|

Gibson

Refrigerator Company in World War Two

Greenville, MI

1877-1900 as Belding-Hall Company

1900-1956 as Gibson Refrigerator Company

1956-1967 as part of Hupp

1967-1986 as part of White Consolidated Industries

1986-2006 as Electrolux

This page added 4-16-2021.

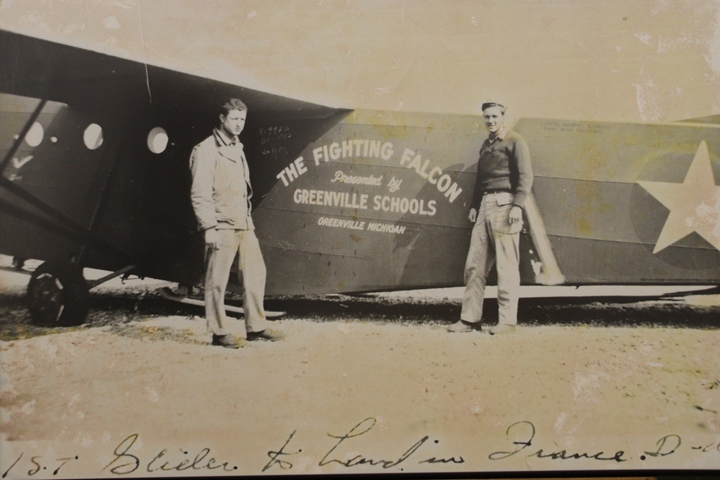

This photo shows a Greenville High School, MI

senior on the same podium with a group of adult civilians and military

personnel in Greenville, MI during World War Two. Gibson-built

CG-4A glider, serial number 42-46574, is behind the podium. This

is part of one of the most interesting stories of World War Two,

beginning in Greenville, MI and ending in Normandy, France on June 6, 1944.

Yet it is largely unknown to the general public and even to the majority

of World War Two historians, which included the author.

Photo courtesy of the Fighting Falcon

Military Museum.

I will come back to this photo later and give

a full explanation of what is happening.

For me, this webpage on the Gibson Refrigerator Company began with one of my many visits to the National

Museum of the United States Air Force in Dayton, OH. I was on a

photo shoot of different parts of aircraft for my research of several

different World War Two companies. Gibson was

not yet included on the list.

For some reason, I looked upward and took note of

this Waco CG-4A Hadrian glider that is hanging from the ceiling in the

museum's World War Two

hangar. I have walked underneath it many times over

the years and have looked up at it before. I walked over to the

information plaque and noted it was built by the Gibson Refrigerator

Company of Greenville, MI and was accepted by the Army Air Force in

July 1945. Looking at the manufacturer's name, I realized I could do

a

page on Gibson Refrigerator Company. In the past I had no doubt

noted the same information and done nothing with it. My focus on this

website has been evolving. Originally, the scope of this website

was exclusively the American Automobile Industry. In the past couple of years,

I have expanded the scope to include non-automotive companies. The scope of my website has changed

since its original inception in 2012.

I also remember thinking this should be a

relatively simple page to do. There was probably not much more

information on Gibson Refrigerator Company except how many of the CG-4A

gliders it built during the war. How wrong I was!

This Gibson-built CG-4A is serial number 45-27948

and is one of the 1,078 that the company built during World War Two.

Of the sixteen CG-4A gliders on display in museums world-wide, this is

the only one whose manufacturer is known.

Two weeks later, some research led me to the

Fighting Falcon Military Museum in Greenville, MI where Gibson

Refrigerator Company built the 1,078 CG-4A gliders. Author's

photo.

I have been to innumerable military museums

over the years. This is the first one I have visited that is in

a former schoolhouse. While this seems an unlikely location for a

military museum, appearances can be deceiving. Per

square foot of display area, this museum is the best I have ever visited

for telling the story of how the local companies helped win World War

Two. The museum not only has an excellent collection of items

relating to the Gibson Refrigerator Company, but also has information

related to other Greenville, MI companies. Author's photo.

This museum is well worth a visit for anyone

interested in World War Two history, although it is somewhat off the

beaten path and has limited visiting hours. However, by contacting

the museum, special appointments can be made to visit the museum.

This is what I did. It will be well worth the effort to visit the

museum.

An addition was added to the rear of the

original structure to house the CG-4A glider reconstruction which is the

centerpiece of the museum.

This leads one back to the original photo.

It was May 19, 1943. Sally Church, Greenville High

School senior, helped and maybe even led the effort for the Class of 1943

to raise $72,000 to purchase four Gibson CG-4A gliders. She is on

the podium with Frank Gibson, Jr., President of Gibson Refrigerator.

In March 1944, the school children of the town took it upon themselves to sell

enough war bonds to pay for one Gibson glider. In two months, they

raised $72,000, which actually paid for four gliders. One glider,

42-46574, was picked out and named by the students "The Fighting Falcon."

This was the naming ceremony. Photo courtesy of the Fighting Falcon

Military Museum.

The Fighting Falcon was towed from the

factory to nearby Black Athletic Field for the ceremony.

Photo courtesy of the Fighting Falcon

Military Museum.

$72,000 in 1943 is $1,094,624 in 2021,

adjusted for inflation.

This was a herculean effort by the school children of Greenville.

One needs to remember there was no internet, no email, no Twitter, no GoFundMe,

nor any other modern method of communication. The only way

for them to get the word out to the public was through public service

messages on the local radio station and in the newspaper. Gas and

tires were being rationed, so any high school student with access to an

automobile would not be able to go very far, if anywhere at all.

During World War Two, if families had an automobile, they only had one.

It is not like today where families have several. So, to raise the

money the students had to go door-to-door to raise the funds. For

this, the 1943 Greenville High School class was awarded the U.S. Treasury

Distinguished Service Award. This was the first time this award

had been given to high school students.

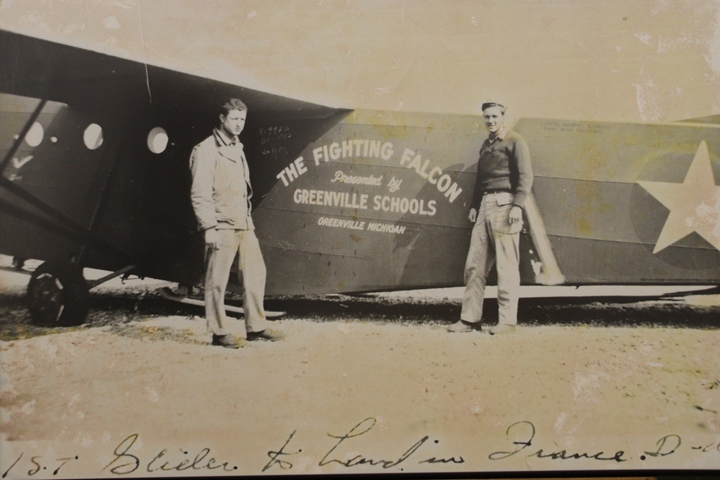

The Fighting Falcon, serial number 42-46574,

like every other GC-4A glider, was disassembled and boxed up for

shipment. It was shipped to England where it was re-assembled.

This was fortuitous, as most of the 60 gliders built by Gibson ended up

staying in the United States as training aircraft. A few ended up

in North Africa and Sicily. After its re-assembly, the Fighting

Falcon was assigned to 434th Troop Carrier Group, which would be

transporting members of the 101st airborne into Normandy. In honor

of the Greenville Class of 1943, the Army Air Force designated the

Fighting Falcon, serial number 42-46574,to be the lead glider of the 52

in the first landing wave early in the morning of June 6,1944. As

the lead glider, the Fighting Falcon would carry Brigadier General Donald

Pratt and his aide, along with the general's jeep.

This is where the story gets complicated.

On June 4, 1944,the pilot of the Fighting Falcon, serial number 42-46574, LTC Michael

Murphy, decided to use another glider for the invasion.

This is because LTC Murphy was concerned about the safety of General

Pratt. Many of the other gliders for the invasion had extra

bracing installed on the fragile nose of the aircraft to protect the

occupants in case of a crash landing. This was known as a Griswold

Nose Protection Device. Therefore, LTC Murphy picked out the 45th glider

in the formation of 52. This turned out to be another Gibson-built

CB-4A, serial number 43-41430. It is unknown whether LTC Murphy

picked out another Gibson glider on purpose, or by chance. Serial

number 43-41430 became the lead glider in the group.

Again, the story becomes more complicated as

the new lead Gibson-built CG-4A glider was also named the Fighting

Falcon and had this quickly painted on the aircraft similar the

original glider. However, the lettering was considerably smaller.

Therefore, there were two Gibson-built CG-4A gliders named Fighting

Falcon that landed in

Normandy with the 101st Airborne on the morning of June 6, 1944. Landing in

the dark, the lead Fighting Falcon, serial number 43-41430, landed in a

small field and crashed into a group of trees at the edge of the field.

The sudden deceleration from an estimated 50-70 mph resulted in the

whiplash death of Brigadier General Donald Pratt, who was

sitting strapped in his command jeep in the glider. The

co-pilot, 2nd Lt. John Butler, was killed by an impact with a tree. LTC Murphy had two broken legs, and the general's aide, 1st Lt John May,

only suffered a concussion. At this point, the outcome of the

original Fighting Falcon's,serial number 42-46574, landing and status

afterwards is unknown.

Assault gliders like the "Fighting Falcon"

were only used during World War Two. They supplemented the

paratroopers by being able to bring in equipment and weapons that could

not be air-dropped. But it was dangerous to land a glider in the dark without the ability

to do a go-around like an aircraft. The "Fighting

Falcon," along with many other gliders, were destroyed upon landing, not

only at Normandy, but other landing zones during the war. After World War Two,

helicopter technology progressed to the point that they took over the

function not only of the glider but also, for the most part, the paratrooper.

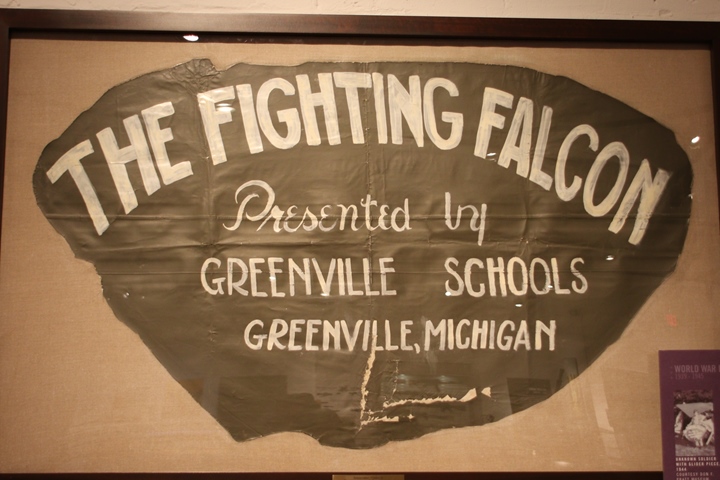

This photo shows the size of the

writing on the side of the original Fighting Falcon, serial number

42-46574. Photo courtesy of the Fighting Falcon

Military Museum.

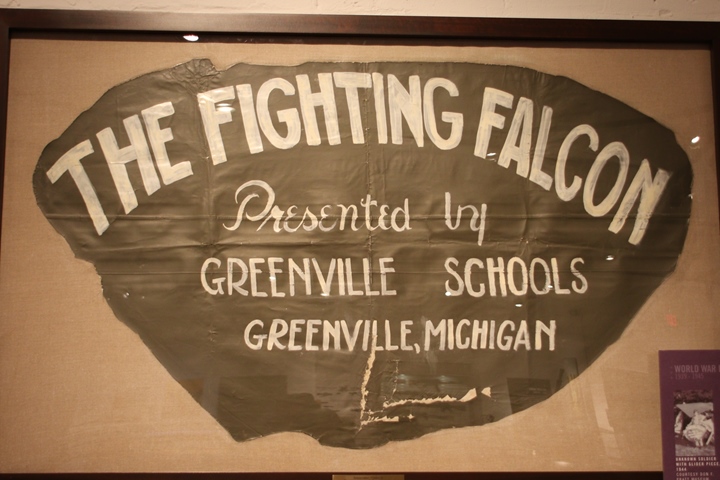

A week after I visited the Fighting Falcon

Military Museum in Greenville, MI, I was at the Kentucky Military

History Museum in Frankfort, KY. There, mounted on the wall, is the fabric that

was removed from the second and lead "Fighting Falcon," serial number

43-41430. This was removed from the wreckage by an unidentified

airborne trooper and eventually became part of the Don F. Pratt Museum

at Fort Campbell, KY. The fabric is on loan to Kentucky Military

History Museum. Author's photo.

This airborne trooper has just removed the section of fabric from the

wreckage of the lead Fighting Falcon, serial number 43-41430. The size of the writing on the fabric is considerably

smaller than what was written on the original Fighting Falcon, serial

number 42-46574, at Greenville MI in May 1943.

Gibson Refrigerator Company World War Two

Products:

I had originally expected to only find

information on the number of gliders Gibson Refrigerator built during

World War Two. However, on my visit to the Fighting Falcon Museum

in Greenville, MI, I was able to learn more about its World War

Two products than I expected. My experience is that most companies'

war production is identifiable

with one main product. For Gibson, this was the CG-4A glider.

The Fighting Falcon Museum has a complete listing and many examples of

what the company built. The different products are listed in Table

1 below. Gibson actually started producing a variety of military products

before the United States entered the war. It was already in

production with many of these products when it took on the building of

gliders.

There were several other companies in

Greenville that manufactured products that helped win World War Two.

The museum also has information on these companies,

providing an excellent overall view of the manufacturing in the town

during the war. This information is in Table 3.

I grew up in Lansing, MI, which is 65 miles

away from Greenville, MI. I don't think I ever heard of

Greenville, MI while living in Lansing. I know I was unaware that

refrigerators were being built there.

Michigan built automobiles, not refrigerators. Therefore, I have

learned information about my home state because of a chance look at a

World War Two glider at the National Museum of the U.S. Air Force.

|

Table 1 - Gibson

Refrigerator Company World War Two Products

The information below was obtained from the Fighting Falcon

Museum in Greenville, MI. It in turn was provided to the

museum by Mr. William Delp, former Gibson Refrigerator Company

employee. Mr. Delp was a tooling engineer with Gibson, and

one of the engineers responsible for putting the CG-4A into

production. Without his historical knowledge of Gibson

during World War Two, the information below and at the museum

would have been lost forever. |

|

Quantity |

Product |

Comments |

| 1,078 |

CG-4A

Combat Gliders |

Gibson was fifth in the number of CG-4A gliders built by the

company.

It produced 7.7% of them. |

|

17,130 |

B-24

Wing Flaps |

These

were built

for the Ford Motor Company B-24 production at Willow Run, MI.

This quantity of flaps was enough for all of the B-24s built by

Ford. |

|

17,158 |

500

Pound Navy Practice Bombs |

|

|

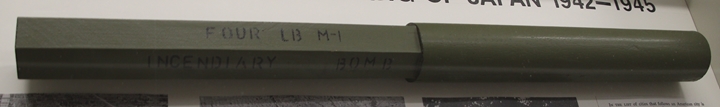

750,000 |

Four

Pound Thermite Incendiary Bombs |

These

were built on contract W799-CWS-152. The original

contracted amount in mid 1941 was 700,182 for a cost of

$513,000. The contract was for only the bomb casings. The bomb casings were then

sent to an ordnance plant to be filled with explosive and

incendiary material. These were used in the low-level

firebombing raids by the B-29s over Japan. |

|

100,000 |

100

Pound Chemical Bombs |

|

|

53,052 |

AN-M26 Parachute Flares |

These

were built on contract W-374-ORD-1344 and W-374-ORD-1899.

The total cost of both contracts was $2,508,000 or $47.27 a

piece. The metal cases were made in the Greenville plant

and then shipped to Gibson's Blending Plant C. There, the

parachutes and flares were installed. |

|

41,860 |

165

Gallon Drop Tanks |

|

| 16 |

Multi-Spindle Lens Polishing Machines |

These

were for Argus Camera in Ann Arbor, MI, which was

making lenses for the Norden Bombsight. |

|

224,214 |

Parts

for 20mm Cannon |

The

information at the Museum indicates these parts were for 20mm Oerlikon

anti-aircraft guns and were supplied to Reo in Lansing, MI. Reo did

not make the 20mm Oerlikon nor did it do any sub-assembly work on them.

This leads to two different possibilities as to what 20mm parts

Gibson actually made. The first possibility is that the parts actually

went to Oldsmobile in Lansing, which did make 77,010 20mm M2

aircraft cannons. It sub-contracted out all of the parts for the

weapon and only did the final assembly. The location of

the Olds and Reo plants were within a mile of each other in

Lansing. Also, the names are similar because they were

both started by Mr. R.E. Olds.

The second possibility is if

they were actually 20mm Oerlikon parts, then they would have

gone either to the Pontiac Motor Division of GM in Pontiac, MI,

or to U.S. Navy's ordnance plant in Centerline, MI, which was

originally managed by the Hudson Motor Car Company, and then

later during the war by Westinghouse. Both locations

built the 20mm Oerlikon. |

|

299,929 |

AN-B-7 and AN-B10 Bomb Shackles |

These

were used by both the U.S. Navy and U.S. Army during World War

Two. The B-7 bomb shackle could hold 100 to 1,100 pound

bombs. The B-10 was for 100 to 1,600 pound bombs. |

| 1,500 |

Refrigerators |

These

were used for military housing. |

|

72,931 |

Sperry T-1 Aluminum Computer Cabinets |

These

went to the AC Spark Plug Division of General Motors which was

building the Sperry Computers under license. The original

design was British, with Sperry building them under license.

The T-1 bombsight was used in several RAF bombers and was well

suited for the night bombing that the RAF engaged in during the

war. |

|

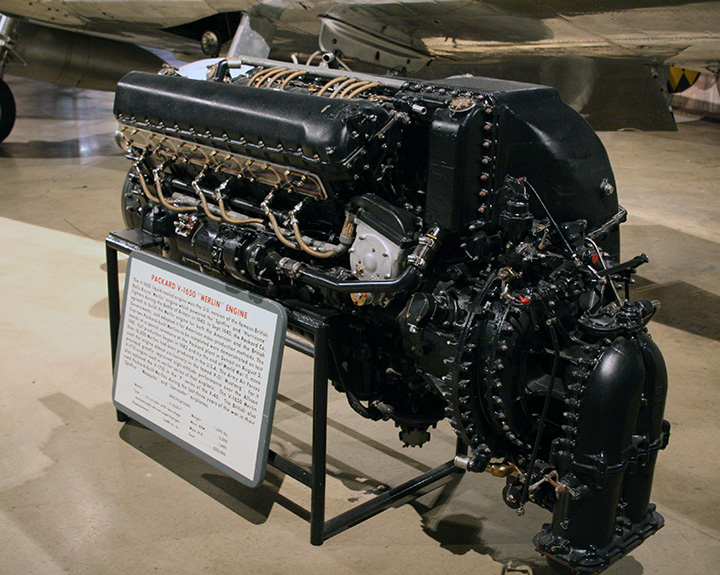

144,914 |

Sets

of Aircraft Parts |

These

were for the Packard-built Rolls-Royce V-1650 Merlin aircraft

engine. |

|

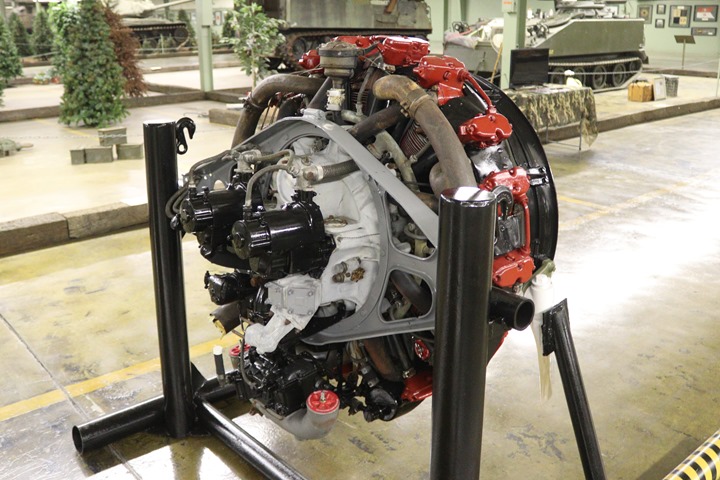

64,295 |

Gear

Blanks for Tank Engines |

These

were for use in tank engines built by Continental Motors Company

in Muskegon, MI. The parts would have been used in either

or both the W-670 and R-975 radial tank engines. |

|

15,754 |

Sets

of Bomb Hoisting Bands |

These

were produced for the Cook Electric Company of Chicago, IL. |

| 105

|

Sets

of Drop Tank Internal Parts |

These

were produced for the Tappan Stove Company of Cleveland, OH. |

| 1,646 |

Rotary Vibrators |

These

were made for the Bendix Aviation Company of South Bend, IL. |

|

Thousands |

40-Inch Electric Ranges |

These

were used for military housing and built in Gibson's Belding, MI

plant B. |

|

Table 2 - Gibson Refrigerator Company CG-4A Contracted Serial

Numbers |

|

U.S. Army Air Force Serial Numbers |

Number |

Comments |

|

42-46552 through 42-46611 |

60 |

42-46574, the original Fighting Falcon, was one of several from

this group to end up in Normandy. Other gliders in this

group were used as trainers in the U.S. Others were sent

to Tunisia and Sicily. |

|

42-46619 through 42-46631 |

13 |

Several of the CG-4As in this group went to the RAF.

|

|

42-52853 through 42-52881 |

29 |

Several of the CG-4As in this group went to the RAF.

|

|

42-55785 through 42-55844 |

60 |

42-55833 was part of Operation Varsity landing 17 Airborne

Division to Wesel, Germany on March 24, 1945. Many others

were transferred to the RAF from USAAF inventory in India. |

|

42-68306 through 42-68335 |

30 |

42-68334 landed with the 82nd Airborne Division at St. Mere-Eglise

in Normandy on June 6,1944. |

|

42-73750 through 42-74112 |

363 |

Gibson gliders from this group served in Tunisia, Sicily, and

Normandy. |

|

43-41279 through 43-41778 |

500 |

Many

of the CG-4As in this group served at Normandy and Operation

Market Garden. |

|

45-27936 through 45-27948 |

13 |

45-27548 is on display at the National Museum of the United

States Air Force. It is the CG-4A Hadrian glider that

initiated this page for the

website. |

|

45-27949 through 45-27961 |

13 |

Three

units cancelled. |

|

45-27962 through 45-27971 |

10 |

Order

cancelled. |

|

Total |

1,091 |

|

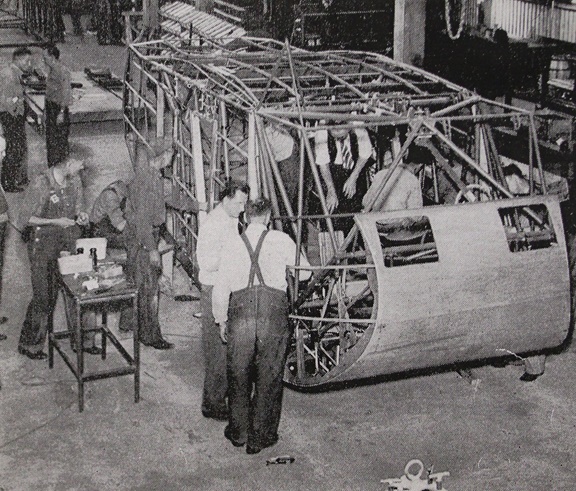

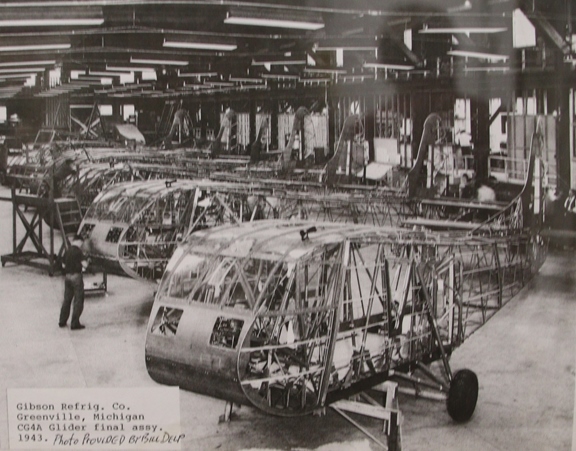

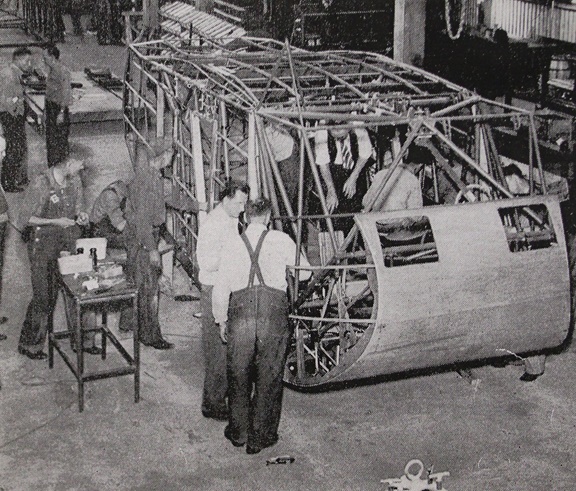

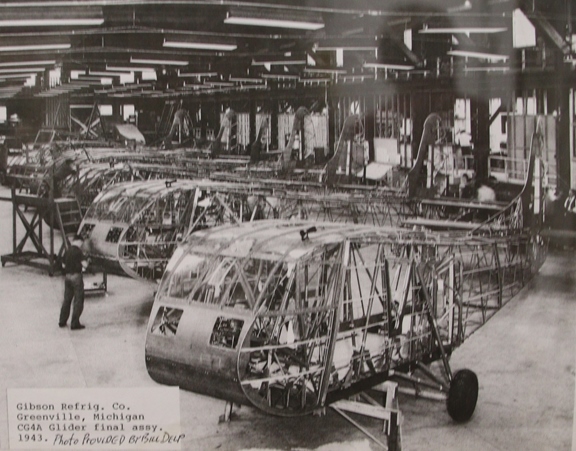

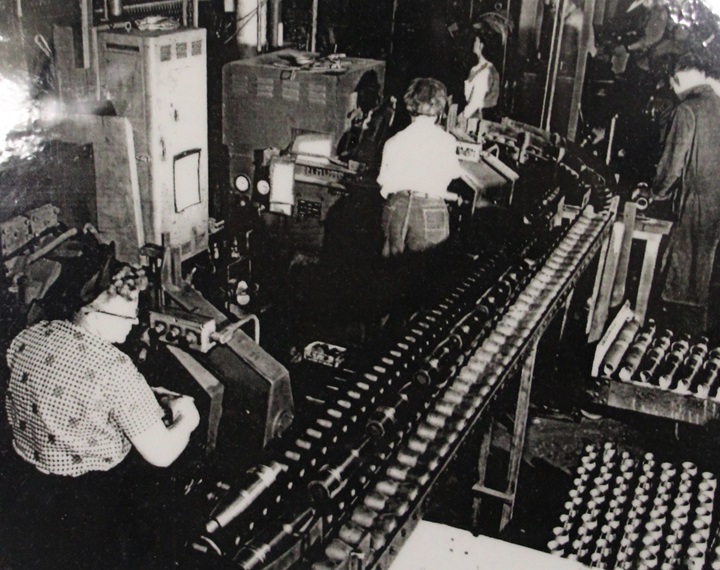

Glider production at Gibson Refrigerator

Company during World War Two. Photo courtesy of the Fighting Falcon

Military Museum.

Photo courtesy of the Fighting Falcon Military

Museum.

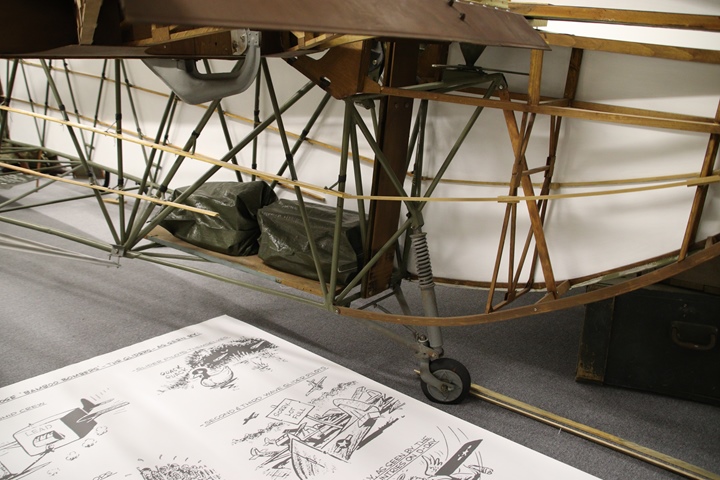

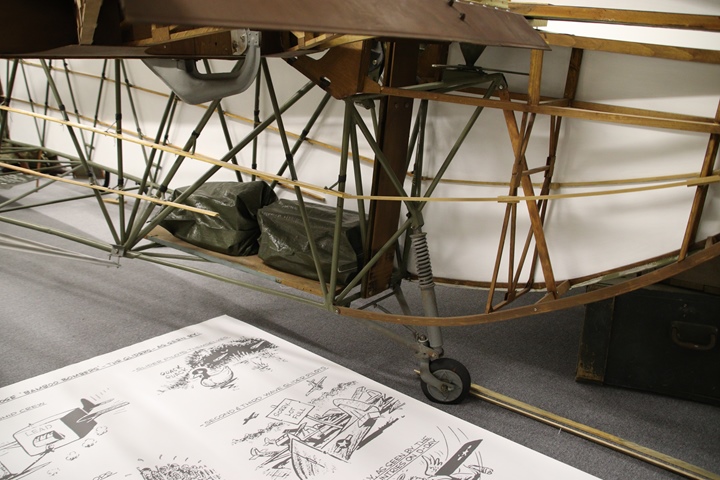

This is what one first sees when entering

the addition to the Fighting Falcon Military Museum, which was added to

display this reconstruction of a Gibson-built CG-4A glider. This

side of the glider does not have the fabric attached to it, and

represents a full-size diorama of a glider under construction.

Author's photo.

Many of the parts for this reconstruction came from the local area.

Many others came from across the United States as word spread of the

project. At the end of World War Two, Gibson had 60 gliders packed

in 300 crates ready for shipment. However, they were no longer

needed, and the company sold each crate for $50 each. Many were

purchased for the wood in the crates, which was used by local farmers to

build small buildings. For the most part, the glider parts were

thrown away or left in a field. The center section of

this glider is the assembly of three center sections found on farms in

the Greenville and Belding areas. The three provided enough good

parts to make one glider for this reconstruction. Author's photo.

Each of the following photos shows a

different section of the glider and all of the different parts that went

into its construction. The tail section of the fuselage came

from a barn ten miles east of Greenville. Author's photo.

The vertical and horizontal

stabilizers, along with the rudder, came from a farm in New Hampshire.

Author's photo.

Author's photo.

The tail section had two weighted bags

installed to provide the proper weight and balance for the glider.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

The landing gear was found at an aircraft parts collector in Chicago,

IL, while the wheels and tires were donated by the Kalamazoo Air Museum.

Author's photo.

The other side of the glider has been

covered with fabric and painted. Author's photo.

The wings were too large for the addition

made to the former school, so only the center section of the wings were

added. Author's photo.

The tow rope is attached to the top of the

fuselage. A communication cable ran down the center of the tow

rope so the pilots in the glider and tow aircraft could

communicate with each other. The tow plane pilot needed to notify the glider when

it needed to release the cable to land in the combat zone. Author's photo.

This original World War Two glider tow rope

is on display at the National Museum of the United States Air Force.

The tow rope was a complete assembly that included the shackle that

attached to the tow aircraft, the rope and then the attachment and

release lever that attached to the glider. The electrical cable

that allowed communication between the tow aircraft and the glider ran

down the middle of the two rope. It is the black rubber cable. The

release handle is the red device. Author's photo.

The metal frame for the nose section came from Ohio

and has some of the original larger steel tubing in it.

However, if it the glider crashes into a grove of trees, as the Fighting

Falcon did at Normandy, the front end is going to collapse. Author's photo.

Author's photo.

The co-pilot's control wheel came from a garage sale in Greenville.

The instrument panel was found on a farm in Pennsylvania. Author's photo.

Other CG-4A Gliders and Pieces:

This CG-4A glider on display at the

Kalamazoo Air and Space Museum has been named the Fighting Falcon.

Author's photo.

This is the fabric that was cut from the

Ford-built CG-4A glider that also crashed at Normandy. It is on

display at the National Museum of the United

States Air Force. Thirty-eight percent of all of the CG-4A gliders

were built in Michigan by the Ford Motor Company and the Gibson

Refrigerator Company. Author's photo.

Other Gibson Refrigerator Company World War

Two Products:

This Ford-built B-24J is on display at the

Barksdale Global Power Museum at Barksdale AFB in Bossier City, LA.

The aircraft has Gibson Refrigerator Company-built flaps on it.

Author's photo.

Gibson was Ford's largest sub-contractor. Author's photo.

Here is the port side Gibson flap.

Author's photo.

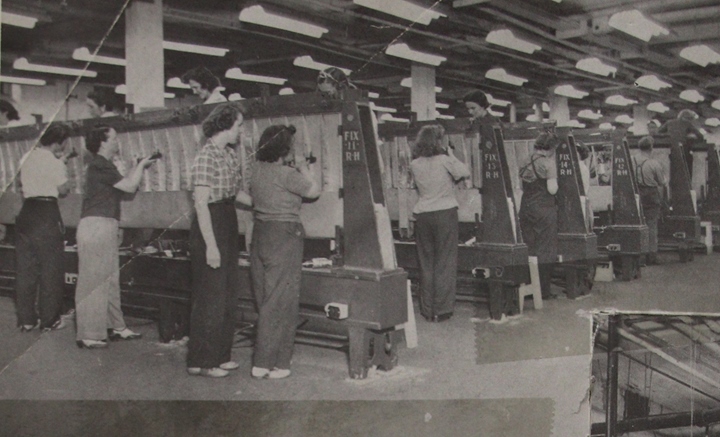

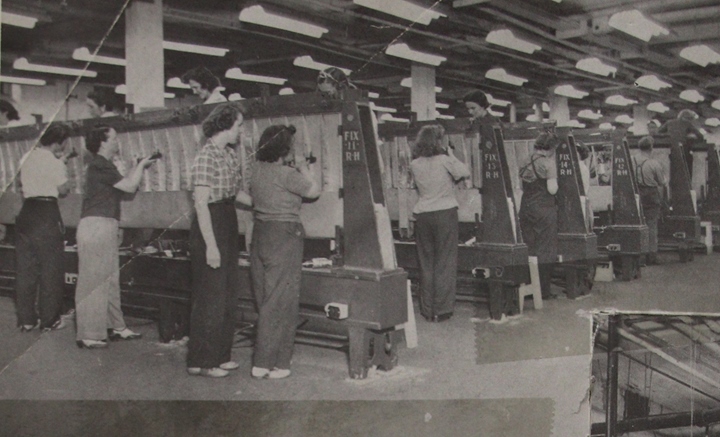

This factory photo shows the wooden fixtures

that were used to build the flaps. The operators in view of the

camera are holding rivet bucking bars. On the other side of the

flap are other operators that have rivet guns. The bucking bar is

pushed up against the rivet to flatten the rivet. The operator at

the right end of the "Fix-11-RH" appears to be new on the job, as a

supervisor is showing her how to buck rivets. The numbers on the

fixtures show that there were at least thirteen of them for the right

hand flaps. Each fixture has at least eight operators installing

the rivets, and there were thousands that were used in the construction

of each one. This was a very labor intensive and tedious

operation. Photo courtesy of the Fighting Falcon Military Museum.

On the left is an air-powered rivet gun and

on the right is a bucking bar. The operator with the rivet gun

would push a rivet through the pre-drilled holes in the sheet metal

pieces being riveted together. The other operator would then push

up against the un-flattened end of the rivet with the bucking bar while

the rivet gun hammered against the head from the opposite side.

The vibration caused the rivet to flatten under the bucking bar.

Above the tools is an example of sheet metal with some rivets in it.

Rivets held World War Two sheet metal parts and aircraft together.

There were probably tens of thousands used in each flap Gibson made for

the Ford B-24s. This was tedious yet very important work for the

operators. Author's photo.

This AN-M26 aircraft flare container was

built by the Gibson Refrigerator Company in November 1942. The

AN-M26 would be dropped by an aircraft over an area for night photo

reconnaissance missions. The parachute would allow the flare to

stay in the air long enough to burn a yellowish color of 800,000

candlepower for up to three minutes. Gibson built 53,052 of these.

Author's photo from the Fighting Falcon Museum.

The practice bomb had all of the ballistic

characteristics of the normal 500 pound bomb. The U.S. Navy would

fill the practice bombs with sand and flour, so when the bombs struck the

practice target area it could be seen where they hit. Author's

photo from the Fighting Falcon Museum.

This stainless steel AN-B10 bomb shackle and 100 pound

chemical bomb are on display in the Fighting Falcon Museum.

Author's photo from the Fighting Falcon Museum.

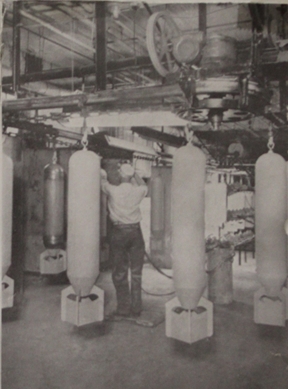

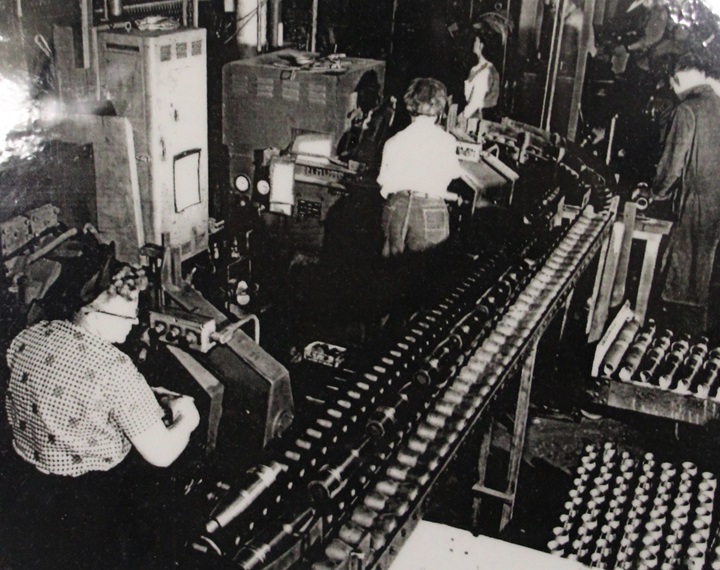

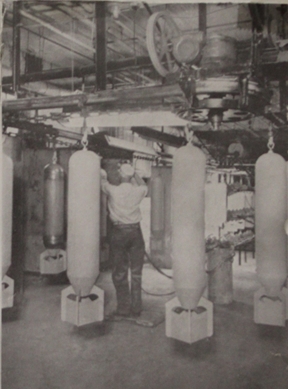

One hundred pound chemical bombs are

traveling on a monorail at the Gibson plant. The bombs in the

foreground appear to be coming out of the paint shop. Photo

courtesy of the Fighting Falcon Military Museum.

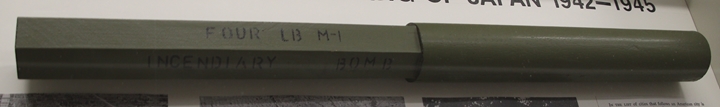

Gibson produced 750,000 four pound thermite

incendiary bombs during the war. It only produced this outer

casing, as the internal incendiary and explosive material were installed

at an ordnance plant. This example at the Fighting Falcon Military

Museum is the only one the author has found in his research.

Author's photo from the Fighting Falcon Museum.

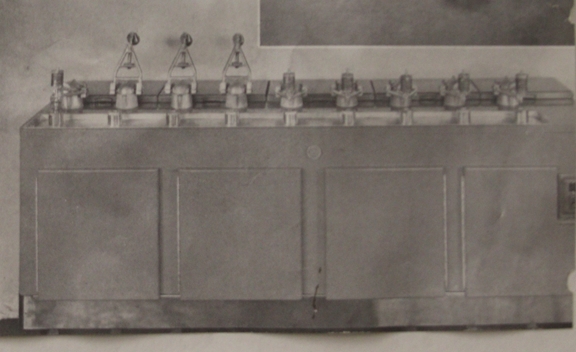

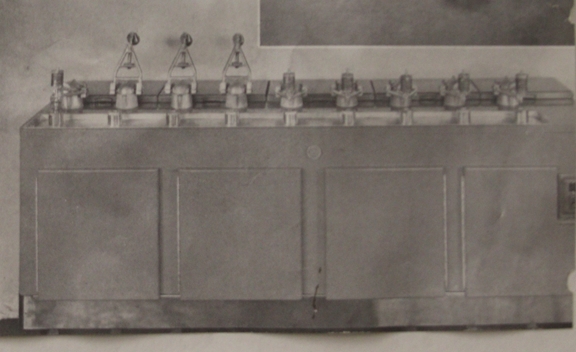

Gibson built sixteen multi-spindle lens

polishing machines for Argus Camera in Ann Arbor, MI. Argus used

them to polish lenses for the Norden bombsight. Photo courtesy of

the Fighting Falcon Military Museum.

This drop tank was produced at the end of

the war and immediately became surplus. This and a second drop

tank were found in the barn of two of the officers of the museum.

The second drop tank is at the Air Zoo Aerospace Museum in Kalamazoo,

MI. Author's photo from the Fighting Falcon Museum.

Gibson built 41,860 drop tanks to extend the

range of American fighter aircraft during World War Two. Author's

photo from the Fighting Falcon Museum.

Author's photo from the Fighting Falcon

Museum.

This finished drop tank is on display at the

National Museum of WWII Aviation in Colorado Springs, CO. Author's

photo added 5-5-2021.

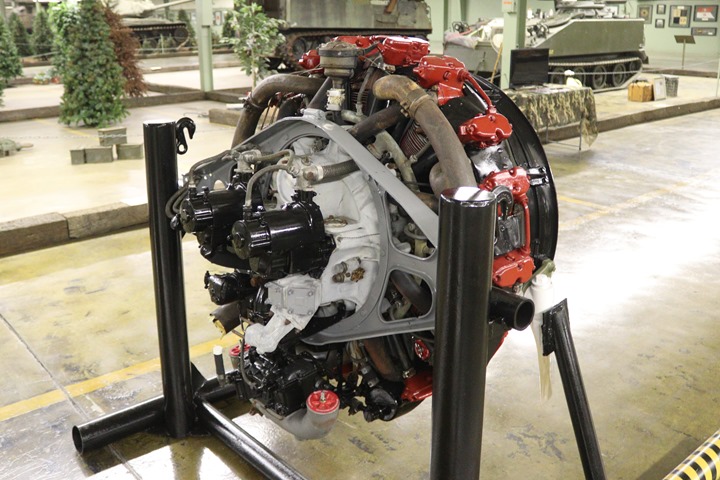

Gibson produced

64,295 gear blanks for radial tank engines built by Continental

Motors in nearby Muskegon, MI. This is an example of a Continental

R-975 that was used in various tanks during World War Two. The

most famous tank in which it was used was the M4/M4A1 Sherman tank. Author's photo.

This is an early World War Two M4A1 Sherman

tank powered by the Continental R-975 engine. Author's photo.

Another armored vehicle that utilized the

R-975 engine was the M18 Hellcat tank destroyer produced by Buick in

Flint, MI. Author's photo.

Continental also produced a smaller radial

engine, designated the W-670, which was used in armored vehicles.

One such application was the LVT-4. Many of these were built by

the Graham-Paige Motors Company in Detroit, MI. Author's photo.

Gibson-built gear blanks could have been used

in over a dozen different types of armored vehicles during World War

Two.

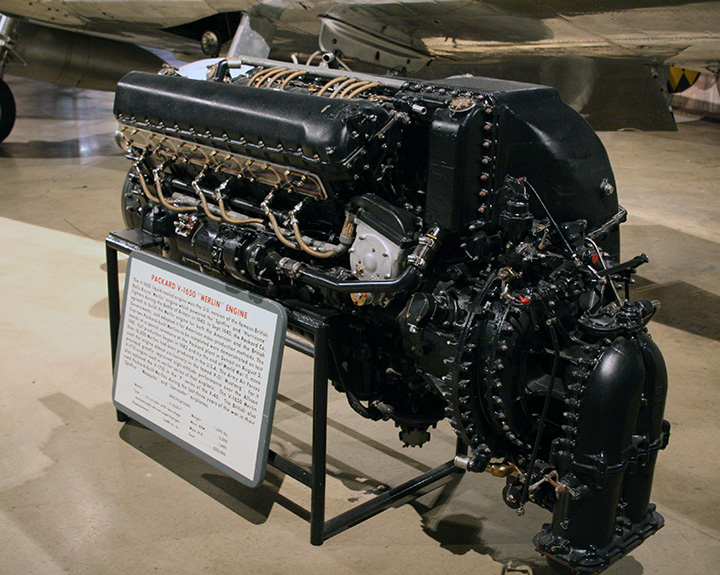

The Packard V-1650 Merlin engine is

legendary for its high altitude performance in the P-51 Mustang over

Europe in World War Two. Gibson Refrigerator helped this

performance by producing 144,914 parts for the 54,714 engines built. Author's photo.

The North American P-51. Author's photo.

This is a Pontiac Motor Division-built 20mm

Oerlikon anti-aircraft gun. Gibson produced

224,214 components for this weapon. Author's photo.

This Sperry T-1-A bombsight computer in the

left of the photo was built by A-C Sparkplug in Flint, MI. It was

used with the sighting head also shown and was used by the Royal Air

Force in many of its bombers. Gibson produced

72,931 T-1-A cabinets for AC Spark Plug during the war. Author's photo.

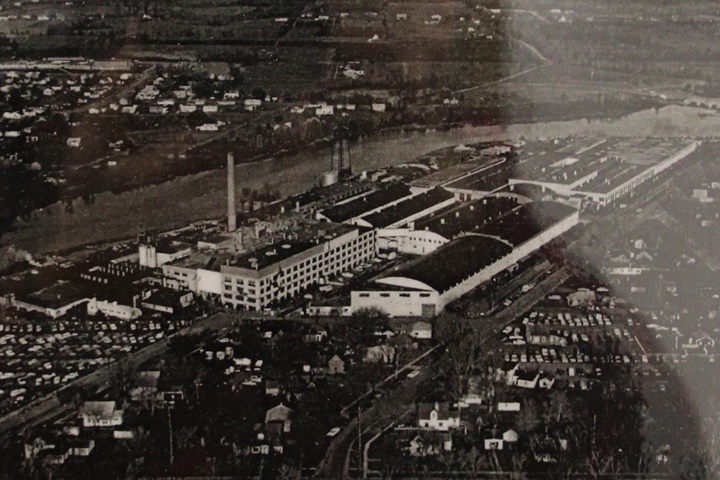

Gibson Refrigerator

Plants:

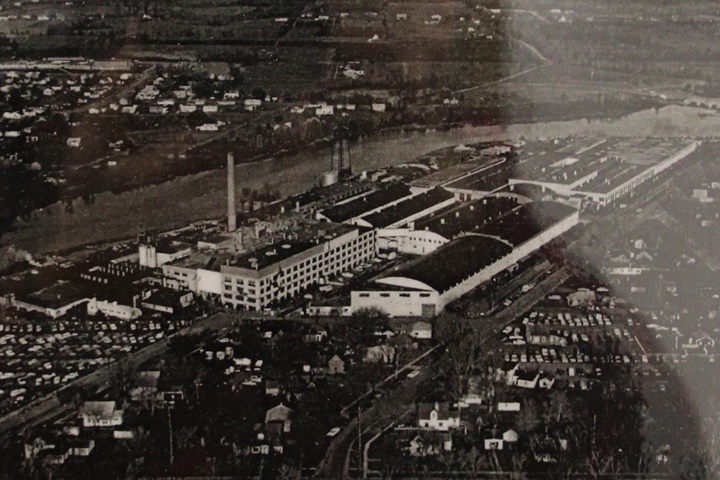

This is the Gibson Refrigerator complex in

Greenville, MI in the early

1950s. Photo courtesy of the Fighting Falcon Military Museum.

Gibson also had several factories in

Belding, MI, several miles to the south of Greenville. Photo

courtesy of the Fighting Falcon Military Museum.

This is plant

B and D in Belding. Photo courtesy of the Fighting Falcon Military

Museum.

This is plant E in Belding. Photo

courtesy of the Fighting Falcon Military Museum.

Gibson Refrigerator Post-World War Two

Military Products:

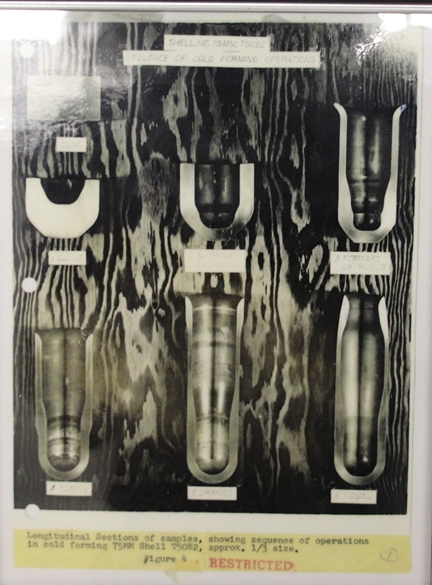

Gibson built the wheel bogies for the M51

Skysweeper 75mm anti-aircraft gun. This weapon was developed to

protect American cities from a Soviet air attack after World War Two. The small number of weapons that were built were quickly replaced by the Nike

anti-aircraft missile system. Gibson also made the shells for this

weapon. Author's photo.

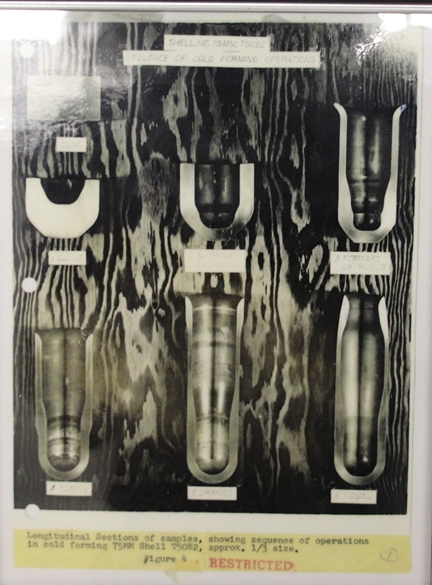

This photo shows the progression of the cold

forming process Gibson used to make over a million 75mm shells for the

Skysweeper anti-aircraft gun. Photo courtesy of the Fighting

Falcon Military Museum.

On October 20, 1954 Gibson produced its

millionth 75mm shell. Photo courtesy of the Fighting Falcon

Military Museum.

Gibson also built engine parts for the X-15. Author's photo.

The company also produced parts for the

C-119 that was built by Kaiser-Fraser in the former Ford Motor Company

B-24 plant at Willow Run, MI. Author's photo.

Other Greenville, MI World War Two

Manufacturers:

|

Table 3 -

Greenville, MI Company World War Two Products

The information below was obtained from the Fighting Falcon

Museum in Greenville, MI. It in turn was provided to the

museum by Mr. William Delp, former Gibson Refrigerator Company

employee. |

|

Company |

Quantity |

Product |

Comments |

| Metzgar Ltd. |

|

20,000 lbs./per

day of Dehydrated Potatoes |

These were

purchased by the Army, Navy, Lend-Lease Agency and the British

Maritime Commission |

| Belshaw

Manufacturing Company |

|

CG-4A Pilot and

Co-Pilot Seats, Three Man Seats and Vertical Stabilizers |

These were built

under sub-contract to Gibson |

| Greenville

Machine Company |

|

Various Stampings

and Machined Parts |

These were for

products built by Gibson, Ranney, and Towers |

| Wolverine Shoe

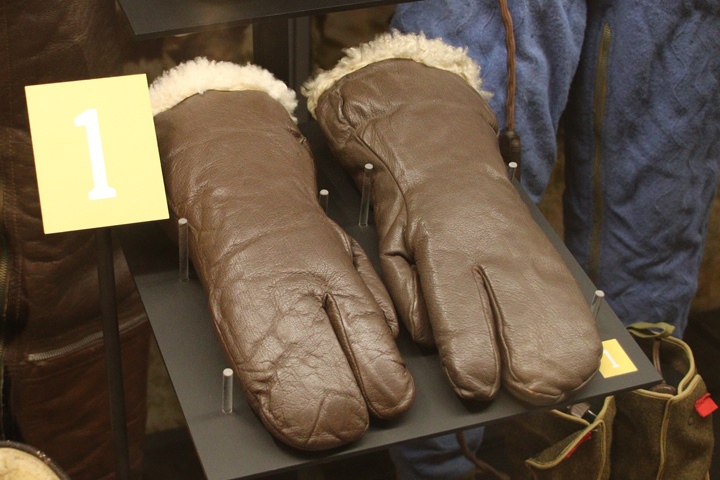

and Tanning Corporation, Glove Division |

|

Various Military

Gloves |

The primary

product was all leather, heavily insulated gloves for the Army

Air Force. These were used by American bomber flight

crews. |

| Ranney

Refrigerator Company |

|

Front Panel for

Sperry T-1 Computer |

This was a

sub-contract to Gibson. |

| Ranney

Refrigerator Company |

|

20mm Oerlikon

Anti-Aircraft Gun Parts |

These were built

under sub-contract to Gibson. |

| Ranney

Refrigerator Company |

|

Various Wooden

Ammunition Boxes and Crates |

These were

produced for both the Army and Navy. |

| R.J. Tower Iron

Works |

|

Thousands of

Bench Mounted Grommeting Machines |

These were used

to fasten metal grommets to all types of cloth material. |

| R.J. Tower Iron

Works |

|

Various Stampings |

These were

sub-contracted from Gibson |

| Federal-Mogul |

|

Brass Castings

for Marine Propellers |

Federal-Mogul

Produced all of the propellers for American-built PT and rescue

boats. It also produced the propellers for the DUKW. |

Federal-Mogul produced three propellers for

each of the 531 PT boats built during World War Two. This is

Higgins-built PT-305 located in New Orleans, LA. Author's photo.

This is the aft end of Higgins-built PT-796

at Battleship Cove, MA, which shows the Federal-Mogul-built propellers.

Author's photo.

Ranney Refrigerator in Greenville, MI

stamped out the front T-1 bombsight computer panels under sub-contract

to Gibson during World War Two. Author's photo.

Ranney also built large quantities of wooden

boxes for both the Army and the Navy. Author's photo from the

Fighting Falcon Museum.

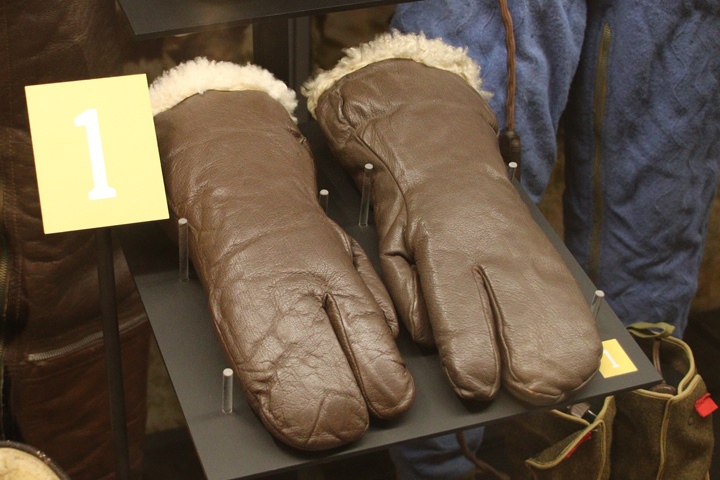

The Wolverine Shoe

and Tanning Corporation, Glove Division in Greenville, MI made

heavy, insulated gloves like this for bomber crews. Author's

photo. |