|

Motor

Products Corporation in World War Two

Detroit, MI

1916 - 1958?

This page added 2-12-2022.

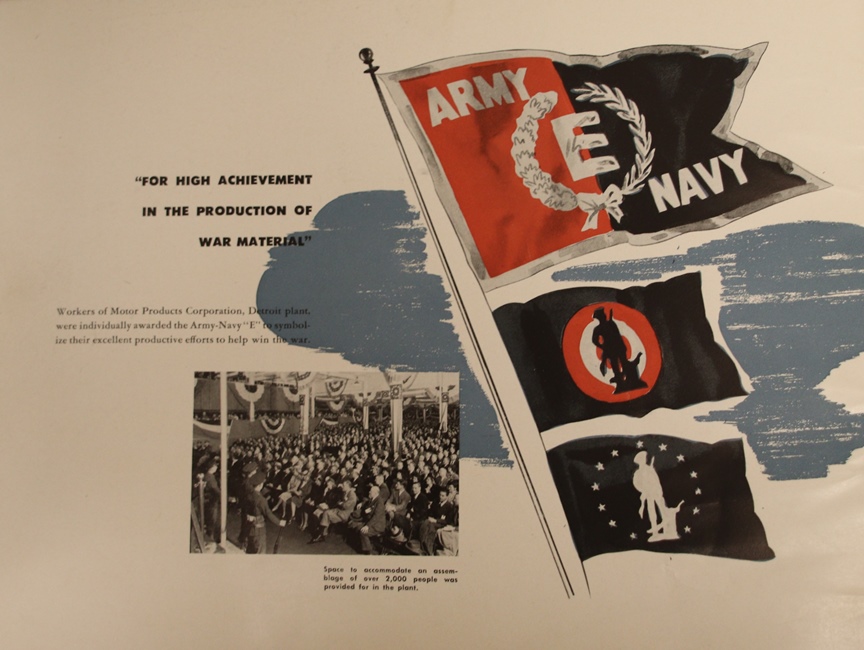

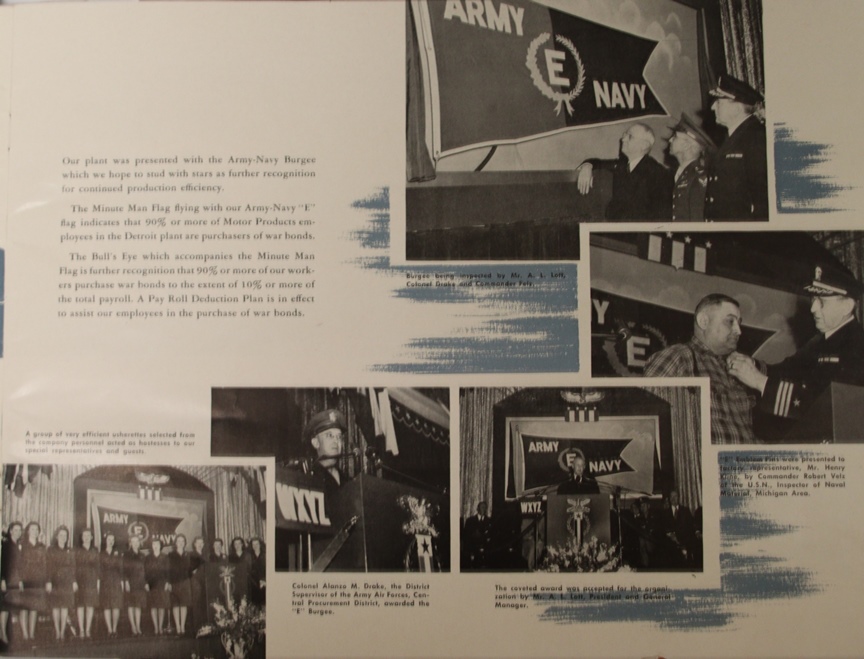

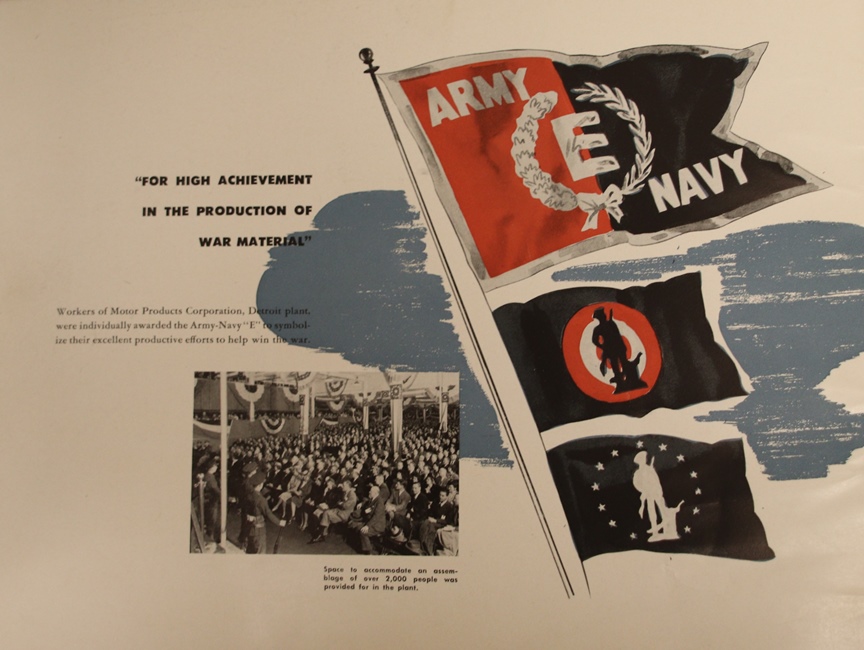

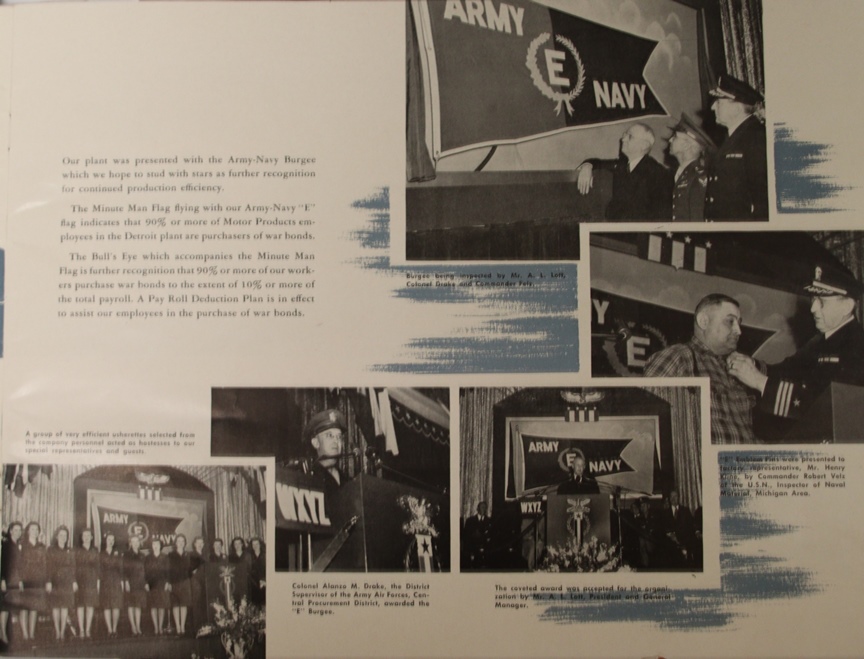

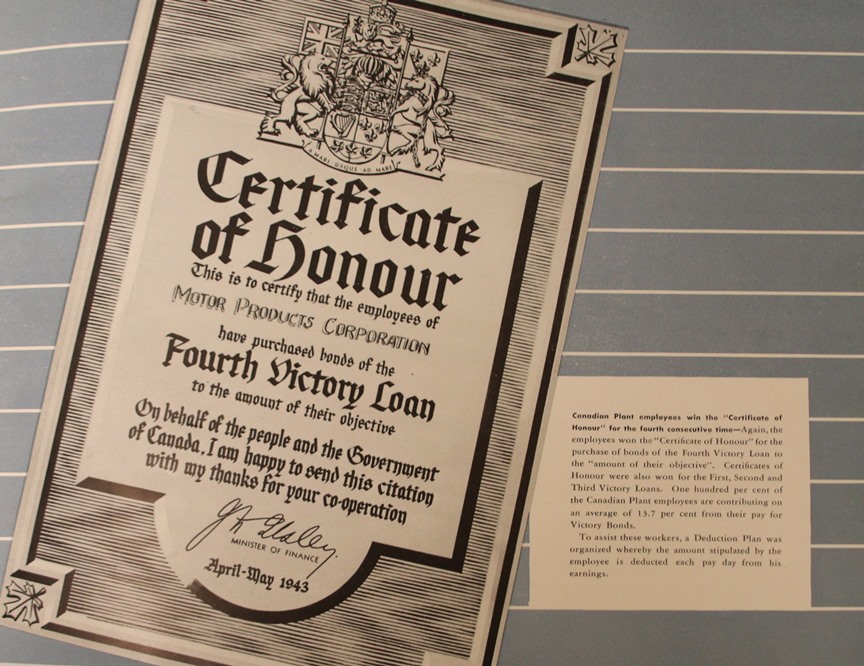

The Motors Products Corporation won the

Army-Navy "E" Award one time during World War Two.

I had never heard of the Motors Products

Corporation until I found Information on the company at the Michigan

Military Historical & Technical Society. This organization has an

excellent museum containing military products made in the state of

Michigan used in defense of the United States. It also has a large

collection of historical documents including the "1943 Year Book" by the

Motors Products Corporation below. I want to thank the staff at

the Michigan Military Historical & Technical Society for allowing me to

use this and tell the forgotten story of the Motors Products Company in

World War Two.

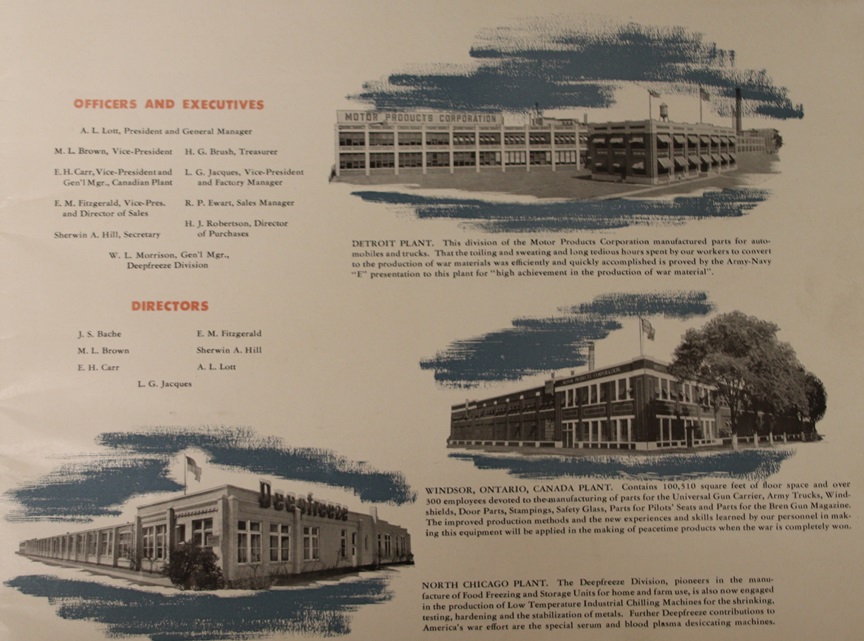

Motors Products Corporation began operations

in Detroit in 1916 supplying trim components to the independent

automakers like Hudson, Nash, and Packard. However, as these

companies fell by the wayside in the 1950s under the competitive pressures

from the Big Three automakers, Motors Products Corporation lost its

customer base and closed not long after Packard Motors closed in 1958.

The company was another in the long list of Detroit auto suppliers that

went out of business as competition increased and the number of

automobile companies decreased.

Table 1 - Motor Products

Corporation's Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. |

|

Product |

Contract Amount |

Contract Awarded

|

Completion

Date |

|

Cartridge Cases |

$2,475,000 |

4-1942 |

4-1943 |

|

Turret Kits |

$55,000 |

12-1942 |

12-1942 |

|

Cases Cartridge |

$2,650,000 |

3-1943 |

12-1943 |

|

Brass Cartridge Cases |

$4,995,000 |

6-1943 |

6-1944 |

|

Gun Turret Assemblies |

$13,274,000 |

9-1943 |

9-1944 |

|

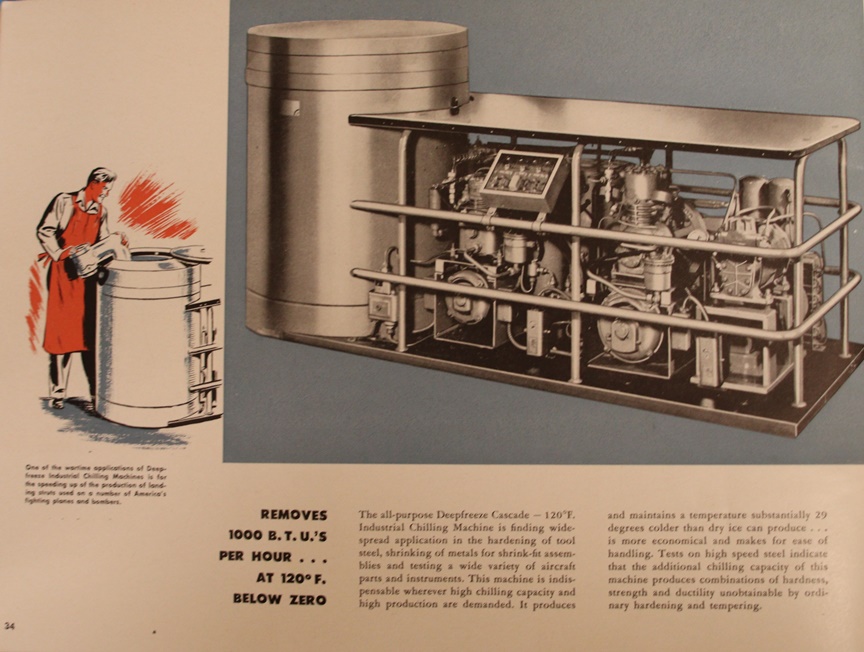

Airplane Parts |

$150,000 |

10-1943 |

6-1944 |

|

Gun Charger Kits |

$161,000 |

1-1944 |

5-1944 |

|

Swivel Valves |

$68,000 |

5-1944 |

8-1945 |

|

Airplane Gun Turrets |

$211,000 |

8-1944 |

4-1945 |

|

Total |

$24,039,000 |

|

|

Table 1 indicates that the company had a total

of $24,039,000 in major contracts during World War Two. One of the

missing items is the bushings mentioned below that went into Sherman

tanks and Wolverine tank destroyers. These and other parts may not

have been considered major contracts and not included in the summary.

However, Table 1 does complement the information below by giving

production dates and the dollar value of the contracts.

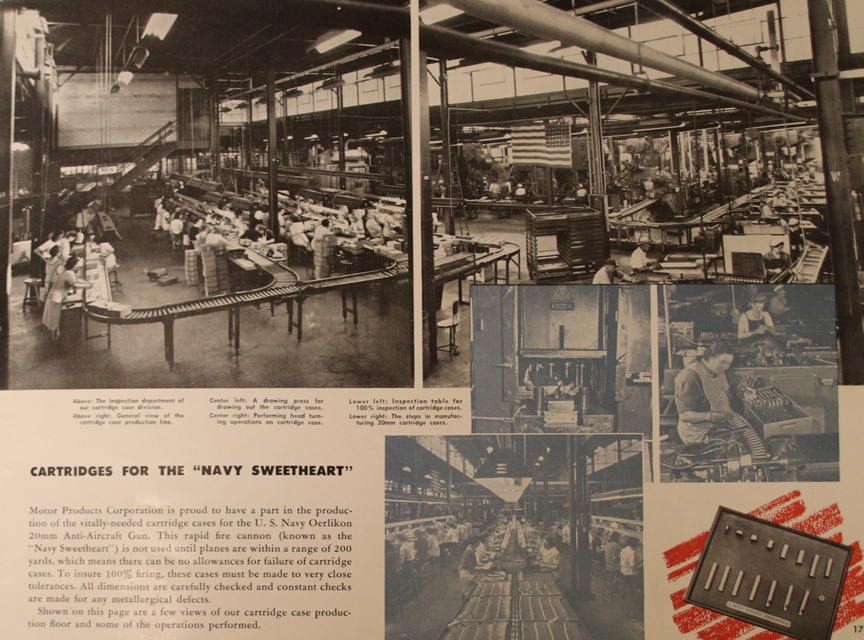

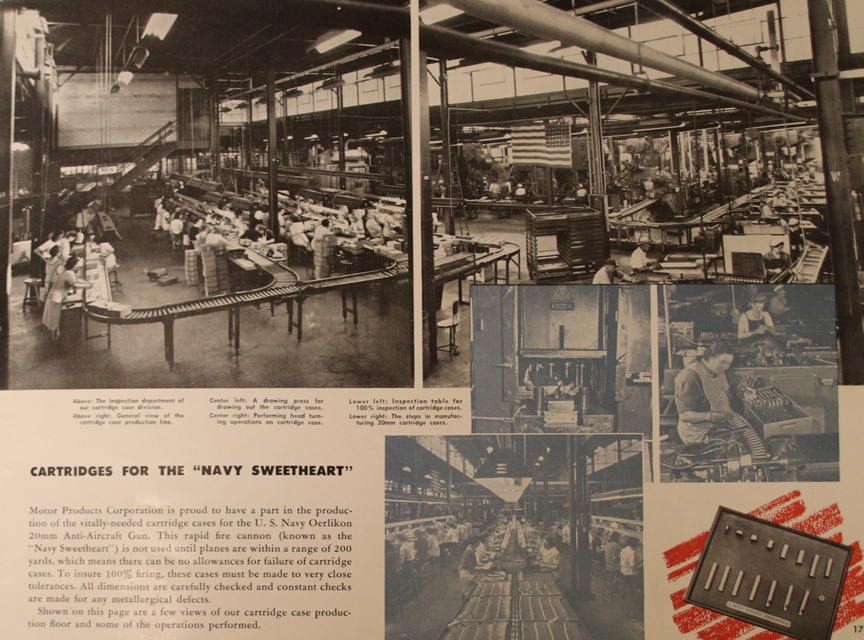

The first contract Motor Products Corporation

was awarded was for cartridge cases. This was very typical of many

companies during World War Two. One thing the military knew was

that it was going to need lots of ammunition, and these were rather easy

items to make compared to some of the more complicated products for

which companies would later be contracted. Motor Products

Corporation had three contracts for 20mm cartridge cases totaling

$10,120,000 or 42% of its World War Two contracts. The three

contracts for gun turrets totaled $13,540,000 or 54% of the company's

major contracts. The two combined made up 96% of Motor Products

Corporation's World War Two major contracts.

The only existing document of the company may well be

the "1943 Year Book - Motors Products Corp - War Development Production

and Expansion."

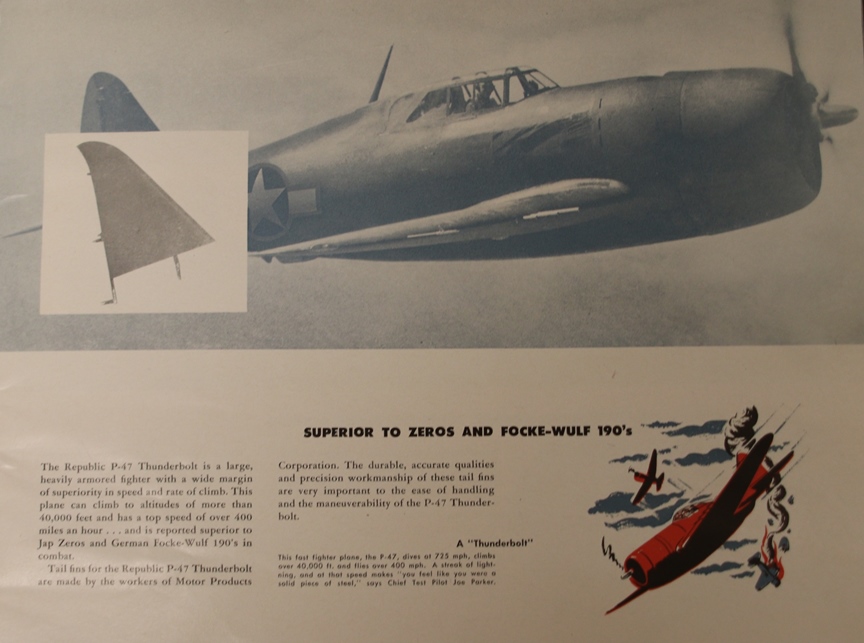

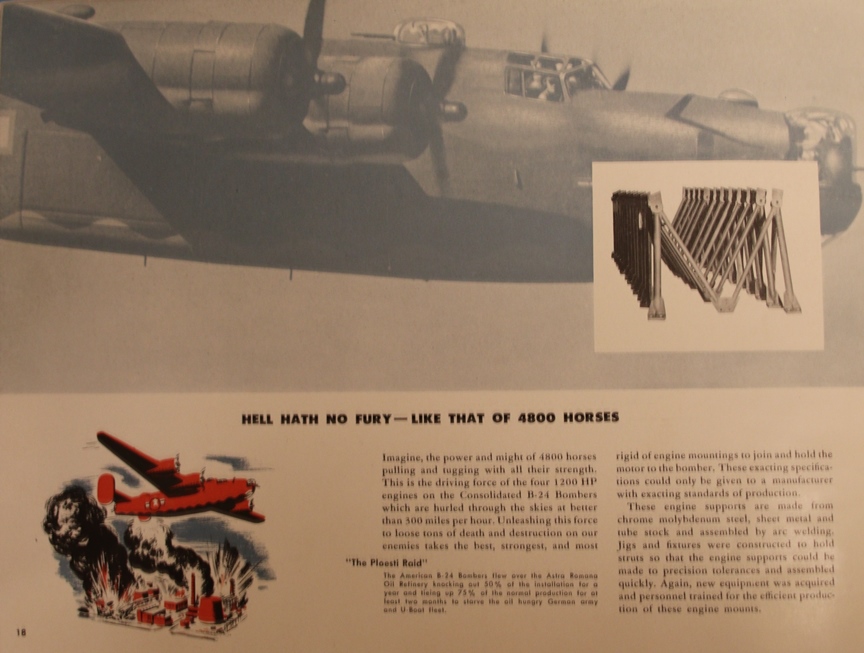

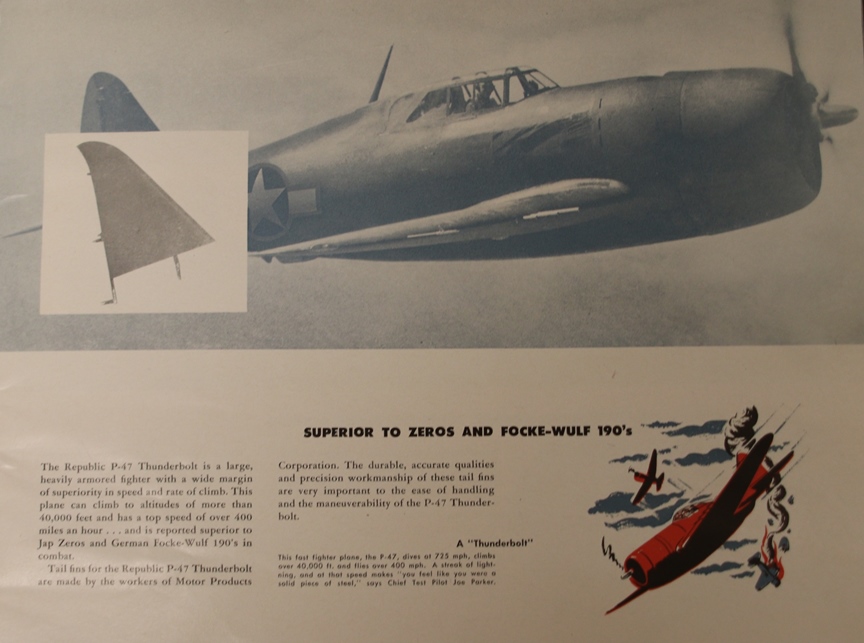

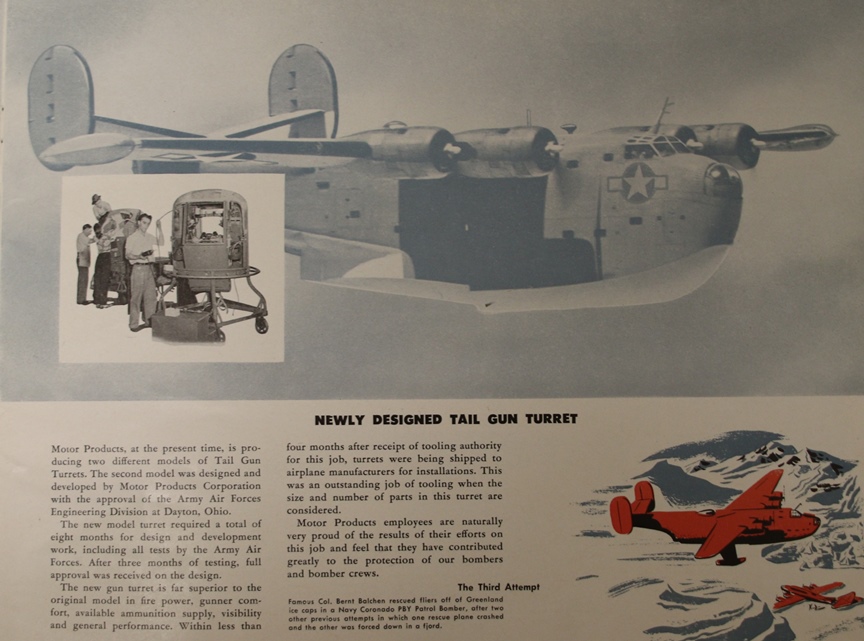

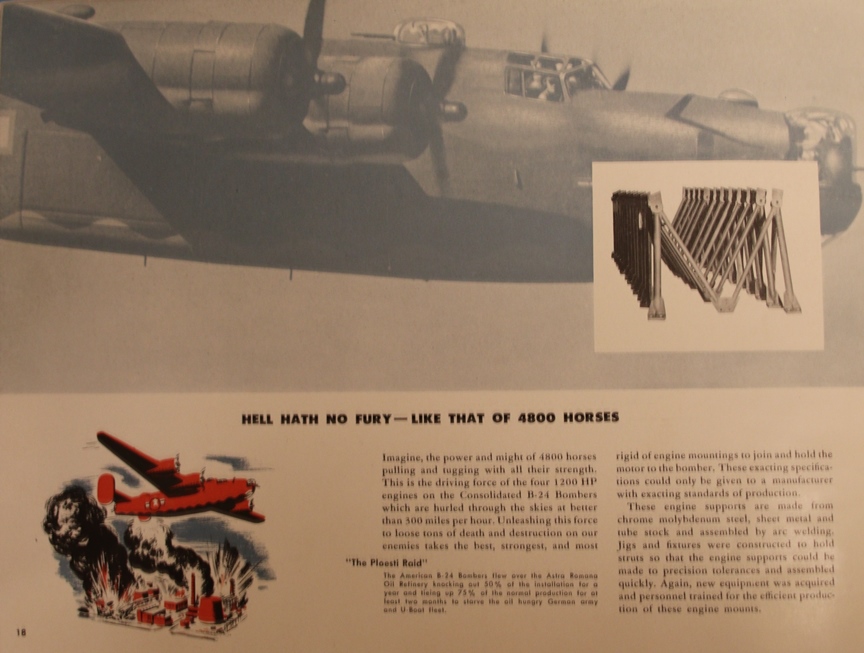

Motor Products Corporation World War Two

Products: The company made two products for the B-24 which

were rear turrets and engine mounts. Most likely, these were for

the B-24s being built by the Ford Motor Company at its Willow Run Bomber

Plant. The company also built M4 series tank and M10 series tank

destroyer bushings, P-47 vertical stabilizers, B-26 cockpit enclosures,

Quonset Hut arch rib sections, and 20mm cartridge

cases for the U.S. Navy.

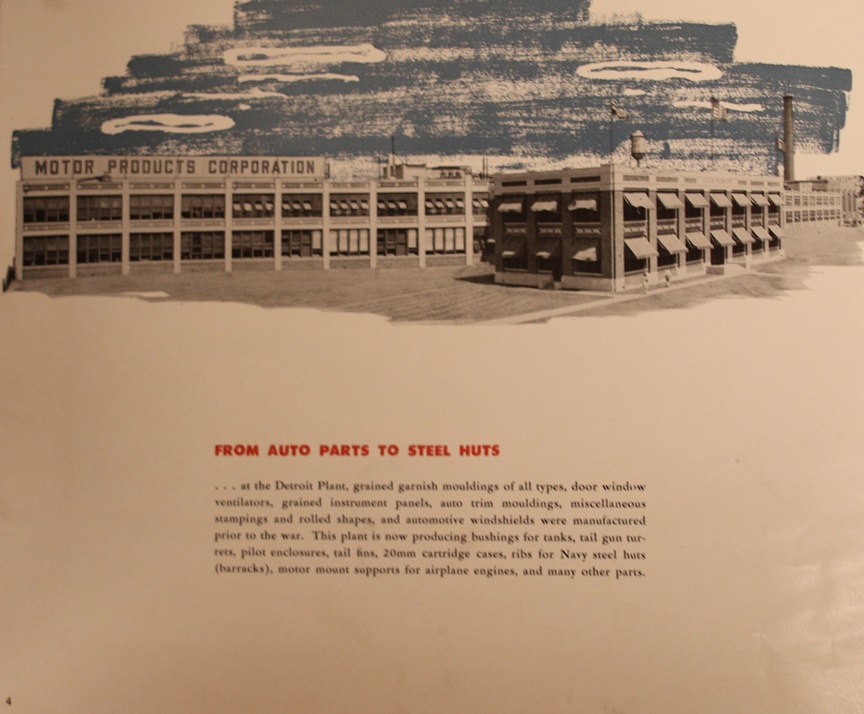

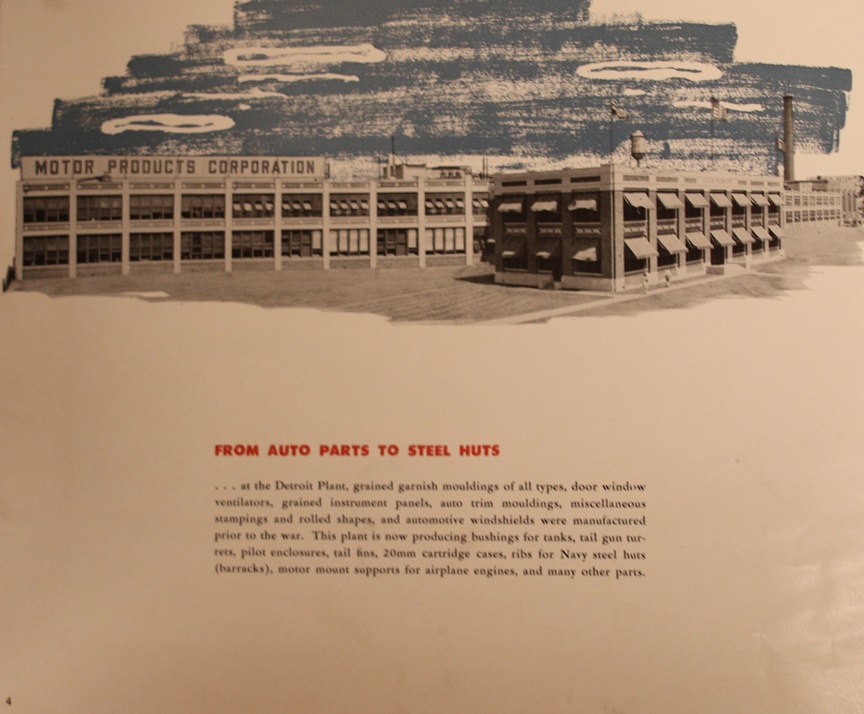

Shown here is a short listing of the

company's pre-war products and the war material it was making in 1943.

Chrysler, Fisher Body Division of General

Motors, and the Ford Motor Company all produced Sherman tanks in southeastern

Michigan in 1943. Motor Products Corporation

could have made bushings for any of these three local companies.

It could have also supplied bushings to the railway industry companies

that also made Sherman tanks. However, only Fisher Body and the

Ford Motor Company produced tank destroyers based on the Sherman tank

chassis.

This Fisher Body-built M4A3(75)VVSS was

built in 1944 and is on display at the U.S. Cavalry Museum at Fort

Riley, KS. It may well have Motor Products bushings in it.

Author's photo.

This M36 Jackson Tank Destroyer is also on display at the U.S. Cavalry

Museum. It was built as a Ford M10A1 with serial number 2274 in April

1943. It started life as an M10A1 Wolverine tank destroyer before

being converted to an M36. This most likely has Motor Products

bushings in it. Author's photo.

Republic Aviation was located on Long

Island, NY but also produced P-47s in Evansville, IN. Motor

Products could have been chosen to supply vertical stabilizers for the

Evansville, IN plant due to its proximity. This P-47D was built at

Evansville. Author's photo.

The vertical stabilizer. Author's photo.

This P-47D was also built in Evansville and

is on display at the Evansville Wartime Museum located at the

Evansville, IN airport. The aircraft is a mile away from the plant

where it was built. Author's photo.

This Martin B-26 Marauder is on display at

the National Museum of the United States Air Force. Author's

photo.

Motor Products Corporation made the sheet metal and Plexiglas framework

that covered the cockpit for the pilot and co-pilot. Author's

photo.

Author's photo.

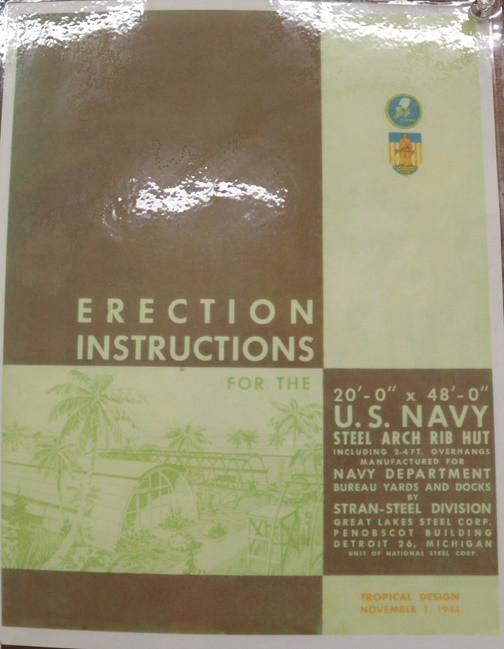

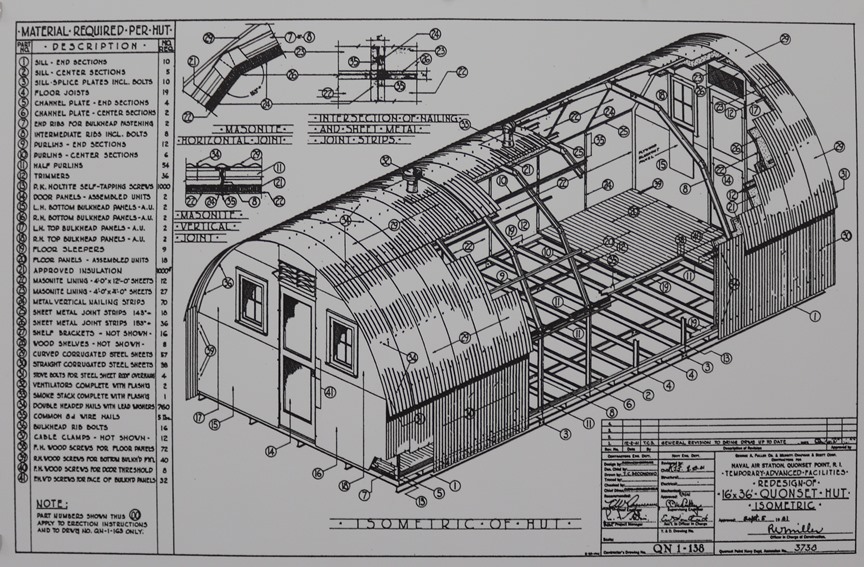

Quonset huts were built in various styles

and sizes by a number of different companies during World War Two.

Many of them were made by the Stran-Steel Division of the Great Lakes

Steel Company in Detroit, MI. It seems reasonable that Motor

Products Corporation would be a supplier of arc rib sections to Stran-Steel.

One of the best places to find Quonset huts is at the Seabee Museum and

Memorial Park in North Kingston, RI. Author's photo.

This is one of several erection instructions

for various sizes of Quonset huts manufactured by Stran-Steel that are

on display at the Seabee Museum in Rhode Island. Author's photo.

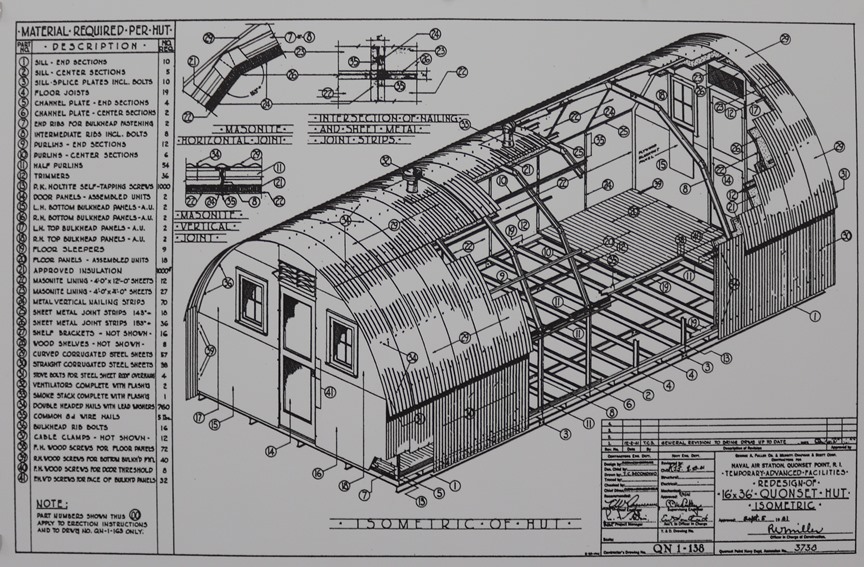

Shown here is an engineering drawing of a

Quonset hut.

Table 1 - Motor Products

Corporation's Major World War Two Aircraft Gun Turret Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. |

|

Product |

Contract Amount |

Contract Awarded

|

Completion

Date |

|

Gun Turret Assemblies |

$13,274,000 |

9-1943 |

9-1944 |

|

Airplane Gun Turrets |

$211,000 |

8-1944 |

4-1945 |

|

Total |

$13,485,000 |

|

|

The Consolidated tail gun turret on this Ford-built B-24J

on display at the at the Barksdale Global Power Museum at Barksdale AFB

in Bossier City, LA looks very much like one in the photo above.

Ford built 6,790 B-24 at its Willow Run, MI plant outside of Detroit.

It was the nearest B-24 assembly plant to Motor Products Corporation.

Motor Products Corporation built the Consolidated A-6B and A-6C tail gun

turret. With 1,200 workers assigned to build rear B-24 turrets,

Motor Products Corporation was most likely the main supplier of these

two models of rear turrets for Ford's B-24s. Author's photo.

Author's photo.

Author's photo.

This is the rear turret on B-24 "Strawberry

Bitch" at the National Museum of the United States Air Force.

Motor Products Corporation was one of several companies that

manufactured rear turrets for the B-24. This turret looks similar

to the one on the page above but is not identical. Most likely

this rear turret was built by another company that was supplying the

rear turrets for this B-24 that were built by Consolidated Aircraft at

its San Diego, CA plant. Author's

photo.

However, the photos do show the complexity

of the rear turrets on the B-24, no matter what type or which company that

manufactured it. Author's photo.

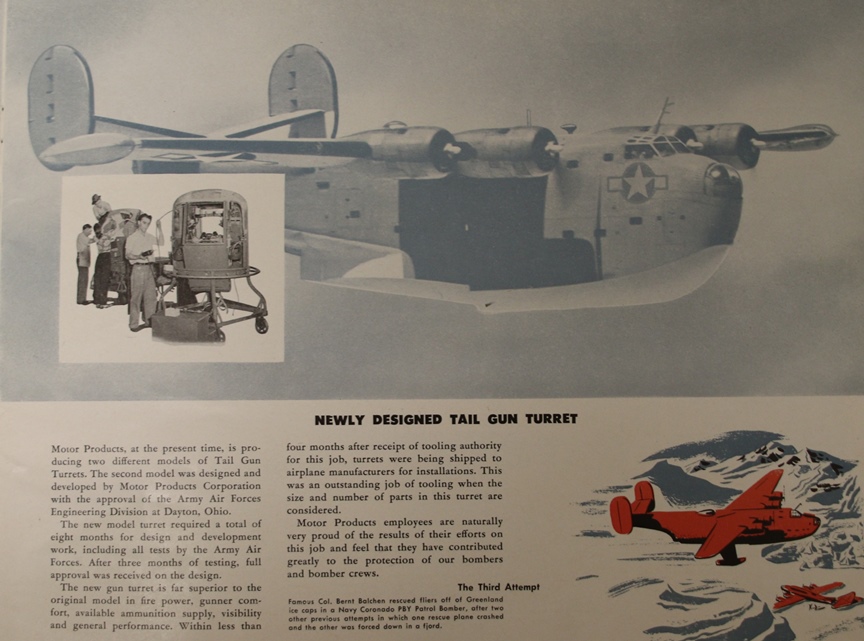

This page is confusing. While the

verbiage notes that the company is working with the Army Air Forces

Engineering Division at Wright Field in Dayton, OH, the photo is of a

U.S. Navy Consolidated PB2Y Coronado patrol aircraft. There is no

connection between the photo and information about a second turret being

developed.

This is a photo of the complete 20mm

projectile, fuze, and shell casing. Motors Products stamped out

the shell casing for the U.S. Navy. In 1943 the U.S. Navy

purchased 468,039,000 rounds of 20mm ammunition from multiple suppliers

including Motors Products Corporation. For the entire war, the

Navy purchased 1,153,639,000 rounds of 20mm ammunition from all

suppliers. Author's photo.

The 20mm Oerlikon started appearing on U.S.

Navy ships in early 1942. By the end of the war, every Navy and

U.S. Merchant Marine ship was armed with the 20mm Oerlikon for close-in

defense against air attack. Motor Products Corporation was a significant contributor

to keeping these weapons firing and protecting American ships and

sailors. Author's photo.

These two 20mm twin mounts are just two of nearly a dozen 20mm mounts on the destroyer escort USS Slater.

Author's photo.

The Motor Products Corporation constructed B-24

engine mounts

that were most likely installed on Ford-built B-24s like this one at

Barksdale AFB, LA.

Author's photo.

Author's photo.

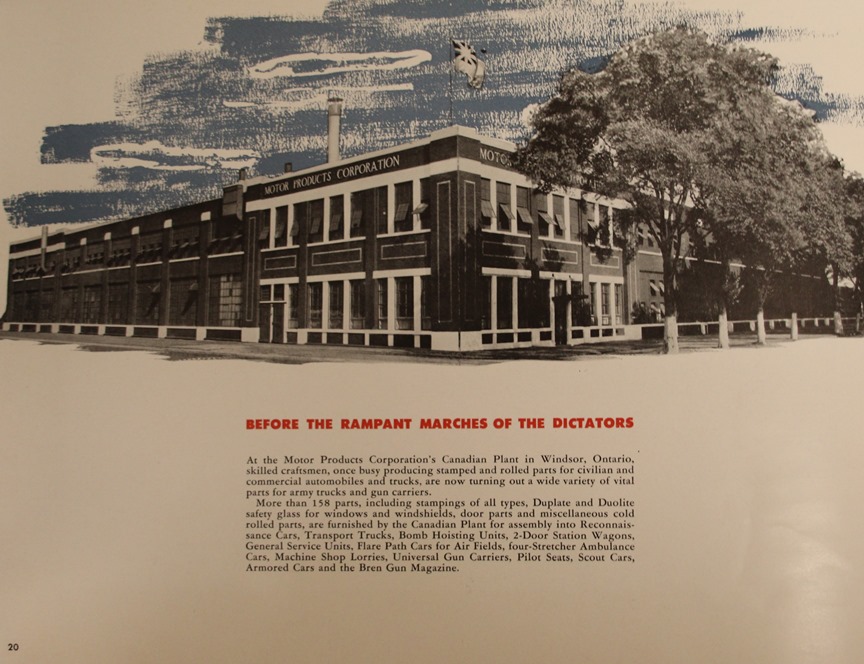

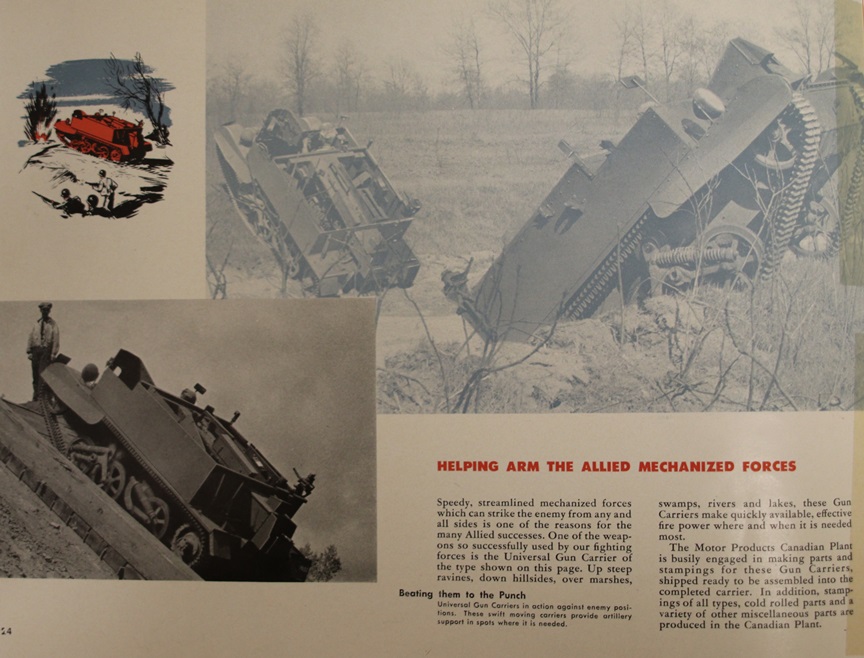

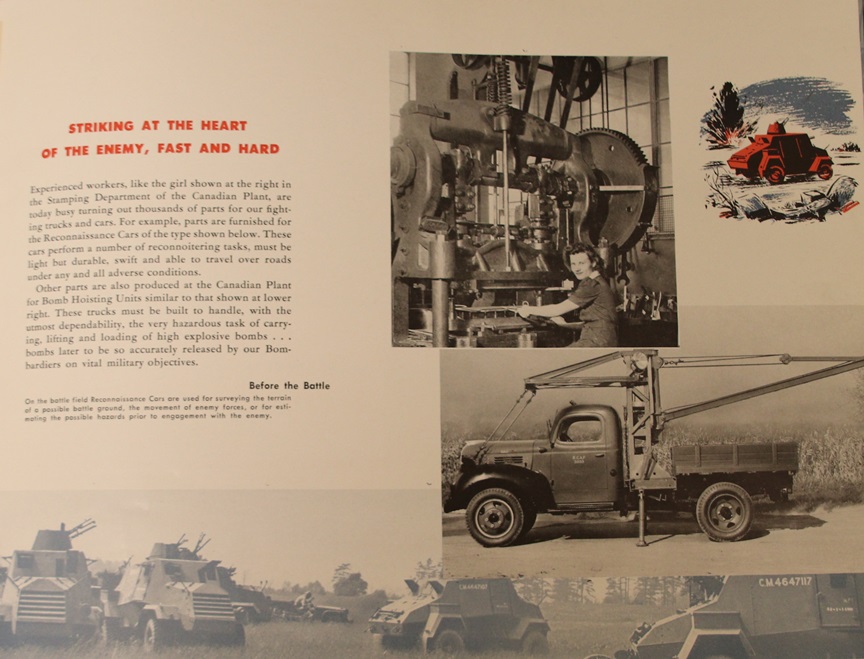

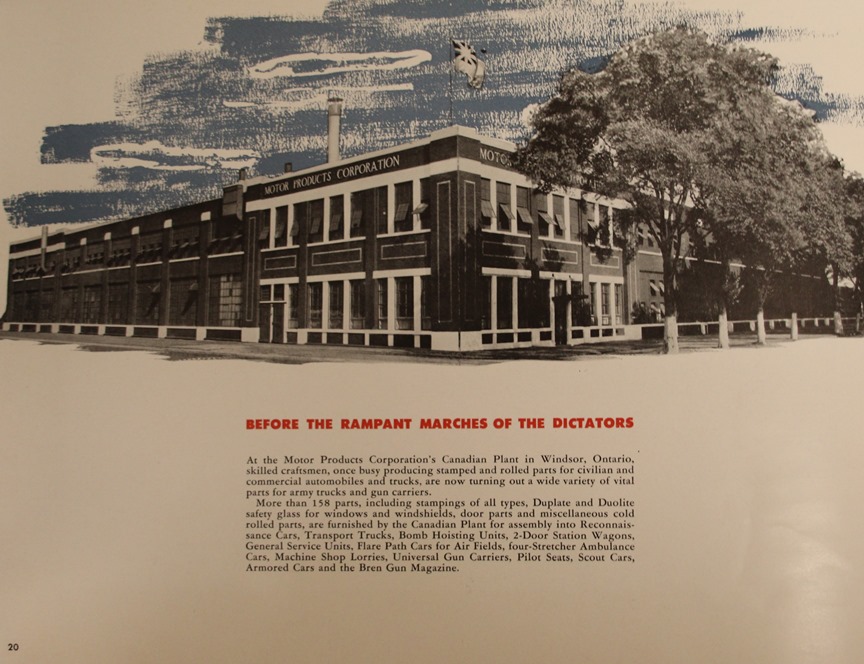

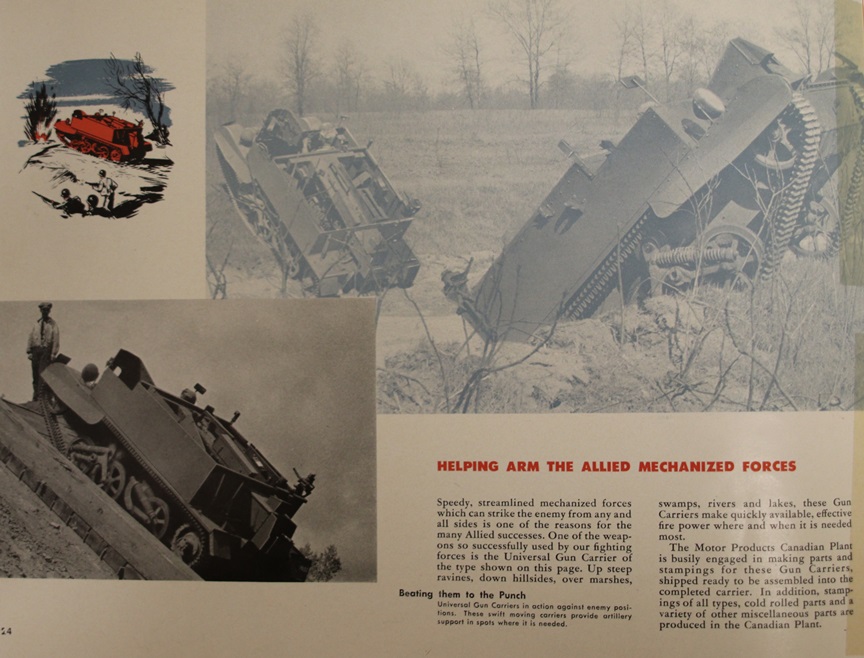

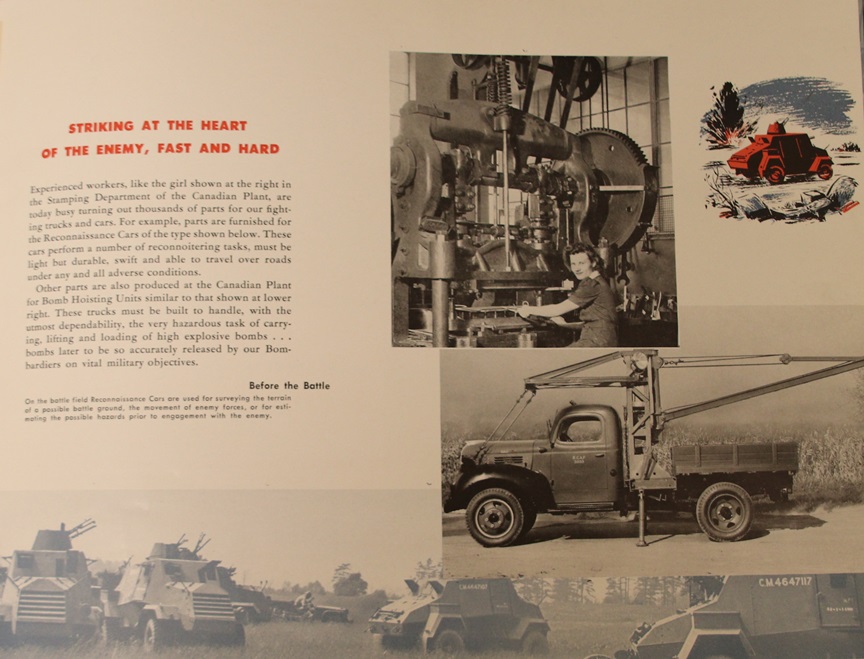

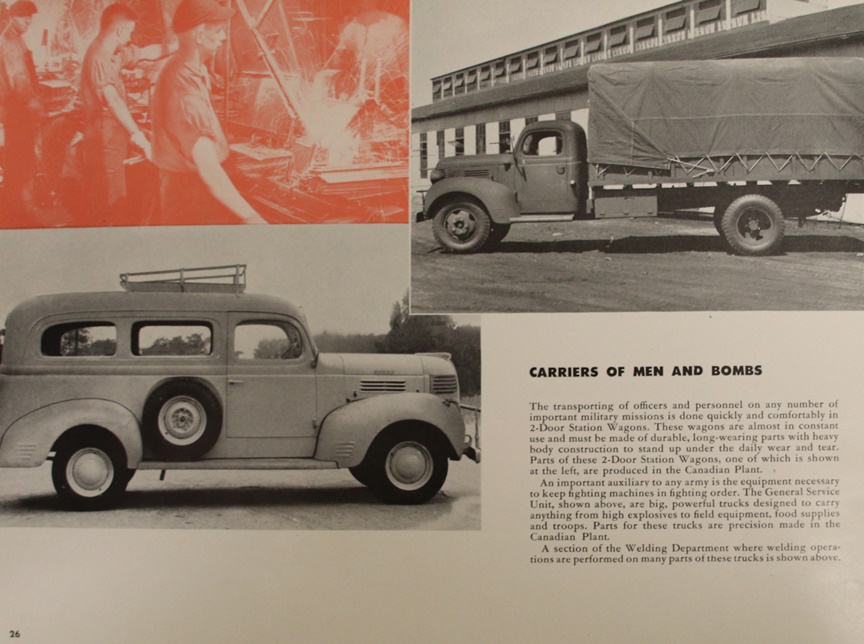

Motor Products Corporation Canadian

Operation World War Two Products: Universal carrier parts and

stampings, 15-CWT 4x4

Canadian Military Pattern Truck parts, and MK.1 Fox armored car components.

This is one of 33,988 Universal Carriers built by Ford at its Windsor, ONT plant

that has Motor Products Canada installed in it. Author's photo.

"Ford Canada" is on a nameplate behind the

drivers' location. Author's photo.

Author's photo.

This is one of 209,000 Canadian Military

Pattern Trucks built by Ford of Canada. Motor Products Canada

supplied many parts to not only these vehicles, but others Ford built at

its Windsor, ONT plant. Author's Photo.

GM of Canada built 201,000 15-CWT 4x4

Canadian Military Pattern Trucks of various types with Motor Products

Canada components installed in them. Author's Photo.

General Motors of Canada built 1,506 MK.1 Fox armored cars during World

War Two with components supplied by Motor Products Canada.

Author's Photo.

|