|

The

American Auto Industry vs. the German V-1 in World War Two

This page added 6-20-2020.

The American Automobile Industry

is recognized for building trucks, jeeps, armored cars, tanks, and even

aircraft to help win World War Two. What is unknown is that the

American Automobile Industry provided several key weapons and pieces of

equipment that were instrumental in the destruction of the German V-1

cruise missile in their attacks on London, England and Antwerp, Belgium

late in World War Two. Here is that untold story.

The Antagonist: The Fieseler Fi

103A-1 V-1

This V-1 was found in the 1990's in

a cave at Nordhausen in the Hartz Mountains, where it was built during

World War Two. This area was part of the Russian occupation after the war that became part of East Germany. In

1948, the Russians sealed all the entrances to the cave system where

slave labor had built the V-1s. After the Berlin Wall came down

and Germany was reunified, explorers found an entrance that had not been

sealed. In 2001, the Flying Heritage and Combat Armor Museum at

Paine Field in Everett, WA purchased this V-1 that was found in the

cave. It is one of only three known original Fieseler Fi 103A-1

V-1s in the United States. Author's photo.

The second original V-1 is, of all places,

located at the Greencastle, IN courthouse 100 miles from where I live.

The third Fieseler Fi 103A-1 V-1 is at the Air and Space Museum in

Washington, DC. This is one of 35,000 V-1s that were built

beginning in March 1944. Author's photo.

This V-1 is on display at the Air Zoo

Aerospace and Science Museum, Kalamazoo, MI. It is on loan from

the National Air and Space Museum. Author's photo.

This V-1 launch ramp is located at the

Dumford Museum complex in England. The 140 foot ramp was set at a

6 degree angle and used steam to propel the cruise missile to 245mph.

Author's photo.

The missile on the ramp is a replica.

Author's photo.

Author's photo.

The Would-be Antagonist: The

Fieseler Fi 103R-IV Reichenberg

The 103R-IV piloted version was

air-launched and flown by a German pilot to the target, where he would,

in theory, bail out before the missile struck the target. The

pilotless V-1 had to fly a straight and level course to the target,

making it predictable to anti-aircraft weapons. A piloted version

would be able to change altitude and make course deviations, making it

more difficult to shoot down. The 103R-IV was never used in

combat. This is also part of the Flying Heritage and Combat Armor

Museum's collection obtained from the caves of the Hartz Mountains.

Author's photo.

The American Automobile Industry's contribution to

the defense against the V-1:

Integrated Anti-Aircraft Gun Defense

System:

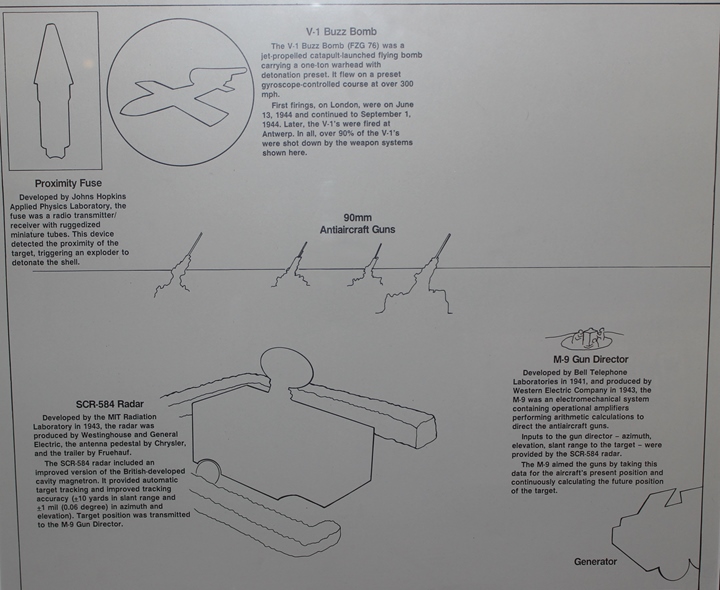

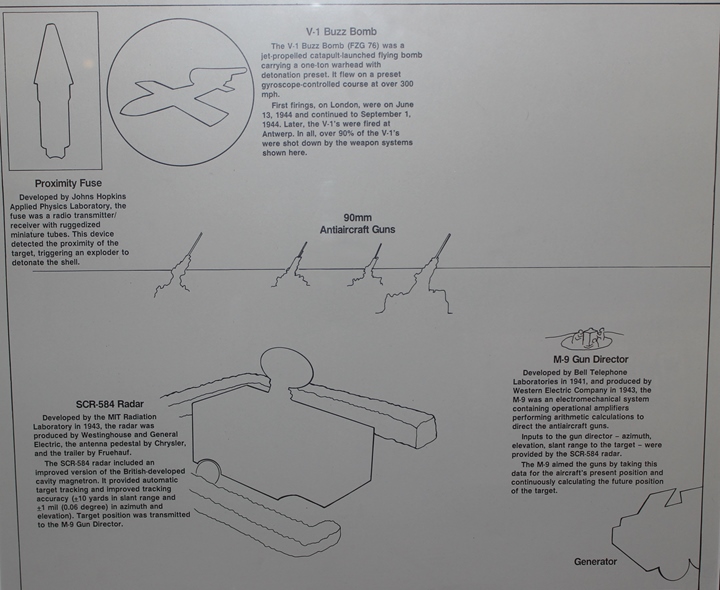

This photo is of an integrated anti-aircraft

defense system which is on display at the National Electronics Museum in

Linthicum, MD. This shows all of the different parts of the system

that were used to help defend London and Antwerp

from V-1 attacks. The V-1 pictured at the top of the photo has

already been addressed in the previous section. In the upper left

hand corner, there is an image of a VT (Variable Timing) proximity fuze for

use in anti-aircraft guns. Crosley Corporation was a significant

manufacturer of the VT fuzes used at London and Antwerp for the 90mm

American weapons and the British 3.7 inch anti-aircraft guns.

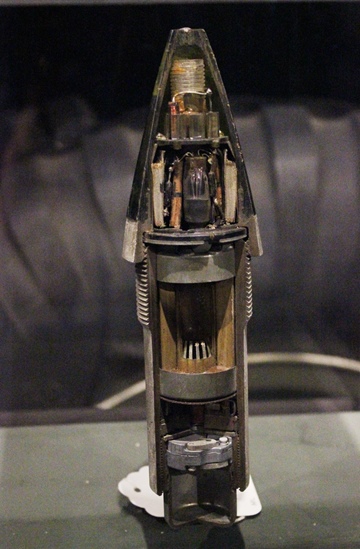

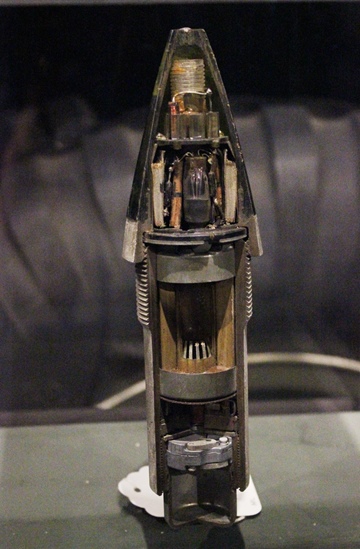

This cut-away of a VT fuze is also on display at the National Electronics

Museum. Crosley built 5,205,913 VT proximity

fuzes in thirteen different models similar to this for the U.S. Army,

U.S. Navy, British Army and British Navy. In the battle against

the V-1, Crosley supplied T-98 and T-149 VT fuzes for the British 3.7

inch weapons. For the American 90mm anti-aircraft gun, Crosley

produced the T-74 and the T-152 VT fuze. Author's photo.

German V-1s had been attacking Antwerp,

Belgium since October 1944. The destruction in the V-1s increased

with the introduction of the VT fuzes. Normally a V-1 would fly at

2,300 feet, giving a 60 second window of opportunity for VT shells

to engage the target. The Germans modified the V-1 to fly as low

as 1,200 feet, after most were being shot down by VT fuzes.

With the lower altitude, the fuzes were not self-destructing after a

miss as they did not have enough time in the air. This meant

there were VT fuzes on the ground that could be recovered by the

enemy. Eastman Kodak started building new self-destruct

switches after two days of intensive around-the-clock design work by

APL. Once complete, the switches were flown to Crosley in

Cincinnati. Winston Churchill ordered special Lancaster

bombers to pick up the completed VT fuzes at Lunken Airport in

Cincinnati and fly them directly to the battlefield at Antwerp.

2,183 of 2,394 of the V-1s that attacked Antwerp were destroyed by

aircraft, normal timed fuze anti-aircraft shells, and VT fuzed

shells. After the release for use of the VT fuze at Antwerp,

most of the V-1s were destroyed by Crosley-built VT fuzes.

SCR-584 Radar: There were 1,610

SCR-584 mobile radar control units built during World War Two.

Chrysler built all of the radar antennas and antenna mounts for the

units. Fruehauf Trailer Company built the trailers that the

antenna sat upon during operation. The trailer housed all of the

electronics. The SCR-584 identified the incoming V-1s and then

provided their locations to the M-9 gun director.

This SCR-584 with Chrysler-built antenna and

Fruehauf-built trailer is on display at the National Electronics Museum

in Linthicum, MD. Author's photo.

This gives a good view of the trailer.

Author's photo.

The Chrysler-built antenna can be seen on

top of the trailer. Author's photo.

Author's photo.

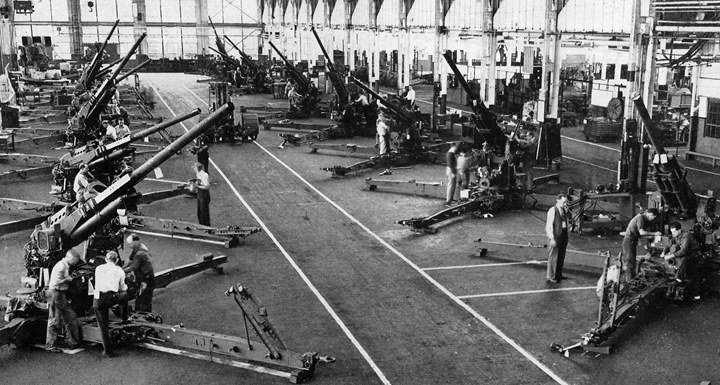

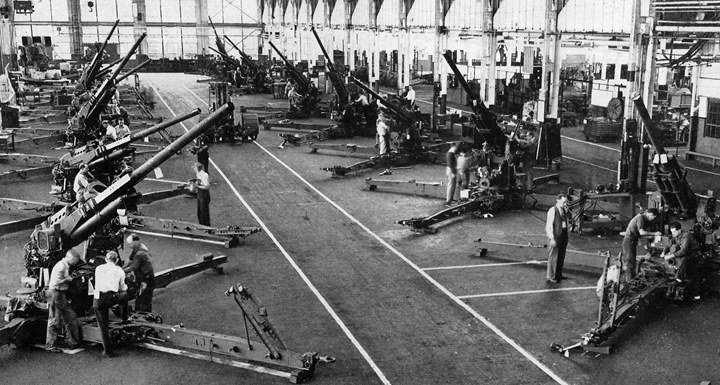

90mm Anti-Aircraft Guns: The

Fisher Body Division of General Motor Pontiac, MI plant built 2,359 90mm

anti-aircraft guns during the period of June 1943 through September 1943. Fisher Body Pontiac was originally contracted to

build 500 per month, but the production was reduced once the U.S. Army

realized the bomber threat to the United States was not going to

materialize. Weapons were still needed for overseas defense.

Pontiac provided 30% of the 7,831 90mm anti-aircraft guns that were built.

Several divisions of General Motors provided components for the 90mm gun

Fisher Body Pontiac assembled. Buick provided the gun mount and

Chevrolet the gun tubes and breeches.

Fisher Body Pontiac built the weapons with two

different types of mounts. 2,105 were on mobile mounts and 254

were on permanent mounts which were developed by Fisher Body.

At least thirteen 90mm anti-aircraft guns

can be seen on the final assembly floor at Fisher Body Pontiac.

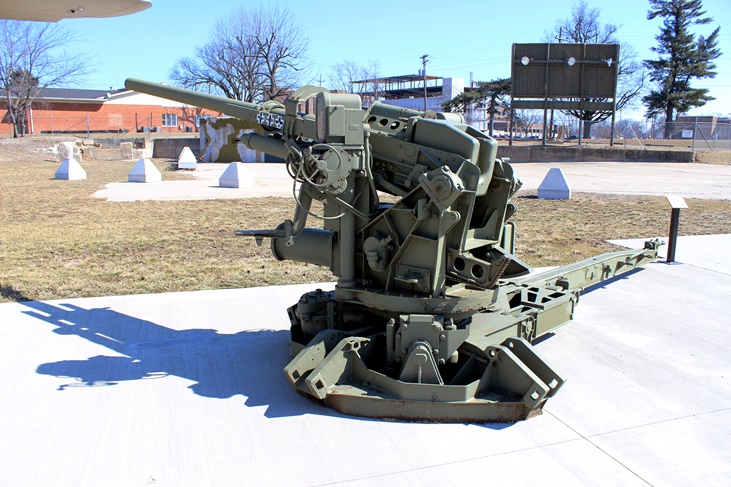

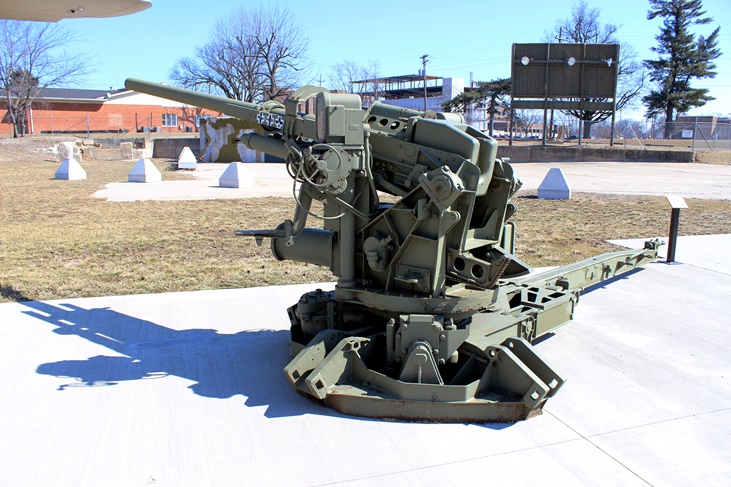

This 90mm anti-aircraft gun is on display at the

Indiana Military Museum in Vincennes, IN. Chevrolet machined the

barrels on 90mm gun tubes. Author's photo.

Author's photo.

Chevrolet built the gun breeches that were

assembled into the Fisher Body Pontiac weapons. Author's photo.

This 90mm anti-aircraft gun is on display at

Jackson Barracks in New Orleans, LA. Author's photo.

Author's photo.

This forlorn looking 90mm anti-aircraft gun

is on display outside the National Electronics Museum in Linthicum, MD.

Author's photo.

V-1 Defense in Depth: There were several

layers of defense against the V-1 besides the anti-aircraft gun system

described above. Using the attacks on London as an example,

fighter aircraft flying out over the English Channel waited for the

flash of a V-1 being launched from its ramp in France. Flying at a

higher altitude, the fighters would then dive to gain enough speed to

catch the V-1s. Initially, the British Hawker Tempests were the

only fighters with enough low attitude speed to catch up with the V-1s.

As the attacks continued, P-51s with specially tuned Detroit-built

Packard engines were introduced into the battle. P-47Ms, many with

Chevrolet built engines, had their boost increased to be able to chase

down the V-1s.

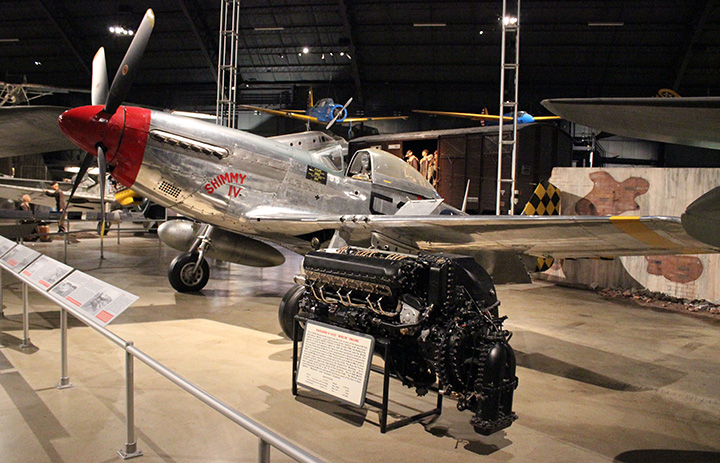

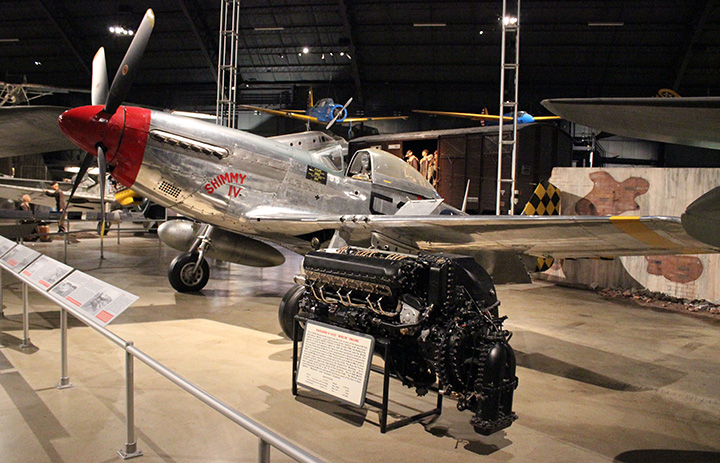

A Packard-built Merlin V-1650 with a P-51

Mustang behind it is on display at the National Museum of the United States

Air Force near Dayton, OH. Author's photo.

This P-47, located at the Peterson Air and Space Museum at Peterson AFB

in Colorado Springs, CO has a Chevrolet Tonawanda, NY built R-2800

engine in it. Author's photo.

The P-47 at the Peterson Air and Space Museum has a Chevrolet engine in

it. Author's photo.

The fighters had the width of the English

Channel to chase down and destroy a V-1. The American and British

anti-aircraft guns were located on the coast. They had been moved

to the coast when the Crosley V-T proximity fuzed shells arrived.

At the point in the war, V-T shells had to be fired over water, so that

dud rounds would not fall on land for Germans to retrieve, and reverse

engineer or develop a defense against it. Any V-1s that made it through the

anti-aircraft defense would then have to fly through barrage balloons.

Barrage Balloons: Three hundred V-1s

are estimated to have been brought down by getting tangled in the cables

tethering the barrage balloons. Firestone and Goodyear both built

barrage balloons that were sent to England and the European Theatre of

Operations during World War Two.

This V-1 has just been brought down after

getting tangled in the barrage balloon's mooring lines.

|