|

Ross

Gear and Tool Company in World War Two

"The Gear"

Lafayette, IN

1906-1964

1964-2015 as a Division of TRW

2015-Current as a Division of

ZF

This page updated on 9-18-2023.

Every half-track built during World War Two

had a steering gear in it manufactured by Ross Gear and Tool Company of Lafayette, IN.

While most persons may want to know what type of engine or transmission

is in a vehicle, they never ask what type of steering gear is in it.

Yet, if one cannot steer and control the direction of the vehicle, the

engine and transmission are not of much use. One has to be able to

control the direction of the vehicle in an easy and reliable manner.

So, while the steering gear is hidden from normal view down in the

engine bay, it performs a very important yet overlooked function.

Without well-engineered steering, the vehicle is going to be hard to

steer and could therefore cause accidents.

All 53,625 half-tracks built by Autocar,

Diamond T, International Harvester, and White were equipped with Ross

TA26 steering gears. This particular half-track, an M16A2, was

built by the White Motor Company in Cleveland, OH. It and its Ross

steering gear served the militaries of two different countries in three

different wars. It served the United States Army in Europe during

World War Two and in Korea and the French in Vietnam. It ended its

military service with the French Foreign Legion in the Horn of Africa.

It was on temporary display at the National Museum of the United States

Air Force in Dayton, OH during the first half of 2021.

Ross Gear and Tool Company steering gears were

in over 70 types of military vehicles during World War Two. This small

company near the banks of the Wabash River north of downtown Lafayette,

IN produced an important but little recognized product that helped to

win World War Two. Below is its story.

"The Gear."

This is the current ZF factory in Lafayette, IN that was originally the Ross Gear

and Tool Company. The plant

is at the corner of Heath Street and North 9th Street in Lafayette and

is known to its employees as "The Gear." The view is looking west.

The Ross Gear and Tool Company was originally located in a small

building at Main and 9th Streets in downtown Lafayette starting in 1906,

until this plant was built in 1912 several blocks north of the original

facility. Author's photo.

The portion of the building with the saw-tooth roof construction is the

original factory. This and any additions built prior to or during

World War Two comprised the plant that built the company's World War Two

products. Author's photo.

The insignia for ZF is on a newer office

building for the facility. The Wabash River is several hundred yards to the west of

the plant. Purdue University is a mile to the west in West

Lafayette.

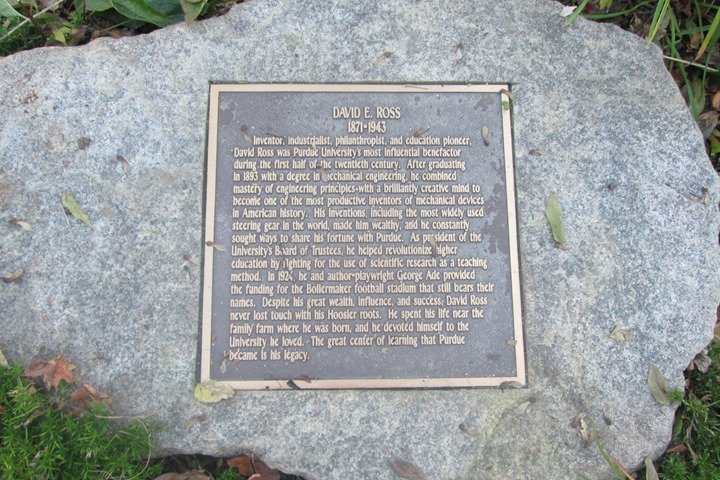

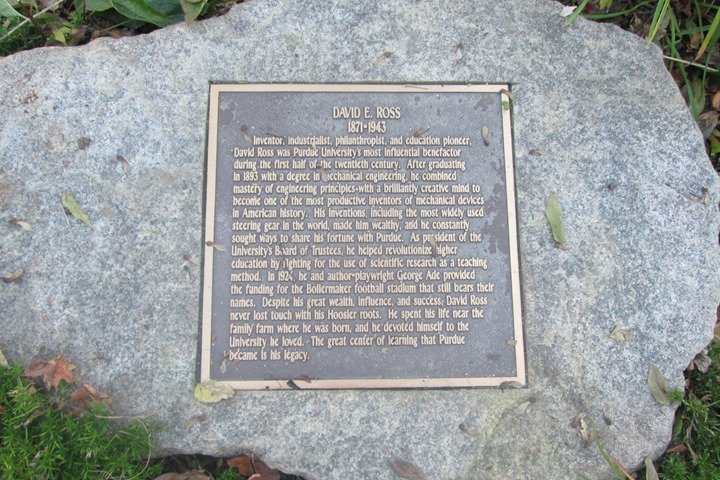

David Edward "Dave" Ross was one of three

Ross family members who started Ross Gear in 1906. Dave Ross was

a Purdue Engineering School graduate, and it was his many steering gear

patents that made the Ross Gear and Tool Company a leader in steering

gears in the United States. Author's photo.

The plant has grown and expanded from its

original building and is a leader in making electric steering systems. Author's photo.

This 1933 plant photo shows the distinctive

saw-tooth roof of the original factory. It also shows the type of

automobiles being produced at the time and the Wabash River in the

background. From the "The Ross Gear/TRW Commercial Steering

Systems Centennial History-1906-2006."

This 1980 aerial photo shows the plant very

much like it is today. From the "The Ross Gear/TRW Commercial

Steering Systems Centennial History-1906-2006."

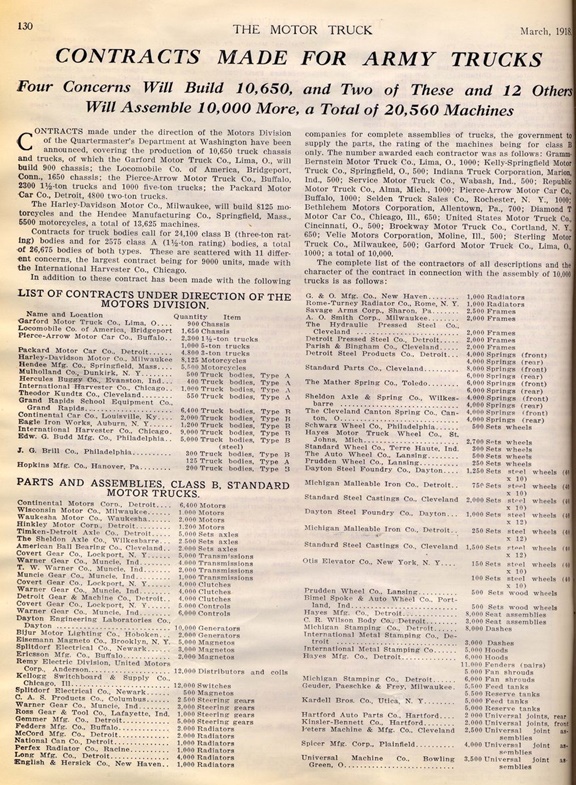

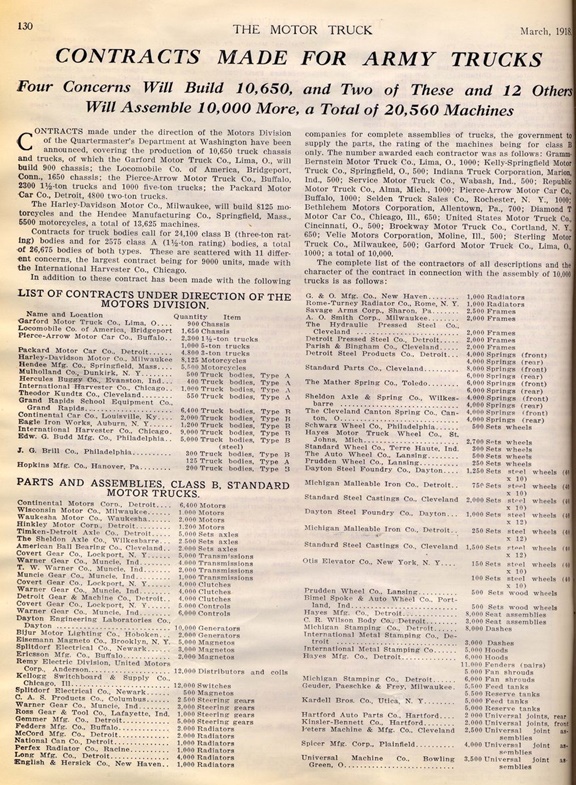

During the first World War, the young company

produced 1,000 steering gears for the Class B Standard Motor Truck.

This was more commonly known as the Liberty Truck. Document

courtesy of Warren Richardson.

This World War One Class B Liberty Truck has

been restored to operating condition by the First Division Museum in

Wheaton, IL. Author's photo.

Brothers David Linn Ross

and William Ross founded Ross Gear and Tool on October 16, 1906. William Ross

was the President,

David Linn was Secretary-Treasurer, and their cousin David Edward "Dave"

Ross was the general manager of the company. Dave Ross, who

graduated from Purdue University in 1893, had been farming since his

graduation. However, he had also been very interested in new

automobiles that were being built. When the new Ross Gear was formed in 1906, he had

already been awarded his first patent for a steering gear.

He sold this and three other designs that he had submitted to the U.S. Patent

Office to the new

company for $3,200. These designs became the technology that helped

establish the Ross Gear and Tool Company as a leader in steering gears. Dave Ross would continue to invent and be the

technical driving force behind Ross Gear until his death in 1943.

He had 84 patents assigned to him between 1906 and 1941. Only four

of the patents were with co-inventors. His patents not only

included steering gears, but an internal combustion engine, highway traffic

safety devices, warm air furnace, and building construction, to name a

few. In his later years, he diversified his interests. His

patents reflect this with predominantly non-gear patents. His first

patent, awarded on February 18,1906, was Patent Number 879414 for

"Steering Gear for Vehicles." His last patent, Number 2247410 and dated

July 1, 1941, was for a "Hydraulic Coupling Device."

For most of his career at the company, David

E. Ross was the General Manager. He was made a vice-president

along with his general manager title in 1920. In 1932 he became

president with the passing of Edward A. Ross. He became chairman

of the Ross Board of Directors in 1938 when David Linn Ross passed away.

But he was the "hands-on" type of person and liked to invent and then

manage the development of his ideas in the plant. He knew

every employee by name and at the same time was either known as "Dave"

or "Mr. Ross" by his employees. In his spare time, he focused on

his position with the Board of Trustees for Purdue University.

The first steering gear the small company

produced was the Model BA, based on a Dave Ross patent. The next

model, introduced in 1908 as the Model BL, was based on another Dave

Ross patent issued that year. The 1911 Model BF followed the same

pattern as the first two Ross Gear models. In 1923 the company

introduced the Dave Ross cam and lever steering gear. This was the

same type of gear used by many medium and heavy duty trucks during World

War Two. Dave Ross, an 1893 graduate of Purdue University, was

nominated by the Purdue Alumni in 1921 to be elected to the Purdue Board

of Trustees. Eventually he would become the President of the

Board. Upon his death in June 1943, most of his estate was given

to the Purdue Research Foundation. He is buried on a small hill

overlooking Stadium Avenue and Purdue University. To the east of

the gravesite is the Ross-Aide football stadium, named in part after

David E. Ross.

The David E. Ross Gravesite at Purdue

University: On November 6, 2021, I was at Purdue University to

watch a football game in Ross-Aide Stadium, which is named in part after

David Ross. I have on previous occasions been to football games at

the stadium but had no idea who the name Ross referred to in the

stadium's name. It was only while researching this page that I

learned that it was named in part after David Ross. After leaving

the game, I found the David E. Ross memorial and gravesite, which is

located on the highest point on the Purdue campus and overlooks the main

university campus to the south.

A memorial marker is located along a paved

sidewalk among a grove of trees on the hilltop. Author's photo

added 11-9-2021.

Author's photo added 11-9-2021.

David Ross' gravesite is a little ways off

to the southwest of the marker. One has to be looking for this,

as its location is not obvious to the casual passerby. Author's

photo added 11-9-2021.

The grave marker is very simple yet

encompasses who David Ross was and his contribution to Purdue

University. Author's photo added 11-9-2021.

I did not attend Purdue University. I graduated from another Big

Ten university and then moved to Indiana. However, after moving to

Indiana, I visited Purdue University for several years for

social reasons. Both of my children graduated from Purdue

University. My wife and I made many weekend trips to visit them in

the combined seven years they attended school there. So, for me, I

have some strong attachments to this university, and it has an important

place in my life. Purdue University has become my adopted

university. David Ross' foresight and influence when

he joined the Board of Trustees 100 years ago helped shape the Purdue

University of today.

A David E. Ross Anecdote: Even

though Dave Ross had been inventing steering gears for automotive use

since 1906, it was not until 1912 that he owned a car. His first

automobile was a used Wescott built in Richmond, IN.

Dave Ross' first automobile may have been a 1908 Wescott.

Actually, there is more to this photo than just the type of vehicle Dave

Ross started driving in 1912 at age 41. More importantly, this

shows the automotive technology for which the infant Ross Gear and Tool

Company was designing and building steering gears at the time. The

automobiles were open and had wooden bodies and wheels. This vehicle

had a 15 hp, two cylinder engine and had a top speed of 35 mph. I

would assume that Dave Ross would have purchased a vehicle that had one

of his steering gears in it. It is always good to buy what you

make. If so, it would have been a Ross model BA or BL.

At the 1929 New York Auto Show, 17 of the 26

cars on display had Ross steering gears in them. Also, in 1928,

the company introduced roller bearings in the cam followers in its cam

and lever steering gears. This resulted in a 50% efficiency

improvement in the

units. During the depression, the company remained the largest

independent manufacturer of passenger car steering gears. It also

began to diversify into trucks, tractors, and off-highway equipment.

In 1934 the twin lever steering gear was introduced after being invented

by Percy Newman. This innovation increased the angular travel

through which the gear could turn. During World War Two, twin lever

steering gears were the dominant type that Ross built for the war

effort.

In 1956 Ross purchased Gemmer Manufacturing

Company, its main independent domestic competitor. Two years

earlier, Chrysler started building its own power steering gears, which

was Gemmer's biggest customer. In 1964 Ross merged with the

larger TRW. This was done as Ross did not have access to the

financial resources needed to compete in the automotive car and truck

market. In 2015 TRW was purchased by the German company ZF.

What is interesting is that Ross licensed its cam and lever

technology to ZF in 1932. What is unknown is whether Ross cam and lever

technology was used not only in American vehicles, but also German ones

during World War Two.

Ross Gear and Tool Company in World

War Two:

The Ross Gear and Tool Company of Lafayette,

IN won the Army-Navy "E" flag five times during World War Two.

It won the first award in November 1942.

World War Two Products: "The Ross Gear/TRW Commercial Steering

Systems Centennial History-1906-2006" has provided a significant amount

of information for this webpage. It notes that Ross Gear supplied steering gears for over 70 different types of

vehicles during World War Two. It produced millions of track pins for tanks and other

armored vehicles . It also produced universal joint yokes for Studebaker

and made

high-strength steel parts for half-track tracks.

Table 2 shows that Ross built at least

836,016 OEM gears for the war effort.

Information from the World War Two Industrial

Facilities Report of 1943 indicates Ross had the capability to produce

240,000 tank track pins per quarter as of July 1943. Track pin

production started in June 1942. The report also shows that

Ross was tooled to produce 80,000 steering gears and parts per quarter.

Note: Both Studebaker US6 2-1/2 ton 6x6

and 6x4 trucks and all half-tracks had two different types of Ross Gear

and Tool Company

parts in them. Both vehicles used Ross steering gears, and the

Studebaker trucks had Ross universal joint yokes. Half-tracks had

Ross steel parts in their tracks.

At the start of World War Two, there were two

other main suppliers of steering gears in the United States besides Ross

Gear and Tool Company. One was the Saginaw Steering Gear Division

of General Motors, which supplied all of the steering gears for

Chevrolet and GMC during the war. The other was Gemmer

Manufacturing Company of Detroit, MI which was the supplier for the

Dodge series of 1/2 ton, 3/4 ton, and 1-1/2 ton trucks and other

vehicles. Gemmer also supplied some of the commercial trucking

industry.

While not a gear supplier to other companies,

the Ford Motor Company made its own steering gears. However, Ross

did supply parts for the steering gears for the Ford-built version of

the Jeep.

This left Ross to supply steering gears to the remainder of the

commercial trucking industry during the war. As

noted above, it supplied steering gears for 70 different vehicles.

Information is shown below on the type of gears and the vehicles in

which they were used.

Ross Gear and Tool Company provided steering gears for the smallest of

the American World War Two vehicles, the famous Jeep. While most

of the Jeeps were produced by the Ford Motor Company and Willys-Overland,

this particular vehicle was one of 2,642 that was produced by the

American Bantam Car Company, which invented the vehicle. Ross Gear

engineers worked with American Bantam engineers during the development

process to obtain the proper steering gear for this new, ground-breaking

vehicle. This may have been the first World War Two project for

the company. Ross Gear would supply all of the T12 steering gears

for the

Jeeps that American Bantam and Willys-Overland made during World War

Two. Ross supplied the steering gear cams to Ford, which chose to

make its own version of the Ross-designed steering gear.

The American Bantam Jeep shown above is on display at the Atterbury-Bakalar

Air Museum at the Columbus, IN airport. This vehicle is serial

number 1398 out of 2642 and was delivered to the Quartermaster Corps in

April 1941. Author's photo.

The Willys-Overland MB Jeep used Ross T12 steering gears.

Author's photo.

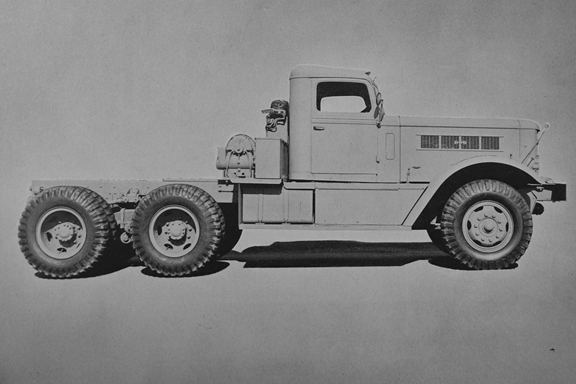

Ross also made the steering gears for the

largest American wheeled vehicle of World War Two, the M26 and M26A1

tank transporter. This was part of the tractor and trailer

combination M25 tank transporter, commonly known in the vernacular as

the Dragon Wagon. This tractor was so large and hard to steer that

it had one of the first Ross power steering systems on it, which was the Ross P780 power steering gear.

This tractor is the M26A1 version.

Author's photo.

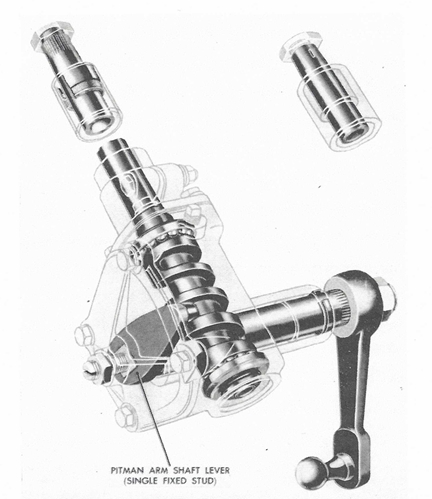

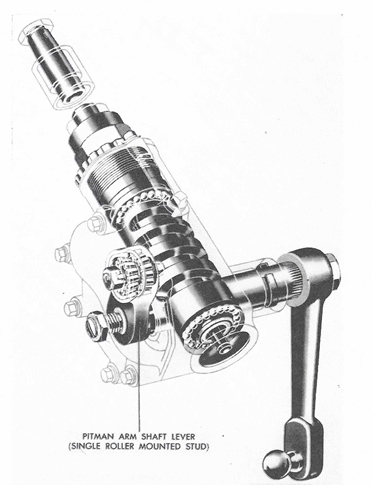

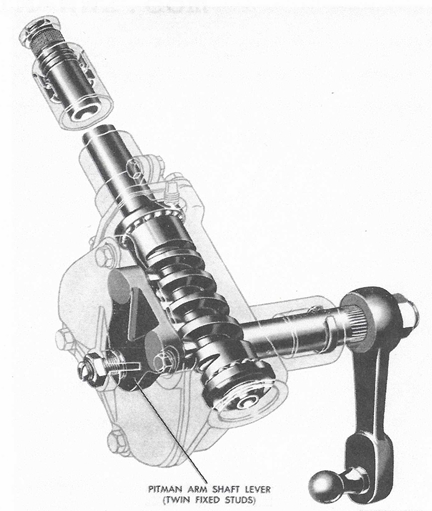

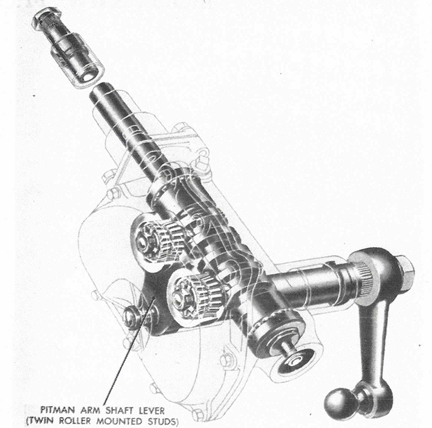

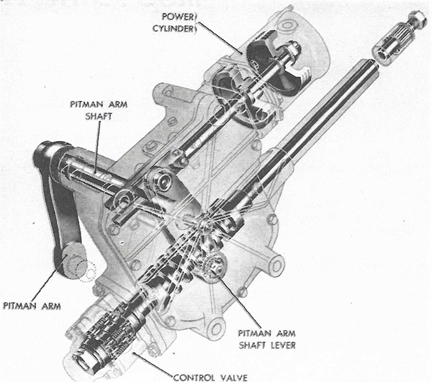

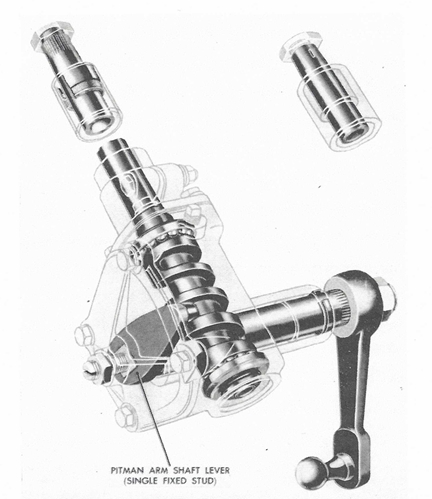

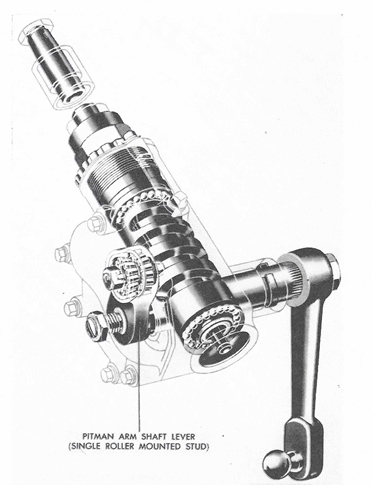

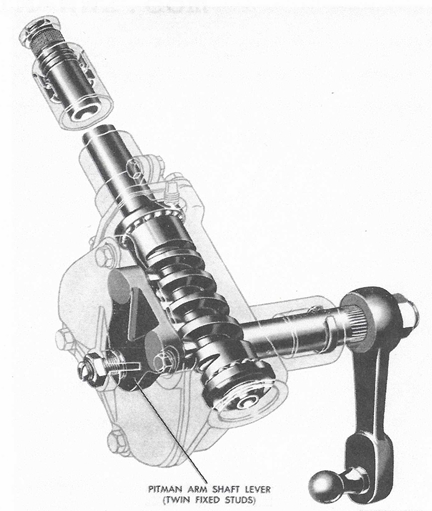

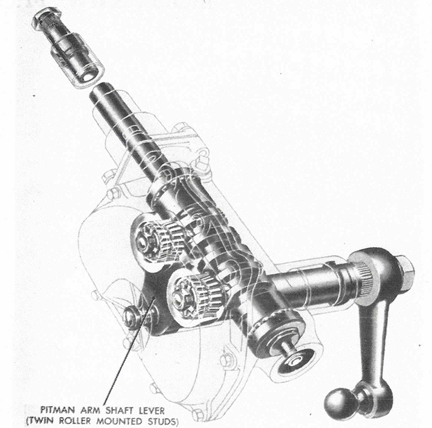

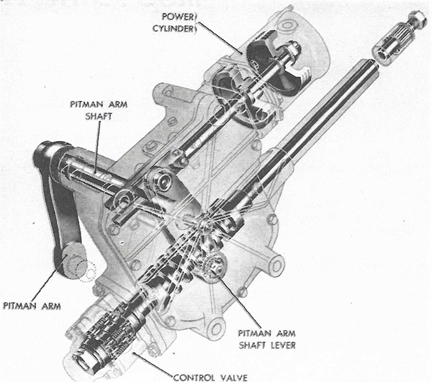

Ross Steering Gear Types:

Ross provided five different types of steering gears for military

vehicles during World War Two. Only three are known to have been used.

Type I Single Lever Fixed Stud: There are no known World War

Two uses for the Type I.

Type II Single Lever Roller Stud:

There are no known World War Two uses for the Type II.

Type III Twin Lever Fixed Stud: Jeeps and medium duty trucks

used the Type III during World War Two.

Type IV Twin Lever Roller Stud: Medium-heavy and heavy-duty

trucks were the big user of the Type IV during World War Two.

Type V Hydraulically Powered: The M26 tank transporter was

the only production vehicle to use the Type V during World War Two.

Tables 1 and 2 below provide information on

Ross Steering Gear part and assembly numbers and the vehicles in which they

were used. Table 1 lists known Assembly and Part Numbers and their Ross Type. The known vehicle applications

are then listed for the Assembly or Part Numbers.

Table 2 lists the vehicles by tonnage and

application. It also includes the number of vehicles of each type built

during World War Two based on Army Ordnance Acceptances of Vehicles.

The astute observer will note that there are many trucks missing that

may be similar to the ones built by the same manufacturer that would

probably have been built with the same or similar Ross gear as those

listed. However, information is not available to confirm that a

Ross gear was actually used. Therefore, they have not been

included. Most of the information in Table 2 came from Army

Ordnance technical manuals or supply manuals. These manuals are

not available for every vehicle built. The ones that are available

are mostly for the type trucks that are still in

existence today and owned and maintained by military vehicle collectors.

Other information was found in the historical literature on the various

vehicles and from actual military vehicle owners.

The assembly numbers give specific dimensional

information on the basic model number. Once a model was designed,

assembly numbers were assigned by adding a "one" to the model number.

Then the last three digits were assigned in numerical order for each

customer application to provide the proper fit and steering ratio.

As the model numbers increase, so does the weight of the vehicle.

An "A" behind a "T" indicates a modification to the original model.

In many cases, as shown below, only the Ross

model number is known. Assembly numbers were stamped on the

steering gear for positive identification and proper ordering of

spare parts.

|

Table 1 -

Ross Steering Gear Assembly and Part Numbers |

|

Assembly Number |

Model Number |

Type |

Known World War Two Vehicle Applications |

|

RG-S13053 |

S12 |

I |

|

|

RG-670718 |

660 |

II |

|

|

RG-730757 |

720 |

II |

|

|

RG-TA13081 |

TA12 |

III |

|

|

RG-T13086 |

T12 |

III |

American Bantam and Willys-Overland

1/4-ton 4x4 Command Car |

|

RG-TA13077 |

TA12 |

III |

|

|

RG-TA15004 |

TA14 |

III |

|

|

RG-TA15013 |

TA14 |

III |

International Harvester M-1-4 1/2-ton 4x4, International

Harvester M-2-4 1-ton 4x4 |

|

RG-TA15020 |

TA14 |

III |

International Harvester M-1-4 1/2-ton 4x4, International

Harvester M-2-4 1-ton 4x4 |

|

RG-TA22004 |

TA21 |

III |

|

|

RG-TA22005 |

TA21 |

III |

|

|

RG-TA22006 |

TA21 |

III |

|

|

RG-TA22006 |

TA21 |

III |

Studebaker US6

2-1/2-ton 6x6 and 6x4, Reo US6 2-1/2- ton 6x6 |

|

RG-TA22031 |

TA21 |

III |

|

|

Unknown Assembly Number |

TA21 |

III |

Federal 2-G-2-1/2-ton 4x2 Dump |

|

RG-TA27004 |

TA26 |

III |

All

Models International Harvester Half-tracks |

|

RG-TA27009 |

TA26 |

III |

|

|

Unknown Assembly Number |

TA26 |

III |

All

Models of Autocar, Diamond T, and White Half-tracks |

|

RG-T27134 |

T26 |

III |

|

|

Unknown Assembly Number |

T26 |

III |

FWD HAR-01 4-ton 4x4 Cargo, White M3A1

Scout Car |

|

RG-T67171 |

T66 |

IV |

|

|

Unknown Assembly Number |

T66 |

IV |

International Harvester M-5-6

2-1/2-ton 6x6 and Low Silhouette Trucks |

|

RG-TA67171 |

TA66 |

IV |

|

|

RG-T71062A |

T70 |

IV |

International Harvester KR-11 |

|

Unknown Assembly Number |

T70 |

IV |

Diamond T 968A 4-ton 6x6 Cargo,

Diamond T969A 4-ton 6x6 Wrecker,

Diamond T 970A 4-ton 6x6 Ponton.

Diamond T 972 4-ton 6x6 Dump, FWD HAR-03 4-ton 4x4 Cargo |

|

RG-T72029 |

T71 |

IV |

|

|

RG-T72118 |

T71 |

IV |

|

|

RG-T72152 |

T71 |

IV |

Autocar U-7144T 4-5-ton 4x4 Tractor, Federal 94x43 4x4 4-ton

Tractor, White 444T 4-5-ton 4x4 Tractor |

|

RG-T72184 |

T71 |

IV |

|

|

RG-T72187 |

T71 |

IV |

|

|

RG-T72225 |

T71 |

IV |

|

|

RG-T72230 |

T71 |

IV |

|

|

Unknown Assembly Number |

T71 |

IV |

FWD

HAR-1 4-ton 4x4 Cargo,

International Harvester

M425/M426 COE 5-ton 4x2, Marmon-Herrington

M425/M426 COE 5-ton 4x2, Kenworth

M425/M426 COE 5-ton 4x2 |

|

RG-T75064 |

T74 |

IV |

50SD6

6-ton 6x6 Prime Mover Models A through D |

|

RG-T75079 |

T74 |

IV |

|

|

RG-T75104 |

T74 |

IV |

Autocar

U-8144T 5-6-ton 4x4 Tractor, FWD 5-6-ton 4x4 Tractor, NJU-1,

Mack NJU-2 5-6-ton 4x4 Tractor |

|

RG-T75109 |

T74 |

IV |

|

|

RG-T75110 |

T74 |

IV |

|

|

RG-T75126 |

T74 |

IV |

|

|

RG-T75135 |

T74 |

IV |

|

|

RG-T75141 |

T74 |

IV |

Diamond T M20

12-ton 6x4 980, 981 Tank Transporter |

|

RG-T75142 |

T74 |

IV |

50SD6

6-ton 6x6 Prime Mover Models E through G |

|

RG-T75143 |

T74 |

IV |

White

666 6-ton 6x6 Prime Mover, White 666 6-ton

6x6 Gas Tank Chassis, 2000 Gallon, White 666 6-ton

6x6 Van, White 666

6-ton Bridge Erection |

|

RG-T75147 |

T74 |

IV |

|

|

RG-T75148 |

T74 |

IV |

Ward-LaFrance 10-ton 6x6 M1 and M1A1 Wrecker, Kenworth 10-ton

6x6 M1 and M1A1 Wrecker |

|

RG-T75152 |

T74 |

IV |

|

|

RG-T75157 |

T74 |

IV |

|

|

RG-T75161 |

T74 |

IV |

Reo 28XS

20-ton 6x4 Tractor, Federal 604 20-ton 6x4 Tractor |

|

RG-T75165 |

T74 |

IV |

|

|

RG-T75183 |

T74 |

IV |

|

|

Unknown Assembly Number |

T74 |

IV |

Ward-LaFrance 10-ton 6x6 M1 and M1A1 Wrecker, Kenworth 10-ton

6x6 M1 and M1A1 Wrecker, White

Model 1064 10-ton 6x4 |

|

RG-P75082 |

P720 |

V |

|

|

RG-P73083 |

P720 |

V |

|

|

RG-P790015 |

P780 |

V |

|

|

Unknown Assembly Number |

P780 |

V |

Pacific Car and Foundry M26 and M26A1,

Corbitt 12-ton 8x8 experimental truck, Cook

Brothers 12-ton 8x8 experimental truck |

|

HP74008 |

HP70 |

V |

|

|

Table 2 - Known

Ross Gear and Tool World War Two Military Steering Gear

Applications |

|

Ross Gear Model |

Vehicle Manufacturer |

Vehicle Application |

Number of Vehicles Built |

Comments |

|

1/4 ton trucks |

|

|

|

|

|

T12 |

American Bantam |

4x4 Command Car |

2,642 |

|

|

T12 |

Willys-Overland |

4x4 Command Car |

350,349 |

|

|

Ford-built T12 |

Ford

Motor Car Company |

4x4 Command Car |

|

282,354 parts only |

|

Ford-built T12 |

Ford

Motor Car Company |

4x4 Amphibian |

|

12,782 parts only |

| |

|

|

|

|

|

1/2 ton trucks |

|

|

|

|

TA-15013

TA-15020 |

International Harvester |

M-1-4 |

1,123 |

TA-15013

used below serial number 1064. TA-15020 used in serial

number 1064 and above. |

| |

|

|

|

|

|

1 ton trucks |

|

|

|

|

TA-15013

TA-15020 |

International Harvester |

M-2-4 |

9,094 |

TA-15013

used below serial number . TA-15020 used in serial number

and above. |

| |

|

|

|

|

| 1-1/2 ton trucks |

|

|

|

|

|

Unknown |

International Harvester |

M-3-4 |

6,532 |

|

| |

|

|

|

|

|

2-1/2 ton trucks |

|

|

|

|

| T66 |

International Harvester |

M-5-6

2-1/2 ton 6x6 and Low Silhouette |

38,528 |

|

|

TA22015 |

Studebaker |

US6 6x6 and 6x4 |

218,863 |

|

|

TA22015 |

Reo |

US6

ton 6x6 |

22,204 |

|

| TA21

|

Federal |

4x2

Dump |

1,493 |

|

| |

|

|

|

|

| 4

ton trucks |

|

|

|

|

| T71 |

Diamond T |

968A 6x6

Cargo |

9,699 |

|

| T71 |

Diamond T |

969A 6x6

Wrecker |

6,420 |

|

| T71 |

Diamond T |

970A 6x6 Ponton |

721 |

|

| T71 |

Diamond T |

972

6x6 Dump |

9,922 |

|

| T26 |

FWD |

HAR-01

4x4 Cargo |

814 |

For

Commonwealth use |

| T70 |

FWD |

HAR-03 4x4 Cargo |

1,848 |

For

Commonwealth use |

| T71

|

FWD |

HAR-1 4x4 Cargo |

9,000 |

For

both American and Commonwealth use |

| |

|

|

|

|

|

4-5 ton trucks |

|

|

|

|

|

RG-T72152 |

Autocar |

U-7144T 4x4 Tractor Truck |

11,104 |

|

|

RG-T72152 |

Federal |

94x43, 94x43B, 94x43C Tractor Truck |

8,119 |

|

|

RG-T72152 |

White |

444T

ton 4x4 Tractor Truck |

2,751 |

|

| |

|

|

|

|

| 5

ton trucks |

|

|

|

|

| T71 |

International Harvester |

M425/M426 COE 5 ton 4x2 |

6,678 |

|

| T71 |

Marmon Herrington |

M425/M426 COE 5 ton 4x2 |

3,200 |

|

| T71 |

Kenworth |

M425/M426 COE 5 ton 4x2 |

1,100 |

|

|

T-71062 |

International Harvester |

KR-11

5 ton 4x2 |

3,410 |

|

| |

|

|

|

|

|

5-6 ton trucks |

|

|

|

|

|

RG-T75104 |

Autocar |

U-8144T 4x4 |

3,319 |

|

|

RG-T75104 |

FWD |

? |

2,700 |

|

|

RG-T75104 |

Mack |

NJU-1, NJU-2 |

700 |

|

| |

|

|

|

|

| 6

ton trucks |

|

|

|

|

T75064 for Models A through D

T75142 for Models E through G |

Corbitt |

50SD6 6x6 Prime Mover |

3,211 |

|

|

T75143 |

White |

666

6x6 Prime Mover |

3,946 |

|

|

T75143 |

White |

666

6x6 Gas Tank Chassis, 2000 Gallon |

25 |

|

|

T75143 |

White |

666

6x6 Van |

1,870 |

|

|

T75143 |

White |

666

Bridge Erection |

1,152 |

|

| |

|

|

|

|

|

7.5 ton trucks |

|

|

|

|

| Unknown Cam

and Lever |

Oshkosh |

W

series |

1,255 |

The

Operations Manual indicates a Ross Cam and Lever Steering Gear.

This was most likely a Type IV. |

| |

|

|

|

|

|

10-Ton |

|

|

|

|

| T74

and T75148 |

Ward-LaFrance |

M1

and M1A1 Wreckers 6x6

|

4,925 |

The

Ordnance Supply Manual shows both the T74 and T75148. The

T74 is to be used until the stock ran out. Then the T75148

was to be used. |

| T74 |

Kenworth |

M1

and M1A1 Wreckers 6x6

|

840 |

The

Ordnance Supply Manual shows both the T74 and T75148. The

T74 is to be used until the stock ran out. Then the T75148

was to be used. |

| T74 |

White

|

1064

6x4 |

2,500 |

|

| |

|

|

|

|

|

12-Ton |

|

|

|

|

|

T75141 |

Diamond T |

M20

6x4 980, 981 Tank Transporter |

5,871 |

|

| P780 |

Corbitt |

8x8

Experimental |

3 |

|

| P780 |

Cook

Brothers |

T20

8x8 Experimental |

1 |

|

| |

|

|

|

|

|

20-Ton |

|

|

|

|

|

T75161 |

Reo |

28XS

6x4 |

700 |

|

|

T75161 |

Federal |

604

6x4 |

1,443 |

|

| |

|

|

|

|

|

40-Ton |

|

|

|

|

| P780 |

Pacific Car and Foundry |

M26

and M26A1 6x6 |

1,372 |

|

| |

|

|

|

|

|

Unknown Tonnage |

|

|

|

|

| T71 |

Sterling |

DD115 |

50 |

|

|

Total Trucks |

|

|

761,497 |

|

| |

|

|

|

|

|

Scout Cars |

|

|

|

|

|

T26 |

White |

M3A1 |

20,894 |

|

| |

|

|

|

|

|

Half-Tracks |

|

|

|

|

| TA26 |

Autocar |

All

Types |

12,168 |

The

Ordnance Supply Manual for Autocar, Diamond T and White only

specifies the TA26. |

| TA26 |

Diamond T |

All

Types |

12,421 |

|

|

TA27004 |

International

Harvester |

All

Types |

13,622 |

The

Ordnance Supply Manual for International is more specific and

calls out the TA27004. |

| TA26 |

White |

All

Types |

15,414 |

|

| |

|

|

53,625 |

|

|

Total Vehicles |

|

|

836,016 |

|

Images of Vehicles with Ross Steering

Gears:

1/2-Ton Trucks:

Ross Gear supplied the steering gears to

nearby International Harvester, 121 miles to the east of Lafayette in

Fort Wayne, IN. The

International M-1-4 1-ton 4x4 was used by both the USMC and the U.S.

Navy. This is one of 892 ambulances that the USMC and Navy

purchased during World War Two. Author's photo added 8-11-2021.

Another 231 M-1-4 1-ton 4x4s were produced

as cargo trucks. Author's photo added 8-11-2021.

1-Ton Trucks:

International Harvester built 9,094 M-2-4

1-ton 4x4 trucks with Ross steering gears. All the trucks were the

cargo version and went to the USMC. Author's photo added 8-11-2021.

1-1/2-Ton

Trucks:

International

produced 6,532 M-3-4 1-1/2-ton that were used in a variety of

applications by the U.S. Navy and USMC. All had Ross steering

gears. Author's photo added 8-11-2021.

2-1/2-Ton Trucks:

This is one of 218,863 2-1/2 ton 6x6 and 6x4

trucks built by Studebaker in South Bend, IN that had Ross steering

gears in them. Author's photo added 9-18-2023.

This truck was built by Reo in Lansing, MI

under license from Studebaker. The dump body was added after World

War Two. The 22,204 Reo-built trucks had Ross steering gears. Author's

photo.

Ross supplied

38,528 T66 steering gears for the International Harvester M-5-6

2-1/2 ton 6x6 truck. Author's photo added 9-18-2023.

Paul Rea owns this Federal 2G dump truck. It runs and is on the list to be restored. It has a

Ross TA21 steering gear. Photo

courtesy of Jeff Lakaszcyck.

4-Ton Trucks:

The Diamond T 696-A 4-ton 6x6 wreckers came

with Ross T71 steering gears. Author's photo.

4-5-Ton Trucks:

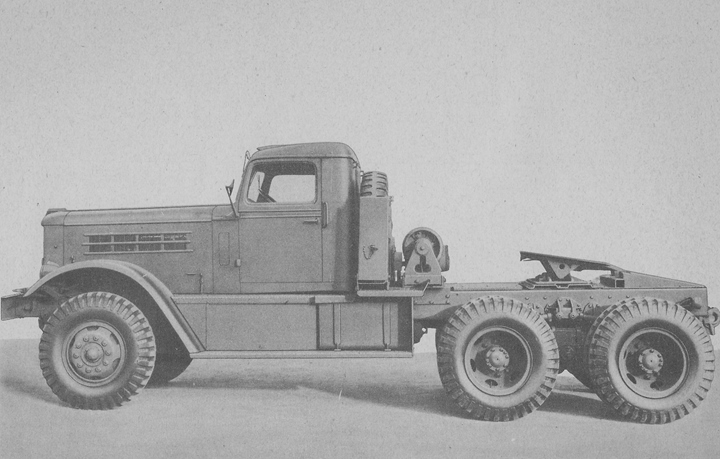

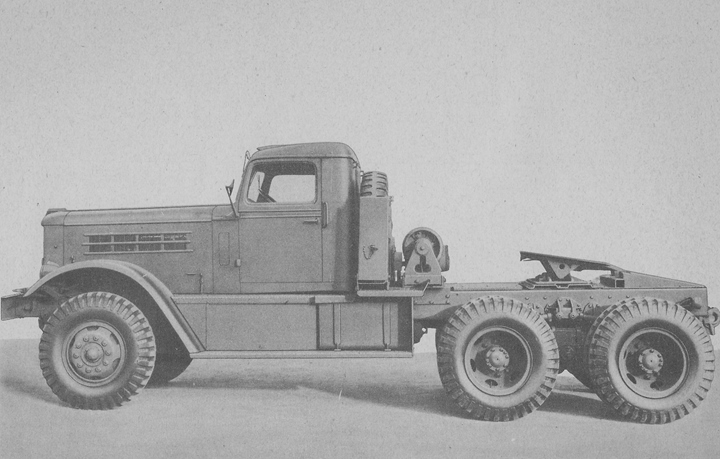

This is one of 11,104 Autocar U-7144T

4-5-ton 4x4 tractors built during World War Two with Ross T72152

Cam and Lever steering gears. Federal and White built

similar models with the Ross T72152 for a total of 21,974 vehicles of this

type.

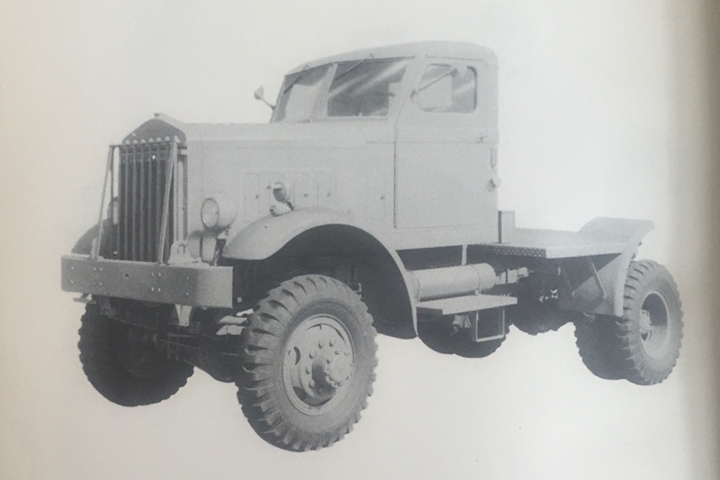

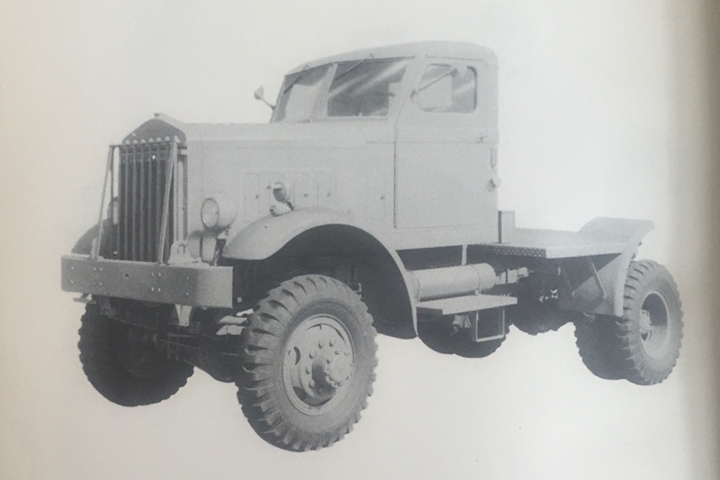

5-Ton Trucks:

10,798

M425/M426 COE 5 ton 4x2 tractors were built by International,

Marmon-Herrington, and Kenworth with Ross T71

Cam and Lever steering gears. Author's photo. This

image added 4-30-2021.

5-6-Ton Trucks:

The 5-6-ton Autocar U-8144T was also produced by FWD

and Mack. This had a longer wheel base than the U-7144T series and used

the Ross T75104 steering gear. There were 6,719 of all three types

built. Author's photo added 9-18-2023.

6-Ton Trucks:

This is one of 3,211 Corbitt 50SD6 6 ton 6x6

prime movers that used

Ross steering gears. Photo

courtesy of Jeff Lakaszcyck.

There were also 3,946 White Motor Company

666 prime movers built based on the Corbitt 50SD6 truck which used Ross

model T75143 steering gear. Author's photo added 8-11-2021.

This White 666 was built in 1945.

White also built another 3,047 666 series trucks with different cargo

bodies. Author's photo added 8-11-2021.

The next three photos show the Ross Model

T75143 as part of the entire steering system. The name "Ross" can

be seen on the steering gear casting in the first two photos.

Author's photo added 8-11-2021.

Author's photo added 8-11-2021.

Author's photo added 8-11-2021.

7-1/2-Ton Trucks:

This Oshkosh W-709-C-T-5 is part of the

collection of vehicles at the National Museum of Military Vehicles in

Dubois, WY. Author's photo added 9-18-2023.

The truck has a Ross Gear and Tool Company

steering wheel that indicates the vehicle has the company's cam and

lever steering system. Author's photo added 9-18-2023.

Author's photo added 9-18-2023.

This Oshkosh W-709 snowplow was purchased by

the U.S. Corps of Engineers in 1943 and utilized a Ross steering gear.

Image courtesy of Tim Wright.

10-Ton Trucks:

Ward-LaFrance built a total of 4,925 M1 and

M1A1 wreckers with the Ross T74 cam and lever steering gear. This

is the M1 version. Author's photo.

This is the M1A1 version of the Ward

LaFrance 10-ton wrecker with the Ross T74 cam and lever steering gear. Author's photo.

12-Ton Trucks:

5,871 Diamond T 980/981s were built with Ross

T-75141 steering gear assemblies. Author's photo.

This

Corbitt Company T20E4 12-ton 8x8 cargo truck has a Ross P780 steering

gear and hydraulic ram booster.

The Cook Brothers' T20 8-ton 8x8 cargo truck

was equipped with a Ross P780 steering gear and hydraulic ram booster.

20-Ton Trucks:

Reo built 700 28-XS 20-ton 6x4 tractors

powered by Cummins HB600 diesel engines with Ross T75161 steering

gear assemblies.

Federal built 1,443 20-ton trucks

the Ross T75161 steering gear assemblies.

Truck Tractors:

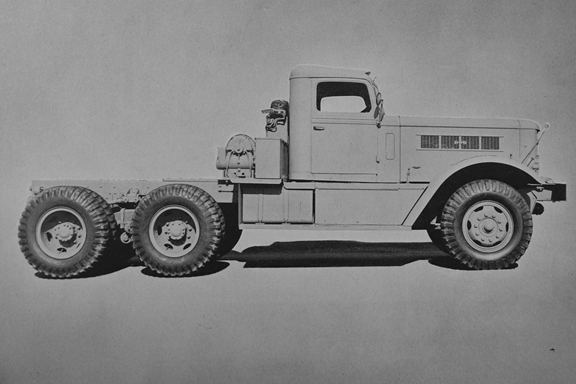

The Pacific Car and Foundry-built M26 had a power assisted Ross

P780 steering gear. Author's photo added 9-18-2023.

The Pacific Car and Foundry-built M26A1 also had a power assisted Ross

P780 steering gear. Author's photo.

Unknown Tonnage:

Fifty

Sterling DD115 4x4s were purchased by the U.S. Navy and had Ross T71

steering gears. Image courtesy of

Warren Richardson added 11-13-2020.

Scout Cars:

The White M3A1 scout car utilized a Ross T26

steering gear. This M3A1 was photographed at the Portland, IN MVPA

show in September 2021. Author's photo added 9-19-2021.

The owner of the vehicle opened up the engine bay for me so I could

photograph the Ross T26 steering gear. Author's photo added

9-19-2021.

The Ross name can be seen in the upper

center of the T26 steering gear. It is upside down in the photo.

Author's photo added 9-19-2021.

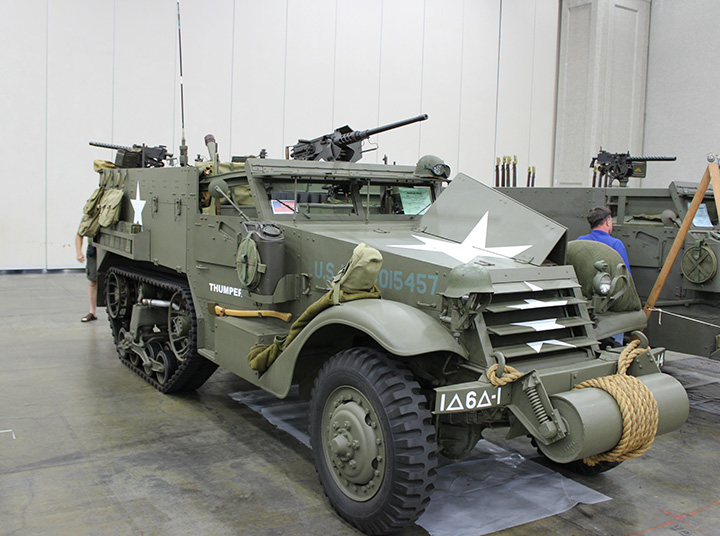

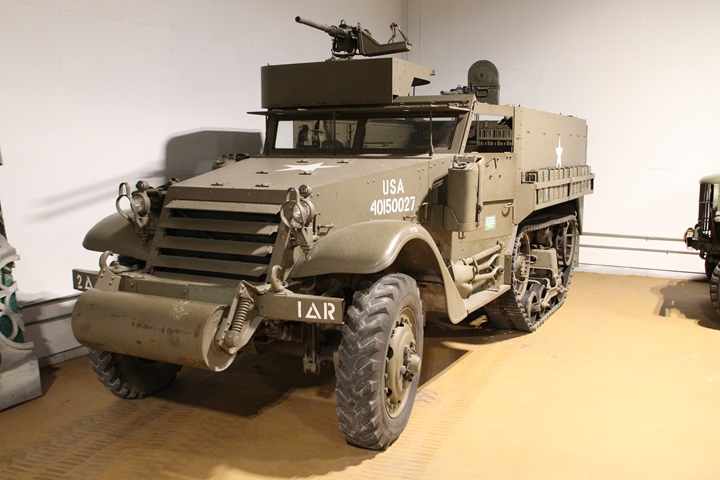

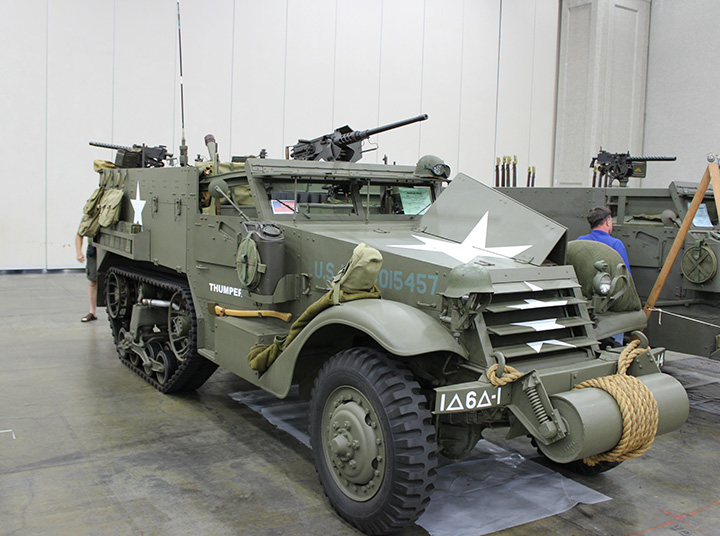

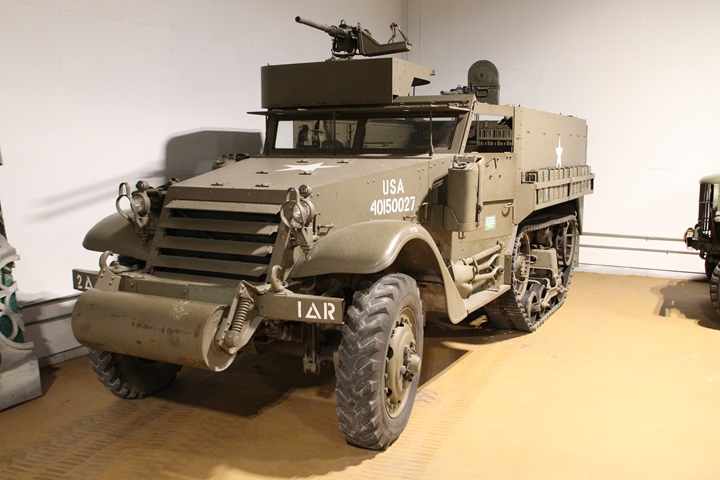

Half-Tracks: All of the half-tracks shown below utilized the

Ross TA26 steering gear.

This Autocar-built M15 was built with a Ross

steering gear assembly. Author's photo.

This Autocar M3 75mm gun carriage is

equipped with Ross steering gears built in Lafayette, IN.

Author's photo.

Diamond T M3 half-tracks built during

the Second World War had Ross steering gears installed in them. Author's photo.

This excellent restoration of an

International Harvester M5 halftrack has a Ross TA27004 gear assembly in

it. Author's photo.

This 1942 White M4A1 81mm mortar carrier

used a Ross steering gear. Author's photo.

This M3A1 half-track is on display at the

Indiana Military Museum in Vincennes, IN.

Author's photo added 8-11-2021.

This is the Ross TA26 steering gear in the

vehicle. The steering gear is only 146 miles from where it was

built in Lafayette, IN.

Author's photo added 8-11-2021.

Other World War Two Products:

Ross manufactured track pins for armored

vehicles during World War Two. While it is unknown which tracked

vehicles used Ross track pins, the M3 and M5 Stuart light tanks used a

large number in each tank tread. The pins were used to join

individual shoes together to make an entire track. On the M5A1

shown here, each small hole on the tread contains a pin. There was a considerable amount used on each

tank. Author's photo.

The M4 high speed tractor used the chassis

from the M3 light tank and was another big user of track pins. Author's

photo.

The best known of the American-built

tanks was the M4 Sherman. Being a medium tank and larger than the light Stuart tank, it had

a longer track that used

even more track pins than the Stuart. There were 158 track pins

used in each Sherman tank tread. This is an M4A3(76) HVSS version

of the Sherman. Author's photo.

Post-World War Two Vehicles with Ross

Steering gears:

Ross Gear supplied the TA67171 steering gear

assembly for the over 240,000 M35 series 2-1/2-ton 6x6 trucks, like this

version built by White Motors in the former Reo plant in Lansing, MI.

Ross supplied 147,000 HP71137 power-assisted steering gear assemblies

for the M54 5-ton 6x6 series truck like this Mack-built M54A2. Author's

photo.

|