|

The

Armed Forces of ACF

American

Car and Foundry in World War Two

Berwick, PA, Buffalo,

NY, Chicago, IL, Detroit, MI, Huntington, WV, Madison, IL, Milton, PA, St.

Charles, MO, St. Louis, MO, and Wilmington, DE

1917-1993

This page updated 4-20-2022.

An American Auto

Industry in World War Two Special Edition

American Car and Foundry is best known among historians and enthusiasts as the sole

World War producer of the M3 light tank series. However, the company produced a considerable

volume of a variety of

equipment that was used to help win the war.

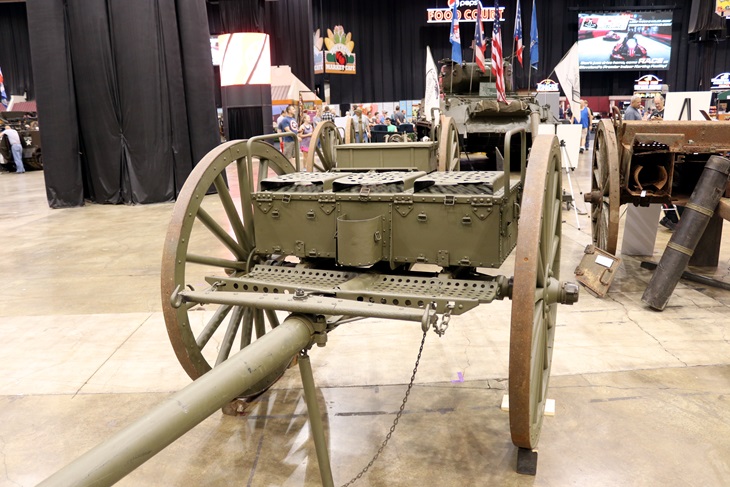

World War One: American Car and

Foundry built several vehicles for use in the First World War. It

manufactured 75mm and 4.7 inch caissons and U.S. battery stores limbers for the

American Expeditionary Forces in 1918.

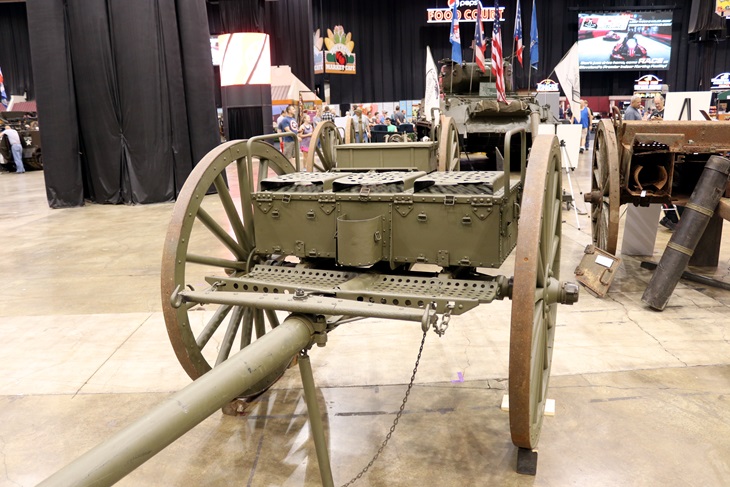

This American Car and Foundry-built 1918

75mm caisson was on display at the 2017 MVPA national convention in

Cleveland, OH. Author's photo added 12-25-2019.

Author's photo added 12-25-2019.

This is Serial Number 9148.

Author's photo added 12-25-2019.

This 1902 battery limber store was also on display at the 2017 MVPA

convention. It carried such

items as telephones, telescopes, and other equipment for operation of the

75mm field gun. Author's photo added 12-25-2019.

Author's photo added 12-25-2019.

Author's photo added 12-25-2019.

This is Serial Number 1858.

Author's photo added 12-25-2019.

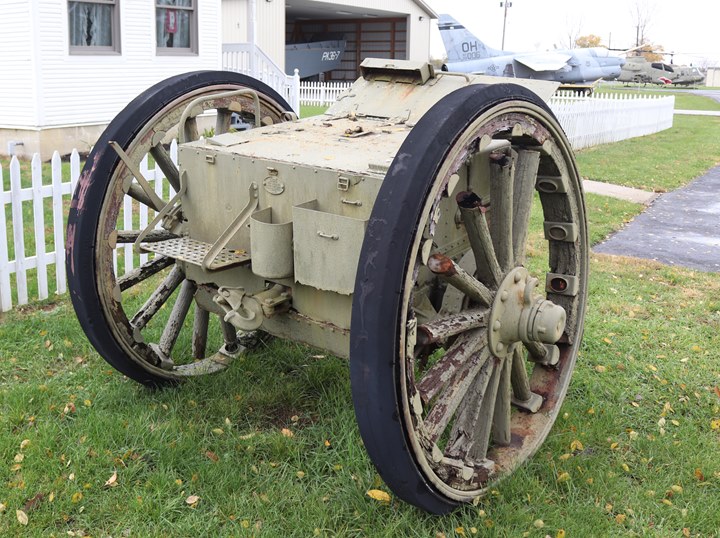

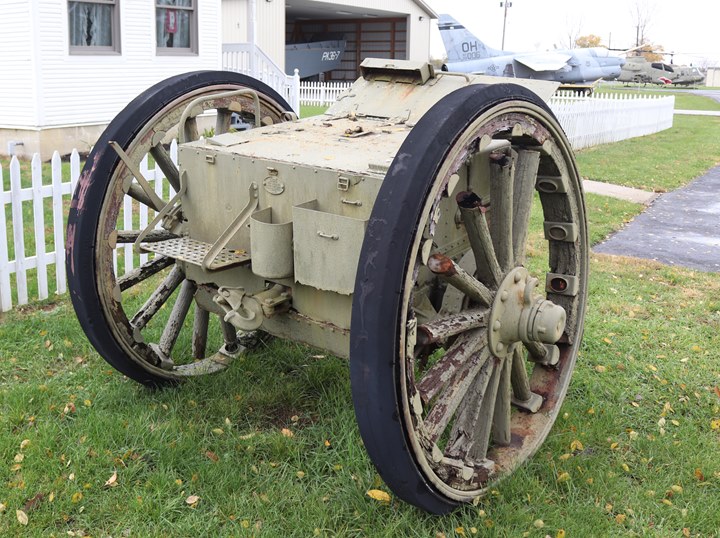

This American Car and Foundry 4.7 inch

caisson is on display at the Motts Military Museum in Groveport, OH.

Author's photo added 12-25-2019.

Author's photo added 12-25-2019.

This caisson is Serial Number

469. Author's photo added 12-25-2019.

The Berwick, PA plant won the Army-Navy "E"

flag on August 19, 1943.

The Chicago, IL plant won the Army-Navy "E" flag one time.

The Wilmington, DE plant won the Army-Navy "E" flag six times.

American Car and Foundry World War Two

Products: 15,224 M2A4, M3 and M5 series light

tanks, 150 M37 105mm Howitzer gun carriages, 1,050 suspension sets for

British-built tanks, 105,000 tons of armor plate, 200,000 9.2-inch and 300,000 7.2-inch shells for the British, 2 million 155mm

shell forgings, 250,000 240mm shells, 85,000 eight-inch shells, 6,000

14-inch shells, 102,000 bronze valves for U.S. Navy ships, 458,000

semi-steel valves for U.S. Army and Navy bases, valves for the Manhattan

Project in Oak Ridge, TN, at least 10,000 Caterpillar D-7 tractors, M44

1,000 pound bombs, Marston mat, 6 million artillery shell fuzes for the

British, millions of U.S. Army and U.S. Navy artillery shell fuzes,

carburetors for various military vehicles, 304 LCMs, 114 other various ships

and boats, LST ramps and doors, hull plates for dry-docks, LST boat

sections, hundreds of ship masts and kingposts, aircraft carrier and

storage bins, wrought iron for anchor chains, ship and boat repair for

the U.S. Navy, several hundred 10-ton capacity pontoons, less than 100

25-ton capacity aluminum pontoons, at least 200 hospital rail cars, 800

kitchen rail cars, 60 10-railcar power trains for Russia, 23 three-car

1,000 kilowatt power plant cars, 1,200,000 railroad car wheels, 26,000

box cars, 5,600 railroad tank cars, 10,000 mine cars, and

480 caboose cars.

|

Table 1 - Plants |

|

Location |

Products |

Comments |

|

Berwick, PA |

13,728 M2A4, M3 and M5 series light tanks, 150 M37 105mm

howitzer gun carriages, 1,050 suspension sets for

British-built tanks, 105,000 tons of armor plate, 10,000

Caterpillar D-7 tractors, finish work on 1,000 pound bombs,

wrought iron for anchor chains, 400 kitchen rail cars, 63

power trains, 3,000 gondolas, tenders and hoppers, 480

caboose cars |

American Car and Foundry representatives met with U.S. Army

and Caterpillar officials on July 12, 1943, to discuss the

building of the D-7. American Car and Foundry received

an initial order of 8,400 tractors as the result of the

meeting. 7,800 of the original order were

bulldozer-equipped. Production began on January 1,

1944. By November 1944 American Car and Foundry was

producing 40 D-7s per day. American Car and Foundry

built one-third of all D-7s built during World War Two. |

|

Buffalo, NY |

200,000 9.2-inch and 300,000

7.2-inch shells for the British, 2 million 155mm shell

forgings, 250,000 240mm shells, 85,000 eight-inch shells

forgings, 110,000 eight-inch shells, 6,000 14-inch shells |

The Buffalo Plant was the only plant making 240mm shells

until 1945. The 14-inch shells were for the U.S. Navy. |

|

Chicago, IL |

Forty kitchen rail cars to be used with hospital cars,

railroad car wheels |

|

|

Detroit, MI |

102,000 bronze valves for U.S. Navy ships,

458,000 semi-steel valves for U.S. Army and Navy bases,

valves for the Manhattan Project in Oak Ridge, TN

|

The valves varied in size from 3/8-inch to 24 inches. |

|

Huntington, WV |

LST ramps and doors, railroad wheels, 10,000 mine cars |

|

|

Madison, IL |

Nine

million square feet of

Marston Mat. |

This was officially identified as pierced steel planking or

PSP. |

|

Milton, PA |

Milton sheared and rolled purchased steel into cylinders for

1,000 pound bombs. The plant also produced ship masts

and kingposts for transport ships and 5,600 railroad tank cars. |

|

|

St. Charles, MO |

1,496

M3 series light tanks, hull

plates for drydocks, LST boat sections, aircraft carrier and

storage bins, railroad car wheels,

|

|

|

St. Louis, MO |

This plant turned out one million fuzes per month for the U.S.

Army and U.S. Navy. It was also producing 8,000

carburetors per day. The plant ran 24 hours per day,

seven days a week. |

This was the Carter Carburetor plant, which was a subsidiary

of American Car and Foundry. |

|

Wilmington, DE |

Several hundred 10-ton capacity pontoons, 100

25-ton capacity aluminum pontoons |

|

American Car and Foundry is best known

for being the exclusive manufacturer of the M3 series light tank.

However, its Wilmington, DE ship yard built 304 LCM landing craft

similar to the one shown above. The company was one of twelve

ship yards that built this craft during World War Two. This photo

was taken in England during preparations for the D-Day landings. There

are several products built by American companies in this photo.

The Jeeps were built by both Ford Motor Company and Willys-Overland.

The LST was American built.

-

American Car and Foundry

had 19,000 employees during World War Two.

-

In October 1941 American

Car and Foundry was producing an M3 series tank every 30 minutes, or

36 per day. In 1939, when American Car and Foundry officials

stated they could build three tanks a day, the U.S. Army was

dubious it could do this.

-

American Car and Foundry

was the only tank manufacturer to produce its own armor plate for

the armored vehicles it built. It produced over 105,000 tons

of armor plate, not only for its own use, but for other armored vehicle

manufacturers.

-

It also produced 14,000

sets of armor plate for use on half-tracks. Each set of half-track

armor weighed one ton. The American Car and Foundry

Berwick, PA, plant supplied 12,421 sets of armor plate to

Diamond T in Chicago for the half-tracks it built.

-

American Car and Foundry

supplied all the armor plate to the other tank manufacturers.

-

500,000 large caliber

artillery shells were produced for the British in 1940-41.

-

The Buffalo plant

produced over 2.34 million heavy caliber shells for the U.S. Army

and the U.S. Navy during World War Two.

-

The Detroit plant

supplied the U.S. Army, U.S. Navy, and Manhattan Project with

over 560,000 valves during the war.

-

The Berwick plant built

at least 10,000 Caterpillar D-7 tractors between January 1, 1944 and

the end of the war.

-

The Madison, IL plant produced

nine million square feet of

Marston Mat.

-

The Carter Carburetor plant ran around

the clock, seven days a week, to produce millions of fuzes and

carburetors.

-

Wilmington, DE produced 418

boats and ships. See Table 3 below.

-

American Car and Foundry produced over

48,000 rail cars of various types.

|

Table 2 - American Car

and Foundry Armored Vehicles

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Tank, Light, M2A4 |

325 |

40 |

|

|

|

|

365 |

| Tank, Light, M3, Gas |

|

2,072 |

2,454 |

|

|

|

4,526 |

| Tank, Light, M3, Diesel |

|

479 |

802 |

4 |

|

|

1,285 |

| Tank, Light, M3A1, Gas |

|

|

4,370 |

40 |

|

|

4,410 |

| Tank, Light, M3A1, Diesel |

|

|

211 |

|

|

|

211 |

| Tank, Light, M3A3, Gas |

|

|

2 |

3,425 |

|

|

3,427 |

| Tank, Light, M5A1 |

|

|

|

415 |

585 |

|

1,000 |

| Total Tanks |

325 |

2,591 |

7,839 |

3,884 |

585 |

|

15,224 |

| Carriage, Motor,

105mm Howitzer, M37 |

|

|

|

|

|

150 |

150 |

| Total Armored

Vehicles |

|

|

|

|

|

|

15,374 |

|

Table 3 - Ships and boats built by American Car and

Foundry at Wilmington, DE |

| Type |

Designation |

Customer |

Number |

Date |

Comments |

| Subchaser |

PC450 |

U.S. Navy |

1 |

May 1940 |

Prototype, 110 foot, later SC450 |

| Tank Lighters |

TKL 1-8 |

U.S. Army |

8 |

Jun 1941 |

|

| Minesweeper |

BYMS 1-4 |

U.S. Navy |

4 |

May -August 1942 |

To Great Britain |

| LCM(3) |

BTL 398-437 |

U.S. Army |

40 |

June 1943 |

|

| LCM(3) |

BTL 873-912 |

U.S. Army |

40 |

July 1943 |

|

| LCM(3) |

? |

U.S.

Navy |

304 |

|

|

| Freighter |

C-24479 |

|

1 |

1943 |

The Richard Brenner |

| Launch |

J801-804 |

U.S. Navy |

4 |

1943 |

|

| Launch |

J831-834 |

U.S. Navy |

4 |

1943 |

|

| Minesweeper |

BYMS

31-36 |

U.S. Navy |

6 |

March

1943-September 1943 |

To

Great Britain |

| Rescue Ship |

ARS

35-36 |

U.S. Navy |

2 |

August 1943, June 1943 |

Originally intended for Great Britain, but went to US Navy as

ARS 35-36 |

| Net Layer |

YN87-90 |

|

4 |

March

1944 -September 1944 |

YN

88-90 to Great Britain |

| Total |

|

|

418 |

|

|

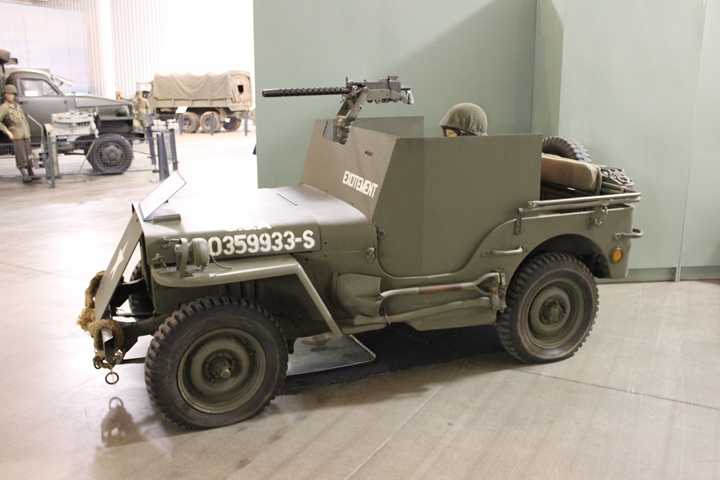

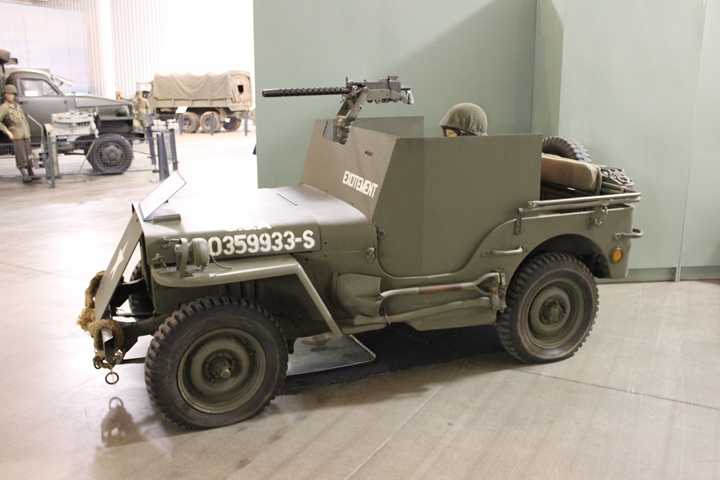

Armor Plate:

In April 1943, American Car and Foundry was

issued an emergency order to produce 50 sets of jeep armor for the 82nd

Airborne Division. Upon completion, the jeep armor was flown to

Europe. Author's photo added 10-2-2020.

The steel was 1/4-inch case carburized

armored plate. Author's photo added 10-2-2020.

Caterpillar D-7: This is one of

the untold stories of industrial production of World War Two. Much

of the following information in this section is from "The D7 Tractor - A

Visual History of the D7 Tractor in U.S. Army Service 1941-1953" by

David Doyle published 2021 by Emfour Publishing Company. Military

historian David Doyle's excellent research has unearthed new information

that had not been published or known until early 2022. I will

refer to it as 'David Doyle's D7 Book.'

Caterpillar could not meet the increased

demand for D7 tractor in 1943 due to other military commitments, including but not limited to road graders, other construction equipment,

marine engines, generator sets, M4 Sherman tank transmissions, and other

sizes of tractors. Therefore, in July 1943 the Army Corps of

Engineers brought American Car and Foundry in to also build D7 tractors

as a subcontractor to Caterpillar which supplied the engines and several

key components. This is one of the reasons that it was not until

David Doyle's D7 Book that there was a better understanding of the

number of D7s American Car and Foundry built and when they were built. The other

reason is that Caterpillar did not want it known that another company had to

build the tractors it could not produce, so the whole program did not

have a lot of publicity.

Between March 1944 and the end of the war, the

American Car and Foundry Berwick, PA plant built between 11,045 to

11,959 Caterpillar D-7 tractors. This compares very favorably

with the 14,609 (Table 5.) Caterpillar built. Most contracts for

military equipment were cancelled starting September 15, 1945.

Half of the tractors had already been built with many in process that

could be built out and completed. Also, as the tractors were under

subcontract, the Berwick plant had to wait until it received the stop

order from Caterpillar.

There is additional information on the number built. According to

David Doyle's D7 Book, the U.S. Corps of Army Engineers reported at the

end of June 1945 that as of the end of May 1945 the Berwick, PA plant

had produced 9,215 D7 tractors. These are confirmed as being

built. The rest of the quantities were planned, so I will assume the actual

production reflected the schedule. This information is in Table 4

below.

The D7s built by American Car and Foundry were

given 4Txxxx serial numbers. However, both the David Doyle D7 Book

and "U.S. WWII Caterpillar D7 Track-Type Tractor" published by Tankograd

Publishing 2011 indicate that the last serial number for the American

Car and Foundry 4T serial numbers was 4T9999. The Army Corps of

Engineers was not going to let production stop at Berwick, PA because

Caterpillar had arbitrarily capped the number of serial numbers.

One of two things happened, either Caterpillar added more serial numbers

to the 4T series, or the D7s built at Berwick were given 3T serial

numbers, which was the serial number sequence for the D7s built by

Caterpillar. I don't see the later as being the case, as

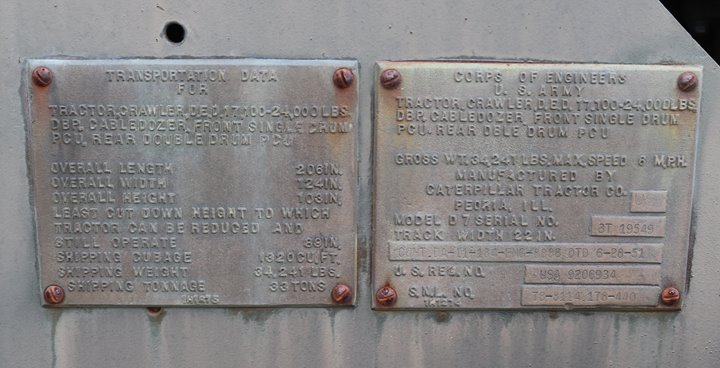

Caterpillar wanted to keep the build location of the tractors identified

in an easy manner.

The D7 Tankograd book indicates that

Caterpillar would start a new series when the production run extended

beyond 9999. This is not true. There is a 1951 D7 on display

at Fort Leonard Wood, MO with serial number 3T19549. Therefore, I

believe Caterpillar extended the 4T series beyond 9999 and the

production line at Berwick, PA continued to crank out D7s until the war

ended.

The 1951 D7 at Fort Leonard Wood, MO.

Author's photo added 4-20-2022.

This D7 has a serial number of 3T19549,

indicating Caterpillar did not necessarily start a new letter series

when the number built reached 9999. Author's photo added

4-20-2022.

|

Table 4 - American Car and

Foundry Berwick, PA Plant Caterpillar D7 Production

Data from "The D7 Tractor - A Visual History of the D7

Tractor in U.S. Army Service 1941-1953" by David Doyle

published 2021 by Emfour Publishing Company. This

table added 4-20-2022. |

|

Date |

Quantity |

|

3-1944 |

16 |

|

4-1944 |

59 |

|

5-1944 |

88 |

|

6-1944 |

213 |

|

7-1944 |

426 |

|

8-1944 |

606 |

|

9-1944 |

617 |

|

10-1944 |

801 |

|

11-1944 |

875 |

|

12-1944 |

1,100 |

|

1944 Total Built |

4,801 |

|

1-1945 |

1,026 |

|

2-1945 |

982 |

|

3-1945 |

926 |

|

4-1945 |

904 |

|

5-1945 |

576 |

|

6-1945 |

915 |

|

7-1945 |

915 |

|

8-1945 |

914 |

|

1945 Total |

7,158 |

|

1944 and 1945 Total Built |

11,959 |

| |

|

|

9-1945 |

830 |

|

10-1945 |

640 |

|

11-1945 |

506 |

|

12-1945 |

448 |

|

Total Late 1945 Planned but not

Built |

2,424 |

|

Total built or planned to be

built |

14,383 |

|

Table

5 -

D7 Production During World War Two 1940-1945

From "U.S. WWII Caterpillar D7 Track-Type Tractor"

published by Tankograd Publishing 2011.

Added 3-12-2022. |

|

Model/Series |

Year |

Number Built |

Serial Numbers |

Comments |

|

D7/7M |

1940-1944 |

9,999 |

7M1 - 7M999 |

|

|

D7(Armored)/1T |

1943 |

138 |

1T1001 - 1T1138 |

For British Army. |

|

D7/3T |

1944-1945 |

3,418 |

3T1 - 3T3418 |

|

|

D7(Military)/4T |

1944-1945 |

11,959 |

4T1 - 4T11959 |

These were built by American Car and Foundry in Berwick, PA.

|

|

D7/6T |

1945 |

1,054 |

6T1 - 6T1054 |

For U.S. Navy. |

|

Total |

|

26,568 |

|

|

According to Table 5, American Car and Foundry

produced 45% of all D7s in a year and a half production time. My

calculation of 11,959 replaced Tankograd's number of 9999 for the last

4T serial number and the number produced.

According to Table 5, Caterpillar built 14,609

D7s.

Lets compare the 14,609 from Table 5 with Table 6. David Doyle

obtained the yearly D7 production numbers from the Caterpillar records.

Table 6 gives a value of 17,444 and this does not include 1940 or 1941

production.

Table 6 - Caterpillar

D7 Production During World War Two 1942-1945

Data from "The D7 Tractor - A Visual History of the D7

Tractor in U.S. Army Service 1941-1953" by David Doyle

published 2021 by Emfour Publishing Company. This

table added 4-20-2022. |

| Year |

D7s Built |

| 1942 |

1,150 |

| 1943 |

1,961 |

| 1944 |

7,094 |

| 1945 |

7,239 |

| Total |

17,444 |

Based on the information in Table 6, American

Car and Foundry built 41% of the D7s.

Caterpillar's production of the D7 increased

dramatically due to the Decatur, IL plant coming online, which was

dedicated to building D7s.

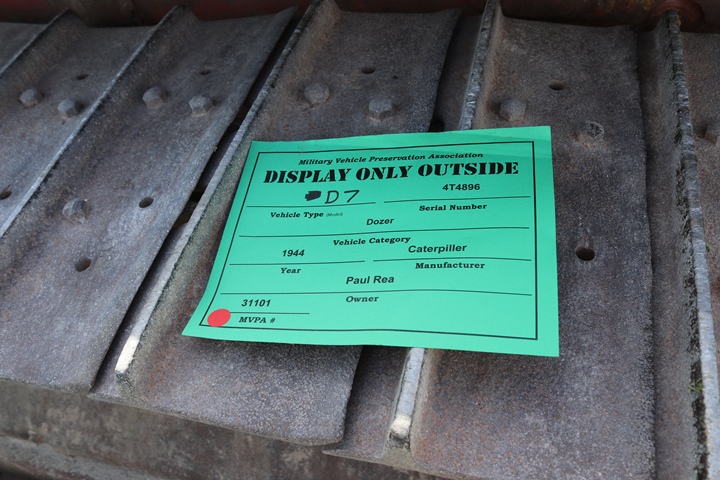

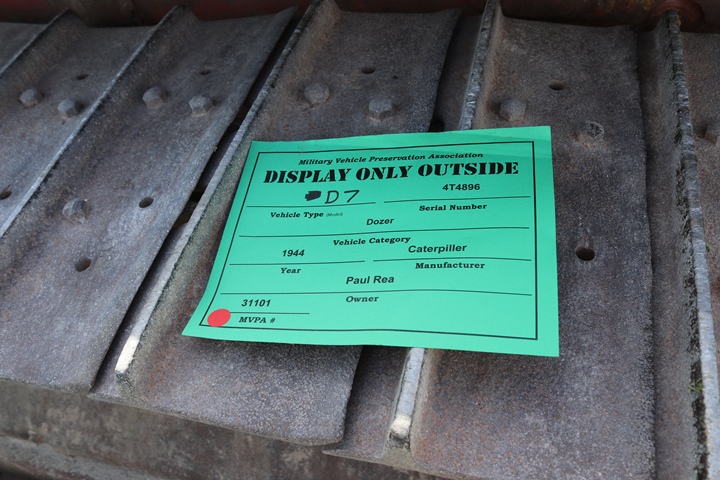

This D7 is owned by Paul Rea in New

Oxford, PA and is in running condition. It is serial number 4T4896

and was built in the Berwick, PA plant in January 1945. Author's

photo added 4-20-2022.

Until David Doyle's D7 Book revealed that

the 4T series was built by American Car and Foundry, I thought this was

a Caterpillar-built D7. Author's photo added 4-20-2022.

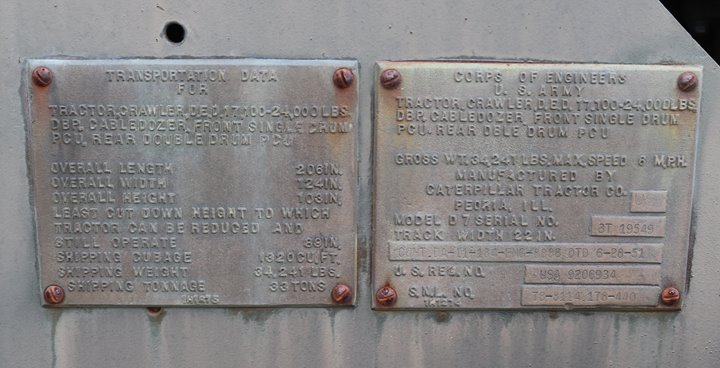

The original shipping information data plate

is still on the D7. The bare metal, the red primer, and the original

OD military paint can be seen in this photo. Author's photo added

4-20-2022.

Here is the owner's information on the D7

indicating the serial number. Author's photo added 4-20-2022.

Marston Mat:

The Madison, IL plant produced over nine

million square feet of Marston Mat. This was primarily used for

temporary runways during the war. It was also used during

invasions to assist wheeled vehicles crossing sand beaches after departing landing

craft. Author's photo added 10-2-2020.

Half-Track Armor Plate: The

American Car and Foundry

Berwick, PA, plant supplied 12,421 sets of armor plate to

Diamond T in Chicago for the half-tracks it built.

This is one of 8,573 M3 half-tracks that Diamond T built for the

war effort with American Car and Foundry armored plate. American

Car and Foundry also supplied armored plate for another three types of

half-tracks that Diamond T built. Author's photo added 12-12-2021.

Author's photo added 12-12-2021.

M3 Series Photos:

M3 Serial Number 156 is on display at the U.S. Veterans

Memorial Museum in Huntsville, AL. It has an early riveted turret

that was installed when it was built in May 1941 at the Berwick plant.

There were 2,000 rivets in each M3. Author's photo.

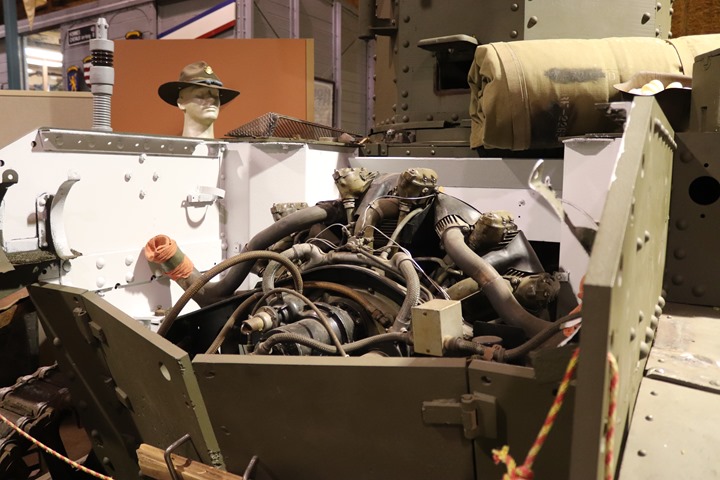

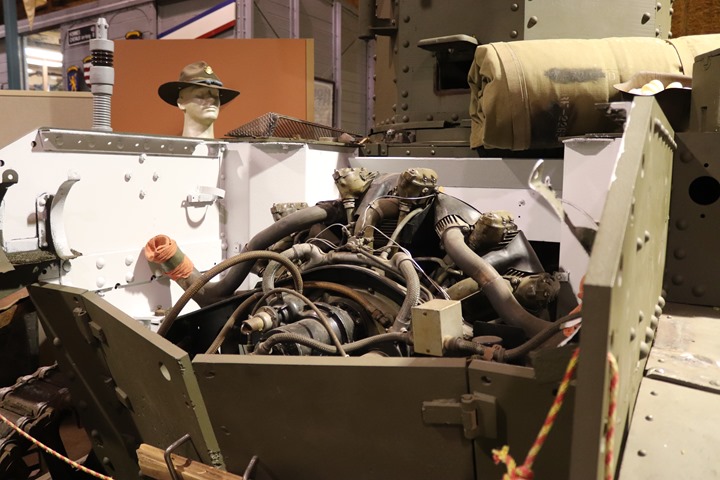

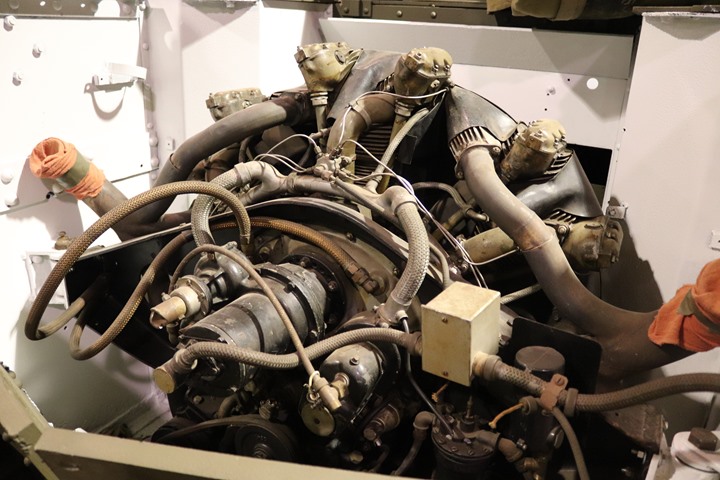

During my visit in 2018, the engine cover was off the rear of the tank,

allowing a look at the Continental seven-cylinder engine. Author's

photo.

Author's photo.

This is M3 Serial Number 1343 which is part of

the U.S. Army Armor and Cavalry Collection, Fort Benning, GA. It

was built in August 1941 at the Berwick Plant with a welded turret.

Author's photo.

Author's photo.

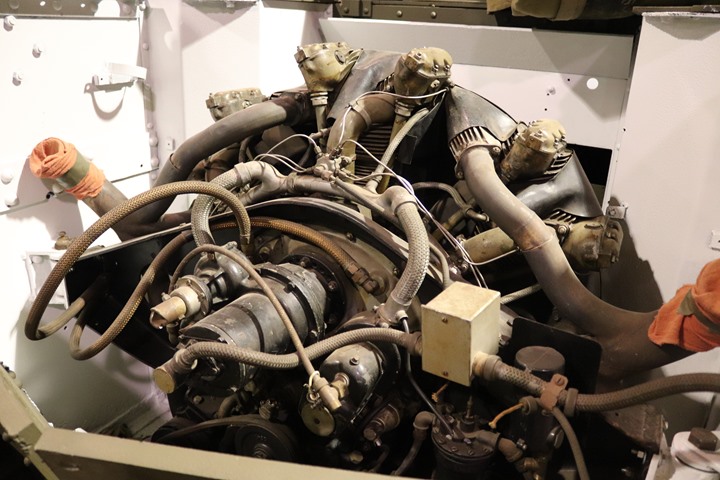

This photo has an example of the Continental

seven-cylinder engine on display behind the tank.

Author's photo.

Serial Number 2564 is also part of the U.S.

Army Armor and Cavalry Collection, Fort Benning, GA. It was

built in January 1942 at Berwick, PA.

Author's photo.

This M3 is on display at the National

Infantry Museum at Fort Benning, GA. It is serial number 4161 and

was built at Berwick in April 1942. Author's photo.

M3A1 Series Photos:

M3A1 Serial Number 10127 is also part of the

U.S. Army Armor and Cavalry Collection, Fort Benning, GA. It was

built in December 1942 at Berwick, PA. Author's photo.

M3A1 Serial Number 10183 is on display in

front of the American Legion in Rome, NY. It was built December

1942 in Berwick, PA. Author's photo.

Author's photo.

M3A1 Serial Number 10316 is on display

at the Indiana Military Museum in Vincennes, IN. It was built in

December 1942 at Berwick, PA. Author's photo.

An M3A1 is part of a diorama at the Wright

Museum of World War Two in Wolfeboro, NH. Author's photo.

Author's photo.

This M3A1 is on outside display at the

Georgia Veterans State Park, Cordele, GA Author's photo.

M3A3 Series Photos:

M3A3 Serial Number 12562 is on display at

the Warsaw, IN courthouse. It was built at Berwick in June 1943.

Author's photo.

There are two M3A3s at the Veteran's Park in

downtown, Richmond, IN. Author's photo.

M37 Photos:

American Car and Foundry built 150 M37 105mm

self-propelled howitzers on Chaffee frames.

This M37 is on display at the Russell

Military Museum in Zion, IL. Author's photo added 4-2-2020.

This M37 is on display at the AAF Tank Museum in

Danville, VA. Author's Photo.

Below is a link to a 93 page book that

American Car and Foundry published after World War Two on its

contribution to the war effort. This is one of the best of its

type that I have found. It is PDF format.

The

Armed Forces of ACF

|