|

American

Auto Industry-Built Anti-Aircraft Guns in World War Two

This page added 7-1-2020.

Military historians have generally overlooked the American

Automobile Industry's contribution to the production of anti-aircraft

guns during World War Two.

While there is some recognition of the 40mm Bofors that Chrysler and the

20mm Oerlikon that Hudson built, the volumes and various types

of anti-aircraft guns built by General Motors and Willys-Overland have

gone unnoticed. When consolidated in the table below, it

can be seen that the American Auto Industry built both anti-aircraft

guns and components of all sizes from the .50 caliber machine gun to the 120mm

anti-aircraft gun, the largest built in the United States during the

war.

Definition: A complete

anti-aircraft gun was the operating gun mechanism and the barrel.

Mounts may or may not have been have been built by the manufacturer of

the operating weapon. In the case of the 40mm Bofors, both

Chrysler and Pontiac built the weapons, but other companies built the

mounts.

Ka-Boom times four! All of the 120mm

anti-aircraft guns, like the four firing simultaneously here, were built

by the General Motors Fisher Body Divisions Grand Rapids plant.

|

Summary Table - American Auto

Industry Built Anti-Aircraft Guns

This table includes not only completed weapons but

components to the weapons that were produced by the American

Automobile Industry. Dark shading indicates assembly of a

complete weapon. |

|

Weapon |

Company |

Gun Mechanisms |

Gun Tubes |

Breeches |

Gun

Mounts |

Complete Anti-Aircraft Guns |

Comments |

| .50

Caliber HB Browning |

AC

Spark Plug Division of GM |

100,000 |

100,000 |

Included in Mechanism |

|

100,000 |

This

is an estimate based on total General Motors build of

1.27million machine guns produced in four different GM Divisions. |

| 1.1 inch

|

Willys-Overland |

|

|

3,374

Breech Housings and Recoil Cylinders for 1.1 inch anti-aircraft

guns |

|

|

|

| 20mm Oerlikon |

Hudson |

33,201 |

33,201 |

Included in Mechanism |

33,201 |

33,201 |

Production started 7-7-41 and ended 10-43. |

| 20mm

Oerlikon |

Pontiac |

Unknown Amount |

47,026 estimated. See

calculations below. |

Included in Mechanism |

39,275 estimated single mounts. 5,760

twin 20mm Oerlikon mounts. |

Yes |

Pontiac started production before

Pearl Harbor. |

| 40mm

Bofors US Navy |

Chrysler |

28,884 |

28,884 |

Included in Mechanism |

|

Yes |

Chrysler reported 14,442 Dual 40mm Bofors at the end of the war. |

| 40mm

Bofors US Army |

Chrysler |

30,095 |

51,684 |

Included in Mechanism |

|

Yes |

Gun

Mechanisms is an end of war number. Gun tubes is as of

3-31-44. |

| 40mm

Bofors US Army |

Pontiac |

4,900 |

17,892 |

Included in Mechanism |

|

Yes |

|

| 40mm

Bofors US Army |

Firestone |

|

|

|

20,231 |

Yes |

Firestone mounted the weapons provided by Chrysler, Pontiac and

other gun manufacturers onto mounts. In essence, it was

the final assembler of a complete weapon. |

| 40mm

Bofors US Navy |

Firestone |

|

|

|

10,434 |

Yes |

Same

as above. |

| 3-inch/50-caliber

Dual Purpose Naval Gun |

Fisher Body Division of GM- Detroit Die and Machine |

|

|

9,459 |

|

|

|

| 90mm

US Army |

Fisher Body Division of GM- Pontiac Plant |

|

|

|

|

2,359 |

|

| 90mm

US Army |

Buick

Division of GM |

|

|

|

2,402 |

|

Buick (2,952) 90mm and 4.7 Anti-Aircraft Gun

Mounts, |

| 90mm

US Army |

Chevrolet

Division of GM |

|

2,000 |

2,000 |

|

|

Breech Block, Breech Ring, Recoil

Rails, and bored and rifled the 15-foot gun tube |

| 120mm

US Army |

Fisher Body Division of GM-Grand Rapids Stamping Plant

|

|

|

|

|

550 |

|

| 120mm

US Army |

Buick

Division of GM |

|

|

|

550 |

|

|

| 5-inch/38-calliber

inch Dual Purpose Naval |

Fisher Body Division of GM- Detroit, MI Die and Machine |

|

|

6,342

total Breech Housings between Detroit and Grand Rapids Plants.

Detroit Die and Machine built the majority of the housings. |

|

|

March

1944: 300 per month both plants combined

|

| 5-inch/38-calliber

inch Dual Purpose Naval |

Fisher Body Division of GM- Grand Rapids, MI Stamping Plant |

|

|

6,342

total Breech Housings between Detroit and Grand Rapids Plants |

|

|

March

1944 300 per month both plants combined

130 per month |

| 5-inch/38-calliber

inch Dual Purpose Naval |

Fisher Body Division of GM-Pontiac, MI |

|

|

|

480 |

|

|

.50 Caliber Browning Machine Guns:

AC Spark Plug Division of General Motors built an estimated 100,000

M2 HB .50 caliber Browning machine guns. The .50 caliber machine

gun was used on just about every type vehicle, small ship, boat, and

aircraft during the war. One of its main functions was providing

low altitude anti-aircraft protection for army units and its vehicles.

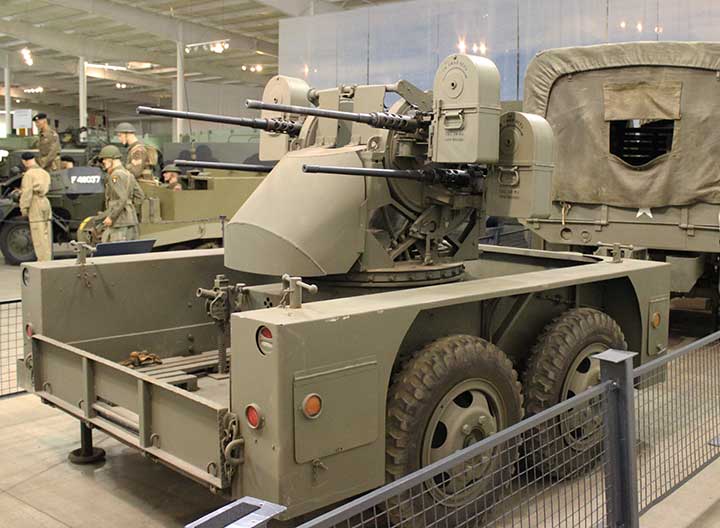

Quartermaster vehicles needed protection

against low-flying aircraft. This GMC CCKW-352 was on display at the

Virginia Museum of Military Vehicles 2016 Open House. Author's

photo.

Four .50 caliber machine guns were used in

the M45 quad mount anti-aircraft gun mount trailer. Author's

photo.

The .50 were also mounted on M3 half-tracks

which were re-designated as M16s. Author's photo.

The M15 half-track mounted two .50 caliber

machine guns and one 37mm cannon for providing anti-aircraft defense.

This on is on display at Fort Jackson, SC. Author's photo.

Author's photo.

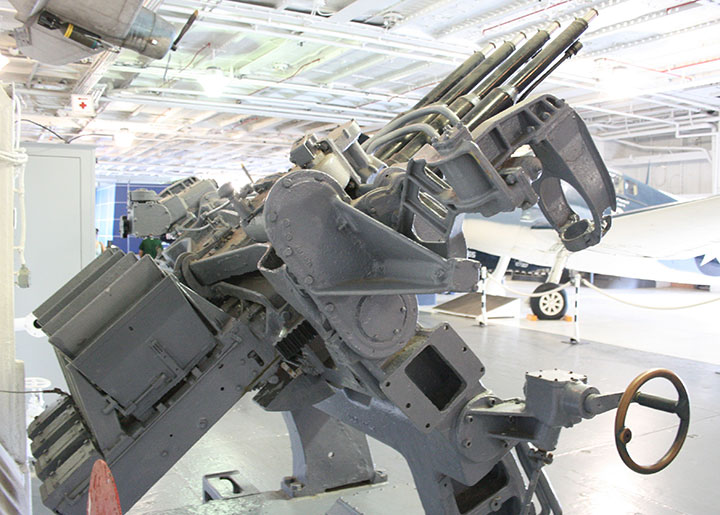

1.1 inch Anti-Aircraft

Guns for the US Navy: Willys-Overland is most well known for

building Jeeps during World War Two. A look at my Willys-Overland

page reveals that it had a large and diversified product line during the

war. Included in this product line were 3,374 breech housings and

recoil cylinders for the weapon. The 1.1 inch quad mount was the

low level anti-aircraft gun on U.S. Navy ships at the beginning of World

War Two. However, the weapon was problematic; and for the most

part was replaced by the 20mm Oerlikon and the 40mm Bofors. At the end of the war, there were still some 1.1 inch weapons

still on navy ships. The 1.1 was too heavy and not able to move

fast enough as a close in-weapon. On the other hand it was too

small a caliber to serve as an intermediate weapon between a heavy

machine gun and a five-inch dual purpose gun. In 1940, even though

the 1.1 was scheduled for replacement by both the 20mm Oerlikon

and 40mm Bofors, production was increased while manufacturers

tooled up for its replacements. A 1.1-inch was better than no

weapon at all. Willys-Overland was part of this pre-war buildup.

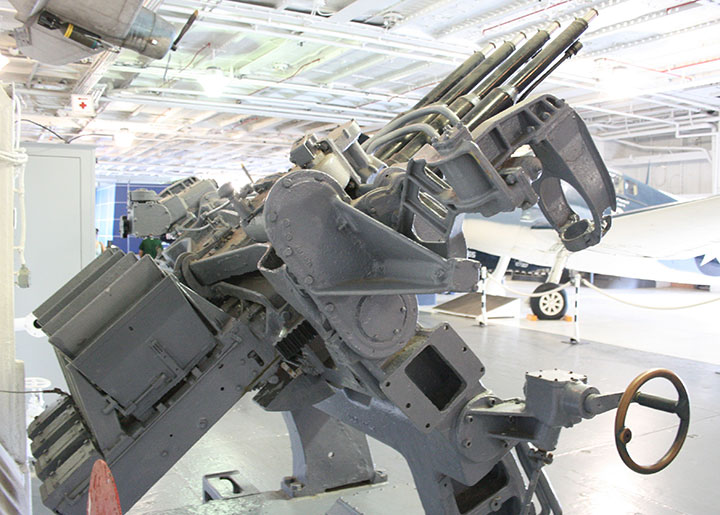

The 1.1-inch (28mm) quad mount anti-aircraft

gun was used by the US Navy during the first part of World War Two.

Prone to overheating and jamming if not properly maintained, the weapons

were replaced on US Navy ships, for the most part, by the both the 20mm Oerlikon and 40mm Bofors cannon

later in the war. Willys built 3,374 breach housings

and recoil cylinders for the weapons starting in 1941 and ending in

1943. As seen on the USS Yorktown at Patriots Point, SC.

Author's Photo.

Author's Photo.

Here is another 1.1-inch quad mount

photographed in Freedom Park, Omaha, NB. This one has one of the

gunner's seats still attached. This weapon may not exist anymore.

Freedom Park is/was right along the Missouri River in Omaha and has been

devastated several times since my visit by flooding. The park is

supposed be moved to safer area. Author's Photo.

This photo gives a good view of the feed trays

for the 1.1-inch shells. Author's Photo.

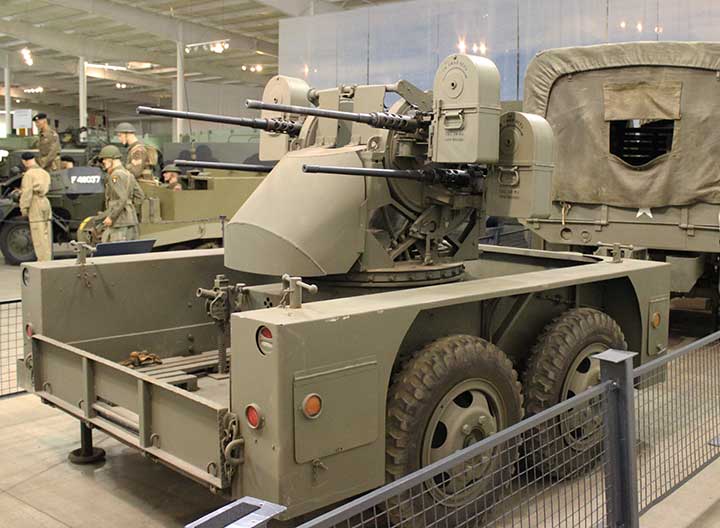

20mm Oerlikon Anti-Aircraft Guns for

the US Navy: There were

four companies that produced 146,956 20mm Oerlikon cannon during World

War Two. Two of them were from the auto industry, Pontiac and

Hudson. The U.S. Navy replaced Hudson with Westinghouse as the

managing company at the U.S. Navy Ordnance plant in Centerline, MI in

October 1943. The fourth company was American Oerlikon Gazda

Corporation.

In December 1941, contracts with each company

gave a monthly production rate. While there are no known

production numbers available for the individual companies of the 20mm

cannon, with the exception of Hudson, a total production is available.

With this information, an estimate of each manufacturer can be made and is done in

Table 1 below.

Pontiac 20mm Oerlikon anti-aircraft cannon

photos: There are two different dates found for the beginning of

the 20mm program at Pontiac. "Pontiac at War," shown below, gives

March 6, 1941. The "U.S. Navy Bureau of Ordnance in WWII" by

Buford Rowland gives a contract signing date of April 3, 1941. In

any event, eight months before Pearl Harbor, Pontiac started work on the

production of the 20mm Oerlikon cannon for the United States Navy. The

original contract was for 2,000 weapons for the British through

Lend-Lease. The contract was then modified for another 4,000

weapons. It is unknown whether the 4,000 units were for the

British or the U.S. Navy. The initial production rate was for

200-400 weapons per month. At the time of Pearl Harbor Pontiac had

delivered 115 weapons.

The weapon included both the gun and the mount

as shown in the first set of photos below.

Between June 1941 and December 1945 a total of

146,956 20mm Oerlikon guns were produced. It is known that Hudson

built 33,201 guns. From the table below, it can be seen that

Pontiac produced an estimated 47,026 20mm Oerlikon cannons.

|

Table 1 -

Production of 20mm Oerlikon Cannon in World War Two |

|

Company |

Contracted Monthly Production Rate - 20mm Oerlikon Cannon |

%

of the Total Production Contracted |

Estimated or Known Number of 20mm Oerlikons built |

Comments |

|

American Oerlikon Gazda Corporation |

500 |

27 |

39,678 - Estimated |

|

|

Pontiac |

600 |

32 |

47,026 - Estimated |

Pontiac delivered 115 weapons previous to Pearl Harbor. |

|

Centerline Naval Ordnance Plant -Hudson |

750 |

41 |

Confirmed

33,201 out of estimated 60,252 |

Hudson did not deliver any weapons until after Pearl Harbor.

Production started 7-7-41 and ended 10-43. |

|

Centerline Naval Ordnance Plant -Westinghouse |

750 |

41 |

27,051 - Estimated |

Westinghouse took over production at Center Line in 10-43. |

|

Totals |

1,850 |

100 |

146,956 |

|

The same thought process can be used to

estimate the number of single weapon mounts that Pontiac and others

built during the war. There were a 122,735 mounts built by the

same four companies at the same three locations.

|

Table 2 -

Production of 20mm Oerlikon Mounts in World War Two |

|

Company |

Contracted Monthly Production Rate - 20mm Oerlikon Mounts |

%

of the Total Production Contracted |

Estimated or Known Number of 20mm Mounts built |

Comments |

|

American Oerlikon Gazda Corporation |

500 |

27 |

33,139 - Estimated |

|

|

Pontiac |

600 |

32 |

39,275 - Estimated |

Pontiac delivered 115 weapons previous to Pearl Harbor.

Pontiac also built 5,760 twin 20mm Oerlikon mounts under a

separate contract starting January 1945. |

|

Centerline Naval Ordnance Plant -Hudson |

750 |

41 |

Confirmed

33,201 out of estimated 50321 |

Hudson did not deliver any weapons until after Pearl Harbor.

Production started 7-7-41 and ended 10-43. |

|

Centerline Naval Ordnance Plant -Westinghouse |

750 |

41 |

27,051 - Estimated |

Westinghouse took over production at Center Line in 10-43. |

|

Total |

|

100 |

122,735 |

|

Hudson: To date, I have been unable to find any of the 33,201 20mm Oerlikon

guns or mounts that Hudson made. Those that I have found were built

by Westinghouse after the U.S. Navy replaced Hudson as the manager of

the Centerline, MI Naval Arsenal with Westinghouse in October 1943.

This Hudson factory photo shows a few of the

33,201 20mm Oerlikon guns and mounts it built over a two year

period during World War Two. Note that Hudson built a solid circular

mount for the weapons. Pontiac produced a different type as shown

below.

Pontiac Motor Division of General Motors:

Pontiac built an estimated 47,026 20mm Oerlikons for the US Navy.

Pontiac's first war job was building

20mm Oerlikon anti-aircraft cannons for the US Navy. This

particular weapon, along with the stand and gun sight, were all built by

Pontiac. This weapon is serial number 223843. Author's photo

from the 2016 Virginian Museum of Military Vehicles Open House.

This is the best and most complete Pontiac

unit I have found. All the components were built by the Pontiac

Motor Division of General Motors. For some unknown reason the data

plates give General Motors Corporation of Pontiac as the builder.

Author's photo.

Author's photo.

Data plates on the Mark 10 20mm gun stand.

The serial number on the middle plate is 267182. This matches the serial

number on the bottom plate. Author's photo.

The serial number on the Mark 4 gun breach

is 223843. Author's photo.

The brass Mark 4 gun sight assembly was also

manufactured by Pontiac. Author's photo.

It has a weight of 12 pounds. Author's

photo.

This twin 20mm Oerlikon anti-aircraft gun is on the destroyer escort USS

Slater in Albany, NY. The weapon closest to the camera was

built by Pontiac. Author's photo.

Both of the 20mm mounts in both gun tubs are

twin mounts. These could be part of the 5,460 Pontiac built.

Author's photo.

This is the USS Massachusetts at Fall River,

MA. The Oerlikon 20mm cannon in the foreground was built by

Pontiac. Author's photo.

Author's photo.

This is Serial Number 43469. Author's

photo.

40mm Bofors Anti-Aircraft Cannon:

Chrysler:

Chrysler built 14,442 Dual 40mm Bofors for the U.S. Navy during

World War Two. Some of these weapons can be found on museum ships.

In many cases the data plates on the weapons are missing, painted over,

or just illegible due to weathering. However, in some cases, the

data plates tell which weapons were built by Chrysler.

During World War Two,

Chrysler built 40mm water cooled Bofors Guns for the US Navy

under license from the Bofors Company of Sweden. After

Chrysler engineers set up the manufacturing and assembly techniques

based on the mass manufacturing, the weapon could be assembled in ten

hours. Bofors in Sweden was taking 450 hours.

This example is located on the USS Sullivans in Buffalo, NY, and is

located on the middle of the ship on the starboard side. It should

be noted that Chrysler built only the firing portion of the total weapon.

The gun mounts were built by other companies.

There is a data plate on each barrel

and assembly. This one is mounted on the breech of the gun facing

the rear of the ship. This Chrysler-built 40mm Bofors gun

mechanism is

serial number 29869. Author's photo.

This is the other gun of the pair. Author's photo added

10-12-2017.

Here is the data plate for the gun mechanism for the gun facing the front of the ship.

This one is serial number 39869. What are the chances of a gun

mount having two Chrysler 40mm guns with serial numbers separated by

exactly10,000 units? Author's photo.

This is the USS Massachusetts at Fall River,

MA. A visit to the USS Massachusetts in June 2019 revealed that

most, if not all, of the 40mm Bofors anti-aircraft guns onboard were

built by Chrysler in 1942. This makes sense because the

Massachusetts was launched in September 1941 and commissioned on May 12,

1942. The Chrysler-built Bofors outfitted the battleship in 1942

as the weapons were coming off the assembly lines. All of the 40mm

Bofors I was able to visit on the USS Massachusetts were built by

Chrysler. Author's photo added 12-16-2019.

The USS Massachusetts bristles with 16-inch,

5-inch and 40mm guns. Author's photo added 12-16-2019.

There are two gun tubs on the fantail

of the USS Massachusetts with two dual 40mm Bofors mounts in each.

Author's photo.

The serial numbers from the four

Chrysler-built 40mm Bofors in the starboard side rear quad 40mm gun tub

are shown below. Author's photo added 12-16-2019.

This is serial number 25067. Author's

photo.

I have lightened this data plate as it was on the shade side of the

weapon. It is so worn that it is hard to read. This is

serial number 25065, just two less than the previous matching gun in the

twin mount. Author's photo.

This is serial number 35065. Author's

photo.

This is serial number 35067, two more than the matching gun in the twin

mount. Author's photo.

Chrysler produced 30,095 gun mechanisms and

51,684 gun tubes for the U.S. Army M1, M1A1, M2 and M2A1 anti-aircraft

guns, and for U.S. Navy M3 single-gun ship-mounted guns.

The Navy used the single mount with Chrysler

40mm gun mechanisms and tubes. Author's photo.

Chrysler-built 40mm mechanisms and gun tubes

went it into Army anti-aircraft guns like this one on display at the

Museum of American Armor on Long Island, NY. Author's photo.

Pontiac Motor Division of General Motors:

Pontiac produced 4,900 gun mechanisms and 17,892 gun tubes through

March 1944.

Pontiac began work on the 40mm Bofors anti-aircraft gun mechanisms and

gun tubes in January 1942.

Pontiac cleared 217,000 square feet of the sheet metal plant space to

manufacture the weapon. The Bofors could fire 130 rounds per

minute, and the two pound projectiles had a range of 5,420 yards.

Author's photo.

The information for the two tables below

comes from "The History of the Americanization of the Bofors 40mm

Automatic Antiaircraft Gun" written by the Historical Section of the

Ordnance Department in May 1944.

Pontiac produced 16.5% of the gun mechanisms

and 20.8% of the gun tubes for the US Army 40mm Bofors like the one

shown above. Note that the information came from an article

written in May 1944. Over a year of war still remained,

and the need for gun tubes continued.

|

Production

of 40mm Gun Mechanisms for the US Army as of March 1944 |

|

Company |

Date |

Quantity |

Percentage |

Comments |

|

Chrysler |

3-31-1944 |

24,802 |

83.5% |

|

|

Pontiac |

After

12-1943 |

4,900 |

16.5% |

This was the scheduled amount that was completed some time

in 1944. |

|

Total |

|

29,702 |

|

|

|

Production

of 40mm Gun Tubes for the US Army as of March 1944 |

|

Company |

Date |

Quantity |

Percentage |

|

Chrysler |

3-31-1944 |

51,684 |

60.2% |

|

Pontiac |

3-31-1944 |

17,892 |

20.8% |

|

Otis Fensom |

3-31-1944 |

16,258 |

18.9% |

|

War Supplies |

10-42 |

40 |

0.1% |

|

Total |

|

85,874 |

|

Firestone Tire and Rubber Company:

Firestone built 20,231 40mm gun carriages for the U.S. Army

during World War Two. It received the assembled gun mechanisms and

tubes from both Chrysler and Pontiac, and then assembled them into the

gun carriages. It also built 10,434 single-gun mounts for the U.S.

for use on submarines, PT boats, and other small water craft.

This 40mm anti-aircraft gun with a Firestone

Navy gun mount is on PT-305 in New Orleans, LA. Author's photo.

This carriage is serial number 16430 which

was built in 1943. Author's photo.

A Firestone-built 40mm Bofors mount and

carriage can be

seen at the Indiana Military Museum in Vincennes, IN. Author's

photo.

This is an M3 mount and is serial number

9899. Author's photo.

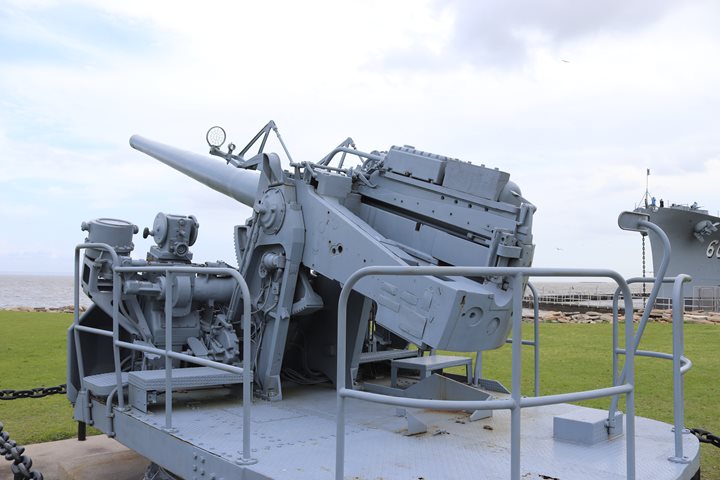

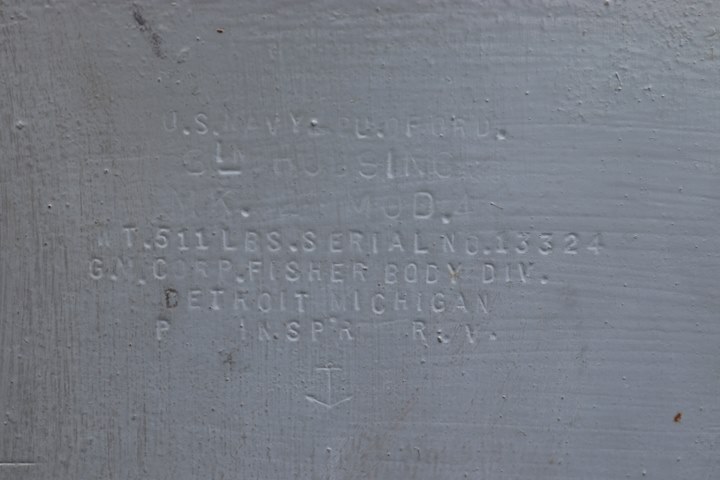

3-inch/50-caliber Naval Dual-Purpose Guns:

The Fisher Body Division of General Motors Die and Machine plant in

Detroit, MI built 9,459 breeches for the 3-inch gun during World War

Two.

The number one three-inch/50-caliber gun on

the USS Slater DE-766 has a Fisher Body-built breech. The USS

Slater is on display along the Hudson River water front in Albany.

It is the only Cannon Class Destroyer Escort on display in the world.

Author's photo.

The number one gun on the USS Slater.

Author's photo.

The tour guide encouraged those on the tour

to get on the gun mount and operate the elevation and transverse

controls. Author's photo.

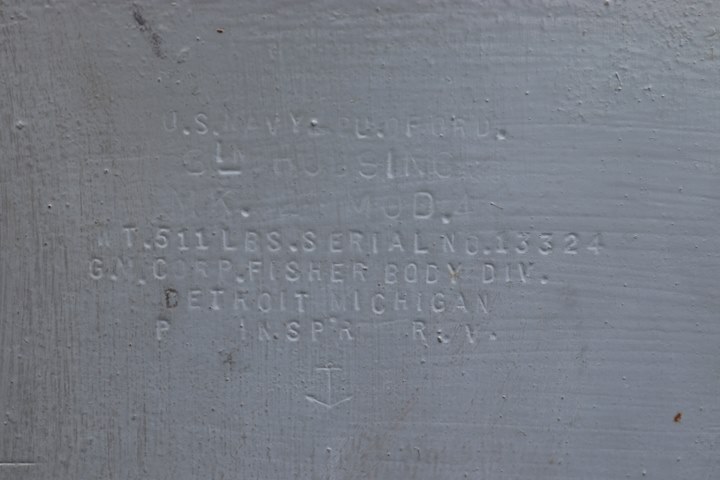

This is Fisher Body three-inch breech serial

number 13324. Author's photo.

The tour guide showed the size of the

three-inch round to my tour group. Author's photo.

Here the tour guide is showing how the shell

is inserted into the Fisher Body-built breech. Author's photo.

Author's photo added 8-25-2017.

90 mm Anti-Aircraft Gun:

Fisher Body Pontiac, MI Plant: This plant built 2,359 90mm

anti-aircraft guns with the parts furnished by several other General

Motors plants. Buick supplied all of the gun mounts for the

weapons, Chevrolet provided at least

2,000 each of the needed Breech Blocks, Breech Rings, and Recoil

Rails It also bored and rifled the 15-foot gun tube.

This 90mm anti-aircraft gun is on display at

Jackson Barracks in New Orleans. It is representative of the 2,359

built by the Pontiac Plant of the Fisher Body Division during World War

Two. Author's photo.

Author's photo.

Author's photo.

Author's photo.

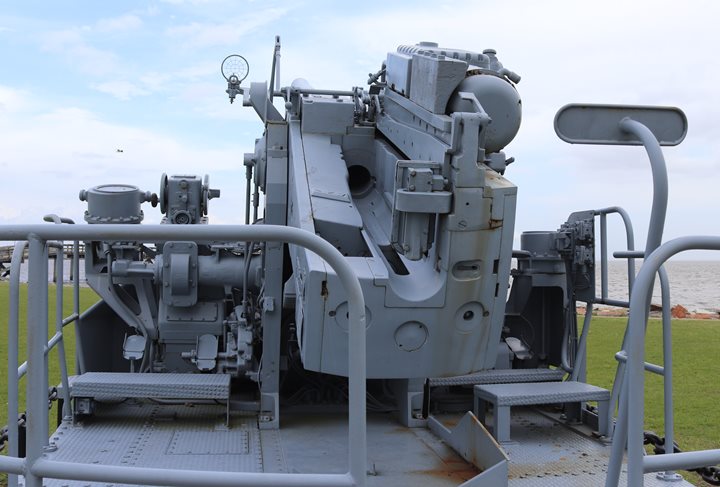

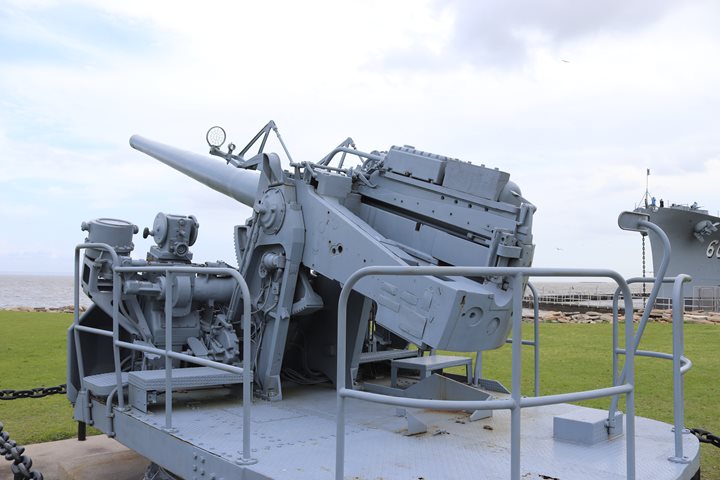

120mm Anti-Aircraft Guns: The

Grand-Rapids plant of the Fisher Body Division of General Motors built

all 550 of the 120mm anti-aircraft guns produced. Buick provided

the gun mounts. There are only a few of the 120mm anti-aircraft

guns left. I have provided several photos below of the weapon on

display at the USS Alabama in Mobile, AL to show all the features and

complexity of the weapon.

This is one of the few surviving 120mm M1

anti-aircraft guns of the 550 built by Fisher Body Grand Rapids during

World War Two. Author's photo.

The M120mm anti-aircraft gun was the

signature weapon produced by Fisher Body Grand Rapids Stamping Plant

during

World War Two. The Power Rammer was designed and built by the

Grand Rapids plant. Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo added 3-20-2018.

Author's photo added 3-20-2018.

Author's photo added 3-20-2018.

Author's photo added 3-20-2018.

One of the last known uses for the Fisher Body

Grand Rapids built M1 120mm anti-aircraft gun was at the Hanford

Engineering Works plutonium production reactor complex along the

Columbia River in Washington. In the early 1950s, 16 batteries of

four M1 anti-aircraft guns were set up around the facility as the Cold

War heated up. 5,000 soldiers of the 501st, 518th, and 519th AAA

Battalions manned the 64 M1s against an air attack from the Soviet

Union. In 1955 the M1s were phased out and replaced by Nike Ajax

anti-aircraft missiles.

5-inch/38-caliber Naval Dual-Purpose Guns:

Both the Fisher Body Grand Rapids, MI and Detroit Die and Machine plants

built 6,342 breech housings for these weapons. The Detroit Die and

Machine plant started producing the housing in April 1941. It

received the Navy "E" flag for shipping breech housings only five months after tooling

began. The Grand Rapids Fisher Body plant tooled up in 1943.

By

March 1944, the two plants were producing 300 5-inch housings per month.

The Pontiac, MI Fisher Body plant produced 480

gun mounts for the five-inch gun between September 1943 and January

1945.

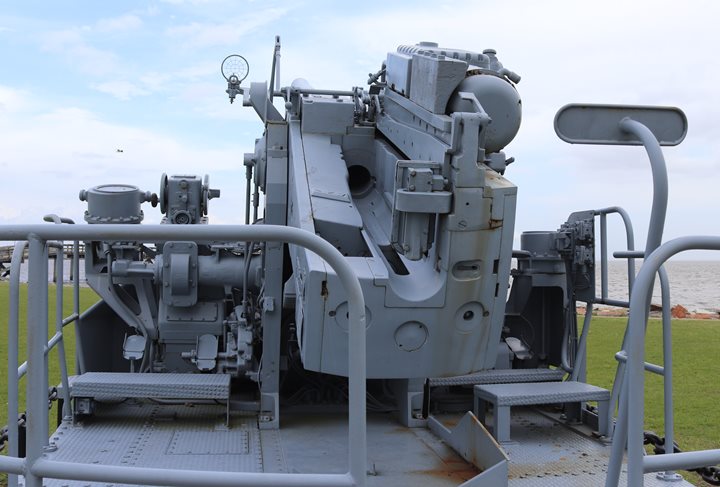

The

Fisher Body Die and Machine plant in Detroit and the Fisher Body in Grand Rapids produced naval gun breeches for five-inch, 38-caliber guns like this one. This five-inch gun can be

seen at the USS Sullivans at the Buffalo and Erie County Naval and

Military Park in Buffalo, NY. Author's photo.

This is one of four five-inch, 38 caliber

naval guns without the turret armor. It is on display at the USS Alabama.

This allows for an excellent inspection of both the breeches and the

mounts. Many non-combat ships had five-inch guns like these for

defensive protection. Liberty ships had a five-inch gun like this,

manned by a Navy crew, on the fantail of these important transport

ships. Author's photo.

The gun mechanism was a complicated and

precision device consisting of 218 components. The Fisher Body

built breech housing weighed 2,932 pounds. It is the component in the

center of the gun mechanism with the opening for the five inch round, to

which the remaining 217 components were added. Author's photo.

One of the seven different components that Fisher Body Pontiac

assembled into the gun mount weighed 5,250 pounds. This was a huge

undertaking on the part of Fisher Body Pontiac. Author's photo.

Author's photo.

|