|

Pressed

Steel Car Company During World War Two

Armored Tank Division

Chicago, IL

1884-1956

This page updated on 3-6-2025.

The Armored Tank Division of the Pressed Steel

Car Company, located in the Hegewisch neighborhood on the south side of

Chicago, was part of a larger company headquartered in Pittsburgh, PA.

The main product of the Pressed Steel Car Company was railroad train

cars, which were produced in several locations in the United States. The Armored Tank Division of the Pressed Steel

Car Company had its beginnings with the U.S. Rolling Stock Company,

which was established in

1871 in New York as a manufacturer of railroad equipment.

The company moved to the Chicago area in 1883,

when the company's president, Adolph Hegewisch, picked the area for his

railroad car plant. This created a need for housing in the area.

The U.S. Rolling Stock Company did not own the housing, but they were

providing it through what was called the Hegewisch Land Co. Hegewisch was

subsequently established as a town in 1884.

In 1889 Hegewisch was annexed onto

Chicago. Adolph died a few years later and the Rolling Stock

Company was absorbed into the Pressed Steel Car Company before

World War I.

The British were in dire need of tanks after

losing the majority of their tanks on the Continent during the German

invasion of The Netherlands, Belgium, and France in May 1940. In

June 1940, the British Purchasing Commission began visiting various

companies in the United States to find prospective suppliers for the M3

medium tank. Pressed Steel Car Company was one of several

companies selected and issued a

purchase order on October 25,1940, for the production of 501 M3 tanks.

The order was worth $15,300,000.

All of the negotiations were conducted at the

Pressed Car Company's headquarters in Pittsburgh, PA. It was there

that the original offices of the Armored Tank Division of Pressed Steel

were first housed. The Hegewisch plant had been idle since 1932

due to lack of orders during The Depression. The plant had not

been maintained and needed a concentrated effort to make it production-worthy. Even parts of the roof were missing. On February

20, 1941, work began to make the plant ready to produce M3 medium tanks.

By April 9, 1941, this work was complete. On July 13, 1941, Pressed

Steel completed the first of 11,502 tanks and motorized gun carriages.

It was an M3 Grant.

Pressed Steel Car Company went out of business

in 1956, and US Steel purchased the former tank plant in Hegewisch for

use as a steel warehouse. The buildings on the site have

since been razed.,

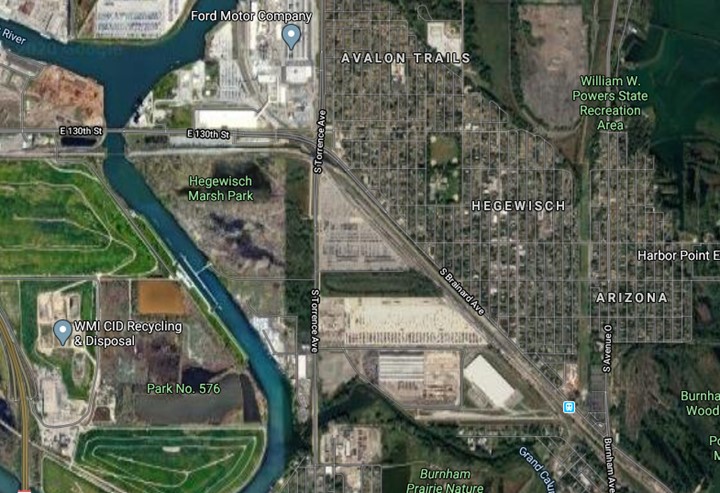

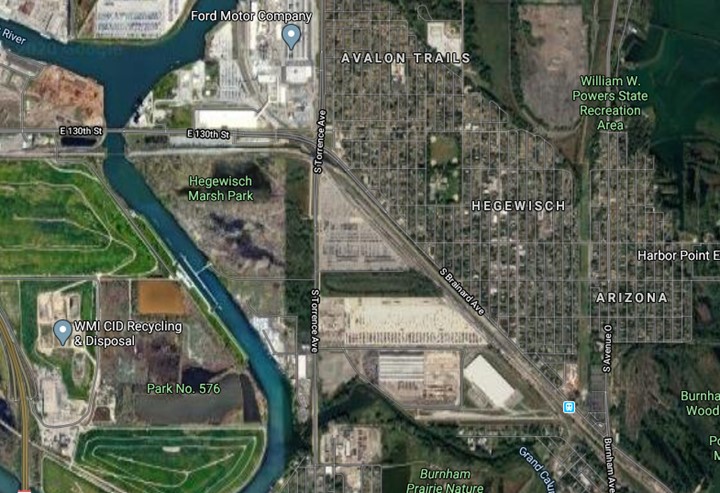

This Google Map satellite photo shows the

triangular area bounded by South Torrence Avenue on the west and South Brainard

Avenue

on the northeast where Pressed Steel in Hegewisch was located. The

former plant site is now a loading point for vehicles built at the Ford

Motor Company plant to the northwest of this location.

This photo shows the plant looking northwest

with South Brainard Avenue and the railroad tracks along the right hand side of

the image. The main assembly rail car plant that was rebuilt to

manufacture armored vehicles is the long dark building. North of

it is the test track where every armored vehicle had to be tested prior

to being accepted by Army Ordnance. Up in the right hand corner of

the photo is the Ford plant that built M8 and M20 armored cars.

This area of Chicago built a significant number of armored vehicles for

the war effort. Photo courtesy of the Southeast Chicago Historical

Society.

Pressed Steel won the Army-Navy "E" Award three times during World War

Two.

It won the first award on September 10, 1942.

Pressed Steel Car Company World War Two

Products: Table 1 shows

that the company had $544,898,000 in major contracts during World War

Two. Table 2 indicates that the M4A1 Sherman tank was 60.2% of the

total contracts. The information in Table 3 gives the quantities

of each type of armored vehicle built by the company. In total,

Pressed Steel Car Company produced 11,052 armored vehicles to help win

World War Two.

Table 1 - Pressed

Steel Car Company's

Major World War

Two Contracts

The information below comes from the "Alphabetical Listing

of Major War Supply Contracts, June 1940 through September

1945." This was published by the Civilian Production

Administration, Industrial Statistics Division, Requirements

and Progress Branch January 21, 1946. |

|

Product - Customer |

Contract Number |

Contract Amount |

Award Date |

Completion

Date |

| Medium Tanks

M3 - Foreign |

|

$15,300,000 |

10-1940 |

7-1942 |

| Shells

Forgings - Army Ordnance |

271-ORD-509 |

$2,191,000 |

12-1940 |

11-1941 |

| Tank Parts -

Foreign |

A4761 |

$56,000 |

4-1941 |

11-1941 |

| Medium Tanks

M4 - Army Ordnance |

271-ORD-717D |

$49,950,000 |

8-1941 |

12-1942 |

| Shells - Army

Ordnance |

271-ORD-778 |

$2,112,000 |

12-1941 |

11-1942 |

| Medium Tanks

M4 - Army Ordnance |

271-ORD-717M |

$67,266,000 |

1-1942 |

3-1943 |

| Medium Tanks

M4 - Army Ordnance |

271-ORD-717E |

$33,633,000 |

1-1942 |

6-1942 |

| Tanks - Army

Ordnance |

271-ORD-717L |

$9,830,000 |

4-1942 |

7-1942 |

| Medium Tanks

M4A1 - Army Ordnance |

271-ORD-717E |

$16,703,000 |

5-1942 |

4-1943 |

| Tank Engines

- Army Ordnance |

271-ORD-717E |

$4,223,000 |

5-1942 |

2-1943 |

|

Bolts Steel - Army Corps of Engineers |

1088-ENG-1680 |

$199,000 |

7-1942 |

9-1942 |

| Gun Motor

Carriages - Army Ordnance |

271-ORD-717E |

$11,954,000 |

7-1942 |

11-1942 |

| Medium Tanks

M4A1 - Army Ordnance |

271-ORD-717E |

$167,463,000 |

9-1942 |

8-1943 |

| Medium Tanks

M4A1 - Army Ordnance |

271-ORD-717E |

$80,357,000 |

9-1942 |

12-1944 |

| Medium Tanks

M4A1 - Army Ordnance |

271-ORD-717E |

$63,687,000 |

6-1944 |

8-1945 |

| Gun Motor

Carriages - Army Ordnance |

271-ORD-717E |

$19,974,000 |

10-1944 |

8-1945 |

| Total |

|

$544,898,000 |

|

|

|

Table 2 - Pressed

Steel Car Company's World War Two Products |

|

Product |

Amount |

Percentage |

|

Medium Tanks M4A1 |

$328,210,000 |

60.2% |

|

Medium Tanks M4 |

$150,849,000 |

27.7% |

| Gun

Motor Carriages |

$31,928,000 |

5.9% |

|

Medium Tanks M3 |

$15,300,000 |

2.8% |

| Tanks

|

$9,830,000 |

1.8% |

|

Shells and Shells Forgings |

$4,303,000 |

0.8% |

| Tank

Engines |

$4,223,000 |

0.8% |

| Bolts

Steel |

$199,000 |

0.4% |

| Tank

Parts |

$56,000 |

0.1% |

|

Total |

$544,898,000 |

~100% |

Table 3 - Pressed Steel

Car Company

World War Two Armored Vehicles Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945"

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Tank, Medium, M3 |

|

104 |

397 |

|

|

|

501 |

| Tank, Medium, M4(75) |

|

|

475 |

525 |

|

|

1,000 |

| Tank, Medium, M4A1(75) |

|

|

699 |

3,001 |

|

|

3,700 |

| Tank, Medium, M4A1(76) |

|

|

|

|

2,171 |

1,255 |

3,426 |

| Tank, Medium,

M4A2(76) |

|

|

|

|

|

21 |

21 |

| Tank, Recovery, M32 (Conversion) |

|

|

|

|

163 |

|

163 |

| Tank, Recovery, M32B1(New) |

|

|

|

31 |

60 |

|

91 |

| Tank, Recovery, M32B1(Conversion) |

|

|

|

6 |

378 |

|

384 |

| Tank, Recovery, M32B3(Conversion) |

|

|

|

|

298 |

|

298 |

| Carrier, Cargo, M30

(T14) |

|

|

60 |

40 |

|

|

100 |

| Carriage, Motor, 105mm Howitzer,

M7B1 |

|

|

|

|

664 |

162 |

826 |

| Carriage, Motor,155mm

Gun, M12 |

|

|

60 |

40 |

|

|

100 |

| Carriage, Motor, 155mm

Gun, M40 (T83) |

|

|

|

|

|

418 |

418 |

| Carriage, Motor, 8 inch

Howitzer, M43 (T89) |

|

|

|

|

|

24 |

24 |

|

Total |

|

104 |

1,691 |

3,643 |

3,734 |

1,880 |

11,052 |

Author's Note

and Disclaimer: The Detroit Office

of Ordnance of the U.S. Army was the primary purchasing entity for

vehicles for the U.S. Army during WWII. It also purchased vehicles

for the USMC, US Navy, and for Lend-Lease. However, there were

other organizations that also purchased vehicles including the Army

Corps of Engineers, U.S. Army Air Force, U.S. Army Signal Corps, Navy

Bureau of Ordnance, Navy Bureau of Aeronautics, and foreign countries

making direct purchases.

Other Tanks and equipment built by the Armored Tank Division of

Pressed Steel:

-

Two T29 Heavy Tank

Prototypes

-

One T12 Heavy Tank

Recovery Vehicle - This was built on the chassis of an M26

Pershing Heavy Tank.

-

41 M4 "Scorpion" Mine

Exploders - This was based on a British design and was mounted

out in front of a tank. It consisted of chains spinning at 100

rpms to explode mines before the tank rolled over them.

-

254 M4A3E2 Sherman

Turrets and Gun Mounts - These were built under a sub-contract

to the Fisher Body Tank Plant in Grand Blanc, MI, which was the

final assembly point for the tanks.

Other World War Two

Products: In September 1940, Pressed Steel received a

$2,191,000 contract from the U.S. Army to produce artillery ammunition

components.

A tank crew trains on a mine exploder.

This M4A3E2 with a Pressed Steel-built

turret is part of the U.S. Army Armor and Cavalry Collection at Fort Benning, GA.

The front and sides of the turret were six inches thick. Author's

photo added 12-6-2021.

The rear section of the turret had two

inches of armor. Author's photo added 12-6-2021.

Pressed Steel-built Armored Vehicle

Photos:

This Pressed Steel-built small hatch

M4A1(75) is serial number 192, built in July 1942. It

is USA number 3014948. It is the oldest Pressed Steel

M4A1(75) known to exist and is owned by the Virginia Military Museum of

Military Vehicles. Note that this tank has the direct vision ports

for the driver and assistant driver. Author's photo.

Pressed Steel originally built this tank as

an M4A1 with serial number 415 in August 1942. Note that it does not have the direct vision

ports. This one was converted to the M42B1 flame thrower configuration

in 1945. It is USA number 3015171. It was photographed by

the author in June 2019 at the former International World War Two Museum

in Natick, MA, which closed early August 2019. The tank

is now owned by the Museum of American Armor on Long Island, NY.

Pressed Steel M4A1, serial number 644, is on

display on the south side of the Georgia National Guard Armory in

Calhoun, GA. The original 75mm main gun was replaced with a

flamethrower. Author's photo added 4-9-2021.

Author's photo added 4-9-2021.

Author's photo added 4-9-2021.

This M4A1(76) is on display at the Heartland Military Museum in

Lexington, NE. Author's photo added 3-6-2025.

This

M4E9(75) was built by Pressed Steel and is on display at the USS Alabama

in Mobile, AL. Note that it has two different types of tracks on

it. Author's photo.

Author's photo.

Author's photo.

This M32B1 Tank Retriever Vehicle was converted to this configuration by

Pressed Steel from one of its own M4A1(75) small hatch tanks. This

vehicle was photographed by the author at Sam Winer Motors in Akron, OH.

Author's photo.

Author's photo.

This

M32B3, serial number 560, was converted by the Pressed Steel Car Company in August 1944.

It was converted from Ford serial number 11903, which was an M4A3(75) built in March 1943.

This tank is located at the American Legion Post 134 in Circleville, OH and has white tent pole going up through the bottom of

the tank and the turret. Author's photo.

This Pressed Steel M4A1(76) HVSS was converted

into

an M32A1B1 by Baldwin. This is part of the National Armor and

Cavalry Collection at Fort Benning, GA. Author's photo.

Author's photo.

Author's photo.

Author's photo.

This Pressed Steel M4A1(76) is on display at

the Hartford City, IN Army National Guard Armory. It is one of

several Pressed Steel M4A1(76)s on display at Indiana Army National

Guard armories. Author's photo.

Author's photo.

Author's photo.

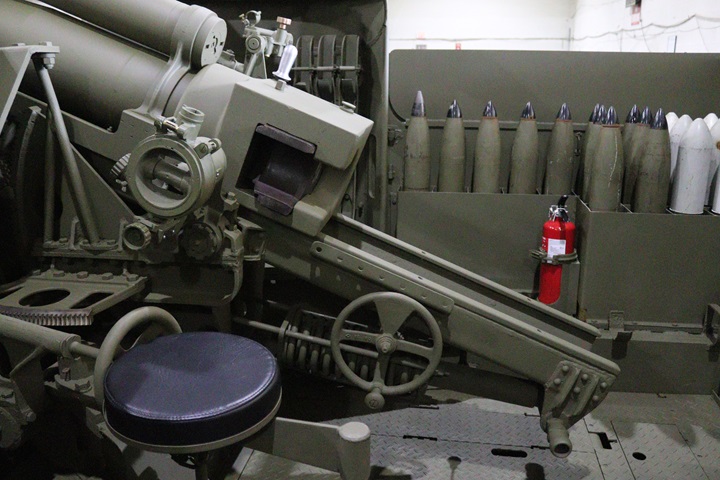

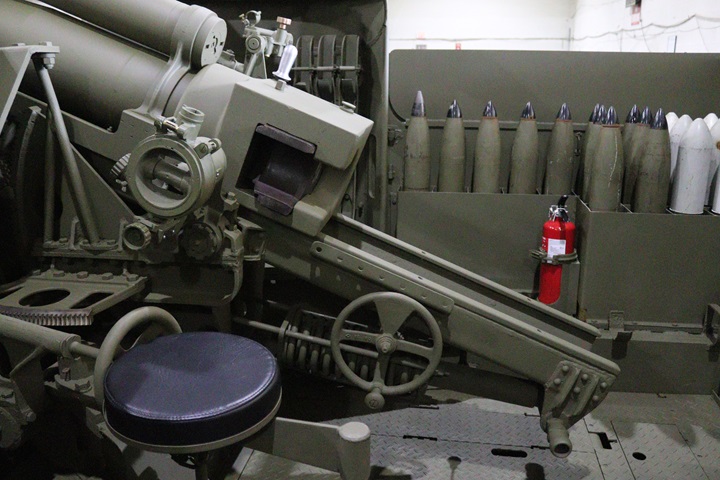

This 1944 Pressed Steel M7B1, serial number

758, was on display at the

2019 MVPA National Convention at York, PA. The following photos

show the high degree of restoration on this vehicle. Author's

photo.

Author's photo.

The strip of brightly colored material laid

across the top of the engine bay was used to identity the

vehicle as friendly to Allied aircraft. Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

This

M43 is located in Wyoming, MI. Pressed Steel built 24 of them.

The Lima Tank Depot operated by the United Motors Division of General

Motors converted 24 others from Pressed Steel-built M40s. It is

unknown which of the two this is. In either case, Pressed Steel built

the chassis. Author's photo.

Author's photo.

Author's photo.

Author's photo.

The Pressed Steel Car Company built two T29 prototype heavy tanks.

Development began in March 1944, and the first one was completed in

September 1945. Chrysler also built eight T29s. It is

unknown which company built this one. Author's photo.

Author's photo.

Author's photo.

Author's photo.

|