|

Fisher

Body - Home

Fisher Body Craftsmanship Goes to War

Fisher Body - Craftsmanship

Fisher Body - Aircraft

Fisher Body - Aircraft

Instruments

Fisher Body - Guns

Fisher Body - Tanks

Fisher Body - Miscellaneous

The Plants

Fisher Body WWII Plant Database

Cleveland Plant #1, OH Plant

Cleveland Plant #2, OH Plant

Detroit Aircraft Unit,

Detroit, MI

Detroit Die and Machine Plant

Fleetwood, Detroit, MI Plant

Flint Plant #1, MI Plant

Grand Blanc, MI Tank Arsenal

Grand Rapids, MI Plant

Lansing, MI Plant

Memphis, TN Plant

Ternstedt Manufacturing Division,

Detroit, MI

Grand Blanc Tank Arsenal Built Tanks and Tank Destroyers

Grand Blanc

built M4A2 Sherman Tank Photos

Grand Blanc

Built M4A3 Tank Photos

Grand

Blanc M10 Tank Destroyer Photos

Grand

Rapids Fisher Body Stamping Plant - General Motors Corporation in World

Two

Wyoming, MI

1936-2011

Rest in Peace

Gone but not Forgotten!!!

This page updated

4-8-2020.

The Fisher Body Grand Rapids Plant was

actually in Wyoming, MI south of Grand Rapids. The

building of the plant was announced on December 20, 1935 as a huge

economic holiday present for the area's unemployed workers during

the dark days of the Great Depression. 2,000 employees were hired

in 1936 to operate the punch presses turning out body parts would earn

$40 a week. This was good money in 1935.

The Grand Rapids Fisher Body Stamping Plant won the

Army-Navy "E" for Excellence Award on July 10, 1945.

Fisher Body Grand Rapids

World War Two Production:

(550) 120mm M1 Anti-Aircraft guns - This was the signature war product for

Fisher Body Grand Rapids. It was the sole producer of 120mm M1

Anti-Aircraft gun which entered service with the US Army in the

Philippines in 1945. This weapon was in service with the US Army

from

1944 until 1960. Army National Guard units were the last to use

it, and it was replaced by the Nike missile system.

Fisher Body Grand Rapids also built components

and assemblies for B-25,

B-29, XP-75 aircraft, and M4, M10, M26, M8, M24 tanks. It produced

five inch Naval Gun Breech Housings, (551,772) 155mm HE

Shells, Machine Tools, and 90mm AA Gun parts along with the loaders and

rammers for the 120mm M1 Anti-Aircraft gun. In February 1944

the U.S. Navy requested that Fisher Body fabricate 2,596 M8 tank turrets

that were modified for a 75mm howitzer. These would be mounted on

the LVT(4)-A 75mm Amtrac. The work was originally assigned to

Ternstedt, but do to the high work load at this plant, most of the work

was transferred to Grand Rapids.

The Fisher Body Grand Rapids plant looking

west not long after it was built in 1936. The opening of the plant

generated highly valued jobs for the Grand Rapids area during the middle of the

depression. Buchanan Avenue SW runs north-south along the east side of the plant, and 36th Street is the east-west

road in front of the plant in the far right of the photo. Today, US

131 is just west of the railroad tracks.

Four Fisher Body Grand Rapids-built 120mm

anti-aircraft guns all firing at the same time. Photo added

5-8-2020.

The signature WWII product for Fisher Body Grand Rapids was the 120mm M1

anti-aircraft gun. In this photo fifteen of the 550 guns the

plant built await shipment. Photo added 5-14-2018.

The huge outrigger base is being machined in

three locations. Photo added 5-22-2018.

The 120mm gun barrel is being installed on

the gun. Note the outrigger base has had the outrigger arms

installed, and there has been a large amount of installation of other

parts in preparation for adding the barrel. Photo added 5-22-2018.

Fisher Body did more that just build the 120mm guns from prints.

It designed the automatic loader and rammer which operated in any angle

of elevation. Photo added 5-22-2018.

After the barrel was installed there was more work to complete the gun.

Photo added 5-22-2018.

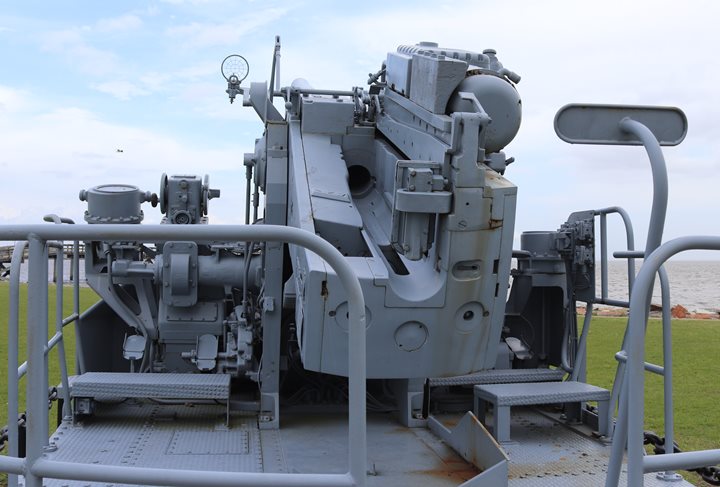

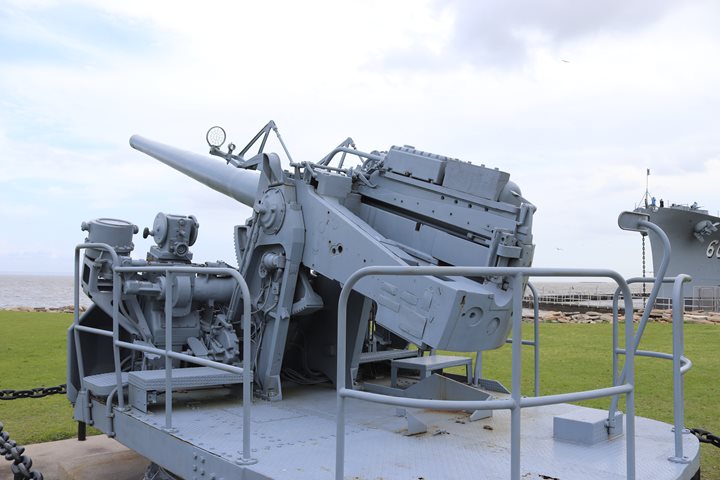

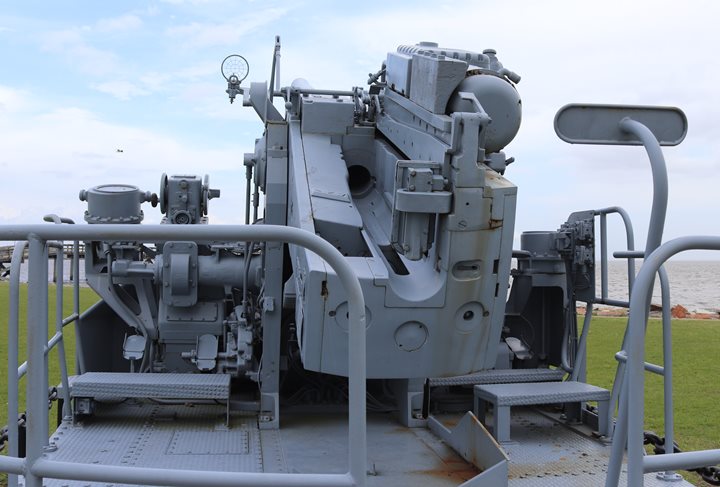

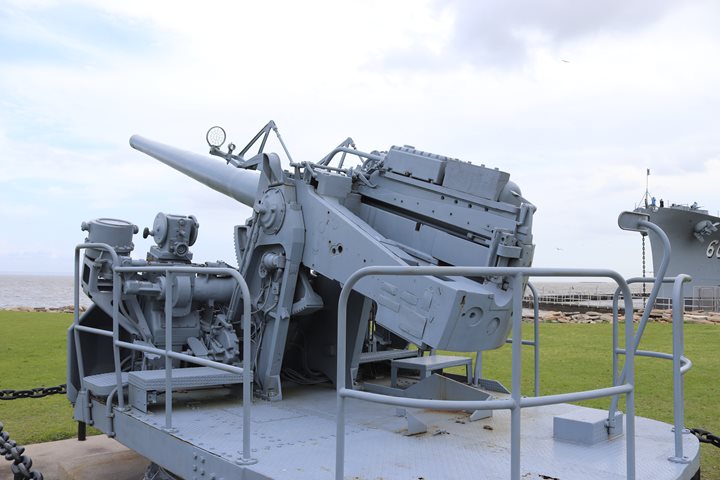

This is one of the few surviving 120mm M1

anti-aircraft guns of the 550 built by Fisher Body Grand Rapids during

WWII. It is on display at the USS Alabama in Mobile, AL.

Author's photo added 3-20-2018.

The M1120mm anti-aircraft gun was the

signature weapon produced by Fisher Body Grand Rapids Stamping Plant in

WWII. Author's photo added 3-20-2018.

Author's photo added 3-20-2018.

Author's photo added 3-20-2018.

Author's photo added 3-20-2018.

Author's photo added 3-20-2018.

Author's photo added 3-20-2018.

Author's photo added 3-20-2018.

Author's photo added 3-20-2018.

Author's photo added 3-20-2018.

One of the last known uses for the Fisher Body

Grand Rapids built M1 120mm anti-aircraft gun was at the Hanford

Engineering Works plutonium production reactor complex along the

Columbia River in Washington. In the early 1950s, 16 batteries of

four M1 anti-aircraft guns were set up around the facility as the Cold

War heated up. 5,000 soldiers of the 501st, 518th, and 519th AAA

Battalions manned the 64 M1a against an air attack from the Soviet

Union. In 1955 the M1s were phased out and replaced by Nike Ajax

anti-aircraft missiles.

The following table shows the increased use

LVTs and LVT(A)a as they became more available during the U.S. Navy's

campaign during World War Two in the Central Pacific. LVTs were

utilized at Guadalcanal for the transport of supplies to the island, not

in the initial assault waves. As the war continued the LVTs became

very important where the islands had coral atolls that prevented the

36-foot wooden landing craft such as the LCP(L)s, LCVs, LCP(R)s and

LCVPs from crossing. Even with their low draft, the landing craft

would get hung up on the atolls. The LVTs with their tracks could

cross over the reef. A shuttle system was instituted where the

wooden landing craft would bring marines and soldiers from the troop

transports to the atoll. There the marines and soldiers would

transfer to the LVTs which would then take them to the beach.

Transfer of the troops at the reef called for previous training by all

involved to safely and efficiently make the troop transfer. Add a

heavy surf and it became even more a dangerous endeavor than normal.

Neither Iwo Jima nor Okinawa had reefs, but by the end of the war the

LVT had become an important part of the landing assault forces.

The LVT(A)s would lead the troop carrying LVTs into the beach.

|

Number of LVTs

and LVT(A)s used in the assault waves during the Central Pacific

Campaign |

|

Island |

Date |

LVT |

LVT(A) |

|

Guadalcanal |

8-1942 |

0 |

0 |

|

Tarawa |

11-1943 |

87 |

0 |

|

Saipan |

6-1944 |

594 |

138 |

| Guam |

7-1944 |

381 |

75 |

|

Tinian |

7-1944 |

453 |

66 |

|

Peleliu |

9-1944 |

223 |

72 |

| Iwo

Jima |

2-1945 |

380 |

68 |

|

Okinawa |

4-1945 |

872 |

92 |

In 1944 Fisher Body Grand Rapids

fabricated most of 2,596 M8 tank turrets with a 75mm howitzer that were

installed on LVT(A)-4 Amtracs. This LVT(A)-4 is part of the

U.S. Army Armor and Cavalry Collection, Fort Benning, GA. Author's

photo added 12-18-2019.

Author's photo added 12-18-2019.

This give a close-up view of the Fisher Body

Grand Rapids-built turret. Author's photo added 12-18-2019.

Author's photo added 12-18-2019.

This LVT(A)-4 is on display at the American

Heritage Museum in Hudson, MA. Author's photo added 12-18-2019.

Author's photo added 12-18-2019.

Author's photo added 12-18-2019.

Author's photo added 12-18-2019.

Author's photo added 12-18-2019.

-4-75mm-84w-1.jpg)

LVT(A)-4s with Fisher Body Grand Rapids-built 75mm

turrets heading for the Okinawa beachhead on April 1, 1945. Photo

added 9-6-2018.

In April 1944 Army Ordnance requested Fisher

Body to produce 155mm artillery shells. Grand Rapids set up one

mile of conveyor lines for movement of the shells from one operation to

the next. It produced the first 155mm shell in September;

and began production in October, a month ahead of schedule. Fisher

Body Grand Rapids did this after having to purchase new machine tools and

large heat treat furnaces to manufacture the shells. Two 300-ton

presses were needed to shape the noses on the shells. When

production stopped at the end of May 1945, the plant had produced

551,772 shells. 116,937 were produced in May 1945, the peak production

month for Fisher Body Grand Rapids. These two examples are at the

Museum of American Armor on Long Island, NY. Photo courtesy of

Rudy Lev.

Fisher Body Grand Rapids produced naval gun breeches for five-inch, 38 caliber guns like this one. This five- inch gun can be

seen at the USS Sullivans at the Buffalo and Erie County Naval and

Military Park in Buffalo, NY. Author's photo added 11-10-2017.

This is one of four five-inch, 38 caliber

naval guns without the turret armor, also on display at the USS Alabama.

Many non-combat ships had five-inch guns like these for defensive

protection. This allows for an excellent inspection of the weapon. Author's photo added 3-20-2018.

The gun mechanism was a complicated and

precision device consisting of 218 components. The Fisher Body

built breech housing weighed 2,932 pounds and is component in the center

of the gun mechanism with the opening for the five inch round to which

the remaining 217 components were added. Author's photo added 3-20-2018.

Author's photo added

3-20-2018.

Author's photo added 3-20-2018.

Below are weapons and equipment built

by other GM divisions.

Fisher

Body Grand Rapids supplied

components and subassemblies for these weapons.

Fisher Body made components for the B-29

program. Author's photo.

The plant also made parts for the B-25s

produced at the North American B-25 plant in Fairfax, KS. Grand

Rapids, along with many of the other Fisher Body plants, contributed a

large percentage of the airframe components used to build the aircraft.

Author's photo.

Grand Rapids contributed parts for this M4A2

Sherman tank built by the Fisher Body Grand Blanc, MI Tank Arsenal.

Author's photo.

It also manufactured parts for the M4A3

version of the Sherman built at Grand Blanc. Author's photo.

This is a Grand Blanc built M10 tank

destroyer. Grand Rapids furnished parts for this important armored

fighting vehicle. Author's photo.

The M26 Pershing was another of the tanks

built by Grand Blanc that Grand Rapids was involved with.

Author's photo.

The M24 built by Cadillac had Grand Rapids

Fisher Body parts in it. Author's photo.

The end of the Grand Rapids Fisher Body plant.

The author's photos below were taken on February 18, 2017 of what

was in 2001 one of the most efficient plants in the United States.

From 2001 to 2007 General Motors invested $100 million in the plant,

only to close it in 2008, and put 1,480 persons out of a livelyhood.

The plant was razed in 2011.

The view looking east along 36th Street. The only remaining

structure of significance is the walkway over 36th Street from the

parking lot on the north side of the road. It is surprising that

it was not torn down with the rest of the plant.

The structure that held the sign identifying the Grand Rapids Stamping Plant stands next to a "For

sale" sign.

Looking north west from Buchanan Avenue SW.

Looking south west from Buchanan Avenue SW.

Everything is gone.

Well almost everything is gone. This

security gate for incoming and outgoing trucks and the scale to weigh

them is still there. The power sub-station for the plant can be

seen in the far right of the photo.

|

-4-75mm-84w-1.jpg)