|

Other Lansing Companies that contributed

to winning World War Two

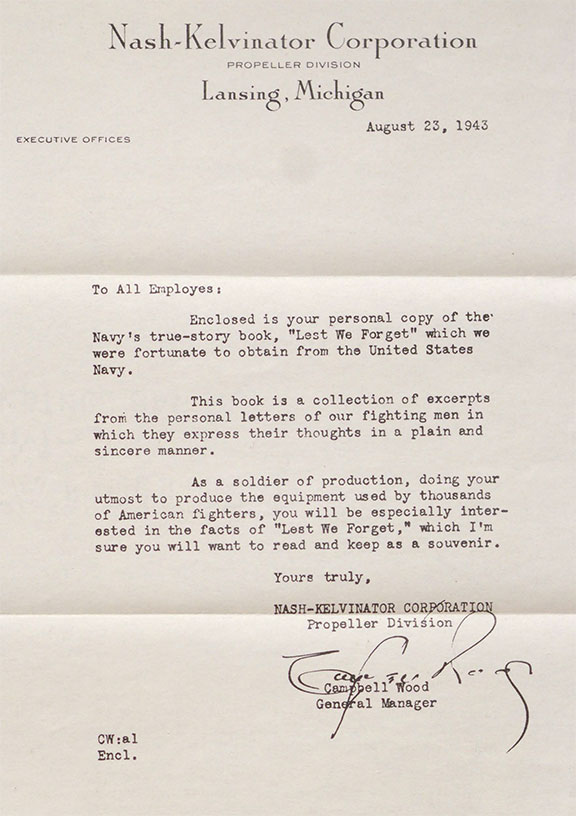

Nash-Kelvinator Lansing Plants in World War Two

Recognizing a Company

from my Hometown that contributed to winning World War Two

Lansing, MI

1941-1945

This page updated 4-8-2022.

Nash-Kelvinator Lansing

Plant World War Two

Products:

158,134 three and four blade propellers and 85,656 spare blades.

Nash-Kelvinator Lansing was second in the amount of US propeller

production during the war. For the month of October 1943, Lansing

produced 7,015 propellers, more than any other manufacturer, making it

the world's leading propeller supplier for the month. The total

value of the Army Air Force contracts totaled

$539,433,000.

The Nash-Kelvinator Plant in Lansing, MI won

the Army-Navy "E" Award on September 17, 1943.

The Plants:

Nash-Kelvinator South Cedar Street

Plant in Lansing, MI:

This is Cedar Street in Lansing, MI looking

north with the former World War Two Nash-Kelvinator plant on the right. The three story building was originally built by Reo and connected to

its main assembly plant with pedestrian bridge over Cedar Street.

The Reo main plant is to the left in this photo and John Bean and former

Nash-Kelvinator propeller plant is on the right. The Defense Plant

Corporation purchased the 457,511 square foot three-story factory in

1940 and Nash-Kelvinator began producing Hamilton-Standard aircraft

propellers in it during 1941. In December 1945 John Bean purchased

the plant from the Reconstruction Finance Corporation. The plant

was located on 9.3 acres of land. This is how the plant looked

during World War Two. I am not sure why Reo even built the

three-story factory when it was continually having problems generating

enough truck sales to stay solvent.

This 1950 photo is looking north. I

do not remember the pedestrian bridge over Cedar Street. In the

background, the railroad crossing for the Grand Truck Railroad can be

seen. Cedar Street is the main north-south road running just

east of downtown Lansing and is a major traffic thoroughfare in the

city. To alleviate traffic backups, an overpass was built over the

tracks.

This is how I remember Cedar Street from when I

was growing up in Lansing. The former Reo, Nash-Kelvinator, and

John Bean plant is now occupied by Rehbel, a cultivator of cannabis .

According to its website, Rehbel considers itself the Jack Daniels of

the cannabis industry. With 10.5 acres on the three floors in the

building, the company has plenty of floor space to cultivate its

product. Author's photo added 9-12-2021.

I took this photo in 2011. The owners

of the building were then attempting to put lofts in it. Author's photo.

Ten years later, in 2021, the plant has added

some climate control units on the roof to maintain the proper

temperature in the building. Otherwise, it is pretty much like I

remember it when I grew up near here. I remember driving

by once and there was a red fire engine in this parking lot that John Bean

was working on. Author's photo added 9-12-2021.

Author's photo added 9-12-2021.

This is the east end of the current Rehbel

facility. Due to the topography, this section is only two stories.

Author's photo added 9-12-2021.

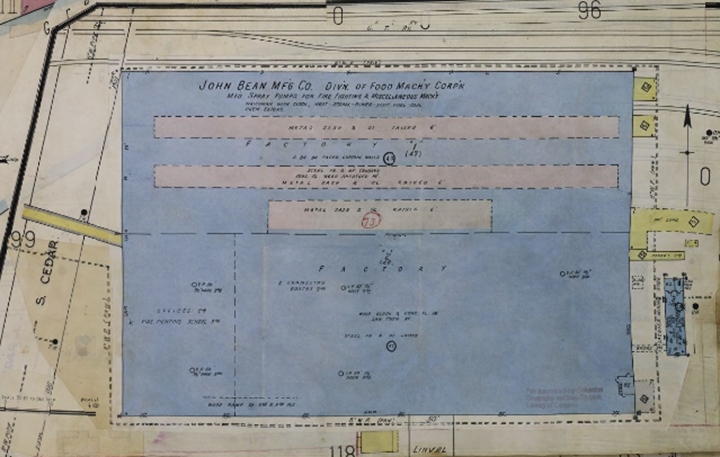

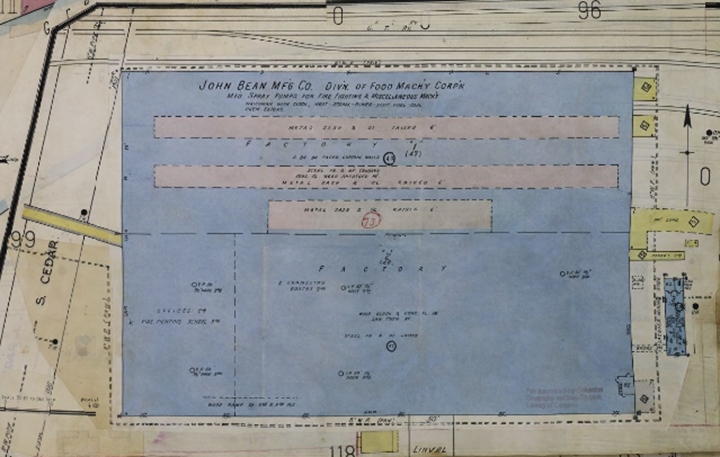

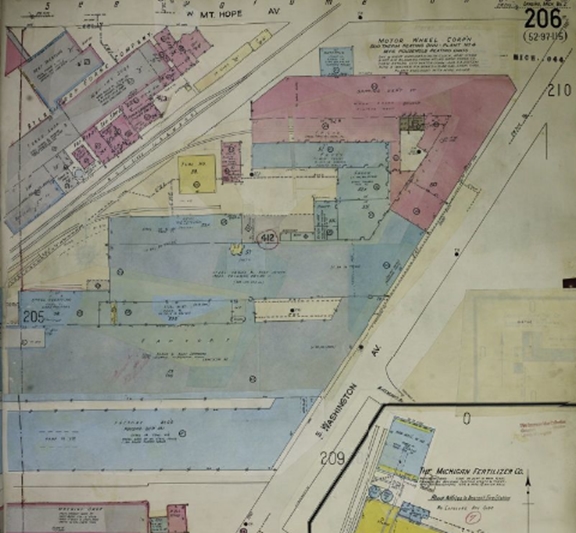

This Sanborn map shows the plant in 1951. The pedestrian bridge

over South Cedar Street is on the map. Image added 9-12-2021.

The first contract

Nash-Kelvinator

received at the plant came on June 28, 1941. It was for 5,000 propellers to be

delivered to the British government starting in 1942. These

propellers would have

been used on Lancaster, Mosquito, and Baltimore aircraft. First

production started in the 450,000 square foot facility in February of

1942, when the first propeller came off the assembly line and was

accepted by inspectors. The Defense Plant Corporation provided $8.5 million worth of

equipment for the manufacture of the propellers in the plant.

In October 1942

Nash-Kelvinator received a second contract from the Army Air Force for

7,000 propellers for its own use. Then, Nash-Kelvinator was issued

a third contract in May of 1942, which was the working contract that was

amended as the war progressed as more propellers were needed. In

March 1942 final assembly and blade manufacturing moved to the former

Duplex Truck plant at Mt.

Hope and Washington Streets, with the Cedar Street plant then

responsible for propeller hub production.

At its peak, the

Nash-Kelvinator Lansing operation employed 8,500 workers.

Nash-Kelvinator

final assembly plant on the southwest corner of Mt. Hope Avenue and

Washington Street in Lansing, MI:

This World War Two-era photo of the former

Duplex plant shows that has sections that parallel both Washington

Ave. to the left in the photo and Mt. Hope Ave. to the right. An

article from the Lansing State Journal dated 9-14-1917 states that the

400 foot main building was nearly complete. The article goes on to

state that the foundation would begin to be laid for a 240 foot building

to the south.

In December 1945 Motor

Wheel purchased this plant from the Reconstruction Finance Corporation

for the manufacture of it Duo-Therm oil heaters and water heaters.

I remember seeing a big Motor Wheel sign on the building while growing

up in the area. Then the sign went away. Apparently, the

Duo-Therm business was not as profitable for the company as expected.

Since there is no sign on the building and the vintage of the vehicles

in the photo, this appears to a World War Two photo. The street parking on Washington Avenue

is surprising to me. There was no parking on it when I grew up.

The next series of photos

was taken in 2011. The building's exterior has changed in some

ways. The brick along Mt. Hope Avenue has been painted and the

first floor windows covered up. Along the Washington Avenue side

of the building, the brick has been covered with sheet metal.

This view is looking at the former Nash-Kelvinator plant

from across the street on Mt. Hope Avenue. When in junior high

school, I would walk the sidewalk in the foreground, not realizing the

significance of the plant across the street or that my grandfather had

worked there during the war. While in college, I would drive this

route to Michigan State University.

Author's photo.

The plant became the final assembly location for Nash-Kelvinator

starting in March of 1942 and produced

158,134 Hamilton-Standard propellers.

I grew up a mile away and walked

by this plant for three years going to junior high school, and then

drove by it for five and a half years when I went to college.

However, it wasn't until 2010 that I became aware of this building's

historical significance or my family's involvement with

the plant. While visiting my uncle in May 2010 in California, he

mentioned that my grandfather had worked in the plant during World War

Two and was foreman in the

propeller balancing department. This came as a complete surprise

to me, as I had no idea of this plant's contribution to the war effort,

nor the fact that my grandfather had ever worked in the plant. The location of the plant allowed him

to walk to work and save valuable rationed gasoline during the war.

After Motor Wheel moved out, this was the location of the first discount /

big box store in Lansing, and I remember when it opened as we went

shopping there on occasion. This would have been around 1960. I actually remember purchasing some

solder at the store I needed for a radio project I was building. The

name of store escapes me, but it

was the predecessor of the K-Marts and others that later opened in the

area. That

lasted for a short time. Since that time, there have been numerous

occupants of the building. Due to its huge size, it has been

sub-divided into smaller sections for companies that do not need over

650,000 square feet. One of the current occupants is the Quality

Dairy, which recently moved there from its longtime location across the street from the former Reo plant.

This view is looking southwest with Washington Ave. on the left. About a half

mile down Washington Ave. on the west side of the road is the

former headquarters for the Michigan National Guard. It was here

that I served out my military commitment in the 1970's. Again, I

was unaware the factory just

to the north of the armory had produced Hamilton-Standard propellers

during World War Two and that my grandfather had worked there.

Author's photo.

The next series of photos was taken in 2021.

The brick along Mt. Hope Avenue has been

restored to a red and looks very elegant in its restored original color.

The Quality Dairy has its corporate headquarters in the building with an

address of 111 West Mt. Hope Avenue. Author's photo added

9-12-2021.

The red brick is very striking in its

appearance and makes the building look newer than its 80 years. It

has been painted as the original mortar was white. This is all

red. Author's photo added 9-12-2021.

This view is about half-way down the complex on

South Washington Street. The intersection

of Washington and Mt. Hope is in the right corner. Note the sheet metal covering over the

original brick and an address of 2010 South Washington Avenue.

Author's photo added 9-12-2021.

In this photo I have rotated the camera to

the left. Here the original construction of red brick can still be

found. The second floor windows also look original. The

address for this section is 2104 South Washington Avenue. Author's

photo added 9-12-2021.

This photo shows the rest of the building

along South Washington Street. There is an address of 2110 on the

corner of the building. Author's photo added 9-12-2021.

This is the south end of the building.

The original red brick and weathered and faded over 80 years. The

complete address for this tenant of the facility is 2126 South

Washington Avenue. Author's photo added 9-12-2021.

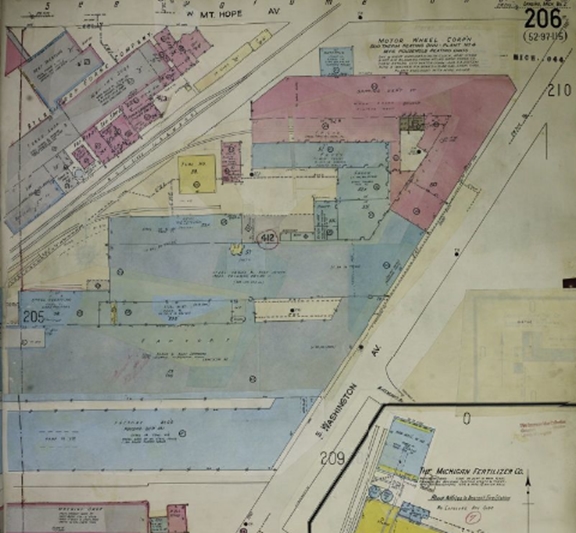

This 1951 Sanborn map shows not only the

Motor Wheel Duo-Therm plant but the Atlas Drop Forge Company in the

upper left. That building still exists with several tenants.

The red building at the bottom was the Federal Drop Forge. It is

gone. Image added 9-12-2021.

Aircraft types with Lansing built

Hamilton-Standard three blade propellers: A-20, C-47, C-53,

B-17, B-24, B-25, Baltimore, Lancaster, and Mosquito.

This is an example of the Hamilton-Standard

propellers made at the Lansing Nash-Kelvinator plant. Author's

photo.

Aircraft types with Lansing-built Hamilton-Standard four blade propellers: F4U-4 and A-26D,

A-26E, and A-26F. These four aircraft were late developments in the war. Goodyear, which

was going to build the four-bladed version of the F4U-4 Corsair as the

FG-4, never went into production with the aircraft. Nash-Kelvinator

Lansing was to be the supplier for the Goodyear FG-4. It is

unknown whether the propellers were routed to the Vought production line

in Connecticut for use on the F4U-4 version that was built there.

The A-26D, A-26E and A-26F were the only versions of

the aircraft that were to have been fitted with four blade props.

They never went into production, even though there had been plans for

750 of the A-26Ds and 2,150 of the A-26E to have been built.

Nash-Kelvinator Lansing built a total of 4,972

four bladed props by the time production stopped at the end of the war.

Table 1 - Nash-Kelvinator

Company Lansing, MI Plant's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. Table added 4-8-2022. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Airplane Prop

Assys - Army Air Force |

$11,738,000 |

6-1941 |

8-1942 |

| Airplane Prop

Assys - Army Air Force |

$19,599,000 |

10-1941 |

2-1943 |

| Airplane Prop

Assys - Army Air Force |

$66,679,000 |

1-1942 |

8-1943 |

| Airplane Prop

Assys - Army Air Force |

$26,922,000 |

7-1942 |

9-1943 |

| Airplane Prop

Assys - Army Air Force |

$27,104,000 |

7-1942 |

7-1943 |

| Airplane Prop

Assys - Army Air Force |

$20,548,000 |

8-1942 |

10-1943 |

| Airplane Prop

Assys - Army Air Force |

$86,375,000 |

10-1942 |

7-1945 |

| Airplane Prop

Assys - Army Air Force |

$47,-78,000 |

12-1942 |

8-1944 |

| Airplane Prop

Assys - Army Air Force |

$18,430,000 |

9-1943 |

2-1944 |

| Airplane Prop

Assys - Army Air Force |

$73,068,000 |

5-1943 |

1-1945 |

|

Airplane Prop Assys - Army Air Force |

$6,401,000 |

6-1943 |

10-1944 |

| Airplane Prop

Assys - Army Air Force |

$12,550,000 |

8-1943 |

8-1944 |

| Airplane Prop

Assys - Army Air Force |

$23,871,000 |

12-1943 |

3-1946 |

| Airplane Prop

Assys - Army Air Force |

$65,049,000 |

3-1944 |

8-1945 |

| Airplane Prop

Assys - Army Air Force |

$34,021,000 |

6-1944 |

6-1945 |

| Total |

$539,433,000 |

|

|

|

Table 2 - Nash-Kelvinator

Company Lansing, MI Plant's World War Two Monthly Propeller

Production |

|

1942 - Model - Hydromatic 3-Blade, Dural,

23-E-50 |

|

Jan |

Feb |

Mar |

Apr |

May |

Jun |

Jul |

Aug |

Sep |

Oct |

Nov |

Dec |

Total |

| - |

- |

135 |

570 |

1,005 |

930 |

1,555 |

1,165 |

2,056 |

2,257 |

2,510 |

2,545 |

14,728 |

| |

|

1943 - Model -

Hydromatic 3-Blade, Dural, 23-E-50, 23EX |

|

Jan |

Feb |

Mar |

Apr |

May |

Jun |

Jul |

Aug |

Sep |

Oct |

Nov |

Dec |

Total |

|

2,560 |

3,010 |

3,511 |

4,005 |

4,505 |

5,002 |

5,509 |

6,015 |

6,509 |

7,015 |

5,004 |

6,005 |

58,650 |

| |

|

1944 - Model -

Hydromatic 3-Blade, Dural, 23-E-50, 23EX |

|

Jan |

Feb |

Mar |

Apr |

May |

Jun |

Jul |

Aug |

Sep |

Oct |

Nov |

Dec |

Total |

|

6,020 |

6,082 |

6,014 |

6,006 |

6,010 |

6005 |

5,510 |

52,81 |

5,054 |

3,370 |

3,750 |

3,720 |

62,822 |

|

1944 - Model -

Hydromatic 4-Blade, Dural, 24-E-60 |

|

Jan |

Feb |

Mar |

Apr |

May |

Jun |

Jul |

Aug |

Sep |

Oct |

Nov |

Dec |

Total |

| - |

- |

- |

- |

- |

- |

- |

- |

70 |

65 |

142 |

155 |

432 |

| |

|

1945 - Model -

Hydromatic 3-Blade, Dural, 23-E-50, 23EX, 33-E-60 |

|

Jan |

Feb |

Mar |

Apr |

May |

Jun |

Jul |

Aug |

Sep |

Oct |

Nov |

Dec |

Total |

|

3,735 |

2,770 |

3,177 |

2,590 |

2,975 |

1,740 |

885 |

240 |

- |

- |

- |

- |

18,112 |

|

1945 - Model -

Hydromatic 4-Blade, Dural, 24-E-60 |

|

Jan |

Feb |

Mar |

Apr |

May |

Jun |

Jul |

Aug |

Sep |

Oct |

Nov |

Dec |

Total |

|

450 |

470 |

468 |

400 |

400 |

470 |

480 |

252 |

|

|

|

|

3,390 |

|

Grand Total |

158,134 |

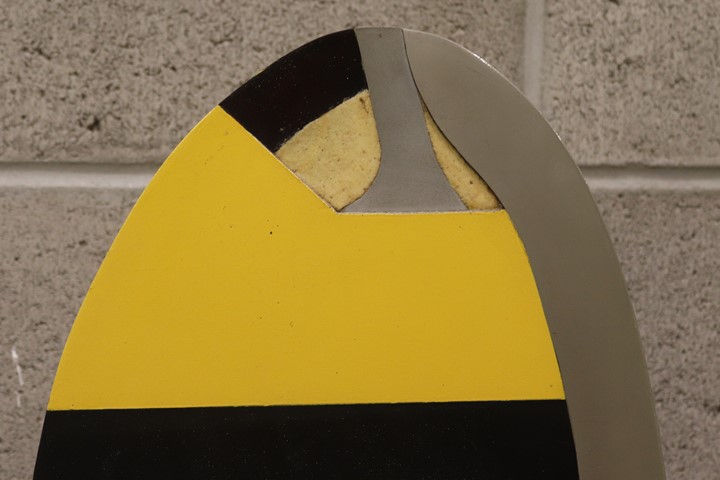

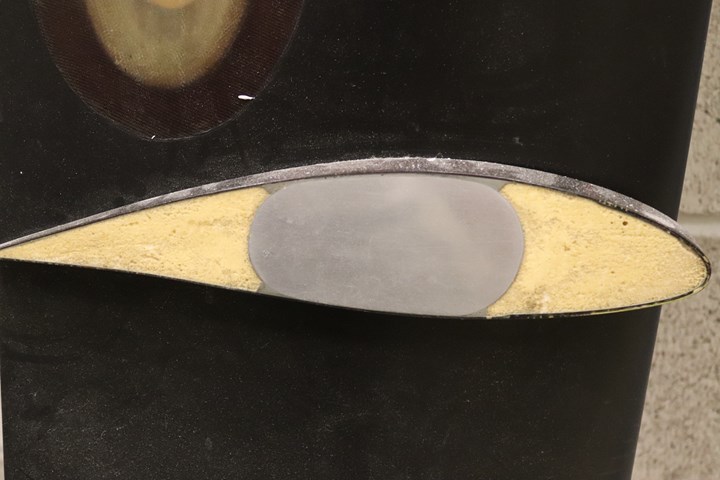

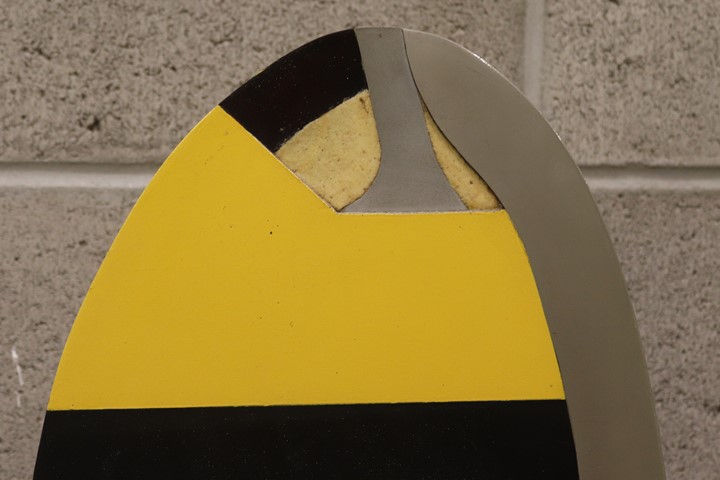

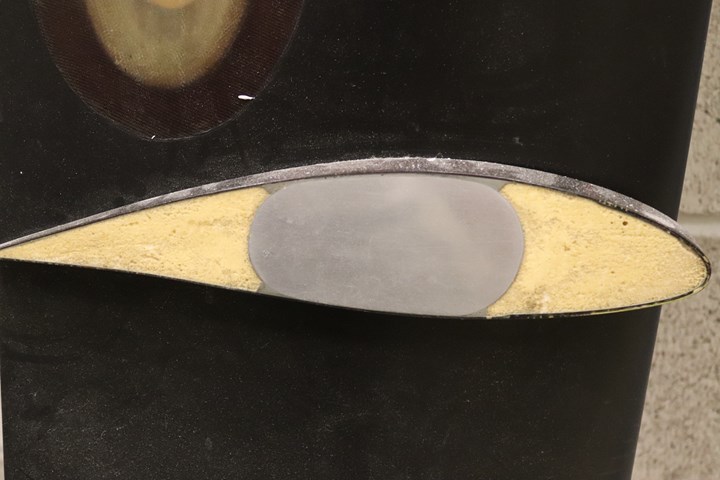

Anatomy of a Hamilton-Standard propeller

blade: Below are photos of a cross-sectioned blade that is on display at

the New England Air Museum in Windsor Lock, CT. Note that there is

a center spar section that runs the length of the blade that is encased

in a foam material. The two outside sections of the blade are

welded together to make a finished product.

Author's photo from the New England Air

Museum added 11-14-2017.

Shown here is the tip of the blade.

Author's photo from the New England Air Museum added 11-14-2017.

Author's photo from the New England Air

Museum added 11-14-2017.

Author's photo from the New England Air Museum added 11-14-2017.

Author's photo from the New England Air Museum added 11-14-2017.

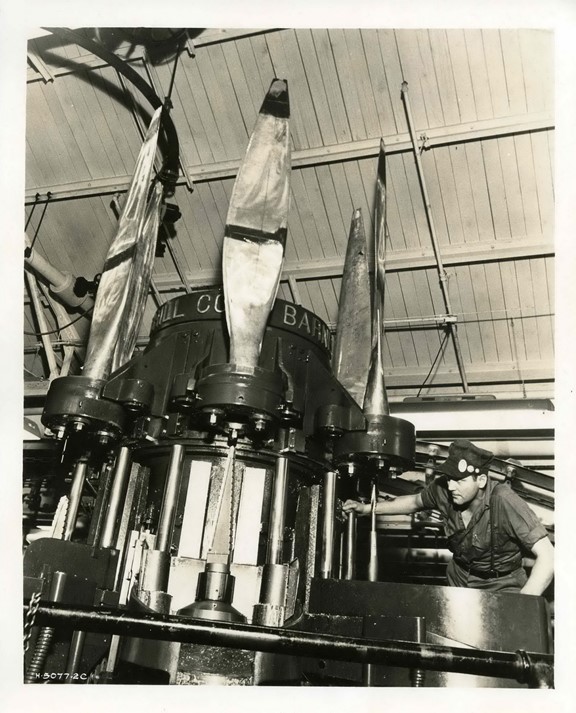

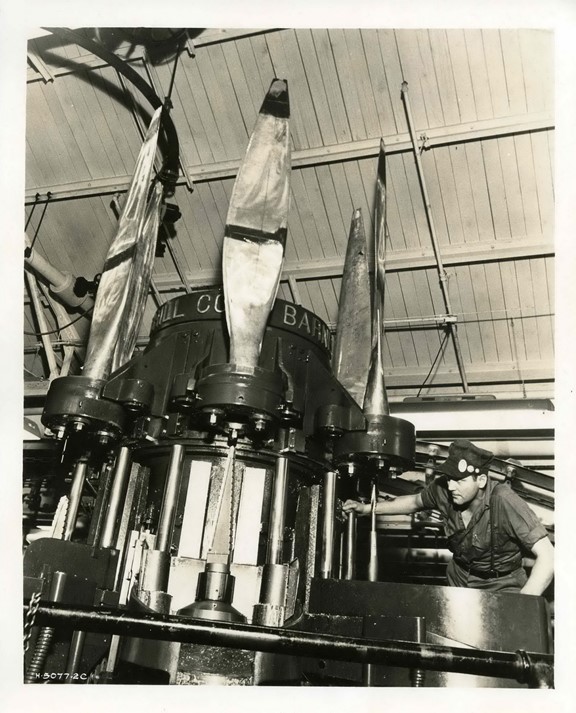

Hamilton-Standard propellers being run at

the Lansing Nash-Kelvinator plant during World War Two. Photo courtesy of

Ken Schroeder added 3-14-2016.

This photo is interesting due to the American automotive industry's

importance in the construction of this late model B-24 (J, L, or M

model). First of all, this is a Ford-built B-24 at the Willow Run,

MI plant. Obviously, the Lansing, MI Nash-Kelvinator plant built

the propellers being installed and the 100,000th milestone has been

reached. My grandfather, Frank Dominik, while not in the photo,

played an important part in this, in that he was the supervisor of the

propeller balancing department back in Lansing. It was his

responsibility to make sure that when the engines on this B-24 fired up,

there were no vibration issues due to out of balance blades.

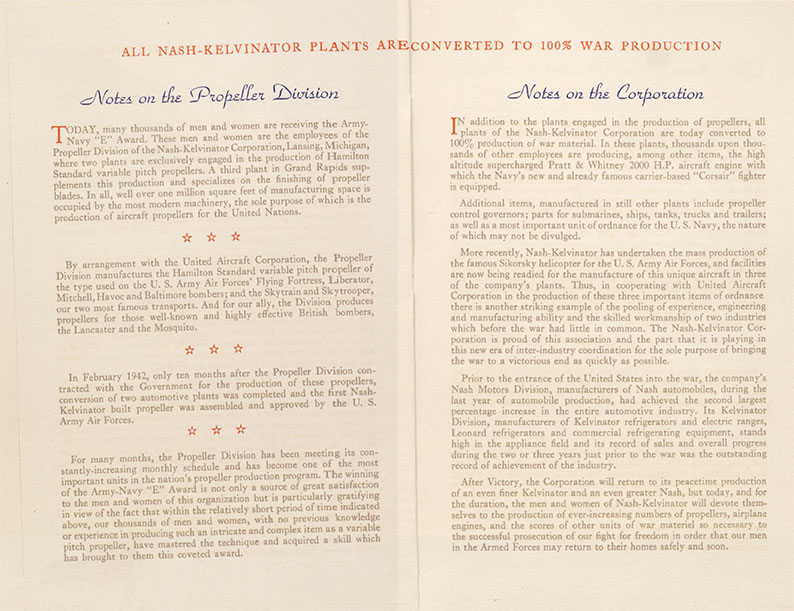

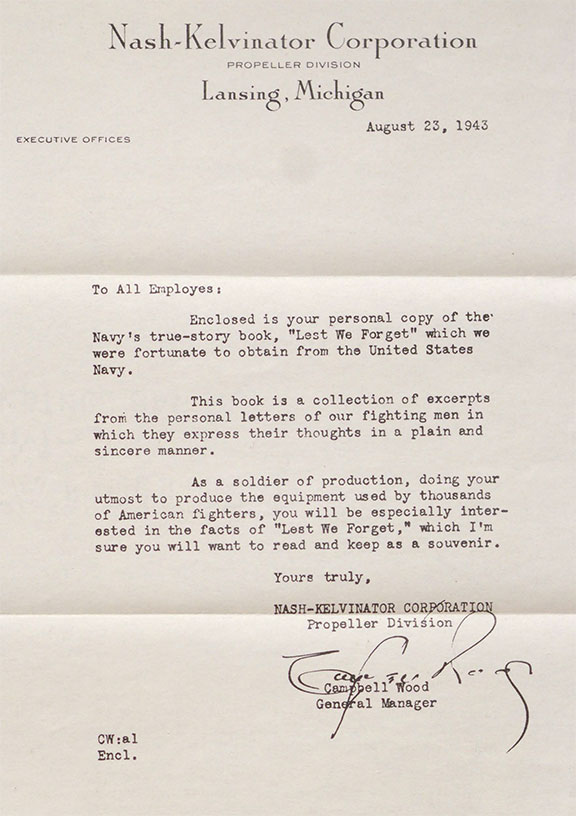

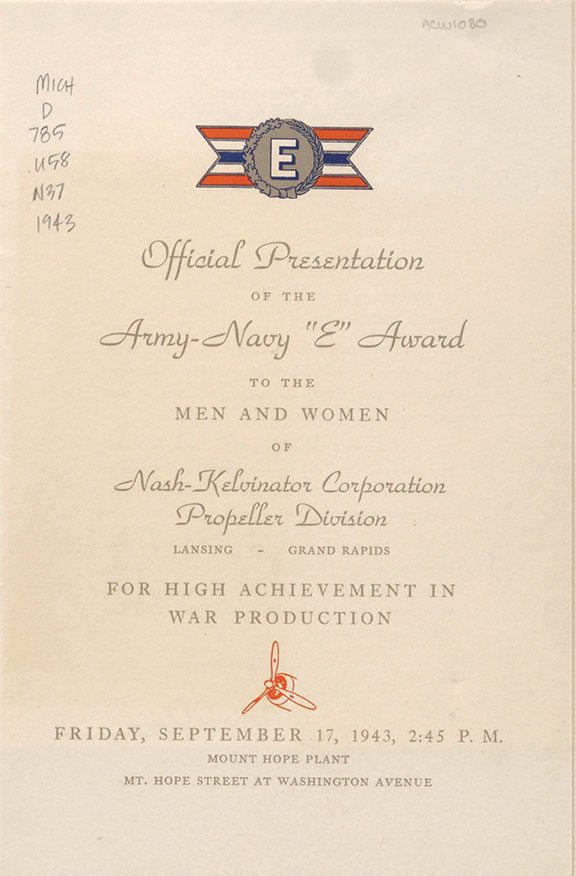

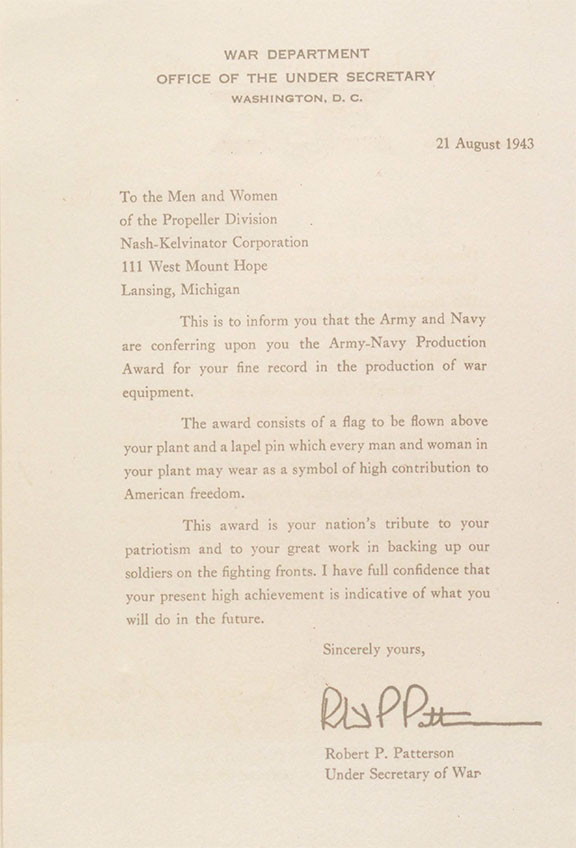

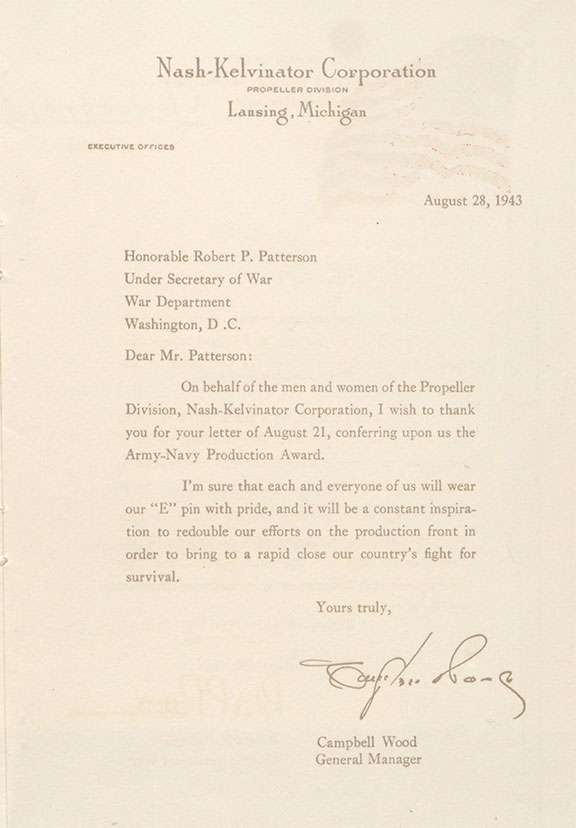

Army-Navy E for Excellence Award:

The Lansing Nash-Kelvinator Plant was awarded

the prestigious Army-Navy E for Excellence Award on September 17, 1943.

Below is the program given to the employees to honor the event.

This page notes production of propellers by

Lansing for use on the US types of aircraft to include the B-17, B-24,

B-25, A-20, C-47, C-53 and the Baltimore. Research indicates all

of the Baltimore production went to the British, which served with

distinction in North Africa.

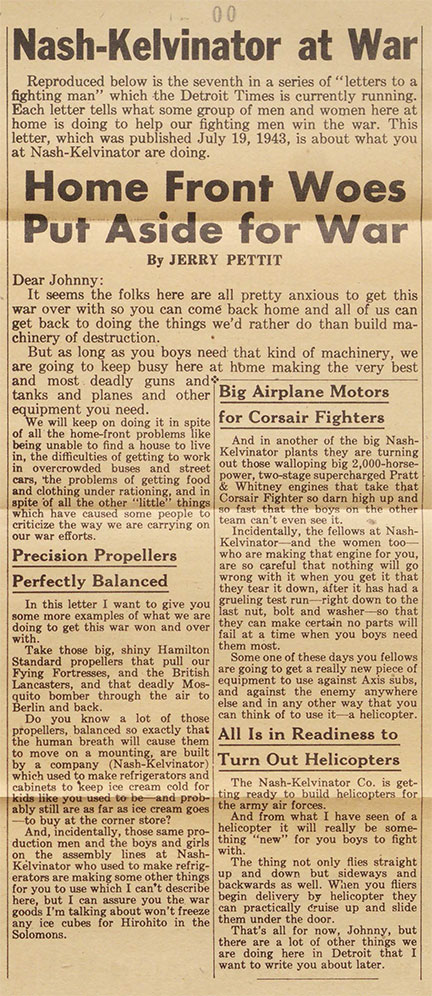

This article from the Detroit Times is

misleading in the section entitled "Precision Propellers Perfectly

Balanced". While I appreciate the author honoring the work my

grandfather did in assuring that the propellers were properly balanced,

it should be noted that Nash-Kelvinator both before and after World War

Two had no operations in Lansing. Therefore, the production men and women in

the Lansing plants did not previously build refrigerators. Because

of this, employees at the Lansing plants were all hired specifically for

war production. My grandfather

came from the Fisher Body plant to help out, and then returned there

when the war was over.

World War Two Aircraft with Lansing-built

Nash-Kelvinator Propellers:

The Boeing B-17 has become one of the most

famous bombers of World War Two, if not the most famous of those in US

service during the war. With over 12,000 built, Nash-Kelvinator

was one of two automakers to supply propellers for this aircraft.

Author's photo.

The Consolidated B-24 was the most widely produced American bomber of World War

Two, with over 18,000 being built in five plants across the country.

Lansing-built propellers were supplied to the Ford Willow Run bomber

plant in southeast Michigan for this aircraft as noted above. Author's photo.

The North American B-25 Mitchell medium bomber. Author's photo.

A rare Douglas A-20 Havoc twin engine attack aircraft. Author's

photo.

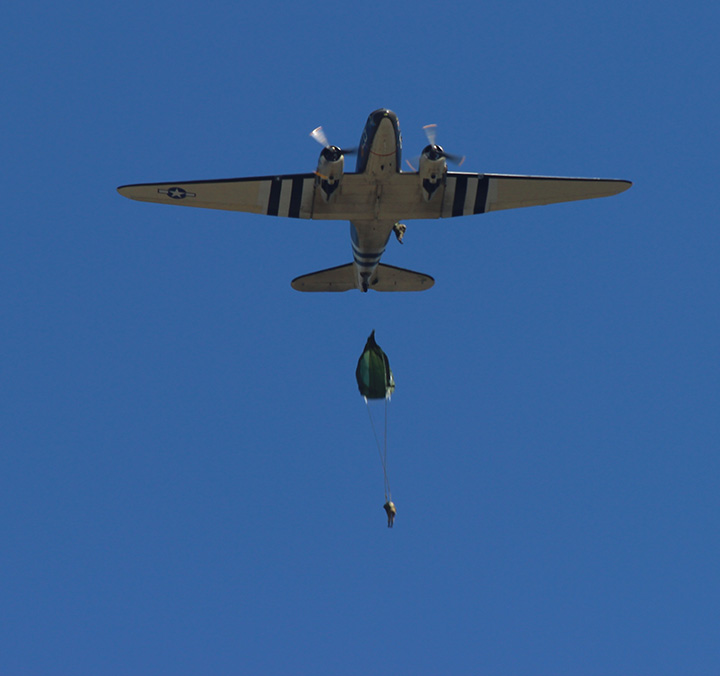

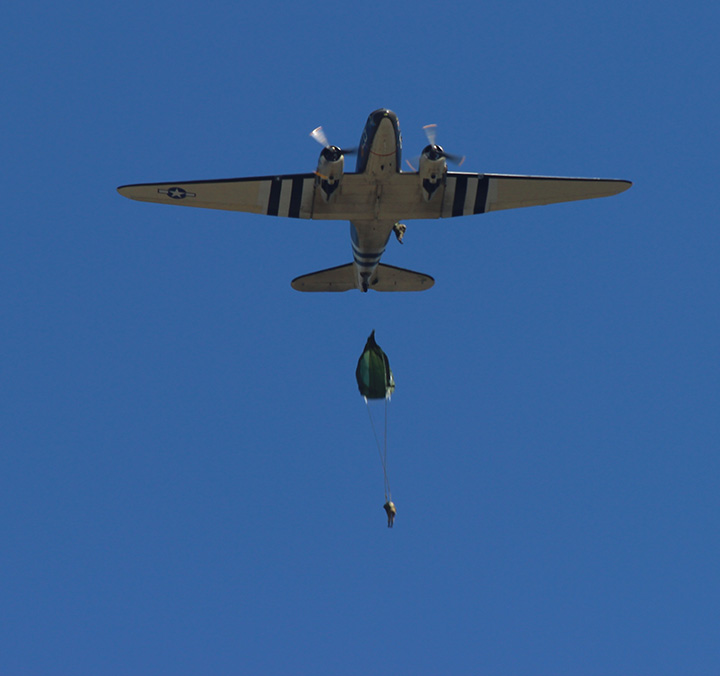

The Douglas C-47 was equipped with Lansing Nash-Kelvinator-produced

propellers. Author's photo.

Early on the morning of June 6, 1944, C-47s like this one, along with

C-53s, pulled through the air by Lansing-built Nash-Kelvinator

propellers, dropped the 82nd and 101st Airborne Divisions into Normandy,

France, to start the D-Day invasion. This C-47, "Tico Belle", is a

Normandy veteran.

Author's photo.

Author's photo.

A close up look at the propellers on a C-47.

Author's photo.

Nash-Kelvinator built the four bladed propellers for the Goodyear

version of the Navy's F4U-4

Corsair, the FG-4, which did not go into production. It is unknown

whether the Lansing-built propellers were diverted to Vought for use on

the F4U-4, like this one pictured here. Author's photo.

Lansing produced propellers for Martin Baltimore bombers, all of which

went to the British under Lend-Lease.

Nash-Kelvinator's original production went to the British for aircraft,

like this Canadian-built Lancaster bomber. Author's photo.

Another British aircraft built in Canada was the DeHavilland Mosquito

shown here, which was also supplied with Lansing-built propellers.

Author's photo.

Other Lansing Companies that contributed

to winning World War Two

|