|

Diamond

Chain and Manufacturing Company During World War Two

1890-xxxx

Indianapolis Chain and Stamping

Indianapolis, IN

1890-2023

This page updated 5-27-2024.

The Diamond Chain and Manufacturing Company

has been in business in Indianapolis, IN since 1890, and at this

location on 402 Kentucky Avenue since 1918. Over the years, there

have been several different corporate owners of the Diamond Chain

Company. In 2020, Timken purchased the company and announced the

plant shown above, located on the near southwest section of downtown

Indianapolis, would close in early 2023. Also, the jobs of the 240

persons who work at the plant are going away when it closes. The

operations that are still performed at this plant will be moved to

Illinois. When this factory was built, multi-story factories were

the norm. Built in an era when public transportation or walking

was the normal way to get to work, factories with several stories were

built with a small footprint. Locating in an industrial area on

the near southwest side of Indianapolis placed the Diamond Chain plant

close to its workers. But times have changed, and it is the last

factory left in the area. Author's photo.

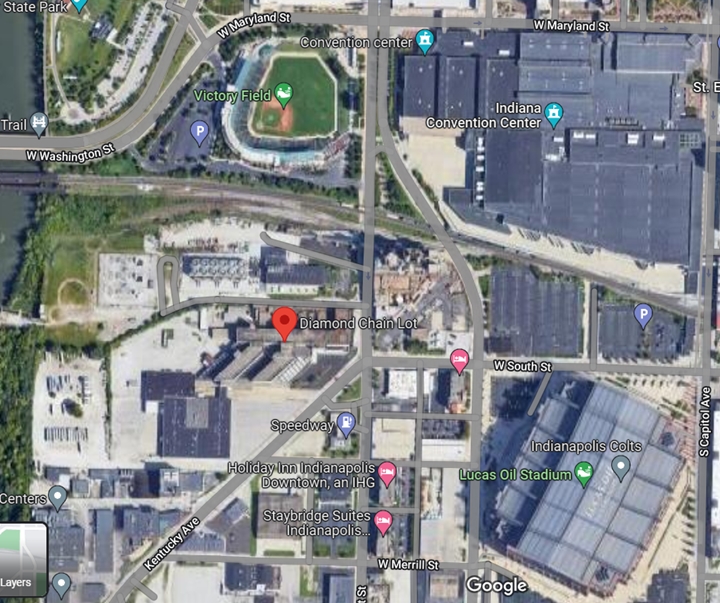

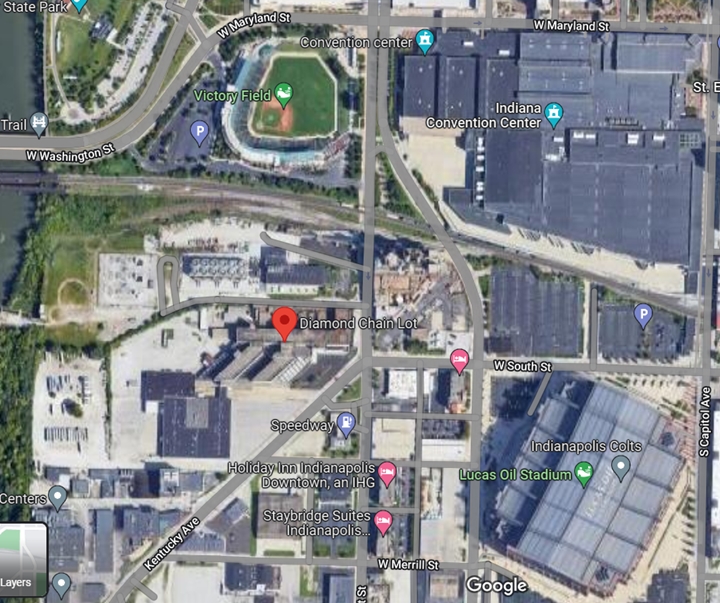

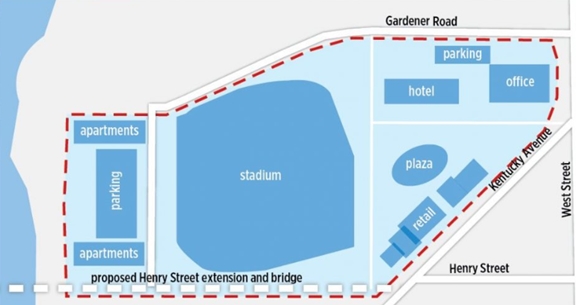

This Google satellite image shows that the

Diamond Chain factory is in an excellent location for redevelopment with

two sports stadiums, the Indiana Convention Center, and two hotels

nearby. The land that the plant sits on is probably worth more

than the factory building itself, so it will be razed in 2023.

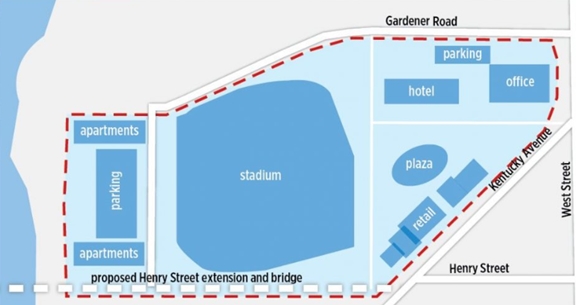

In fact, the 18-acre property was purchased by a real estate developer

in 2022 for $7.6 million. By 2025, there are plans to have a

20,000 seat soccer stadium, apartments, a hotel, and retail stores at

this location.

The Diamond Chain Company

of Indianapolis, IN was the first company in the United States to

produce bicycle chains.

One of Diamond Chain's customers was a

couple of brothers that operated this shop at 22 South Williams Street

in Dayton, OH. Their names were Wilbur and Orville. Author's

photo.

In 1895, a relative of Eula Baker purchased

this Wright Brothers' Van Cleve Model bicycle for her. She later

donated it to the National Museum of the United States Air Force in

Riverside, OH. Author's photo added 12-31-2022.

Author's photo added 12-31-2022.

This may well have the original Diamond

Chain bicycle chain on it. Author's photo added 12-31-2022.

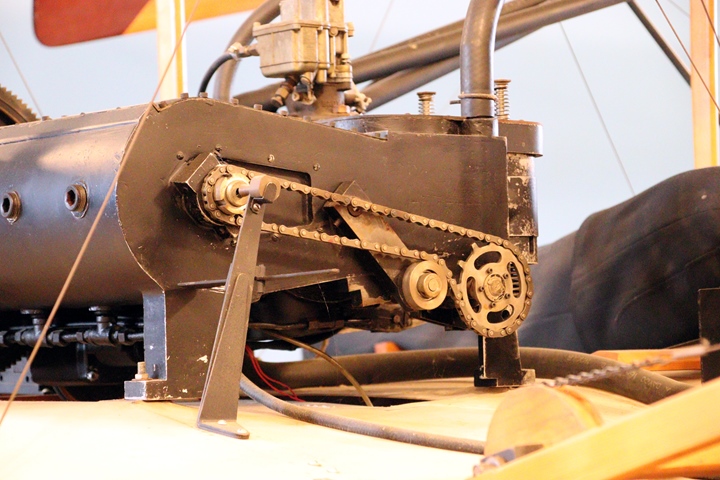

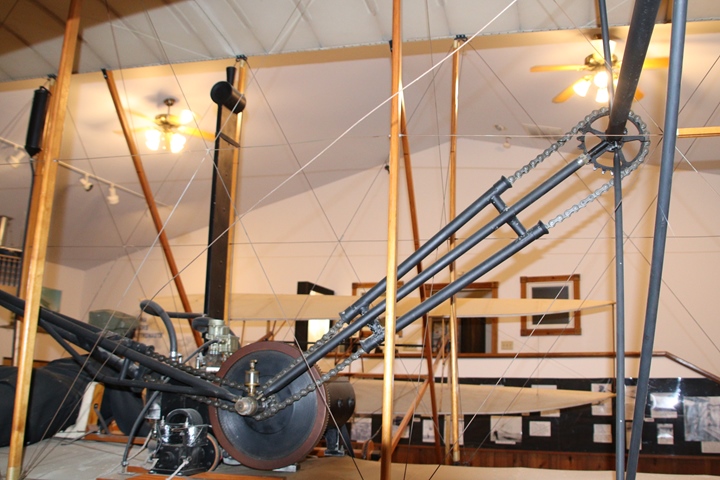

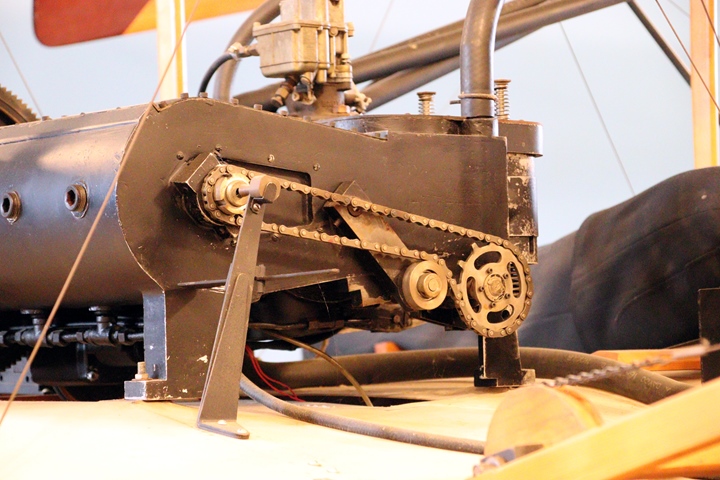

When it came time for Orville Wright to make

his historic first flight on December 17, 1903, there were seven Diamond

Chain and Manufacturing Company chains on the 1903 Wright Flyer when it

took to the air at Kill Devil Hills, NC. Author's photo from the

Wilbur Wright Birthplace Museum in Hagerstown, IN.

Two Diamond Chain Company chains drove the

two propellers. Author's photo.

This Diamond-made chain was used as the

timing chain on the engine. Four other chains were used to operate

the control services on the aircraft. Author's photo.

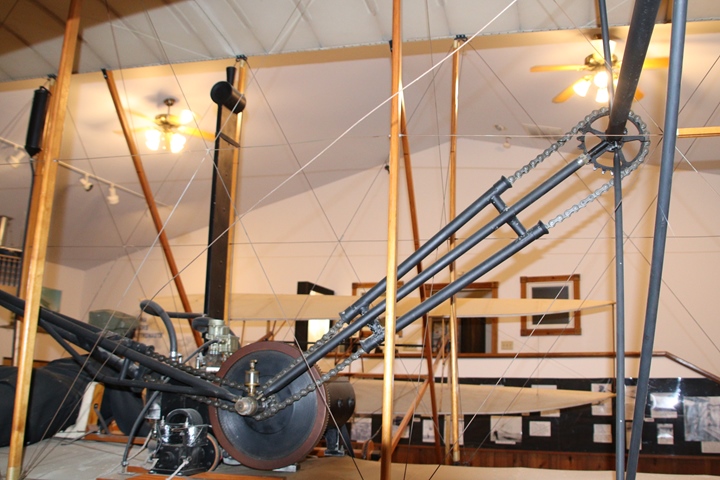

Quite a few of the aviation museums I have

visited around the United States have replica Wright Flyers just like

the one on display at the Wilbur Wright Birthplace Museum.

However, at this museum the Wright Flyer is the featured display and not

one of many aircraft on display. I have visited this museum quite

a few times over the years and always enjoy my return trips. I

consider it to be one of the 'Hidden Gem Museums' that I like to find

and visit. While not very big and out in the middle of east

central farming country, it is well worth the trip for aviation

historians and enthusiasts. One thing that is most noticeable at

the museum when one gets out of his vehicle is the quiet. It is

far enough away from 'civilization' that it is very, very quiet in the

area. Author's photo.

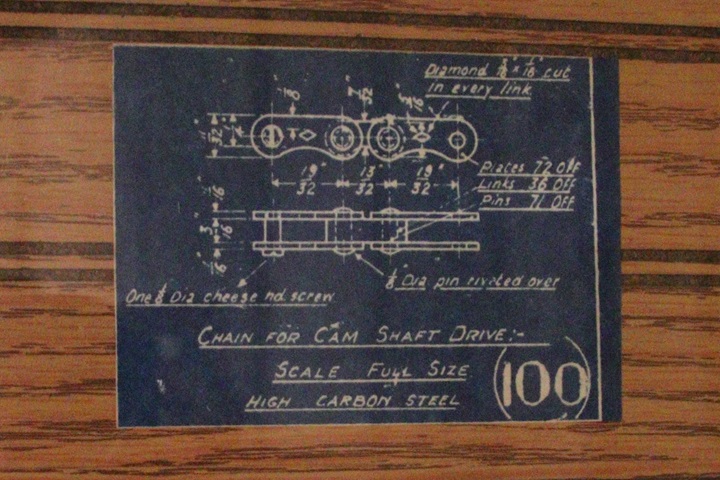

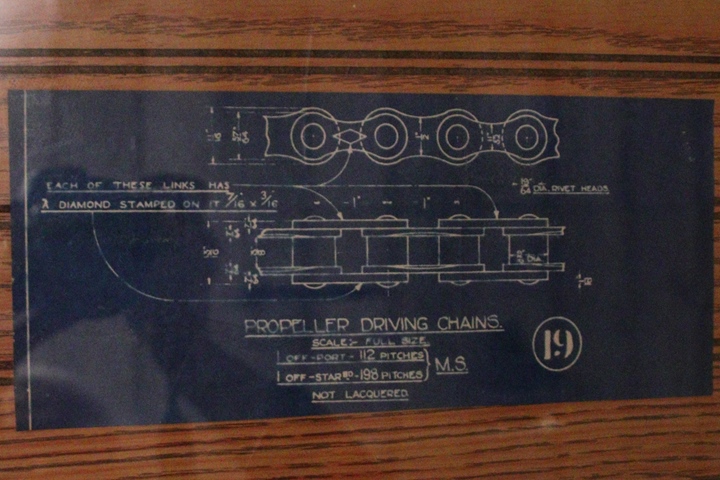

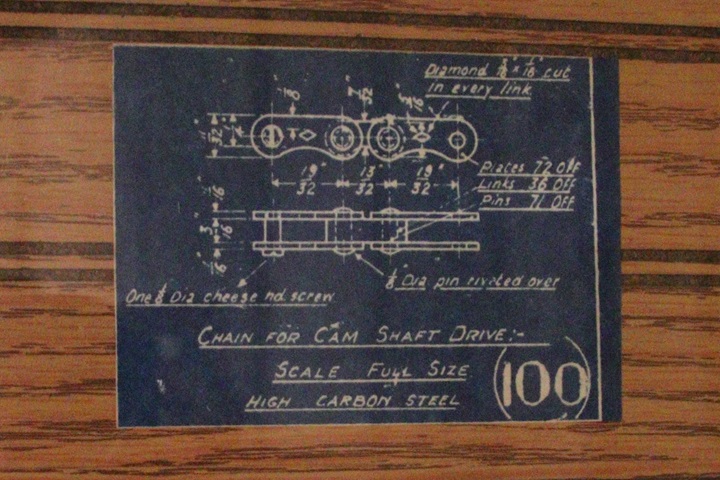

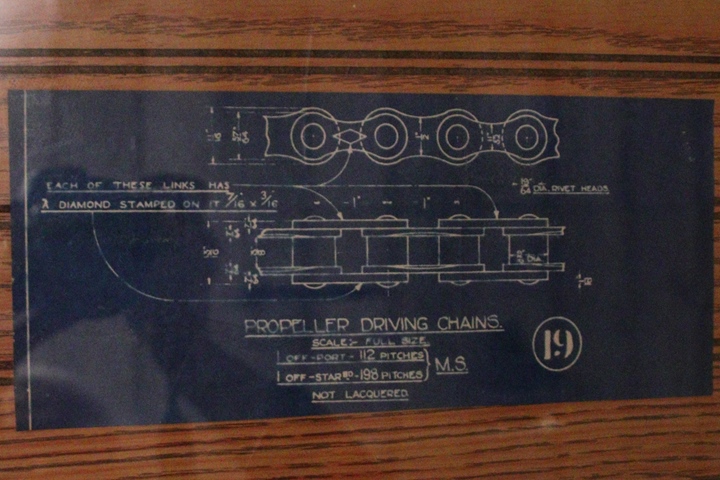

On display at the museum are several Diamond

Chain blueprints for the chains used on the 1903 Wright Flyer. The

one above is for the cam shaft drive.

Author's photo.

The museum has the blueprint for the

propeller driving chains. Author's photo.

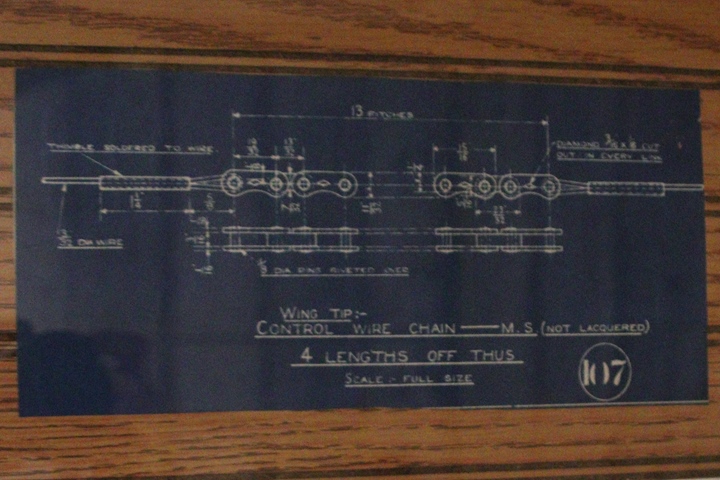

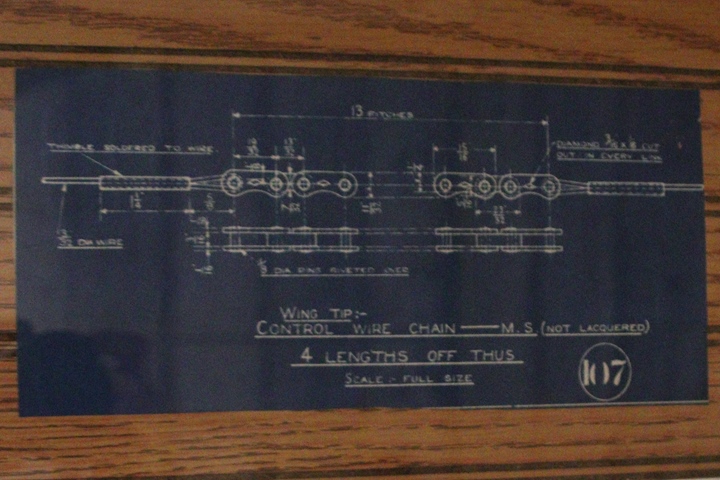

This is one of four control surface chain

and cable assemblies on the Wright Flyer. Author's photo.

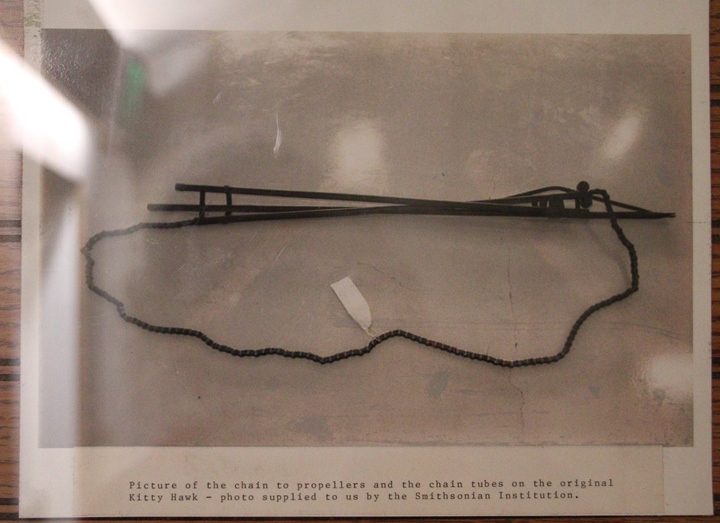

Each Diamond-built chain on the Flyer was

specially built to the Wright Brothers' specifications. Author's

photo.

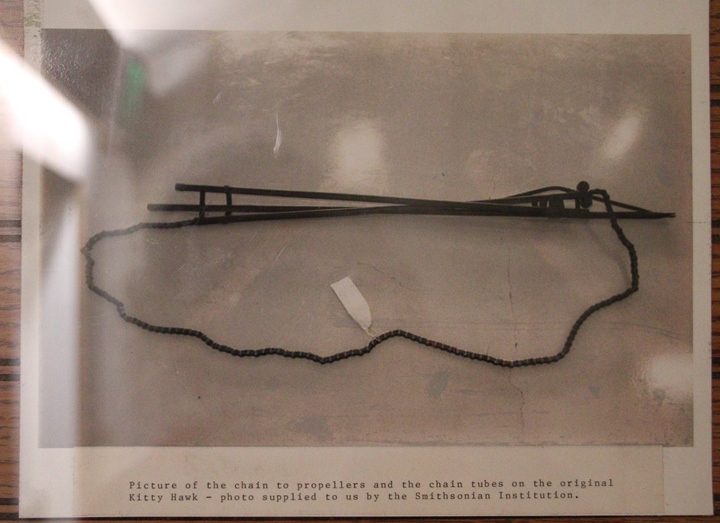

This photo of the original Diamond Chain

Company chain to propellers and chain tubes used on the 1903 Flyer is on

display at the museum. The original 1903 Wright Flyer is on

display at the National Air and Space Museum in Washington, DC.

Author's photo.

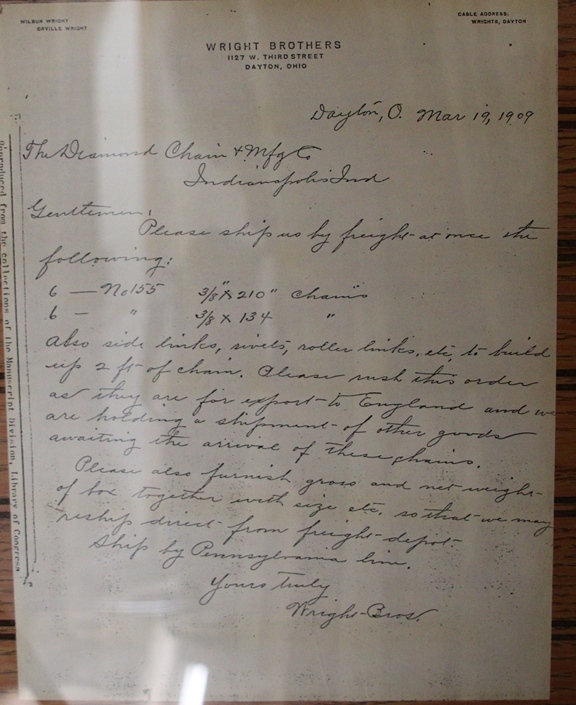

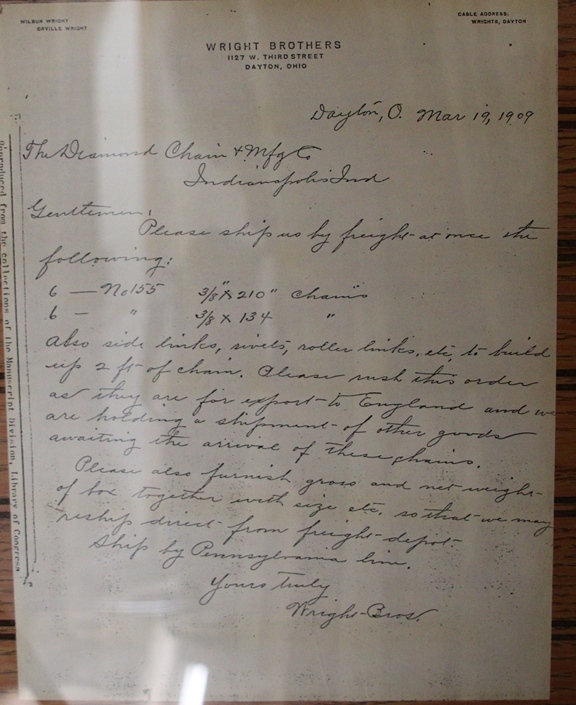

The Wright Brothers continued to use

Diamond Chain for later projects. Author's photo.

The Diamond Chain and Manufacturing Company

has a strong connection with the Ford Highland Park Assembly Plant.

Ford instituted the moving assembly line for the Model T at the Highland

Park Plant. For the first month, a rope was used to pull the

vehicles down the assembly line. After that, the assembly was

equipped with a continuous Diamond Chain and Manufacturing Company chain

to move the Model Ts down the assembly line. There is no doubt

that Diamond Chain went on to supply chains for the other Ford plants as

they converted to the moving assembly line along with many of Ford's

competitors. Author's photo.

Parts of the Highland Park plant still

exist. One can just imagine the Model T's moving down the long

assembly line pulled by a Diamond Chain and Manufacturing Company's

roller chain. Author's photo.

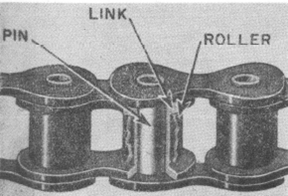

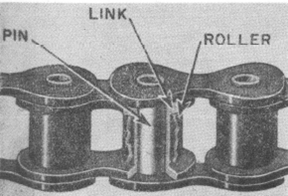

Diamond Chain and Manufacturing Company's

World War Two Products: Roller chains are ubiquitous.

While their best known use is for bicycles, they have a multitude of

uses. Below are the known applications for the company's chains

and sprockets during World War Two. There is no doubt that there

are hundreds of Diamond roller chain applications yet to be discovered

that helped win World War Two.

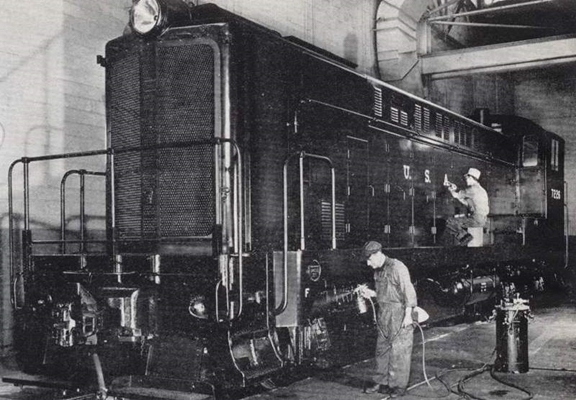

Diesel Locomotives:

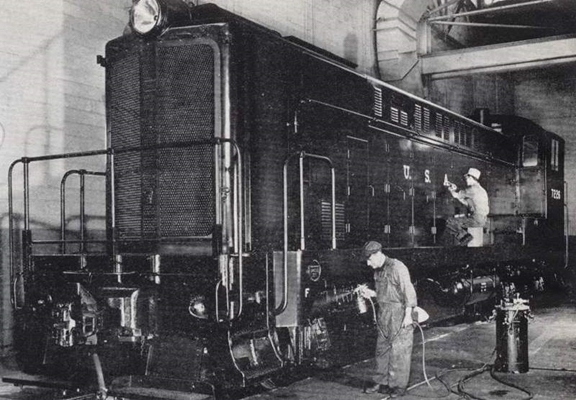

The Baldwin Locomotive Works produced 26

Model VO1000 diesel-electric locomotives like this one for the U.S. Army

during World War Two. Baldwin also made 40 for the U.S. Navy.

All of them had timing chains furnished by Diamond.

Motorcycles: Diamond Chain and

Manufacturing Company supplied the rear drive chain for the

Harley-Davidson WLA motorcycle. This was the predominant

motorcycle used by the U.S. Army during World War Two.

There were 62,486 WLAs built during World

War Two. Author's photo.

Diamond Chain supplied 62,486 rear drive

chains plus spare chains and parts. Author's photo.

Tanks: Marmon-Herrington was one

mile west of the Diamond Chain plant in Indianapolis, IN. When it

needed roller chains for the many types of vehicles it produced,

Diamond's close proximity allowed for quick interfacing during the

design process. A Diamond Chain World War Two magazine

advertisement shows a Marmon-Herrington tank.

This Marmon-Herrington CTMS-1TB1 Light Tank is

one of several types of tank that the company produced early in

World War Two. It is unknown what applications the

Diamond-produced chains were used for in these tanks. Author's

photo.

Aircraft: During

World War Two, Diamond Chain supplied chains and sprockets for 25

manufacturers of fighters, bombers, trainers, and transport aircraft.

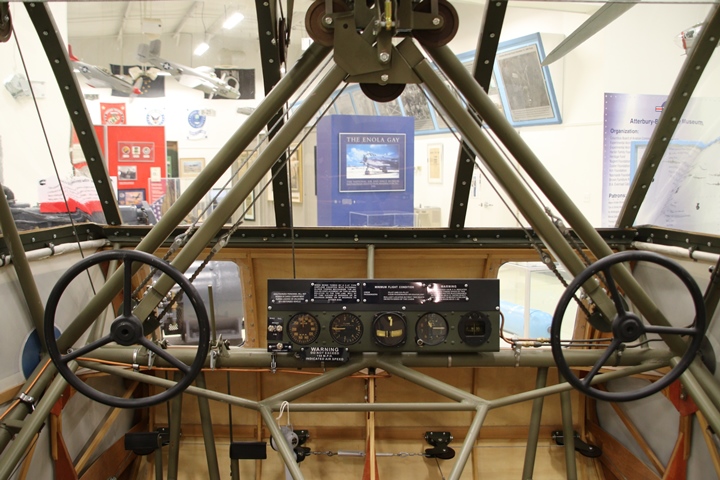

This is one of 13,903 CG-4As combat gliders

built by sixteen different companies to help win World War Two.

Each of the 13,903 CG-4As came equipped with two Diamond Chain and

Manufacturing Company aileron control chains. Author's photo.

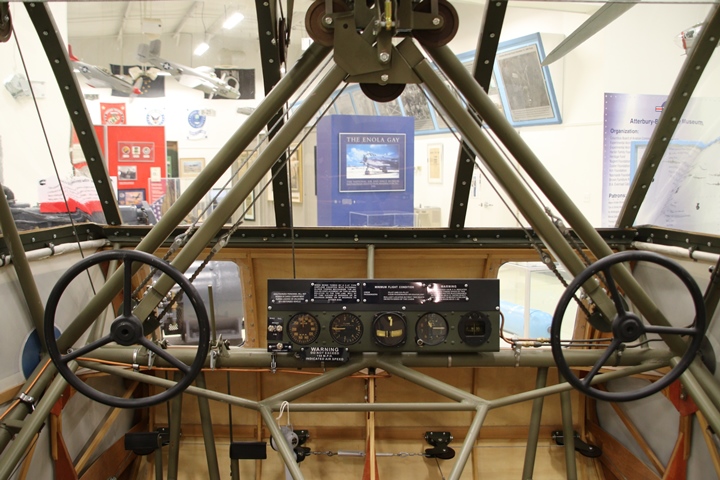

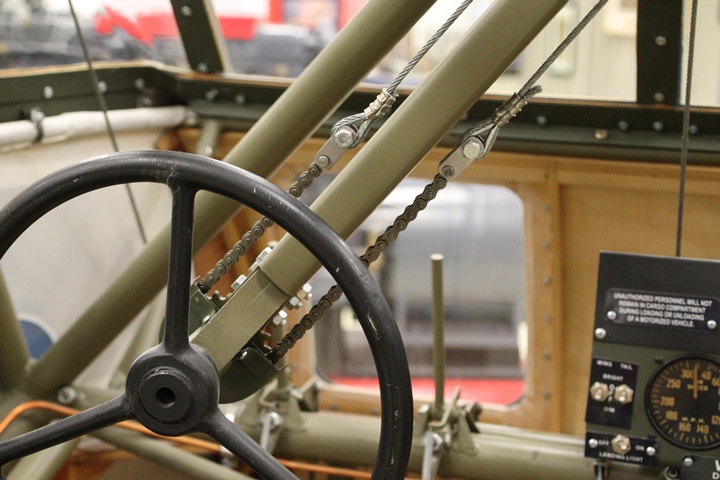

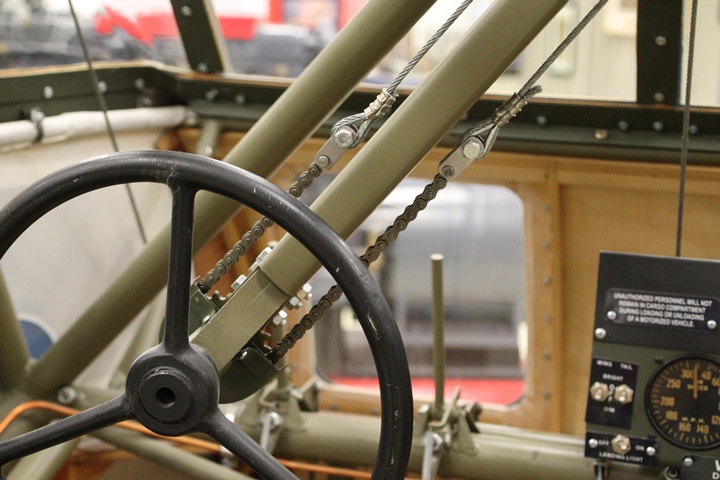

This cockpit of a CG-4A shows the chains

connected to the cables that run out to the ailerons. Author's

photo.

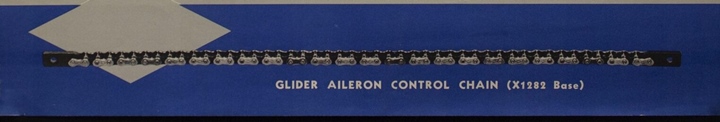

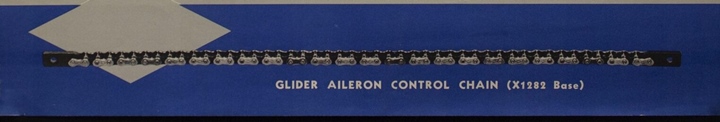

This Diamond Chain document shows that the

glider aileron control chain was an X-1282 base.

Diamond Chain may also have furnished the

sprockets for the aileron control assembly. Interestingly enough,

there was no standard length of chain used by the sixteen different

manufacturers, so various lengths were used. Author's photo.

According to Diamond Chain and Manufacturing

Company's World War Two advertising, the Douglas C-47 also used the

company's roller chains. Author's photo.

Diamond Chain and Manufacturing Company

supplied chains and sprockets for the Martin B-26 Marauder. These

components were used in the nose wheel and main wheel gear door

mechanisms. These were Diamond Chain part numbers X-1466 chain

with 26 tooth sprockets and X-1348 chain with 15, 23, 30, and 33 tooth

sprockets. Author's photo.

Diamond Chain furnished chains for the bomb

bay door operating mechanisms for the PBM-3C version of the Martin PBM

series of aircraft. This was Diamond chain X-133459 with 11 and 33

tooth sprockets. Author's photo.

Diamond Chain supplied chain part number

X-12867 for the Vought F4U-1C Corsair. This chain, along with 9

and 25 tooth sprockets, was used to open and close the tail wheel door.

Author's photo.

Diamond Chain and Manufacturing Company

Landing Gear Retraction and Extension Applications: The

company provided several types of roller chains and sprockets for

operating landing gear retraction and extension systems for both the

U.S. Army Air Forces and U.S. Navy. Chains used for the gear

retractions were Diamond Chain part numbers X-1282, X-5282, X-1365,

X-1466, X-12867, XH-12867, XH-52867, X-1348, and X-1548. The

coupling used for these applications was part number XT-5282. The

light weight sprockets used ranged from 8 to 59 teeth.

Grumman produced 1,768 F4F Wildcat fighters

in several different versions early in World War Two. The Grumman

Wildcat was the first line fighter for both the U.S. Navy and USMC

during 1941-1943. This fighter held the line against the Japanese

Navy and Army Air Forces until more modern fighters could be built and

pilots trained to fly them. In late 1942 and early 1943, the

Grumman Wildcat engaged almost daily with Japanese fighters over the key

battleground of Guadalcanal. As each F4F took off from Henderson

Field on Guadalcanal to defend against enemy air attacks, a Diamond

Chain and Manufacturing Company's chain retracted the main landing gear.

Authors' photo.

The gear retraction system with the Diamond

chain can be seen in this photo. Authors' photo.

In early 1943, the Eastern Aircraft Division

of General Motors began producing the Wildcat under license as the FM-1

and FM-2. Eastern Aircraft produced 1,060 FM-1s and 4,777 FM-2s

which also used Diamond chains in the landing gear system. FM-1s

and FM-2s worked off of small escort carriers and performed

anti-submarine patrols. They provided air cover during island

invasions. Diamond chains were in the thick of the fighting all

through the Pacific War.

The Wildcat shown above is an Eastern

Aircraft-built FM-1.

This is one of four surviving Curtiss O-52s

of the 203 originally built. It is on display at the National

Museum of the United States Air Force. Author's photo added

12-31-2022

This and the next photos show the Diamond

roller chain inside the port main gear bay. Author's photo added

12-31-2022

Author's photo added 12-31-2022

This photo shows the Diamond roller chain

inside the starboard main landing gear bay. Author's photo added

12-31-2022

This Beech AT-11 was one of several versions

of the company's Model 18 that was used in various roles during World

War Two. The AT-11 was used to train bombardiers and gunners.

It used a Diamond chain system to retract and extend the landing gears.

Other Beech models that also used Diamond-built chains and sprockets

were the C-45, AT-7, and the SNB. Authors' photo.

The Diamond Chain and Manufacturing Company

supplied several different roller chains and sprockets for the Bell P-39

Airacobra. These were for the motor-driven and hand-operated

landing gear retraction system, flap drives, aileron trim tab control

system, rudder trim tab control system, and elevator trim tab control

system. Diamond was also the manufacturer of the nose wheel shaft

coupling. Bell Aircraft built 9,588 P-39s during World War Two.

Author's photo.

The Bell P-63 King Cobra was a larger and

newer version of the P-39 which also used Diamond Chain and

Manufacturing Company chains and sprockets for extending and retracting

the gear. There were 3,273 P-63s built. Author's photo.

The Bell P-59 series of aircraft was the first jet aircraft produced in

the United States. The first XP-59 flight was on October 2, 1942.

A total of 66 XP-59s, YP-59s, P-59As, and P-59Bs used a Diamond Chain

system to extend and retract the landing gear. Author's photo.

The Republic P-47 was the fighter that

gained air supremacy over Europe before the D-Day invasion of Europe on

June 6, 1944. Diamond Chain supplied the chains and sprockets for

P-47's gear retraction and extension system. Republic built 15,686

P-47s in several different models. Author's photo.

The Beech UC-43, better known as the Beech

Staggerwing, also utilized Diamond Chain and Manufacturing Company

roller chains. This is one of 240 ordered by the U.S. Army Air

Forces during World War Two. Author's photo added 12-31-2022.

This is a Cessna T-50 which was also built

under the designations AT-18, AT-17, and UC-78. In total, 5,400

were built in all designations during World War Two. All types

utilized Diamond Chain roller chains in the landing gear system.

Author's photo added 12-31-2022.

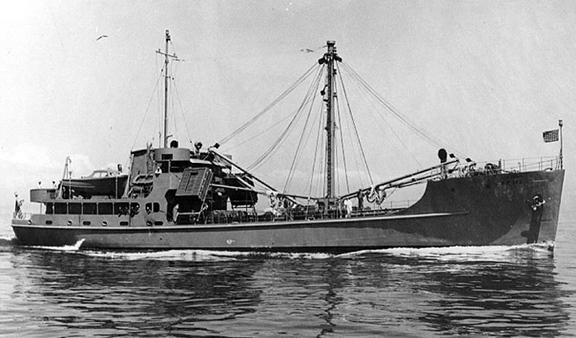

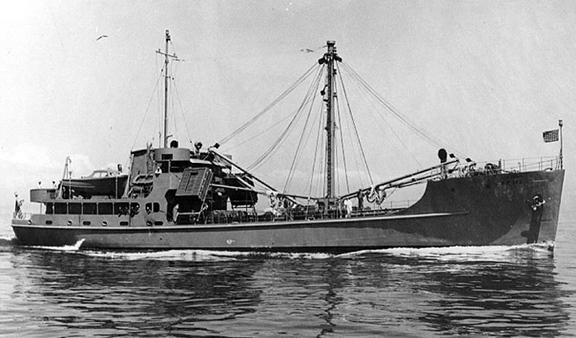

U.S. Army Coastal Freighters:

Higgins Industries of New Orleans built 100 170-foot coastal freighters like

this one for the U.S. Army. In the southwest Pacific, the Army

had its own navy to supply its various island bases. Diamond

Chain and Manufacturing Company supplied roller chains for the two

transmissions in each ship.

The two engines in the ships were

non-reversing right hand drive units. Transmissions with Diamond

Chain roller chains allowed the ship's propellers to run in both forward

and reverse directions.

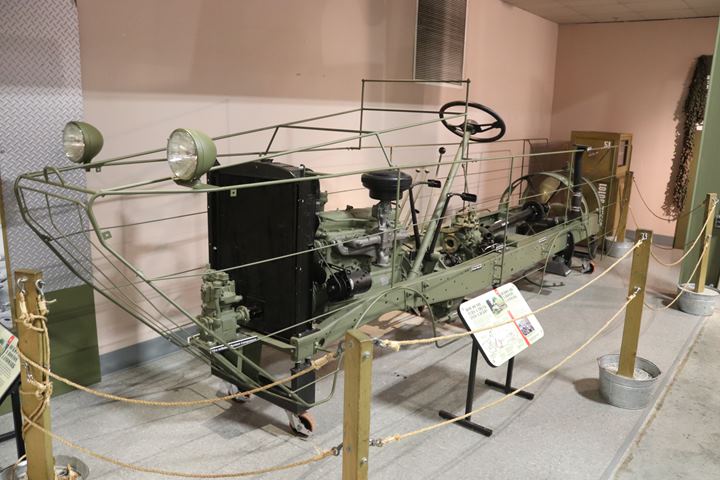

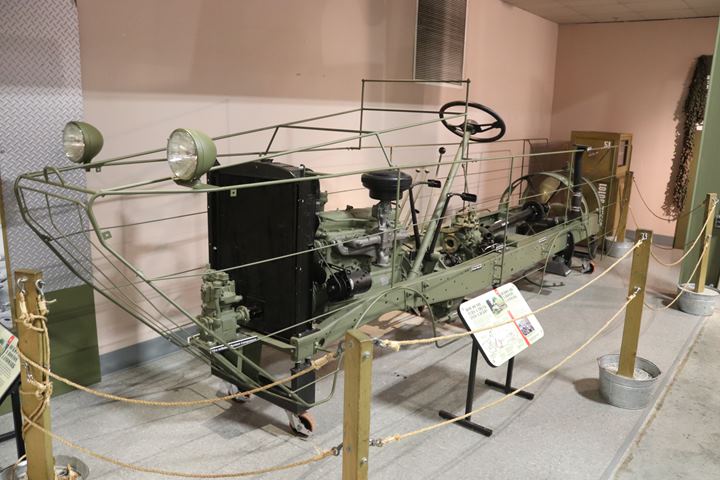

DUKW:

The GMC DUKW was an amphibious truck based

on the CCKW 2-1/2-ton truck. GMC and Chevrolet built a combined

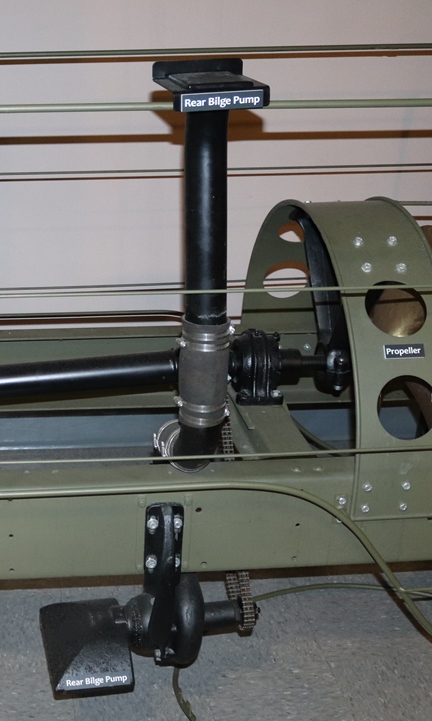

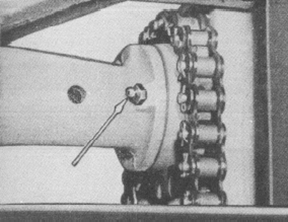

total of 21,147 DUKWs. The chains to drive the two bilge pumps on

the DUKW were provided by the Diamond Chain and Manufacturing Company of

Indianapolis, IN.

Author's photo.

This is a very cool space-frame

display of the DUKW at the Wright Museum of WWII, Wolfeboro, NH.

The frame rails have been pulled into the width of the drive train so

the visitor can see the inner workings of the DUKW. Author's

photo.

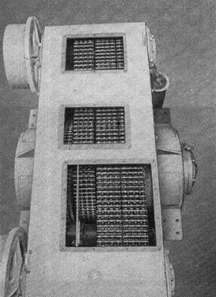

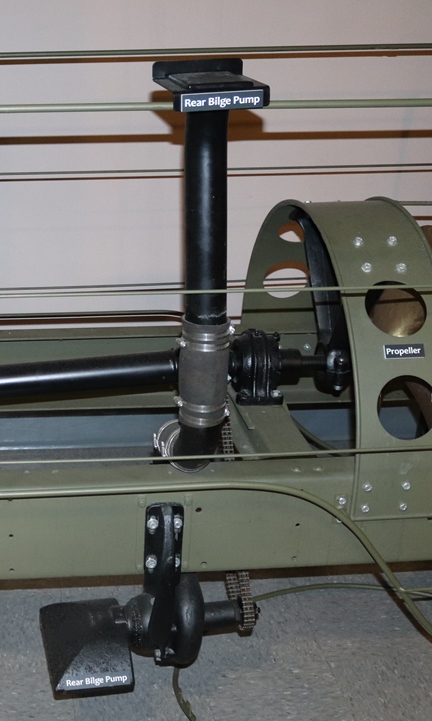

The forward and rear bilge pumps on the DUKW

were very important for the safe operation of the vehicle. Without

operating bilge pumps, the DUKW would fill with water due to its low

freeboard. At Normandy, a number of DUKWs sank when they ran out of

fuel and could no longer operate their bilge pumps. The Diamond chains that drove the bilge pumps were an

important part of keeping the DUKW afloat. Author's photo.

Author's photo.

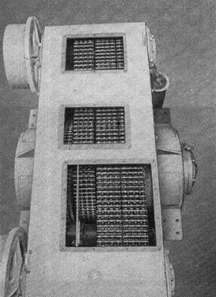

The forward bilge pump used a double row of

Diamond roller chain. Author's photo.

Author's photo.

The rear bilge pump also used a Diamond

Chain double row roller chain. Author's photo.

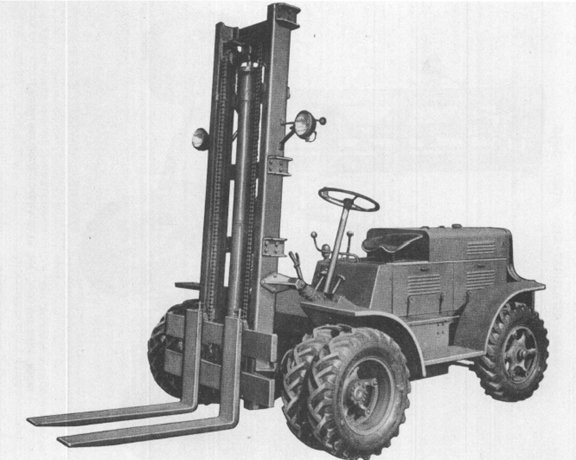

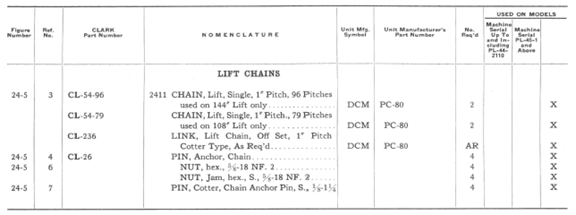

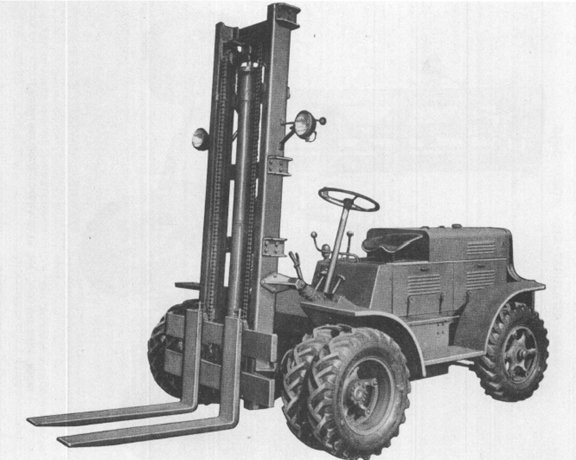

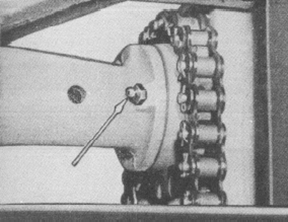

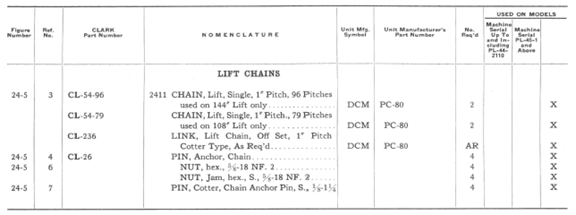

Clark Equipment Company "Planeloader"

Forklift Truck: The Clark Equipment Company produced an

unknown number of forklift trucks for loading and unloading transport

aircraft during World War Two. Diamond Chain and Manufacturing

Company provided two chains to lift and lower the forks.

DCM is the abbreviation for Diamond Chain

and Manufacturing Company.

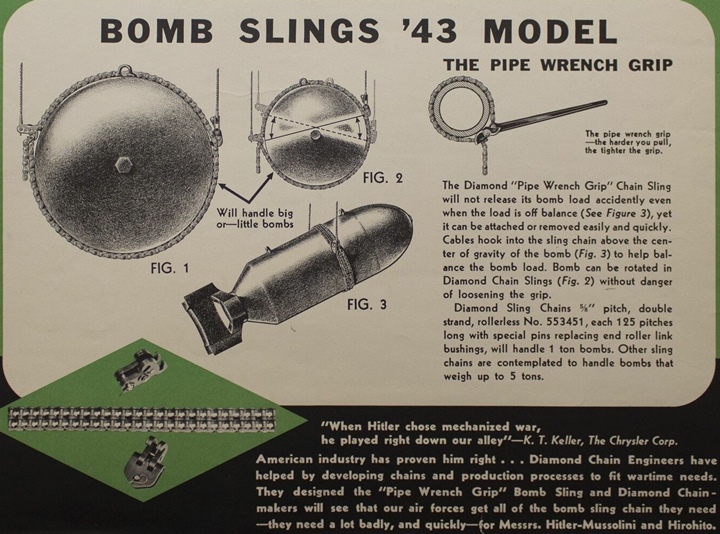

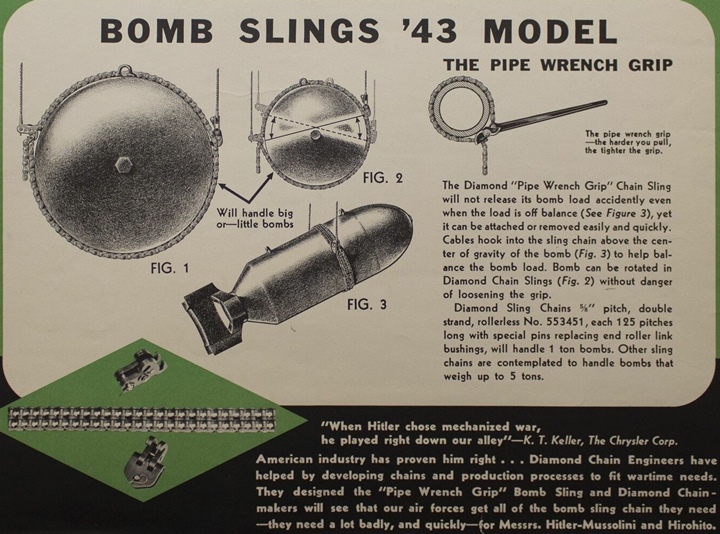

Bomb Hoist Slings: The company

produced the Army Type A-2 Sling-Hoists. These were approximately

78 inches in length.

The Diamond Chain and

Manufacturing Company Plant: As previously noted, the

Indianapolis operation will be shuttered in early 2023 and the plant

shown below will be razed for redevelopment. The original portion

of the factory was built in 1918 with additions added as more capacity

was needed. For 104 years, the company in this factory has supplied

the world with roller chain and provided thousands of jobs for

Indianapolis, IN workers. It will be sad to see this icon of

American industry disappear from the near south side Indianapolis

landscape and take its factory jobs with it.

Author's photo.

Author's photo.

Author's photo.

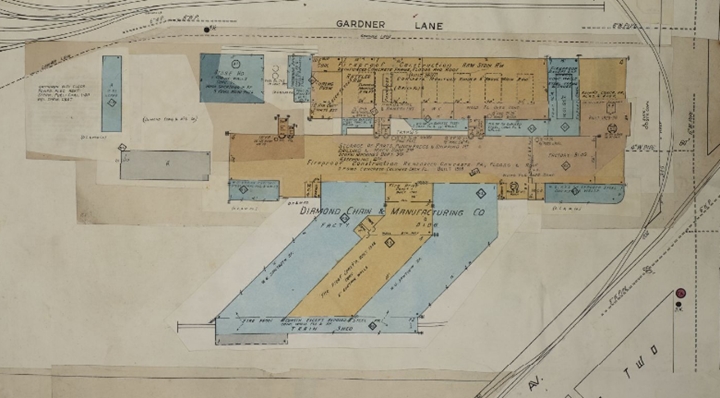

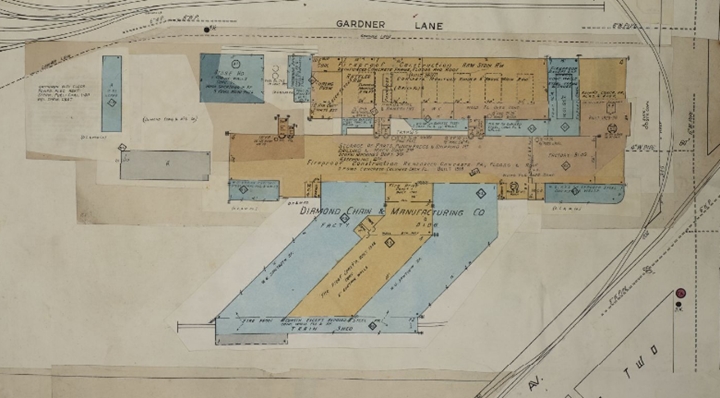

This post-World War Two era Sanborn fire map

shows the plant layout. The north section along Gardner Lane was

the location of the original 1918 factory.

Next is a series of Google Earth images that

give an excellent view of the Diamond Chain plant that already has been

razed. These images are being added over a year after the

demolition began. Luckily, Google Earth has not yet been updated

as of May 27, 2024.

The former Diamond Chain plant was a most

unique design with the angled additions paralleling Kentucky Avenue.

Google Earth image added 5-27-2024.

This low angle view is looking north at the

Diamond Chain plant. Google Earth image added 5-27-2024.

This image is looking west and shows the

modern one story addition at the south end of the plant. Google

Earth image added 5-27-2024.

This is looking south and shows the original

plant building. Google Earth image added 5-27-2024.

When the Diamond Chain plant was built in

1918, Indianapolis was not the city it has currently grown up to be.

Having a factory near the downtown area was a good and common practice

as workers needed public transportation to get to work, or walked from

their nearby homes. But 100 years later, the near south side

of Indianapolis has changed. The Diamond Chain plant was only a

block away from the stadium where the Indianapolis Colts play. An

underutilized multi-story factory no longer fits into the long term growth

of a city that now focuses on both amateur and professional sports teams

as a job generating mechanism. Google Earth image added 5-27-2024.

This view looking northeast shows the former

Diamond Chain plant was a factory on the edge of the downtown business

and entertainment district. Google Earth image added 5-27-2024.

As of the end of May 2024, the future of the

former Diamond Chain factory location for a professional soccer team and

other development is not clear. It is locked up in politics and

whether the developer that tore down the factory has the funding to

actually move forward with the project. It is unclear whether the

soccer field will actually be built at this or some other location

within the city. Maybe the developers got ahead of themselves and

tore down a very cool factory building for no reason at all.

|