|

Brockway

Motor Company in World War Two

Cortland, NY

1875-1977

Rest in Peace

This page

updated 11-11-2023.

Brockway Motor Company was founded in 1875 by William Brockway, for the

manufacturer of horse carriages. The original name for the firm

was the Brockway Carriage Works. William Brockway's son George

changed the course for the company in 1909 by going into the production of

trucks. In 1956, Mack purchased Brockway Motor Company and

ran it as a separate division until it closed the Cortland, NY operation

in 1977.

World War One: Brockway was one of fifteen companies that made

9,364 standardized 4x2 Liberty trucks for the U.S. Army from 1917-1918.

Brockway built 589 trucks. The company also produced a number of

fire engines for the U.S. Army Quartermaster Corps.

-126w-1.jpg)

This image shows that Brockway built at

least five fire trucks for the U.S. Army during World War One.

Photo courtesy of the National Archives via Jeff Lakaszcyck added

11-11-2023..

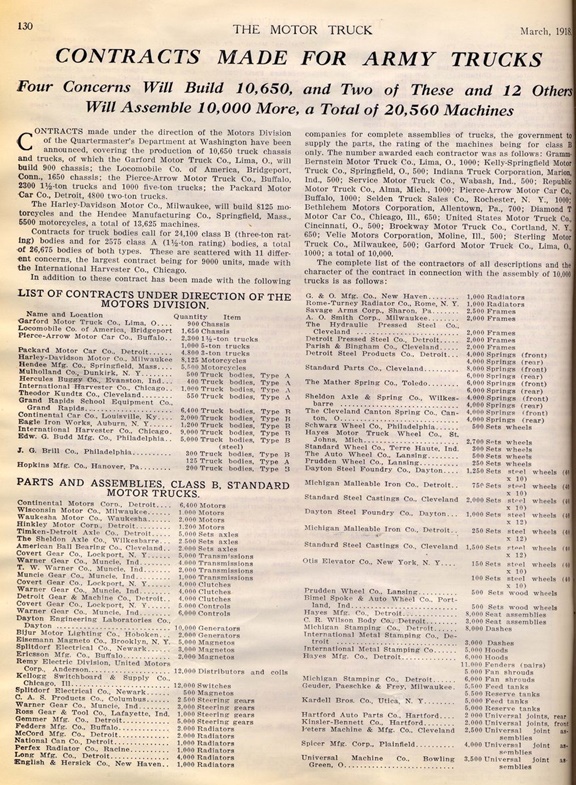

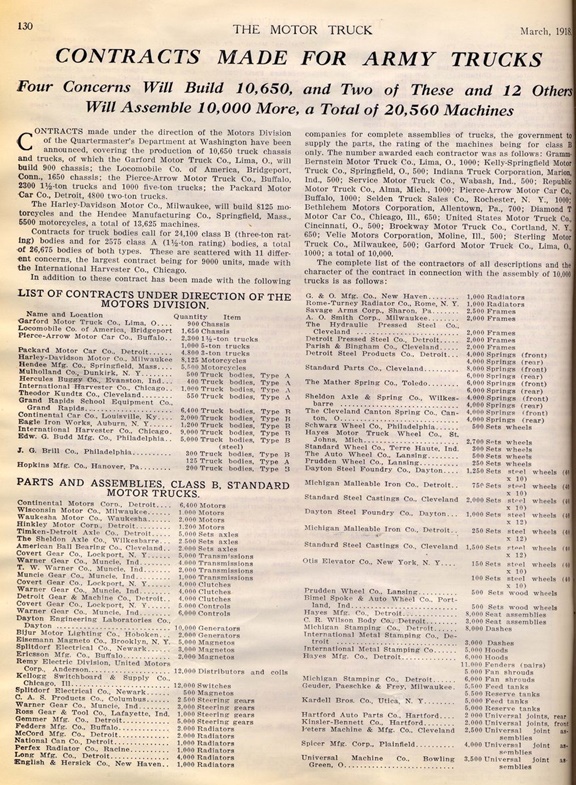

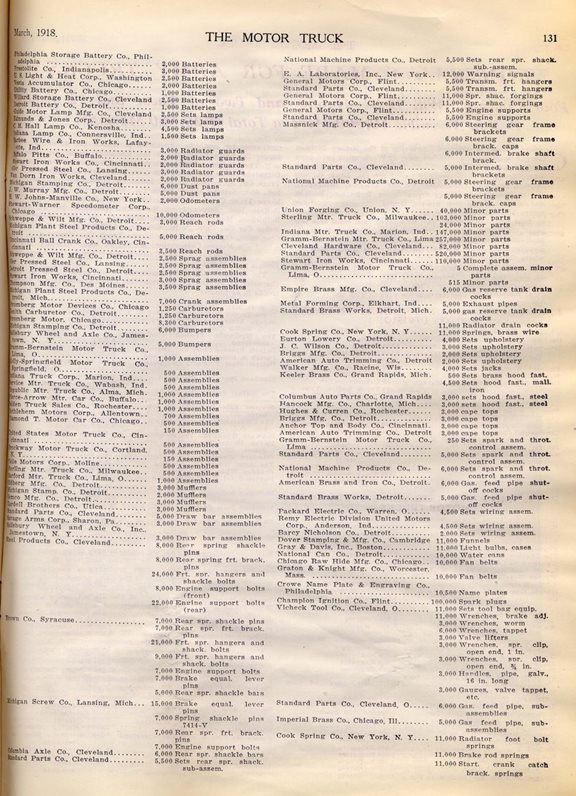

The

two pages below are from the March 1918 issue of "The Motor Truck."

This provides invaluable information that reveals the types, numbers,

and suppliers of motor vehicles and components that the U.S. Army

Quartermaster contracted for in World War One. The document shows

that Brockway was originally contracted for 500 Liberty trucks.

However, by the end of the war in November 1919, Brockway had actually

built 589 units.

Document courtesy of Warren Richardson added

11-11-2023.

Brockway is listed in the left column about

three quarters of the way down the page. Document courtesy of

Warren Richardson added 11-11-2023.

-126w-1.jpg)

At least 28 Brockway-built Liberty trucks

are shown in this posed photo.

These trucks are of the first series

because they have electrical lighting. Wires for the electrical

current have been routed from holes below the headlights. The

second series eliminated the electrical lighting and the associated

battery, distributor, and generator.

Photo courtesy of the National Archives via Jeff Lakaszcyck added

11-11-2023.

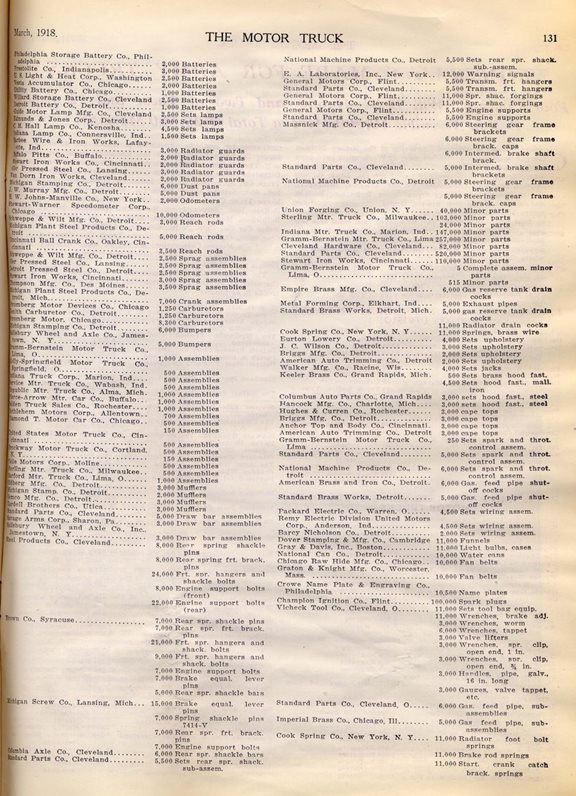

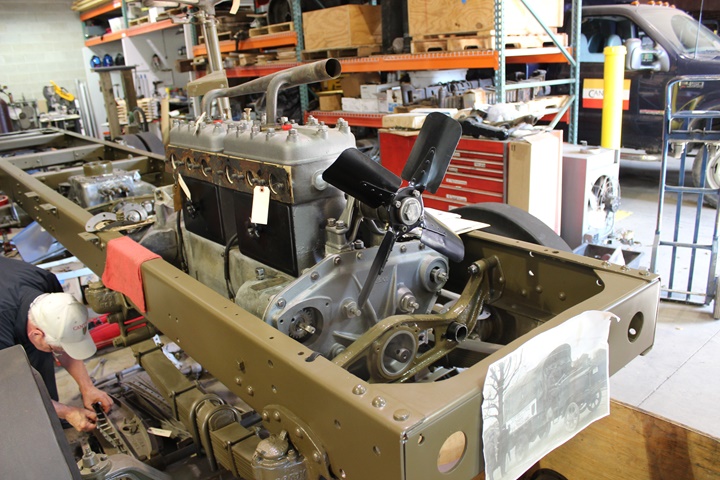

In 2015 this World War One Liberty truck

chassis and drive train were undergoing restoration at the First

Division Museum in Wheaton, IL. This restoration is not

specifically associated with any of the fifteen companies that built the

Liberty truck because the parts are from various sources. Author's

photo added 11-11-2023.

This completed Standard B Liberty

truck is of the second series as photographed in 2019. The electrical headlights have

been replaced with oil wick lamps. A carbide gas spot light used

as a driving light is mounted on the top of the firewall. This

vehicle has been restored to operating condition and is driven around

the First Division Museum complex on special occasions. Author's

photo added 11-11-2023.

Author's photo added 11-11-2023.

Author's photo added 11-11-2023.

Author's photo added 11-11-2023.

The copper tube from the gas generator for

the spot light can be seen coming out of the fire wall and being routed

to the light. A flexible rubber hose at the spot light allows it

to be aimed by the assistant driver. Author's photo added

11-11-2023.

The replica data plate shows the vehicle

having chassis no. 14480 and a date of 7-27-1918. Author's photo

added 11-11-2023.

Brockway Commercial Trucks:

This 1924 Brockway 1-1/2-ton truck is on

display at the Iowa 80 Trucking Museum. Author's photo added

11-11-2023.

This 1949 Brockway 260-XW truck is on

display at the Iowa 80 Trucking Museum. The wooden framed doors

have exterior wood trim. Author's photo added 11-11-2023.

Brockway Motor Company

World War Two Production: Table 1 shows

that during World War Two Brockway had eighteen major contracts worth $36,392,000.

Table 2 shows that the U.S. Army was Brockway's largest customer during

the war and had 97% of the wartime contracts. Table 3 shows that

the U.S. Army accepted 2,953 trucks in the 2-1/2-ton, 6-ton, and 10-ton sizes

built under wartime contracts. Brockway also built an estimated

100 trucks for the U.S. Navy and another estimated 134 trucks under U.S.

Treasury contracts for the United Kingdom.

Table 1 -

Brockway Motor Company's Major World War Two Contracts

-

Table added

11-11-2023.

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. |

|

Product - Customer |

Contract Number |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Tractors Trucks -

Army Quartermaster |

398-QM-29L |

$229,000 |

6-1941 |

8-1941 |

| Motor Trucks -

Navy |

110-S-90030 |

$57,000 |

6-1941 |

8-1941 |

| Trucks

Gasoline Tank - Army Quartermaster |

398-QM-148L |

$420,000 |

10-1941 |

12-1941 |

| Trucks -

Army Quartermaster |

398-QM-00206L |

$171,000 |

12-1941 |

4-1942 |

| Trucks -

Army Quartermaster |

398-QM-13542 |

$3,570,000 |

1-1942 |

5-1943 |

| Truck Chassis -

Army Ordnance |

740-ORD-2709 |

$7,452,000 |

1-1942 |

3-1943 |

| Trucks - Navy |

140-S-97178 |

$78,000 |

2-1942 |

3-1942 |

| Trucks - U.S.

Treasury |

TPS-27352L |

$519,000 |

5-1942 |

6-1942 |

| Trucks - Army

Ordnance |

740-ORD-2709 |

$7,556,000 |

5-1942 |

1-1945 |

| Trucks - U.S.

Treasury |

TPS-17352L |

$95,000 |

9-1942 |

4-1943 |

| Trucks - Army

Ordnance |

740-ORD-3552 |

$5,788,000 |

3-1943 |

7-1944 |

| Truck Parts -

Army Ordnance |

740-ORD-3686 |

$1,225,000 |

5-1943 |

2-1945 |

| Tractor Trucks -

Navy |

NXS-36694 |

$320,000 |

10-1943 |

9-1944 |

| Crane Chassis -

Army Ordnance |

30115-ORD-312 |

$6,963,000 |

10-1943 |

6-1945 |

| Trucks - Army

Ordnance |

30115-ORD-1238 |

$1,340,000 |

6-1944 |

10-1945 |

| Motor Truck Parts

B666 - Army Ordnance |

30115-ORD-1330 |

$217,000 |

6-1944 |

5-1945 |

| Motor Truck Parts

B666 - Army Ordnance |

30115-ORD-1331 |

$78,000 |

6-1944 |

5-1945 |

| Trucks - Army

Ordnance |

30115-ORD-1919 |

$314,000 |

1-1945 |

12-1945 |

| Total |

|

$36,392,000 |

|

|

|

Table 2 -

Brockway Motor

Company's

Major World War Two Contracts by Customer -

Table added 11-11-2023. |

|

Customer |

Total Contract Value |

Number of Contracts |

Percentage |

| U.S Army |

$35,323,000 |

13 |

97% |

|

U.S. Treasury |

$614,000 |

2 |

1.7% |

|

Navy |

$455,000 |

3 |

1.3% |

|

Total |

$36,392,000 |

18 |

100% |

|

Table 3- Brockway

Motor Company World War Two Trucks

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

Brockway Model |

Purchase Order Number |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| 2 1/2-ton 4x2,

Chassis, for 1000 gal gas tank |

? |

398-QM-148 |

|

50 |

|

|

|

|

50 |

| 6-ton 6x6 Chassis

w/w for the Daybrook M-II-A Bridge Erector |

B-666 |

74-ORD-2709 |

|

|

384 |

271 |

|

|

655 |

| 6-ton 6x6 Chassis

w/w for the Daybrook M-II-A Bridge Erector |

B-666 |

74-ORD-2710 |

|

|

|

370 |

141 |

|

511 |

| Total

|

|

|

|

|

384 |

641 |

141 |

|

1,166 |

| |

|

|

|

|

|

|

|

|

|

| 6-ton 6x6 Chassis

w/w for Quickway Crane |

C-666 |

74-ORD-3552 |

|

|

|

237 |

297 |

|

634 |

| 6-ton 6x6 Chassis

w/w for Quickway Crane |

C-666 |

30115-ORD-312 |

|

|

|

|

312 |

318 |

630 |

| 6-ton 6x6 Chassis

w/w for Quickway Crane |

C-666 |

30115-ORD-1238 |

|

|

|

|

|

148 |

148 |

|

Total |

|

|

|

|

|

237 |

609 |

466 |

1,312 |

| |

|

|

|

|

|

|

|

|

|

| 6-ton 6x6

Chassis, Fire |

B-666, F-666 |

740-ORD-2710 |

|

|

|

|

174 |

26 |

200 |

| 6-ton 6x6

Chassis, Fire |

B-666, F-666 |

30115-ORD-312 |

|

|

|

|

|

36 |

36 |

| 6-ton 6x6

Chassis, Fire |

B-666, F-666 |

30115-ORD-1919 |

|

|

|

|

|

34 |

34 |

| Total

|

|

|

|

|

|

|

174 |

96 |

270 |

| |

|

|

|

|

|

|

|

|

|

| 6-ton 4x2, Tank

Chassis, Gas, 2000 gallons |

? |

398-QM-148 |

|

50 |

|

|

|

|

50 |

| 10-ton 6x4,

Tractor |

? |

398-QM-29 |

|

50 |

|

|

|

|

50 |

|

10-ton 4x2, Hoist Dump |

? |

398-QM-00206L |

|

|

25 |

|

|

|

25 |

|

Total |

|

|

|

150 |

409 |

878 |

924 |

562 |

2,953 |

Author's Note

and Disclaimer: The Detroit Office

of Ordnance of the U.S. Army was the primary purchasing entity for

vehicles for the U.S. Army during World War Two. It also purchased vehicles

for the USMC, US Navy, and for Lend-Lease. However, there were

other organizations that also purchased vehicles including the Army

Corps of Engineers, U.S. Army Air Force, U.S. Army Signal Corps, Navy

Bureau of Ordnance, Navy Bureau of Aeronautics, and foreign countries

making direct purchases.

Table 4 below matches contract numbers with

the number of trucks accepted by the U.S. Army as shown in Table 3.

With this information, in most cases for the U.S. Army trucks the unit

cost can be calculated. However, contracts 398-QM-13542 and 740-ORD-2710

both represent two different types of trucks, one of which can not be

identified from the existing records. These will be left

uncalculated.

|

Table 4 - Brockway

Motor Company World War Two Trucks

Unit Costs - Table added 11-11-2023. |

|

Product - Customer |

Contract Number |

Contract Amount |

Type |

Quantity |

Unit Cost |

Comments

|

| Tractors Trucks -

Army Quartermaster |

398-QM-29L |

$229,000 |

10-ton 6x4,

Tractor |

50 |

$4,580 |

|

| Motor Trucks -

Navy |

110-S-90030 |

$57,000 |

? |

? |

? |

|

| Trucks

Gasoline Tank - Army Quartermaster |

398-QM-148L |

$420,000 |

6-ton 4x2, Tank

Chassis, Gas, 2000 gallons and

2 1/2-ton 4x2,

Chassis, for 1000 gal gas tank |

50 + 50 =100 |

$4,200 |

|

| Trucks -

Army Quartermaster |

398-QM-00206L |

$171,000 |

10-ton 4x2, Hoist Dump |

25 |

$6,840 |

|

| Trucks -

Army Quartermaster |

398-QM-13542 |

$3,570,000 |

? |

|

|

Same as 740-ORD-2710 |

| Truck Chassis -

Army Ordnance |

740-ORD-2709 |

$7,452,000 |

6-ton 6x6 Chassis

w/w for the Daybrook M-II-A Bridge Erector |

655 |

$11,377 |

|

| Trucks - Navy |

140-S-97178 |

$78,000 |

? |

? |

? |

|

| Trucks - U.S.

Treasury |

TPS-27352L |

$519,000 |

? |

? |

? |

|

| Trucks - Army

Ordnance |

740-ORD-2710 |

$7,556,000 |

6-ton 6x6 Chassis

w/w for the Daybrook M-II-A Bridge Erector and

6-ton 6x6

Chassis, Fire |

511+ 200=711 |

|

Same as 398-QM-13542 |

| Trucks - U.S.

Treasury |

TPS-17352L |

$95,000 |

? |

? |

? |

|

| Trucks - Army

Ordnance |

740-ORD-3552 |

$5,788,00 |

6-ton 6x6 Chassis

w/w for Quickway Crane |

634 |

$9,129 |

|

| Tractor Trucks -

Navy |

NXS-36694 |

$320,000 |

? |

? |

? |

|

| Crane Chassis -

Army Ordnance |

30115-ORD-312 |

$6,963,000 |

6-ton 6x6 Chassis

w/w for Quickway Crane and

6-ton 6x6

Chassis, Fire |

630 and 36 |

? |

|

| Trucks - Army

Ordnance |

30115-ORD-1238 |

$1,340,000 |

6-ton 6x6 Chassis

w/w for Quickway Crane |

148 |

$9,054 |

|

| Trucks - Army

Ordnance |

30115-ORD-1919 |

$314,000 |

6-ton 6x6

Chassis, Fire |

34 |

$9,325 |

|

Table 4 - Brockway

Motor Company B-666

Bridge Pontoon Truck and C666 Crane Truck Partial Serial and

Registration Number Listing

From TM-1528 dated January 1, 1944 - Table added 1-15-2024. |

|

Model |

Brockway Serial Number |

USA Registration Number |

Quantity |

|

|

B666 |

1

- 655 |

W-511955 - W-512609 |

655 |

|

|

B666 |

656 - 1075 |

W-519666 - W-520085 |

420 |

|

|

B666 |

1076 - 1132 |

W-544006 - W-54062 |

57 |

|

|

B666 |

1133 - 1366 |

0077176 - 0077409 |

234 |

|

|

Total B666 |

|

|

1,366 |

|

|

C666 |

1

- 237 |

0050937 - 0051173 |

237 |

|

|

C666 |

238 - 534 |

0079146 - 0079442 |

297 |

|

|

Total C666 |

|

|

534 |

|

There are also three U.S. Navy and two U.S.

Treasury Department contracts in Table 4 for which the unit cost cannot

be calculated as the trucks were not accepted by the U.S. Army.

However, I have made some assumptions and made my best attempt to

estimate how many trucks Brockway produced for the U.S. Navy and U.S.

Treasury. With these calculations, I can then estimate the total

number of trucks the Brockway Motor Company built to help win World War

Two.

This 1943 photo of a Brockway indicates that

the U.S. Navy purchased a number of 4x2 tractors for its use during

World War Two. In this particular case, it is being used to

transport sailors in the attached semi-trailer bus. While it may

not appear that the bus could hold 100 sailors, I did have personal

experience of riding in a similar bus during Army basic training.

We called them "cattle cars," and the drill sergeants were very adept at

stuffing as many recruits into one of these as possible. Historic

photo courtesy of Dan Souday added

11-11-2023.

But I digress. Table 4 indicates that

the U.S. Army purchased under contract 398-QM-29L fifty 10-ton 6x4

tractors for $4,580. While the U.S. Navy tractor shown in the

photo has been estimated to be more in the range of a five-ton tractor,

I will still use the $4,580 to estimate how many trucks Brockway built

for the Navy.

The total of the three Navy contracts is

$455,000. This number divided by $4,580 equals 99.34 which can be

rounded up to 100.

One source indicates that Brockway built a

number of 4x2 trucks that were smaller than the 6-ton 6x6 trucks it

built for cranes and bridging for the United Kingdom. The U.S.

Treasury did purchase equipment for foreign nations during World War

Two. Once again, I will assume that these were 4x2 tractors that

cost $4,580. Dividing this value into the total U.S. Treasury

contract number of $614,000 gives 134 units.

While both the 100 and 134 numbers are gross

estimates, they do show that the Brockway Motor Company built an

estimated several hundred trucks beyond the 2,953 that the U.S. Army

accepted and is normally given as what the company built during World

War Two.

My analysis shows that the Brockway Motor

Company built over 3,000 trucks to help win World War Two.

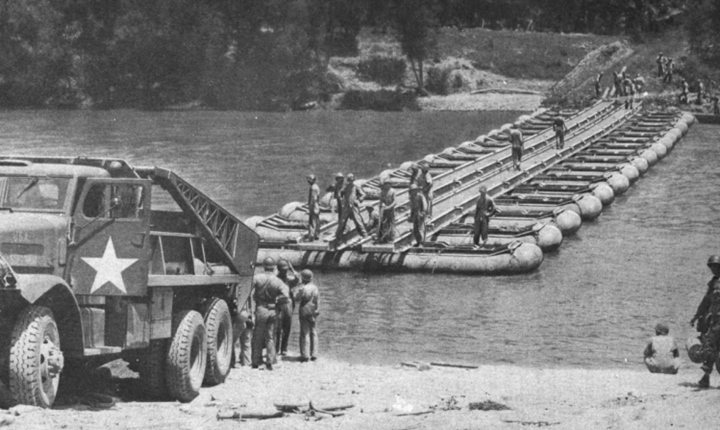

Bridging Trucks: Brockway is

best known for its construction of 1,166

6-ton 6x6 Model B-666 Bridge Erector Trucks. The 1,166 bridge erector

trucks were 40% of the trucks the company built for the U.S. Army during

World War Two. The

Brockway B-666 series of 6x6, 6-ton trucks was based on the Corbitt

50SD6. Brockway was one of four manufacturers of this type of vehicle. Corbitt, Ward LaFrance, and White Motor Company were the others.

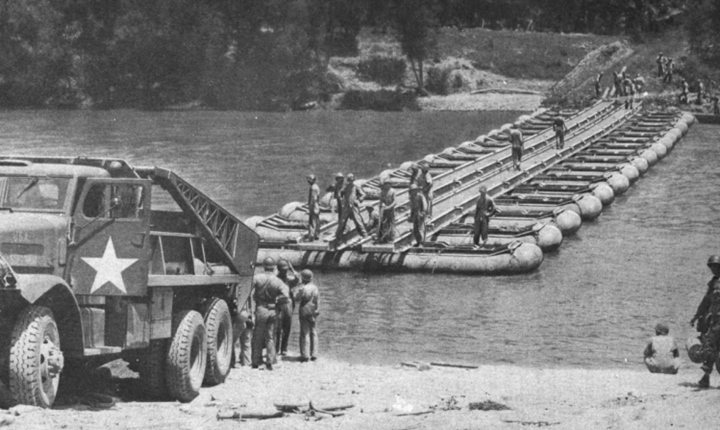

Bridging equipment was extremely important

to the mechanized American Army of World War Two. Water obstacles

consisted of rivers, streams, drainage ditches, gullies and canals.

In most cases, the retreating enemy would destroy any existing bridges as

it fell back under the American advance. In Europe, rivers wider

than 75-100 yards were encountered on the average of every 45 to 50

miles. Also, the tactical or strategic situation might demand a

river crossing in some location where there was no existing bridge.

Brockway B-666 bridging trucks were an important tool of the Army Combat

Engineers in keeping the American offense moving.

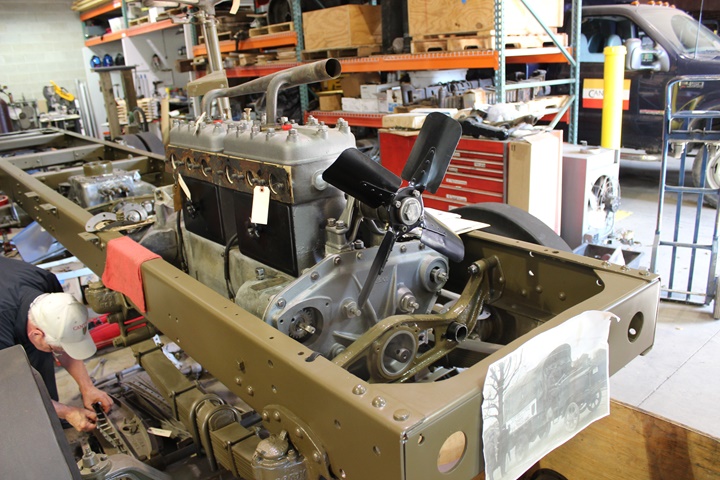

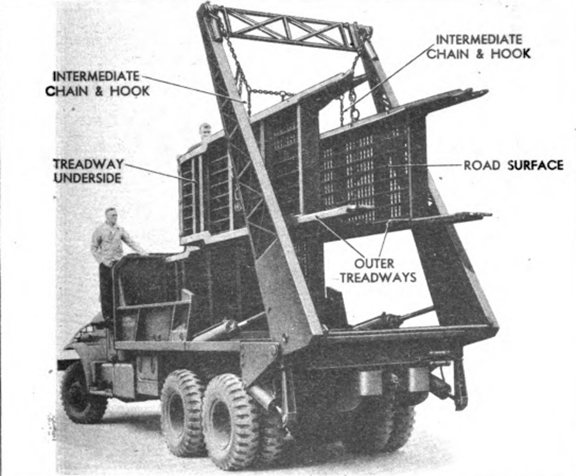

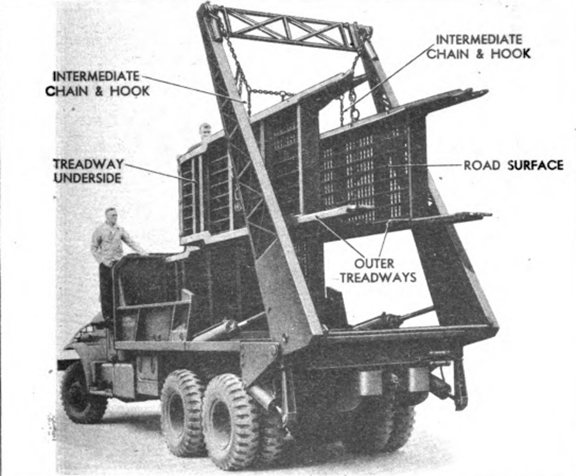

This 6-ton 6x6 Brockway Model B-666 chassis

with installed bridge-erecting equipment is on display at the National

Museum of Military Vehicles in Dubois, WY. B-666s had a 220-inch wheelbase and

a 25,000-pound front winch. The twin-boom 4-ton hydraulic crane

could lift the 45-inch wide bridge treadways directly on and off the

truck. The vehicle had an oversize air brake system for filling

the pontoons. Author's photo added 11-11-2023.

I first published this page on Brockway in

August 2018. Since that time I have been looking to find a

Brockway bridging truck to personally see and photograph. The

timing of my visit to the National Museum of Military Vehicles was

excellent as this truck was placed on display just two months before I

arrived. I had canceled several attempts to visit the museum in

previous years. If I had gone through with one of my earlier

trips, this vehicle would not have been on display. Author's photo

added 11-11-2023.

The open cab on this truck indicates it was

built after mid-1943. Author's photo added 11-11-2023.

Author's photo added 11-11-2023.

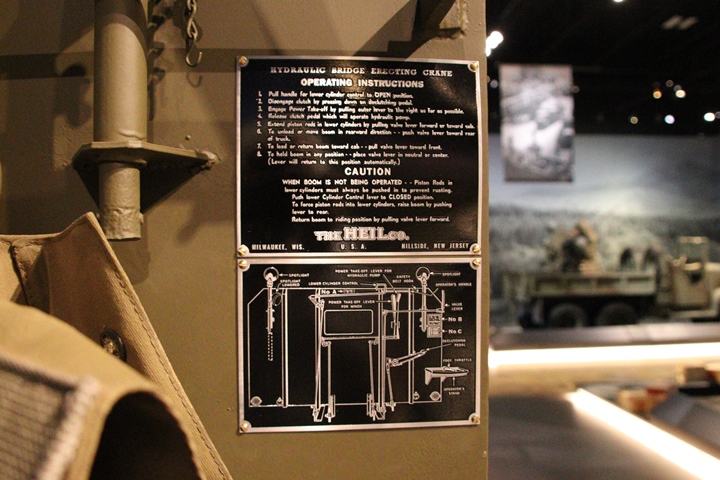

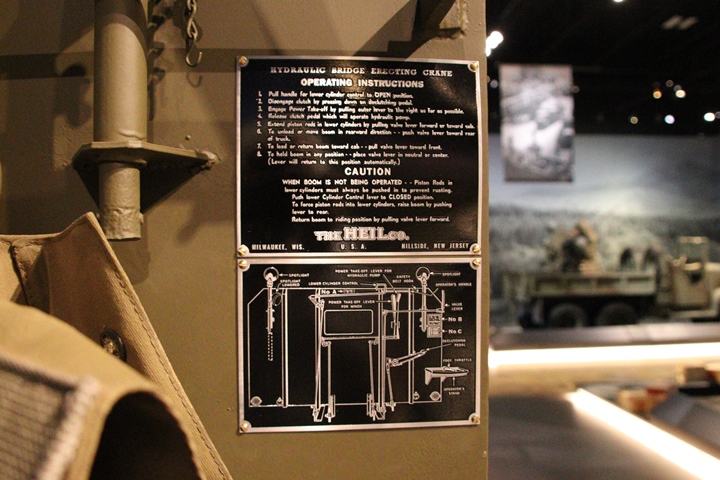

This Brockway B-666 bridging truck is

equipped with a Heil Company steel treadway bridge hydraulic crane,

M-II-A. The Daybrook Hydraulic Corporation was also a supplier of

the steel treadway bridge hydraulic crane. Author's photo added

11-11-2023.

The Brockway B-666 six-ton truck with either

a Heil or Daybrook steel treadway bridge hydraulic crane was a vehicle

that was unique to the Army Corps of Engineers. It was no doubt a

huge asset for the engineers as they set up treadway bridges during the

war. No other country had trucks and cranes to assist them like

these used by the U.S. Army. Author's photo added 11-11-2023.

Author's photo added 11-11-2023.

This image of the crane from the Heil

technical manual shows a fully loaded vehicle. Image added

11-11-2023.

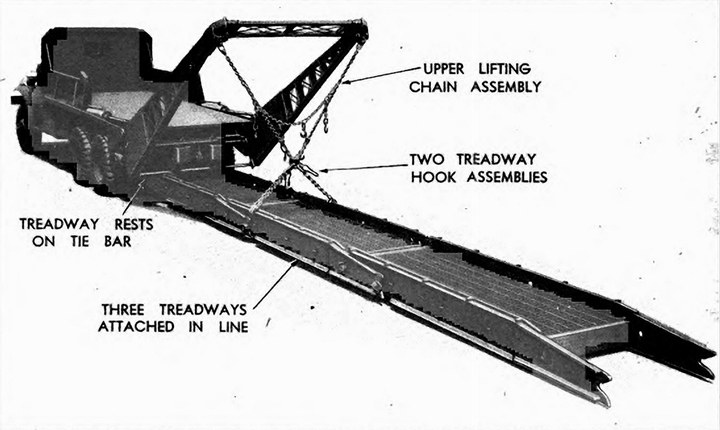

The hydraulic crane can lift two treadways

out from the truck at a time. Image added 11-11-2023.

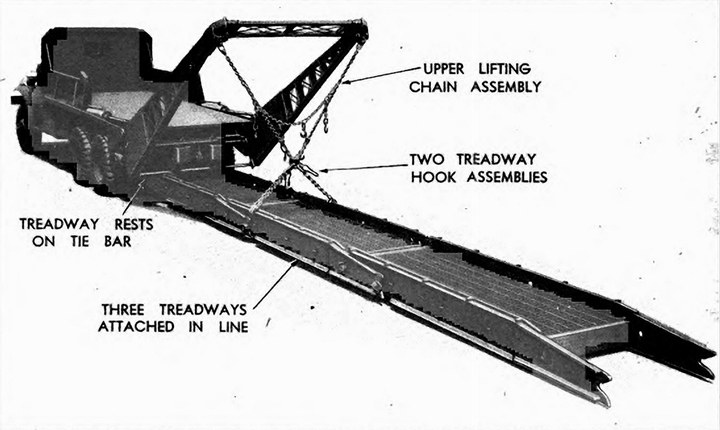

By using the crane to set the treadways in a

row, army engineers could bolt them together on land and then have the

truck lift them out onto the pontoons. Image added 11-11-2023.

75th

D-Day Anniversary Special:

Below are two that

were photographed at the 2019 D-Day activities in Normandy, France.

This is the hard cab version of the Brockway

B-666. Photo added 6-19-2019 is courtesy of Pierre-Olivier Buan.

Note that there are treadway in the

body of the truck just like they were shown in the technical manual

photo above. There appears to be deflated pontoons at the rear.

Photo added 6-19-2019 is courtesy of Pierre-Olivier Buan.

This soft top version of the B-666 has its

Daybrook Bridge Erector unit in the upright position. As the unit

started to rise, a pontoon located on it would slide into the water.

Photo added 6-19-2019 is courtesy of Pierre-Olivier Buan.

Photo added 6-19-2019 is courtesy of

Pierre-Olivier Buan.

Crane Trucks: Another important

truck that the Brockway Motor Company built for use by the Army Corps of

Engineers was the C-666 crane truck for the mounting of a Quick-Way

crane on the body. Brockway produced 1,312 of these to help win

World War Two. The 1,312 units were 44% of the total trucks

Brockway produced during World War Two for the U.S. Army.

This is a Brockway C-666 6-ton 6x6 Chassis

with/winch with a Quick-Way Crane. Quick-Way Power Shovel was

located in Denver, CO. It is unknown whether the truck chassis

were shipped to Denver, or the cranes were shipped to Cortland, NY for

final assembly.

It turns out that this "Quick-Way" Model E

on a Brockway chassis is located 16 miles from the World War II American

Experience Museum in Gettysburg, PA. I was unaware it was there

during my September 2022 trip to the area. There are several collections of World

War Two vehicles in the Gettysburg, PA area. John Gott photo via

Jeff Lakaszcyck.

John Gott photo via Jeff Lakaszcyck.

John Gott photo via Jeff Lakaszcyck.

While I missed personally seeing the vehicle

shown above while in the Gettysburg, PA area during my September 2022

trip, I was able to see the unrestored Brockway crane truck at the World

War II American Experience Museum. It is my understanding that the

volunteers at the museum have been able to get the truck shown below

running in 2023. This is the first step in the restoration

process.

This "Quick-Way" crane mounted on a Brockway

chassis is awaiting restoration at the World War II American Experience

Museum in Gettysburg, PA. Author's photo added 11-11-2023.

The standard crane length for the Model E

was 25 feet. Two five-foot sections could be added for a 35-foot

total length. The one at the museum has the two five-foot

extensions added. There are nut plates on the boom where the

sections join together. Author's photo added 11-11-2023.

This Brockway chassis is equipped with a

Heil 12,000 pound front winch. Author's photo added 11-11-2023.

This image shows the right hand side of the

Hercules 202HP HXD engine. Author's photo added 11-11-2023.

Author's photo added 11-11-2023.

This view shows the left hand side of the

engine. Author's photo added 11-11-2023.

The Brockway bridging truck had a half cab

which allowed the crane to rest where the assistant driver would

normally sit. Author's photo added 11-11-2023.

Author's photo added 11-11-2023.

Author's photo added 11-11-2023.

Author's photo added 11-11-2023.

Class 155 Fire Trucks:

In late 1943 the Army Corps of Engineers had redesigned the Class

155 Fire Truck. Contracts were secured with Kenworth and Brockway.

Both Mack and American LaFrance produced the bodies for these vehicles.

Each fire truck had a 1,000-gallon water tank and two high pressure

turrets on the top of the body. Brockway built 270 fire trucks

which was 9% of the vehicles it built for the U.S. Army.

Brockway B-666 or F-666 Chassis with

an American LaFrance body in 1944. American LaFrance installed a

model 155, 2-stage high speed centrifugal pump rated at 250 gallons per

minute at 600 psi that was powered by an American LaFrance 12-cylinder

engine.

Only the Brockway B-666 Chassis was built

with the Mack body. They came with Hale Model ZEY, 325 gallon per

minute, 600 psi high pressure pumps. Power for the pump was

provided by a Continental 6-cyliner engine.

The Brockway Motor Company Factory:

The Brockway Motor Company factory continued to operate in Cortland,

NY under Mack ownership until 1977. Currently, the former truck

plant in Cortland is still in use by new owners.

| |

Image courtesy of Google Maps added

11-11-2023.

This image is looking east along Court

Street. Like many older factories, the outside walls have been

recovered with sheet metal which gives the plant a modern looking

exterior. Image courtesy of Google Maps added 11-11-2023.

1924 LaFrance Brockway Torpedo Fire Truck:

I photographed the vehicle shown below in August 2018 at Vic's Antiques

and Uniques in Edinburgh, IN. This was one of four pieces of

equipment that were not at the store in March 2018 when I was there last.

It is really a shame to display this piece outside in the elements, when it should

be stored inside.

11-11-2018 Update: As of this date, this vehicle is no

longer outside in the elements at Vic's. Hopefully the vehicle was

purchased.

The LaFrance Brockway Torpedo was built between 1920 and 1924. It

was targeted at small, volunteer fire departments with limited budgets.

American LaFrance and Brockway would team up again in World War Two to

produce Class 155 fire trucks for the U.S. Army. Author's photo.

Author's

photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

|

-126w-1.jpg)

-126w-1.jpg)

|

|