|

Allison

Division of General Motors in World War Two

Speedway, IN

(Indianapolis, IN)

1915 - 1993

This page added

2-17-2020.

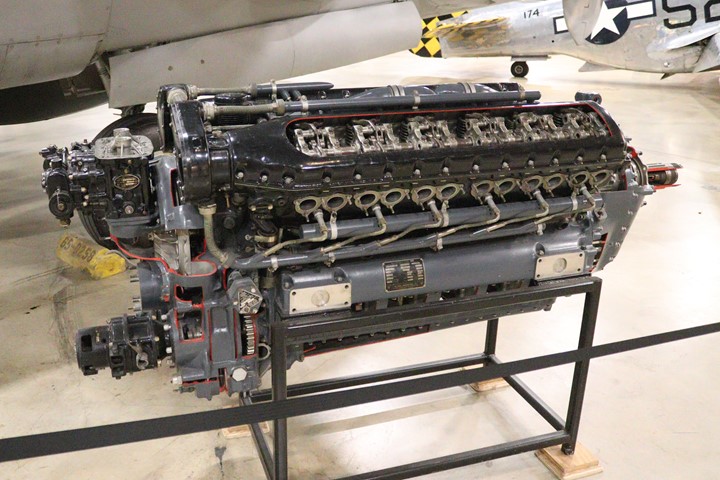

The P-40 was the Army Air Corp's front line

fighter in December 1941 when the United States entered World War Two.

Powered by the Allison V-1710 engine, it held the line against enemy

forces until more modern fighters came off the American assembly lines

and entered the fight. Author's photo.

The majority of the tens of thousands of

American companies producing products to help win World War Two normally had

several types of products that they made. Not so for the

Allison Division of General Motors. It had only one product line of

significance;

V-1710 inline aircraft engines. During the early and dark days of

World War Two, the Allison V-1710 engine powered U.S. Army Air Forces

P-38s, P-39s, and P-40s that held the line against Japanese and German

forces until newer fighters could be produced. The P-40 was

especially important, yet today is overlooked for its significance in

defending the country in the early years of the war. Powered by

the Allison V-1710, the P-40 fought not only with American forces all

around the globe but also with British Commonwealth countries. In

the southwest Pacific, small numbers of the twin-engine P-38 in General

George Kenney's Fifth Air Force took the war to the Japanese. In the

process, the Allison powered P-38 produced the top two American aces of World War Two. The

P-38 had 3,785 and the P-40 had 2,225.5 aerial kills during World War Two, ranking 3rd and 5th respectively

among all American fighter aircraft.

The first modern fighters to enter service

were the P-38s with their twin Allison V-1710-F series engines.

Author's photo.

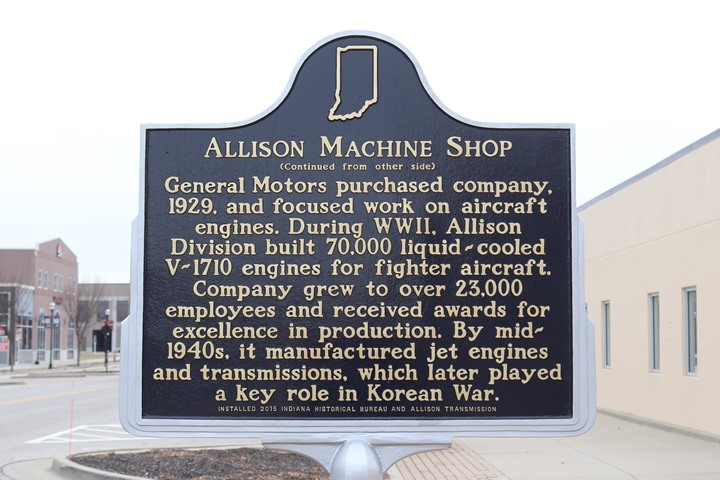

The Allison Division of

General Motors won the Army-Navy "E" Award four times during World War

Two.

The first award was given on November 15, 1942, the second in

February 1943, the third in 1944, and fourth on April 21, 1945.

The Plants:

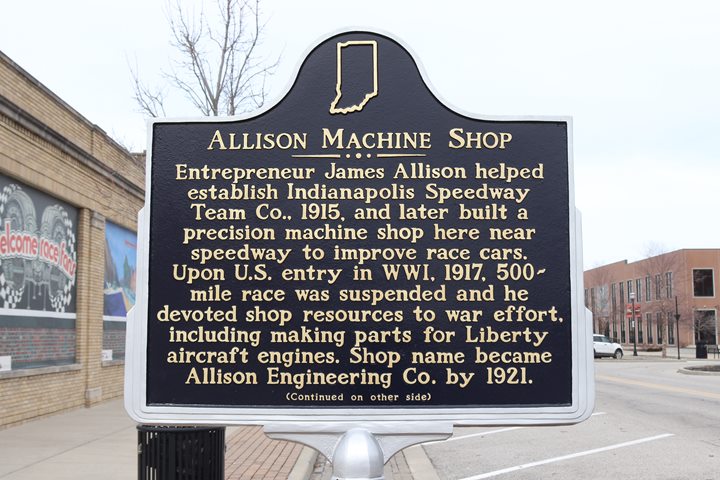

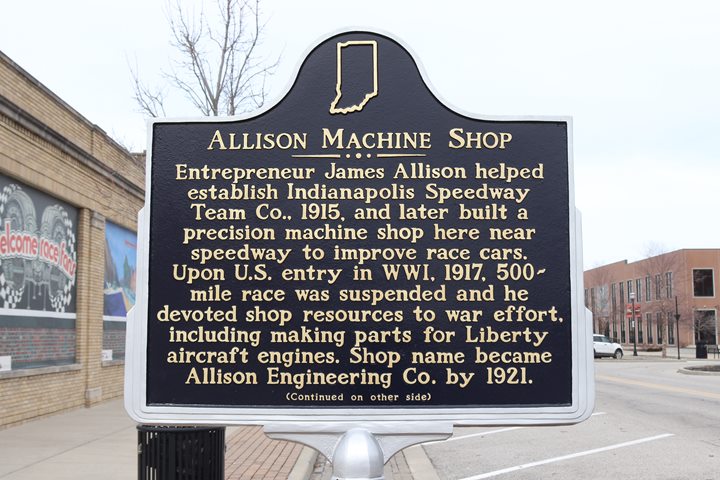

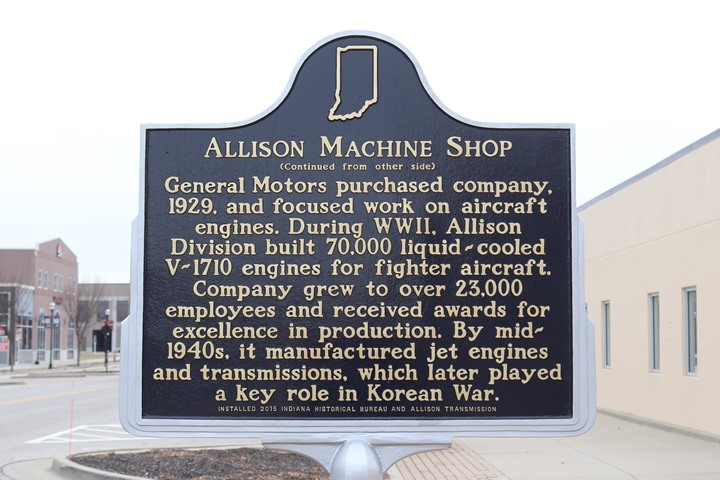

This was Allison Plant One at 1200 Main Street in Speedway, IN.

This building was occupied by James Allison in 1915. He started a

machine shop in the building to the to provide engineering assistance to the

Indianapolis Speedway Team. Allison and several others, as part of

the Indianapolis Speedway Team, had started the nearby speedway, now

known as the Indianapolis Motor Speedway. The location of the plant was

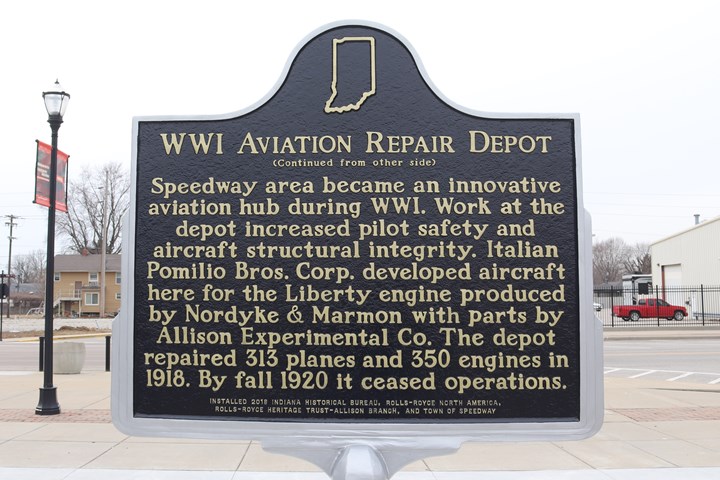

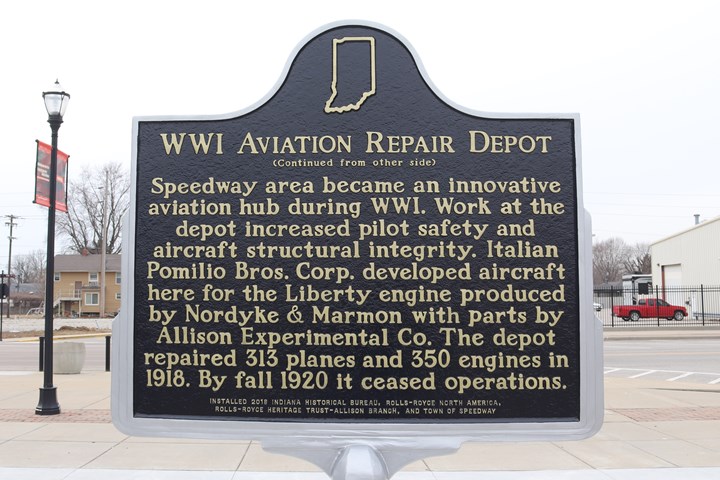

fortuitous. During World War One, the U.S. Army built an aircraft

engine repair deport across the street from this location.

Allison's machine shop was in the right place at the right

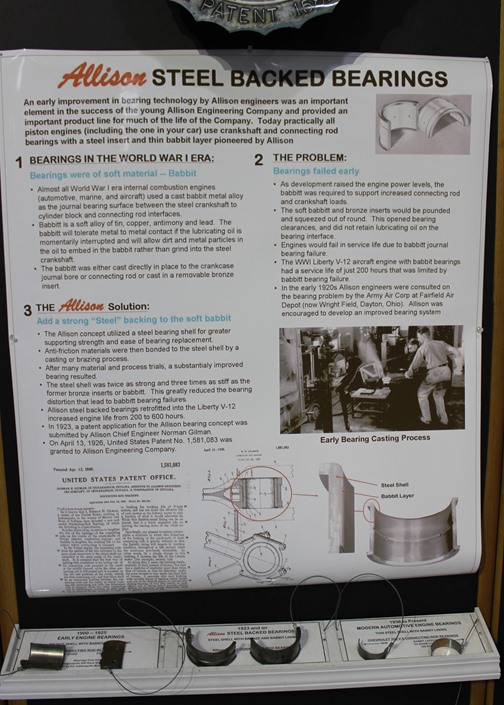

time to provide machine shop assistance. The bearings in the

Liberty engines, that the Depot was repairing, were only lasting 200

hours. Allison developed a new steel-backed bearing to increase

the lifetime of the bearings. Author's photo.

James Allison started a trend that continues

today in Speedway, as there are currently several racing teams building

race cars located along Main Street.

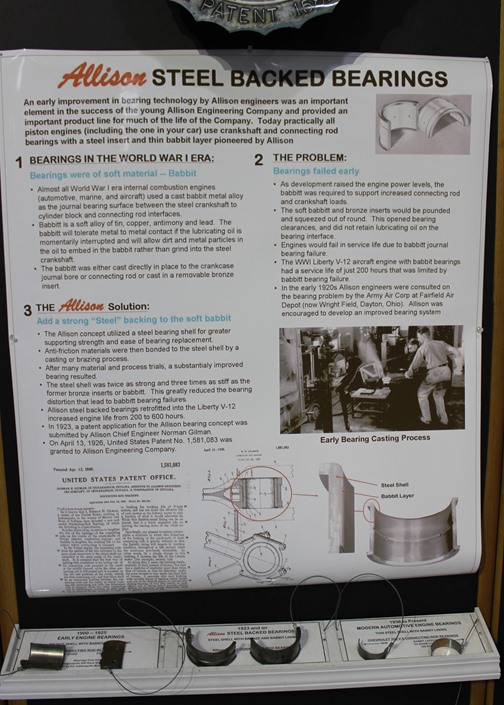

This photo was taken in 2014 at the previous

Rolls-Royce Allison Heritage Center at Plant 5. It explains the

bearing problem and solution. When the Heritage Center moved to

downtown Indianapolis in 2017, this information and many other excellent

historical displays were left behind. Author's photo.

Allison also made parts and rebuilt Liberty

engines in this plant. It was the beginning of aviation engine

development by Allison that led to the manufacture of the World War Two

V-1710 engine. Author's photo.

Author's photo.

Looking northwest in February 2019 along

Main Street in Speedway, IN. Author's photo.

The location of the depot was to the left of

the asphalt walking trail, which used to be a railroad track. The

Depot has direct access to the railroads, which was the primary means of

transportation in World War One. Author's photo.

Author's photo.

Plant 3 is three blocks to the south of 1200

Main Street, and was the main production plant when World War Two began.

The plant expanded three times during the war totaling an added 650,000

square feet. Today it is the main manufacturing plant for Allison

Transmission. The town of Speedway and the Allison name have been

locked together ever since 1915. Author's photo.

More capacity was needed for the production

of the Allison V-1710 engine, and the government erected Plant 5 five

miles to the south of Speedway on South Tibbs Avenue in Indianapolis.

The work on the foundations began in July 1942, and the plant was

completed on November 11, 1942. The complex covered 216 acres and

the buildings enclosed 1,619,000 square feet. The two story

offices building was 101,000 square feet. Author's photo.

| |

Author's photo.

After over 75 years of service Plant 5 is

slowly being taken off-line. One day it will be torn down, and

only a memory of its importance to the winning of World War Two will

remain. During World War Two the parking lots were full of cars, as

23,000 employees worked to produce 70,326 Allison V-1710 engines.

Author's photo.

In 2019 the place looks sort of desolate.

Author's photo.

The one story manufacturing building behind and to the east of the

offices was 960 feet by 1,500 feet with 18 foot overhead clearances.

The manufacturing plant was air-conditioned with no windows. It

had 1,373,000 square feet of manufacturing floor space for the building

of the Allison V-1710. Author's photo.

In 1944 Allison established a test hangar at

Indianapolis Weir Cook Airport (Indianapolis International Airport).

This photo was taken in the early 1950s and has a mixture of propeller

and jet aircraft on the ramp.

|

Allison

built V-1710 engines built during World War Two |

|

Allison Engine Type |

Air Corps Model Number |

Number built |

Applications |

Comments |

|

V-1710-C15 |

|

~2,580 |

(2,550)P-40 ,Consolidated A-11A, Curtiss X/YP-37, XP-40,

P-40, P-40B, P-40C, XP-38, P-322 |

End of Production 8-1941. |

|

V-1710-D2 |

|

44 |

(14)Bell X/YFM-1 Airacudas |

Same as C Model except designed for pusher engines.

October 1940 to September 1941 |

|

V-1710-E19 |

V-1710-85 |

~19,000 |

(9,588) P-39, (3,273) P-63 |

Designed for remote gearbox |

|

V-1710-F |

V-1710-51,

89 |

48,700 |

P-38, P-40, XP-55, P-60, P-51A, A-36 |

|

|

V-1710-F32 |

|

2 |

(2)XP-51J |

|

|

Total |

|

70,326 |

|

|

Another

750 V-1710s were built after World War Two for the F-82.

Allison

built V-1710 P-38 Engine Types

The P-38 had both a right and left turning engine to

cancel out engine torque. On the XP-38, the top of the

propellers turned inward toward the fuselage. On the

rest of the models this was reversed, and the top of the

propellers turned away from the fuselage. |

|

P-38 Model |

Year built |

Number of P-38s built |

Allison Engine Type |

Air Corps Model Number |

Horsepower |

Comments |

| XP-38 |

1938, 1939 first flight |

1 |

V-1710-C15 ??? C-9 |

11

(left), 15 (right) |

1,150 |

|

|

YP-38 |

1940 first flight |

13 |

F-2 |

27(F2R), 29(F2L) |

1,150 |

|

|

P-38 |

6-1941 to 8-1941 |

29 |

F-2 |

27(F2R), 29(F2L) |

1,150 |

|

|

RP-322-I |

1940 |

22 |

F-2 |

|

1,150 |

Cancelled British Order taken over by USAAF -

Non-counter-rotating props |

|

RP-322-II |

1940 |

121 |

F-2 |

27(F2R), 29(F2L) |

1,150 |

Cancelled British Order taken over by USAAF -

Counter-rotating props |

|

P-38D |

8-1941 to 10-1941 |

36 |

F-2 |

27(F2R), 29(F2L) |

1,150 |

|

|

P-38E |

10-41 to 2-1942 |

210 |

F-2 |

27(F2R), 29(F2L) |

1,150 |

|

|

F-4-1 |

1942 |

99 |

F-2 |

27(F2R), 29(F2L) |

1,150 |

|

|

P-38F |

1942 |

527 |

F-5 |

49, 53 |

1,325 |

|

|

F-4A-1 |

1942 |

20 |

F-5 |

49, 53 |

1,325 |

|

|

P-38G |

1942 |

1082 |

F-10 |

51, 55 |

1,325 |

|

|

F-5A |

1942 |

180 |

F-10 |

51, 55 |

1,325 |

|

|

P-38H |

1943 |

601 |

F-17 |

89, 91 |

1,425 |

Due to an insufficient cooling system, the engines were not

allowed operate at more than 1,240 horsepower. |

|

P-38J |

1943 to 1944 |

2,970 |

F-17 |

89, 91 |

1,425 |

Engine cooling system problems solved by moving the

intercoolers from the behind outer wing leading edges to the

engine nacelles. |

|

F-5B |

9-1943 to 10-1943, 12-1943 |

200 |

F-17 |

89, 91 |

1,425 |

|

|

P-38L |

6-1944 to 8-1945 Lockheed

1-1945 to 6-1945 Consolidated |

3,923 |

|

111, 113 |

1,425 |

The 80 P-38M models were conversions of the P-38L.

They were not new production. |

| |

Total P-38s built |

10,034 |

|

|

|

20,068 Allison V-1710 engines were built for the P-38 during

World War Two, not including spares. This was 29% of

the V-1710s built. |

| Allison

built V-1710 P-39 Engine Types |

|

P-39 Model |

Year built |

Number of P-39s built |

Allison Engine Type |

Air Corps Model Number |

Horsepower |

Comments |

| XP-39 |

1939 |

1 |

E2 |

17 |

1,150 |

|

| XP-39B |

1939 |

1 |

E5 |

37 |

1,090 |

|

| YP-39 |

1940 |

13 |

E5 |

37 |

1,090 |

|

| P-39C |

1941 |

20 |

E4 |

35 |

1,150 |

|

| P-400 |

1940-1941 |

675 |

E4 |

35 |

1,150 |

|

| P-39D |

1941 |

60 |

E4 |

35 |

1,150 |

|

| P-39D-1,2 |

1941 |

864 |

E4, E6 |

35, 63 |

1,150, 1,325 |

|

| P-39F |

1941 |

231 |

E4 |

35 |

1,150 |

|

| P-39J |

1942 |

25 |

E12 |

59 |

1,100 |

|

| P-39K |

1942 |

210 |

E6 |

63 |

1,325 |

|

| P-39L |

1942 |

250 |

E6 |

63 |

1,325 |

|

| P-39M |

1942 |

240 |

E8, E18 |

67, 83 |

1,200 |

|

| P-39N |

1942 |

2,095 |

E19 |

85 |

1,200 |

|

| P-39Q |

1942-1944 |

4,905 |

E19 |

85 |

1,200 |

|

| |

Total P-39s built |

9,590 |

|

|

|

9,590 Allison V-1710 engines were built for the P-39 during

World War Two, not including spares. This was 13.6% of

the V-1710s built. |

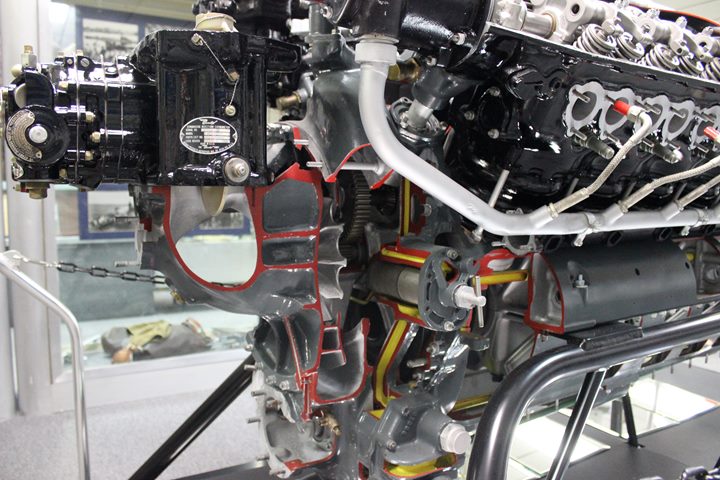

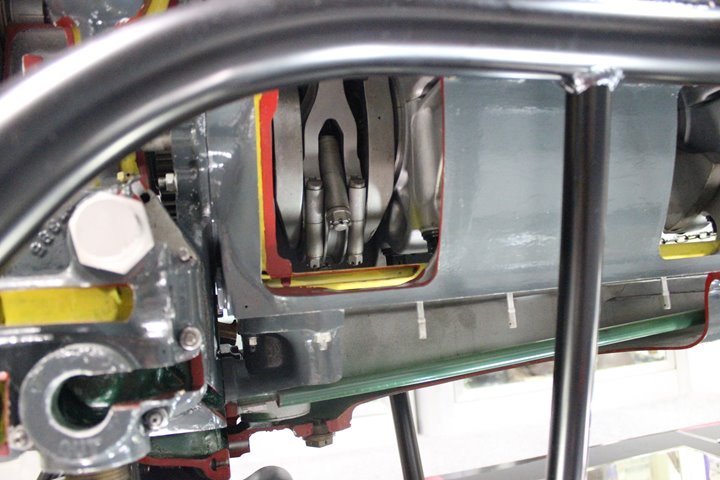

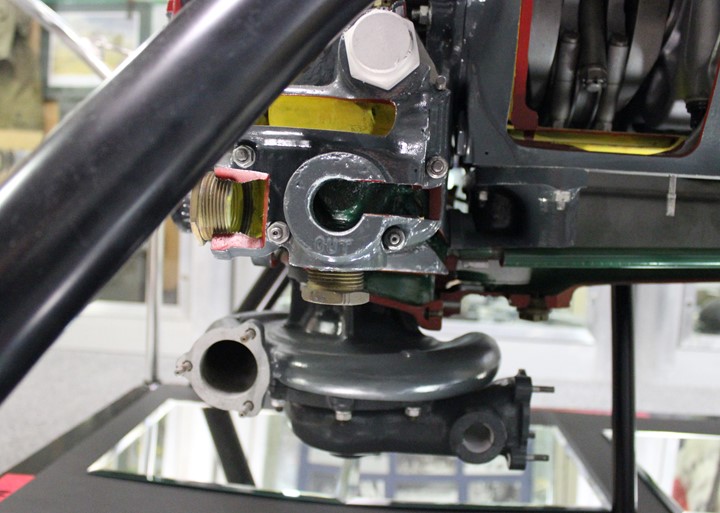

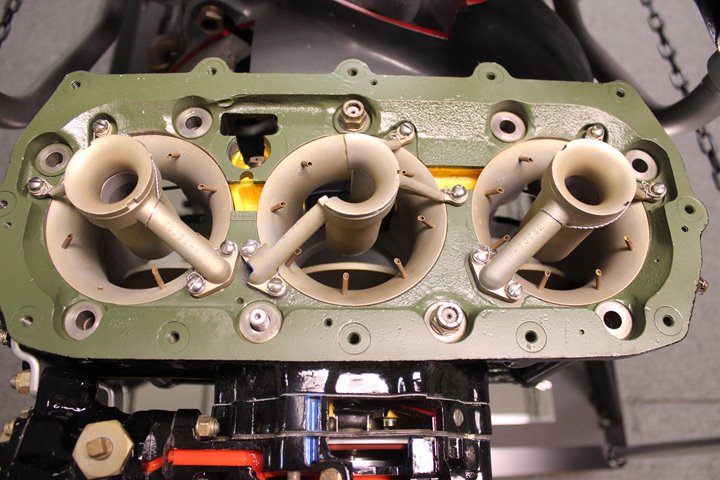

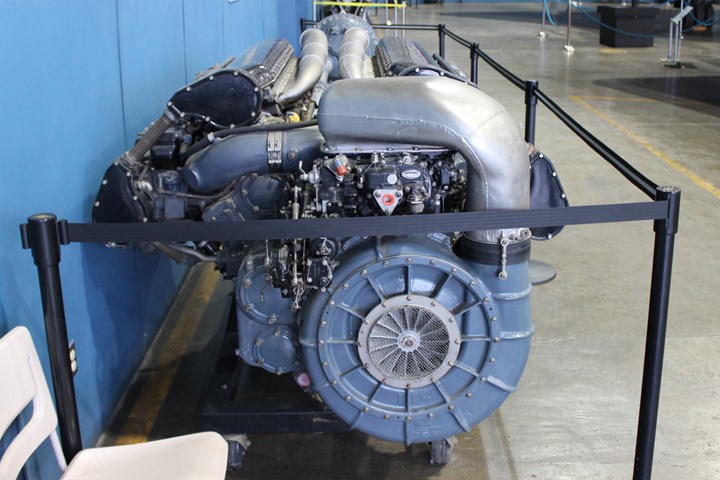

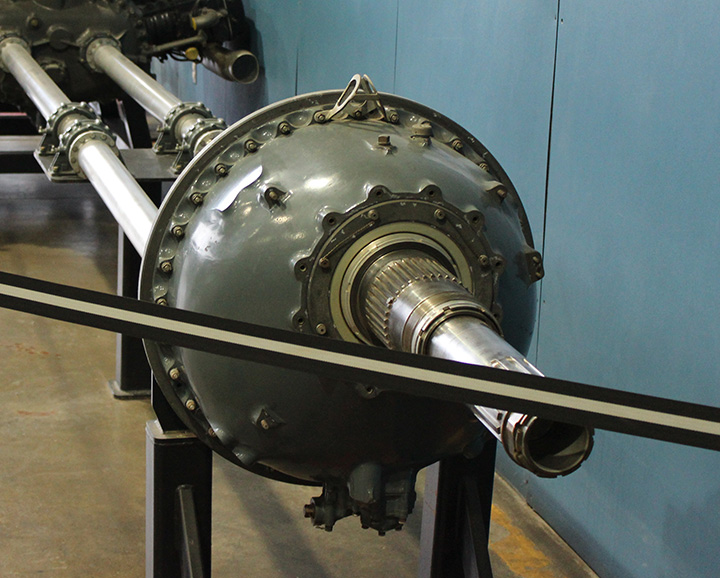

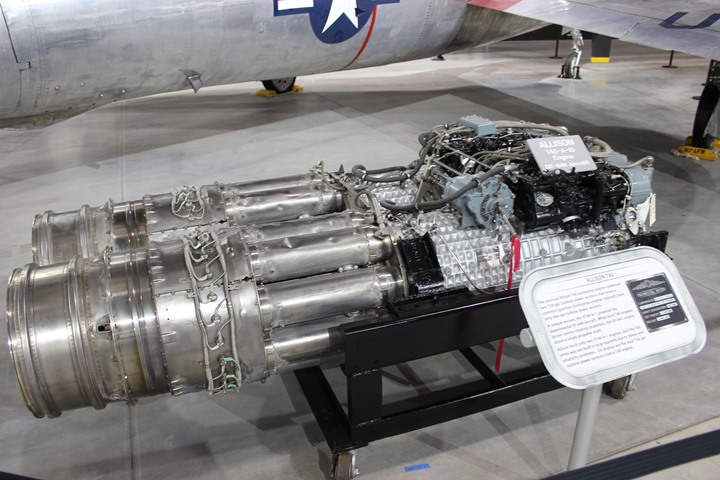

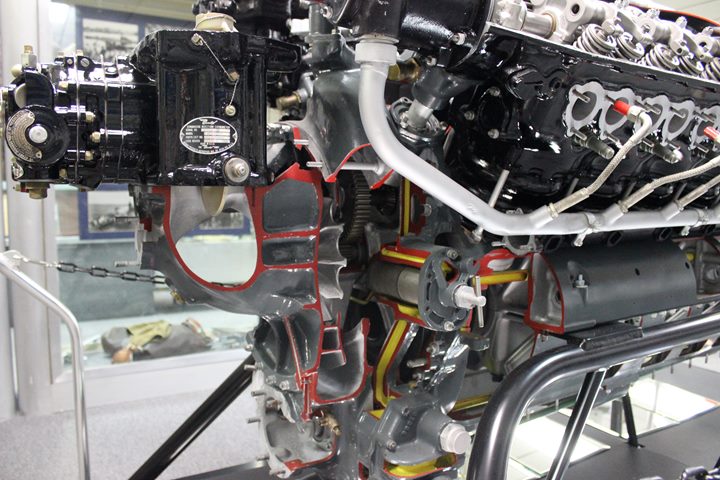

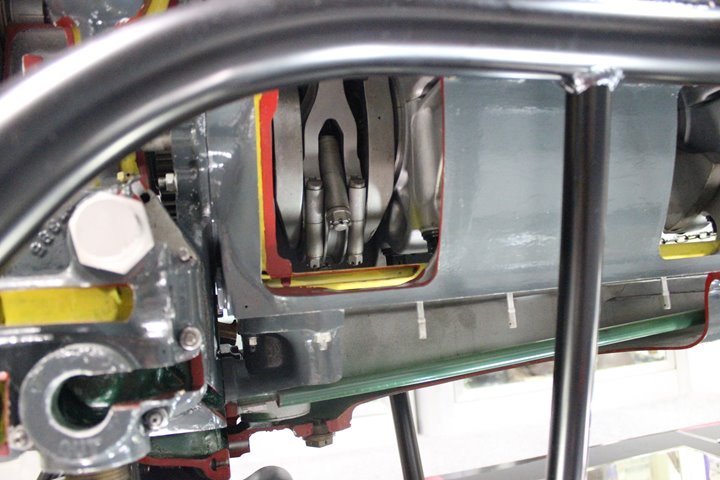

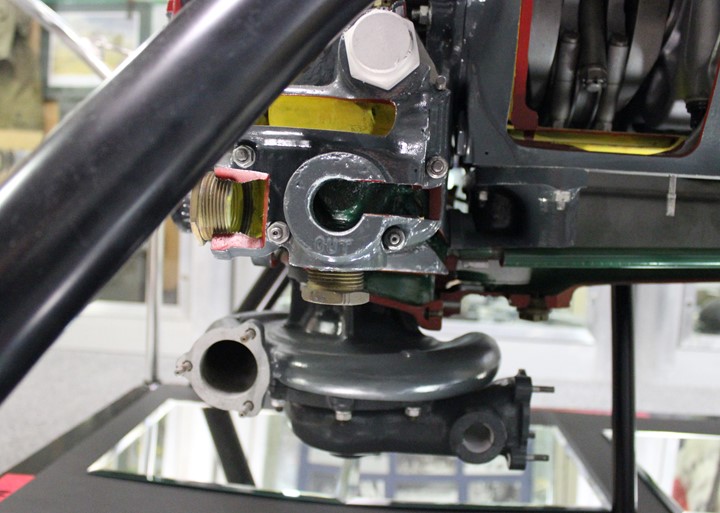

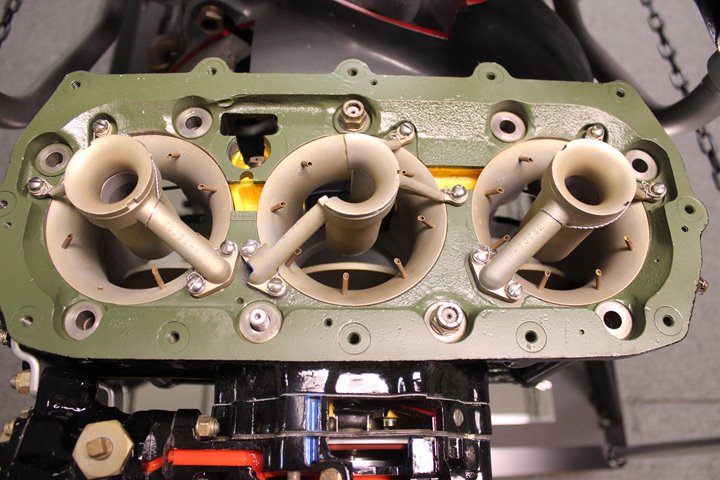

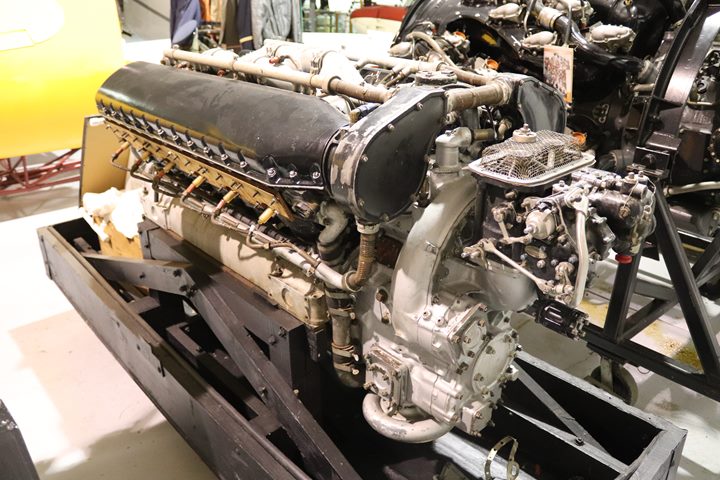

Long nose Allison V-1710 C-15-33 at the Valiant Air Command

Museum in Titusville, FL:

This is an extremely rare example of the V-1710 C-15 as only 2,580

were built. This is also the best display of an Allison V-1710

engine I

have seen at any museum. It is worth the visit to Titusville, FL, to

see this excellent cutaway example of the Allison V-1710. This

type engine was used by the P-40Bs flown by the Flying Tigers.

Author's Note: As of July 23,

2021, this engine display is no longer at the museum. The docent I

talked to about it had no idea what happened to it.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

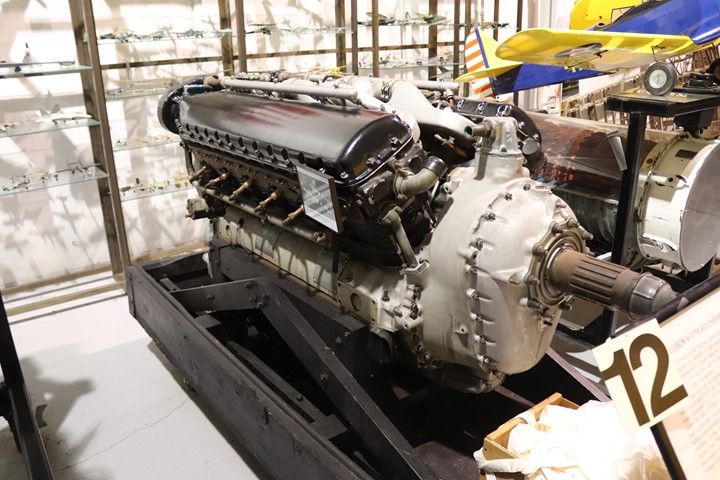

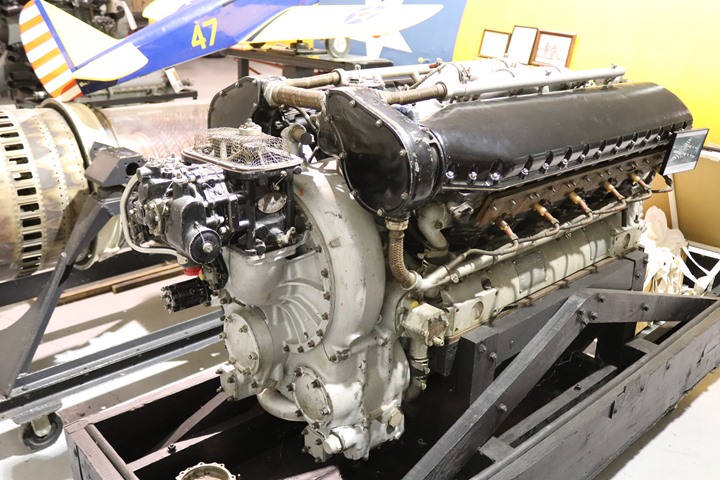

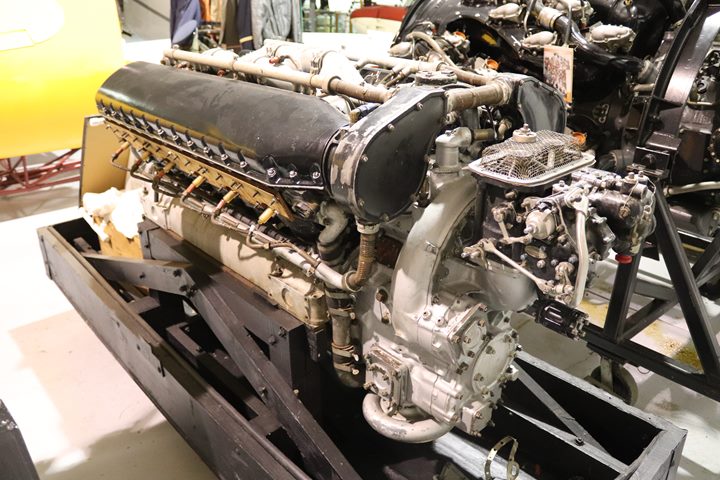

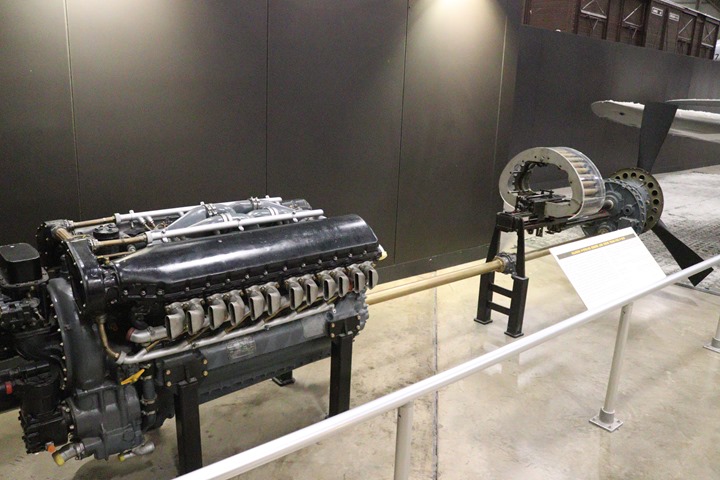

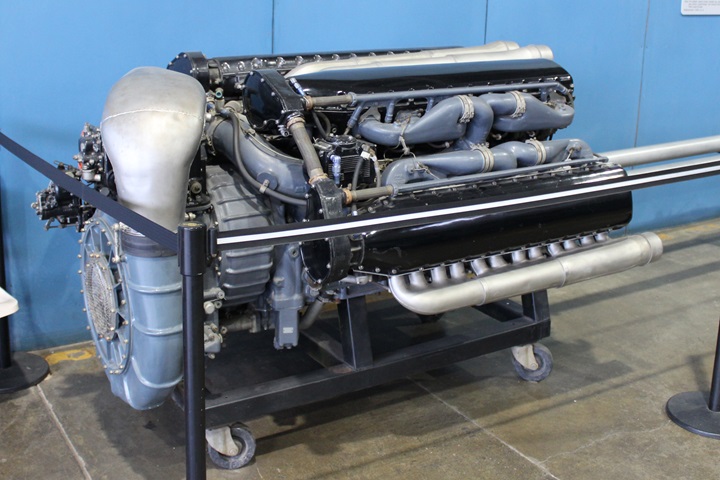

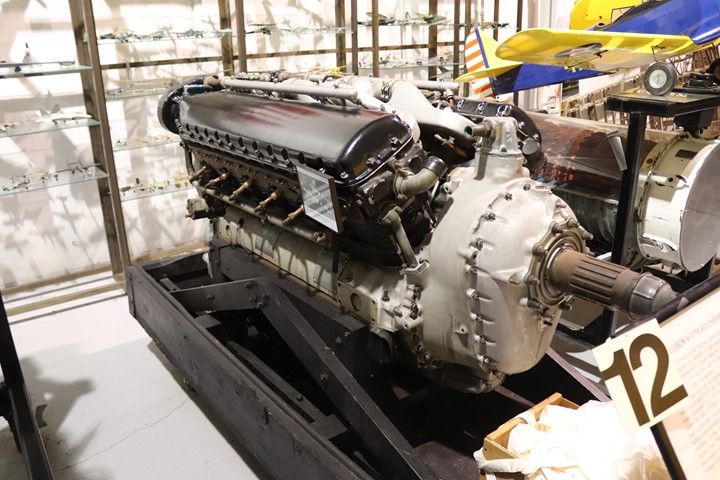

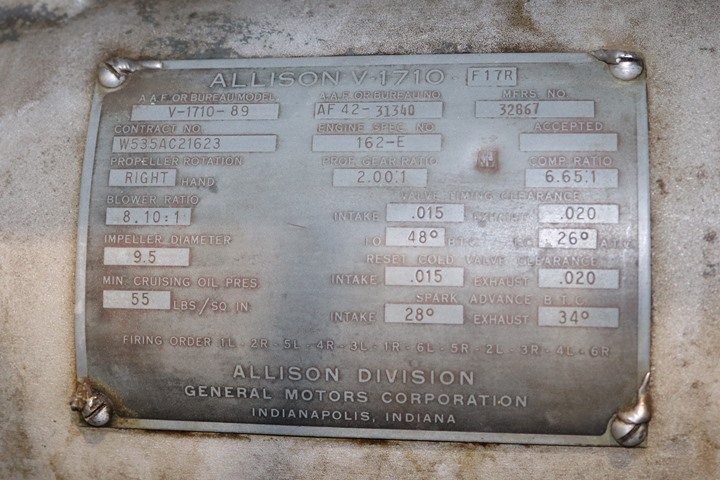

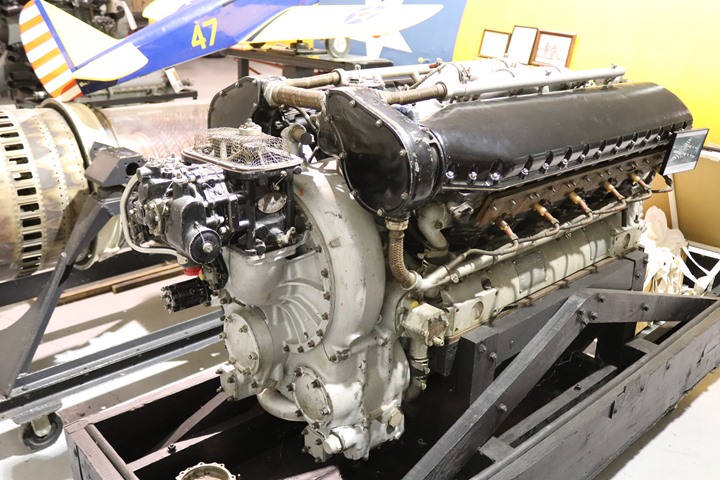

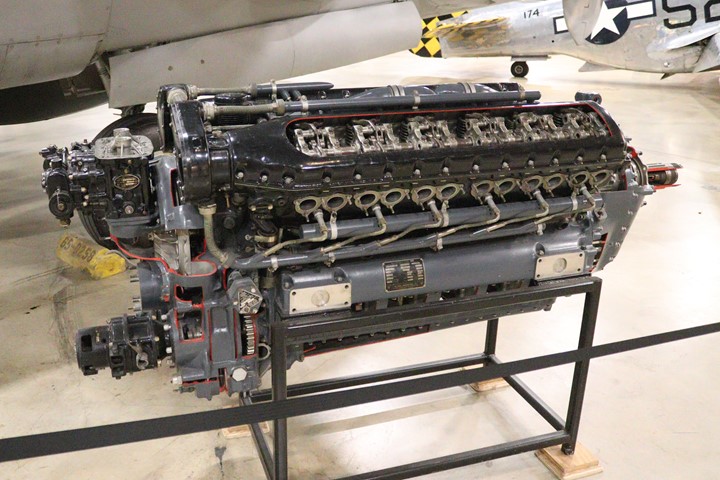

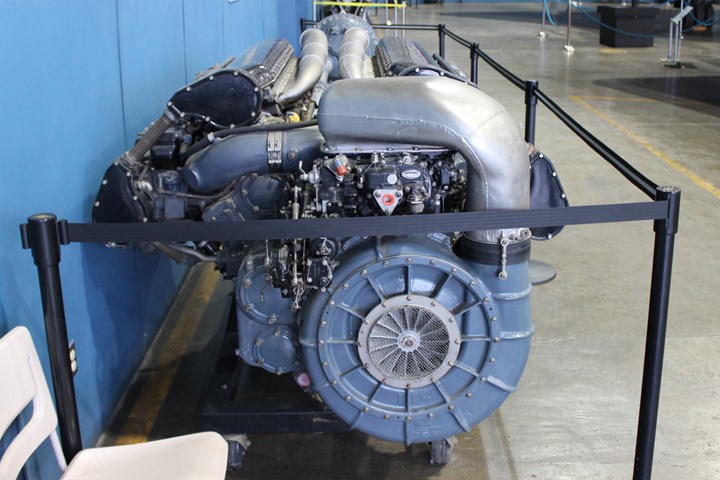

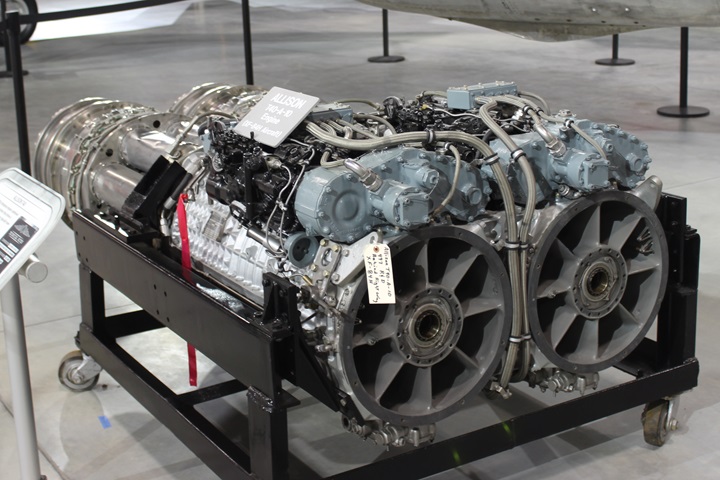

Allison V-1710-17R right hand rotation for

P-38J and P-38L at the Hoosier Air Museum in Auburn, IN:

Author's note: This museum closed in late 2020.

Author's photo.

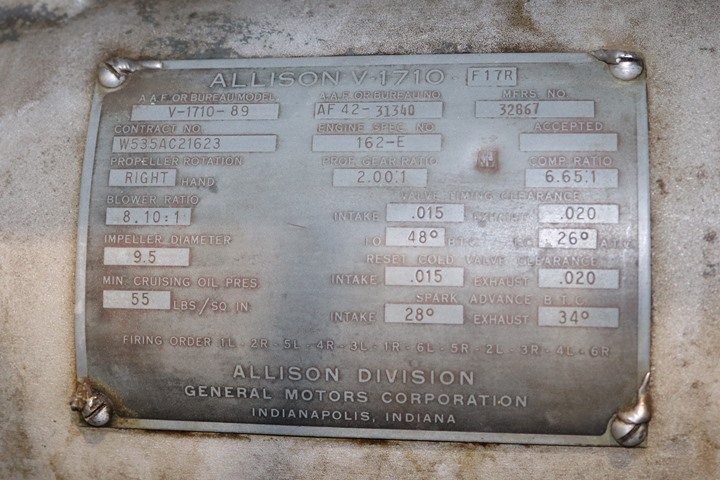

The Allison V-1710-F-17R was the AAF

V-1710-89. Author's photo.

Most of the F models came with a single-stage supercharger, although

some late models had a two-stage supercharger. The P-38 also had a

turbosupercharger connected to this type engine. Author's photo.

Author's photo.

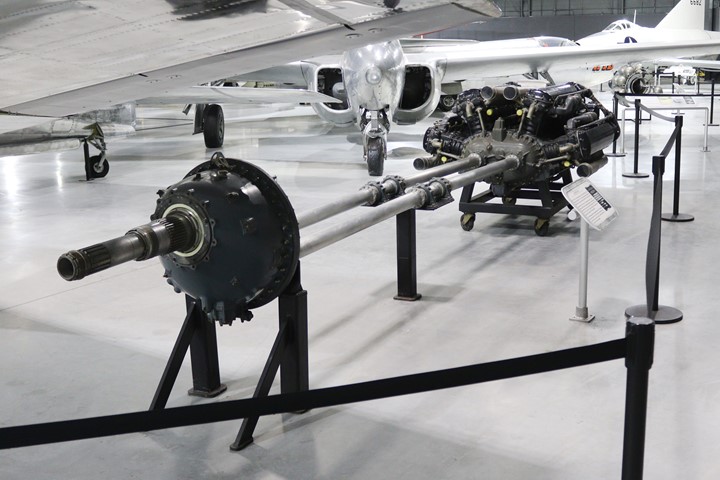

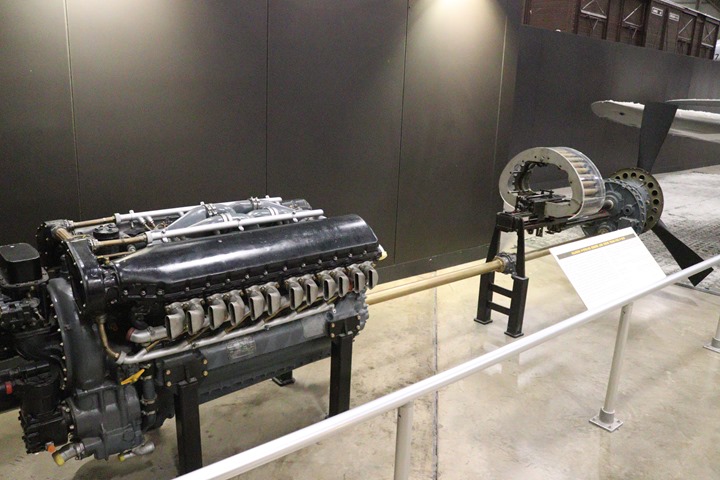

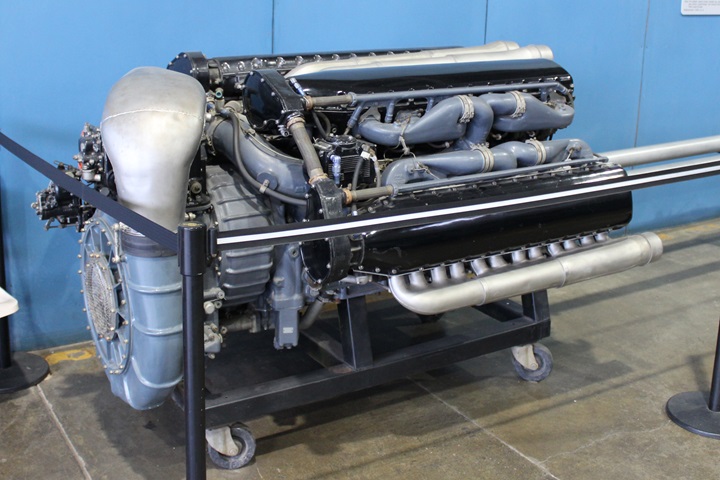

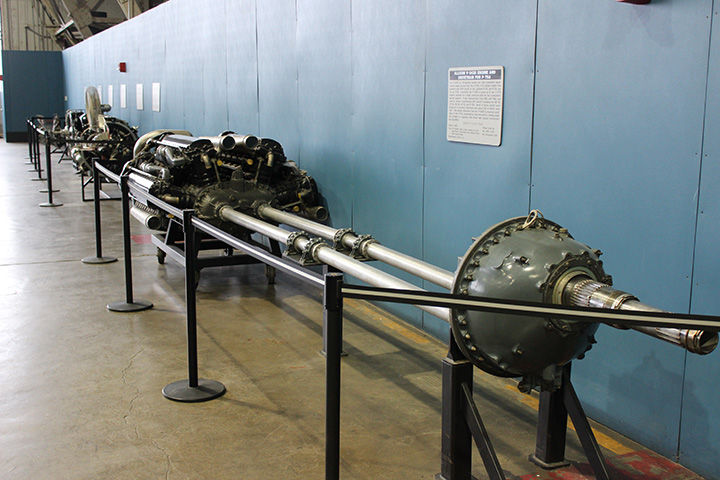

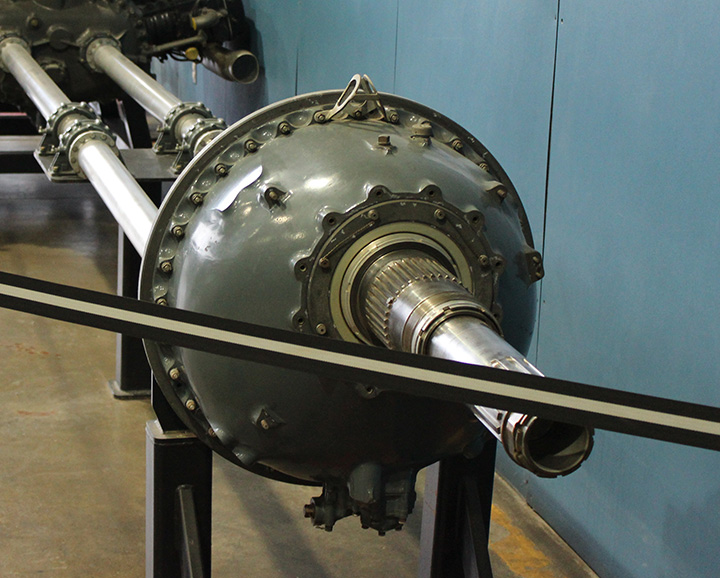

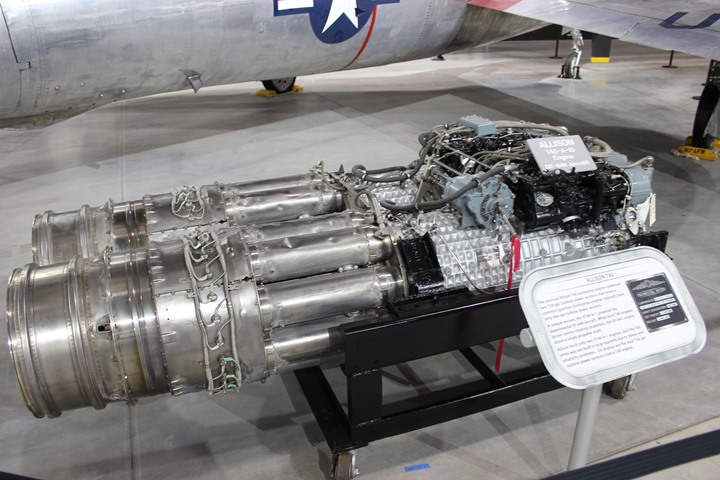

Allison V-1710-10R right hand rotation for

P-38J and P-38L at the National Museum of the USAF, Dayton, OH:

3,923 P-38s were L models. Author's

photo.

Author's photo.

The Allison V-1710-F-10R was the Air Corps V-1710-51. Author's

photo.

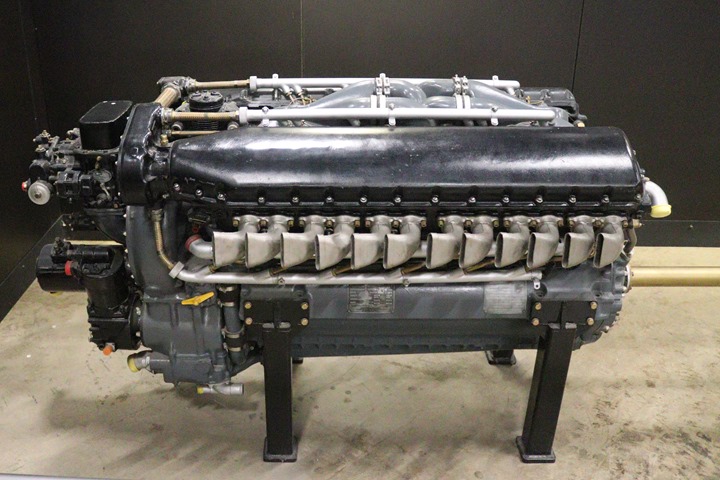

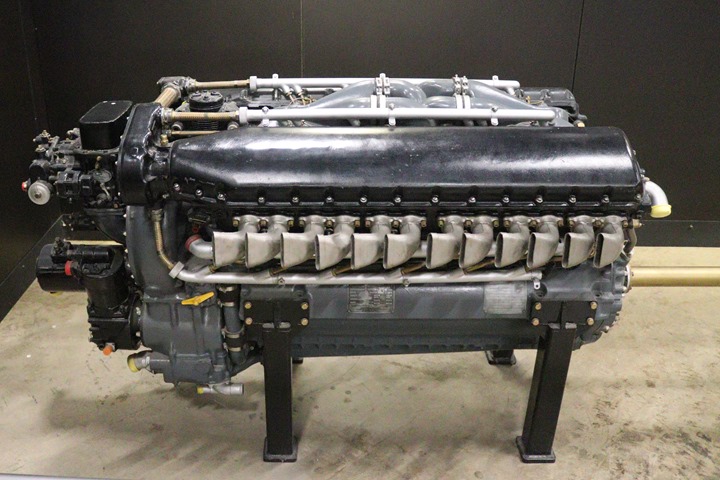

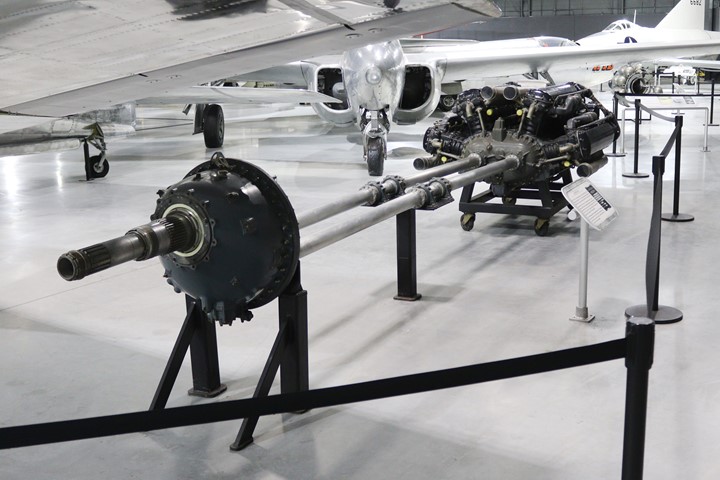

Allison V-1710-E19 for the P-39 and P-63 at the

National Museum of the USAF, Dayton, OH:

Author's photo.

Author's photo.

The Allison V-1710-E19 was the AAF V-1710-85. Author's photo.

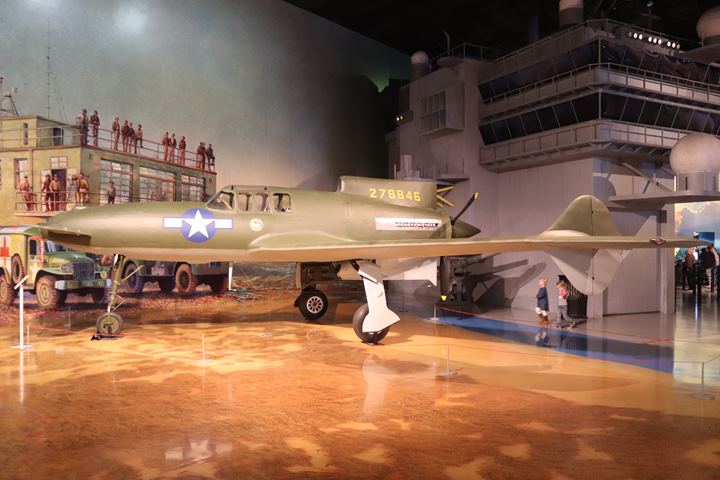

The P-39Q is on display at the Air Zoo

Aerospace and Science Museum, Kalamazoo, MI. Author's photo.

This shows how the Allison V-1710 was

stuffed into the aft fuselage of the P-39. Author's photo.

Various Allison V-1710 engines at the Fantasy of Flight, Polk City, FL:

For years I had heard stories about all of V-1710 engines Kermit

Weeks had in storage at his Fantasy of Flight. In July 2011 I

found out the stories were true.

These Allison V-1710s are located in the

restoration building at Fantasy of Flight. Author's photo

Note that there are two of the rare

V-1710-C-15 long nose engines in the storage racks. Author's

photo.

More Allison engines are in the display

hangar located northwest of the main complex. Author's photo.

Aircraft with Allison V-1710 engines:

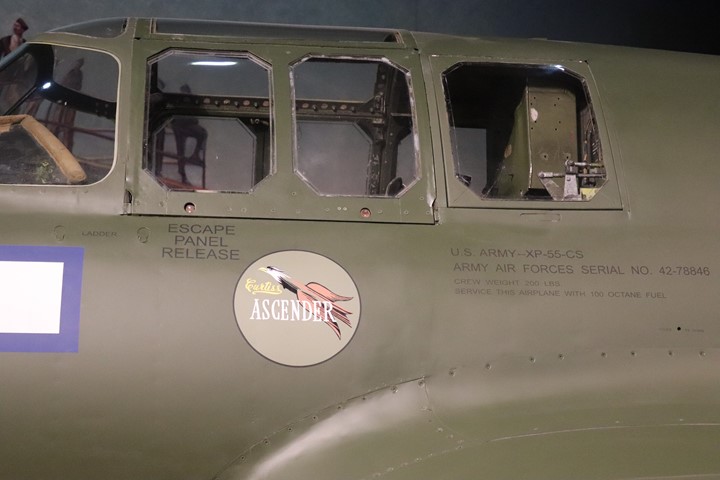

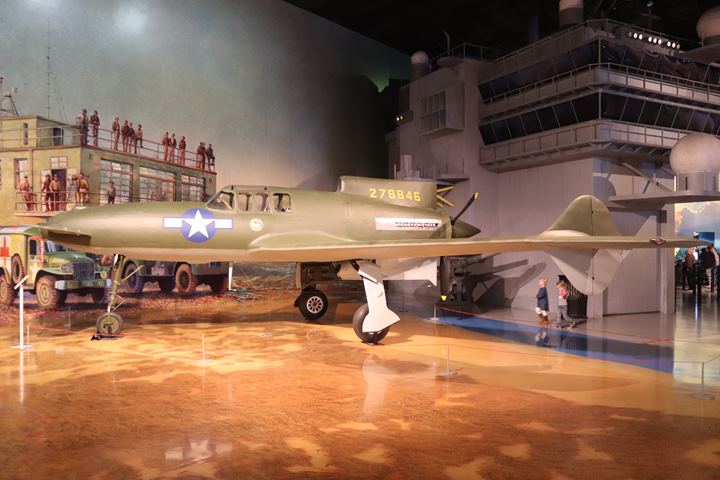

During World War Two there were several

experimental aircraft built with Allison and other

manufacturers' engines. When the one or two experimental

aircraft were rejected for use or production, the experimental aircraft

were scrapped. This is really too bad, as there were some really

cool and interesting aircraft designed and built that never went into

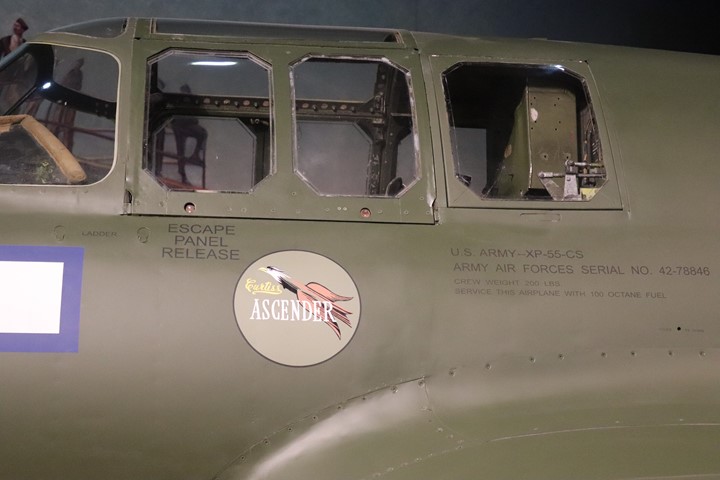

production. However, in the case of the Curtiss XP-55 Ascender,

one still exists. It is on display at the Air Zoo Aerospace and Science

Museum, Kalamazoo, MI. Author's photo.

Author's photo.

The XP-55 was powered by an Allison

V-1710-17 engine. Author's photo.

Author's photo.

The V-1710-87 was used in 500 North American A-36 dive bombers.

Officially named the Mustang by North American Aviation and the USAAF,

it also went by the nickname of Apache and Invader. Author's photo.

The Bell P-63 utilized the Allison

V-1710-E19. Author's photo.

The P-51A was powered by the V-1710-81. Author's photo.

P-38F-5-LO, Army Air Force serial number

42-12652, is the only World War Two P-38 combat veteran that is still

flying today. "White 33" was part of the 475th Fighter Group in

New Guinea, when it lost part of its wing in an air-to-air collision

with a Japanese Zero, on December 29,1943. Its twin Allison V-1710

engines brought her home for an emergency landing. The aircraft was

written off, and then buried at end the war. It is now part of the

collection of the National Museum of World War Two Aviation in Colorado

Springs, CO. Author's photo.

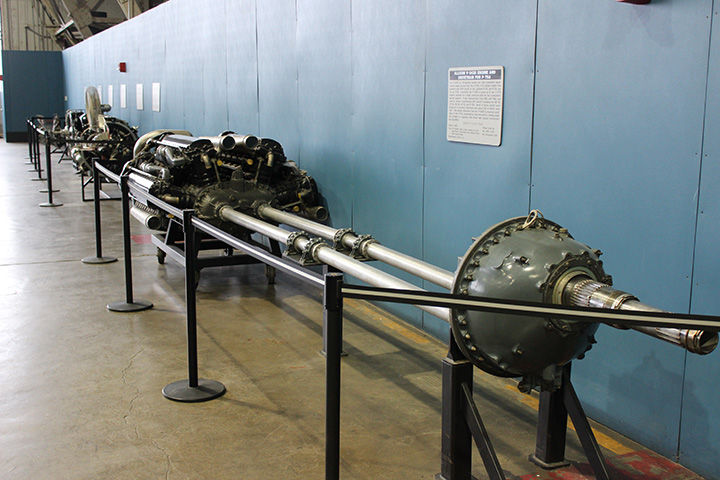

The Allison V-3420 aircraft engine: Allison

built 120 of these engines. Only fourteen were used in the P-75

project which was cancelled on October 6, 1944 for lack of performance.

It was also used in the

XB-19, XP-58, XB-39, and XP-75.

This is one of two V-3420 engines that I

have found so far and been able to photograph. This was photographed in 2014 at the old Rolls-Royce

Heritage Center - Allison Branch. It was not moved in 2017 to the

new venue for the Heritage Center. Author's photo.

The other known V-3420 is at the National

Museum of the United States Air Force. This set of photos was

taken in 2013 in the former annex located in World War Two hangars.

Since that time, the engine has been moved to the new fourth hangar of

the main museum when the annex closed. The lighting in the new

building is not the best for photos, so I will use the 2013 photos which

had better lighting. Sometimes, newer is not better!

Author's photo.

Author's photo.

The engine on display is part of the

drive train for the Fisher XP/P-75. Author's photo.

The old World War Two hangars had glass in

the main door, allowing lots of natural light for the photos.

Author's photo.

Author's photo.

This is the current display at the museum.

The artificial light does not do the display any justice. Proper

lighting is everything in photography. Author's photo.

Author's photo.

The original plan was for Fisher Body to

build 2,500 P-75s in its Cleveland plant number 2. The P-75 was

never the performer it was planned to be, and only fourteen XP-75s were

built. This is the only survivor. Author's photo.

Author's photo.

Allison and Fisher Body installed four

Allison V-3420 engines on a B-29. The new configuration was the

XB-39.

Post WWII Aviation Engines: Since

World War Two,

Allison has built numerous jet and turbine powered engines for all sorts of applications.

The

former Allison Division of General Motors, now part of the Central Indiana

Rolls-Royce operation since 1995, builds, the lift fan for the

F-35B Lightning II among other products,. Below are a few examples of early post World

War Two aircraft with Allison built engines.

750 V-1710-143 or 145 engines, depending on

rotation, were built for the 250 F-82 Twin Mustangs that were powered by

the Allison Engine. Interestingly, while this F-82 is painted to look

like an Allison powered F-82G, it is actually a F-82B which had Packard

Rolls-Royce Merlin engines in it. Author's photo.

J33 Engine: The Allison J33 is

the production version of the GE J31, which was developed during World

War Two. Both GE and Westinghouse were given contracts for the

development of jet engines, because they both built steam turbines, and

the military thought the technologies were similar. Also, the

military did not allow existing aviation engine manufacturers to work on

them, so all resources could be applied to building current products for

the war effort. After the war, Allison purchased Plant 5 from the

government. With its World War Two expertise, Allison began producing the J33

engine with experienced engineers and workers. The engine had

several applications, among them several experimental aircraft.

Author's note: Unless noted, the series

of photos below were taken at the National Museum of the United States

Air Force in Dayton, OH.

A cut-away of the Allison J33 is on display at

the Rolls-Royce Heritage Center in downtown Indianapolis, IN.

Author's photo.

The Convair XF-92A was the first jet aircraft to fly with

a Delta wing, and reached a maximum speed of 715 mph with an Allison

built J33 engine. It had a

ceiling of 40,000 feet. Author's photo.

Author's photo.

The P-80R with a modified J33 set the

official world speed record of 623.753 June 19, 1949, returning the speed record to U.S. after 24 years.

The one built had a smaller canopy and shorter wings than the normal

P-80s. Author's photo.

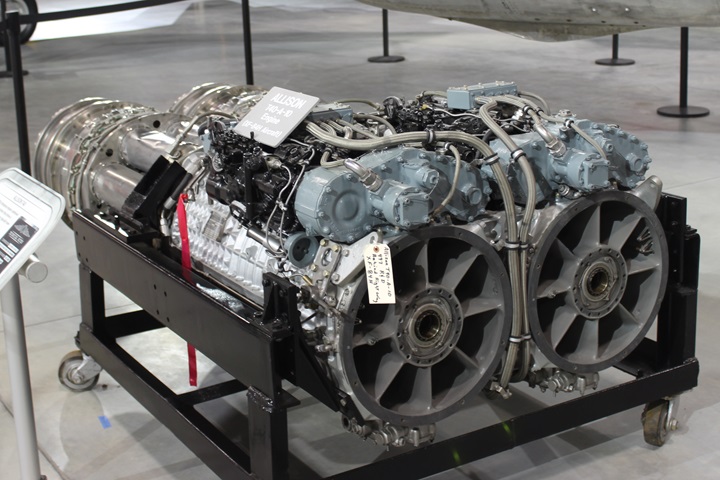

J35 Engine: This was also a GE

design that Allison built. It was the first axial flow engine for

the U.S. military.

A J35-A-17D is nearly identical to the J35-A-17A used on Bell X-5

in the next photo. Author's photo.

The Bell X-5 was the first high performance aircraft with sweepback wings.

They could be swept back 60 degrees. Author's photo.

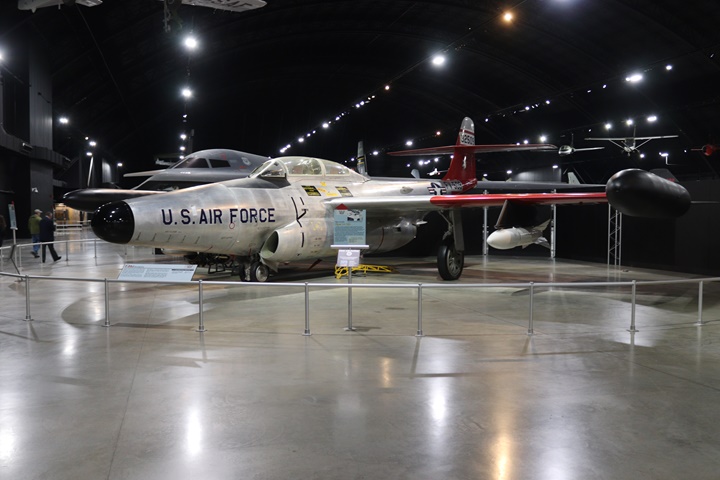

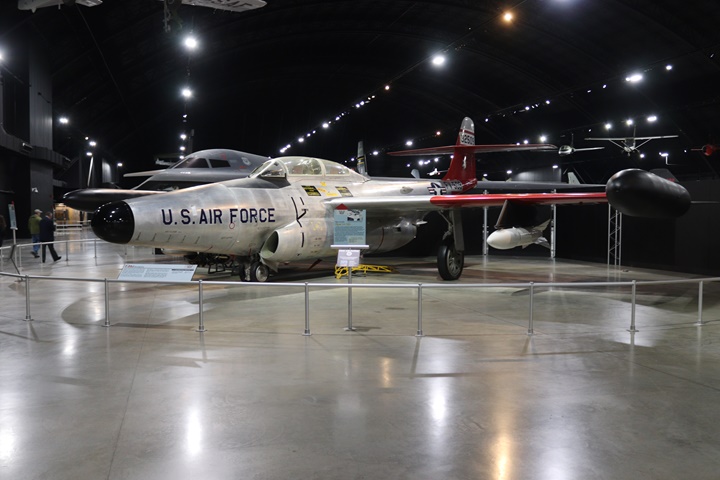

The Northrop

F89J Scorpion was powered by the Allison J35. Author's photo.

The

J35A35A on display was one of 500 built for use in the F89D, J, and H

models. There were 14,000 J35s built. Author's photo.

The J35 also powered the Republic YRF-84F

Ficon experimental "parasite fighter." Author's photo.

T40-X-1 Engine:

Only two T40-X-1s were built for the two

Republic XF-84Hs. The T40-X-1 had two T38 gas turbines stuck

together, driving a single drive shaft. Author's photo.

Author's photo.

The Republic XF-84H has the honor of being

the noisiest aircraft ever built. It would actually make persons

near it sick when running, and could be heard 25 miles away. At

Edwards AFB, it was moved to a remote area for start-ups due to the

obnoxious noise. This is the remaining example of the two built.

Author's photo.

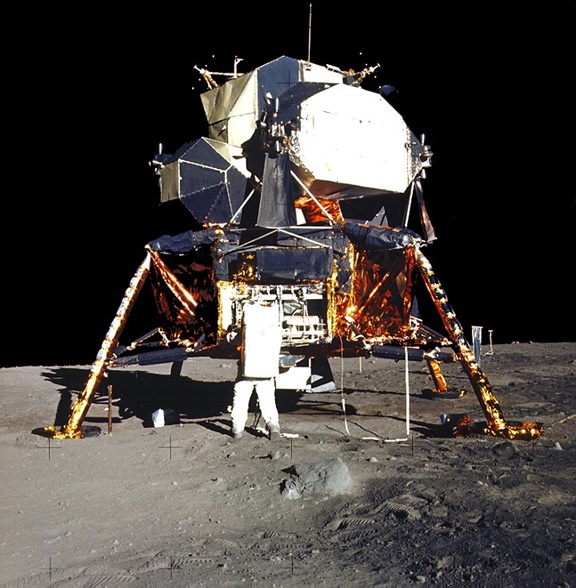

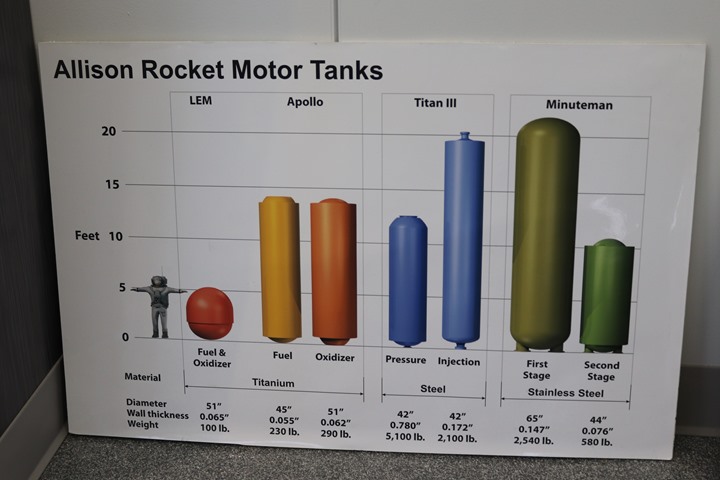

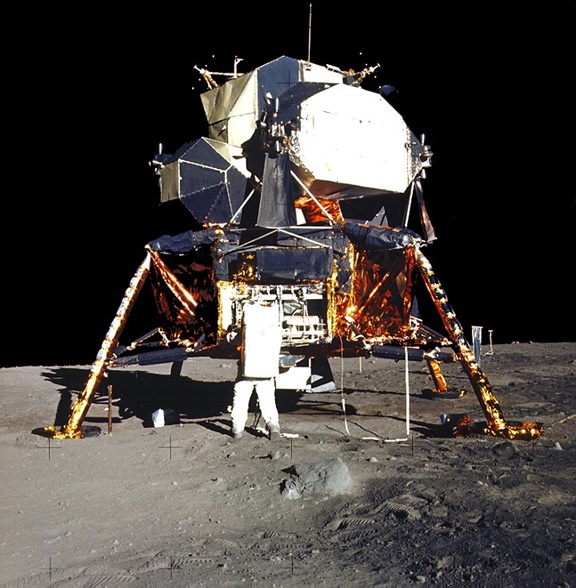

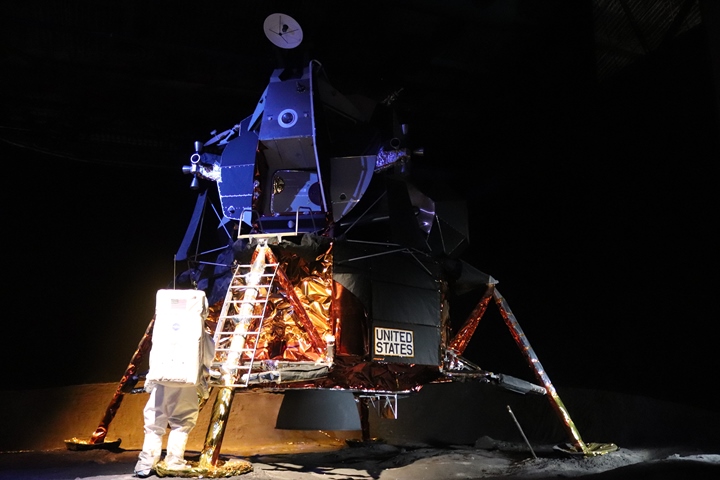

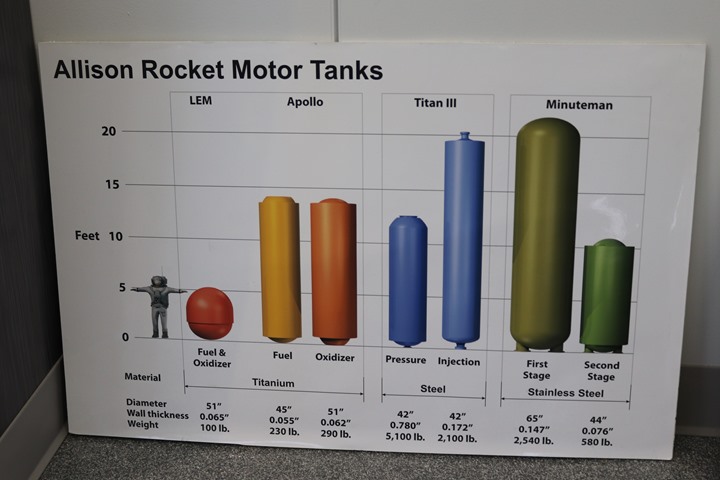

The Space Program: Descent

propellant fuel tanks for moon landing modules and fuel tanks for the

Apollo Service Module.

This photo was taken by Neil Armstrong of

Buzz Aldrin removing the equipment from LM-5 to perform the scientific

experiments on the moon. The fuel tanks that provided the

propellant to land were built by Allison Division of General Motors.

They, along with LM-5, are still on the moon. Photo courtesy of

NASA added 2-17-2020.

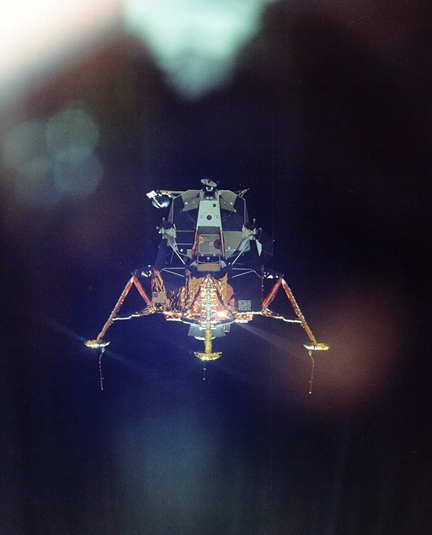

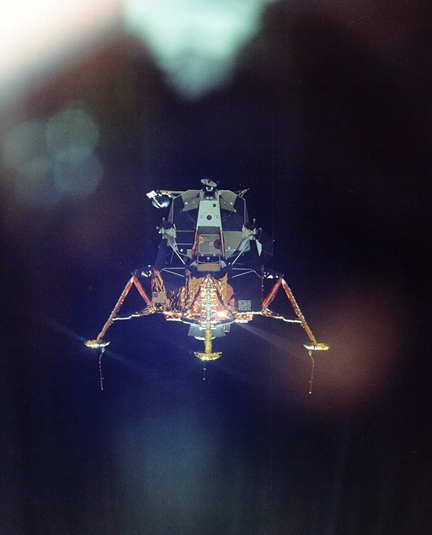

This photo of LM-5 was taken by Michael

Collins from the Command Module after Buzz Aldrin and Dean Armstrong had

launched and were on their way to the moon. Photo courtesy of NASA

added 2-17-2020.

Michael Collins took the above photo from

the windows of the Apollo Command Module "Columbia." Author's

photo added 2-17-2020.

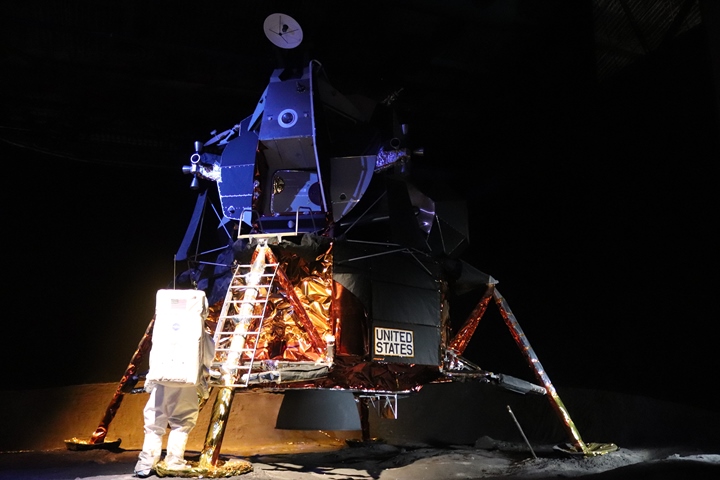

How cool is this? I have been to many

museums, but this display at the Cradle of Aviation Museum on Long

Island, NY is one of my favorites and most remembered. This

diorama of a moon landing with LM-13 is most impressive. Author's

photo added 2-17-2020.

Author's photo added 2-17-2020.

Photo added 2-17-2020.

Allison built 700 fuel tanks for the Titian

III and Minuteman programs. Photo added 2-17-2020.

|

|

|