|

Other Kalamazoo Companies

in World War Two:

Checker Car Company

Fuller Manufacturing Company

Gibson Guitar

Shakespeare Company

Ingersoll

Steel and Disc During World War Two

1884-1904 -

Sandoval Manufacturing Company - Sandoval, IL

1904-1929 - Galesburg Coulter-Disk Company - Galesburg, IL

1929-1937 - Galesburg Coulter-Disk Company, Division of Borg-Warner-

Galesburg, IL

1937-1950 - Ingersoll Steel and Disk, Division of Borg-Warner, after

Borg-Warner Purchased Pressed Steel Products in Kalamazoo, MI

1950-19?? - Ingersoll Products Division of Borg-Warner, Kalamazoo, MI

Unknown Dates - Kalamazoo Division of Borg-Warner, Kalamazoo, MI

Unknown Date to Current - Ingersoll Tillage Group in Hamilton, ONT (Not

part of Borg-Warner)

This page updated

3-15-2022.

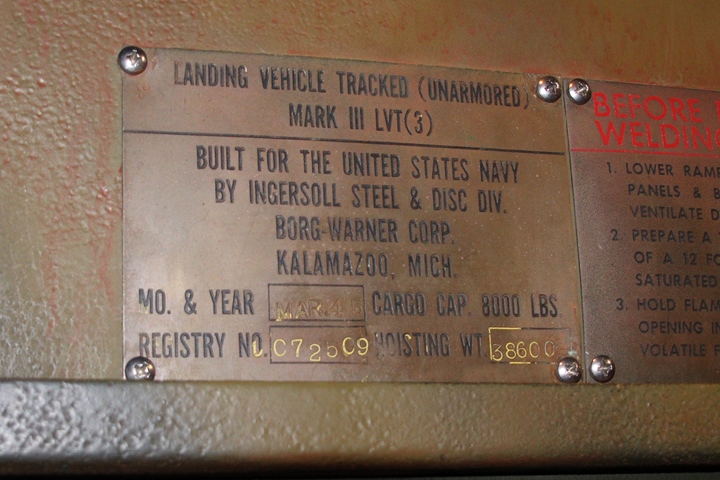

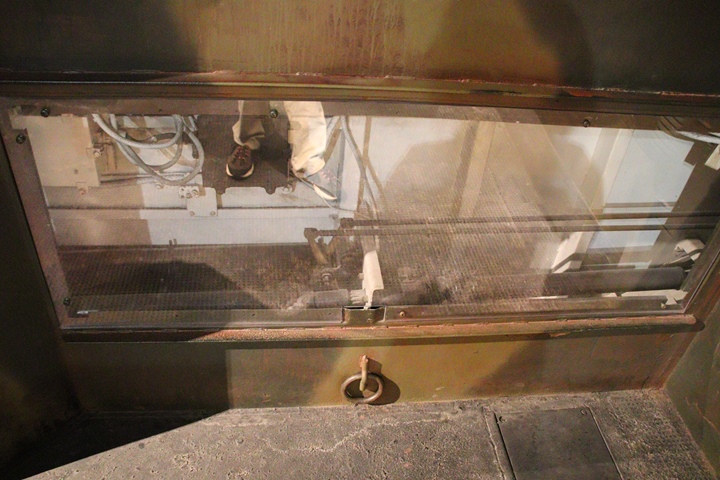

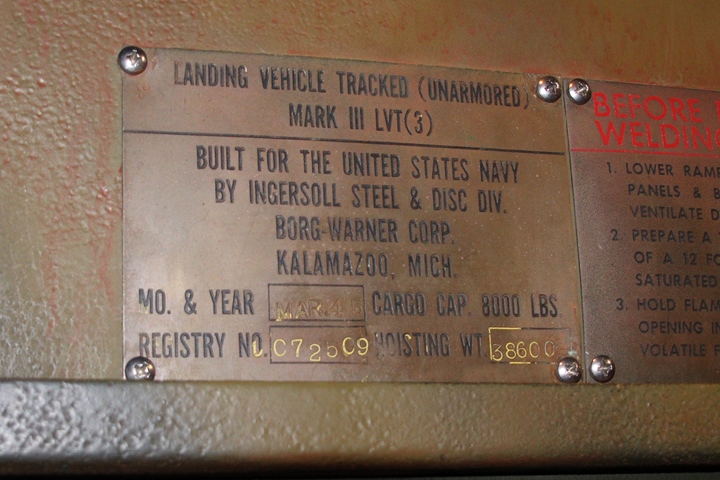

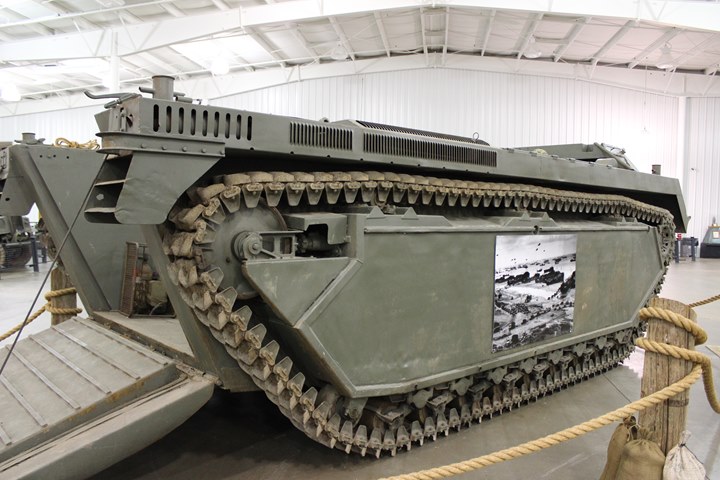

LVT-3s are very rare. To find one with

the manufacturer's date plate is exceptional. This data plate on

the LVT-3 on display at the National Museum of the United States Marine

Corps shows that this unit was built in March 1945. It is U.S. Navy

Registry Number C72509. Normally, data plates

are on or near the driver's location. This one was probably moved

from its original location to the bulkhead behind the cockpit for museum

display purposes.

Author's photo.

During World War Two, Ingersoll Steel and

Disk reversed the proverbial phrase of turning swords into plowshares by

turning plowshares into swords. In this case, the sword was the

LVT-3. In 1884, the company started when Steven Ingersoll

purchased a coulter disk company in Sandoval, IL. Working with his

son Roy, the two developed new heat treating methods to produce longer

lasting disks for its farmer customers. The current Ingersoll

Tillage Group in Hamilton, Ontario continues the production of coulter

disks. Author's photo.

In 1945, the Ingersoll Steel and Disc Division of Borg-Warner won the

Army-Navy "E" flag one time.

Several workers from the Ingersoll Steel and

Disk Division were photographed during the acceptance of their Army-Navy

"E" flag.

Ingersoll Steel and Disk World War Two

Production: The company had $81,384,000 in war contracts, of

which $71,744,000 was for the building of several types of LVTs.

This was 88% of the company's total World War Two contracts. The

company built an estimated 2,984 of the 18,621 total LVTs built during

the war. This was 16%. It was also the prime builder of the

LVT-3, which was a Borg-Warner designed vehicle, producing an estimated

2,306 of the LVT-3s. This was 78% of the total LVT-3s built.

Table 1 -

Ingersoll Steel and

Disk's Major World

War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. |

|

Product |

Contract Amount |

Contract Awarded

|

Completion

Date |

Contract Number |

| Tractors |

$3,089,000 |

1-1942 |

9-1942 |

Nos 98120 |

| Tractors

Amphibian |

$100,000 |

11-1942 |

3-1943 |

Obs 881 |

| Landing

Vehicles LVT |

$13,148,000 |

12-1942 |

4-1944 |

Obs 862 |

| Landing

Vehicles LVT |

$16,950,000 |

10-1943 |

12-1944 |

Obs 1344 |

| Landing

Vehicles LVT |

$30,331,000 |

4-1944 |

7-1945 |

Obs 1667 |

| Ships LVT3 |

$250,000 |

7-1944 |

11-1945 |

Obs 1876 |

| Vehicle Parts

LVT |

$9,105,000 |

11-1945 |

6-1945 |

Obs 1989 |

| Landing

Vehicles LVT |

$7,876,000 |

12-1944 |

8-1945 |

Obs 2014 |

| Overhaul

Tools |

$125,000 |

12-1944 |

3-1945 |

Xxs 85945 |

| End Connector

Kits |

$410,000 |

4-1945 |

6-1945 |

Obs 22907 |

| Total |

$81,384,000 |

|

|

|

The terms Tractors, Tractors Amphibian, and

Landing Vehicles LVT are interchangeable terms for the Landing Vehicle,

Tracked or LVT. It would have made my life easier if the type of

LVT was identified for each contract.

Ingersoll Steel and Disk built Landing

Vehicles, Tracked (LVT) of several types during World War Two.

Using Tables 1 and 3, it can be determined how many of each type the

company built.

Contract Nos 98120: Table 1 shows

contract number Nos 98120 was for tractors that were built between

January and September 1942. Table 3 shows that the LVT-1 was

the only vehicle of this type built in 1942, indicating that contract Nos

98120 was for the LVT-1. According to Information from "LVT(4) Amtrac - The Most Widely Used

Amphibious Tractor of World War II" by David Doyle, the

range of costs of an LVT-4 was from $22,000 to $26,200. I will

assume that the other types of LVTs fell within this same range. I

will use an average $24,000 for calculating the estimated numbers of

LVTs built by Ingersoll Steel and Disk during World War Two.

Dividing $24,000 into the contracted amount of $3,089,000 results in an

estimated 127 LVT-1s.

Contract Nos 881: The time period

for this contract matches up best with the LVT-1. Dividing $24,000

into the contracted amount of $100,000 results in 4. Given the

previously stated range, the calculated cost of each unit for this

contract was $25,000.

Contract Nos 862: The time period

for this contract matches up with LVT(A)-1, LVT-2, and LVT(A)-2. I

am going to pick LVT-2 as this had the largest number of vehicles built.

Dividing $24,000 into the contracted amount of $13,146,000 results in an

estimated 547 LVT-2s.

Contract Nos 1344: Production of

the LVT-3, the company's own design began in late 1943 with the vast

majority of the production in 1944 and 1945. This most likely was

the first contract for the construction of the LVT-3. Dividing

$24,000 into the contracted amount of $16,950,000 results in an

estimated 706 LVT-3s.

Contract Nos 1667: The dates of

1944 and 1945 indicate this was LVT-3 production. Dividing $24,000

into the contracted amount of $30,331,000 results in an estimated 1,264

LVT-3s.

Contract Nos 1876: This contract actually states the contract

is for LVT-3s. Dividing $24,000 into the contracted amount of

$250,000 results in an estimated 10 LVT-3s. Given the previously

stated range, the calculated cost of each unit for this contract was

$25,000.

Contract Nos 2014: The

dates of 1944 and 1945 indicate this was LVT-3 production.

Dividing $24,000 into the contracted amount of $7,876,000 results in an

estimated 328 LVT-3s.

|

Table 2 - Estimated Number of

LVTs of all types built by Ingersoll Steel and Disk |

|

Type LVT |

Number Built |

Source |

Contract |

|

LVT-1 |

127 |

Estimated from Tables 1 and 3. |

Nos 98120 |

|

LVT-1 |

4 |

Estimated from Tables 1 and 3. |

Nos 881 |

|

LVT-2 |

547 |

Estimated from Tables 1 and 3. |

Nos 862 |

| LVT-3 |

706 |

Estimated from Tables 1 and 3. |

Nos

1344 |

|

LVT-3 |

1,264 |

Estimated from Tables 1 and 3. |

Nos

1667 |

|

LVT-3 |

10 |

Estimated from Tables 1 and 3. |

Nos

1876 |

|

LVT-3 |

328 |

Estimated from Tables 1 and 3. |

Nos

2014 |

|

Total LVT-3 |

2,306 |

This is an estimate. |

|

|

Total LVTs of all types |

2,984 |

This is an estimate. |

|

The estimated total of 2,306 is less than the

total LVT-3 total of 2,964. This allows another estimated 658 to

be built by the Graham-Paige Company which was the other builder of the

LVT-3.

Table 3 - World War Two LVT Production

From "Amtrack: US Amphibious Assault Vehicles by

Steven Zaloga published 1987 |

|

Type |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

|

LVT-1 |

72 |

851 |

302 |

|

|

1,225 |

|

LVT(A)-1 |

|

3 |

288 |

219 |

|

510 |

|

LVT-2 |

|

|

1,540 |

1,422 |

|

2,962 |

|

LVT(A)-2 |

|

|

200 |

250 |

|

450 |

|

LVT-3 |

|

|

1 |

733 |

2,230 |

2,964 |

|

LVT-4 |

|

|

11 |

4,980 |

3,360 |

8,351 |

|

LVT(A)-4 |

|

|

|

1,489 |

401 |

1,890 |

|

LVT(A)-5 |

|

|

|

|

269 |

269 |

|

Totals |

72 |

854 |

2,342 |

9,093 |

6,260 |

18,621 |

While the production of LVT-1s, LVT-2s, and

LVT-3s was done at the Ingersoll Steel and Disk plant in Kalamazoo, MI

during the World War Two, it was one of several Borg-Warner divisions

that participated in the development of not only the Borg-Warner

designed LVT-3, but also its earlier version of the LVT-1, the Model A.

The U.S. Navy invited Borg-Warner to look at

the early design of the Food Machinery Company (FMC) LVT-1 and submit a

competing version. This was Borg-Warner's Model A. While it

did have some advantages over FMC's LVT-1, they were not enough to

change suppliers and disrupt early production. The U.S. Navy did

encourage Borg-Warner to continue work and re-submit another entry.

The actual engineering of the new and improved vehicle, denoted as Model B, was

engineered by the Rockford Clutch Division in Rockford, IL. The

Navy accepted the new design as the LVT-3.

LVT-3s on the assembly line at the Ingersoll

Steel and Disc Company.

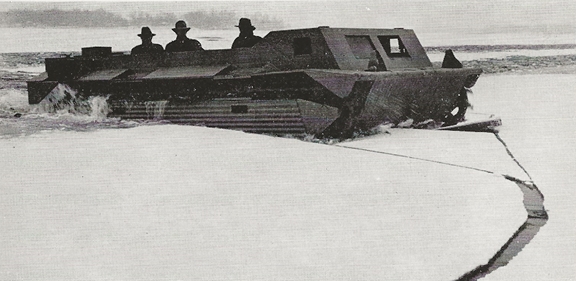

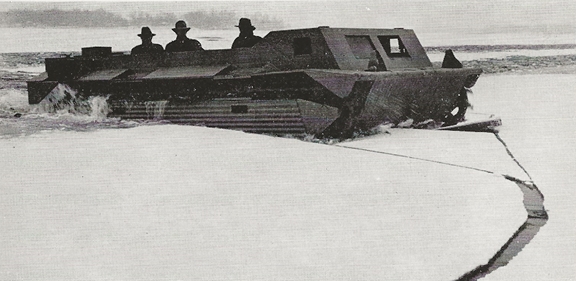

The Model B prototype is undergoing testing

in a

partially frozen lake near Kalamazoo, MI.

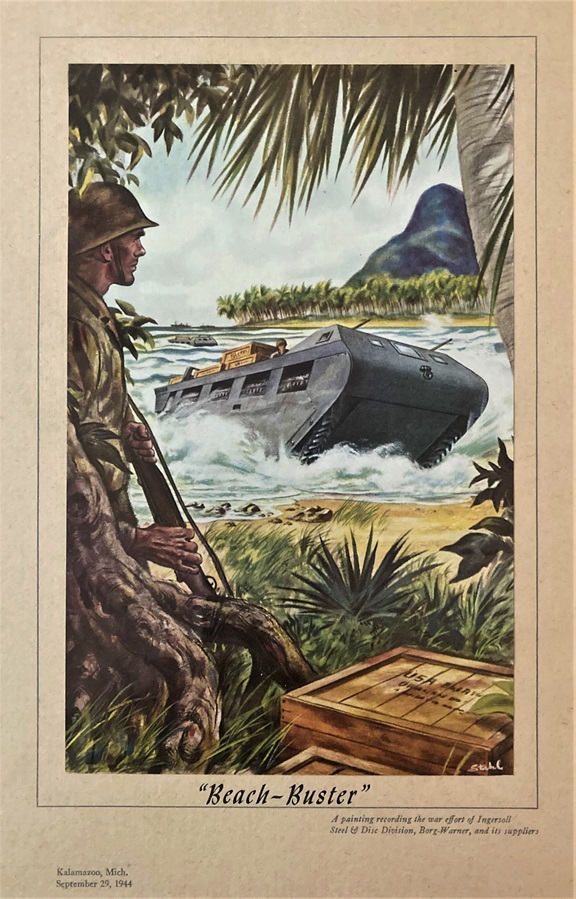

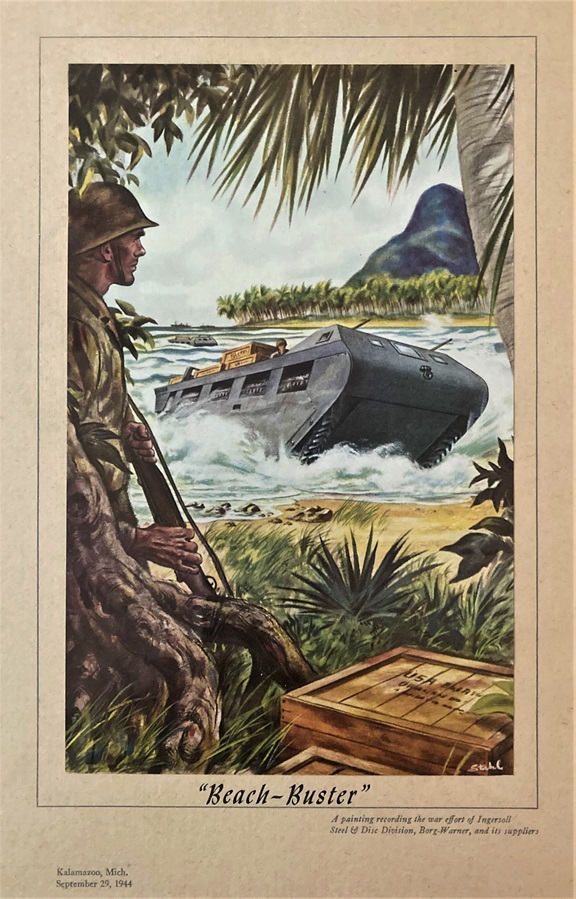

Ingersoll Steel and Disc commissioned this

water-color painting of its LVT-3 in 1944. This painting added

12-29-2021 is courtesy of Mr. Frank Antos.

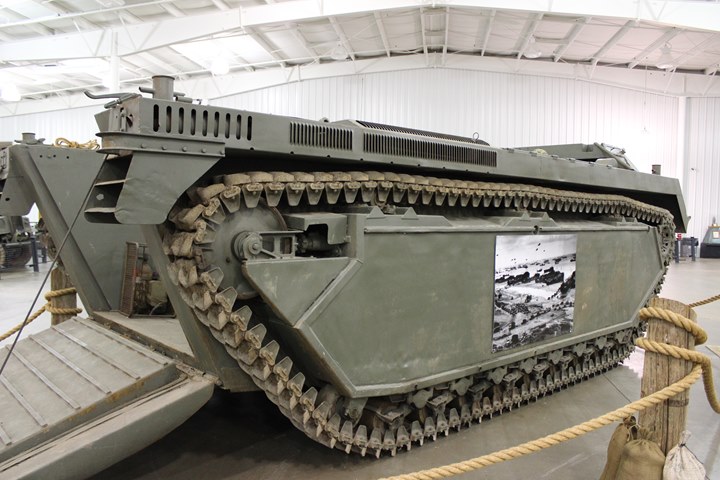

Currently, the LVT-3 on display at the

National Museum of the United States Marine Corps is the only one

available for public viewing in the United States. Author's photo.

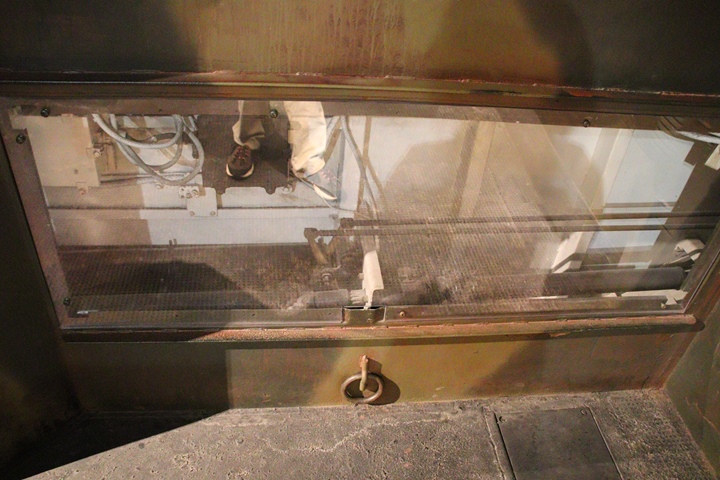

The driver had a seat belt to keep him securely in position in rough

waters. The machine gunner did not have a seat belt.

Author's photo.

The USMC Museum has added the expanded metal

screen to protect the contents of the cockpit Author's photo.

Author's photo.

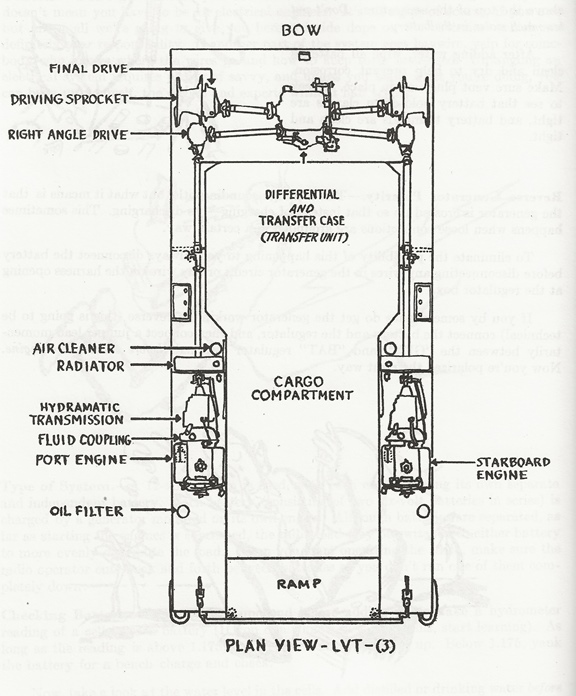

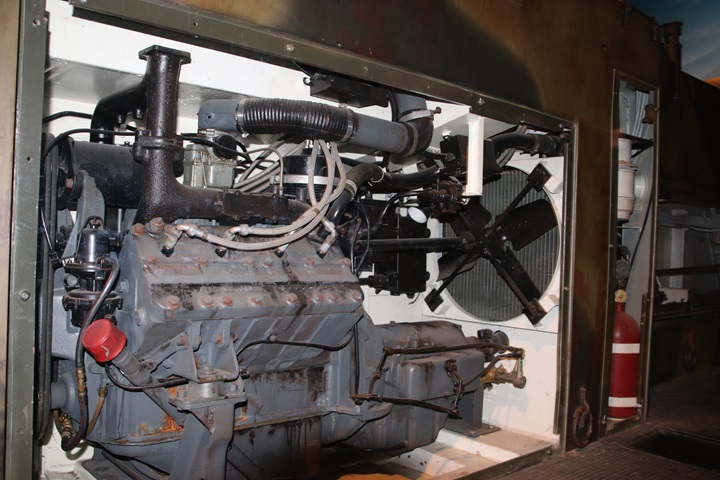

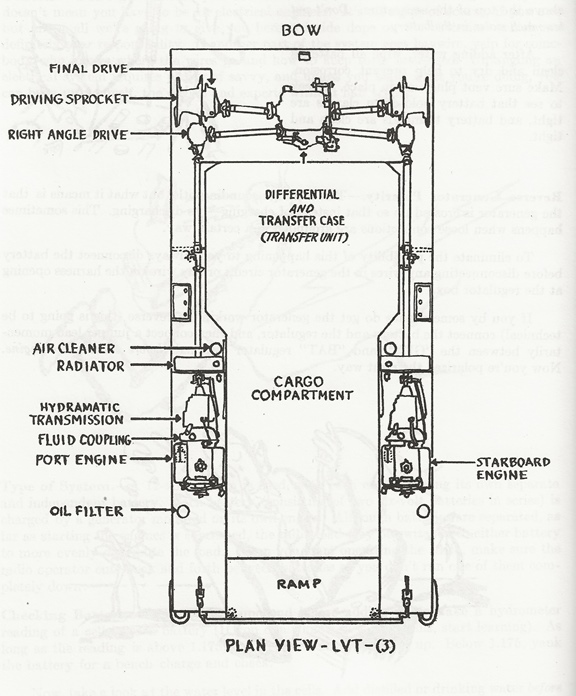

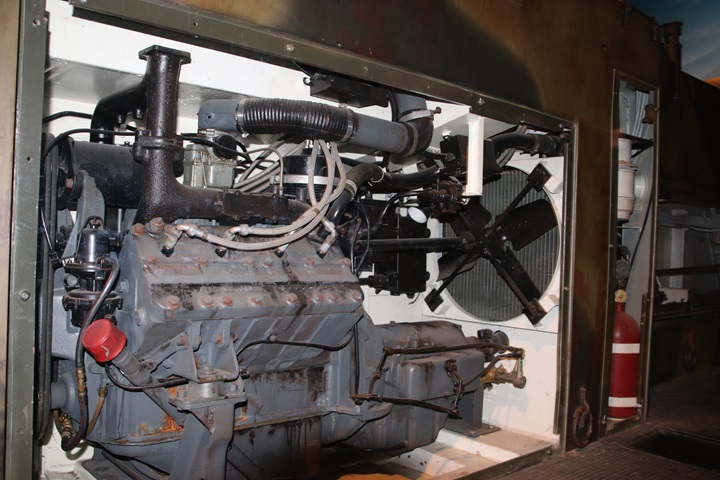

The LVT-3 used two Cadillac V-8 engines and

two Detroit Transmission Hydro-Matic transmissions mounted in the

sponsons. This utilized normally unused space in the LVT-1, 2, and

3s. It allowed for more cargo space behind the driver's position

where the engines were located in the LVT-2 and LVT-4. In the

LVT-1, the engine was mounted in the rear of the vehicle. The LVT-3

had more cargo space than the similar LVT-4. Both the LVT-3 and

LVT-4 had ramps at the rear of the vehicle.

The next series of photos is of the port sponson from front to rear. This view shows the drive shaft and

transmission and engine linkages. Author's photo.

The air cleaner is in the next compartment

along with a fire extinguisher. Author's photo.

The engine and transmission compartment show the linkages coming into

the compartment to the transmission and engine. Author's photo.

Previously, M5 Stuart light tank used Cadillac V-8 engines and

Hydra-Matic transmissions. Production of the M5 series ended in June 1944, freeing up production of

the units for use in the LVT-3. Production of the LVT-3 began in

earnest in early 1944. Author's photo.

Author's photo.

Author's photo.

This LVT-3 was photographed in 2013 at a former

military museum in Auburn, IN. Since that time, the museum

has closed. The current location of the LVT-3 shown here is unknown.

Author's photo.

Author's photo.

Author's photo.

Other Ingersoll Steel and Disk World War

Two LVT Production: While the Rockford Clutch Division of

Borg-Warner was engaged in engineering development for the LVT-3, the

Ingersoll Steel and Disc Division built an estimated 131 LVT-1s.

Borg Warner's original Model A LVT was bested in completion by the Food

Machinery Company's LVT-1 like the one seen here. Borg Warner

engineers redesigned its original entry into its Model B that became the

LVT-3.

The Ingersoll Steel and Disc Division built

an estimated 131 of the total amount of 1,225 LVT-1's. This diorama at the National

Museum of the USMC depicts am LVT-1 going over a log barricade at Tarawa.

Author's photo.

This and the following photo show that the

rear is a solid piece with no ramp. The Marines had to go over the

side, as shown here, and jump down eight feet to the sand. The

Borg-Warner-designed LVT-3 included a ramp at the rear of the vehicle so

the Marines would no longer have to jump over the side. Author's

photo.

Author's photo.

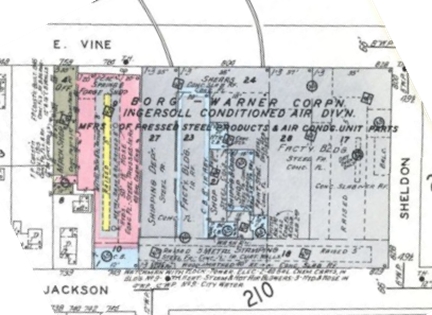

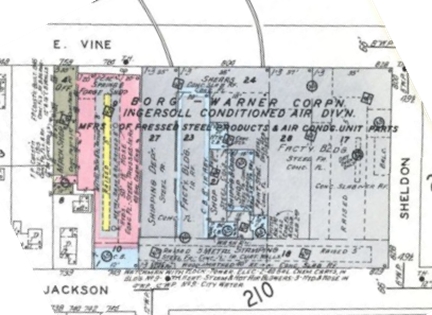

The Ingersoll Steel and Disc Company World

War Two Plant: The company was located on the southwest corner of Vine

and Shelton Streets in Kalamazoo.

Borg-Warner purchased the plant in 1937 from the U.S. Steel Products

Company. It moved the Galesburg Coulter-Disk Company from

Galesburg, IL and combined it with U.S. Steel Products Company to create

the Ingersoll Steel and Disc Company. After World War Two,

the company added a larger plant on North Pitcher Street. That

plant no longer exists but the one on Vine Street still does.

This view is looking southwest from

Vine Street. Like many older factories, the original facade of the

plant has been covered with steel sheet metal. It was in this

plant that Ingersoll Steel and Disc built an estimated 2,306 LVT-3s built in World War Two.

It was a busy place during World War Two. Author's photo.

This 1958 Sanborn Map shows the plant as the

Ingersoll Conditioned Air Division of Borg-Warner. These were built for

Borg-Warner's Norge Division.

This is a current Google Maps satellite view

of the facility.

Post-World War Two LVT-3Cs:

After World War Two, the Marines modified

the original open top LVT-3s to be fully enclosed with an armored roof

to protect the crew and passengers inside. The 1,500 vehicles that

were modified were designated as LVT-3Cs.

The Continental Aviation and

Engineering Company did the modifications in 1950.

This LVT-3C is on display at the Georgia

Veterans Memorial Park in Cordele, GA. Author's photo.

Author's photo.

Post-World War Two Military Products:

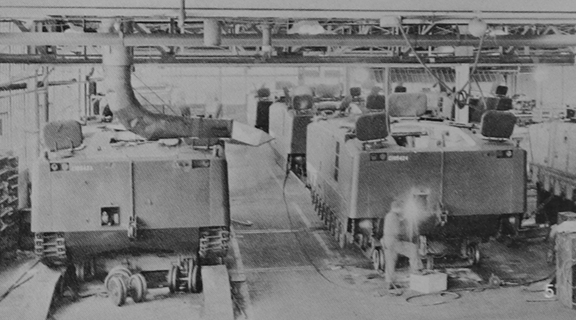

During the Korean War, the Ingersoll Products Division designed and then

with other companies produced 1,124 LVTP5 and 210 LVTH6s.

These were replacement vehicles for the earlier LVT-3. Production

began in 1952 and was completed by 1957. Both the LVTP5 and LVTH6

were fully amphibious and totally enclosed to protect the crew and

passengers.

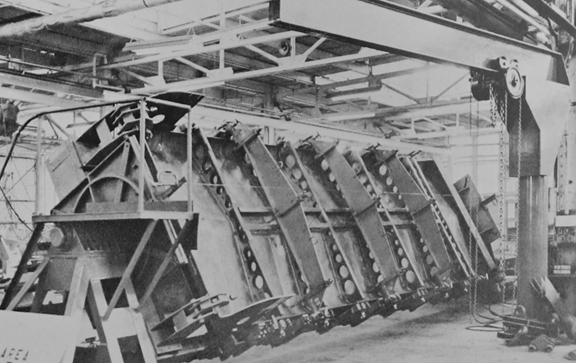

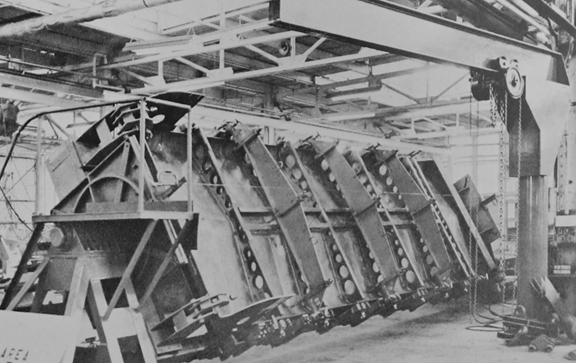

Ingersoll Products Division built this

rotisserie to assist in construction and welding.

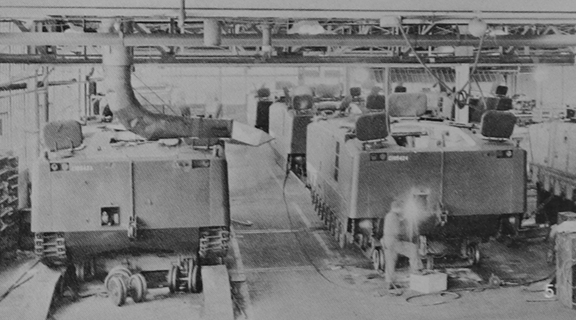

Several LVTP5s are under construction at the

Ingersoll Products Division plant.

This LVTP5 is on display at the Georgia

Veterans Memorial Park in Cordele, GA. Author's photo.

This is a monstrous vehicle for something

that operates in water. The Sand People's Sand Crawler in Star

Wars has a resemblance to the LVTP5. Both are massive. Author's photo.

This rare LVTH6 is on display at the Mott Military Museum in Groveport,

OH. The LVTH6 weighs 34 tons and is armed with a 105mm howitzer. Author's photo.

The LVTH6 is fully amphibious abd

totally enclosed to protect the crew and passengers. Author's photo.

In 1958 Ingersoll Kalamazoo Division was

contracted to design and build prototypes for two new types of wheeled

amphibious vehicles to replace the DUKW. The first was the LARC 5

which had a 5 ton cargo capacity. Author's photo.

This is marked as LARC 5 5X as it was the

fifth of seven prototypes built by the Ingersoll Kalamazoo Division.

It had a very interesting career before being placed on display at the

Army Transportation Museum. After being loaned to the U.S. Navy

for testing, it was assigned to NASA and participated in the Mercury

Program. It was then assigned to Fort Bragg, NC where it

participated in a Combat Readiness Demonstration for President Kennedy.

It was the last survivor of the prototypes when it arrived at the museum in

1968. Author's photo.

Author's photo.

At the same time, the Ingersoll Kalamazoo Division

designed the larger LARC 15 which had a 15 ton load capacity. This LARC

15 is also on display at the Army Transportation Museum. Author's

photo.

|