|

Vilter

Manufacturing Company in World War Two This page added 6-8-2022. Vilter Manufacturing Company was formed in Milwaukee, WI by Peter Weisel and Ernst Vilter to supply steam engines to other companies operating in Milwaukee. In 1882 the company used a Corliss steam engine to drive a horizontal ammonia compressor which put the company in the refrigeration business. Previously, vertical compressors had been used for early refrigeration, but the horizontal compressor was more efficient. In 1910, the Santa Fe Railroad contracted with Vilter to build an ice making plant that could produce 225 tons of ice per day. This allowed the railroad to move perishable fruit to market.

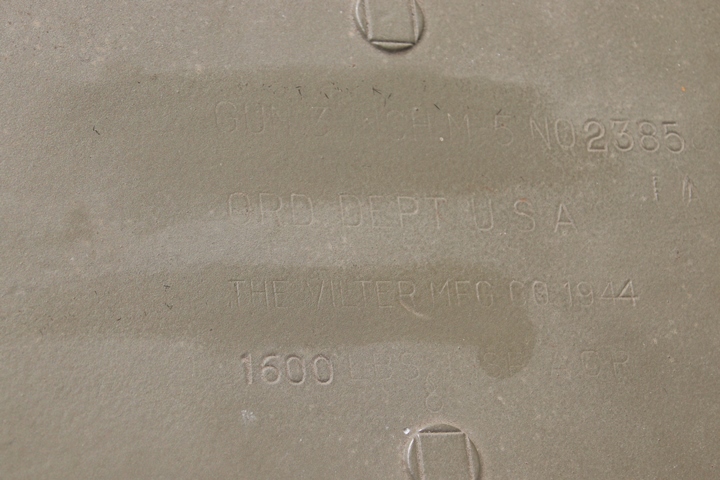

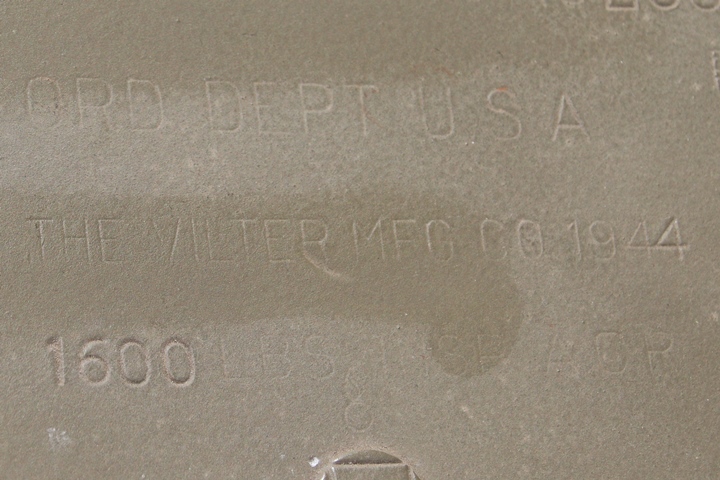

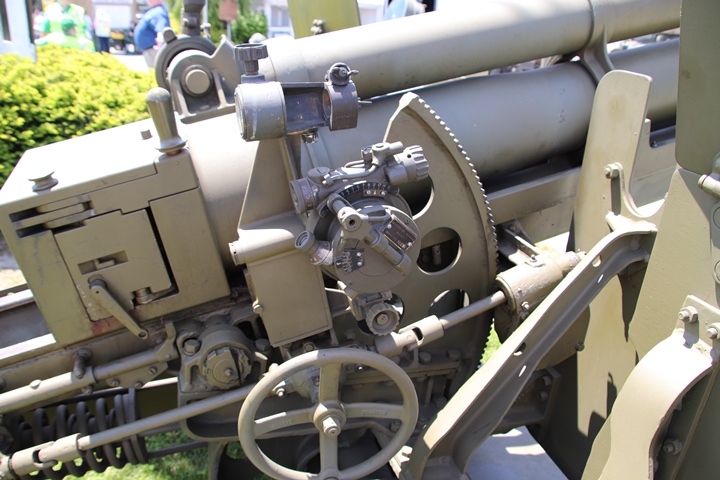

During World War One, Vilter produced a 500-ton ice plant that was used by the U.S. Army in Europe to keep 5,000 tons of beef cool for the American Expeditionary Force. During World War Two, the company continued to provide refrigeration equipment to help win World War Two. In this case, Vilter built pack ice machines that were used on transport ships that brought fresh food to American forces all over the world. This allowed American troops to be the best fed of the war. The company also produced armaments. The two photos below are from the breech of a M5 three-inch anti-tank gun that was on display at the annual Findlay, OH military show.

The barrel manufacturer is not identified on the weapon. It is unknown whether Vilter produced that, or it was manufactured by some other company or arsenal. The Vilter Manufacturing Company may well have been the final assembly point for a portion of the weapons built, with major components produced by other companies. Table 1 below indicates that the Vilter Manufacturing Company was a significant and important producer of artillery weapons for the U.S. Army. With the exception of one contract for Climate Test Chambers of $62,000, Vilter was responsible for $11,613,000 for the manufacture of guns, 105mm howitzers, and various components and subassemblies. Its first contract in June 1942 was for howitzers. Most likely these were 105mm howitzers, as various company histories indicate that the company was deeply involved with making 105 howitzers for the war effort. To an artilleryman, a gun and a howitzer are two different weapons. A gun is a long barreled cannon which has a low trajectory and a long range. A howitzer has a shorter barrel and has a higher trajectory for the shell which can be used to bombard reverse slopes. In Table 1 it is unknown whether early in the war the contracting officers knew the difference. It may well be that to a contracting officer, a gun and howitzer were the same. The eight contracts for "Guns" may well have been for howitzers. Later in the war, the type of weapon was added to the description for clarity.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||