|

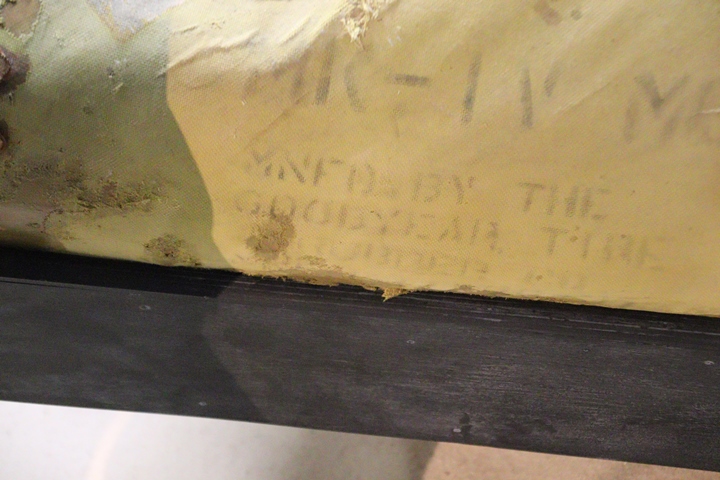

Goodyear

Tire and Rubber Company

in World War Two

Akron, OH

1898-Current

This page updated 5-28-2023.

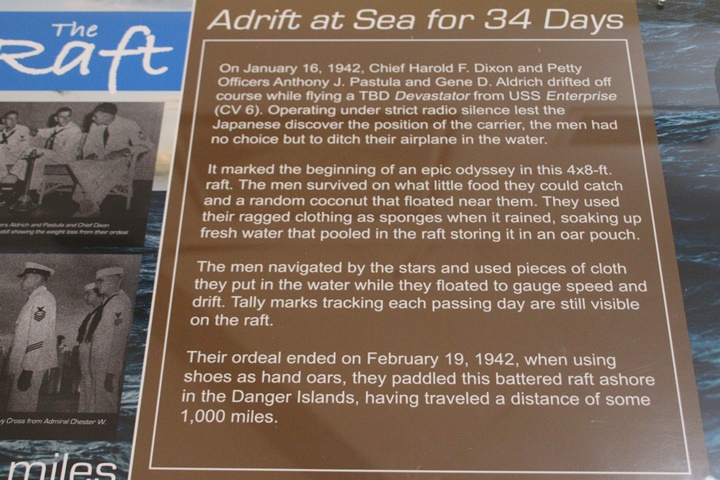

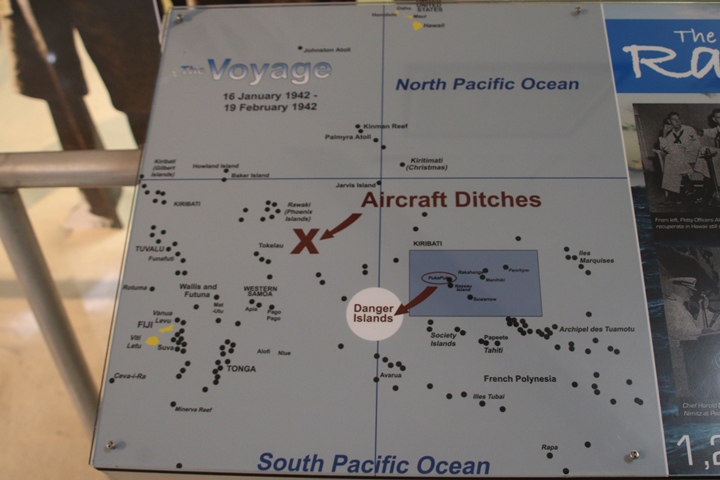

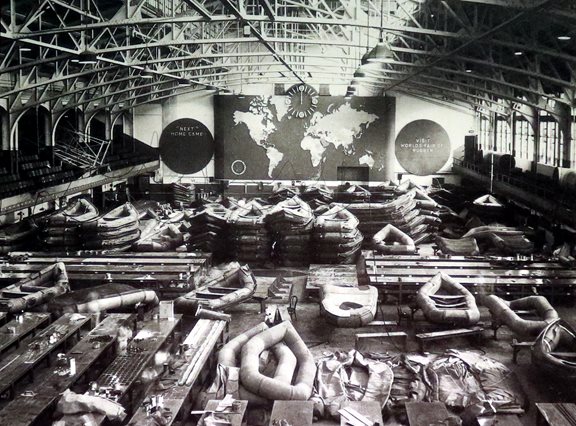

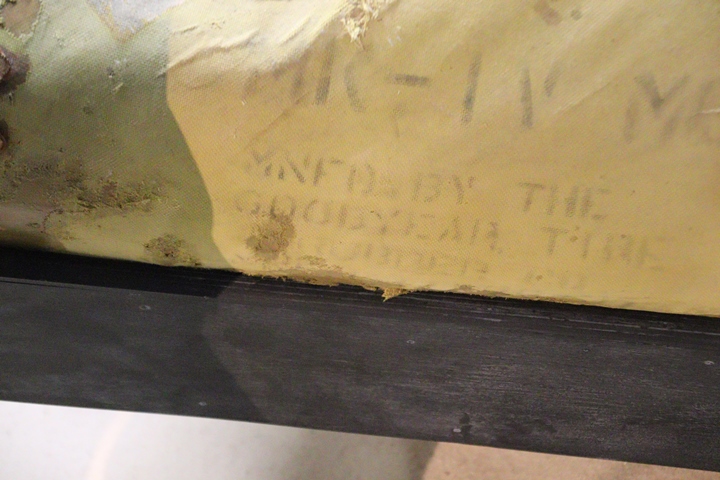

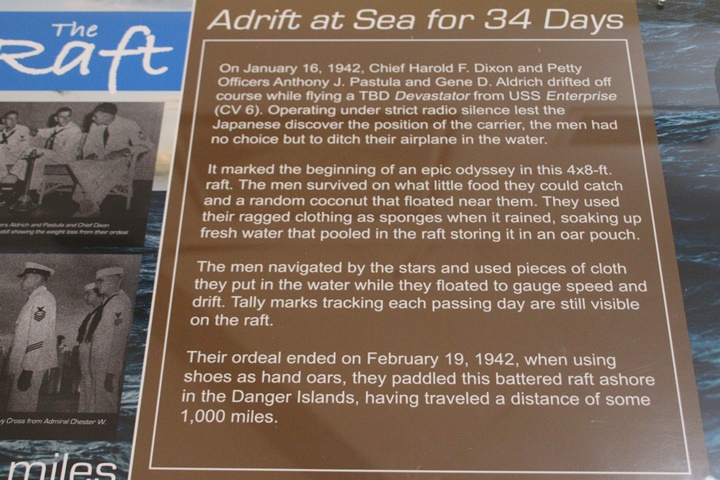

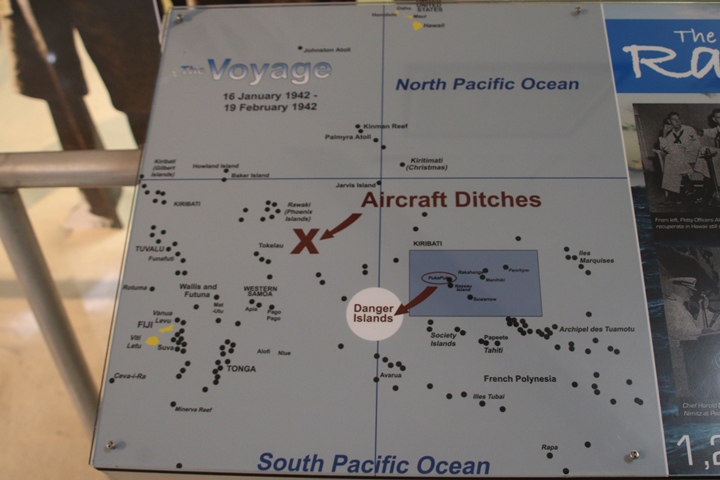

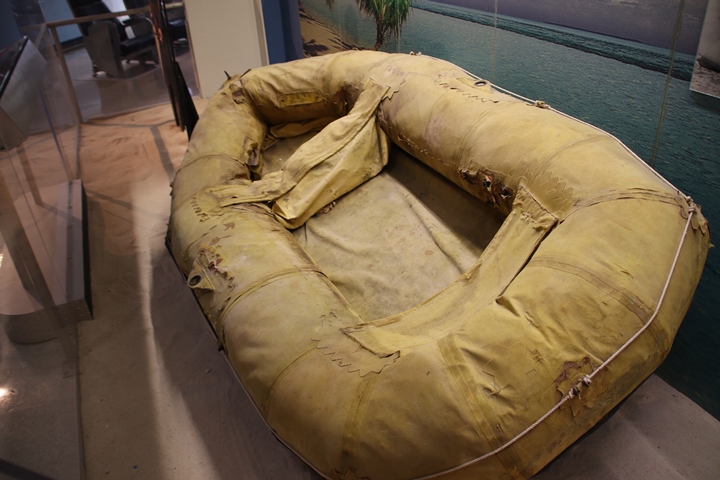

This display at the National Aviation Museum is titled:

Raft - A Story of Survival at Sea

This could also read:

A Goodyear Raft - How it Saved The Lives of Three Naval Aviators

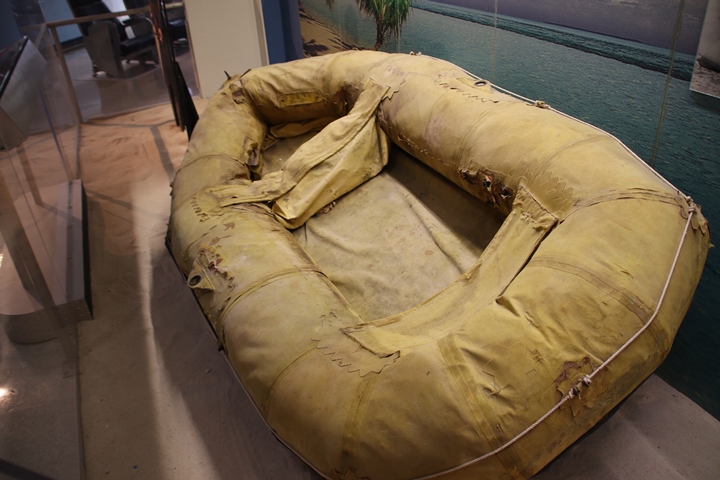

The center piece of this

display at the museum is the raft that the three naval aviators spent 34

days on in the Pacific Ocean. This raft was produced by the

Goodyear Tire and Rubber Company. Author's photo added 5-28-2023.

Author's photo added 5-28-2023.

Author's photo added 5-28-2023.

Author's photo added 5-28-2023.

Author's photo added 5-28-2023.

Photo added 5-28-2023.

This raft is a testament to the

quality of the work by the Goodyear workers that produced this raft

which saved the lives of three naval aviators. Goodyear did more

than just help win World War Two, it also saved lives with the rafts it

produced. Author's photo added 5-28-2023.

Goodyear Tire and Rubber (Goodyear) was formed

in 1898 in Akron, OH by Frank Seiberling to produce bicycle and carriage

wheels. The company then grew into the automotive tire business

for which it is best

known. The company could have been known worldwide as Seiberling Tire and Rubber if Mr. Seiberling

hadn't decided to name the company after Charles Goodyear, who invented

vulcanized rubber. Currently, Goodyear is a multinational company

and is the only American company still in the top four tire companies in

volume. During World War Two Goodyear was 30th in the production

of war products in the United States. While the company is best

known for its tires and rubber products, during World War Two the

company produced a variety of products at multiple locations as noted in Table 1 below.

The

Goodyear Decatur Mills, AL plant won the Army-Navy "E" award three times

during World War Two.

The

Goodyear Gadsden, AL plant won the Army-Navy "E" award one time during

World War Two.

The

Goodyear Clearwater Mills plant #1, Cedartown, GA, won the Army-Navy "E"

award two times during World War Two.

The

Goodyear Clearwater Mills #2, Rockmart, GA won the Army-Navy "E" award

two times during World War Two.

The Goodyear Clearwater Mills #3, Cartersville, GA won the Army-Navy "E"

award two times during World War Two.

The

Goodyear Engineering Corporation, Hoosier Ordnance Plant, Charlestown,

IN won the Army-Navy "E" award five times during World War Two.

The

Goodyear Aircraft Corporation, Akron Plant won the Army-Navy "E" award

one time during World War Two. This included the Millersburg, Newark,

and Uhrichsville, OH plants.

The

Goodyear Tire and Rubber Plant #3, Akron, OH won the Army-Navy "E"

award one time during World War Two.

Goodyear Tire and Rubber World War Two

Products: The Goodyear wartime products were very diverse and

manufactured in the company's many plants located in various parts of

the United States. This information has been captured in Table 1.

Table 2 shows the company's production of airships, or blimps, during the

war. Table 3 shows the number of tracks the company made for the

half-track.

Table 1 - Goodyear World War Two Products by Plant

The information provided in this table is from,

"Authorizations of War

Industrial Facilities Financed with Public and Private Funds,

June 1940 - July 1945" by the Civilian Production

Administration.

This document provides the most comprehensive coverage of

Goodyear's contribution to winning World War Two that is

available, as there is not much else in the way of documentation

available on what the company did during the war. That

being said, some of the entries are not quite descriptive enough

to identify the product. But in most cases, this is an

excellent view of what Goodyear's many plants contributed to the

war effort. |

|

Plant |

Location |

Product |

Comments |

|

Goodyear Tire and Rubber Company |

Akron, OH |

Aircraft nose and tail wheels, aircraft brakes, barrage

balloons, half-track tracks, combat tire rims, 20-1/2 x 6-1/4

road wheels, 22 x 6-1/4 idle wheels, gun carriage tracks,

synthetic rubber softeners, bullet sealing fuel tanks,

rubberized fabrics, plastic containers, reclaimed rubber, tires

and tubes, bullet seal hose, hydraulic brake hose, aircraft fuel

oil and coolant hose, gas masks, agricultural V-belts, steel

cable V-belts, earth mover tires, large rubber landing craft,

electric power transmission |

|

|

Goodyear Tire and Rubber Company - Goodyear Aircraft Corporation |

Akron, OH |

FG-1,

F2G, airships, B-26 outer wings, B-29 fuselages and empennage

assemblies, P-61 outer wings and empennage assemblies, aircraft

wheels, aircraft brakes, assemblies for B-33, TBF, P-38 control

surfaces, control surfaces for F6F, F3 |

The

B-33 is assumed to be the Convair B-32 Dominator. The F3

is unknown. |

|

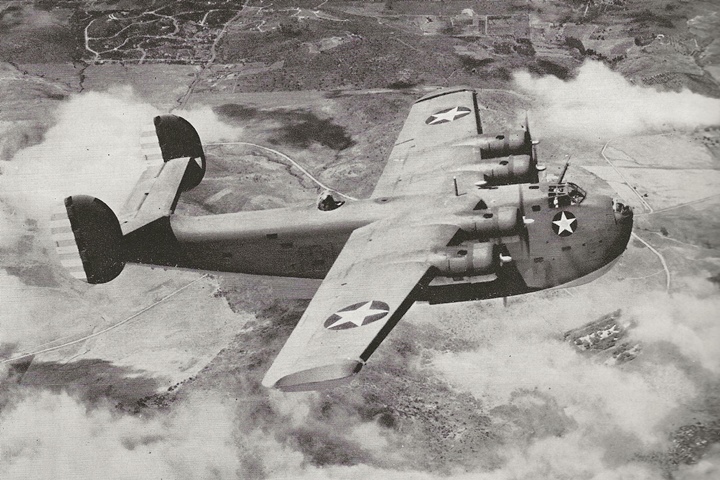

Goodyear Tire and Rubber Company - Goodyear Aircraft Corporation |

Litchfield Park, AZ |

PB4Y

wing panels, control surfaces, and empennages, PB2Y flight

decks, non-rigid aircraft |

|

|

Goodyear Farms |

Litchfield Park, AZ |

Pre-Fabricated Buildings |

|

|

Goodyear Tire and Rubber Company - Goodyear Clearwater Mills |

Atco,

GA |

Plied

yarns, army duck canvas, and tire cord |

|

|

Goodyear Tire and Rubber Company - Goodyear Decatur Mills |

Decatur, AL |

Plied

yarns and Rayon tire fabric |

|

|

Goodyear Tire and Rubber Company - Goodyear Engineering

Corporation, Hoosier Ordnance Plant |

Charlestown, IN |

75mm,

105mm, 155mm, M1A1 155mm, 1MZ 155mm howitzer charges |

|

|

Goodyear Tire and Rubber Company - Goodyear Fabric Corporation |

New

Bedford, MA |

Barrage balloons, life rafts, self-sealing aircraft fuel and oil

cells |

|

|

Goodyear Tire and Rubber Company - Goodyear Fabric Corporation |

Woonsocket, RI |

Pneumatic water targets |

|

|

Goodyear Tire and Rubber Company - Goodyear Michigan Corporation

|

Jackson, MI |

Three-inch anti-tank guns |

|

|

Goodyear Tire and Rubber Company - Goodyear Synthetic Rubber

Corporation |

Akron, OH |

Copolymer type synthetic rubber |

|

|

Goodyear Tire and Rubber Company - Goodyear Synthetic Rubber

Corporation |

Houston, TX |

Copolymer type synthetic rubber |

|

|

Goodyear Tire and Rubber Company - Goodyear Synthetic Rubber

Corporation |

Los

Angeles, CA |

Six

and twelve-ton pontoons, copolymer type synthetic rubber,

aircraft fuel and oil cells, rubber dipped fabric, gas mask nose

cups and face pieces, truck and aircraft tires |

|

|

Goodyear Tire and Rubber Company - Goodyear Tennessee

Corporation |

Nashville, TN |

Heavy

duty military tires |

|

|

Goodyear Tire and Rubber Company |

Des

Moines, IA |

Self-sealing fuel tanks |

|

|

Goodyear Tire and Rubber Company

|

Detroit, MI |

Rubber tires, tanks, rafts, belting,

etc. |

|

|

Goodyear Tire and Rubber Company |

Kokomo, IN |

Beadlock bands for the heavy truck program |

|

|

Goodyear Tire and Rubber Company |

Lincoln, NE |

Self-sealing fuel and oil cells, tires, mixed rubber stock |

|

|

Goodyear Tire and Rubber Company |

Muncie, IN |

Combat tank tracks, Boeing motor parts |

|

|

Goodyear Tire and Rubber Company |

Natrium, WV |

Vinylidene and chloride copolymer. diethyl maleate copolymer |

|

|

Goodyear Tire and Rubber Company |

New

Bedford, MA |

Fuel

cells, tires |

|

|

Goodyear Tire and Rubber Company |

Saint

Marys, OH |

Bushings for tank blocks, tank assembly blocks, tank shoes,

hydraulic aircraft blade???, aircraft motor mounts, pliofilm |

|

|

Goodyear Tire and Rubber Company |

Suffield, OH |

Aircraft surface parts, wheels, brakes, etc. |

|

|

Goodyear Tire and Rubber Company |

Topeka, KS |

Military tires |

|

|

Goodyear Tire and Rubber Company |

Woonsocket, RI |

Rubber targets |

|

|

Goodyear Tire and Rubber Company - Goodyear Tire and Rubber

Company of Alabama |

Gadsden, AL |

Dispersite, self-sealing fuel tanks, non-combatant gas masks,

truck tires, rubber dipped fabrics, reclaimed and synthetic

fiber |

|

|

Goodyear Tire and Rubber Company - Goodyear Tire and

Rubber Company of Michigan |

Jackson, MI |

Self-sealing fuel tanks, tires and tubes |

|

|

Goodyear Tire and Rubber Company- Kelly Springfield Tire Company |

Cumberland, MD |

Ammunition, 50 cal,

Shells - 8 inch M106 H.E.,

Tires and tubes, automotive

Tires and tubes, bus and truck |

|

|

Goodyear Tire and Rubber Company - Kelly Springfield Tire

Company |

Houston, TX |

Heavy

duty military tires |

|

|

Goodyear Tire and Rubber Company - Goodyear Yellow Pine Company |

Picayune, MS |

Creosote lumber piling |

|

|

Table 2 - Goodyear Deliveries of Airships World War Two |

| Type |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| K |

4 |

20 |

92 |

17 |

0 |

133 |

| L |

2 |

9 |

10 |

0 |

0 |

19 |

| G |

0 |

0 |

6 |

1 |

0 |

7 |

| M |

0 |

0 |

1 |

3 |

0 |

4 |

| Total |

6 |

29 |

109 |

21 |

0 |

163 |

|

Table 3 -

Goodyear World

War Two Half-Track Tracks

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

Same as |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Tracks, 12-inch,

58 pitch band |

B.F. Goodrich,

Firestone |

|

44 |

4,000 |

11,160.5 |

10,820 |

5,626.5 |

31,651 |

The most recognizable and well-known of Goodyear's World War Two

products was the FG-1 Corsair, a licensed copy of the Vought F4U

Corsair. Goodyear built 4,007 of these famous

fighters in Akron, OH. This example is on display that the

Kalamazoo Air Zoo Aviation Museum. Author's photo.

This is Goodyear construction number 3770.

Author's photo.

Goodyear built 4,001 FG-1s during

World War Two. During 1944 it produced its 3,000th of these aircraft,

like this FG-1 owned by the Commemorative Air Force. Author's

photo.

|

Table4 - Goodyear World War Two FG-1 U.S. Navy

Monthly Acceptances

This table added 9-28-2022. |

|

Month |

Number Accepted |

| 1943 |

|

| April |

2 |

| May |

7 |

| June |

16 |

| July |

22 |

|

August |

30 |

|

September |

77 |

|

October |

63 |

|

November |

78 |

|

December |

82 |

|

1943 Total |

377 |

| |

|

|

1944 |

|

|

January |

150 |

|

February |

147 |

| March |

222 |

| April |

220 |

| May |

220 |

| June |

160 |

| July |

170 |

|

August |

168 |

|

September |

180 |

|

October |

182 |

|

November |

145 |

|

December |

144 |

|

1944 Total |

2,108 |

| |

|

|

1945 |

|

|

January |

103 |

|

February |

178 |

| March |

262 |

| April |

205 |

| May |

195 |

| June |

179 |

| July |

180 |

|

August |

151 |

|

1945 Total |

1,453 |

|

September |

68 |

|

Grand Total |

1,521 |

Goodyear also manufactured eight F2Gs.

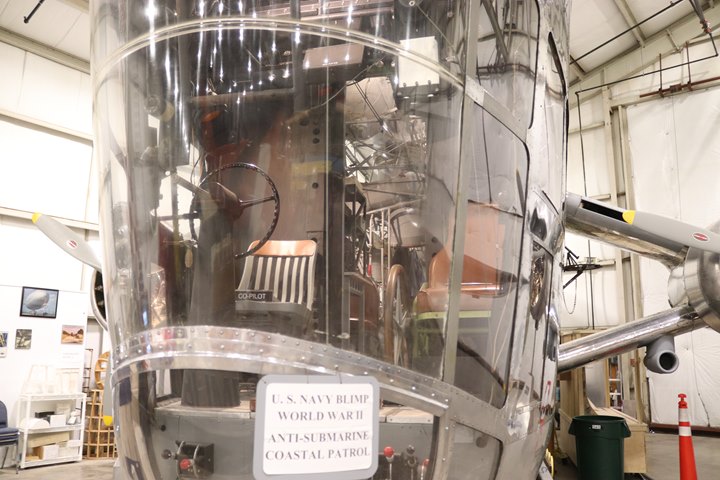

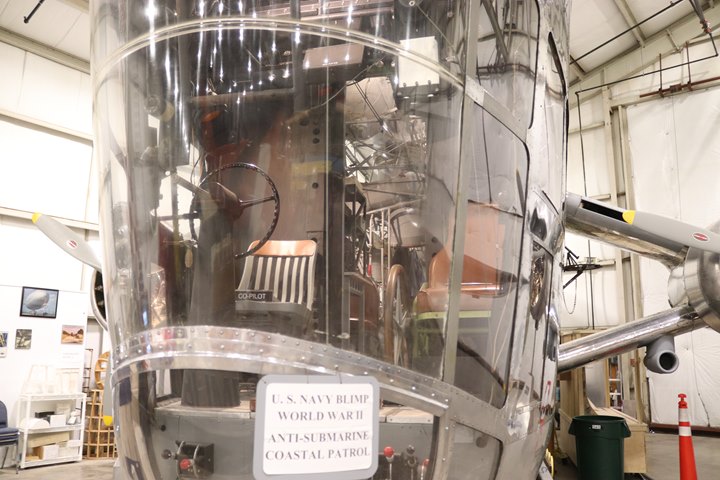

The most unique product that Goodyear built

for the war effort was the airship for the U.S. Navy. It was

the only company to build airships during the war effort. The United

States was the only country to operate airships during World War Two. This fully restored crew

cabin from K-28 is on display at the New England Air Museum.

Author's photo.

The most significant, yet unknown, Goodyear

World War Two products were the forward and rear bomb bay fuselage

sections that Goodyear built for the B-29 Enola Gay. Goodyear also

supplied the rudder, vertical stabilizer, dorsal fin assembly, elevator

assembly, and horizontal stabilizer assembly for the Enola Gay.

These components were built at the same facility as the

FG-1 Corsairs at the Akron Airport in Akron, OH, and for 530 other B-29s as

well. Author's photo.

The most unusual weapon was the M5 three-inch

anti-tank gun made by the Goodyear Michigan Corporation in Jackson, MI.

It is unusual because one does not normally think of a tire and rubber

company making weapons of this size. Pullman-Standard built the

carriage for this particular M5 that is on display at the Indiana

Military Museum in Vincennes, IN. There is no identification as to

which company or arsenal built the barrel and recoil assemblies.

Normally, the Rock Island Arsenal built recoil assemblies for

weapons of this type, and the Watervliet Arsenal built the barrels.

However, an entry in Table 1 identifies the Goodyear plant in Jackson,

MI as making three-inch anti-tank guns. It could be that the plant was

making a subassembly for the weapon. The plant is

identified in a second entry as making self-sealing fuel tanks, tires, and tubes.

These are

more in line with Goodyear's normal product lines. Author's photo.

Goodyear Aircraft Corporation:

This photo shows a Goodyear-built airship as

it keeps

watch over a convoy heading to England with important war products

and food. Airships were one of the many weapons used to combat the

German U-Boat menace during World War Two.

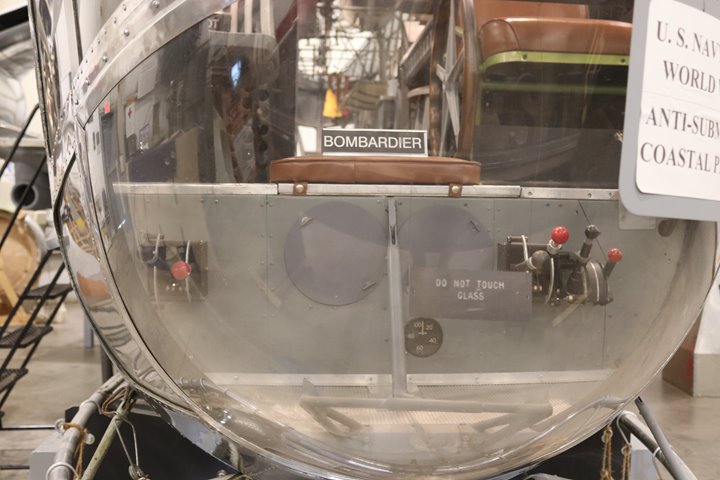

The next series of photos show more of

K-28's restored crew cabin at the New England Air Museum. Author's

photo.

Author's photo.

Author's photo.

Author's photo.

The pilot controlled pitch and altitude

while the co-pilot controlled the course. Author's photo.

The co-pilot and rear observer had

office-type chairs. Author's photo.

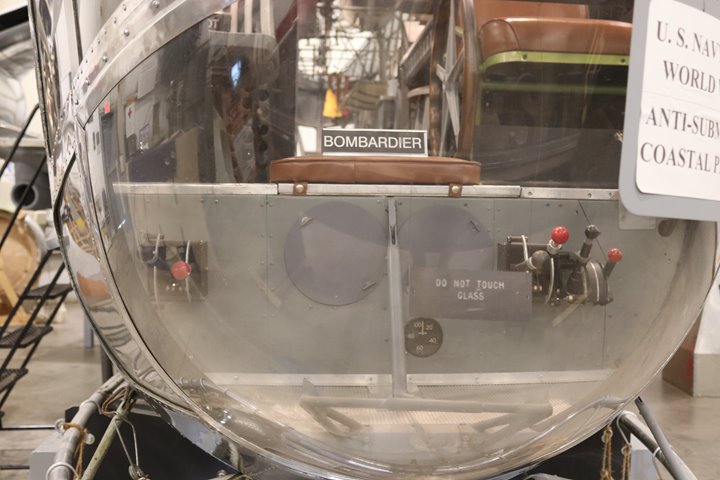

The bombardier laid down at his position to

drop bombs or depth charges. Author's photo.

The airships used sandbags to assist in

keeping them on the ground when not in operation. Author's photo.

A .30 caliber machine gun was mounted in the

nose for self-defense. Author's photo.

Author's photo.

Goodyear Aircraft Corporation, Akron, OH:

The following aircraft and aircraft components were produced in Akron.

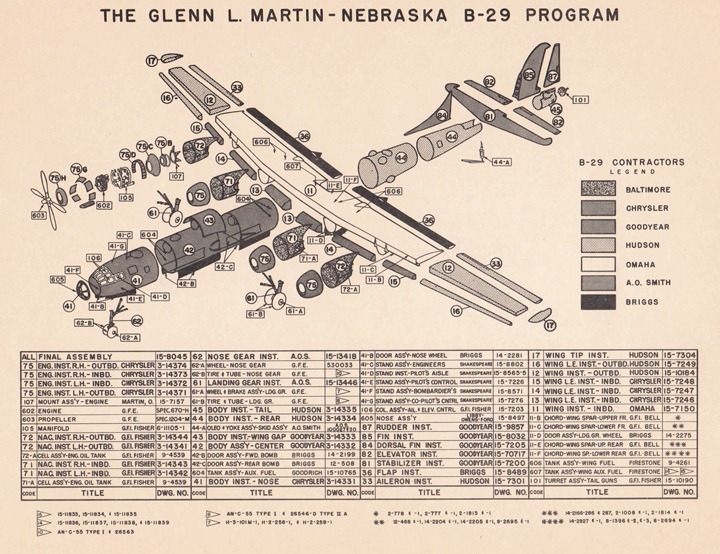

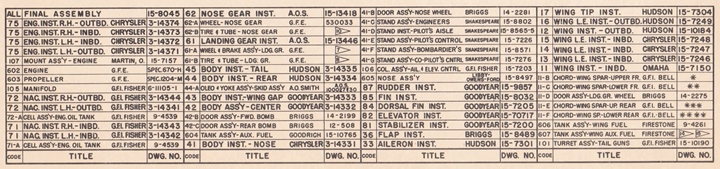

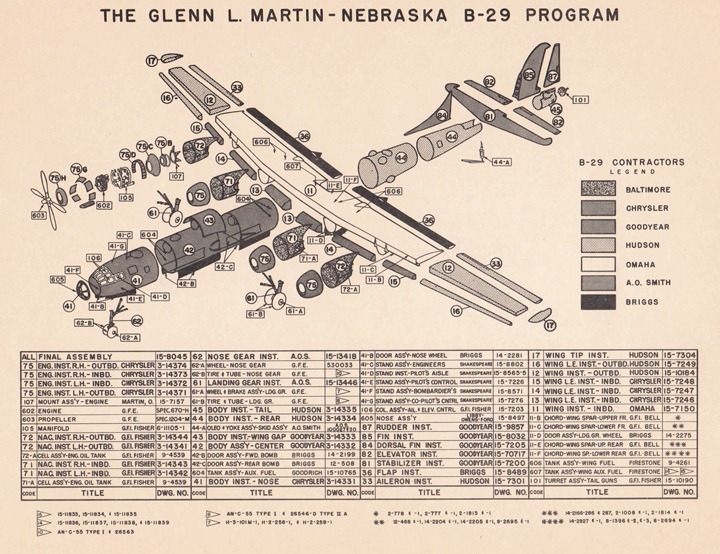

Beginning in May 1944, and extending through

September 1945, Goodyear provided 531 each of the following airframe

components to Glenn L. Martin B-29 plant in Omaha, NE. These were

the forward and rear bomb bay fuselage sections, rudders, vertical

stabilizers, dorsal fin assemblies, elevator assemblies, and horizontal

stabilizer assemblies. Author's photo.

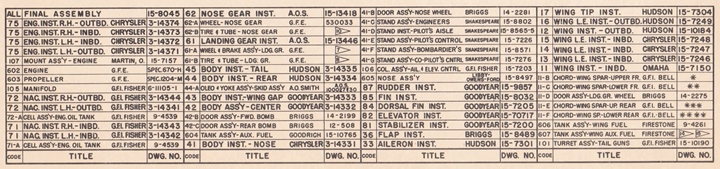

This primary document from the Glenn Martin

plant in Nebraska shows the fuselage and aircraft control surfaces

Goodyear manufactured for the B-29 program. The B-29 was the most

expensive project undertaken by the United States during World War Two.

It was even more expensive than the Manhattan Project.

As the Martin information from World War Two shows,

the US auto industry was the major supplier of airframe and structural

components to Omaha.

The front fuselage section was built by

Chrysler. Goodyear built the front bomb bay fuselage section, starting at the seam just forward of the propeller. The

Goodyear-built rear bomb bay fuselage section is adjacent to the wings. Author's photo.

Goodyear built outer wing sections for the Martin B-26

like this one on display at the National Museum

of the United States Air Force Dayton, OH. Author's photo.

Goodyear produced control surfaces for the

Lockheed P-38. Author's photo.

The Grumman TBM had Goodyear assemblies in

it. Author's photo taken at

the Liberty Aviation Museum.

Goodyear also produced control surfaces for

the Grumman F6F Hellcat. The Grumman F6F shot down more Japanese

aircraft during World War Two than any other aircraft, operating

primarily from the Essex Class Aircraft Carriers. This example is

on display at the Kalamazoo Air Zoo Aviation Museum. Author's

photo.

Goodyear built outer wing sections for the

Northrop P-61 Black Widow night fighter. This one is on display at the Udvar-Hazy

Center of the National Air and Space Museum. Author's photo.

Goodyear Aircraft Corporation,

Litchfield Park, AZ: The following aircraft components

were produced in Litchfield Park.

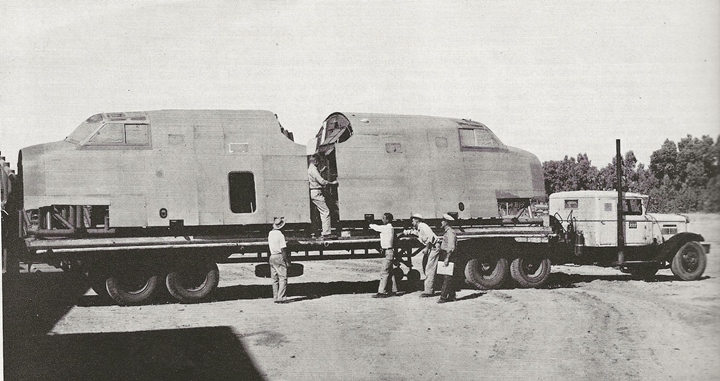

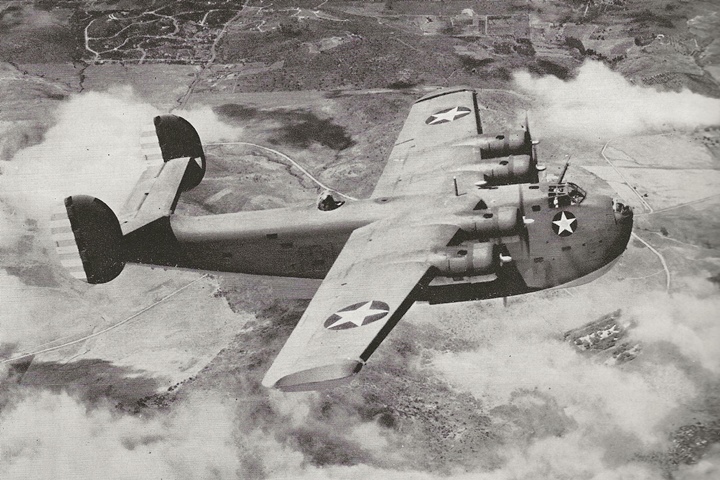

Consolidated Aircraft Corporation in San

Diego, CA produced 217 PB2Y Coronado flying boat patrol bombers.

Goodyear at Litchfield Park, AZ

produced the flight deck for the aircraft.

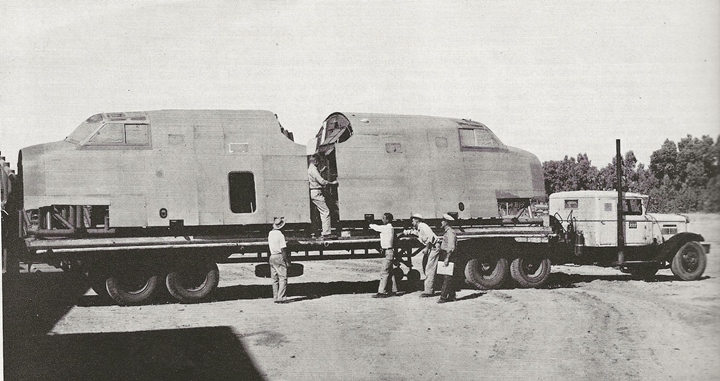

Two flight PB2Y decks are being loaded onto

a semi-trailer for shipment to San Diego during World War Two.

This was a complicated piece of the aircraft. In an

area that only had cotton farms and no heavy industry until the Goodyear

plant was built, this factory was an impressive accomplishment.

This is the only surviving example of the

217 PB2Y Coronados that were built. This particular aircraft was

converted into an admiral's transport aircraft and flew Admiral Nimitz

to the signing of the Japanese surrender ceremony in Tokyo Bay on

September 2, 1945. Admiral Nimitz and his staff were able to land

in Tokyo Bay and then be transported by small boat the USS Missouri.

Author's photo.

Author's photo.

Author's photo.

This view shows the flight deck built by

Goodyear in Litchfield Park, AZ. Photo courtesy of the National

Naval Aviation Museum.

The radio operator and navigator were

located on the flight deck behind the pilot and co-pilot.

Photo courtesy of the National Naval Aviation Museum.

The Goodyear Litchfield Park, AZ facility

produced wing panels, control surfaces, and empennages for the 739 PB4Y

aircraft built. Author's photo.

Goodyear produced the rubber tires for the

M24 Chaffee light tank. Author's photo.

Author's photo.

Author's photo.

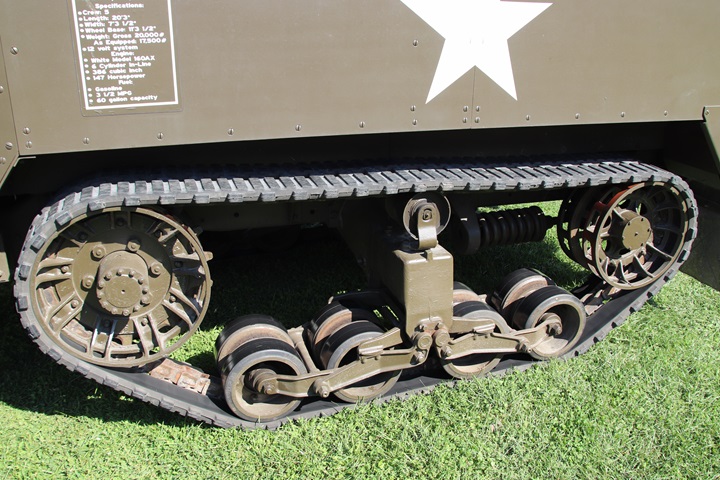

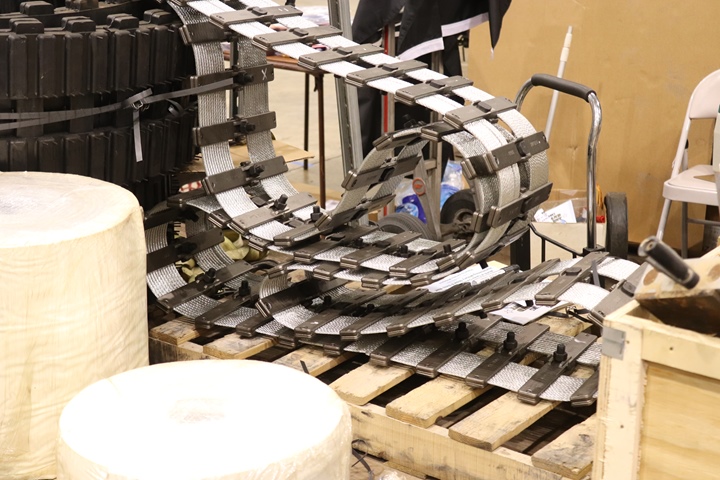

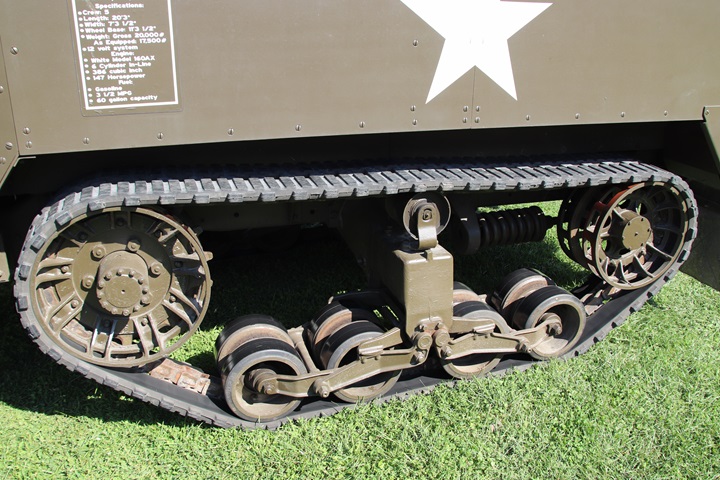

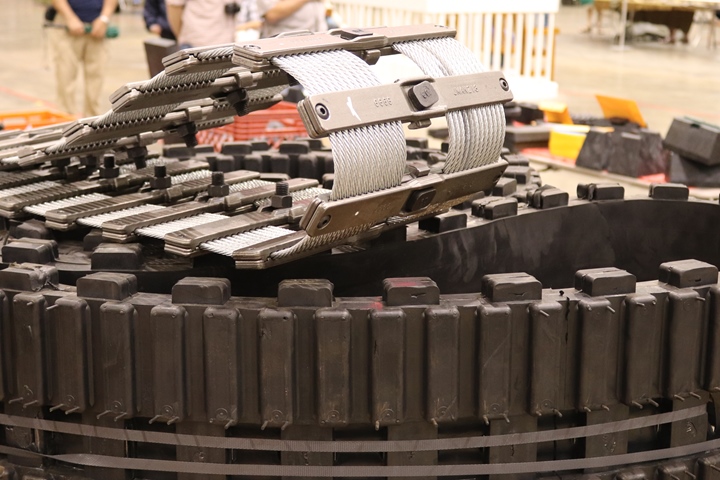

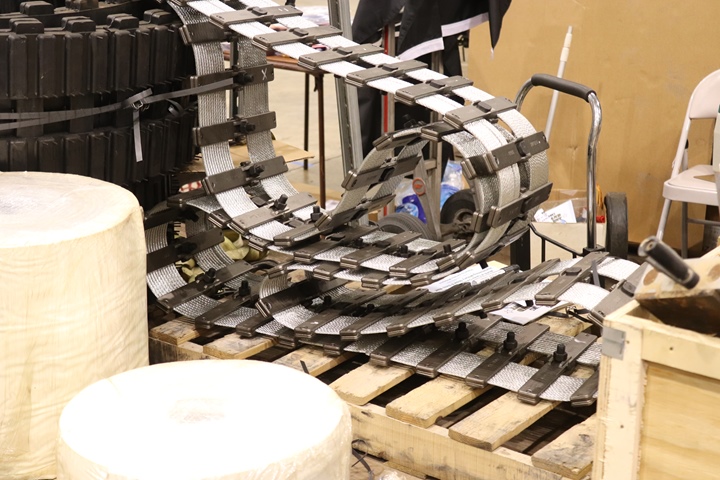

Goodyear produced 31,651 halftrack tracks. Author's photo.

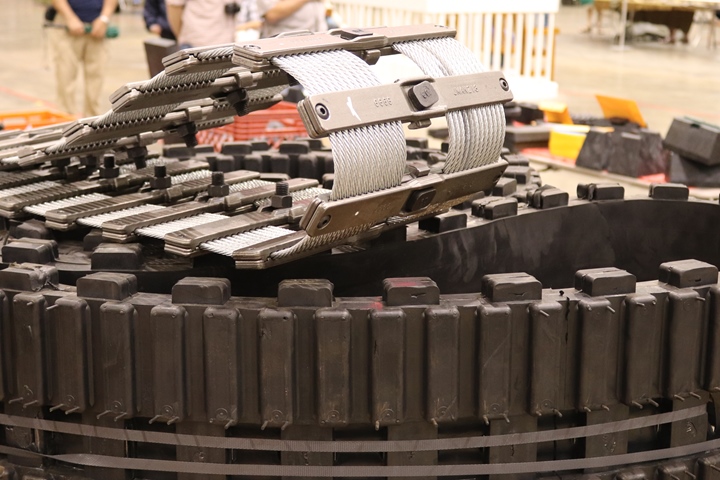

The tracks were constructed with a

continuous steel rope over-molded with rubber. Author's photo.

Shown here are new tracks that can be purchased to replace worn tracks

on restored half-tracks. Author's photo.

This photo shows the two continuous steel

ropes that are joined together with steel brackets and fasteners.

Author's photo.

Author's photo.

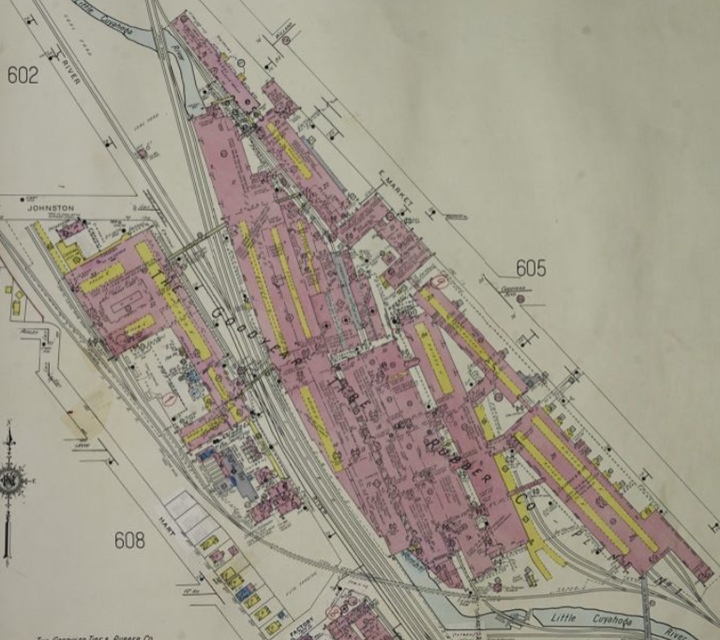

Goodyear Plants-Akron, OH: During

World War Two Goodyear had plants on the east side of Akron, at the

municipal airport on the southeast side of town, and east of town at

Wingfoot Lake.

Eastside Complex:

The six story red-brick building is the

former headquarters of Goodyear. The Goodyear sign still remains even

though the headquarters is a mile south of this location on Innovation

Way. The gray triangular shaped building in front of it is a bank.

This view is looking southeast down Market Street. Author's photo.

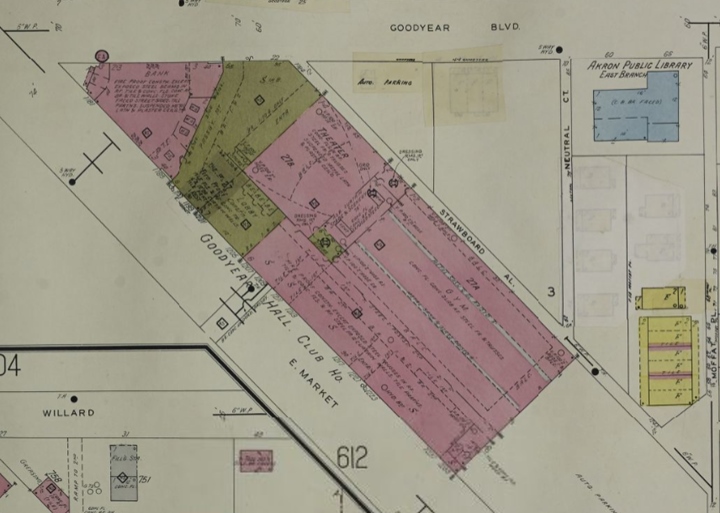

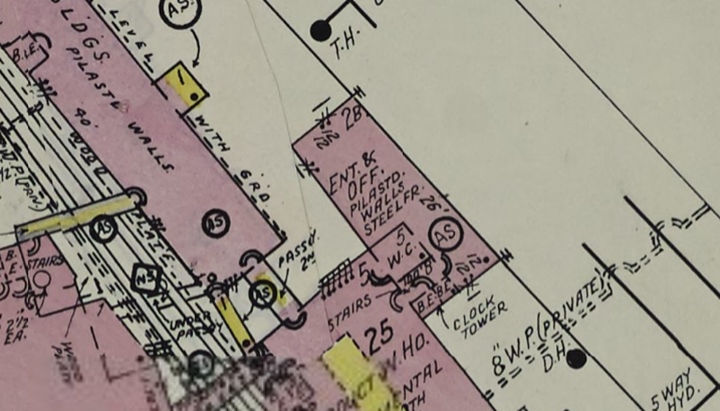

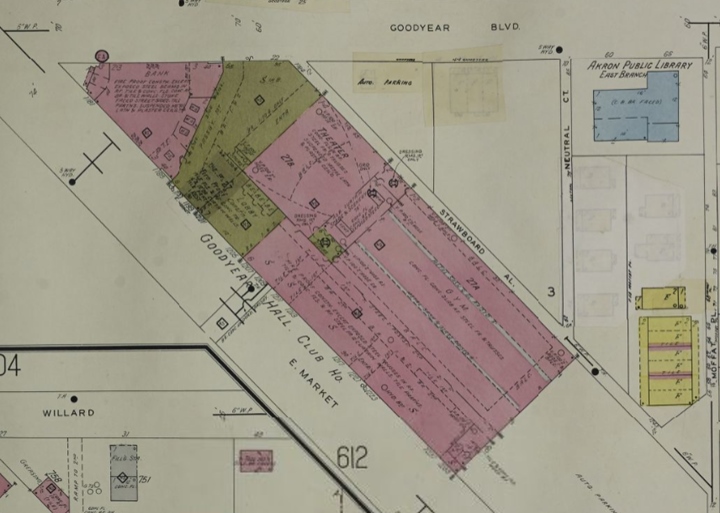

This 1951 Sanborn fire map shows the building

as it would have been during World War Two. The headquarters building

had a theater and employee gymnasium. The library is still there,

and I was able to do some Goodyear research there when I visited Akron.

This is the southeast section of the

Goodyear headquarters building. The company's employee gymnasium

is on the east side of the building. The theater is at the far end of the

building where there are no windows. Author's

photo.

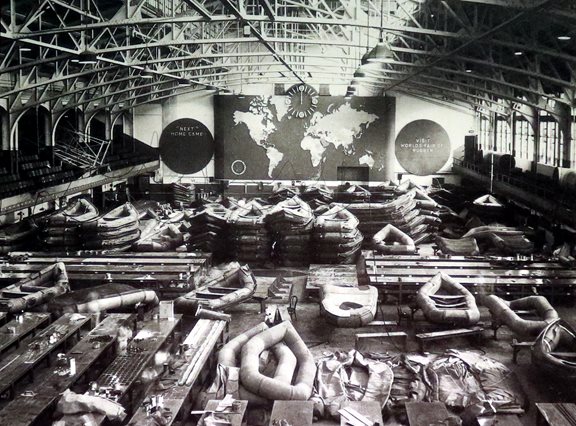

During World War Two aircraft rubber assault

boats and life rafts were assembled in the gymnasium.

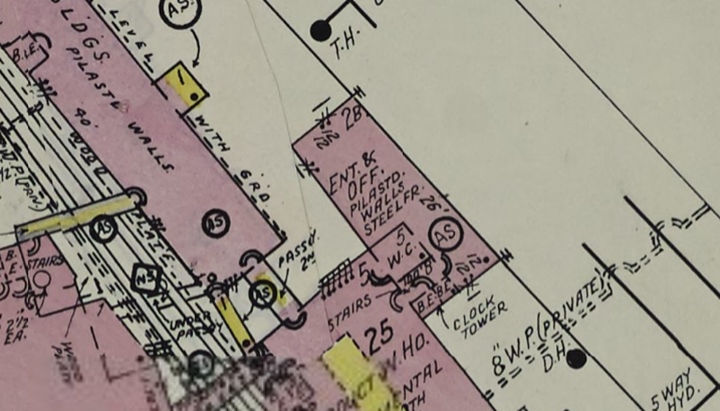

The Goodyear clock tower is north of the

former Goodyear headquarters and on the opposite side of Market

Street. Some of the

former Goodyear manufacturing plant in Akron was located behind the

brick wall. Author's photo.

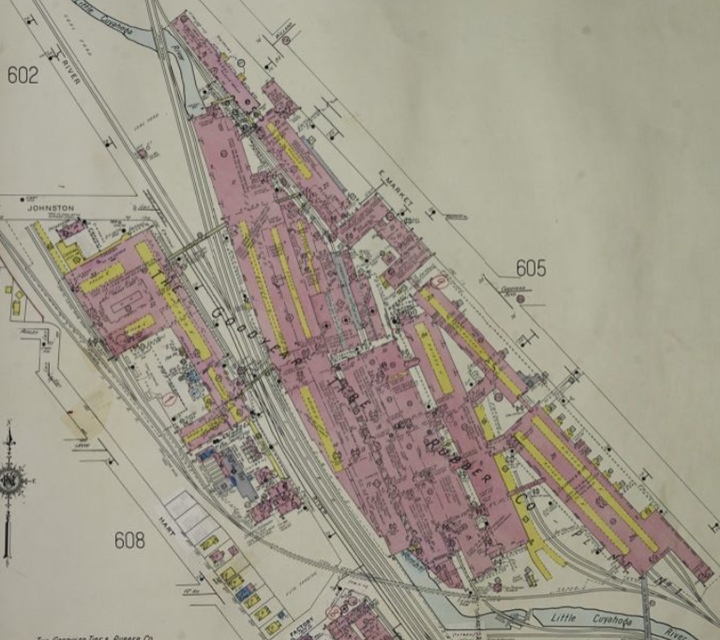

This Sanborn map shows the massive Goodyear

manufacturing plant across Market Street from the former headquarters

building.

A current Google Maps satellite view shows

that about 50% of the former Goodyear manufacturing plant still stands.

This enlargement of the Sanborn map shows

the clock tower.

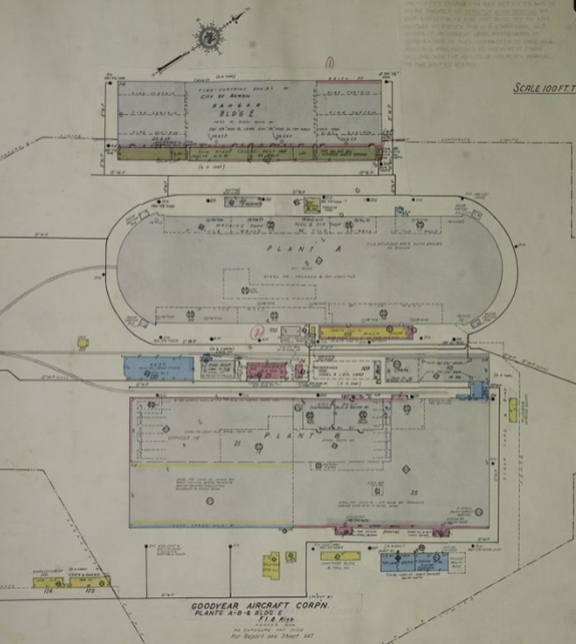

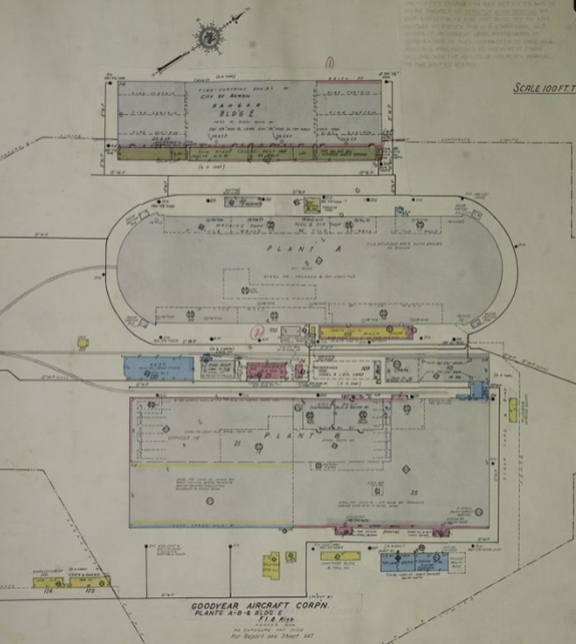

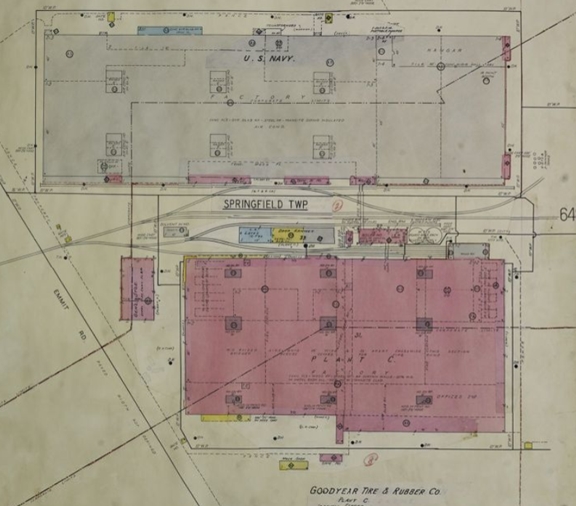

Akron Municipal Airport Complex:

In 1942 there were 32,000 persons working at

this facility making a variety of aviation products. The products

included: FG-1 Corsairs,

F2Gs, airships, B-26 outer wings, B-29 fuselages and empennage

assemblies, P-61 outer wings and empennage assemblies, aircraft

wheels, aircraft brakes, assemblies for B-32, assemblies for TBF, P-38 control

surfaces, and F6F control surfaces.

There were 531 B-29 bomb bay fuselage

sections and 4,001 FG-1 Corsairs built at this facility along with all

of the other aircraft components.

This Google Maps satellite view shows the

former Goodyear Aircraft Corporation complex as it is today.

The building in the middle is the Airdock.

Today the Airdock and building at the bottom of the map is owned by

Lockheed-Martin and the top building is owned by Waste Management.

This photo was taken several years ago after

the Airdock had caught on fire from a lightning strike. The Akron

Fire Department was able to extinguish the fire and save this historical

building. Author's photo.

This photo was taken after the repairs were

made to the building. Author's photo.

Author's photo.

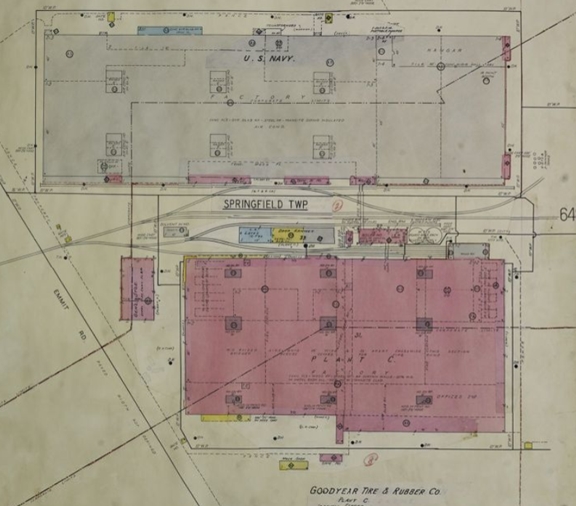

After World War Two, the U.S. Navy had a

Naval Air Reserve Station at the Akron Municipal Airport. The 1951

Sanborn map reflects this. During World War Two, Goodyear used the

building for production. Today there are several occupants in the

facility.

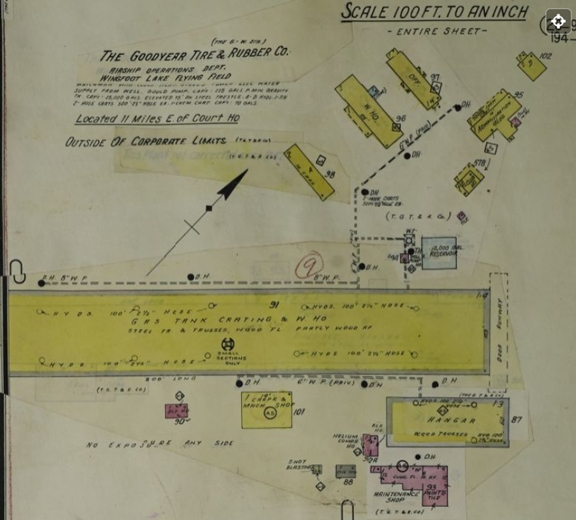

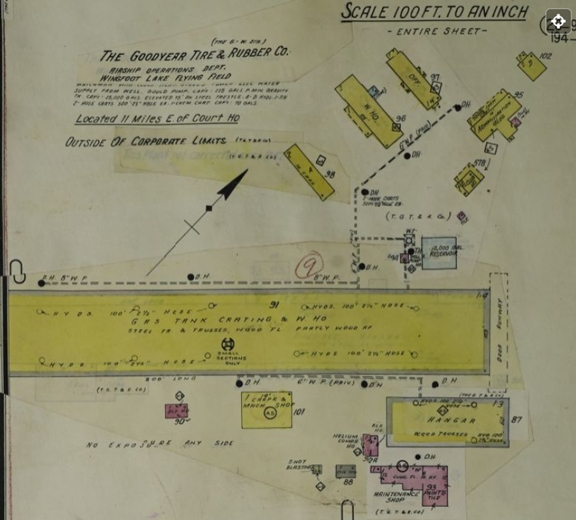

Wing Foot Lake: This is the

operating base for the Goodyear blimp. During World War Two, it

engaged in the manufacture and testing for the Navy airships.

Author's photo.

Author's photo.

The Sanborn map shows several buildings in 1951 that the Google Satellite view below shows are now

gone.

Goodyear Plant - Litchfield Park, AZ:

In 1916, Goodyear executive Paul Litchfield came to the Phoenix

area to find local cotton farmers to provide cotton required for the

cord in the company's tires. When he found the farmers were not

interested, he suggested to company management that Goodyear purchase

farms and produce the cotton for its own use. So, Goodyear Farms

came into being and Goodyear had a large presence in the area twenty

miles west of Phoenix. As World War Two approached, the U.S. Navy

came to Paul Litchfield, now chairman and CEO of Goodyear, and requested

the company build and operate a new Navy-owned aircraft manufacturing

plant in the same area as its cotton farms. In August 1941,

construction began on the new facility.

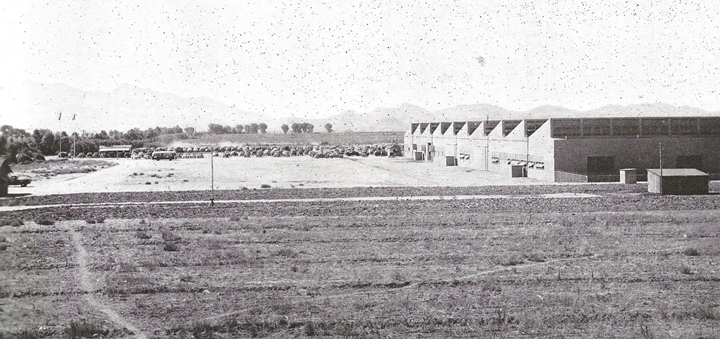

This World War Two-era photo shows the south

end of the plant and the water tower at the west end of the facility.

This current Google Maps street view shows

the water tower and the south end of the original plant. There

have been expansions and much growth in the area in the past 80 years.

This section of the Google Satellite view

shows the same area with the water tower at the left of the photo.

This view is to the south.

This view shows how the plant grew after

World War Two and what it currently looks like. Goodyear no longer

has a presence here.

|