|

The American

Auto Industry in World War Two

An Overview

See the "Revisions" page for my new and updated information as it is added.

This

page updated 4-18-2020.

There is no greater testament to the US

Automobile Industry's contribution to help win World War Two than this

Fisher Body Grand Blanc Tank Arsenal-built M4A3 Sherman Tank combat

veteran, on display in downtown Bastogne, Belgium. It was knocked

out of combat during one of the most famous battles of World War

Two, the Battle of the Bulge, on December 30, 1944.

It was fighting with B Company, 41st

Tank Battalion, 11th Armored Division when it was put out of action near

Renuamont, Belgium. It had been named "Barracuda" by its crew. It

sits at the intersection of several roads in Bastogne that made the town

an important military objective during the battle. The town has

been completely rebuilt since the war. German artillery fire

virtually leveled the town in attempting to drive out the American

soldiers defending it. The tank has been on display since 1948.

Author's photo.

The Purpose of this

Website: The purpose of

this website is to bring together in one location that which the US

Automobile industry produced during the Second World War. What the

products were, which company made them, the numbers produced, and their

manufacturing locations. At the beginning of World War Two, there were

twelve auto makers left in the United States, down from the hundreds

that had been producing auto early in the 20th century. All twelve

are included in this website.

While there are many good

historical sources on the US auto industry in World War Two, most focus on the

Big Three and are Detroit-centric. Not only are the other nine

auto makers of the era covered in a comprehensive manner on this

website, but all of the GM Divisions of the time are also included.

General Motors had five car divisions: Buick (Flint, MI), Cadillac

(Detroit, MI), Chevrolet (Flint, MI and other locations), Oldsmobile

(Lansing, MI), and Pontiac (Pontiac, MI). GMC was the truck

division located in Pontiac, MI. The Fisher Body Division of GMC

was headquartered in Detroit but had multiple plants where each of the

car assembly plants were located. General Motors also had a host

of component divisions located in such towns as Anderson, IN;

Kokomo, IN;

Dayton, OH; Flint, MI; and Lockport, NY. These plants produced

such items as starters, batteries, radios, sparkplugs, radiators, and

steering wheels. Chevrolet and Fisher Body each had over a dozen

plants, and each was as large or larger than Ford at the time, and

both were larger than Chrysler.

The format for each auto

maker, GM division, truck manufacturer, and auto supplier includes a

short history of the company, followed by a listing of items produced

during the war, with production numbers, if available.

Contemporary photos of the products are used for the most part instead

of historical photos.

Overview:

The U.S. auto industry produced 20% of the total U.S. output of the

material manufactured to fight World War Two, with the total value of

goods produced by the U.S. automobile industry in the war effort

surpassing $29 billion. GM produced $12 billion of that or 41% the

industry output and 8% of the entire American war economy. Ford

came in second with $3.9 billion, and Chrysler was right behind with

$3.5 billion in war contracts. Willys-Overland had $7.34 million for the

nineteen wartime projects it had. While

the auto companies were the logical manufacturers of trucks, armored

cars, jeeps and tanks, their wartime product lines were extensive, and many of the

items built were new to the industry. Both Ford and General Motors

built entire warplanes for the conflict, and many aircraft

components were produced by the industry.

Below are a few of the items

produced by the auto industry during World War Two. Some are

readily associated with the industry, while others are totally

unassociated with what the industry commonly produced at that time.

The American Auto Industry produced all of the

fully tracked tank destroyers during World War Two. Here are three of the

most important ones, as seen at the Virginia Museum of Military Vehicles

at Nokesville, VA. On the left is a Fisher Body Grand Blanc, MI

produced M10 Wolverine. In the center is an M18 Hellcat built in

Flint, MI by the Buick Motor Car Division of GM. On the end is an M36. This originally was built as

an M10A1 Wolverine at either

Ford's Highland Park, MI plant, or Fisher Body's Grand Blanc, MI tank

arsenal. It was later converted into the

M36 which replaced the 3-inch main gun with a more powerful 90mm cannon.

Author's photo.

Two American automotive industry products in the same photo. An M36

built on a Ford M10A1 chassis is in the foreground, and a Fisher Body

M4A3(75) is in the background. Of the 39 M36s still known to

existence in the world, only two have been positively identified as

being built on a Ford M10A1 chassis. Author's photo taken at the

US Cavalry Museum at Fort Riley, KS added

4-27-2018.

The nose section of the B-29 "Enola Gay".

This is one of the most famous, or infamous aircraft of all time, being

the first bomber to drop a nuclear weapon. The B-29 is not a World

War Two

weapon that one would normally associate with the American auto

industry. The eighteen foot long nose section of the fuselage that

has the name "Enola Gay" painted on it was built by Chrysler DeSoto

Division in Detroit, MI. Author's photo.

With the exception of the wing center

section, all of the other major wing, fuselage, and control surface

sections in the Enola Gay were built by the US Auto Industry. These companies were

Briggs, Chrysler, Firestone, Hudson, Goodrich, Goodyear, and

Libby-Owens-Ford. Several Fisher Body Divisions, along with

seventeen component divisions of GM, supplied parts. Dodge

supplied the engines. For the complete story, please see the

dedicated B-29 page above. Author's photo.

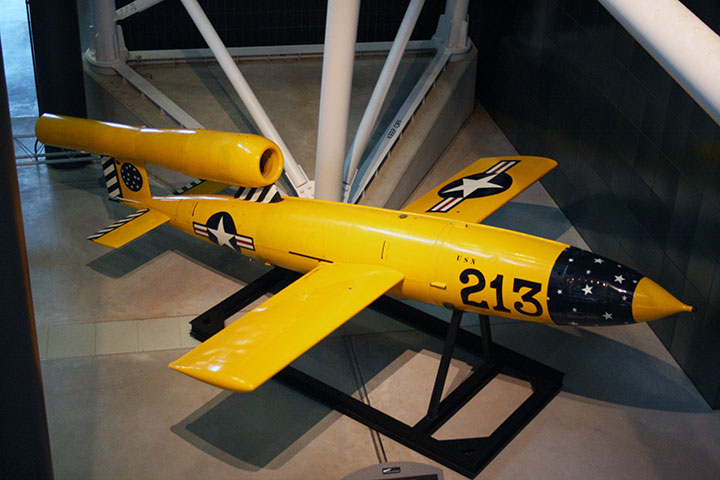

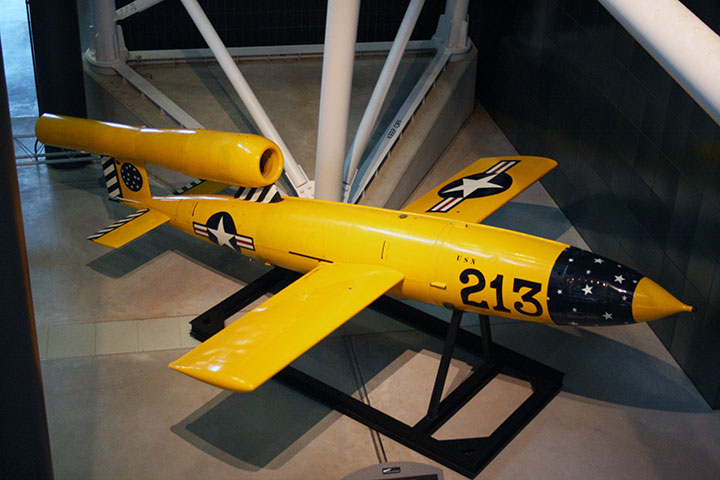

This JB-2 "Loon" cruise missile is another

weapon one would not associate with the American Auto Industry. Willys-Overland,

better known for its production of Jeeps during WWII, built America's

first cruise missile in Toledo, OH under contract from Republic

Aviation. The engine was built by the Ford Motor Car Company.

The JB-2 was a reverse engineered copy of the German V-1 "Buzz Bomb".

It was intended for use by the US Navy in the invasion of Japan.

Author's photo.

Pontiac Motor Car Division built aerial

launched torpedoes at its facilities in Pontiac, MI. Pontiac's

plant 11, which manufactured the torpedoes, was the first American automaker

to receive the Navy "E" award in January 1942. Author's photo.

The Eastern Aircraft Division of General Motors built the navy torpedo

bombers to carry the Pontiac-built torpedoes. Eastern Aircraft

built 7,546 TBMs during World War Two. Eastern also built 1,060

FM-1 and 4,777 FM-2 fighters for the navy. Author's photo taken at the Liberty Aviation

Museum.

This is a SCR-584 anti-aircraft radar unit

is another unusual product not typically identifiable with the American Auto Industry. Chrysler produced 2,098 radar

antenna mounts and parabolic antennas; and then installed them in

the ten-ton Fruehauf built trailer. The radar antenna mount is

stowed inside the trailer for travel. It dropped straight down to

where the table and mannequin are located. Note the cables on the

wall have slack in them, to allow for the up and down movement of the

antenna unit. This photo was taken at the National Electronics

Museum in the Baltimore, MD area, which exhibits a history of the former

Westinghouse Electronics Division (now Northrop-Grumman) located in the

area. Westinghouse installed the electronics within the trailer

after receiving it from Chrysler. Author's photo added 10-7-2016.

When World War Two ended, Nash-Kelvinator

had built more helicopters than the American aviation industry. It

built the most advanced Sikorsky Helicopter design of the war, the R-6A

Hoverfly II, which can be seen at the National Museum of the US Air

Force in Dayton, OH. Author's photo.

All American-built PT boats were powered by

three Packard 4M2500 marine engines which had Delco-Remy starters and DC

generators and Harrison Radiator heat exchangers. The 60mm mortar

on the bow could have a Firestone Tire and Rubber company base plate.

Pontiac built 20mm Oerlikon cannons like the one on the bow of PT-305.

Other PT boats were equipped with Oldsmobile 37mm cannons. The AC Spark

Plug and Frigidaire Divisions of GM built .50 caliber machine guns.

This Higgins Industries-built 78 foot PT boat is the only World War Two

combat veteran still in existence. The author's photo was taken in

the PT-305 boat house on Lake Pontchartrain in New Orleans, LA operated

by the National WWII Museum. Photo added 4-27-2018.

The 40mm gun mount on the stern of PT-305

was built by Firestone. Chrysler and Pontiac both built gun

mechanisms and gun tubes for weapons like this. Author's photo

added 4-27-2018.

The American Automobile Industry was a major

source of anti-aircraft guns for both the army and navy during World War

Two. The Fisher Body Plant in Pontiac, MI built 2,359 90mm

anti-aircraft guns like this one. Three Fisher Body plants

provided tooling to make parts and another three plants provided parts

for the big guns. Chevrolet built 2,000 gun tubes, breech ring and

blocks, and recoil rails for the weapon. Buick built 2,952 gun

mounts. It was a truly a General Motors corporate endeavor.

Author's photo added 4-18-2020.

The USS Slater is the only Cannon Class

Destroyer Escort on display in the world, and is located on the Hudson

River in downtown Albany, NY. The 72 Cannon Class DEs had four Cleveland Diesel

Division of GM diesel

engines driving generators which provided power to four electric motors

for main propulsion, and four more for

ship's electrical power. The USS Slater also has a 3-inch gun with a

Fisher Body breech, 20mm Oerlikon cannons and gun mounts built by Pontiac, and heat exchangers

for the main engines built by the Harrison Radiator Division of GM.

The 97 ships in the Evarts class of DEs had the same compliment of

Cleveland Diesel engines. Author's photo added 10-29-2017.

Graham-Paige built LVT-1's, like this one

displayed in the main lobby of the National Museum of the USMC in

Quantico, VA. Reo Motor Car Company built the bogies for the LVT

series of tracked landing craft. This diorama depicts the LVT-1 going over a log

barrier on Tarawa. Author's photo.

Yes, this is a photo of a replica of the

first atomic bomb dropped during World War Two. It is located at the

National Museum of the US Air Force. Chrysler delivered 1,000

railroad cars of equipment for the diffusion using hexafluoride gas to

separate U-235 from U-238 at Oak Ridge, TN (The Secret City) during

World War Two. Author's photo.

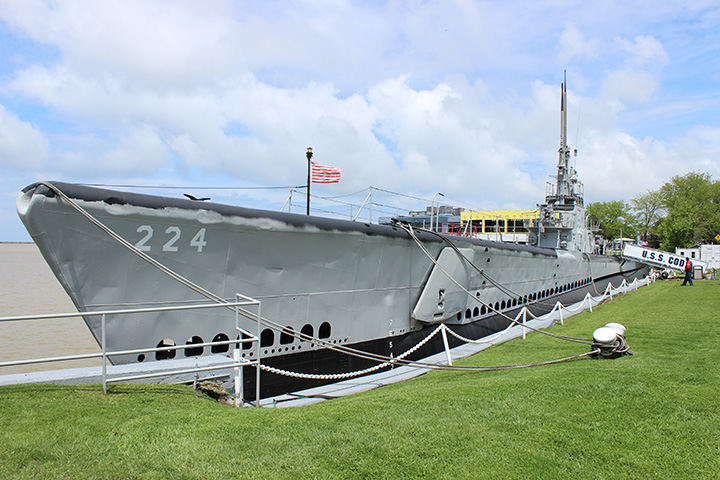

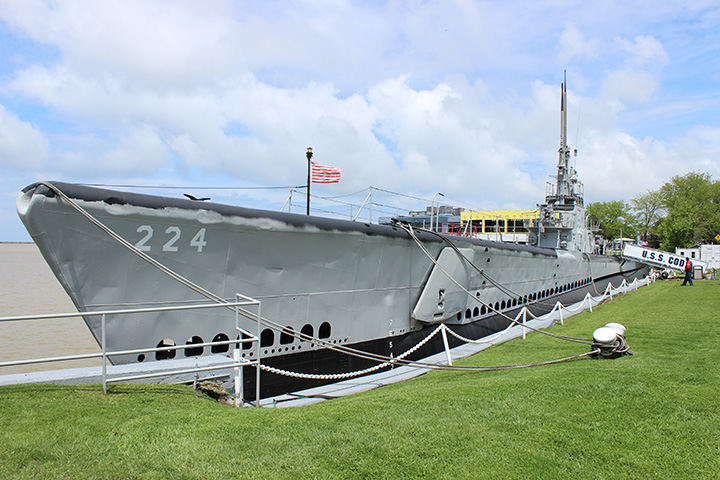

The Cleveland Diesel Division of General

Motors of Cleveland, OH supplied half of the diesel engines installed in

the US submarine fleet of World War Two. Today the World War Two era submarine USS

Cod can be seen along the waterfront in Cleveland, OH. One of the

four Cleveland Diesels Engines on the submarine is operational. Author's photo.

The Bofors 40mm cannon gun mount on the deck of the USS Cod

was built by Firestone Tire and Rubber Company. Author's photo.

Last website revision date: 7-6-2025

Original publication date: 8-30-2013

|