|

Otto Zachow and William Besserdich

Patents

Four Wheel Drive

Auto Company (FWD) During World War Two

Clintonville, WI

1909 - 1910 as the Badger Four Wheel Drive Auto

Company

1910-1958 as the Four Wheel Drive Auto Company (FWD)

1958 - ? as FWD

?- Current as Seagrave

1941-? Eagle Division -

Appleton, WI

May 1943 - August 1945 Stevens Point, WI

This page updated

1-13-2024.

This Four Wheel Drive Auto Company (FWD)-built

USMC Model SU-COE is probably the only one of its type still in existence.

There were only 250 of this type of SU-COE built during World War Two.

This excellent restoration was done by the Marine Depot Maintenance

Command at Albany, GA after being found in a scrap yard in San Diego,

CA. Photo courtesy of the Marine Depot Maintenance Command at

Albany, GA.

Somewhere in the Central or South Pacific a

USMC SU-COE 5-6-ton 4x4 truck follows a Caterpillar D-7 tractor onto the

beach. It was common practice during landings in the Pacific for a

tractor with a bulldozer blade to be the first vehicle out of the LSTs.

If needed, the tractor could build a sand road for the wheeled vehicles

if the water was too deep. Or, if there were obstructions

on the beach, it could clear them out so trucks like the FWD SU-COE

could proceed inland. In this case, it appears the beach was just

fine for the SU-COE to traverse across the beach. Photo courtesy

of the Tim Wright Collection.

The SU-COE is piled high with sleeping bags.

The body had a second set of side rails installed so the truck could

carry an extra-large load of personal belongings ashore. It

appears the SU-COE is pulling a 90mm anti-aircraft gun. Experience

had taught American invading forces in the Pacific that Japanese

aircraft would contest island landings the same day or evening of the

invasion. Setting up anti-aircraft guns was one of the first

objectives after securing the beachhead. Photo courtesy of

the Tim Wright Collection.

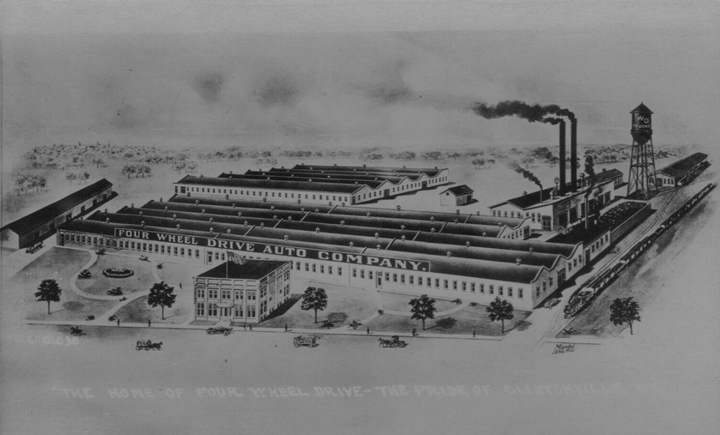

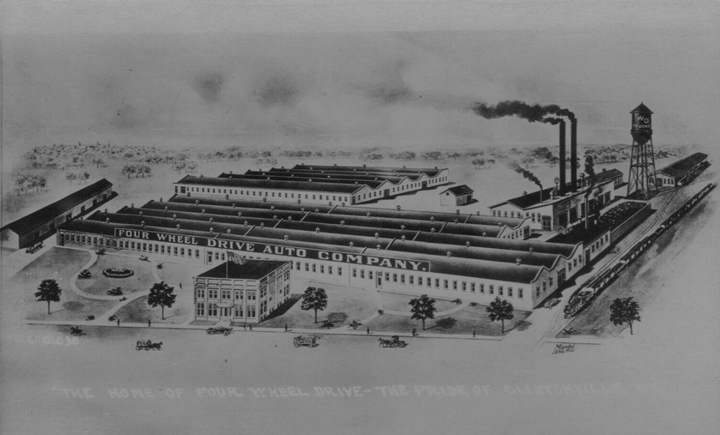

The Four Wheel Drive Auto Company of

Clintonville is a company whose World War Two contributions have been

overlooked and forgotten in the United States. There are several

reasons for this. Firstly, 93% of the 15,724 vehicles that FWD built during World War Two were for foreign use. This

was either through direct purchases by foreign countries or by

Lend-Lease. These vehicles

were primarily used by Canada and Great Britain, with a small percentage

going to the Soviet Union. Secondly, and a result of the previous

reason, there are no vehicles in the United States for collectors to

obtain. Thirdly, because the FWD vehicles were primarily not used

by American forces, American military vehicle enthusiasts do not have an

interest in obtaining such vehicles.

That being said, the Four Wheel Drive Auto

Company made many vehicles that were welcomed by Canada, Great Britain,

and Russia to provide needed transportation of supplies for their

fighting forces. The company was recognized by several

organizations for its contribution to help win World War Two.

In the end, FWD had the last laugh as it still

exists as Seagrave at the original factory location in Clintonville, WI.

Many of the original buildings are still used to make parts and the

original office building is still in use. That cannot be said for

Diamond T or the White Motor Company that took business away from FWD

during World War Two. They are long gone while Clintonville, WI

area residents still go to work at the original FWD factory site making

fire trucks.

Firstly, we need to find out why the Four

Wheel Drive Auto Company chose to build four wheel drive vehicles in

Clintonville, WI. Actually, it was an invention in the town that

resulted in the formation of the company to produce four-wheel drive

vehicles at this location.

One thing that is certain is where and how the

initial idea that eventually developed into the Four Wheel Drive Auto

Company got its start. This is where the

story begins.

This former machine shop in Clintonville, WI

is where the concept of power to all four wheels, or four-wheel drive,

was conceived in 1908. This is also

where the Four Wheel Drive Auto Company began, which was the first manufacturer of

four-wheel drive vehicles. Author's photo.

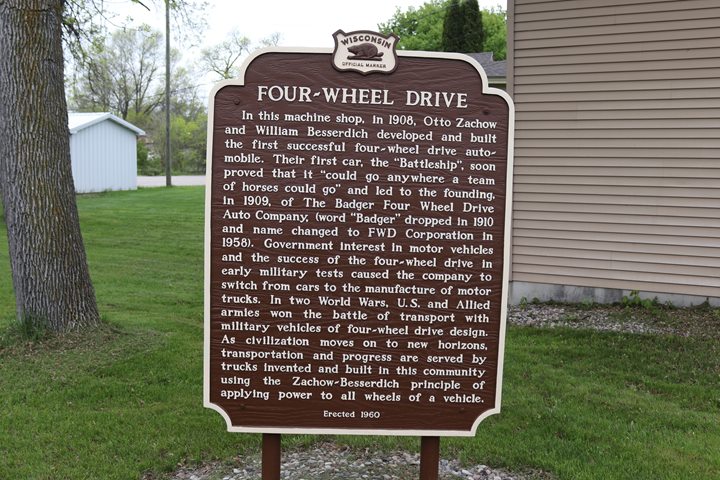

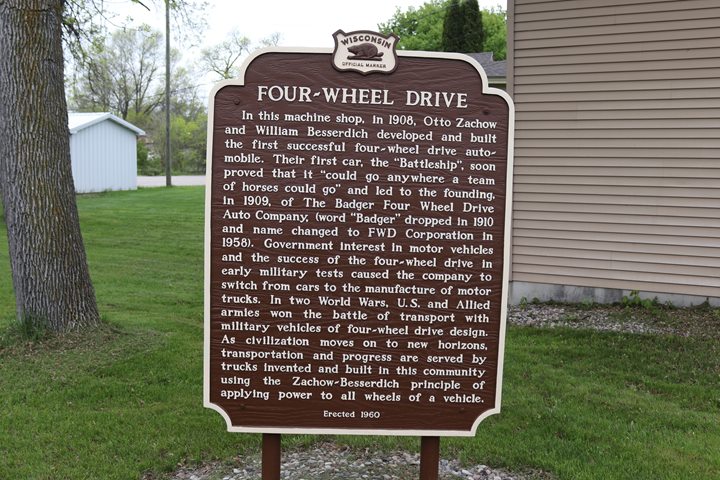

The information on the historical marker is

accurate as far as it goes. However, it does not mention that by

1912 Otto Zachow had cashed in his 350 shares for $9,000 and went back

to his machine shop. Then, in

1914, William Besserdich left the Four Wheel Drive Auto Company and then

formed what became today's Oshkosh Corporation. Previously,

The sign is in Clintonville, WI,

home of FWD and the FWD Museum. When this historical marker was

erected in 1960, the two companies were competitors in a limited market.

FWD lost market share, eventfully purchased Seagrave and began making

fire apparatus in Clintonville. Oshkosh obtained several key military contracts

and became a dominant manufacturer of all-wheel drive military vehicles. Author's

photo.

In 1908, the Badger Four Wheel Drive Auto

Company, under the direction of Mr. Zachow and Mr. Besserdich, built its

first ever four-wheel drive vehicle named the "Battleship" as stated on

the historical marker. Another ten cars were built but the market

was not receptive to a four-wheel car at the time. Therefore, the

company moved into producing trucks, which was a path taken by several

other car companies early in the history of the automobile. The

passengers in the "Battleship" include William Besserdich's

granddaughter, great grandson, and great, great grandson. Tom

Cihowiak photo via Tim Wright.

Author's Note: Many of the photos

included in this webpage are from the Tim Wright Collection. Mr.

Wright has been collecting FWD memorabilia and photos for many years and

is a well-known Four Wheel Drive Auto Company historian. Mr.

Wright has been gracious enough to allow me to use many of his photos in

order for me to tell the full story of how the FWD Company helped win

World War Two. I want to thank Mr. Wright for allowing me to use

his photographs in this website. Mr. Wright is the person driving

the FWD Battleship in the above photo.

Today, the machine shop where four-wheel and

all-wheel drive was invented is part of the FWD Seagrave Museum located

in Clintonville. Author's photo.

Today, four-wheel and all-wheel drive

vehicles are

commonplace. Now four-wheel drive is pretty much standard equipment

on pickup trucks, and many SUVs are equipped with all-wheel drive.

For this to have happened, Otto Zachow and William Besserdich designed

the first really workable method of applying power to the front wheels

needed to steer the vehicle. That was done in this building. For those

of us who

drive trucks with four-wheel drive and SUVs with all-wheel drive, we are indebted to Mr. Zachow and

Mr. Besserdich. Author's photo.

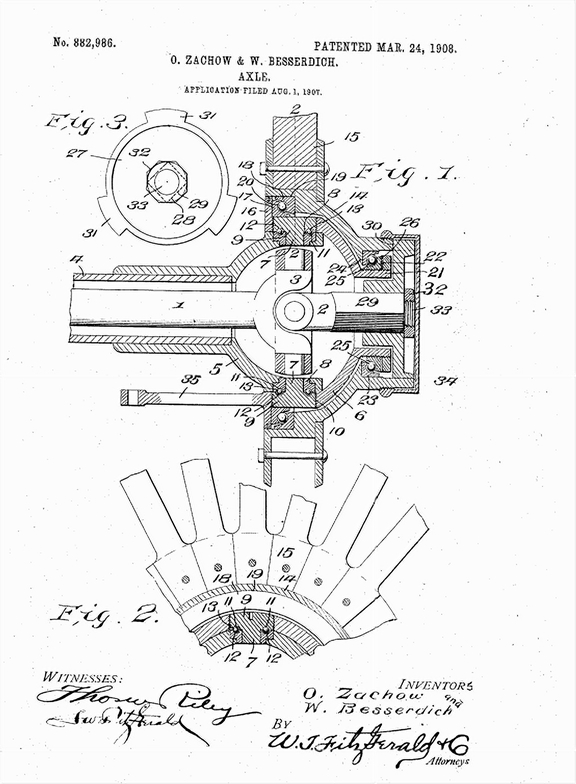

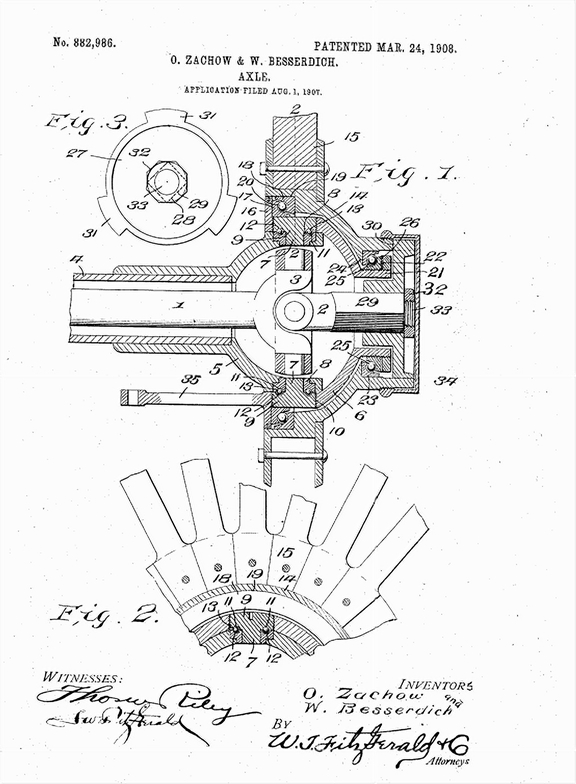

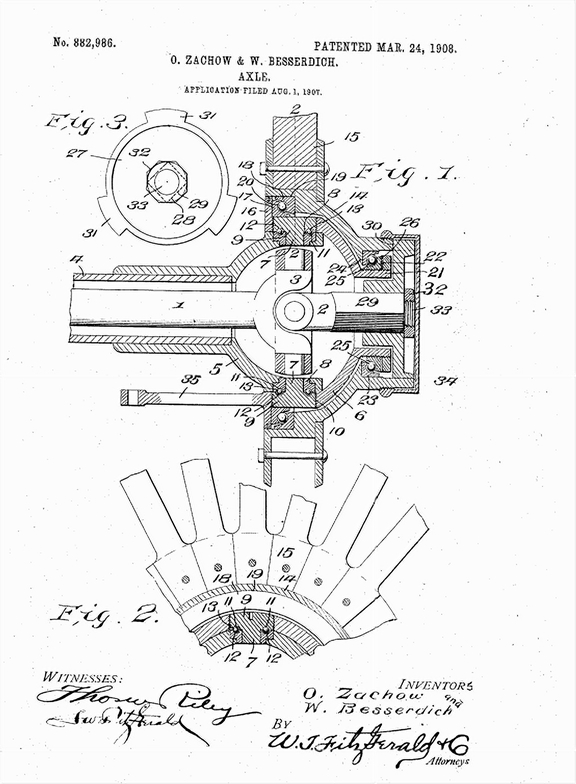

This is the first of two patents that Otto

Zachow and William Besserdich were awarded. Unlike previous attempts and patents relating to four-wheel drive vehicles,

their patents evenly divided the power to front and rear wheels.

The U.S. Army was so impressed by this particular design that was used

on the FWD Model B in World War One, that it purchased both patents from

the company and gave the technology to other truck companies.

Both patents can be viewed in their entirety

at the link at the top of this page.

In 1908, Otto Zachow and William Besserdich had two patents but were short on

cash to move forward. Dr. W.H. Finney of Clintonville provided

$1,800 in financing to assist the two men. However, in 1910 Dr.

Finney reversed his position and withdrew his support and money from the

fledging enterprise. At this point, a lawyer, Walter A. Olen, gave

up his law practice to become the company's person in charge of sales

and marketing. Staging a large public competition among many auto

makers in a Clintonville FWD company's sand pit, all of the other contestants had

to be pulled out by the FWD competitor. Mr. Olen used the

enthusiasm generated at the event to persuade local residents to invest

in their local vehicle manufacturer. With this initial funding,

the company built a small factory in Clintonville.

As noted above, both Mr. Zachow and Mr. Besserdich left the

company they created. Otto Zachow left in 1912 and returned to his

machine shop.

William Besserdich stayed another two years. Differences of opinion with the

company's president, Walter Owen, and an engineer, Mr. Battenberg,

caused his departure. In 1914 he sold his shares in the Four Wheel

Drive Auto Company and moved on. William Besserdich then teamed up with

Bernhard Mosling, an established businessman in Clintonville. The

two formed the Wisconsin Duplex Auto Company in Clintonville and set up

shop in Mr. Mosling's mercantile store. However, the Four Wheel

Drive Auto Company dominated the business atmosphere in Clintonville.

Therefore, the first vehicle built by the fledgling company in 1917 was

a one-ton 4x4 built at Andrews Motor Manufacturing under the

guidance of William Besserdich. This four-wheel drive truck was

named "Old Betsy." The same year the operation moved to

Oshkosh, WI and became the Oshkosh Motor Truck Company.

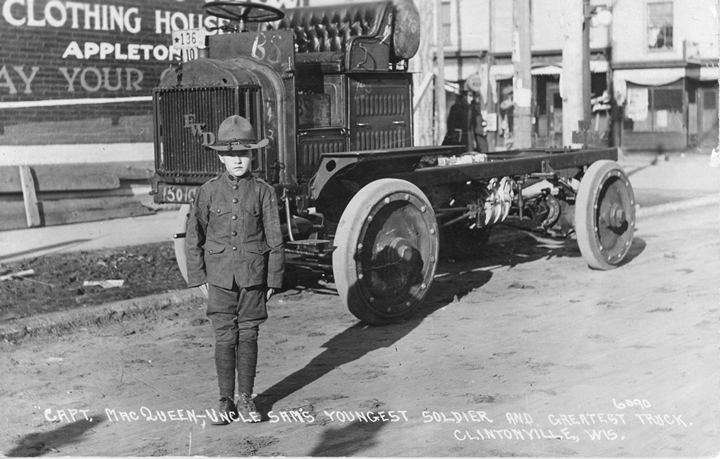

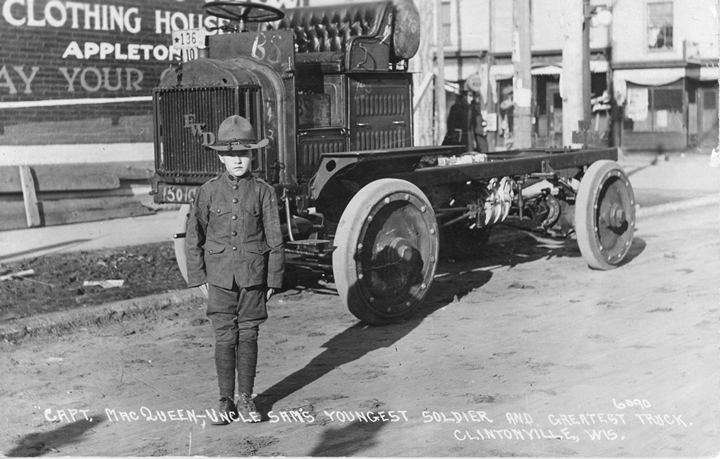

Early Military Vehicles: In 1910,

the one year old company sold its first military vehicle after U.S. Army

Quartermaster officer Captain Alexander E. Williams noticed a newspaper

ad for the new company's product. In his current assignment he was investigating several vehicle companies and had purchased

several trucks for testing. Once Captain Williams read the ad on

the new four-wheel drive truck, he took the train to Clintonville, WI to

see the new vehicle for himself. While at Clintonville, Mr. Zachow

and Besserdich drove him all over the country side in the second

automobile the company had made. Impressed by what he saw during

the test drive, Captain Williams purchased one of the original ten

automobiles for $1,900. The vehicle was modified with an army

escort wagon box which turned it into a truck. Besides being the

first military sale for the fledging company, it may well have been the first sale of any type of four-wheel drive truck for the U.S. Army. This was the first of many military truck

sales for the small company.

In 1912, Captain Williams organized a

1,509 mile endurance test for the trucks he had purchased.

On February 28, 1912, the test began at Washington, D.C. Besides the FWD

vehicle Captain Williams had purchased, trucks from Autocar, Sampson,

and White were also in the test. Each vehicle was loaded with one and a

half tons of supplies plus another half ton of sand. Captain

Williams wanted to prove that motorized vehicles could perform the same

function as the horse drawn supply wagon. The course went south to

Atlanta, GA over muddy roads and open fields. Once in Atlanta, the

vehicles turned north and proceeded to Fort Benjamin Harrison on the east

side of

Indianapolis, IN. The Sampson had to drop out due to failure of

the connecting rod bearings, but the other three trucks arrived at Fort

Harrison on March 28, 1912. After a second endurance run in Iowa

and Wisconsin, Captain Williams chose FWD, Mack, and White for further

use and testing.

After World War One started in 1914, FWD

received an order for two trucks from the British firm of Gaston,

Williams, and Wigmore. After evaluating the two vehicles, the

British company ordered another 50 trucks, which were more vehicles than

what FWD had previously built in its limited existence. In 1915, the

company shipped 400 trucks to Great Britain and expanded the size of its factory in

Clintonville several times. It became an international company

with sales not only to Britain, but Argentina, Brazil, France, Portugal,

Russia, and Spain.

On March 9, 1916, Pancho Villa crossed the

U.S.-Mexican border and attacked Columbus, NM. This resulted in an

order of 147 FWD 3-ton 4x4 trucks for General John Pershing's

Mexican Expedition. This was FWD's largest order to date for

the U.S. Army.

There are at least sixteen Model Bs ready to

move into Mexico in search of Pancho Villa. Photo courtesy of the

Tim Wright Collection.

This is another line of FWD Model B's in New

Mexico. Photo courtesy of the Tim Wright Collection.

World War One: The Four Wheel Drive Company-designed Model B

was one of several types of 4x4 trucks supplied to the U.S. Army during

World War One. There was a total of 16,000 built. It should

be noted that FWD did not have the production capacity to build the

16,000 in the time required by the U.S. Army. Therefore, four other

companies, Kissel, Mitchell, Peerless, and Premier, were licensed to build the Model B during World War One. FWD built

approximately half of the Model Bs while the other companies built the

rest. FWD's first World War One Army contract was awarded in 1917 when the

company received a $12,000,000 contract for 3,750 Model B 3-ton 4x4

trucks. This was a unit price of $3,200. The Model B was powered by a 56 hp engine and a

three-speed transmission. The transfer shaft was driven by a Morse

five-inch silent chain to provide power to both the front and rear drive

shafts. Of special interest is the fact that the company used a

vanadium steel in its ladder type chassis. The Model B could carry

its own weight in freight and had multiple uses in World War One.

Besides being used to move cargo and supplies, the Model B was also used

to carry ammunition and had a special steel body mounted to the chassis

for this function.

FWD Model Bs were the largest group of

American trucks to serve on the Western Front during World War One.

The large variety of trucks and the large number of various required

spare parts was the reason for the creation of the Standard B truck with

standardized parts. But it was too little too late, and

only a few were shipped to Europe. However, the FWD Model Bs were

there in quantity and helped win World War One.

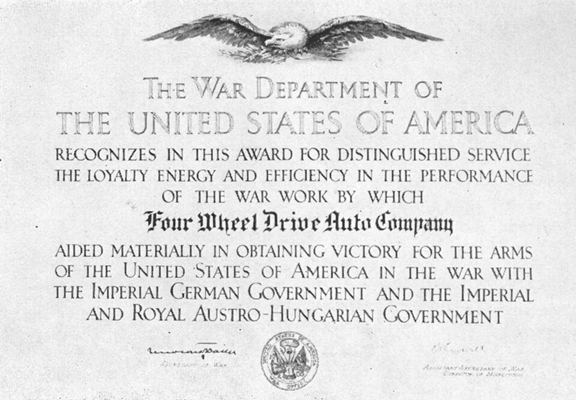

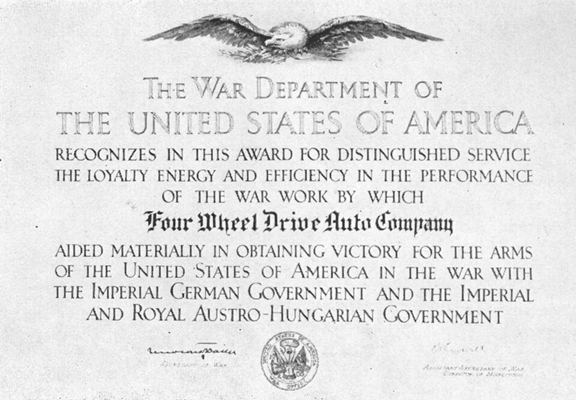

The Four Wheel Drive Auto Company was

recognized for its contribution to the winning of World War One by the

War Department. Photo from FWD World War Two newsletter in the Tim

Wright Collection.

The FWD Seagrave Museum in Clintonville, WI

has a working example of a Model B. Photo courtesy of the Tim

Wright Collection.

Photo courtesy of the Tim Wright Collection.

This FWD Model B belonged to the Army Signal

Corps Aviation Section and is truck number 1035. Note that

the cab has been weatherized by a clear plastic and rubber enclosure.

Photo courtesy of the Tim Wright Collection.

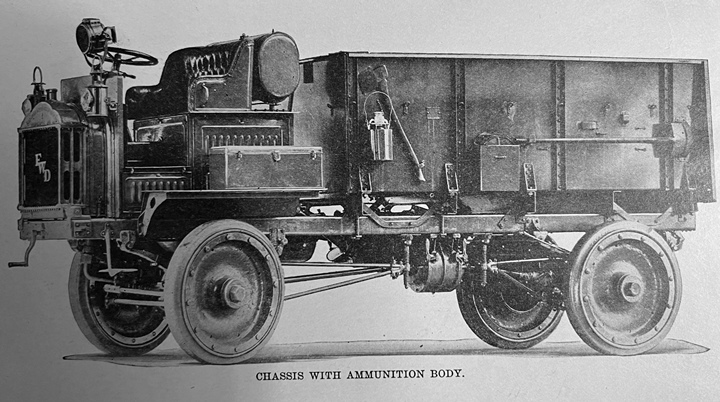

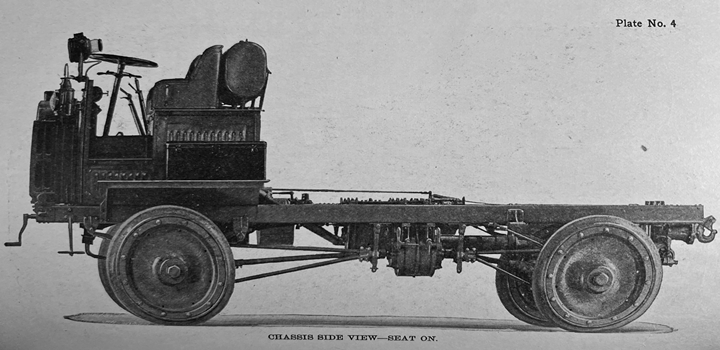

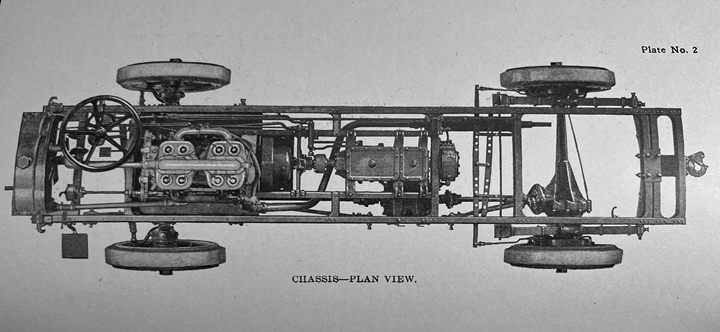

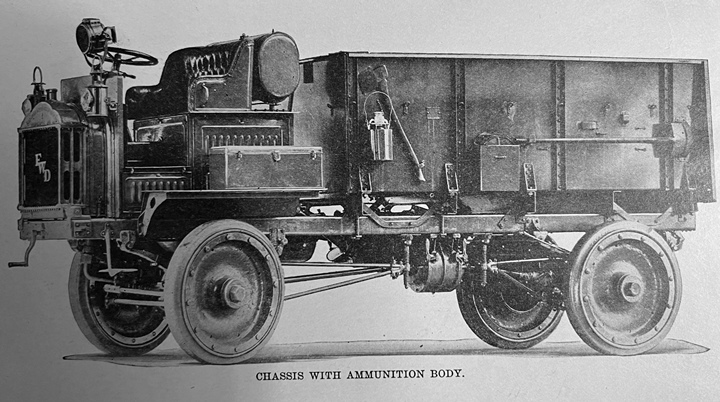

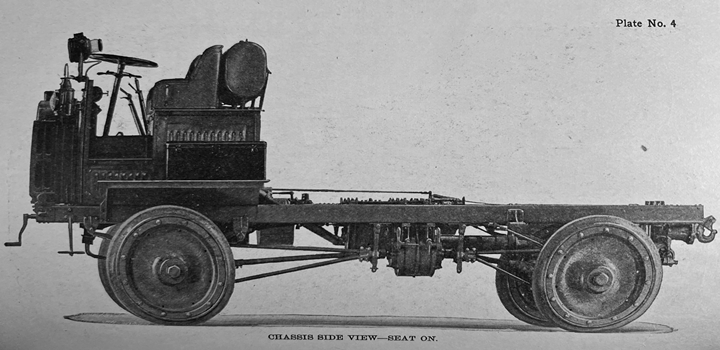

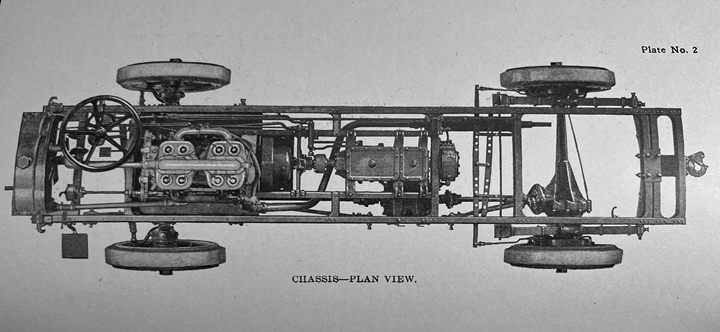

This image from the FWD Handbook shows Model B-1917

equipped with a steel ammunition body. The transfer case is

a gear driven unit as described in Mr. Zachow's and Mr. Besserdich's Patent

No. 907,940. This 1908 patent was for a "Power Applying

Mechanism." In World War Two the company used chain driven

transfer cases. Photo courtesy of the Tim Wright Collection.

Photo courtesy of the Tim Wright Collection.

Photo courtesy of the Tim Wright Collection.

Photo courtesy of the Tim Wright Collection.

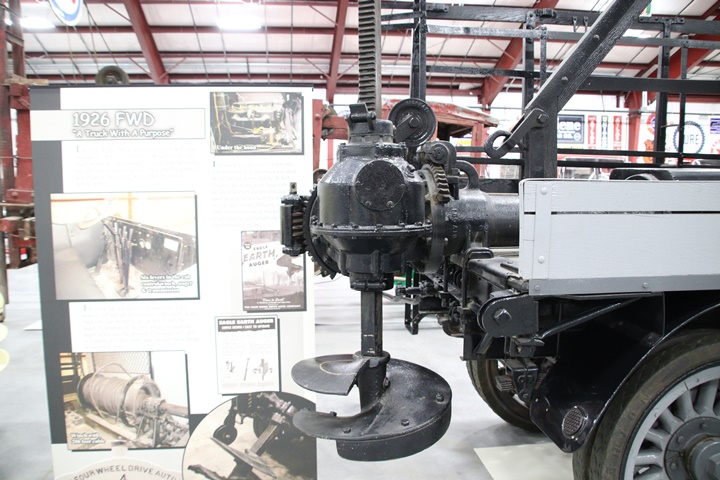

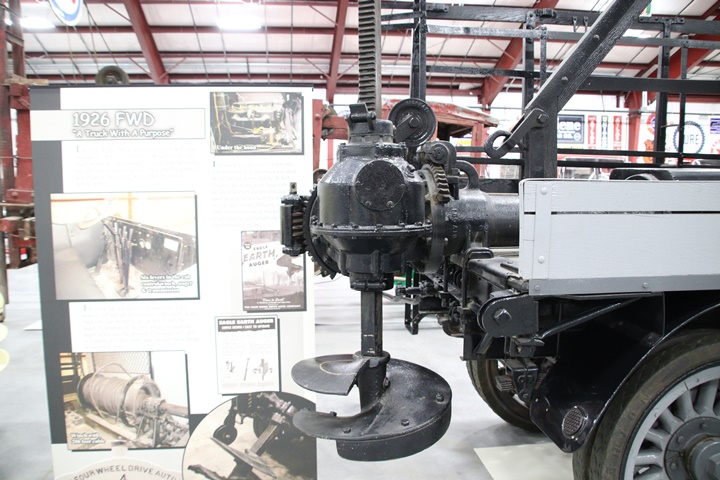

This 1926 FWD Model BT is on display at the

Iowa 80 Trucking Museum. Note that the truck and the location of

manufacture is well identified on the top of the radiator housing.

Author's photo added 1-13-2024.

The Model BT was a heavy duty work truck weighing 13,400 lbs. Author's

photo added 1-13-2024.

Mounted on the rear of the truck is a boring machine that could bore

holes up to eight feet deep. Author's photo added 1-13-2024.

The boring machine could bore 25-30 holes

per day compared to 8-10 men being able to bore only an average of eight

per day. During the 1920s and 1930s, the United States was

undergoing an intense program of rural electrification. The FWD

Model BT with the boring machine was instrumental in boring holes for

power poles throughout the United States. Author's photo added

1-13-2024.

This former military M20

crane carrier has an FWD chassis and a Gar Wood crane. It is part

of the large and excellent collection at the Historical Construction

Equipment Association at Bowling Green, OH. Note that FWD departed

from its normal 4x4 configuration and specifically designed and built

the 6x6 chassis for this vehicle.

Author's photo added 1-13-2024.

Author's photo added 1-13-2024.

FWD began production of this unit in 1952 as

the model MUC. The MUC chassis during its service time had other

cranes and shovels mounted on it. However, the units with the Gar

Wood crane were most prominent and eventually designated as M20s.

This particular one was purchased as military surplus by a construction

company in Ohio and then donated to the

Historical Construction Equipment

Association in 2020.

Author's photo added 1-13-2024.

World War Two: After World War One, FWD sold its patent rights to the United States

Army. This allowed the American military to have other truck

companies begin to use the patented four-wheel drive system on a variety

of different models and sizes. When the United States military

began ordering trucks for its use in World War Two, it had a larger

selection of companies from which to

choose to provide all-wheel drive vehicles. Also, in trucks

larger than 2-1/2-tons, the U.S. Army preferred 6x6 vehicles.

Because the Four-Wheel Drive Auto Company specialized in 4x4 trucks, the

company was not considered for major Army contracts. Therefore,

the company's 4-ton 4x4 HAR series trucks lost out to Diamond T's 4-ton 6x6

truck during World War Two. FWD also had the SU-COE series 5-6-ton

4x4 trucks which did not fit into the standard size of trucks the U.S.

Army had developed. Also, FWD was located in a small town of only

several thousand persons in northern Wisconsin which did not have the capacity

or the estimated workforce to produce trucks in the quantities

that the U.S. Army was going to need.

While the U.S. military, for the most part, was

not interested in FWD's products during World War Two, Great Britain

was. The British military favored 4x4 trucks and took all of

the FWD trucks it could get. Canada and the USSR also received

some, but Great Britain was the biggest user of the trucks built in

Clintonville, WI. As noted at the top of this page, the USMC used

a small number of modified SU-COEs in the Pacific. The U.S. Army

Corps of Engineers and the U.S. Navy also purchased small quantities of

FWD trucks during World War Two.

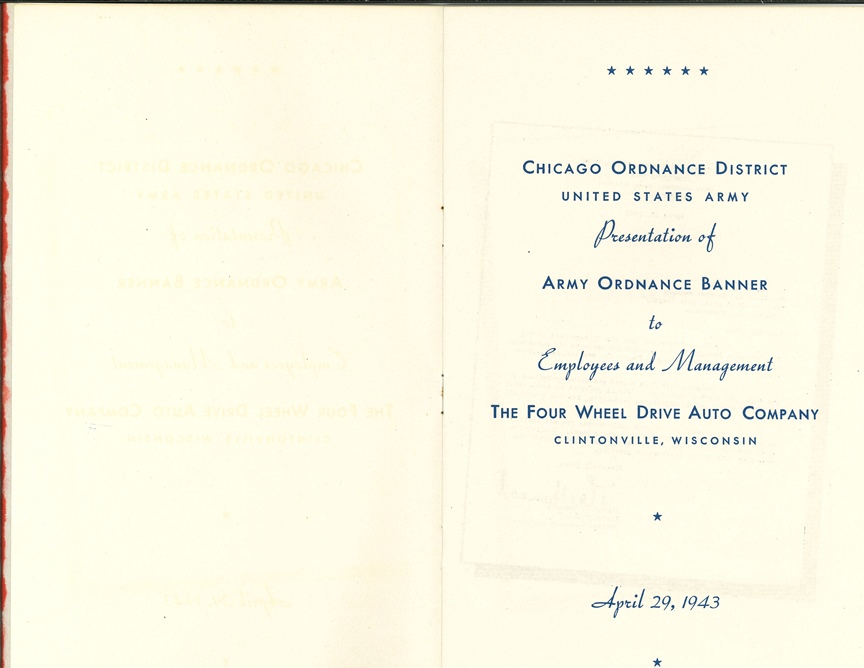

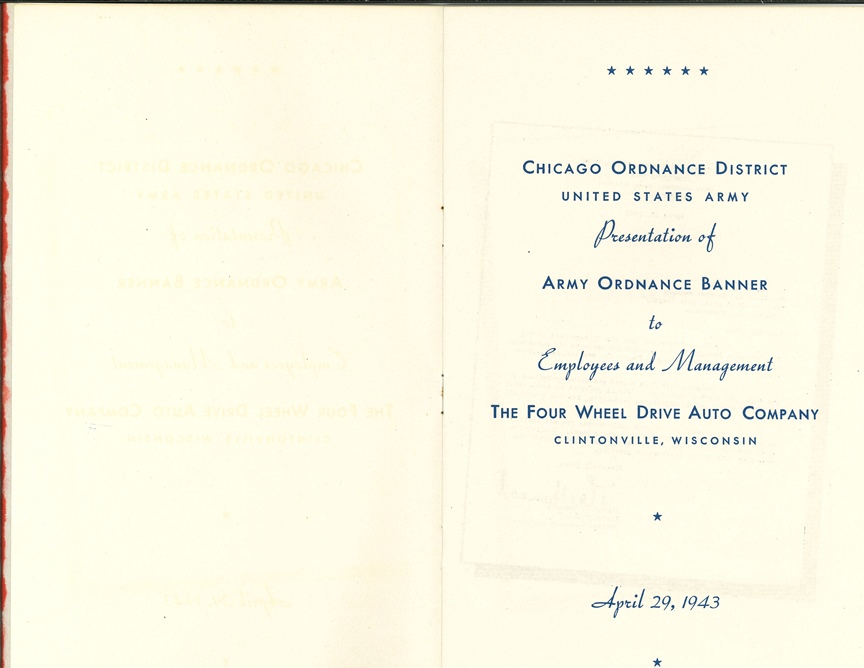

Awards: The Four Wheel Drive Auto Company, while not a big

producer for the U.S. military, was still recognized for its

contributions to the war effort by the number of awards it received.

This 1942 Production Drive Award Pin appears

to have been company generated. As soon as the United States

entered World War Two, the company began a newsletter as a motivator to

increase production. The Four Wheel Drive Auto Company awarded

its employees with this pin in 1942 for their contribution to meeting

schedules and getting trucks out the back door.

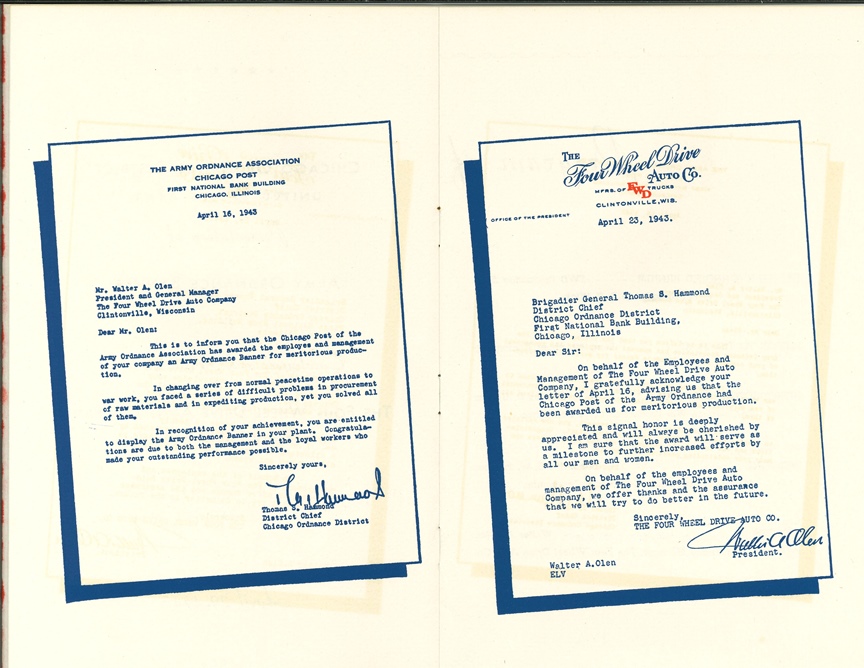

The U.S. Ordnance Chicago District awarded the company its own flag.

This is the only one I have ever seen in my years of researching World

War Two companies. This may well have been an award that only the

Chicago District did for companies with which it worked. In the

case of FWD, one of the main reasons given for the award was that it

disassembled HAR-1 trucks after testing to be packed into crates

so that they took up less shipping space on railcars and ships. FWD was a

leader in this type of operation. Photo courtesy of the Tim

Wright Collection.

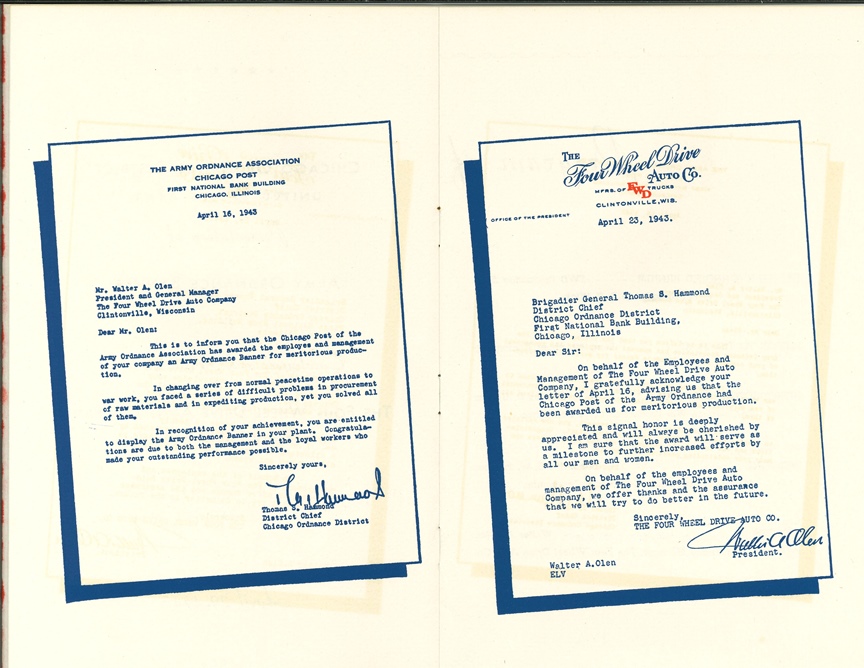

This document gives the FWD employees

instruction for attending the Army Ordnance Award ceremony.

Apparently, FWD had just completed an expansion with a new final

assembly building in which it held the presentation. Photo courtesy of the Tim

Wright Collection.

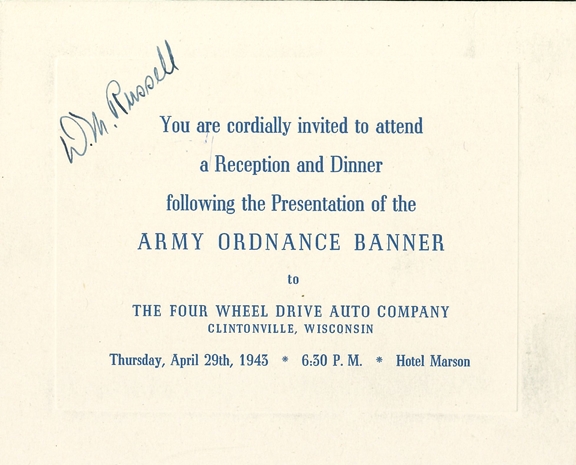

This took place on second shift. It

remains to be seen whether the second shift workers were allowed to

attend this dinner. Photo courtesy of the Tim

Wright Collection.

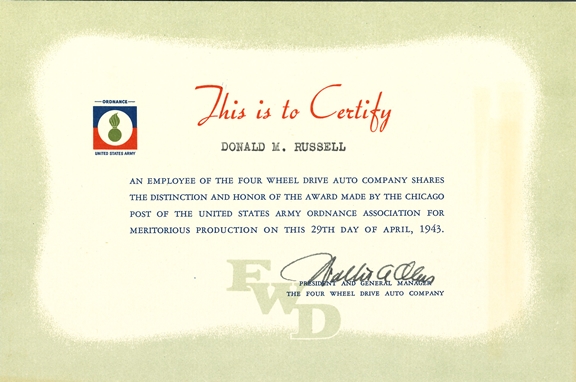

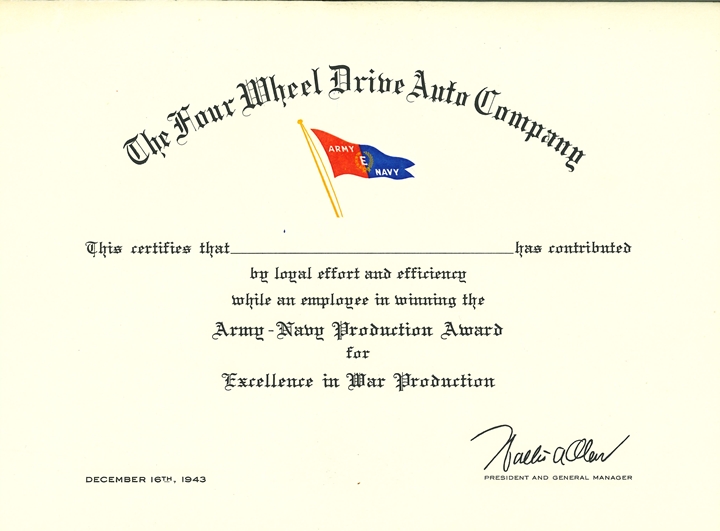

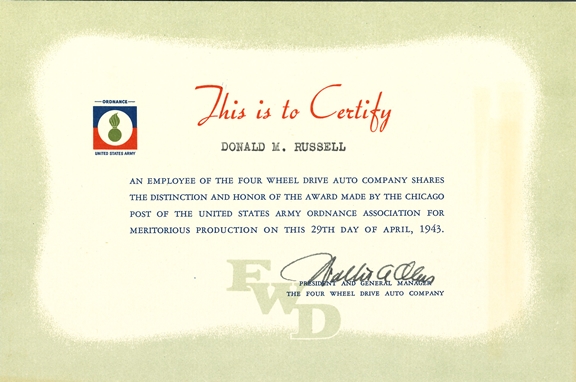

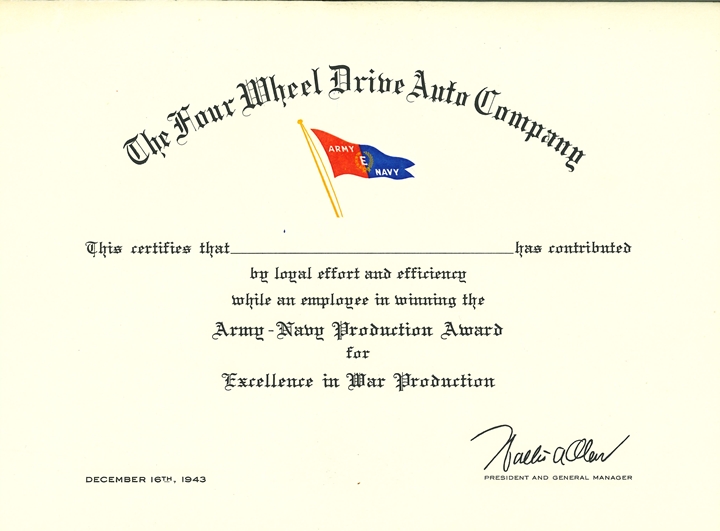

Each employee received a certificate with

his or her name on it. This is very similar to the certificate

that was awarded employees who won the Army-Navy "E" Award. Photo courtesy of the Tim

Wright Collection.

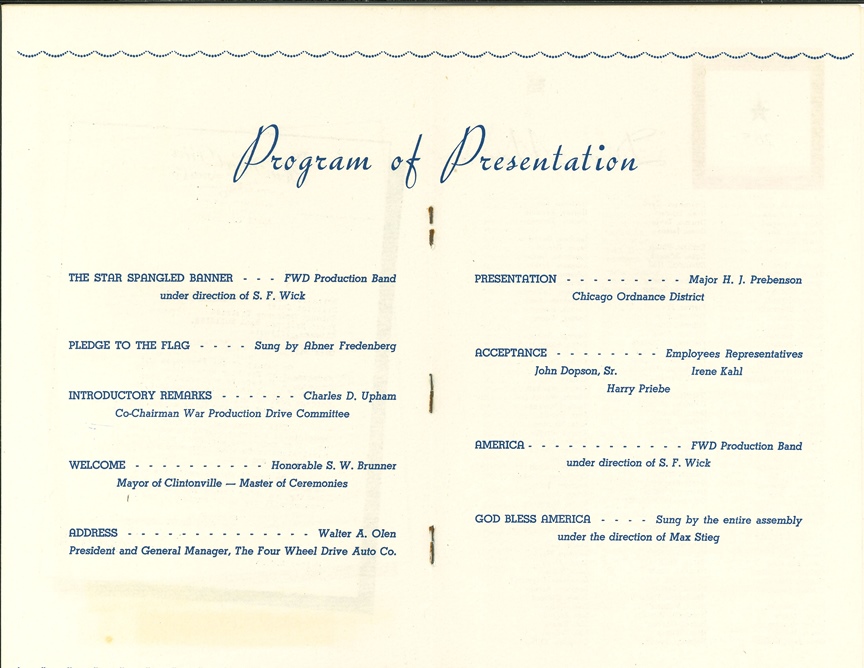

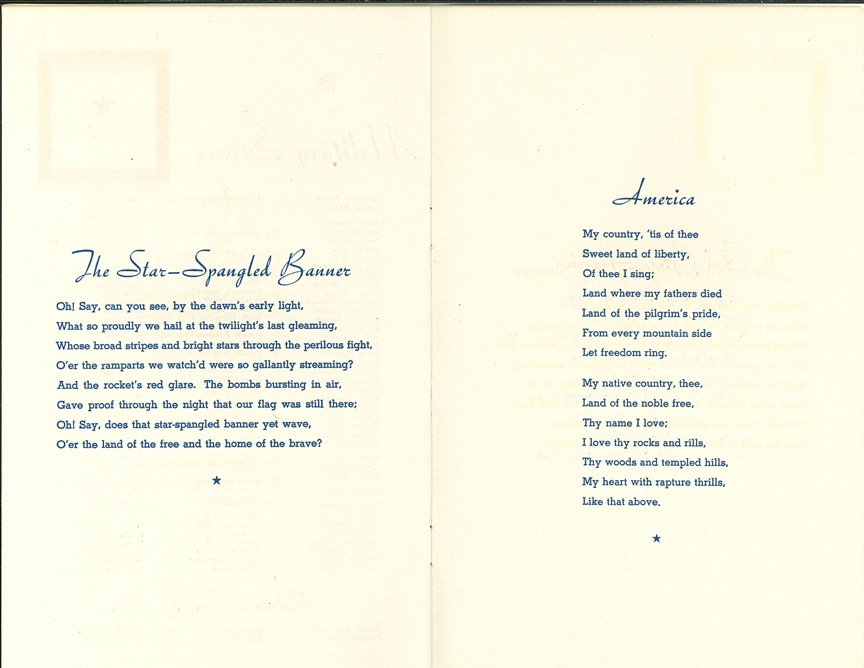

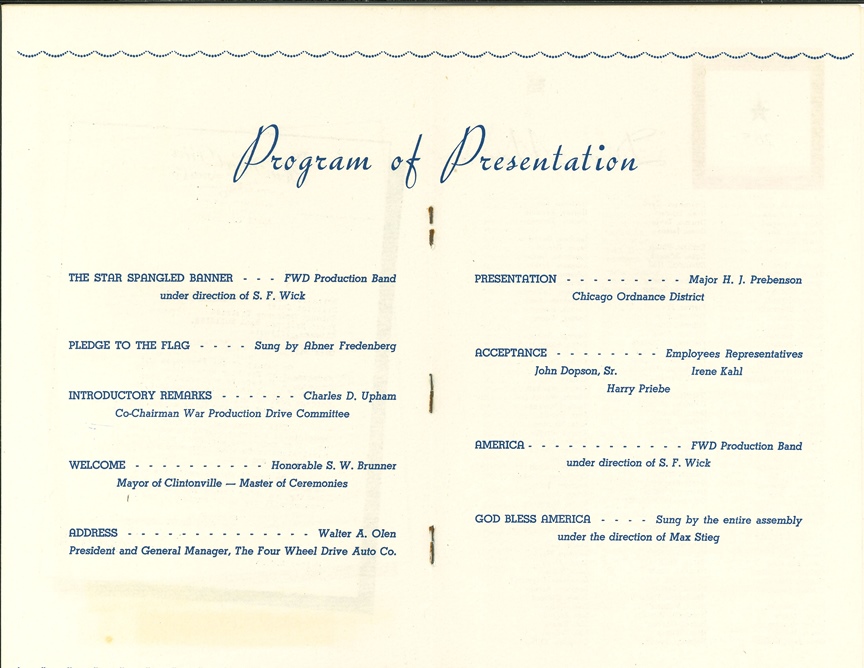

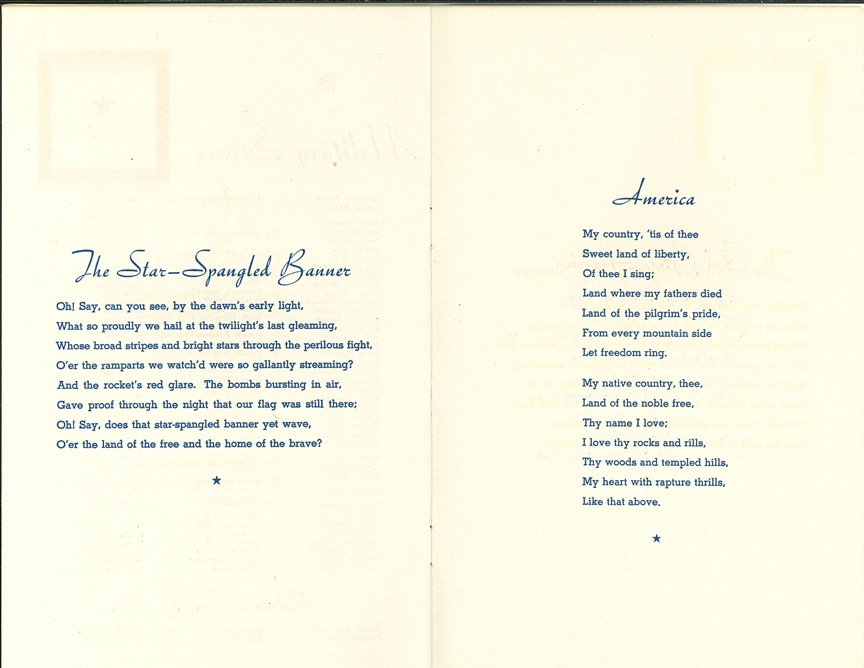

The program that each employee received is

very similar to the ones given out for the "E" Award. Photo courtesy of the Tim

Wright Collection.

Photo courtesy of the Tim

Wright Collection.

Photo courtesy of the Tim

Wright Collection.

Photo courtesy of the Tim

Wright Collection.

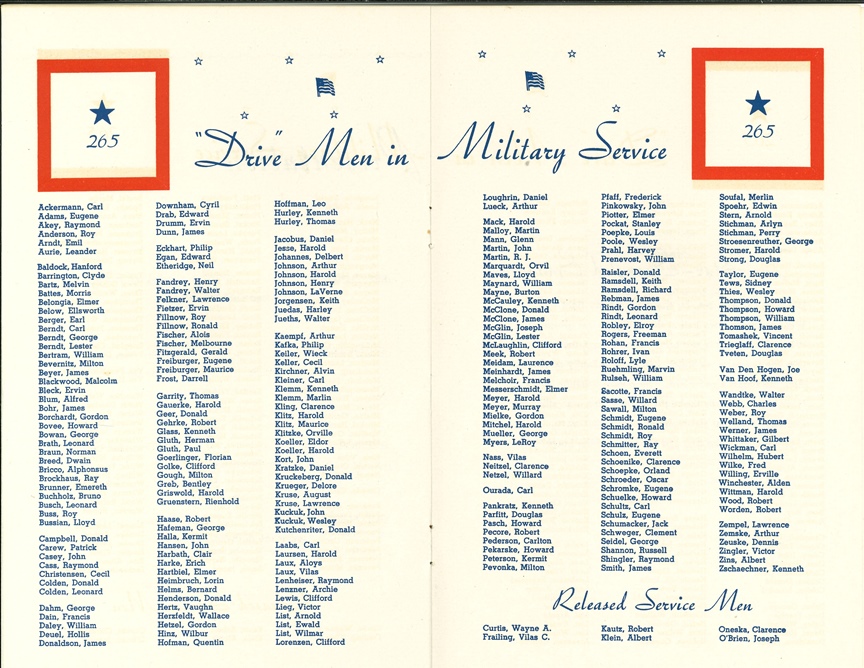

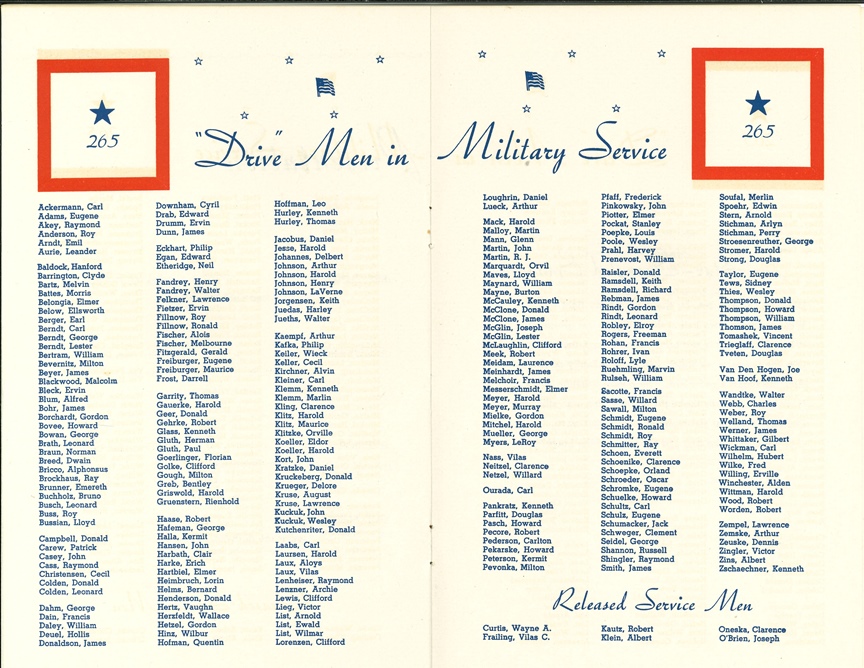

At the end of 1944, the FWD Clintonville

operation had 303 salaried employees and 1,850 hourly workers.

Having had 265 or 12.4% of the company's employees enter the military no

doubt resulted in a big push for replacements. Photo courtesy of the Tim

Wright Collection.

Photo courtesy of the Tim

Wright Collection.

Photo courtesy of the Tim

Wright Collection.

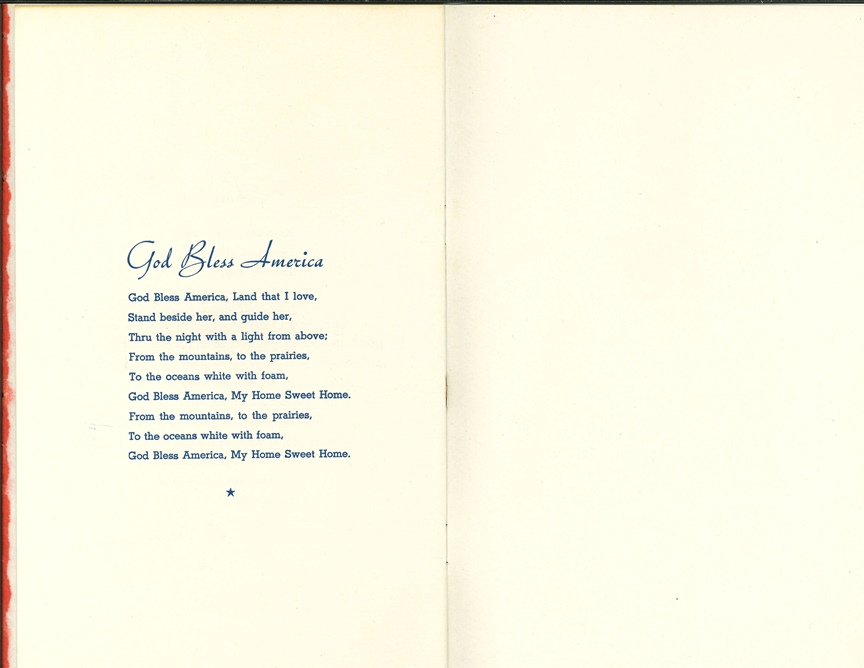

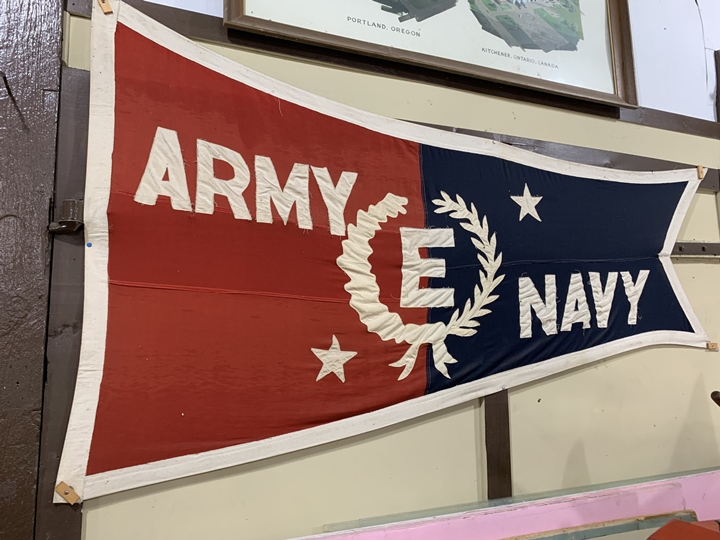

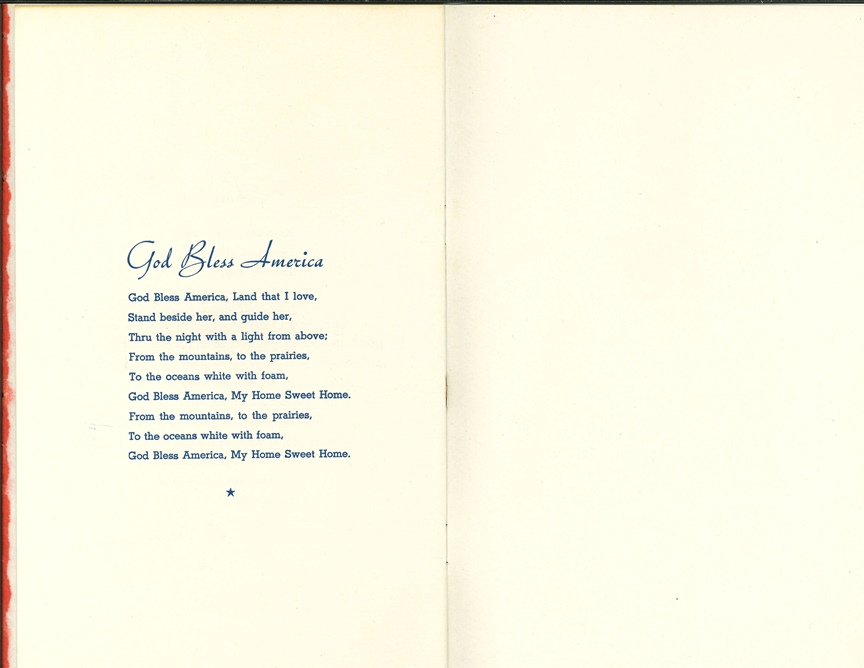

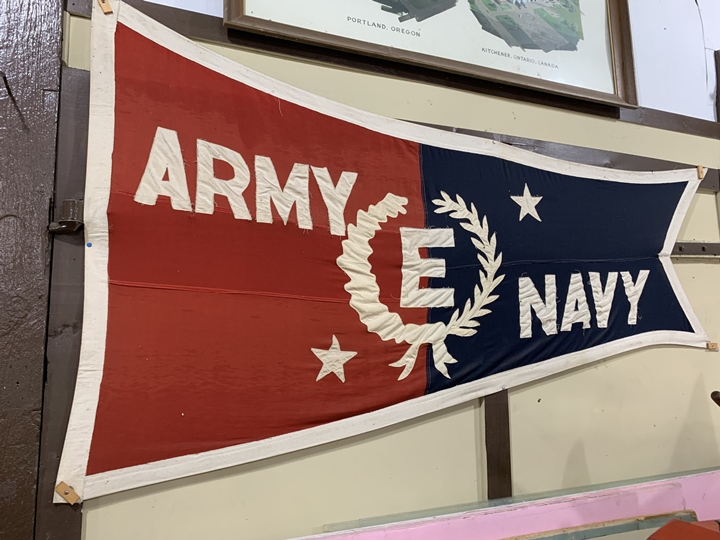

This award shows that while the Four Wheel

Drive Auto Company did not have the product line and capacity the U.S.

Army needed in World War Two, the company was producing trucks for the

Allies ahead of schedule and without labor strikes. The company

was awarded Army-Navy "E" flag by the U.S. Army four times during

World War Two. In other words, the company was doing all the right

things to get trucks out the door to Great Britain, Canada, and the

USSR. This "E" flag is on display at the FWD Seagrave Museum in

Clintonville, WI. This is the third of four flags the company was

awarded, as it has two stars on it. The original flag had no

stars, and a star was added each time the award was renewed every six

months. FWD was awarded its first "E" award on December 16, 1943.

Photo courtesy of the Tim Wright Collection.

Photo courtesy of the Tim Wright Collection.

This flag was awarded for 100% FWD employees' participation in purchasing at least

10% of their wages in U.S. Savings Bonds. Photo courtesy of the

Tim Wright Collection.

This image shows the U.S. Treasury's Bulls-eye Flag

at the bottom. The Treasury Department contracted with FWD five

times during World War Two. Photo from FWD World War Two

newsletter in the Tim Wright Collection.

Four Wheel Drive Auto Company World War Two

Products: There are 13 tables on this page. Eleven are

in this section.

Table 1 is a listing of all of the trucks the

Four Wheel Drive Auto Company built in World War Two. For the

casual reader, this may be all one needs. FWD built an estimated

15,724 trucks during World War Two.

Table 2 shows that the Four Wheel Drive Auto

Company's main plant at Clintonville, WI plant had $92,488,000 in major

contracts during World War Two.

Table 3 shows that the Four Wheel Drive Auto

Company's Steven's Point, WI plant had $3,122,000 in major contracts.

Table 4 shows the FWD major product

categories. Trucks, truck

chassis, and tractors comprised 92.1% of the contracts.

Spare parts was the next largest at 4.5%.

Table 5 shows the FWD-produced vehicles accepted

by Army Ordnance. This was 12,140 vehicles.

Table 6 associates data from Tables 2 and 5

for the Clintonville plant.

Table 7 is data on British Commonwealth

purchased HAR-01 and HAR-03 vehicles. These were ordered before

Lend-Lease was enacted and were direct purchases.

Table 8 is data on USMC type SU-COE trucks.

Table 9 is data U.S. Army Corps of Engineers SU-COE Trucks.

Table 10 contains FWD SU-COE Serial Numbers.

Table 11 contains information on Four Wheel Drive Auto

Company's Lend-Lease Transfers.

Table 12 associates data from Tables 2 and 5

for the Stevens Point plant. This is in the Stevens Point section.

Table 13 is in the SU-COE section.

|

Table 1 - Total Four Wheel Drive Auto Company World War Two Truck Production |

|

Type |

FWD Model |

Quantity |

Comments |

|

Truck,

3-1/2-ton 4x4 with winch behind cab, chassis and cab only |

HAR-01 |

1,633 |

814 units are a verified quantity. 819 units are a

estimated quantity. From Table 7. |

|

Tractor,

4-ton, 4x4 |

HAR-03 |

1,524 |

This is a verified quantity. Purchased by Canada for its use and for

use by Great Britain. From Table 7. |

| Truck, 4-ton

4x4, Cargo |

HAR-1 |

7,000 |

This is a verified quantity. Purchased

by Army Ordnance for Lend-Lease to Canada, Great Britain, and

the USSR. From Table 6. |

|

Truck, 4x4, Dump |

Unknown |

6 |

This is an estimated quantity. This

is based on a photo of six dump trucks that purchased for the

Navy Construction Battalions.

|

|

Truck 4-ton, 4x4, Bridge Erecting |

SU-COE |

71 |

This is an estimated quantity. These

were for the Army Corp of Engineers. From Table 9.

|

| Truck, 5-6-ton,

4x4, Cargo |

SU-COE |

1,460 |

This is a verified quantity. Purchased

by Army Ordnance for Lend-Lease to Canada, Great Britain, and

the USSR. From Table 6. |

| Truck, 5-6-ton,

4x4, Prime Mover |

SU-COE |

2,700 |

This is a verified quantity. Purchased

by Army Ordnance for Lend-Lease to Canada, Great Britain, and

the USSR. From Table 6. |

| Truck, 5-6-ton,

4x4, Cargo |

SU-COE |

250 |

This is an estimated quantity.

120 were

built at the Stevens Point, WI operation beginning in May 1943.

From Table 8. |

| Truck,

5-6(7)-ton, 4x4, Cargo |

|

700 |

This is a verified quantity. Purchased

by Army Ordnance for the Department of Agriculture. From

Table 6. |

| Truck,

5-6(7)-ton, 4x4, Tractor |

|

50 |

This is a verified quantity. Purchased

by Army Ordnance for the Department of Agriculture. From

Table 6. |

| Truck,

5-6(7)-ton, 4x4, Timber Hauler |

|

35 |

This is a verified quantity. Purchased

by Army Ordnance for the Department of Agriculture. From

Table 6. |

| Truck, 6-ton,

6x6, W/W Chassis for Bridge Erecting |

Same as Brockway and White |

168 |

This is a verified quantity. Purchased

by Army Ordnance for U.S. Army. From Table 6. |

| Truck, 6-ton,

6x6, W/W Chassis for Crane |

Same as Brockway |

26 |

This is a verified quantity. Purchased

by Army Ordnance for U.S. Army. From Table 6. |

| 12-ton 6x4

Tractor M20 |

Same as Diamond T

Model 980, 981 |

100 |

Several sources note that FWD built

100 Diamond T Model 980s and 981s under contract. Because they

were built under contract, the data plate would still note it

was a Diamond T vehicle. There is also a photo of this type

of

truck in World War Two parade in Clintonville, WI. |

| Truck, 15-ton,

4x4, Tractor |

|

1 |

This is a verified quantity. From

Table 6. |

|

Total |

|

15,724 |

|

|

Table 2 - Four Wheel Drive Auto

Company's Major World War Two Contracts - Clintonville, WI Plant

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

Contract Number |

Associated Table(s) |

|

Trucks - Foreign |

$3,081,000 |

9-1940 |

3-1941 |

A-1395 |

7 |

| Tools Machine -

Foreign |

$194,000 |

9-1940 |

11-1940 |

A-1534 |

|

|

Trucks - Foreign |

$3,061,000 |

10-1940 |

3-1941 |

A-1593 |

7 |

| Turret Parts -

Navy |

$293,000 |

5-1941 |

1-1942 |

NOS-886014 |

|

| Trucks - USMC |

$423,000 |

5-1941 |

11-1941 |

NOM-30129 |

8 |

| Trailers - Army |

$196,000 |

6-1941 |

8-1942 |

227-SC-3454 |

|

|

Tractors - Army |

$190,000 |

7-1941 |

1-1942 |

398-QM-35 |

5, 6 |

| Transportation

Equipment - Army Engineers |

$248,000 |

8-1941 |

11-1941 |

145-ENG-249 |

9 |

| Tractors -

Foreign |

$760,000 |

9-1941 |

3-1942 |

- |

7 |

| Tools Machine -

Army Engineers |

$172,000 |

10-1941 |

4-1942 |

978-ENG-160L |

|

|

Trucks - Army |

$2,482,000 |

11-1941 |

9-1942 |

2710-ORD-2781D |

5, 6 |

| Trucks - Army |

$289,000 |

12-1941 |

3-1942 |

398-QM-183L |

5, 6 |

| Tractors -

Foreign |

$690,000 |

1-1942 |

6-1942 |

- |

7 |

| Tractors -

Foreign |

$1,769,000 |

1-1942 |

7-1942 |

- |

7 |

| Trucks - USMC |

$577,000 |

2-1942 |

8-1942 |

NOM-33200 |

8 |

| Spare Parts

- USMC |

$54,000 |

3-1942 |

6-1942 |

NOM-33832 |

|

|

Cargo Trucks - Army |

$35,225,000 |

7-1942 |

12-1944 |

271-ORD-2675 |

5, 6 |

| Trucks - USMC |

$913,000 |

11-1942 |

5-1943 |

NOM-38159 |

8 |

| Toboggans - Army |

$109,000 |

11-1942 |

3-1942 |

271-ORD-2782 |

|

| Truck Parts

- Army |

$78,000 |

12-1942 |

4-1943 |

271-ORD-5589 |

|

| Truck Parts

- Army |

$359,000 |

12-1942 |

3-1944 |

271-ORD-5576 |

|

| Truck Parts

- Army |

$359,000 |

12-1942 |

3-1944 |

271-ORD-5584 |

|

| Machinery Road -

Army Engineers |

$385,000 |

1-1943 |

1-1943 |

1088-ENG-2036 |

9 |

|

Trucks - Army |

$8,500,000 |

8-1943 |

9-1944 |

11022-ORD-213S |

5, 6 |

| Truck Parts -

Treasury |

$110,000 |

5-1944 |

11-1944 |

TPS-55706L |

|

| Cargo Trucks -

Army |

$16,345,000 |

5-1944 |

3-1945 |

11022-ORD-213S |

5, 6 |

| Truck Parts -

Treasury |

$467,000 |

8-1944 |

3-1945 |

TPS-61389L |

|

| Motor Vehicle

Parts - Treasury |

$416,000 |

8-1944 |

12-1944 |

TPS-62992L |

|

|

Trucks - Army |

$7,030,000 |

10-1944 |

6-1945 |

11022-ORD-5389 |

5, 6 |

| Truck Parts

- Army |

$360,000 |

1-1945 |

11-1945 |

11022-ORD-6612 |

|

| Truck Parts

- Army |

$750,000 |

1-1945 |

11-1945 |

11022-ORD-6611 |

|

| Truck Parts

- Army |

$303,000 |

3-1945 |

12-1945 |

11022-ORD-7923 |

|

| Truck Parts -

Treasury |

$77,000 |

4-1945 |

12-1945 |

TPS-79745L |

|

|

Truck Chassis - Army |

$791,000 |

4-1945 |

6-1946 |

11022-ORD-8759 |

5, 6 |

| Truck Parts

- Army |

$1,028,000 |

4-1945 |

1-1946 |

11022-ORD-8523 |

|

| Truck Chassis

Cabs - Treasury |

$2,202,000 |

7-1945 |

9-1945 |

TPS-89073L |

|

| Cargo Bodies -

Treasury |

$2,202,000 |

7-1945 |

9-1945 |

TPS-89074L |

|

| Total |

$92,488,000 |

|

|

|

|

|

Table 3 - Four Wheel Drive Auto

Company's Major World War Two Contracts - Stevens Point, WI

Plant

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

Contract Number |

| Trucks - Army |

$3,122,000 |

3-1945 |

8-1945 |

11022-Ord-7890 |

Table 4 - Four Wheel Drive Auto Company's Major World War Two Product Categories

Includes both Clintonville and Stevens Point, WI

plants |

|

Product |

Amount |

Percentage |

|

Trucks, Truck Chassis,

Tractors (Clintonville and Stevens Point) |

$88,083,000 |

92.1% |

|

Tools Machine |

$366,000 |

0.4% |

| Turret Parts |

$293,000 |

0.3% |

| Trailers |

$196,000 |

0.2% |

| Spare

Parts |

$4,361,000 |

4.5% |

| Toboggans |

$109,000 |

0.1% |

| Cargo Bodies -

Treasury |

$2,202,000 |

2.3% |

|

Total |

$95,610,000 |

~100% (99.9%) |

Table 5 -

Four Wheel Drive Auto Company Vehicles

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

FWD Model |

Contract Number |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Truck, 4-ton,

4x4, Cargo |

HAR-1 |

171-2675 |

|

|

|

4,584 |

2,416 |

|

7,000 |

| |

|

|

|

|

|

|

|

|

|

| Truck, 5-6-ton,

4x4, Cargo |

SU-COE |

11-022-213 |

|

|

|

|

500 |

|

500 |

| Truck, 5-6-ton,

4x4, Cargo |

SU-COE |

11-022-5389 |

|

|

|

|

|

721 |

721 |

| Truck, 5-6-ton,

4x4, Cargo |

SU-COE |

11-022-5389 |

|

|

|

|

|

239 |

239 |

|

Total Truck, 5-6-ton,

4x4, Cargo |

SU-COE |

|

|

|

|

|

500 |

960 |

1,460 |

| |

|

|

|

|

|

|

|

|

|

| Truck, 5-6-ton,

4x4, Prime Mover |

SU-COE |

11-022-213 |

|

|

|

|

1637 |

863 |

2,700 |

| Truck,

5-6(7)-ton, 4x4, Cargo |

|

271-2781l DA 181 |

|

|

700 |

|

|

|

700 |

| Truck,

5-6(7)-ton, 4x4, Tractor |

|

398-QM-35 / DA 35 |

|

32 |

18 |

|

|

|

50 |

| Truck,

5-6(7)-ton, 4x4, Timber Hauler |

CU |

398-QM-183L / DA 183 |

|

|

35 |

|

|

|

35 |

| Truck, 6-ton,

6x6, W/W Chassis for Bridge Erecting |

same as Brockway |

11-022-7890 |

|

|

|

|

|

168 |

168 |

| Truck, 6-ton,

6x6, W/W Chassis for Crane |

same as Brockway |

11-022-5759 |

|

|

|

|

|

26 |

26 |

| Truck, 15-ton,

4x4, Tractor |

|

3029 |

1 |

|

|

|

|

|

1 |

| Total |

|

|

|

|

|

|

|

|

12,140 |

|

Table 6 - This

table associates the contracts from Table 2 and Table 5 |

|

From Table 5 |

|

From Table 2 |

|

Type |

FWD Model |

Total |

Common

Contract Number |

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

Average Cost per Unit |

| Truck, 4-ton,

4x4, Cargo |

HAR-1 |

7,000 |

271-ORD-2675 |

Cargo Trucks -

Army |

$35,225,000 |

7-1942 |

12-1944 |

$5,032 |

| |

|

|

|

|

|

|

|

|

| Truck, 5-6-ton,

4x4, Cargo |

SU-COE |

500 |

|

|

|

|

|

|

| Truck, 5-6-ton,

4x4, Prime Mover |

SU-COE |

2,700 |

|

|

|

|

|

|

| Total

|

|

3,200 |

11-022-213 and 11022-ORD-213S |

Trucks - Army |

$8,500,000 |

8-1943 |

9-1944 |

$2,656 |

| |

|

|

|

|

|

|

|

|

| Truck, 5-6-ton,

4x4, Cargo |

SU-COE |

721 |

|

|

|

|

|

|

| Truck, 5-6-ton,

4x4, Cargo |

SU-COE |

239 |

|

|

|

|

|

|

| |

|

960 |

11-022-5389 |

Trucks - Army |

$7,030,000 |

10-1944 |

6-1945 |

$7,322 |

| |

|

|

|

|

|

|

|

|

| Truck,

5-6(7)-ton, 4x4, Cargo |

|

700 |

2710-Ord-2781 / DA 35 |

Trucks - Army |

$2,482,000 |

11-1941 |

9-1942 |

$3,545 |

| |

|

|

|

|

|

|

|

|

| Truck,

5-6(7)-ton, 4x4, Tractor |

|

50 |

398-QM-35 |

Tractors - Army |

$190,000 |

7-1941 |

1-1942 |

$3,800 |

| |

|

|

|

|

|

|

|

|

| Truck,

5-6(7)-ton, 4x4, Timber Hauler |

|

35 |

398-QM-183L

/ DA 183 |

Trucks - Army |

$385,000 |

12-1941 |

3-1942 |

$8,257 |

| |

|

|

|

|

|

|

|

|

| Truck, 6-ton,

6x6, W/W Chassis for Crane |

same as Brockway |

26 |

11022-Ord-8759 |

Truck Chassis -

Army |

$791,000 |

4-1945 |

6-1946 |

$30,423 |

| |

|

|

|

|

|

|

|

|

| Truck, 15-ton,

4x4, Tractor |

|

1 |

Unknown |

|

Less than $50,000, so not shown

on Major Contract Listing |

|

|

|

| |

|

|

|

|

|

|

|

|

| Stevens Point

Plant |

|

|

|

|

|

|

|

|

| Truck, 6-ton,

6x6, W/W Chassis for Bridge Erecting

Parts based on original Brockway

truck |

same as Brockway,

WL, White |

168 |

11022-Ord-7890 |

Trucks

- Army |

$3,122,000 |

3-1945 |

8-1945 |

$18,583 |

There is a problem in Table 7 with trying to

match up known contacts for the HAR-03. Volumes and contract

values do not make any sense as they range from $1,474 to $28,750 per

unit cost. I have also done an average cost. These strange

average cost values have no effect on the number of trucks produced.

Table 7 - Four Wheel

Drive Auto Company

World War Two HAR-01 and HAR-03 Foreign Contracts

Information for this came from "FWD HAR-Series Trucks:

American Full time All-wheel Drive 'Conventions' of World War

II" published in "Wheels & Tracks" Volume 5, 1983, pages

14-33 |

|

Type |

Foreign Contract number |

Number |

Serial Numbers |

U.S. Contract Number From Table 1 |

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

Average Cost per Unit |

| HAR-01 3-1/2-ton 4x4 with winch

behind cab, chassis and cab only |

Canada USP-6382 |

Calculated as 819 |

For Canadian Use -

Unknown Serial Numbers |

A-1395 |

Trucks - Foreign |

$3,081,000 |

9-1940 |

3-1941 |

Unknown- Assumed to be $3,760 as

below |

| HAR-01 3-1/2-ton 4x4 with winch

behind cab, chassis and cab only |

Canada USP-12045 |

814 |

For British Use -

L4688568-571, L4688575-850, L4688584-587, L4785291-6090 |

A-1593 |

Trucks - Foreign |

$3,061,000 |

10-1940 |

3-1941 |

$3,760

|

|

Total Har-01 |

|

1,633 |

|

|

|

|

|

|

|

| HAR-03

4-ton 4x4 tractor |

Canada

200

USP 18311 |

1,200 |

110446-111645 Inclusive |

? |

Trucks - Foreign |

$1,769,000 |

1-1942 |

7-1942 |

$1,474 |

| HAR-03

4-ton 4x4 tractor |

Canada

203

USP 19181 |

24 |

111647-111670 Inclusive |

? |

Trucks - Foreign |

$690,000 |

1-1942 |

6-1942 |

$28,750 |

| HAR-03

4-ton 4x4 tractor |

Canada

214

USP 18311 |

300 |

111671 - 111870 Inclusive |

? |

Trucks - Foreign |

$760,000 |

9-1941 |

3-1942 |

$2,533 |

|

Total HAR-03 |

|

1,524 |

|

|

|

$3,219,000 |

|

|

$2,112 |

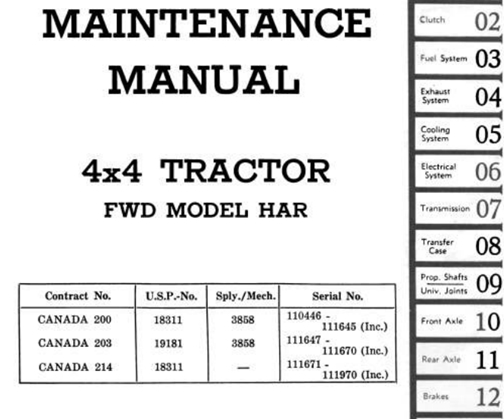

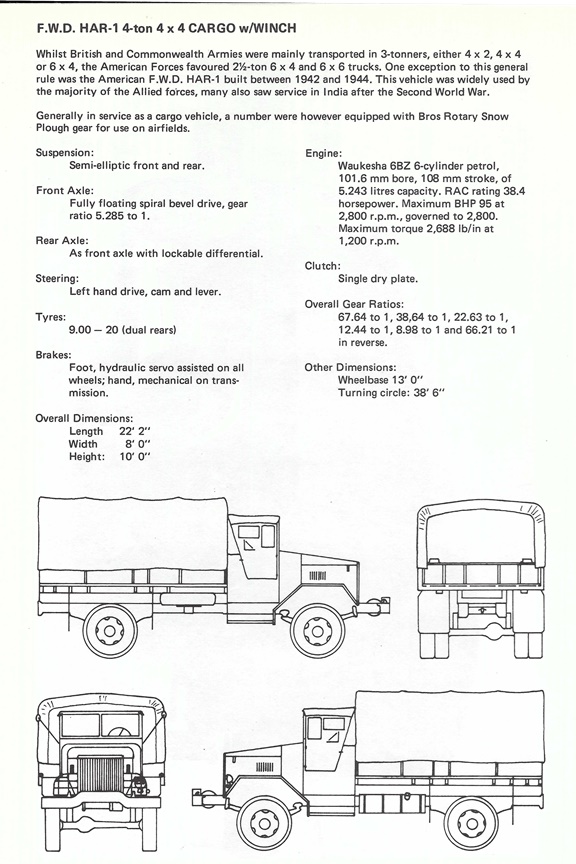

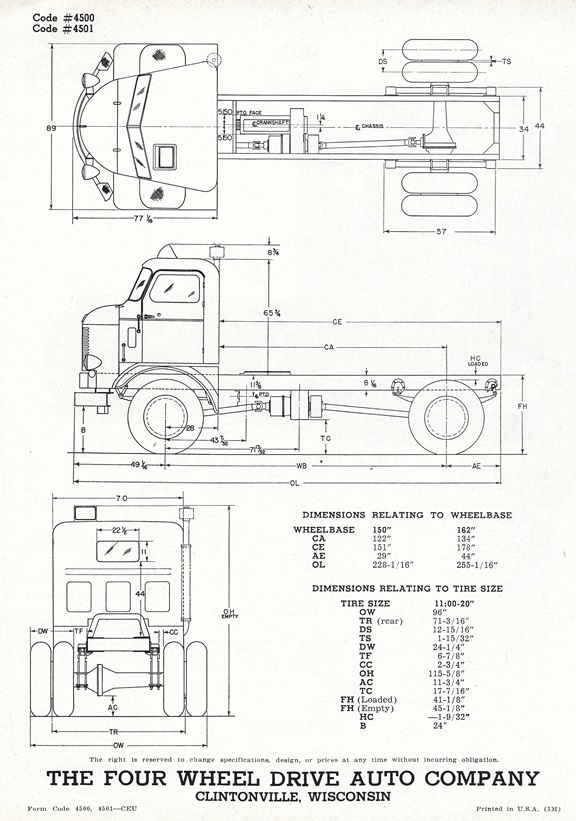

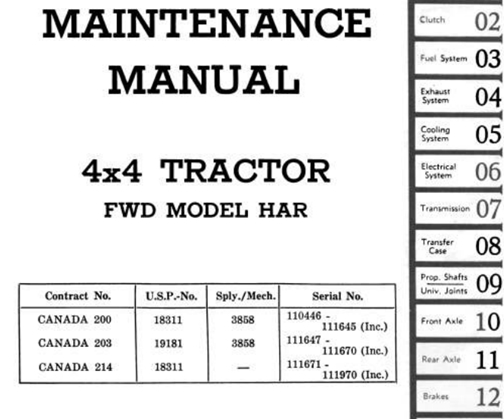

This image is from the Maintenance Manual for the

HAR-03. It provides contract and serial numbers.

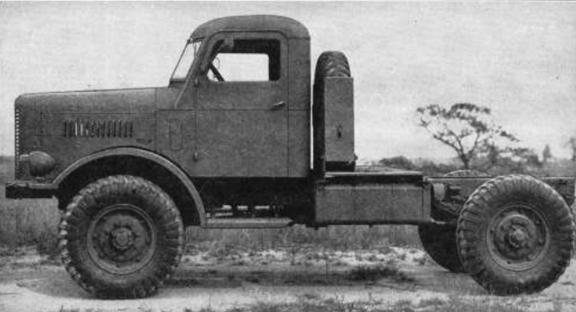

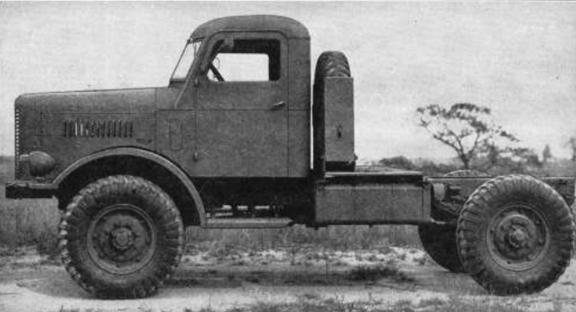

This is a HAR-03 with a Waukesha BZ 95 hp

engine.

|

Table 8 -

USMC SU-COE Trucks |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

Contract Number |

Comments |

Quantity |

| Trucks - USMC |

$913,000 |

11-1942 |

5-1943 |

NOM-38159 |

The September 16, 2016, issue of

the Portage County Gazette notes that the FWD Stevens

Point Plant built 120 USMC trucks when it started production

in May 1943. While the contract was supposedly

completed in May 1943, this particular contract is the only

one of the three USMC contracts that best matches with its

dates. The photo in the Stevens Point Plant section

shows a completed USMC SU-COE at the plant. $913,000 divided

by 120 equals $7,608 cost per USMC SU-COE. |

120 |

| Trucks - USMC |

$423,000 |

5-1941 |

11-1941 |

NOM-30129 |

This is an estimated quantity. $423,000 divided by $7,608 =

55 |

55 |

| Trucks - USMC |

$577,000 |

2-1942 |

8-1942 |

NOM-33200 |

This is an estimated quantity. $577,000

divided by $7,608 = 75 |

75 |

|

Total |

|

|

|

|

|

250 |

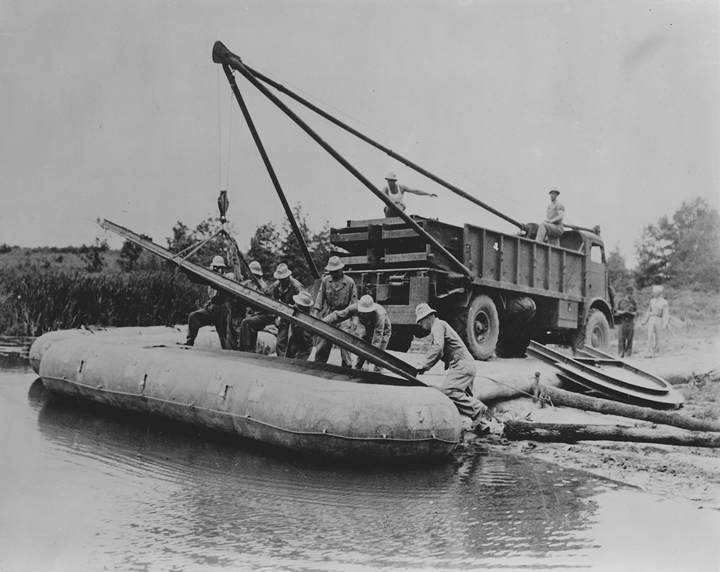

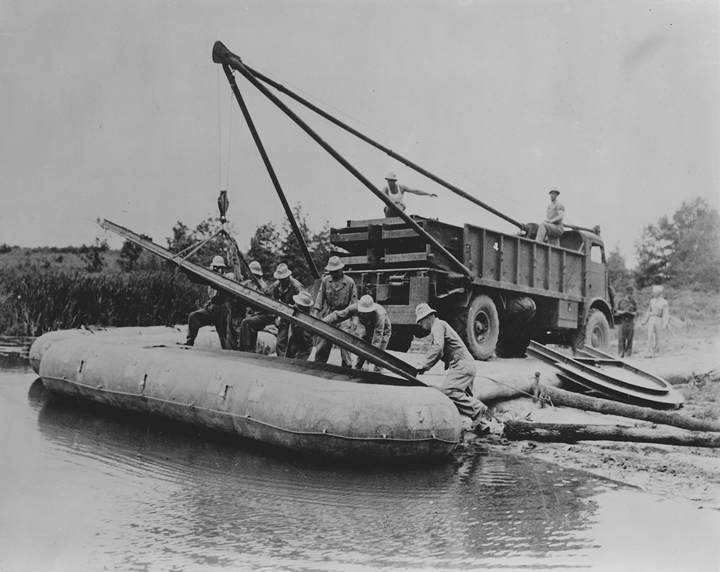

The Army Corps of Engineers purchased 28 FWD YUs

under Contract Number 145-ENG-249. This was a $248,000, contract

indicating that each FWD YU cost an average of $8,857. The YU was

the U.S. Army's first attempt to build a bridging truck. FWD

developed the design shown above which included the detachable A-frame

that was used as a crane. This was used for maneuvering the bridge

treadways into place as shown above. The FWD YU also included an

air compressor and air storage tanks for inflating pontoons.

Fourteen FWD YU bridging trucks were evaluated

during the Carolina Maneuvers. It was found that the biggest

drawback to the YU was that it took fifteen minutes to set up and

assemble the A-frame. This was considered too long for a combat

situation. Therefore, the Army Corps of Engineers suggested to use

two parallel swinging arms mounted to the truck body that could start

placing treadways in 90 seconds. This concept was generated by FWD

and it proposed another bridging truck with this design.

Concurrently, the Army Corps of Engineers was investigating other

similar methods proposed by other companies. In the end, it

decided on the Daybrook Hydraulic Corporation's design to be mounted on

Brockway 6-ton 6x6 trucks as its bridging truck.

The FWD YU shown here is being used by Army

Engineers to build a pontoon bridge at Fort Knox, KY on September 24, 1942. Photo courtesy of the

Tim Wright Collection.

The photo above and the one below are the only

known photographic evidence that the Army Corps of Engineers

purchased a number of trucks from FWD.

This truck has USA registration number

W-609046. Photo courtesy of the

Tim Wright Collection.

Both of the contracts below are assumed to be for the purchase of trucks

with added bridging equipment. Sometimes the contracts are not

completely clear on what is being ordered. The estimated number of

trucks estimated below is 71. While the exact cost is unknown, it

can be assumed that the Corps of Engineers purchased no more than 100

trucks.

|

Table 9 -

U.S. Army Corps of Engineers YU Trucks |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

Contract Number |

Comments |

Quantity |

| Transportation

Equipment - Army Engineers |

$248,000 |

8-1941 |

11-1941 |

145-ENG-249 |

The assumed cost is $9,000 as

these trucks have bridging equipment. $248,000

divided by $9,000 = 28. |

28 |

| Machinery Road -

Army Engineers |

$385,000 |

1-1943 |

1-1943 |

1088-ENG-2036 |

The assumed cost is $9,000 as these

trucks have bridging equipment. $385,000 divided by

$9,000 = 28. |

43 |

|

Total |

|

|

|

|

|

71 |

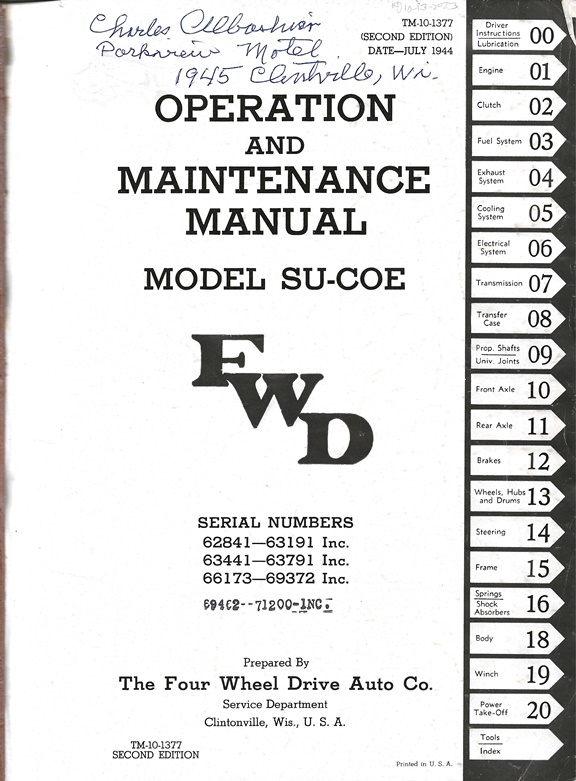

Table 10 shows the FWD

serial numbers associated with the production of the SU-COE for Army

Ordnance. This is for reference only and is not required for the

calculation of the number of SU-COEs FWD made.

Table 10 - FWD SU-COE Serial Numbers

From Tech Manual 10-1377 dated July, 1944 |

|

Type |

Serial Numbers |

Number |

Comments |

|

Cargo Body |

62841-63191, inclusive |

350 |

|

| Cargo Body |

63441-63791, Inclusive |

350 |

|

| Cargo Body |

66173-66672, Inclusive |

500 |

|

|

Cargo Body

Total |

|

1,200 |

Table

5 shows that Army Ordnance accepted 1,460 SU-COE cargo trucks.

There were 260 more units accepted than there were serial numbers. |

| Tractors, w/w |

66674-69372, Inclusive |

2,698 |

Table

5 shows that Army Ordnance accepted 2,700 SU-COE tractors.

The two numbers are only off by 2. |

| Tractors, w/w |

69462-72300, Inclusive |

2,832 |

This

series of numbers was penciled in on one image of a tech manual

I found. There may have been a series of numbers added

late in the war when more trucks were built than originally

anticipated. |

|

Tractor Body Total |

|

5,530 |

|

|

Grand

Total |

|

6,730 |

|

|

Table 11 - Four Wheel Drive Auto

Company's Lend-Lease Transfers |

|

Type |

FWD Model |

United Kingdom |

USSR |

Canada |

Total |

| Truck, 5-6-ton,

4x4, Prime Mover |

SU-COE |

2,148 |

90 |

144 |

2,382 |

| Truck, 5-6-ton,

4x4, Cargo |

SU-COE |

500 |

|

|

500 |

|

Total |

|

2,618 |

90 |

144 |

2,882 |

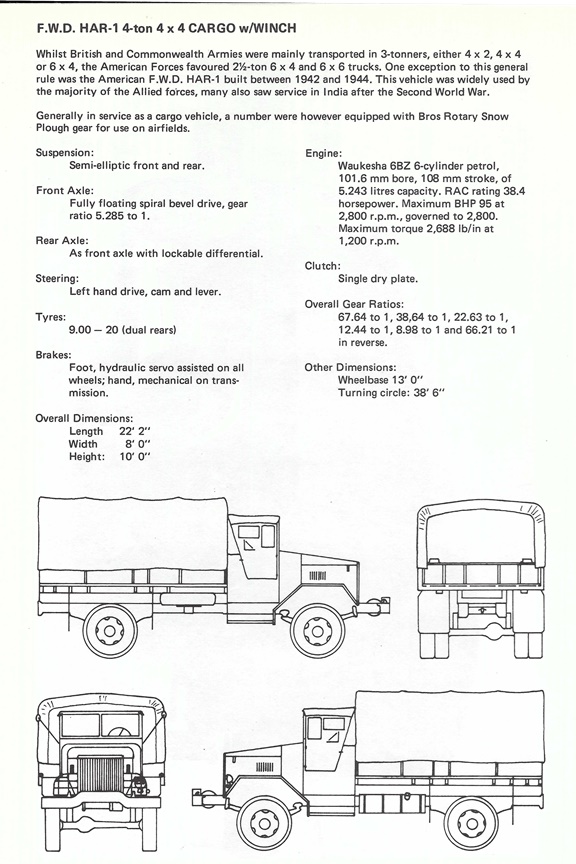

HAR-1 Trucks:

The FWD Clintonville, WI plant built 7,000 HAR-1 4-ton 4x4 trucks under

Army contract

271-ORD-2675 awarded July 1942 totaling $35,225,000. This

was FWD's largest dollar and truck contract of World War Two. The

unit price for each HAR-1 was $5,032.

This HAR-1 is traversing the back roads of

Wisconsin during a road test. Interestingly enough, while the

HAR-1 was ordered by Army Ordnance for the Lend-Lease program and

British use, it was a left-hand drive vehicle. The later SU-COE

was a right-hand drive truck.

HAR-1 Walk Around:

The Four Wheel Drive Auto Company HAR-1

shown below is owned by the Wheels of Liberation in Gettysburg, PA.

I was able to photograph it with the engine cowling and cab removed

after it came back from bead blasting. The HAR-1 was purchased in

the sand color shown in the first three photos. The Wheels of

Liberation decided to repaint the truck in the original olive-drab paint

scheme. This is the only known HAR-1 in the United States.

Between early 1943 and mid-July 1944, the

Clintonville plant produced 7,000 HAR-1s for Lend-Lease. This is

an average monthly run rate of 378.

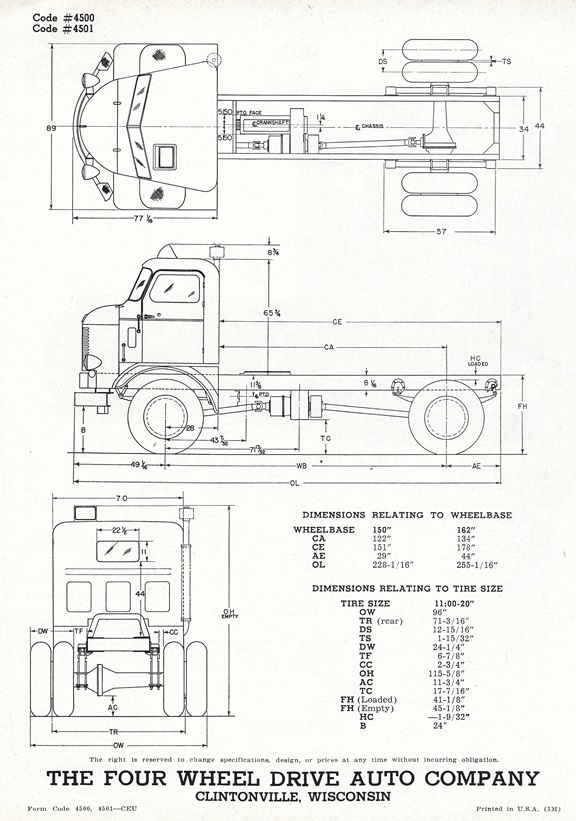

This HAR-1 specification sheet has been

added 1-13-2024 courtesy of Tim Wright.

The majority of the trucks were provided to

the United Kingdom for its use. Note the fuel tank on the vehicle.

In the photos below, it has been removed for cleaning and repainting.

Photo courtesy of Jeff Lakaszcyck.

In the photos below, the cab, hood, engine

cowling, fenders, bumper, and winch have all been removed for bead

blasting and repainting. The FWD HAR-1 has the classic lines of an

American World War Two truck. It is a very nice looking vehicle.

Photo courtesy of Jeff Lakaszcyck.

In the photos below, the interior of the

truck has also been removed. Photo courtesy of Jeff Lakaszcyck.

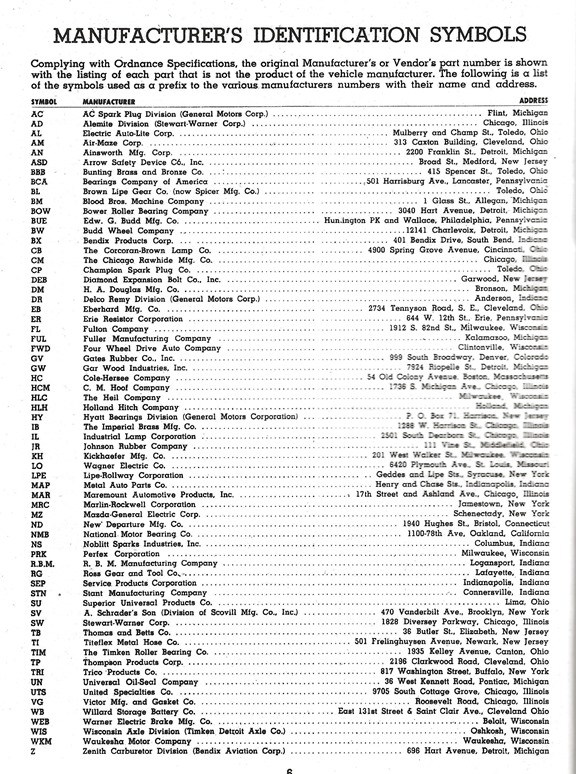

FWD made several of the components for the

FWD including the axles and frame. However, like other truck

manufacturers, it relied on outside suppliers to furnish many of the

components for the FWD. Below is the supplier listing for this

vehicle.

Many of the same companies on this list were

suppliers for the other American truck manufacturers of World War Two.

Some of the companies are still in existence today, while many have gone

by the wayside over the past 80 years. Some of the component

manufacturers will be identified in the photos below.

The walk around will begin at the

driver's side front corner. This allows us to start by viewing

first hand Otto Zachow's and William Besserdich's original patent that made

four-wheel -drive a useful technology. Author's photo.

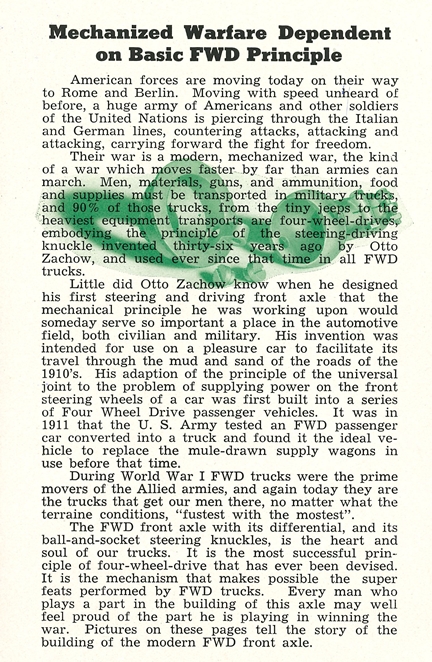

This article is from the volume 2, issue 2

of the FWD's World War Two employee newsletter. It explains the

importance of the concept for the existence of the company. What

it does not say is that after World War One, the company sold the patents

to the U.S. Army which allowed its competitors to have the same

technology. Photo courtesy of the Tim Wright Collection.

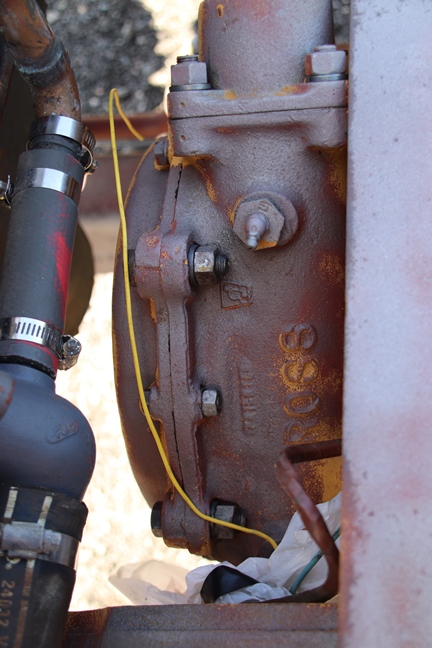

At the intersection of the driveshaft

and the front wheel is the ball and socket noted in the above article.

Author's photo.

Within the ball and socket is the double Y

joint that Otto Zachow and William Besserdich invented. The

complete text of the patent is on the

Otto Zachow and William Besserdich Patents

page. Author's photo.

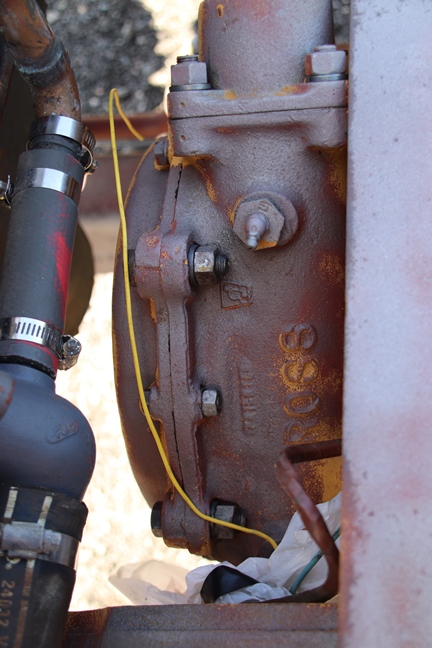

This view is a close-up photo of the

ball and socket assembly. Author's photo.

The upside down "FWD" can be seen on the

front axle. At the right of the photo is the ball-and-socket

assembly. On the left is the front differential noted in the

newsletter above. Author's photo

The chassis still had blue masking tape on

it after returning from the bead blaster. The radiator was

supplied by Perfex Corporation of Milwaukee, WI. Author's photo.

Note that even the wood body was bead

blasted to remove the sand-colored paint. Author's photo.

Budd Wheel Company of Detroit, MI, furnished

the wheels for this and most of the heavy duty trucks built during World

War Two. Author's photo.

The power plant for the 7,000 HAR-1s was the

Waukesha Motor Company's Model 6BZ 6-cylinder gasoline engine

that produced 95 HP at 2800 rpms. Waukesha Motor Company was

located in Waukesha, WI. Author's photo.

The engine came equipped with a carburetor

from the Zenith Carburetor Division of Bendix Aviation. The

generator, starter, regulator, distributor, and coil were all furnished

by Auto-Lite of Toledo, OH. Author's photo.

Fuller Manufacturing of Kalamazoo, MI was

the supplier of the 5B-33-SP five-speed transmission and the hand brake

system. This includes the brake lever, brake release spoon,

connecting rod, and the hand brake assembly. Author's photo.

The Fuller transmission is shown in this

close-up photo along with the hand brake lever pivot mechanism.

Author's photo.

The drum and brake lining are shown in this

image. The two studs are for securing the cab of the truck.

Author's photo.

Author's photo.

This FWD-made bracket was used to mount and

secure the cab to the frame. Author's photo.

Behind the hand brake is the transfer case.

The front wheel drive propeller shaft is in the lower left of the photo.

This appears to have been built by FWD. Author's photo.

This side view of the transfer case shows

both the front and rear propeller shafts. Otto Zachow and William Besserdich

had a second patent, Patent No.

907,940 for a "Power Applying Mechanism." This was for their

version of the transfer case which applied power to both the front and

rear axles. The Otto Zachow and William Besserdich transfer case

was a gear driven unit. The transfer case shown here is a chain

driven unit, indicating that FWD had moved on to a more advanced and

common technology for the transfer of power to both front and rear

axles. Also, there was no mention of the transfer case in the

newsletter article above. The complete text of the patent is on the

Otto Zachow and William Besserdich Patents

page. Author's photo.

Author's photo.

The front differential on this truck has its

roots in the origin of the company and the original 1908 Patent No.

882,986 by Otto Zachow and William Besserdich. Author's photo.

The information on the universal joint says it was made by the Blood

Brothers Machine Company of Allegan, MI, which is a company name I had

not seen before. At the turn of the 20th Century, the Blood

Brothers began making bicycles in Kalamazoo, MI. In 1914, the

brothers purchased a factory in Allegan, MI, and began making race cars

with their own unique chain drive. The Cornelian race car

was driven by Louis Chevrolet in the 1915 Indianapolis 500. Mr.

Chevrolet had to drop out due to engine valve failure but did place 20th

in the event. Further investigation indicates the Blood Brothers

supplied universal joints for about half of the different truck models

used in World War Two. But I digress. All of the universal

joints on the HAR-1 were provided by the Blood Brothers. Author's

photo.

The wood portions of the bed appear to have

been made by FWD as there is no other supplier given. However, all

of the steel parts on the bed were supplied by the Edward G. Budd

Manufacturing Company of Philadelphia, PA. Author's photo.

There is a steel step on the tailgate to

assist soldiers in getting into the bed of the vehicle. Author's

photo.

The Holland Hitch Company of Holland, MI

provided the pintle hook. The bumperettes and the mud flaps appear

to have been manufactured by FWD. Author's photo.

The rear axle was built by FWD.

Author's photo.

Author's photo.

The rear axle, differential, and springs

were all manufactured by FWD. The rear and front brakes were

supplied by the Wagner Electric Company of St. Louis, MO. The

drums and hubs were provided by the Kickhaefer Manufacturing Company of

Milwaukee, WI. Author's photo.

This image shows some of the construction of

the bottom of the body and how it was mounted to the frame. The

Maremount Automotive Products Company of Chicago, IL supplied the

muffler for the FWD HAR-1. The two brackets are used for mounting the fuel

tank. Author's photo.

The 40 gallon fuel tank was out of the truck

for cleaning and painting. The cap was supplied by Stant

Manufacturing of Connersville, IN. Author's photo.

This brings us around to the front of the

vehicle. The front axle, differential, and driveshaft were all

produced by FWD. The steering wheel, tube, and steering gear

components came from Ross Gear in Lafayette, IN. Author's photo.

The manufacturer of the shock absorber that

is mounted to the frame and the middle of the front spring assembly is a

mystery. It has a manufacturer's code of HH in the parts manual.

As can be seen in the list of manufacturers at the top of this

section, there is no HH code. The steering drag links and tie rods

were furnished by the Thompson Products Corporation of Cleveland,

OH. Author's photo.

The steering assembly was manufactured by

Ross Gear. It includes the steering wheel, tube, and the steering

gear. Author's photo.

The name "Ross" can be seen on the

steering gear. Author's photo.

This photo was taken in mid-July 1944. Production stopped at

7,000, which fulfilled U.S. Army Ordnance contract number 171-2675.

These units are sitting outside of the Clintonville, WI plant waiting on

missing parts before being shipped. One of the obvious absences is

the body. It is unknown whether these were installed at

Clintonville or by a sub-contractor at another location. Photo

courtesy of the Tim Wright Collection.

With the completion of the

HAR-1 contract, FWD could focus on the production of 960 SU-COE cargo

trucks and 2,700 SU-COE prime movers for Lend-Lease.

Other Surviving FWD HAR-1

Trucks:

The FWD HAR-1 shown above is the proud

possession of Mr. Hein Klop of the Netherlands. Mr. Klop has been

able to fully restore the truck to its original configuration.

Image courtesy of Mr. Klop added 1-13-2024.

Image courtesy of Mr. Klop added 1-13-2024.

Image courtesy of Mr. Klop added 1-13-2024.

Mr. Klop also has this HAR-1 in his

collection. Mr. Klop is currently searching for the missing parts

of this vehicle to also make it a complete restoration. Image

courtesy of Mr. Klop added 1-13-2024.

U.S. Navy Trucks:

These six trucks are destined for the U.S.

Navy. The information with the photo indicates these were for the

U.S. Navy Seabee Construction Battalions of World War Two. If so,

the manufacture of these would have been after March 5, 1942, when the

Seabees were created. The trucks appear to be FWD commercial

trucks furnished to the Navy. Table 1 indicates that there were no

major contracts for these trucks. However, if the order was only

for the six units shown here, the value of the contract would have been

less than $50,000 and therefore not recorded in Table 1. Photo courtesy of

the Tim Wright Collection.

This appears to have been

a one-time order. During World War Two, the U.S. Navy Seabees used

GMC CCKW cargo dump trucks in its construction of facilities.

SU-COE Trucks:

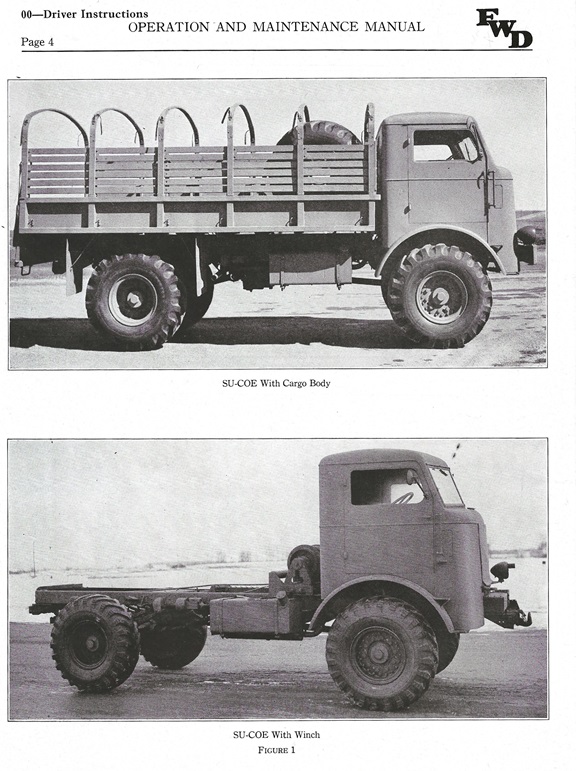

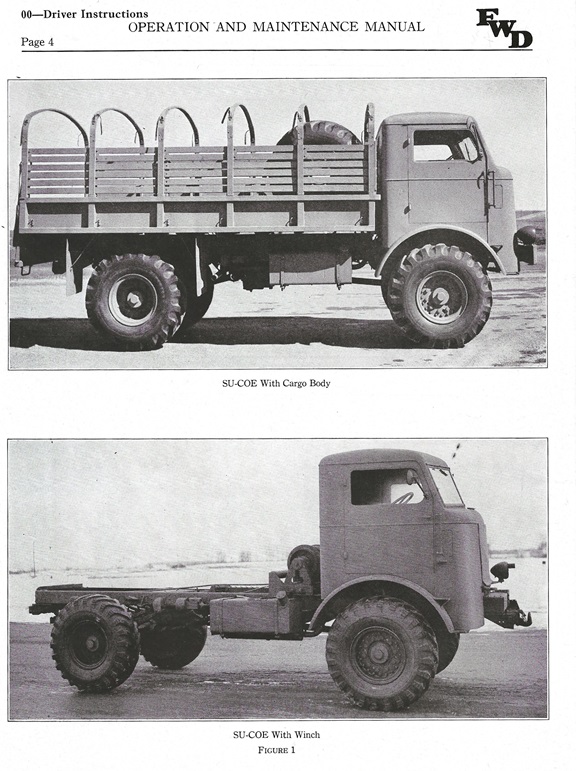

The SU-COE was produced in two basic different versions during World War

Two. The first version of 250 went to the USMC and were built in

both Clintonville and Stevens Point, WI. After these were

completed at Stevens Point and production HAR-1 production ended in

Clintonville, the company began producing a right-hand drive version

under U.S. Army contracts for British Lend-Lease. In 1944 and 1945,

the company produced 1,460 SU-COE cargo versions and 2,700 prime movers.

The SU-COE also had a

number of limited production and experimental designs. It was the

truck chassis that FWD used to promote other military uses during World

War Two.

This extended cab truck is described as

being an FWD line unit with earth borer for the U.S. Engineers.

This appears to be a prototype of what might have been a very small

production run for the Army engineers early in the war. The engine

has been moved forward from that of an SU-COE, which seems to be more of a

cab forward design than a COE. Photo courtesy of the Tim Wright

Collection.

This photo is described as a snow removal

unit, which has been mounted to an SU-COE chassis. Photo courtesy

of the Tim Wright Collection.

This image shows an Army engineer SU-COE

being tested in the FWD proving ground mud hole. Photo courtesy of

the Tim Wright Collection.

How cool is this? There are at least

73 FWD-built SU-COE cargo trucks awaiting shipment. All still need

to have the cargo body installed. There are five trucks with

identifiable USA registration numbers. They are 533681, 533689,

533690, 533691, and 533695. The vehicles are destined for the

United Kingdom as they are right-hand drive. Photo courtesy

of the Tim Wright Collection.

This photo is of a USMC SU-COE undergoing a

test demonstration drive. Photo courtesy of the Tim Wright

Collection.

This appears to be a slushy spring day at

the Clintonville plant during shift change. Of interest is that

the company had at least six SU-COE

cabs outside along the driveway. Photo courtesy of the Tim Wright

Collection.

This and the next photo may or may not be the

same SU-COE, as they were taken at different times of the year.

Both appear to be the right hand drive Lend-Lease version. This

one is described as a cargo transport tractor. Photo courtesy of the Tim

Wright Collection.

This one is described as a medium artillery

tractor. Both of these trucks are different than the ones shown

sitting in the yard at Clintonville, as these two have a winch. The

others don't. Photo courtesy of the Tim Wright Collection.

This Wisconsin winter photo shows what was

described as a bomb recovery unit. There was a reference or two in

1942 FWD company newsletters that FWD bomb removal trucks were in use in

England. Note that this is a right-hand drive truck with the

headlights covered over and no blackout light. As the photo below

shows, Lend-Lease SU-COEs did not have headlights and only one blackout

light. Photo courtesy of the Tim Wright Collection.

The vehicle above may have

been a prototype of a very limited production run. I have not been

able to find a corresponding contract for bomb removal trucks. If

there was a limited number of these built for the British and the

contract was less than $50,000, it would not have shown up in the Major

Contract listing.

Photo courtesy of the Tim Wright Collection.

This photo of the SU-COE shows the truck had

two fuel tanks and the front wheel drive propeller shaft and differential are on

the opposite side of the driver. Photo courtesy of the Tim Wright

Collection.

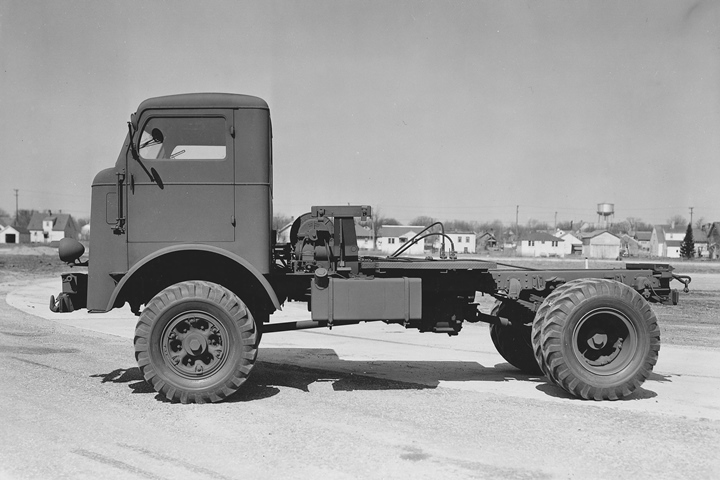

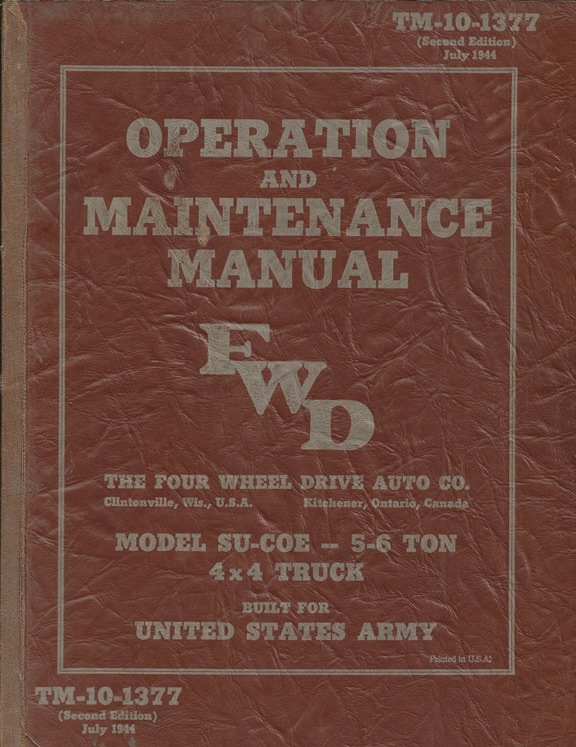

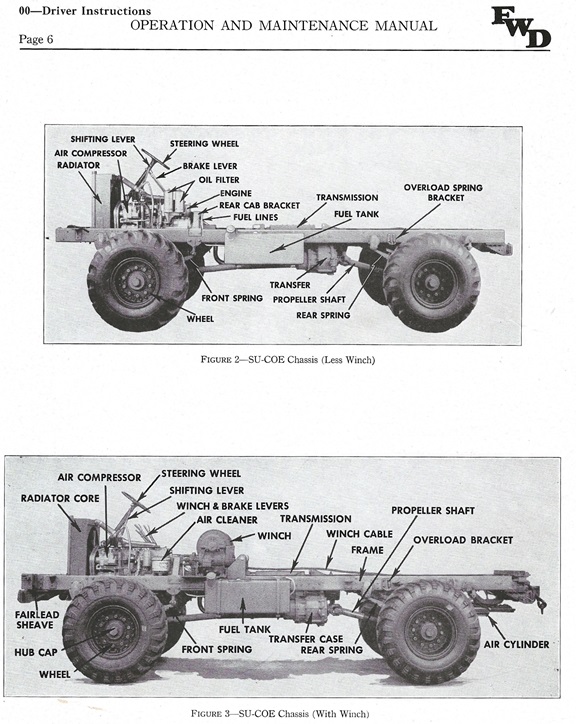

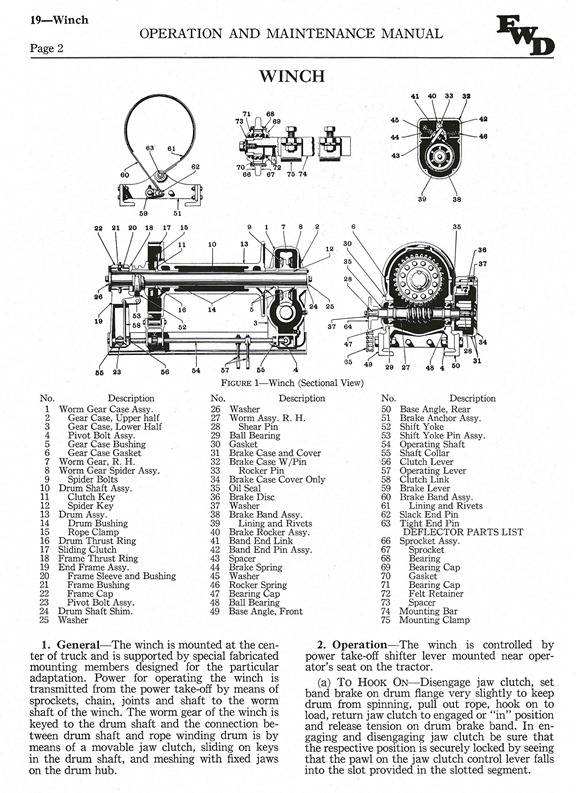

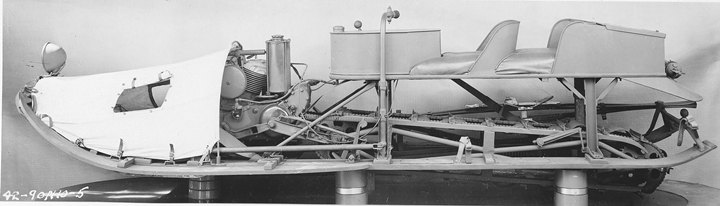

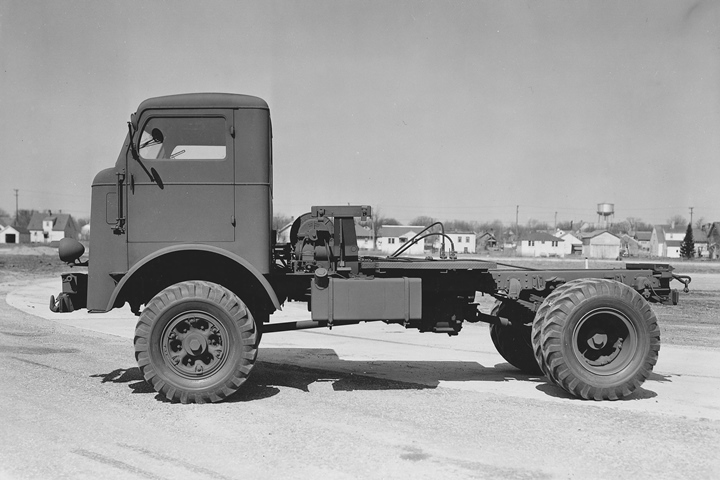

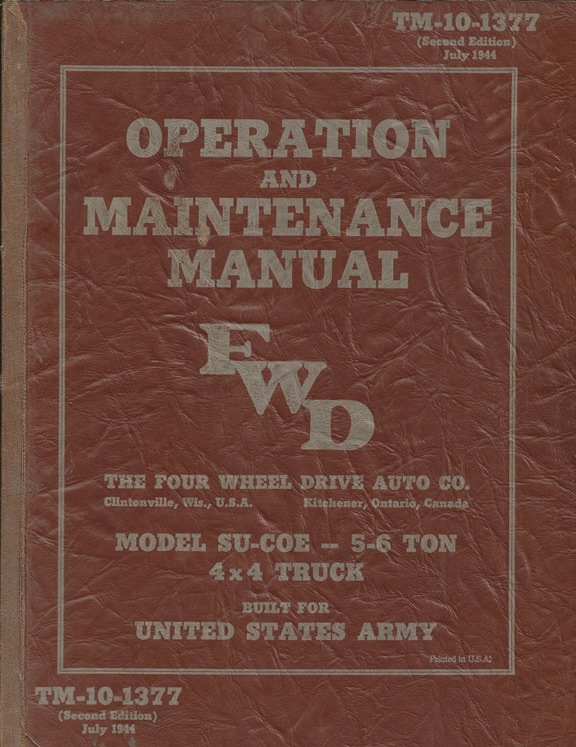

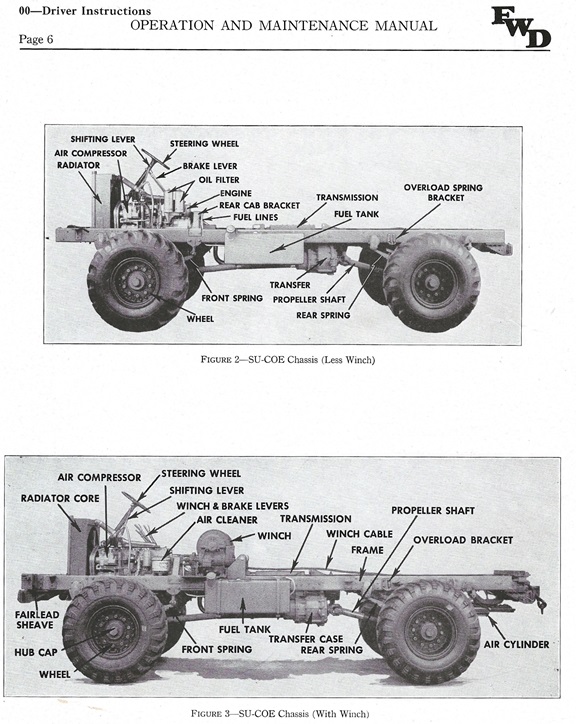

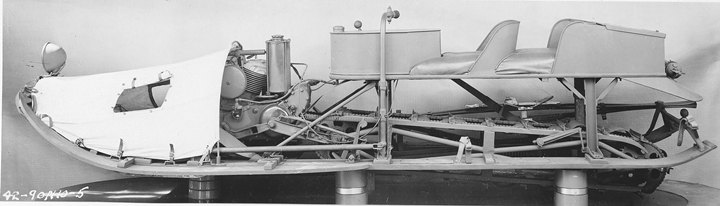

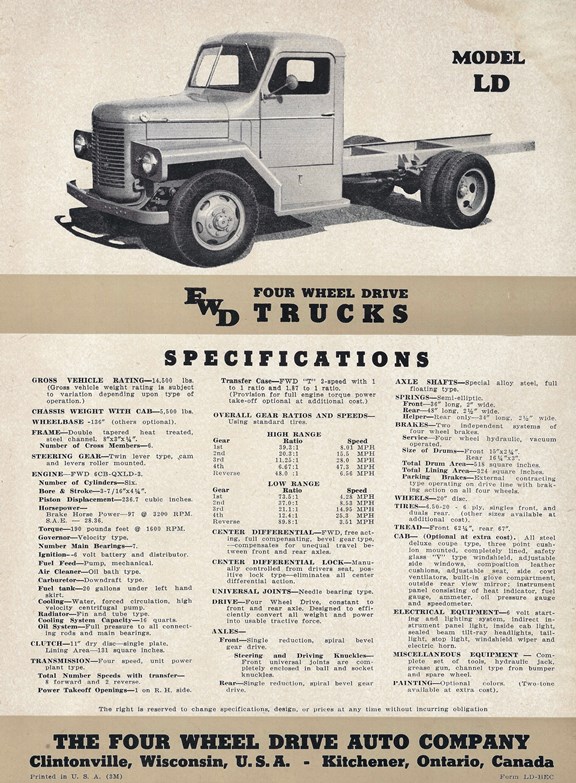

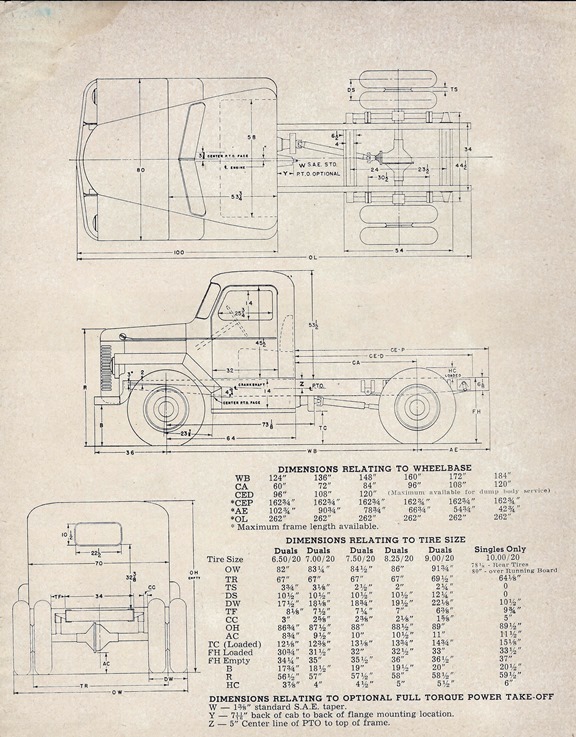

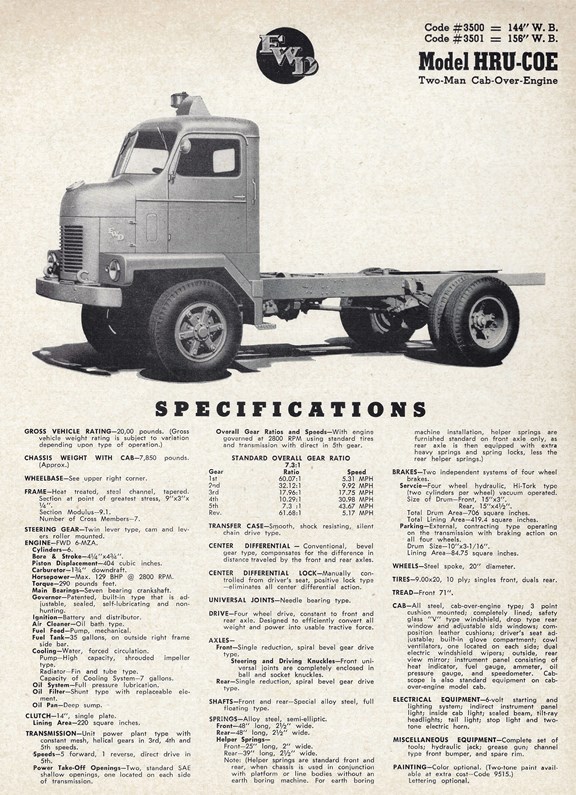

Anatomy of the FWD SU-COE: For

the FWD HAR-1, I was able to do walk around of a vehicle under

restoration. For the SU-COE, there are currently no vehicles

available to do this with. This is a very rare vehicle in the

United States. Therefore, I will use the SU-COE Operation and

Maintenance Manual, TM-10-1377 to provide information about this

vehicle.

There is a considerable amount of

information in this manual that cannot be found anywhere else. The

FWD SU-COE is one the most obscure, if not THE most obscure World War

Two truck built by an American truck company. The section below

will hopefully shed more light on this rare vehicle. Image added

1-13-2024.

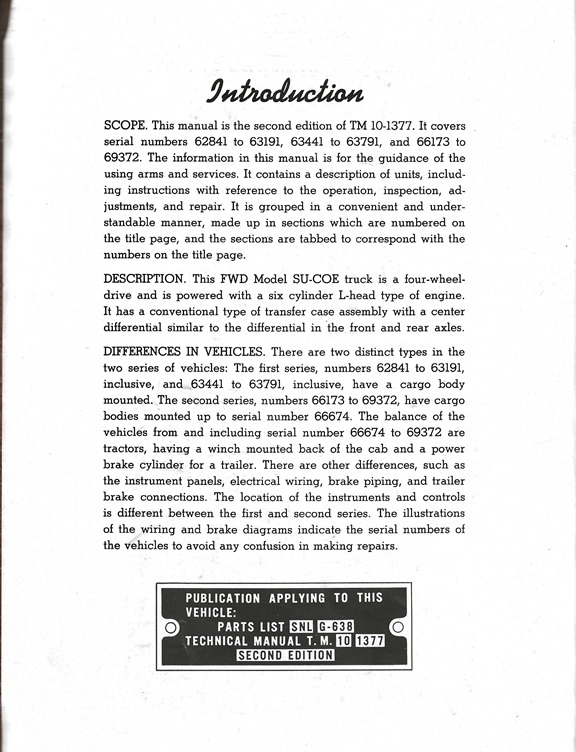

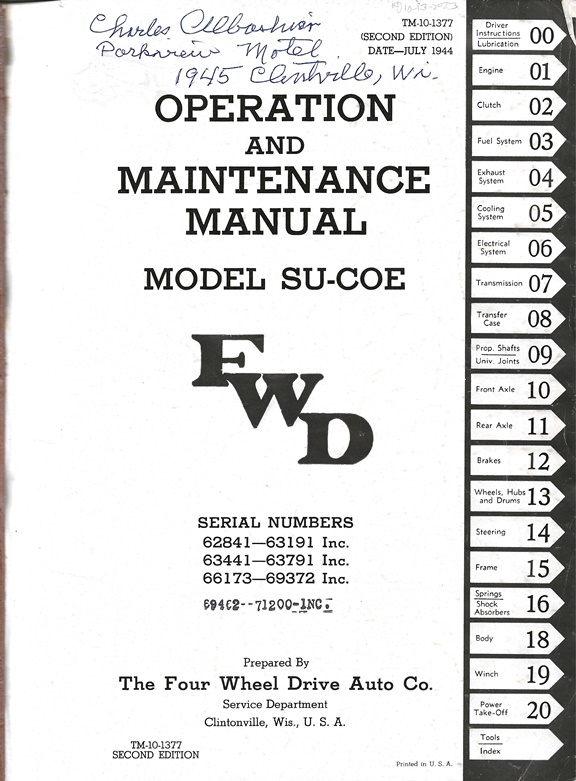

This second addition of this manual has a

rubber stamped "69462--71200-INC." on this page. Normally, these

numbers are found penciled in on other manuals Ihave seen. This

gives me further confidence that this series of trucks was actually

produced. Image added 1-13-2024.

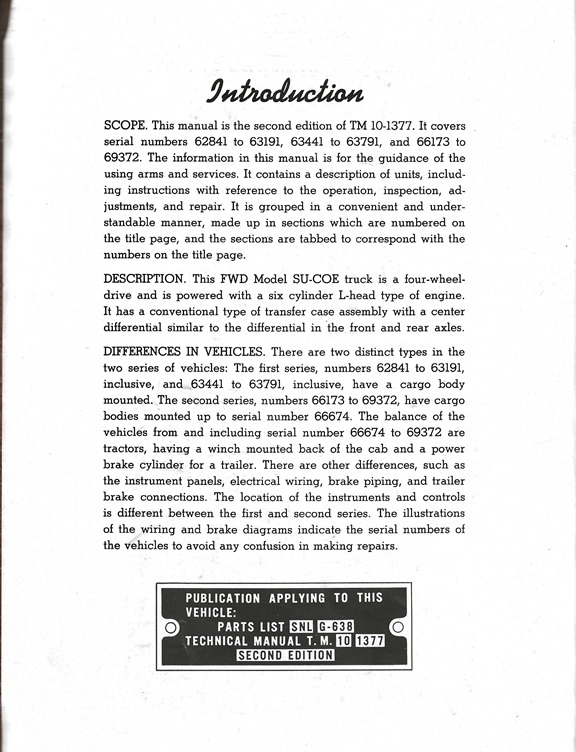

Image added 1-13-2024.

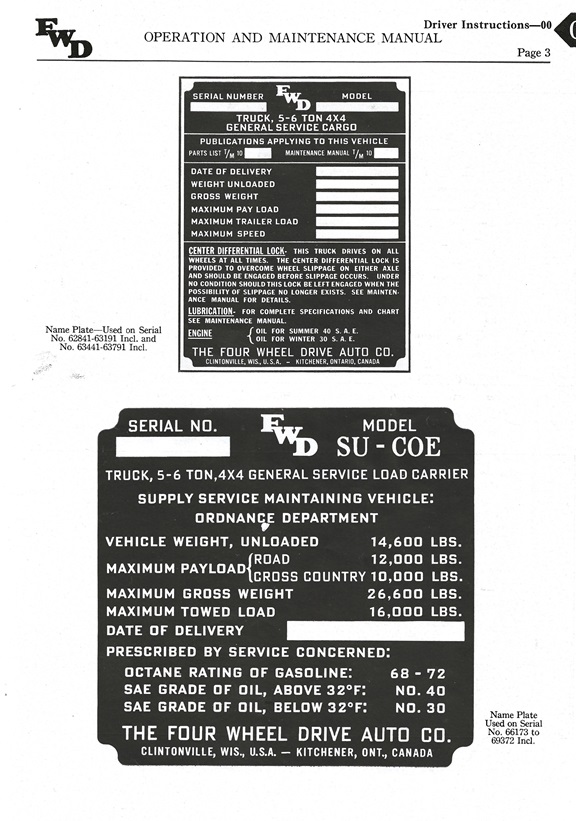

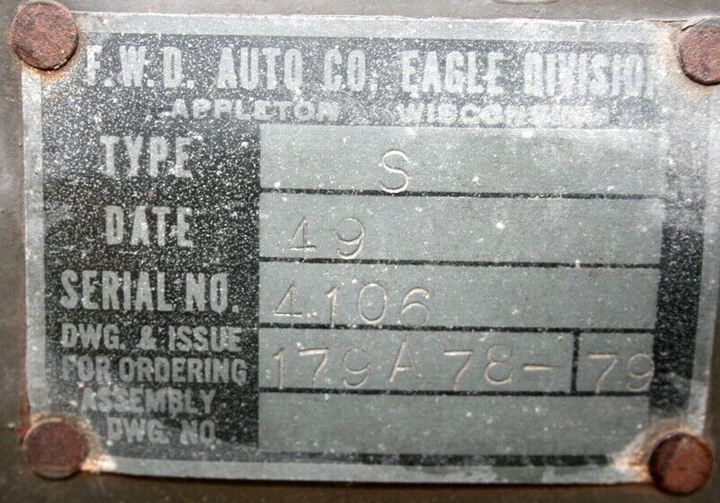

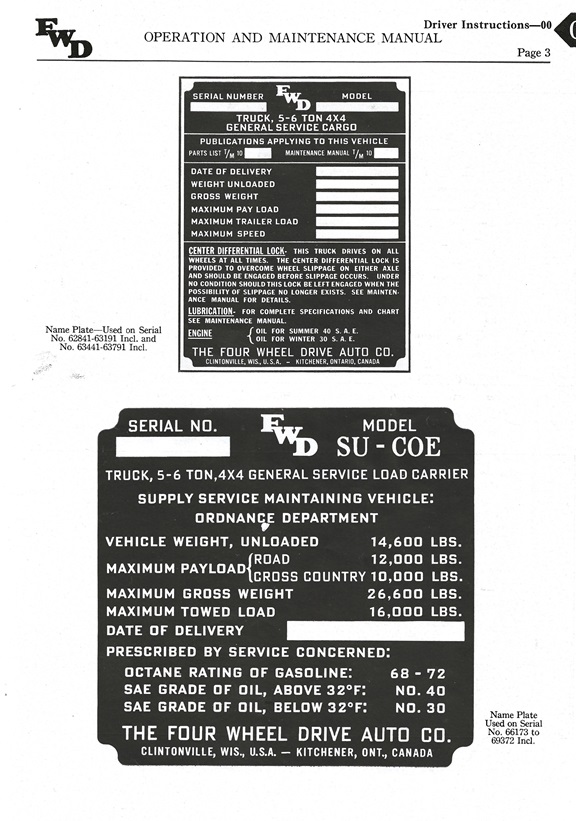

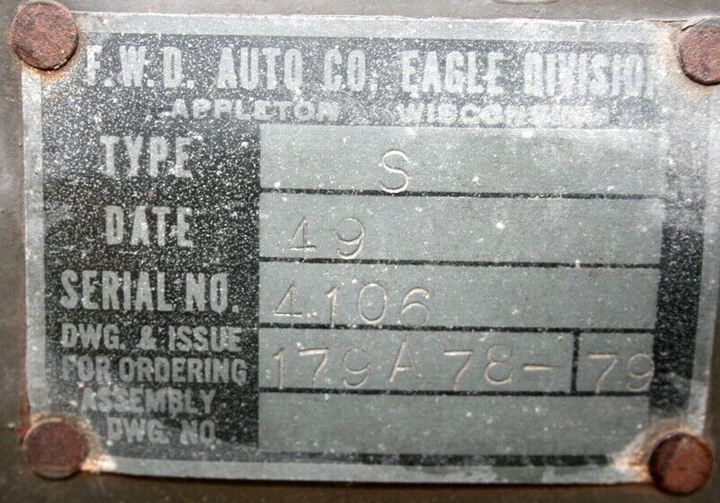

There were two different data plates for the

SU-COE series, depending on the serial numbers. Image added

1-13-2024.

Image added 1-13-2024.

Image added 1-13-2024.

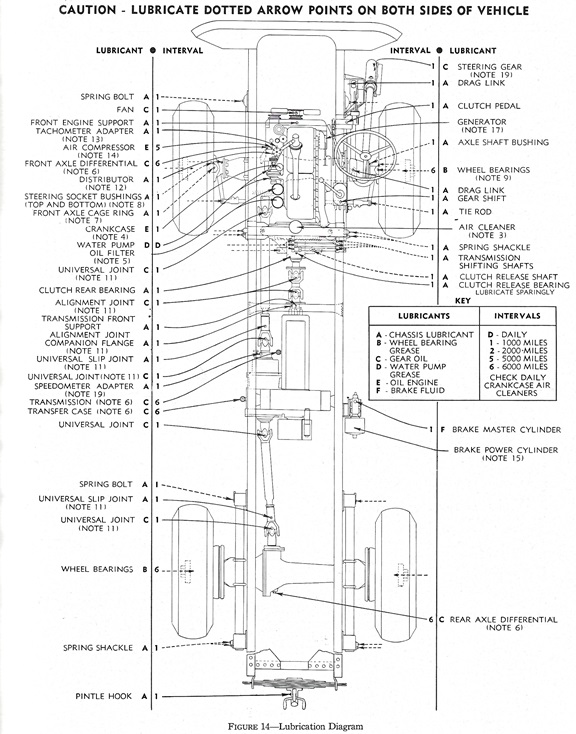

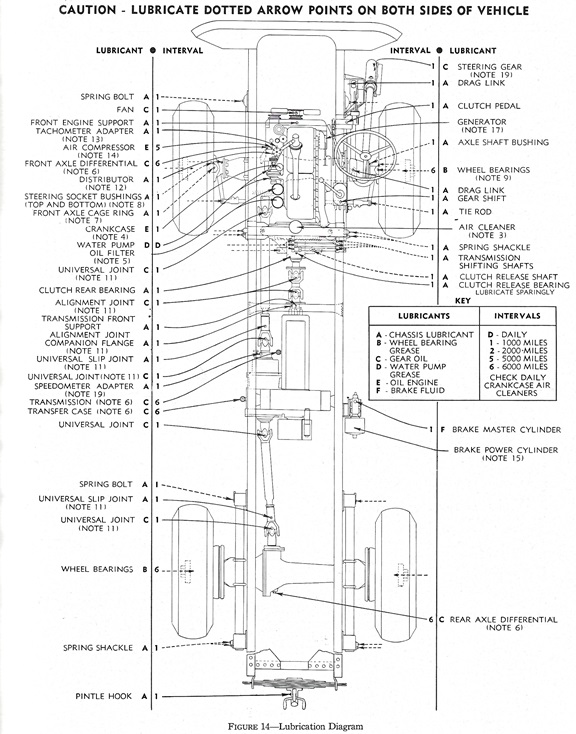

Lubrication diagrams are a good way to show

the drive train components on a vehicle. They also show how far

the technology has come in the past 80 years. Currently,

most, if not all components like those shown here are self-lubricating.

Image added 1-13-2024.

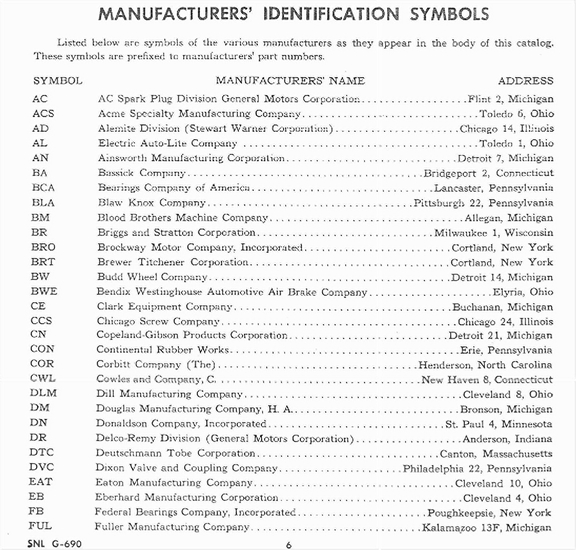

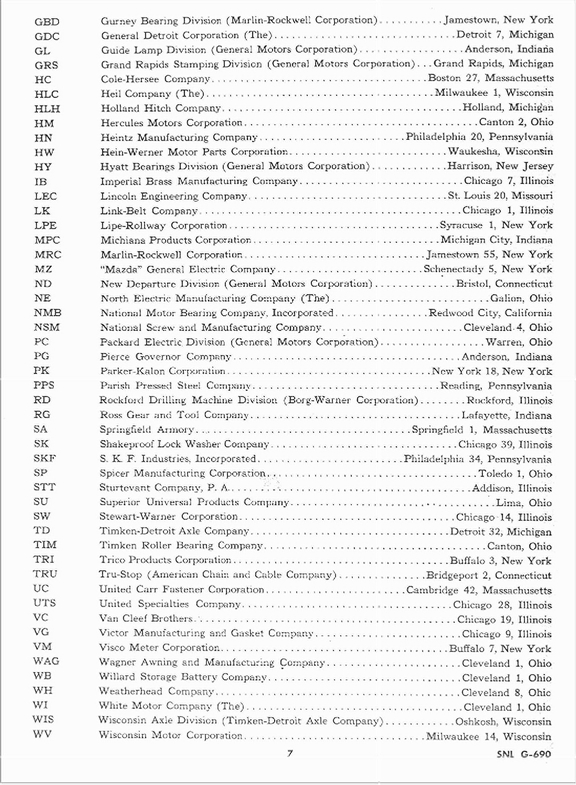

Table 13 below shows all of the different

manufacturers that contributed to the manufacture of the SU-COE during

World War Two.

|

Table 13 -

FWD SU-COE Components - Table added 1-13-2024. |

|

Component |

Manufacturer |

Model |

Other Information |

|

Engine |

Waukesha |

SPKR |

Six

cylinder, 126 h.p. |

|

Clutch |

Brown-Lipe |

Single Plate |

14 inch |

|

Carburetor |

Zenith |

4257-2" |

|

|

Fuel Pump |

AC |

Mechanical |

|

|

Fuel Filter |

AC |

|

|

|

Fuel Tanks |

FWD |

|

Two 40 gallon tanks |

|

Muffler |

Maysteel |

|

39 inch length, 6 inch diameter |

|

Radiator |

Pertex |

|

Tubular |

|

Electrical |

|

|

|

|

Generator |

Auto-Lite |

GEH-5002-2 |

12 volt, 27 amps, positive ground |

|

Regulator |

Auto-Lite |

VRG-4102B |

Positive ground |

|

Starting Motor |

Auto-Lite |

MAS-409 |

|

|

Distributor |

Delco-Remy |

640-C or 1110180 |

It is interesting that FWD used two different companies for

the electrical components, spliting them between Auto-Lite

and Delco-Remy. Normally, the generator, starter, and

ignition system is all supplied by one company. While

not noted in the manual, it is assumed the ignition coil was

furnished by Delco-Remy. |

|

Spark Plugs |

Champion |

Commercial 1 and J9 |

7/8 inch and 14mm |

|

Battery |

Willard |

Standard Duty |

153 amp-hour |

|

Horn |

Delco-Remy |

Twin Electric |

|

|

Head Lamps |

Corcoran-Brown |

|

|

|

Radio Interference Suppression |

TobeDeutschmann Corp. |

|

|

| |

|

|

|

|

Transmission |

FWD |

U |

Direct in 5th |

|

Transfer Case |

FWD |

"S" |

Chain drive |

|

Universal Joint - Front- Rear |

Blood Brothers |

6N |

Four joints |

|

Universal Joint - Alignment |

Blood Brothers |

5N |

Two joints |

|

Propeller Shafts - Front and Rear |

FWD |

|

3-1/4 inch diameter tube |

|

Front Axle |

FWD |

Two Piece |

Full floating, bevel drive |

|

Rear Axle |

FWD |

Two Piece |

Full floating, bevel drive |

|

Brake |

Lockheed Hydrulic |

|

Internal Expanding |

|

Trailer Power Cylinder |

Hanna |

|

|

|

Air Power Cylinder |

Wagner Electric Company |

A-357 an A-840 |

|

|

Air Compressor |

Wagner Electric Company |

D-Rotary |

Clockwise, Belt drive |

|

Electric Hand Control |

Wagner Electric Company |

|

|

|

Hydraulic Relay Valve |

Bendix |

|

|

|

Conversion Valve |

Bendix |

|

|

|

Parking Brake |

FWD |

|

|

|

Wheels |

Kelsey-Hayes |

Divided Disc |

20 x 10.00 |

|

Steering Gear |

Ross |

T-74 |

Twin-Lever Roller |

|

Frame |

Assumed to be FWD |

|

|

|

Springs-Front |

Assumed to be FWD |

14 Leaves |

|

|

Springs-Rear |

Assumed to be FWD |

16 Leaves |

|

|

Springs-Rear Auxiliary |

Assumed to be FWD |

7

Leaves |

|

|

Cab |

FWD |

COE |

66 inches long by 84 inches wide |

| |

|

|

|

|

Cab Components |

For SN 62841-63191, inclusive

and 63441-63791, Inclusive |

|

Instrument Panel |

Stewart Warner |

|

Ammeter, Oil Gauge, Speedometer, Heat Indicator, Fuel Gauge |

|

Lighting Switch |

Douglas |

|

|

|

Ignition Switch |

Douglas |

|

|

|

K.D. Switch |

K.D. Lamp Company |

|

|

|

Tilt-Ray Switch |

Douglas |

|

|

|

S.P.DT Switch |

Douglas |

|

|

|

Starter Switch |

Delco-Remy |

|

|

|

Trouble Lamp Socket |

Cole-Hersee Company |

|

|

|

Vacuum Gauge |

Bendix |

|

|

|

Air Pressure Gauge |

Bendix |

|

|

|

Hand Throttle |

Shakespeare Products |

|

|

|

Choke Assembly |

FWD |

|

|

|

Windshield Wiper |

Trico |

|

|

| |

|

|

|

|

Cab Components |

For SN 66674-69372, Inclusive

and

69462-72300, Inclusive |

|

Instrument Panel |

Stewart Warner |

|

Ammeter, Oil Gauge, Speedometer, Temperature Gauge, Fuel

Gauge |

|

Twin Horns |

Delco-Remy |

|

There is no listing for horns for the other set of serial

numbers. This may have been an oversight. |

|

Windshield Wiper |

Trico |

|

|

|

B.O. Head Lamps |

Corcoran-Brown |

|

|

|

Lighting Switch |

Douglas |

|

|

|

Ignition Switch |

Douglas-United Specialties |

|

|

|

K.D. Switch |

K.D. Lamp Company |

|

|

|

Tilt-Ray Switch |

Douglas-Delco Remy |

|

|

|

S.P.DT Switch |

Douglas-Sampson United Company |

|

|

|

Starter Switch |

Delco-Remy |

|

|

|

Trouble Lamp Socket |

Cole-Hersee Company |

|

|

| |

|

|

|

|

Body |

Galion and Stoughton |

Cargo |

Inside Length=186", Inside Width=88", Inside Height=59",

Sides=14" |

|

Winch |

Gar Wood |

4MB |

Back of Cab |

|

Power Take-Off |

Gar Wood |

74Y |

|

Engines and transmissions in World

War Two trucks are what are normally documented in publications on

the vehicles. However, underneath the trucks and sometimes

hiding in plain sight are other components of the vehicle that are

just as important as the engines and transmissions. But no one

really pays any attention to them. I have decided to feature

several of those below.

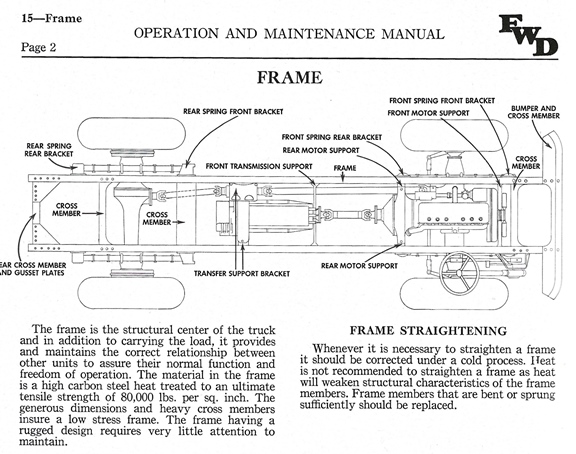

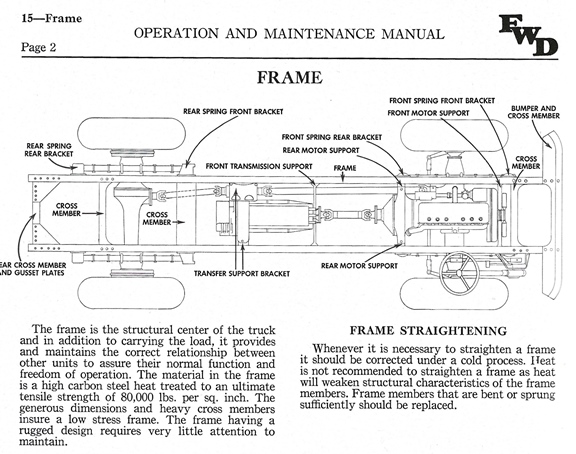

Every good truck starts with a solid frame.

However, it is hidden underneath the vehicle, and like the late Rodney

Dangerfield used to say, "Gets No Respect!" Without a well

designed and built frame, the truck will not be able to carry the load

that is required of it. It is the backbone of the truck.

This page not only denotes the type and strength of the steel used in

the frame, but also how it can be straightened, if necessary.

Image added 1-13-2024.

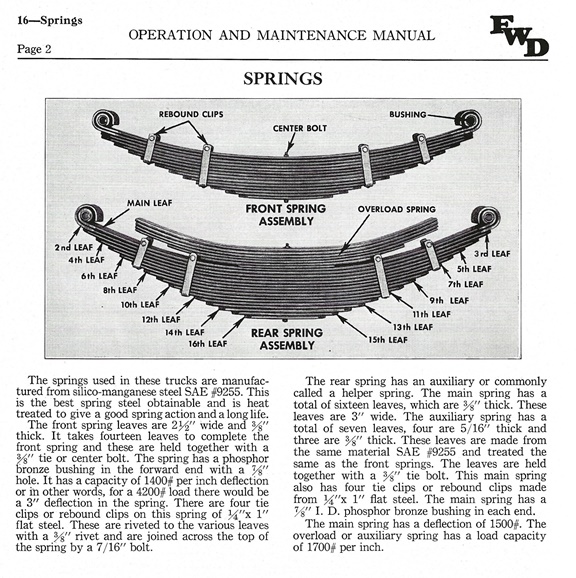

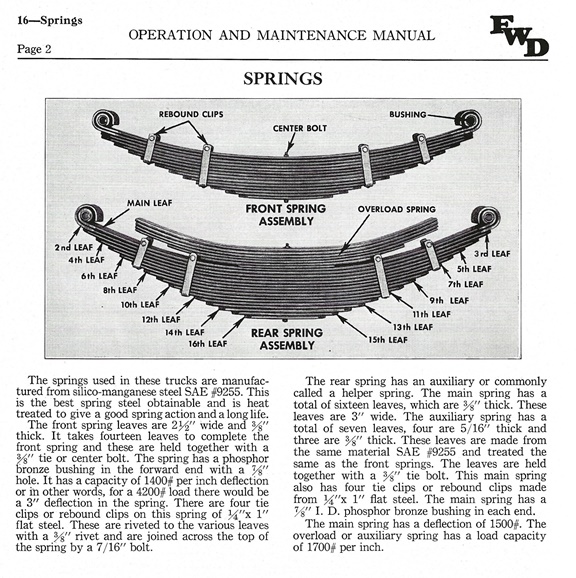

Springs are another hidden component

underneath the vehicle. Both the frame and the springs were

considered by the Four Wheel Drive Company to be important enough for

the company to manufacture them in-house. Image added 1-13-2024.

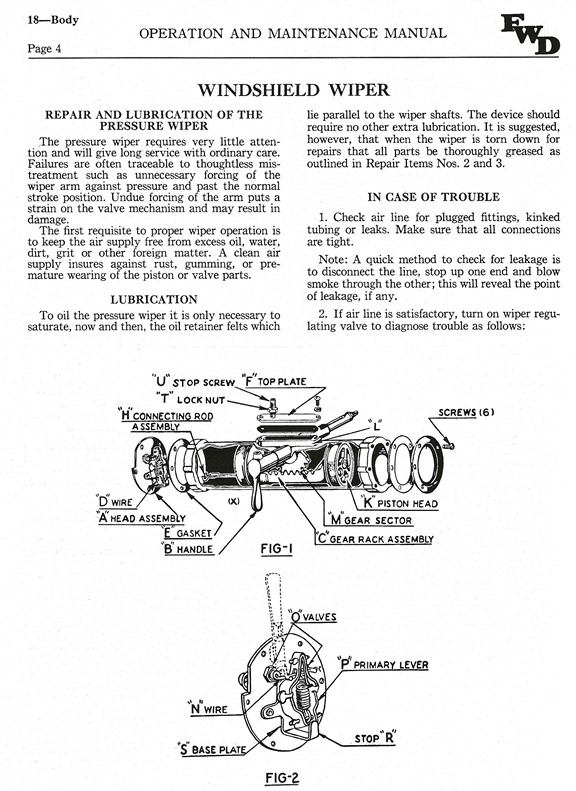

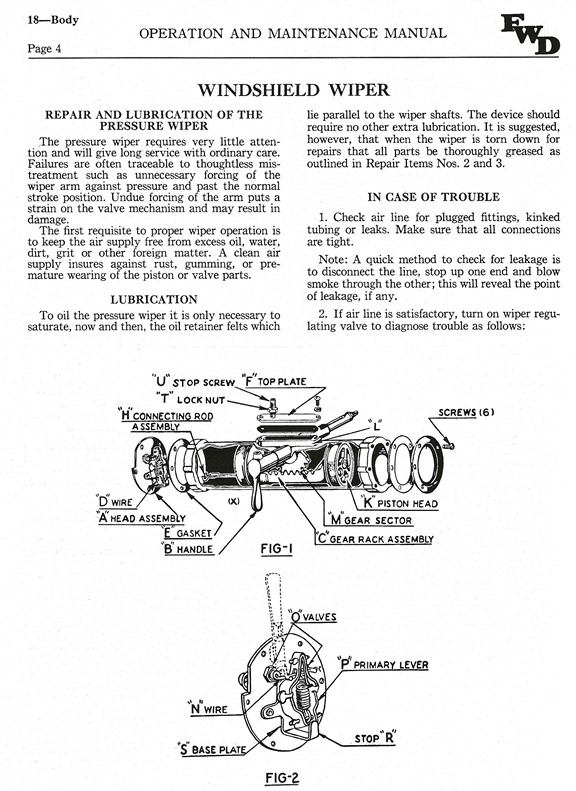

Hiding in plain sight is the windshield

wiper and motor assembly which is driven by air pressure or vacuum off

the engine and was mounted at the top of the windshield. Have you

ever been driving at night in a driving rainstorm and had your

windshield wiper motor go out? I have. It is not a pleasant

experience, to say the least. Military trucks have to run through

all sorts of inclement weather such as rain and snow at all times of the

day and night. A military truck's windshield wipers and motors

must be reliable for safe driving. FWD did not make its own

windshield wipers. Like all of the other World War Two truck

manufacturers, FWD purchased this important safety item from the Trico

Products Corporation of Buffalo, NY. Image added 1-13-2024.

This photo shows that the SU-COE had two

wipers, with the wipers mounted to the inside of the windshield frame.

The driveshaft goes through the frame and actuates the wiper blade on

the outside of the windshield. Image added 1-13-2024.

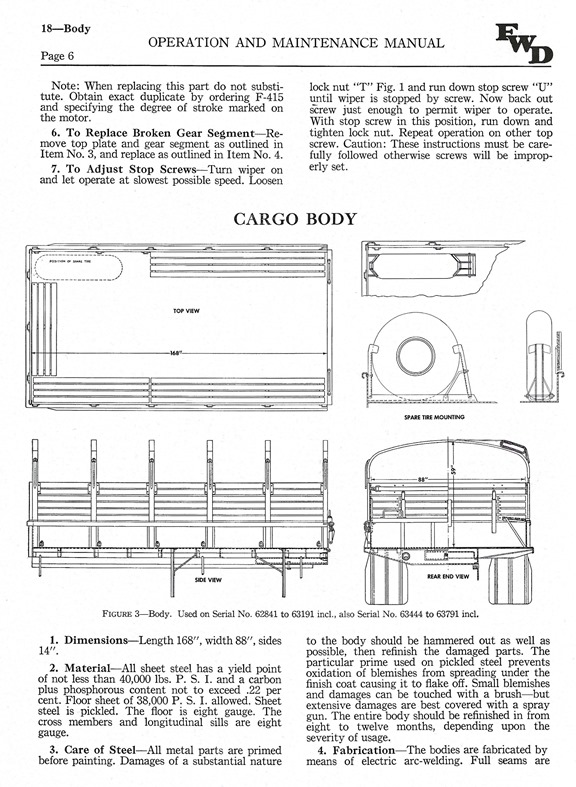

The cargo body also hides in plain sight and

is the reason the truck is built so that it can carry a useful load.

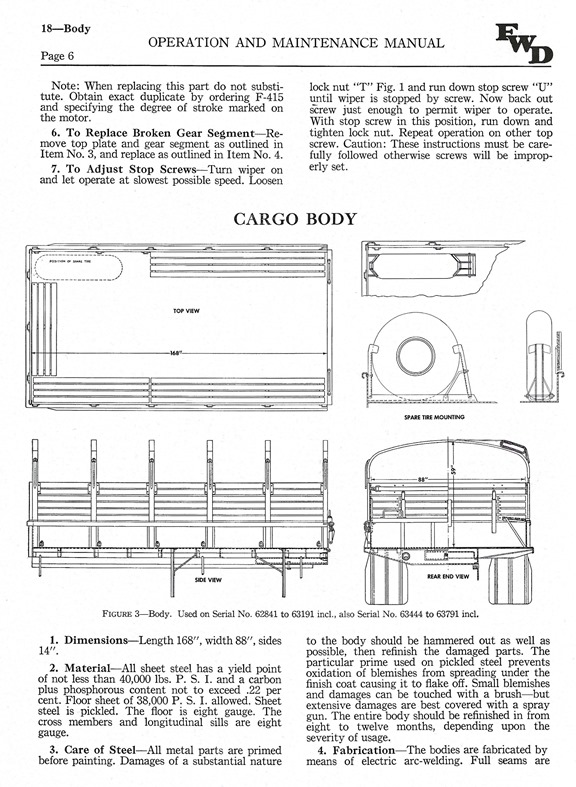

There are two different sets of drawings for the cargo body. This

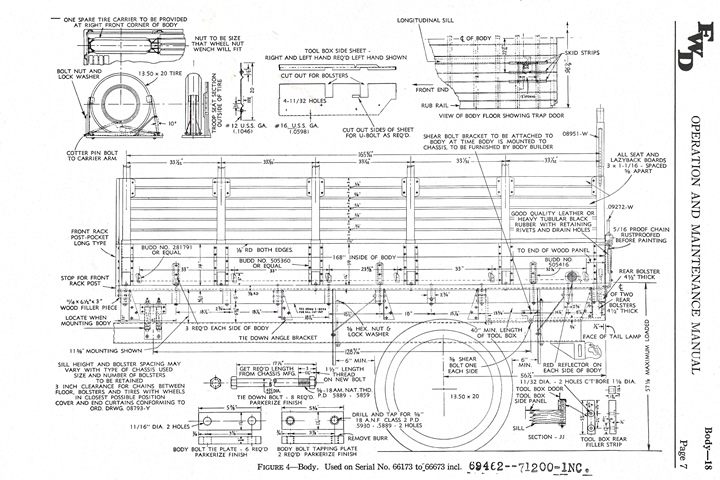

one is for serial numbers 62841-63191 inclusive and 63441-6379 inclusive.

Image added 1-13-2024.

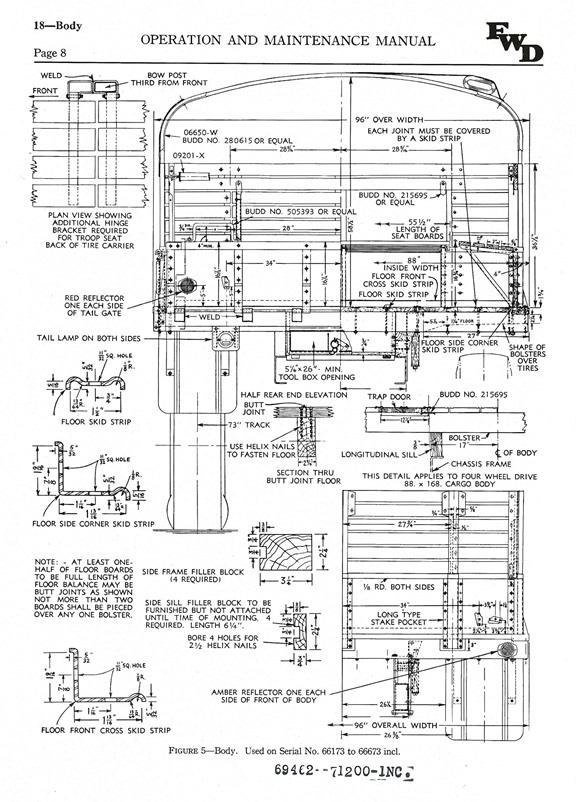

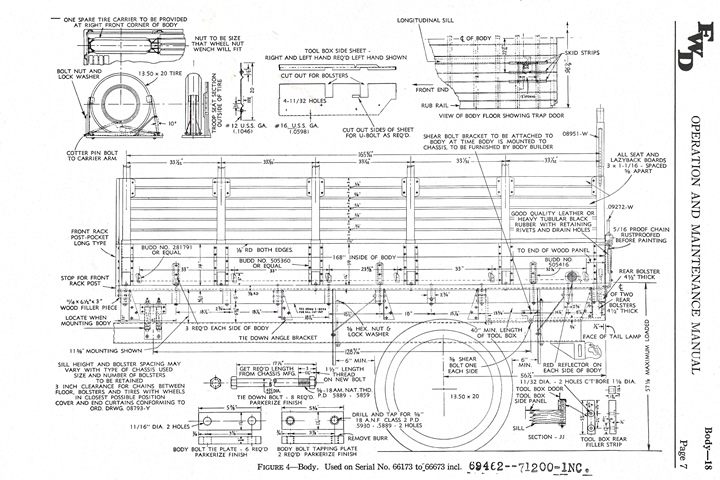

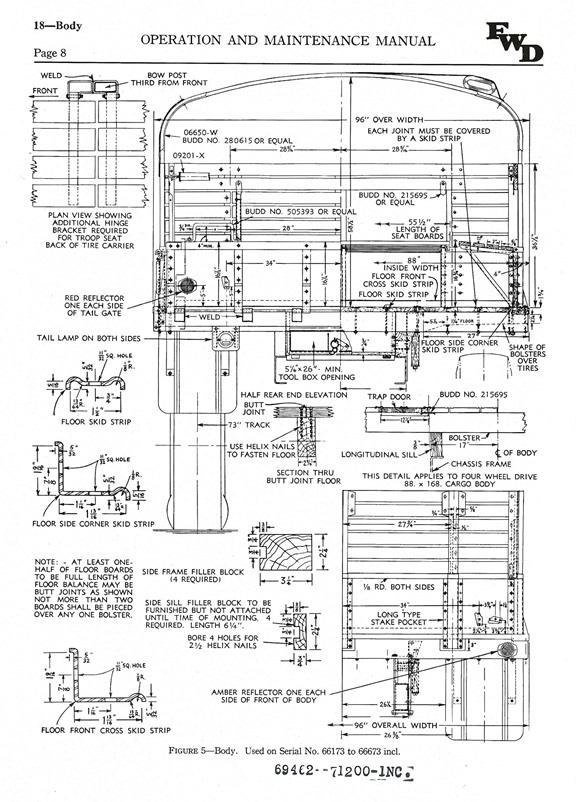

This one has two pages and is considerably

more detailed. It is for serial numbers 66674-69372 inclusive and

69462-72300 inclusive. Image added 1-13-2024.

Image added 1-13-2024.

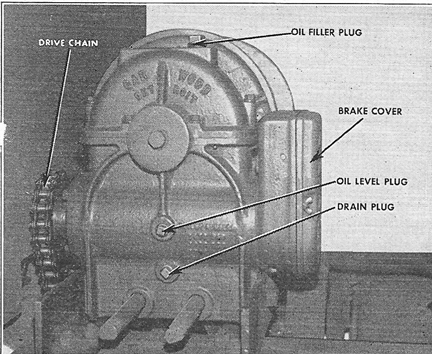

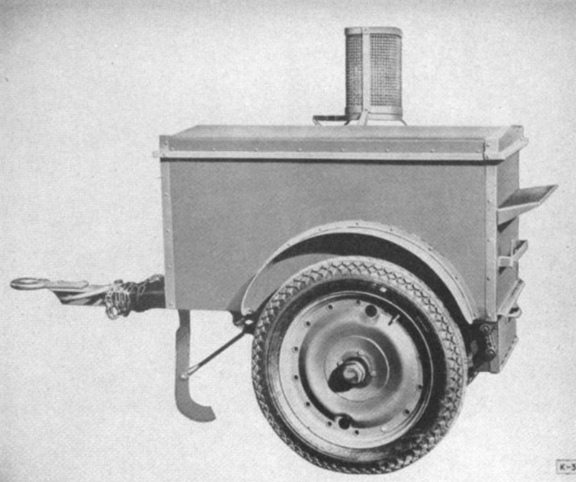

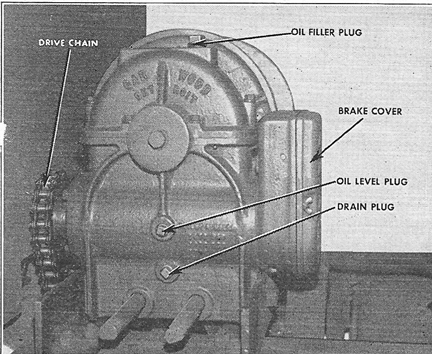

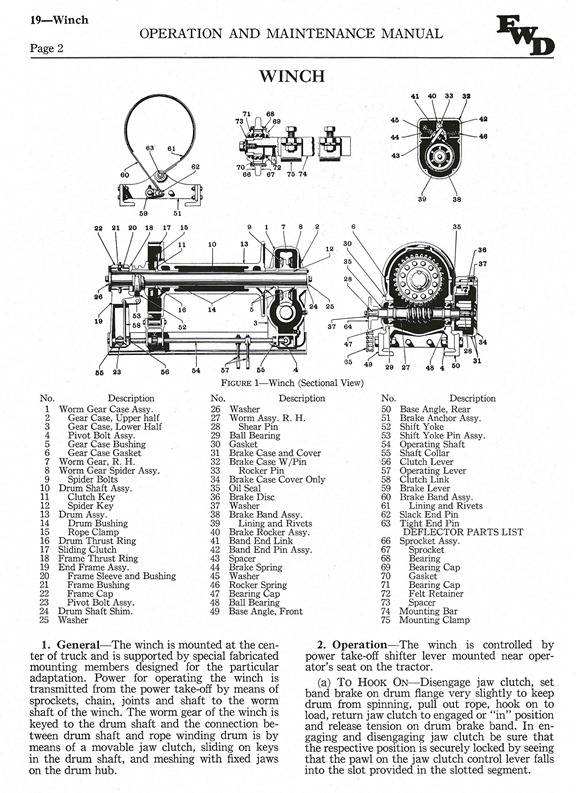

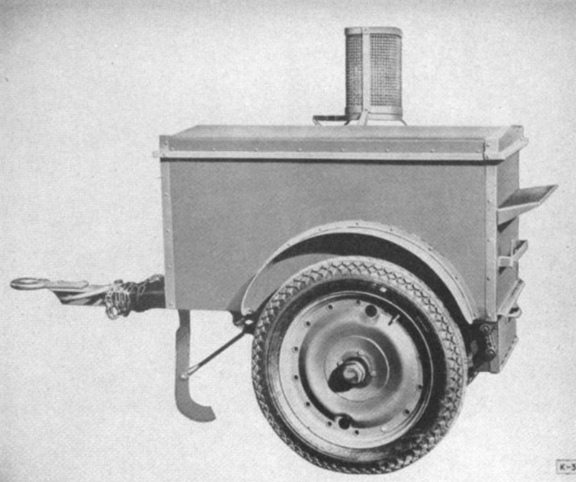

Also hiding in plain sight is the winch.

This image shows the exterior of the Gar Wood Model 4MB. The

outside view shows that the interior winch mechanism is encased in

several castings. Image added 1-13-2024.

While the winch does not look complicated

from the outside, this interval view shows that the device consists of

75 different components. Image added 1-13-2024.

Diamond T Model 980 or 981, 12-ton,

6x4 M20 Trucks:

FWD produced under subcontract 100 Diamond T Model 980 tank

transporters. These are mentioned in early FWD 1942 newsletters

indicating work may have begun on them in 1941. Because they were

built under contract, any survivors built by FWD cannot be identified, as

they will have Diamond T data plates.

FWD produced 100 of the hardtop cab version

of Diamond T Model 980/981. There is a small chance this vehicle was actually built by FWD in Clintonville,

WI. Author's photo.

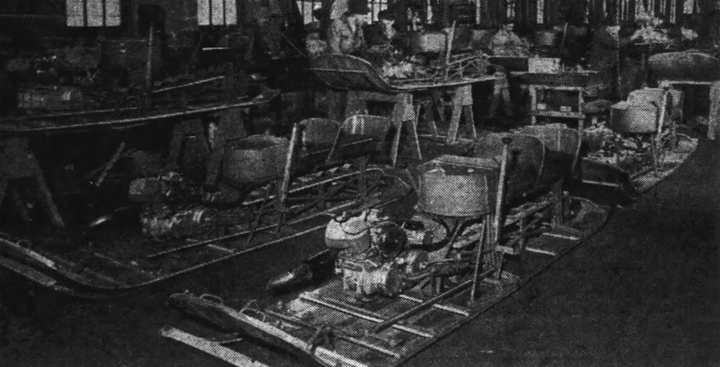

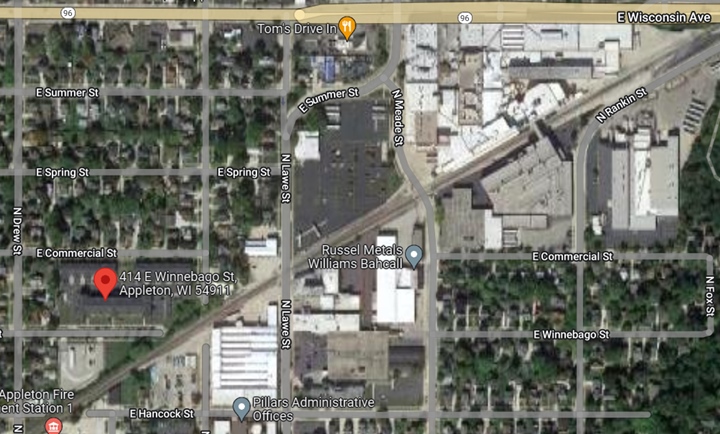

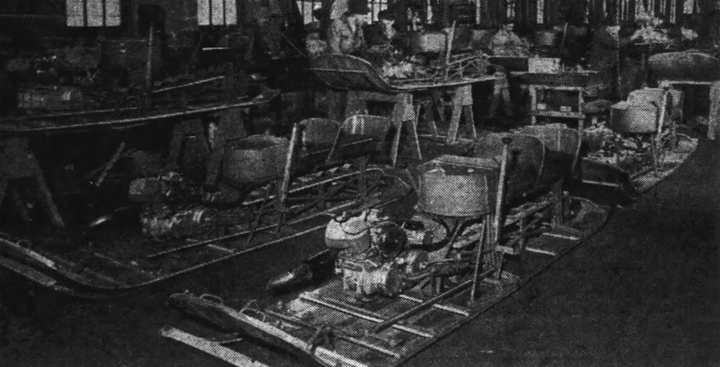

The Stevens Point, WI Plant:

The Clintonville FWD operation could not keep up with the orders it was

receiving and needed another facility to assemble trucks. Nearby

Stevens Point, WI had a new county highway garage that had enough space

for final assembly. Since the beginning of World War Two, Stevens

Point business leaders had been looking for a company that could come to

town to augment the several paper mills in the area. In late April

1943, Portage County Commissioners voted to allow FWD to utilize the

county highway department garage for the duration of the war.

Stevens Point provided $5,000 and the Chamber of Commerce provided

$2,500 to the county to relocate the county highway office workers to

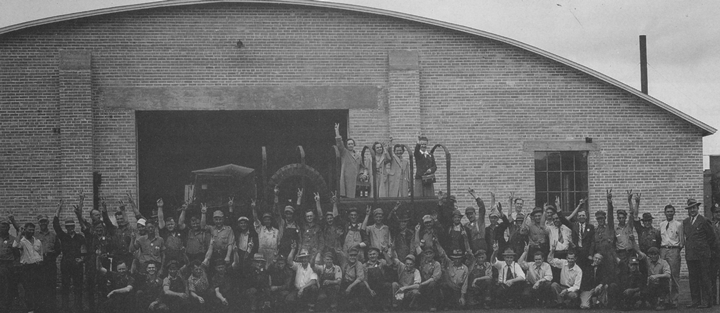

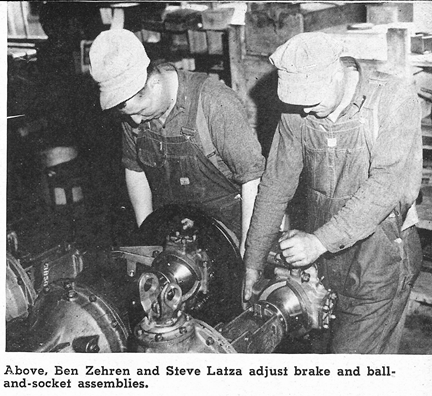

another temporary location. This was all done as the plant needed