|

Ford Overview

Ford Victory Pictorial

Ford WWII Production Database

Ford M4A3 Sherman Tank Photos

Ford Highland Park Tank Plant

Highland Park, MI

1910-Current

This page update 2-17-2023.

The Ford Highland Park Plant that introduced

the world to automobile mass production still exists. Not

all of it still stands, but enough of it exists to make a visitor realize how big it once was. It was massive

and was located on 60 acres of land!

Automotive production moved to the River Rouge

in the late 1920s. Then Highland Park produced automotive trim.

During World War Two the plant used its skill in automotive trim to make squad tents

for the US Army.

Highland Park allocated 789,624 square feet of floor space for the

production of the M4A3(75) Sherman tank and the M10A1 Wolverine tank

destroyer.

Highland Park World War Two Production

Statistics: 1,690 M4A3 Tanks, 1,038 M10A1 Tank Destroyers, 1,202

Gun Directors, 9,498 Squad Tents, 19,985 M34 and M34A1 Sherman Tank Gun

Mounts, and parts for P&W R-2800 aircraft engines built at Ford

River Rouge.

The Ford Motor Car Company began production

of the Model T in this plant in 1910. It was not until October 7,

1913, that the moving assembly line was introduced. This plant was

in the world to have one; and at the time was the largest manufacturing

facility in the world. Use of the moving assembly

line cut the price of a Model T in half.

This is the former administration building.

This building faces west on Woodward Avenue, one of the main streets in the

Detroit area.

The photo above closely replicates the location of the original photo below,

which was taken to the southwest of where I took this photo. Both

photos include the administration building with the factory

behind. This photo was taken 101 years after the one shown below.

What was a bustling auto plant that put the United States in

motor vehicles in 1915, is now an unused office building and a repurposed

factory.

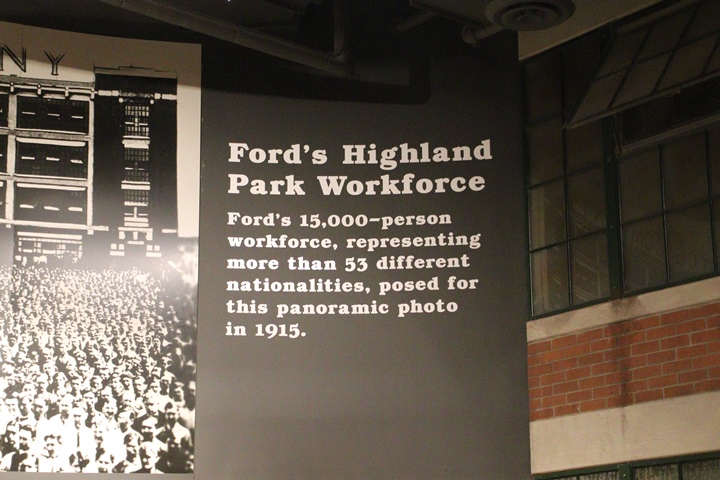

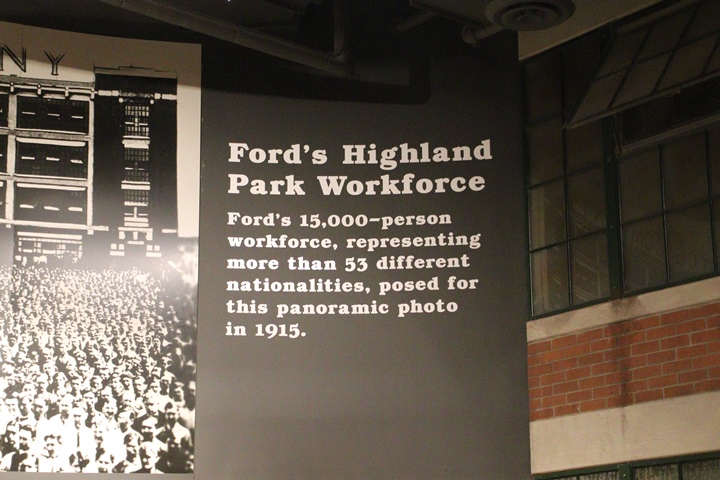

This photo is on display at the Michigan

History Center in Lansing, MI. Author's photo added 2-17-2023.

The key fact here is that the plant employed

workers from 53 different nationalities. Today, most Americans

have conveniently forgotten their roots and that their ancestors came

over in boats from many corners of the globe. It makes life easier

for them to forget this important fact that we are all "boat people."

I know that my mother's family was looked down on as "foreigners" by

many earlier arrivals to this country. We all came from somewhere.

For some of us, it was Moravia, Scotland, and Switzerland. No doubt

those three were included in the 53 nationalities at the Highland plant

in 1915. Author's photo added 2-17-2023.

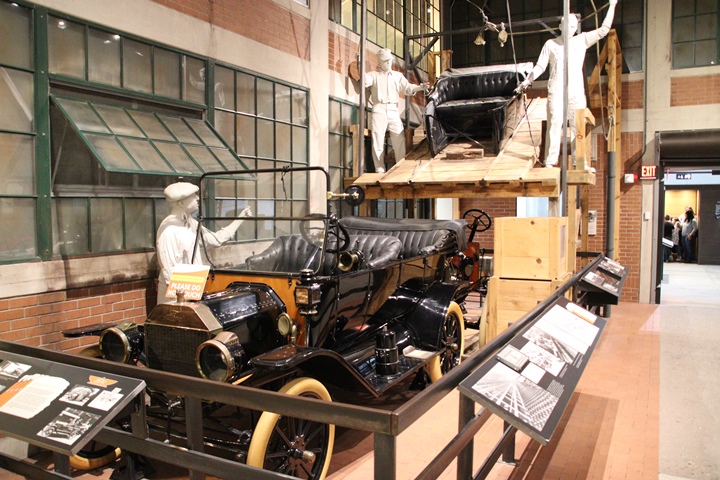

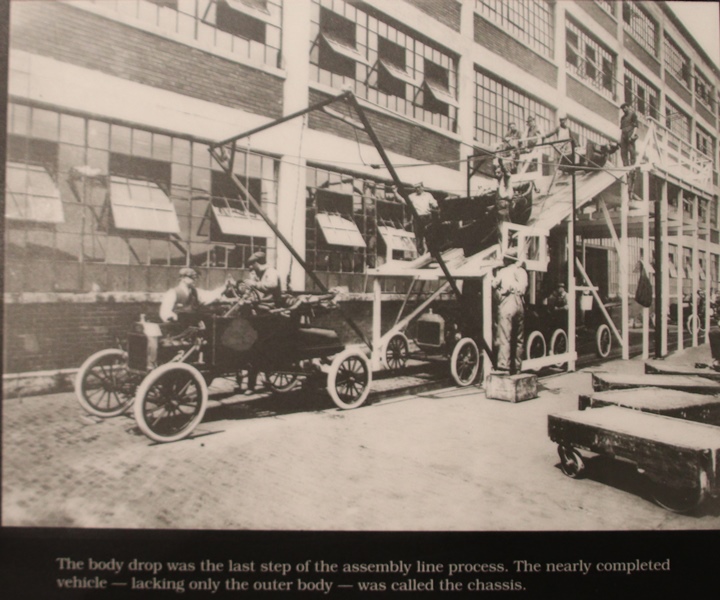

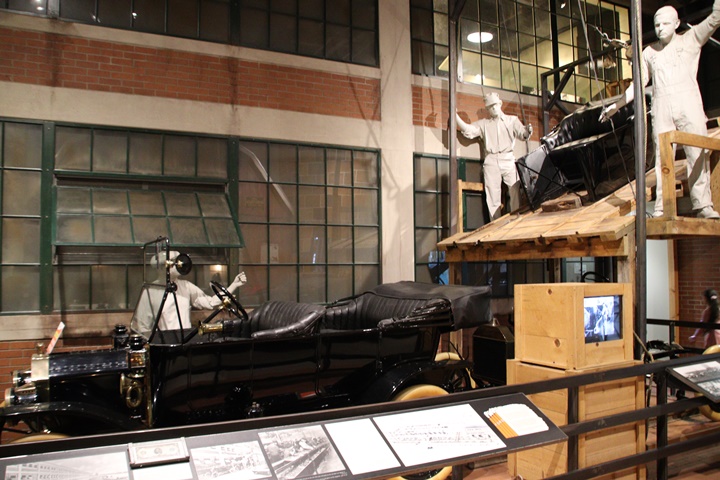

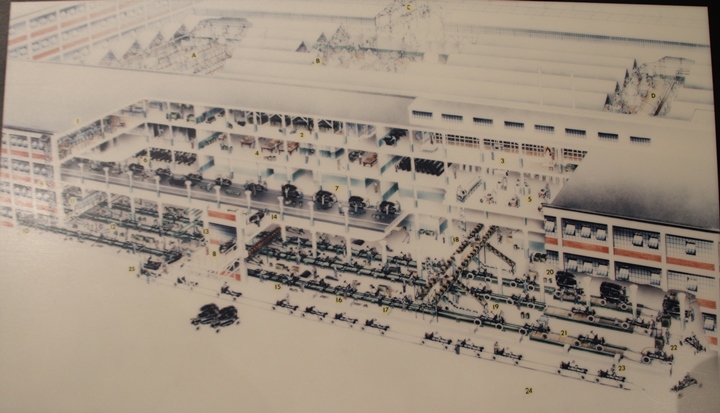

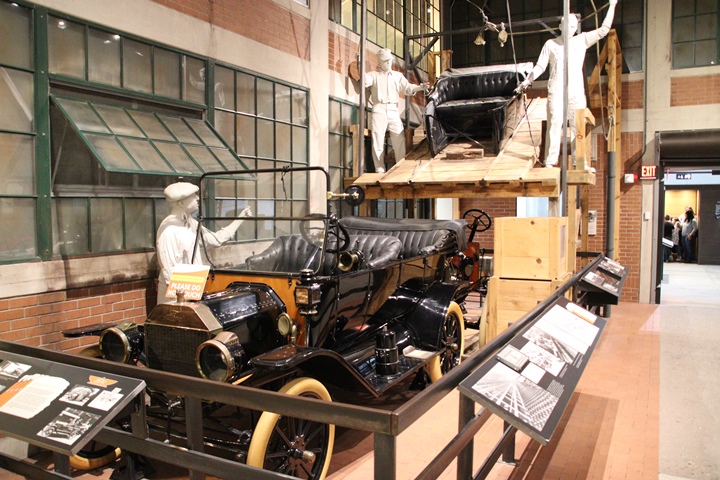

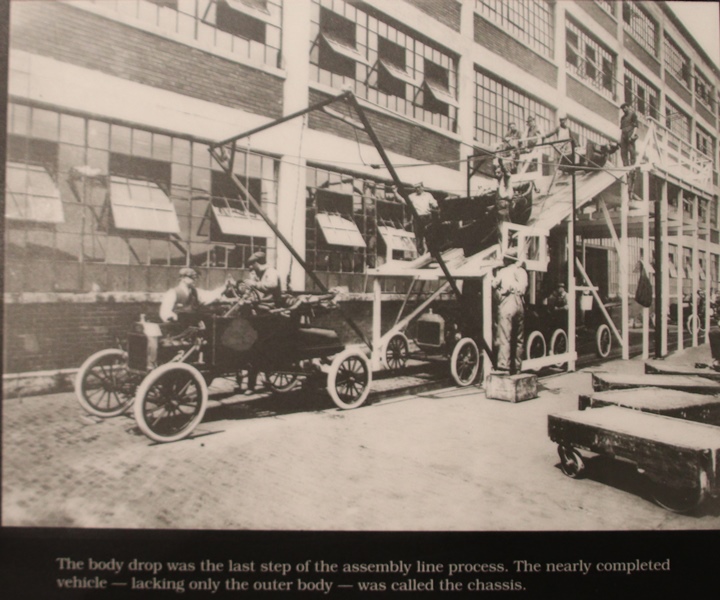

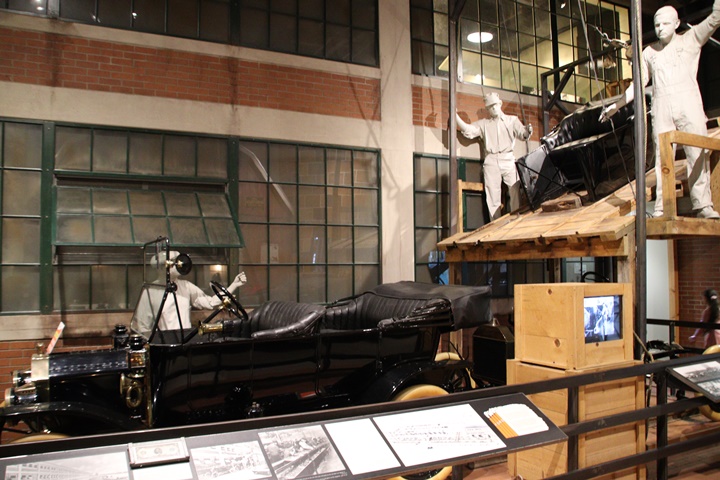

The next five images are of a diorama at the

Michigan History Center. They depict the body drop onto the

chassis of the Model T. The diorama depicts a time when the body

drop was done outside the factory walls. Author's photo added

2-17-2023.

At some point, this no doubt was moved

inside. Image added 2-17-2023.

Author's photo added 2-17-2023.

Not only was the platform the body slid down

made of wood, but so was the body of the Model T itself. Author's

photo added 2-17-2023.

Author's photo added 2-17-2023.

Author's photo added 2-17-2023.

Looking east of the former complex along

Manchester Street. This portion is two city blocks long.

About 20% of the original structure still

stands. A small part of it is still being used.

The plant complex extended to the

trees in the distance.

Not only did the plant complex cover 60

acres, but this building is six stories tall and 865 feet long. It

is 75 feet wide and known as the Crystal Palace to the workers.

Architect Albert Kahn insisted on natural light for the workers.

There is more than 50,000 square feet of glass in the building.

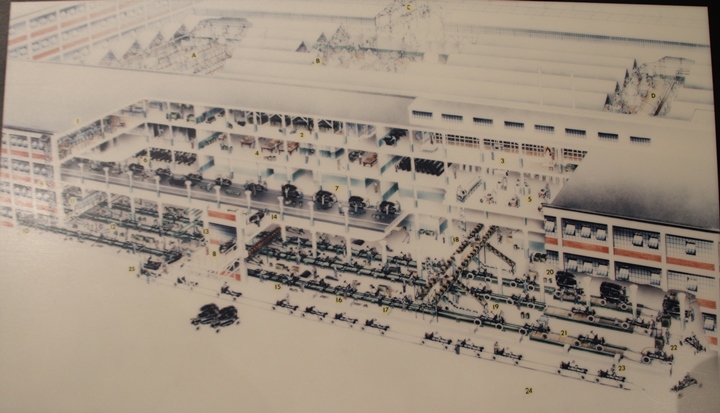

This cutaway drawing of the plant shows that

the plant was wide enough to run the chassis assembly line back and

forth three times on the first floor. The body assembly was on the

third floor. At the right end of the image, the completed chassis came

outside the factory where they mated with the bodies depicted in the

diorama above. Image added 2-17-2023.

This image is looking west from the east end

of the complex. There is another six story building that runs

north at the end of the complex.

This view is from the southeast corner of the Highland Park

complex looking north.

This is one of 165,382 1914 Model T touring

cars produced in Highland Park's first year of production. This is

one of over 40 Model Ts on display at the Model T Museum in Richmond,

IN. This museum is a "gold nugget" find of a museum that is located

just north of downtown Richmond. Author's photo added 2-17-2023.

The Model T Museum also has a 1926 touring

car on display. The Model T touring car was one of only two models

to be made during the production of the vehicle. The last Model T

was produced in May 1927. Author's photo added 2-17-2023.

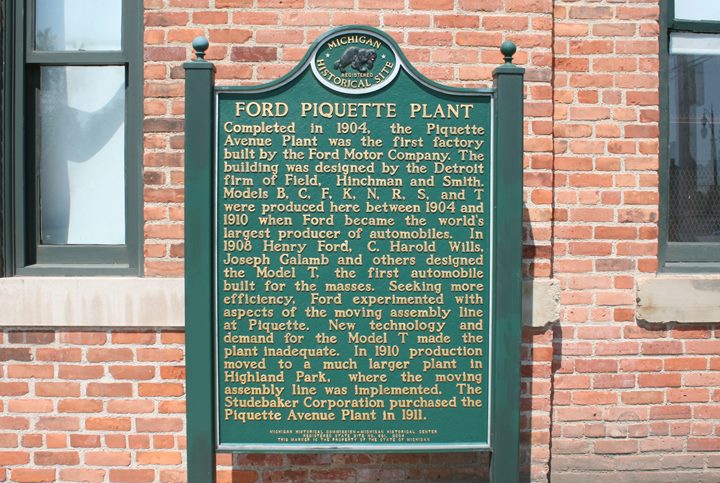

Before Highland Park:

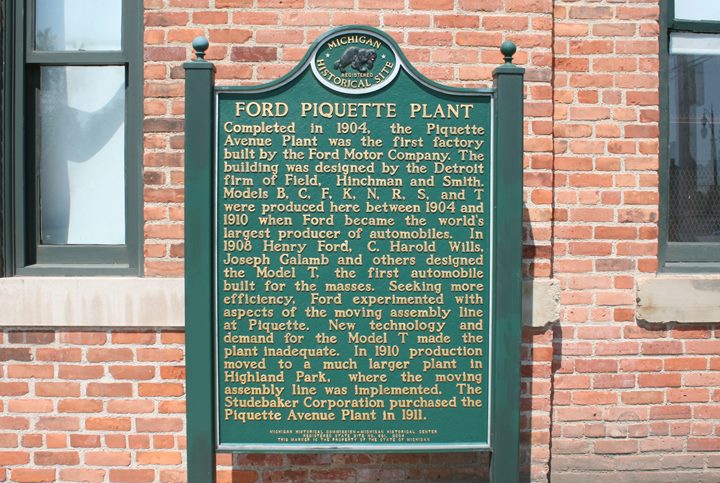

In 1904 Henry Ford began assembling

automobiles in this plant at the corner of Piquette and Beaubein Streets

in Detroit. The first Model Ts were built here.

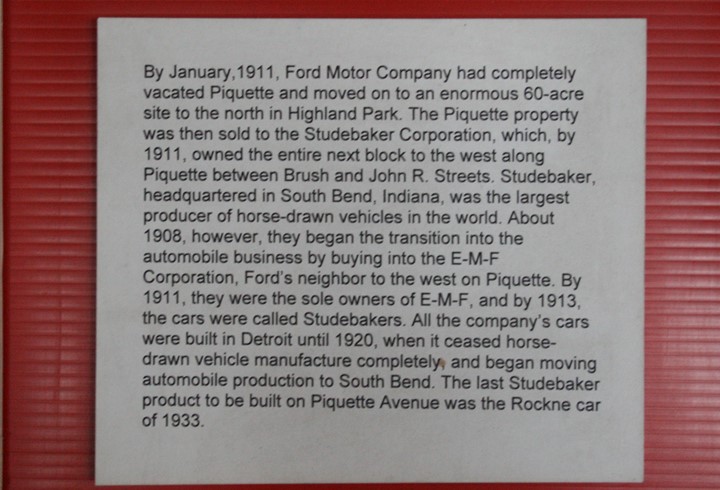

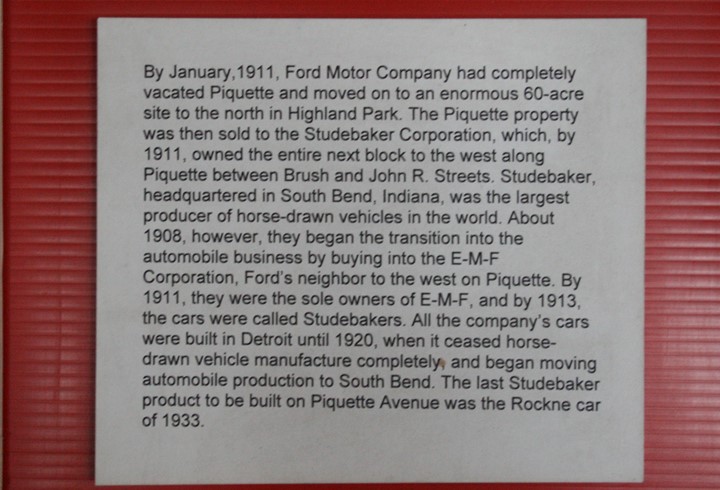

I visited the very fine Studebaker

Museum in South Bend, IN several times. To my knowledge, there is

no mention of Studebaker's operations in Detroit, even though

Studebakers were produced in Ford's former Piquette plant for twenty

years. The Studebaker

Museum is very South Bend centric.

Ford Highland Park Plant World War Two Products

This is one of 1,690 M4A3(75) Sherman tanks built at

Highland Park. It is located at

the American Legion Post 201 in West

Jefferson, OH. It was built in August 1943 and is

serial number 12638.

Ford built 57,851 Pratt & Whitney R-2800

radial aircraft engines during World War Two at its River Rouge aircraft

engine plant. Highland Park produced many of the components for the

engines built at River Rouge.

This particular engine was built for the

Lockheed PV-2 Harpoon. Ford River Rouge also built the R-2800 for

the Curtiss C-46, Douglas A-26,

Martin B-26, Northrop P-61, Republic P-47, and the Lockheed B-34.

Ford Highland Park supplied components for all of these engines.

Ford Highland Park produced 9,498 tents for

the US Army.

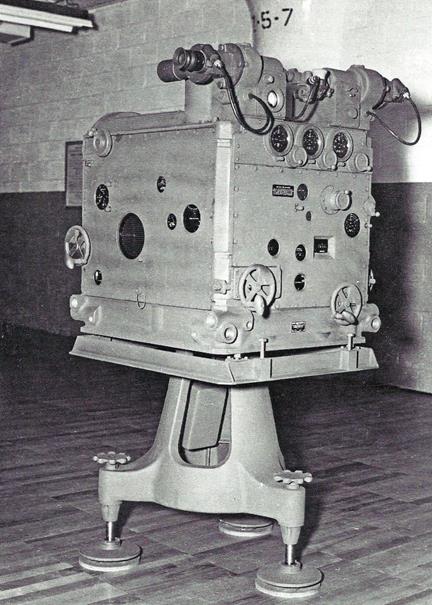

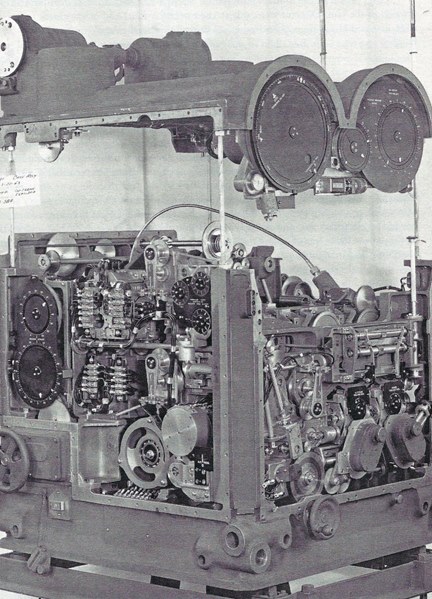

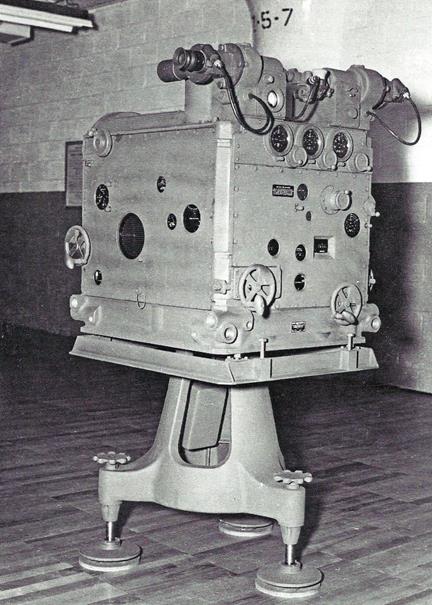

This M7 gun director was designed by the

Sperry Gyroscope Company for the US Army to track fast, low flying

aircraft, and aiming anti-aircraft weapons. The next photo shows

that it was a complicated mechanical analog computer. The US Army

was looking for a company to mass produce this gun director. It

turned to Ford due to its experience in mass production. Making

something this complex using mass production techniques had not been

previously done. Ford Highland Park was up to the task of making

1,202 of them.

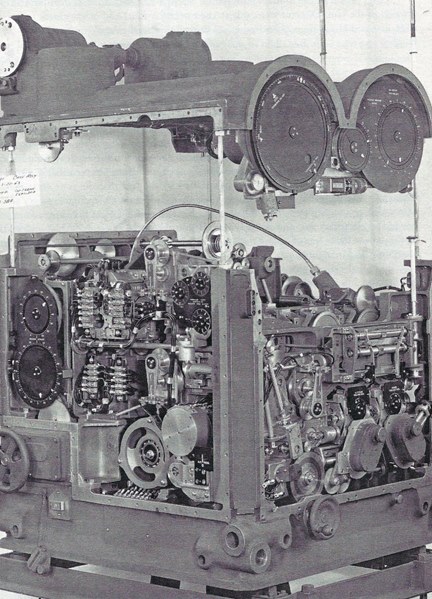

The M7 gun director was a mechanical

computer which included 276 aluminum die castings. Also, this

complex device contained 721 gears on 380 shafts, made of a special

nickel alloy. To add to the difficulty of building this device, it

had 549 ball bearings designed to make all the shafts and gears move

smoothly.

Ford assembled 19,985 M34/M34A1 gun mounts at the Highland Park plant

from parts made at the River Rouge. Six manufacturers of the

Sherman tank then assembled them into the tanks. Author's photo

added 2-1-2018.

|