|

Warner

Gear In World War Two

Muncie, IN

1901-2009

A Division of Borg-Warner after 1928

This page updated 6-1-2024.

The Jeep is the most famous and recognizable

vehicle of World War Two. This 1/4-ton 4x4 truck was ubiquitous

for its service in the war. It was so well-designed and

utilitarian that vehicles with the Jeep name are still being made today.

Many of them still closely resemble the ones built during World War

Two. All 631,927 Jeeps that were built during World War Two by the

Ford Motor Company and Willys-Overland had Warner Gear transmissions in

them. This Willys-Overland-built Jeep was produced in Toledo, OH

in June 1944 with a Warner Gear transmission model number AS2-T-84-J.

Willys-Overland Jeeps were designated MB.

Author's photo.

The Ford-built Jeep in this photo

displays the markings of the United States Marine Corps. It is one

of 281,578 that Ford built with Warner Gear transmissions.

Ford-built Jeeps were designated at GP and GPWs. Author's photo.

This Ford-built GPW was delivered May 1943

with a Warner Gear AS2-T-84-J transmission. Not only did American

forces use the Jeep on a world-wide basis during World War Two, but

other countries used the Jeep in their military services. This one

is shown as a British Long Range Desert Group vehicle. Author's photo.

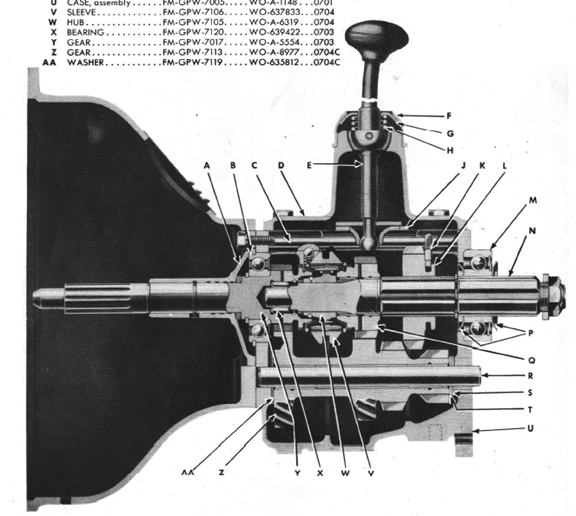

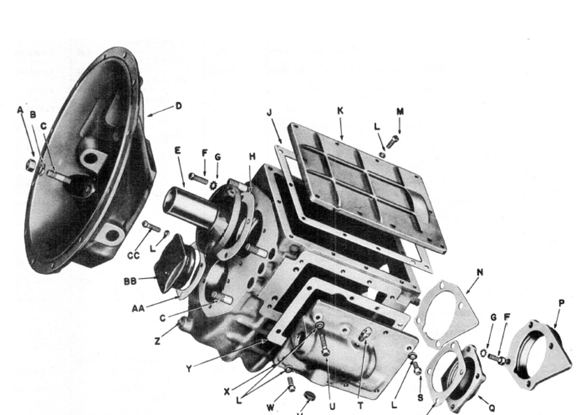

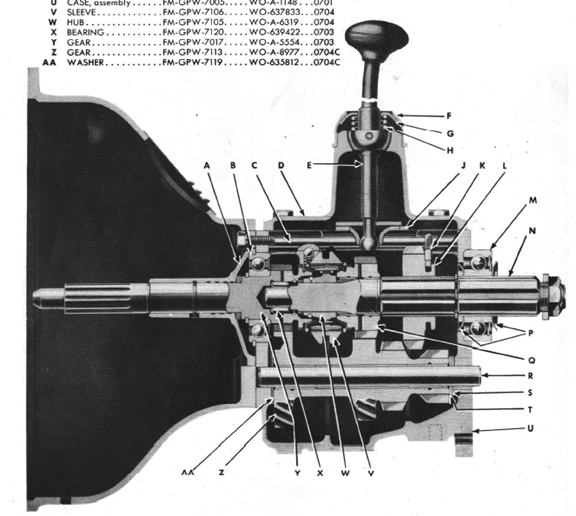

The Warner Gear transmission model

number AS2-T-84-J.

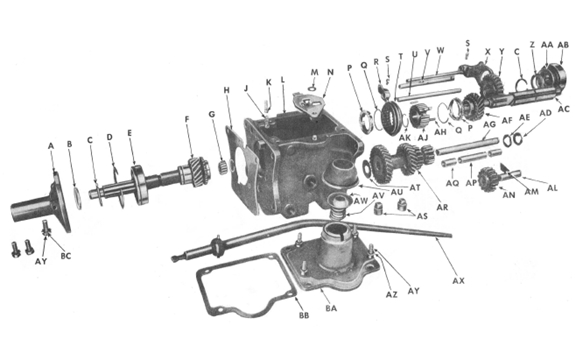

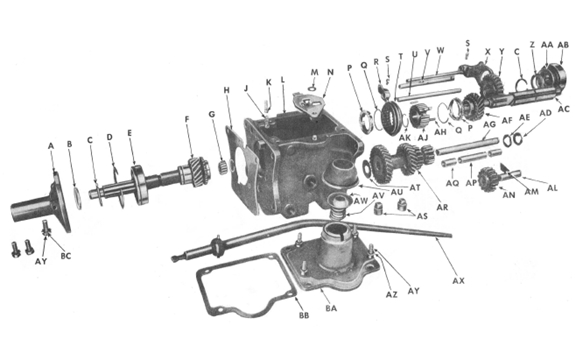

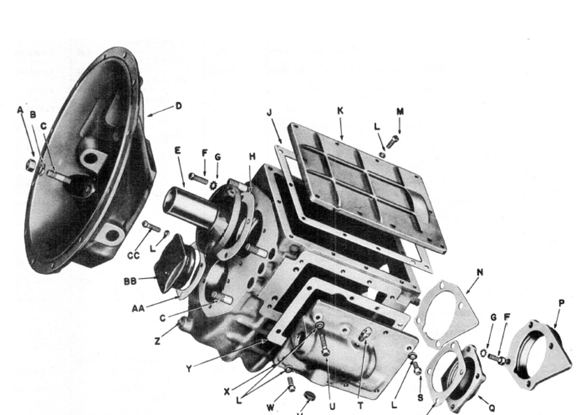

This is an exploded view of the Warner

Gear AS2-T-84-J.

The Warner Gear Company was established in

1901 by brothers Tom and Harry Warner in Muncie, IN. They started

manufacturing a transmission of their design with a differential gear

that allowed the wheels on a vehicle to turn at different speeds when

the vehicle turned.

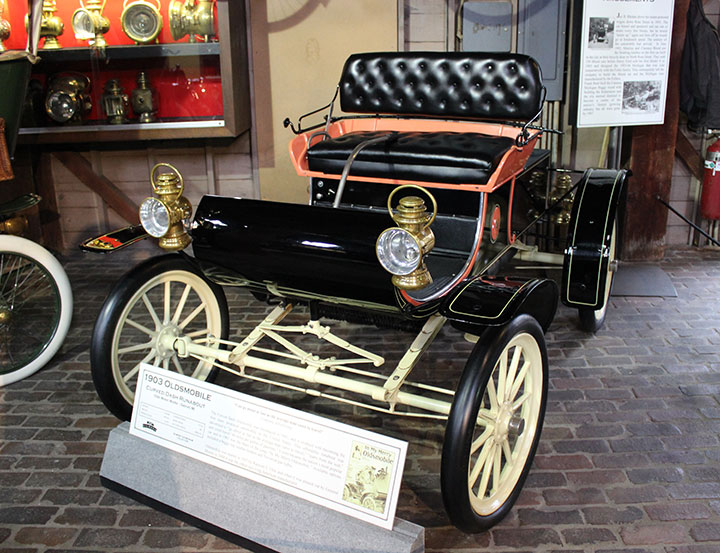

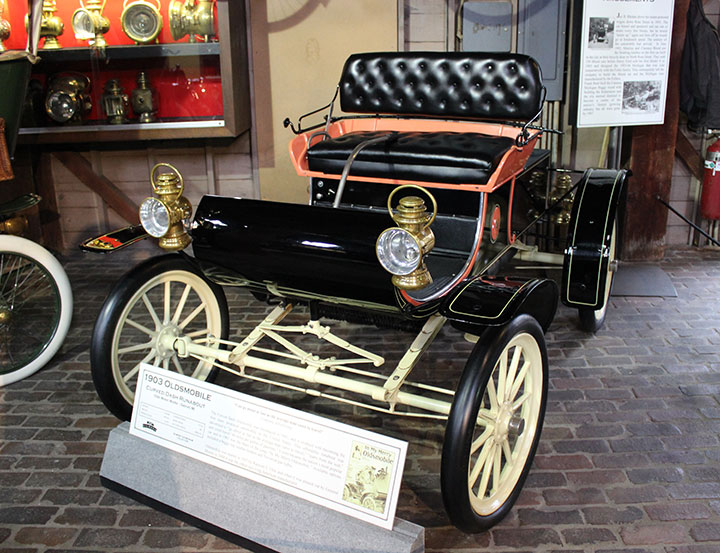

R.E. Olds was so impressed with the Warner

brothers' transmission that he purchased 4,000 of them for the Curved

Dash Oldsmobile.

Author's photo.

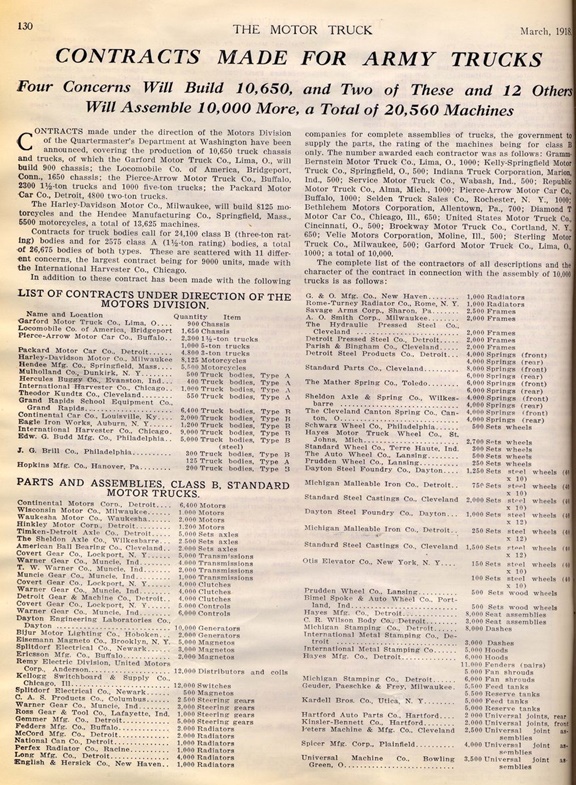

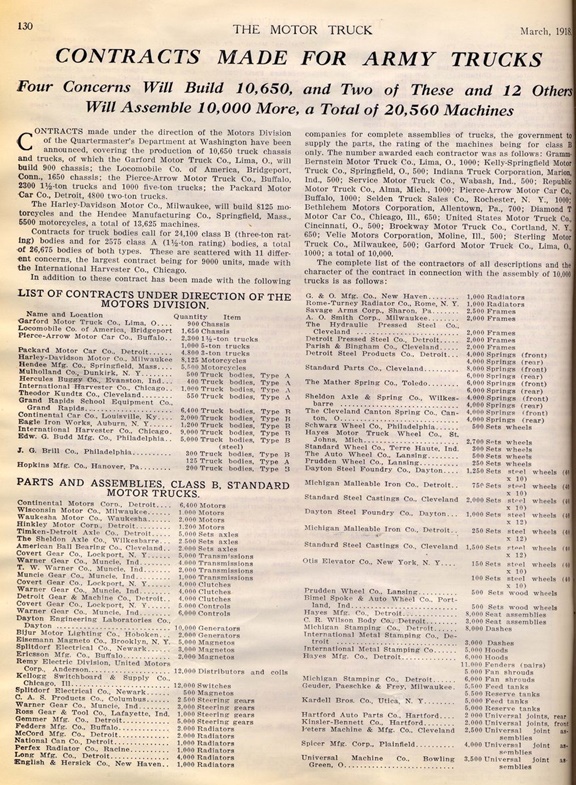

During the first World War, Warner Gear had

orders for 4,000 transmissions, 4,000 clutches, 6,000 controls, and

2,000 steering gears for the Class B, Standard Motor Truck. This was more commonly known as the Liberty Truck. Document

courtesy of Warren Richardson.

This World War One Class B Liberty Truck has

been restored to operating condition by the First Division Museum in

Wheaton, IL. Author's photo.

In 1919, Warner Gear developed and began

marketing a standard automotive transmission, the T-64. This

transmission was used in many vehicles of the era, as it was mass

produced and the most cost effective transmission on the market.

In 1920 and 192,9 Warner Gear built plants in the near southeast side of

Muncie in the area of South Hackley and East Seymour Streets.

In 1928 Warner Gear became a division of Borg Warner that was formed

from Warner Gear and several other companies. In 1930 a new plant was built on the west side of Muncie.

This half mile long site would later become the company's main manufacturing plant.

In 1940 the company was the first to manufacture a transfer case for a

four-wheel drive vehicle. The company reached peak employment in the early

1950s with 6,100 employees. Warner Gear was the first company to

build the T-10 manual transmission for the new Chevrolet Corvette. After

a general decline over the post-World War Two years, Warner Gear shut

down its operations on April 24, 2009.

Warner Gear World War Two Production: The company built

901,397 transmissions to help win World War Two as noted in Table 1.

It also built at least 12,314 transfer cases for the war effort. Warner Gear also built

241,067 parkng brakes, gear sets

for light tanks,

37 types of aircraft gears, truck brake hangars, bearing retainers,

de-clutching units, brake drums, output shafts, axle gears, cylinder

sleeves, aircraft turret elevating shafts, and super charger shafts.

Table 1 - World War Two Vehicles

Accepted by Detroit Ordnance, US Army with Warner Gear

Transmissions

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Warner Gear Model Number |

Type |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| AS2-T-84-J |

Willys-Overland Truck, 1/4-ton,

4x4, Command (Jeep) |

9,129 |

83,739 |

91,955 |

108,806 |

56,720 |

350,349 |

| AS2-T-84-J |

Ford Truck, 1/4-ton,

4x4, Command (Jeep) |

3,700 |

88,987 |

80,721 |

73,262 |

34,908 |

281,578 |

T93 with

Cleveland U-joint flange

AS1-T93 without U-joint flange |

Studebaker US6

2-1/2-ton, 6x6 Cargo Truck |

3,912 |

20,642 |

31,440 |

41,965 |

30,162 |

128,121 |

T93 with

Cleveland U-joint flange

AS1-T93 without U-joint flange |

Studebaker US6

2-1/2-ton, 6x4 Cargo Truck |

|

18,166 |

22,068 |

33,256 |

17,252 |

90,742 |

T93 with

Cleveland U-joint flange

AS1-T93 without U-joint flange |

Reo-built US6

2-1/2-ton, 6x6 Cargo Truck |

|

|

|

13,004 |

9,200 |

22,204 |

| T-95 |

Ford M8 6x6

Armored Car |

|

|

4,299 |

3,383 |

841 |

8,523 |

| T-95 |

Ford M20 6x6

Armored Car |

|

|

1,624 |

1,337 |

830 |

3,791 |

| Total Wheeled

Vehicles |

|

16,741 |

211,534 |

232,107 |

275,013 |

149,913 |

885,308 |

| |

|

|

|

|

|

|

|

| T-84-J |

Studebaker Carrier,

Cargo, Light, M28 (T15) |

|

306 |

460 |

|

|

766 |

| T-84-J |

Studebaker Cargo,

Carrier, Light, M29 (T24) |

|

|

1,525 |

2,951 |

|

4,476 |

| T-84-J |

Studebaker Cargo,

Carrier, Light, M29C (T24) |

|

|

|

4,401 |

6,446 |

10,847 |

| Total Tracked

Vehicles |

|

|

306 |

1,985 |

7,352 |

6,446 |

16,089 |

| Grand Total

Vehicles and Transmissions |

|

16,741 |

211,840 |

234,092 |

282,365 |

156,359 |

901,397 |

The historical record indicates that Warner

Gear built a total of 1.6 million transmissions for the war effort.

As Table 1 indicates, only 901,397 have been identified. While the

Ordnance Supplier Catalogs for the CCKW series trucks only lists the

Clark Equipment 204-VO series 5-speed transmission for use in the

vehicle, the CCKW Maintenance Manual also lists the Warner Gear AS1-T93

transmission for use. With only 549,977 CCKW series trucks built,

and two companies sharing the supply of transmissions, this still does

not account for all of the uses of Warner Gear transmissions in World

War Two.

Table 2 - World War Two Vehicles

Accepted by Detroit Ordnance, US Army with Warner Gear Transfer

Cases

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Warner Gear Model Number |

Type |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| AS1-J5 |

Ford M8 6x6

Armored Car |

|

|

4,299 |

3,383 |

841 |

8,523 |

| AS1-J5 |

Ford M20 6x6

Armored Car |

|

|

1,624 |

1,337 |

830 |

3,791 |

| Grand Total

Vehicles and Transfer Cases |

|

|

|

5,923 |

4,720 |

1,671 |

12,314 |

Table 3 - World War Two Vehicles

Accepted by Detroit Ordnance, US Army with Warner Gear Parking

Brakes

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Warner Gear Model Number |

Type |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| 1AA28-12 |

Studebaker US6

2-1/2-ton, 6x6 Cargo Truck |

3,912 |

20,642 |

31,440 |

41,965 |

30,162 |

128,121 |

| 1AA28-12 |

Studebaker US6

2-1/2-ton, 6x4 Cargo Truck |

|

18,166 |

22,068 |

33,256 |

17,252 |

90,742 |

| 1AA28-12 |

Reo-built US6

2-1/2-ton, 6x6 Cargo Truck |

|

|

|

13,004 |

9,200 |

22,204 |

| Grand Total

Parking Brakes |

|

3,912 |

38,808 |

53,508 |

88,225 |

56,617 |

241,067 |

Table 4 - Warner Gear's Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division, Requirements and Progress

Branch January 21, 1946. |

|

Product-Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Forgings -

Foreign |

$66,000 |

3-1941 |

4-1941 |

| Supercharger

Drives - Navy |

$110,000 |

6-1943 |

11-1943 |

| Transmission

Assys - Army Ordnance |

$2,757,000 |

1-1945 |

11-1945 |

| Total |

$2,933,000 |

|

|

Warner Gear supplied 241,067 T93 series

transmissions and parking brakes for the US6 2-1/2-ton 6x6 and 6x4 trucks built by

Studebaker and the Reo Motor Car Company.

Author's photo.

Studebaker was the designer of the truck and

Reo built them under license. Nearly all of the trucks were sent

to the Soviet Union under Lend-Lease where the word truck became

synonymous with the name Studebaker.

Author's photo.

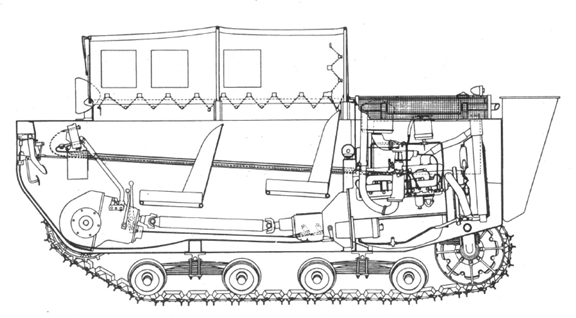

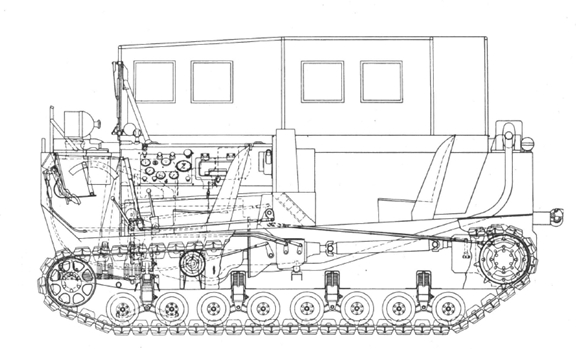

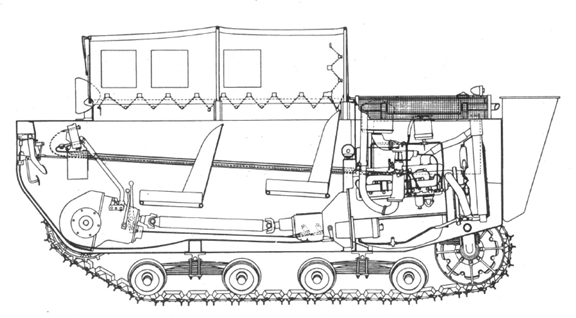

Another Studebaker product for which Warner

Gear supplied transmissions during World War Two was the tracked cargo

carrier. The M28 version applied power to the tracks at the front

of the vehicle. The Warner Gear T-84-J transmission was connected

to driver's controls via linkages. The M28 only had room for the

driver and a passenger behind him.

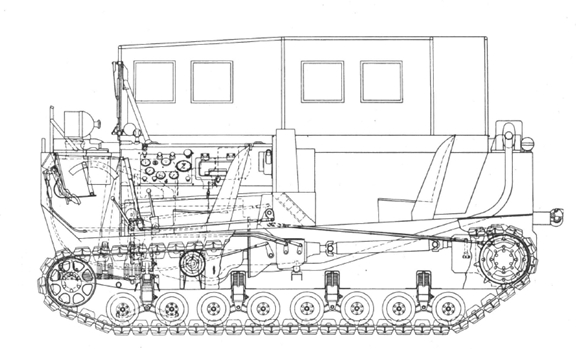

The improved M29 version of the cargo

carrier applied the power to the rear of the vehicle and could seat a

total of four persons.

Author's photo.

The M29C version of the Studebaker cargo

carrier was amphibious.

Author's photo.

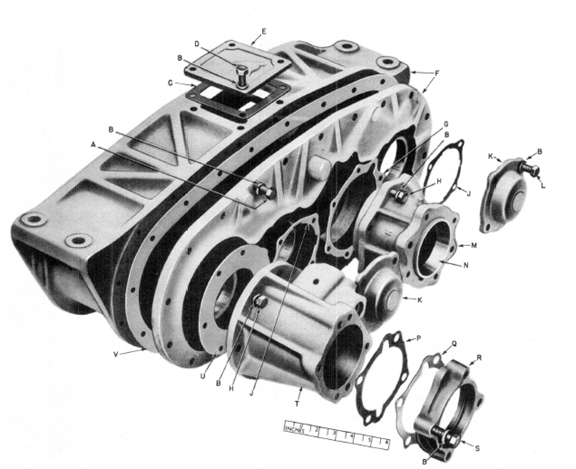

The 8,523 M8 armored cars were equipped with Warner Gear

T-95 transmissions and AS1-J5 transfer cases. The

Author's photo.

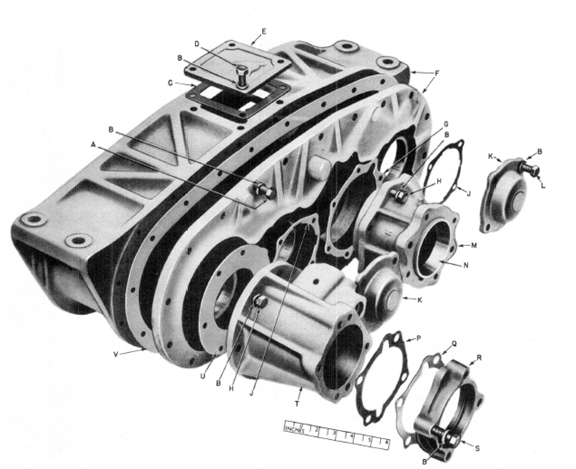

This is an exploded view of the T-95.

The Warner Gear AS1-J5 transfer case as used

on the M8 and M20 armored cars.

The 3,791

M20 command armored cars also were equipped with the T-95 and AS1-J5.

Author's photo.

In the final stages of World War Two,

General George Patton used an M20 command car equipped with a Warner

Gear T-95 transmission. This is a replica of what General Patton's

M20 looked like.

Author's photo.

The Plants:

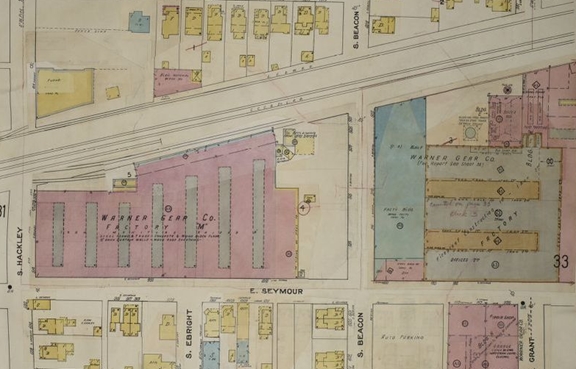

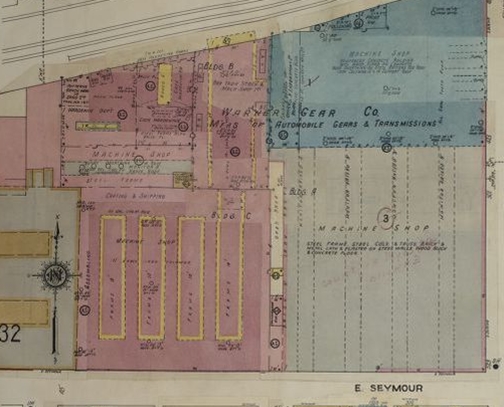

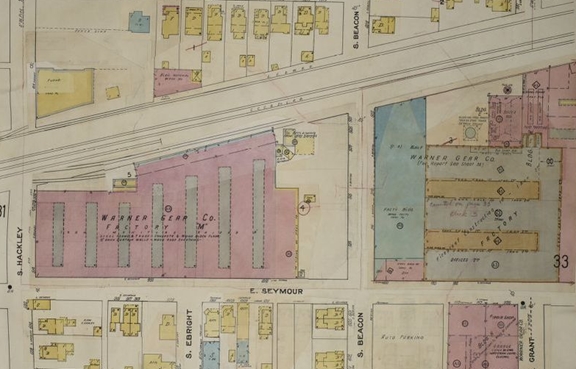

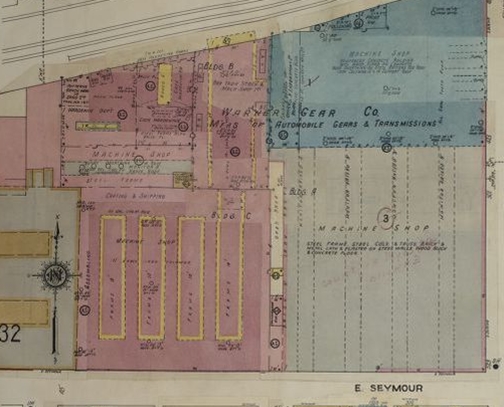

In 1929 Warner Gear Plant Two was built at

South Hackley and East Seymour Streets in Muncie. The plant to the

east may be the original Warner Gear Plant One. During World War

Two, this Warner Gear plant was the address listed as the headquarters

for the company. In working on this project, this was the first

time I was aware of this former Warner Gear plants in Muncie. While the scales of the two pages

from the 1950 Sanborn maps don't quite match up, it shows that Warner

Gear had a substantial facility at this location.

This is the former Warner Gear Plant Two at

the corner of South Hackley and East Seymour Streets in Muncie, IN.

The original plant had large windows that have been bricked over with a

slightly different color of brick. What an elegant looking factory

in the late afternoon autumn sunlight. Author's photo.

This is the plant that is to the east of Plant Two and is at the corner

of South Beacon and East Seymour Streets. This building still has

the windows in it. This building may be 100 years old, but it is

still in very good condition for its age. It was built to last.

This was most likely the original Warner Gear Plant One in Muncie.

Author's photo.

The address given in World War Two U.S. Army

documents shows 1108 Seymour Street as being the address of Warner Gear.

The current address 80 years later differs by only two numbers.

This entrance appears to be the main entrance, indicating this plant was

the original plant and headquarters location for Warner Gear. Most

likely where it currently says, "Downtown Industrial Center" it

previously said "Warner Gear." Author's photo.

This Google Earth view shows the entire

expanse of the former Warner Gear Plant Two at 1108 Seymour Street in

Muncie, IN. Image added 6-1-2024.

This view is looking west at the complex.

South Blaine Street is in the foreground. Google Earth image

added 6-1-2024.

Google Earth image added 6-1-2024.

Google Earth image added 6-1-2024.

This is the Warner Gear plant I was familiar

with. It was located along State Road 32, or Kilgore Avenue as it

is called as it comes into Muncie. I live just a mile from State

Road 32 and my total travel distance is eleven miles from this former plant. The half mile long plant

was on the south side of the road. I have gone past this site hundreds

of times over the years on my way to Muncie. Photo courtesy of the

Muncie Public Library.

This Google Earth shows Pant 3 some

time after the above photo. The plant is no longer being used and

the buildings in the upper right have already been razed. Image

added 6-1-2024.

Google Earth image added 6-1-2024.

Google Earth image added 6-1-2024.

This shows the back side of the

complex and the floor for the razed buildings can be seen in the lower

left. This was a huge facility for the manufacture of

transmissions. Google Earth image added 6-1-2024.

The end of Warner Gear and Plant Three:

The photos below were taken on a cold and gray overcast day in December

2017. Just as dreary and cold as the day were the remains of Plant

3 as it was being dismantled for scrap. The was the sad end for a

great company that had for over 100 years been a part of Muncie and for

all the workers it had employed. In other words, this is a very

depressing set of photos.

This photo is looking west from the east

property line.

Author's photo.

Scrappers always start tearing down plants in the back, away from the

public eye. In this photo the demolition has proceeded to the

front of the plant along State Road 32.

Author's photo.

A considerable amount of the front side of

the plant was still standing in December 2017. It is all razed now.

There are still piles of bricks remaining that don't appear to be worth

salvaging.

Author's photo.

This was the former main entrance along

State Road 32.

Author's photo.

This photo is looking west from the same

location of the previous photo.

Author's photo.

This photo was taken from the southwest

corner of the property and the view is back to the east. There was

still a considerable amount of the factory still standing.

Author's photo.

|