|

St. Louis

Car Company During World War Two

St. Louis, MO

1887-1974

This page added

3-12-2022.

This LVT-4 was built by the St. Louis Car Company in 1945. It is

the only known existing LVT-4 that has been identified as to which

company manufactured it. Author's photo.

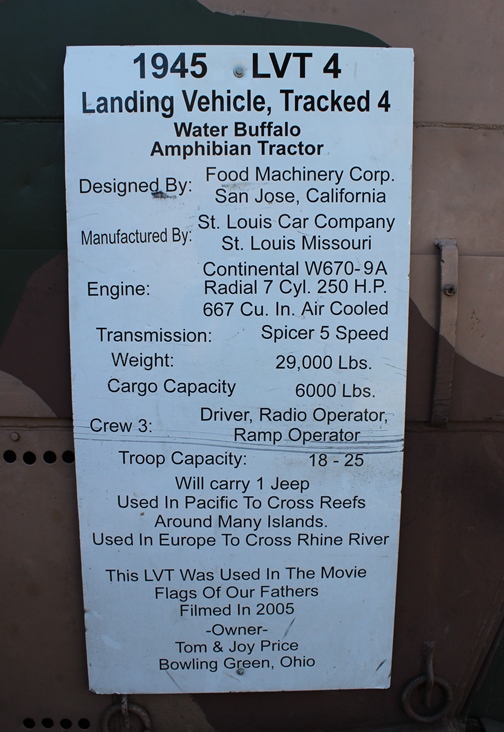

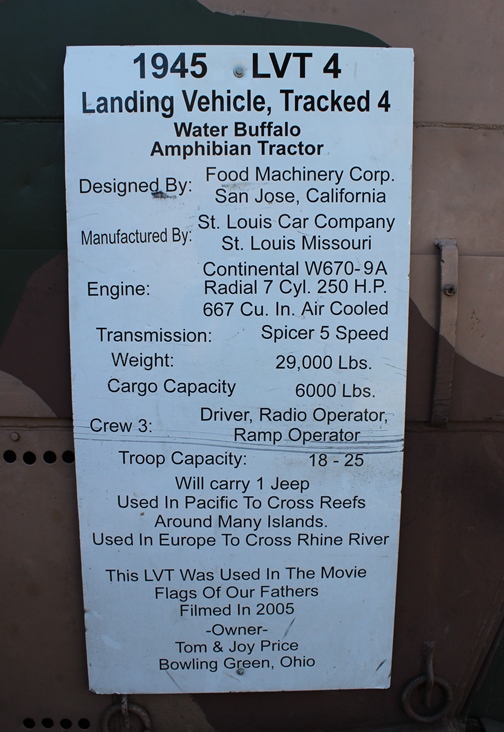

This is the information board that is displayed with the LVT-4 showing

that it was built by the St. Louis Car Company. Author's photo.

The St. Louis Car Company was formed in 1887 to manufacture streetcars

and other rolling stock for the rail industry. During its long

life it also made automobiles, railroad cars, locomotives, and trolley

buses. Its last products before closing were subway cars for New

York City. It also manufactured the passenger capsules that are

used in the St. Louis Arch. I have ridden on one of these along

with my family when we visited the Arch.

Even on an overcast morning, the St. Louis

Arch with its St. Louis Car Company-built passenger capsules can be seen

from the Great Mound at Cahokia, IL. Author's photo.

St. Louis Car Company World War Two Products: Table 1 shows

that the St. Louis Car Company had three major products during World War

Two. They were ammunition cars, landing craft, and electric

generators. Tracked amphibious landing craft was the largest

portion of the company's business during World War Two with $54,470,000

or 79.4% of the total. Generator sets of various types at

$13,378,000 or 19.5% of the total amount contracted was second.

Ammunition cars, which was the company's first major contract that was

awarded in August 1941 was for $745,00 or 1%.

Many of the streetcars and

other rail equipment the company made before and after World War Two

were electrically powered. The manufacture of generator sets for

the war effort was a good fit for this company.

Table 1 - St. Louis Car

Company's Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. |

|

Product |

Contract Amount |

Contract Awarded

|

Completion

Date |

Contract Number |

|

Cars Ammunition |

$745,000 |

8-1941 |

6-1942 |

|

|

Landing Craft |

$2,682,000 |

1-1942 |

10-1942 |

Nos 97599 |

|

Electric Generators |

$781,000 |

8-1942 |

9-1943 |

|

|

Generators |

$641,000 |

9-1942 |

4-1943 |

|

|

Generating Plants |

$3,772,000 |

9-1942 |

9-1943 |

|

|

Landing Craft LVT |

$12,676,000 |

12-1942 |

12-1943 |

NObs 858 |

|

Diesel Generator Units |

$5,807,000 |

11-1943 |

8-1944 |

|

|

Landing Vehicles LVT |

$17,775,000 |

1-1944 |

4-1945 |

NObs 1469 |

|

Landing Vehicles. LVT |

$13,695,000 |

4-1944 |

8-1944 |

NObs 8588 |

|

Landing Vehicles. LVT |

$7,642,000 |

6-1944 |

8-1945 |

NObs 1789 |

|

Diesel Generator Stations |

$2,377,000 |

3-1945 |

10-1945 |

|

|

Total |

$68,593,000 |

|

|

|

St. Louis Car Company built Landing

Vehicles, Tracked (LVT) of several types during World War Two.

Using Tables 1, 3, and 4, it can be determined in some cases how many of each type the

company built.

Contract Nos 97599: Table 1

shows contract number Nos 97599 for landing craft that were built

between January and October 1942. Table 3 shows that the LVT-1 was

the only vehicle of this type built in 1942, indicating that contract

Nos 97599 was for the LVT-1. Table 4 shows that

the average cost of a St. Louis Car Company-built LVT-4

was between $22,000 and $24,050. Using a value of $23,000 for the

cost of an LVT-1 and dividing that into the $2,682,000 for contract Nos

97599 results in 116. Therefore, for the first LVT contract, the

company built approximately 116 LVT-1s. This result is displayed

in Table 2.

Contract NObs 858: The next

contract for landing craft is contract number NObs 858 that was issued

in December 1942 and completed in December 1943. Again, using the

average of $23,000 cost per unit and dividing that into the contracted

amount of $12,676,000 gives a value of 551 units. Table 3 shows

that there were several types of LVTs built in 1943. However, only

the LVT-2 was built in a large enough volume to include the estimated

551 units for which St. Louis Car was contracted. This result is

displayed in Table 2.

Contract NObs 1469: This

contract was for the LVT-4. Using information from Table 4 and

adding 497 and 293 results in 790 total units for this contract.

Dividing 790 into the $17,775,000 total contracted cost gives an average

cost per unit of $22,500, which agrees with one of the two values for

average cost shown for this contract in Table 4. Information from

Table 1 and Table 4 agree.

Contract NObs 8588: For this

contract listed in Table 1, there is not an associated contract number

listed in Table 4. Dividing $23,000 estimated average cost per

unit into the contract value of $13,695,000 yields 795 units. Not

being listed in Table 4 indicates this may have been something other than an

LVT-4. There were several other types of LVTs that were built in

1944. However, St. Louis Car Company did not build the LVT-3, which

leaves the LVT-2 or LVT(A)-4. Within the short period of five months

from contract release until completion, it is most likely that this was an expedited

build of the LVT(A)-4, which was an armed version of the LVT-4 and

needed to provide short range artillery fire support for the landing

forces. With the short time frame involved and the addition of an

armored turret, the average cost would no doubt be more than $23,000.

Therefore, using a higher estimated cost of $30,000 for the units

results in 456 units.

Until further information is found, this

value will be used. This is one of the hazards of trying to

determine what was produced 80 years ago with limited information. It is not uncommon to find

conflicting and confounding information.

Contract NObs 1789: Table 4

shows that there were 518 units in this contract. However, when

one divides 518 into the amount of the contract,

$7,642,000, the resulting cost per unit is $14,753, not the

$22,000 per unit as shown in Table 4.

I will use the 518 as the number of units

built and ignore the cost issue.

|

Table 2 - Estimated Number of

LVTs of all types built by the St. Louis Car Company |

|

Type LVT |

Number Built |

Source |

Contract |

|

LVT-1 |

116 |

Estimated from Tables 1 and 3. |

Nos 97599 |

|

LVT-2 |

551 |

Estimated from Tables 1 and 3. |

NObs 858 |

|

LVT-4 |

790 |

From Tables 1 and 4.

|

NObs 1469 |

|

LVT(A)-4 ? |

456? |

Estimated |

NObs 8588 |

|

LVT-4 |

518 |

From Table 4 |

NObs 1789 |

|

Total |

2,431 |

This is an estimate. |

|

Table 3 - World War Two LVT Production

From "Amtrack: US Amphibious Assault Vehicles by

Steven Zaloga published 1987 |

|

Type |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

|

LVT-1 |

72 |

851 |

302 |

|

|

1,225 |

|

LVT(A)-1 |

|

3 |

288 |

219 |

|

510 |

|

LVT-2 |

|

|

1,540 |

1,422 |

|

2,962 |

|

LVT(A)-2 |

|

|

200 |

250 |

|

450 |

|

LVT-3 |

|

|

1 |

733 |

2,230 |

2,964 |

|

LVT-4 |

|

|

11 |

4,980 |

3,360 |

8,351 |

|

LVT(A)-4 |

|

|

|

1,489 |

401 |

1,890 |

|

LVT(A)-5 |

|

|

|

|

269 |

269 |

|

Totals |

72 |

854 |

2,342 |

9,093 |

6,260 |

18,621 |

Table 4 - St. Louis Car Company LVT-4 Contracted Production

Information from "LVT(4) Amtrac - The Most Widely Used

Amphibious Tractor of World War II" by David Doyle |

|

Number Contracted |

U.S. Navy Hull Numbers |

U.S. Navy Contract Number

|

Cost per LVT-4 |

| 497 |

C-58855 - C-59351 |

NObs 1469 |

$22,500 |

| 293 |

C-63790 - C-64082 |

NObs 1469 |

$24,050 |

| 390 |

C-88869 - C-89258 |

NObs 1789 |

$22,000 |

| 518 |

C-90707 - C-91224 |

NObs 1789 |

$22,000 |

| 1,698 |

Total |

|

|

Table 5 - Total LVT-4 Contracted Production

Information from "LVT(4) Amtrac - The Most Widely Used

Amphibious Tractor of World War II" by David Doyle published

2020 |

|

Company |

Number Contracted |

Percentage |

|

FMC Riverside, CA |

1,876 |

19.4% |

|

FMC San Jose, CA |

3,451 |

35.6% |

|

FMC Lakeland, Lakeland, CA |

1,825 |

18.9% |

|

FMC Sub-Total |

7,152 |

74% |

|

St. Louis Car Company |

1,698 |

17.6% |

|

Graham-Paige |

757 |

7.8% |

|

Unknown |

60 |

.62% |

|

Total |

9,667 |

100% |

|

Cancelled LVT-4s in August 1945 |

1,838 |

|

|

Total Production |

7,829 |

|

St. Louis Car Company was contracted

to build 1,698 out of 9,667 LVT-4s during World War Two. With

the termination of hostilities in August 1945, 1,300 units were

cancelled among the four companies building the LVT-4. It is

unknown how many of the 1,698 LVT-4s St. Louis Car was contracted

for were

actually built and accepted by the U.S. Navy.

While the U.S. Navy was the military

organization that contracted for the LVT-4, 74% were transferred to

the U.S. Army., who used most of them in Europe

for river crossings, many of them under fire.

The following table shows

the increased use of LVTs as they became more available during the U.S.

Navy's World War Two campaign in the Central Pacific. LVTs

were utilized at Guadalcanal for the transport of supplies to the

island, not in the initial assault waves. As the war continued the

LVTs became very important where the islands had coral atolls that

prevented the 36-foot wooden landing craft such as the LCP(L)s, LCVs,

LCP(R)s and LCVPs from crossing. Even with their low draft, the

landing craft would get hung up on the atolls. The LVTs with their

tracks could cross over the reef. A shuttle system was instituted

where the wooden landing craft would bring marines and soldiers from the

troop transports to the atoll. There, the marines and soldiers

would transfer to the LVTs, which would then take them to the beach.

Transfer of the troops at the reef called for previous training by all

involved to safely and efficiently make the troop transfer. Add a

heavy surf and it became an even more dangerous endeavor than normal.

Neither Iwo Jima nor Okinawa had reefs, but by the end of the war the LVT had become an important part of the landing assault forces.

|

Table 6 -

Number of LVTs and LVT(A)s used in the Assault Waves during the

Central Pacific Campaign

The first LVT(A)s were armed with 37mm cannons and the later

ones with 75mm howitzers. These provided close-in fire

support for the LVTs as they made their run-in to the beach.

It is unknown whether Graham-Paige made this type vehicle. |

|

Island |

Date |

LVT |

LVT(A) |

|

Guadalcanal |

8-1942 |

0 |

0 |

|

Tarawa |

11-1943 |

87 |

0 |

|

Saipan |

6-1944 |

594 |

138 |

| Guam |

7-1944 |

381 |

75 |

|

Tinian |

7-1944 |

453 |

66 |

|

Peleliu |

9-1944 |

223 |

72 |

| Iwo

Jima |

2-1945 |

380 |

68 |

|

Okinawa |

4-1945 |

872 |

92 |

St. Louis Car Company built an

estimated 116 LVT-1's in 1942. This diorama at the National Museum

of the USMC depicts an LVT-1 going over a log barricade at Tarawa.

Author's photo.

This and the following photo show that the rear is a solid piece with no

ramp. The Marines had to go over the side as shown here and jump

down eight feet to the sand. Author's photo.

Author's photo.

Below are more photos of the St.

Louis Car Company-built LVT-4.

Note the internal and external armament. Author's photo

The LVT-4 was the first in the series to

have a ramp. On the LVT-1 and 2, the soldiers and marines had to

make an eight foot jump over the side to get out, and small

vehicles could not be carried without the ramp. Author's photo.

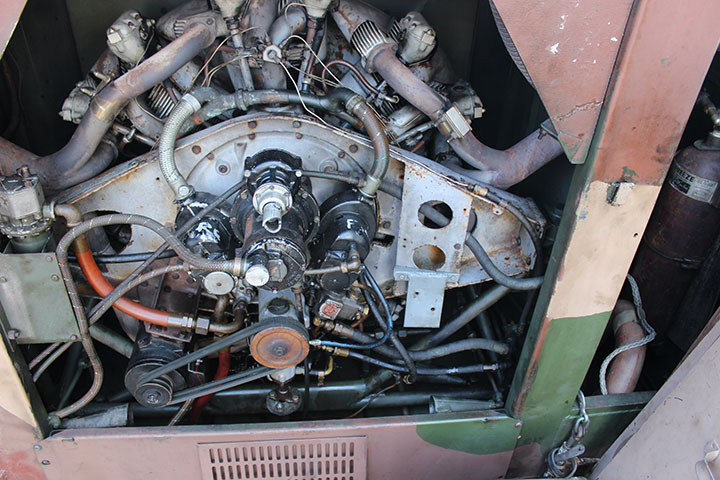

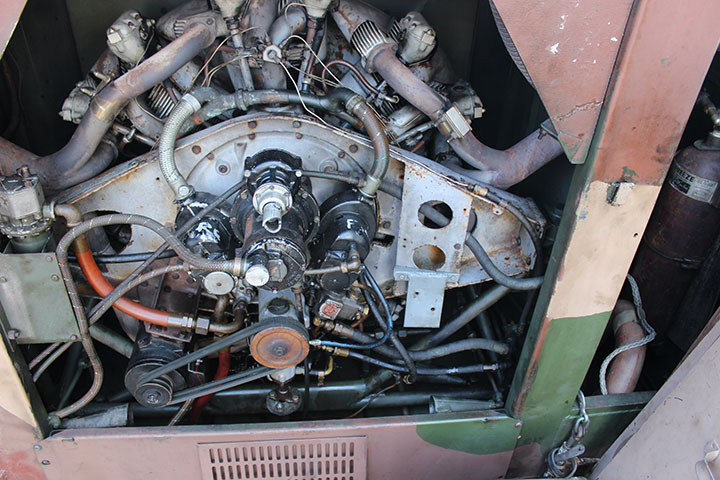

The LVT-4 was powered by a Continental

R-670-9A seven cylinder radial aircraft engine producing 250 hp.

The radial engines, being originally designed to operate at relatively

constant speeds for aircraft, did not work out well when having to

constantly change RPMs when being shifted through the five speeds of the

Spicer transmission. Author's photo.

The driver's station with the Spicer transmission just visible to the

right and the powered axle in front of the controls and instrument

panel. Author's photo.

The instrument panel inside the LVT-4.

Author's photo.

The radio control box is at the left.

Author's photo.

The gunner's position with the .30 caliber

machine gun. One can see the transmission better in this photo

and the covering over the driveshaft from the engine. Author's

photo.

The first use of the LVT was at the landings

at Guadalcanal on August 7, 1942, where they were used to bring supplies

ashore. St. Louis Car Company-built LVT-1 could be among those

pictured here.

This LVT-(A)4, which is armed with a 75mm

howitzer, is on display at the American Heritage Museum in Hudson, MA.

My research above indicates that St. Louis Car could have built LVT-(A)-4s

like this one. Author's photo

|