|

MacKenzie Muffler Company During World War Two

Youngstown, OH

~1938 - ~1960

This page updated 2-26-2023.

The MacKenzie Muffler Company's major

contribution to the winning of World War Two was the high volume

production of aircraft disposable fuel tanks used by United States Army

Air Forces and the U.S. Navy. Historical records

show that the company built 100 gallon, 165 gallon, and 175 gallon drop

tanks for the war effort. Drop tanks provided by MacKenzie Muffler

extended the range of P-38s, P-47s, P-51s, F6Fs, and F4Us in all

theaters of operation. Disposable fuel tanks

allowed P-47s, P-38s, and P-51s to escort B-17s and B-24s on their bombing

missions into Europe. In the Southwest Pacific Theater of

Operations, drop tanks were a necessary requirement for the P-38s that

had to fly long distances over the Pacific Ocean to reach their targets.

I have estimated that MacKenzie Muffler

Company produced approximately 174,000 drop tanks for both the USAAF and

the U.S. Navy.

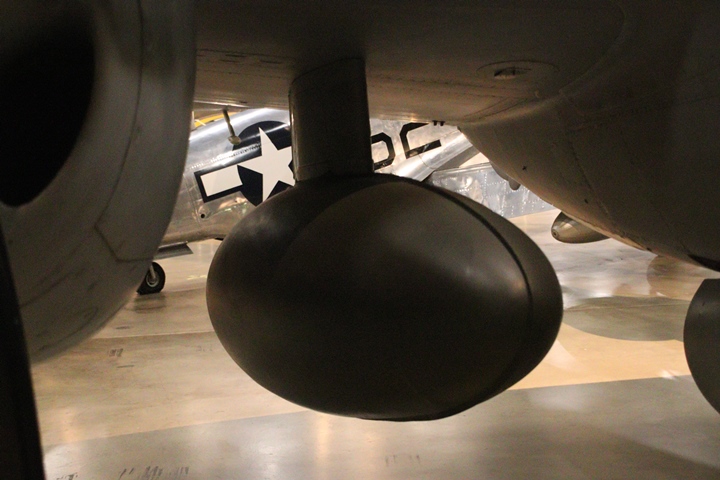

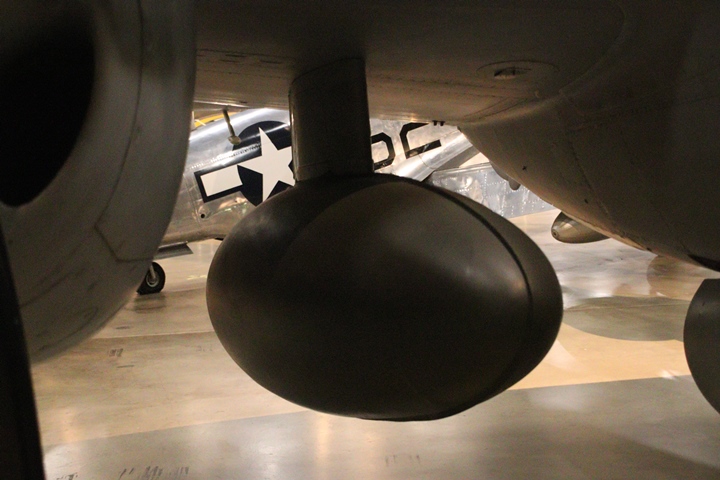

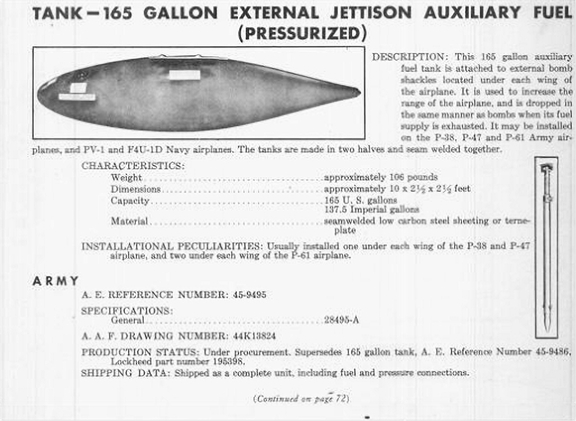

This 165 gallon drop tank is on display at

the National Museum of WWII Aviation in Colorado Springs, CO. In

the later parts of World War Two, MacKenzie Muffler Company was

manufacturing the 165 gallon drop tank for $95 per unit. Author's

photo.

Mr. Roy MacKenzie moved to Youngstown, OH in

the late 1930s and began making automotive mufflers for the American

automobile industry. Previously, he was owner and President of

Buffalo Pressed Steel Company and the Buffalo Body Corporation of

Buffalo, NY. Both of these companies were then folded into the new

MacKenzie Muffler Company that Mr. MacKenzie created when he moved to

Youngstown, OH in on or around 1938. His new company employed 300

persons making automotive mufflers for not only the auto industry, but

for International Harvester trucks as well. During World War Two,

International Harvester continued to utilize mufflers supplied by the MacKenzie Muffler

Company on several of the trucks it produced to help win World War Two.

During World War Two, MacKenzie Muffler Company expanded into eleven

factories in the Youngstown area and employed 3,000 workers making

aircraft drop tanks and automotive mufflers.

MacKenzie Muffler Company World War Two

Products: Table 1 shows that during World War Two, the company

had $23,098,000 in major contracts.

$21,786,000 of these contracts, or 94.3%, were for aircraft drop tanks.

Table 1 also shows the company had fulfilled its last contract for

drop tanks with the USAAF by the end of 1944. It also produced canister

body components for the U.S. Army Signal Corps and shell fin assemblies

for Army Ordnance for the remainder of the conflict.

MacKenzie Muffler also had $2,257,000 in drop

tank contracts with the U.S. Navy. These contracts were also for 165 gallon

tanks that were used to extend the range of the Grumman F6F Hellcat and

Vought F4U Corsair fighters that saw service in the Pacific Theater of

Operations.

Table 1 - MacKenzie Muffler

Company's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. |

|

Product - Customer |

Contract Amount |

Contract Awarded

Date |

Completion

Date |

| Tanks Fuel -

USAAF |

$110,000 |

9-1942 |

10-1942 |

| Braces

Sway - USAAF |

$101,000 |

10-1942 |

3-1943 |

| Tanks Fuel

- USAAF |

$692,000 |

10-1942 |

4-1943 |

| Tanks Fuel

- USAAF |

$1,410,000 |

11-1942 |

1-1943 |

| Tank

Assemblies - USAAF |

$13,089,000 |

12-1942 |

7-1944 |

| Droppable

Fuel Tanks - Navy |

$918,000 |

8-1943 |

5-1944 |

| Droppable Steel

Tanks - USAAF |

$425,000 |

9-1943 |

1-1944 |

| Droppable Fuel

Tanks - Navy |

$479,000 |

2-1944 |

8-1944 |

| Droppable Fuel

Tanks - Navy |

$860,000 |

4-1944 |

9-1944 |

| Fuel Tanks -

USAAF |

$3,803,000 |

5-1944 |

12-1944 |

| Canister Bodies

Disks - Army Chemical Corps |

$763,000 |

5-1944 |

7-1945 |

| Shell Fin

Assemblies - Army Ordnance |

$58,000 |

11-1944 |

3-1945 |

| Canister Bodies -

Army Chemical Corps |

$390,000 |

2-1945 |

6-1945 |

| Total |

$23,098,000 |

|

|

|

Table 2 - MacKenzie Muffler

Company's

Major World War Two Product Categories |

|

Product |

Contract Amount |

Percentage |

|

Droppable Fuel Tanks |

$21,786,000 |

94.3% |

|

Braces Sway |

$101,000 |

0.4% |

|

Canister Bodies Disks and Canister Bodies |

$58,000 |

0.3% |

| Shell

Fin Assemblies |

$1,153,000 |

5% |

| Total |

$23,098,000 |

100% |

|

Table 3 -

MacKenzie Muffler Company's

Drop Tanks by

Military Service |

|

Service |

Model |

Value |

Percentage |

|

USAAF |

155-A (165 Gallon), 300 (175 Gallon), 110-A (100) Gallon) |

$19,529,000 |

91% |

|

Navy |

165-A (165 Gallon) |

$2,257,000 |

9% |

|

Total |

|

$21,786,000 |

|

Tables 1 and 4 allows for calculation

of estimated quantities for the number of sway braces and drop tanks

produced. These estimates are shown in Table 4.

-

Using the higher

cost of $30 for the sway braces and dividing that into $101,000

gives a quantity of 3,367 units built.

-

Assuming the first

three USAAF contracts for fuel tanks totaling $2,212,000 were

built at the original cost of $400 gives a quantity of 5,530

built. A local undated newspaper article a explains that

when the company began producing drop tanks, they were

constructed of aluminum and plastic and cost upwards of $400 per

piece. MacKenzie developed an improved version of a thin

gauge of steel produced by one of the many steel companies in

the Youngtown area. These were most likely 100 gallon

tanks as the drop tanks kept getting larger as the war

progressed.

-

Adding the last

three USAAF contracts awarded on 12-1942, 9-1943, and 5-1944

gives a total of $17,317,000. One is not able to determine

which contracts were for 165 gallon tanks and which ones were

for 175 gallon drop tanks. Therefore, I will use the

average of the two costs for the two tanks. This is

$122.50. Using the $122.50 unit cost yields 141,363 drop tanks.

-

MacKenzie also

produced 165 gallon drop tanks for the U.S. Navy. This was

the company's model 165-A. The three Navy contracts

totaled $2,257,000. Once again using the $95 unit cost

yields 23,757 drop tanks for the U.S. Navy.

Table 4 -

MacKenzie Muffler Company's

Drop Tanks

Information

The information in this was obtained from "Stock List -

Dead Items Stock List" published by the Army Air

Forces on May 19, 1946 and revised January 19, 1947.

|

|

Part Name |

Model Number |

Cost |

Estimated Number Built |

| Brace

-Sway |

800-11 |

$25 |

3,300 |

| Brace

-Sway |

800-A12 |

$30 |

|

Strap Assy - Sway Brace |

800-A4 |

$50 |

Unknown |

|

Tank - 165 Gallon Metal Tank for P-38 and P-47 |

155-A |

$95 |

USAAF: 141,363

U.S. Navy: 23,757

Total: 165,120 |

|

Tank - 175 Gallon Steel Tank for P-39 |

300-A |

$150 |

Included with USAAF 165 gallon tanks |

|

Tank - 100 Gallon Steel Tank for P-47 |

110-A |

$85 final inventory cost. Calculated early WWII cost

of $400. |

5,530 |

Table 4 shows that MacKenzie Muffler

Company produced several types of sway braces and at least three

different sizes of aircraft fuel tanks. An undated Youngstown,

OH newspaper article published after World War Two notes that in

1944, the company was producing ten to fifteen boxcar loads of 165

gallon drop tanks per day. The article also notes that the

tanks cost around $100 each. This matches up very well with

the $95 cost shown in Table 4. It was this design that

became the Model 155A and cost $95.

Table 1 shows that the company began

producing fuel tanks in September 1942. This date is

significant because on August 7, 1942, the USMC invaded the island

of Guadalcanal. It was in the air battles that ensued over the

island between American and Japanese over the next five months that

the USAAF P-38 with drop tanks was introduced. By April 1943,

P-38s at Guadalcanal were normally using two 165 gallon drop tanks.

The most famous of all of the

missions flown by P-38s was flown on April 18, 1943, when eighteen

P-38s took off from Guadalcanal early in the morning to intercept

and shoot down the Mitsubishi G4M carrying Japanese Admiral Isoroku

Yamamoto. In order to avoid detection on the inbound flight,

the P-38s took a 600 mile over ocean route. After the

successful attack, the P-38s then had to make a 400 mile return trip

to Guadalcanal. For the mission, each P-38 had one 165 gallon

drop tank and one 300 gallon drop tank especially flown in for the

mission. MacKenzie Muffler Company had four contracts to

provide drop tanks to the USAAF that were awarded in September,

October, November, and December 1942. MacKenzie Muffler-built

165 gallon drop tanks may very well have been used on this historic

mission. However, it should be noted that five other companies

also produced 165 gallon drop tanks for the USAAF during World War

Two.

In any event, there is no doubt with

as many 165 drop tanks the company produced that many of them were

used in the day-to-day mission flown by Army Air Force P-38s in the

Southwest Pacific Theater of Operations. When P-47s and P-51s

arrived in the area, they also would have used MacKenzie-built 165

gallon drop tanks.

This Lockheed P-38L is on display at the

National Museum of the United States Air Force in Riverside, OH.

This P-38 is on display with two drop tanks. Author's photo.

It is hard to determine the actual capacity

of the drop tanks, as they are not marked. This appears to be a

165 gallon tank but could also be a 150 gallon unit. Author's

photo.

Aviation fuel weighs six lbs. per gallon.

Each 165 gallon tank added 990 lbs.of take-off weight. For the

Yamamoto attack, each P-38 took off with 2,790 lbs. of added fuel in the

300 and 165 gallon tanks. Author's photo.

This particular 165 gallon drop tank was

produced by the Gibson Refrigerator Company of Greenville, MI.

This is one of 41,860 drop tanks the company made during World War Two.

This and the next three photos are being added to give several different

views of a 165 gallon tank. Note that the weld seam on this fuel

tank is different than the one featured at the top of this page.

This drop tank was produced at the end of

the war and immediately became surplus. This and a second drop

tank were found in a barn. Author's photo from the Fighting Falcon Museum.

Author's

photo from the Fighting Falcon Museum.

Author's photo from the Fighting Falcon

Museum.

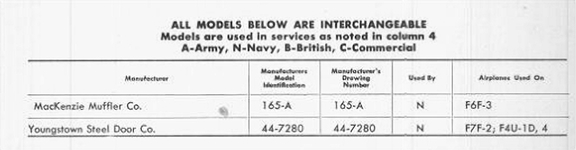

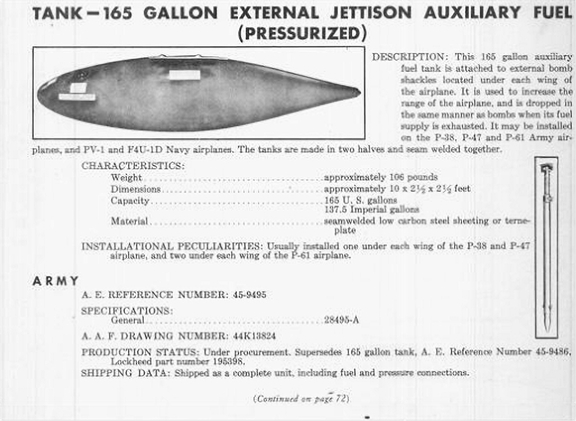

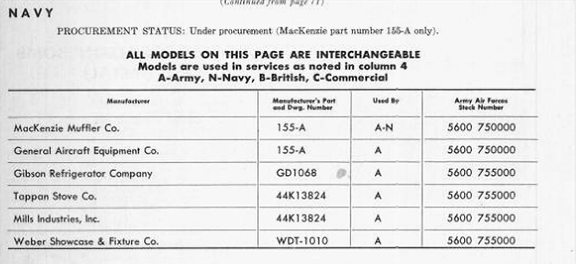

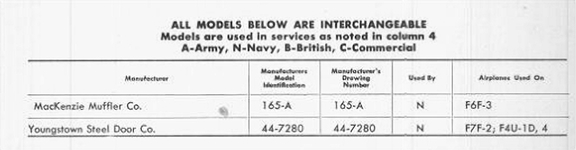

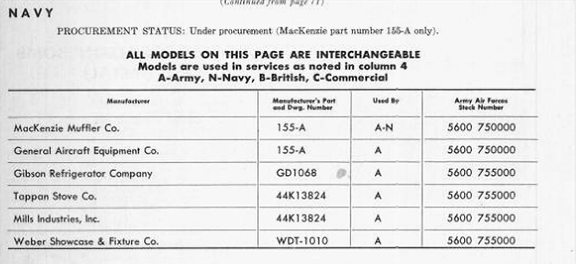

This document contains a considerable amount

of information. At the top it shows that MacKenzie Muffler and

nearby Youngstown Steel Door Company both produced 165 gallon drop tanks

for the U.S. Navy. While the "Airplane Used On" column shows that

the MacKenzie tanks were used on the F5F and the Youngstown tanks on the

F7F and F4U fighters, the drop tanks from both companies would have been

used on both the F6F and F4U. These were the main fighters used by

the U.S. Navy in the Pacific. The F7F did not see any combat

during World War Two.

The table at the bottom appears to be

erroneously titled, as the six companies listed produced 165 gallon drop

tanks for the USAAF, not the U.S. Navy. Note that the MacKenzie

Model 155-A could also be used by the U.S. Navy.

The information above comes from the Index of

Army-Navy Aeronautical Equipment; Miscellaneous, T.O. No. 03-1-46,

10-July-1945. The document shows that as of that date, only MacKenzie

was still producing or approved to supply 165 gallon drop tanks to the

USAAF. It also shows that MacKenzie 165 gallon drop tanks were

approved to be used on USAAF aircraft types P-38, P-47, and P-61.

It also shows that they could be used on U.S. Navy F4Us and PV-2s.

This Northrop P-61 is also on display at the

National Museum of the United States Air Force. This P-61 is on

display with four 165 gallon drop tanks. These may very well be

MacKenzie-built units, as the P-61C model was a late World War Two

aircraft. As noted above, MacKenzie was the only producer of the

165 gallon tanks for the USAAF at the end of World War Two.

Author's photo.

The P-61 carried a drop tank both inboard

and outboard of the engines. Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

This P-61 is being restored to flying

condition by the Mid-Atlantic Air Museum in Reading, PA. Author's

photo.

This photo shows a 165 gallon drop tank

under each wing. Author's photo.

Author's photo.

Both MacKenzie Muffler Company models 155-A

and 165-A were approved for use on U.S. Navy aircraft. This

Grumman F6F with drop tank is on display at the New England Air Museum

in Windsor Locks, CT. Author's photo.

This F4U-5 is equipped with a drop tank.

Author's photo.

The Lockheed PV-2 Harpoon was a land based

patrol bomber that could carry a MacKenzie-built 165 gallon drop tank

under each wing. Author's photo.

This PV-2 was on display at an aviation

event in Topeka, KS in 2013. It is painted in the late World War

Two all navy blue paint scheme. Author's photo.

Author's photo.

This PV-2 at the National Museum of Naval

Aviation at NAS Pensacola is painted in the early World War Two

tri-color paint scheme. The 165 gallon drop tanks have been

painted in two of the colors. Author's photo.

Mufflers: Besides building drop

tanks for both the U.S. Army Air Forces and the U.S. Navy, MacKenzie

Muffler Company also produced its peacetime product of automotive

mufflers for several types of International Harvester trucks used in

World War Two.

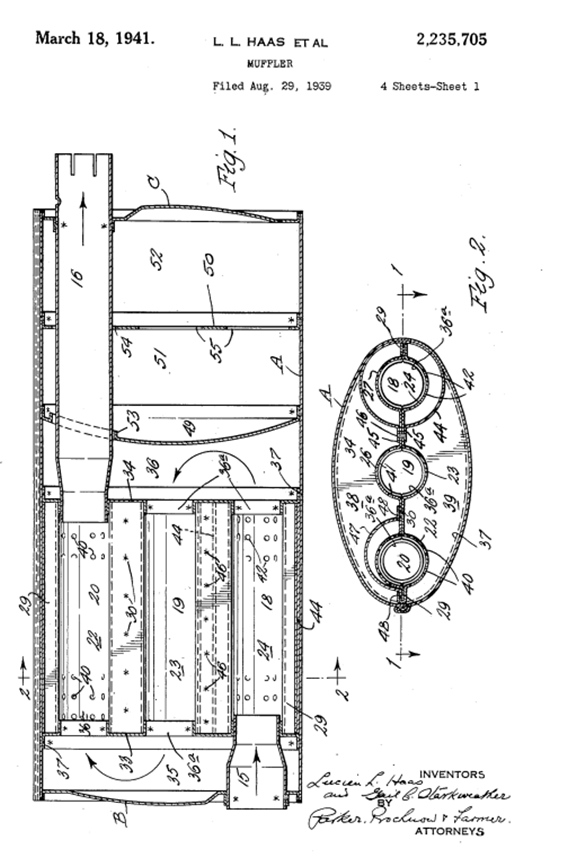

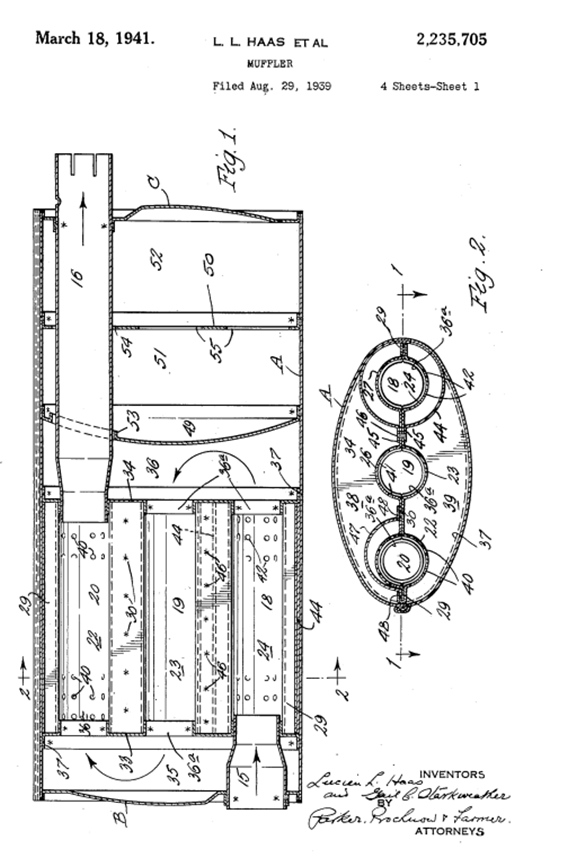

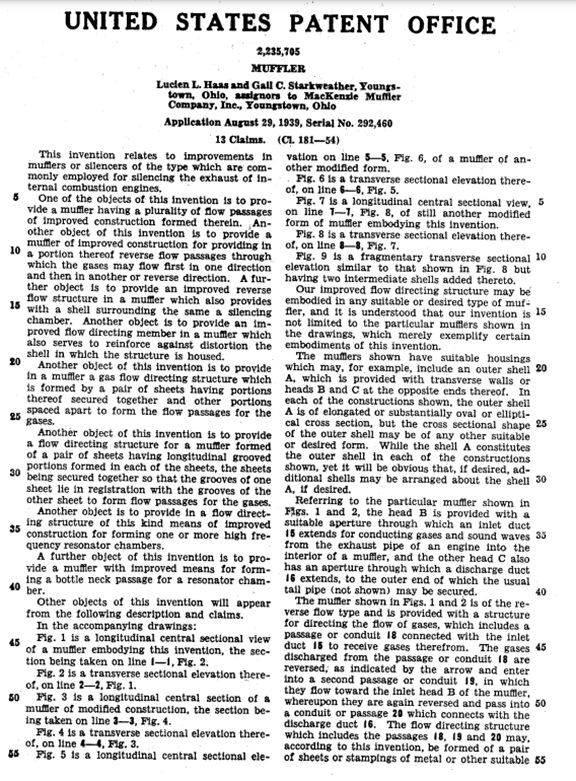

This and the next image show two pages from

a patent the company received in 1941 for an improved muffler.

This shows the company was not only producing mufflers, but inventing

and adding to the technology of the product.

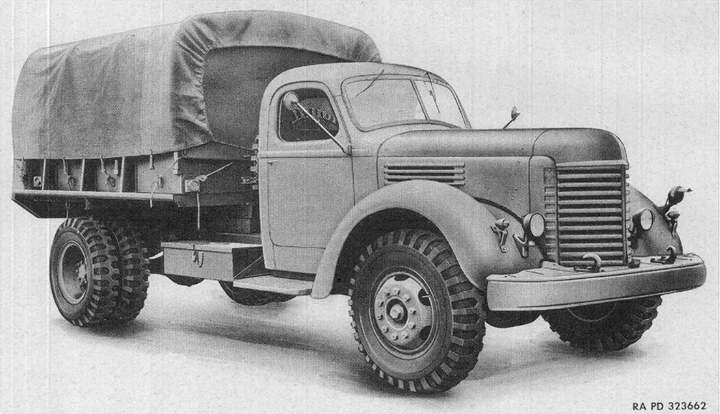

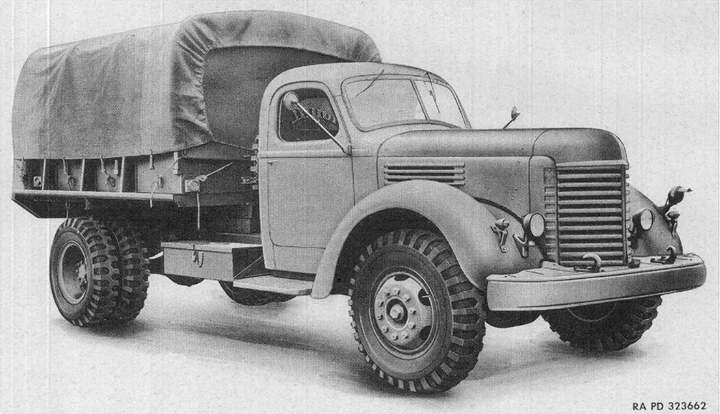

Pictured here is the International

H-542-9, 5-ton 4x2 tractor owned by the Navistar Corporation and stored

at its Melrose Park, IL plant. The military designation for the

H-542-9 was the M425. International built 4,640 in 1944 and 1945.

International also built 6,678 H-542-15 with military designation M426.

They were nearly identical, except for larger tires and a heavier duty

suspension which allowed it to pull larger

loads. These trucks used MacKenzie Model MKM 11145A mufflers.

Author's photo.

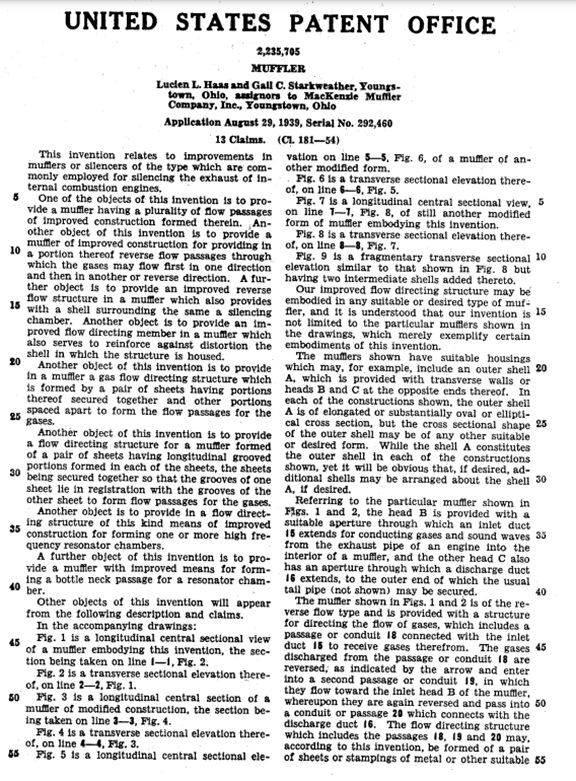

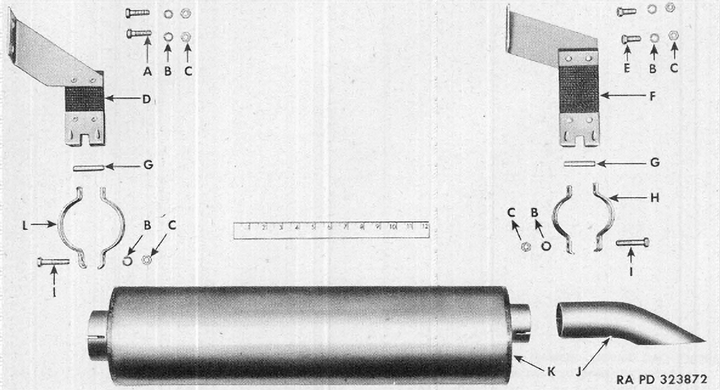

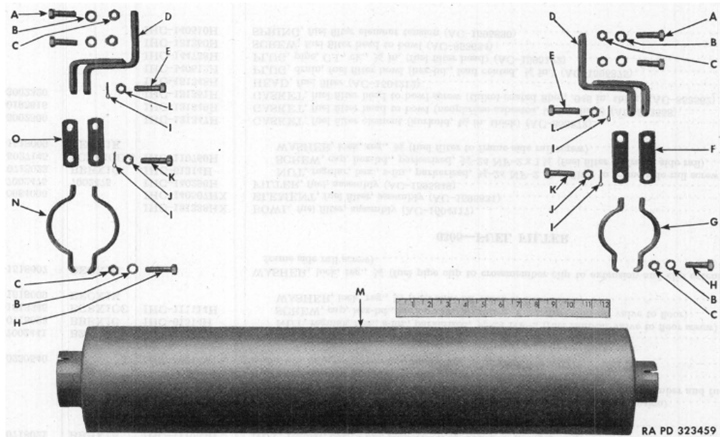

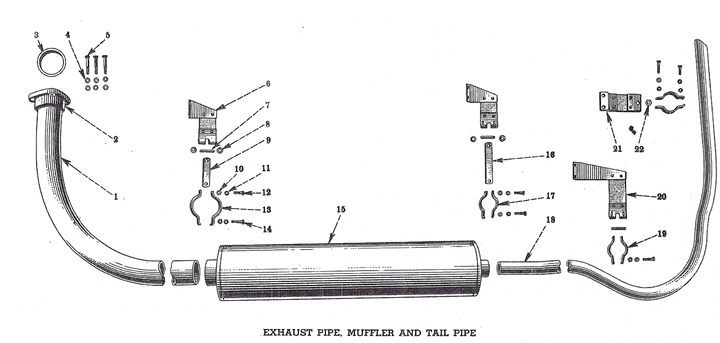

This image is from the supply manual for the

M425 and M426 trucks. This image shows the

MacKenzie Model MKM 11145A.

This 1945 Marmon-Herrington-built M426 was

seen at the World War II American Experience Museum in Gettysburg, PA.

It was on outside display for an open house at this excellent museum.

Marmon-Herrington and Kenworth also built the M426 under license from

International Harvester. Kenworth built 1,100 and

Marmon-Herrington built 3,200. Author's photo.

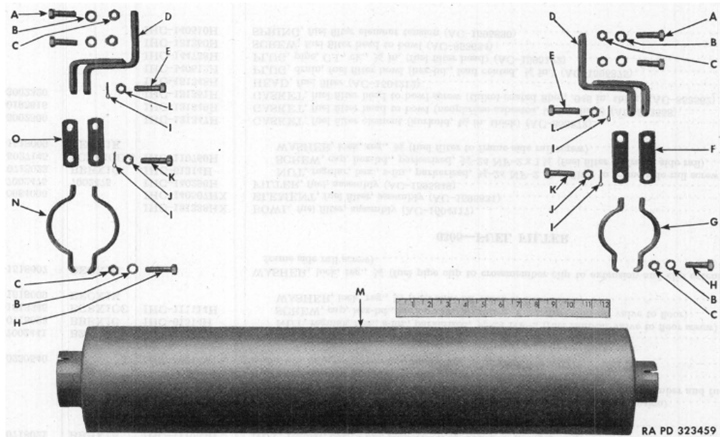

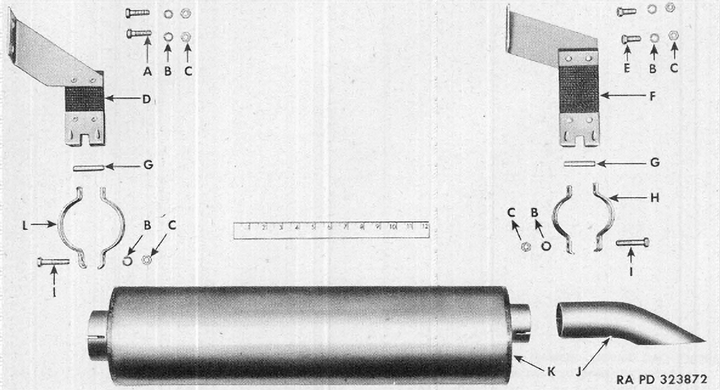

International also built

3,308 Model KR-11 5 ton 4x2s as dump trucks and another 102 as cargo

trucks as shown here. These trucks came equipped with

MacKenzie Model MKM 12050 mufflers.

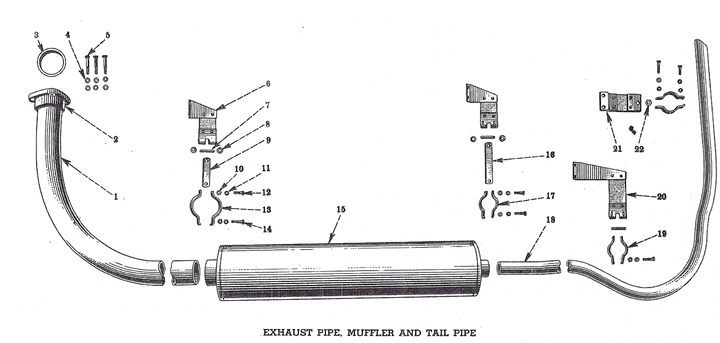

This image from the KR-11 supply manual

shows the

MacKenzie Model MKM 12050 muffler.

This image shows an International Harvester

Model M-5H-6 2-1/2-ton 6x6 truck that went to the Soviet Union under

Lend-Lease and is currently on display in Russia.

If this is the original muffler on the

vehicle, it is a MacKenzie Model

MKM11025.

The image below shows that the original tail

pipe was longer than the one currently on the truck.

The MacKenzie Model

MKM11025.

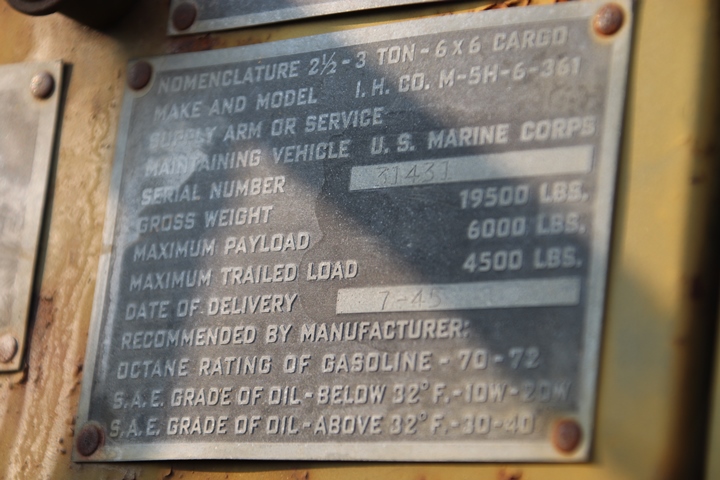

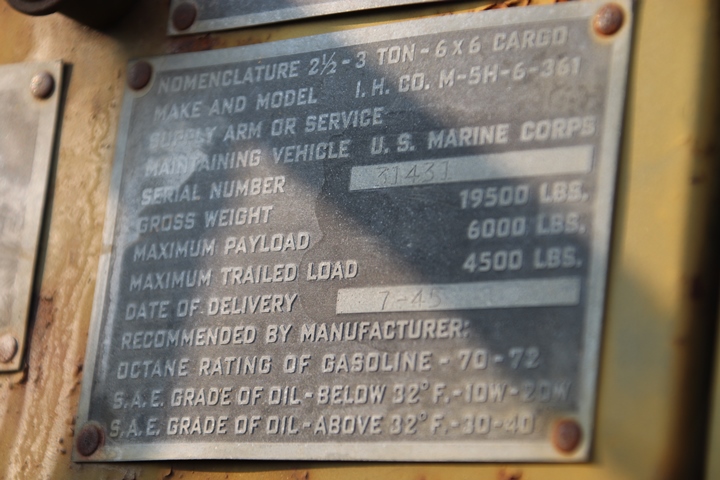

This is a very rare International Harvester

M-5H-6 2-1/2-ton 6x6 truck that the company built for the USMC.

This is the only one I have found and it is awaiting restoration at the

World War II American Experience in Gettysburg, PA. While the

truck's data plate indicates that it was built for the USMC, this dump

truck version of the vehicle was used by the Navy Seabees. Author's photo

added 2-26-2023.

This vehicle is serial number 31431 and was

delivered in July 1945. It is one of 40,087 that were built during World War Two.

Note that this was built for the USMC. Author's photo added

2-26-2023.

The image in the lower right hand corner of

the driver's door indicates that this was used not by the USMC, but by the

Navy Seabees. Author's photo added 2-26-2023.

This vehicle came equipped from the factory with a MacKenzie Model

MKM11025 muffler. Author's photo added 2-26-2023.

The MacKenzie Muffler Company Plant:

This is the Google Maps satellite view of

the former MacKenzie Muffler Company factory location.

This is the Google Maps street view.

The company appears to have gone out of

business in the mid-1960s and its former plant on North Meridian Road in

Youngstown has been razed. I see too much of this. Companies

that contributed so much to the winning of World War Two go out of

business, their former plants are torn down, and the company

forgotten. But this is why I do what I do, so that some of these

companies get the recognition they deserve.

|