|

VT

Proximity Fuze Manufacturers of World War Two

This page added 5-6-2021.

An American Auto

Industry in World War Two Special Edition

The VT proximity fuze program was one of

three top secret programs the United States had during World War Two.

It was the only one that remained secret throughout the war

and was never discovered by the enemy in action nor through spies.

The Manhattan Project was penetrated by spies. The American

radar program was only secret in that it had the magnetron tube.

The Germans and other combatants had radar. The VT

program was so secret that VT fuzes were taken to nearby airports

in unmarked trucks to be flown to their final destination. The

aircraft flew directly to military bases, where the fuzes were then

attached to shells. If the fuzes were shipped by train in a

boxcar, a U.S. Marine guard would be in the boxcar at all times

until the load arrived at its final destination.

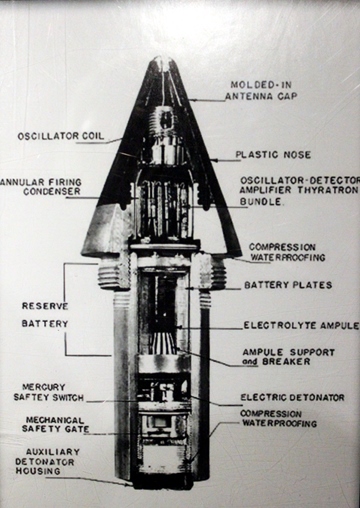

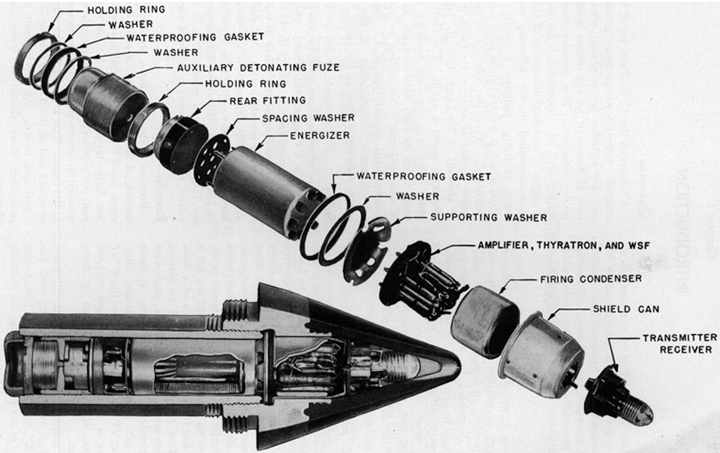

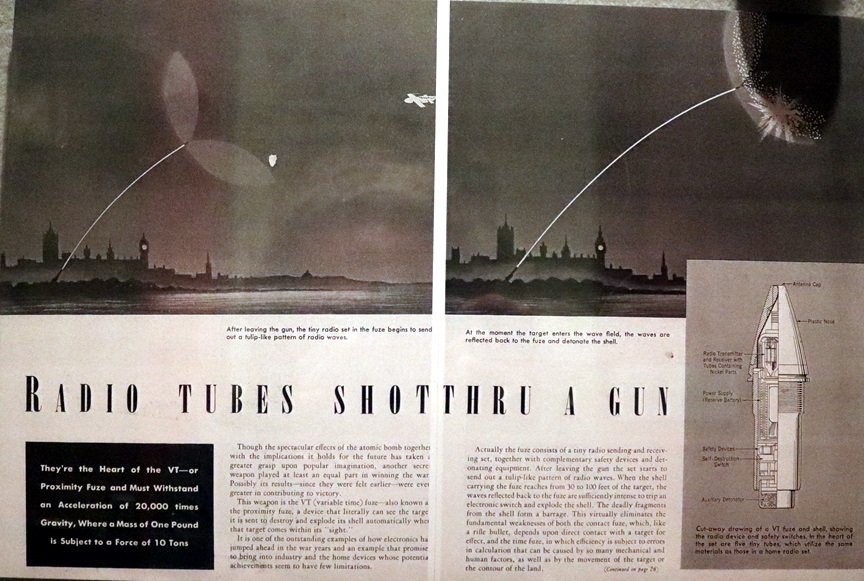

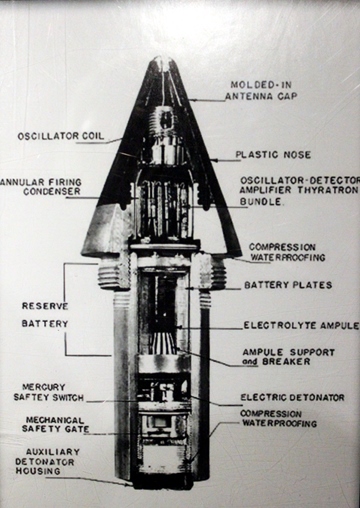

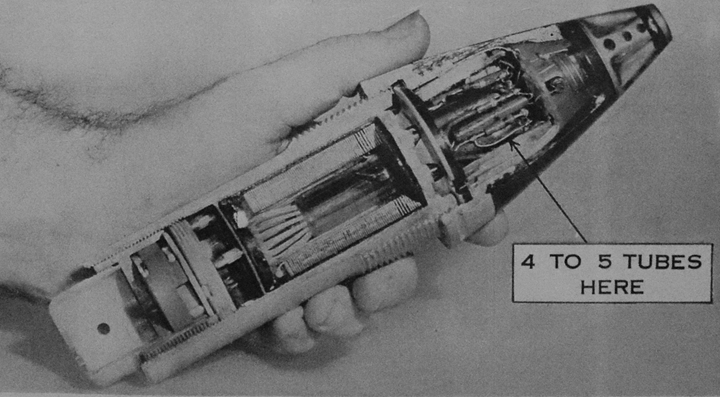

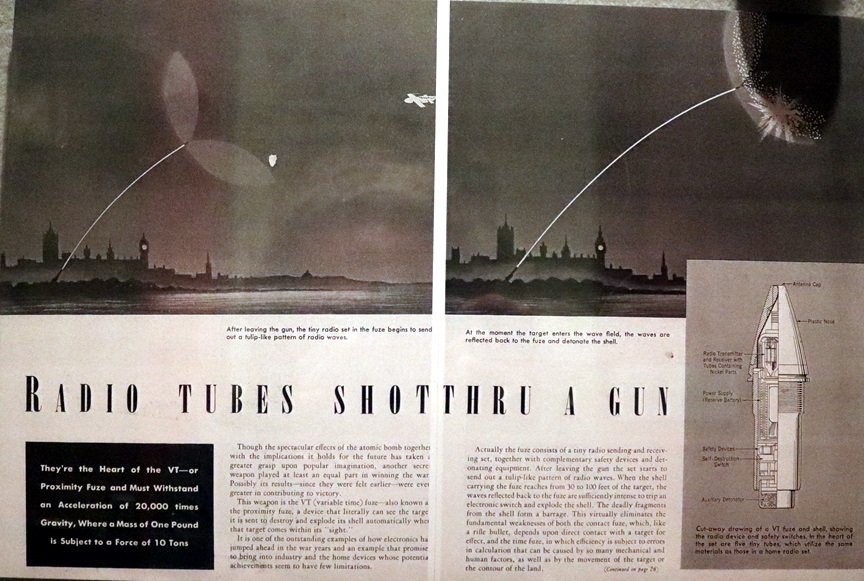

The VT fuze consisted of a small radio

transmitter and receiver of several miniature electronic tubes,

electronic components, and safety devices that were mounted in the nose

of anti-aircraft shells. When fired at an attacking aircraft, the

VT shell would detect a change in the received frequency when near an

enemy aircraft, and the VT fuze would detonate the shell. This was

far superior to the other method of pre-setting the time-to-detonation

of a fuze of an anti-aircraft shell before the shell was loaded in the

anti-aircraft gun. This was problematic at its best in attempting

to predict, in the heat of an aerial attack, how long it would take a

shell to reach the area of fast moving enemy aircraft.

For the U.S. Navy, the VT fuze is

considered to be one of the main reasons it was able to progress so quickly

back across the Pacific during World War Two. It was shown at

Pearl Harbor and the sinking of HMS Repulse and HMS Prince of Wales

three days later that aircraft were the biggest threat to the American

fleet in the Pacific. With the aid of the VT fuze built by Crosley,

Eastman Kodak,

McQuay-Norris, RCA, and Sylvania,

it is estimated that the U.S. Navy's Pacific campaign advanced months

faster than it would have without it. Many lives were saved, and

fewer ships were sunk than if the VT fuze had not been produced by

these companies.

The U.S. and British Navies were

the first users and the driving force behind the vast scientific,

engineering, and manufacturing project. When first used

in combat, they were only used on ships, so any duds would fall into the

ocean. In doing so, duds could not be recovered by enemy troops, reverse

engineered, and used against the Navy. Later, they were used over

land in defending Antwerp, Belgium from V-1 attacks. Another

version of the VT fuze was designed for artillery shells for air bursts

against enemy ground forces. This was first used very effectively

during the Battle of the Bulge.

Engineering and development of the VT

proximity fuzes was carried out at the Applied Physics Laboratories

(APL) of John Hopkins University.

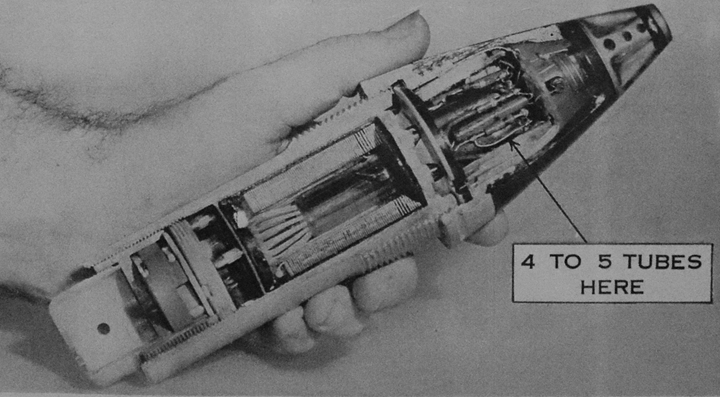

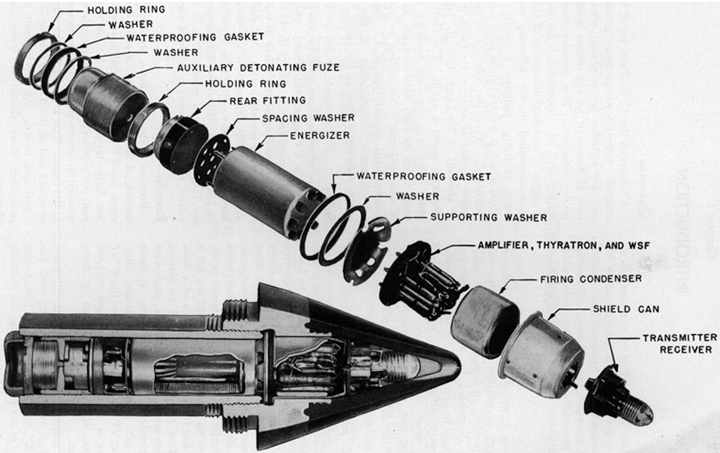

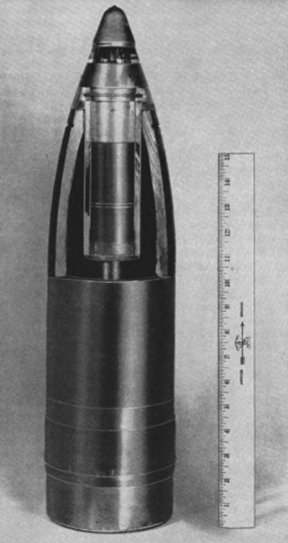

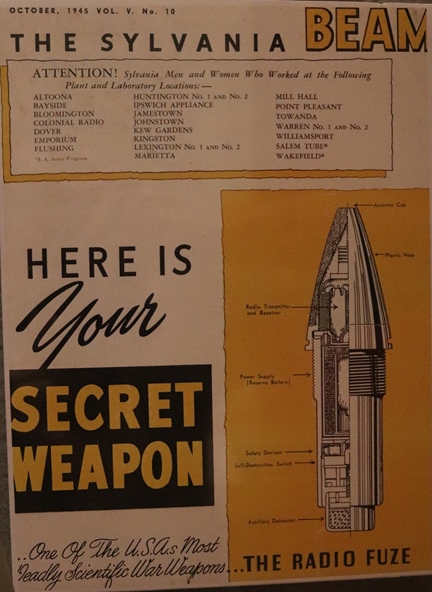

This cut-away diagram shows the major components of the VT fuze.

The VT fuze was made from

components purchased from U.S. Navy authorized

suppliers. The original cost of a VT fuze in 1942 was $732.

By 1945 it had been reduced to $18. This is $11,514 and $256 in

2020 dollars, respectively.

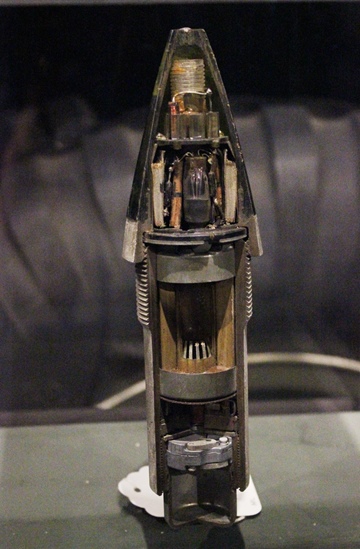

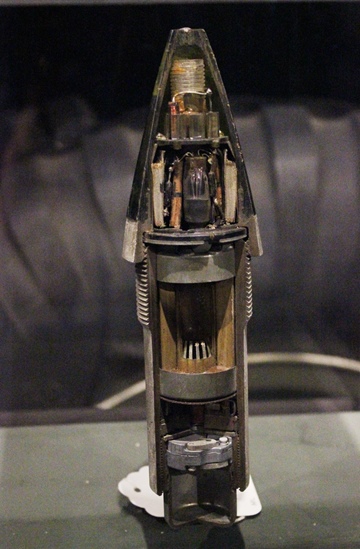

This cut-away of a VT fuze is on display at the National Electronics

Museum in Linthicum, MD. Author's photo.

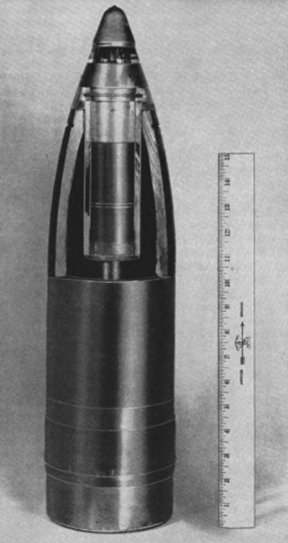

This cut-away shows how the VT fuze fit in a shell.

There are several excellent websites that

explain the technical issues and the end use of the proximity fuze

during World War Two. However, this is the only one that

recognizes the many different companies that contributed to the making

of the fuze that was so important to an expedited U.S. Navy's winning of

the war in the central Pacific. Most of the companies listed in

the several tables on this page no longer exist. Over eighty years

after the U.S. Navy began working on the concept of a proximity fuze and

over 75 years after the end of the war, time, technology advancement, and

attrition have reduced the number of companies to just a handful that

contributed to this important product. For a person who grew up

after World War Two, many of the names of the companies on this page are

recognizable. Someone considerably younger will have a difficult

time recognizing any of the names on this page.

Final Assembly Plants: Five

different companies built the VT fuze. Crosley was the first into

production. RCA had two plants dedicated to the production of the

VT fuze. The Sylvania plant in Ipswich, MA produced the most VT

fuzes of the six locations. Eastman-Kodak was the only company

that continued to build the VT fuzes after World War Two.

Crosley Corporation was the first of the VT fuze

producers to cease to exist. On August 8, 1945, even while the war in the Pacific was still in

progress, the owners sold the company to AVCO and Crosley became a

division of AVCO. By 1956 it was gone. Eastman Kodak still

exists,

although it had to file for bankruptcy in 2012. It is a former

shadow of itself. RCA only remains as a brand name, which is owned by a

foreign company. Sylvania is also now a brand name owned by a

foreign company. McQuay-Norris was an auto parts manufacturer that

merged with Eaton Yale & Towne in 1969.

McQuay-Norris of St. Louis, MO has the

distinction of being the only automobile industry company that

contributed significantly to the VT fuze program. St. Louis was

also as far west as any of the suppliers were located. Most were

in NJ, NY, and PA.

|

Table 1 -

VT Fuze Final Assembly Companies and Locations |

|

Company |

Number Built |

Number Shipped for Combat Use |

Number Tested |

|

Crosley - Cincinnati, OH |

5,205,913 |

5,096,552 |

109,361 |

|

Eastman Kodak - Rochester, NY |

2,443,914 |

2,352,304 |

91,610 |

|

McQuay-Norris - St. Louis, MO |

2,862,368 |

2,843,249 |

19,119 |

|

RCA - Bloomington, IN |

3,525,843 |

3,446,829 |

79,014 |

|

RCA - Camden, NJ |

2,352,411 |

2,323,548 |

28,863 |

|

Sylvania - Ipswich, MA |

5,683,032 |

5,622,675 |

60,357 |

|

Total |

22,073,481 |

21,685,157 |

388,324 |

Major Suppliers: Over the

course of the VT fuze program in World War Two, many companies from a

variety of industries supplied components for the fuze. Some were

used in the initial phase or for a short period of time. The

companies

listed in Table 2 below contributed large amounts of critical components

for use in the VT fuze. The complete list of suppliers in Table

10. Early suppliers are listed in Table 9.

Jefferson Electric and the Hoover Company

together supplied 100,000 mercury safety switches per day at peak

production. These were the most difficult of the products made for

the fuze. The Hoover Company is a classic example of a company

that produced highly technical products during World War Two that were

totally foreign to its normal non-war products. For Hoover this

was vacuum cleaners. It was one of many American companies that

ended up making products during World War Two that were totally

different from their peacetime products.

|

Table 2 -

Major VT Fuze Component Companies and Locations |

|

Company |

Product |

Comments |

|

Sylvania - Mill Hall, PA |

Miniature Tubes |

10,000 workers were employed at Mill Hall, PA and the other

Sylvania plants making the tubes and their components. At

peak production, Sylvania employees were producing a 400,000 per

day. Prior to World War Two, the entire American tube industry was

producing 600,000 per day. |

|

Hoover Company, North Canton, OH |

Safety Devices and Batteries |

The

safety devices were mercury switches. As of VJ Day, Hoover

was producing 5,000 batteries per day. |

|

Jefferson Electric, Bellwood, IL |

Safety

Devices |

The safety

devices were mercury switches. |

|

National Carbon, Winston-Salem, NC |

Batteries |

As of

VJ Day, National Carbon was producing 73,000 batteries per day. |

|

Eastman Kodak, Rochester, NY |

Batteries |

As of VJ Day,

Hoover was producing 23,000 batteries per day. |

|

International Resister Company, Philadelphia, PA |

Resistors |

This was the main supplier of resistors for the VT fuze. |

RCA: RCA had two plants

committed to the production of the VT fuze during World War Two.

The Bloomington, IN plant made radios prior to World War Two. Then

it became RCA's main television assembly plant after the war. The Bloomington

plant received the Navy "E" Award after the end of hostilities in

recognition of it producing its VT fuzes in a timely manner. It

could not receive the award during the war because of the top secret

nature of the VT fuze.

Photo courtesy of the Monroe County

Historical Center added 8-23-2020.

The RCA plant in Bloomington, IN.

|

Table 3 - Number of VT

Proximity Fuzes built by RCA Bloomington, IN during World War Two

Primary Source: Bureau of Ordnance, U.S. Navy, History

of the Bureau of Ordnance, World War II, vol.2, pt. 2.

T designations are U.S. Army, unless otherwise noted for British

Army.

Mk designations are U.S. Navy, unless otherwise noted for

British Navy. |

|

Fuze Type |

Number Built |

Number Shipped for Combat Use |

Number Tested |

| T76 -

Large Howitzer |

472,603 |

457,870 |

14,733 |

| T76 -

Large Howitzer RB6 |

123,301 |

119,862 |

3,439 |

| T80 -

Small Howitzer |

888,719 |

874,520 |

14,199 |

| T80 -

Small Howitzer RB6 |

1,115,890 |

1,105,001 |

10,889 |

| T80 -

Small Howitzer RB12 |

118,575 |

116,712 |

1,863 |

| T97 -

British Small Howitzer RB6 |

331,303 |

328,224 |

3,079 |

| T100

- British Large Howitzer |

39,895 |

39,000 |

895 |

| Mk 33

- British Navy |

223,515 |

205,940 |

17,575 |

| Mk 41

- British Navy |

212,042 |

199,700 |

12,342 |

|

Totals |

3,525,843 |

3,446,829 |

79,014 |

Table 4 - Number of VT

Proximity Fuzes built by RCA Camden, NJ during World War Two

Primary Source: Bureau of Ordnance, U.S. Navy, History

of the Bureau of Ordnance, World War II, vol.2, pt. 2.

T designations are U.S. Army, unless otherwise noted for British

Army.

Mk designations are U.S. Navy, unless otherwise noted for

British Navy. |

|

Fuze Type |

Number Built |

Number Shipped for Combat Use |

Number Tested |

| Mk 173 - Five

Inch Rocket |

11,076 |

10,000 |

1,076 |

| T31 - Mark

170 4.5 Inch Rocket |

3,071 |

2,648 |

423 |

| T76 -

Large Howitzer |

367,912 |

363,000 |

4,912 |

| T76 -

Large Howitzer RB6 |

829,293 |

821,088 |

8,205 |

| T76 -

Large Howitzer RB12 |

532 |

0 |

532 |

| T80 -

Small Howitzer |

375,139 |

370,404 |

4,735 |

| T80 -

Small Howitzer RB6 |

655,644 |

648,948 |

6,696 |

| T100

- British Large Howitzer |

42,663 |

41,460 |

1,203 |

| T100

- British Large Howitzer RB6 |

67,081 |

66,000 |

1,081 |

| Totals |

2,352,411 |

2,323,548 |

28,863 |

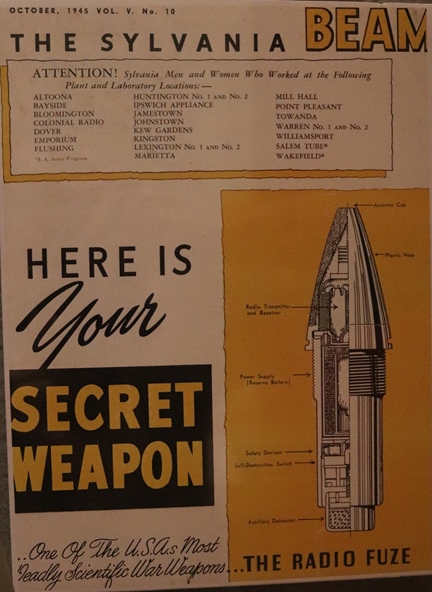

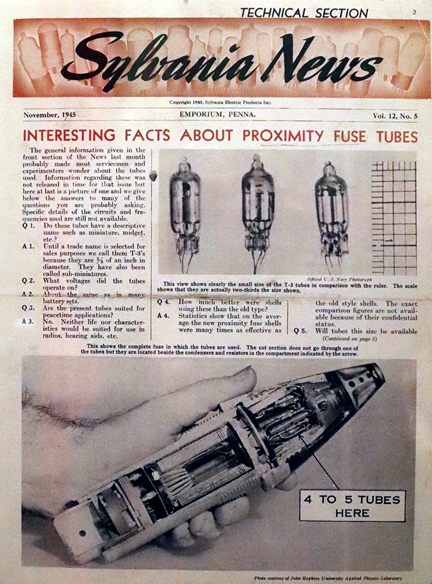

Sylvania: Sylvania was a key

company to the VT fuze program with twenty-three plants. Fifteen

were dedicated to the production of components and the final assembly of

the VT fuze. The company was supplying

400,000tubes per day at peak production.

The miniature tubes were held in place by

wax, to protect them from the intense g-forces when being fired from an

anti-aircraft gun. The wax also held them in place from the large rotational

g-forces of the shell. Sylvania produced over 100 million tubes

for the VT program.

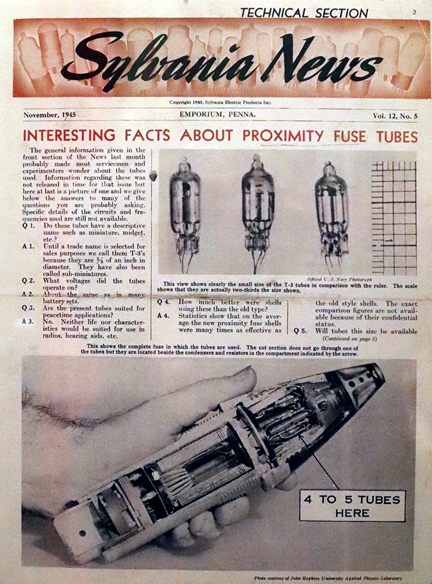

Below are three Sylvania

post-war documents detailing the VT fuze and the miniature tubes.

Table 5 - Number of VT

Proximity Fuzes built by Sylvania, Ipswich, MA during World War Two

Primary Source: Bureau of Ordnance, U.S. Navy, History

of the Bureau of Ordnance, World War II, vol.2, pt. 2.

T designations are U.S. Army, unless otherwise noted for British

Army.

Mk designations are U.S. Navy, unless otherwise noted for

British Navy. |

|

Fuze Type |

Number Built |

Number Shipped for Combat Use |

Number Tested |

| T73 -

75mm AC |

1,000 |

1,000 |

0 |

| T74 -

90mm AA |

525,122 |

517,472 |

7,650 |

| T80 -

Small Howitzer |

1,853,579 |

1,838,018 |

15,561 |

| T80 -

Small Howitzer RB6 |

1,003,984 |

998,535 |

5,449 |

| T97 -

British Small Howitzer |

36,296 |

36,000 |

296 |

| T97 -

British Small Howitzer RB6 |

236,746 |

235,515 |

1,231 |

| T152

- 90mm AA Short |

227,989 |

224,900 |

3,089 |

| Mk 32

- 5"/38 |

686,347 |

672,609 |

13,738 |

| Mk 40

- 5"/38 |

139,184 |

138,000 |

1,184 |

| Mk 53

- 5"/38 |

400,175 |

395,503 |

4,672 |

| Mk 58

- 3"/50 |

572,610 |

565,123 |

7,487 |

|

Total |

5,683,032 |

5,622,675 |

60,357 |

Crosley Corporation:

For a more comprehensive look at the Crosley Corporation's

participation in the VT fuze program and its other World War Two

products, please visit my Crosley page listed at the top of this page.

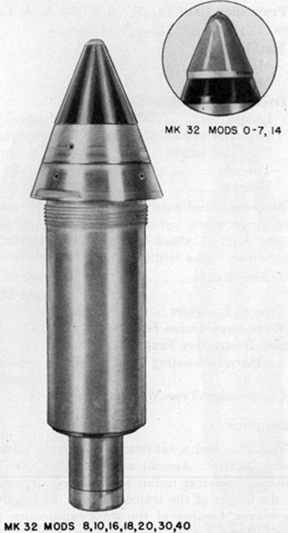

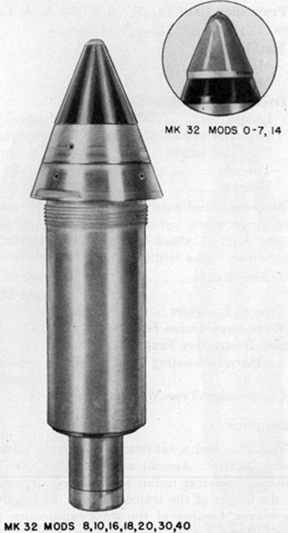

The Mk 32 was the first VT fuze used in the

Navy's 5"/38 dual purpose gun. It was 12 inches long, 3.3

inches in diameter at its widest point, and weighed 6.81 lbs. It

would detonate within fifty feet of a target. When tested at an

over-water firing range, it would detonate 130 feet above the water.

Note the number of modifications the Mk 32 had over its lifetime and the

change in the shape of the antenna cap. It was a Crosley-built Mk

32 that shot down the drones in navy testing, and a Crosley Mk 32 was

the first VT fuze to shoot down a Japanese aircraft in the Pacific.

Crosley built 1,368,785 Mk 32s.

|

Table 6 - Number of VT

Proximity Fuzes built by Crosley during World War Two

Primary Source: Bureau of Ordnance, U.S. Navy, History

of the Bureau of Ordnance, World War II, vol.2, pt. 2.

T designations are U.S. Army, unless otherwise noted for British

Army.

Mk designations are U.S. Navy, unless otherwise noted for

British Navy. |

|

Fuze Type |

Number Built |

Number Shipped for Combat Use |

Number Tested |

| T74 -

90mm AA |

974,628 |

951,000 |

23,628 |

| T75 -

120mm AA |

621 |

333

|

288

|

| T98 -

3.7 in AA British |

628,068 |

615,574 |

12,494 |

| T149

- 3.7 in AA British Short Round |

124,238 |

122,592 |

1,646

|

| T152

- 90mm AA Short |

552,295 |

545,736 |

6,559

|

| Mk 32

- 5"/38 |

1,368,785 |

1,335,798 |

32,987 |

| Mk 40

- 5"/38 |

200,432 |

195,000 |

5,432

|

| Mk 45

- 3"/50 Mod 11 |

79,186 |

75,852 |

3,334

|

| Mk 47

- 6"/47 |

27,205 |

26,532 |

673

|

| Mk 53

- 5"/38 |

880,042 |

863,855 |

16,187 |

| Mk 56

- 3"/50 - British Navy |

121,610 |

119,624 |

1,986

|

| Mk 59

- 5"/54 |

32,414 |

31,635 |

779

|

| Mk 60

- British Navy |

216,389 |

213,021 |

3,368

|

|

Totals |

5,205,913 |

5,096,552 |

109,361 |

Eastman Kodak: The company at the

end of the war was producing 23,000 batteries per day along with doing

final assembly. After World War Two, Eastman Kodak continued to

make the VT fuze.

|

Table 7 - Number of VT

Proximity Fuzes built by Eastman Kodak Rochester, NY during World War Two

Primary Source: Bureau of Ordnance, U.S. Navy, History

of the Bureau of Ordnance, World War II, vol.2, pt. 2.

T designations are U.S. Army, unless otherwise noted for British

Army.

Mk designations are U.S. Navy, unless otherwise noted for

British Navy. |

|

Fuze Type |

Number Built |

Number Shipped for Combat Use |

Number Tested |

| T80 -

Small Howitzer |

1,351,517 |

1,299,000 |

52,517 |

| T80 -

Small Howitzer RB2 |

92,668 |

90,000 |

2,668 |

| T80 -

Small Howitzer RB6 |

641,935 |

630,000 |

11,935 |

| T97 -

British Small Howitzer |

69,425 |

66,624 |

2,801 |

| Mk 33

- British Navy |

117,195 |

101,920 |

15,275 |

| Mk 53

- 5"/38 |

190 |

0 |

190 |

| Mk 58

- 3"/50 |

170,984 |

164,760 |

6,224 |

|

Totals |

2,443,914 |

2,352,304 |

91,610 |

McQuay-Norris:

|

Table 8 - Number of VT

Proximity Fuzes built by

McQuay-Norris St. Louis, MO during World War Two

Primary Source: Bureau of Ordnance, U.S. Navy, History

of the Bureau of Ordnance, World War II, vol.2, pt. 2.

T designations are U.S. Army, unless otherwise noted for British

Army.

Mk designations are U.S. Navy, unless otherwise noted for

British Navy. |

|

Fuze Type |

Number Built |

Number Shipped for Combat Use |

Number Tested |

| T80 -

Small Howitzer |

2,492,711 |

2,476,111 |

16,600 |

| T80 -

Small Howitzer RB6 |

369,647 |

367,138 |

2,519 |

| Total |

2,862,368 |

2,843,249 |

19,119 |

Other suppliers:

|

Table 9 -

Early Suppliers and Research Facilities utilized in the VT Fuze

Program |

|

State and Company |

City |

Comments/Product |

| CT |

|

|

|

Remington Arms Company, Inc. |

Bridgeport |

Research |

| DE |

|

|

| Hercules Powder

Company |

Wilmington |

Research and

Squib Production |

| IL |

|

|

| C.F. Burgess

Laboratories, Inc. |

Elgin |

Battery Research |

| Erwood Company |

Chicago |

Prototype

Components and Final Assembly |

| General Sintering

Corporation |

Evanston |

Powdered Metal

Parts |

| Jefferson Switch

Company |

Bellwood |

Research and

Mercury Switch Production |

| KY |

|

|

| Ken-Rad Tube &

Lamp Company |

Owensboro |

Research |

| MA |

|

|

| Hytron

Corporation |

Salem |

Research and Tube

Production |

| Raytheon

Manufacturing Company |

Newton |

Research and Tube

Production |

| Waltham Watch

Company |

Waltham |

Research |

| MD |

|

|

| John Hopkins

University |

Baltimore |

Research |

| MI |

|

|

| University of

Michigan |

Ann Arbor |

Research |

| NJ |

|

|

| Henry L. Crowley

& Company |

West Orange |

Powdered Metal

Parts |

| National Union

Radio Corporation |

Newark |

Research |

| Princeton

University |

Princeton |

Research |

| Radio Corporation

of America |

Camden |

Research and

Final Assembly |

| Radio Corporation

of America |

Harrison |

Final Assembly |

| NM |

|

|

| University of New

Mexico |

Albuquerque

|

Research |

| NY |

|

|

| American

Electro-Metal Company |

Yonkers |

Powdered Metal

Parts |

| General Electric

Company |

Schenectady |

Research |

| National Carbon

Company |

New York |

Research and

Battery Production |

| Sylvania Electric

Products |

New York |

Tubes and Final

Assembly |

| Bell Telephone

Laboratories - Western Electric Company |

New York |

Research and Tube

Production |

|

Eastman Kodak Company |

Rochester |

Research and

Final Assembly |

| OH |

|

|

| National Carbon

Company |

Cleveland |

Battery

Production |

| Crosley

Corporation |

Cincinnati |

Development and

Final Assembly |

| Delco Moraine

Division of General Motors |

Dayton |

Powdered Metal

Parts |

| Hoover Company |

North Canton |

Mercury Switch

Production |

| OK |

|

|

| Carter Oil

Company - Geophysical Research Laboratory |

Tulsa |

Mercury Switch

Design and Research |

| PA |

|

|

| Keystone Carbon

Company |

St. Marys |

Sintered Metal

Cap Production |

| Powdered Metal

Products |

St. Marys |

Sintered Metal

Cap Production |

| Washington, DC |

|

|

| Carnegie

Institution of Washington |

|

Research |

| WI |

|

|

| Thomas R. Gibbs &

Company |

Delavan |

Research |

|

Table 10 -

All Suppliers by State engaged in VT Fuze Component Production

as of March 1945 |

|

State and Company |

City |

Comments/Product |

| CT |

|

|

|

Coastal Machine Works |

Bridgeport |

|

|

Goodyear Rubber Sundries |

New

Haven |

|

| The

Stratfield Company |

Bridgeport |

|

| GA |

|

|

|

Miller-Hydro Company |

Bainbridge |

|

|

Reynolds Corporation |

Macon |

|

| IL |

|

|

|

American Condenser Company |

Chicago |

Capacitors |

| John

E. Fast |

Chicago |

|

|

Hegeler Zinc Company |

Danville |

|

|

Illinois Zinc Company |

Chicago |

|

|

Jefferson Electric Company |

Bellwood |

|

| Lion

Manufacturing Company |

Chicago |

|

|

Mathieson & Hegeler Zinc Company |

LaSalle |

|

| Muter

Company |

Chicago |

|

|

Santay Corporation |

Chicago |

|

|

Vaughn Novelty Company |

Chicago |

|

| IN |

|

|

|

Aluminum Company of America |

Lafayette |

|

|

Durham Manufacturing Company |

Muncie |

This

company was a surprise to me, as its former plant location is

only 13 miles

from my residence. During peace time the company built

furniture. During World War Two, Durham manufactured 20mm

and 40mm projectiles for the U.S. Navy. The Navy awarded it the

Army-Navy "E" flag five times during the war. With such an

excellent production record the Navy brought the company into

the VT fuze program.

For more information on this company. go to my Durham Manufacturing

Company link at the top of the page. |

| RCA

Manufacturing Company |

Bloomington |

|

| KY |

|

|

|

Sylvania Electric Products, Inc. |

Lexington |

|

| MA |

|

|

|

American Fireworks Company |

West

Hannover |

|

| Bolta

Company |

Lawrence |

|

|

Cornell-Dubilier |

New

Bedord |

Capacitors |

|

Cornell-Dubilier |

Worchester |

Capacitors |

|

General Electric |

Lynn |

|

|

General Electric |

Pittsfield |

|

|

Prophylactic Brush Company |

Florence |

|

|

Sickles Company |

Chicago |

|

|

Sprague Electric Company |

North

Adams |

Capacitors |

|

Sylvania Electric Products, Inc. |

Ipswich |

|

| Tobe

Deutschmann Corporation |

Canton |

|

| MI |

|

|

|

Electronics Products |

Dexter |

|

| King-Seely

Corporation |

Ann

Arbor |

|

|

Modern Plastics Corporation |

Benton Harbor |

|

|

Thermo Plastics Division of Standard Products Company |

St.

Clair |

|

|

Tecumseh Products Company |

Tecumseh |

|

| MO |

|

|

|

McQuay-Norris Manufacturing Company |

St.

Louis |

|

| St.

Louis Moulding Company |

St.

Louis |

|

| NC |

|

|

|

National Carbon Company |

Winston-Salem |

Batteries |

|

Wright Automotive Company |

Durham |

|

| NH |

|

|

|

Sylvania Electric Products, Inc. |

Dover |

Tubes

and Final Assembly |

| NJ |

|

|

|

Automatic Winding Company |

East

Newark |

|

|

Callite Tungsten |

Union

City |

|

|

Thomas A. Edison Company |

West

Orange |

|

|

Eisler Engineering Company |

Newark |

|

|

Federal Telephone and Radio Corporation |

Newark |

|

|

General Aniline and Film Corporation |

Graselli |

|

|

Interchemicals Specialties, Incorporated |

Bound

Brook |

|

| RCA

Manufacturing Company |

Camden |

Final

Assembly |

| Solar

Manufacturing Company |

Bayonne |

|

|

Standard Tool Company |

Arlington |

|

| Tube

Reducing Corporation |

Wallington |

|

|

Wallington Tube Company |

Wallington |

|

| NY |

|

|

|

American Brass Company |

Buffalo |

|

| B.G.

Corporation |

New

York |

|

|

Beech-Nut Packing Company |

Canajoharie |

|

| C.C.

Bradley Company |

Homer |

|

| C.C.

Bradley Company |

Syracuse |

|

|

Colonial Radio Corporation |

Buffalo |

|

|

Control Instrument Corporation |

Brooklyn |

|

|

Doehler Die Casting Company |

Batavia |

|

|

Dumont Electric Company |

New

York |

|

|

Eastman Kodak |

Rochester |

Batteries and Final Assembly |

|

Electrical Reactance |

Franklinville |

|

| H & R

Tool Works |

Buffalo |

|

|

Hercules Powder Company |

Port

Ewen |

|

| Ideal

Plastics Corporation |

Long

Island |

|

| King

Laboratories |

Syracuse |

|

| New

Jersey Zinc Company |

New

York |

|

|

Sampson United Corporation |

Oswego |

|

| Solar

Manufacturing Company |

New

York |

|

|

Sylvania Electric Products, Inc. |

Flushing, Long Island |

Tube

Components |

|

Sylvania Electric Products, Inc. |

Kew

Gardens |

Tube

Components |

| OH |

|

|

| Barth

Stamping and Machine Company |

Cleveland |

|

|

Clippard Instrument Company |

Cincinnati |

|

|

Corcoran-Brown Division of Auto-Lite |

Cincinnati |

|

|

Crosley Corporation |

Cincinnati |

Final

Assembly |

|

Detroit Harvester |

Toledo |

|

|

General Electric |

Cleveland |

|

|

Hoover Company |

North

Canton |

Batteries and Mercury Safety Switches |

|

National Carbon Company |

Cleveland |

|

|

National Cash Register Company |

Dayton |

|

| Recto

Molded Products |

Cincinnati |

|

| J.C.

Ulmer Companyi |

Cleveland |

|

|

Western Automatic Screw Machine Corporation |

Elyria |

|

|

Westinghouse Electric & Manufacturing Company |

Mansfield |

|

| PA |

|

|

| Acme

Die and Machine |

Latrobe |

|

|

Aluminum Company of America |

Pittsburgh |

|

| Atlas

Powder Company |

Reynolds |

|

|

Cameron Manufacturing |

Reynoldsville |

|

| Erie

Resistor Corporation |

Erie |

Resistors |

|

General Aniline and Film Corporation |

Easton |

|

| P.R.

Hoffman Company |

Carlisle |

|

|

International Resistance Company |

Philadelphia |

Resistors |

|

Marine Aircraft Instrument Company |

Clearfield |

|

| Speer

Resistor Company |

St.

Mary's |

Resistors |

|

Swanson Machine & Tool Company |

Erie |

|

|

Sylvania Electric Products, Inc. |

Altoona |

Tube

Components |

|

Sylvania Electric Products, Inc. |

Austin |

Tube

Components |

|

Sylvania Electric Products, Inc. |

Emporium |

Tube

Components |

|

Sylvania Electric Products, Inc. |

Mill

Hall |

Tube

Components |

|

Sylvania Electric Products, Inc. |

Montoursville |

Tube

Components |

|

Sylvania Electric Products, Inc. |

Smethport |

Tube

Components |

|

Sylvania Electric Products, Inc. |

Towanda |

Tube

Components |

|

Sylvania Electric Products, Inc. |

Warren |

Tube

Components |

|

Sylvania Electric Products, Inc. |

Williamsport |

Tube

Components |

| RI |

|

|

|

Cornell-Dubilier |

Providence |

Capacitors |

|

Kleistone Rubber Company |

Warren |

|

| VT |

|

Batteries |

|

National Carbon Company |

Bennington |

|

| WV |

|

|

|

Sylvania Electric Products, Inc. |

Huntington |

Tube

Components |

| WI |

|

|

|

Centralab Division of Globe Union |

Milwaukee |

Capacitors |

|

Wisconsin Screw Machine Company |

Racine |

|

|