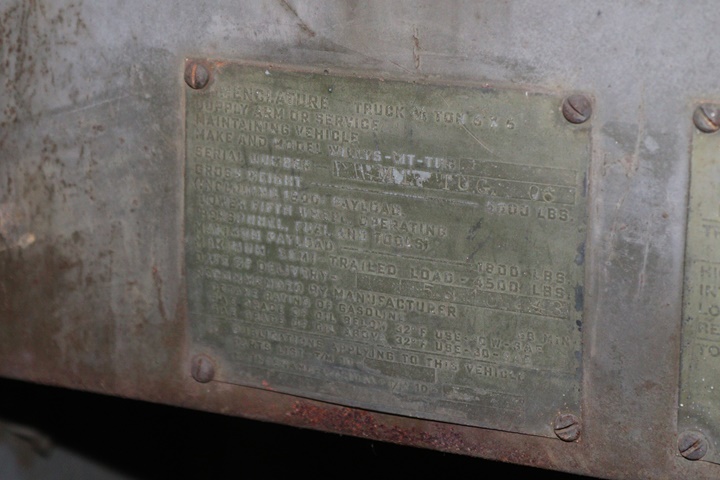

The data plate. MT Tug Serial Number

06. Photo added 7-29-2019.

This auto level color version of the data

plate highlights the nomenclature of the vehicle. Photo added

3-11-2025.

Photo added 7-29-2019.

Photo added 7-29-2019.

During World War Two, Willys-Overland

was the third largest producer of aluminum forgings in the United States totaling

29 million pounds.

It also produced steel

forgings, not only for its in-house products but on a subcontract basis

also. See the accompanying "Willys-Overland War Production Record"

for the complete list of parts.

The accompanying

"Willys-Overland War Production Record" linked above is a ten-page

typed primary source document from the end of the war that not only gives the

production numbers, but more detailed information on product usage and

production dates.

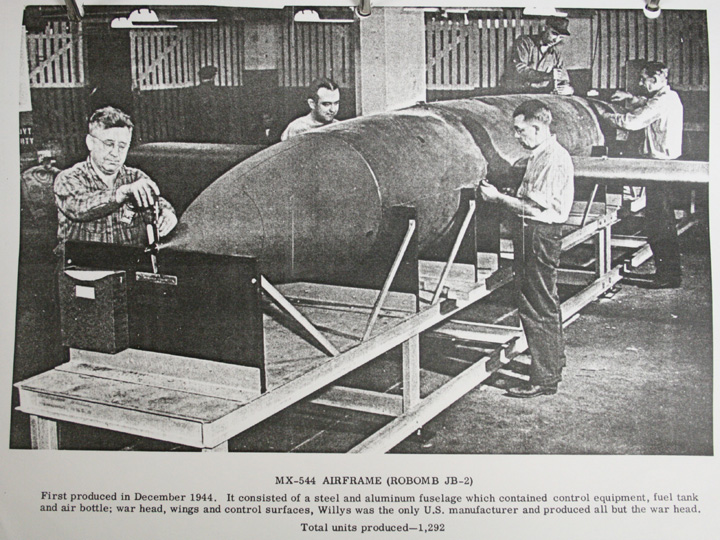

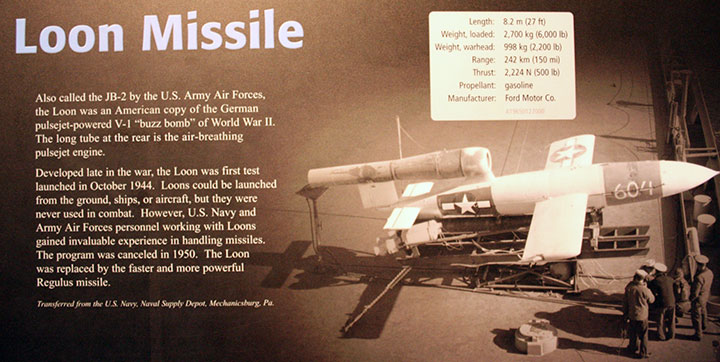

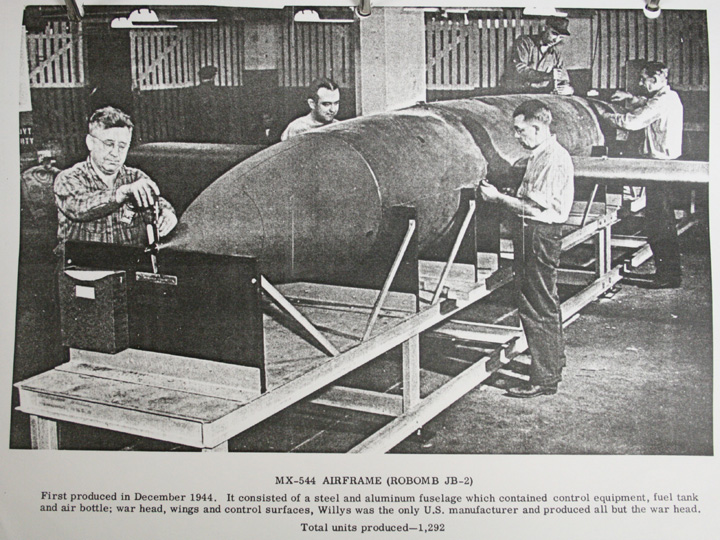

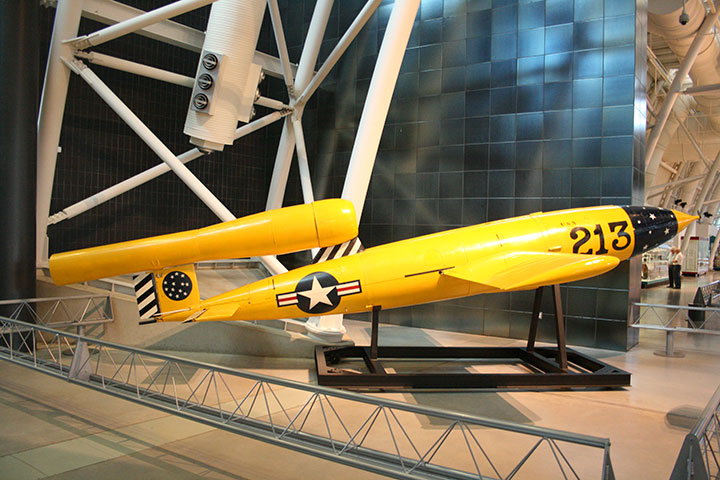

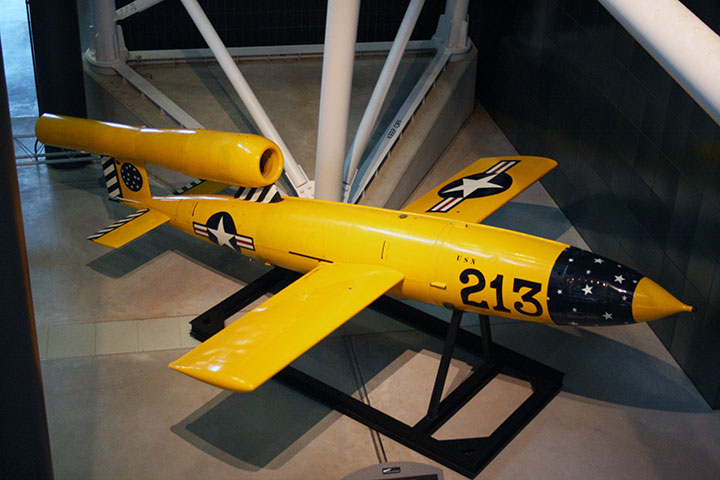

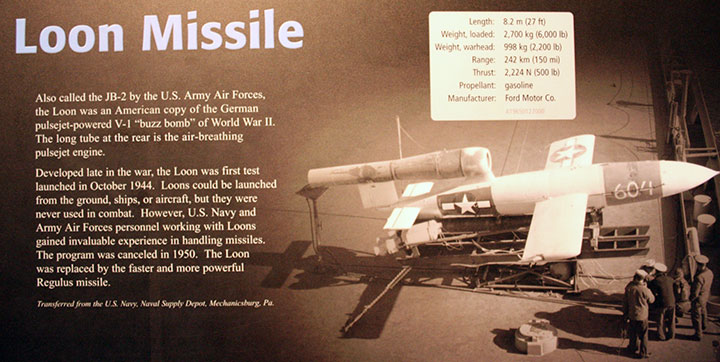

It was a total and unexpected surprise when Willys/Jeep Historian Ron

Szymanski showed me this photo in January of 2012. I had not

even imagined that Willys-Overland was responsible for the manufacture

of the JB-2 Loon, which was the first cruise missile and very high tech

for its time. It was also the American reverse engineered copy of

the German V-1 "Buzz Bomb". As noted above, Willys was the only

manufacturer of the 1,292 produced.

The 1,292 Willys-Overland JB-2 Loons were being produced

for use in the planned invasion of Japan. Republic Aircraft had the

contract for the airframe and Ford built the engine. However, Willys-Overland

was subcontracted to build the airframe after Republic built ten

prototypes. But Republic was still in full

production of the P-47 Thunderbolt and did not have the capacity to

manufacture it in high volume. This one and only

photo above shows a JB-2 being assembled in the Toledo Willys-Overland

plant. Photo courtesy of Ron Szymanski.

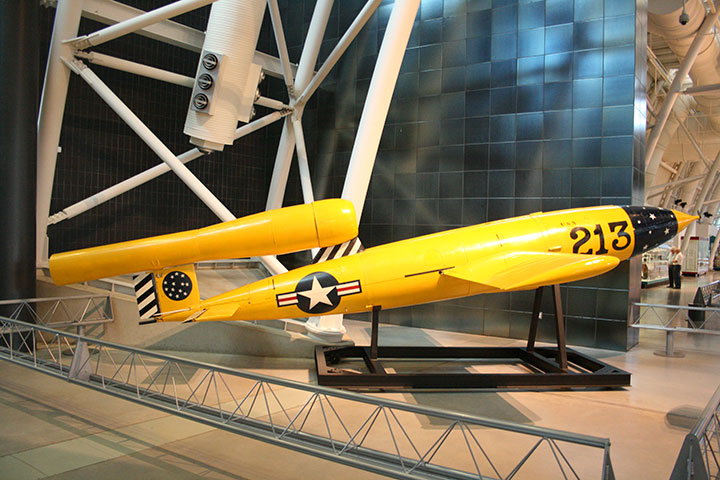

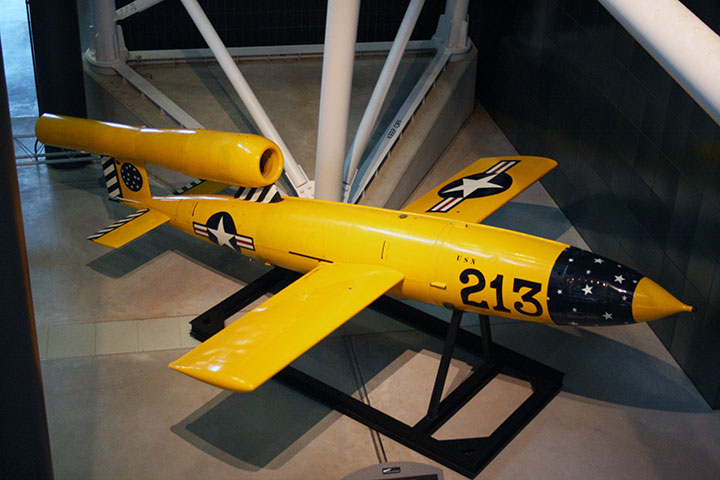

This is the final product after Republic

added the Ford-built engine. This Willys-built JB-2 can be seen on

display at The Udvar-Hazy Center

in Chantilly, Virginia, which is part of the National Air and Space

Museum. When I took this photo in 2011, I was still unaware that Willys built

it. One of the best kept secrets

of World War Two, intentionally or

unintentionally, is of Willys' contribution to the war effort.

Author's Photo.

There are 11 other Willys-Overland-built

JB-2 Loons on display around the world. One is outside of the United

States Museum of Transport and Technology, Auckland, New Zealand.

Those residing in the US can be seen at: National Museum of the

United States Air Force, Dayton, Ohio (This is painted as a German V-1

"Buzz Bomb".); US Air Force Armament Museum at Eglin AFB; FL, Evergreen

Aviation and Space Museum, McMinnville, Oregon; Museum of Alaska

Transportation and Industry in Wasilla, Alaska; Hill Aerospace Museum,

Hill AFB, Utah; Point Mugu Missile Park, NAS Point Mugu, CA; Cradle of

Aviation Museum, Garden City, NY; Milford Township Park at Milford, IL;

American Legion post in Wheaton, MN; White Sands Missile Range Museum,

NM. Author's Photo.

Even the curators at the Air and Space

Museum make mistakes, as shown here on the information plaque.

Note that Ford, not Republic, gets credit for being the manufacturer

while it only built the engine. There is no mention of Willys-Overland at

all. Actually, it should be called Republic/Ford/Willys-Overland

JB-2 Loon.

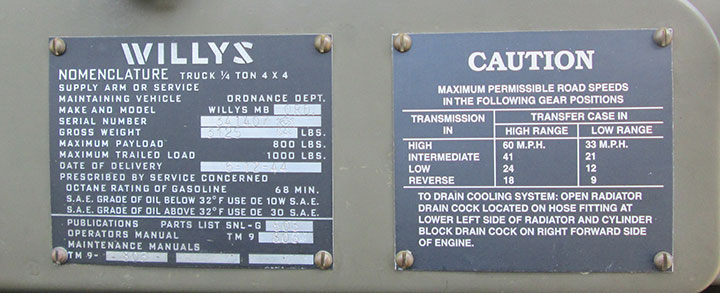

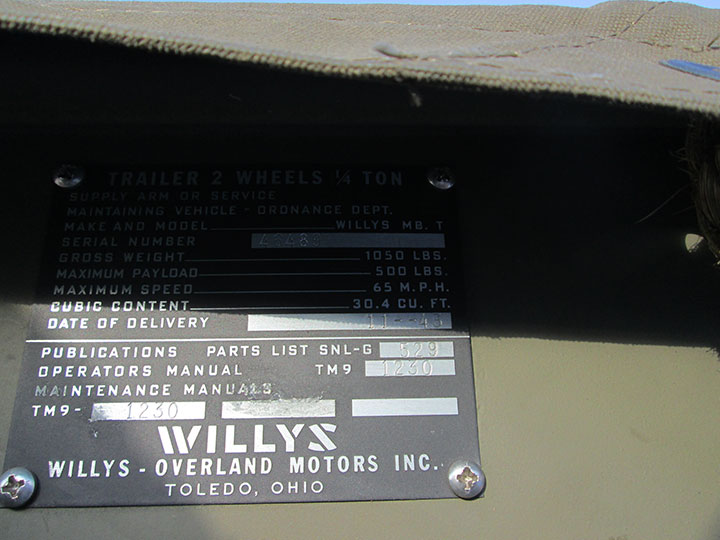

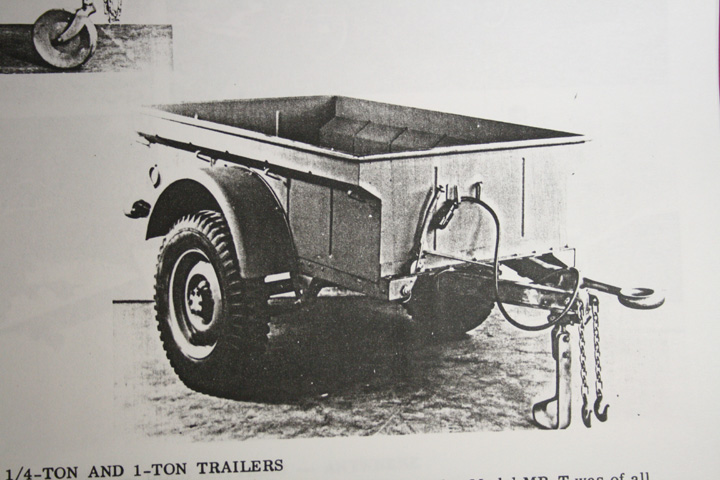

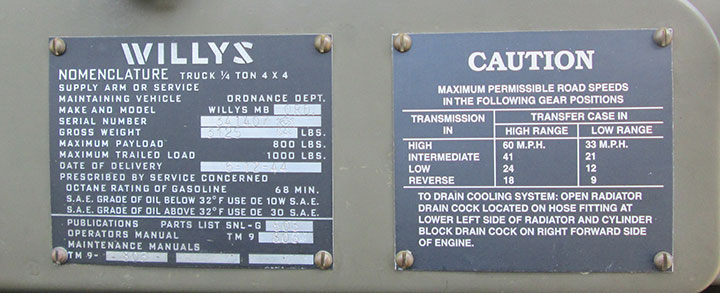

The jeep is the Willys-Overland signature product line

for the Second World War. This is a Jeep with a 1/4-ton trailer as seen at

the 2013 Wings over Houston Airshow. Author's Photo.

Author's Photo.

This Willys Jeep came off the Toledo, OH

assembly line on June 12, 1944. It is serial number 341407.

Author's Photo.

Author's Photo.

Author's Photo.

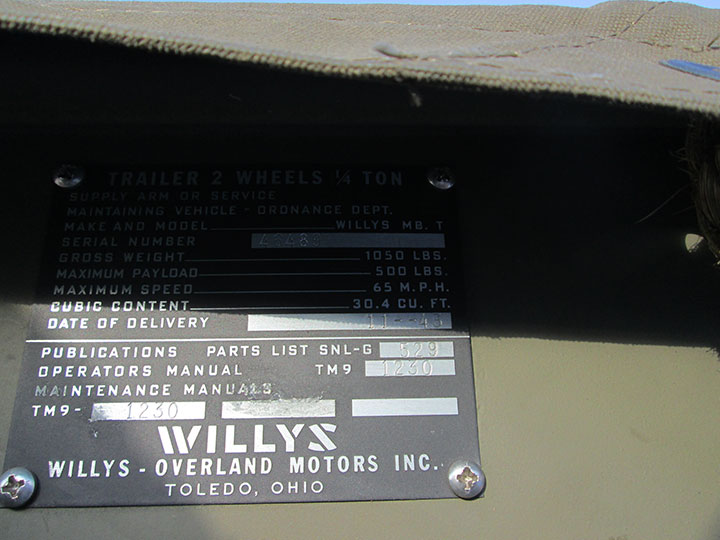

The trailer is serial number 46489 and it

was built in November 1943. Author's Photo.

The original Willy's Jeep.

Photo courtesy of Ron Szymanski.

Photo courtesy of Ron Szymanski.

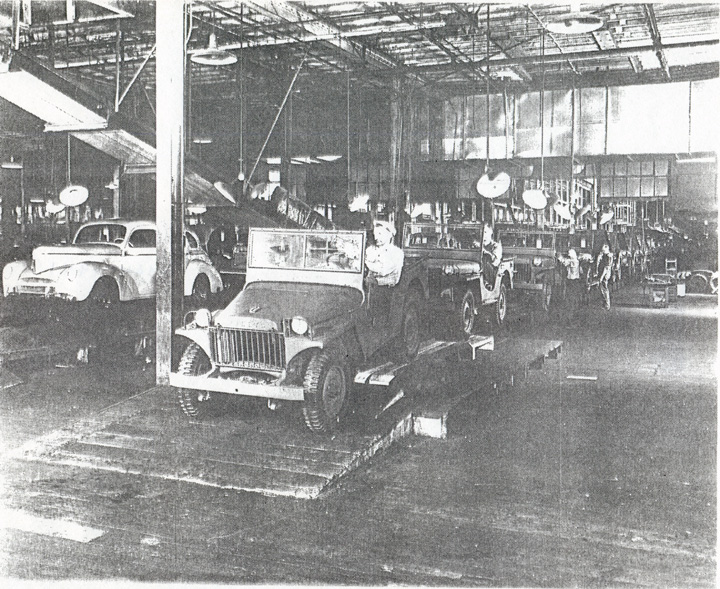

The next two photos are post-November 1940, when the US government

ordered 1,500 Jeeps from Willys but before February 1942, when all car

production stopped in the United States. The automobiles pictured

here

are the Willys-Overland Americar. Photo courtesy of Ron Szymanski.

These are the first of 358,941 MA and MB Jeeps built by Willys during World

War Two. Photo courtesy of Ron Szymanski.

Four early jeeps by three different

manufacturers are on display at the U.S. Veterans Memorial Museum in

Huntsville, AL. From farthest to closest are a Ford prototype

jeep, a 1941 Ford GP, a 1941 Bantam BRC 40, and a 1941 Willy Model MA.

It is one of 1,500 MAs that were produced for testing. Author's

photo added 5-8-2020.

Author's photo added 5-8-2020.

Author's photo added 5-8-2020.

This MA is serial number 855044. Most

of the MA jeeps were sent to Russia after testing. The improved MB

became the production version of the Willys-Overland jeep.

Author's photo added 5-8-2020.

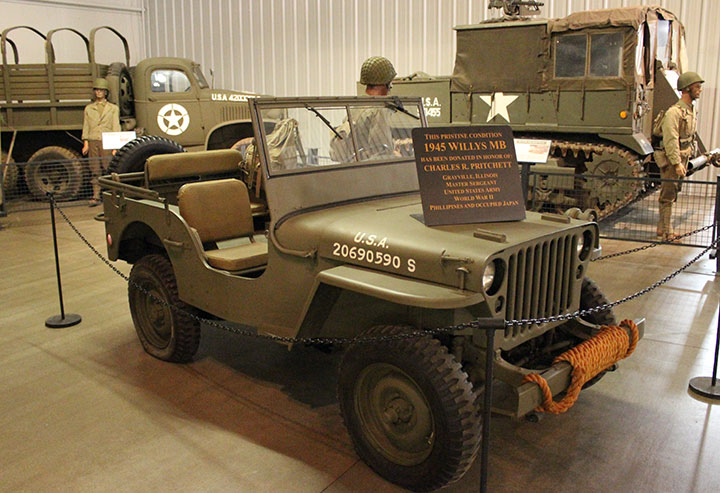

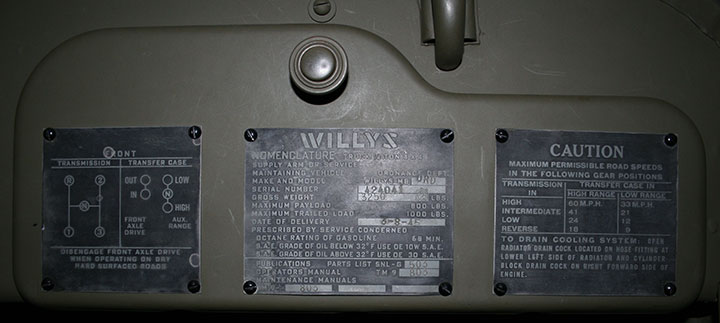

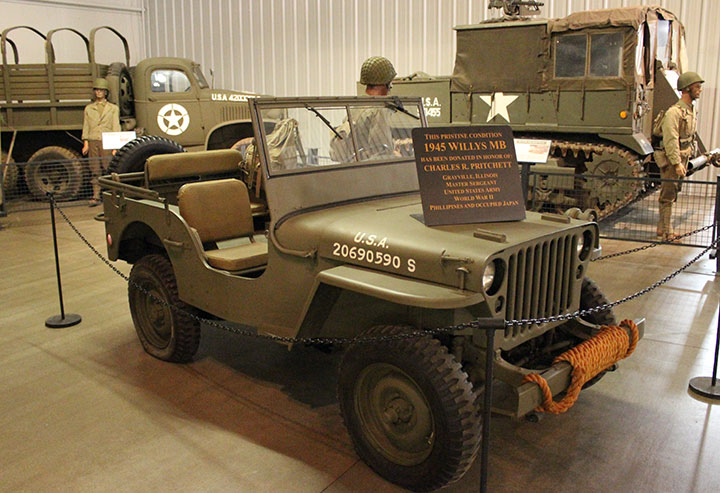

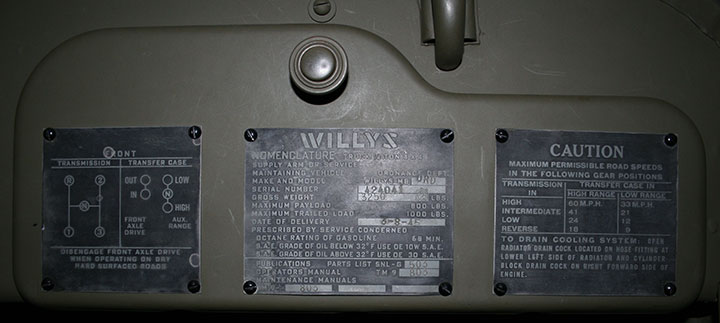

Here is a 1945 Willys MB Jeep at the

National Military History Center in Auburn, IN. Author's Photo.

Serial Number 424041 delivered on 6-8-45.

Author's Photo.

This Willys MB Jeep at the

National Military History Center in Auburn, IN has had 5/16 steel plate

added as armor. Author's Photo.

This Willys Jeep at the Patton Museum at

Fort Knox, KY was used by General George Patton to review the

troops. Author's Photo.

Author's Photo.

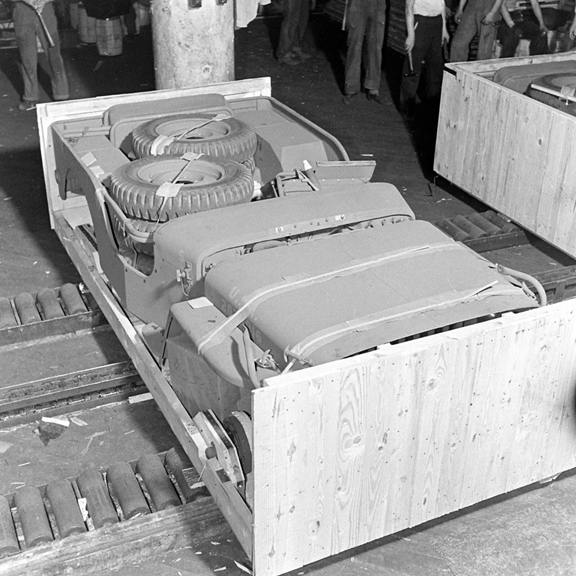

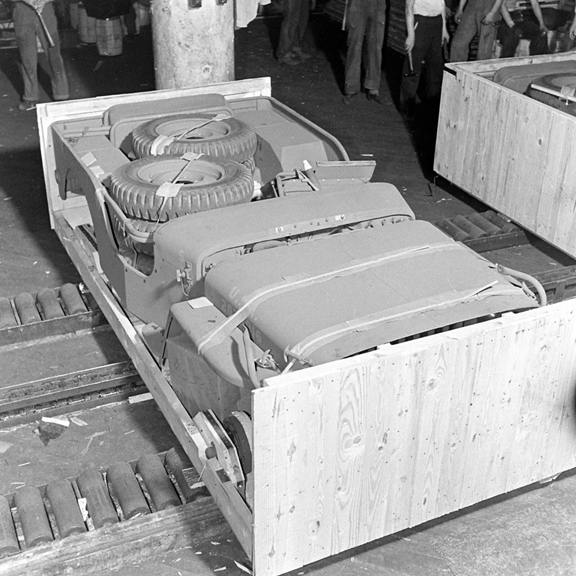

This display of a Willy-Overland-built

quarter ton truck in a packing crate is on display at the World War II

American Experience in Gettysburg, PA. It depicts how once the

Jeep was assembled and tested, it was then disassembled and packed for

shipment overseas. Once at its final destination the vehicle was

reassembled. Author's photo added 3-11-2025.

Author's photo added 3-11-2025.

Author's photo added 3-11-2025.

This World War Two photo shows that the

packing process took place on an assembly line. Image added 3-11-2025.

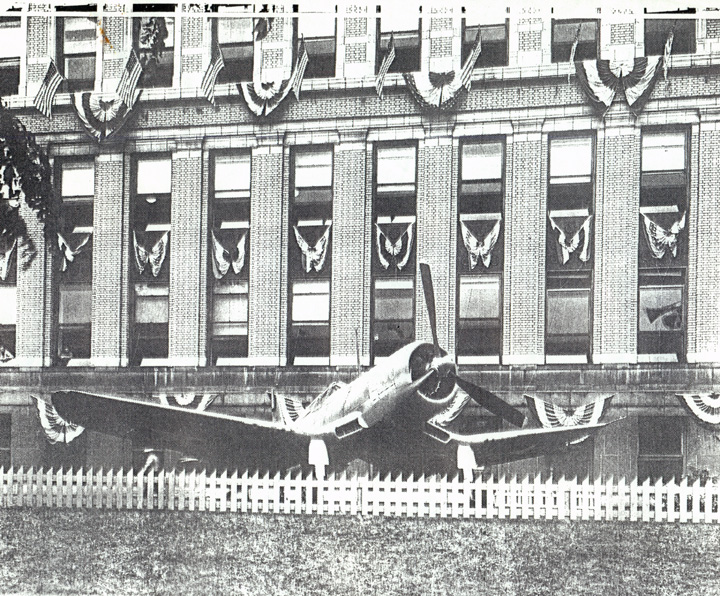

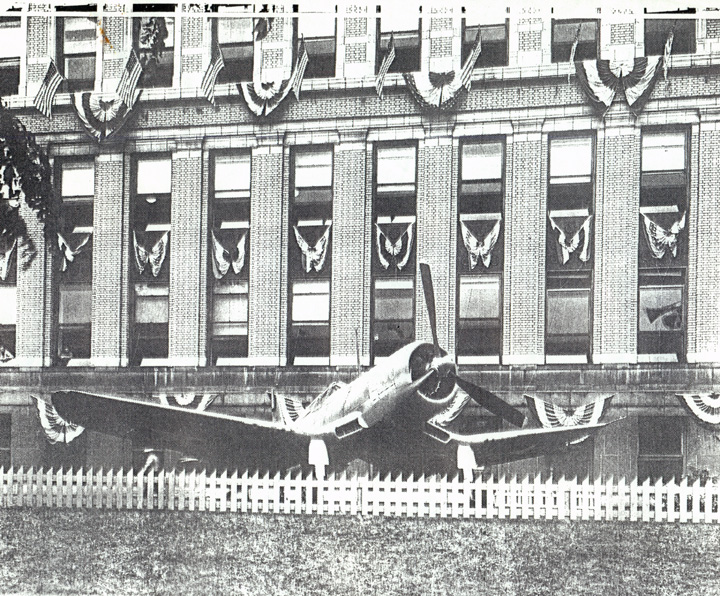

Because the company was building the center

section of the Vought F4U Corsair's wing during World War Two, one was trucked to the

plant and put on display for the employees to see. Photo courtesy

of Ron Szymanski.

This section was extremely difficult to

manufacture due to the curvature and the 1,500 parts and 360 assemblies. Photo courtesy of Ron Szymanski.

This photo shows the curved center section of the wing that

gave the F4U Corsair its distinctive look, as seen at the 2013 Hillsdale,

MI Airshow. Author's Photo.

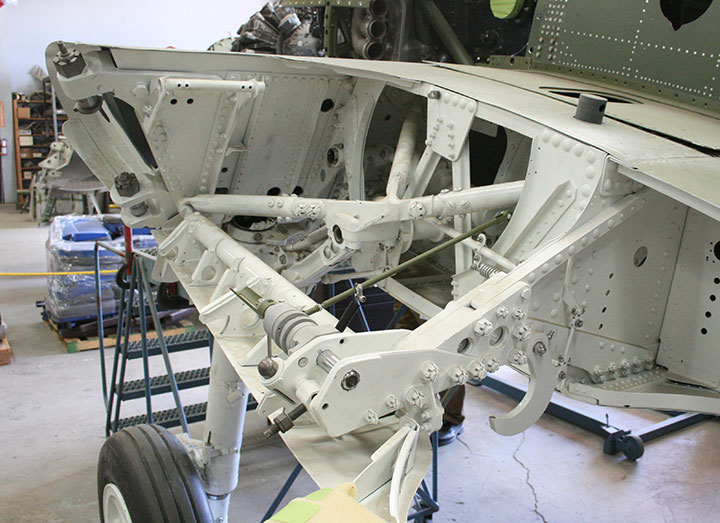

This Corsair under restoration shows the

complex curvature of the wing center section. Author's Photo added

10-10-2017.

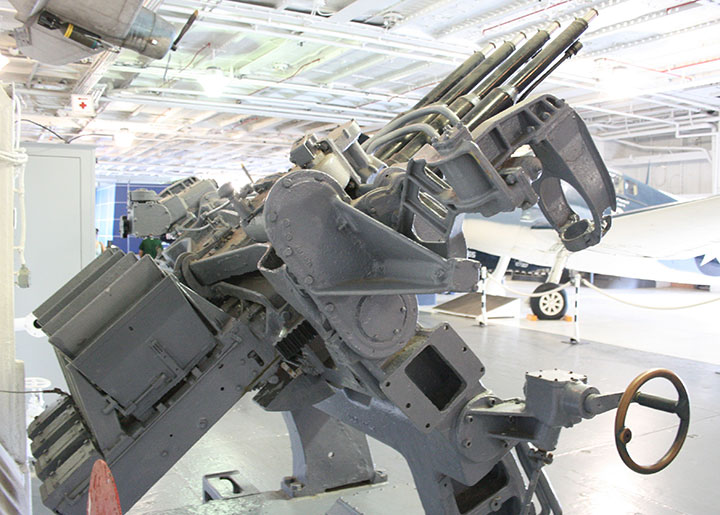

A 1.1-inch (28 mm) quad mount anti-aircraft

gun that was used by the US Navy during the first part of World War Two.

Prone to overheating and jamming if not properly maintained, the weapons

were replaced on US Navy ships later in the war by both the 20 mm Oerlikon and 40 mm Bofors cannons. Willys built 3,374 breach housings

and recoil cylinders for these weapons starting in 1941 and ending in

1943. As seen on the USS Yorktown at Patriots Point, SC.

Author's Photo.

Author's Photo.

Here is another 1.1-inch quad mount

photographed in Freedom Park, Omaha, NB. This one has one of the

gunner's seats still attached. Author's Photo.

This photo gives a good view of the feed trays

for the 1.1-inch shells. Author's Photo.

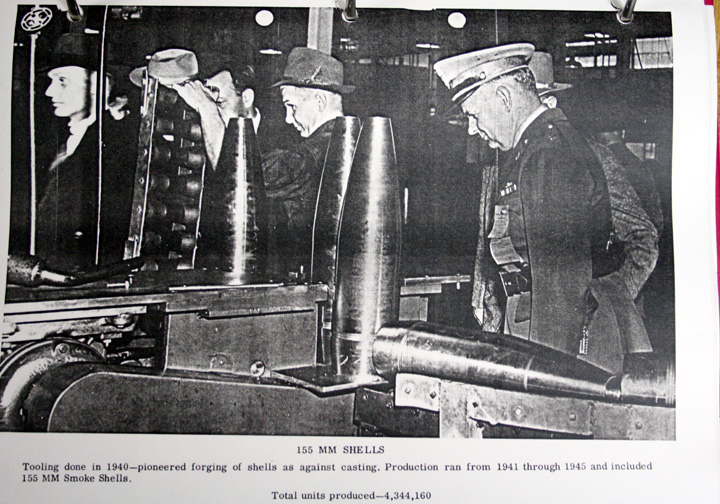

From 1941 to 1945,

Willys produced 4,344,160 of the 155mm shells as shown above. Smoke shells for the 155mm were developed by Willys in

1943.

Photo

courtesy of Ron Szymanski.

A 155mm cannon "Long Tom" like this one could hurl the 100-pound Willys-Overland-built

155mm shells up to 13.7 miles away. Author's Photo

added 10-10-2017.

This Grumman F6F-3 Hellcat is under

restoration at the Yanks Air Museum in Chino, CA. Willys built

6,096 landing gears for this type of aircraft. Author's Photo.

This photo shows the internal structure and

mechanism to retract the gear. The gear will be fully locked in

the up position when it rests on the hook in the foreground. The

Hellcat landing gear was robust in order to withstand the "controlled

crashes" that it made in landing on an aircraft carrier. The Navy

required that a Hellcat's landing gear at landing weight be able to

withstand a free drop of six feet. Grumman successfully tested the

aircraft to ten feet thereby exceeding the Navy's requirement.

Author's Photo.

This Grumman F6F-5 Hellcat as seen at the 2009

Chino, CA Airshow. Grumman built 12,275 Hellcats during the war.

So, Willys provided a significant amount of landing gears for the aircraft.

The F6F created more Naval aces than any other aircraft during the

Second World War and was responsible for the destruction of more

Japanese aircraft that any other Allied fighter. Author's Photo.

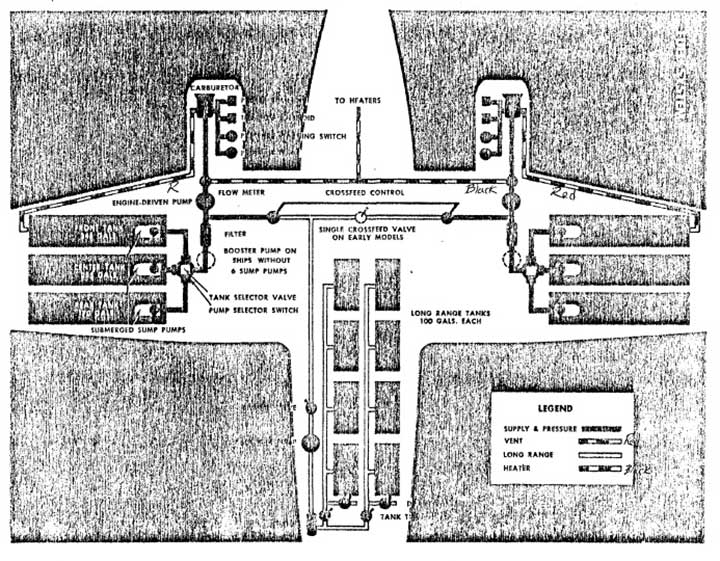

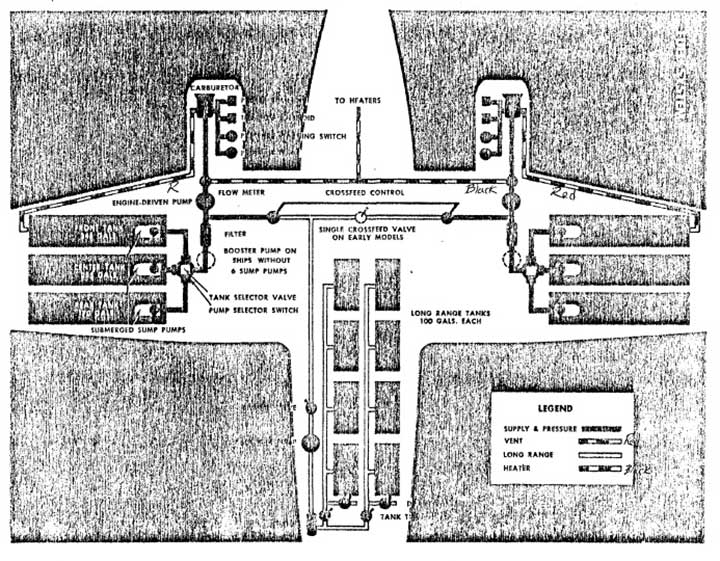

The Curtiss C-46 Commando was the largest

twin engine transport used by the US in World War Two. In 1945 Willys produced

3,065 fuel tanks for this aircraft. Each wing contained three tanks

that were twelve feet long and were outboard of the engines. This

C-46 was photographed at the 2013 World War Two Weekend in Reading, PA.

Author's Photo.

The front fuel tank had a capacity of 245

gallons, the center tank had a capacity of 285 gallons, and the rear

tank could hold 170 gallons, for 700 gallons per side, and a total capacity of

1,400 gallons. It is not known which of the three fuel tanks Willys-Overland built.

Photo courtesy of Ron Szymanski.

Photo courtesy of Ron Szymanski.

Photo courtesy of Ron Szymanski.

A shipment of MA model Jeeps is awaiting

transportation to the US military. Photo

courtesy of Ron Szymanski.

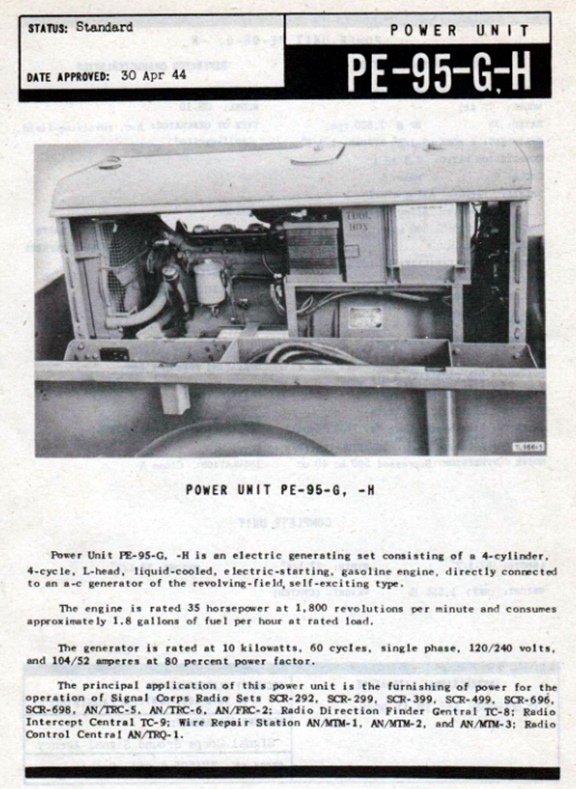

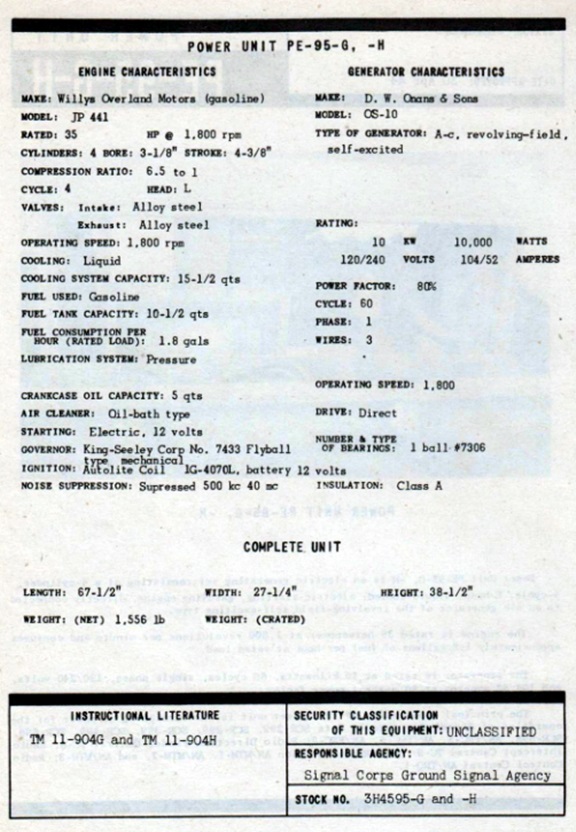

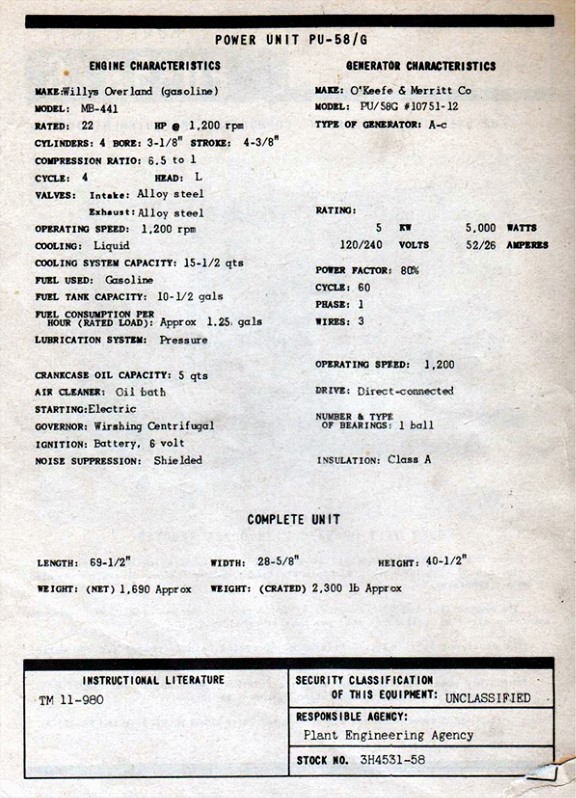

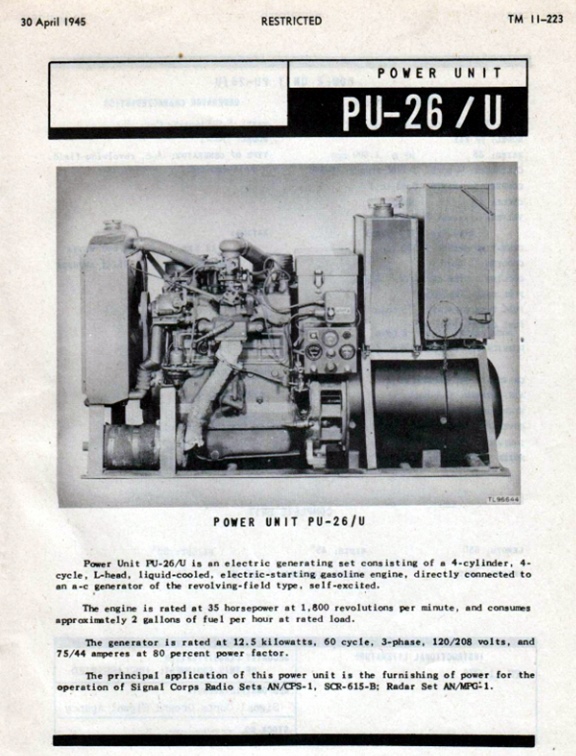

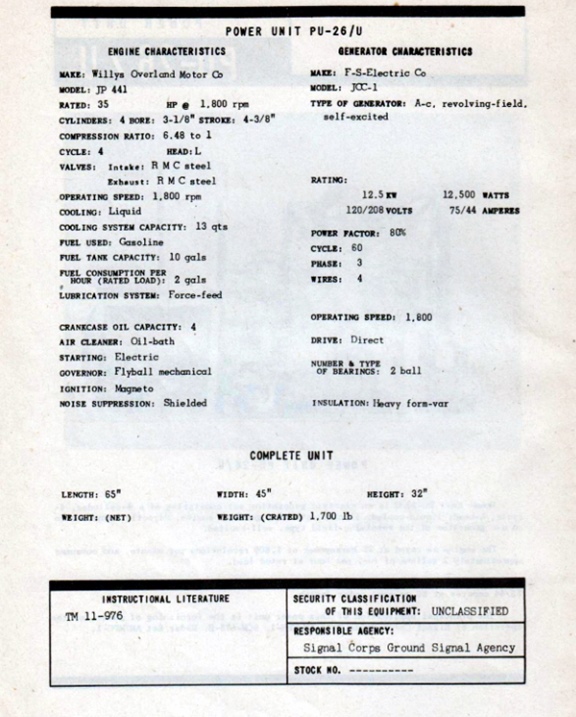

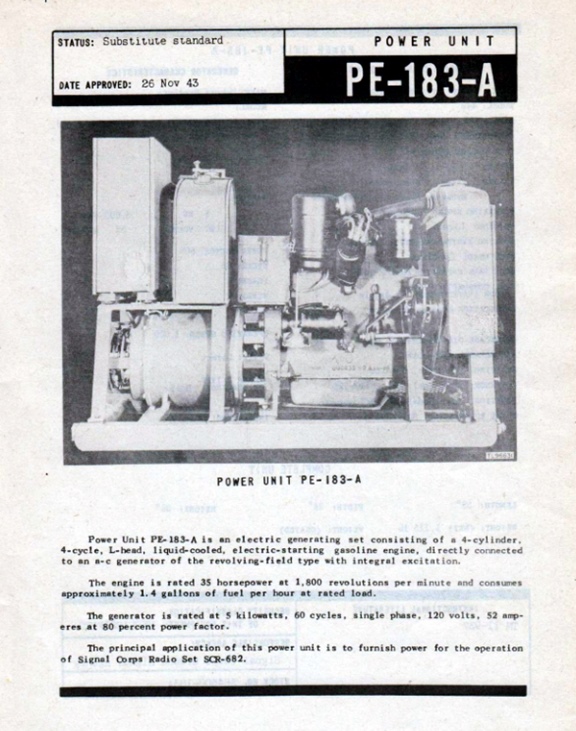

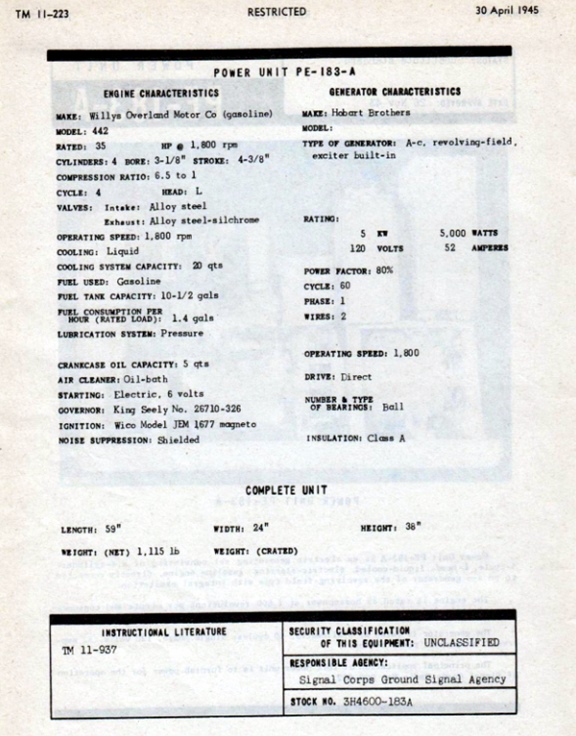

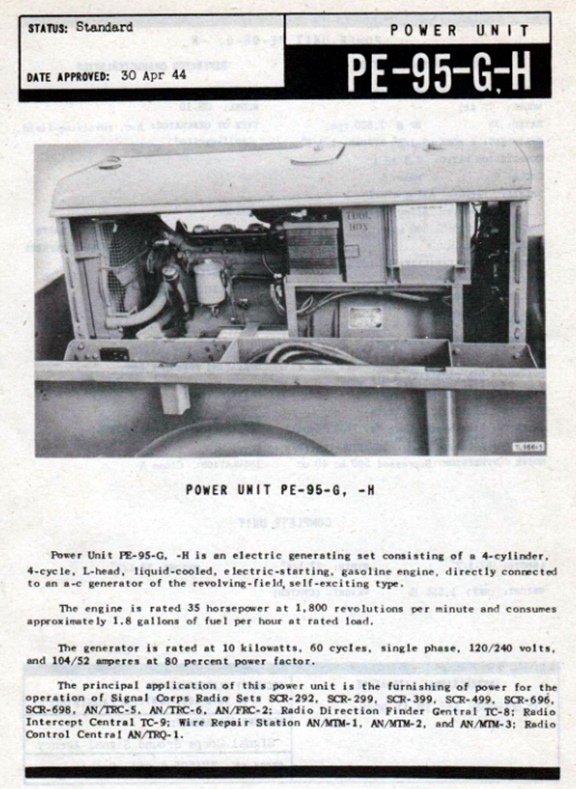

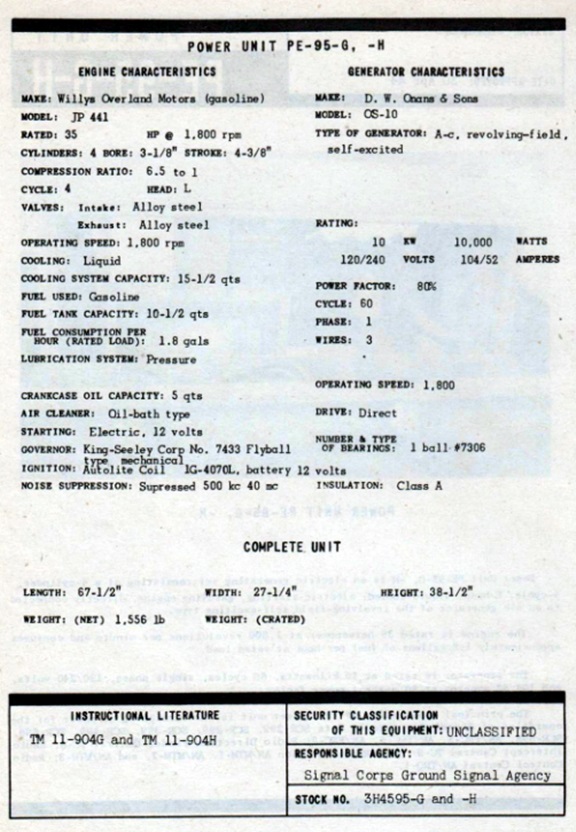

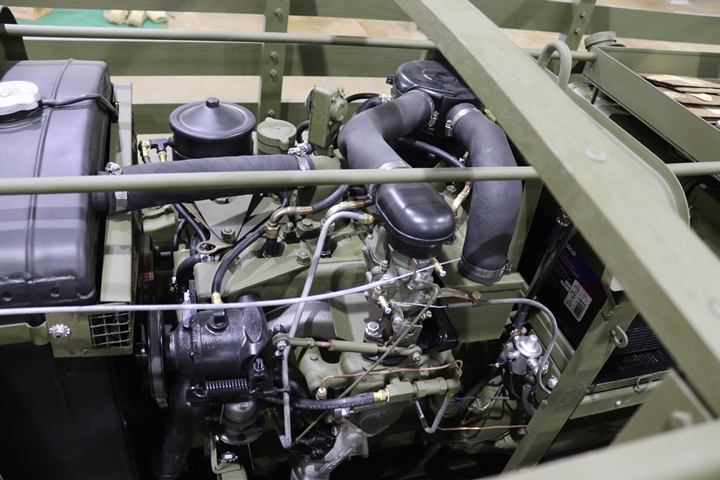

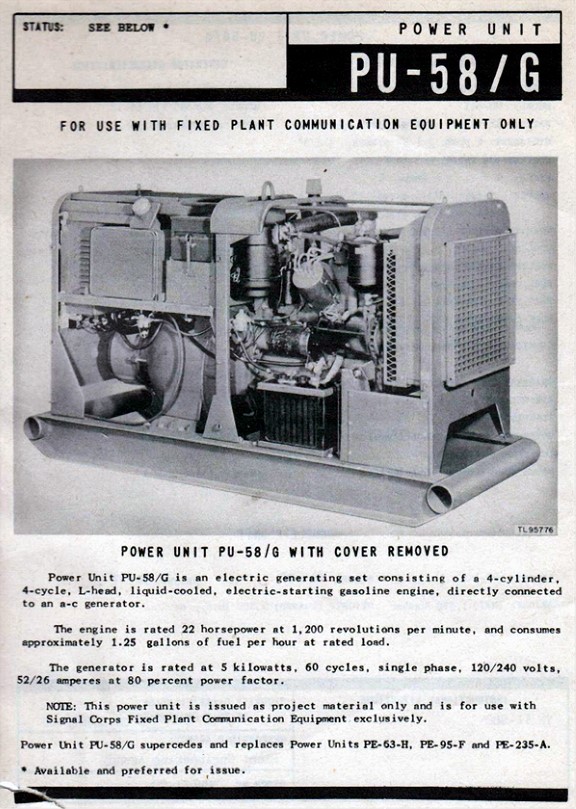

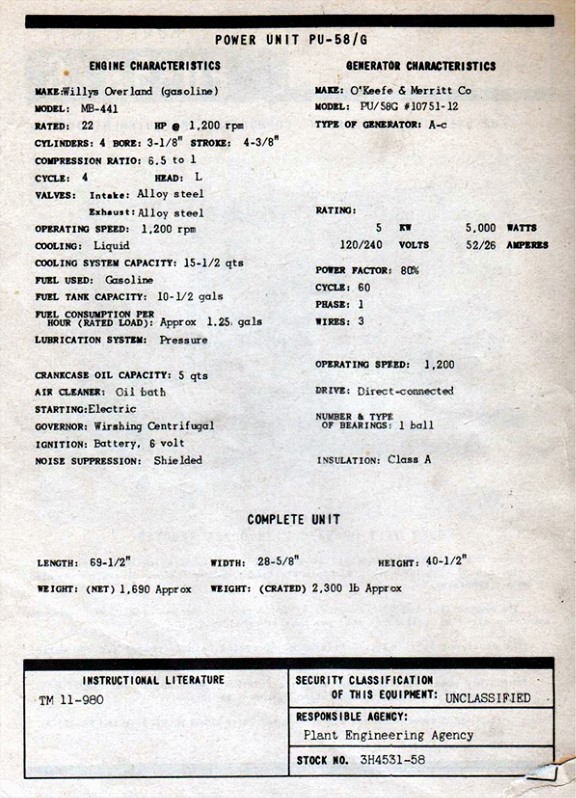

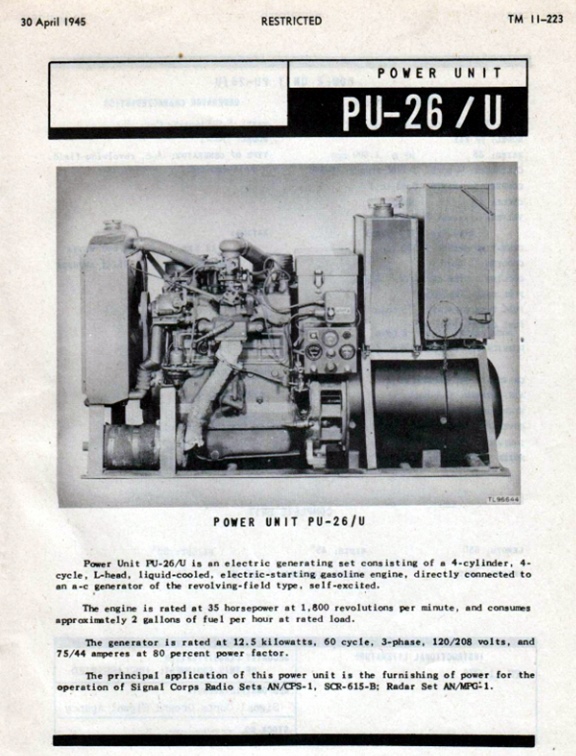

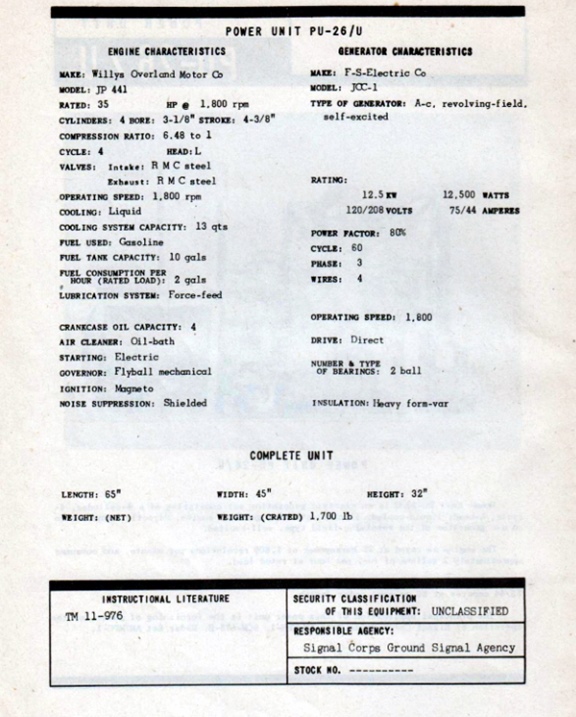

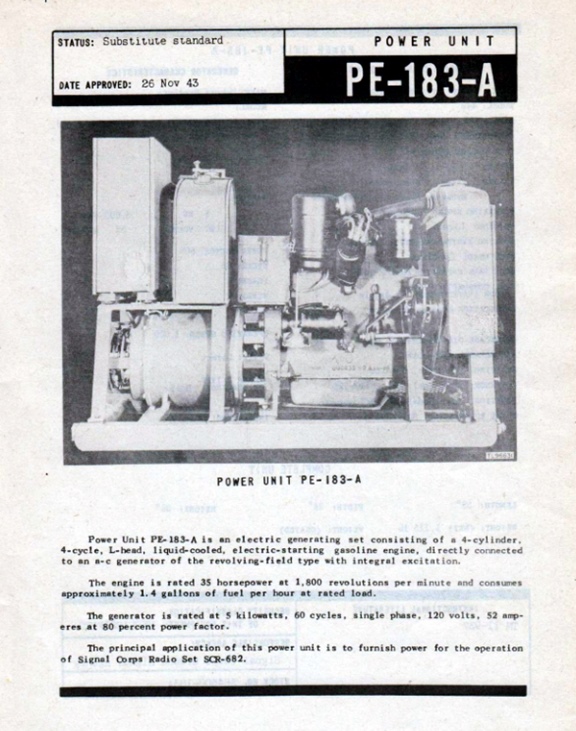

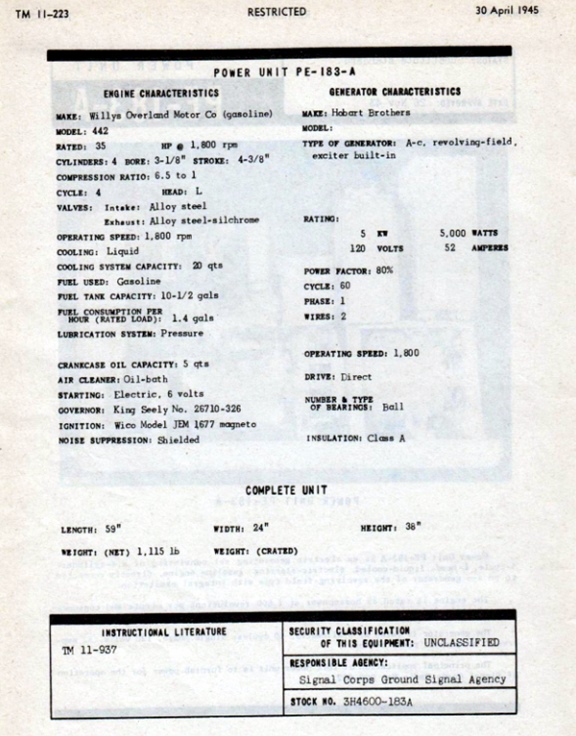

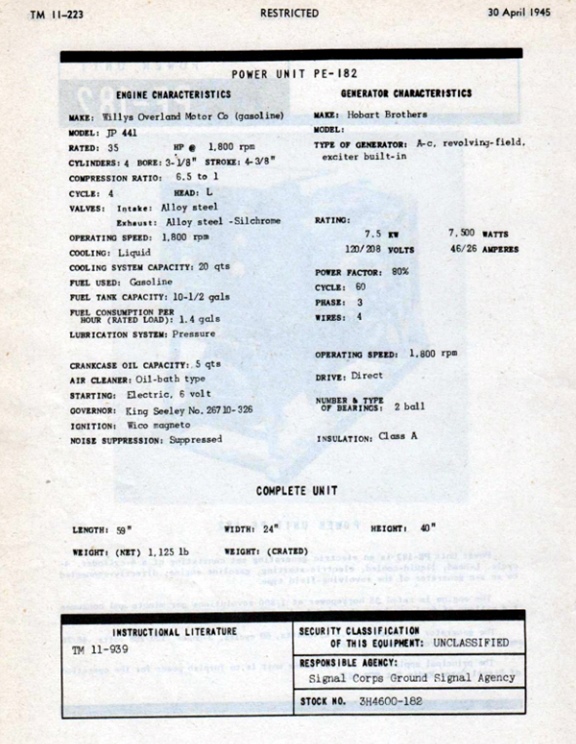

U.S. Army Signal Corps Power Plants with

Willys-Overland Engines: The company supplied the engine used

in the jeep for five different models of Signal Corps generators.

Image added 3-11-2025.

Image added 3-11-2025.

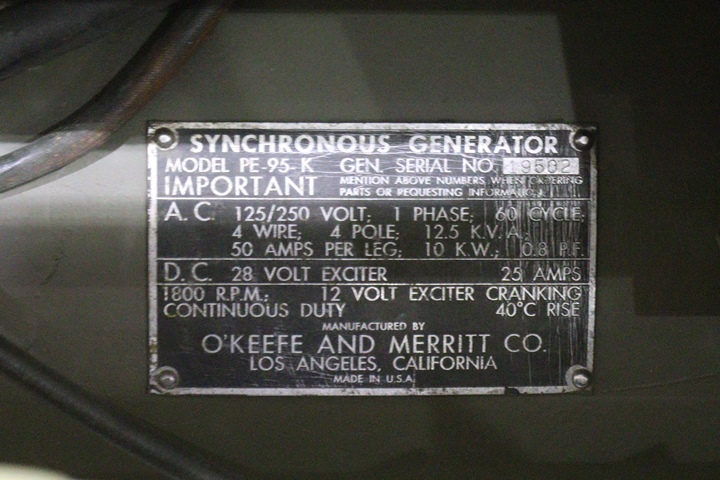

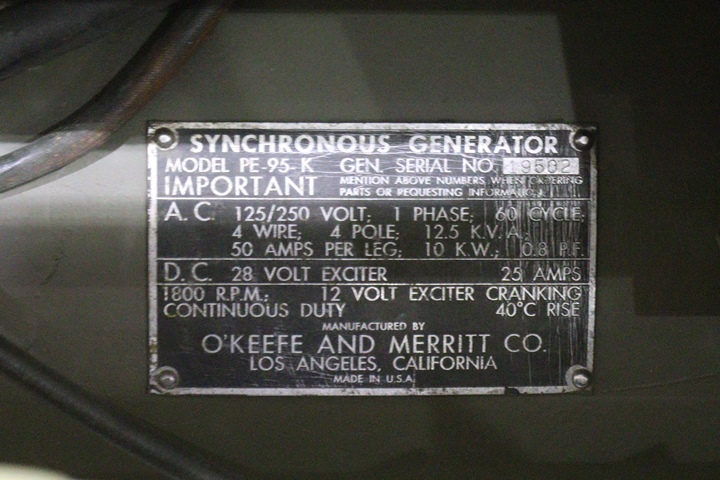

This O'Keefe & Merritt-built PE-95-K generator was

photographed at the 2019 MVPA National Convention in York, PA. It

is mounted in a Ben-Hur Mfg. Company-designed and built one-ton trailer.

Author's photo added 3-11-2025.

Author's photo added 3-11-2025.

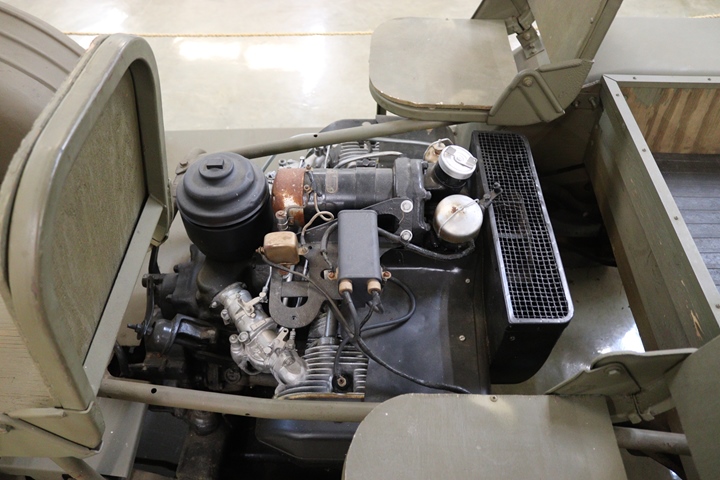

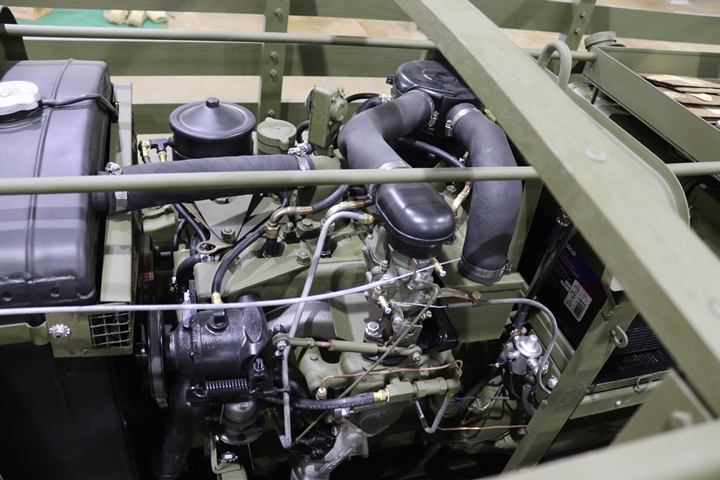

The gasoline engine is a Willys-Overland

JP-441. This is a version of the famous Willys-Overland "Go

Devil" World War Two jeep engine. Author's photo added

3-11-2025.

Author's photo added 3-11-2025.

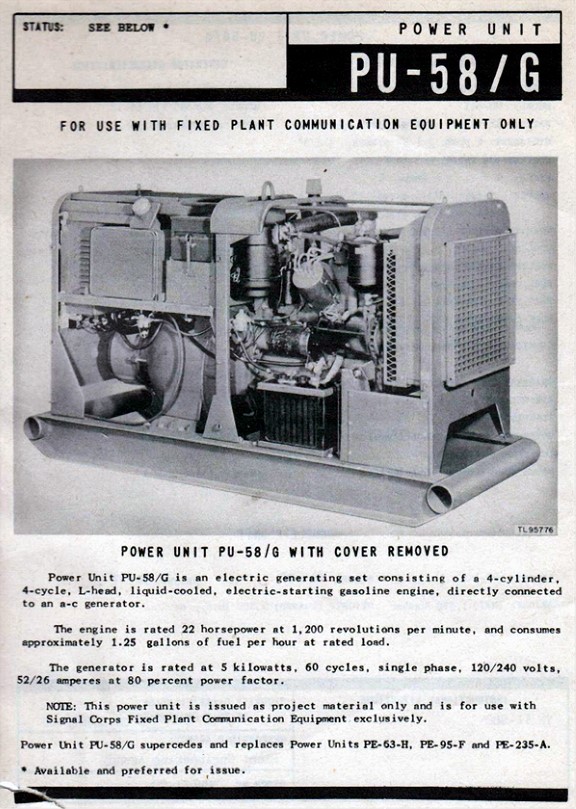

Image added 3-11-2025.

Image added 3-11-2025.

Image added 3-11-2025.

Image added 3-11-2025.

Image added 3-11-2025.

Image added 3-11-2025.

Image added 3-11-2025.

Image added 3-11-2025.

|